Page 1

Cat. No. I544-E1-05

USER’S MANUAL

OMNUC W SERIES

MODELS R88M-W@

(AC Servomotors)

MODELS R88D-WN@-ML2

(AC Servo Drivers)

AC SERVOMOTORS/SERVO DRIVERS

WITH BUILT-IN MECHATROLINK-II COMMUNICATIONS

Page 2

Thank you for choosing this OMNUC W-series product. Proper use and handling of the product will ensure proper product performance, will length product life, and may prevent possible

accidents.

Please read this manual thoroughly and handle and operate the product with care.

1.To ensure safe and proper use of your OMRON Servomotors and Servo Drivers, please read this manual

(Cat. No. I544-E1) to gain sufficient knowledge of the products, safety information, and precautions before

actual use.

2.The products are illustrated without covers and shieldings to enable showing better detail in this manual.

For actual use of the products, make sure to use the covers and shieldings as specified.

3.Copies of this manual and other related manuals must be delivered to the actual end users of the products.

4.Please keep a copy of this manual close at hand for future reference.

5.If a product has been left unused for a long time, please consult with your OMRON sales representative.

NOTICE

1.This manual describes the functions of the product and relations with other products. You

should assume that anything not described in this manual is not possible.

2.Although care has been given in documenting the product, please contact your

OMRON representative if you have any suggestions on improving this manual.

The product contains dangerous high voltages inside. Turn OFF the power and wait for at least

3.

five minutes to allow power to discharge before handling or working with the product. Never

attempt to disassemble the product.

4.We recommend that you add the following precautions to any instruction manuals you prepare

for the system into which the product is being installed.

• Precautions on the dangers of high-voltage equipment.

• Precautions on touching the terminals of the product even after power has been turned

OFF. (These terminals are live even with the power turned OFF.)

5.Specifications and functions may be changed without notice in order to improve product performance.

6.Positive and negative rotation of AC Servomotors described in this manual are defined as looking at the end of the output shaft of the motor as follows: counterclockwise rotation is positive

and clockwise rotation is negative.

7.Do not perform withstand-voltage or other megameter tests on the product. Doing so may

damage internal components.

8.Servomotors and Servo Drivers have a finite service life. Be sure to keep replacement products on hand and to consider the operating environment and other conditions affecting the service life.

9.The OMNUC W Series can control both incremental and absolute encoders. Differences in

functions or specifications according to the encoder type are indicated in this manual. Be sure

to check the model that is being used, and follow the relevant specifications.

• Servomotors with incremental encoders: R88M-W@H-@

• Servomotors with absolute encoders: R88M-W@T- @

Items to Check After Unpacking

1.Check the following items after removing the product from the package:

• Has the correct product been delivered (i.e., the correct model number and specifications)?

• Has the product been damaged in shipping?

• Are any screws or bolts loose?

Page 3

USER’S MANUAL

OMNUC W SERIES

MODELS R88M-W@

(AC Servomotors)

MODELS R88D-WN@-ML2

(AC Servo Drivers)

AC SERVOMOTORS/SERVO DRIVERS

WITH BUILT-IN MECHATROLINK-II COMMUNICATIONS

Page 4

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything

else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 6

Page 7

General Warnings

Observe the following warnings when using the OMNUC Servomotor and Servo Driver and all connected or peripheral devices.

This manual may include illustrations of the product with protective covers removed in order to

describe the components of the product in detail. Make sure that these protective covers are on the

product before use.

Consult your OMRON representative when using the product after a long period of storage.

!WARNING Always connect the frame ground terminals of the Servo Driver and the Servomo-

tor to a class-3 ground (to 100

result in electric shock.

!WARNING Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

!WARNING Do not remove the front cover, terminal covers, cables, Parameter Units, or

optional items while the power is being supplied. Doing so may result in electric

shock.

!WARNING Installation, operation, maintenance, or inspection must be performed by autho-

rized personnel. Not doing so may result in electric shock or injury.

Ω or less). Not connecting to a class-3 ground may

!WARNING Wiring or inspection must not be performed for at least five minutes after turning

OFF the power supply. Doing so may result in electric shock.

!WARNING Do not damage, press, or put excessive stress or heavy objects on the cables.

Doing so may result in electric shock.

!WARNING Do not touch the rotating parts of the Servomotor in operation. Doing so may

result in injury.

!WARNING Do not modify the product. Doing so may result in injury or damage to the product.

!WARNING Provide an appropriate stopping device on the machine side to secure safety. (A

holding brake is not a stopping device for securing safety.) Not doing so may result

in injury.

!WARNING Provide an external emergency stopping device that allows an instantaneous stop

of operation and power interruption. Not doing so may result in injury.

!WARNING Do not come close to the machine immediately after resetting momentary power

interruption to avoid an unexpected restart. (Take appropriate measures to secure

safety against an unexpected restart.) Doing so may result in injury.

!Caution Use the Servomotors and Servo Drivers in a specified combination. Using them

incorrectly may result in fire or damage to the products.

Page 8

!Caution Do not store or install the product in the following places. Doing so may result in

fire, electric shock, or damage to the product.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

!Caution Do not touch the Servo Driver radiator, regeneration resistor, or Servomotor while

the power is being supplied or soon after the power is turned OFF. Doing so may

result in a skin burn due to the hot surfaces.

Storage and Transportation Precautions

!Caution Do not hold the product by the cables or motor shaft while transporting it. Doing so

may result in injury or malfunction.

!Caution Do not place any load exceeding the figure indicated on the product. Doing so

may result in injury or malfunction.

!Caution Use the motor eye-bolts only for transporting the Motor. Using them for transport-

ing the machinery may result in injury or malfunction.

Installation and Wiring Precautions

!Caution Do not step on or place a heavy object on the product. Doing so may result in

injury.

!Caution Do not cover the inlet or outlet ports and prevent any foreign objects from entering

the product. Doing so may result in fire.

!Caution Be sure to install the product in the correct direction. Not doing so may result in

malfunction.

!Caution Provide the specified clearances between the Servo Driver and the control panel

or with other devices. Not doing so may result in fire or malfunction.

!Caution Do not apply any strong impact. Doing so may result in malfunction.

Page 9

!Caution Be sure to wire correctly and securely. Not doing so may result in motor runaway,

injury, or malfunction.

!Caution Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

!Caution Use crimp terminals for wiring. Do not connect bare stranded wires directly to ter-

minals. Connection of bare stranded wires may result in burning.

!Caution Always use the power supply voltage specified in the User's Manual. An incorrect

voltage may result in malfunction or burning.

!Caution Take appropriate measures to ensure that the specified power with the rated volt-

age and frequency is supplied. Be particularly careful in places where the power

supply is unstable. An incorrect power supply may result in malfunction.

!Caution Install external breakers and take other safety measures against short-circuiting in

external wiring. Insufficient safety measures against short-circuiting may result in

burning.

!Caution Take appropriate and sufficient countermeasures when installing systems in the

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution Do not reverse the polarity of the battery when connecting it. Reversing the polar-

ity may damage the battery or cause it to explode.

Operation and Adjustment Precautions

!Caution Confirm that no adverse effects will occur in the system before performing the test

operation. Not doing so may result in equipment damage.

!Caution Check the newly set parameters for proper execution before actually running

them. Not doing so may result in equipment damage.

!Caution Do not make any extreme adjustments or setting changes. Doing so may result in

unstable operation and injury.

!Caution Separate the Servomotor from the machine, check for proper operation, and then

connect to the machine. Not doing so may cause injury.

Page 10

!Caution When an alarm occurs, remove the cause, reset the alarm after confirming safety,

and then resume operation. Not doing so may result in injury.

!Caution Do not use the built-in brake of the Servomotor for ordinary braking. Doing so may

result in malfunction.

Maintenance and Inspection Precautions

!Caution Resume operation only after transferring to the new Unit the contents of the data

required for operation. Not doing so may result in an unexpected operation.

!Caution Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

may result in malfunction, fire, or electric shock.

Page 11

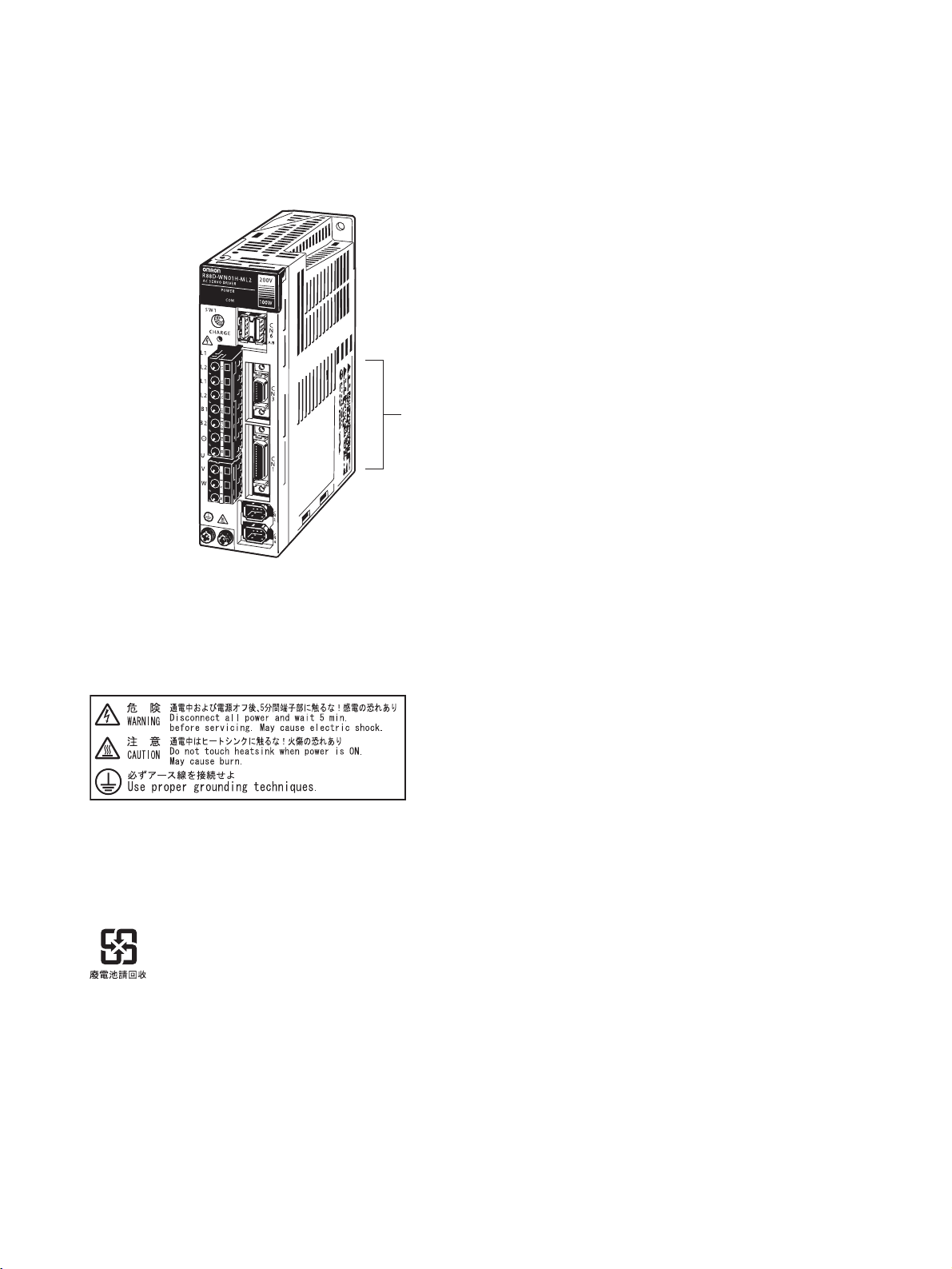

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to follow the

instructions given there.

Warning label

Precautions for Safe Use

Dispose of the product and batteries according to local ordinances as they apply.

Have qualified specialists properly dispose of used batteries as industrial waste.

Page 12

Page 13

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 14

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 15

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 16

Page 17

Table of Contents

Chapter 1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Servo Driver Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-4 Applicable Standards and Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-5 System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Chapter 2. Standard Models and Specifications. . . . . . . . . . . . . . . . 2-1

2-1 Standard Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Servo Driver and Servomotor Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-3 External and Mounted Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2-4 Servo Driver Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

2-5 Servomotor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

2-6 Cable and Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-93

2-7 External Regeneration Resistor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-121

2-8 Absolute Encoder Backup Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-122

2-9 Reactor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-124

2-10 MECHATROLINK-II Repeater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-126

Chapter 3. System Design and Installation . . . . . . . . . . . . . . . . . . . . 3-1

3-1 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-3 Regenerative Energy Absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3-4 Adjustments and Dynamic Braking When Load Inertia Is Large . . . . . . . . . . . . . . . . . . . . . 3-38

Chapter 4. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1 Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3 User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-4 Operation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

4-5 Trial Operation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

4-6 Making Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

4-7 Advanced Adjustment Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-103

4-8 Using Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-130

4-9 Using Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-132

Chapter 5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1 Measures when Trouble Occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5-4 Overload Characteristics (Electronic Thermal Characteristics) . . . . . . . . . . . . . . . . . . . . . . . 5-43

5-5 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

5-6 Replacing the Absolute Encoder Battery (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Page 18

Table of Contents

Chapter 6. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-1 Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Parameter Setting Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-3 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-1

Page 19

Chapter 1

Introduction

1-1 Features

1-2 System Configuration

1-3 Servo Driver Nomenclature

1-4 Applicable Standards and Models

1-5 System Block Diagrams

Page 20

Introduction

Chapter 1

1-1 Features

OMNUC W-series AC Servo Drivers with built-in MECHATROLINK-II Communications

are designed specifically for use with the MECHATROLINK-II high-speed motion field

network.

Combining these Servo Drivers with MECHATROLINK-II-compatible Motion Control

Units (CS1W-MCH71 or CJ1W-MCH71) or Position Control Units (CJ1W-NCF71) is an

easy way to create a high-speed servo control system with a communications link

between the Servo Drivers and the Controllers.

■ Data Transfer by MECHATROLINK-II Communications

When a Servo Driver is combined with a MECHATROLINK-II-compatible Motion Control Unit (CS1WMCH71 or CJ1W-MCH71) or Position Control Unit (CJ1W-NCF71), all control data is transferred

between the Servo Driver and the Controller by means of data communications.

Control commands are transferred by means of data communications, so Servomotor performance is

not limited by control interface specifications, such as response frequencies for input pulses and

encoder feedback pulses. This allows the Servomotor to perform to its fullest capacity.

Moreover, system data control is simplified by having all Servo Driver parameters and monitor data

managed by the host controller.

■ Built-in Communications Interface

The MECHATROLINK-II communications interface has been built into the Servo Driver. In comparison with earlier W-series Servo Drivers, in which the MECHATROLINK-II Application Module is

installed, only 60% of the installation surface area is required. (for 200-V/100-W Servo Drivers). This

allows a great saving of space in the control panel.

■ W-series Servomotor Compatibility

A W-series Servomotor can be used as is, including the encoder cable and power cable, so the system can be upgraded without changing the structural design.

The W-series product line offers 3,000-r/min Servomotors (Cylinder-style: 50-W to 3-kW; Flat-style:

100-W to 1.5-kw), 1,000-r/min Servomotors (300-W to 2-kW), and 1,500-r/min Servomotors (450-W

to 1.8-kW). Also, IP67 (waterproof) Servomotors can be connected in the same way.

■ High-speed, High-precision Motion Control Capability

A less-deviation control function and a predictive control function are provided to shorten the Servomotor's settling time and achieving high tracking capability.

The W-series Servomotors handle motion control with increased speed and precision, including synchronous control in combination with CS1W-MCH71 or CJ1W-MCH71 Motion Control Units.

1-2

Page 21

Introduction

■ Regenerative Power Processing

In addition to the built-in regenerative power processing function using regeneration resistance,

external regeneration resistance can also be connected, allowing the W Series to be used for applications with high regenerative energy on vertical axes.

■ Conformity to Standards

The W Series conforms to EC Directives (both low-voltage and EMC) as well as to UL and cUL

requirements, thereby assisting the user in meeting required standards.

■ High-frequency Current Countermeasures

On Servo Drivers of 1 kW and above, a current reactor connection terminal is provided to assist the

user in controlling high-frequency current.

Chapter 1

1-3

Page 22

Introduction

INC

ABS

Controller (MECHATROLINK-II Type)

Controller (MECHATROLINK-II Type)

MCH71

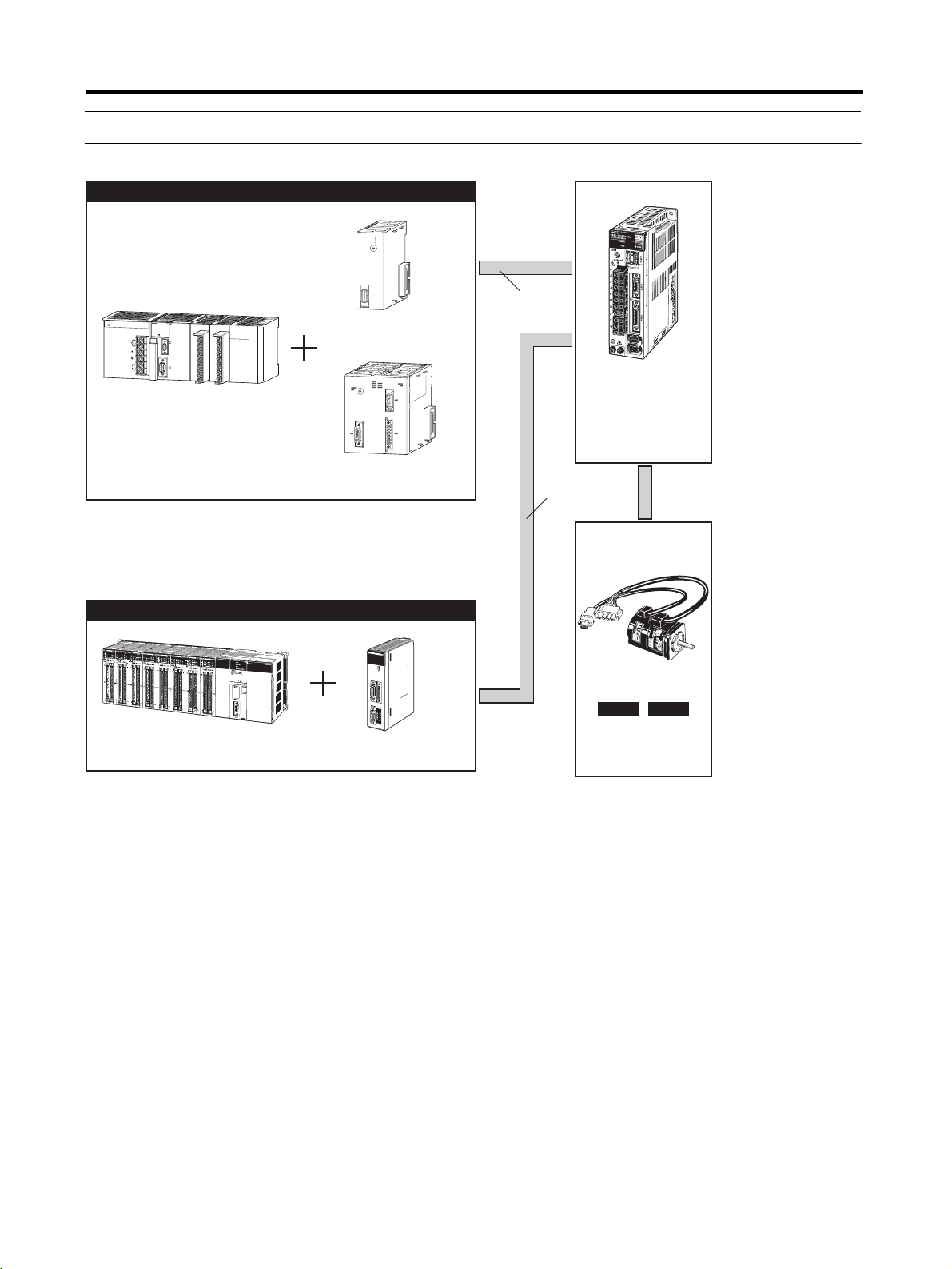

1-2 System Configuration

Controller (MECHATROLINK-II Type)

N

C

F

7

1

M

L

K

R

U

N

E

R

C

E

R

H

E

R

M

C

B

D

A

U

NIT

9

E

0

8

F

1

7

N

o.

2

6

3

5

4

M

LK

P

A

2

0

5

R

P

S

O

Y

W

E

R

SYSMAC CJ1

Programmable Controller

R

U

S

N

M

A

C

E

R

R

/

A

L

M

C

J

1

G

C

P

U

4

4

I

N

H

P

R

O

G

R

A

M

M

A

B

L

E

P

R

P

H

L

C

O

N

T

R

O

L

L

E

R

C

O

M

M

O

P

E

N

M

C

P

W

R

L

1

B

U

S

Y

A

C

1

0

0

2

4

0

V

I

N

P

U

T

L

2

/

N

P

ERI

PH

E

R

AL

R

U

N

O

U

T

P

U

T

A

C

2

4

0

V

D

C

2

4

V

P

O

R

T

CJ1W-NCF71

Position Control Unit

M

C

H

7

1

C

B

D

A

9

E

0

8

F

1

7

2

6

3

5

4

CJ1W-MCH71

Motion Control Unit

Chapter 1

MECHATRO

LINK-II

R88D-WN@@@-ML2

OMNUC W-series AC

Servo Driver with builtin MECHATROLINK-II

Communications

MECHATRO

LINK-II

Controller (MECHATROLINK-II Type)

SYSMAC CS1

Programmable Controller

M

C

H

7

1

R

U

N

E

R

C

E

R

H

E

R

1

E

R

3

E

R

2

E

R

4

S

S

I

M

L

K

U

N

I

T

N

o

.

T

.

B

.

S

S

I

I

/

O

M

L

K

CS1W-MCH71

Motion Control Unit

INC

ABS

R88M-W@

OMNUC W-series

AC Servomotor

1-4

Page 23

Introduction

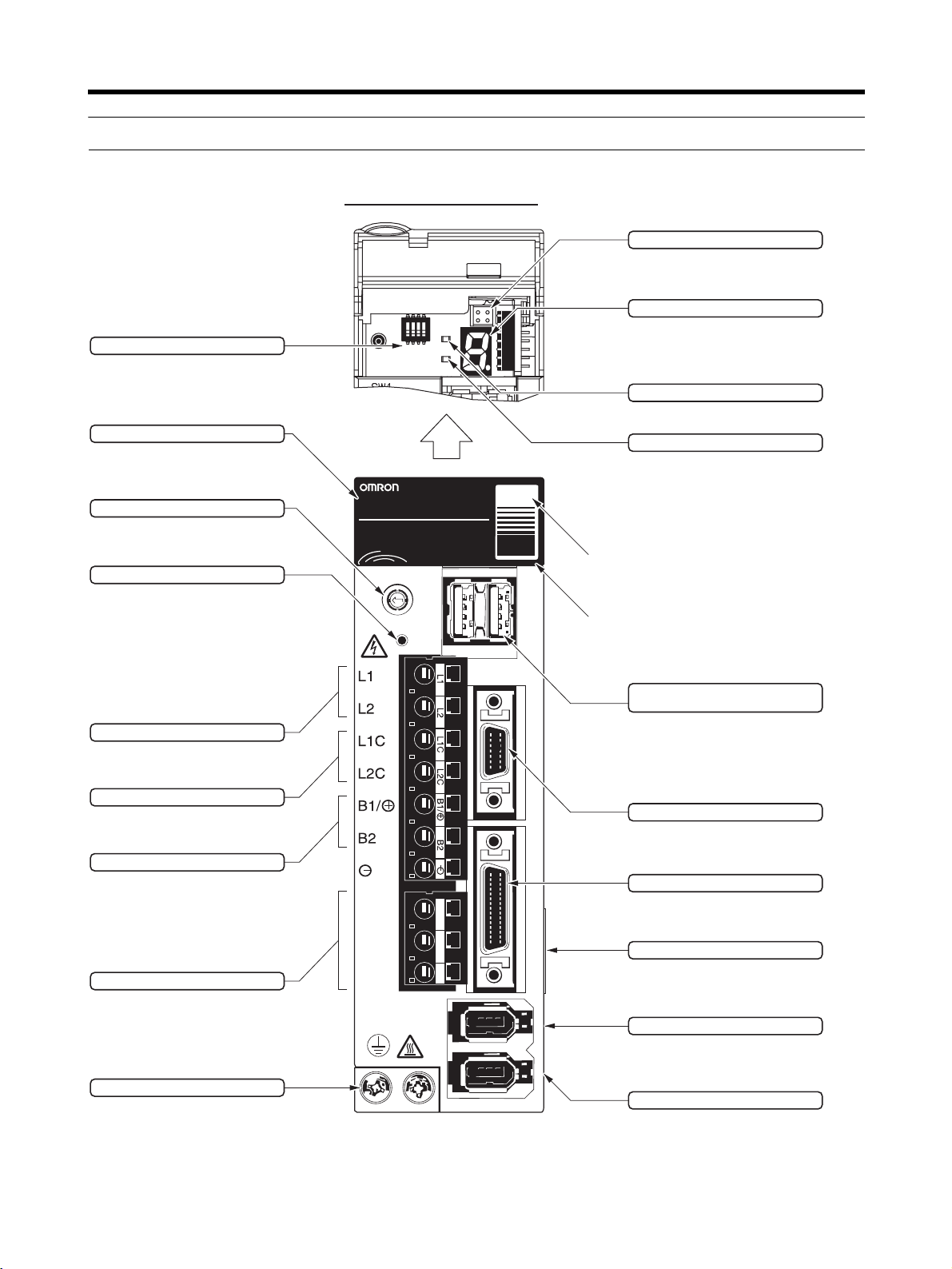

1-3 Servo Driver Nomenclature

With Top Cover Open

ON

SW1

4

3

2

1

0

F

E

CHARGE

1234

POWER

5

6

7

8

9

A

B

C

D

POWER

COM

COM

DIP Switch

Used for MECHATROLINK-II

communications settings.

Model Number

Rotary Switch (SW1)

Used for setting MECHATROLINK-II

node address.

Charge Indicator

Lit when the main-circuit is powered.

Also, for Servo Drivers of 1 kW or less,

the indicator lights dimly when only the

control power supply is ON. Even after

the power is turned OFF, it remains lit

as long as an electric charge remains in

the main-circuit capacitor, so do not

touch the Servo Driver's terminals

during this period.

Main-circuit Power Terminals

These are the input terminals for

the main-circuit power supply.

R88D-WN01H-ML2

AC SERVO DRIVER

200

100

W

V

A/B

Chapter 1

Analog Monitor Connector (CN5)

Motor rotation speeds, torque

command values, etc., can be

monitored using a special cable.

Panel Display

Displays Servomotor status with

a 7-segment LED display.

Power Indicator (POWER)

Lit when the control power is

being supplied.

Communications Indicator (COM)

Lit when MECHATROLINK-II

communications are in progress.

Input voltage

C

N

6

C

N

3

Top cover

MECHATROLINK-II Communications

Connectors (CN6A, CN6B)

Connect either a special cable for

a MECHATROLINK-II system or

a Terminating Resister.

Control Power Terminals

These are input terminals for the

control power supply.

Regenerative Resistance Terminals

These are terminals for external

regenerative resistance.

Servomotor Connector Terminals

These are connector terminals

for Servomotor power line.

Ground Terminals

These are ground terminals for

preventing electrical shock.

Connect to 100 Ω or less.

U

V

W

U V W

Personal Computer Connector (CN3)

This is the connector for

communications with a personal

computer.

C

N

1

I/O Signal Connector (CN1)

This is the connector for

command input signals and

sequence I/O signals.

Nameplate (Side Panel)

The nameplate shows the Servo

Driver model number and ratings.

C

N

2

C

N

4

Encoder Connector (CN2)

This is the connector for the

encoder provided for the

Servomotor.

Expansion Connector (CN4)

This is a supplementary

connector for future expansion. It

cannot presently be used, so do

not connect anything to it.

1-5

Page 24

Introduction

Chapter 1

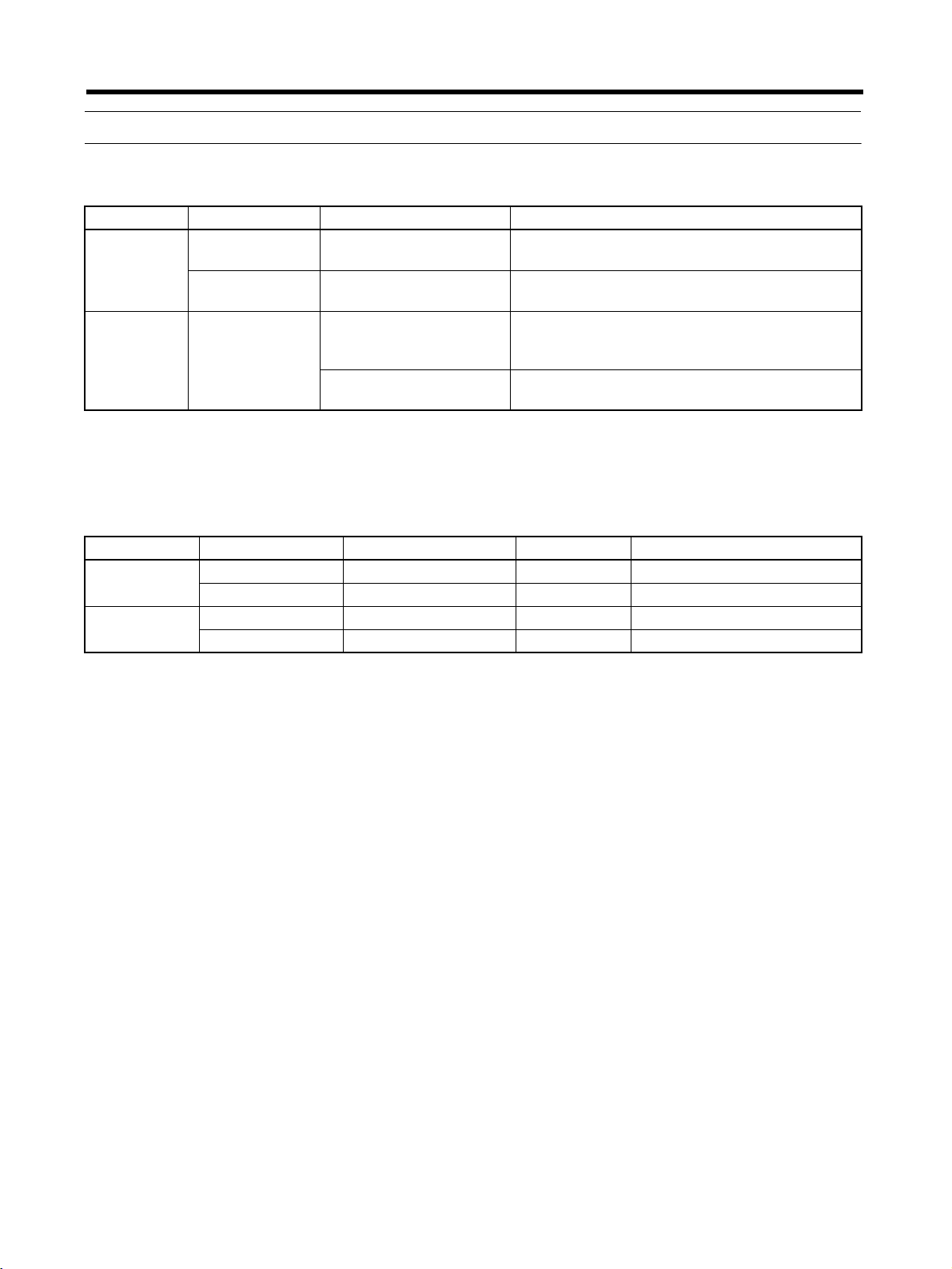

1-4 Applicable Standards and Models

■ EC Directives

EC Directive Product Applicable standard Remarks

Low Voltage AC Servo Drivers EN50178 Safety requirements for electrical equipment for

measurement, control, and laboratory use.

AC Servomotors IEC60034-8

EN60034-1, -5, -9

EMC AC Servo Drivers

and AC Servomotors

EN55011 class A group 1 Limits and methods for measuring radio distur-

EN61000-6-2 Electromagnetic compatibility generic immunity

Note Installation under the conditions specified in 3-2-5 Wiring for Conformity to EMC Directives is

required to conform to EMC Directives.

■ UL/cUL Standards

Rotating electrical machines.

bance characteristics of industrial, scientific, and

medical (ISM) radio-frequency equipment.

standard in industrial environments

Standards Product Applicable standard File No. Remarks

UL AC Servo Drivers UL508C E179149 Power conversion equipment

AC Servomotors UL1004 E179189 Electric motors

cUL AC Servo Drivers cUL C22.2 No. 14 E179149 Industrial control equipment

AC Servomotors cUL C22.2 No. 100 E179189 Motors and generators

1-6

Page 25

Introduction

r

Chapter 1

1-5 System Block Diagrams

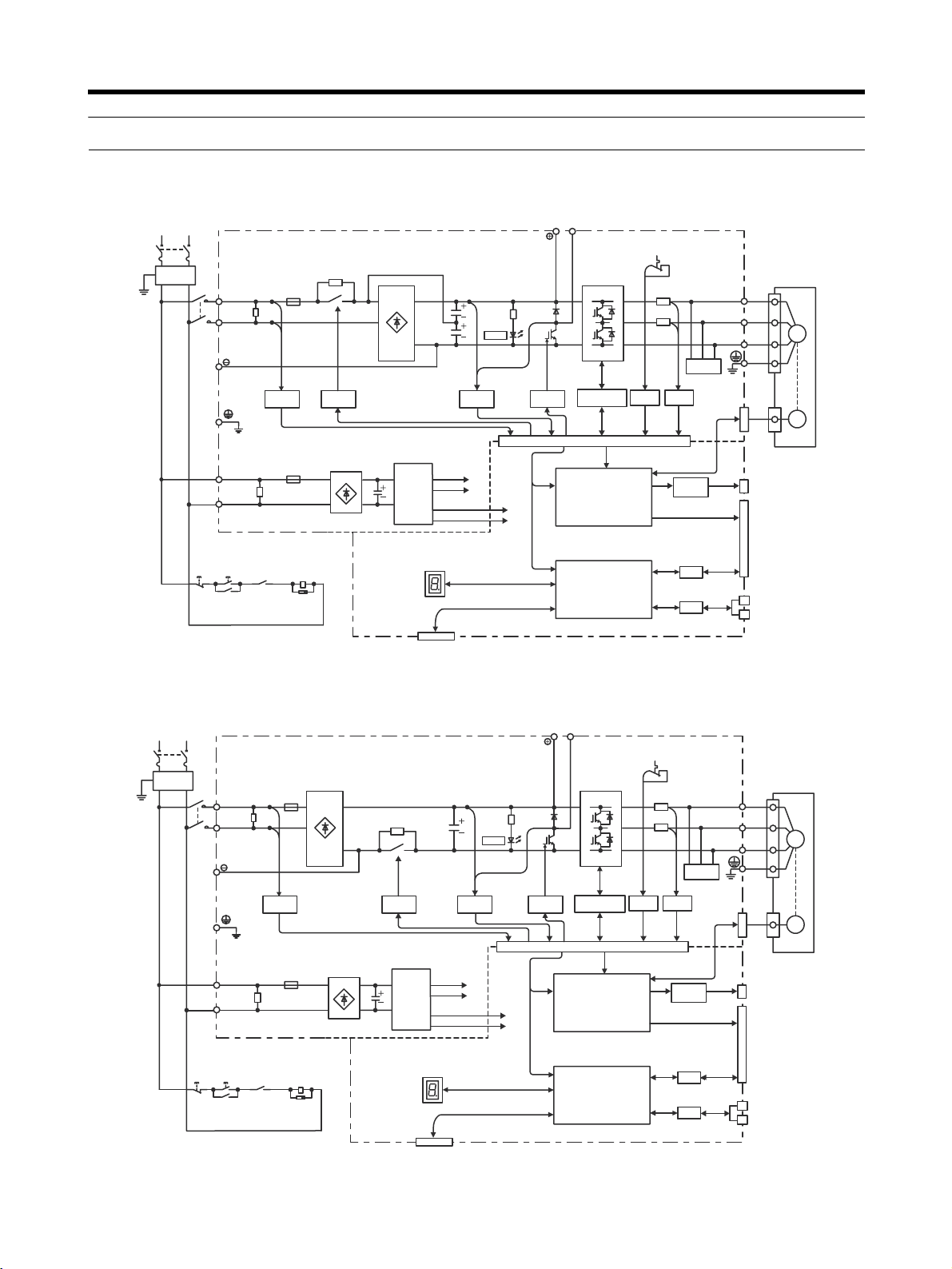

■ 100 V AC: R88D-WNA5L-ML2/WN01L-ML2/-WL02L-ML2/-WN04L-ML2

Single-phase 100 to 115 V

+10%/−15% (50/60 Hz)

Noise

filter

1KM

L1

L2

L1C

L2C

Varistor

Varistor

Voltage

detection

Relay

drive

Control

power

supply

Voltage

detection

±5 V

15 V

B1/ B2

Servomotor

U

V

CH

AR

G

E

Gate

drive

Gate drive overcurrent protection

Temperature

detection

Current

detection

Dynamic

brake circuit

W

CN2

CN10

CN5

Analog voltage

conversion

CN1

5 V

±12 V

ASIC (PWM

control, etc.)

M

PG

Analog monitor

output

Encoder output

Power

Power

ON

1KM

Open for

servo alarm

1Ry

1KM

Surge

protector

Status indicator

CN3

Personal computer

CPU (position,

speed calculations,

etc.)

I/O

Control I/O

CN6A

I/F

CN6B

MECHATROLINK-II

OFF

■ 200 V AC: R88D-WNA5H-ML2/WN01H-ML2/-WL02H-ML2/-WN04H-ML2

Single-phase 200 to 230 V

+10%/−15% (50/60 Hz)

Noise

filter

1KM

L1

L2

L1C

L2C

Varistor

Voltage

detection

Varistor

Relay

drive

Control

power

supply

Voltage

detection

±5 V

15 V

C

HARG

E

5 V

±12 V

B1/ B2

Gate

drive

Gate drive overcurrent protection

CN10

ASIC (PWM

control, etc.)

Temperature

detection

Current

detection

Analog voltage

conversion

Dynamic

brake circuit

U

V

W

CN2

CN5

CN1

Servomoto

M

PG

Analog monitor

output

Encoder output

Power

OFF

Power

ON

1KM

Open for

servo alarm

1Ry

1KM

Surge

protector

Status indicator

CN3

Personal computer

CPU (position,

speed calculations,

etc.)

I/O

Control I/O

CN6A

I/F

CN6B

MECHATROLINK-II

1-7

Page 26

Introduction

p

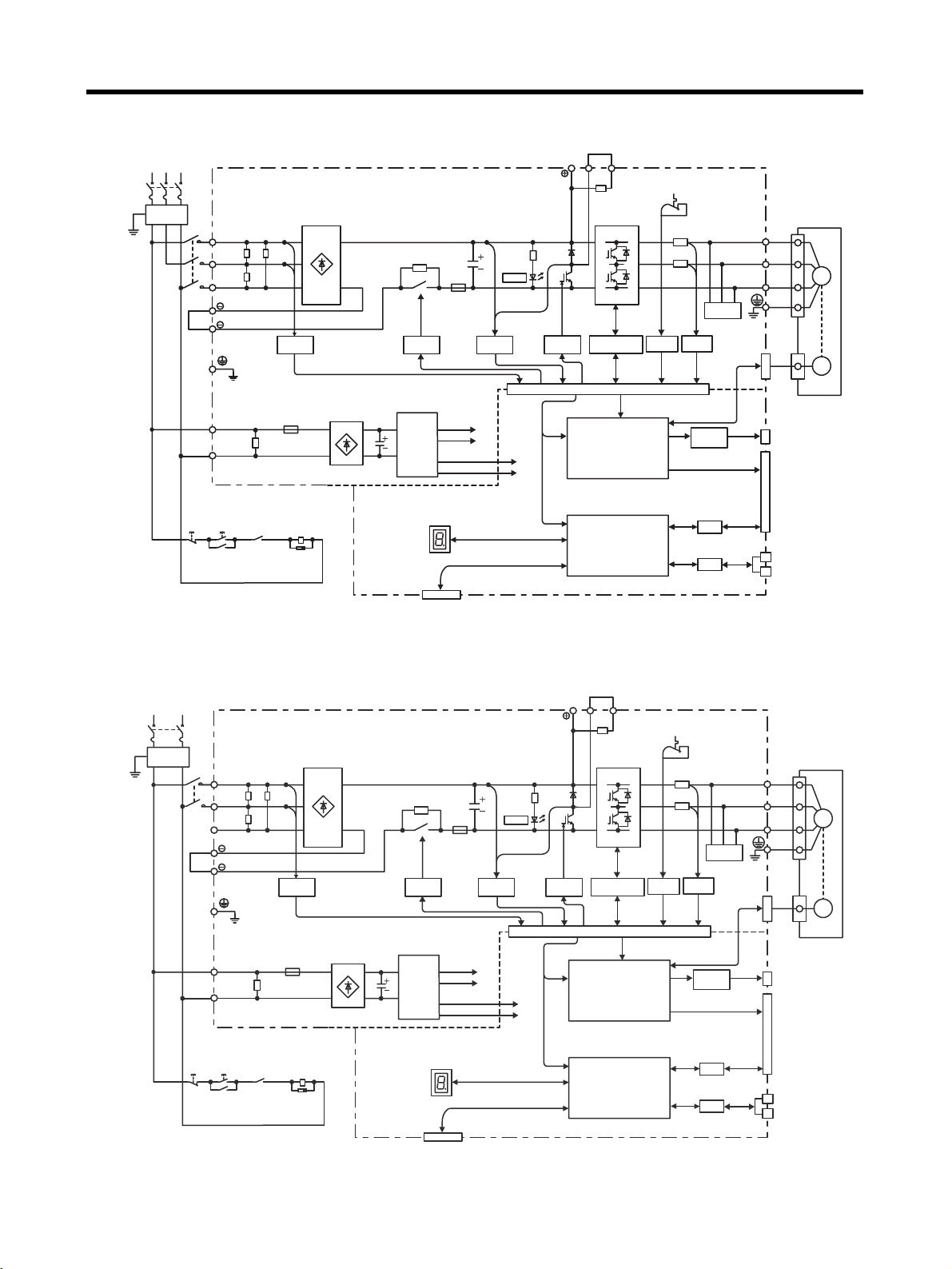

■ 200 V AC: R88D-WN05H-ML2/WN10H-ML2

Three-phase 200 to 230 V

+10%/−15% (50/60 Hz)

Noise

filter

1KM

Power

OFF

L1

L2

L3

1

2

L1C

L2C

Power

ON

1KM

Varistor

Varistor

Open for

servo alarm

1Ry

Voltage

detection

1KM

Surge

protector

Relay

drive

Control

power

supply

Status indicator

Personal computer

CN3

Voltage

detection

±5 V

15 V

CHARGE

5 V

±12 V

B1/ B2 B3

Gate

Gate drive overcurrent protection

drive

CN10

CPU (position,

speed calculations,

etc.)

ASIC (PWM

control, etc.)

Temperature

detection

Current

detection

Analog voltage

conversion

Chapter 1

U

V

W

Dynamic

brake circuit

CN2

CN5

CN1

I/O

CN6A

I/F

CN6B

Servomotor

M

PG

Analog monitor

output

Encoder output

Control I/O

MECHATROLINK-II

■ 200 V AC: R88D-WN08H-ML2

Single-phase 200 to 230 V

+10%/−15% (50/60 Hz)

Noise

filter

1KM

Power

OFF

L1

L2

L3

L1C

L2C

Power

ON

1KM

1

2

Varistor

Varistor

Open for

servo alarm

1Ry

Voltage

detection

1KM

Surge

protector

Relay

drive

Control

power

supply

Status indicator

Personal com

CN3

uter

Voltage

detection

±5 V

15 V

CHARGE

5 V

±12 V

B1/ B2 B3

Gate

Gate drive overcurrent protection

drive

CN10

CPU (position,

speed calculations,

etc.)

ASIC (PWM

control, etc.)

Temperature

detection

Current

detection

Analog voltage

conversion

Dynamic

brake circuit

I/O

I/F

CN2

CN5

CN1

CN6A

CN6B

U

V

W

Analog monitor

output

Encoder output

Control I/O

MECHATROLINK-II

Servomotor

M

PG

1-8

Page 27

Introduction

p

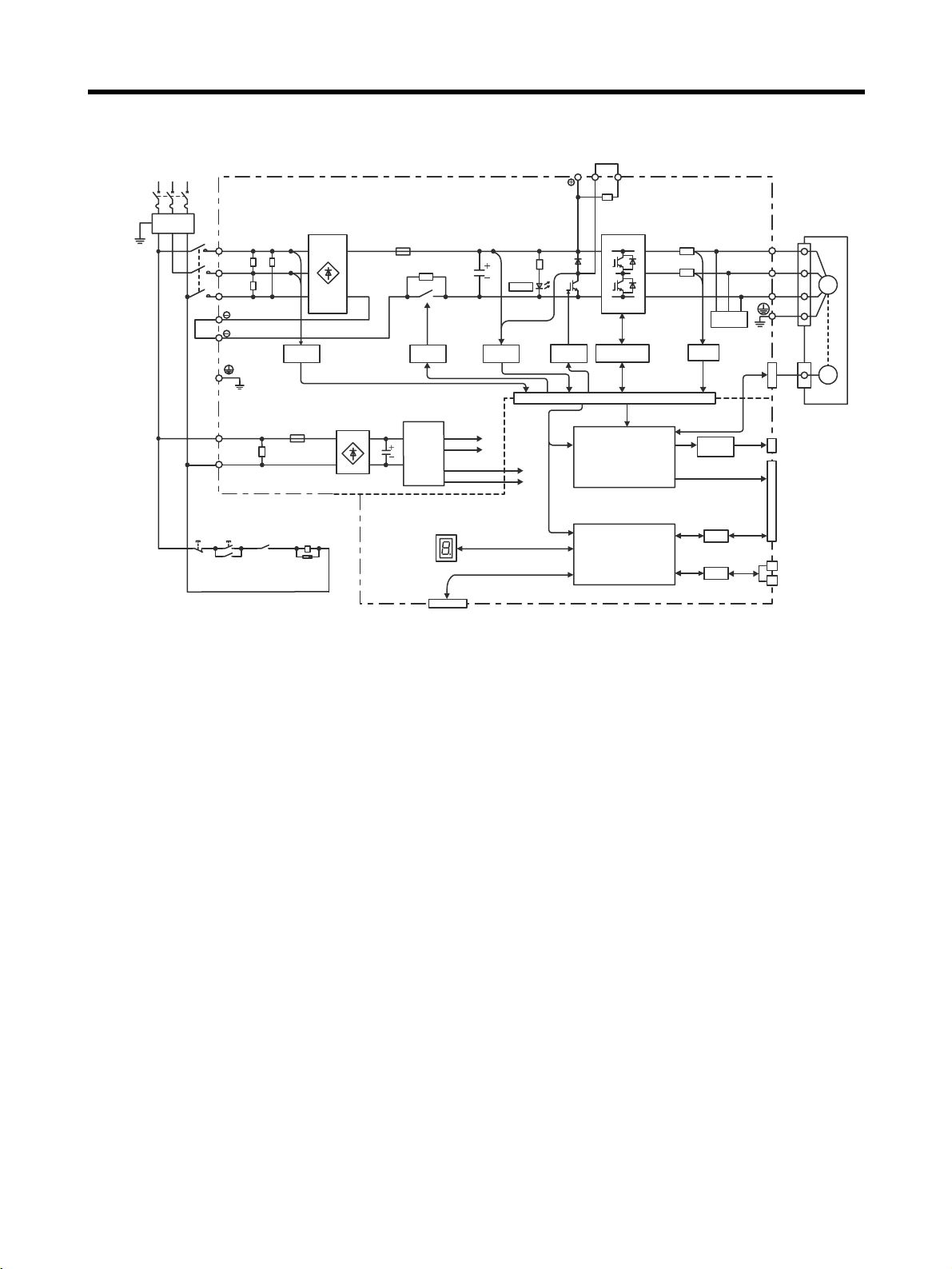

■ 200 V AC: R88D-WN15H-ML2/-WN20H-ML2/-WN30H-ML2

Three-phase 200 to 230 V

+10%/−15% (50/60 Hz)

B1/ B2 B3

Chapter 1

Noise

filter

1KM

Power

OFF

L1

L2

L3

L1C

L2C

Power

ON

1KM

1

2

Varistor

Varistor

Open for

servo alarm

1Ry

Voltage

detection

1KM

Surge

protector

Relay

drive

Control

power

supply

Status indicator

Personal com

CN3

uter

Voltage

detection

±5 V

15 V

CHARGE

5 V

±12 V

Gate

drive

CPU (position,

speed calculations,

etc.)

Gate drive overcurrent protection

CN10

ASIC (PWM

control, etc.)

Current

detection

Analog voltage

conversion

Dynamic

brake circuit

I/O

I/F

CN2

CN5

CN1

CN6A

CN6B

U

V

W

Analog monitor

output

Encoder output

Control I/O

MECHATROLINK-II

Servomotor

M

PG

1-9

Page 28

Introduction

Chapter 1

1-10

Page 29

Chapter 2

Standard Models and Specifications

2-1 Standard Models

2-2 Servo Driver and Servomotor Combinations

2-3 External and Mounted Dimensions

2-4 Servo Driver Specifications

2-5 Servomotor Specifications

2-6 Cable and Connector Specifications

2-7 External Regeneration Resistor Specifications

2-8 Absolute Encoder Backup Battery Specifications

2-9 Reactor Specifications

2-10 MECHATROLINK-II Repeater Specifications

Page 30

Standard Models and Specifications

2-1 Standard Models

Chapter 2

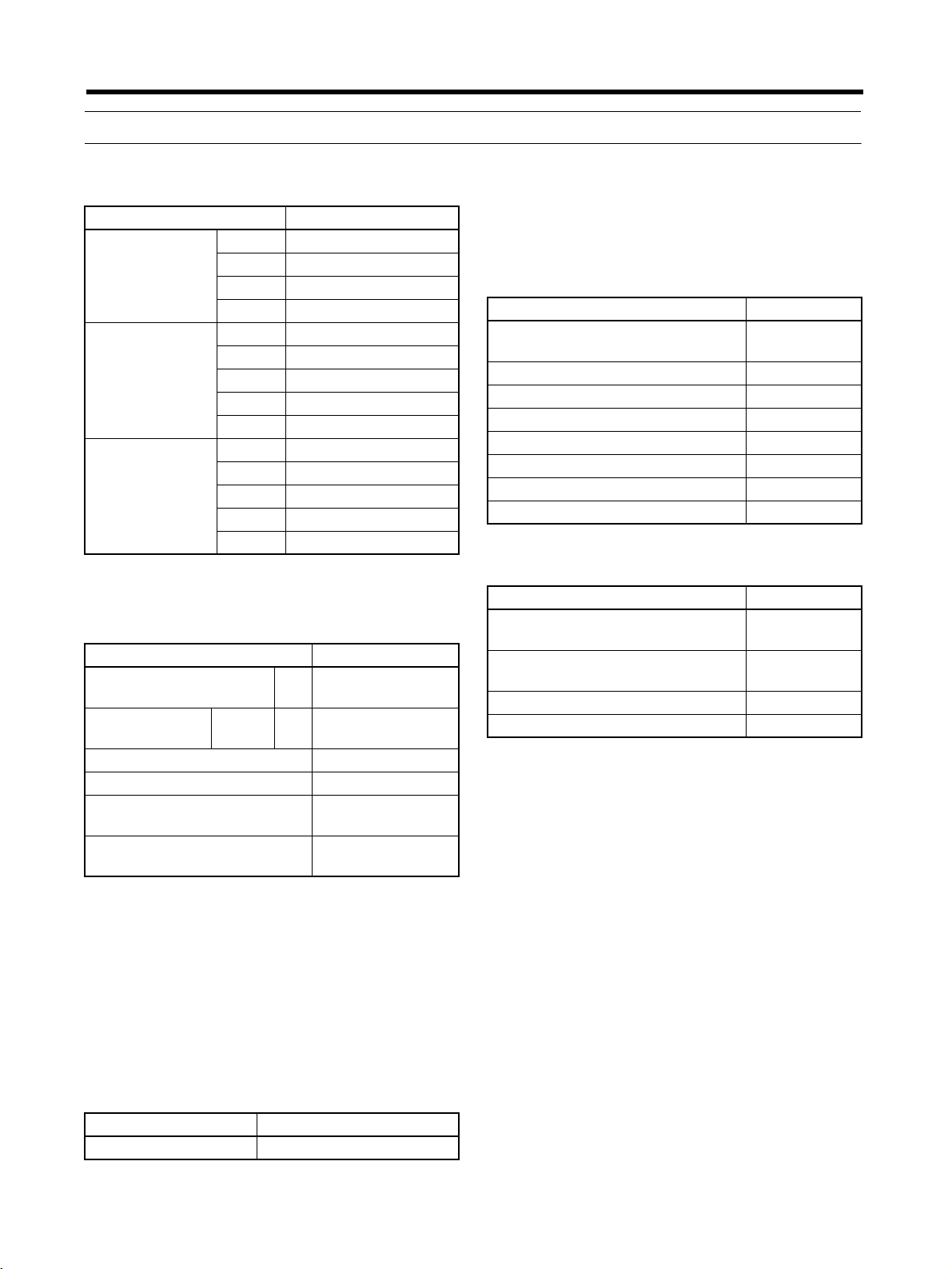

■ Servo Drivers

Specifications Model

Single-phase

100 V AC

Single-phase

200 V AC

Three-phase

200 V AC

■ Peripheral Cables and

50 W R88D-WNA5L-ML2

100 W R88D-WN01L-ML2

200 W R88D-WN02L-ML2

400 W R88D-WN04L-ML2

50 W R88D-WNA5H-ML2

100 W R88D-WN01H-ML2

200 W R88D-WN02H-ML2

400 W R88D-WN04H-ML2

750 W R88D-WN08H-ML2

500 W R88D-WN05H-ML2

1.0 kW R88D-WN10H-ML2

1.5 kW R88D-WN15H-ML2

2.0 kW R88D-WN20H-ML2

3.0 kW R88D-WN30H-ML2

Connectors

Specifications Model

Analog Monitor Cable

(CN5)

Computer Monitor Cable (CN3)

Control I/O Connector (CN1) R88A-CNW01C

Encoder Connector (CN2) R88A-CNW01R

Encoder Connector for Motor

End

Absolute Encoder Battery

Cable (with Battery)

DOS/V 2 m R88A-CCW002P2

1 m R88A-CMW001S

R88A-CNW02R

R88A-CRWC0R3C

Note Required when using a Servomotor with

an absolute encoder. The cable and connector are included.

■ Reactors

Specifications Model

For R88D-WNA5L-ML2/01L-ML2/

02H-ML2

For R88D-WN02L-ML2/04H-ML2 R88A-PX5054

For R88D-WN04L-ML2/08H-ML2 R88A-PX5056

For R88D-WNA5H-ML2/01H-ML2 R88A-PX5052

For R88D-WT04H-ML2 R88A-PX5069

For R88D-WN05H-ML2/10H-ML2 R88A-PX5061

For R88D-WN15H-ML2/20H-ML2 R88A-PX5060

For R88D-WN30H-ML2 R88A-PX5059

■ Front-panel Brackets

Specifications Model

For R88D-WNA5L-ML2 to 04LML2

For R88D-WNA5H-ML2 to 10HML2

For R88D-WN15H-ML2 R88A-TK06W

For R88D-WN20H-ML2/30H-ML2 R88A-TK07W

R88A-PX5053

R88A-TK05W

R88A-TK05W

Note Required when mounting a Servo Driver

from the front panel.

Note In order to use a personal computer to

monitor a Servo Driver and set its parameters, Computer Monitor Cable and Computer Monitor Software are required.

Please ask an OMRON representative for

details.

■ Absolute Encoder Backup

Battery

Specifications Model

1,000 mA·h, 3.6 V R88A-BAT01W

2-2

Page 31

Standard Models and Specifications

Chapter 2

■ Standard Encoder Cables (for

Incremental and Absolute

Encoders)

Specifications Model

For 3,000-r/

min Servomotors

For 3,000-r/

min Flat-style

Servomotors

For 1,000-r/

min Servomotors

For 1,500-r/

min Servomotors

30 to

750 W

1 to

3kW

100 W

to

1.5 kW

300 W

to

2.0 kW

450 W

to

1.8 kW

3 m R88A-CRWA003C

5 m R88A-CRWA005C

10 m R88A-CRWA010C

15 m R88A-CRWA015C

20 m R88A-CRWA020C

30 m R88A-CRWA030C

40 m R88A-CRWA040C

50 m R88A-CRWA050C

3 m R88A-CRWB003N

5 m R88A-CRWB005N

10 m R88A-CRWB010N

15 m R88A-CRWB015N

20 m R88A-CRWB020N

30 m R88A-CRWB030N

40 m R88A-CRWB040N

50 m R88A-CRWB050N

3 m R88A-CRWA003C

5 m R88A-CRWA005C

10 m R88A-CRWA010C

15 m R88A-CRWA015C

20 m R88A-CRWA020C

30 m R88A-CRWA030C

40 m R88A-CRWA040C

50 m R88A-CRWA050C

3 m R88A-CRWB003N

5 m R88A-CRWB005N

10 m R88A-CRWB010N

15 m R88A-CRWB015N

20 m R88A-CRWB020N

30 m R88A-CRWB030N

40 m R88A-CRWB040N

50 m R88A-CRWB050N

■ Standard Power Cable

● Power Cable for 3,000-r/min

Servomotors

Specifications Model

Without brake With brake

30 to

750 W

1 to

2kW

3 kW 3 m R88A-CAWD003S R88A-CAWD003B

● Power Cable for 3,000-r/min Flat-style

3 m R88A-CAWA003S R88A-CAWA003B

5 m R88A-CAWA005S R88A-CAWA005B

10 m R88A-CAWA010S R88A-CAWA010B

15 m R88A-CAWA015S R88A-CAWA015B

20 m R88A-CAWA020S R88A-CAWA020B

30 m R88A-CAWA030S R88A-CAWA030B

40 m R88A-CAWA040S R88A-CAWA040B

50 m R88A-CAWA050S R88A-CAWA050B

3 m R88A-CAWC003S R88A-CAWC003B

5 m R88A-CAWC005S R88A-CAWC005B

10 m R88A-CAWC010S R88A-CAWC010B

15 m R88A-CAWC015S R88A-CAWC015B

20 m R88A-CAWC020S R88A-CAWC020B

30 m R88A-CAWC030S R88A-CAWC030B

40 m R88A-CAWC040S R88A-CAWC040B

50 m R88A-CAWC050S R88A-CAWC050B

5 m R88A-CAWD005S R88A-CAWD005B

10 m R88A-CAWD010S R88A-CAWD010B

15 m R88A-CAWD015S R88A-CAWD015B

20 m R88A-CAWD020S R88A-CAWD020B

30 m R88A-CAWD030S R88A-CAWD030B

40 m R88A-CAWD040S R88A-CAWD040B

50 m R88A-CAWD050S R88A-CAWD050B

Servomotors

Specifications Model

Without brake With brake

100 to

750 W

3 m R88A-CAWA003S R88A-CAWA003B

5 m R88A-CAWA005S R88A-CAWA005B

10 m R88A-CAWA010S R88A-CAWA010B

15 m R88A-CAWA015S R88A-CAWA015B

20 m R88A-CAWA020S R88A-CAWA020B

30 m R88A-CAWA030S R88A-CAWA030B

40 m R88A-CAWA040S R88A-CAWA040B

50 m R88A-CAWA050S R88A-CAWA050B

2-3

Page 32

Standard Models and Specifications

Chapter 2

Specifications Model

Without brake With brake

1.5 kW 3 m R88A-CAWB003S R88A-CAWB003B

5 m R88A-CAWB005S R88A-CAWB005B

10 m R88A-CAWB010S R88A-CAWB010B

15 m R88A-CAWB015S R88A-CAWB015B

20 m R88A-CAWB020S R88A-CAWB020B

30 m R88A-CAWB030S R88A-CAWB030B

40 m R88A-CAWB040S R88A-CAWB040B

50 m R88A-CAWB050S R88A-CAWB050B

● Power Cable for 1,000-r/min

Servomotors

Specifications Model

Without brake With brake

300 to

900 W

1.2 to

2kW

3 m R88A-CAWC003S R88A-CAWC003B

5 m R88A-CAWC005S R88A-CAWC005B

10 m R88A-CAWC010S R88A-CAWC010B

15 m R88A-CAWC015S R88A-CAWC015B

20 m R88A-CAWC020S R88A-CAWC020B

30 m R88A-CAWC030S R88A-CAWC030B

40 m R88A-CAWC040S R88A-CAWC040B

50 m R88A-CAWC050S R88A-CAWC050B

3 m R88A-CAWD003S R88A-CAWD003B

5 m R88A-CAWD005S R88A-CAWD005B

10 m R88A-CAWD010S R88A-CAWD010B

15 m R88A-CAWD015S R88A-CAWD015B

20 m R88A-CAWD020S R88A-CAWD020B

30 m R88A-CAWD030S R88A-CAWD030B

40 m R88A-CAWD040S R88A-CAWD040B

50 m R88A-CAWD050S R88A-CAWD050B

● Power Cable for 1,500-r/min

Servomotors

Specifications Model

Without brake With brake

450 to

1.3 kW

1.8 kW 3 m R88A-CAWD003S R88A-CAWD003B

3 m R88A-CAWC003S R88A-CAWC003B

5 m R88A-CAWC005S R88A-CAWC005B

10 m R88A-CAWC010S R88A-CAWC010B

15 m R88A-CAWC015S R88A-CAWC015B

20 m R88A-CAWC020S R88A-CAWC020B

30 m R88A-CAWC030S R88A-CAWC030B

40 m R88A-CAWC040S R88A-CAWC040B

50 m R88A-CAWC050S R88A-CAWC050B

5 m R88A-CAWD005S R88A-CAWD005B

10 m R88A-CAWD010S R88A-CAWD010B

15 m R88A-CAWD015S R88A-CAWD015B

20 m R88A-CAWD020S R88A-CAWD020B

30 m R88A-CAWD030S R88A-CAWD030B

40 m R88A-CAWD040S R88A-CAWD040B

50 m R88A-CAWD050S R88A-CAWD050B

■ Encoder Cables for Robot

Cables (for Incremental and

Absolute Encoders)

Specifications Model

For 3,000-r/

min Servomotors

30 to

750 W

1 to

3kW

3 m R88A-CRWA003CR

5 m R88A-CRWA005CR

10 m R88A-CRWA010CR

15 m R88A-CRWA015CR

20 m R88A-CRWA020CR

30 m R88A-CRWA030CR

40 m R88A-CRWA040CR

50 m R88A-CRWA050CR

3 m R88A-CRWB003NR

5 m R88A-CRWB005NR

10 m R88A-CRWB010NR

15 m R88A-CRWB015NR

20 m R88A-CRWB020NR

30 m R88A-CRWB030NR

40 m R88A-CRWB040NR

50 m R88A-CRWB050NR

2-4

Page 33

Standard Models and Specifications

Chapter 2

Specifications Model

For 3,000-r/

min Flat-style

Servomotors

100 W

to

1.5 kW

3 m R88A-CRWA003CR

5 m R88A-CRWA005CR

10 m R88A-CRWA010CR

15 m R88A-CRWA015CR

20 m R88A-CRWA020CR

30 m R88A-CRWA030CR

40 m R88A-CRWA040CR

50 m R88A-CRWA050CR

For 1,000-r/

min Servomotors

For 1,500-r/

min Servomotors

300 W

to

2.0 kW

450 W

to

1.8 kW

3 m R88A-CRWB003NR

5 m R88A-CRWB005NR

10 m R88A-CRWB010NR

15 m R88A-CRWB015NR

20 m R88A-CRWB020NR

30 m R88A-CRWB030NR

40 m R88A-CRWB040NR

50 m R88A-CRWB050NR

■ Power Cable for Robot Cables

● Power Cable for 3,000-r/min

Servomotors

Specifications Model

Without brake With brake

30 to

750 W

1 to

2kW

3 m R88A-CAWA003SR R88A-CAWA003BR

5 m R88A-CAWA005SR R88A-CAWA005BR

10 m R88A-CAWA010SR R88A-CAWA010BR

15 m R88A-CAWA015SR R88A-CAWA015BR

20 m R88A-CAWA020SR R88A-CAWA020BR

30 m R88A-CAWA030SR R88A-CAWA030BR

40 m R88A-CAWA040SR R88A-CAWA040BR

50 m R88A-CAWA050SR R88A-CAWA050BR

3 m R88A-CAWC003SR R88A-CAWC003BR

5 m R88A-CAWC005SR R88A-CAWC005BR

10 m R88A-CAWC010SR R88A-CAWC010BR

15 m R88A-CAWC015SR R88A-CAWC015BR

20 m R88A-CAWC020SR R88A-CAWC020BR

30 m R88A-CAWC030SR R88A-CAWC030BR

40 m R88A-CAWC040SR R88A-CAWC040BR

50 m R88A-CAWC050SR R88A-CAWC050BR

Specifications Model

Without brake With brake

3 kW 3 m R88A-CAWD003SR R88A-CAWD003BR

5 m R88A-CAWD005SR R88A-CAWD005BR

10 m R88A-CAWD010SR R88A-CAWD010BR

15 m R88A-CAWD015SR R88A-CAWD015BR

20 m R88A-CAWD020SR R88A-CAWD020BR

30 m R88A-CAWD030SR R88A-CAWD030BR

40 m R88A-CAWD040SR R88A-CAWD040BR

50 m R88A-CAWD050SR R88A-CAWD050BR

● Power Cable for 3,000-r/min Flat-style

Servomotors

Specifications Model

Without brake With brake

100 to

750 W

1.5 kW 3 m R88A-CAWB003SR R88A-CAWB003BR

● Power Cable for 1,000-r/min

3 m R88A-CAWA003SR R88A-CAWA003BR

5 m R88A-CAWA005SR R88A-CAWA005BR

10 m R88A-CAWA010SR R88A-CAWA010BR

15 m R88A-CAWA015SR R88A-CAWA015BR

20 m R88A-CAWA020SR R88A-CAWA020BR

30 m R88A-CAWA030SR R88A-CAWA030BR

40 m R88A-CAWA040SR R88A-CAWA040BR

50 m R88A-CAWA050SR R88A-CAWA050BR

5 m R88A-CAWB005SR R88A-CAWB005BR

10 m R88A-CAWB010SR R88A-CAWB010BR

15 m R88A-CAWB015SR R88A-CAWB015BR

20 m R88A-CAWB020SR R88A-CAWB020BR

30 m R88A-CAWB030SR R88A-CAWB030BR

40 m R88A-CAWB040SR R88A-CAWB040BR

50 m R88A-CAWB050SR R88A-CAWB050BR

Servomotors

Specifications Model

Without brake With brake

300 to

900 W

3 m R88A-CAWC003SR R88A-CAWC003BR

5 m R88A-CAWC005SR R88A-CAWC005BR

10 m R88A-CAWC010SR R88A-CAWC010BR

15 m R88A-CAWC015SR R88A-CAWC015BR

20 m R88A-CAWC020SR R88A-CAWC020BR

30 m R88A-CAWC030SR R88A-CAWC030BR

40 m R88A-CAWC040SR R88A-CAWC040BR

50 m R88A-CAWC050SR R88A-CAWC050BR

2-5

Page 34

Standard Models and Specifications

Specifications Model

Without brake With brake

1.2 to

2kW

● Power Cable for 1,500-r/min

Servomotors

Specifications Model

450 to

1.3 kW

1.8 kW 3 m R88A-CAWD003SR R88A-CAWD003BR

3 m R88A-CAWD003SR R88A-CAWD003BR

5 m R88A-CAWD005SR R88A-CAWD005BR

10 m R88A-CAWD010SR R88A-CAWD010BR

15 m R88A-CAWD015SR R88A-CAWD015BR

20 m R88A-CAWD020SR R88A-CAWD020BR

30 m R88A-CAWD030SR R88A-CAWD030BR

40 m R88A-CAWD040SR R88A-CAWD040BR

50 m R88A-CAWD050SR R88A-CAWD050BR

Without brake With brake

3 m R88A-CAWC003SR R88A-CAWC003BR

5 m R88A-CAWC005SR R88A-CAWC005BR

10 m R88A-CAWC010SR R88A-CAWC010BR

15 m R88A-CAWC015SR R88A-CAWC015BR

20 m R88A-CAWC020SR R88A-CAWC020BR

30 m R88A-CAWC030SR R88A-CAWC030BR

40 m R88A-CAWC040SR R88A-CAWC040BR

50 m R88A-CAWC050SR R88A-CAWC050BR

5 m R88A-CAWD005SR R88A-CAWD005BR

10 m R88A-CAWD010SR R88A-CAWD010BR

15 m R88A-CAWD015SR R88A-CAWD015BR

20 m R88A-CAWD020SR R88A-CAWD020BR

30 m R88A-CAWD030SR R88A-CAWD030BR

40 m R88A-CAWD040SR R88A-CAWD040BR

50 m R88A-CAWD050SR R88A-CAWD050BR

Chapter 2

2-6

Page 35

Standard Models and Specifications

■ Servomotors

Specifications Model

With incremental encoder With absolute encoder

Straight shaft without

key

● 3,000-r/min Servomotors

Without

brake

With

brake

200 V 50 W R88M-W05030H R88M-W05030H-S1 R88M-W05030T R88M-W05030T-S1

100 W R88M-W10030H R88M-W10030H-S1 R88M-W10030T R88M-W10030T-S1

200 W R88M-W20030H R88M-W20030H-S1 R88M-W20030T R88M-W20030T-S1

400 W R88M-W40030H R88M-W40030H-S1 R88M-W40030T R88M-W40030T-S1

750 W R88M-W75030H R88M-W75030H-S1 R88M-W75030T R88M-W75030T-S1

1 kW R88M-W1K030H R88M-W1K030H-S2 R88M-W1K030T R88M-W1K030T-S2

1.5 kW R88M-W1K530H R88M-W1K530H-S2 R88M-W1K530T R88M-W1K530T-S2

2 kW R88M-W2K030H R88M-W2K030H-S2 R88M-W2K030T R88M-W2K030T-S2

3 kW R88M-W3K030H R88M-W3K030H-S2 R88M-W3K030T R88M-W3K030T-S2

200 V 50 W R88M-W05030H-B R88M-W05030H-BS1 R88M-W05030T-B R88M-W05030T-BS1

100 W R88M-W10030H-B R88M-W10030H-BS1 R88M-W10030T-B R88M-W10030T-BS1

200 W R88M-W20030H-B R88M-W20030H-BS1 R88M-W20030T-B R88M-W20030T-BS1

400 W R88M-W40030H-B R88M-W40030H-BS1 R88M-W40030T-B R88M-W40030T-BS1

750 W R88M-W75030H-B R88M-W75030H-BS1 R88M-W75030T-B R88M-W75030T-BS1

1 kW R88M-W1K030H-B R88M-W1K030H-BS2 R88M-W1K030T-B R88M-W1K030T-BS2

1.5 kW R88M-W1K530H-B R88M-W1K530H-BS2 R88M-W1K530T-B R88M-W1K530T-BS2

2 kW R88M-W2K030H-B R88M-W2K030H-BS2 R88M-W2K030T-B R88M-W2K030T-BS2

3 kW R88M-W3K030H-B R88M-W3K030H-BS2 R88M-W3K030T-B R88M-W3K030T-BS2

Straight shaft with key Straight shaft without

Chapter 2

Straight shaft with key

key

● 3,000-r/min Flat-style Servomotors

Without

brake

With

brake

200 V 100 W R88M-WP10030H R88M-WP10030H-S1 R88M-WP10030T R88M-WP10030T-S1

200 W R88M-WP20030H R88M-WP20030H-S1 R88M-WP20030T R88M-WP20030T-S1

400 W R88M-WP40030H R88M-WP40030H-S1 R88M-WP40030T R88M-WP40030T-S1

750 W R88M-WP75030H R88M-WP75030H-S1 R88M-WP75030T R88M-WP75030T-S1

1.5 kW R88M-WP1K530H R88M-WP1K530H-S1 R88M-WP1K530T R88M-WP1K530T-S1

200 V 100 W R88M-WP10030H-B R88M-WP10030H-BS1 R88M-WP10030T-B R88M-WP10030T-BS1

200 W R88M-WP20030H-B R88M-WP20030H-BS1 R88M-WP20030T-B R88M-WP20030T-BS1

400 W R88M-WP40030H-B R88M-WP40030H-BS1 R88M-WP40030T-B R88M-WP40030T-BS1

750 W R88M-WP75030H-B R88M-WP75030H-BS1 R88M-WP75030T-B R88M-WP75030T-BS1

1.5 kW R88M-WP1K530H-B R88M-WP1K530H-BS1 R88M-WP1K530T-B R88M-WP1K530T-BS1

● 1,000-r/min Servomotors

Without

brake

With

brake

200 V 300 W R88M-W30010H R88M-W30010H-S2 R88M-W30010T R88M-W30010T-S2

600 W R88M-W60010H R88M-W60010H-S2 R88M-W60010T R88M-W60010T-S2

900 W R88M-W90010H R88M-W90010H-S2 R88M-W90010T R88M-W90010T-S2

1.2 kW R88M-W1K210H R88M-W1K210H-S2 R88M-W1K210T R88M-W1K210T-S2

2 kW R88M-W2K010H R88M-W2K010H-S2 R88M-W2K010T R88M-W2K010T-S2

200 V 300 W R88M-W30010H-B R88M-W30010H-BS2 R88M-W30010T-B R88M-W30010T-BS2

600 W R88M-W60010H-B R88M-W60010H-BS2 R88M-W60010T-B R88M-W60010T-BS2

900 W R88M-W90010H-B R88M-W90010H-BS2 R88M-W90010T-B R88M-W90010T-BS2

1.2 kW R88M-W1K210H-B R88M-W1K210H-BS2 R88M-W1K210T-B R88M-W1K210T-BS2

2 kW R88M-W2K010H-B R88M-W2K010H-BS2 R88M-W2K010T-B R88M-W2K010T-BS2

2-7

Page 36

Standard Models and Specifications

● 1,500-r/min Servomotors

Without

brake

With

brake

■ IP67 (Waterproof) Servomotors

● 3,000-r/min Servomotors

Without

brake

With

brake

200 V 450 W --- --- R88M-W45015T R88M-W45015T-S2

850 W --- --- R88M-W85015T R88M-W85015T-S2

1.3 kW --- --- R88M-W1K315T R88M-W1K315T-S2

1.8 kW --- --- R88M-W1K815T R88M-W1K815T-S2

200 V 450 W --- --- R88M-W45015T-B R88M-W45015T-BS2

850 W --- --- R88M-W85015T-B R88M-W85015T-BS2

1.3 kW --- --- R88M-W1K315T-B R88M-W1K315T-BS2

1.8 kW --- --- R88M-W1K815T-B R88M-W1K815T-BS2

Specifications Model

With incremental encoder With absolute encoder

Straight shaft without

key

200 V 1 kW R88M-W1K030H-O R88M-W1K030H-OS2 R88M-W1K030T-O R88M-W1K030T-OS2

1.5 kW R88M-W1K530H-O R88M-W1K530H-OS2 R88M-W1K530T-O R88M-W1K530T-OS2

2 kW R88M-W2K030H-O R88M-W2K030H-OS2 R88M-W2K030T-O R88M-W2K030T-OS2

3 kW R88M-W3K030H-O R88M-W3K030H-OS2 R88M-W3K030T-O R88M-W3K030T-OS2

200 V 1 kW R88M-W1K030H-BO R88M-W1K030H-BOS2 R88M-W1K030T-BO R88M-W1K030T-BOS2

1.5 kW R88M-W1K530H-BO R88M-W1K530H-BOS2 R88M-W1K530T-BO R88M-W1K530T-BOS2

2 kW R88M-W2K030H-BO R88M-W2K030H-BOS2 R88M-W2K030T-BO R88M-W2K030T-BOS2

3 kW R88M-W3K030H-BO R88M-W3K030H-BOS2 R88M-W3K030T-BO R88M-W3K030T-BOS2

Straight shaft with key Straight shaft without

Chapter 2

Straight shaft with key

key

● 3,000-r/min Flat-style Servomotors

Without

brake

With

brake

200 V 100 W R88M-WP10030H-W R88M-WP10030H-WS1 R88M-WP10030T-W R88M-WP10030T-WS1

200 W R88M-WP20030H-W R88M-WP20030H-WS1 R88M-WP20030T-W R88M-WP20030T-WS1

400 W R88M-WP40030H-W R88M-WP40030H-WS1 R88M-WP40030T-W R88M-WP40030T-WS1

750 W R88M-WP75030H-W R88M-WP75030H-WS1 R88M-WP75030T-W R88M-WP75030T-WS1

1.5 kW R88M-WP1K530H-W R88M-WP1K530H-WS1 R88M-WP1K530T-W R88M-WP1K530T-WS1

200 V 100 W R88M-WP10030H-BW R88M-WP10030H-BWS1 R88M-WP10030T-BW R88M-WP10030T-BWS1

200 W R88M-WP20030H-BW R88M-WP20030H-BWS1 R88M-WP20030T-BW R88M-WP20030T-BWS1

400 W R88M-WP40030H-BW R88M-WP40030H-BWS1 R88M-WP40030T-BW R88M-WP40030T-BWS1

750 W R88M-WP75030H-BW R88M-WP75030H-BWS1 R88M-WP75030T-BW R88M-WP75030T-BWS1

1.5 kW R88M-WP1K530H-BW R88M-WP1K530H-BWS1 R88M-WP1K530T-BW R88M-WP1K530T-BWS1

● 1,000-r/min Servomotors

Without

brake

With

brake

200 V 300 W R88M-W30010H-O R88M-W30010H-OS2 R88M-W30010T-O R88M-W30010T-OS2

600 W R88M-W60010H-O R88M-W60010H-OS2 R88M-W60010T-O R88M-W60010T-OS2

900 W R88M-W90010H-O R88M-W90010H-OS2 R88M-W90010T-O R88M-W90010T-OS2

1.2 kW R88M-W1K210H-O R88M-W1K210H-OS2 R88M-W1K210T-O R88M-W1K210T-OS2

2 kW R88M-W2K010H-O R88M-W2K010H-OS2 R88M-W2K010T-O R88M-W2K010T-OS2

200 V 300 W R88M-W30010H-BO R88M-W30010H-BOS2 R88M-W30010T-BO R88M-W30010T-BOS2

600 W R88M-W60010H-BO R88M-W60010H-BOS2 R88M-W60010T-BO R88M-W60010T-BOS2

900 W R88M-W90010H-BO R88M-W90010H-BOS2 R88M-W90010T-BO R88M-W90010T-BOS2

1.2 kW R88M-W1K210H-BO R88M-W1K210H-BOS2 R88M-W1K210T-BO R88M-W1K210T-BOS2

2 kW R88M-W2K010H-BO R88M-W2K010H-BOS2 R88M-W2K010T-BO R88M-W2K010T-BOS2

2-8

Page 37

Standard Models and Specifications

● 1,500-r/min Servomotors

Without

brake

With

brake

200 V 450 W --- --- R88M-W45015TO R88M-W45015T-OS2

850 W --- --- R88M-W85015TO R88M-W85015T-OS2

1.3 kW --- --- R88M-W1K315TO R88M-W1K315T-OS2

1.8 kW --- --- R88M-W1K815TO R88M-W1K815T-OS2

200 V 450 W --- --- R88M-W45015T-BO R88M-W45015T-BOS2

850 W --- --- R88M-W85015T-BO R88M-W85015T-BOS2

1.3 kW --- --- R88M-W1K315T-BO R88M-W1K315T-BOS2

1.8 kW --- --- R88M-W1K815T-BO R88M-W1K815T-BOS2

Chapter 2

■ Servomotors with Gears

● Combination Table for Servomotors with Standard Gears

Standard Gears are highly accurate gears, with a maximum backlash of 3 degrees. The standard

shaft is a straight shaft with a key. (Models without keys can also be manufactured for 3,000-r/min

motors from 30 to 750 W and for 3,000-r/min flat-style motors. Models without keys have a suffix of G@@B.)

Note A check mark in a box indicates that the two models can be combined. If the box is unchecked,

then the models cannot be combined.

3,000-r/min Servomotors

Specifications Basic model Gear (deceleration rate)

1/5 1/9 1/11 1/20 1/21 1/29 1/33 1/45

-G05BJ -G09BJ -G11BJ -G20BJ -G21BJ -G29BJ -G33BJ -G45BJ

200 V 50 W R88M-W05030H/T Yes Yes Yes Yes

100 W R88M-W10030H/T Yes Yes Yes Yes

200 W R88M-W20030H/T Yes Yes Yes Yes

400 W R88M-W40030H/T Yes Yes Yes Yes

750 W R88M-W75030H/T Yes Yes Yes Yes

1 kW R88M-W1K030H/T Yes Yes Yes Yes Yes

1.5 kW R88M-W1K530H/T Yes Yes Yes Yes Yes

2 kW R88M-W2K030H/T Yes Yes Yes Yes Yes

3 kW R88M-W3K030H/T Yes Yes Yes Yes Yes

3,000-r/min Flat-style Servomotors

Specifications Basic model Gear (deceleration rate)

1/5 1/9 1/11 1/20 1/21 1/29 1/33 1/45

-G05BJ -G09BJ -G11BJ -G20BJ -G21BJ -G29BJ -G33BJ -G45BJ

200 V 100 W R88M-WP10030H/T Yes Yes Yes Yes

200 W R88M-WP20030H/T Yes Yes Yes Yes

400 W R88M-WP40030H/T Yes Yes Yes Yes

750 W R88M-WP75030H/T Yes Yes Yes Yes

1.5 kW R88M-WP1K530H/T Yes Yes Yes Yes

2-9

Page 38

Standard Models and Specifications

Chapter 2

1,000-r/min Servomotors

Specifications Basic model Gear (deceleration rate)

1/5 1/9 1/11 1/20 1/21 1/29 1/33 1/45

-G05BJ -G09BJ -G11BJ -G20BJ -G21BJ -G29BJ -G33BJ -G45BJ

200 V 300 W R88M-W30010H/T Yes Yes Yes Yes Yes

600 W R88M-W60010H/T Yes Yes Yes Yes Yes

900 W R88M-W90010H/T Yes Yes Yes Yes Yes

1.2 kW R88M-W1K210H/T Yes Yes Yes Yes Yes

2 kW R88M-W2K010H/T Yes Yes Yes

1,500-r/min Servomotors

Specifications Basic model Gear (deceleration rate)

1/5 1/9 1/11 1/20 1/21 1/29 1/33 1/45

-G05BJ -G09BJ -G11BJ -G20BJ -G21BJ -G29BJ -G33BJ -G45BJ

200 V 450 W R88M-W45015T Yes Yes Yes Yes Yes

850 W R88M-W85015T Yes Yes Yes Yes Yes

1.3 kW R88M-W1K315T Yes Yes Yes Yes Yes

1.8 kW R88M-W1K815T Yes Yes Yes Yes

■ Combination Table for Servomotors with Economy Gears

Economy Gears are low-cost gears, with a maximum backlash of 45 degrees. The shaft is a straight

shaft with key. Models without keys are not available.

Note 1. The 1,000-r/min and 1,500-r/min Servomotors cannot be combined with Economy Gears.

Note 2. A check mark in a box indicates that the two models can be combined. If the box is un-

checked, then the models cannot be combined.

3,000-r/min Servomotors

Specifications Basic model Gear (deceleration rate)

1/5 1/9 1/15 1/25

-G05CJ -G09CJ -G15C -G25CJ

200 V 50 W R88M-W05030H/T

100 W R88M-W10030H/T Yes Yes Yes Yes

200 W R88M-W20030H/T Yes Yes Yes Yes

400 W R88M-W40030H/T Yes Yes Yes Yes

750 W R88M-W75030H/T Yes Yes Yes Yes

1 kW R88M-W1K030H/T

1.5 kW R88M-W1K530H/T

2 kW R88M-W2K030H/T

3 kW R88M-W3K030H/T

2-10

Page 39

Standard Models and Specifications

3,000-r/min Flat-style Servomotors

Specifications Basic model Gear (deceleration rate)

1/5 1/9 1/15 1/25

-G05CJ -G09CJ -G15C -G25CJ

200 V 100 W R88M-WP10030H/T Yes Yes Yes Yes

200 W R88M-WP20030H/T Yes Yes Yes Yes

400 W R88M-WP40030H/T Yes Yes Yes Yes

750 W R88M-WP75030H/T Yes Yes Yes Yes

1.5 kW R88M-WP1K530H/T

Chapter 2

2-11

Page 40

Standard Models and Specifications

Chapter 2

● Servomotors with Standard Gears (Straight Shaft with Key)

3,000-r/min Servomotors

Specifications Model

With incremental encoder With absolute encoder

Without brake With brake Without brake With brake

200 V 50 W 1/5 R88M-W05030H-G05BJ R88M-W05030H-BG05BJ R88M-W05030T-G05BJ R88M-W05030T-BG05BJ

1/9 R88M-W05030H-G09BJ R88M-W05030H-BG09BJ R88M-W05030T-G09BJ R88M-W05030T-BG09BJ

1/21 R88M-W05030H-G21BJ R88M-W05030H-BG21BJ R88M-W05030T-G21BJ R88M-W05030T-BG21BJ

1/33 R88M-W05030H-G33BJ R88M-W05030H-BG33BJ R88M-W05030T-G33BJ R88M-W05030T-BG33BJ

100 W 1/5 R88M-W10030H-G05BJ R88M-W10030H-BG05BJ R88M-W10030T-G05BJ R88M-W10030T-BG05BJ

1/11 R88M-W10030H-G11BJ R88M-W10030H-BG11BJ R88M-W10030T-G11BJ R88M-W10030T-BG11BJ

1/21 R88M-W10030H-G21BJ R88M-W10030H-BG21BJ R88M-W10030T-G21BJ R88M-W10030T-BG21BJ

1/33 R88M-W10030H-G33BJ R88M-W10030H-BG33BJ R88M-W10030T-G33BJ R88M-W10030T-BG33BJ

200 W 1/5 R88M-W20030H-G05BJ R88M-W20030H-BG05BJ R88M-W20030T-G05BJ R88M-W20030T-BG05BJ

1/11 R88M-W20030H-G11BJ R88M-W20030H-BG11BJ R88M-W20030T-G11BJ R88M-W20030T-BG11BJ

1/21 R88M-W20030H-G21BJ R88M-W20030H-BG21BJ R88M-W20030T-G21BJ R88M-W20030T-BG21BJ

1/33 R88M-W20030H-G33BJ R88M-W20030H-BG33BJ R88M-W20030T-G33BJ R88M-W20030T-BG33BJ

400 W 1/5 R88M-W40030H-G05BJ R88M-W40030H-BG05BJ R88M-W40030T-G05BJ R88M-W40030T-BG05BJ

1/11 R88M-W40030H-G11BJ R88M-W40030H-BG11BJ R88M-W40030T-G11BJ R88M-W40030T-BG11BJ

1/21 R88M-W40030H-G21BJ R88M-W40030H-BG21BJ R88M-W40030T-G21BJ R88M-W40030T-BG21BJ

1/33 R88M-W40030H-G33BJ R88M-W40030H-BG33BJ R88M-W40030T-G33BJ R88M-W40030T-BG33BJ

750 W 1/5 R88M-W75030H-G05BJ R88M-W75030H-BG05BJ R88M-W75030T-G05BJ R88M-W75030T-BG05BJ

1/11 R88M-W75030H-G11BJ R88M-W75030H-BG11BJ R88M-W75030T-G11BJ R88M-W75030T-BG11BJ

1/21 R88M-W75030H-G21BJ R88M-W75030H-BG21BJ R88M-W75030T-G21BJ R88M-W75030T-BG21BJ

1/33 R88M-W75030H-G33BJ R88M-W75030H-BG33BJ R88M-W75030T-G33BJ R88M-W75030T-BG33BJ

1 kW 1/5 R88M-W1K030H-G05BJ R88M-W1K030H-BG05BJ R88M-W1K030T-G05BJ R88M-W1K030T-BG05BJ

1/9 R88M-W1K030H-G09BJ R88M-W1K030H-BG09BJ R88M-W1K030T-G09BJ R88M-W1K030T-BG09BJ

1/20 R88M-W1K030H-G20BJ R88M-W1K030H-BG20BJ R88M-W1K030T-G20BJ R88M-W1K030T-BG20BJ

1/29 R88M-W1K030H-G29BJ R88M-W1K030H-BG29BJ R88M-W1K030T-G29BJ R88M-W1K030T-BG29BJ

1/45 R88M-W1K030H-G45BJ R88M-W1K030H-BG45BJ R88M-W1K030T-G45BJ R88M-W1K030T-BG45BJ

1.5 kW 1/5 R88M-W1K530H-G05BJ R88M-W1K530H-BG05BJ R88M-W1K530T-G05BJ R88M-W1K530T-BG05BJ

1/9 R88M-W1K530H-G09BJ R88M-W1K530H-BG09BJ R88M-W1K530T-G09BJ R88M-W1K530T-BG09BJ

1/20 R88M-W1K530H-G20BJ R88M-W1K530H-BG20BJ R88M-W1K530T-G20BJ R88M-W1K530T-BG20BJ

1/29 R88M-W1K530H-G29BJ R88M-W1K530H-BG29BJ R88M-W1K530T-G29BJ R88M-W1K530T-BG29BJ

1/45 R88M-W1K530H-G45BJ R88M-W1K530H-BG45BJ R88M-W1K530T-G45BJ R88M-W1K530T-BG45BJ

2 kW 1/5 R88M-W2K030H-G05BJ R88M-W2K030H-BG05BJ R88M-W2K030T-G05BJ R88M-W2K030T-BG05BJ

1/9 R88M-W2K030H-G09BJ R88M-W2K030H-BG09BJ R88M-W2K030T-G09BJ R88M-W2K030T-BG09BJ

1/20 R88M-W2K030H-G20BJ R88M-W2K030H-BG20BJ R88M-W2K030T-G20BJ R88M-W2K030T-BG20BJ

1/29 R88M-W2K030H-G29BJ R88M-W2K030H-BG29BJ R88M-W2K030T-G29BJ R88M-W2K030T-BG29BJ

1/45 R88M-W2K030H-G45BJ R88M-W2K030H-BG45BJ R88M-W2K030T-G45BJ R88M-W2K030T-BG45BJ

3 kW 1/5 R88M-W3K030H-G05BJ R88M-W3K030H-BG05BJ R88M-W3K030T-G05BJ R88M-W3K030T-BG05BJ

1/9 R88M-W3K030H-G09BJ R88M-W3K030H-BG09BJ R88M-W3K030T-G09BJ R88M-W3K030T-BG09BJ

1/20 R88M-W3K030H-G20BJ R88M-W3K030H-BG20BJ R88M-W3K030T-G20BJ R88M-W3K030T-BG20BJ

1/29 R88M-W3K030H-G29BJ R88M-W3K030H-BG29BJ R88M-W3K030T-G29BJ R88M-W3K030T-BG29BJ

1/45 R88M-W3K030H-G45BJ R88M-W3K030H-BG45BJ R88M-W3K030T-G45BJ R88M-W3K030T-BG45BJ

2-12

Page 41

Standard Models and Specifications

Chapter 2

3,000-r/min Flat-style Servomotors

Specifications Model

With incremental encoder With absolute encoder

Without brake With brake Without brake With brake

200 V 100 W 1/5 R88M-WP10030H-G05BJ R88M-WP10030H-BG05BJ R88M-WP10030T-G05BJ R88M-WP10030T-BG05BJ

1/11 R88M-WP10030H-G11BJ R88M-WP10030H-BG11BJ R88M-WP10030T-G11BJ R88M-WP10030T-BG11BJ

1/21 R88M-WP10030H-G21BJ R88M-WP10030H-BG21BJ R88M-WP10030T-G21BJ R88M-WP10030T-BG21BJ

1/33 R88M-WP10030H-G33BJ R88M-WP10030H-BG33BJ R88M-WP10030T-G33BJ R88M-WP10030T-BG33BJ

200 W 1/5 R88M-WP20030H-G05BJ R88M-WP20030H-BG05BJ R88M-WP20030T-G05BJ R88M-WP20030T-BG05BJ

1/11 R88M-WP20030H-G11BJ R88M-WP20030H-BG11BJ R88M-WP20030T-G11BJ R88M-WP20030T-BG11BJ

1/21 R88M-WP20030H-G21BJ R88M-WP20030H-BG21BJ R88M-WP20030T-G21BJ R88M-WP20030T-BG21BJ

1/33 R88M-WP20030H-G33BJ R88M-WP20030H-BG33BJ R88M-WP20030T-G33BJ R88M-WP20030T-BG33BJ

400 W 1/5 R88M-WP40030H-G05BJ R88M-WP40030H-BG05BJ R88M-WP40030T-G05BJ R88M-WP40030T-BG05BJ

1/11 R88M-WP40030H-G11BJ R88M-WP40030H-BG11BJ R88M-WP40030T-G11BJ R88M-WP40030T-BG11BJ

1/21 R88M-WP40030H-G21BJ R88M-WP40030H-BG21BJ R88M-WP40030T-G21BJ R88M-WP40030T-BG21BJ

1/33 R88M-WP40030H-G33BJ R88M-WP40030H-BG33BJ R88M-WP40030T-G33BJ R88M-WP40030T-BG33BJ

750 W 1/5 R88M-WP75030H-G05BJ R88M-WP75030H-BG05BJ R88M-WP75030T-G05BJ R88M-WP75030T-BG05BJ

1/11 R88M-WP75030H-G11BJ R88M-WP75030H-BG11BJ R88M-WP75030T-G11BJ R88M-WP75030T-BG11BJ

1/21 R88M-WP75030H-G21BJ R88M-WP75030H-BG21BJ R88M-WP75030T-G21BJ R88M-WP75030T-BG21BJ

1/33 R88M-WP75030H-G33BJ R88M-WP75030H-BG33BJ R88M-WP75030T-G33BJ R88M-WP75030T-BG33BJ

1.5 kW 1/5 R88M-WP1K530HG05BJ

1/11 R88M-WP1K530H-

G11BJ

1/21 R88M-WP1K530H-

G21BJ

1/33 R88M-WP1K530H-

G33BJ

R88M-WP1K530HBG05BJ

R88M-WP1K530HBG11BJ

R88M-WP1K530HBG21BJ

R88M-WP1K530HBG33BJ

R88M-WP1K530T-G05BJ R88M-WP1K530T-

R88M-WP1K530T-G11BJ R88M-WP1K530T-

R88M-WP1K530T-G21BJ R88M-WP1K530T-

R88M-WP1K530T-G33BJ R88M-WP1K530T-

BG05BJ

BG11BJ

BG21BJ

BG33BJ

2-13

Page 42

Standard Models and Specifications

Chapter 2

1,000-r/min Servomotors

Specifications Model

With incremental encoder With absolute encoder

Without brake With brake Without brake With brake

200 V 300 W 1/5 R88M-W30010H-G05BJ R88M-W30010H-BG05BJ R88M-W30010T-G05BJ R88M-W30010T-BG05BJ

1/9 R88M-W30010H-G09BJ R88M-W30010H-BG09BJ R88M-W30010T-G09BJ R88M-W30010T-BG09BJ

1/20 R88M-W30010H-G20BJ R88M-W30010H-BG20BJ R88M-W30010T-G20BJ R88M-W30010T-BG20BJ

1/29 R88M-W30010H-G29BJ R88M-W30010H-BG29BJ R88M-W30010T-G29BJ R88M-W30010T-BG29BJ

1/45 R88M-W30010H-G45BJ R88M-W30010H-BG45BJ R88M-W30010T-G45BJ R88M-W30010T-BG45BJ

600 W 1/5 R88M-W60010H-G05BJ R88M-W60010H-BG05BJ R88M-W60010T-G05BJ R88M-W60010T-BG05BJ

1/9 R88M-W60010H-G09BJ R88M-W60010H-BG09BJ R88M-W60010T-G09BJ R88M-W60010T-BG09BJ

1/20 R88M-W60010H-G20BJ R88M-W60010H-BG20BJ R88M-W60010T-G20BJ R88M-W60010T-BG20BJ

1/29 R88M-W60010H-G29BJ R88M-W60010H-BG29BJ R88M-W60010T-G29BJ R88M-W60010T-BG29BJ

1/45 R88M-W60010H-G45BJ R88M-W60010H-BG45BJ R88M-W60010T-G45BJ R88M-W60010T-BG45BJ

900 W 1/5 R88M-W90010H-G05BJ R88M-W90010H-BG05BJ R88M-W90010T-G05BJ R88M-W90010T-BG05BJ

1/9 R88M-W90010H-G09BJ R88M-W90010H-BG09BJ R88M-W90010T-G09BJ R88M-W90010T-BG09BJ

1/20 R88M-W90010H-G20BJ R88M-W90010H-BG20BJ R88M-W90010T-G20BJ R88M-W90010T-BG20BJ

1/29 R88M-W90010H-G29BJ R88M-W90010H-BG29BJ R88M-W90010T-G29BJ R88M-W90010T-BG29BJ

1/45 R88M-W90010H-G45BJ R88M-W90010H-BG45BJ R88M-W90010T-G45BJ R88M-W90010T-BG45BJ

1.2 kW 1/5 R88M-W1K210H-G05BJ R88M-W1K210H-BG05BJ R88M-W1K210T-G05BJ R88M-W1K210T-BG05BJ

1/9 R88M-W1K210H-G09BJ R88M-W1K210H-BG09BJ R88M-W1K210T-G09BJ R88M-W1K210T-BG09BJ

1/20 R88M-W1K210H-G20BJ R88M-W1K210H-BG20BJ R88M-W1K210T-G20BJ R88M-W1K210T-BG20BJ

1/29 R88M-W1K210H-G29BJ R88M-W1K210H-BG29BJ R88M-W1K210T-G29BJ R88M-W1K210T-BG29BJ

1/45 R88M-W1K210H-G45BJ R88M-W1K210H-BG45BJ R88M-W1K210T-G45BJ R88M-W1K210T-BG45BJ

2 kW 1/5 R88M-W2K010H-G05BJ R88M-W2K010H-BG05BJ R88M-W2K010T-G05BJ R88M-W2K010T-BG05BJ

1/9 R88M-W2K010H-G09BJ R88M-W2K010H-BG09BJ R88M-W2K010T-G09BJ R88M-W2K010T-BG09BJ

1/20 R88M-W2K010H-G20BJ R88M-W2K010H-BG20BJ R88M-W2K010T-G20BJ R88M-W2K010T-BG20BJ

1,500-r/min Servomotors

Specifications Model

With incremental encoder With absolute encoder

Without brake With brake Without brake With brake

200 V 450 W 1/5 --- --- R88M-W45015T-G05BJ R88M-W45015T-BG05BJ

1/9 --- --- R88M-W45015T-G09BJ R88M-W45015T-BG09BJ

1/20 --- --- R88M-W45015T-G20BJ R88M-W45015T-BG20BJ

1/29 --- --- R88M-W45015T-G29BJ R88M-W45015T-BG29BJ

1/45 --- --- R88M-W45015T-G45BJ R88M-W45015T-BG45BJ

850 W 1/5 --- --- R88M-W85015T-G05BJ R88M-W85015T-BG05BJ

1/9 --- --- R88M-W85015T-G09BJ R88M-W85015T-BG09BJ

1/20 --- --- R88M-W85015T-G20BJ R88M-W85015T-BG20BJ

1/29 --- --- R88M-W85015T-G29BJ R88M-W85015T-BG29BJ

1/45 --- --- R88M-W85015T-G45BJ R88M-W85015T-BG45BJ

1.3 kW 1/5 --- --- R88M-W1K315T-G05BJ R88M-W1K315T-BG05BJ

1/9 --- --- R88M-W1K315T-G09BJ R88M-W1K315T-BG09BJ

1/20 --- --- R88M-W1K315T-G20BJ R88M-W1K315T-BG20BJ

1/29 --- --- R88M-W1K315T-G29BJ R88M-W1K315T-BG29BJ

1/45 --- --- R88M-W1K315T-G45BJ R88M-W1K315T-BG45BJ

1.8 kW 1/5 --- --- R88M-W1K815T-G05BJ R88M-W1K815T-BG05BJ

1/9 --- --- R88M-W1K815T-G09BJ R88M-W1K815T-BG09BJ

1/20 --- --- R88M-W1K815T-G20BJ R88M-W1K815T-BG20BJ

1/29 --- --- R88M-W1K815T-G29BJ R88M-W1K815T-BG29BJ

2-14

Page 43

Standard Models and Specifications

Chapter 2

● Servomotors with Economy Gears (Straight Shaft with Key)

3,000-r/min Servomotors

Specifications Model

With incremental encoder With absolute encoder

Without brake With brake Without brake With brake

200 V 100 W 1/5 R88M-W10030H-G05CJ R88M-W10030H-BG05CJ R88M-W10030T-G05CJ R88M-W10030T-BG05CJ

1/9 R88M-W10030H-G09CJ R88M-W10030H-BG09CJ R88M-W10030T-G09CJ R88M-W10030T-BG09CJ

1/15 R88M-W10030H-G15CJ R88M-W10030H-BG15CJ R88M-W10030T-G15CJ R88M-W10030T-BG15CJ

1/25 R88M-W10030H-G25CJ R88M-W10030H-BG25CJ R88M-W10030T-G25CJ R88M-W10030T-BG25CJ

200 W 1/5 R88M-W20030H-G05CJ R88M-W20030H-BG05CJ R88M-W20030T-G05CJ R88M-W20030T-BG05CJ

1/9 R88M-W20030H-G09CJ R88M-W20030H-BG09CJ R88M-W20030T-G09CJ R88M-W20030T-BG09CJ

1/15 R88M-W20030H-G15CJ R88M-W20030H-BG15CJ R88M-W20030T-G15CJ R88M-W20030T-BG15CJ

1/25 R88M-W20030H-G25CJ R88M-W20030H-BG25CJ R88M-W20030T-G25CJ R88M-W20030T-BG25CJ

400 W 1/5 R88M-W40030H-G05CJ R88M-W40030H-BG05CJ R88M-W40030T-G05CJ R88M-W40030T-BG05CJ

1/9 R88M-W40030H-G09CJ R88M-W40030H-BG09CJ R88M-W40030T-G09CJ R88M-W40030T-BG09CJ

1/15 R88M-W40030H-G15CJ R88M-W40030H-BG15CJ R88M-W40030T-G15CJ R88M-W40030T-BG15CJ

1/25 R88M-W40030H-G25CJ R88M-W40030H-BG25CJ R88M-W40030T-G25CJ R88M-W40030T-BG25CJ

750 W 1/5 R88M-W75030H-G05CJ R88M-W75030H-BG05CJ R88M-W75030T-G05CJ R88M-W75030T-BG05CJ

1/9 R88M-W75030H-G09CJ R88M-W75030H-BG09CJ R88M-W75030T-G09CJ R88M-W75030T-BG09CJ

1/15 R88M-W75030H-G15CJ R88M-W75030H-BG15CJ R88M-W75030T-G15CJ R88M-W75030T-BG15CJ

1/25 R88M-W75030H-G25CJ R88M-W75030H-BG25CJ R88M-W75030T-G25CJ R88M-W75030T-BG25CJ

3,000-r/min Flat-style Servomotors

Specifications Model

With incremental encoder With absolute encoder

Without brake With brake Without brake With brake

200 V 100 W 1/5 R88M-WP10030H-G05CJ R88M-WP10030H-BG05CJ R88M-WP10030T-G05CJ R88M-WP10030T-BG05CJ

1/9 R88M-WP10030H-G09CJ R88M-WP10030H-BG09CJ R88M-WP10030T-G09CJ R88M-WP10030T-BG09CJ

1/15 R88M-WP10030H-G15CJ R88M-WP10030H-BG15CJ R88M-WP10030T-G15CJ R88M-WP10030T-BG15CJ

1/25 R88M-WP10030H-G25CJ R88M-WP10030H-BG25CJ R88M-WP10030T-G25CJ R88M-WP10030T-BG25CJ

200 W 1/5 R88M-WP20030H-G05CJ R88M-WP20030H-BG05CJ R88M-WP20030T-G05CJ R88M-WP20030T-BG05CJ

1/9 R88M-WP20030H-G09CJ R88M-WP20030H-BG09CJ R88M-WP20030T-G09CJ R88M-WP20030T-BG09CJ

1/15 R88M-WP20030H-G15CJ R88M-WP20030H-BG15CJ R88M-WP20030T-G15CJ R88M-WP20030T-BG15CJ

1/25 R88M-WP20030H-G25CJ R88M-WP20030H-BG25CJ R88M-WP20030T-G25CJ R88M-WP20030T-BG25CJ

400 W 1/5 R88M-WP40030H-G05CJ R88M-WP40030H-BG05CJ R88M-WP40030T-G05CJ R88M-WP40030T-BG05CJ

1/9 R88M-WP40030H-G09CJ R88M-WP40030H-BG09CJ R88M-WP40030T-G09CJ R88M-WP40030T-BG09CJ