Programmable Controllers

From Machine Control to Information Management _

Multiple-application Controllers with a Wide Range of Functions

Note: Do not use this document to operate the Unit.

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530

Japan

Tel: (81)75-344-7109

Fax: (81)75-344-7149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/

Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg,

IL 60173 U.S.A.

Tel: (1)847-843-7900/ Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel: (65)6835-3011/Fax :(65)6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120 China

Tel:(86)21-5037-2222/Fax:(86)21-5037-2200

Printed on 100%

Recycled Paper

Authorized Distributor:

Note: Specifications subject to change without notice.

Cat. No. R090-E1-04

Printed in Japan

0705-1M

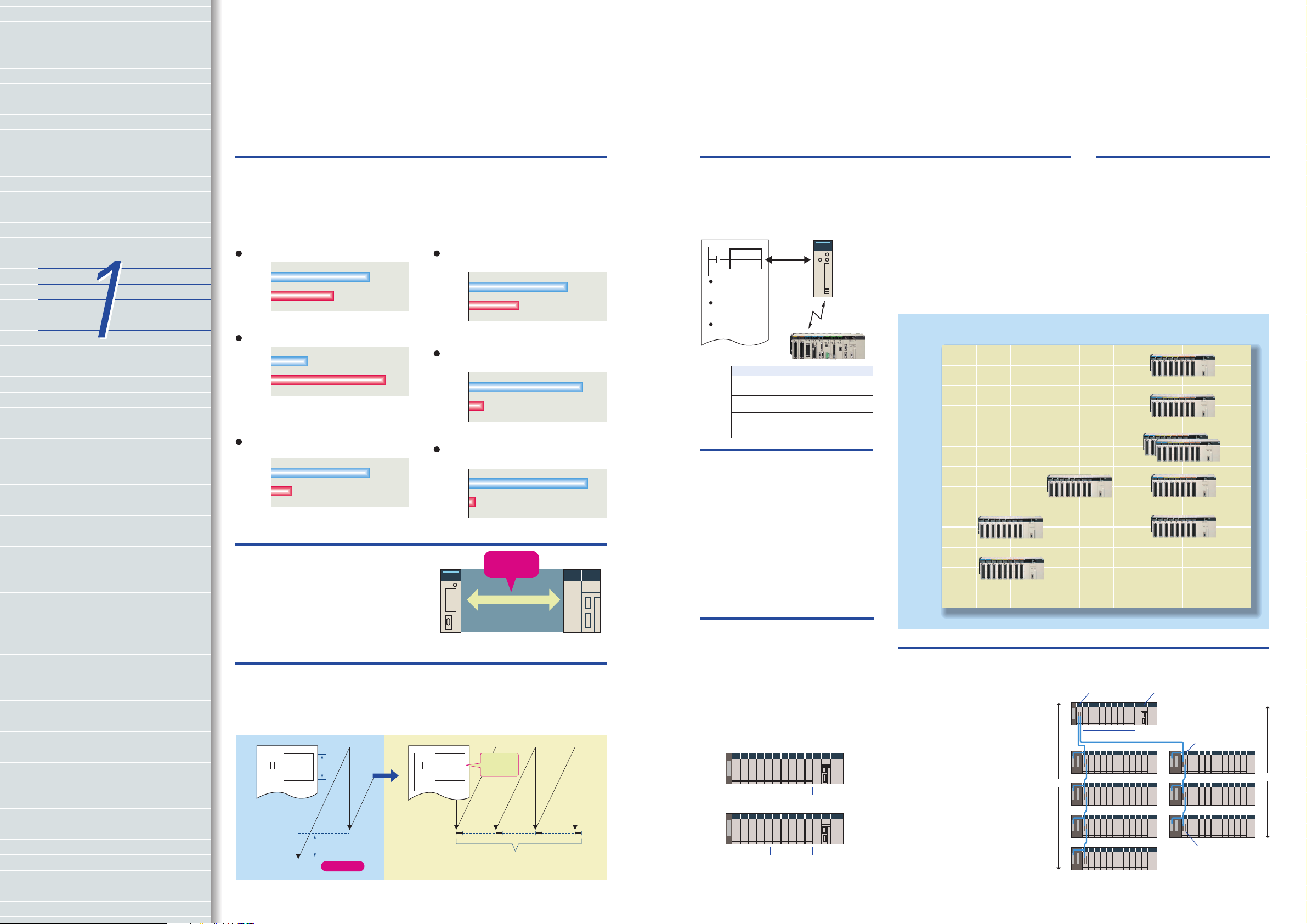

The popular SYSMAC CS1 is better than ev er _ finely tuned

to allow new levels of control.

Price Competition

Time to Market

Meeting Tighter

Deadlines

Global Standards

International

Competition

Total Cost Reduction

Manufacturing

Industry

Customization

Diversification

The current climate of ever-intensifying

competition has created a large number of

different needs for manufacturing industries

around the world. To meet these needs,

OMRON has made further improvements to its

SYSMAC CS1 PLCs, which have been used

successfully in thousands of systems, to deliver

even greater performance. With an "H" for Hyper

Controller, the new PLCs boast the highest

standards in performance, functionality, and

expandability.

Original Products

Developing

Core Technologies

Cost

Programmable Controllers are

abbreviated as "PLC" in this catalog.

The term "personal computers" is

fully written out, and not abbreviated.

In order to create facilites that have the production capability

to withstand sudden changes in demand, or to create

machinery that is easily distinguished from that created by

market competitors, a top-speed controller that can deliver

the performance required to support these needs is

required. The SYSMAC CS1 PLCs have been equipped with

the highest I/O responsiveness and data control functionality

to significantly reduce processing time and to control

machinery movement with greater precision.

In order to allow easier development of complex programs,

in addition to an integrated Windows-based development

environment, the new PLCs are equipped with a variety of

instructions. Structured programming functionality has been

improved to allow programs to be reused with greater

efficiency and thereby reduce labor requirements and cut

costs.

The know-how that our customers have accumulated

through the years forms the core of their competitive

strength. At OMRON, we believe in enhancing this knowhow to the utmost. The key to doing this is 100% upward

compatibility. CS1 PLCs allow existing Units and programs

to be used without any changes.

Unit Versions

Unit versions have been introduced to

control differences in functions featured

by CPU Units that are the result of

version upgrades.

The unit version is marked on the

nameplates of products subject to

version control, as shown in the

diagram.

Unit

CS1H-CPU67H

CPU UNIT

Lot No. 031001 0000 Ver. 3.0

OMRON Corporation MADE IN JAPAN

Unit version

2 3

Use the improved SYSMAC CS1 PLCs to scal e advanced systems to

Long

execution

time

the optimum size.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

Faster Instruction Execution and Faster Overall Performance

In addition to further improvements to

the instruction execution engine, which

is the core of overall PLC performance,

the high-speed RISC chip has been

upgraded to realize the fastest

instruction execution performance in

Common Processing: 1.6 Times Faster

Previous CS1

models

New CS1

models

The figures above are for high-speed, general-purpose PLCs with

interchangeable boards.

0.3 ms

0.5 ms

PCMIX Value: 3 Times Higher

Previous CS1

models

New CS1

models

The PCMIX is the average number of instructions that can be

executed in 1 µs and expresses the over execution performance of

the ladder program. This unit was conceived to allow comparing

the performance of PLCs from different manufacturers using a

common metric.

Cycle Time: 2.5 to 4.8 Times Shorter

(Cycle time for 128 inputs and 128 outputs)

Previous CS1

models

New CS1

models

With normal I/O refresh, 1-ms pulses are not lost even for largecapacity (e.g., 30-Kstep) programs. This allows use in applications

requiring a high working accuracy, such as molding equipment.

5

16

8 Ksteps/ms

Basic instructions only: 38 Ksteps/ms

Including special instructions:

22 Ksteps/ms

System Bus Baud Rate Doubled

The data transfer rate between the CPU

Unit and certain Units has been

doubled to further improve total system

performance.

the industry. Also, the new models

have a mode where instruction

execution and peripheral processing are

processed in parallel, enabling balanced

improvements in overall speed.

LD Instruction Processing Speed:

2 Times Faster

Previous CS1

models

New CS1

models

The development of a special LSI to execute instructions and use

of a high-speed RISC chip enable high-speed processing at the

CPU.

20 ns

OUT Instruction Processing Speed:

8 Times Faster

Previous CS1

models

New CS1

models

Programs consisting mainly of basic instructions are processed at

ultrahigh speed.

20 ns

Subroutine Processing Speed:

17.6 Times Faster

Previous CS1

models

New CS1

models

Cycle time overhead due to program structuring is minimized.

2.1

µ

s

Baud rate

doubled

System bus

CS1 Basic I/O Units

CS1 Special I/O Units

CS1 CPU Bus Units

Reduced Variation in Cycle Time During Data Processing

Instructions that require long execution

time, such as table data processing

instructions and text string processing

instructions, are processed over

Table data/

text string

processing

Long

Long

execution

execution

time

time

The cycle is temporarily

extended when the instruction

is executed.

Variation

multiple cycles to minimize variations in

cycle time and maintain stable I/O

response.

Table data/

text string

processing

Only start of

processing

designated.

Background processing performed over several

cycles to limit the impact on cycle time and thus

reduce variation in cycle time.

40 ns

170 ns

CPU Unit

37 µs

Improved Refresh Performance for Data Links,

Remote I/O Communications, and Protocol Macros

In the past, I/O refresh processing with

the CPU Bus Unit only occurred during

I/O refresh after instructions were

CPU Unit

DLNK

CIO Area words

allocated to CPU

Bus Units

DM Area words

allocated for CPU

Bus Units

Specific Area for

CPU Bus Units

Controller Link Unit

DeviceNet Unit

Serial Communications

Unit

Ethernet Unit

Immediate

I/O refresh

n

CPU Bus

Unit n

Data exchange

during communications cycle

Refresh functionUnit name

Data links

Remote I/O

Protocol macros

Socket service based

on manipulation of

specific bits.

executed. With the new CS1, however,

I/O can be refreshed immediately by

using the DLNK instruction. Immediate

refreshing for processes peculiar to the

CPU Bus Unit, such as for data links and

DeviceNet remote I/O communications,

and for allocated CIO Area/DM Area

words when instructions are executed,

means greater refresh responsiveness

for CPU Bus Units.

Product lineup (Example: LD instruction processing speed, DM capacity)

Program

Capacity

250 Ksteps

120 Ksteps

60 Ksteps

Large Capacity CPU Units for

Greater Component Control

Power

The CS1 CPU Units boast amazing

capacity with up to 5,120 I/O points, 250

Ksteps of programming, 448 Kwords of

data memory (including expanded data

memory) and 4,096 timers/counters

each. With a large programming

capacity, CS1 PLCs are not only ideal

for large-scale systems but easily

handle value-added applications and

other advanced data processing.

30 Ksteps

20 Ksteps

(LD: 0.04 µs, DM: 64 Kwords)

10 Ksteps

(LD: 0.04 µs, DM: 64 Kwords)

Control Up to 960 Points with

Units Mounted to the CPU Rack

The CS1 provides a high level of space

efficiency. As many as 960 I/O points

can be controlled by simply mounting

ten Basic I/O Units, with 96 I/O points

each, to the CPU Rack. Alternatively, as

many as 80 analog I/O points can be

used by mounting five Analog Input

Units and five Analog Output Units.

Ten I/O Units of 96 points each

Five Analog Output

Units of 8 points each

Five Analog Input Units of

8 points each

Two Series of Expansion Racks Up to 50 m Long for

Long-distance Expansion with Up to 72 Units and 7 Racks

With an expansion capacity of up

to 80 Units and 7 Racks over a

distance of 12 meters, the CS1 can

meet large-scale control needs.

Alternatively, an I/O Control Unit

and I/O Interface Units can be used

to connect two series of CS1 Longdistance Expansion Racks

extending up to 50 m each and

containing a total of up to 72 Units

and 7 Racks. CS1 Basic I/O Units,

CS1 Special I/O Units, and CS1

CPU Bus Units can be mounted

anywhere on the Racks and

programmed without being

concerned about special remote

programming requirements.

Note: C200H Units cannot be mounted on the Longdistance Expansion Racks.

Wide Lineup Makes It Easy to

Build the Optimum System

A total of nine CPU Unit models

provide for a wide range of applications,

from small-scale systems to large. The

lineup also includes Memory Cards,

Serial Communications Boards, and a

wide selection of Special I/O Units that

can be used with any CPU Units to

flexibly build the system that meets the

requirements.

(LD: 0.02 µs, DM: 448 Kwords)

(LD: 0.02 µs, DM: 256 Kwords)

(LD: 0.02 µs, DM: 128 Kwords)

(LD: 0.04 µs, DM: 128 Kwords)

(LD: 0.04 µs, DM: 64 Kwords)

960 pts 1,280 pts 5,120 pts

I/O Control Unit

9 Units

50 m

(LD: 0.02 µs, DM: 64 Kwords)

(LD: 0.02 µs, DM: 64 Kwords)

Number of I/O points

CPU

2 Series of

Expansion Racks;

Up to 7 Racks Total

I/O Interface Unit

Terminating

Resistor

50 m

4

5

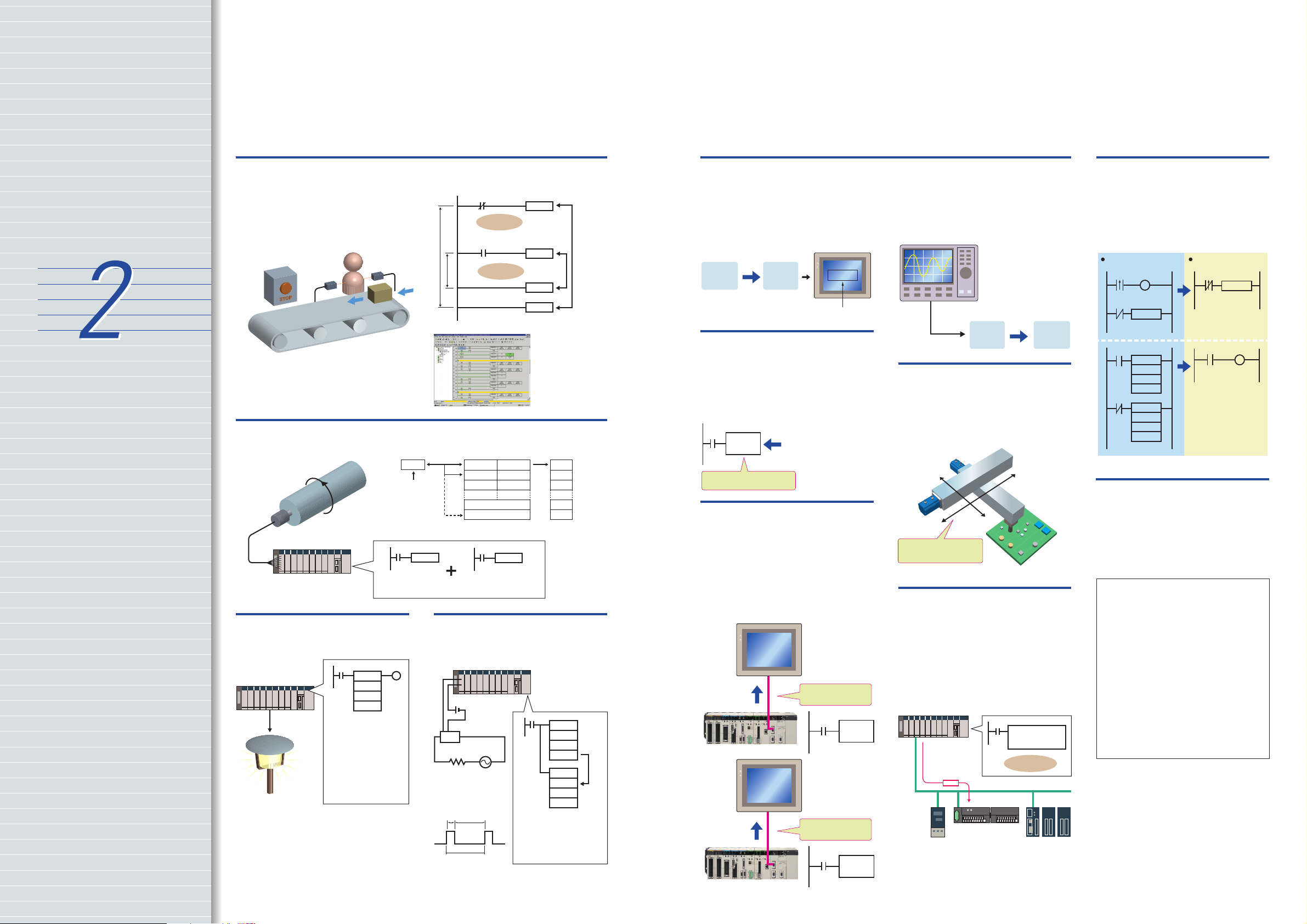

Equipped with functions demanded by the production site to

suit a variety of applications.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

Nested Interlocks (for CPU Unit Ver. 2.0 or Later)

Although strictly speaking the present

interlock instructions do not allow

nesting, applications can be created to

include combination of complete and

partial interlock conditions that achieve

nested interlocks.

Emergency

stop button

(1) Conveyor operates

(2) Contact "a" turns ON when operator is present and

products are supplied.

(3) When the emergency stop button is pressed, the

conveyor and product addition both stop.

Operator

Contact a

Product added

by contact a

CX-Programmer Screen

Emergency

stop button

Conveyor

operates

Worker present (a)

Product

added

Easy Cam Switch Control with Ladder Instructions

(for CPU Unit Ver. 2.0 or Later)

Cam switch

Absolute

encoder

Parallel

wiring

Easy Calendar Timer Function

(for CPU Unit Ver. 2.0 or Later)

=

DT

Compares two

dates/times Comparison

can be limited to any

combination of years,

months, days, hours,

minutes, or seconds.

Example:

A calendar timer function

can be easily set up to

start a process at exactly

Turn ON at 5:00

every evening

5:00 every evening.

Angular data

Value

converted by

GRY

instruction

GRY

Gray code converted

into binary, BCD, or

angles.

TIME-PROPORTIONAL

OUTPUT (TPO) Instruction

(for CPU Unit Ver. 2.0 or Later)

Comparison table Output

Upper limit Lower limit

Compared using

BCMP2 instruction

BCMP2

Compared to see whether

data is between upper

and lower limits.

SSR

20 % 80 %

1 s

Time-proportioning PID

control can be handled

by the PLC by combining

the PID and TPO

(TIME-PROPORTIONAL

OUTPUT) instructions.

MILH 0

MILH 1

MILC 1

MILC 0

Support Software

clearly shows the

interlock status.

ON

OFF

OFF

ON

OFF

The time interval

for execution by

the GRY

instruction is

determined by the

response speed

for reading data

from the absolute

encoder.

PID

S

C

D

TPO

S

C

B

Manipulated variable

Convert Between Floating-point Decimal and Character Strings

The new CS1 can convert floating-point

decimal (real numbers) to character

strings (ASCII) for display on a PT

(operator interface). The data can be

displayed on the PT as a characterstring display element.

Conversion instruction

Floatingpoint

decimal

E.g., 500.00 353030E23030

Character

string

Character-string

display element

PT

500.00

PID Autotuning

The new CS1 can autotune PID

constants with a PID control instruction.

The limit cycle method is used for

autotuning, so the tuning is completed

quickly. This is particularly effective for

multiple-loop PID control.

PIDAT

PID control instruction with

autotuning

Autotuning for PID constants

The new CS1 can convert ASCII

character strings read from

measurement devices by serial

communications to floating-point

decimal data for use in data processing.

Measurement device

(example)

Conversion instruction

Serial

communications

Character

string

Floatingpoint

decimal

Highly Accurate Positioning

with XY Tables

The new CS1 has many doubleprecision processing instructions for

floating-point decimal operations,

enabling positioning with greater

accuracy.

Error Status Generation for

Debugging

A specified error status can be

simulated by executing the diagnostic

instructions (FAL/FALS). With the new

CS1, debugging is simple for

applications that display messages on a

PT or other display device based on the

error status of the CPU Unit.

(Example)

An error has

occurred at unit

number xx.

There is a

possibility that

rack number xx

is disconnected.

PT

Error in Special I/O

Unit

FAL

PT

I/O bus error

FALS

Floating-point

decimal instruction

High-precision positioning

Easy Reading of Maintenance

Data via DeviceNet

(for CPU Unit Ver. 2.0 or Later)

The addition of special explicit message

instructions makes it easy to send

explicit messages without having to

consider FINS commands. Transferring

data among PLCs with explicit

messages is also simplified.

Special explicit

message instruction

No need to

consider FINS

DeviceNet

Simpler Ladder Programs

Ladder programs that use a lot of basic

instructions can be simplified using

differentiation instructions LD NOT,

AND NOT, and OR NOT, and

instructions that access bits in the DM

and EM Areas.

With CS1-series PLCsWith other PLCs

a

a

a

ORW

D00000

#0001

D00000

a

ANDW

D00000

#FFFE

D00000

OUTB

D00000

#0000

Binary Set Values for

Timer/Counter Instructions

The SV for a timer or counter

instruction can be specified using either

BCD or binary. Using binary SV enables

longer timers and higher-value

counters.

Examples: Timer/Counter Instructions

TIM (BCD): 0 to 999.0 s

TIMX(550) (binary) 0 to 6553.5 s

CNT (BCD): 0 to 999 counts

CNTX(546) (binary) 0 to 65,535 counts

Applicable Timer/Counter Instructions

TIMER: TIMX(550)

COUNTER: CNTX(546)

HIGH-SPEED TIMER: TIMHX(551)

ONE-MS TIMER: TMHHX(552)

ACCUMULATIVE TIMER: TTIMX(555)

LONG TIMER: TIMLX(553)

MULTI-OUTPUT TIMER: MTIMX(554)

REVERSIBLE COUNTER: CNTRX(548)

RESET TIMER/COUNTER: CNRX(547)

6

7

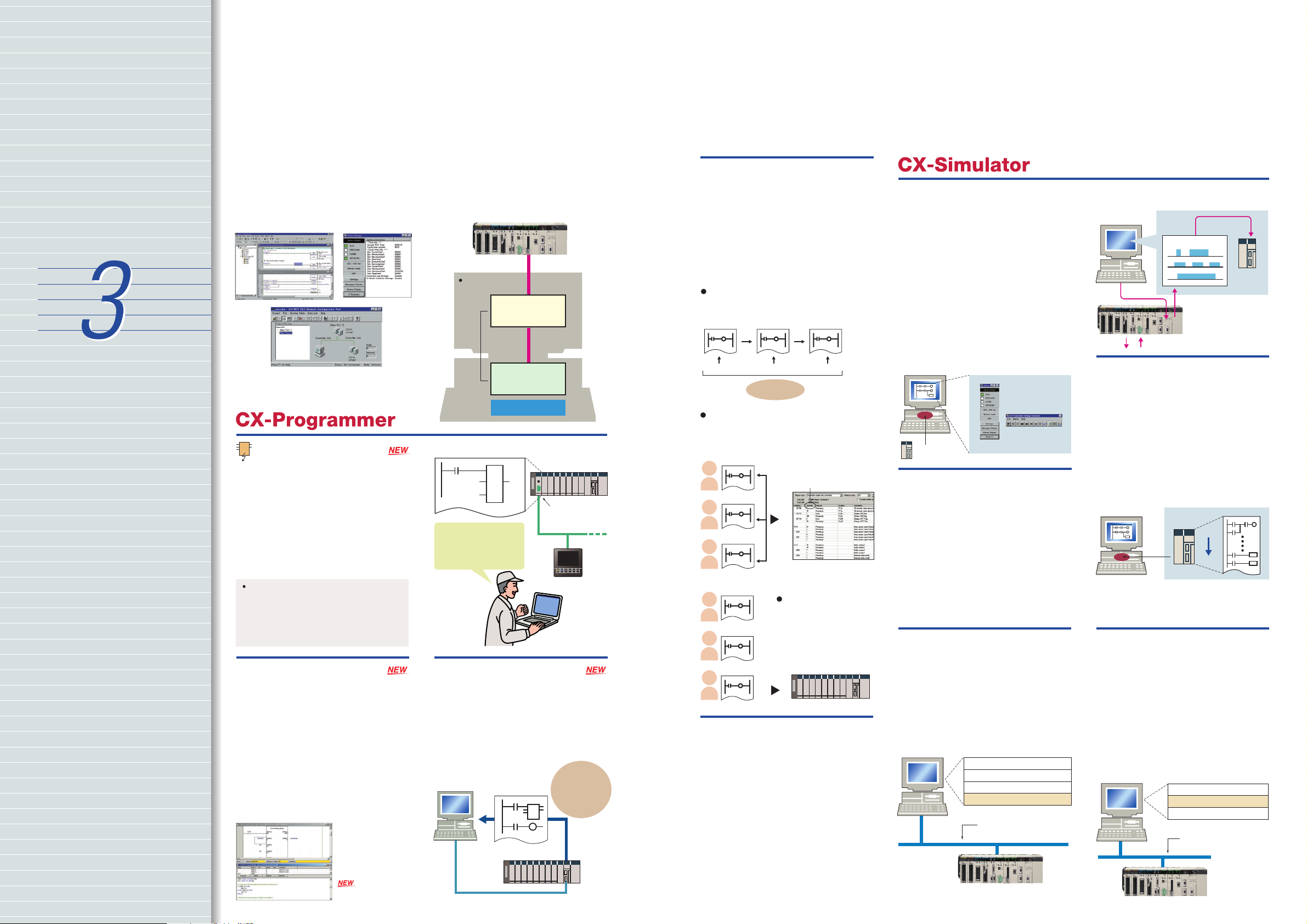

Easier and more efficient design, developmen t, and maintenance with

Windows-based software and middleware.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

Improved Support Software for an Integrated

Windows-based Development Environment

More efficient design and development using the CX-Programmer for programming

and network configuration, and CX-Simulator for operation simulation.

CX-Programmer CX-Simulator

CX-Net Network Configuration Tool

FB

OMRON FB Library

(Unit Ver. 3.0 or later)

The OMRON FB library provides

function blocks for setting SPs, reading

PVs, and reading/writing RUN/STOP

status and other Temperature Controller

parameters. The programmer simply

pastes function blocks from the OMRON

FB Library into the ladder program. The

desired functions can be utilized simply

by inputting the Temperature Controller

unit number and address.

What is the OMRON FB Library?

The OMRON FB Library is a set of functional objects for

ladder programming for OMRON CS/CJ-series PLCs. By

incorporating the OMRON function blocks provided by

OMRON into a ladder program, the program interface for

different control devices is easily completed. This reduces the

number of working hours required for program development

and, at the same time, improves product quality through

standardization.

The Structured Text (ST)

Language Enables Trigonometric

Functions and other Arithmetic

Processes

In addition to ladder programming,

function block logic can be written in ST,

which conforms to IEC61131-3. With ST,

arithmetic processing is also possible,

including processing of absolute values,

square roots, logarithms, and

trigonometric functions (SIN, COS, and

TAN). Processing difficult to achieve in

ladder programs becomes easy to write.

(Unit Ver. 3.0 or later)

System PLC

CS1

Online connection

Inside the personal

computer

CX-Programmer

(Programming

software)

Integrated

development

environment

(Virtual CPU Unit)

Example: Function Block for Writing Temperature Controller SPs

Temperature

Controller

unit number

Address

Simply paste a function block

from the OMRON FB Library

into the ladder program and

enter the unit number, set

point, and other parameters.

Online connection

CX-Simulator

Windows

Normal

end

SYSMAC CJ-series PLC

(See note.)

DeviceNet

Master Unit

DeviceNet

Temperature

Controller

Recovery Possible by

Uploading Function Blocks

from Working PLC

Programs with function blocks can be

uploaded from CPU Units, just like

normal programs, without the need for

additional memory, such as a Memory

Card.

CX-Programmer

Ver.5.0

FB

CS/CJ-series

Unit Ver. 3.0

(Unit Ver. 3.0 or later)

Programs with

function blocks

can be uploaded

from working

PLCs.

Enhanced Efficiency for

Program Development Teams

(for CPU Unit Ver. 2.0 or Later)

Multiple programmers will enjoy better

efficiency when working on task-based

programs, thanks to automatic

checking for address duplication

among tasks, downloading and

uploading in task units, and easy

monitoring of task operating status.

The execution status of each task can be

monitored with CX-Programmer to improve

debugging efficiency.

Task 1

Executing

Checking for address duplication among

tasks developed by multiple programmers is

automatically executed with the cross

reference report of CX-Programmer.

Download only the revised tasks.

Task 1

Executing

Monitoring with

CX-Programmer

When development is

done by several people,

only the tasks that have

been revised need to be

downloaded from CXProgrammer.

Task 1

Executing

The report shows that this

address is used in the

program in the right

column, and tells how

many times it is used.

CX-Programmer list of

Check for duplicate addresses

duplicate addresses

Copy and Paste between

Spreadsheets and Symbol Tables

You can use your favorite spreadsheet

application to prepare an allocation

table with symbol names, addresses,

and I/O comments, then copy and paste

it into a symbol table, and also do the

reverse. This greatly improves

programming productivity.

Programs Can Be Executed,

Monitored, and Debugged

without an Actual PLC

The CX-Simulator Software simulates

ladder execution of the new CS1 CPU

this data to the CX-Simulator as virtual

external input data.

CX-Simulator

Virtual external

input

Sequential data

Unit on a computer. Online functions,

such as monitoring of I/O bit status,

monitoring of I/O memory present

values, forced set/reset, differential

Virtual

CPU Unit

monitoring, data tracing, and online

editing, can be performed by connecting

to the virtual CPU Unit on the computer

from the CX-Programmer using the CX-

Actual PLC

CS1

Simulator. This reduces the total lead

time to machine or system startup.

CX-Simulator

System status

setting window

Comprehensive Debugging

Functions Including Ladder

Step Execution and Break Points

The new CS1 has comprehensive

debugging functions, including ladder

Debugging console

Virtual

CPU Unit

window

Data Logging On-site and

Operation Verification in the

Office

Sequential data from I/O memory in the

actual PLC can be obtained and saved

step execution (execution by instruction),

start point settings, break point setting,

I/O break conditions, and scan execution.

This enables more detailed debugging

without using an actual PLC. Interrupt

tasks can be simulated, enabling more

realistic debugging.

Virtual

CPU Unit

Start

as a data recreation file (CSV format).

On-site PLC ladder execution can be

recreated on a computer by inputting

Stop

Middleware to Support PLC-centered System Construction

Easy development of user applications for communications with the new CS1.

SYSMAC Compolet:

Accessing the CS1 with

Visual Basic

Use SYSMAC Compolet for

communications with OMRON PLCs to

greatly reduce development time of

user applications for CS1 I/O memory

read and write, forced set/reset, and

FINS message communications using

Visual Basic.

Visual Basic user application

Compolet

Fins Gateway

Network board or port

Network support: Controller

Link, Ethernet, or RS-232C

serial communications

CS1

PLC Reporter 32:

Add-on Software for Accessing

the New CS1 Using Excel

Use PLC Reporter 32 to automatically

collect specific CS1 I/O memory data

into Excel 97 or Excel 2000 cells without

special programming. Basically, a

system can be constructed with a

computer, PLC Reporter 32, Excel, and a

host link cable. The cost of constructing

a monitoring system can thus be greatly

reduced.

Excel

PLC Reporter (Fins Gateway)

Network board or port

Network support: Controller

Link, Ethernet, or RS-232C

serial communications

CS1

CX-Programmer Ver. 5.0 or

8 9

higher is required.

Further improvements to communications f unctions.

Seamless networks increase production site transparency.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

The Solution for Communicating

across Network Levels

The SYSMAC CS1 enables FINS

message communications across a

maximum of eight levels (See note)

(using CX-Programmer Ver. 4.0 or

higher) in comparison with three levels

in previous OMRON systems

Expansion up to eight levels lets you

build a seamless communications

system for sending FINS messages

across multiple levels of Ethernet and

Controller Link networks.

Note: For CPU Unit Ver. 2.0 or later.

A Wide Range of Systems,

from Small-scale to Large

OMRON offers a full lineup of reliable

PLCs including the "flagship" CS1

Series, and ranging from the smallscale CQM1H to the large-scale CV

Series. The CS1 Series meets the needs

not only of small-scale to large-scale

systems, but of distributed systems as

well. This allows the construction of the

optimum system for the scale and

applications of the production site.

Flexible System Building

Based on the DeviceNet

The CS1 Series supports the worldwide

multivendor bus standard, DeviceNet.

Component connections in a

multivendor environment are greatly

enhanced by connecting to up to 64

nodes for a wide range of FA

applications, and by device profiles and

configurator tools that ensure high

reliability and easy maintenance.

Production systems can be configured

even more flexibly by incorporating

products such as the MULTIPLE I/O

TERMINAL.

Functions for Better Ethernet

Support

Ethernet is becoming an increasingly

important standard for information

networks. Up to eight socket interfaces

for TCP/IP and UDP/IP are supported, in

addition to FINS messages, FTP file

transfers, and mail notification, so that

production management can now be

organically linked with the production

site.

High Event Responsiveness and High-speed Instruction Execution

The new CS1 has an operating mode

that allows parallel processing for

program execution and peripheral

services. This has the following benefits.

Fast exchange with host computers of

large amounts of data, without

dependence on the program capacity of

the new CS1.

Smooth refreshing of data exchanged

with SCADA software without variations

in timing.

Cycle time not affected if communications

traffic or networks increase when

expanding facilities in the future.

Normal mode Parallel processing mode

(Instruction execution)

Host

SCADA software

CS1

(Peripheral servicing)

Peripheral servicing

Fast large-volume data

exchange

No variations in data

exchange timing

Peripheral services

independent from

cycle time.

Cycle time

Response time:

Approx. 1/3

Sending/receiving FINS

commands and other

event processing.

Add a Redundant Optical Ring

to Your Controller Link

Communications

A redundant network configuration will

keep communications flowing over the

duplicate ring-shaped path in the event

of a broken optical fiber, preventing

system malfunction.

Head office, remote office,

home, business trip destination

• CX-Programmer

Modem

FINS message

Email

Information network

CS1

Ethernet Unit

• TCP/IP or UDP/IP socket service

• FINS message communications

• Message client (SMTP) function

• FTP server function

(File read/write to Memory Card)

Controller Link

FINS message

Seamless

Controller network

Controller Link Unit Controller Link Unit

FINS message

Remote Monitoring via the Web

Connecting via an ONC enables remote

monitoring from a Web browser with a

user-defined Web application (using

Web Tool Kit). It is also possible to

automatically collect data on a Memory

Card mounted to an ONC and

automatically transfer data to the host

PLC (using Data Collection/Distribution

Software).

Head office or remote office

• Web browser

• CX-Programmer

Public telephone line

Modem

Serial communications

Data links

CS1

FINS message

DeviceNet

Ethernet

(Intranet)

DeviceNet

Configurator

DeviceNet

Unit

RS-232C

CS1

Remote I/O communications

ONC

Internet

Head office,

remote office,

home, business

trip destination

• Web browser

Email

HTTP/socket

Automatic FTP transfer of

collected data

Open Network Controller

• Web server function

• Email client (SMTP)

• FTP client

(Collected data file

transferred to host using

FTP when transfer

conditions are met.)

• FINS message

communications

CS1

CJ1

10

I/O refresh

Peripheral service

Peripheral services cannot

be executed

than cycle time.

in shorter period

I/O refresh

Can be executed

in shorter period

than cycle time.

Parallel processing

Event services with

Special I/O Units, CPU

Bus Units, and Inner

Boards.

Peripheral and RS-232C

port servicing.

Event services using

Communications Board.

CS1

Component network

DeviceNet Unit

(can operate as

master or slave)

Temperature

Controller (PID and

other parameter

settings possible

from the

DeviceNet

Configurator).

DeviceNet Slave

DRT2-series Series

Robot or

other device

Programmable

Slave

CompoBus/S

11

Construction of systems in multivendor env ironments simplified

with protocol macros.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

Serial Gateway

(CPU Unit Ver. 3.0 or later)

(Serial Communications Units/Boards with Ver. 1.2 or later)

Truly Seamless Incorporation of OMRON Components

and Other Devices into Networks

When the CPU Unit (Ver. 3.0 or later) or

Serial Communications Board or Serial

Communications Unit (Ver. 1.2 or later)

receive a FINS command containing a

CompoWay/F command (see note 1) via

network or serial communications, the

command is automatically converted to

a protocol suitable for the message and

forwarded using serial communications.

CompoWay/F (See note 2.)

Host Link FINS

(Possible only with Serial Communications Boards or

Serial Communications Units Ver. 1.2 or later)

Serial Gateway System (Reference)

When CompoWay/F commands are

enclosed in FINS commands and sent

to Serial Communications Boards or

Serial Communications Units (Ver.

1.2) or serial ports on CPU Unit Ver.

3.0, the enclosed CompoWay/F

command is retrieved using a Serial

Gateway Function and sent as a

CompoWay/F command.

More Ports for Even More

Serial Device Connections

Protocol macros make it easy to create

serial communications protocols

(communications frames, error checks,

retries, error processing, etc.) to match

those of remote communications

devices. Multiple ports are provided for

this function. Each PLC supports up to

16 Serial Communications Units (32

ports total) and one Serial

Communications Board (with 2 ports).

This makes it possible to connect up to

34 devices with serial communications

at a speed of 38.4 Kbps. Message

length has been increased from 256 to

1,000 bytes to give communications

more power than ever before.

Gateway

Serial

Component/PLC

Note 1: FINS

Abbreviation for Factory Interface Network Service. A

command system for message services common to

OMRON networks. FINS commands can be sent across

up to 8 network levels, including serial

communications paths using a serial gateway.

(Possible only with CS/CJ-series CPU Unit Ver. 2.0 or

later.)

Note 2: CompoWay/F

CompoWay/F is an integrated communications

protocol used for OMRON general-purpose serial

communications. It is used by Temperature Controllers,

Digital Panel Meters, Timer/Counters, Smart Sensors,

Cam Positioners, Safety Controllers, etc. (as of July

2004).

Temperature

Controller

OMRON Components

communications

Windows-based Software

Simplifies Serial Device

Connections

Protocol macros for Serial

Communications Units and Boards can

be created using the CX-Protocol, thus

enabling message tracing and greatly

reducing the time involved in

connecting various serial devices.

FINS network

FINS command received

Serial Gateway: FINS

command "capsule"

opened and contents

retrieved.

Sent as a CompoWay/F

command

Smart Sensor

Enhanced Protocol Macro

Functionality

(Serial Communications Units/Boards with Ver. 1.2 or later)

Baud rate increased from 38,400 bps

to 57,600 bps for faster

communications.

Standard system protocol added for

greater connectability with

components and PLCs.

•CompoWay/F Master

•Host Link Master functions

•Mitsubishi Computer Link Master

Wide Range of Applicable

Protocols Allows for High

Value-added Programs

The CS1 Series supports a wide range

of serial communications protocols,

such as Host Link, no-protocol, NT Link,

peripheral bus, and more. These allow

for high value-added programs such as

MMI, communications, and data

processing.

The Fastest Communications

in the Industry with

High-speed NT Links

Combine with one of the NS Series

Programmable Terminals (NS8, NS10,

or NS12) to enable connecting Highspeed NT Links. Using NT Link

terminology together with a

communications speed of 115 Kbps

provides high-speed response.

NT Links (1:N Mode)

Programmable

Terminal

PLC-to-PT connection in NT Link (1:N mode) communications can be either one-to-one or one-to-many.

Programmable

Terminal

Serial Communications

Configuration Example

Host computer, etc.

Host Link

ASCII Unit Serial Communications Unit

Commercially-available

external device

General-purpose protocol

using BASIC in ASCII Unit

Protocol macros

Temperature controller,

bar code reader, etc.

Serial

Communications Board

CPU Unit

Protocol macros

Commercially-available

external device

Protocol macros

Microcomputer,

etc.

Host Links No-protocol

Sending Host Link and

FINS commands

Reading and writing

Device

of I/O memory and

operating modes

Response

Serial

Communications

Unit

TXD instruction

or

RXD instruction

using Serial

Communications

Unit

Data input from

a bar code reader

Supports No-protocol Communications

(Serial Communications Units/Boards with Ver. 1.2 or later)

No-protocol communications supported for Serial

Communications Units and Serial Communications

Boards

This mode enables components to be connected to

multiple communications ports using no-protocol

communications.

Serial port I/O instructions executable using noprotocol communications from Serial

Communications Units and Serial Communications

Boards (TXDU, RXDU, TXD, and RXD) are

supported for CPU Units with Ver. 3.0 or later.

Programming Devices

CX-Programmer

CX-Protocol

CX-Motion

Data output to printer

Programming

Console

Peripheral bus

(Programming

Console bus)

Programmable

Terminal

NT Link

Non-OMRON

PLCs, etc.

CPU Unit

RS-232C Port

Serial

Communications

Board

TXD instruction

or

RXD instruction

using CPU Unit's

RS-232 port or Serial

Communications Board

12 13

Advanced management and resource inheri tance providing powerful support for

maintenance and operation.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

Remote Maintenance

1. Program or monitor a

remote PLC via a modem

connection.

2. Program or monitor a

network PLC via a Host

Link connection.

3. Send e-mail for errors

from PLCs connected to

Ethernet.

1. Remote programming/monitoring

via modem

Note: The same kind of programming and monitoring

performed via normal Host Link is possible.

(See note.)

Modem

Memory Cards for Data File

Management

User programs, I/O memory, or system

parameters can be converted to

Windows-based files and stored in

Memory Cards or in EM file memory in

the CPU Unit. It is also possible to

automatically read the user program

and other data from the Memory Card

to the CPU Unit at startup, replacing

ROM operation. Change programs onsite using only a Memory Card and

Programming Console, or use Memory

Cards to store symbol tables or I/O

comments. Connecting a Programming

Device allows monitoring operations

with ladder programs with comments.

It is also possible to save and read data

such as DM data to a Memory Card

during operation, and the Memory

Cards are ideal for operations such as

saving quality data and reading recipes.

3. Mail

Phone line

Office

PC Card

Adapter

Memory Card

Ethernet

Modem

Host Link

2. Remote programming/

monitoring via Host Link

(See note.)

Upload

Download

Boost Program Security

by Keeping Part of It Hidden

(for CPU Unit Ver. 2.0 or Later)

You can prevent access to special tasks

by requiring the user to have a

password to read them.

Task 1

Use a password to prevent

reading of only task 2.

CX-Programmer

Ver. 4.0

Task 2

Task 3

Crucial

programming

cannot be

read.

This allows you to hide crucial parts of

the program.

By applying write protection, you can

also prevent a user from inadvertently

writing over the hidden part of the

program. This provides additional

protection for your program.

Read protection

Write protection

Internal Flash Memory-based

Battery-free Operation

Flash memory (non-volatile memory) is

built into the new CS1's CPU Unit. User

programs and system parameters (e.g.,

PC Setup and data link tables) are

automatically saved to this flash

memory. This means that the new CS1

can operate without a Memory Card

and battery.

Built-in flash memory

User program

Parameter area data

CS1

Prevent Information Leaks

from PLCs

(for CPU Unit Ver. 2.0 or Later)

In addition to applying read protection

functions to the user program area and

tasks, you can also protect against the

transfer of user programs to a Memory

Card.This prevents leaks of proprietary

information by completely protecting

against the reading of programs inside

the PLC.

Read

protection

CX-Programmer

Ver. 4.0

No transfer

possible

Memory Card

Easy Replacement of Existing

Models

Programs designed for existing models

(C200HX/HG/HE, CVM1, or CV-series

PLCs) using the CX-Programmer can be

converted for use with the new CS1.

The following functions are available to

make the conversion to the new CS1

even easier.

CV-CS address conversion instruction to

convert programs designed for the

CVM1/CV that include internal I/O

memory addresses.

C200HX/HG/HE: Region comparison (ZCP

and ZCPL) instructions.

C200HX/HG/HE

CVM1/CV

Easy replacement

CS1

Write Protection from a Specific

Node over the Network

(for CPU Unit Ver. 2.0 or Later)

You can now stop specific nodes from

writing over the network.By preventing

unintentionally writes to the PLC while

monitoring data over the network, you

can prevent potential problems.

Reading

possible

Write protection

Reading

possible

Write enabled

Replace Malfunctioning Units

without Turning OFF the Power

(Online Unit Replacement)

When an I/O Unit, a Special I/O Unit, or

a CPU Bus Unit is malfunctioning, it is

now possible to replace the faulty Unit

while the system continues operating.

This is particularly effective for systems

that cannot be stopped when a problem

has occurred in another part of the

system.

(This function requires a CS1D-CPU S CPU

Unit, a CS1D-BC082 or CS1D-BI092 Backplane,

and a CS1D-PA207R or CS1D-PD024 Power

Supply Unit.)

(1) (2)

Remove the

faulty Unit

after

stopping

access to it.

Faulty Unit

CPU

PS

Resume

access after

replacing the

Unit.

14

Production

site

Programming

Console

Battery-free

operation

with no Memory

Card.

CX-Programmer Ver. 5.0 or higher required.

Store All I/O Comments, Symbol Names, Rung Comments,

and Other Information in CPU Unit Comment Memory

(Unit Ver. 3.0 or later)

When downloading projects, the

Memory Card, EM file memory, or

comment memory (in the CPU Unit's

flash memory) can be selected as the

transfer destination for I/O comments,

symbol names, rung comments, and

other data. This enables data such as

I/O comments, symbol names, and

rung comments to be stored in the CPU

Unit's internal comment memory when

a Memory Card or EM file memory are

both not available. (PLC models: CS/CJseries with unit version 3.0 or later

only.)

15

Machine performance improved with

high-speed, high-precision motion control.

The evolution of

the SYSMAC CS1 is

accelerating advances in

the production site.

Position Control Units

Two Types of Outputs and

Control of 1, 2, or 4 Axes

Select from 1-axis, 2-axis, and 4-axis

models with either open-collector

output or line-driver output to suit a

number of different applications.

A Variety of Positioning

Functions

There are 2 operating modes: direct

operation (position, speed, acceleration,

and deceleration data specified from

the ladder program), which is effective

for setting target positions and speeds

immediately or during operation, and

memory operation, where fixed

patterns are stored beforehand in the

Unit and used for operation. There are

also a variety of positioning functions,

such as interrupt feeding, which is

effective for feeder control, and forced

interrupt, which is useful in

emergencies.

Advanced Motion Control Units

Easy System Construction

Up to 30 physical axes and two virtual

axes, making a total of 32, can be

controlled, and the servo interface is

handled by high-speed servo

communications (MECHATROLINK-II, a

registered trademark of Yaskawa

Electric Corporation). This makes it

possible to control multiple axes with

less wiring.

Easy Data Control

High-speed servo communications lets

you read programs and parameter

settings from CX-Programmer on a PC.

You can also read and track the

operating status of parameter settings

inside the Servo Driver.

Easy Motion Control

Motion control, including positioning,

synchronizing (electronic gears,

electronic cams, tracking), speed, and

torque control, can all be handled by

the CS1.

Eight motion tasks can be used for

simultaneous motion program

execution.

Motion Control Units Customizable Counter Units

Easy Programming with

G Language and Multitasking

The Motion Control Units use G

language to ensure easy programming.

The Units have a large programming

capacity of up to 100 programs and

2,000 program blocks, and allow

independent operation of 4 tasks.

High-speed Interlocks

Interrupt programs can be executed

from the motion control program using

D codes (interrupt codes). Easy, fast

interlocks ensure greater production

efficiency.

Motion

Control

Units

Communications

SMART

STEP

Units

Pulses

JUSP-NS115

Interface Unit for

MECHATROLINK-II

(Yaskawa)

A Whole New Concept

A high-speed PLC with 20 I/O points, a

2-axis high-speed counter, and 2 pulse

or analog outputs have all been

combined into 1 Unit. The

Customizable Counter Units allow easy

execution of complicated applications.

Customizable

Counter Unit

PLC

High-speed

PLC

overhead

0.1 ms

Customizable Counter UnitsPosition Control

Analog

W Series

20 I/O points

Pulse output

Analog output

Analog input

Counter

Encoder

Easy Control for Bending and

Pressing

It is possible to switch between speed

control and torque control from the

ladder program, enabling bending

operation for metals and pressing

operation for bonding.

Pulse/analog output

CX-Programmer

Servo Driver

Torque

Speed

CX-Motion

CX-Position

MC-Miel

(free software)

Torque Sensor

CS1W-HCA22

Torque Speed

Position

Servomotor

Analog input

Servo Driver

Synchronous Control with

Electronic Cam

Counter input and pulse output that

previously could only be connected via

a CPU Unit can now both be handled by

the same Unit. The built-in high-speed

PLC enables synchronous control of, for

example, electronic cams. The cam

curve that determines the relationship

between counter input and pulse

output can be defined freely using the

line-segment approximation function

from the ladder program.

Design Costs Reduced by

Modularization

Ladder programs and I/O instructions to

be re-used or shared by designers can

be transferred from the main CPU Unit

to the Units, allowing "modularization"

that helps to reduce design costs. Up to

96 Units can be used, enabling easy

system expansion in the future.

Motion Applications with

High-speed Response

A wide range of interrupt functions and

superior response performance enable

motion applications requiring highspeed response using pulse I/O.

16

ServomotorServomotorServomotorServomotor

17

Smart Process Control

OMRON PLC-based Process Control brings Major Innovations to Process Automation

The evolution of

the SYSMAC CS1

accelerates DCS

downsizing.

Function block programming

Sequence programming

using either step ladders or

sequence tables

A direct link to HMI products

DCS functionality in a PLC

Analog Units with signal

conversion functions

A scaleable system

configuration

PLC-based

PLC-based

Process Control

Process Control

Duplex

operation

supported

Complete

maintenance

functions

Diversified Loop Control is even easier to use.

Programming becomes even easier with function-block programming.

Packed with complete DCS functionality,

the LCBs/LCUs are programmed with

function blocks designed specifically for

process control. Similar to preparing a

flow sheet, function blocks are pasted

and connections made using a graphic

interface. A wide array of control

methods, from basic PID control to

cascade and feed-forward control, are

possible.

Example: Cascade Control

(Heating and Cooling)

Temperature

Analog

Input Unit

Analog

Output Unit

Cooling

water

Drain

Loop Control

Unit/Board

PV1

PV2

Split

conversion

Temperature

PID1

PID2

Heat

exchange

MV2

MV1

RSP1

Steam

With Function

Blocks:

Isolated-type

Ai4 Terminal

Y1

Y2

Y3

Y4

PID1

Basic PID

PV

PVE

RSP

MIE

MVE

Basic PID

PV

PVE

RSP

MIE

MVE

PID2

Split

Conversion

SP

Y1

MV

SP

Y1

MV

X1

Isolated-type

Ao4 Terminal

Y1

Y2

X1

Y1

X2

Y2

X3

Y3

X4

Y4

Provides an exceptionally open environment with PLC-based

process control to advance standardization and IT integration of

the process control system.

Operation, Monitoring, and Data Logging

Touch Panels

NS-series PT

PLC Reporter

PLC data can be collected

and written in Excel.

Compolet

Communications

programming

between a PC and

PLC can be

accompllshed

easlly with ActiveX

control.

User Application

PLC (CS1 Duplex)

CS1D Process-control CPU

Unit

Duplex Process-control CPU

Unit can help reduce risk

insystems that must not stop.

Process I/O Units

Analog I/O Units are available

for diverse functions such as

Isolators, power supplies, and

signal conversion.

Special HMI software

CX-Process Monitor Plus

Commercially available

HMI software

HMI software

compatible with

FinsGateway

Ethernet/Controller Link

PLC (CS-series)

HMI Software

Loop Control Board/Unit

Condenses DCS functions

in a compact Unit and

enables function-block

programming.

CX-Process Tool

Function blocks can be

pasted into windows and

graphic programming can

be perfomed by arranging

blocks with the mouse.

PLC-based Process Control Application Examples

In-line Blending in a Food Plant

RSView32

Monitoring Screen

(collecting and

saving data)

SYSMAC CS1 PLC with advanced

Loop Control Board

Flowrate control (blended

PID control)

Materials tanks

A

B

C

Flowrate Control outputs

Motor

Intermediate tank

Personal computer

HMI software

Ethernet

Product tanks

A

B

Batch Control in a Chemical Factory

Personal computer

HMI software

Ethernet

SYSMAC CS1 Duplex PLC

(CS1D Process-control CPU Unit)

Reaction control

Motor

Motor

Motor Motor

18

Drying equipment

19

A Complete Lineup of Units for Optimum C ontrol.

CPU Rack

Note: Connection is not possible

to a 2-slot CPU Backplane.

Long-distance

Expansion

Connecting Cables

CV500-CN 2

CS1 I/O

Connecting Cables

CS1W-C 3

(30 or 70 cm; 2, 3, 5, 10, or 12 m)

CS1 to C200H

I/O Connecting Cables

CS1W-CN

(30 or 70 cm; 2, 3, 5, 10, or 12 m)

I/O Control

Unit

CS1W-IC102

I/O Interface

Note: C200H

Units cannot be

mounted on the

Long-distance

Expansion

Racks.

Unit

CS1W-II102

CS1 Expansion Rack

C200HX/HG/HE

Expansion I/O Rack

CPU Backplanes

Serial

Communications

Loop

Control

Board

Board

CS1W-SCB21-V1

CS1W-SCB41-V1

CS1W-LCB01/05

Terminating

Resistor

CV500-TER01

(Two provided with

CS1W-IC102.)

CS1 Expansion

Backplanes

CS1W-BI 2

(3, 5, 8, or 10 slots)

Note: These Expansion Backplanes are for CS1

Units only. Use a CS1W-BI 3 Backplane

CS1W-BC 2

(2, 3, 5, 8, or 10 slots)

Note: Expansion is not

possible for 2-slot

Backplanes. These

Backplanes are for CS1

Units only.

Use a CS1W-BC 3

Backplane for C200H Units.

CPU Units Power Supply

Units

CS1H-CPU H

CS1G-CPU H

C200HW-PA204/PA204R/

PA204S/PA209R/PD024/

PD025/PD106R

Memory Card

HMC-372/672

Power Supply

Units

C200HWPA204/

PA204S/

PA209R/

PD024/PD025/

PD106R

Basic I/O Units

CS1 Basic I/O Units

16 pts

Input Unit:

CS1W-ID211

32 inputs/32 outputs

I/O Units:

CS1W-MD26

Interrupt Input Unit

Interrupt function

supported on CPU

Rack only.

(Two Units

mountable on

CPU Rack.)

C200H Interrupt Input

Unit can also be used.

16 pts

CS1W-INT01

Special I/O Units

CS1

Special I/O

Unit

Analog Input Units

CS1W-AD041-V1

/AD081-V1

32 pts

Input Unit:

CS1W-ID231

48 inputs/48 outputs

I/O Units:

CS1W-MD29

Analog Timer Unit B7A Interface Units

Analog Input Unit

CS1W-AD161

64 pts

Input Unit:

CS1W-ID261

16 pts

AC Input Units:

CS1W-IA111/211

C200H-TM001

96 pts

Input Unit:

CS1W-ID291

8 pts

Triac Output Unit:

CS1W-OA201

16 pts

C200H-B7A11/O1

Analog Output Units

CS1W-DA041/

DA08V/DA08C

Note: C200H Basic I/O Units and C200H Group 2 High-density I/O Units can also be used.

16 pts

Output Units:

CS1W-OD21

16 pts

Triac Output Unit:

CS1W-OA211

32 pts

Output Units:

CS1W-OD23

8 pts (independent)

Relay Output Unit:

CS1W-OC201

64 pts

Output Units:

CS1W-OD26

16 pts

Relay Output Unit:

CS1W-OC211

96 pts

Output Units:

CS1W-OD29

32 inputs/

32 outputs

TTL I/O Unit:

CS1W-MD561

Safety Relay UnitHigh-speed Input Unit

Group-2 Unit

C200H-B7A02/12/21/22

Analog I/O Unit

CS1W-MAD44

16 pts

CS1W-IDP01

Process I/O Units

CS1W-P (-V1)

CS1W-SF200

Position Control

Units

CS1W-NC

20

C200H I/O

Connecting Cables

C200H-CN 1

(30 or 70 cm; 2, 5, or 10 m)

CS1 CPU Bus Units

Loop Control

Unit

CS1W-LC001

Motion Control

Unit

CS1W-MCH71

Serial Communications Unit

CS1W-SCU21-V1

C200HX/HG/HE

Expansion I/O Rack

Ethernet Units

CS1W-ETN21

CS1D-ETN21D

C200HX/HG/HE

Expansion

I/O Backplanes

C200HW-BI 1(-V1)

(3, 5, 8, or 10 slots)

Controller Link Units

CS1W-CLK21-V1/12-V1/52-V1

Power Supply

Units

SYSMAC Link Units

(coaxial, optical)

CS1W-SLK21/SLK11

C200HWPA204/

PA204S/

PA204R/

PA209R/

PD024/

PD025

DeviceNet Unit

CS1W-DRM21-V1

Motion Control

Units

CS1W-MC221/

MC421-V1

High-speed Counter

Units

CS1W-CT021/041

Customizable

Counter Units

CS1W-HCP22-V1/

HCA22-V1/HCA12-V1

/HIO01-V1

ID Sensor Units

CS1W-V600C11

CS1W-V600C12

GP-IB Interface Unit

CS1W-GPI01

C200H Special I/O Units

Temperature

Sensor Units

C200H-TS

ASCII Units*

C200H-ASC

Note 1. Only CS1-series Units (i.e., with model numbers starting ÒCS1WÓ) can be used with CS1D PLCs.

2. The HMC-EF372/EF672 cannot be used with CS1G-CPU H, CS1H-CPU H, CJ1G-CPU H, and CJ1H-CPU H CPU Units with lot numbers of 02108 or earlier (i.e., CPU Units manufactured before 8

January 2002) or with NS7-series PTs with lot numbers of 0852 or earlier (i.e., PTs manufactured before 8 May 2002). Be careful when ordering.

3. There are restrictions in data transfers with the CPU Unit for bit and DM Area specifications for the C200H Special I/O Units marked with asterisks, as well as in data transfers programmed from these Units.

Refer to CS-series PLC Operation manuals for details.

Temperature

Control Units

C200H-TC

C200H-TV

DeviceNet

I/O Link Unit

C200HW-DRT21

PID Control Units

C200H-PID0

CompoBus/S

Master Unit

C200HW-SRM21-V1

Cam Positioner

Unit*

C200H-CP114

High-speed

Counter Units*

C200H-CT

Position Control

Units*

C200HW-NC

2-axis Motion

Control Unit*

C200H-MC221

ID Sensor Units*

C200H-IDS

21

Specifications and Models

Specifications by Model

Item

Model

No. of I/O points

Program capacity

DM Area

EM Area

LD instruction time

Control

I/O control

Programming language

Instruction length

No. of instructions

No. of tasks

Interrupt types

Internal communications port

Mountable optional

products

Main functions

CS1H-CPU67H

CS1D-CPU67S

250 Ksteps

32 kW x 13 banks 32 kW x 7 banks 32 kW x 3 banks 32 kW x 1 bank 32 kW x 1 bank 32 kW x 1 bank 32 kW x 1 bank 32 kW x 1 bank32 kW x 3 banks

Parallel peripheral service processing, constant (minimum) cycle time, cycle time monitoring, input time constant settings, debugging (online edit, error simulation, forced set

and reset, data trace, differential monitoring, etc.), program protection, diagnostic check, error history, clock,

power OFF detection delay time, remote programming and monitoring, eight-level communications, etc. (See note.)

CS1H-CPU66H CS1H-CPU65H

Scheduled interrupts, I/O interrupts, power OFF interrupt, and external I/O interrupts (interrupts from Inner Boards and CPU Bus Units).

CS1D-CPU65S

5,120 (No. of Expansion Racks: 7)

60 Ksteps 30 Ksteps 20 Ksteps 60 Ksteps 30 Ksteps 20 Ksteps 10 Ksteps120 Ksteps

20 ns

Note: CPU Unit must be Unit Ver. 2.0 or later for 8 levels of communications (Pre-Ver. 2.0 CPU Units allow communications over three network levels).

CS1H-CPU64H

Both cyclic scan method and on-demand mode can be used.

Memory Cards, Inner Boards (e.g., Serial Communications Boards)

Specifications

CS1H-CPU63H

Stored program method

Ladder diagram

1 to 7 steps/instruction

Approx. 400

288 (256 shared with interrupt tasks)

1 peripheral port and 1 RS-232C port

CS1G-CPU45H CS1G-CPU44H

32 kW

CS1D-CPU44S

1,280

(No. of Expansion

Racks: 3)

CS1G-CPU43H CS1G-CPU42H

960 (No. of Expansion Racks: 2)

40 ns

CS1D-CPU42S

Configuration Devices (CPU and Expansion Units)

Name

CPU Units

CPU Unit

(with on-line replacement

capability)

CPU Backplanes

CPU Backplanes

(for CS1 Units only)

CS1D CPU Backplane (with

on-line replacement capability)

Expansion Backplanes

CS1 Expansion

Backplanes

(for CS1 Units only)

CS1D Expansion Backplane

(with on-line replacement

capability)

Power Supply Units

CS1D Power Supply

Unit (with on-line

replacement capability)

I/O Control Unit

I/O Interface Unit

Memory Cards

Serial Communications

Boards

Loop Control Board

Programming Consoles

Model

CS1H-CPU67H

CS1H-CPU66H

CS1H-CPU65H

CS1H-CPU64H

CS1H-CPU63H

CS1G-CPU45H

CS1G-CPU44H

CS1G-CPU43H

CS1G-CPU42H

CS1D-CPU67S

CS1D-CPU65S

CS1D-CPU44S

CS1D-CPU42S

CS1W-BC023

CS1W-BC033

CS1W-BC053

CS1W-BC083

CS1W-BC103

CS1W-BC022

CS1W-BC032

CS1W-BC052

CS1W-BC082

CS1W-BC102

CS1D-BC082S 8 slots (use together with the CS1D-CPU S)

CS1W-BI033

CS1W-BI053

CS1W-BI083

CS1W-BI103

CS1W-BI032

CS1W-BI052

CS1W-BI082

CS1W-BI102

CS1D-BI092

C200HW-PA204

C200HW-PA204S

C200HW-PA204R

C200HW-PA209R

C200HW-PD024

C200HW-PD025

C200HW-PD106R

CS1D-PA207R

CS1D-PD024

CS1D-PD025

CS1W-IC102

CS1W-II102

HMC-EF372

HMC-EF672

HMC-AP001

CS1W-SCB21-V1

CS1W-SCB41-V1

CS1W-LCB01

CS1W-LCB05

CQM1-PRO01-E

C200H-PRO27-E

5,120 I/O points

5,120 I/O points

5,120 I/O points

5,120 I/O points

5,120 I/O points

5,120 I/O points

1,280 I/O points

960 I/O points

960 I/O points

5,120 I/O points

5,120 I/O points

1,280 I/O points

960 I/O points

2 slots (Expansion I/O Units cannot be connected.)

3 slots

5 slots

8 slots

10 slots

2 slots (Expansion I/O Units cannot be connected.)

3 slots

5 slots

8 slots

10 slots

3 slots

5 slots

8 slots

10 slots

3 slots

5 slots

8 slots

10 slots

9 slots (use together with the CS1D-CPU S)

100 to 120 VAC/200 to 240 VAC; Output capacity: 5 VDC at 4.6 A, 26 VDC at 0.625 A, total 30 W max.

100 to 120 VAC/200 to 240 VAC (with 24 VDC, 0.8-A service power supply); Output capacity: 5 VDC at 4.6 A, 26 VDC at 0.625 A, total 30 W ma

100 to 120 VAC/200 to 240 VAC (with RUN output); Output capacity: 5 VDC at 4.6 A, 26 VDC at 0.625 A, total 30 W max.

100 to 120 VAC/200 to 240 VAC (with RUN output); Output capacity: 5 VDC at 9 A, 26 VDC at 1.3 A, total 45 W max.

24 VDC; Output capacity: 5 VDC at 4.6 A, 26 VDC at 0.625 A, total 30 W max.

24 VDC, Output capacity: 5 VDC at 5.3 A, 26 VDC at 1.3 A, total 40 W max.

100 VDC; Output capacity: 5 VDC at 6 A, 26 VDC at 1.0 A, total 30 W max.

100 to 120 V AC/200 to 240 V, 50/60 Hz (RUN output), output capacity: 5 V DC at 7 A,

26 V DC at 1.3 A, total 35 W max. (for both Duplex-CPU Systems and Single-CPU Systems)

24 V DC, Output capacity: 5 V DC at 4.3 A, 26 V DC at 0.56 A, total 28 W max. (for both Duplex-CPU Systems and Single-CPU Systems)

24 VDC, Output capacity: 5 VDC at 5.3 A, 26 VDC at 1.3 A, total 40 W max. (for both Duplex-CPU Systems and Single-CPU Systems)

For long distance expansion exceeding 12 m (50 m max.). (With 2 terminating resistors.)

For long distance expansion exceeding 12 m (50 m max.).

Flash memory, 30 Mbytes

Flash memory, 64 Mbytes

Memory Card Adapter (for PCMIA slot on personal computer)

Two RS-232C ports

One RS-232C port and one RS-422/485 port

50 blocks maximum including both adjustment and operation blocks

500 blocks maximum including both adjustment and operation blocks

Console for on-site operation

Console for on-site operation

22 23

Specifications International standards

250 Ksteps

120 Ksteps

60 Ksteps

30 Ksteps

20 Ksteps

60 Ksteps

30 Ksteps

20 Ksteps

10 Ksteps

250 Ksteps

60 Ksteps

30 Ksteps

10 Ksteps

448 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 13 banks)

256 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 7 banks)

128 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 3 banks)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

128 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 3 banks)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

448 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 13 banks)

128 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 3 banks)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

64 Kwords of data (DM: 32 Kwords, EM: 32 Kwords x 1 bank)

CPU Unit Inner Board for CS1 Series

A C200H Expansion Backplane can be used in addition to the above Backplanes.

x.

UC1, N, L, CE

UC1, N, L, CE

U, C, N, L, CE

U, C, N, CE

UC1, N, CE, L

U, C, N, L, CE

U, C, N, CE

UC1, N, L, CE

U, C, N, L, CE

U, C

U, C, N, L, CE

UC1, N, L, CE

approval pending

UC1, L (

UC

UC1, N, L, CE

UC1, CE, N, L

approval pending

UC1, L (

U, C, CE

L, CE

CE

U, C, N, L, CE

UC1, N, CE

U, C, N, CE

), N, CE

), N, CE

Support Software

Product name

CX-One FA integrated Tool Package

CX-Programmer Ver. 6.

CX-Simulator Ver. 1.

CX-Protocol Ver. 1.

CX-Motion Ver. 2.

CX-Position Ver. 2.

CX-Process Tool Ver. 4.

CX-Process Monitor Plus

Support Software for

Process I/O Unit

DeviceNet Configurator Software

Model

CX-ONE-AL01C-E

CX-ONE-AL03C-E

CX-ONE-AL10C-E

WS02-CXPC1-E-V6

WS02-CXPC1-E03-V6

WS02-CXPC1-E10-V6

WS02-SIMC1-E

WS02-PSTC1-E

WS02-MCTC1-EV2

WS02-NCTC1-EV2

WS02-LCTC1-EV4

WS02-LCTC1-EV4L03

WS02-LCTC1-EV4L10

WS02-LCMC1-E

WS02-PUTC1-E

WS02-CFDC1-E

Middleware

Product name Model

SYSMAC Compolet Version 2003

PLC Reporter 32

FinsGateway Version 2003

SCPL-SYSFL-2003E

SDKY-95HLK-E97

SDKY-95MLT-E97

SFGW-RT-2003

CS1-series Basic I/O Units

Classification

Input Units

Output Units

I/O Units

Name

DC Input Unit

AC Input Unit

Interrupt Input Unit

High-speed Input Unit

Safety Relay Unit

Relay Contact Output Units

Transistor Output Unit

Triac Output Unit

Mixed I/O Units

DC Input/Transistor Outputs

Units

TTL I/O Unit

Model

CS1W-ID211

CS1W-ID231

CS1W-ID261

CS1W-ID291

CS1W-IA111

CS1W-IA211

CS1W-INT01

CS1W-IDP01

CS1W-SF200

CS1W-OC201

CS1W-OC211

CS1W-OD211

CS1W-OD212

CS1W-OD231

CS1W-OD232

CS1W-OD261

CS1W-OD262

CS1W-OD291

CS1W-OD292

CS1W-OA201

CS1W-OA211

CS1W-MD261

CS1W-MD262

CS1W-MD291

CS1W-MD292

CS1W-MD561

One license

Three licenses

Ten licenses

CX-One includes CX-Programmer, CX-Simulator, CX-Protocol, CX-Motion, CX-Position, and CX-Process

Tool can still be ordered individually using the following model numbers.

One license

Three licenses

Ten licenses

One license

One license

One license

One license

One license

Three licenses

Ten licenses

Loop Control Board, Unit Monitoring Software

OS: Windows 2000, NT4.0

Process I/O Unit Settings Software

OS: Windows 95, 98, NT4.0, 2000

DeviceNet Configuration Software

OS: Windows 95, 98, Me, NT4.0, 2000, XP

Specifications

Software for communications with OMRON PLCs

Simple Data Collection Software (host link version)

Simple Data Collection Software (multi-network version

Communications Middleware

Specifications

7 mA, 24 VDC, 16 inputs

6 mA, 24 VDC, 32 inputs

6 mA, 24 VDC, 64 inputs

Approx. 5 mA, 24 VDC, 96 inputs

100 to 120 VAC, 100 to 120 VDC, 16 inputs

200 to 240 VAC, 16 inputs

7 mA, 24 VDC, 16 inputs

7 mA, 24 VDC, 16 inputs

24 VDC, 1 word/2 word shared input, 4 commons

2 A, 250 VAC, 2 A, 24 VDC, 0.1 A, 120 VDC max., independent contacts, 8 outputs

2 A, 250 VAC, 2 A, 24 VDC, 0.1 A, 120 VDC max., 16 outputs

0.5 A, 12 to 24 VDC, 16 sinking outputs

0.5 A, 24 VDC, 16 sourcing outputs, with load short-circuit protection and alarm function

0.5 A, 12 to 24 VDC, 32 sinking outputs

0.5 A, 24 VDC, 32 sourcing outputs, with load short-circuit protection and alarm function

0.3 A, 12 to 24 VDC, 64 sinking outputs

0.3 A, 24 VDC, 64 sourcing outputs, with load short-circuit protection and alarm function

0.1 A, 12 to 24 VDC, 96 sinking outputs

0.1 A, 12 to 24 VDC, 96 sourcing outputs

1.2 A, 250 VAC max., 8 outputs.

0.5 A, 250 VAC max., 16 outputs.

6 mA, 24 VDC, 32 inputs/ 0.3 A, 12 to 24 VDC, 32 sourcing outputs

6 mA, 24 VDC, 32 inputs/0.3 A, 24 VDC, 32 sourcing outputs,

with load short-circuit protection and alarm function

Approx. 5 mA, 24 VDC, 48 inputs/ 0.1 A, 12 to 24 VDC, 48 sinking outputs

Approx. 5 mA, 24 VDC, 48 inputs/ 0.1 A, 12 to 24 VDC, 48 sourcing outputs

5 VDC, 32 inputs, 32 outputs

CX-One is a package that integrates the Support Software for OMRON PLCs and components. CX-One

operates on the following OS

OS: Windows 98SE, Me, NT4.0 (service Pack 6a), 2000 (Service Pack 3 or higher), or XP.

CX-One includes CX-Programmer Ver. 6.@., CX-Simulator Ver. 1.@., CX-Protocol Ver. 1.@., CX-Motion

Ver. 2.@., CX-Position Ver. 2.@., CX-Process Tool Ver. 4.@

For details, refer to the CX-One Catalog (Cat. No. R134).

PLC programming software

OS: Windows 98SE, Me, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or higher), or XP

Ladder program simulation software

Support Software for Windows.

OS: Windows 98SE, Me, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or higher), or XP

Software to create protocol macros

OS: Windows 98SE, Me, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or higher), or XP

Motion Control Unit support software

OS: Windows 98SE, Me, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or higher), or XP

Position Control Unit support software

OS: Windows 98SE, Me, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or higher), or XP

Loop Controller programming software

OS: Windows 98SE, Me, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or higher), or XP

Specifications

Corresponding operating system

Windows2000/XP

Windows98/Me/2000/XP

Windows98/Me/2000/XP

Windows2000/XP

International standards

C200H and C200HW Basic I/O Units can be used in addition to the above Units.

UC1, N, L, CE

U, C, N, L, CE

UC1, N, L, CE

UC, N, L, CE

UC1, N, L, CE

U, C, CE

UC1, N, L, CE

U, C, N, CE

UC1, N, L, CE

UC, N, L, CE

UC1, N, L, CE

U, C, N, L, CE

UC, N, L, CE

UC1, N, L, CE

U, C, N, L, CE

UC, N, L, CE

Specifications and Models

Special I/O Units

Temperature Control Units

PID Control Units

Cam Positioner Unit

ASCII Units

Analog Input Units

Analog Output Units

Analog I/O Unit

Process

I/O Units

High-speed Counter Units

GP-IB Interface Units

Motion Control Units

Position Control Units

ID Sensor Unit

DeviceNet I/O Link Unit

CompoBus/S Master Unit

Customizable Counter Units

Isolated Thermocouple Input (high resolution)

Isolated Resistance Thermometer Input

(high resolution)

Isolated DC Input (high resolution)

Isolated Thermocouple Input

(economical type)

Isolated Resistance Thermometer Input

(economical type)

Isolated DC Input (economical type)

Isolated Thermocouple Input

Isolated Platinum-resistance Thermometer Input

Isolated Temperature Resistance Input (Ni508.4 ½)

Isolated Two-wire Transmitter Input 4 inputs, 4 to 20 mA, 1 to 5 V

Isolated DC Input 4 inputs, 4 to 20 mA, 0 to 20 mA, 1 to 5 V, 0 to 5 V, ±5 V, 0 to 10 V, ±10 VCS1W-PDC01

Isolated Control Output 4 outputs, 4 to 20 mA, 1 to 5 V

Isolated Control Output 4 outputs, 0 to 10 V, ±10 V, 0 to 5 V, ±5 V, 0 to 1 V, ±1 V

Power Transducer Input 8 inputs, 0 to 1 mA, ±1 mA

DC Input (100 mV) 8 inputs, 0 to 100 mV, ±100 mV

Name

Model

C200H-TC001

C200H-TC002

C200H-TC003

C200H-TC101

C200H-TC102

C200H-TC103

C200H-PID01

C200H-PID02

C200H-PID03

C200H-CP114

C200H-ASC11

C200H-ASC21

C200H-ASC31

CS1W-AD041-V1

CS1W-AD081-V1

CS1W-AD161

CS1W-DA041

CS1W-DA08V

CS1W-DA08C

CS1W-MAD44

CS1W-PTS11

CS1W-PTS12

CS1W-PDC11

CS1W-PTS51

CS1W-PTS55

CS1W-PTS52

CS1W-PTS56

CS1W-PDC55

CS1W-PTS01-V1

CS1W-PTS02

CS1W-PTS03

CS1W-PTW01

CS1W-PPS01Isolated Pulse Input

CS1W-PMV01

CS1W-PMV02

CS1W-PTR01

CS1W-PTR02

CS1W-CT021

CS1W-CT041

CS1W-GPI01

CS1W-MC421

CS1W-MC221

CS1W-NC113

CS1W-NC213

CS1W-NC413

CS1W-NC133

CS1W-NC233

CS1W-NC433

CS1W-V600C11

CS1W-V600C12

C200HW-DRT21

C200HW-SRM21-V1

CS1W-HCA12-V1

CS1W-HCP22-V1

CS1W-HCA22-V1

CS1W-HIO01-V1

Specifications

Thermocouple input, feed-forward PID or ON/OFF transistor output

Thermocouple input, feed-forward PID or ON/OFF voltage output

Thermocouple input, feed-forward PID or ON/OFF current output

Platinum-resistance thermometer input, feed-forward PID or ON/OFF transistor output

Platinum-resistance thermometer input, feed-forward PID or ON/OFF voltage output

Platinum-resistance thermometer input, feed-forward PID or ON/OFF current output

Voltage input/current input, feed-forward PID or ON/OFF transistor output

Voltage input/current input, feed-forward PID or ON/OFF voltage output

Voltage input/current input, feed-forward PID or ON/OFF current output

48 cam outputs (16 external outputs/32 internal outputs)