Page 1

New Product

!

Refer to Safety Precautions for All Power Supplies and Safety

Precautions on page 12.

12

S8VK- T@@@@@

1. Power Ratings

120: 120 W

240: 240 W

480: 480 W

960: 960 W

2. Output voltage

24: 24 V

Switch Mode Power Supply

(120/240/480/960 W Models)

S8VK-T

Worldwide 3-phase Power Supply

Resistant in tough environments

Easy and fast installation

The most compact class on the market

• Wide input range for worldwide applications:

380 to 480 VAC (320 to 576 VAC)

• Possible for 2-phase input usage*:

380 to 480 VAC (340 to 576 VAC)

*When using the 960 W at 2-phase input, the power rating is 768 W.

• DC input can be available*:

450 to 600 VDC (450 to 810 VDC)

*Excluding 960 W

• High efficiency 91% typ. at 480 W model

• Wide operation temperature range: –40 to 70°C

• Power Boost function at 120%

• Meets LR maritime standards

• EMS: Conforms to EN 61204-3

EMI: EN61204-3 Class B

• RoHS Compliant

• Three years Warranty

Note: Three years warranty conditions: Rated input voltage, 80% load,

Ambient operating temperature: 40°C, Standard mounting

Model Number Structure

Model Number Legend

Ordering Information

Note: For details on normal stock models, contact your nearest OMRON representative.

Power ratings Input voltage Output Voltage Output current Boost Current Model number

120 W

240 W 24 V 10 A 12 A S8VK-T24024

480 W 24 V 20 A 24 A S8VK-T48024

960 W

2-phase and 3-phase

380 to 480 VAC

450 to 600 VDC

3-phase

380 to 480 VAC

2-phase

380 to 480 VAC

24 V 5 A 6 A S8VK-T12024

24 V 40 A 48 A

S8VK-T96024

24 V 32 A -

1

Page 2

S8VK-T

Specifications

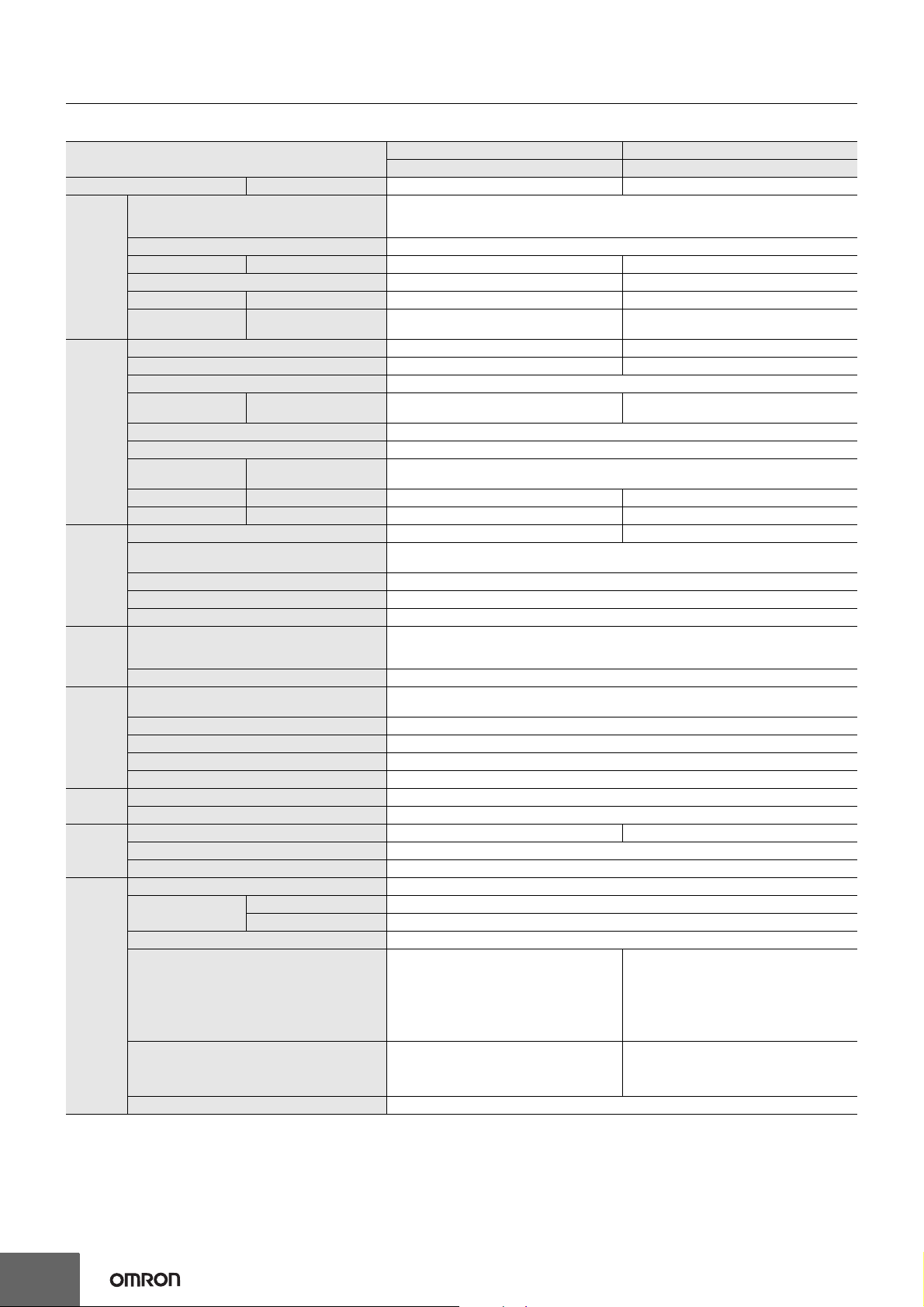

Ratings, Characteristics, and Functions

Power rating 120 W 240 W

Item Output voltage 24 V 24 V

Efficiency

Voltage range *1

Frequency *1 50/60 Hz (47 to 63 Hz)

Input

Output

Additional

functions

Insulation

Environment

Reliability

Construction

Standards

Current

Power factor --

Leakage current 3-phase, 400 VAC input 3.5 mA max./1.3 mA typ. 3.5 mA max./1.4 mA typ.

Inrush current (for a

cold start at 25°C) *2

Rated output current 5 A 10 A

Boost current 6 A 12 A

Voltage adjustment range *3 22.5 to 29.5 VDC (with V.ADJ) (guaranteed)

Ripple & Noise

voltage *4

Input variation influence *13 0.5% max.

Load variation influence *12 1.5% max.

Temperature

variation influence

Start up time *2

Hold time *2

Overload protection Yes, automatic reset Yes, automatic reset

Overvoltage protection

Series operation Yes (For up to two Power Supplies, external diodes are required.)

Parallel operation Yes (Refer to Engineering Data) (For up to two Power Supplies)

Output indicator Yes (LED: Green), lighting from 80% to 90% or more of rated voltage

Withstand voltage

Insulation resistance 100 MΩ min. (between all output terminals and all input terminals / PE terminal) at 500 VDC

Ambient operating temperature

Storage temperature –40 to 85°C (with no condensation or icing)

Ambient operating humidity 0% to 95% (Storage humidity: 0% to 95%)

Vibration resistance 10 to 55 Hz, 0.375-mm half amplitude for 2 h each in X, Y, and Z directions

Shock resistance 150 m/s2, 3 times each in ±X, ±Y, and ±Z directions

MTBF 135,000 hrs min.

Life expectancy *10 10 years min.

Weight 700 g max. 1,000 g max.

Cooling fan No

Degree of protection IP20 by EN / IEC 60529

Harmonic current emissions Conforms to EN 61000-3-2

EMI

EMS Conforms to EN 61204-3 high severity levels

Approved Standards *6

Conformed Standards

SEMI Conforms to F47-0706 (3-phase, 380 to 480 VAC input)

Note: Refer to page 4 for notes 1 to 13.

3-phase, 400 VAC input *11

3-phase, 400 VAC input *11

3-phase, 400 VAC input 28 A typ. 29 A typ.

3-phase, 400 VAC input *11

3-phase, 400 VAC input 0.05%/°C max.

3-phase, 400 VAC input *11

3-phase, 400 VAC input *11

Conducted Emission

Radiated Emission Conforms to EN 61204-3 Class B EN 55011 Class B

89% typ. 89% typ.

3-phase, 380 to 480 VAC (allowable range: 320 to 576 VAC)

2-phase, 380 to 480 VAC (allowable range: 340 to 576 VAC)

450 to 600 VDC (allowable range: 450 to 810 VDC) *8

0.38 A typ. 0.69 A typ.

160 mV p-p max. at 20 MHz of bandwidth 190 mV p-p max. at 20 MHz of bandwidth

700 ms typ. 600 ms typ.

30 ms typ. 20 ms typ.

Yes, 130% or higher of rated output voltage, power shut off (shut off the input voltage and turn on

the input again) *5

3.0 kVAC for 1 min. (between all input terminals and output terminals) cutoff current 20 mA

2.5 kVAC for 1 min. (between all input terminals and PE terminal) cutoff current 20 mA

1.0 kVAC for 1 min. (between all output terminals and PE terminal) cutoff current 30 mA

–40 to 70°C (However, only startup is guaranteed for between –40°C to –25°C. (3-phase only))

(Derating is required according to the temperature.) (with no condensation or icing)

Conforms to EN 61204-3 Class B EN 55011 Class B

UL Listed: UL 508 *7

UL Listed: UL 508 *7

EN: EN 50178

Lloyd’s standards *9

ANSI/ISA 12.12.01 *7

SELV (EN 50178), PELV(EN 60204-1, EN 50178)

Safety of Power Transformers (EN 61558-2-16)

EN 50274 for Terminal parts

UL UR: UL 60950-1 (Recognition)

cUR: CSA C22.2 No.60950-1

CSA: CSA C22.2 No.60950-1

EN: EN 50178, EN 60950-1

Lloyd’s standards *9

ANSI/ISA 12.12.01 *7

SELV (EN 60950-1/EN 50178/UL 60950-1)

PELV (EN 60204-1, EN 50178)

Safety of Power Transformers (EN 61558-2-16)

EN 50274 for Terminal parts

2

Page 3

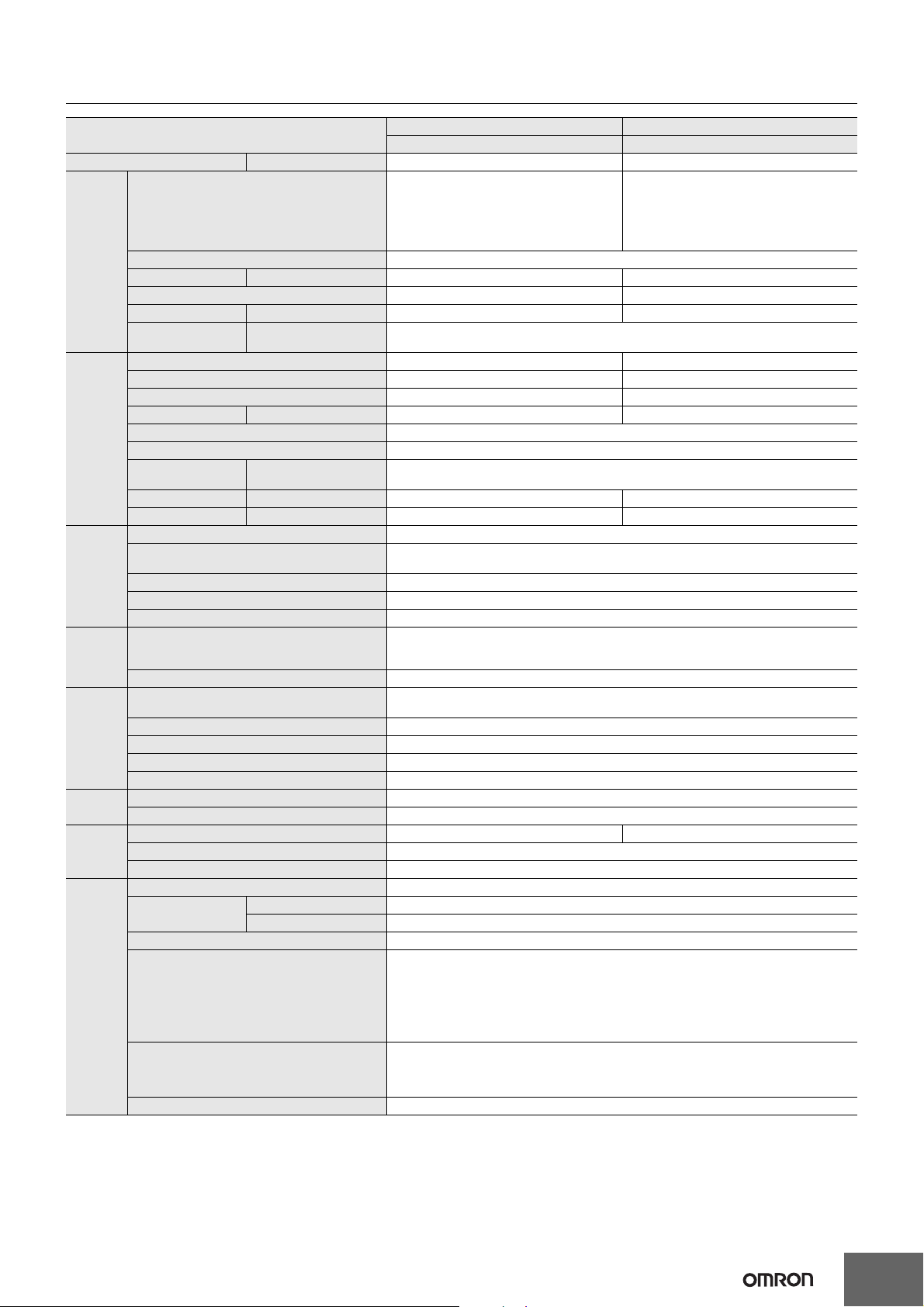

Power rating 480 W 960 W (768 W *18)

Item Output voltage 24 V 24 V

Efficiency

Input

Output

Additional

functions

Insulation

Environment

Reliability

Construction

Standards

Voltage range *1

Frequency *1 50/60 Hz (47 to 63 Hz)

Current

Power factor --

Leakage current 3-phase, 400 VAC input 3.5 mA max./1.0 mA typ. 3.5 mA max./1.2 mA typ.

Inrush current (for a

cold start at 25°C) *2

Rated output current 20 A 40 A at 3-phase (32 A at 2-phase)

Boost current 24 A 48 A at 3-phase (Not possible at 2-phase)

Voltage adjustment range *3 22.5 to 29.5 VDC (with V.ADJ) (guaranteed) 22.5 to 29.5 VDC (with V.ADJ) (guaranteed) *14

Ripple & Noise voltage *4

Input variation influence *13 0.5% max.

Load variation influence *12 1.5% max.

Temperature

variation influence

Start up time *2

Hold time *2

Overload protection Yes, automatic reset

Overvoltage protection

Series operation Yes (For up to two Power Supplies, external diodes are required.)

Parallel operation Yes (Refer to Engineering Data) (For up to two Power Supplies)

Output indicator Yes (LED: Green), lighting from 80% to 90% or more of rated voltage

Withstand voltage

Insulation resistance 100 MΩ min. (between all output terminals and all input terminals / PE terminal) at 500 VDC

Ambient operating temperature

Storage temperature –40 to 85°C (with no condensation or icing)

Ambient operating humidity 0% to 95% (Storage humidity: 0% to 95%)

Vibration resistance 10 to 55 Hz, 0.375-mm half amplitude for 2 h each in X, Y, and Z directions

Shock resistance 150 m/s2, 3 times each in ±X, ±Y, and ±Z directions

MTBF 135,000 hrs min.

Life expectancy *10 10 years min.

Weight 1,600 g max. 2,700 g max.

Cooling fan No

Degree of protection IP20 by EN / IEC 60529

Harmonic current emissions Conforms to EN 61000-3-2 *15

EMI

EMS Conforms to EN 61204-3 high severity levels

Approved Standards *6

Conformed Standards

SEMI Conforms to F47-0706 (3-phase, 380 to 480 VAC input) *17

3-phase, 400 VAC input *11

3-phase, 400 VAC input *11

3-phase, 400 VAC input 28 A typ.

3-phase, 400 VAC input *11

3-phase, 400 VAC input

3-phase, 400 VAC input *11

3-phase, 400 VAC input *11

Conducted Emission

Radiated Emission Conforms to EN 61204-3 Class B EN 55011 Class B *16

91% typ. 92% typ.

3-phase, 380 to 480 VAC

(allowable range: 320 to 576 VAC)

2-phase, 380 to 480 VAC

(allowable range: 340 to 576 VAC)

450 to 600 VDC

(allowable range: 450 to 810 VDC) *8

1.2 A typ. 2.1 A typ.

130 mV p-p max. at 20 MHz of bandwidth 90 mV p-p max. at 20 MHz of bandwidth

0.05%/°C max.

500 ms typ. 700 ms typ.

20 ms typ. 20 ms typ.

Yes, 130% or higher of rated output voltage, power shut off (shut off the input voltage and turn on

the input again) *5

3.0 kVAC for 1 min. (between all input terminals and output terminals) cutoff current 20 mA

2.5 kVAC for 1 min. (between all input terminals and PE terminal) cutoff current 20 mA

1.0 kVAC for 1 min. (between all output terminals and PE terminal) cutoff current 30 mA

–40 to 70°C (However, only startup is guaranteed for between –40°C to –25°C. (3-phase only))

(Derating is required according to the temperature.) (with no condensation or icing)

Conforms to EN 61204-3 Class B EN 55011 Class B *16

UL Listed: UL 508 *7

UL UR: UL 60950-1 (Recognition)

cUR: CSA C22.2 No.60950-1

CSA: CSA C22.2 No.60950-1

EN: EN 50178, EN 60950-1

Lloyd’s standards

ANSI/ISA 12.12.01 *7

SELV (EN 60950-1/EN 50178/UL 60950-1)

PELV (EN 60204-1, EN 50178)

Safety of Power Transformers (EN 61558-2-16)

EN 50274 for Terminal parts

3-phase, 380 to 480 VAC

(allowable range: 320 to 576 VAC)

2-phase, 380 to 480 VAC

(allowable range: 340 to 576 VAC)

Note: Refer to page 4 for notes 1 to 18.

S8VK-T

3

Page 4

S8VK-T

*1. Do not use an inverter output for the Power Supply. Inverters with an output frequency of 50/60 Hz are available, but the rise in the internal

temperature of the Power Supply may result in ignition or burning.

*2. For a cold start at 25°C. Refer to Engineering Data on page 7 to 8 for details.

*3. If the output voltage adjuster (V. ADJ) is turned, the voltage will increase by more than 29.5 VDC of the voltage adjustment range.

When adjusting the output voltage, confirm the actual output voltage from the Power Supply and be sure that the load is not damaged.

*4. A characteristic when the ambient operating temperature is between –25 to 70°C.

*5. Refer to Overvoltage Protection on page 8 for the time when input voltage shuts off and input turns on again.

*6. To meet safety standards, the S8VK-T must be protected with an external circuit-breaker or a fuse.

Be sure to use an external circuit-breaker or a fuse. Refer to Precautions for Safe Use on page 13 for details.

*7. The following supplementary Fuse/Circuit Breaker must be installed in accordance with NEC.:

Model FAZ-D5/3-NA, FAZ-D5/3-RT or FAZ-D5/3-DU, EATON INDUSTRIES (AUSTRIA) GMBH (E235139), Model KLKD5, LITTELFUSE INC.

(E10480)

*8. Safety Standards for a DC Input

The following standards apply to a 450 to 600 VDC input: UL 60950-1, EN 50178, EN 60950-1, and Lloyd's standards.

*9. In the case of using side-mounting bracket (S82Y-VK10S, S82YVK20S), Lloyd's Standards are not applicable.

*10. The value is when rated output current is 50% or less, the ambient operating temperature is 40°C or less, standard mounting, and rated input

voltage.

*11. The value is when both rated output voltage and rated output current are satisfied.

*12. 380 to 480 VAC input, in the range of 0 A to the rated output current.

*13. This is the maximum variation in the output voltage when the input voltage is gradually changed within the allowable input voltage range at

the rated output voltage and rated output current.

*14. Use at 26.4 VDC or lower for 2-phase input.

*15. The S8VK-T Power Supply conforms to EN 61000-3-2 under the following conditions for 2-phase input.

480 W: rated output voltage, and 65% or less of rated output current

960 W: rated output voltage, and 45% or less of rated output current

*16. The S8VK-T Power Supply conforms to EMI under the following conditions for 2-phase input.

480 W: Conforms to class B: rated output voltage, and 65% or less of rated output current/

Conforms to class A: rated output voltage, and 65% to 100% of rated output current

960 W: Conforms to class B: rated output voltage, and 45% or less of rated output current/

*17. 480 W: rated output voltage, and 50% or less of rated output current.

*18. When using 2-phase input. Refer to 2-Phase Input Operation For 960 W Model in Precautions for Safe Use on page 16 for details.

Conforms to class A: rated output voltage, and 45% to 100% of rated output current

960 W: rated output voltage, and 92.5% or less of rated output current.

4

Page 5

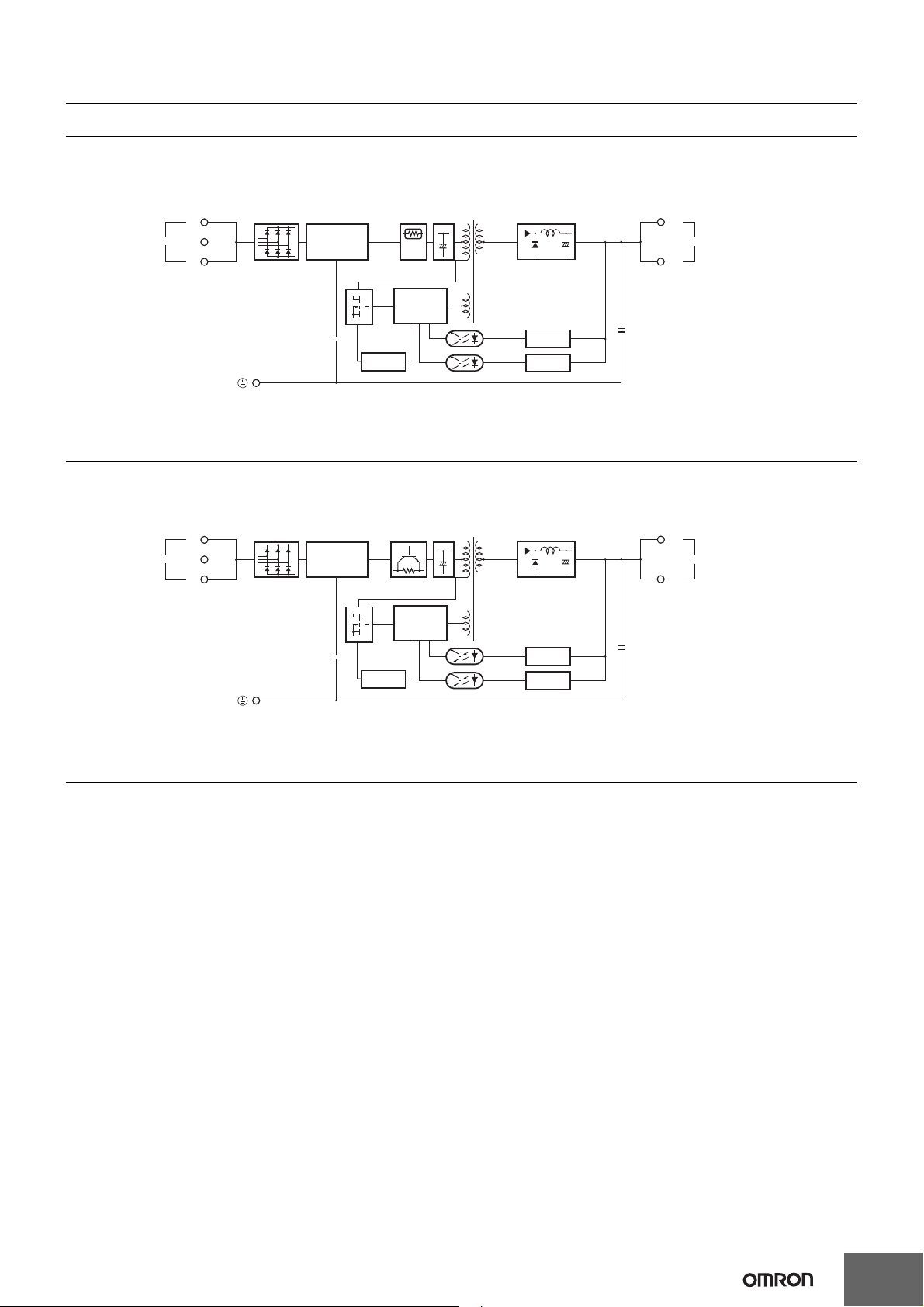

Connections

S8VK-T12024 (120 W)

S8VK-T24024 (240 W)

S8VK-T48024 (480 W)

S8VK-T96024 (960 W)

Block Diagrams

S8VK-T

INPUT

INPUT

L1

L2

L3

L1

L2

L3

Rectifier

Rectifier

Noise filter

Noise filter

Overcurrent

detection circuit

Overcurrent

detection circuit

lnrush

current

protection

Drive

control

circuit

lnrush

current

protection

Drive

control

circuit

Smoothing

circuit

Photocoupler

Smoothing

circuit

Photocoupler

Rectifier/

smoothing

circuit

Voltage

detection circuit

Overvoltage

detection circuit

Rectifier/

smoothing

circuit

Voltage

detection circuit

Overvoltage

detection circuit

+V

DC OUTPUT

−V

+V

DC OUTPUT

−V

5

Page 6

S8VK-T

12

3

5

4

12

3

5

4

6

Note:

A: The output current can use 100% of the rated output current.

B: Overcurrent protection limits the output current to 80% of the rated

output current.

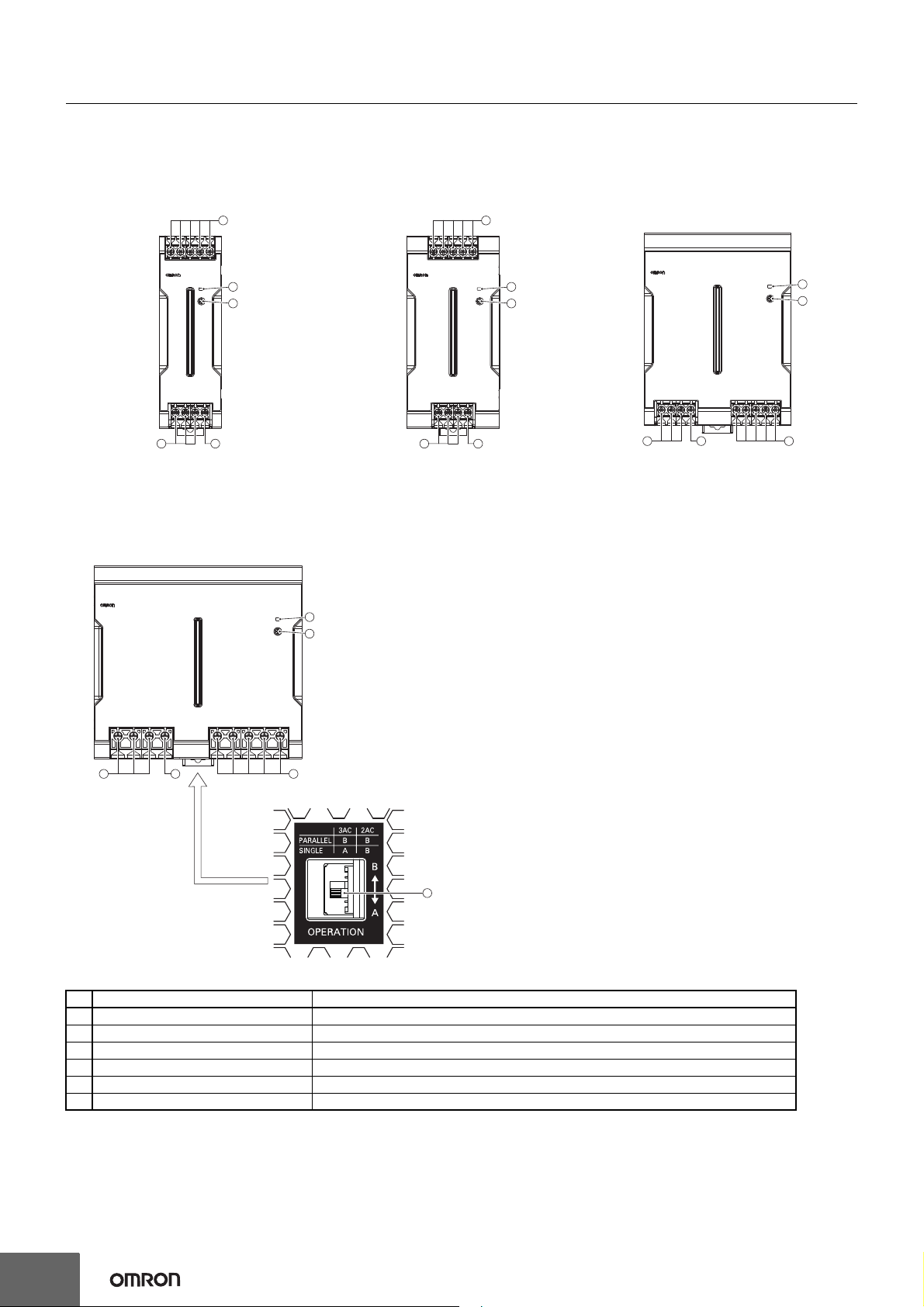

Construction and Nomenclature

Nomenclature

120 W Model 240 W Model 480 W Model

S8VK-T12024 S8VK-T24024 S8VK-T48024

3

960 W Model

S8VK-T96024

4

5

12

12

4

5

3

No. Name Function

1 Input terminals (L1), (L2), (L3) Connect the input lines to these terminals. *1

2 Protective Earth terminal (PE) / Ground Connect the ground line to this terminal. *2

3 DC Output terminals (−V), (+V) Connect the load lines to these terminals.

4 Output indicator (DC ON: Green) Lights while a direct current (DC) output is ON.

5 Output voltage adjuster (V.ADJ) Use to adjust the voltage.

6 Operation Switch *3 *4 To operate in parallel or 2-phase input, set the switch to the "B" side. (960 W model only).

*1. For wiring, refer to Wiring in Precautions for Safe Use on page 13.

*2. This is the protective earth terminal specified in the safety standards. Always ground this terminal.

*3. For parallel operation, refer to Parallel Operation in Precautions for Safe Use on page 15.

*4. For 2-phase input, refer to 2-Phase Input Operation For 960 W Model in Precautions for Safe Use on page 16.

6

Page 7

Engineering Data

−40 −25 −10 0 10 20 30 40 50 60 70 80

120

100

80

60

40

20

0

A

B

C

Load ratio (%)

Ambient temperature (°C)

−40 −25 −10 0 10 20 30 40 50 60 70 80

120

100

80

60

40

20

0

A

B

C

Load ratio (%)

Ambient temperature (°C)

−40 −25 −10 0 10 20 30 40 50 60 70 80

120

100

80

60

40

20

0

A

B

C

Load ratio (%)

Ambient temperature (°C)

Derating Curve

120 W (S8VK-T12024)

Note: This is the guaranteed value for startup. (3-phase only)

A. Standard mounting

B. Face-up mounting at 480 VAC or lower or 678 VDC or lower

C. Face-up mounting at 576 VAC or lower or 810 VDC or lower

240 W (S8VK-T24024)

S8VK-T

960 W (S8VK-T96024): Standard mounting

120

100

80

Load ratio (%)

60

40

20

0

−40 −25 −10 0 10 20 30 40 50 60 70 80

Ambient temperature (°C)

Note: This is the guaranteed value for startup. (3-phase only)

A. 3-Phase (340 VAC or over to 576 VAC or lower)

For less than 340 VAC, it is possible to use with output voltage at

28.5 VDC or lower and load rate 60% or lower.

B. 2-Phase (380 VAC or over to 576 VAC or lower, and output voltage

26.4 VDC or lower)

C. 2-Phase (360 VAC or over to 380 VAC or lower, and output voltage

26.4 VDC or lower)

For 340 VAC or over to less than 360 VAC, it is possible to use with

output voltage at 26.4 VDC or lower, and whichever is the smaller of

the load rate 60% or lower or the value of C.

960 W (S8VK-T96024): Face-up mounting

120

100

80

Load ratio (%)

B

C

A

D

E

F

Note: This is the guaranteed value for startup. (3-phase only)

A. Standard mounting

B. Face-up mounting at 480 VAC or lower or 678 VDC or lower

C. Face-up mounting at 576 VAC or lower or 810 VDC or lower

480 W (S8VK-T48024)

Note: This is the guaranteed value for startup. (3-phase only)

A. Standard mounting

Over 528 VAC: the derating is 0.21%/VAC

Over 746 VAC: the derating is 0.16%/VDC

B. Face-up mounting at 480 VAC or lower or 678 VDC or lower

C. Face-up mounting at 576 VAC or lower or 810 VDC or lower

60

40

20

0

−40 −25 −10 0 10 20 30 40 50 60 70 80

Ambient temperature (°C)

Note: This is the guaranteed value for startup. (3-phase only)

D. 3-Phase (340 VAC or over to 576 VAC or lower)

For less than 340 VAC, it is possible to use with output voltage at

28.5 VDC or lower and load rate 60% or lower.

E. 2-Phase ( 380 VAC or over to 480 VAC or lower, and output voltage

26.4 VDC or lower)

F. 2-Phase (Over 480 VAC to 576 VAC or lower)

For 340 VAC or over to less than 380 VAC, it is possible to use with

output voltage at 26.4 VDC or lower, and whichever is the smaller of

the load rate 60% or lower or the value of F.

7

Page 8

S8VK-T

(B) Face-up mounting

(A) Standard (Vertical) mounting

The values shown in the above diagrams are for reference only.

050100

Output current (%)

Output voltage (V)

Intermittent operation

29.5 V

22.5 V

0 V

+30%

(approx.)

Overvoltage protection

operating

Variable range

Rated output

voltage

Output voltage (V)

The values shown in the above diagram is for reference only.

90%

96.5%

Startup time

AC input

voltage

AC input

current

Output

voltage

Inrush current on input application

Input OFF

Input ON

Hold time

Mounting

Overload Protection

The load and the power supply are automatically protected from

overcurrent damage by this function.

Overload protection is activated if the output current rises above

121% of the rated current.

When the output current returns within the rated range, overload

protection is automatically cleared.

Overvoltage Protection

Consider the possibility of an overvoltage and design the system so

that the load will not be subjected to an excessive voltage even if the

feedback circuit in the Power Supply fails. If an excessive voltage that

is approximately 130% of the rated voltage or more is output, the

output voltage is shut OFF. Reset the input power by turning it OFF

for at least five minutes and then turning it back ON again.

Note: Do not turn ON the power again until the cause of the

overvoltage has been removed.

Inrush Current, Startup Time, Output Hold Time

Note: 1. Internal parts may occasionally deteriorate or be damaged

if a short-circuited or overcurrent state continues during

operation.

2. Internal parts may possibly deteriorate or be damaged if the

Power Supply is used for applications with frequent inrush

current or overloading at the load end. Do not use the Power

Supply for such applications.

Note: Twice the input current or above will flow during the parallel

operation or redundant system.

Therefore, check the fusing characteristics of fuses and

operating characteristics of breakers making sure that the

external fuses will not burn out and the circuit breakers will not

be activated by the inrush current.

Reference Value

Value

Reliability

(MTBF)

Definition

Life expectancy 10 years. Min.

Definition

120 W: 390,000 h

240 W: 350,000 h

480 W: 280,000 h

960 W: 260,000 h

MTBF stands for Mean Time Between

Failures, which is calculated according to the

probability of accidental device failures, and

indicates reliability of devices.

Therefore, it does not necessarily represent a

life of the product.

The life expectancy indicates average

operating hours under the ambient

temperature of 40°C and a load rate of 50%.

Normally this is determined by the life

expectancy of the built-in aluminum electrolytic

capacitor.

8

Page 9

S8VK-T

S8VK-T12024 (120 W)

S8VK-T24024 (240 W)

6.35 6.35

30 25

19.8

(26.8)

Rail Stopper

4.7

(Sliding: 7.5 max.)

(10)

125±1

145.6

(4)140

(1)

150

±1

52.3

95

±1

S8VK-T48024 (480 W)

S8VK-T96024 (960 W)

Dimensions (Unit: mm)

±1

40

6.35

104.6 125±1

6.35

19.8

104.6

4.7

(Sliding: 7.5 max.)Rail Stopper

60

±1

6.35

6.35

(1)

125±1

122.2±1

117.8

112.2

(4)

(10)

150

(1)

±1

145.6

(4)140

4.7

(Sliding: 7.5 max.)

135

±1

(1)

125±1

10.16

10.16

19.8

Rail Stopper

47.9

(10)

180

175.6

170

±1

(4)

19.8

(36.7)

41.78 32.95

Rail Stopper

4.7

(Sliding: 7.5 max.)

(10)

9

Page 10

S8VK-T

4.5

15 25 25

10 10

1,000 (500) *

25 25 15(5) *

35

±

0.3

7.3

±

0.15

27

±

0.15

1

* Values in parentheses are for the PFP-50N.

4.5

15 25 25

10 10

1,000

25 25 15

1 1.5

29.2242735

±

0.3

16

1.3

4.8

35.5

35.5

1.8

1.8

10

6.2

1

50

11.5

10

M4 spring washer

M4×8 pan-

head screw

DIN Rail (Order Separately)

Note: All units are in millimeters unless otherwise indicated.

Mounting Rail (Material: Aluminum)

PFP-100N

PFP-50N

Mounting Rail (Material: Aluminum)

PFP-100N2

End Plate

PFP-M

Note: If there is a possibility that the Unit will be subject to vibration or shock, use a steel DIN Rail. Otherwise, metallic filings may result from

aluminum abrasion.

10

Page 11

Mounting Brackets

140

±0.1

50

±0.1

15.5

±0.1

150125

73

4-4.5 dia.

±0.1

4940

t = 2.0

Name Model Qty used

Front-mounting bracket (for 120, 240 and 480 W models) S82Y-VK10F 1

Front-mounting bracket (for 960 W model) S82Y-VK10F 2

Side-mounting bracket (for 120 W model) S82Y-VK10S 1

Side-mounting bracket (for 240 W model) S82Y-VK20S 1

Note: Be sure to use the accessory screws.

Mounting screw tightening torque (recommended): 4.43 to 5.31 lb-in (0.5 to 0.6 N·m)

Type Model Dimensions Appearance

S8VK-T

Front-mounting

bracket

(for 120, 240,

480 W and 960 W

models)

S82Y-VK10F

5.4

4-4.5 dia.

t = 2.0

120 W model

±0.1

±0.1

140

For 960W type

150

240 W model

960 W model

±0.1

25

38

±0.1

64

Left-side mounting Right-side mounting

Side-mounting

bracket

(For 120 W model)

Side-mounting

bracket

(For 240 W model)

S82Y-VK10S

S82Y-VK20S

Left-side mounting

(DIN Rail) *

Right-side mounting

(DIN Rail) *

Left-side mounting Right-side mounting

73

±0.1

40

59

t = 2.0

50

4-4.5 dia.

±0.1

15.5

±0.1

±0.1

140

Left-side mounting

150125

(DIN Rail) *

Right-side mounting

(DIN Rail) *

* You can mount the side of the Power Supply to a DIN Rail by removing the DIN Rail Back-mounting Bracket and then attaching a Side-mounting

Bracket to the Power Supply.

11

Page 12

S8VK-T

Safety Precautions

Warning Indications

Indicates a potentially hazardous

CAUTION

Precautions for

Safe Use

Precautions for

Correct Use

Meaning of Product Safety Symbols

Used to warn of the risk of electric shock under

specific conditions.

Used to warn of the risk of minor injury caused by

high temperatures.

situation which, if not avoided, may

result in minor or moderate injury or in

property damage.

Supplementary comments on what to

do or avoid doing, to use the product

safely.

Supplementary comments on what to

do or avoid doing, to prevent failure to

operate, malfunction or undesirable

effect on product performance.

Used for general mandatory action precautions

for which there is no specified symbol.

Used to indicate prohibition when there is a risk of

minor injury from electrical shock or other source

if the product is disassembled.

!CAUTION

Minor electric shock, fire, or Product failure may

occasionally occur. Do not disassemble, modify, or

repair the Product or touch the interior of the

Product.

Minor burns may occasionally occur. Do not touch

the Product while power is being supplied or

immediately after power is turned OFF.

Fire may occasionally occur. Tighten terminal screws

to the specified torque.

S8VK-T12024, S8VK-T24024, S8VK-T48024:

4.43 to 5.31 lb-in (0.5 to 0.6 N•m)

S8VK-T96024:

10.62 to 13.28 lb-in (1.2 to 1.5 N•m)

Minor injury due to electric shock may occasionally

occur. Do not touch the terminals while power is

being supplied.

Minor electric shock, fire, or Product failure may

occasionally occur. Do not allow any pieces of metal

or conductors or any clippings or cuttings resulting

from installation work to enter the Product.

If the external breaker or fuse is tripped, the

equipment may have been seriously damaged.

Do not turn ON the input again.

12

Page 13

Precautions for Safe Use

L1

TT

L2

L3

N

L1

IT

L2

L3

+

DC

-

PE

FUSE

Wiring

• Connect the ground completely. A protective earthing terminal

stipulated in safety standards is used. Electric shock or malfunction

may occur if the ground is not connected completely.

• Minor fire may possibly occur. Ensure that input and output

terminals are wired correctly.

• Do not apply more than 75-N force to the terminal block when

tightening it.

• Be sure to remove the sheet covering the Product for machining

before power-ON so that it does not interfere with heat dissipation.

• To comply with safety standards and to ensure equipment safety,

connect the input to the S8VK-T through one of the following

Breakers or Fuses.

S8VK-T

• Use the following material for the wires to be connected to the

S8VK-T to prevent smoking or ignition caused by abnormal loads

or phase failure.

• Wire the input as shown in the following figures depends on your

power distribution system. Do not connect the neutral line in a

3-phase, 4-wire system.

TN-S

TN-C

2-phase

Power circuit-breakers

Model Input Power circuit-breakers

Circuit breaker Conforming UL/CE

S8VK-T12024

S8VK-T24024

3-phase

2-phase/DC

480 V, 5 A, characteristic D, 3-pole, or

equivalent breaker

Fuse Conforming

Fast Acting or identical function fuse

Circuit breaker Conforming UL/CE

S8VK-T48024

S8VK-T96024

3-phase

2-phase/DC

480 V, 5 A, characteristic D, 3-pole, or

equivalent breaker

Fuse Conforming

UL/CE 600 V, 10 A

Fast Acting or identical function fuse

Note: Do not use the S8VK-T96024 with a DC input.

UL/CE 600 V, 5 A

L1

L2

L3

N

PE

Recommended Wire Type/Cross-sectional Area and Stripping Length

INPUT OUTPUT PE / Ground

Model

S8VK-T12024 AWG22 to 10

S8VK-T48024 AWG20 to 10

S8VK-T96024 AWG16 to 6

American

Wire Gauge

Solid Wire

/Stranded Wire

0.35 to 6 mm

2

/0.35 to 4 mm

0.35 to 6 mm

2

/0.35 to 4 mm

0.5 to 6 mm

/0.5 to 4 mm

1.5 to 16 mm

2

2

2

/1.5 to 16 mm

American

Wire Gauge

AWG18 to 10

2

AWG14 to 10

2

AWG12 to 10

AWG8 to 6

2

Solid Wire

/Stranded Wire

0.75 to 6 mm

/0.75 to 4 mm

2.5 to 6 mm

/2.5 to 4 mm

4 to 6 mm

2

/4 mm

10 to 16 mm

/10 to 16 mm

2

2

2

2

2

2

American

Wire Gauge

2

AWG14 to 10

AWG14 to 6

PEN

FUSE

mm

mm

mm

mm

2

2

2

2

L1

L2

(L3)

PE

Wire tripping

Length

8 to 10 mmS8VK-T24024 AWG22 to 10

13 to 16 mm

L1

L2

L3

Solid Wire

/Stranded Wire

2.5 to 6

/2.5 to 4

2.5 to 16

/2.5 to 16

• The wire insertion hole, and applicable screwdriver of the terminal block are as follows.

Model

S8VK-T12024

Wire Insertion Hole

(Refer to the diagram on the right)

W L No.

Applicable Screwdriver

Driver

Diameter

Length

L

2.9 2.9 #2 4.9 mm max. 10 mm min.S8VK-T24024

S8VK-T48024

S8VK-T96024 5.4 5 #2 5.1 mm max. 12 mm min.

Installation Environment

• Do not use the Power Supply in locations subject to shocks or

vibrations. In particular, install the Power Supply as far away as

possible from contactors or other devices that are a vibration

source. For usage onboard a ship, always attach an End Plate

(PFP-M) to both sides of the Power Supply to hold the Power

Supply in place.

• Install the Power Supply well away from any sources of strong,

high-frequency noise and surge.

Operating Life

• The life of a Power Supply is determined by the life of the

electrolytic capacitors used inside. Here, Arrhenius Law applies,

doubled for each drop of 10°C. The life of the Power Supply can

thus be increased by reducing its internal temperature.

Ambient Operating and Storage Environments

• Store the Power Supply at a temperature of −40 to 85°C and a

humidity of 0% to 95%.

• Do not use the Power Supply in areas outside the derating curve

otherwise, internal parts may occasionally deteriorate or be

damaged.

• Use the Power Supply at a humidity of 0% to 95%.

• Do not use the Power Supply in locations subject to direct sunlight.

• Do not use the Power Supply in locations where liquids, foreign

matter, or corrosive gases may enter the interior of Products.

W

i.e., the life will be cut in half for each rise of 10°C or the life will be

13

Page 14

S8VK-T

*1. Convection of air

*2. 20 mm min.

*1

*1

*2

(C)

30 mm min.

Rail stopper

[A]

Ip: Boost current

Rated current

lave: Average current

t2

t1

output current

Mounting

• Take adequate measures to ensure proper heat dissipation to

increase the long-term reliability of the Product. Be sure to allow

convection in the atmosphere around devices when mounting. Do

not use in locations where the ambient temperature exceeds the

range of the derating curve.

• When cutting out holes for mounting, make sure that cuttings do

not enter the interior of the Products.

• Improper mounting will interfere with heat dissipation and may

occasionally result in deterioration or damage of internal parts. Use

the Product within the derating curve for the mounting direction that

is used.

Overload Protection

• Internal parts may possibly deteriorate or be damaged if a

short-circuited or overcurrent state continues during operation.

• Internal parts may possibly deteriorate or be damaged if the Power

Supply is used for applications with frequent inrush current or

overloading at the load end. Do not use the Power Supply for such

applications.

• The DC ON indicator (green) flashes if the overload protection

function operates.

Charging a Battery

If you connect a battery as the load, install overcurrent control and

overvoltage protection circuits.

Power Boost Function

For All Models

Power Boost is a function that can output the temporary repeated

boost current larger than the rated current.

However, it should meet the following four Boost current conditions.

1. Time that the boost current flows: t1

2. The maximum value of the boost current: lp

3. The average output current: lave

4. The time ratio of the boost current flow: Duty

Note: Boost current conditions

• t1

≤ 10 s

• Ip

≤ Rated boost current

• lave

≤ Rated current

t1

t1 + t2

× 100 [%] ≤ 30%

Duty=

• Do not allow the boost current to continue for more than 10

seconds.

Also, do not let the duty cycle exceed the boost current conditions.

These conditions may damage the Power supply.

• Ensure that the average current of one cycle of the boost current

does not exceed the rated output current.

This may damage the Power Supply.

• Lessen the load of the boost load current by adjusting the ambient

temperature and the mounting direction.

• Power Boost Function is not possible for the S8VK-T 960 W at

2-phase input or in parallel operation.

14

Output Voltage Adjuster (V.ADJ)

• The output voltage adjuster (V.ADJ) may possibly be damaged if it

is turned with unnecessary force. Do not turn the adjuster with

excessive force.

• After completing output voltage adjustment, be sure that the output

capacity or output current does not exceed the rated output

capacity or rated output current.

DIN Rail Mounting

To mount the Block on a DIN Rail, hook portion (A) of the Block onto

the rail and press the Block in direction (B).

(A)

(B)

To dismount the Block, pull down portion (C) with a flat-blade

screwdriver and pull out the Block.

Series Operation

Two power supplies can be connected in series.

+V

L1

L2

−V

L3

+V

L1

L2

L3

−V

Note: 1. The diode is connected as shown in the figure. If the load is

short-circuited, a reverse voltage will be generated inside

the Power Supply. If this occurs the Power Supply may

possibly deteriorate or be damaged. Always connect a

diode as shown in the figure.

Select a diode having the following ratings.

Type Schottky Barrier diode

Dielectric strength (V

Forward current (I

RRM) Twice the rated output voltage or above

F) Twice the rated output current or above

2. Although Products having different specifications can be

connected in series, the current flowing through the load

must not exceed the smaller rated output current.

Load

Page 15

S8VK-T

+V

−V

+V

−V

+V

0 V

−V

L1

L2

L3

L2

L1

L3

LoadLoad

+V

−V

+V

−V

L1

L2

L3

L2

L1

L3

LoadLoad

Load

D2

D1

Making Positive/Negative Outputs

• The outputs are floating outputs (i.e., the primary circuits and

secondary circuits are separated). You can therefore make

positive and negative outputs by using two Power Supplies.

You can make positive and negative outputs with any of the

models.

If positive and negative outputs are used, connect Power Supplies

of the same model as in the following figure. (Combinations with

different output capacities or output voltages can be made.

However, use the lower of the two maximum rated output currents

as the current to the loads.)

• Depending on the model, internal circuits may be damaged due to

startup failure when the power is turned ON if loads such as a

servomotor or operational amplifier may operate in series.

Therefore, connect bypass diodes (D

following figure.

If the list of models that support series connection of outputs says

that an external diode is not required, an external diode is also not

required for positive/negative outputs.

1, D2) as shown in the

Parallel Operation

Parallel operation is used when the output current from one Power

Supply is insufficient for the load. Power Supplies are connected in

parallel to increase the output current.

Two Power Supplies can be connected in parallel.

1. Parallel operation is possible only if the standard mounting and

3-phase input is used.

Maintain an ambient temperature of between -25 and 40°C.

2. For parallel operation, always use two Power Supplies with the

same capacity.

3. Use the output voltage adjusters (V. ADJ) to adjust the difference

in the output voltages between the two Power Supplies to 50 mV

or less.

4. If the output current from the two Power Supplies is not balanced,

the Power Supply with the higher output voltage will operate in an

overcurrent protection state, which will extremely reduce its

service life. After you adjust the difference in the output voltages

between the two Power Supplies, make sure that the currents are

well balanced.

5. The length and thickness of each wire connected to the load and

each unit must be the same so that there is no difference in the

voltage drop value between the load and the output terminals of

each Power Supply.

6. For Parallel Operation with units 120 W, 240 W S8VK-T Power

Supplies, connect diodes or S8VK-R to the outputs of each unit if

sudden load variation influence occurs in the ambient operation

environment.

Refer to the S8VK-R datasheet (Catalog No.: T059) for S8VK-R

specifications and the model number for each capacity.

S8VK-T

L1

L2

L3

S8VK-T

L1

L2

L3

+V

−V

+V

−V

S8VK-R

IN 1

IN 2

+V

Load

−V

• Use the following information as a guide to the diode type,

dielectric strength, and current.

Type Schottky Barrier diode

Dielectric strength (V

Forward current (I

RRM) Twice the rated output voltage or above

F) Twice the rated output current or above

7. The internal parts may occasionally be deteriorated or broken. Be

sure to set the OPERATION SWITCH to B when using S8VK-T

480 W, 960 W for Parallel Operation.

For Parallel Operation with units 960 W S8VK-T Power Supplies,

connect diodes to the outputs of each unit if sudden load variation

influence occurs in the ambient operation environment.

+V

L1

L2

−V

L3

+V

L1

L2

L3

−V

Load

• Use the following information as a guide to the diode type,

dielectric strength, and current.

Type Schottky Barrier diode

Dielectric strength (V

Forward current (I

RRM) Twice the rated output voltage or above

F) Twice the rated output current or above

15

Page 16

S8VK-T

+V

−V

+V

−V

+V

−V

L1

L2

L3

L2

L1

L3

Load

S8VK-R

IN 1

IN 2

S8VK-T

S8VK-T

+V

−V

+V

−V

L1

L2

L3

L2

L1

L3

A

B

D

1

D2

Load

Note:

A: The output current can use 100%

of the rated output current.

B: Overcurrent protection limits the

output current to 80% of the rated

output current.

Backup Operation

Backup operation is possible if you use two Power Supplies of the

same model.

Even if one Power Supplies fails, operation can be continued with the

other Power Supply.

Make sure that the maximum load does not exceed the capacity of

one Power Supply.

For backup operation, connect the S8VK-R for 120 W, 240 W, and

480 W.

Refer to the S8VK-R datasheet (Catalog No.: T059) for S8VK-R

specifications and the model number for each capacity.

For 960 W, always connect diodes to the output sides of the two

Power Supplies as shown in the following diagram.

In Case There Is No Output Voltage

The possible cause for no output voltage may be that the overcurrent

or overvoltage protection has operated. The internal protection may

operate if a large amount of surge voltage such as a lightening surge

occurs while turning ON the power supply.

In case there is no output voltage, please check the following points

before contacting us:

• Checking overload protected status:

Check whether the load is in overload status or is short-circuited.

Remove wires to load when checking.

• Checking overvoltage or internal protection:

Turn the power supply OFF once, and leave it OFF for at least

5 minutes. Then turn it ON again to see if this clears the condition.

2-Phase Input Operation For 960 W Model

The internal parts may occasionally be deteriorated or broken. Be sure

to set the OPERATION SWITCH to B when using S8VK-T 960 W at

2-phase input.

• Use the following information as a guide to the diode type,

dielectric strength, and current.

Type Schottky Barrier diode

Dielectric strength (V

Forward current (I

RRM) Twice the rated output voltage or above

F) Twice the rated output current or above

• Increase the output voltage setting of Power Supply A and Power

Supply B by the drop in the forward voltage (V

2.

D

F) of diodes D1 and

Also, the diodes will cause a power loss equivalent to the Power

Supply output current (I

OUT) times the diode forward voltage (VF).

Therefore, cooling measures must be implemented so that the

temperature of the diodes decreases to the catalog value or lower.

• Because of the load power and power loss due to the diodes, do

not exceed the rated power of one Power Supply (rated output

voltage × rated output current).

16

Page 17

S8VK-T

(1) Failures that result from handling or operation of the product under conditions or in environments that are not given in this document and

not given in any other specifications exchanged between OMRON and the customer

(2) Failures that originate in causes other than the delivered product itself

(3) Failures caused by disassembly, modification, or repair of the product by anyone other than OMRON

(4) Failures caused by applications or uses for which the product was not originally intended

(5) Failures caused by factors that could not be anticipated with the scientific or technical knowledge available when the product was shipped

(6) Failures caused by other causes for which OMRON is not responsible, such as natural disasters and other acts of God

This warranty is limited to the individual product that was delivered and does not cover any secondary, subsequent, or related damages.

Period and Terms of Warranty

Warranty Period

The product warranty is valid for a period of three years from the date of shipment from the factory.

Terms of Warranty

The warranty is valid only for the following operating conditions.

1. Average ambient operating temperature of the product: 40°C max.

2. Average load rate: 80% max.

3. Mounting method: Standard mounting

* The maximum ratings must be within the derating curve.

If the product fails for reasons attributable to OMRON within the above warranty period, OMRON will repair or replace the faulty part of the product

at the place of purchase or the place where the product delivered without charge.

This warranty does not cover the following types of failures.

Recommended Replacement Periods and Periodic Replacement for

Preventive Maintenance

The recommended replacement period for preventive maintenance is greatly influenced by the application environment of the product. As a

guideline, the recommended replacement period is 7 to 10 years.*

To prevent failures or accidents that can be caused by using a product beyond its service live, we recommend that you replace the product as early

as possible within the recommended replacement period.

However, bear in mind that the recommended replacement period is for reference only and does not guarantee the life of the product.

Many electronic components are used in the product and the product depends on the correct operation of these components to achieve the original

product functions and performance.

However, the influence of the ambient temperature on aluminum electrolytic capacitors is large, and the service life is reduced by half for each

10°C rise in temperature (Arrhenius law).

When the capacity reduction life of the electrolytic capacitor is reached, the product failures or accidents may occur.

We therefore recommend that you replace the product periodically to minimize product failures or accidents in advance.

* The recommended replacement period applies under the following conditions: rated input voltage, load rate of 50% max., ambient temperature

of 40°C max., and the standard mounting method. (The fan is excluded for models with fans.)

This product model is designed with a service life of 10 years minimum under the above conditions.

17

Page 18

Terms and Conditions Agreement

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have

any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship

for a period of twelve months from the date of sale by Omron (or such other period expressed in writing

by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL

SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on infringement by the Products

or otherwise of any intellectual property right. (c) Buy

er Remedy. Omron’s sole obligation hereunder shall be

, at Omron’s election,

to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price

of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other

claims or expenses regarding the Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or

unsuitability or the results from the use of Products in combination with an

y electrical or electronic components, circ

uits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable

third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself is

not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system,

or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with

respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE

QUANTITIES WITHOUT ENSURING

THAT THE SYSTEM AS A W

HOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the user must correlate it

to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice

to change part numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be

assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical or proofreading errors or omissions.

Page 19

OMRON Corporation Industrial Automation Company

Kyoto, JAPAN

Contact: www.ia.omron.com

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China CSM_8_1_1116

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2014-2016 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. T061-E1-02

0616 (0414)

Loading...

Loading...