Omron Sysmac FH, Sysmac FH-1, Sysmac FH-2, Sysmac FH-L, Sysmac FH-3 Hardware Setup Manual

...Page 1

Vision Sensor

FH Series

Vision System

Hardware Setup Manual

FH-1£££/FH-1£££-££

FH-2£££-££/FH-2£££-££

FH-3£££/FH-3£££-££

FH-5£££-££/FH-5£££-££

FH-L£££/FH-L£££-££

Z366-E1-07

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• This software is based in part on the work of the Independent JPEG Group.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD, SDHC, microSD, and microSDHC logos are trademarks of SD-3C, LLC.

,

• QR Code is a registered trademark of DENSO W

AVE INCORPORATED.

• MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the FH Series.

This manual contains information that is necessary to use the FH Series.

Please read this manual and make sure you understand the functionality and performance of the FH

Series before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• FH-1£££

• FH-1£££-££

• FH-2£££

• FH-2£££-££

• FH-3£££

• FH-3£££-££

• FH-5£££

• FH-5£££-££

• FH-L£££

• FH-L£££-££

Part of the specifications and restrictions are given in other manuals. Refer to Relevant Manuals on

Relevant Manuals on page 2 and Related Manuals on page 25.

FH Series Vision System Hardware Setup Manual (Z366-E1)

1

Page 4

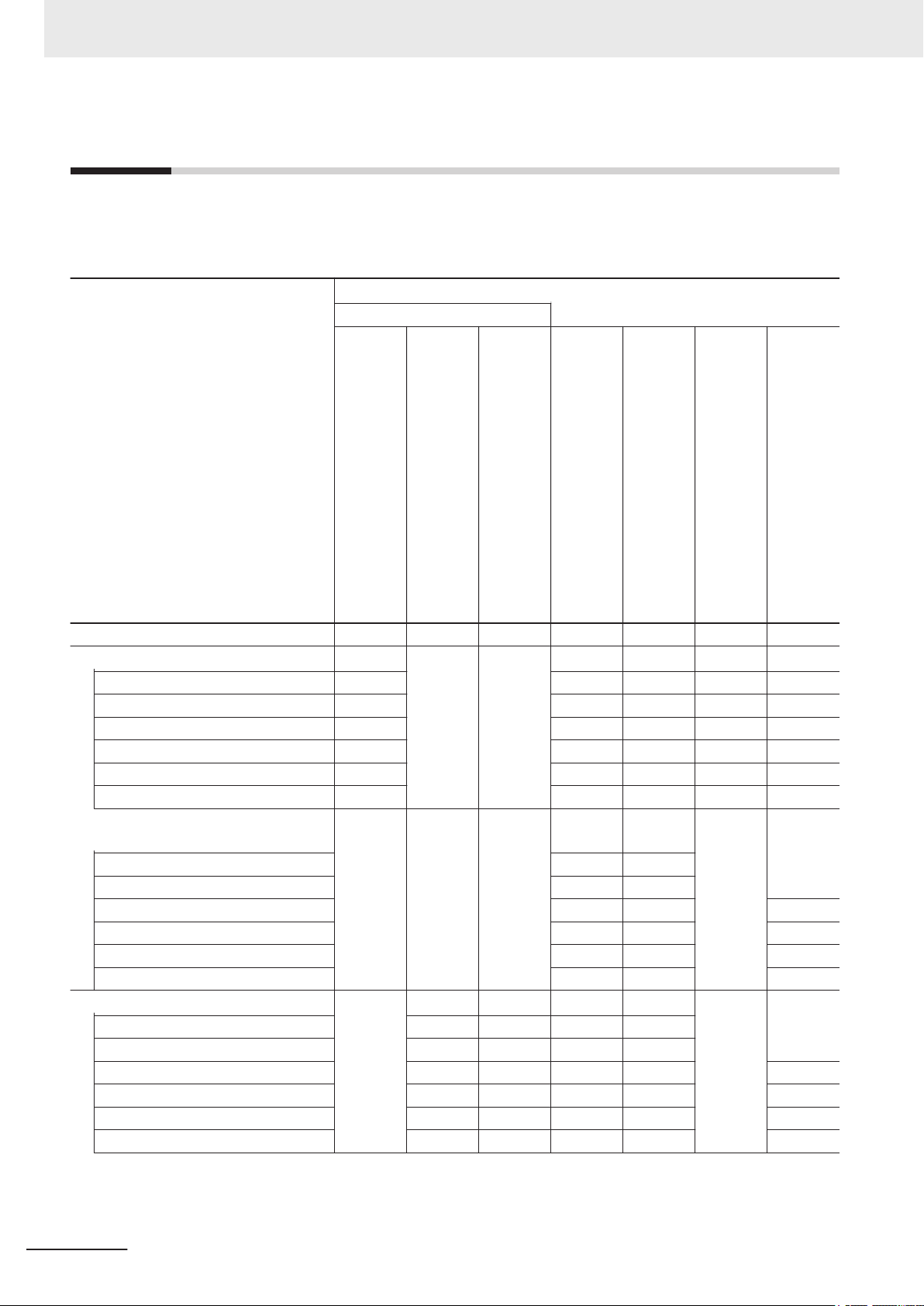

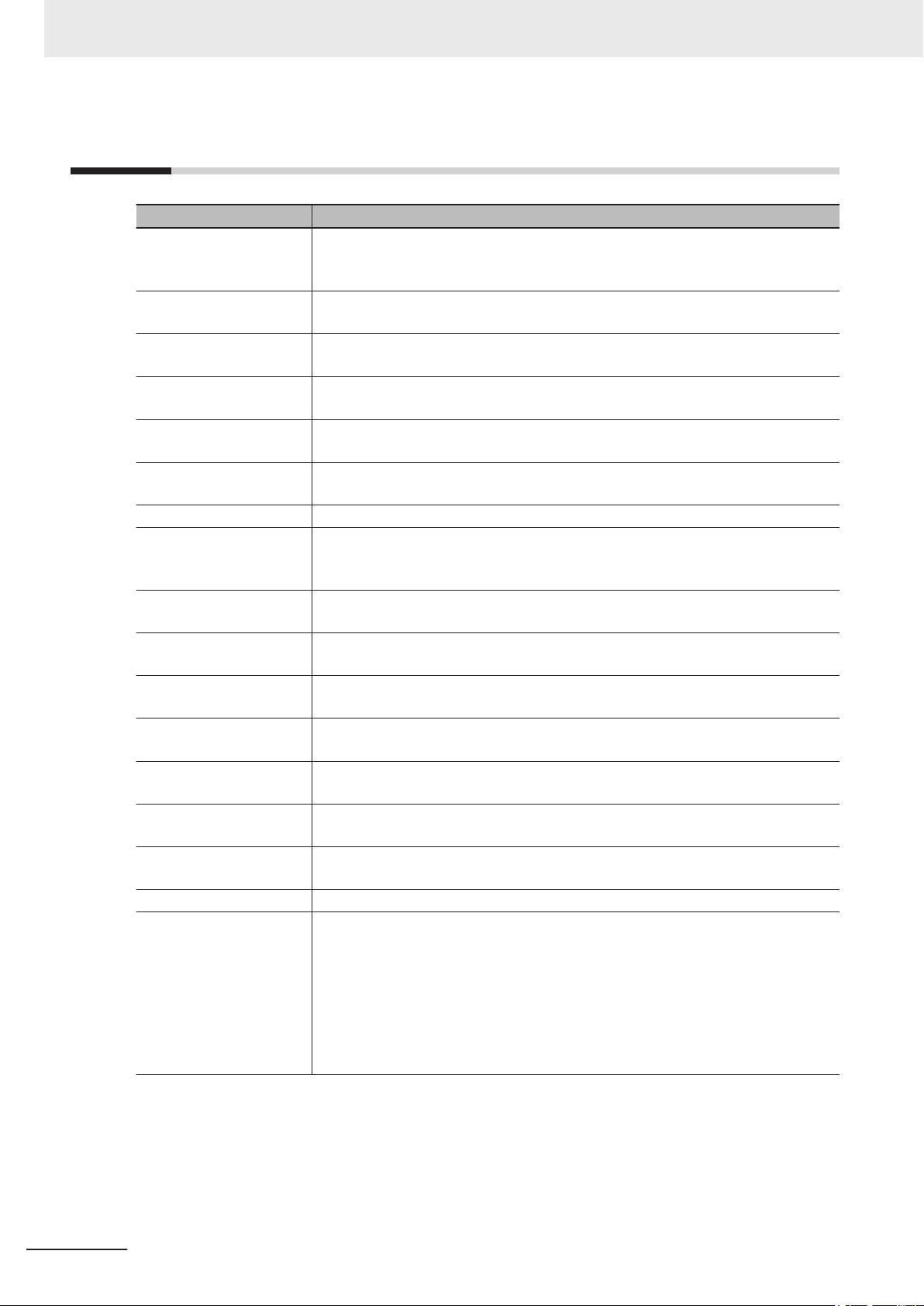

Relevant Manuals

Relevant Manuals

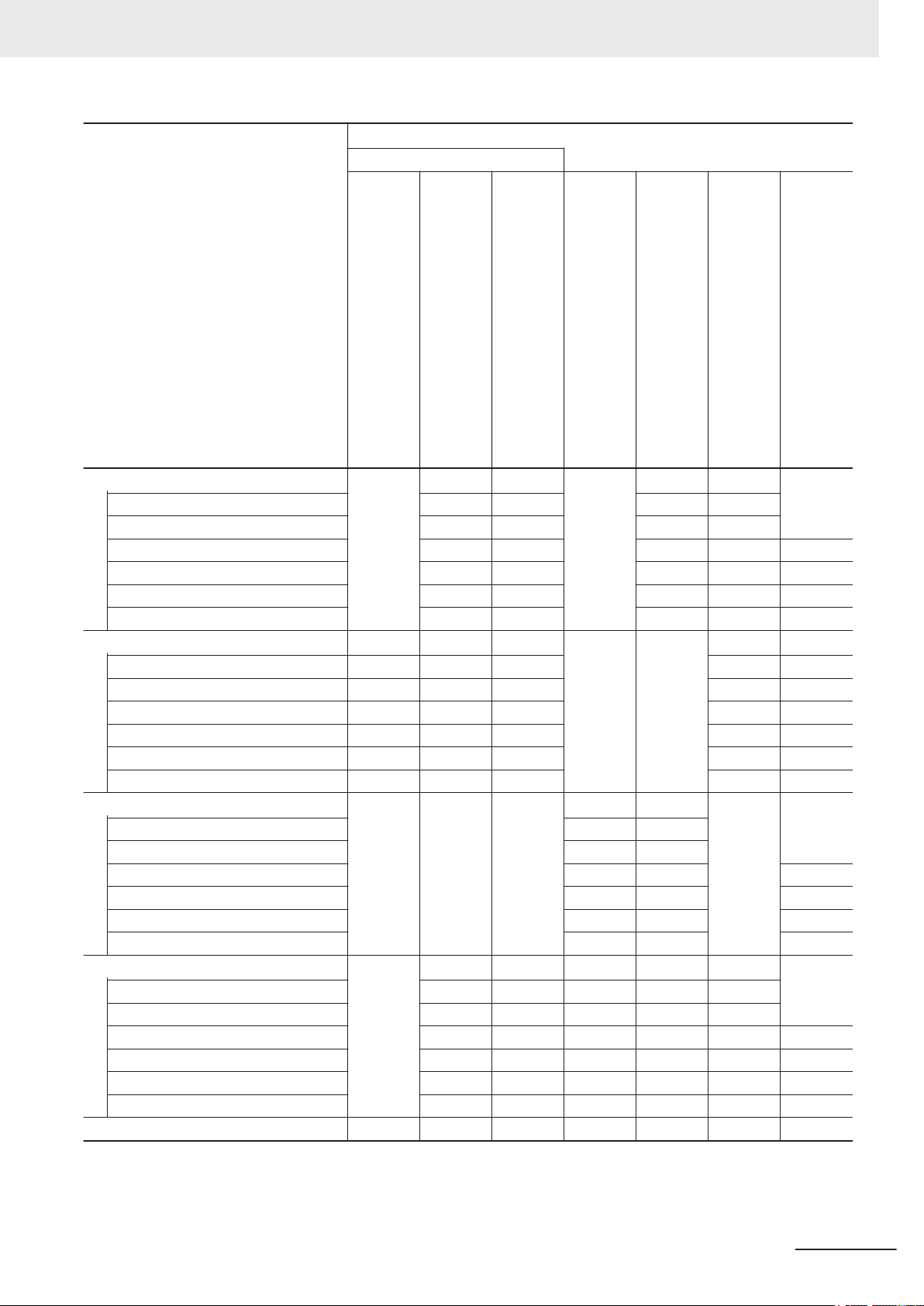

The following table provides the relevant manuals for the FH Series.

Read all of the manuals that are relevant to your system configuration and application before you use

the FH Series.

User's Manual

Purpose of use

Basic information

FH/FHV Series Vision System

FH Series Vision System

Hardware Setup Manual

Manual

FHV Series Smart Camera

Setup Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

Programming Manual

FH Series Vision System

Macro Customize Functions

FH/FHV Series Vision System

User’s Manual for Communications Settings

FH Series Vision System

Operation Manual for Sysmac Studio

Overview of FH series

Setup and Wiring

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the communication setting of Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

l l

l l

l

l l l l

l

l l

2

FH Series Vision System Hardware Setup Manual (Z366-E1)

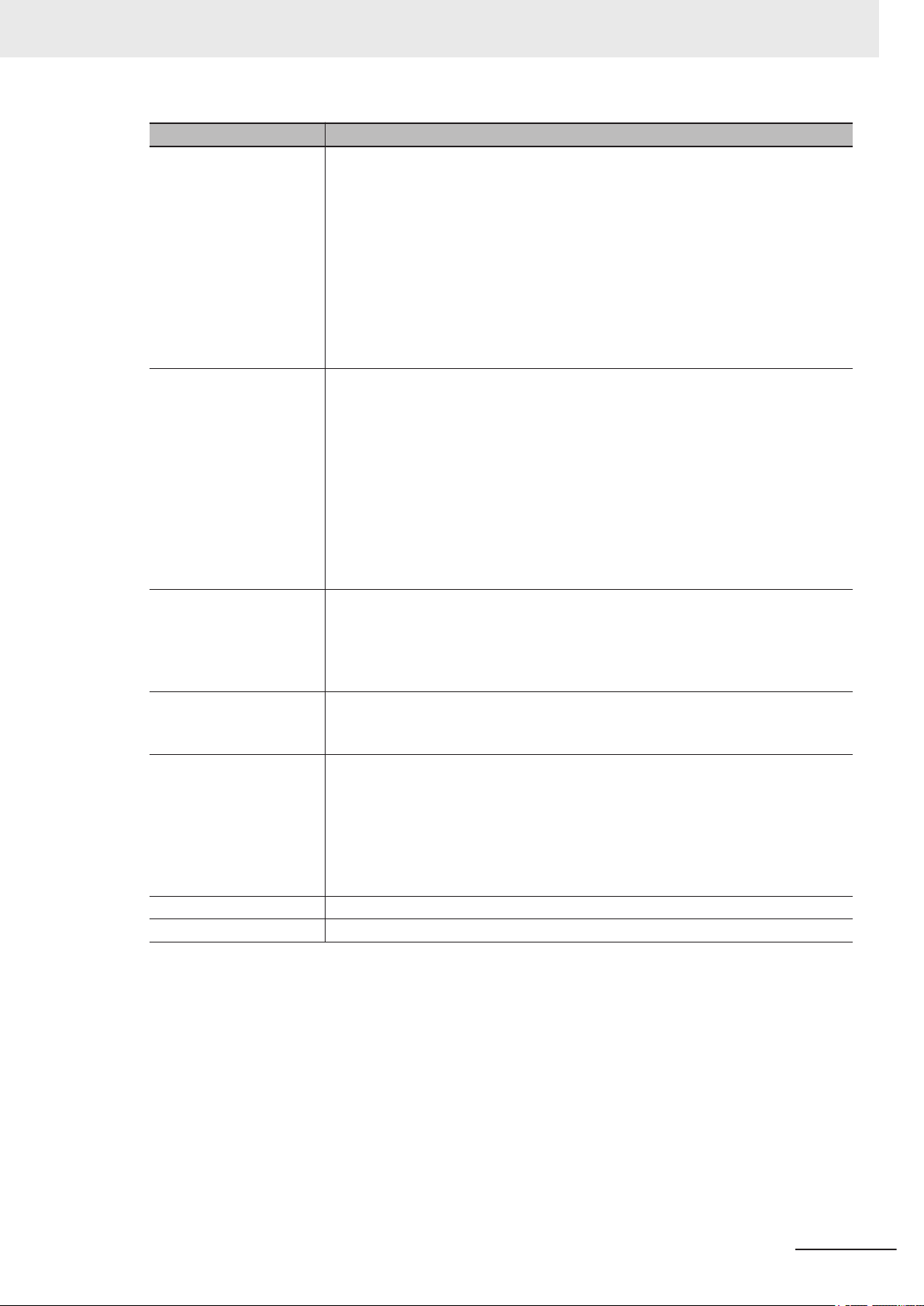

Page 5

Purpose of use

Basic information

FH/FHV Series Vision System

User's Manual

Hardware Setup Manual

FH Series Vision System

FHV Series Smart Camera

Setup Manual

Relevant Manuals

Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

FH Series Vision System

Macro Customize Functions

Programming Manual

FH/FHV Series Vision System

User’s Manual for Communications Settings

FH Series Vision System

Operation Manual for Sysmac Studio

Create and Set the Scene

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Optimizing the Scene Flow

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Connecting the Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Using Helpful Functions

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Troubleshooting and Problem Solving

l

l l

l l

l

l l l l

l

l

l

FH Series Vision System Hardware Setup Manual (Z366-E1)

3

Page 6

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

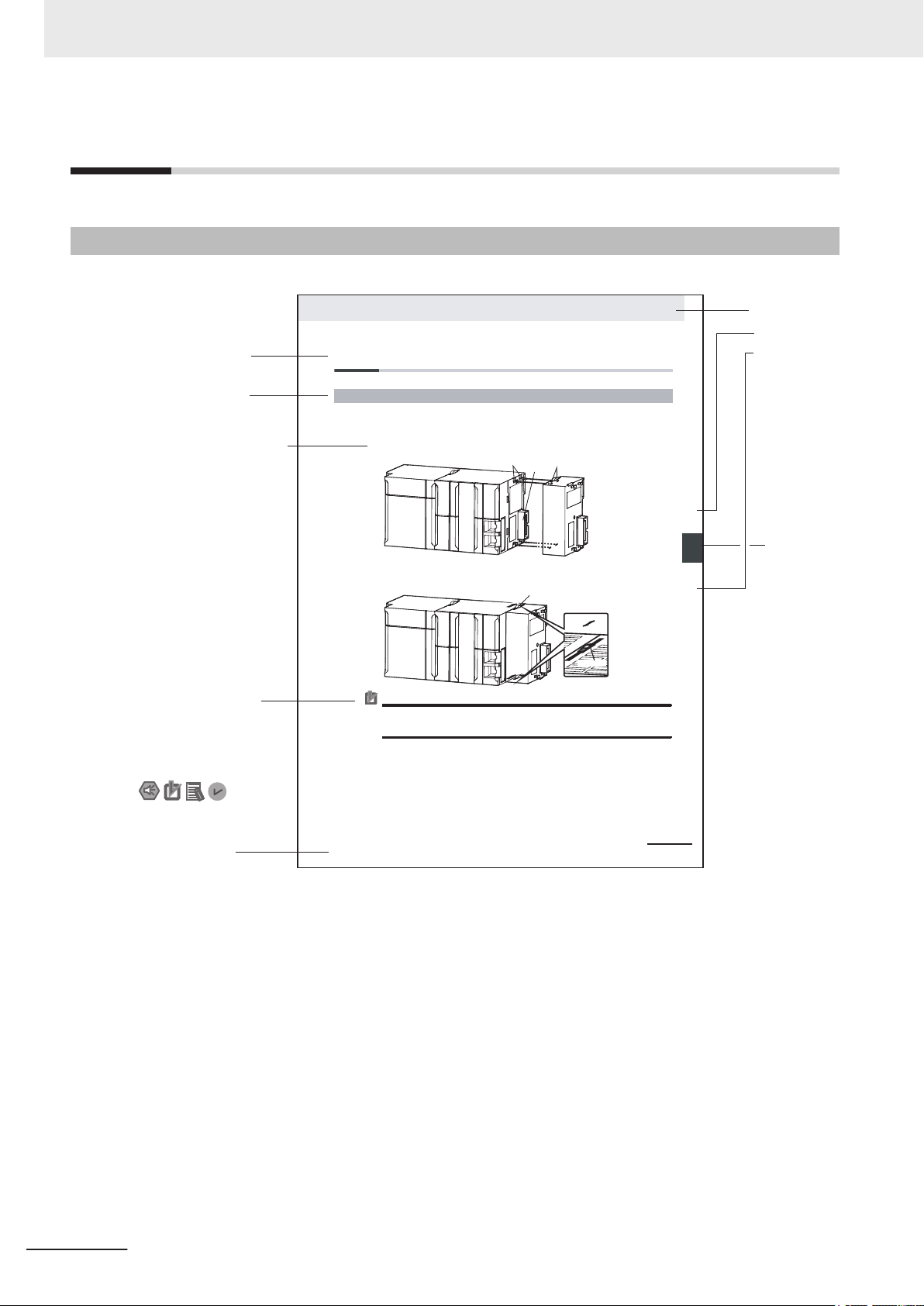

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simpl y b y p res sin g t he Un it s to ge th e r

and locking the sliders by moving them toward the back of the Units . The End Co v er is connect ed in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

4

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 7

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier

Manual Structure

.

FH Series Vision System Hardware Setup Manual (Z366-E1)

5

Page 8

Manual Structure

6

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 9

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience

Applicable Products ......................................................................................................................................... 1

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information .......................................................................................................................................... 5

Terms and Conditions Agreement........................................................................ 11

Warranty, Limitations of Liability .................................................................................................................... 11

Application Considerations ............................................................................................................................12

Disclaimers ....................................................................................................................................................12

Safety Precautions................................................................................................. 14

Symbols and the Meanings for Safety Precautions Described in This Manual .............................................14

Meanings of Alert Symbols ............................................................................................................................ 14

Warning..........................................................................................................................................................15

CONTENTS

...........................................................................................................................................1

Precautions for Safe Use ...................................................................................... 16

Condition of the Fitness of OMRON Products ............................................................................................... 16

Installation Environment ................................................................................................................................16

Power Supply and Wiring ..............................................................................................................................17

Grounding ...................................................................................................................................................... 17

Others ............................................................................................................................................................ 17

Precautions for Correct Use ................................................................................. 19

Installation and Storage Sites (FH-1000/2000/3000/5000 series) ................................................................. 19

Installation and Storage Sites (FH-L series) .................................................................................................. 19

Orientation of Product....................................................................................................................................19

Ambient Temperature ....................................................................................................................................19

Noise Resistance...........................................................................................................................................20

Component Installation and Handling............................................................................................................20

Maintenance ..................................................................................................................................................20

Communications with Upper Device..............................................................................................................20

Failsafe Measures .........................................................................................................................................21

Connecting the Sensor Controller and Monitor with a Switcher and Splitter .................................................21

Regulations and Standards .................................................................................. 22

All Series........................................................................................................................................................ 22

FH-1000/2000/3000/5000 series ...................................................................................................................22

FH-L series ....................................................................................................................................................23

Related Manuals..................................................................................................... 25

Terminology............................................................................................................ 26

Revision History..................................................................................................... 31

Sections in This Manual ........................................................................................ 33

FH Series Vision System Hardware Setup Manual (Z366-E1)

7

Page 10

CONTENTS

Section 1 Confirm the Package

1-1 Sensor Controller.................................................................................................................1 - 2

1-1-1

1-1-2 FH-1£££-10/FH-2£££-10/FH-3£££-10/FH-5£££-10 Series.........................................1 - 2

1-1-3 FH-1£££-20/FH-2£££-20/FH-3£££-20/FH-5£££-20 Series.........................................1 - 3

1-1-4 FH-L£££ Series .....................................................................................................................1 - 3

1-1-5 FH-L£££-10 Series ................................................................................................................1 - 3

FH-1£££/FH-2£££/FH-3£££/FH-5£££ Series..............................................................1 - 2

1-2 Sold Separately .................................................................................................................... 1 - 5

1-2-1 Cameras and Related ...............................................................................................................1 - 5

1-2-2 Monitor ......................................................................................................................................1 - 7

1-2-3 Lighting and Lighting Controller ................................................................................................1 - 8

1-2-4 Accessories...............................................................................................................................1 - 9

1-2-5 Cable.......................................................................................................................................1 - 10

1-2-6 Software ..................................................................................................................................1 - 12

Section 2 Overview of FH series

2-1 Overview of System.............................................................................................................2 - 2

2-1-1 Basic System of Measurement .................................................................................................2 - 2

2-1-2 FH-1000/FH-2000/FH-3000/FH-5000 Series ............................................................................2 - 4

2-1-3 FH-L Series ...............................................................................................................................2 - 5

2-2 System Configuration..........................................................................................................2 - 6

2-2-1 FH-1000/2000/3000/5000 Series ..............................................................................................2 - 6

2-2-2 FH-L Series ...............................................................................................................................2 - 7

2-3 Flow of Use Procedure ........................................................................................................ 2 - 8

Section 3 Configuration

3-1 Sensor Controller.................................................................................................................3 - 3

3-1-1

3-1-2 FH-L Series .............................................................................................................................3 - 14

3-2 Camera................................................................................................................................3 - 19

3-2-1 High-speed digital CMOS Camera (FH-S camera series) ......................................................3 - 19

3-2-2 Digital CMOS Camera.............................................................................................................3 - 24

3-2-3 Digital CCD Camera: FZ-S Camera Series.............................................................................3 - 27

3-2-4 High-speed Digital CCD Camera: FZ-SH Camera Series.......................................................3 - 29

3-2-5 Small Digital CCD Cameras: FZ-S Camera Series.................................................................3 - 30

3-2-6 Intelligent Compact Digital CMOS Camera: FZ-S camera Series...........................................3 - 33

3-3 Camera Cable ..................................................................................................................... 3 - 36

3-3-1 Camera Cable and Right-angle Camera Cable ......................................................................3 - 36

3-3-2 Bend resistant Camera Cable and Bend resistant Right-angle Camera Cable ......................3 - 37

3-3-3 Long-distance Camera Cable and Long-distance Right-angle Camera Cable .......................3 - 38

3-3-4 Cable Connection Table ..........................................................................................................3 - 39

3-3-5 Cable Extension Units.............................................................................................................3 - 43

3-4 Lens.....................................................................................................................................3 - 47

3-4-1 C-mount Lens for 1/3-inch Image Sensor (SV-V Series) ........................................................3 - 47

3-4-2 C-mount Lens for 2/3-inch Image Sensor (SV-H Series) ........................................................3 - 48

3-4-3 C-mount Lens for 1-inch Image Sensor (VS-H1 Series) .........................................................3 - 49

3-4-4 C-mount Lens for 4/3-inch Image Sensor (VS-LLD Series) ....................................................3 - 50

3-4-5 M42-mount Lens for Large Image Sensor (VS-L/M42-10 Series)...........................................3 - 51

3-4-6 Lenses for Small Camera (FZ-LES Series).............................................................................3 - 51

3-4-7 Vibration and Shock Resistant C-mount Lens for 2/3-inch Image Sensor (VS-MCA Series)..3 - 52

3-4-8 Vibration and Shock Resistant C-mount Lens for 1-inch Image Sensor (VS-MCH Series) ....3 - 54

3-4-9 Vibration and Shock Resistant C-mount Lens for 1-inch Image Sensor (VS-MCH1 Series) ..3 - 57

3-4-10 Vibration and Shock Resistant M42-mount Lens for 1.8-inch Image Sensor (VS-MCL/

FH-1000/2000/3000/5000 Series ..............................................................................................3 - 3

M42-10 Series)........................................................................................................................3 - 60

8

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 11

CONTENTS

3-4-11 High-resolution

TCH Series) ............................................................................................................................3 - 62

3-4-12 High-resolution Telecentric Lens for C-mount Lens for 1.1-inch Image Sensor (VS-TEV

Series).....................................................................................................................................3 - 64

3-4-13 Extension Tubes......................................................................................................................3 - 65

3-4-14 Meaning of Optical Chart ........................................................................................................3 - 66

Telecentric Lens for C-mount Lens for 2/3-inch Image Sensor (VS-

3-5 Touch Panel Monitor and Cable .......................................................................................3 - 82

3-6 LCD and Cable ...................................................................................................................3 - 88

3-7 Sysmac Studio ...................................................................................................................3 - 91

Section 4 Handling and Installation Environment

4-1 All Series...............................................................................................................................4 - 2

4-2

FH-1000/2000/3000 Series ...................................................................................................4 - 4

4-3 FH-L Series ........................................................................................................................... 4 - 5

Section 5 Setup and Wiring

5-1 When turning ON and OFF..................................................................................................5 - 2

5-1-1

5-1-2 FH-1000/2000/3000/5000 Series ..............................................................................................5 - 3

5-1-3 FH-L Series ...............................................................................................................................5 - 3

5-2 Fail-Safe Measures ..............................................................................................................5 - 4

5-3 Sensor Controller Installation.............................................................................................5 - 5

5-3-1 All Series ...................................................................................................................................5 - 5

5-3-2 FH-1000/2000/3000/5000 Series ..............................................................................................5 - 5

5-3-3 FH-L Series .............................................................................................................................5 - 11

5-4 Setup Touch Panel Monitor or Monitor ............................................................................5 - 20

5-4-1 All Series .................................................................................................................................5 - 20

5-4-2 FH-1000/2000/3000/5000 Series ............................................................................................5 - 20

5-4-3 FH-L Series .............................................................................................................................5 - 20

5-5 Camera Installation............................................................................................................5 - 22

5-5-1 All Series .................................................................................................................................5 - 22

5-5-2 FH-1000/2000/3000/5000 Series ............................................................................................5 - 23

5-5-3 FH-L Series .............................................................................................................................5 - 24

5-6 Insert/Remove SD Memory Card or USB memory .......................................................... 5 - 25

5-6-1 Common in all series...............................................................................................................5 - 25

5-7 Use by Connecting Software ............................................................................................5 - 26

5-7-1 Sysmac Studio FH Tool ...........................................................................................................5 - 26

5-7-2 FZ_FH Remote Operation Tool ...............................................................................................5 - 26

5-7-3 Simulation Software ................................................................................................................5 - 26

5-8 Installation in a Control Panel ..........................................................................................5 - 27

5-8-1 All Series .................................................................................................................................5 - 27

5-8-2 FH-1000/2000/3000/5000 Series ............................................................................................5 - 29

5-8-3 FH-L Series .............................................................................................................................5 - 31

All Series ...................................................................................................................................5 - 2

Section 6 I/O Interface

6-1 Parallel Interface ..................................................................................................................6 - 2

6-1-1 All Series ...................................................................................................................................6 - 2

6-1-2 FH-1000/2000/3000/5000 Series ..............................................................................................6 - 3

6-1-3 FH-L Series .............................................................................................................................6 - 12

6-1-4 Other (Parallel Converter Cable).............................................................................................6 - 18

FH Series Vision System Hardware Setup Manual (Z366-E1)

9

Page 12

CONTENTS

6-2 Encoder Interface...............................................................................................................6 - 29

6-3 EtherCAT Interface.............................................................................................................6 - 32

6-4 Ethernet Interface ..............................................................................................................6 - 34

6-5 Serial Interface ...................................................................................................................6 - 38

Index

6-2-1

6-3-1 FH-1000/2000/3000/5000 Series ............................................................................................6 - 32

6-4-1 FH-1000/2000/3000/5000 Series ............................................................................................6 - 34

6-4-2 FH-L Series .............................................................................................................................6 - 36

6-5-1 All Series .................................................................................................................................6 - 38

FH-1000/2000/3000/5000 Series ............................................................................................6 - 29

10

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 13

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

l

Omron’s exclusive warranty is that the Products will be free from defects in materials and work-

manship for a period of twelve months from the date of sale by Omron (or such other period ex-

pressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

l

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

l

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Compa-

nies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

FH Series Vision System Hardware Setup Manual (Z366-E1)

11

Page 14

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

W

ARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

’s application or use of the Product. At Buy-

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIP-

MENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

. It may represent the result of

12

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However

FH Series Vision System Hardware Setup Manual (Z366-E1)

, some specifications of the Product may

Page 15

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’

time to confirm actual specifications of purchased Product.

s representative at any

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever

, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

FH Series Vision System Hardware Setup Manual (Z366-E1)

13

Page 16

Safety Precautions

Safety Precautions

Symbols and the Meanings for Safety Precautions Described in This Manual

The following notation is used in this manual to provide precautions required to ensure safe usage of a

Sensor Controller. The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoid-

WARNING

ed, will result in minor or moderate injury

ous injury or death.

Additionally there may be significant property damage.

, or may result in seri-

Caution

Meanings of Alert Symbols

General Prohibition

Indicates general prohibitions, including warnings, for which there is no specific

symbol

General Caution

Indicates general cautions, including warnings, for which there is no specific symbol.

Electrical Hazard

Indicates the possible danger of electric shock under specific conditions.

Explosion Hazard

Indicates the possible danger of explosion under specific conditions.

LED light Hazard

Indicates the possible danger of LED radiation or light.

Indicates a potentially hazardous situation which, if not avoid-

ed, may result in minor or moderate injury or in property dam-

age.

14

High Temperature Caution

Indicates the possible danger of injury by high temperature under specific conditions.

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 17

Warning

This product must be used according to this manual and Instruction Sheet. Failure to observe this may result in the impairment of functions and performance of the product.

This product is not designed or rated for ensuring the safety of persons. Do not use it for

such purposes.

Never connect the AC power supply with this product. When the AC power supply is connected, it causes the electric shock and a fire.

A lithium battery is built into the Controller and may occasionally combust, explode, or burn if

not treated properly. Dispose of the Controller as industrial waste, and never disassemble,

apply pressure that would deform, heat to 100°C or higher, or incinerate the Controller.

Safety Precautions

WARNING

If you keep watching the LED light, it may have an adverse effect on the eyes, do not stare

directly into the light emitted from the LED. If a specular object is used, take care not to allow

reflected light to enter your eyes.

Do not touch the terminals while the power supply is ON. Doing so may result in electrical

shock.

Please take external safety measures so that the system as a whole should be on the safe

side even if a failure of a Sensor Controller or an error due to an external factor occurred. An

abnormal operation may result in serious accident.

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal conductor disconnection and/or momentary power interruption.

An abnormal operation may result in a serious accident.

Caution

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal conductor disconnection and/or momentary power interruption. An abnormal operation

may result in a serious accident.

FH Series Vision System Hardware Setup Manual (Z366-E1)

15

Page 18

Precautions for Safe Use

Precautions for Safe Use

Condition of the Fitness of OMRON Products

• Please do not use this product to directly or indirectly use to detect the human body for the purpose

of ensuring the safety. In the same application, please use the safety sensor that is published on our

sensor catalog.

• Omron products are designed and manufactured as general-purpose products for use in general in-

dustrial applications. They are not intended to be used in the following critical applications. If you are

using Omron products in the following applications, Omron shall not provide any warranty for such

Omron products, unless otherwise specifically agreed or unless the specific applications are intend-

ed by Omron.

a) Applications with stringent safety requirements, including but not limited to nuclear power control

equipment, combustion equipment, aerospace equipment, railway equipment, elevator/lift equip-

ment, amusement park equipment, medical equipment, safety devices and other applications

that could cause danger/harm to people's body and life.

b) Applications that require high reliability, including but not limited to supply systems for gas, water

and electricity, etc., 24 hour continuous operating systems, financial settlement systems and oth-

er applications that handle rights and property.

c) Applications under severe condition or in severe environment, including but not limited to out-

door equipment, equipment exposed to chemical contamination, equipment exposed to electro-

magnetic interference and equipment exposed to vibration and shocks.

d) Applications under conditions and environment not described in specifications.

(1) In addition to the applications listed from (a) to (d) above, Omron products (see definition) are not

intended for use in vehicles designed human transport (including two wheel vehicles). Please do

NOT use Omron products for vehicles designed human transport. Please contact the Omron

sales staff for information on our automotive line of products.

(2) The above is part of the Terms and Conditions Agreement. Please use carefully read the contents

of the guarantee and disclaimers described in our latest version of the catalog, data sheets and

manuals.

Installation Environment

• Do not use the product in the environment with flammable or explosive gases.

• Install the product so that the air can flow freely through its cooling vents.

• Regularly clean the vent holes or fan outlet to prevent dust or particles blocking them. Internal tem-

perature increases when those are blocked, it causes malfunction.

• To secure safety for operation and maintenance, install the product apart from high-voltage devices

and power devices.

• Make sure to tighten all screws in mounting.

• When mounting the product using DIN rail mounting brackets, be sure to tighten all screws.

• Make sure to mount the product on DIN-rail securely.

16

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 19

Power Supply and Wiring

• Make sure to use the product within the power voltage specified by catalog, this manual, or instruc-

tion sheet.

Never connect the product to AC power. If connected, it causes malfunction.

•

• Select and use the appropriate wire size based on consumption current.

• Keep the power supply wires as short as possible.

• Provide the power from a DC power supply (safety extra-low voltage circuits) that has been taken

measures not to generate high-voltage.

• Check the following again before turning on the power.

- Is the voltage and polarity of the power supply correct? (24 VDC)

- Is not the load of the output signal short-circuited?

- Is the load current of the output signal appropriate?

- Is not the mistake found in wiring?

- Is the voltage and polarity of the encoder power (ENC0_VDD/GND ENC1_VDD/GND) supply?

(5VDC)

• The recommended power supply for FH-L series is the S8VS-£££24 (manufactured by OMRON)

or S8VK-G-£££24 (manufactured by OMRON).

Precautions for Safe Use

Grounding

• Since the power supply circuit for the Sensor Controller is described in the manual and instruction

sheet, please check it.

When a base is packed in a camera that will be connected to the Sensor Controller, make sure to

•

mount the camera using the base. Since the enclosure of the camera body is connected to the inter-

nal circuits, the circuits may cause short-circuit with FG if the base is not used to mount the camera

and result in malfunction or damage.

• Apply Class D grounding (grounding resistance: 100 [Ω] or less) Wire the grounding wire for the

Sensor Controller independently. If the grounding wire is shared with other devices or connected to

a building beam, the Sensor Controller may be adversely affected.

• Check the wiring again before turning on the power.

• Do not ground the plus (+) terminal when the FH series Sensor Controller is connected to the FH-

SC12/FH-SM12. The internal circuits may cause a short-circuit and result in malfunction.

• Do not ground the plus (+) terminal of the 24 VDC power source when the FH series Sensor Con-

troller is connected to the FH-MT12 with a USB cable. The internal circuits may cause a short-circuit

and result in malfunction.

• When using the Sensor Controller and the peripheral devices such as a monitor, USB connection

devices, RS-232C connection devices, there should be no potential difference in ground level. If not,

it may cause malfunction. Take measures that the potential difference does not occur between the

grounds for the Sensor Controller and the peripheral devices.

Others

• Use only the camera and cables designed specifically for the product. Use of other products may

result in malfunction or damage of the product.

Always turn OFF the power of the Sensor Controller and peripheral devices before connecting or

•

disconnecting a camera or cable. Connecting the cable with power supplied may result in damage of

the camera or peripheral devices.

FH Series Vision System Hardware Setup Manual (Z366-E1)

17

Page 20

Precautions for Safe Use

• For the cable that is flexed repeatedly, use the robotic cable type (Bend resistant camera cable) to

prevent damages.

•

Do not apply torsion stress to the cable. It may damage the cable.

• Secure the minimum bending radius of the cable. Otherwise the cable may be damaged.

• Do not apply stress to the connector by pulling or bending the cable. It may damage the connector.

• Do not attempt to dismantle, repair, or modify the product.

• Should you notice any abnormalities, immediately stop use, turn OFF the power supply, and contact

your OMRON representative.

• While the power is ON or immediately after the power is turned OFF, the Sensor Controller and

camera case are still hot. Do not touch the case.

• When disposing of the product, treat it as an industrial waste.

• Do not drop the product nor apply excessive vibration or shock to the product. Doing so may cause

malfunction or burning.

• This product is heavy. Be careful not to drop it while handling.

• A lithium battery is incorporated, so a severe injury may rarely occur due to ignition or explosion.

• Be sure to take fail-safe measures externally when controlling stages and robots by using the meas-

urement results of the Sensor Controller (axis movement output by calibration and alignment meas-

urement).

18

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 21

Precautions for Correct Use

Precautions for Correct Use

Installation and Storage Sites (FH-1000/2000/3000/5000 series)

Install and store the product in a location that meets the following conditions:

• Surrounding temperature of 0 to +50°C*1 (-20 to +65°C in storage)

*1. FH-5000 Series: Surrounding temperature of 0 to 45°C

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 35 to 85%

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight

• Place where it will not come into contact with water, oils or chemicals

• Place not affected by strong electro-magnetic waves

• Place not near to high-voltage, or high-power equipment

Installation and Storage Sites (FH-L series)

Install and store the product in a location that meets the following conditions:

•

Surrounding temperature of 0 to +55°C (-25 to +70°C in storage)

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 10 to 90%

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight

• Place where it will not come into contact with water, oils or chemicals

• Place not affected by strong electro-magnetic waves

• Place not near to high-voltage, or high-power equipment

Orientation of Product

• For efficient heat dissipation, install the product only with the orientation written in this manual or the

Instruction Sheet. Install the product so that the air can flow freely through its cooling vents.

Ambient Temperature

• To secure good ventilation, install the product with clearance written in this manual or the Instruction

Sheet.

Do not install the product immediately above significant heat sources, such as heaters, transform-

•

ers, or large-capacity resistors.

• Use the product within the operating temperature range based on the specifications of it.

• Install a forced cooling fan or air conditioner not to exceed the operating temperature range when

the ambient temperature is close to the upper limit of its range.

FH Series Vision System Hardware Setup Manual (Z366-E1)

19

Page 22

Precautions for Correct Use

Noise Resistance

• Do not install the Sensor Controller in a cabinet with high-voltage equipment installed.

Mount the Sensor Controller at 200 [mm] or more from power cables apart.

•

Component Installation and Handling

• Touching Signal Lines:

When touching a terminal part or a signal wire in a connector

strap or another device to prevent damage from static electricity.

• Handling a USB Memory/SD memory card: (Refer to Using External Storage Device in the Vision

System FH/FHV Series User’s Manual (Cat. No. Z365).

Do not insert an SD memory card in the reverse orientation, at an angle, or in a twisting manner.

Before removing a USB memory device, make sure that data is not being read or written to them.

Before removing a SD memory card, make sure that data is not being read or written to them.

For a USB memory device, the memory device's LED flashes or lights while data is being read or

written, so make sure that it is turned OFF before removing the memory.

For SD memory card, the SD BUSY LED flashes or lights while data is being read or written, so

make sure that it is turned OFF before removing the memory.

• Turning OFF the Power:

When a message is displayed indicating that a task is in progress, do not turn OFF the power. Doing

so causes the data in the memory to be corrupted, resulting in the product not operating properly

upon the next start-up.

Do not turn OFF during saving data to Sensor Controller.

When turns OFF, conform the followings proceedings have completed. and then operate again.

- When saves using Sensor Controller: Confirm the save processing is completed and next opera-

tion is possible.

- When saves using communication command: Intended command is completed. BUSY signal is

turned OFF.

• Setting of Power Source:

The power source need to be supplied from DC power source apparatus which is taken a save ultra-

low voltage circuit: to protect high voltage.

, take anti-static measures using a wrist

Maintenance

• Turn OFF the power and ensure the safety before maintenance.

Clean the lens with a lens-cleaning cloth or air brush.

•

• Lightly wipe off dirt with a soft cloth.

• Dirt on the image element must be removed using an air brush.

• Do not use thinners or benzine.

• To secure safety for operation and maintenance, install the product apart from high-voltage devices

and power devices.

Communications with Upper Device

• After confirming that the product is started up, communicate with the high-order device. Since uncer-

tain signals may be output from the high-order interface at the product start-up, take measures such

as clearing the reception buf

20

fer of your device at the initial stage.

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 23

Precautions for Correct Use

Failsafe Measures

• Be sure to take fail-safe measures externally when controlling stages and robots by using the meas-

urement results of the Sensor Controller (axis movement output by calibration and alignment meas-

urement).

On a Sensor Controller side, supplementary use operations and branches of the Sensor Controller

•

to configure a check flow such as “data should not be externally provide if the data is in a range from

-XXXXX to XXXXX” based on the stage/robots range of movement.

Connecting the Sensor Controller and Monitor with a Switcher and Splitter

• Do not use devices that may require re-recognition of the monitor by the Sensor Controller when a

switching operation was performed. If such re-recognition processing happens at switching opera-

tion, it may cause measurement time to be longer

.

FH Series Vision System Hardware Setup Manual (Z366-E1)

21

Page 24

Regulations and Standards

Regulations and Standards

All Series

Using Product Outside Japan

If you export (or provide a non-resident with) this product or a part of this product that falls under the

category of goods (or technologies) specified by the Foreign Exchange and Foreign Trade Control

Law as those which require permission or approval for export, you must obtain permission or approval

or service transaction permission) pursuant to the law.

U.S. California Notice:

This product contains a lithium battery for which the following notice applies: Perchlorate Material -

special handling may apply.

See "www.dtsc.ca.gov/hazardouswaste/perchlorate".

Conformance to KC Standards

Observe the following precaution if you use this product in Korea.

• Guidance for users

This product meets the electromagnetic compatibility requirements for business use. There is a risk

of radio interference when this product is used in home.

WEEE Directive

Dispose of in accordance with WEEE Directive

FH-1000/2000/3000/5000 series

Conformance to EC/EU Directives

The product is compliant with the standards below:

22

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 25

Regulations and Standards

• EC Directive 2004/108/EC (Until April 19 2016) / EU Directive 2014/30/EU (After April 20 2016)

EN61326-1 Electromagnetic environment: Industrial electromagnetic environment (EN/IEC 61326-1

T

able 2)

• Also, the following condition is applied to the immunity test of this product.

- If the level of disturbance of the video is such that characters on the monitor are readable, the test

is a pass.

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices that

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions

of the equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall ma-

chine conform to EMC standards.

• If there is a need to respond to the EC / EU directive, please use by an analog RGB output.

Conformance to UL Standards (FH-1000/FH-3000 series)

This product complies with UL Standards.

•

UL508

Conformance to UL Standards (FH-2000/FH-5000 series)

This product complies with UL Standards.

•

UL61010-2-201

FH-L series

Conformance to EC/EU Directives

The product is compliant with the standards below:

•

EC Directive 2004/108/EC (Until April 19 2016) / EU Directive 2014/30/EU (After April 20 2016)

EN61326-1 Electromagnetic environment: Industrial electromagnetic environment (EN/IEC 61326-1

Table 2)

• Also, the following condition is applied to the immunity test of this product.

- If the level of disturbance of the video is such that characters on the monitor are readable, the test

is a pass.

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices that

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions

of the equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall ma-

chine conform to EMC standards.

• If there is a need to respond to the EC / EU directive, please use by an analog RGB output.

Conformance to UL Standards

This product complies with UL Standards.

FH Series Vision System Hardware Setup Manual (Z366-E1)

23

Page 26

Regulations and Standards

• UL61010-2-201

24

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 27

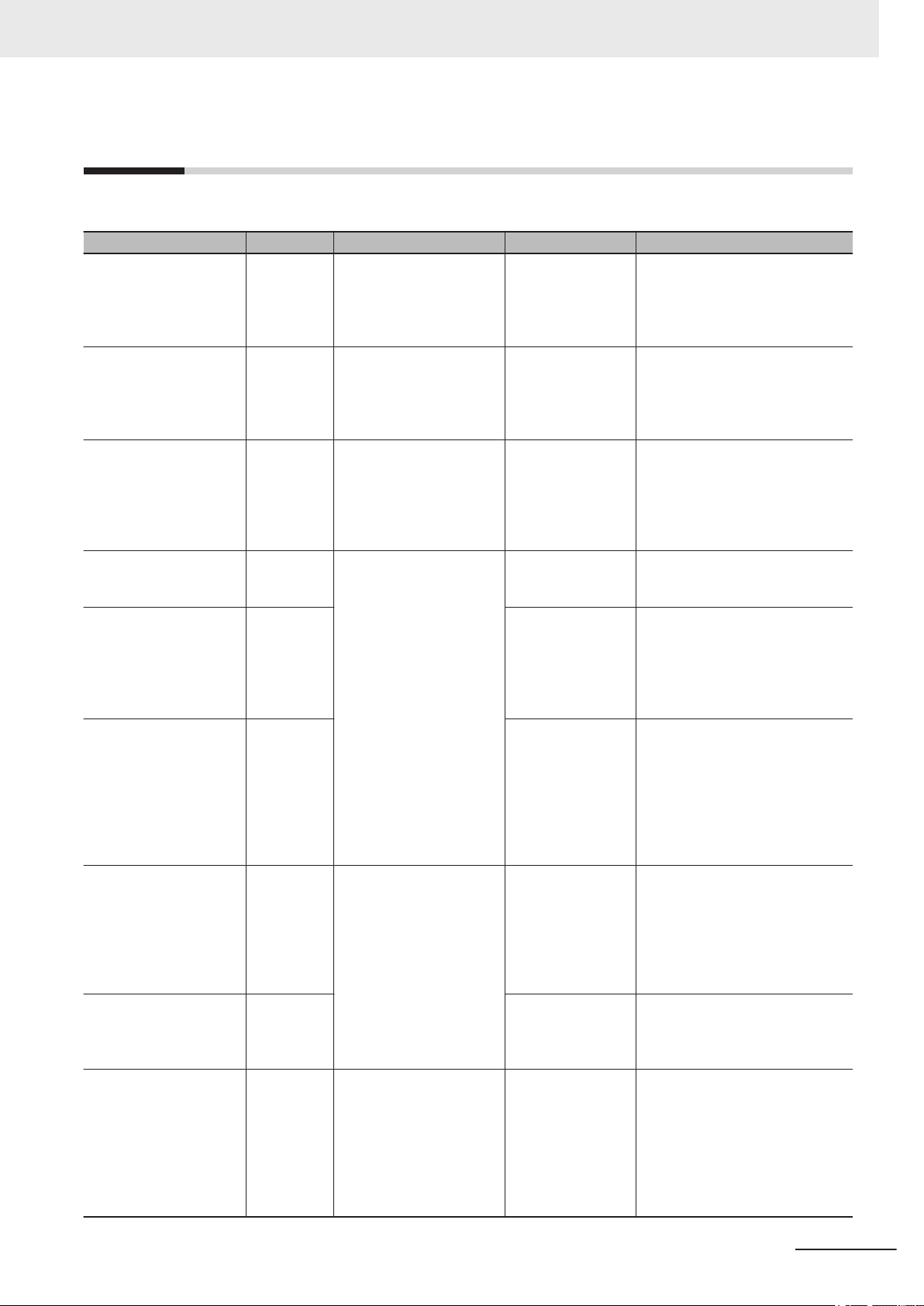

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Name of Manual Cat. No.. Model Purpose Contents

Vision System

FH Instruction Sheet

Vision System

FH Instruction Sheet

Vision System

FH-L Instruction Sheet

Vision System

FH/FHV Series

User's Manual

Vision System

FH/FHV series

Processing Item Function

Reference Manual

Vision System

FH/FHV Series

User's manual for Communications Settings

Vision System

FH series

Hardware Setup Manual

Vision System

FH series

Macro Customize Functions Programming Manual

Vision System

FH Series

Operation Manual

for Sysmac Studio

9608337-2

3102269-4

9606631-1

Z365

Z341 When User confirm

Z342 When User confirm

Z366

Z367 When User operate

Z343

FH-1£££

FH-1£££-££

FH-3£££

FH-3£££-££

FH-2£££

FH-2£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

To confirm the safety

and usage precautions of the V

System FH series

Sensor Controller.

To confirm the safety

and usage precautions of the V

System FH series

Sensor Controller.

To confirm the safety

and usage precautions of the V

System FH-Lite series Sensor Controller.

When User want to

know about the

FH/FHV series.

the details of each

processing items at

the create the measurement flow or operate it.

the setting of communication functions.

When User want to

know about the

Hard-ware specifications or to setup the

Sensor Controller of

the V

FH series.

or programming using Macro Customize

functions.

When User connect

to NJ/NX series via

EtherCA

cation.

ision

ision

ision

ision System

T communi-

Describes the definitions of basic

terms, meaning of signal words, and

precautions for correct use of FH

series in the manual.

To confirm the safety and usage precautions of the Vision System FH

series Sensor Controller.

Describes the definitions of basic

terms, meaning of signal words, and

precautions for correct use of FH-L

series in the manual.

Describes the soft functions, setup,

and operations to use FH/FHV series/

Describes the software functions,

settings, and operations for using

FH/FHV series.

Describes the functions, settings,

and communications methods for

communication between FH/FHV

series and PLCs.

The following communications protocol are described.

Parallel, PLC Link, EtherNet/IP

EtherCAT, and Non-procedure.

Describes FH series specifications,

dimensions, part names, I/O information, installation information, and

wiring information.

Describes the functions, settings,

and operations for using Macro Customize function of the FH series.

Describes the operating procedures

for setting up and operating FH series Vision Sensors from the Sysmac

Studio FH Tools.

Related Manuals

,

FH Series Vision System Hardware Setup Manual (Z366-E1)

25

Page 28

Terminology

Terminology

Term Definition

FH Series All FH series model names as follows:

FH-1000 series

FH-2000 series

FH-3000 series

FH-5000 series

FH-L series

FHV Series All FHV series model names.

FZ5 series All FZ series name shows the following:

FZ5-600 series

FZ5-800 series

FZ5-1100 series

FZ5-1200 series

FZ5-L series

Sensor Controller It is a generic name of FH/FZ5 series. For FHV series, it has the same meaning as

Measurement flow (abbreviated as flow)

Measurement processing Executing processing items for inspections and measurements.

Measurement ID Information of time when the sensor controller receives the measurement trigger

FH-1£££, FH-1£££-££, FH-2£££, FH-2£££-££, FH-3£££, FH-3£££££, FH-5£££, FH-5£££-££, FH-L£££, FH-L£££-££

All FH-1£££

FH-1£££, FH-1£££-££

All FH-2£££

FH-2£££, FH-2£££-££

All FH-3£££

FH-3£££, FH-3£££-££

All FH-5£££

FH-5£££, FH-5£££-££

All FH-L£££

FH-L£££, FH-L£££-££

FZ5-6££, FZ5-6££-££, FZ5-8££, FZ5-8££-££, FZ5-1

£, FZ5-12££, FZ5-12££-££, FZ5-L35£, FZ5-L35£-££

All FZ5-6££ series name the following:

FZ5-6££, FZ5-6££-££

All FZ5-8££ series name the following:

FZ5-8££, FZ5-8££-££

All FZ5-11££ series name the following:

1££, FZ5-11££-££

FZ5-1

All FZ5-12££

FZ5-12££, FZ5-12££-££

All FZ5-L35£

FZ5-L35£, FZ5-L35£-££

Smart Camera.

A continuous flow of measurement processing. A measurement flow consists of a

scene created from a combination of processing items.

and the line no.

Format of measurement ID: YYYY

(YYYY: Year, MM: Month, DD: Date, HH: Hour, MM: Minute, SS: Second, XXXX:

Millisecond and Line number.)

series model names as follows:

series model names as follows:

series model names as follows:

series model names as follows:

series model names as follows:

1££, FZ5-11££-£

series name the following:

series name the following:

-MM-DD_HH-MM-SS-XXXX

• Example:

Measurement time: 11:10:25.500 AM, December 24, 2007 and Line 0, the measurement ID is "2007-12-24_11-10-25-5000".

26

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 29

Terminology

Term Definition

Processing item Any of the individual items for vision inspections that are partitioned and packaged

so that they can be flexibly combined.

These include the Search, Position Compensation, and Fine Matching items.

Processing items can be classified for image input ([Input image]), inspection/

measurement ([Measurement]), image correction ([Compensate image]), inspection/measurement support ([Support measurement]), process branching ([Branch]),

results external output ([Output result]), resulting image display ([Display result]),

etc.

ou can freely classify processing items to handle a wide range of applications.

Y

A scene (i.e., a unit for changing the measurement flow) is created by registering

the processing items as units.

Scene A unit for changing the measurement flow that consists of a combination of proc-

essing items.

Scene is used because of the correspondence to the scene (i.e., type of measurement object and inspection contents) where measurements are performed.

A scene is created for each measurement or measurement contents.

ou can easily achieve a changeover simply by changing the scene when the

Y

measurement

object or inspection content changes.

Normally you can set up to 128 scenes. If you need more than 128 scenes, you

can separate them into different groups or use the Conversion Scene Group Data

Tool to create a scene group that contains over 128 scenes.

Processing unit (abbreviated as unit)

Measurement trigger A trigger for executing measurements.

Test measurement A measurement that is performed to manually test (check) measurements under

Single measurement A measurement that is executed only once in synchronization with the trigger input.

Continuous measurement Measurements are executed repeatedly and automatically without a trigger input.

A processing item that is registered in a scene.

Numbers are assigned to processing units in order from the top and they are executed in that order

Processing items are registered for the processing units to create a scene (i.e., a

unit for changing the measurement flow).

With a parallel interface, the STEP signal is used. With a serial interface, an Execute One Measurement or a Start Continuous Measurement command is used.

the conditions that are set in the currently displayed scene.

est measurements can be executed on an Adjustment Window. Processing is

T

completed inside the Controller and the measurement results are not normally output on an external interface.

However, you can select Output in Test measurement to output the measurement

results after executing measurements.

.

FH Series Vision System Hardware Setup Manual (Z366-E1)

27

Page 30

Terminology

Operation mode

Parallel processing (an

option for any of the

above operation modes)

Multi-input function A function that is used to consecutively and quickly input images.

Term Definition

• Double Speed Multi-input:

A mode that processes the measurement flow for the first trigger and then processes the measurement flow in parallel for the second trigger to achieve a highspeed trigger input interval. It is used together with the multi-input function.

• Multi-line Random-trigger:

A trigger mode that allows you to independently processing multiple measurement flows.

With traditional image processing, two or more triggers cannot be acknowledged

at the same time. In Multi-line Random-trigger Mode, you can randomly input

multiple triggers into one Controller to independently process multiple scenes in

parallel.

• Non-stop adjustment mode:

A mode that allows you to adjust the flow and set parameters while performing

measurements.

The enables adjustments without stopping the line or stopping inspections.

• Standard:

A logging mode that allows complete parallel processing of measurements and

logging.

raditionally, logging was not possible while processing measurements. Either

T

measurements or logging had to be given priority and the other one had to wait.

With this mode, you can save the measurement images in external storage without affecting the transaction time.

Parallel processing splits part of the measurement flow into two or more tasks, and

processes each task in parallel to shorten the transaction time.

Processing items for parallel processing are used so that the user can specify the

required parallel processing.

It allows the next STEP signal to be acknowledged as soon as the image input

processing is completed. There is no need to wait for measurement processing to

be completed.

ou can check whether image input processing has been completed with the status

Y

of the READY signal. Even if the READY signal is ON when measurement processing is being executed, the next STEP signal can be acknowledged.

28

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 31

When position of object to be measured is deflected

When position deflection correction is set in advance:

Object to be measured

overflows Measurement area.

Reference position

Measurement area and objects to be measured

are correctly aligned.

Object to be measured

Measurement area

Measurement will be carried out

after measured object enters into Measurement area.

Measurement will be carried out after

moving the Measurement area for a

corresponding deflection.

Measurement will be carried out

after moving the image for a

corresponding deflection and

returning to the reference position.

Terminology

Term Definition

Position compensation When the location and direction of measured objects are not fixed, the positional

deviation between reference position and current position is calculated and measurement is performed after correcting.

Please select processing items that are appropriate to the measurement object

from processing items that are related to position compensation.

Reference position The point that is always the reference. If the location of the registered model is dif-

Model The image pattern that serves as the inspection target. Characteristics portions are

ferent from the reference position, the setting should be changed in Ref. setting.

extracted from images of the object and registered as model registration.

FH Series Vision System Hardware Setup Manual (Z366-E1)

29

Page 32

−“1” expresses with 2’s Complement (for 8 bits)

00000000 (= 0)

-)

(In the case of 1, minus 1)

00000001 (= 1)

11111111 (=-1)

00000001 (= 1)

11111110

11111111 (=-1)

Invert all bits

Plus 1

11111111 (= -1)

00001001 (= 9)

+)00001010 (= 10)

Terminology

2's complement Binary numbers are generally used to represent negative numbers.

Term Definition

Negative numbers are expressed by Inverting all bits of a positive number and

adding 1 to the result.

Ex. -1 is expressed as 2's complement.

-1 can be calculated by 0-1.

There are methods for simple calculation without performing this kind of computation.

For instance, Negative number = inverting all bits of a positive number and then

adding 1 to the result.

The first digit is used to judge whether the number is positive or negative.

• When 0: Positive number (or 0)

• When 1: Negative number

The advantage of two's complement numbers is that positive and negative numbers can be used as is in calculations.

Ex. When -1+10=9

30

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 33

Revision History

Revision code

Cat. No. Z366-E1-07

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Rev. Code Rev. Date Revision Contents

01 Apr. 2016 Original product

02 Aug. 2016 Corrected mistakes

03 Apr. 2017 Corrected mistakes and revisions for the support of NY series

04 Apr. 2017 Corrected mistakes

05 June 2017 Revisions for the support of FZ5-800 Series, FZ5-1200 Series,

06 July 2018

07 July 2019 Removed FZ5 series, adjusted the layout, and corrected mistakes

Revision History

and FZ-S£5M3

Added FH-2000 series, FH-5000 series, and FH-S£21R/FH-S

£X12

FH Series Vision System Hardware Setup Manual (Z366-E1)

31

Page 34

Revision History

32

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 35

Sections in This Manual

1

2

3

4

5

1

2

3

4

5

Confirm the Package

Overview of FH series

Configuration

Handling and Installation Environment

Setup and Wiring

I

6

I

6

I

I/O Interface

Index

I

Sections in This Manual

FH Series Vision System Hardware Setup Manual (Z366-E1)

33

Page 36

Sections in This Manual

34

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 37

Confirm the Package

1-1 Sensor Controller......................................................................................... 1 - 2

1-1-1

1-1-2 FH-1£££-10/FH-2£££-10/FH-3£££-10/FH-5£££-10 Series ............ 1 - 2

1-1-3 FH-1£££-20/FH-2£££-20/FH-3£££-20/FH-5£££-20 Series ............ 1 - 3

1-1-4 FH-L£££ Series ......................................................................................... 1 - 3

1-1-5 FH-L£££-10 Series.................................................................................... 1 - 3

1-2 Sold Separately ............................................................................................1 - 5

1-2-1 Cameras and Related................................................................................... 1 - 5

1-2-2 Monitor.......................................................................................................... 1 - 7

1-2-3 Lighting and Lighting Controller .................................................................... 1 - 8

1-2-4 Accessories .................................................................................................. 1 - 9

1-2-5 Cable .......................................................................................................... 1 - 10

1-2-6 Software...................................................................................................... 1 - 12

FH-1£££/FH-2£££/FH-3£££/FH-5£££ Series ................................. 1 - 2

1

1

FH Series Vision System Hardware Setup Manual (Z366-E1)

1 - 1

Page 38

1 Confirm the Package

1-1

1-1-1

Sensor Controller

First, please check to see whether the package has all the necessary Sensor Controller parts.

FH-1£££/FH-2£££/FH-3£££/FH-5£££ Series

• Sensor Controller: 1

FH-1£££/FH-2£££/FH-3£££/FH-5£££: 1

•

Instruction sheet: 1

• Instruction Installation Manual for FH series: 1

• General Compliance Information and Instructions for EU: 1

• Membership registration: 1

• Power source: 1 (male)

FH-XCN: 1

• Ferrite core for camera cable: 2

1-1-2

FH-1£££-10/FH-2£££-10/FH-3£££-10/FH-5£££-10 Series

• Sensor Controller: 1

FH-1£££-10/FH-2£££-10/FH-3£££-10/FH-5£££-10: 1

Instruction sheet: 1

•

• Instruction Installation Manual for FH series: 1

• General Compliance Information and Instructions for EU: 1

• Membership registration: 1

• Power source: 1 (male)

FH-XCN: 1

• Ferrite core for camera cable: 4

1 - 2

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 39

1-1-3

1 Confirm the Package

1-1 Sensor Controller

FH-1£££-20/FH-2£££-20/FH-3£££-20/FH-5£££-20 Series

1

1-1-4

• Sensor Controller: 1

FH-1£££-20/FH-2£££-20/FH-3£££-20/FH-5£££-20: 1

Instruction sheet: 1

•

• Instruction Installation Manual for FH series: 1

• General Compliance Information and Instructions for EU: 1

• Membership registration: 1

• Power source: 1 (male)

FH-XCN: 1

• Ferrite core for camera cable: 8

FH-L£££ Series

• Sensor Controller: 1

FH-L£££: 1

•

Instruction sheet: 1

• Instruction Installation Manual for FH-L series: 1

• General Compliance Information and Instructions for EU: 1

• Membership registration: 1

• Power source: 1 (male)

FH-XCN-L: 1

1-1-3 FH-1£££-20/FH-2£££-20/FH-3£££-20/FH-5£££-20 Series

1-1-5

FH Series Vision System Hardware Setup Manual (Z366-E1)

FH-L£££-10 Series

• Sensor Controller: 1

FH-L£££-10: 1

1 - 3

Page 40

1 Confirm the Package

• Instruction sheet: 1

•

Instruction Installation Manual for FH-L series: 1

• General Compliance Information and Instructions for EU: 1

• Membership registration: 1

• Power source: 1 (male)

FH-XCN-L: 1

1 - 4

FH Series Vision System Hardware Setup Manual (Z366-E1)

Page 41

1-2

1 Confirm the Package

1-2 Sold Separately

Sold Separately

1-2-1

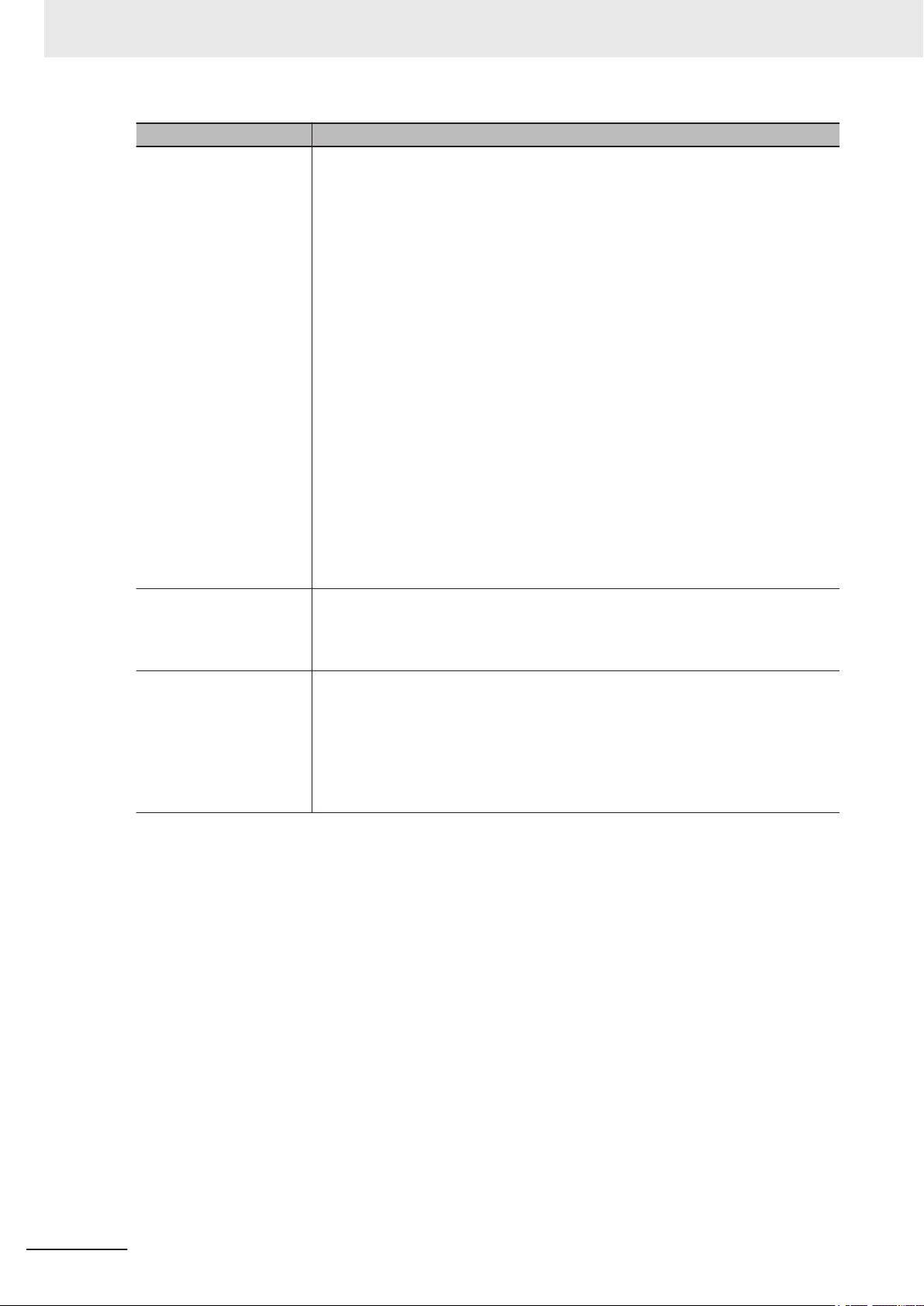

Cameras and Related

Camera

Appear-

ance

High-speed Digital CMOS

Cameras

(Lens required)

High-speed Digital CMOS

Cameras

(Lens required)

High-speed Digital CMOS

Cameras

(Lens required)

Type Description

Color/

Mono-

chrome

12 megapixels

(Up to four cameras can be connected to one

Controller

era on page

1 - 5)

5 megapixels Color

0.4 megapixels Color

12 megapixels

(Up to four cameras can be connected to one

Controller

4 megapixels Color

2 megapixels Color

0.3 megapixe Color 3.3 ms FH-SC

. Cam-

. *4)

Color

Monochrome

Monochrome

Monochrome

Color

Monochrome

Monochrome

Monochrome

Monochrome

Image Ac-

quisition

*1

T

ime

24.9 ms

10.3 ms

1.9 ms

25.7 ms

8.5 ms

4.6 ms

*2

*2

*3

*2

*2

*2

FH-SCX12

FH-SMX12

FH-SCX05

FH-SMX05

FH-SCX

FH-SMX

FH-SC12

FH-SM12

FH-SC04

FH-SM04

FH-SC02

FH-SM02

FH-SM

1

1-2-1 Cameras and Related

Model