Omron R88M-U03030LA, R88M-U03030HA-B, R88M-U10030LA, R88M-U05030HA, R88M-U05030HA-B User Manual

...Page 1

Thank you for choosing this OMNUC UP-series product.

This manual provides details on the installation, wiring, troubleshooting, and maintenance of OMNUC

UP-series products along with parameter settings for the operation of the products.

S Make

sure that actual users of this product will read this manual thoroughly and handle and operate the product with care.

S Retain this manual for future reference.

S This

manual describes the specifications and functions of the product and relations with other products. Assume that noth

ing described in this manual is possible.

S Specifications and functions may change without notice to improve product performance.

S Forward

shaft of the motor as follows: counterclockwise rotation (CCW) is forward and clockwise rotation (CW) is reverse.

and reverse rotation of AC Servomotors described in this

manual are defined as looking at the end of the output

General Instructions

1. Refer to Precautions first and carefully read and be sure to understand the information provided.

2. Familiarize

vo Driver for proper use.

3. The

cal

engineering.

4. We

recommend that you add the following precautions to any instruction manuals you prepare for the system

into which the product is being installed.

S Precautions on the dangers of high-voltage equipment.

S Precautions

are live even with the power turned off.)

not perform withstand voltage or other megameter tests on the product. Doing so may damage internal com

5. Do

ponents.

6. Servomotors

consider the operating environment and other conditions affecting the service life.

7. Do

not set any parameter not described in this manual, otherwise the Servomotor or Servo Driver may malfunc

tion. Contact your OMRON representatives if you have any inquiry.

8. The

are being used before proceeding.

S HA/LA/V/W AC Servo Drivers: R88D-UPjjHA, R88D-UPjjLA, R88D-UPjjV, and R88D-UPjjW

S H/L AC Servo Drivers: R88D-UPjjH and R88D-UPjjL

yourself with this manual and understand the functions and performance of the Servomotor and

Servomotor and Servo Driver must be wired and the Parameter Unit must be operated by experts in electri

on touching the terminals of the product even after power has

and Servo Drivers have a finite service life. Be sure to keep replacement products on hand and to

functions and specifications dif

fer

for the various models, as shown below

been turned of

. Be sure to check which models

f. (These terminals

Ser

-

-

-

-

-

NOTICE

Before using the product under the following conditions, consult your OMRON representatives, make

sure

that the ratings and performance characteristics of the product are good enough for the systems,

machines,

or equipment, and be sure to provide the systems, machines, or equipment with double safety

mechanisms.

1. Conditions not described in the manual.

application of the product to nuclear control systems, railroad systems, aviation systems, vehicles, com

2. The

bustion systems, medical equipment, amusement machines, or safety equipment.

3. The

application of

life and property if they are used improperly.

the product to systems, machines, or equipment that may have a serious influence on human

Items to Check After Unpacking

Check the following items after removing the product from the package:

S Has the correct product been delivered (i.e., the correct model number and specifications)?

S Has the product been damaged in shipping?

The product is provided with this manual. No connectors or mounting screws are provided.

-

Page 2

USER’S MANUAL

OMNUC U SERIES

MODELS R88M-Uj

(AC Servomotors)

MODELS R88D-UPj

(AC Servo Drivers)

AC SERVOMOTORS/DRIVERS (30 to 750-W Pulse-train Inputs)

Page 3

No. 6182

OMRON Corporation

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

1

Page 4

No. 6182

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

2

Page 5

No. 6182

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

3

Page 6

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates

!

or serious injury.

WARNING Indicates

!

or serious injury.

Caution Indicates

!

or moderate injury, or property damage.

an imminently hazardous situation which, if not avoided, will

a potentially hazardous situation which, if not avoided, could result in death

a potentially hazardous situation which, if not avoided, may result in minor

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name

of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation

for anything else.

result in death

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 1994

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying,

recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein.

Moreover, because OMRON is constantly striving to improve its high-quality products, the

information contained in this manual is subject to change without notice. Every precaution

has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Page 7

General Warnings

Observe the following warnings when using the OMNUC Servomotor and Servo Driver.

This manual may include illustrations of the product with protective covers removed in order

to describe the components of the product in detail. Make sure that these protective covers

are on the product before use.

Consult your OMRON representative when using the product after a long period of storage.

WARNING Always

!

to

in electric shock.

WARNING Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

!

WARNING Do

!

items while the power is being supplied. Doing so may result in electric shock.

WARNING Operation,

!

Not doing so may result in electric shock or injury.

WARNING Wiring

!

supply. Doing so may result in electric shock.

WARNING Do

!

so may result in electric shock.

WARNING Do not touch the rotating parts of the Servomotor under operation. Doing so may

!

result in injury.

connect the frame ground terminals of the Servo Driver and the Servomotor

a class-3 ground (to 100 Ω or less). Not connecting to

not remove the front cover

maintenance, or inspection must be performed by authorized personnel.

or inspection must be performed at least

not damage, press, or put excessive stress or heavy

, terminal covers, cables, Parameter Units, or optional

5 minutes after turning of

a class-3 ground may result

f the power

objects on the cables. Doing

WARNING Do

!

Caution Use the Servomotors and Servo Drivers in a specified combination.

!

Caution Do

!

not modify the product. Doing so may result in injury or damage to the

result in fire or damage to the products.

not store or install in the following places. Doing so may result in fire or damage to

the Product.

S Locations subject to direct sunlight.

S Locations subject to temperatures or humidity outside the range specified in the

specifications.

S Locations

S Locations subject to corrosive or flammable gases.

S Locations subject to dust (especially iron dust) or salts.

S Locations subject to shock or vibration.

S Locations subject to exposure to water, oil, or chemicals.

subject to condensation as the result of severe changes in

product.

Doing so may

temperature.

Page 8

Caution Do

!

not touch the Servo Driver radiator or Servomotor while the power is being sup

plied or soon after the power is turned of

the hot surface.

f. Doing so may

result in a skin burn due to

Storage and Transportation Precautions

Caution Do not hold by the cables or motor shaft while transporting the product. Doing so

!

may result in injury or malfunction.

-

Caution Do

!

Caution Use

!

not place any load exceeding the figure indicated on the product.

result in injury or malfunction.

the motor eye-bolts only for transporting the

the machinery may result in injury or malfunction.

Installation and Wiring Precautions

Caution Do

!

Caution Do

!

Caution Be

!

Caution Provide

!

not step on or place a heavy object on the

not cover the inlet or outlet ports and prevent any foreign objects from entering

the product. Doing so may result in fire.

sure to install the product in the correct direction. Not doing so may result in mal

function.

the specified clearances between the Servo Driver and the

with other devices. Not doing so may result in fire or malfunction.

Doing so may

Motor

. Using them for transporting

product. Doing so may result in injury

control panel or

.

-

Caution Do not apply any strong impact. Doing so may result in malfunction.

!

Caution Be sure to wire correctly and securely. Not doing so may result in motor runaway,

!

injury, or malfunction.

Caution Be

!

Caution Use

!

Caution Always use the power supply voltage specified in the User’s Manual. An incorrect

!

sure that all

are tightened to the torque specified in the relevant manuals. Incorrect tightening

torque may result in malfunction.

crimp terminals for wiring. Do not connect bare stranded wires directly to termi

nals. Connection of bare stranded wires may result in burning.

voltage may result in malfunction or burning.

the mounting screws, terminal screws, and cable connector screws

-

Page 9

Caution Take

!

appropriate

and

frequency is supplied.

measures to ensure that the specified power with the rated voltage

Be particularly careful in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

Caution Install

!

external breakers and take other safety measures against short-circuiting in

external wiring. Insufficient safety measures against short-circuiting may result in

burning.

Caution Provide an appropriate stopping device on the machine side to secure safety. (A

!

holding

brake is not a stopping device

for securing safety

.) Not doing so may result in

injury.

Caution Provide

!

an external emergency stopping device that allows an instantaneous stop

operation and power interruption. Not doing so may result in injury.

Caution Take

!

appropriate and suf

ficient

countermeasures when installing systems in the fol

lowing locations:

S Locations subject to static electricity or other forms of noise.

S Locations subject to strong electromagnetic fields and magnetic fields.

S Locations subject to possible exposure to radioactivity.

S Locations close to power supplies.

of

-

Operation and Adjustment Precautions

Caution Check

!

Not doing so may result in equipment damage.

Caution Do not make any extreme adjustments or setting changes. Doing so may result in

!

unstable operation and injury.

Caution Separate the Servomotor from the machine, check for proper operation, and then

!

connect to the machine. Not doing so may cause injury.

Caution When an alarm occurs, remove the cause, reset the alarm after confirming safety,

!

and then resume operation. Not doing so may result in injury.

Caution Do not come close to the machine immediately after resetting momentary power

!

interruption

safety against an unexpected restart.) Doing so may result in injury.

Caution Do

!

result in malfunction.

the newly

set parameters for proper execution before actually running them.

to avoid an unexpected restart. (T

not use the built-in brake

ake appropriate measures to secure

of the Servomotor for ordinary braking. Doing so may

Page 10

Maintenance and Inspection Precautions

WARNING Do

!

not attempt to disassemble, repair

, or modify any Units. Any attempt to do so may

result in malfunction, fire, or electric shock.

Caution Resume operation only after transferring to the new Unit the contents of the data

!

required for operation. Not doing so may result in an unexpected operation.

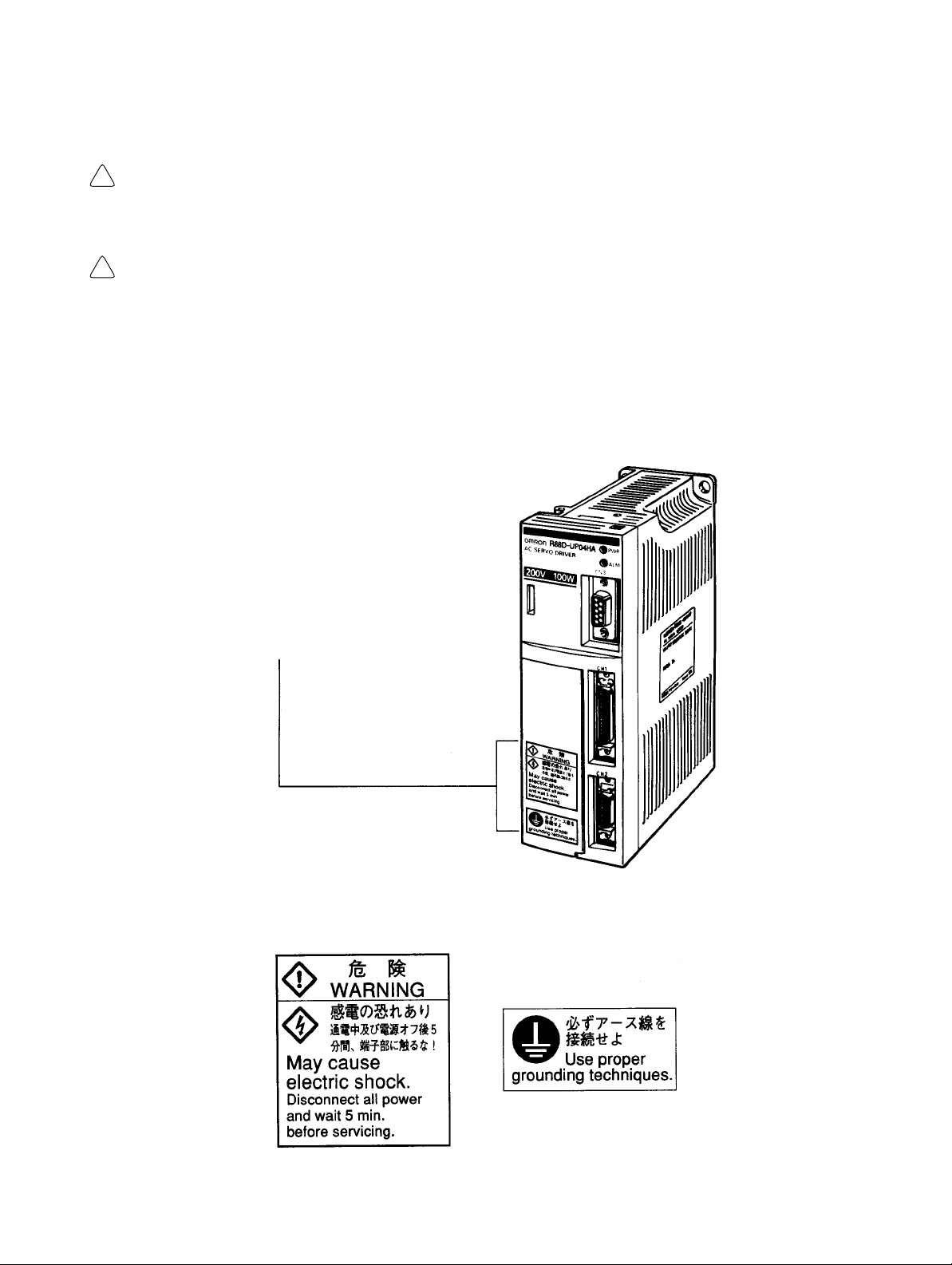

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to

follow the instructions given there.

Warning

labels

Warning Labels for Non-conforming Models

Warning

label 1

W

arning label 2

Page 11

Warning Labels for Models Conforming to EC Directives

W

arning label 2

Warning

label 1

Page 12

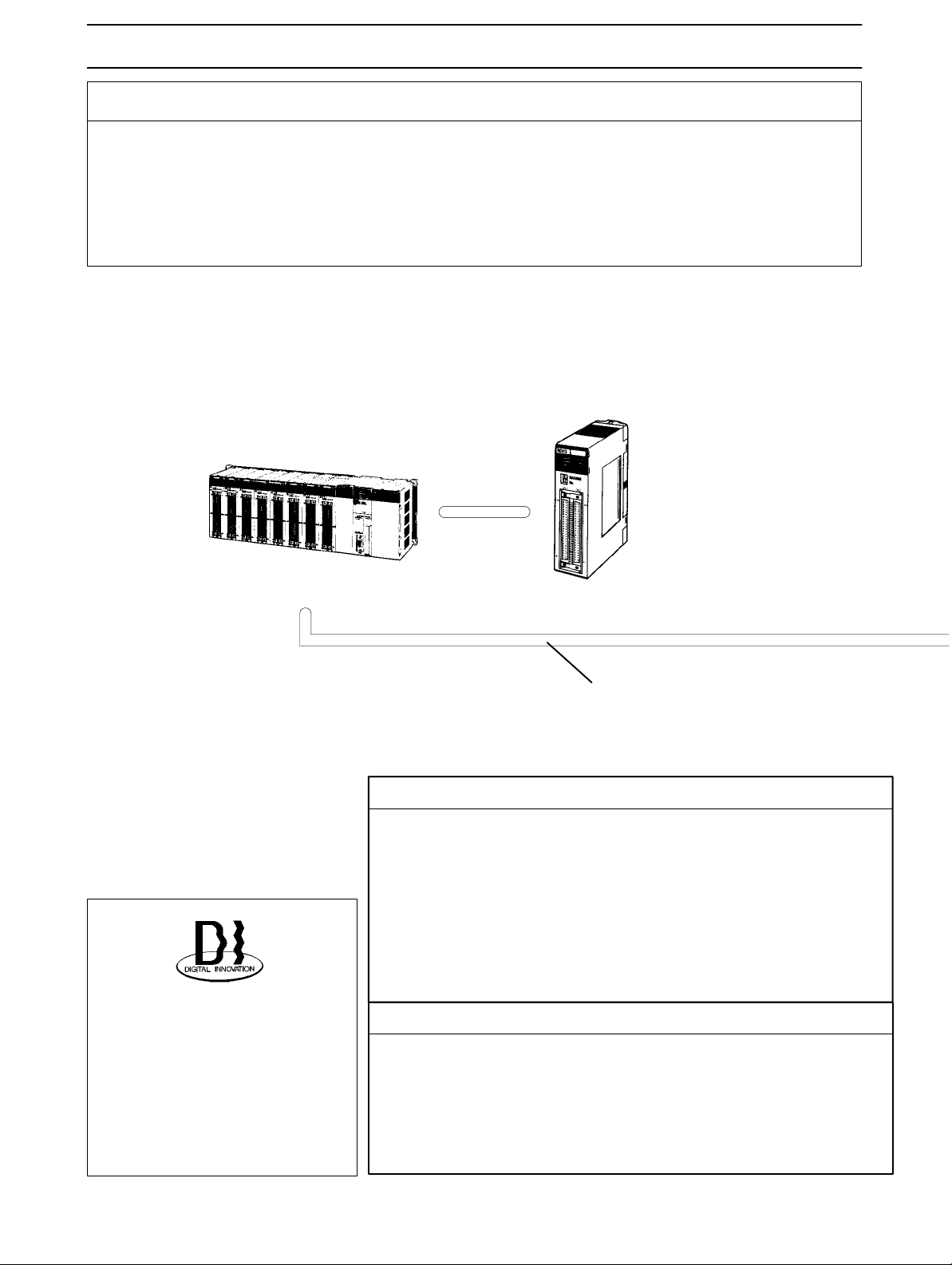

VISUAL INDEX

For users who wish to operate soon.

- The

following portions of

Be

sure you fully understand at least the

tion.

Chapter

ter 3 Operation.

Instructions for jog operation using a Parameter Unit are provided in 3-6.

2 System Design and Installation, and sections

this manual provide the minimum information required for operation.

information in these portions before attempting opera

3-1,

3-2,

3-3,

SYSMAC CS1/C/CV

Programmable Controller

3-4,

3-5, and

3-6 of Chap

Position Control Unit

C200HW-NC113

C200HW-NC213

C200HW-NC413

C200H-NC112

C200H-NC211

C500-NC113

C500-NC211

-

-

OMNUC U is a series of fully

software-controlled AC servo

drivers

built on advanced

OM

RON software servo technology. It provides high performance, a sensitive man-machine

interface, and economy

Controller Connecting Cable

Chapter 5: 5-3-1

Setting Functions

- Setting User Parameters: Section 3-5-1

- Internally Set Speed Control: Section 3-5-3

- Electronic Gears: Section 3-5-4

- Encoder Dividing: Section 3-5-5

- Bias: Section 3-5-6

- Torque Control: Section 3-5-7

- Brake Interlock: Section 3-5-8

Adjustments and Troubleshooting

- Adjustments: Section 3-7

-

- Displays: Section 4-1

- Monitor Outputs: Section 4-2

- Protections and Diagnostics: Section 4-3

- Troubleshooting: Section 4-4

.

Pulse input

Page 13

I/O Operations

Chapter 5: 5-1-3

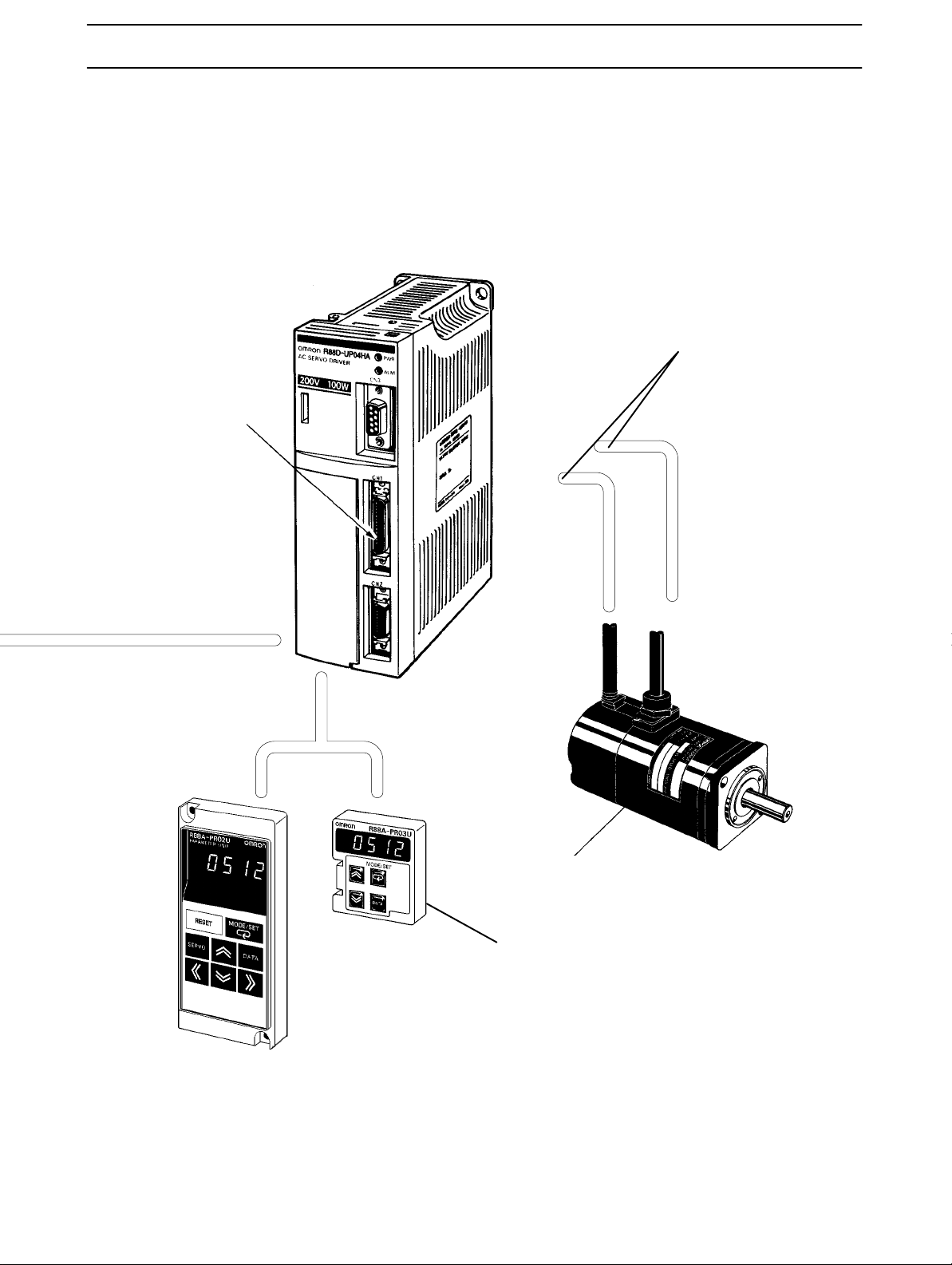

OMNUC U Series

OMNUC U-series AC Servo Driver

Encoder

signals

Cable Specifications

Chapter 5: 5-3-2, 5-3-3

Power

signals

Parameter Units

OMNUC U-series

AC Servomotor

Motor Specifications

Chapter 5: 5-2

Operation Method

Chapter 3: 3-3, 3-4, 3-5

Page 14

Table of Contents

Chapter 1. Introduction .

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Servo Driver Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Applicable Standards and Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 UL/cUL Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring Products Conforming to UL/cUL

2-3 Wiring Products Conforming to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. System Design and Installation. . . . . . . . . . . . . . . . . . . . . .

2-1-1 External Dimensions (Unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Wiring Products Not Conforming to Any Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Connecting OMRON Servo Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Connector-Terminal Conversion Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Wiring Servo Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Wiring for Noise Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-5 Peripheral Device Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Connecting Servo Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Wiring Servo Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 Wiring Products Conforming to EMC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-4 Peripheral Device Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

3-1 Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Turning On Power and Checking Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Using Parameter Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Initial Settings: Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Setting Functions: User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Items to Check Before Turning On Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Turning On Power and Confirming the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Parameter Unit Keys and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 Modes and Changing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-3 Mode Changes and Display Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-1 Setting and Checking Setup Parameters (Cn-01, 02) . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-2 Setup Parameter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-3 Important Setup Parameters (Cn-01 and Cn-02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-1 Setting and Checking User Parameters (Cn-04 to 29) . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-2 User Parameter Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-3 Internal Speed Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-4 Electronic Gear Function: Position Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-5 Encoder Dividing Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-6 Bias Function: Position Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-7 Torque Limit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-8 Brake Interlock (For Motors with Brakes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-1 Preparations for Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-2 Jog Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 15

Table of Contents

3-7 Making Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-1 Auto-tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-2 Manually Adjusting Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Regenerative Energy Absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-1 Calculating Regenerative Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-2 Servo Driver Absorbable Regenerative Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-3 Absorption of Regenerative Energy with the External Regeneration Resistor

(Models Conforming to UL/cUL Standards

and Models Not Conforming to Any Standards) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-4 Processing Regenerative Energy with Multiple Axes

(Models Conforming to EC Directives) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

4-1 Using Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Using the Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Protective and Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

5-1 Servo Driver Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Servomotor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Parameter Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Regeneration Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Front-surface Mounting Bracket Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-2 Status Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-3 Monitor Mode (Un-) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-4 Checking Servomotor Parameters (Cn-00 Set to 04) . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Alarm Displays and Alarm Code Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-2 Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-3 Overload Characteristics (Electron Thermal Characteristics) . . . . . . . . . . . . . . . . . . .

4-3-4 Alarm History Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-3 I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-4 Explanation of User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-3 Torque and Rotational Speed Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-4 Allowable Loads on Servomotor Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-5 Encoder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-1 Controller Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-2 Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-3 Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

6-1 Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Servo Connector Terminal Connection Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 OMNUC U-series Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Parameter Setting Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Supplementary Materials. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 16

1

Chapter 1

Introduction

1-1 Features

1-2 System Configuration

1-3 Servo Driver Nomenclature

1-4 Applicable Standards and Models

Page 17

Introduction Chapter 1

1-1 Features

OMNUC

and perform precision position control. There are 7 types of AC Servomotors: 30-W, 50-W, 100-W,

200-W, 300-W, 400-W, and 750-W.

AC Servo Drivers control the power supplied to AC Servomotors with pulse-train input signals

H Motor Output Capacity

AC Servomotors with the following output capacities are available.

S For 200/230-VAC (170 to 253 V) single-phase, 50/60-Hz Input

30 W, 50 W, 100 W, 200 W, 400 W, and 750 W

S For 100/115-VAC (85 to 127 V) single-phase, 50/60-Hz Input

30 W, 50 W, 100 W, 200 W, and 300 W

The Servomotors also come with and without brakes, and with and without keys on the straight

shaft. Servomotors that conform to EC Directives, however, are available only with keys on the

shaft.

H Models Conforming to UL/cUL Standards Available (UL/cUL Markings)

AC

Servomotors and Servo Drivers that conform to UL/cUL Standards are now available. Their

formance,

els. They are useful for obtaining approvals required for specific applications.

Models

(HA/LA)

functionality

conforming to UL/cUL Standards have the same

models. As shown in the following table, they are distinguished by

, and appearance are the same as the conventional U-series (HA/LA) mod

product names as conventional U-series

the manufacturing date.

per

-

-

Model Manufacturing date Type Remarks

Models not conforming to

any standards

Models conforming to

UL/cUL Standards

Before April 1998

After May 1998 HA/LA UL/cUL markings are

H/L, HA/LA

Production of H/L models

discontinued.

attached to products.

H EC Directives (CE Markings)

AC Servomotors and Servo Drivers that conform to EC low-voltage and EMC directives are now

available.

and will aid in obtaining specifications.

These provide the same performance and functions as the rest of the

U Series (HA/LA),

H Control Functions

Any one of the following 4 control modes can be selected in the parameter settings.

S Position Control (Factory Setting)

Controls

Any one of the following 3 pulse trains can be selected: forward/reverse pulses, feed pulses/

directional signals, or 90_ differential phase (A/B phases) signals.

S Position Control with Pulse Stop Input Enabled (HA/LA/V/W Models)

Turning

during position control.

the position and speed of the Servomotor very precisely with pulse-train input signals.

ON the Pulse Stop Input (IPG) prevents the control signals from being read by the

Unit

1-2

Page 18

Introduction Chapter 1

S Internal Speed Control Settings

The

speed of the motor is controlled with the three speeds (No. 1, No. 2, and No. 3 internal speed

settings) set in the parameters. This mode is effective for simple position control or speedswitching operation.

S Internal Speed Control Setting + Position Control (HA/LA/V/W Models)

Speed

formed with pulse-train inputs.

control can be performed with the internal speed settings and position control can be per

H Auto-tuning

The

gain can be adjusted automatically when the responsiveness has been selected to match the

rigidity of the mechanical system. The auto-tuning feature automatically finds the optimum adjust

ment to match the load, with no need for difficult operations.

H Monitor

Displays the driver’s operating status on the Parameter Unit.

The following items can be monitored: speed feedback, speed commands, torque commands,

number of pulses from the U-phase edge, electrical angle, internal status (bit display), command

pulse’s speed, position deviation, and the input pulse counter.

H Jog Operation

Forward/Reverse

be set in the parameters.

motor operation can be controlled from the Parameter Unit. Rotational speed can

H Electronic Gear Function (Position Control)

The

number of pulses used to rotate the motor is calculated by multiplying the number of command

pulses by the electronic gear ratio. This function is useful in the following kinds of cases.

-

-

S When

S When

S When you want to set the movement/pulse to a certain amount, such as 0.01 mm/pulse

The

The

0.01 to 100, i.e., 0.01 ≤ G1/G2 ≤ 100.

you want to finely adjust the position and speed of two lines that need to be synchronized

you want to increase the control pulse frequency of a controller with a low pulse frequency

electronic gear ratio is set with parameters G1 and G2 (G1=numerator and G2=denominator).

setting range for parameters G1 and G2 is 1 to 65,535. The setting range for the gear ratio is

H Encoder Resolution Function

This

function allows the encoder

pulses/revolution.

signal output from the driver to be set anywhere from 16 to 2,048

H Software Start Function (Internal Speed Control Settings)

This

function causes the motor to be started/stopped in the preset acceleration/deceleration times,

allowing a simple position control system to be constructed without a Positioner or Host Controller

The acceleration and deceleration times are set separately, and the setting range is 0 to 10 s for

each.

.

1-3

Page 19

Introduction Chapter 1

H Pulse Smoothing Function (Position Control)

Even

high-frequency commands

in the command pulses. The same setting is used for

and the setting range is 0 to 64 ms.

H Reverse Mode

Forward/Reverse

motor or encoder.

commands can be switched

H Brake Interlock Output

Outputs

ing brake of a motor with a brake can be operated reliably.

a timing signal interlocked with the motor’s ON/OFF status and rotational speed. The hold

H Overtravel Sequence

An

overtravel sequence compatible with the system can be selected. There are three deceleration

methods

deceleration (parameter setting).

available: dynamic brake deceleration, free-run deceleration, and emergency-stop torque

can be executed smoothly by including acceleration/deceleration

both

the acceleration and deceleration times,

in the parameters, without changing the wiring to the

-

H Feed-forward and Bias Functions (Position Control)

These functions reduce the position control time.

S Feed-forward Function

Reduces

counter.

S Bias Function

Reduces

deviation counter value exceeds the position completion range.

the position control time by reducing the number of pulses accumulated in the

the position control time by adding the bias revolutions to

the speed control when the

deviation

H Computer Monitor Software (HA/LA/V/W Models)

The special Servo Driver Communications Software allows parameter setting, speed and current

monitoring,

puter.

tor the operation of several drivers. Refer to the

(I513)

I/O monitoring, auto-tuning, and jog operations to be performed from

It is also possible to perform multiple-axis communications that set the parameters and moni

Computer Monitor Software Instruction Manual

for OMNUC U-series Servo Drivers for more details.

a personal com

-

-

1-4

Page 20

Introduction Chapter 1

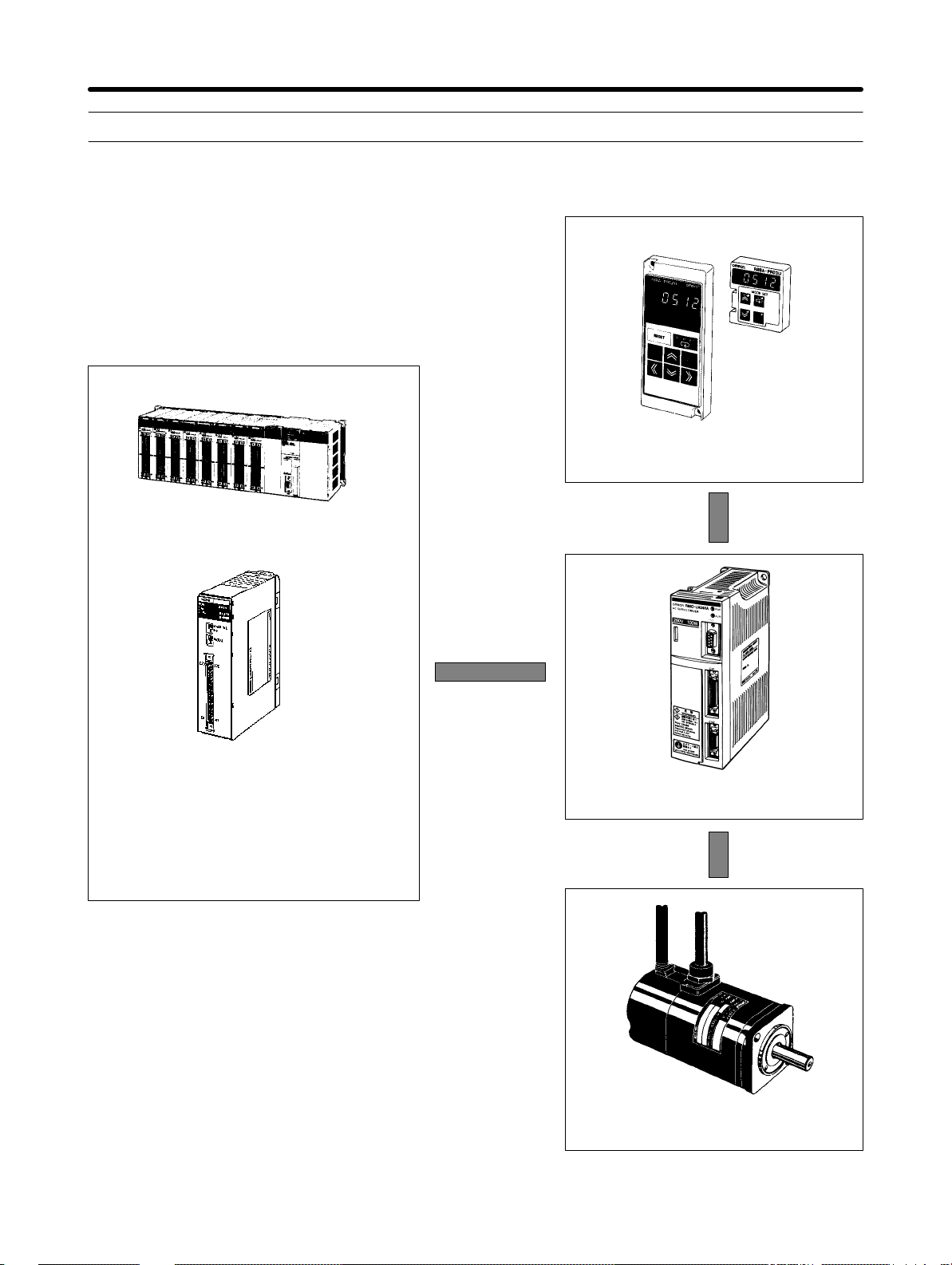

1-2 System Configuration

Parameter Units

SYSMAC CS1/C/CV

Programmable Controller

C200HW-NC113

C200HW-NC213

C200HW-NC413

C200H-NC112

C200H-NC211

C500-NC113

C500-NC211

Position Control Unit

OMNUC U-series

AC Servo Driver

OMNUC U-series

AC Servomotor

1-5

Page 21

Introduction Chapter 1

1-3 Servo Driver Nomenclature

H Front View

CN4: Connector for monitor output

Power supply indicator

Alarm indicator

CN3: Parameter Unit connector

Terminal block

CN1: Control I/O connector

CN2: Encoder connector

1-6

Page 22

pp y

Introduction Chapter 1

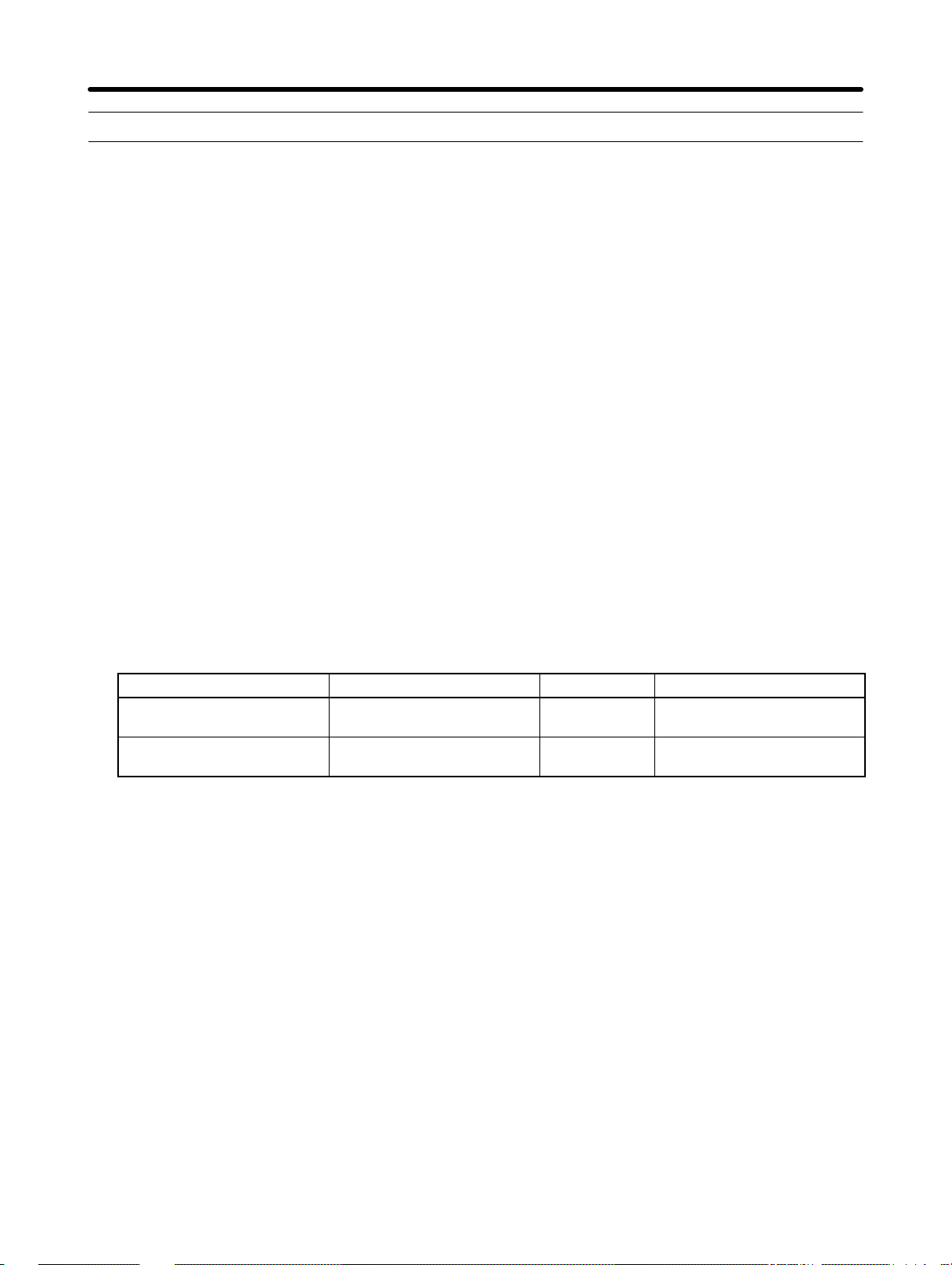

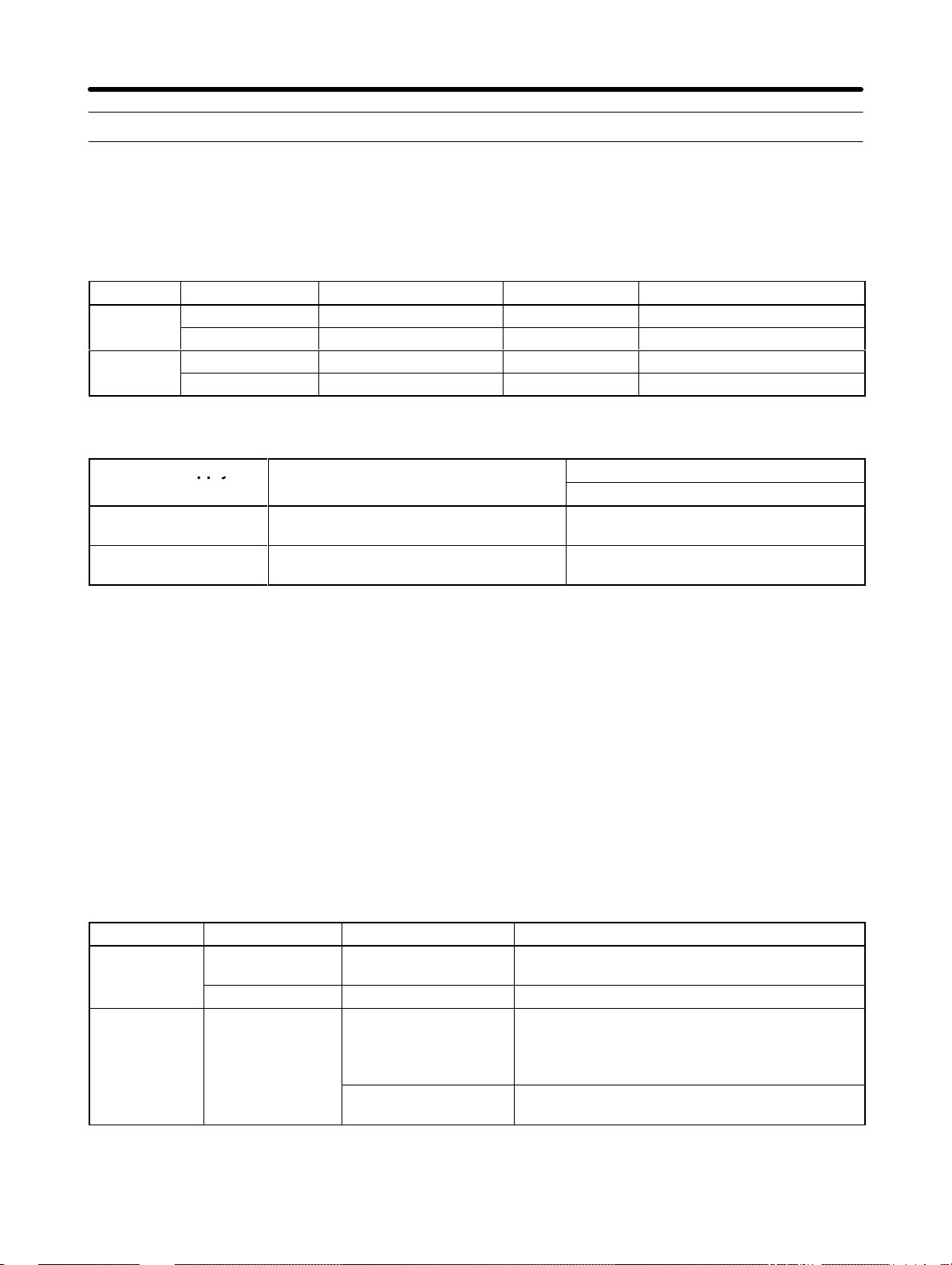

1-4 Applicable Standards and Models

1-4-1 UL/cUL Standards

H Applicable Standards

Standard Product Applicable Standard File No. Remarks

UL

cUL

H Applicable Models

AC Servo Driver UL508C E179149 Power conversion equipment

AC Servomotor UL1004 E179189 Electric motors

AC Servo Driver cUL C22.2 No. 14 E179149 Industrial control equipment

AC Servomotor cUL C22.2 No.100 E179189 Motor and generators

Power supply

200 VAC R88D-UPjjHA

100 VAC R88D-UPjjLA

AC Servo Drivers

(See note 1.)

(See note 1.)

R88M-Ujjj30HA-j

R88M-Ujjj30LA-j

AC Servomotors

With incremental encoder

(See note 2.) (See note 3.)

(See notes 2.) (See note 3.)

Note 1. Maximum output current: for example, “04” means approx. 4 A.

Note 2. Motor capacity: for example, “100” means 100 W.

Note 3. Optional specifications

None: Straight shaft without keys and without brake

B: Straight shaft without keys and with brake

S1: Straight shaft with keys and without brake

BS1: Straight shaft with keys and with brake

Note 4. UL/cUL Standards apply to models manufactured after May 1998.

1-4-2 EC Directives

H Applicable Standards

EC Directive Product Directive Remarks

Low voltage

EMC AC Servo Driver

Note Installation under the conditions specified in

tives

AC Servo Driver EN61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use.

AC Servomotor IEC34-1, -5, -8, -9 Rotating electrical machines.

AC Servomotor

EN55011 class A

group 1

EN50082-2 Electromagnetic compatibility generic immunity

Limits and methods of measurement of radio

disturbance characteristics of industrial,

scientific, and medical (ISM) radio-frequency

equipment.

standard, Part 2 Industrial environment.

2-3-3 Wiring Products Conforming to EMC Direc-

is required to conform to EMC Directives.

1-7

Page 23

pp y

Introduction Chapter 1

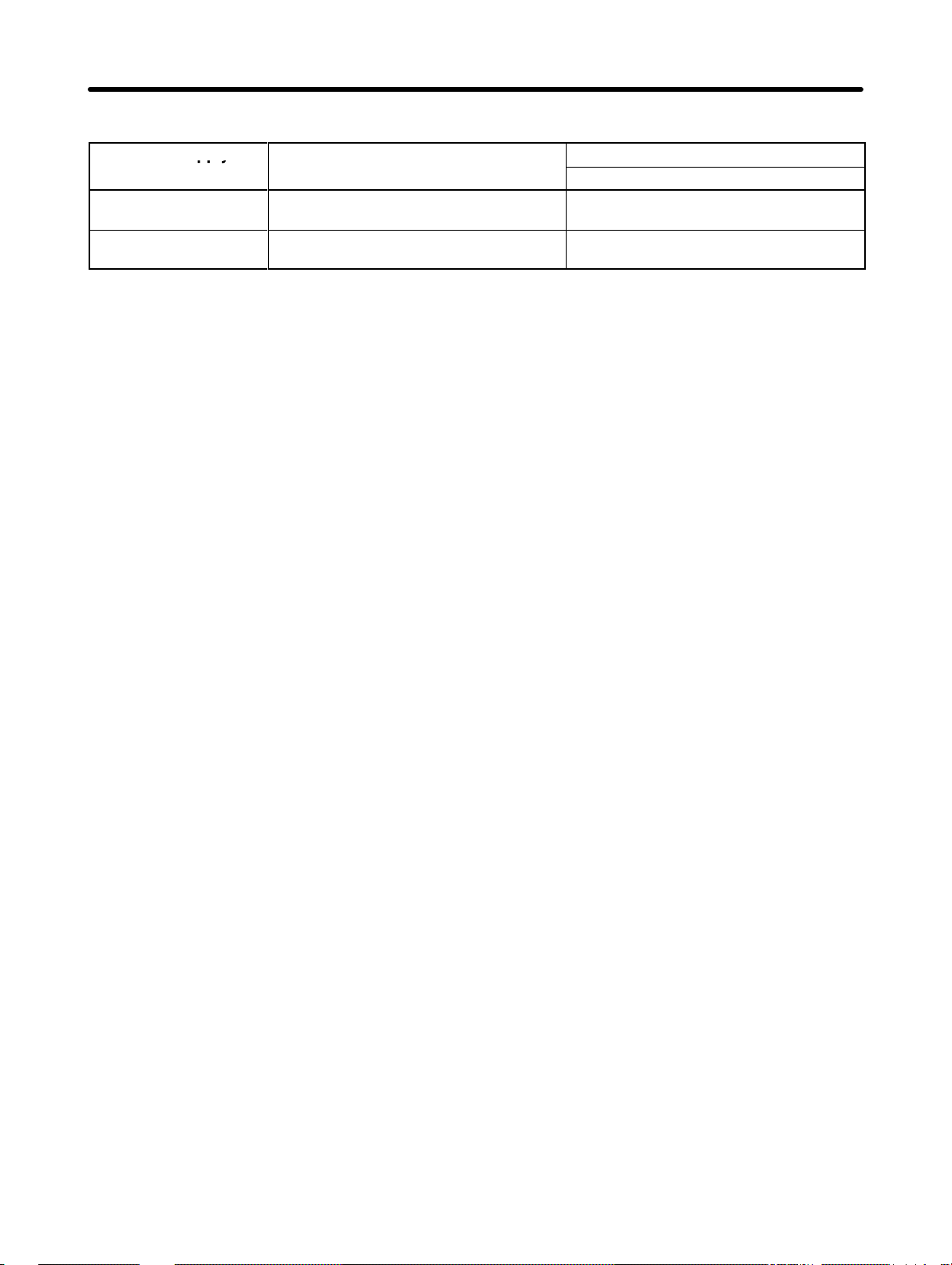

H Applicable Models

Power supply

200 VAC R88D-UPjjV R88M-Ujjj30VA-j

100 VAC R88D-UPjjW R88M-Ujjj30WA-j

Note Optional specifications (shaft profile: straight shaft with keys)

S1: Straight shaft with keys and without brake

BS1: Straight shaft with keys and with brake

AC Servo Drivers

AC Servomotors

With incremental encoder

(See note.)

(See note.)

1-8

Page 24

2

Chapter 2

System Design and Installation

2-1 Installation

2-2 Wiring Products Conforming to UL/cUL

and Wiring Products Not Conforming to Any

Standards

2-3 Wiring Products Conforming to EC Directives

Page 25

System Design and Installation

Installation and Wiring Precautions

!

Caution Do

not step on or place a

heavy object on the product. Doing so may result in injury

Chapter 2

.

!

Caution Do

!

Caution Be

!

Caution Provide

!

Caution Do not apply any strong impact. Doing so may result in malfunction.

!

Caution Be sure to wire correctly and securely. Not doing so may result in motor runaway,

!

Caution Be

!

Caution Use

!

Caution Always use the power supply voltage specified in the User’s Manual. An incorrect

not cover the inlet or outlet ports and prevent any foreign objects from entering

the product. Doing so may result in fire.

sure to install the product in the correct direction. Not doing so may result in mal

function.

the specified clearances between the

with other devices. Not doing so may result in fire or malfunction.

injury, or malfunction.

sure that all the mounting screws, terminal screws, and cable connector screws

are tightened to the torque specified in the relevant manuals. Incorrect tightening

torque may result in malfunction.

crimp terminals for wiring. Do not connect bare stranded wires directly to termi

nals. Connection of bare stranded wires may result in burning.

voltage may result in malfunction or burning.

Servo Driver and the control panel or

-

-

!

Caution Take

!

Caution Install

!

Caution Provide an appropriate stopping device on the machine side to secure safety. (A

!

Caution Provide

!

Caution Take

appropriate measures to ensure that the specified power with the rated voltage

and

frequency is supplied. Be particularly careful in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

external breakers and take other safety measures

external wiring. Insufficient safety measures against short-circuiting may result in

burning.

holding

injury.

operation and power interruption. Not doing so may result in injury.

lowing locations:

S Locations subject to static electricity or other forms of noise.

S Locations subject to strong electromagnetic fields and magnetic fields.

S Locations subject to possible exposure to radioactivity.

S Locations close to power supplies.

brake is

an external emergency stopping device that

appropriate and suf

not a stopping device for securing safety

ficient countermeasures when installing systems in the fol

against short-circuiting in

.) Not doing so may result in

allows an instantaneous stop of

-

2-2

Page 26

System Design and Installation

2-1 Installation

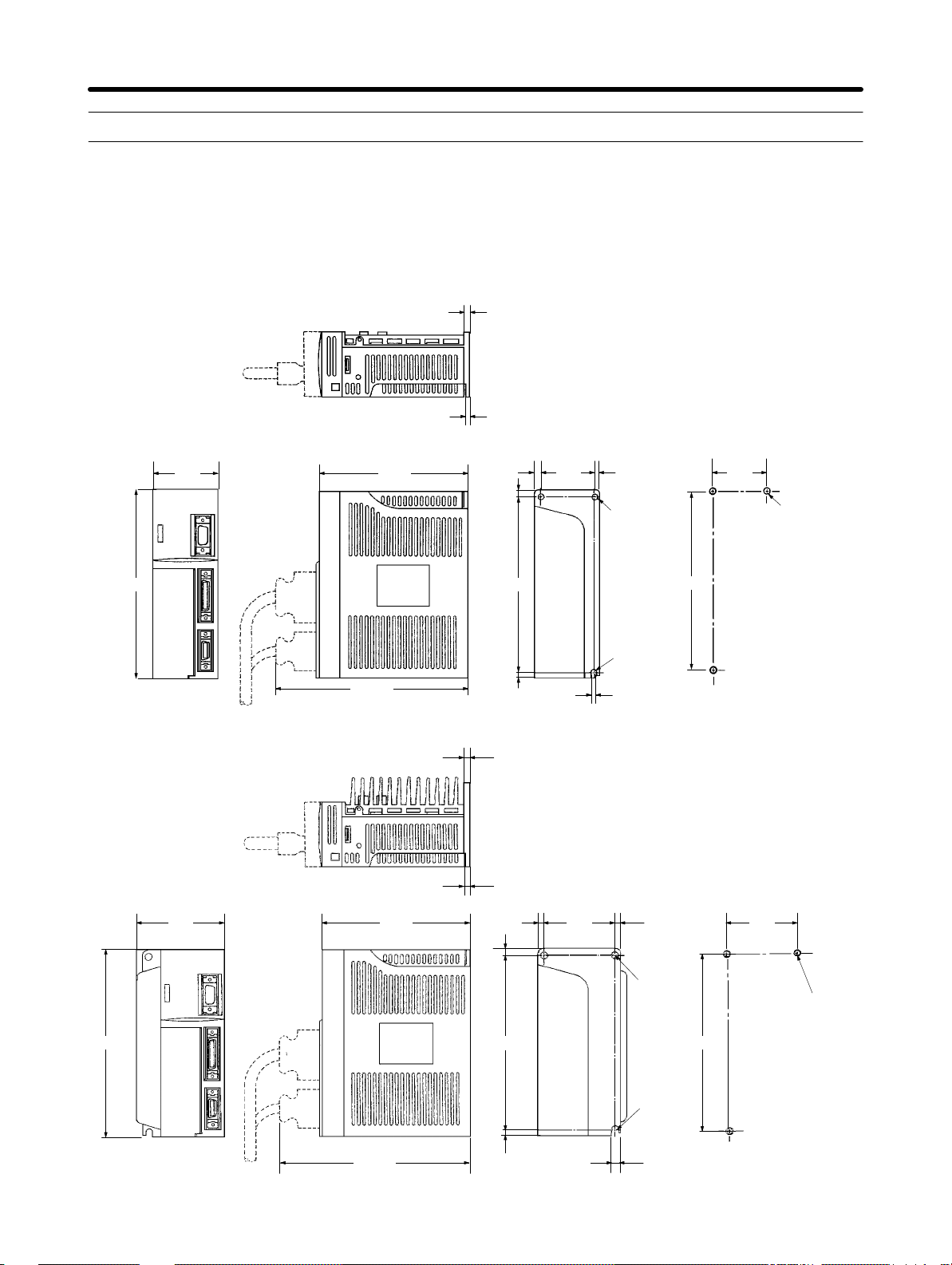

2-1-1 External Dimensions (Unit: mm)

H AC Servo Drivers Conforming to UL/cUL Standards and AC

Servomotors Not Conforming to Any Standards

D R88D-UP02H(A)/UP03H(A)/UP04H(A)/UP08H(A) (200 VAC, 30 to 200 W)

R88D-UP03L(A)/UP04L(A)/UP10L(A) (100 VAC, 30 to 100 W)

5

Chapter 2

160

55 130

(165)

4

5

(6)

149

5

45 (5) 45

Two,

6 dia.

R3

6

Installation dimensions

149

D R88D-UP12H(A) (200 VAC, 400 W) and R88D-UP12L(A) (100 VAC, 200 W)

5

Three, M4

160

4

75 130 60 (5)

(165)

(6)

149

5

5

Two,

6 dia.

R3

6

Installation dimensions

60

Three, M4

149

2-3

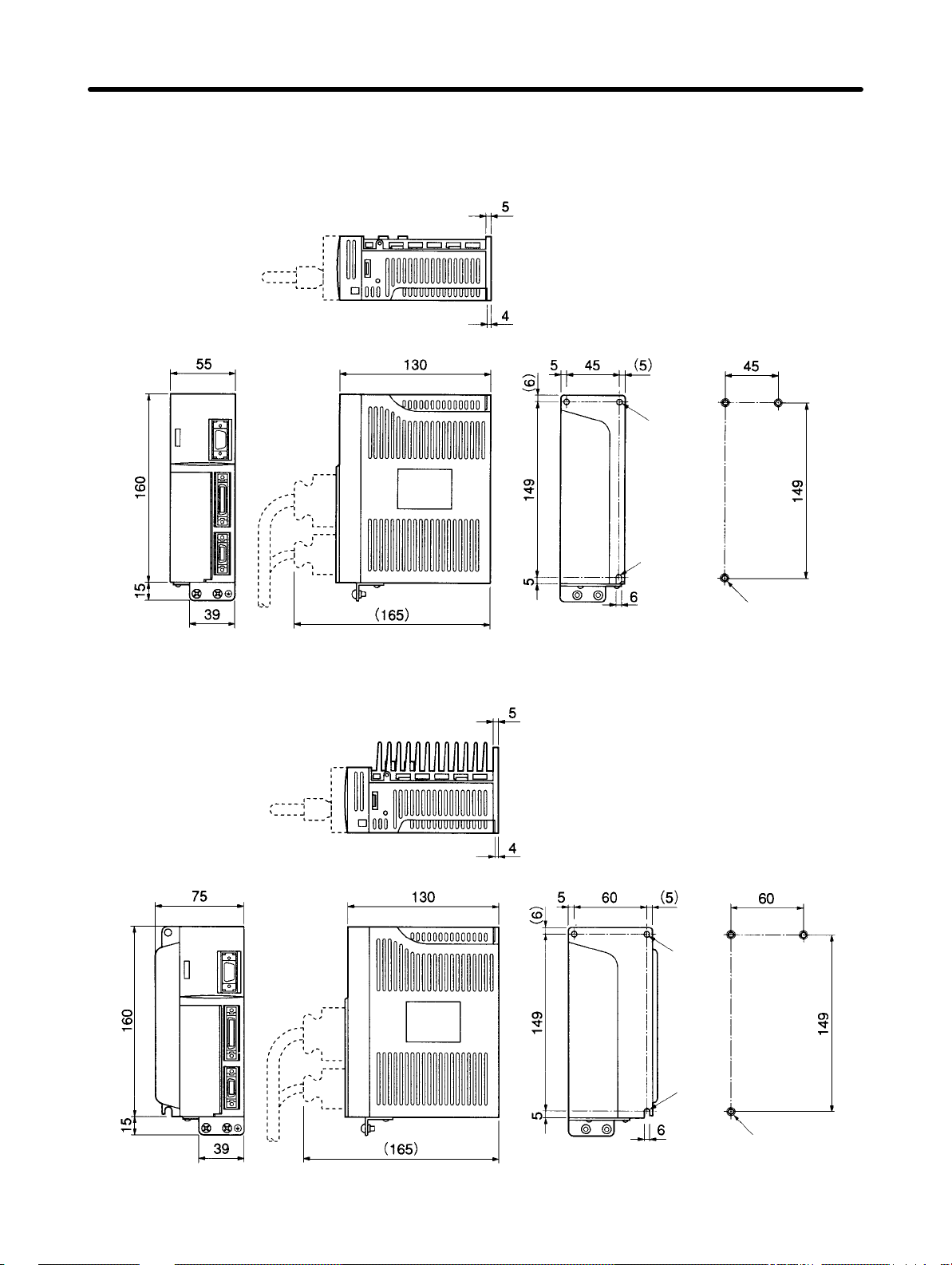

Page 27

System Design and Installation

H AC Servo Drivers Conforming to UL/cUL Standards and AC

Servomotors Not Conforming to Any Standards (Contd.)

D R88D-UP20H(A) (200 VAC, 750 W) and R88D-UP15LA (100 VAC, 300 W)

3.5

7

105 130 90

6

(8)

Two, 6 dia.

Chapter 2

160

(165)

Installation

dimensions

149

Two, R3

5

66

90

Four, M4

149

2-4

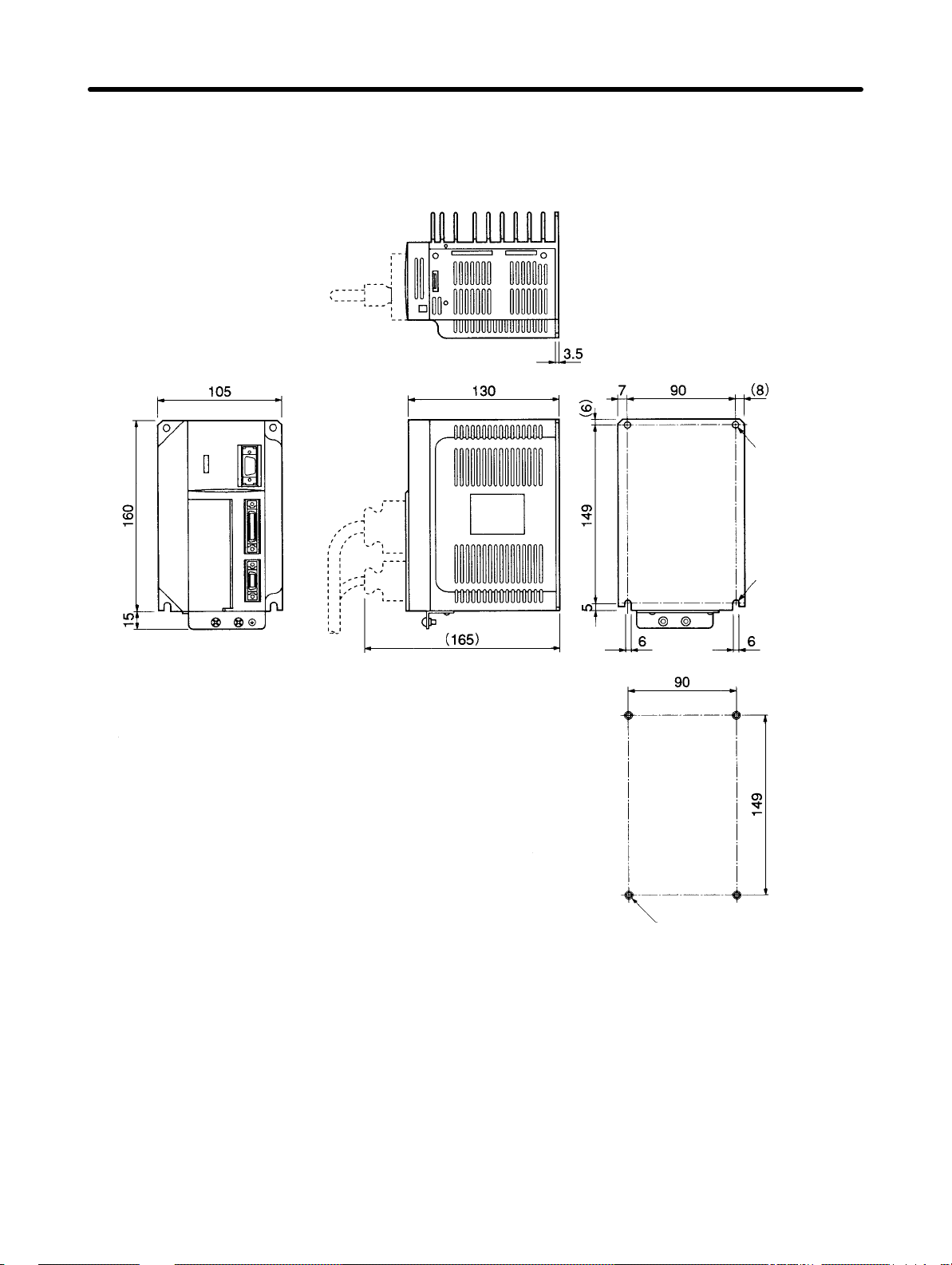

Page 28

System Design and Installation

H AC Servo Drivers Conforming to EC Directives

D R88D-UP02V/UP03V/UP04V/UP08V (200 VAC, 30 to 200 W)

R88D-UP03W/UP04W/UP10W (100 VAC, 30 to 100 W)

Two,

Chapter 2

Installation

dimensions

6 dia.

D R88D-UP12V (200 VAC, 400 W)

R88D-UP12W (100 VAC, 200 W)

R3

Two,

Three, M4

Installation

dimensions

6 dia.

R3

Three, M4

2-5

Page 29

System Design and Installation

H AC Servo Drivers Conforming to EC Directives (Contd.)

D R88D-UP20V (200 VAC, 750 W)

R88D-UP15W (100 VAC, 300 W)

Chapter 2

Two,

6 dia.

Installation

dimensions

Two, R3

Four, M4

2-6

Page 30

System Design and Installation

H Regeneration Unit

D R88A-RG08UA

160

(15)

130 149

15

(6)

25

5

25

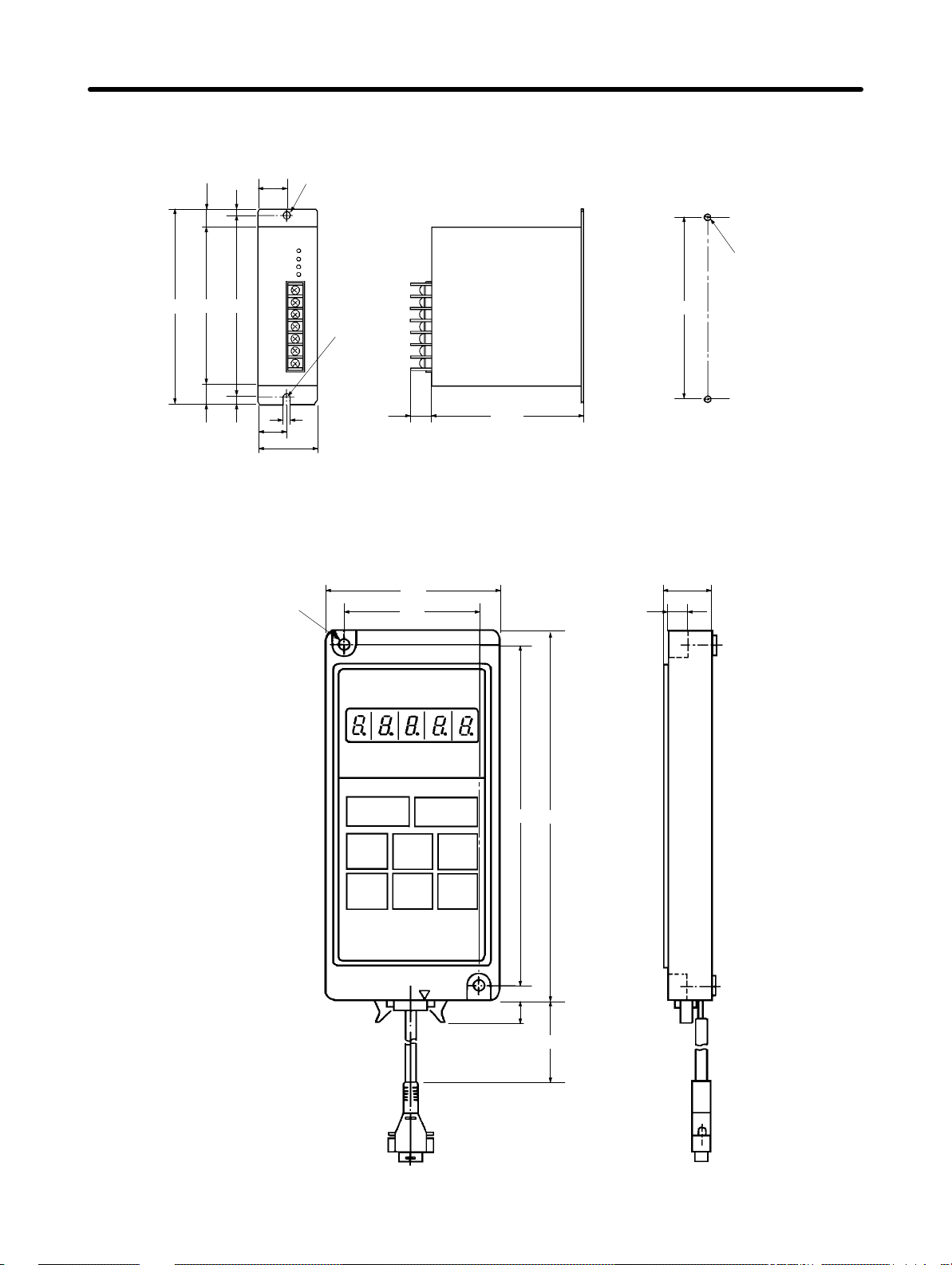

H Parameter Units

50

6

Dia.:

R3

(18.5) 130

6

Chapter 2

Installation dimensions

Two, M4

149

D R88A-PR02U

Two,

4.5 dia.

63

50

(8)

125

18.5

7

135

1000

2-7

Page 31

System Design and Installation

D R88A-PR03U

54

57.5

15

Chapter 2

6.9

2-8

Page 32

System Design and Installation

H AC Servomotors Conforming to UL/cUL Standards and AC

Servomotors Not Conforming to Any Standards

D 30-W/50-W/100-W Standard Models:

R88M-U03030HA, R88M-U05030HA, R88M-U10030HA

R88M-U03030LA, R88M-U05030LA, R88M-U10030LA

300±30

6.5 4

17

35

300±30

5

9.5

2.5

Encoder adapter

Motor plug

6h6 dia.

30h7 dia.

Two,

4.3 dia.

46

dia.

18

14

dia.

6

Four, R3.7

40

Chapter 2

33

LL 25

L

D 30-W/50-W/100-W Models with Brake:

R88M-U03030HA-B, R88M-U05030HA-B, R88M-U10030HA-B

R88M-U03030LA-B, R88M-U05030LA-B, R88M-U10030LA-B

300±30

6.5

35

300±30

9.5

2.55

17

33 LB

25LL

L

Encoder adapter

Motor plug

Two,

4.3 dia.

6h6 dia.

30h7 dia.

46

dia.

40

21

14

dia.

4

40

Four, R3.7

40

Standard Models

Model L LL S

R88M-U03030HA

94.5 69.5 6

R88M-U03030LA

R88M-U05030HA

102.0 77.0 6

R88M-U05030LA

R88M-U10030HA

119.5 94.5 8

R88M-U10030LA

Models with Brake

Model L LL LB S

R88M-U03030HA-B

R88M-U03030LA-B

R88M-U05030HA-B

R88M-U05030LA-B

R88M-U10030HA-B

R88M-U10030LA-B

126 101 31.5 6

133.5 108.5 31.5 6

160 135 40.5 8

2-9

Page 33

System Design and Installation

H AC Servomotors Conforming to UL/cUL Standards and AC

Servomotors Not Conforming to Any Standards (Contd.)

D 200-W/300-W/400-W Standard Models:

R88M-U20030HA, R88M-U40030HA

R88M-U20030LA, R88M-U30030LA

300±30

5.2 7

35

300±30

12

17

63

Encoder adapter

Motor plug

Four,

5.5 dia.

14h6 dia.

70

dia.

50h7 dia.

21

14

dia.

Four, R5.3

60

Chapter 2

34

LL 30

L

D 200-W/300-W/400-W Models with Brake:

R88M-U20030HA-B, R88M-U40030HA-B

R88M-U20030LA-B, R88M-U30030LA-B

300±30

35

5.2 5.5 7

17

34 39.5

LL 30

L

300±30

12

63

60

Encoder adapter

Motor plug

14

Four,

5.5

dia.

14h6 dia.

70 dia.

50h7 dia.

21

dia.

Four, R5.3

60

60

Model L LL

R88M-U20030HA

R88M-U20030LA

R88M-U40030HA

R88M-U30030LA

2-10

Standard Models

126.5 96.5

154.5 124.5

Models with Brake

Model L LL

R88M-U20030HA-B

R88M-U20030LA-B

R88M-U40030HA-B

R88M-U30030LA-B

166 136

194 164

Page 34

System Design and Installation

H AC Servomotors Conforming to UL/cUL Standards and AC

Servomotors Not Conforming to Any Standards (Contd.)

D 750-W Standard Models: R88M-U75030HA

300±30

35

85.2

17

300±30

15

83

Encoder adapter

Motor plug

Four,

7 dia.

21

14 dia.

Chapter 2

Four, R8.2

16h6 dia.

35

34

145 40

185

D 750-W Models with Brake: R88M-U75030HA-B

300±30

35

85.2

17

300±30

15

83

90 dia.

70h7 dia.

Encoder adapter

Motor plug

Four,

7 dia.

80

80

21

14 dia.

Four, R8.2

34 44.5

189.5 40

229.5

16h6 dia.

35

90 dia.

80

70h7 dia.

80

2-11

Page 35

System Design and Installation

H AC Servomotors Conforming to EC Directives

D 30-W/50-W/100-W Standard Models:

R88M-U03030VA-S1, R88M-U05030VA-S1, R88M-U10030VA-S1

R88M-U03030WA-S1, R88M-U05030WA-S1, R88M-U10030WA-S1

14

dia.

Chapter 2

Sh6 dia.

Two, 4.3 dia.

46 dia.

30h7 dia.

Four, R3.7

D 30-W/50-W/100-W Models with Brake:

R88M-U03030VA-BS1, R88M-U05030VA-BS1, R88M-U10030VA-BS1

R88M-U03030WA-BS1, R88M-U05030WA-BS1, R88M-U10030WA-BS1

14

dia.

Sh6 dia.

Two, 4.3 dia.

46 dia.

30h7 dia.

Four, R3.7

Model L LL S

R88M-U03030VA-S1

R88M-U03030WA-S1

R88M-U05030VA-S1

R88M-U05030WA-S1

R88M-U10030VA-S1

R88M-U10030WA-S1

2-12

Standard Models

94.5 69.5 6

102.0 77.0 6

119.5 94.5 8

Models with Brake

Model L LL LB S

R88M-U03030VA-BS1

R88M-U03030WA-BS1

R88M-U05030VA-BS1

R88M-U05030WA-BS1

R88M-U10030VA-BS1

R88M-U10030WA-BS1

126 101 31.5 6

133.5 108.5 31.5 6

160 135 40.5 8

Page 36

System Design and Installation

Chapter 2

H AC Servomotors Conforming to EC Directives (Contd.)

D 200-W/300-W/400-W Standard Models: R88M-U20030VA-S1, R88M-U40030VA-S1

R88M-U20030WA-S1, R88M-U30030WA-S1

14

dia.

Four,

14h6 dia.

50h7 dia.

5.5 dia.

70 dia.

Four, R5.3

D 200-W/300-W/400-W Models with Brake: R88M-U20030VA-BS1,

R88M-U40030VA-BS1, R88M-U20030WA-BS1, R88M-U30030WA-BS1

14

dia.

Four,

14h6 dia.

50h7 dia.

5.5 dia.

70 dia.

Four, R5.3

Standard Models Standard Models

Model L LL

R88M-U20030VA-S1

R88M-U20030WA-S1

R88M-U40030VA-S1

R88M-U30030-WA-S1

126.5 96.5

154.5 124.5

Models with Brake

Model L LL

R88M-U20030VA-BS1

R88M-U20030WA-BS1

R88M-U40030VA-BS1

R88M-U30030WA-BS1

166 136

194 164

2-13

Page 37

System Design and Installation

H AC Servomotors Conforming to EC Directives (Contd.)

D 750-W Standard Models: R88M-U75030VA-S1

14

dia.

Chapter 2

16h6 dia.

D 750-W Models with Brake: R88M-U75030VA-BS1

70h7

Four

90 dia.

dia.

, 7 dia.

Four, R8.2

2-14

16h6 dia.

70h7

90 dia.

dia.

Four

, 7 dia.

14

dia.

Four, R8.2

Page 38

System Design and Installation

H Shaft Dimensions of Motors With Keys

Standard

(produced

model number. Key slots are based on JIS B1301-1976.

D 30-W/50-W Models

Without Brake: R88M-U03030jj-S1, R88M-U05030jj-S1

With Brake: R88M-U03030jj-BS1, R88M-U05030jj-BS1

D 100-W Models

Without Brake: R88M-U10030jj-S1

With Brake: R88M-U10030jj-BS1

U-series AC Servomotors do not have keys on the shafts. The dimensions of motors with keys

on order) are shown below

. Motors with keys are

Dia.:

Dia.:

6h6

8h6

2

2

14

14

indicated by adding “-S1” to the end of the

1.2

1.8

3

Chapter 2

3

D 200-W/300-W/400-W Models

Without Brake: R88M-U20030jj-S1, R88M-U40030jj-S1, R88M-U30030jj-S1

With Brake: R88M-U20030jj-BS1, R88M-U40030jj-BS1, R88M-U30030jj-BS1,

20

Dia.:

14h6

5

3

5

D 750-W Models

Without Brake: R88M-U75030jj-S1,

With Brake: R88M-U75030jj-BS1

30

Dia.:

16h6

3

5

5

2-15

Page 39

É

É

É

É

É

É

É

É

É

É

É

System Design and Installation

Chapter 2

2-1-2 Installation Conditions

H AC Servo Drivers

D Space Around Drivers

• Install

• Mount the Servo Drivers vertically (so that the model number and writing can be read).

Servo Drivers according to the dimensions shown in the following illustration to ensure proper

heat

dispersion

and convection inside the panel. Also install a fan for circulation if Servo Drivers are

installed side by side to prevent uneven temperatures from developing inside the panel.

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

50

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

30 mm min.

ЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙЙ

Fan Fan

Servo Driver

W

W = 10 mm min.

Servo Driver

Servo Driver

W

mm min.

50 mm min.

Side

of

Unit

D Operating Environment

Be sure that the environment in which Servo Drivers are operated meets the following conditions.

• Ambient operating temperature: 0°C to +55°C

• Ambient operating humidity: 35% to 85% (RH, with no condensation)

• Atmosphere: No corrosive gases.

D Ambient Temperature

• Servo Drivers should be operated in environments in which there is minimal temperature rise to

maintain a high level of reliability.

• Temperature

temperature

ent temperature of the Servo Driver from exceeding 55°C.

• Unit

surface temperatures

resistant materials for wiring, and keep separate any devices or wiring that are sensitive to heat.

service life of a Servo Driver is largely determined by the temperature around the internal elec

• The

trolytic

ume

due

capacitors. The service life of an electrolytic capacitor is af

and an increase in internal resistance, which can result in overvoltage alarms, malfunctioning

to noise, and damage to individual elements. If a Servo Driver is

mum ambient temperature of 55°C, then a service life of approximately 50,000 hours can be expected. A drop of 10°C in the ambient temperature will double the expected service life.

2-16

rise in any Unit installed in a closed space, such as a control box, will cause the ambient

to rise inside the entire closed space. Use a fan or a air conditioner to prevent the ambi

may rise to as much as 30°C above the ambient temperature. Use heat-

fected by a drop in electrolytic vol

always operated at the maxi

-

-

-

-

Page 40

System Design and Installation

Chapter 2

D Keeping Foreign Objects Out of Units

• Place

a cover over the Units or take other preventative measures to prevent foreign objects, such as

drill

filings, from getting into the Units during installation. Be sure to

tion is complete. If the cover is left on during operation, heat buildup may damage the Units.

remove the cover after installa

-

• Take

measures during installation and operation to

oil, machining oil, dust, or water from getting inside of Servo Drivers.

prevent foreign objects such as metal particles,

H AC Servomotors

D Operating Environment

Be sure that the environment in which the Servomotor is operated meets the following conditions.

• Ambient operating temperature: 0°C to +40°C

• Ambient operating humidity: 20% to 80% (RH, with no condensation)

• Atmosphere: No corrosive gases.

D Impact and Load

• The

Servomotor is resistant to impacts of up

{98

m/s2}.

during

tion,

tor areas when transporting it.

• Always use a pulley remover to remove pulleys,

couplings, or other objects from the shaft.

• Secure cables so that there is no impact or load placed on the cable connector areas.

Do not subject it to heavy impacts or loads

transport, installation, or positioning. In addi

do not hold onto the encoder

, cable, or connec

to 10 G

-

-

D Connecting to Mechanical Systems

• The

axial loads for Servomotors are specified in sec

tion

5-2-4. If an axial load greater than that

is

applied to a Servomotor

life

of the motor bearings and may damage the motor

shaft.

When connecting to a load, use couplings that

can sufficiently absorb mechanical eccentricity and

variation.

Recommended Coupling

Name Maker

Oldham coupling Myghty Co., Ltd

• For spur gears, an extremely large radial load may

be applied depending on the gear precision. Use

gears with a high

spur

ple,

JIS class 2: normal line pitch error of 6 µm max.

for

a pitch circle diameter of 50 mm). If the gear

sion is not adequate, allow backlash to ensure that

no radial load is placed on the motor shaft.

, it will reduce the service

degree of accuracy (for exam

specified

preci

-

Motor shaft center line

-

Backlash

-

Ball screw center line

Shaft core

displacement

Adjust backlash

by adjusting the

distance between

shafts.

2-17

Page 41

System Design and Installation

• Bevel gears will cause a load to be applied in the

thrust direction depending on the structural precision, the gear precision, and temperature changes.

Provide appropriate backlash or take other measures to ensure that no thrust load is applied which

exceeds specifications.

• Do not put rubber packing on the flange surface. If

the

flange is mounted with rubber packing, the motor

flange may separate due to the tightening strength.

Chapter 2

Bevel gear

Make moveable.

• When

connecting to a V

-belt or timing belt, consult the maker for belt selection and

tension. A radial

load twice the belt tension will be placed on the motor shaft. Do not allow a radial load exceeding

specifications

plied,

the motor shaft may be damaged. Set up

large

radial load may also be applied as a result of belt vibration. Attach a brace and adjust Servo

to be placed on the motor shaft due to belt tension. If an excessive radial load is ap

the structure so that the radial load can be adjusted. A

Driver gain so that belt vibration is minimized.

Belt

Pulley

Tension

Motor shaft

Make adjustable.

Load shaft

D Water and Drip Resistance

• The

Servomotor does not have a

tive structure is covered by the following JEM (The Japan Electrical Manufacturers’ Association)

standards.

Models

Conforming to UL/cUL Standards and Models Not Conforming to Any Standards: IP-42

EC Directive Models: IP-44 (except shaft penetration point)

• If

the Servomotor is used in an environment in which condensation occurs, water may enter inside of

the encoder from

sures

to ensure that water cannot penetrate

machinery

is not in use, water penetration can be avoided by taking measures, such as keeping the

the end surfaces of cables due to motor temperature changes. Either take mea

motor in servo-lock status, to minimize temperature changes.

water-proof structure. Except for the connector areas, the protec

in this way

, or use water-proof connectors. Even when

-

-

-

• If

machining oil with surfactants (e.g., coolant fluids) or their spray penetrate inside of the motor

sulation defects or short-circuiting may occur

. T

ake measures to prevent machining oil

penetration.

D Oil Seals

If

the motor shaft is exposed to oil or grease, use a Servomotor with oil seals (available as special

specification). (Inquire for details.)

2-18

, in

-

Page 42

System Design and Installation

Chapter 2

D Other Precautions

• Do not apply commercial power directly to the Servomotor. The Servomotors run on synchronous

AC and use permanent magnets. Applying 3-phase power will burn out the motor coils.

• Do

not carry or otherwise handle the Servomotor by its cable, otherwise the cable may become dis

connected or the cable clamp may become damaged.

• Take measures to prevent the shaft from rusting. The shafts are coated with anti-rust oil when

shipped, but anti-rust oil or grease should also be applied when connecting the shaft to a load.

-

• Absolutely

are aligned in the Servomotor. If they become misaligned, the motor will not operate.

do not remove the encoder

cover or take the motor apart. The magnet and the encoder

2-19

Page 43

System Design and Installation

Chapter 2

2-2 Wiring Products Conforming to UL/cUL and Wiring

Products Not Conforming to Any Standards

2-2-1 Connecting OMRON Servo Controllers

Use

general-purpose control cables (purchased separately) or Servo Relay Units for the

C200H

trollers.

H Connecting SYSMAC C-series Position Control Units

to connect U-series AC Servomotors and Servo Drivers to OMRON Servo Con

-

SYSMAC C-series

Programmable Controller

Position Control Units for SYSMAC

C-series Programmable Controllers

3G2A5-NC111-EV1

C500-NC113

C500-NC211

C200H-NC112

C200H-NC211

C200HW-NC113

C200HW-NC213

C200HW-NC413

General-purpose Control Cable

R88A-CPUjjjS

OMNUC U-series

AC Servo Driver

Encoder Cable

R88A-CRUjjjC

Note Refer to

2-20

Chapter5 Specifications

Power Cable

R88A-CAUjjjS

R88A-CAUjjjB

OMNUC U-series

AC Servomotor

for connector and cable specifications.

Page 44

System Design and Installation

Chapter 2

H Connecting SYSMAC C200H and C500Position Control Units (Using

Servo Relay Units)

C200H Position

Control Unit (1 axis)

C200H-NC112

Position Control Unit Connecting

Cable (for C200H-NC112)

XW2Z-050J-A1 (0.5 m)

XW2Z-100J-A1 (1 m)

Terminal Connection Unit

(for C200H-NC112)

XW2B-20J6-1B

to

Note 1. Refer

ple for Relay Unit terminal blocks.

Note 2. A Relay Unit is also available for the

CQM1-CPU43-V1, CQM1H-PLB21 (with

pulse I/O capability).

Section

6

for a connection exam

C200H Position

Control Unit (2 axes)

C200H-NC211

C500 Position Control Unit

C500-NC113 (1 axis)

C500-NC211 (2 axes)

Position Control Unit Connecting

Cable (for C200H-NC211 and

C500-NC113/211)

XW2Z-050J-A2 (0.5 m)

XW2Z-100J-A2 (1 m)

Terminal Connection Unit

(for C200H-NC211)

XW2B-40J6-2B

-

Servo Driver Connecting Cable

XW2Z-100J-B1 (1 m)

XW2Z-200J-B1 (2 m)

Note Two cables are required when using the

C200H-NC211, C500-NC211 (two axes).

OMNUC U-series

AC Servo Driver

Power Cable

R88A-CAUjjjS

R88A-CAUjjjB

Encoder Cable

R88A-CRUjjjC

Note Refer to documentation on the XW2B Servo Relay Unit for details.

OMNUC U-series

AC Servomotor

2-21

Page 45

System Design and Installation

Chapter 2

H Connecting SYSMAC C200HX/HG/HE Position Control Units (Using

Servo Relay Units)

SYSMAC C200HX/HG/HE

Position Control Units

C200HW-NC113 (1 axis)

Position Control Unit Connecting

Cable (for C200HW-NC113)

XW2Z-050J-A6 (0.5 m)

XW2Z-100J-A6 (1 m)

Terminal Connection Unit

(for C200H-NC112)

XW2B-20J6-1B

to

Note 1. Refer

ple for Relay Unit terminal blocks.

Note 2. A Relay Unit is also available for the

CQM1-CPU43-V1, CQM1H-PLB21 (with

pulse I/O capability).

Section

6

for a connection exam

SYSMAC C200HX/HG/HE

Position Control Unit

C200HW-NC213 (2 axes)

C200HW-NC413 (4 axes)

Position Control Unit Connecting

Cable (for C200HW-NC213/413)

XW2Z-050J-A7 (0.5 m)

XW2Z-100J-A7 (1 m)

Note Two sets of Relay Units and

Position

ing Cables are required when

using the C200HW-NC413.

Terminal Connection Unit

(for C200H-NC211)

XW2B-40J6-2B

-

Servo Driver Connecting Cable

XW2Z-100J-B1 (1 m)

XW2Z-200J-B1 (2 m)

Note Two cables are required when using the

C200HW-NC213

are required when using the C200HWNC413 (4 axes).

(2 axes) and four cables

Control Unit

Connect

-

OMNUC U-series

AC Servo Driver

Power Cable

R88A-CAUjjjS

R88A-CAUjjjB

Encoder Cable

R88A-CRUjjjC

Note Refer to documentation on the XW2B Servo Relay Unit for details.

2-22

OMNUC U-series

AC Servomotor

Page 46

System Design and Installation

Chapter 2

2-2-2 Connector-Terminal Conversion Unit

The AC Servo Driver can be easily connected to the Connector-Terminal Conversion Unit through a

special cable without soldering.

Controller

XW2B-40F5-P

Connector-Terminal

Conversion Unit

R88A-CTUjjjN

Connector Cable for

Connector-Terminal Conversion Unit

Encoder Cable

R88A-CRUjjjC

Note Refer to

Chapter5 Specifications

OMNUC U-series

AC Servo Driver

Power Cable

R88A-CAUjjjS

R88A-CAUjjjB

OMNUC U-series

AC Servomotor

for connector and cable specifications.

2-23

Page 47

y

gg ( )

System Design and Installation

Chapter 2

2-2-3 Wiring Servo Drivers

Provide proper wire diameters, ground systems, and noise resistance when wiring terminal blocks.

H Wiring Terminal Blocks

Power supply input terminals

Main-circuit DC output terminals

To Motor

Power Cable

R88A-CAUjjjS

R88A-CAUjjjB (with brake)

(The broken lines indicate signal

lines for the brake. There is no

polarity on these lines.)

Terminal

label

R

T

P

N

U

V

W Blue

Name Function

Power supply

input

Main circuit DC The terminals for connecting Regeneration Units (R88A-RG08UA). Connect

output

Motor connection

terminals

Frame ground Green The ground terminal for both the motor output and power supply in-

The commercial power supply input terminals for the main circuit and the

control circuitry.

R88D-UPjjH(A): Single-phase 200/230 VAC (170 to 253 V) 50/60 Hz

R88D-UPjjL(A): Single-phase 100/115 VAC (85 to 127 V) 50/60 Hz1

these terminals when there is a high level of regenerative energy. (See note.)

Red

White

Red

White

Blue

Green

Black

Black

These are the output terminals to the Servomotor. Be careful to wire

them correctly.

put. Ground to a class-3 ground (to 100 Ω or less) or better.

24 VDC

Note Refer

2-24

to

3-8 Regenerative Energy Absorption

for the methods to calculate regenerative energy

.

Page 48

()

System Design and Installation

H Terminal Block Current and Wire Sizes

The

following table shows the rated ef

electrical wires.

D Servo Drivers with 200-VAC Input (R88D-UPjjH(A))

Driver

(Watts)

Power supply input current (R, T)

Motor output current (U, V, W)

Power supply input terminal wire

size

Motor output

terminal wire size

Ground terminal

wire size

Note If

the cable length

tion speeds of 2,500 r/min or higher may drop by approximately 7%.

R88D-UP02H(A)

W)

(30

1.3 A 1.5 A 2.5 A 4.0 A 6.0 A 11.0 A

0.42 A 0.6 A 0.87 A 2.0 A 2.6 A 4.4 A

0.75 mm2 or AWG 18 min. 1.25 mm

0.5 mm2 or AWG 20 AWG 20 (see note) to AWG 18

Use OMRON standard cable. The applicable wire size for motor connectors is AWG22 to AWG18.

Use 2.0-mm2 external ground wires. Use the same wire as used for the motor output.

is 15 meters or longer for a 750-W Servomotor

fective currents flowing to the Servo Driver and the sizes of the

R88D-UP03H(A)

(50 W)

R88D-UP04H(A)

(100 W)

R88D-UP08H(A)

Chapter 2

(200 W)

R88D-UP12H(A)

(400 W)

2

, the momentary maximum torque at rota

R88D-UP20H(A)

(750 W)

2

2.0 mm

-

D Servo Drivers with 100-VAC Input (R88D-UPjjL(A))

Driver model

(Watts)

Power supply input current (R, T)

Motor output current (U,

V, W)

Power supply input terminal wire size

Motor output terminal

wire size

Ground terminal wire

size

R88D-UP03L(A)

(30 W)

2.0 A 2.6 A 4.5 A 8.0 A 10.0 A

0.63 A 0.7 A 2.2 A 2.7 A 3.7 A

0.75 mm2 or AWG 18 min. 1.25 mm

0.5 mm2 or AWG 20 AWG 20 to AWG 18

Use OMRON standard cable. The applicable wire size for motor connectors is AWG22 to

AWG18.

Use 2.0-mm2 external ground wires. Use the same wire as used for the motor output.

R88D-UP04L(A)

(50 W)

R88D-UP10L(A)

(100 W)

R88D-UP12L(A)

(200 W)

2

R88D-UP15LA

(300 W)

2

2 mm

H Wire Sizes and Allowable Current

The

following table shows allowable currents when there are three electrical wires. Use values equal to

or lower than the specified values.

D Heat-resistant Vinyl Wiring, UL1007, Rated Temperature 80°C (Reference Value)

AWG size Nominal cross-

20 0.5 19/0.18 39.5 6.6 5.6 4.5

--- 0.75 30/0.18 26.0 8.8 7.0 5.5

18 0.9 37/0.18 24.4 9.0 7.7 6.0

16 1.25 50/0.18 15.6 12.0 11.0 8.5

sectional area

(mm2)

Configuration

(wires/mm

2

Conductive

)

resistance

(Ω/km)

Allowable current (A) for

ambient temperature

40°C 50°C 60°C

2-25

Page 49

System Design and Installation

Chapter 2

2-2-4 Wiring for Noise Resistance

H Wiring Method

Noise resistance will vary greatly depending on the wiring method used. Resistance to noise can be

increased by paying attention to the items described below.

AC power supply

3.5mm

Class-3 ground

(to 100 Ω or less)

2

Ground

MCCB

Fuse

plate

Surge

absorber

2 mm2min.

Control

ground

board

Noise filter

Controller power supply

123

NF

E

Contactor

X1

4

Servo Driver

R88DUjjjj

TB

R

T

CN2

TB

Metal

U

V

W

Machine

ground

Servomotor

R88MUjjjjjj

duct

M

RE

Thick power line

(3.5 mm

2

)

• Ground the motor’s frame to the machine ground when the motor is on a movable shaft.

a grounding plate for the frame ground for each Unit, as shown in the illustration, and ground to a

• Use

single point.

ground lines with a minimum thickness of 3.5 mm2, and arrange the wiring so that the ground lines

• Use

are as short as possible.

no-fuse breakers (MCCB) are installed at the top and the power supply line is wired from the

• If

duct,