Omron R88M-1 Series, NX1P2-1140DT, R88M-1M10030S, R88D-1SN01L-ECT, NX1P2-1040DT Startup Manual

...Page 1

Machine Automation Controller NJ/NX-series

Startup Guide

for Motion Control

NX1P2-

NX701-

NJ501-

NJ301-

NJ101-

SYSMAC-SE20

R88M-1

R88D-1SN-ECT

W514-E1-02

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Windows is either a registered trademark or a trademark of Microsoft Corporation in the United States and other

countries.

• EtherCAT

• Celeron, Intel, and Intel Core are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other

countries.

• Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Page 3

Introduction

Thank you for purchasing an NJ/NX-series CPU Unit and the Sysmac Studio.

This NJ/NX-series Startup Guide for Motion Control (hereafter referred to as “this Guide”) describes the

startup procedures that are required to use the NJ/NX-series Motion Control Function Module for the

first time and provides operating instructions for the Sysmac Studio. You can follow the procedures that

are given in this Guide to set axis parameters and perform simple one-axis positioning and two-axis linear interpolation. This Guide does not contain safety information and other details that are required for

actual use of an NJ/NX-series Controller. Thoroughly read and understand the manuals for all of the

devices that are used in this Guide to ensure that the system is used safely. Review the entire contents

of these materials, including all safety precautions, precautions for safe use, and precautions for correct

use.

For the startup and operating instructions for NJ/NX-series CPU Units, refer to the NJ/NX-series Star-

tup Guide for CPU Units (Cat. No. W513).

Introduction

Intended Audience

This Guide is intended for the following personnel, who must also have knowledge of electrical systems

(an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

Applicable Products

This Guide covers the following products.

• CPU Units of NJ/NX-series Machine Automation Controllers

• Sysmac Studio Automation Software

Special Information

The icons that are used in this Guide are described below.

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

NJ/NX-series Startup Guide for Motion Control (W514)

1

Page 4

Terms and Conditions Agreement

Terms and Conditions Agreement

CPU Units of NJ/NX-series Machine Automation Controllers

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

2

NJ/NX-series Startup Guide for Motion Control (W514)

Page 5

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NJ/NX-series Startup Guide for Motion Control (W514)

3

Page 6

Terms and Conditions Agreement

Sysmac Studio Automation Software

WARRANTY

• The warranty period for the Software is one year from the date of purchase, unless otherwise specifically agreed.

• If the User discovers defect of the Software (substantial non-conformity with the manual), and

return it to OMRON within the above warranty period, OMRON will replace the Software without

charge by offering media or download from OMRON’s website. And if the User discovers defect of

media which is attributable to OMRON and return it to OMRON within the above warranty period,

OMRON will replace defective media without charge. If OMRON is unable to replace defective

media or correct the Software, the liability of OMRON and the User’s remedy shall be limited to

the refund of the license fee paid to OMRON for the Software.

LIMITATION OF LIABILITY

• THE ABOVE WARRANTY SHALL CONSTITUTE THE USER’S SOLE AND EXCLUSIVE REMEDIES AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. IN NO EVENT, OMRON WILL BE LIABLE FOR ANY

LOST PROFITS OR OTHER INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF USE OF THE SOFTWARE.

• OMRON SHALL HAVE NO LIABILITY FOR DEFECT OF THE SOFTWARE BASED ON MODIFICATION OR ALTERNATION TO THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

• OMRON SHALL HAVE NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

APPLICABLE CONDITIONS

USER SHALL NOT USE THE SOFTWARE FOR THE PURPOSE THAT IS NOT PROVIDED IN

THE ATTACHED USER MANUAL.

CHANGE IN SPECIFICATION

The software specifications and accessories may be changed at any time based on improvements

and other reasons.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however,

no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

4

NJ/NX-series Startup Guide for Motion Control (W514)

Page 7

Precautions

• When building a system, check the specifications for all devices and equipment that will make up the

system and make sure that the OMRON products are used well within their rated specifications and

performances. Safety measures, such as safety circuits, must be implemented in order to minimize

the risks in the event of a malfunction.

• Thoroughly read and understand the manuals for all devices and equipment that will make up the

system to ensure that the system is used safely. Review the entire contents of these materials,

including all safety precautions, precautions for safe use, and precautions for correct use.

• Confirm all regulations, standards, and restrictions that the equipment and devices in the system

must adhere to.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

Precautions

NJ/NX-series Startup Guide for Motion Control (W514)

5

Page 8

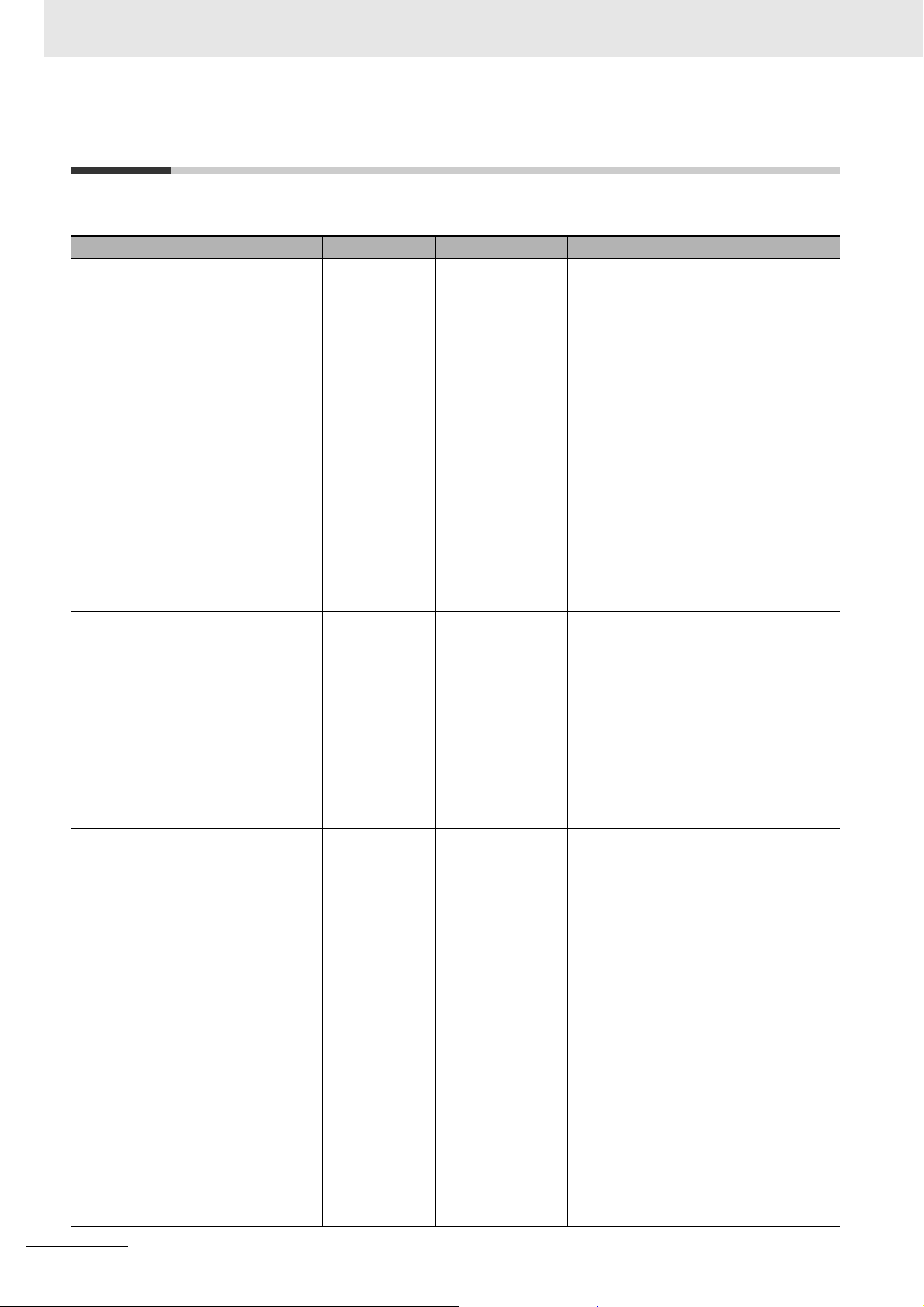

Related Manuals

Related Manuals

The following manuals are related to the NJ/NX-series Controllers. Use these manuals for reference.

Manual name Cat. No. Model Application Meaning

NX-series NX1P2

CPU Unit Hardware User’s

Manual

NX-series

NX1P2 CPU Unit

Built-in I/O and Option Board

User's Manual

NX-series CPU Unit

Hardware User’s Manual

NJ-series CPU Unit Hardware

User’s Manual

NJ/NX-series CPU Unit Software User’s Manual

W578

W579

W535

W500

W501 NX701-

NX1P2-

NX1P2-

NX701-

NJ501-

NJ501-

NJ301-

NJ101-

NX1P2-

Learning the basic

Learning the basic

specifications of the

NX-series NX1P2

CPU Units, including

introductory information, designing, installation, and

maintenance.

Mainly hardware information is provided.

Learning about the

details of functions

only for an NX-series

NX1P2 CPU Unit and

an introduction of

functions for an

NJ/NX-series CPU

Unit.

Learning the basic

specifications of the

NX701 CPU Units,

including introductory

information, designing,

installation, and maintenance.

Mainly hardware information is provided.

specifications of the

NJ-series CPU Units,

including introductory information,

designing, installation, and maintenance.

Mainly hardware

information is provided.

Learning how to program and set up an

NJ/NX-series CPU

Unit.

Mainly software information is provided.

An introduction to the entire NX1P2 CPU Unit

system is provided along with the following

information on the NX1P2 CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Of the functions for an NX1P2 CPU Unit, the

following information is provided.

• Built-in I/O

• Serial Communication Option Boards

• Analog I/O Option Boards

An introduction of following functions for an

NJ/NX-series CPU Unit is also provided.

• Motion control functions

• EtherNet/IP communications functions

• EtherCAT communications functions

An introduction to the entire NX701 system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the NJ/NX-series

CPU Unit Software User’s Manual (Cat. No.

W501).

An introduction to the entire NJ-series system

is provided along with the following information

on a Controller built with an NJ501 CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the NJ/NX-series

CPU Unit Software User’s Manual (Cat. No.

W501).

The following information is provided on a Controller built with an NJ/NX-series CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3 lan-

guage specifications

Use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500).

6

NJ/NX-series Startup Guide for Motion Control (W514)

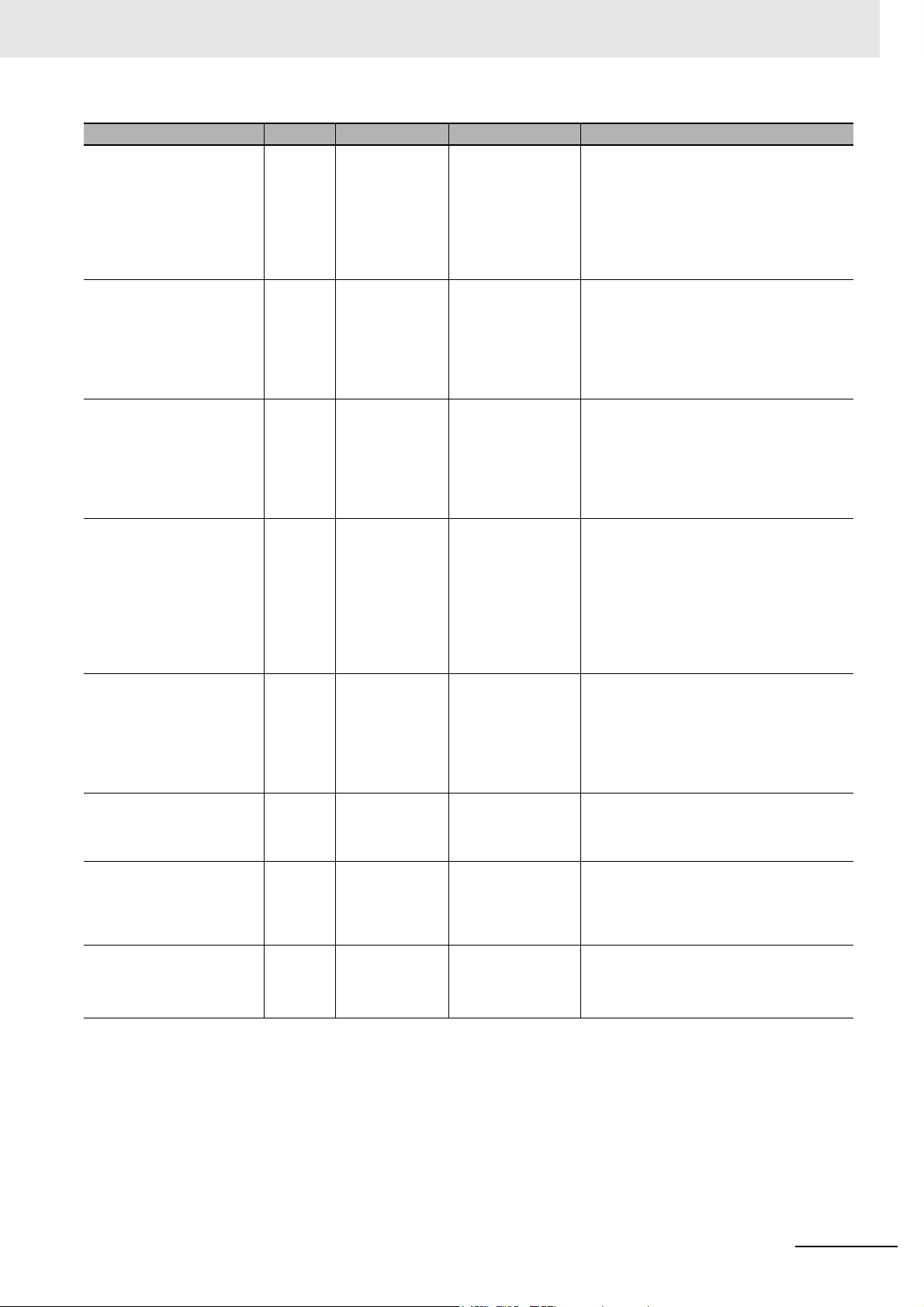

Page 9

Manual name Cat. No. Model Application Meaning

NJ/NX-series CPU Unit Motion

Control User’s Manual

NJ/NX-series Instructions Reference Manual

NJ/NX-series Motion Control

Instructions Reference Manual

NJ/NX-series CPU Unit Builtin EtherCAT® Port U ser’s

Manual

NJ/NX-series Troubleshooting Manual

Sysmac Studio Version 1

Operation Manual

AC Servomotors/Servo Drives

1S-series with Built-in EtherCAT® Communications User’s

Manual

Servo System 1S-series

Startup Guide

W507 NX701-

NJ501-

NJ301-

NJ101-

NX1P2-

W502 NX701-

NJ501-

NJ301-

NJ101-

NX1P2-

W508 NX701-

W505 NX701-

W503 NX701-

W504

I586 R88M-1

I823 R88M-1L/-1M

NJ501-

NJ301-

NJ101-

NX1P2-

NJ501-

NJ301-

NJ101-

NX1P2-

NJ501-

NJ301-

NJ101-

NX1P2-

SYSMAC-SE2

R88D-1SN-ECT

(AC Servomotors)

R88D-1SN-ECT

(AC Servo Drives)

Learning about

motion control settings and programming concepts.

Learning detailed

specifications on the

basic instructions of

an NJ/NX-series CPU

Unit.

Learning about the

specifications of the

motion control

instructions.

Using the built-in

EtherCAT port on an

NJ/NX-series CPU

Unit.

Learning about the

errors that may be

detected in an

NJ/NX-series Controller.

Learning about the

operating procedures and functions

of the Sysmac Studio.

Learning how to use

the Servomotors/Servo Drives

with built-in EtherCAT

Communications.

Gaining a basic

understanding of a

1S-series AC Servomotors/Servo Drives.

The settings and operation of the CPU Unit and

programming concepts for motion control are

described.

When programming, use this manual together

with the NJ/NX-series CPU Unit Hardware

User’s Manual (Cat. No. W500) and NJ/NX-

series CPU Unit Software User’s Manual (Cat.

No. W501).

The instructions in the instruction set (IEC

61131-3 specifications) are described.

When programming, use this manual together

with the NJ/NX-series CPU Unit Hardware

User’s Manual (Cat. No. W500) and NJ/NX-

series CPU Unit Software User’s Manual (Cat.

No. W501).

The motion control instructions are described.

When programming, use this manual together

with the NJ/NX-series CPU Unit Hardware

User’s Manual (Cat. No. W500), NJ/NX-series

CPU Unit Software User’s Manual (Cat. No.

W501) and NJ/NX-series CPU Unit Motion Control User’s Manual (Cat. No. W507).

Information on the built-in EtherCAT port is provided.

This manual provides an introduction and provides information on the configuration, features,

and setup.

Use this manual together with the NJ/NX-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ/NX-series CPU Unit Software

User’s Manual (Cat. No. W501).

Concepts on managing errors that may be

detected in an NJ/NX-series Controller and

information on individual errors are described.

Use this manual together with the NJ/NX-series

CPU Unit Hardware User’s Manual (Cat. No.

W500) and NJ/NX-series CPU Unit Software

User’s Manual (Cat. No. W501).

The operating procedures of the Sysmac Studio are described.

Describes the hardware, setup methods and

functions of the Servomotors/Servo Drives with

built-in EtherCAT Communications.

Describes the procedures for installation and

setup of a 1S-series AC Servo Drive.

Related Manuals

NJ/NX-series Startup Guide for Motion Control (W514)

7

Page 10

Revision History

W514-E1-02

Cat. No.

Revision code

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision

code

01 November 2011 Original production

02 February 2017 Made changes accompanying the addition of NX1P2 CPU Units and

Date Revised content

1S-series AC Servomotors / Servo Drivers

8

NJ/NX-series Startup Guide for Motion Control (W514)

Page 11

Revision History

NJ/NX-series Startup Guide for Motion Control (W514)

9

Page 12

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Intended Audience ...................................................................................................................................... 1

Applicable Products .................................................................................................................................... 1

Special Information ..................................................................................................................................... 1

Terms and Conditions Agreement...........................................................................2

CPU Units of NJ/NX-series Machine Automation Controllers ..................................................................... 2

Warranty, Limitations of Liability ................................................................................................................. 2

Application Considerations ......................................................................................................................... 3

Disclaimers ................................................................................................................................................. 3

Sysmac Studio Automation Software ......................................................................................................... 4

Precautions................................................................................................................5

Software Licenses and Copyrights ............................................................................................................. 5

Related Manuals........................................................................................................6

Revision History........................................................................................................8

Section 1 Features and System Configuration of NJ/NX-series

Controllers and 1S-series AC Servo Systems

1-1 Features of NJ/NX Series and 1S Series ............................................................................... 1-2

1-2 System Configuration and Configuration Devices............................................................... 1-4

1-2-1 Devices Used in This Guide........................................................................................................ 1-4

1-2-2 Configuration of the System Constructed in This Guide .............................................................1-5

Section 2 Before You Begin

2-1 Installing the Sysmac Studio.................................................................................................. 2-2

2-2 Wiring the Devices................................................................................................................... 2-3

2-2-1 Wiring the NX1P CPU Unit Power Supply...................................................................................2-3

2-2-2 Wiring the Servo Drive Power Supply ......................................................................................... 2-3

2-2-3 Laying EtherCAT Communications Cables ................................................................................. 2-4

2-2-4 Wiring the Servo Drives and the Servomotors ............................................................................ 2-5

2-2-5 Wiring the Control Input Signals for the Servo Drives.................................................................2-6

Section 3 Setting Up a Single-axis Servo System

3-1 Single-axis Servo System Operation ..................................................................................... 3-2

3-2 System Setup Procedures ......................................................................................................3-3

3-3 Creating a Project .................................................................................................................... 3-4

3-4 Creating the EtherCAT Network Configuration..................................................................... 3-7

10

3-5 Programming ........................................................................................................................... 3-9

3-5-1 Setting the Axis ...........................................................................................................................3-9

3-5-2 Creating the Program................................................................................................................3-17

3-5-3 Checking the Program .............................................................................................................. 3-27

3-6 Transferring the Project to the CPU Unit ............................................................................. 3-28

NJ/NX-series Startup Guide for Motion Control (W514)

Page 13

CONTENTS

3-7 Confirming System Operation.............................................................................................. 3-32

3-7-1 Checking for Controller Errors .................................................................................................. 3-32

3-7-2 Resetting the Absolute Encoder from the Sysmac Studio ........................................................ 3-35

3-7-3 Checking the Servo Drive Wiring.............................................................................................. 3-38

3-7-4 Checking Program Operation ................................................................................................... 3-44

3-7-5 Using Data Tracing to Check Operation ................................................................................... 3-50

Section 4 Two-axis Linear Interpolation Program

4-1 Two-axis Servo System Operation......................................................................................... 4-2

4-2 System Setup Procedures ......................................................................................................4-3

4-3 Changing the Program............................................................................................................ 4-4

4-3-1 Setting Axis 0 to a Motion Control Axis....................................................................................... 4-4

4-3-2 Adding a Servo Drive to the EtherCAT Network Configuration................................................... 4-5

4-3-3 Adding Axis 1 and Setting an Axes Group.................................................................................. 4-7

4-3-4 Adding Instructions and Checking the Program ....................................................................... 4-15

4-3-5 Transferring the Project to the CPU Unit...................................................................................4-21

4-4 Confirming System Operation.............................................................................................. 4-22

4-4-1 Checking the New Axis 1.......................................................................................................... 4-22

4-4-2 Checking Program Operation ................................................................................................... 4-22

4-4-3 Using Data Tracing to Check Operation ................................................................................... 4-29

Appendices

A-1 Settings When Control Input Signals Are Not Wired ...........................................................A-2

A-2 Using the 3D Motion Trace Display Mode to Check Operation ...........................................A-7

NJ/NX-series Startup Guide for Motion Control (W514)

11

Page 14

12

CONTENTS

NJ/NX-series Startup Guide for Motion Control (W514)

Page 15

1

Features and System Configuration of NJ/NX-series

Controllers and 1S-series AC Servo Systems

This section describes the configuration of the Servo system that is constructed in this

Guide and the products that make up that system.

1-1 Features of NJ/NX Series and 1S Series . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration and Configuration Devices . . . . . . . . . . . . . . . . . . . 1-4

1-2-1 Devices Used in This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-2 Configuration of the System Constructed in This Guide . . . . . . . 1-5

NJ/NX-series Startup Guide for Motion Control (W514)

1-1

Page 16

1 Features and System Configuration of NJ/NX-series Controllers and 1S-series AC Servo

Required substantial time for wiring work.

Any wiring errors also required time to check.

Only one cable: easy connections and no mistakes!

Many cables, high

cost, complicated

ordering, and

many maintenance

materials.

External wiring used

screw-type terminal

blocks, requiring labor

for screw tightening and

periodic re-tightening.

Only one EtherCAT

cable.

Push-in terminal block makes

connections of Servo systems easy.

No need for a relay terminal block.

40

J

6

-

2B

CJ1W

-

21

3/

NC4

13

4

0J6

-

2B

C

J

1

W

-

21

3

/

NC4

13

Traditional System Using Position Control Units

External

wiring

External

wiring

NX1P and 1S Series

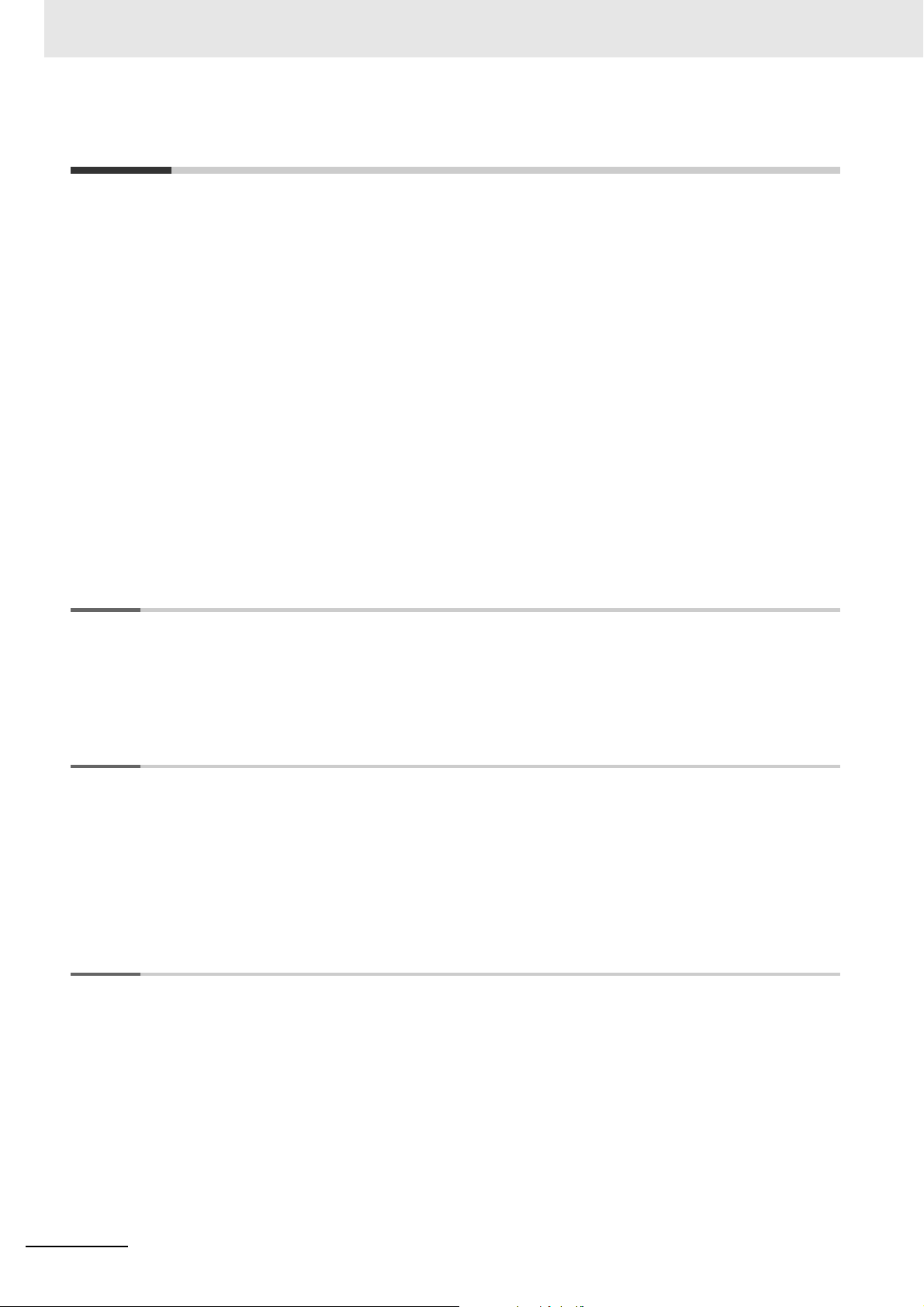

Three software were used for Position Control Unit

settings, ladder programming, and Servo System

settings respectively. You had to create a program while

monitoring and tuning the settings.

The Sysmac Studio, which integrates ladder programming, motion, and configuration, facilitates positioning

control. Simple monitoring and modification!

Servo power ON

Relative

positioning

Distance

Velocity

Acceleration

Deceleration

Ladder + motion

Servo System

Traditional System Using Position Control Units

NX1P and 1S Series

CPU Unit Position Control Unit

User programUser program

NC processorNC processorNC processor

User program

Parameter

Settings

Pulse

output

PLC bus

1-1 Features of NJ/NX Series and 1S Series

The NX/NJ-series Machine Automation Controllers provide advanced motion control previously executed by dedicated controllers or Special Units.

The CPU Units have a built-in EtherCAT port for real-time machine control.

Easy Wiring

Easy Motion Programming

1-2

NJ/NX-series Startup Guide for Motion Control (W514)

Page 17

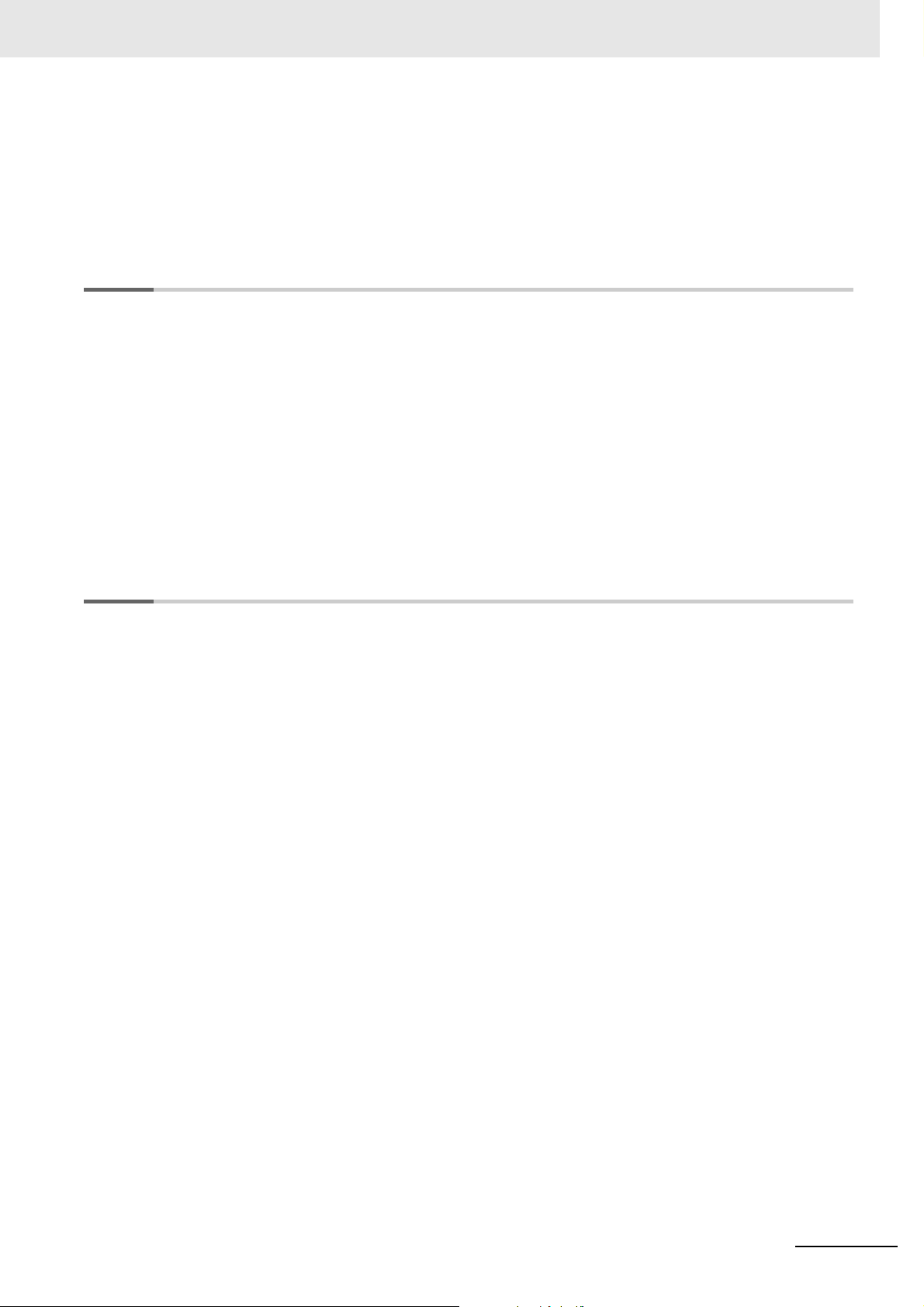

1 Features and System Configuration of NJ/NX-series Controllers and 1S-series AC Servo

The actual equipment was required to check operation

during debugging.

You can check 3D operation at your desk, shortening

on-site debugging time. While viewing the programmed

Servomotor path, you can review operation with the

machine engineers prior to system completion and fix

problems in advance!

Traditional System Using Position Control Units

NX1P and 1S Series

N

1-1 Features of NJ/NX Series

3D Simulation Makes Debugging Easy

and 1S Series

1

Fast Recovery after Power Interruptions with the Standard-feature

Absolute Encoder

After an emergency stop

or power interruption

Traditional Servo System Using Incremental Encoder

Homing operation was required to resume positioning

because home information was cleared.

NX1P and 1S Series

Introducing an absolute encoder to the 1S-series

Servomotor eliminates the need for homing operation,

so you can resume positioning immediately. The

battery-free encoder retains the absolute positions. No

battery, no maintenance!

Homing

1S

1S

1S

NX1P

NJ/NX-series Startup Guide for Motion Control (W514)

1-3

Page 18

1 Features and System Configuration of NJ/NX-series Controllers and 1S-series AC Servo

1-2 System Configuration and Configuration Devices

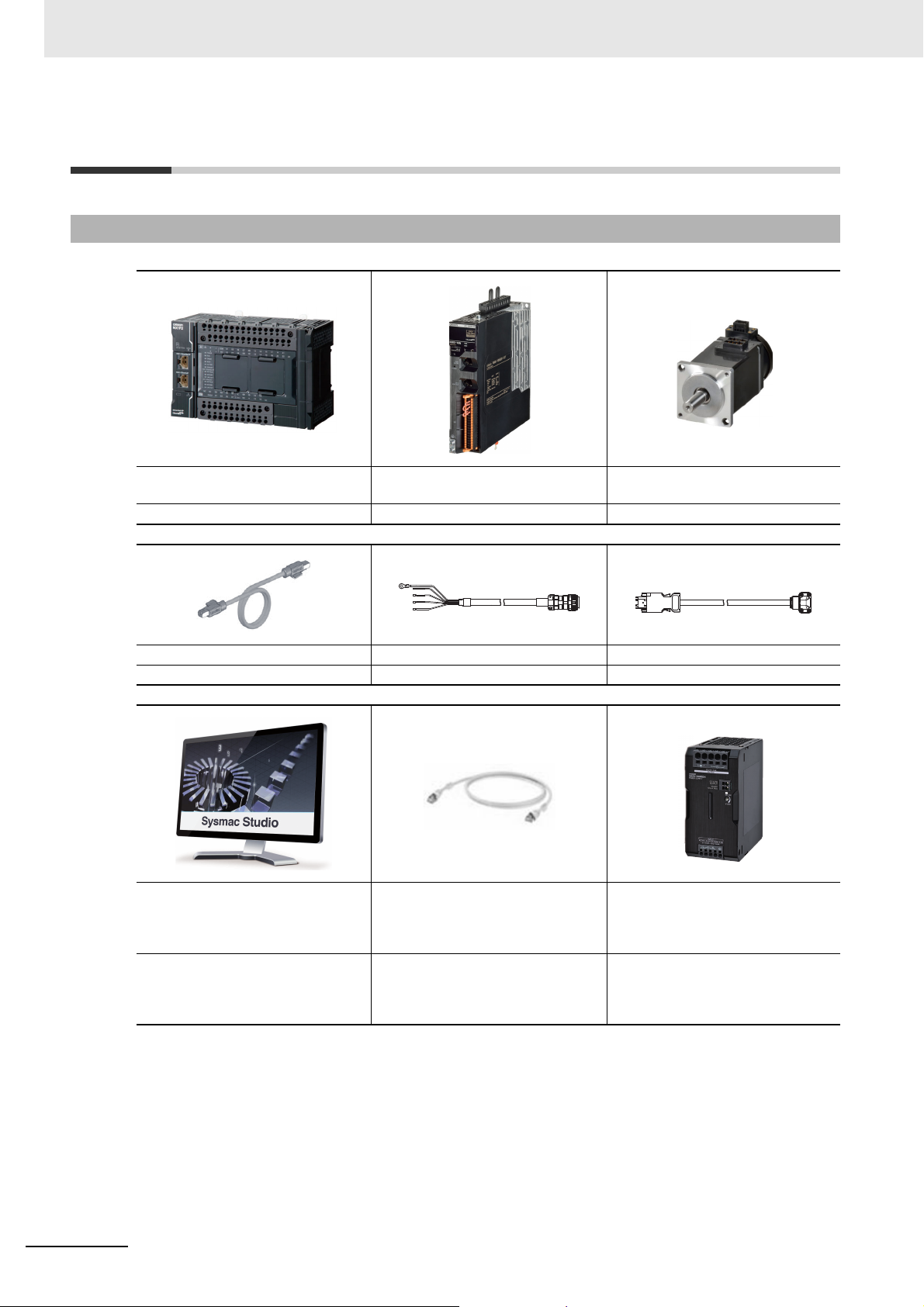

1-2-1 Devices Used in This Guide

NX1P

Machine Automation Controller

1S-series AC Servo Drive 1S-series AC Servomotor

NX1P2-1140DT R88D-1SN01L-ECT R88M-1M10030S

EtherCAT Communications Cable Motor Power Cable Encoder Cable

XS5W-T421-MD-K R88A-CA1A003S R88A-CR1A003C

Sysmac Studio

Automation Software

Standard Edition

Ethernet Cable

(100BASE-TX/10BASE-T)

24 VDC Power Supply

Version 1.17 or higher

SYSMAC-SE200D

(Media only)

SYSMAC-SE201L

--- Example: S8VK-S

(One license)

1-4

NJ/NX-series Startup Guide for Motion Control (W514)

Page 19

1 Features and System Configuration of NJ/NX-series Controllers and 1S-series AC Servo

RUN

E

R

R

I

N

L

/

A

R

88

D-1

S

N

L

/

A

FS

OU

T

E

th

e

r

CA

T

RUN

E

R

R

I

N

L

/

A

R88

D-1

S

N

L

/

A

FS

OU

T

E

th

e

r

CA

T

Sysmac Studio

Ethernet Cable

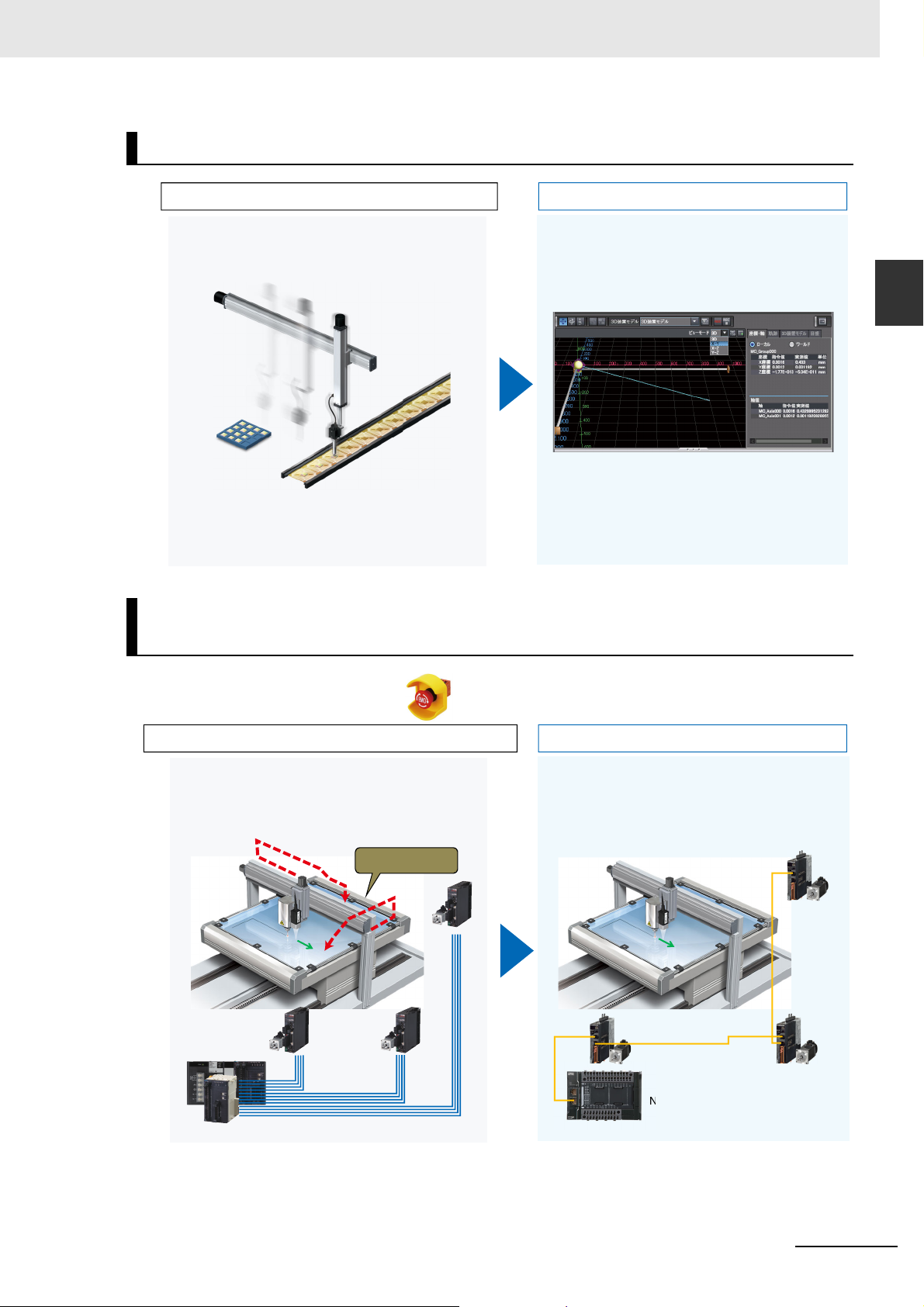

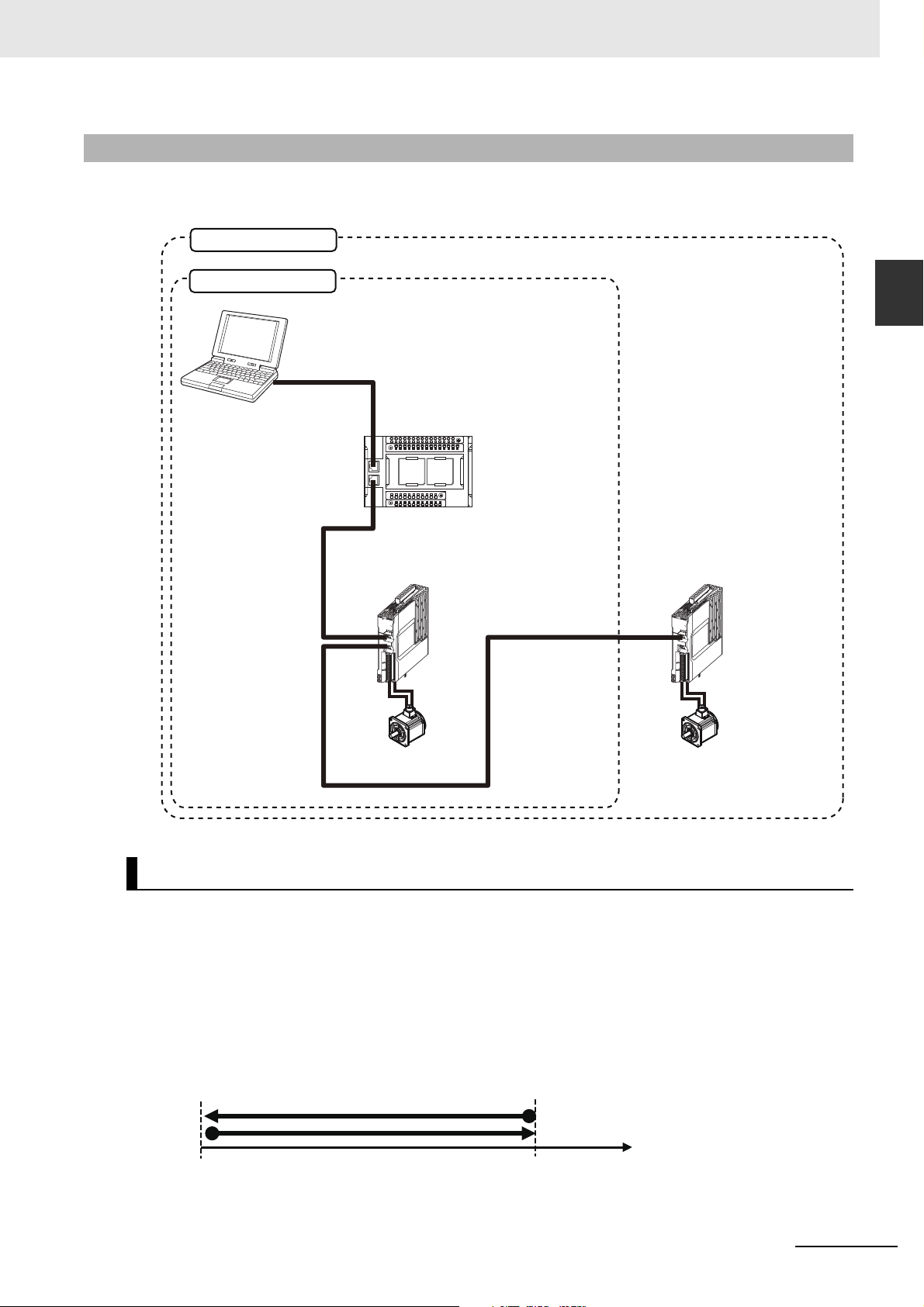

Two-axis Servo System

Single-axis Servo System

NX1P2-1140DT

CPU Unit

R88D-1SN01L-ECT Servo Drive (1st Drive)

Node Address 1 (Axis 0)

R88M-1M10030S

Servomotor

R88D-1SN01L-ECT Servo Drive

(2nd Drive)

Node Address 2

(Axis 1)

R88M-1M10030S Servomotor

EtherCAT communications cables

Section 4 Two-axis Linear Interpolation Program

Section 3 Setting Up a Single-axis Servo System

1-2-2 Configuration of the System Constructed in This Guide

This NJ/NX-series Startup Guide for Motion Control (hereafter referred to as "this Guide") builds the

Servo system in the following two steps.

1-2 System Configuration and

Configuration Devices

1

1-2-2 Configuration of the System Constructed in This Guide

Single-axis Servo System

This system performs single-axis positioning using a Servo Drive and Servomotor for one axis. The

steps from device wiring to software design and debugging are described.

Device connections are described in Section 2 Before You Begin, and software design and debugging

are described in Section 3 Setting Up a Single-axis Servo System.

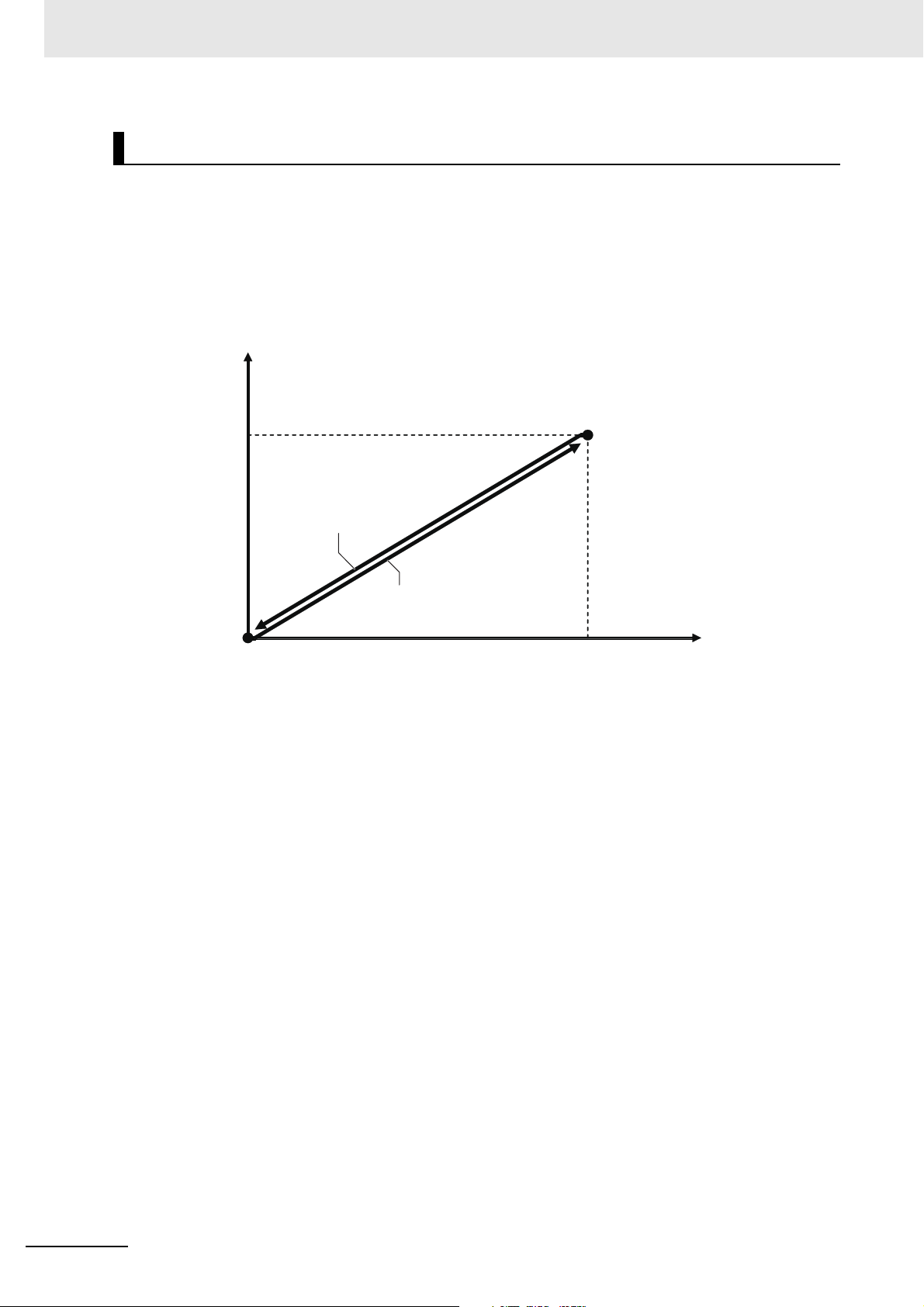

Positioning example:

Single-axis positioning

Velocity : 10.000 mm/s

Acceleration rate : 200.000 mm/s

Deceleration rate : 200.000 mm/s

Axis 0

2

2

0.000 mm 20.000 mm

NJ/NX-series Startup Guide for Motion Control (W514)

1-5

Page 20

1 Features and System Configuration of NJ/NX-series Controllers and 1S-series AC Servo

Axis 0

800.000 mm X

600.000 mm

Linear 2

Linear 1

Y

0.000 mm

0.000 mm

Axis 1

Interpolation velocity : 200.000 mm/s

Acceleration rate : 400.000 mm/s

2

Deceleration rate : 400.000 mm/s

2

Two-axis Servo System

This system performs linear interpolation using Servo Drives and Servomotors for two axes. The steps

from device wiring to software design and debugging are described.

Device connections are described in Section 2 Before You Begin, and software design and debugging

are described in Section 4 Two-axis Linear Interpolation Program.

The NX1P2-9024DT/-9024DT1 cannot be used in this linear interpolation example.

Use the NX1P2-1040DT/-1040DT1, NX1P2-1140DT/-1140DT1, NJ-series CPU Unit, or NX7 CPU Unit.

Positioning example:

1-6

NJ/NX-series Startup Guide for Motion Control (W514)

Page 21

Before You Begin

This section describes the installation of the Sysmac Studio and the process of assembling and wiring the hardware.

2-1 Installing the Sysmac Studio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Wiring the Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2-1 Wiring the NX1P CPU Unit Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2-2 Wiring the Servo Drive Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2-3 Laying EtherCAT Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-2-4 Wiring the Servo Drives and the Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-2-5 Wiring the Control Input Signals for the Servo Drives . . . . . . . . . . . . . . . . . . . 2-6

2

NJ/NX-series Startup Guide for Motion Control (W514)

2-1

Page 22

2 Before You Begin

Additional Information

Precautions for Correct UsePrecautions for Correct Use

2-1 Installing the Sysmac Studio

The Sysmac Studio is the Support Software that you use for an NJ/NX-series Controller. On it, you can

create the Controller configuration and settings, you can write the programs, and you can debug and

simulate operation.

Use the following procedure to install the Sysmac Studio.

1

Set the Sysmac Studio installation disk into the DVD-ROM drive.

The setup program is started automatically and the Select Setup Language Dialog Box is displayed.

2

Select the language to use, and then click the OK Button.

The Sysmac Studio Setup Wizard is started.

3

Follow the instructions given by the Setup Wizard to complete the installation.

4

Restart the computer when the installation is completed.

• The system requirements for the Sysmac Studio are given in the following table.

OS CPU RAM Display

Windows 7

(32-bit or 64-bit edition)

Windows 8

(32-bit or 64-bit edition)

Windows 8.1

(32-bit or 64-bit edition)

Windows 10

(32-bit or 64-bit edition)

• Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) if you are unable to

install the Sysmac Studio with the above instructions.

If CX-One version 4 or lower is installed, the installation is cancelled and the Sysmac Studio cannot be installed. In that case, uninstall the CX-One before you install the Sysmac Studio.

Minimum

Recommended

IBM AT or compatible with

®

Celeron® processor

Intel

540 (1.8 GHz)

IBM AT or compatible with

®

CoreTM i5 M520 pro-

Intel

cessor (2.4 GHz) or the

equivalent

2 GB XGA 1,024 768,

16 million colors

4 GB

min.

WXGA 1,280 800,

16 million colors

2-2

NJ/NX-series Startup Guide for Motion Control (W514)

Page 23

2-2 Wiring the Devices

24 VDC

+ −

Servo Drive

Protection

element

Noise filter

Servomotor

U

V

W

EncoderEncoder

L1

L2

L3

24V

0V

U

V

W

This section describes how to wire the assembled the hardware devices.

This section gives an overview of the wiring procedures. Refer to the manuals for the devices that are

used in the system for detailed wiring procedures and safety precautions.

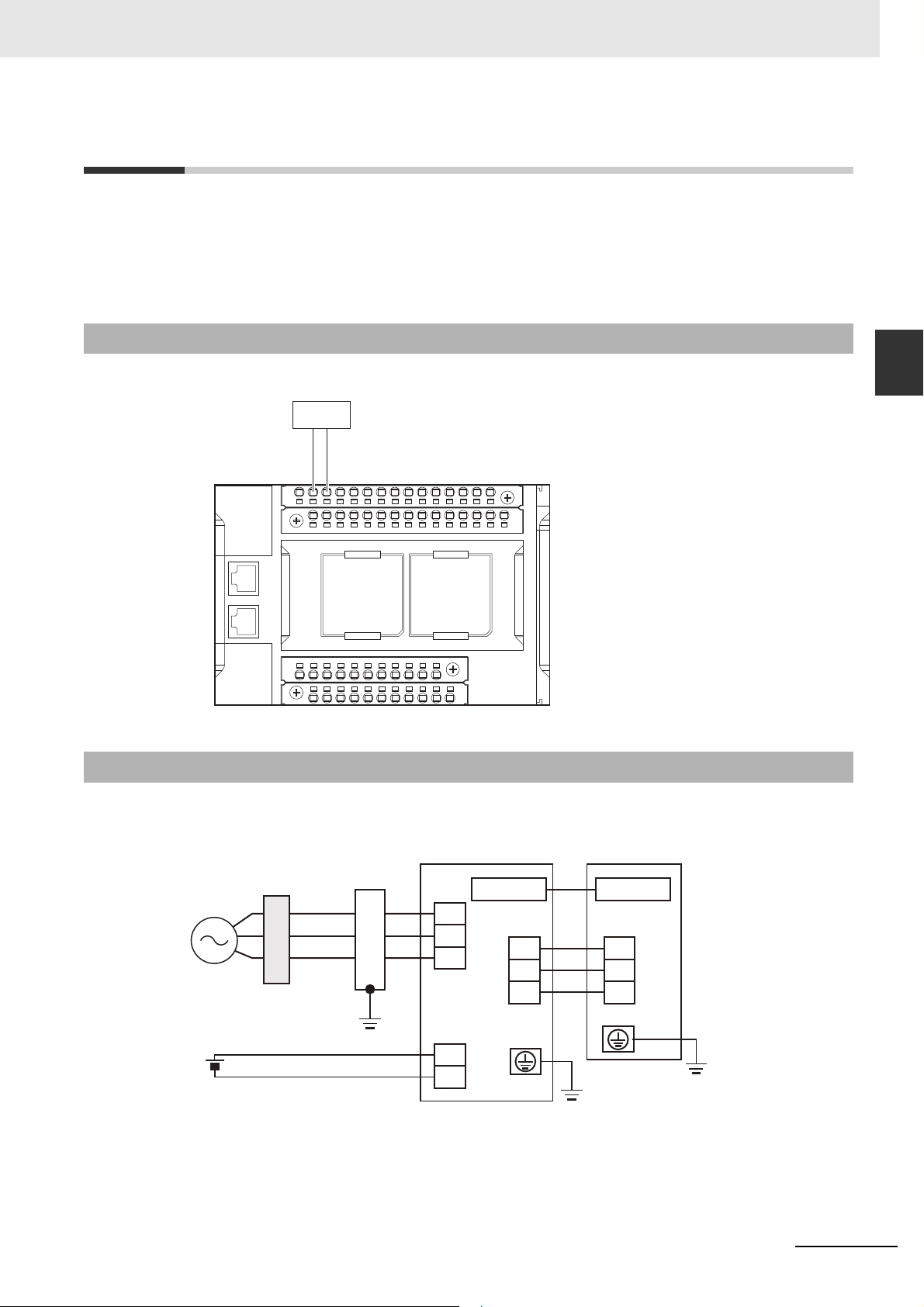

2-2-1 Wiring the NX1P CPU Unit Power Supply

Wire the CPU Unit to the DC power supply.

2 Before You Begin

2-2 Wiring the Devices

2

2-2-1 Wiring the NX1P CPU Unit Power Supply

2-2-2 Wiring the Servo Drive Power Supply

Wire the Servo Drives to the power supply as shown in the following figure.

NJ/NX-series Startup Guide for Motion Control (W514)

2-3

Page 24

2 Before You Begin

RUN INOUT

FS

L/A L/A

ERR

RUN INOUT

FS

L/A L/A

ERR

Built-in EtherCAT port

Built-in EtherNet/IP port

NX-series NX1P2 CPU Unit

First Servo Drive

Second Servo Drive

Connector IN port for

EtherCAT communications

Connector OUT port for

EtherCAT communications

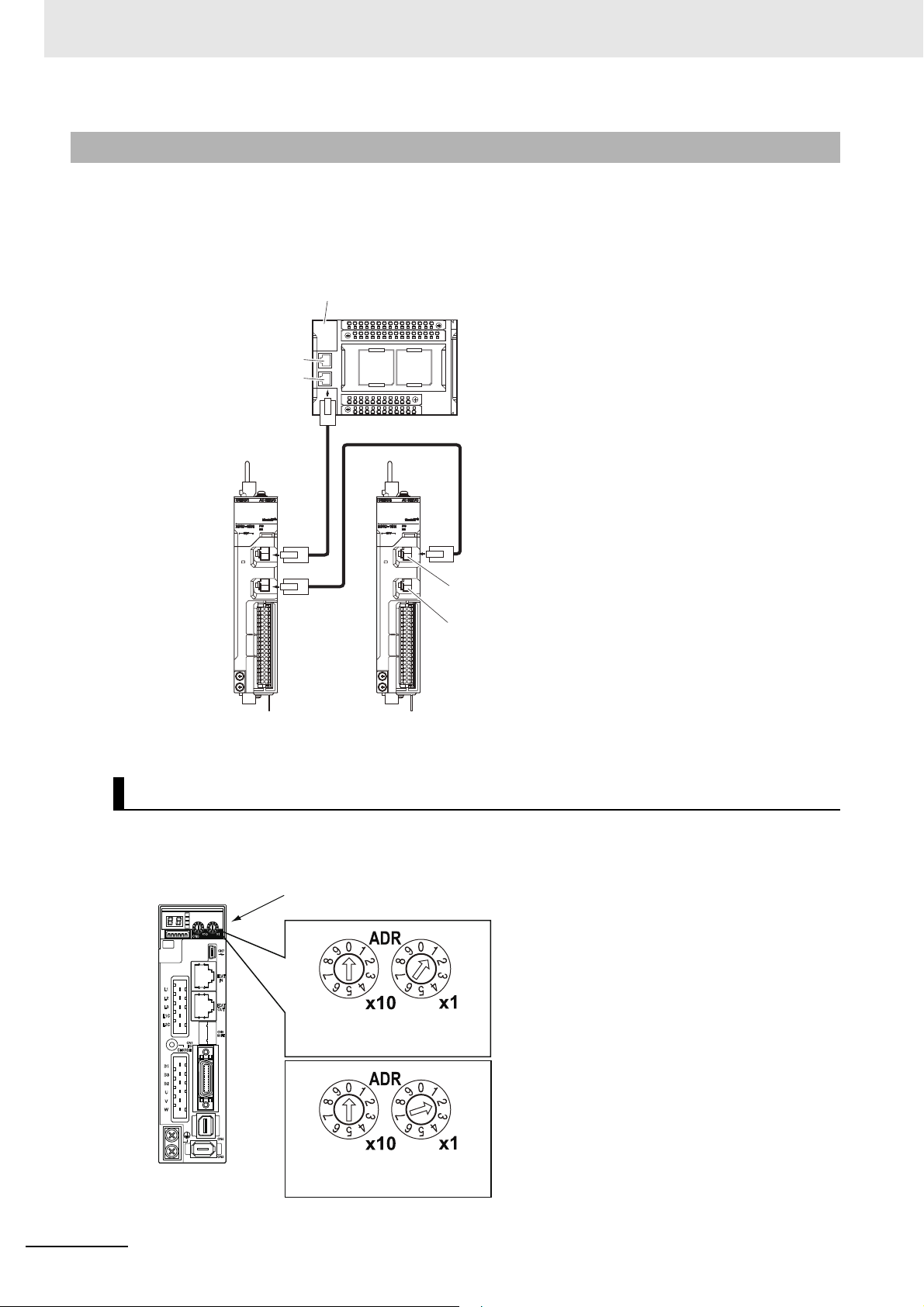

2-2-3 Laying EtherCAT Communications Cables

Connect the EtherCAT slave communications cables between the built-in EtherCAT port on the CPU

Unit and the EtherCAT slaves as shown in the following figure.

Connect the communications cable from the built-in EtherCAT port to the input port on the first slave,

and then connect the communications cable to the next slave to the output port on the first slave.

Do not connect anything to the output port of the slave at the end of the network.

Setting the Node Addresses of the Servo Drives

Set the node addresses of the Servo Drives as shown below.

Only the first Servo Drive is used in Section 3 Setting Up a Single-axis Servo System.

The second Servo Drive is added in Section 4 Two-axis Linear Interpolation Program.

Rotary switches for setting

ADR

the node address

10s digit

Set to 0. Set to 1.

10s digit

Set to 0. Set to 2.

First Servo Drive

1s digit

Second Servo Drive

1s digit

2-4

NJ/NX-series Startup Guide for Motion Control (W514)

Page 25

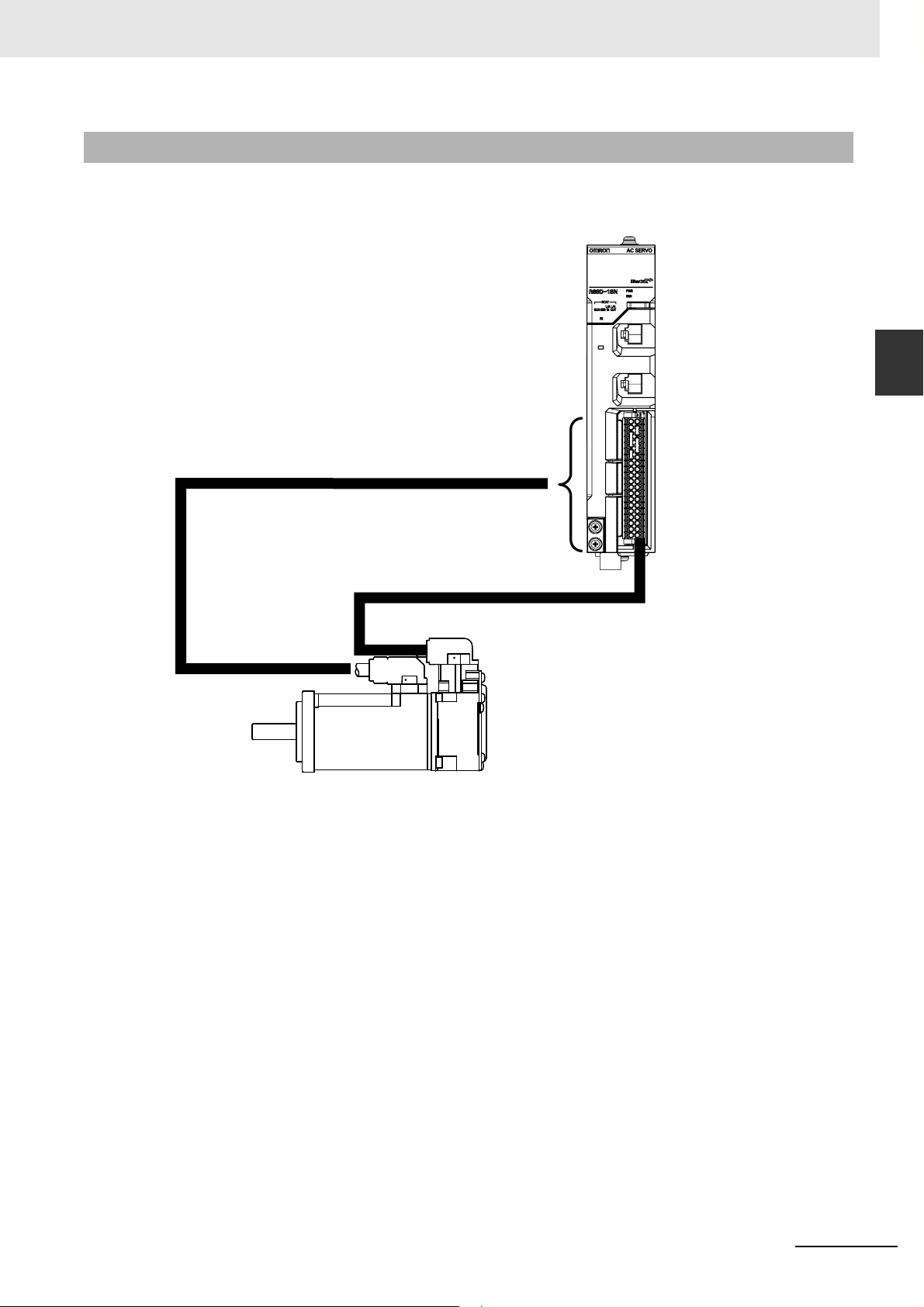

2-2-4 Wiring the Servo Drives and the Servomotors

Motor Power Cable

R88A-CA1A003S

Servomotor

Encoder Cable

R88A-CR1A003C

Servo Drive

2 Before You Begin

Wire the Servo Drives and the Servomotors as shown in the following figure.

2-2 Wiring the Devices

2

2-2-4 Wiring the Servo Drives and the Servomotors

NJ/NX-series Startup Guide for Motion Control (W514)

2-5

Page 26

2 Before You Begin

Additional Information

CN7

ID

x1

x16

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

9

A

B

C

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

9

A

B

C

Main circuit connector (CNA)

terminal

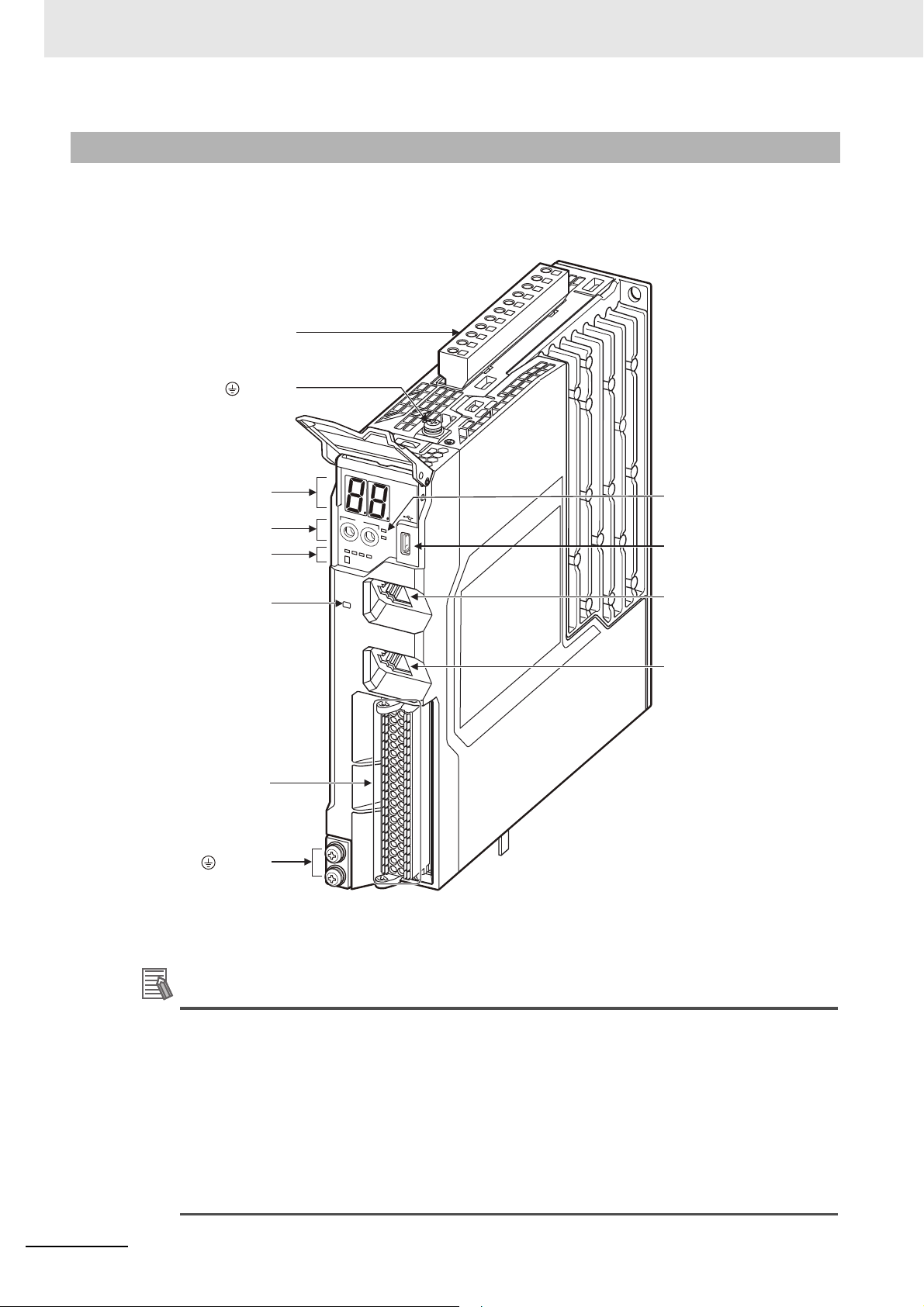

7-segment LED display

ID switches

Status indicators

Charge lamp

Control I/O connector

(CN1)*1

terminal

Status indicators

USB connector (CN7)

EtherCAT communications

connector

(ECAT IN CN10)

EtherCAT communications

connector

(ECAT OUT CN11)

2-2-5 Wiring the Control Input Signals for the Servo Drives

Wire the control input signals for the Servo Drive using the R88A-CN101C Control I/O connector (CN1).

For details on wiring, refer to the AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT Com-

munications User's Manual (Cat. No. I586).

*1 Control I/O Connector (CN1):

Used for command input signals, I/O signals, and as the safety device connector. The short-circuit wire is

installed on the safety signals before shipment.

• If you use the default Servo parameters, you must wire the immediate stop input, negative

drive prohibit input, and the positive drive prohibit input.

If these inputs are not wired, the CPU Unit will remain in the drive prohibit signal and emergency stop signal detected state, and a minor fault level Controller error will occur. The minor

fault level Controller errors that will occur are an Immediate Stop Input Error and a Drive Prohibition Input Error. (The event codes are 68220000 and 64E30000.)

• If the above signals are temporarily not wired while commissioning the system, you can temporarily change the Servo parameters to prevent these errors from occurring in the CPU Unit.

Refer to A-1 Settings When Control Input Signals Are Not Wired for details on the settings that

you must change in this case.

2-6

NJ/NX-series Startup Guide for Motion Control (W514)

Page 27

Setting Up a Single-axis Servo

System

This section describes the procedures and operations required to set up a Servo system for one axis.

3-1 Single-axis Servo System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 System Setup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 Creating a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-4 Creating the EtherCAT Network Configuration . . . . . . . . . . . . . . . . . . . . . . 3-7

3-5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-5-1 Setting the Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-5-2 Creating the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-5-3 Checking the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3-6 Transferring the Project to the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3-7 Confirming System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3-7-1 Checking for Controller Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3-7-2 Resetting the Absolute Encoder from the Sysmac Studio . . . . . . . . . . . . . . . 3-35

3-7-3 Checking the Servo Drive Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3-7-4 Checking Program Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

3-7-5 Using Data Tracing to Check Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

3

NJ/NX-series Startup Guide for Motion Control (W514)

3-1

Page 28

3 Setting Up a Single-axis Servo System

Velocity

Position after traveling

in the positive direction

Position after traveling

in the negative direction

Operation of Axis 0 (Node Address 1)

The operation is repeated.

Time

Positive direction

Negative direction

Travel distance: −20.000 mm

Speed: 10.000 mm/s

Acceleration rate: 200.000 mm/s

2

Deceleration rate: 200.000 mm/s

2

Travel distance: 20.000 mm

Speed: 10.000 mm/s

Acceleration rate: 200.000 mm/s

2

Deceleration rate: 200.000 mm/s

2

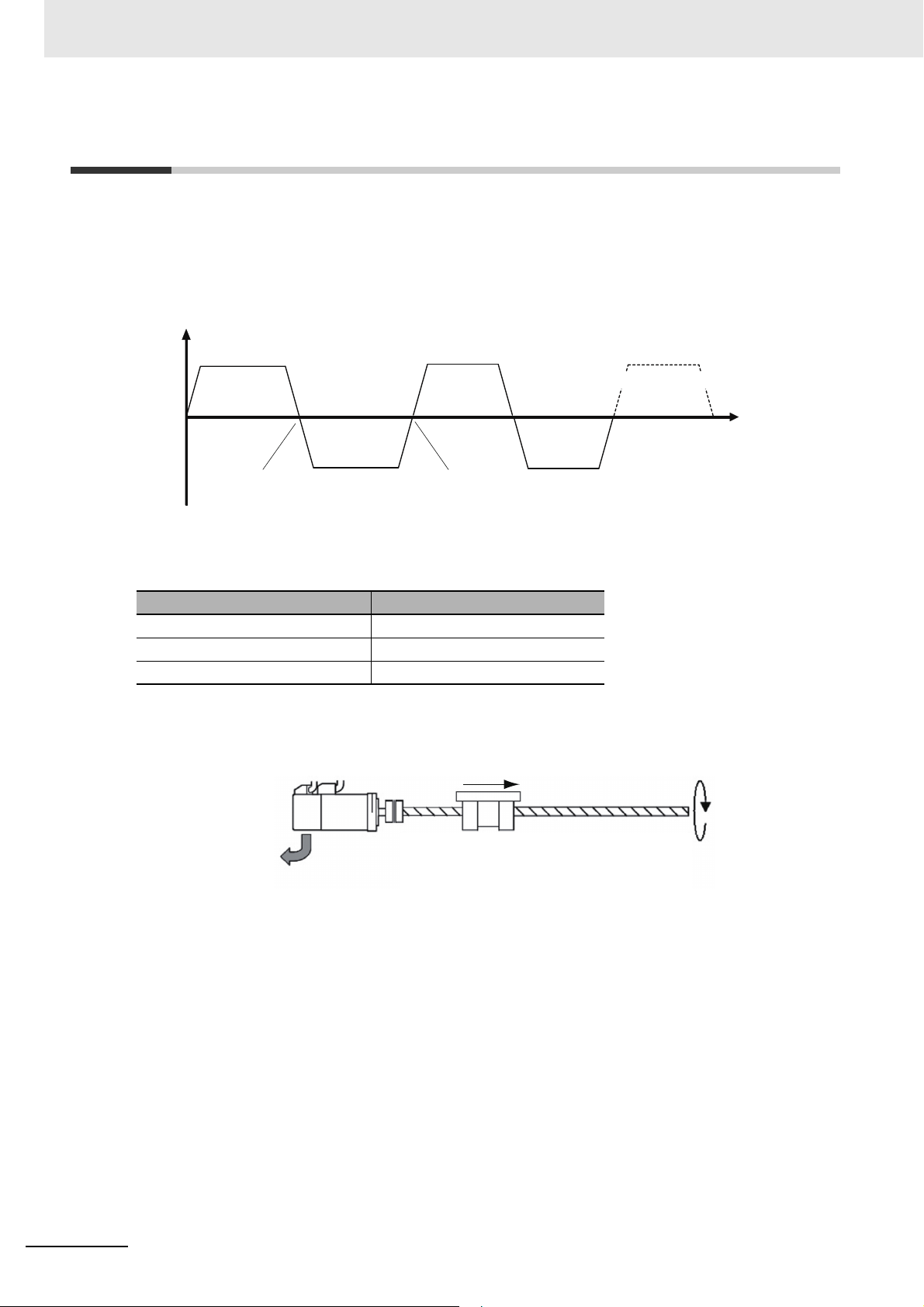

3-1 Single-axis Servo System Operation

This section describes the operation of the single-axis Servo system that is set up in this Guide.

Axis 0 performs alternating single-axis positioning in the positive and negative directions.

The mechanical configuration of axis 0 is as shown in the following table.

Item Axis 0 mechanical configuration

Motor rated speed 3,000 r/min

Ball screw pitch 10.000 mm

Encoder resolution 23 bits/rotation

Servomotor

Encoder resolution: 23 bits/rotation

Rated speed: 3,000 r/min

Command pulse count per motor rotation

23 bits = 8,388,608

10 mm

Ball screw

Ball screw pitch: 10 mm

1 rotation

3-2

NJ/NX-series Startup Guide for Motion Control (W514)

Page 29

3 Setting Up a Single-axis Servo System

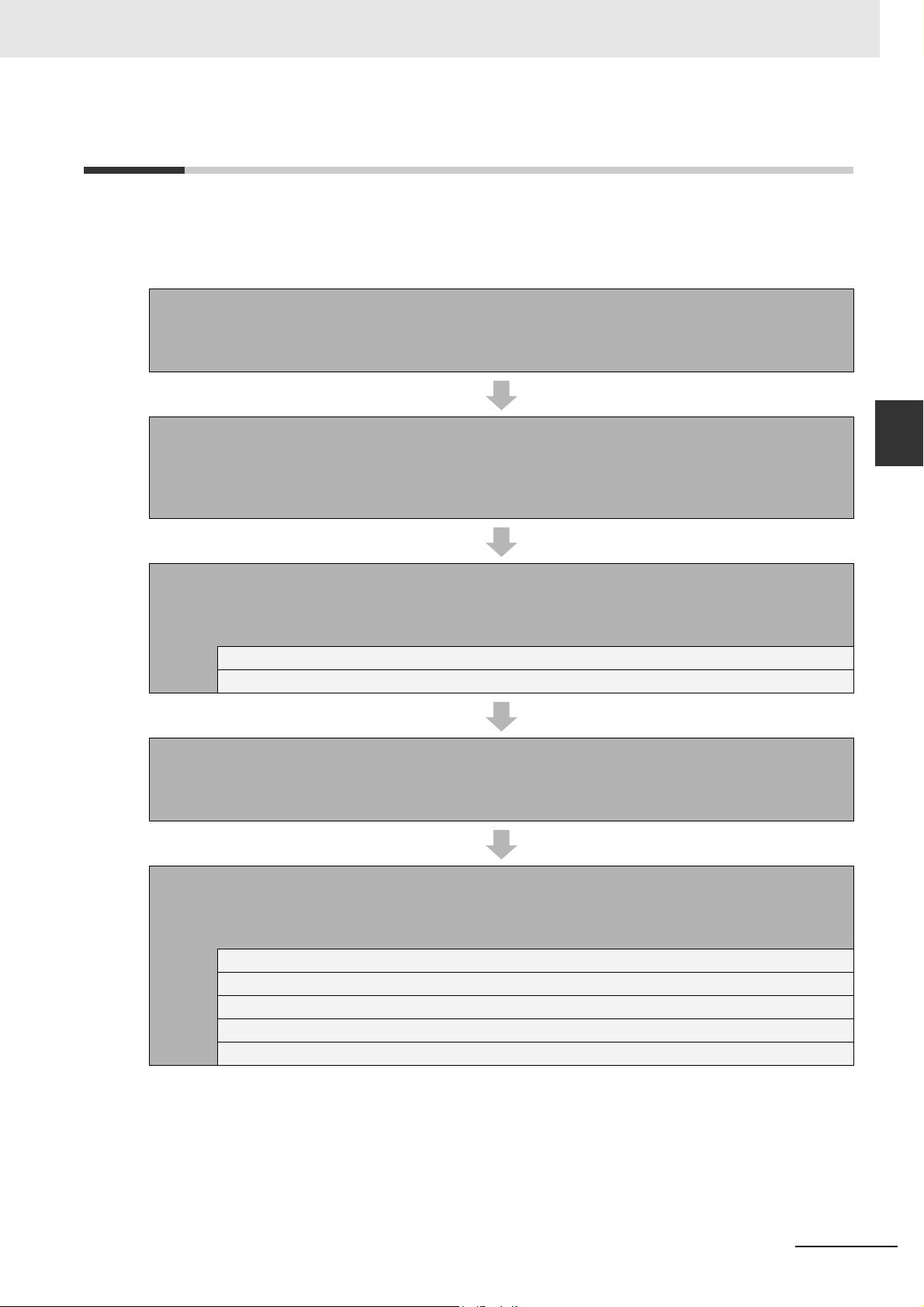

3-2 System Setup Procedures

The basic design flow to follow to design a Servo system is shown below.

The startup operations in this Guide are described in the following steps.

STEP 1. Create a Project (page 3-4)

Create a project file.

STEP 2. Create the EtherCAT Network Configuration (page 3-7)

Create the EtherCAT slave configuration that will connect to the CPU Unit’s built-in EtherCAT port.

STEP 3. Start Programming (page 3-9)

Register an axis variable and create and check the POU program.

STEP 3-1 Set the axis (page 3-9).

STEP 3-2 Create the program (page 3-17) and check the program (page 3-27).

3-2 System Setup Procedures

3

STEP 4. Transfer the Project to the CPU Unit (page 3-28)

Transfer the project, which contains the user program, to the CPU Unit.

STEP 5. Confirm System Operation (page 3-32)

Perform a check to test system operation. (Use online debugging.)

STEP 5-1 Check for Controller errors (page 3-32).

STEP 5-2 Reset the Absolute Encoder from the Sysmac Studio (page 3-35).

STEP 5-3 Check the Servo Drive wiring (page 3-38).

STEP 5-4 Check program operation (page 3-44).

STEP 5-5 Use data tracing to check operation (page 3-50).

NJ/NX-series Startup Guide for Motion Control (W514)

3-3

Page 30

3 Setting Up a Single-axis Servo System

3-3 Creating a Project

Start the Sysmac Studio and create a project.

Starting the Sysmac Studio

Use one of the following methods to start the Sysmac Studio.

• Double-click the Sysmac Studio shortcut icon on your desktop.

• Select All Programs

OMRON Sysmac Studio Sysmac Studio from the Windows Start Menu.

The Sysmac Studio starts and the following window is displayed.

3-4

NJ/NX-series Startup Guide for Motion Control (W514)

Page 31

Creating a Project

Create a project in the Sysmac Studio.

1

Click the New Project Button in the Project Window.

Click the Button.

3 Setting Up a Single-axis Servo System

3-3 Creating a Project

3

2

In the Project Properties Dialog Box, select NXP12-1140DT in the Device Box and the version

to use in the Version Box, and then click the Create Button.

• Select the following device:

NXP12-1140DT

• Select the version you will use.

Click the Button.

A project file is created and the following window is displayed.

This concludes the procedure to create a project file.

NJ/NX-series Startup Guide for Motion Control (W514)

3-5

Page 32

3 Setting Up a Single-axis Servo System

Programming

Header

Configurations

and Setup Header

(1)

(7)

(6)

(5)(4)

(3)

(10) (11) (12) (13)(9)(8)

(2)

Menu bar

Toolbar

Status Bar

Parts of the Window

This section gives the names and functions of the parts of the Sysmac Studio Window.

No. Name

(1) Multiview Explorer This pane is your access point for all Sysmac Studio data. It is separated

into Configurations and Setup and Programming Layers.

(2) Filter Pane The Filter Pane allows you to search for color codes and for items with an

error icon. The results are displayed in a list.

(3) Edit Pane The Edit Pane is used to display and edit the data for any of the items.

It is separated into Configurations and Setup and Programming Layers.

(4) Toolbox The Toolbox shows the objects that you can use to edit the data that is

displayed in the Edit Pane.

(5) Search and Replace Pane In this pane, you can search for and replace strings in the data in the Pro-

gramming Layer.

(6) Controller Status Pane The Controller Status Pane shows the current operating status of the

Controller. The Controller Status Pane is displayed only while the Sysmac

Studio is online with the Controller.

(7) Simulation Pane The Simulation Pane is used to set up, start, and stop the Simulator for

the Controller.

(8) Cross Reference Tab Page A Cross Reference Tab Page displays a list of where variables, data

types, I/O ports, functions, and function blocks are used in the Sysmac

Studio.

(9) Output Tab Page The Output Tab Page shows the results of building.

(10) Watch Tab Page The Watch Tab Page shows the monitor results of the Simulator or online

Controller.

(11) Build Tab Page The Build Tab Page shows the results of program checks and building.

(12) Search and Replace Results

Tab Page

(13) Differential Monitor Tab Page You can detect the number of times the specified BOOL variable or mem-

The Search and Replace Results Tab Page shows the results when

Search All or Replace All is executed.

ber changes to TRUE or FALSE and display the count in this tab page.

3-6

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for details on the Sysmac

Studio panes and tab pages.

NJ/NX-series Startup Guide for Motion Control (W514)

Page 33

3 Setting Up a Single-axis Servo System

3-4 Creating the EtherCAT Network

Configuration

A R88D-1SN01L-ECT Servo Drive is registered in the EtherCAT network configuration to operate as

axis 0.

1

Double-click EtherCAT under Configurations and Setups in the Multiview Explorer.

3-4 Creating the EtherCAT Network Configuration

3

The EtherCAT Tab Page is displayed in the Edit Pane.

NJ/NX-series Startup Guide for Motion Control (W514)

3-7

Page 34

3 Setting Up a Single-axis Servo System

Additional Information

2

Drag the R88D-1SN01L-ECT from the Toolbox to the master on the EtherCAT Tab Page.

The Servo Drive is added under the master with a node address of 1.

This concludes the creation of the EtherCAT network configuration.

If the physical EtherCAT network configuration is already connected, you can automatically create the virtual network configuration in the Sysmac Studio based on the physical network configuration.

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for specific proce-

dures.

3-8

NJ/NX-series Startup Guide for Motion Control (W514)

Page 35

3-5 Programming

In this section we will create the user program.

A Servo axis for axis 0 will be added and set up, and a program will be created to control the Servo

Drive.

3-5-1 Setting the Axis

This section describes how to add the axis that is used to control the Servo Drive, assign it to the Servo

Drive, and set the axis parameters. In this example, the Control Function of the axis to add is set to Single-axis Position Control Axis in order to perform single-axis position control.

3 Setting Up a Single-axis Servo System

3-5 Programming

3

3-5-1 Setting the Axis

Adding the Axis Settings

Add the axis settings for axis 0.

1

Right-click Axis Settings in the Multiview Explorer and select Add Single-axis Position

Control Axis from the menu.

NJ/NX-series Startup Guide for Motion Control (W514)

3-9

Page 36

3 Setting Up a Single-axis Servo System

Axis 0 is added to the Multiview Explorer.

The axis is added as MC_Axis000. This axis is called axis 0.

Assigning a Servo Drive to the Axis

Next, assign the Servo Drive in the EtherCAT network configuration to the new axis 0 (MC_Axis000).

1

Right-click MC_Axis000 (axis 0) in the Multiview Explorer and select Edit from the menu.

3-10

NJ/NX-series Startup Guide for Motion Control (W514)

Page 37

3 Setting Up a Single-axis Servo System

The Axis Basic Settings are displayed on the Axis Parameter Settings Tab Page in the Edit

Pane.

3-5 Programming

3

3-5-1 Setting the Axis

2

Select Servo axis in the Axis type Box.

NJ/NX-series Startup Guide for Motion Control (W514)

3-11

Page 38

3 Setting Up a Single-axis Servo System

3

Select thne Servo Drive to use in the Output device Box (Node: 1, Device: R88D-1SN01L-ECT).

This will assign node 1 and device R88D-1SN01L-ECT as the output device for axis 0.

3-12

Now, node 1 with device R88D-1SN01L-ECT can be used as an axis in the EtherCAT network

configuration.

NJ/NX-series Startup Guide for Motion Control (W514)

Page 39

3 Setting Up a Single-axis Servo System

Setting the Axis Parameters

Set the axis parameters for axis 0 based on the mechanical configuration of the system.

The input axis parameters are shown in the following table according to the mechanical configuration of

axis 0.

Icon on Settings Tab Page Item Set value

Unit Conversion Settings Unit of Display mm

Command Pulse Count Per Motor

Rotation

Work Travel Distance per Motor

Rotation

Operation Settings Maximum Velocity 500 mm/s

8,388,608

10.000 mm

3-5 Programming

Maximum Jog Velocity 50 mm/s

Position Count Settings Encoder type Absolute encoder

1

Set the parameters on the Axis Parameter Settings Tab Page.

Click an icon on the Axis Parameter Settings Tab Page to display the settings for that particular

icon.

Set the axis parameters as indicated below.

• Unit Conversion Settings

3

3-5-1 Setting the Axis

NJ/NX-series Startup Guide for Motion Control (W514)

3-13

Page 40

3 Setting Up a Single-axis Servo System

• Operation Settings

• Position Count Settings

3-14

NJ/NX-series Startup Guide for Motion Control (W514)

Page 41

3 Setting Up a Single-axis Servo System

Additional Information

You can also set the parameters for all axes on the same tab page.

Right-click Axis Settings in the Multiview Explorer and select Axis Setting Table from the menu

to display the Axis Setting Table. The Axis Setting Table allows you to set the axis settings and

axis parameters for all axes that have been added.

3-5 Programming

3

3-5-1 Setting the Axis

NJ/NX-series Startup Guide for Motion Control (W514)

3-15

Page 42

3 Setting Up a Single-axis Servo System

Confirming That the Axis Variable Is Registered

A structure variable that is defined to hold information on an axis, such as physical quantities, status,

and error information, is called an axis variable.

The axis variables are used in the user program to specify axes.

When an axis is added, an axis variable for that axis is automatically added to the global variable table.

Use the following method to check the axis variables.

1

Right-click Global Variables under Programming - Data in the Multiview Explorer and select

Edit from the menu.

The global variable table is displayed in the Edit Pane.

You can confirm that the MC_Axis000 axis variable for axis 0 has been added automatically.

3-16

NJ/NX-series Startup Guide for Motion Control (W514)

Page 43

Precautions for Correct UsePrecautions for Correct Use

3-5-2 Creating the Program

Create the instructions that control the Servo Drive in section 0 of program 0. Program 0 is automatically created when you create a project.

The following instructions are created. To do so, we will use an axis variable and motion control instructions.

3 Setting Up a Single-axis Servo System

3-5 Programming

3

3-5-2 Creating the Program

Refer to the NJ/NX-series Startup Guide for CPU Units (Cat. No. W513) for details on how to create

ladder diagrams.

The sample programming that is provided in this Guide includes only the programming that is

required to operate the Servomotors. When programming actual applications, also program

EtherCAT communications, device interlocks, I/O with other devices, and other control procedures.

NJ/NX-series Startup Guide for Motion Control (W514)

3-17

Page 44

3 Setting Up a Single-axis Servo System

Opening the Ladder Editor

To enter the program, you must start the Ladder Editor and open section 0 of program 0.

1

Right-click Section0 under Programming POUs Programs Program0 in the Multiview

Explorer, and select Edit from the menu.

The local variable table and Ladder Editor are displayed in the Edit Pane. From here, you can

register local variables and create a ladder diagram.

3-18

NJ/NX-series Startup Guide for Motion Control (W514)

Page 45

3 Setting Up a Single-axis Servo System

Enter an input for the ServoLock variable

to control turning the Servo ON and OFF.

Definitions of any variables that you enter in the Ladder Editor

are automatically registered in the local variable table.

Creating the Instructions That Turn the Servo ON and OFF

You must turn ON the Servo in order to execute single-axis positioning from the Servo Drive. The

MC_Power (Power Servo) instruction is used to control turning the Servo ON and OFF.

1

Enter an input for the ServoLock variable to control turning the Servo ON and OFF.

3-5 Programming

3

3-5-2 Creating the Program

• How to enter an NO input

Right-click the horizontal line in the Ladder Editor and select Insert Input from the menu. Or,

press the C Key.

• How to display external variables and internal variables

Select Variable Table from the View menu.

2

Drag MC_Power from the Motion Area of the Toolbox to the right side of the ServoLock input.

NJ/NX-series Startup Guide for Motion Control (W514)

3-19

Page 46

3 Setting Up a Single-axis Servo System

Enter Power1 as the instance name.

Definitions of any variables for instance names that you enter in the

Ladder Editor are automatically registered in the local variable table.

An MC_Power instruction is inserted to the right of the ServoLock input.

3

Enter Power1 as the instance name for the MC_Power instruction.

3-20

NJ/NX-series Startup Guide for Motion Control (W514)

Page 47

3 Setting Up a Single-axis Servo System

Enter MC_Axis000 (the axis variable

of axis 0).

Enter the initial letter "m" to display

the selectable axis variables.

The variable automatically

appears on the output side when

it is entered on the input side.

4

Enter the in-out variable for the Power1 instance.

Specify the axis variable of the axis to control for the Axis in-out variable of the Power1 instance.

The axis variable for axis 0 is MC_Axis000.

3-5 Programming

3

3-5-2 Creating the Program

This concludes the creation of the instructions to control turning the Servo ON and OFF.

NJ/NX-series Startup Guide for Motion Control (W514)

3-21

Page 48

3 Setting Up a Single-axis Servo System

Creating the Instructions That Perform Single-axis Positioning

Here, the MC_MoveRelative (Relative Positioning) instruction is used to perform single-axis control.

We will use two instances of this instruction to repeatedly perform round-trip operation with single-axis

positioning.

1

Enter an input for the Start1 variable to control the Relative Positioning instruction.

To add a rung, select the left bus bar and press the R Key.

Definitions of any variables that you enter

in the Ladder Editor are automatically

registered in the local variable table.

Enter an input for the Start1 variable to

control the Relative Positioning instruction.

2

Enter an NC input for the Complete1 variable to control the repeated single-axis positioning.

To enter an NC input, select the horizontal line in the Ladder Editor and press the / Key.

Definitions of any variables that you enter in the Ladder

Editor are automatically registered in the local variable table.

Enter an NC input for the Complete1 variable, which is

turned ON when the round-trip operation is completed.

3-22

NJ/NX-series Startup Guide for Motion Control (W514)

Page 49

3 Setting Up a Single-axis Servo System

Insert an MC_MoveRelative

(Relative Positioning) instruction.

Enter Move1 as the instance name.

Definitions of variables for any instance names that you enter in the

Ladder Editor are automatically registered in the local variable table.

3

Insert an MC_MoveRelative (Relative Positioning) instruction.

3-5 Programming

3

3-5-2 Creating the Program

4

Enter Move1 as the instance name for the MC_MoveRelative instruction.

NJ/NX-series Startup Guide for Motion Control (W514)

3-23

Page 50

3 Setting Up a Single-axis Servo System

Enter MC_Axis000 (the axis

variable of axis 0).

The variable automatically

appears on the output side when

it is entered on the input side.

5

Enter the in-out variable for the Move1 instance.

Specify the axis variable of the axis to control for the Axis in-out variable of the Move1 instance.

The axis variable for axis 0 is MC_Axis000.

3-24

NJ/NX-series Startup Guide for Motion Control (W514)

Page 51

3 Setting Up a Single-axis Servo System

Set the values of the input variables.

6

Enter the values given in the following table for the input variables of the MC_MoveRelative

instruction.

Input variable Meaning Set value

Distance Travel Distance (mm) 20

Velocity Target Velocity (mm/s) 10

Acceleration

Deceleration

Acceleration Rate (mm/s

Deceleration Rate (mm/s

2

)

2

)

200

200

3-5 Programming

3

3-5-2 Creating the Program

NJ/NX-series Startup Guide for Motion Control (W514)

3-25

Page 52

3 Setting Up a Single-axis Servo System

Additional Information

Enter an output for the Complete1 variable to turn

ON when the round-trip operation is completed.

7

Insert the second MC_MoveRelative (Relative Positioning) instruction.

Enter Move2 as the instance name, enter the axis variable of axis 0 (MC_Axis000) for the in-out

variable, and enter the values in the following table for the input variables.

Input variable Meaning Set value

Distance Travel Distance (mm) 20

Velocity Target Velocity (mm/s) 10

Acceleration

Deceleration

Acceleration Rate (mm/s

Deceleration Rate (mm/s

Insert the second MC_MoveRelative (Relative Positioning) instruction

as follows:

a. Insert an MC_MoveRelative (Relative Positioning) instruction.

b. Enter Move2 as the instance name.

c. Enter MC_Axis000 (the axis variable of axis 0) for the in-out variable.

d. Set the values of the input variables.

2

)

2

)

200

200

c.

d.

b.

a.

Cascade connections are possible for Ladder Diagram Instructions (e.g., LD (Load) and AND

(AND)), for FB instructions (e.g., MC_MoveRelative (Relative Positioning)), and for FUN instructions (e.g., MOVE (Move)). In this program, the Move2 instance is started after relative positioning for the Move1 instance is completed.

8

Enter an output for the Complete1 variable to turn ON when the round-trip operation is com-

pleted.

3-26

This concludes the creation of the instructions to repeatedly execute single-axis positioning.

NJ/NX-series Startup Guide for Motion Control (W514)

Page 53

3-5-3 Checking the Program

Useful Function

Double-click any error line to

jump to the rung where the

error was detected.

Check the program that you created.

1

Select Check All Programs from the Project Menu.

3 Setting Up a Single-axis Servo System

3-5 Programming

3

3-5-3 Checking the Program

The results of the program check are displayed on the Build Tab Page.

If there are any errors, correct them.

Warnings such as "A parameter is not entered for the output." may be displayed because variables and actual inputs are not assigned in the I/O map. In this case, ignore the warnings and

continue the procedure.

NJ/NX-series Startup Guide for Motion Control (W514)

3-27

Page 54

3 Setting Up a Single-axis Servo System

The Sysmac Studio goes

online and the color of the

bar at the top of the Edit

Pane changes to yellow.

The Controller status is

displayed.

3-6 Transferring the Project to the CPU

Unit

The project, which contains the user program, is transferred to the CPU Unit.

Turn ON the power supply to the Controller and to the Servo Drive.

Online Connection

1

Use one of the following methods to go online.

Method 1: Select Online from the Controller

Menu.

Method 2: Click the Button on the

Toolbar.

Method 3: Press the Ctrl + W

Keys.

The CPU Unit name is written to the Controller, and the Sysmac Studio goes online with the

Controller.

Ctrl

W

3-28

NJ/NX-series Startup Guide for Motion Control (W514)

Page 55

3 Setting Up a Single-axis Servo System

The results of comparison of the data on the

computer and the data in

the physical Controller

are displayed.

Click this button to transfer

the project from the

computer to the CPU Unit.

Click this button to transfer

the project from the CPU

Unit to the computer.

Transferring the Project

You must transfer the project to the CPU Unit. The synchronize operation is used to transfer the

project. Here, “synchronize” means to automatically compare the data for the Sysmac Studio on the

computer with the data in the physical Controller and transfer the data in the direction that is specified by the user.

1

Use one of the following methods to display the Synchronize Pane.

Method 1: Select Synchronize from the

Controller Menu.

Method 2: Click the Button on the

Toolbar.

Method 3: Press the Ctrl + M

Keys.

Ctrl

M

3-6 Transferring the Project to the CPU Unit

3

Comparison of the data on the computer and the data in the physical Controller is started.

The comparison results are displayed after the comparison is completed.

NJ/NX-series Startup Guide for Motion Control (W514)

3-29

Page 56

3 Setting Up a Single-axis Servo System

2

Click the Transfer to Controller Button.

Click the Button.

3

Click the Yes Button.

Click the Button.

The operating mode changes to PROGRAM mode, and the Sysmac Studio starts transferring

the project to the CPU Unit. During the transfer, a progress bar appears in the Synchronize

Pane.

4

The following dialog box is displayed when the transfer is completed. Click the No Button.

Do not change to RUN mode at this time (i.e., remain in PROGRAM mode).

Click the Button.

3-30

NJ/NX-series Startup Guide for Motion Control (W514)

Page 57

3 Setting Up a Single-axis Servo System

5

Click the Close Button at the lower right of the Synchronize Pane.

Click the Button.

The Synchronize Pane closes.

3-6 Transferring the Project to the CPU Unit

3

NJ/NX-series Startup Guide for Motion Control (W514)

3-31

Page 58

3 Setting Up a Single-axis Servo System

3-7 Confirming System Operation

Confirm that the system is operating correctly.

Place the CPU Unit online with the Sysmac Studio before you perform the procedures that are given in

this section.

3-7-1 Checking for Controller Errors

The color of the ERR/ALM indicator in the Controller Status Pane of the Sysmac Studio shows the

presence of any errors. If ERR/ALM is red, an error has occurred. Follow the instructions that are given

below to check the details of the error.

1

Click the Button on the Toolbar of the Controller Status Pane.

The Detailed View of the Controller Status Pane is displayed.

Indicates a Controller error.

2

Use one of the following methods to open the Troubleshooting Window.

Method 1: Select Troubleshooting from the

Tools Menu.

3-32

Method 2: Click the Button on the Toolbar.

NJ/NX-series Startup Guide for Motion Control (W514)

Page 59

3 Setting Up a Single-axis Servo System

A list of Controller

errors is displayed.

Details on the errors and possible

solutions are displayed in this area.

Click the Display Switch Button to

switch between the detailed error

information and possible solutions.

The Troubleshooting Window is displayed for the Edit Pane.

From there, you can check detailed information on any errors that have occurred and find out

how to troubleshoot them.

3-7 Confirming System Operation

3

3-7-1 Checking for Controller Errors

3

4

Click the Button.

5

Click the Button.

Refer to the error details and troubleshooting information to solve the problems and eliminate all

errors.

Click the Reset All Button in the Troubleshooting Window.

The following confirmation dialog box appears.

Click the Yes Button.

All errors are reset.

If the cause of the error is not removed, the error will occur again.

NJ/NX-series Startup Guide for Motion Control (W514)

3-33

Page 60

3 Setting Up a Single-axis Servo System

Additional Information

• If an EtherCAT communications cable is not properly connected or if power is not supplied to a

Remote I/O Unit, a minor fault level Controller error (a Link OFF Error or Network Configuration Verification Error) will occur. If you are sure that all EtherCAT communications cables are

properly connected, first check to make sure that power is being supplied to the Remote I/O

Units before you reset the errors.

• If you use the default Servo parameters, you must wire the immediate stop input, negative

drive prohibit input, and the positive drive prohibit input.

If these inputs are not wired, the CPU Unit will remain in the drive prohibit signal and emergency stop signal detected state, and a minor fault level Controller error will occur. The minor

fault level Controller errors that will occur are an Immediate Stop Input Error and a Drive Prohibition Input Error. (The event codes are 68220000 and 64E30000.)

If the above signals are temporarily not wired while commissioning the system, you can

temporarily change the Servo parameters to prevent these errors from occurring in the CPU

Unit. Refer to A-1 Settings When Control Input Signals Are Not Wired for details on the settings that you must change in this case.

3-34

NJ/NX-series Startup Guide for Motion Control (W514)

Page 61

3 Setting Up a Single-axis Servo System

3-7-2 Resetting the Absolute Encoder from the Sysmac Studio

The absolute encoder must be set up the first time it is used, and when the rotation data is initialized to 0.

1

Right-click the Servo Drive and select Setup and Tuning from the menu.

The Setup and Tuning Portal appears.

2

Click the Quick Parameter Setup and I/O Monitor Button.

3-7 Confirming System Operation

3

3-7-2 Resetting the Absolute Encoder from the Sysmac Studio

The following dialog box appears. Click the Yes Button.

The Motor and Encoder setting Page appears.

NJ/NX-series Startup Guide for Motion Control (W514)

3-35

Page 62

3 Setting Up a Single-axis Servo System

3

Click the Launch Motor and Encoder view Button.

The Encoder Properties Tab Page appears.

4

Click the Clear system Button.

An Absolute Value Clear Error (error display number: 2701) will occur, and a dialog box indicating "Restart the drive to complete the operation."

3-36

NJ/NX-series Startup Guide for Motion Control (W514)

Page 63

3 Setting Up a Single-axis Servo System

5

Click the Yes Button.

The multiple rotation data of the absolute encoder is cleared.

3-7 Confirming System Operation

3

3-7-2 Resetting the Absolute Encoder from the Sysmac Studio

NJ/NX-series Startup Guide for Motion Control (W514)

3-37

Page 64

3 Setting Up a Single-axis Servo System

3-7-3 Checking the Servo Drive Wiring

Use the MC Test Run operation in the Sysmac Studio to check the wiring of the Servo Drive.

The wiring is checked in PROGRAM mode to prevent a user program for which operation has not been