Page 1

Switch Mode Power Supply

S8VS 15/30/60/120/240/480 W Models

Compact High capacity, Natural Cooling Power Supply Range from

0.65 A up to 20 A with Output Voltage of 24 VDC

• Only 6 models to cover all applications

• EMI Class B Compliant

• Output indicator LED green

• Mount to DIN Rail.

• Complies with SEMI F47-0200 (200 VAC input).

• RoHS-compliant.

• Safety standards:

UL508/60950-1,

CSA C22.2 No. 107.1/60950-1 (60 W to 480 W),

EN50178 (= VDE0160),

EN60950-1 (= VDE0805 Teil 1)

Note: Refer to Safety Precautions on page 11

Model Number Structure

Model Number Legend

S8VS- @@@@@

1 2

1. Power Ratings

015: 15 W

030: 30 W

060: 60 W

120: 120 W

240: 240 W

480: 480 W

2. Output voltage

24: 24 V

Ordering Information

List of Models

Power ratings Input voltage Output voltage Output current Model number

15 W

30 W 1.3 A S8VS-03024

60 W 2.5 A S8VS-06024

120 W 5 A S8VS-12024

240 W 10 A S8VS-24024

480 W

100 to 240 VAC 24 VDC

0.65 A S8VS-01524

20 A

Peak current 30 A (200 VAC)

S8VS-48024

1

Page 2

S8VS

Specifications

Ratings/Characteristics

Item Power ratings 15 W 30 W 60 W

Efficiency (typical) 77% min. 80% min. 78% min.

Voltage*1 100 to 240 VAC (85 to 264 VAC)

Frequency *1 50/60 Hz (47 to 450 Hz)

Current

Input

Output

Additional

functions

Other

*1) Do not use an inverter output for the Power Supply. Inverters with an output frequency of 50/60 Hz are available, but the rise in the internal temperature of the Power

Supply may result in ignition or burning.

*2) Refer to

*3) If the output voltage adjuster (V. ADJ) is turned, the voltage will increase by more than +15% of the voltage adjustment range. When adjusting the output voltage, confirm

the actual output voltage from the Power Supply and be sure that the load is not damaged.

Power factor ---

Harmonic current emissions Conforms to EN61000-3-2

Leakage

current

Inrush

current *2

Voltage adjustment range *3 −10% to 15% (with V.ADJ)

Ripple 2.0% (p-p) max. (at rated input/output voltage)

Input variation influence 0.5% max. (at 85 to 264 VAC input, 100% load)

Load variation influence

(rated input voltage)

Temperature variation influence 0.05%/°C max.

Startup time *2

Hold time *2 20 ms min. (at rated input/output voltage)

Overload protection *2

Overvoltage protection *2 Yes (a zener diode clamp) *4 Yes *5 Yes

Undervoltage alarm indication Yes (color: red) No

Parallel operation No

Series operation Yes for up to 2 Power Supplies (with external diode)

Operating ambient temperature Refer to the derating curve in

Storage temperature −25 to 65°C

Operating ambient humidity 25% to 85% (Storage humidity: 25% to 90%)

Dielectric strength

Insulation resistance 100 MΩ min. (between all outputs and all inputs/ PE terminals) at 500 VDC

Vibration resistance

Shock resistance

Output indicator Yes (color: green)

EMI

EMS Conforms to EN61204-3 high severity levels

Approved standards

SEMI F47-0200 (200 VAC input)

MTBF *7 > 500.000 hrs > 250.000 hrs

Weight 160 g max. 180 g max. 330 g max.

Engineering Data

on page 7 for details.

100 V input 0.45 A max. 0.9 A max. 1.7 A max.

200 V input 0.25 A max. 0.6 A max. 1.0 A max.

100 V input 0.5 mA max.

200 V input 1.0 mA max.

100 V input 25 A max. (for a cold start at 25°C)

200 V input 50 A max. (for a cold start at 25°C)

Conducted

Emissions

Radiated

Emissions

2.0% max. (5 V), 1.5% max. (12 V, 24 V),

(with rated input, 0 to 100% load)

100 ms max.

(at rated input/output voltage)

105% to 160% of rated load current,

voltage drop, automatic reset

3.0 kVAC for 1 min. (between all inputs and outputs; detection current: 20 mA)

2.0 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)

1.0 kVAC for 1 min. (between all outputs and PE terminals; detection current: 20 mA)

500 VAC for 1 min. (between all outputs and alarm outputs; detection current: 20 mA) (only for 60 W)

10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y, and Z directions

10 to 150 Hz, 0.35-mm single amplitude (5 G max.) for 80 min each in X, Y, and Z directions (only for 60 W)

150 m/s2, 3 times each in ±X, ±Y, and ±Z directions

Conforms to EN61204-3 EN55011 Class B and based on FCC Class A

Conforms to EN61204-3 EN55011 Class B

UL: UL508 (Listing; Class 2: Per UL1310), UL60950-1, UL1604 (Class I/Division2)

cUL: CSA C22.2 No.14 (Class 2), No.60950-1, No.213 (Class I/Division2)

cUL: CSA C22.2 No.14 (Class 2), No.60950-1, No.213 (Class I/Division2)

EN/VDE: EN50178 (=VDE0160), EN60950-1 (SELV) (=VDE0805 Teil 1)

According to VDE0106/P100, IP20 (except terminal block)

1,000 ms max. (at rated input/output voltage)

105% to 160% of rated load current, voltage drop, intermittent operation,

automatic reset

Engineering Data

. (with no icing or condensation)

1.5% max. (with rated input, 0 to

100% load)

Conforms to EN61204-3 EN55011

Group 1 Class B and based on FCC Class A

Conforms to EN61204-3 EN55011

Group 1 Class B

UL for standard models: UL508 (Listing;

Class 2:Per UL1310), UL60950-1

cUL: CSA C22.2 No.107.1(Class 2:

Per CSA C22.2 No. 223)

cUR: CSA No.60950-1

EN/VDE: EN50178 (= VDE0160),

EN60950-1

(SELV) (= VDE0805 Teil 1)

According to VDE 0106/P100, IP20

(except terminal block)

2

Page 3

S8VS

Item Power ratings 120 W 240 W 480 W

Efficiency (typical) 80% min. 83% min.

Voltage *1 100 to 240 VAC (85 to 264 VAC)

Frequency *1 50/60 Hz (47 to 63 Hz)

Current

Input

Output

Additional

functions

Other

*4) The overvoltage protection of the S8VS-01524 uses a zener diode clamp. If the internal feedback circuit is destroyed by any chance, the load may be destroyed by the

clamped output voltage (approx. 140% to 190% of the rated output voltage).

*5) To reset the protection, turn OFF the input power for three minutes or longer and then turn it back ON.

*6) To ensure the emission rating, a ferrite ring core should be used in all cabling (SEIWA E04SR301334 or equivalent model).

*7) MTBF stands for mean Time Between Failures, which is calculated according to the probability of accidental device failures,

and indicates reliability of devices.

Power factor 0.95 min.

Harmonic current emissions Conforms to EN61000-3-2

Leakage current

Inrush current *2

Voltage adjustment range *3 −10% to 15% (with V.ADJ) (guaranteed)

Ripple 2.0% (p-p) max. (at rated input/output voltage)

Input variation influence 0.5% max. (at 85 to 264 VAC input, 100% load)

Load variation influence

(rated input voltage)

Temperature variation influence 0.05%/°C max.

Startup time *2 1,000 ms max. (at rated input/output voltage)

Hold time *2 20 ms min. (at rated input/output voltage)

Overload protection *2

Overvoltage protection *2 Yes

Parallel operation No

Series operation Yes for up to 2 Power Supplies (with external diode)

Operating ambient temperature Refer to the derating curve in

Storage temperature −25 to 65°C

Operating ambient humidity 25% to 85% (Storage humidity: 25% to 90%)

Dielectric strength

Insulation resistance 100 MΩ min. (between all outputs/ alarm outputs and all inputs/ PE terminals) at 500 VDC

Vibration resistance

Shock resistance

Output indicator Yes (color: green)

EMI

EMS Conforms to EN61204-3 high severity levels

Approved standards

SEMI F47-0200 (200 VAC input)

MTBF*7 >250.000 hrs

Weight 550 g max. 1,150 g max. 1,700 g max.

100 V input 1.9 A max. 3.8 A max. 7.4 A max.

200 V input 1.1 A max. 2.0 A max. 3.9 A max.

100 V input 0.5 mA max.

200 V input 1.0 mA max.

100 V input 25 A max. (for a cold start at 25°C)

200 V input 50 A max. (for a cold start at 25°C)

1.5% max. (with rated input, 0 to 100% load)

105% to 160% of rated load current,

Conducted

Emissions

Radiated

Emissions

voltage drop, intermittent, automatic

reset

3.0 kVAC for 1 min. (between all inputs and outputs/ alarm outputs; detection current: 20 mA)

2.0 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)

1.0 kVAC for 1 min. (between all outputs/ alarm outputs and PE terminals; detection current: 240 W, 20 mA/ 480 W,

30 mA)

500 VAC for 1 min. (between all outputs and alarm outputs; detection current: 20 mA)

10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y, and Z directions

10 to 150 Hz, 0.35-mm single amplitude (5 G max.) for 80 min each in X, Y, and Z directions (only for 240 W)

10 to 150 Hz, 0.35-mm single amplitude (3 G max.) for 80 min each in X, Y, and Z directions (only for 480 W)

150 m/s2, 3 times each in ±X, ±Y, and ±Z directions

Conforms to EN61204-3 EN55011 Group 1 Class B and based

on FCC Class A

Conforms to EN61204-3 EN55011 Group 1 Class B

UL: UL508 (Listing), UL60950-1

cUL: CSA C22.2 No. 107.1

UL: UL508 (Listing), UL60950-1

cUR: CSA No. 60950-1

EN/VDE: EN50178 (= VDE0160), EN60950-1 (SELV) (= VDE0805 Teil 1)

According to VDE0106/P100, IP20 (except terminal block)

105% to 160% of rated load current, voltage drop, automatic reset

Engineering Data

. (with no icing or condensation)

Conforms to EN61204-3 EN55011

Class A and based on FCC Class A

Conforms to EN61204-3 EN55011

Class B *6

Conforms to EN61204-3 EN55011

Class A

Conforms to EN61204-3 EN55011

Class B *6

UL: UL508 (Listing), UL60950-1

cUL: CSA C22.2 No. 107.1

UL: UL508 (Listing), UL60950-1

cUR: CSA No. 60950-1

EN/VDE: EN50178 (= VDE0160),

EN60950-1 (SELV) (= VDE0805 Teil 1)

According to VDE0106/P100, IP20

(except terminal block)

3

Page 4

Connections

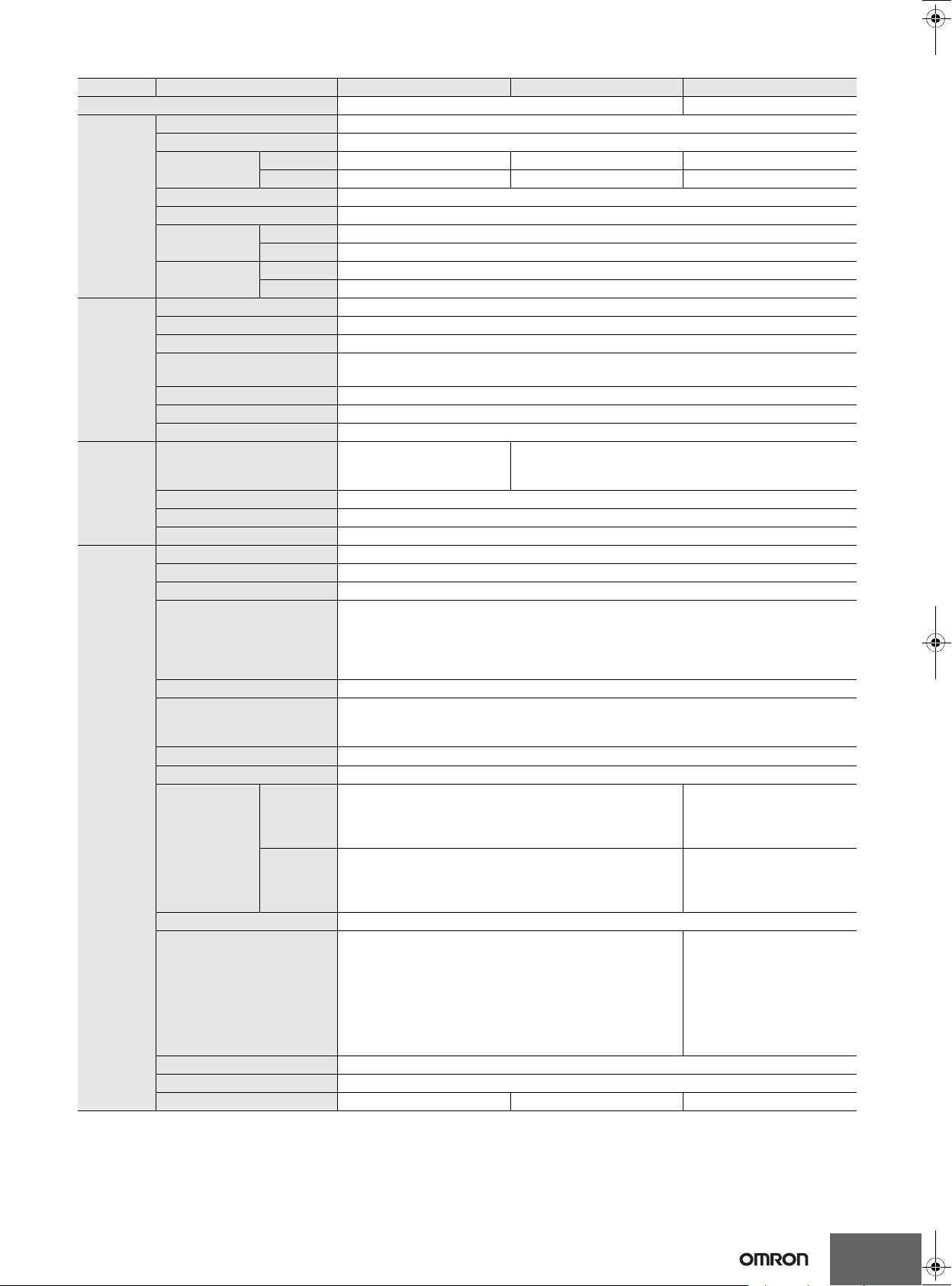

Block Diagrams

S8VS-01524 (15 W)

Fuse

2.5 A

AC (L)

INPUT

AC (N)

Noise filter

Inrush current

protection

circuit

Overcurrent

detection circuit

Rectifier/

smoothing

circuit

Drive control

circuit

Photocoupler

Rectifier/

smoothing

circuit

Voltage

detection circuit

Undervoltage

indicator

Overvoltage

protection

S8VS

+V

DC OUTPUT

−V

S8VS-03024 (30 W)

Fuse 3.15 A

AC (L)

INPUT

AC (N)

Noise filter

S8VS-06024 (60 W)

Fuse 3.15 A

AC (L)

INPUT

AC (N)

Noise filter

S8VS-12024 (120 W)

Fuse 3.5 A

AC (L)

INPUT

AC (N)

Inrush

current

protection

circuit

Noise filter

Inrush current

protection

circuit

Inrush current

protection

circuit

Rectification

Rectifier/

smoothing

circuit

Drive control

circuit

Rectifier/

smoothing

circuit

Drive control

circuit

Harmonic

current

suppression

Photocoupler

Photocoupler

Rectifier/smoothing circuit

Overcurrent

circuit

Rectifier/smoothing circuit

Overcurrent

circuit

Smoothing

Undervoltage

indicator

Current detection

circuit

Voltage

detection circuit

Overvoltage

detection circuit

Current detection

circuit

Volt age

detection circuit

Overvoltage

detection circuit

Rectifier/smoothing circuit

+V

DC OUTPUT

−V

+V

DC OUTPUT

−V

+V

DC OUTPUT

−V

4

Overcurrent

circuit

Drive control

circuit

Photocoupler

Volt age

detection circuit

Overvoltage

detection circuit

Page 5

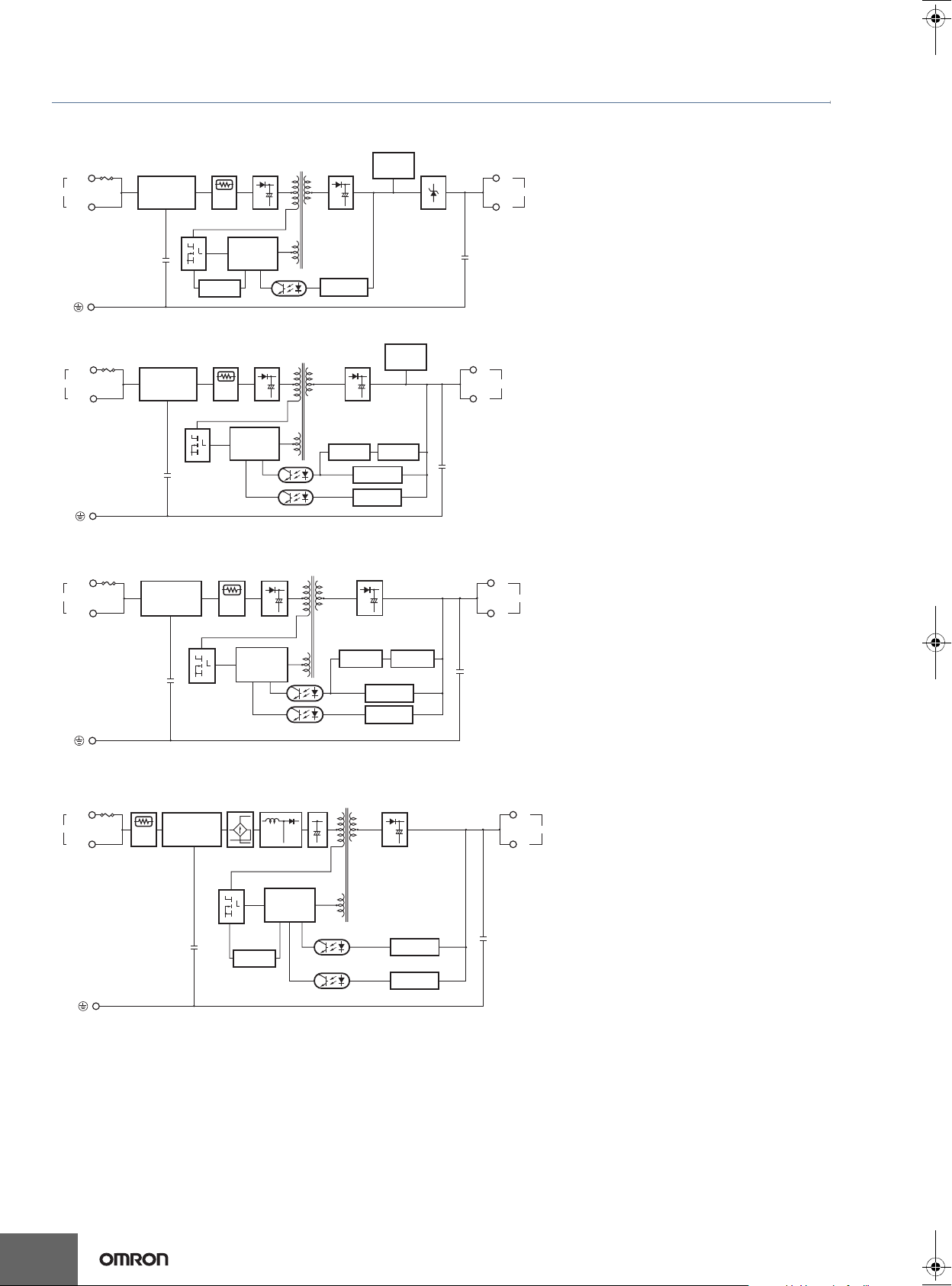

S8VS-24024 (240 W)

S8VS

Fuse 7.5 A

AC (L)

INPUT

AC (N)

Noise filter

S8VS-48024 (480 W)

Fuse 12A

AC (L)

INPUT

AC (N)

Noise filter

Rectification

Inrush current

protection

circuit

Inrush

current

protection

circuit

Harmonic

current

suppression

Drive control

circuit

Rectification

Smoothing

Photocoupler

Harmonic

current

suppression

Rectifier/smoothing circuit

Overcurrent

circuit

Current

detection circuit

Volt age

detection circuit

Overvoltage

detection circuit

Smoothing

Auxiliary power

supply circuit

Drive circuit

Rectifier/

smoothing

circuit

+V

+V

−V

−V

Overvoltage

detection circuit

Control

circuit

Arithmetic

operation

circuit

DC OUTPUT

Rectifier/

smoothing circuit

Volt age

detection circuit

Current

detection circuit

Overcurrent

circuit

+V

+V

+V

DC OUTPUT

−V

−V

−V

5

Page 6

Construction and Nomenclature

Nomenclature

15 W, 30 W Models

1

No. Name Function

1 AC Input terminals (L), (N) Connect the input lines to these terminals. *1

2 Protective Earth terminal (PE) Connect the ground line to this terminal. *2

2

3 DC Output terminals (−V), (+V) Connect the load lines to these terminals.

S8VS-03024

Note: The S8VS-03024 is shown above.

60 W Models 120 W Models

S8VS-06024

1

4 Output indicator (DC ON: Green) Lights while a direct current (DC) output is ON.

4

5 Undervoltage indicator (DC LOW: Red) Lights when a drop is detected in the output voltage.

5

6 Output voltage adjuster (V.ADJ) Use to adjust the voltage.

6

*1) The fuse is located on the (L) side. It is NOT user-replaceable.

*2) This is the protective earth terminal specified in the safety standards. Always ground this terminal.

3

S8VS-12024

2

12

S8VS

S8VS-01524/S8VS-03024

240 W Models

S8VS-24024

12

3

480 W Models

S8VS-48024

1 2

4

5

4

5

3

3

4

5

No. Name Function

AC Input terminals

1

(L), (N)

Protective Earth termi-

2

nal (PE)

DC Output terminals

3

(−V), (+V)

Output indicator

4

(DC ON: Green)

Output voltage

5

adjuster (V.ADJ)

4

5

3

*1) The fuse is located on the (L) side. It is NOT user-replaceable.

*2) This is the protective earth terminal specified in the safety stan-

dards. Always ground this terminal.

Connect the input lines to these

terminals. *1

Connect the ground line to this

terminal. *2

Connect the load lines to these

terminals.

Lights while a direct current (DC)

output is ON.

Use to adjust the voltage.

6

Page 7

Engineering Data

S8VS

Derating Curve

S8VS-01524

120

100

Load ratio (%)

80

60

40

20

0

−20 −10 0 10 20 30 40 50 60 70 80

*1 Standard mounting

*2 Face-up mounting

*3 Horizontal mounting

Ambient temperature (°C)

S8VS-03024

120

100

Load ratio (%)

80

60

1

1

Mounting

Standard mounting with DIN rail

*1

*2

*3

*1

*2

Standard mounting with S82Y-VS30P

Note: The Side-mounting Bracket can be mounted from either side.

Horizontal mounting with S82Y-VS30P*

Face-up mounting with DIN rail

Face-up mounting with S82Y-VS30P

S82Y-VS30P

Side with label

40

20

0

−20 −10 0 10 20 30 40 50 60 70 80

*1 Standard mounting

*2 Face-up mounting/Horizontal mounting

Note: 1.

Internal parts may occasionally deteriorate or be damaged.

Ambient temperature (°C)

Do not use the Power Supply in areas outside the derating

curve (i.e., the area shown by shading

A

in the above graph).

2. If there is a derating problem, use forced air-cooling.

3. Provide a space of at least 20 mm when using standard

mounting and horizontal mounting. If 20 mm is not available,

make sure that the space is at least 10 mm. In this case,

reduce the corresponding derating curve by 5°C.

S8VS-06024/12024/24024/48024

120

100

Load (%)

80

60

40

20

1

See note 1.

Note: 1. Improper mounting will interfere with heat dissipation and

may occasionally result in deterioration or damage of

internal parts. Use the Product within the derating curve for

the mounting direction that is used. Do not use the Power

Supply mounted in any way not shown above.

2. Use a mounting bracket (S82Y-VS30P, sold separately)

when the Product is mounted horizontally.

3. Heat dissipation will be adversely affected. When the

Product is mounted facing horizontally, always place the

side with the label facing horizontally.

4. Use PFP-M End Plates on the top and bottom of the Power

Supply when mounting horizontally on a DIN rail.

Upper

Upper

Correct Incorrect

Standard mounting Face-up mounting

Note: Improper mounting will interfere with heat dissipation and may

occasionally result in deterioration or damage of internal parts.

Use the standard mounting method only.

0

−20 −10 0 10 20 30 40 50 60 70 80

Ambient temperature (°C)

Note: 1. Using side mounting bracket for right-side mounting

(excluding 240-W models).

2.

Internal parts may occasionally deteriorate or be damaged.

Do not use the Power Supply in areas outside the derating

curve (i.e., the area shown by shading

A

in the above graph).

3. If there is a derating problem, use forced air-cooling.

4. When using a 480 W model at an input voltage of 95 VAC or

less, derate the load by at least 80%.

7

Page 8

Overload Protection

The load and the power supply are automatically protected from

overcurrent damage by this function.

Overload protection is activated if the output current rises above

105% of the rated current.

When the output current returns within the rated range overload

protection is automatically cleared.

15-W Models 30-W Models

+30%

(approx.)

+15%

Output voltage (V)

Rated output

voltage

−10%

Variable range

Overvoltage protection

operating

S8VS

Output voltage (V)

0 100 50

60 W Models 120 W/240 W/480 W Models

Output voltage (V)

Intermittent operation

0 50 10 0 0 50 100

The values shown in the above diagrams are for reference only.

Output current (%)

Output current (%)

Output voltage (V)

0 100 50

Output voltage (V)

Intermittent

operation

Output current (%)

Output current (%)

Note: 1. Internal parts may occasionally deteriorate or be damaged

if a short-circuited or overcurrent state continues during

operation.

2. Internal parts may possibly deteriorate or be damaged if the

Power Supply is used for applications with frequent inrush

current or overloading at the load end. Do not use the Power

Supply for such applications.

Peak Output Current (S8VS-48024 only)

The peak current must satisfy the following conditions.

Input voltage range: 200 to 240 VAC

Peak current value: 30 A max.

Peak current pulse width: 2 s max.

Cycle: 60 s min.

Note: 1. Two seconds after the peak current is reached, the peak

current limiting function operates to stop the peak current

flow.

2. It takes 60 seconds for the peak current to be able to flow

again.

3. The peak current limiting function prevents the peak current

from flowing at 100 to 120 VAC.

Peak current limit

Peak current

condition

Overcurrent

protectionpoint

Output current

0 A

2 s

60 s min.

Overvoltage Protection

Consider the possibility of an overvoltage and design the system so

that the load will not be subjected to an excessive voltage even if the

feedback circuit in the Power Supply fails.

This power supply automatically protects itself and the load from

overvoltage.

When an excessive voltage that is approximately 130% of the rated

voltage or more is output, the output voltage is shut OFF.

Reset the input power by turning it OFF for at least three minutes and

then turning it back ON again.

0 V

The values shown in the above diagram is for reference only.

Note: 1. Do not turn ON the power again until the cause of the

overvoltage has been removed.

2. The overvoltage protection of the S8VS-01524 uses a zener

diode clamp. The output voltage will be clamped at approx.

140% or higher of the rated output voltage (approx. 140% to

190%). If the internal feedback circuit is destroyed by any

chance, the load may be destroyed by the clamped output

voltage (approx. 140% to 190% of the rated output voltage).

The power Supply will not restart if the output is turned OFF

by the overvoltage protection operation. If this occurs,

replace the Power Supply.

Undervoltage Alarm Indication

LED (DC LOW red) lights to warn of output voltage drop.

Detection voltage is set to approx. 80% (75 to 90%) of the rated

output voltage.

Note: This function monitors the voltage at the power supply output

terminals. To check actual voltage, measure voltage on the load

side.

Reference Values (15 W to 480 W Models)

Item Valu e Definition

MTBF stands for Mean Time

Between Failures, which is calculated according to the probability of

accidental device failures, and

indicates reliability of devices.

Therefore, it does not necessarily

Reliability

(MTBF)

15 W to 240 W:

135,000 hrs min.

480 W:

60,000 hrs min.

represent the life of the Product.

The life expectancy indicates

average operating hours under the

Life expectancy

10 yrs. min.

ambient temperature of 40°C and

a load rate of 50%. Normally this is

determined by the life expectancy

of the built-in aluminum electrolytic

capacitor.

Inrush Current, Startup Time, Output

Hold Time

AC input

voltage

AC input

current

Output

voltage

Input ON

Inrush current on input application

90%

Startup time (1,000 ms max.)

Input OFF

Hold time

(20 ms min.)

96.5%

8

Page 9

Dimensions

Note: All units are in millimeters unless otherwise indicated.

S8VS-01524 (15 W)

S8VS-03024 (30 W)

4.8

(Sliding: 10 max.)

S8VS

35.2

4

Note: The illustration is the S8VS-03024 model.

S8VS-06024 (60 W)

35.4

S8VS-12024 (120 W)

34.9

85

4.8

96.4

97

1

108.3

110.5

Rail stopper

Five, M4

with square washer

11.3

10.8

22.5

74

Rail stopper

Five, M4

with square washer

94

(Sliding: 10 max.)

10

95

40

4.5

(Sliding: 15 max.)

10

115

S8VS-24024 (240 W)

S8VS-48024 (480 W)

34.9

34.9

1

121.3

125.3

120.3

Screwless block (2.5-mm pitches)

Screwless block (2.5-mm pitches)

127.2

123.8

50

Rail stopper

Seven, M4

with square washer

94

Rail stopper

115

94

4.5

(Sliding: 15 max.)

100

115

10

50

Nine, M4 with square washer

4.5 (Sliding: 15 max.)

Rail stopper

150

115

Screwless block (2.5-mm pitches)

Rail stopper

10

70

4.5 (Sliding: 15 max.)

Rail stopper

9

Page 10

Mounting Brackets

Type Model Dimensions Appearance

Side-mounting Bracket

(For 15, 30 W models)

Side-mounting Bracket

(For 60, 120 W models)

S82Y-VS30P

S82Y-VS10S

85.4

S8VS

0.5

109.4

28

34

3.5

15

93.6

t = 0.8

±0.1

4.5 dia.

±0.1

80

35

64

t = 2.0

60

±0.1

55

13

7.1

±0.1

3.5 dia.

15

22.5

15

Left-side mounting Right-side mounting

Side-mounting Bracket

(For 240 W models)

S82Y-VS20S

Front-mounting Bracket

(For 60, 120, and 240 W

S82Y-VS10F

models) *1

*1) Two required to mount a 240 W model.

Note: Brackets cannot be used for 480 W models.

±0.1

4.5 dia.

80

60

114

t = 2.0

41

4.5 dia.±0.1

35

±0.1

35

40

50

±0.1

60

±0.1

13

55

78

25

7.3

10

Left-side mounting

*Right-side mounting also possible.

(For 60 W,

120 W types)

(For 240 W type)

*Use two S82Y-VS10F

brackets for the 240 W type.

10

Page 11

Safety Precautions

!CAUTION

Minor electric shock, fire, or Product failure may

occasionally occur. Do not disassemble, modify, or repair

the Product or touch the interior of the Product.

Minor burns may occasionally occur. Do not touch the

Product while power is being supplied or immediately

after power is turned OFF.

Fire may occasionally occur. Tighten terminal screws to

the specified torque (15 and 30 W models: 0.8 to 1.0 N·m/

60, 120, 240, and 480 W models: 1.08 N·m).

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Always close the terminal cover after wiring.

Minor electric shock, fire, or Product failure may

occasionally occur. Do not allow any pieces of metal or

conductors or any clippings or cuttings resulting from

installation work to enter the Product.

Precautions for Safe Use

Mounting

Take adequate measures to ensure proper heat dissipation to

increase the long-term reliability of the Product. Be sure to allow

convection in the atmosphere around devices when mounting. Do

not use in locations where the ambient temperature exceeds the

range of the derating curve.

When cutting out holes for mounting, make sure that cuttings do not

enter the interior of the Products.

*1

*1. Convection of air

*2

*1

(15 W and 30 W Models)

Improper mounting will interfere with heat dissipation and may

occasionally result in deterioration or damage of internal parts. Use

the Product within the derating curve for the mounting direction that

is used.

Use a mounting bracket when the Product is mounted facing

horizontally.

Heat dissipation will be adversely affected. When the Product is

mounted facing horizontally, always place the side with the label

facing upward.

Always provide a space of 20 mm even when mounting horizontal or

facing horizontal. If a space of 20 mm is not available, reduce the

temperatures given in the derating curve on page 7 by 5°C and

provide a space of at least 10 mm.

(60 W, 120 W, 240 W, and 480 W Models)

Improper mounting will interfere with heat dissipation and may

occasionally result in deterioration or damage of internal parts. Use

the standard mounting method only.

The internal parts may occasionally deteriorate and be broken due to

adverse heat radiation. Do not loosen the screw on the side face of

the main body.

*2. 20 mm min.

S8VS

Wiring

Connect the ground completely. A protective earthing terminal

stipulated in safety standards is used. Electric shock or malfunction

may occur if the ground is not connected completely.

Minor fire may possibly occur. Ensure that input and output terminals

are wired correctly.

Do not apply more than 100 N force to the terminal block when

tightening it.

Be sure to remove the sheet covering the Product for machining

before power-ON so that it does not interfere with heat dissipation.

Use the following material for the wires to be connected to the S8VS

to prevent smoking or ignition caused by abnormal loads.

Recommended Wire Type

15 W and 30 W Models

Stranded wire Solid wire

AWG20 to 14

(0.5 to 2.0 mm

2

)

60 W, 120 W, 240 W, and 480 W Models

Model

S8VS-06024

S8VS-12024

S8VS-24024

S8VS-48024

Note: The rated current for output terminals is 10 A per terminal. Be

sure to use multiple terminals simultaneously for current that

exceeds the terminal rating.

AWG14 to 20

(Cross section 0.517 to 2.081 mm

AWG14 to 18

(Cross section 0.823 to 2.081 mm

Input terminals

AWG 14 to 16

(Cross section 1,309 to 2,081 mm

Output terminal

(see note 1.)

AWG 14

(Cross section 2,081 mm

Installation Environment

Do not use the Power Supply in locations subject to shocks or

vibrations. In particular, install the Power Supply as far away as

possible from contactors or other devices that are a vibration source.

Install the Power Supply well away from any sources of strong,

high-frequency noise and surge.

Operating Life

The life of a Power Supply is determined by the life of the electrolytic

capacitors used inside. Here, Arrhenius Law applies, i.e., the life will

be cut in half for each rise of 10°C or the life will be doubled for each

drop of 10°C. The life of the Power Supply can thus be increased by

reducing its internal temperature.

Ambient Operating and Storage Environments

Store the Power Supply at a temperature of −25 to 65°C and a

humidity of −25% to 90%.

Do not use the Power Supply in areas outside the derating curve

otherwise, internal parts may occasionally deteriorate or be

damaged.

Use the Power Supply at a humidity of 25% to 85%.

Do not use the Power Supply in locations subject to direct sunlight.

Do not use locations where liquids, foreign matter, or corrosive gases

may enter the interior of Products.

AWG20 to 16

(0.5 to 1.1 mm2)

Recommended wire size

For screw terminal

2

)

2

)

2

)

2

)

11

Page 12

S8VS

Overcurrent Protection

Internal parts may possibly deteriorate or be damaged if a

short-circuited or overcurrent state continues during operation.

Internal parts may possibly deteriorate or be damaged if the Power

Supply is used for applications with frequent inrush current or

overloading at the load end. Do not use the Power Supply for such

applications.

Dielectric Strength Test

If a high voltage is applied between an input and the case (FG), it will

pass though the LC of the built-in noise filter and energy will be

stored. If the high voltages used for dielectric strength testing are

turned ON and OFF with a switch, timer, or similar device, impulse

voltage will be generated when the voltage is turned OFF and

internal parts may possibly be damaged. To prevent the generation

of impulse voltages, reduce the applied voltage slowly with a variable

resistor on the test device or turn the voltage ON and OFF at the

zero-cross point.

Inrush Current

When two or more Power Supplies are connected to the same input,

the total current is the sum of the currents for each Supply. Select

fuses and circuit breakers giving sufficient consideration to the fusing

or operating characteristics so that fuses will not burn and breakers

will not break due to inrush current.

Output Voltage Adjuster (V.ADJ)

The output voltage adjuster (V.ADJ) may possibly be damaged if it is

turned with unnecessary force. Do not turn the adjuster with

excessive force.

After completing output voltage adjustment, be sure that the output

capacity or output current does not exceed the rated output capacity

or rated output current.

15 W, 30 W Models

If the output voltage is set to a value less than −10%, the

undervoltage alarm function may operate.

60 W, 120 W, 240 W, and 480 W Models

If the output voltage is set to a value less than 20 V (the factory

setting), the undervoltage alarm function may operate.

DIN Rail Mounting

To mount the Block on a DIN Rail, hook portion (A) of the Block onto

the rail and press the Block in direction (B).

(A)

(B)

To dismount the Block, pull down portion (C) with a flat-blade

screwdriver and pull out the Block.

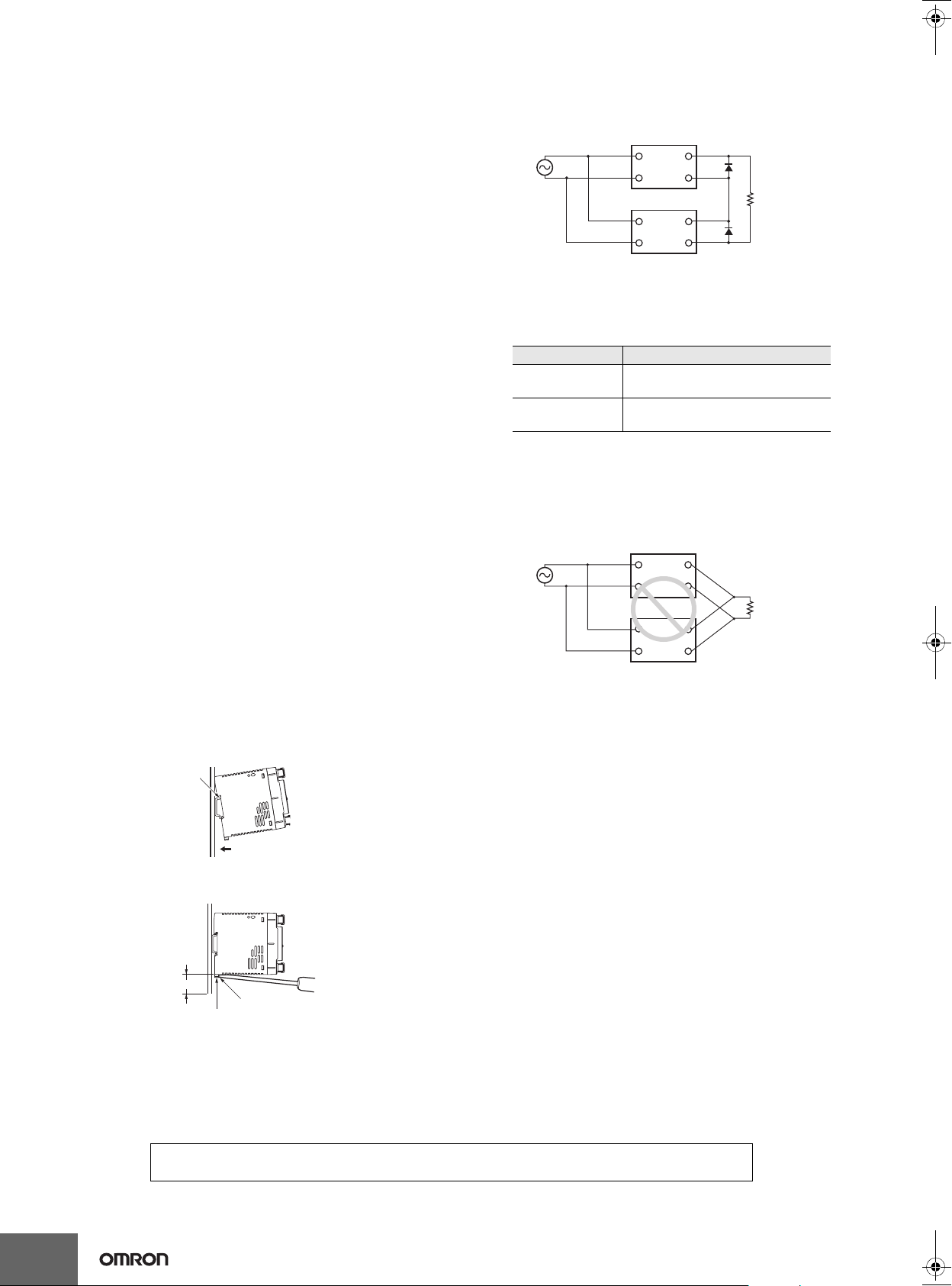

Series Operation

Two power supplies can be connected in series.

Correct

AC (L)

AC (N)

AC (L)

AC (N)

+V

−V

+V

−V

Note: 1. The diode is connected as shown in the figure. If the load is

short-circuited, a reverse voltage will be generated inside

the Power Supply. If this occurs the Power Supply may

possibly deteriorate or be damaged. Always connect a

diode as shown in the figure.

Select a diode having the following ratings.

Type Schottky Barrier diode

Dielectric strength

RRM)

(V

Forward current

F)

(I

Twice the rated output voltage or

above

Twice the rated output current or

above

2. Although Products having different specifications can be

connected in series, the current flowing through the load

must not exceed the smaller rated output current.

Parallel Operation

The Product is not designed for parallel operation.

Incorrect

AC (L)

AC (N)

AC (L)

AC (N)

+V

−V

+V

−V

In Case There Is No Output Voltage

The possible cause for no output voltage may be that the overcurrent

or overvoltage protection has operated. The internal protection may

operate if a large amount of surge voltage such as a lightening surge

occurs while turning ON the power supply.

In case there is no output voltage, please check the following points

before contacting us:

• Checking overload protected status:

Check whether the load is in overload status or is short-circuited.

Remove wires to load when checking.

• Checking overvoltage or internal protection (except for 15 W

models):

Turn the power supply OFF once, and leave it OFF for at least 3

minutes. Then turn it ON again to see if this clears the condition.

Cat.No. T01E-EN-02_OEE

12

Buzzing Noise When the Input Is Turned ON

(120 W, 240 W, and 480 W Models)

30 mm min.

Track stopper

(C)

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

In the interest of product improvement, specifications are subject to change without notice.

A harmonic current suppression circuit is built into the Power Supply.

This circuit can create noise when the input is turned ON, but it will

last only until the internal circuits stabilize and does not indicate any

problem in the Product.

Loading...

Loading...