Page 1

AC Servo System 1S-series

Startup Guide

for Multi-axis Setup and Tuning

R88M-1L[]/-1M[] (AC Servomotors)

R88D-1SN[]-ECT (AC Servo Drives)

SYSMAC-SE20[][] (Automation Software)

I827-E1-01

Page 2

NOTE

All rights reserved. No part of this publication may be reprodu c ed, st or ed in a retrieval system,

or transmitted, in any for m , or by any means, mechanical, photocopying, recording, or

otherwise, without the prio r w r it t en per m iss ion of OMRON.

No patent liability is assume d with respect to the use of the information contained herein.

Moreover, because OMRON is const antly striving to improve its h igh-quality products, the

information contained in t his manual is subject to change without notice. Every precauti on has

been taken in the preparation o f this manual. Nevertheless, O M RON assumes no

responsibility for errors or omissions. Neither is any l iability assumed for damages r esulting

from the use of the informat ion contained in this publication.

2

Page 3

Introduction

The Servo System 1S-Series Star t up Guide for Multi-axis Setup and T un in g (hereinafter, may

be referred to as "this Guide") describes the procedures for installation and setup of 1S Servo

Drives, where an NJ/NX-series CPU Unit is used in combination with 1S-series AC

Servomotors/Servo Drives and NX-series Safety Unit, by using the Sy smac Studio. A simple

installation model is used for t he discussion. You can perform the procedur es that are

presented in this Guide to quickly gain a basic understanding o f a 1S-series AC

Servomotors/Servo Drives.

This Guide does not contain sa fety infor mation and ot her detai ls that are requ ir ed for actu al us e.

Thoroughly read and u nderstand t he manua ls for all of the device s that are u sed in th is Guide t o

ensure that the system is used safely. Review the entire contents of these materials, inc lud ing

all safety precautions, precautions for safe use, and pr ecautions for correct use.

Intended Audience

This Guide is intended for t he following personnel.

• Personnel in charge of introducing FA systems

• Personnel in charge of de signing FA systems

The personnel must also hav e t he following knowledge.

• Knowledge of electrical sy s t em s ( an el ectrical engineer or the equ iv alent )

• Knowledge of NJ/NX-series CP U Units

• Knowledge of Servomotors/Drives

• Knowledge of operation pr ocedure of Sysmac Studio

Applicable Products

This Guide covers the foll ow ing products.

• CPU Units of NJ/NX-series Machine Automation Controllers

• Automation Software Sy smac Studio

• 1S-series Servomotors/Servo Drives

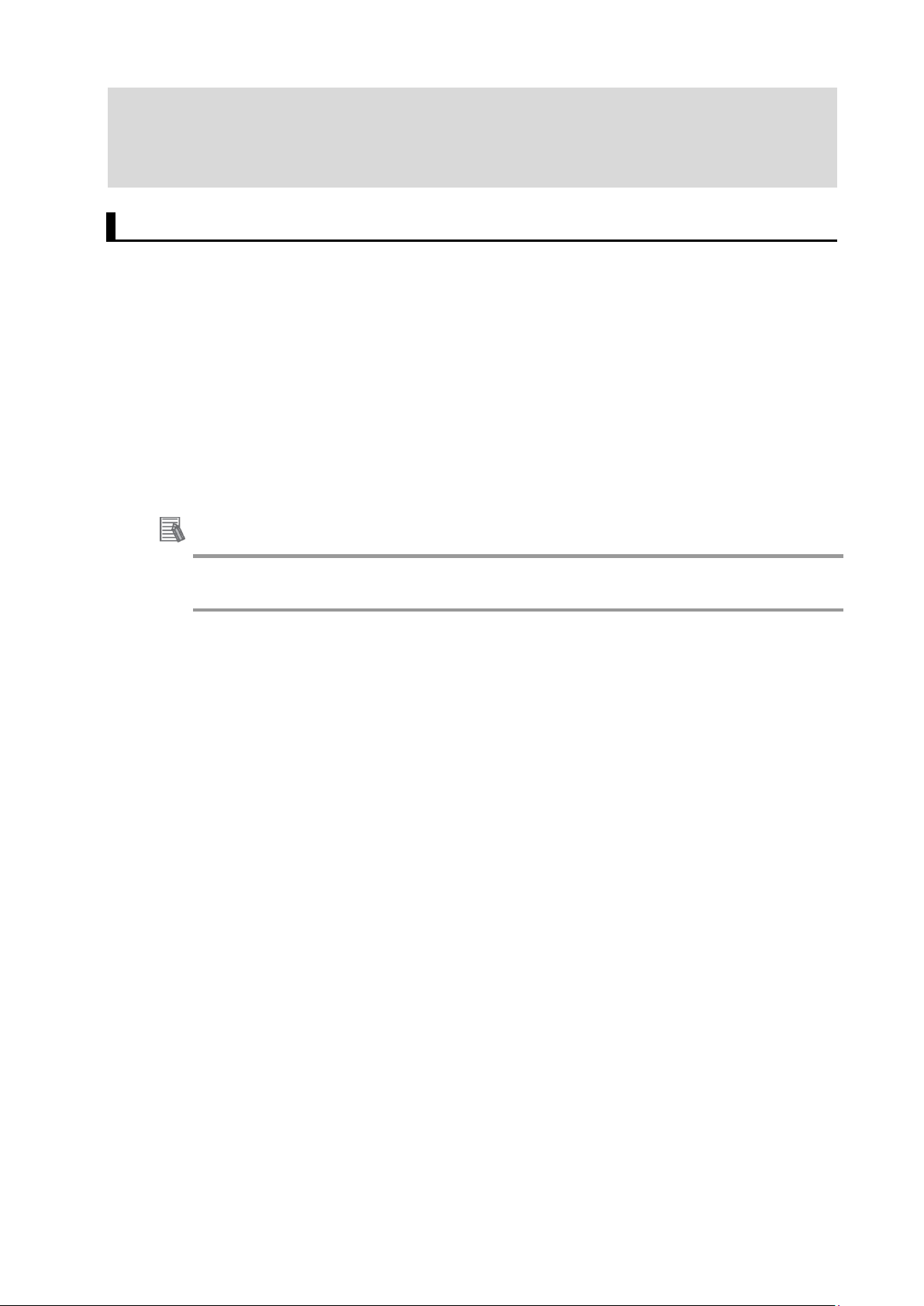

Special Information

The icons that are used in this G uid e ar e described below.

Precautions for Safe Use

Precautions on what to do and w hat not to do to ensure safe usage o f the pr oduct.

Precautions for Correct Use

Precautions on what to do and w hat not to do to ensure proper operat i on and

performance.

Additional Inf or mation

Additional information to read as required.

This information is provid ed to increase understanding or m ake operation easier.

3

Page 4

Terms and Conditions A gree ment

Warranties

(a) Exclusive Warranty . Omro n’s exclusive warranty is that t he Pr oducts will be free from

defects in materials and w or km anship for a period of twelve months from the date of sale by

Omron (or such other period expressed in writing by Omron). Omron discla ims all other

warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

IMPLIED, ABOUT NON-INFRINGEMENT, M ERCHANTA BILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE

HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY ME ET T HE REQ UI R EME N TS

OF THEIR INTENDED US E.

Omron further disclaims a l l w ar r ant ies and responsibility of any t ype for claims or expenses

based on infringement by the Products or otherwise of any intellectual property right. (c) Buyer

Remedy.

Omron’s sole obligation hereunder shall be, at Omr on’s election, to (i) replace ( in the form

originally shipped with Buyer r es ponsi ble for labor charges for removal or r eplacement thereof)

the non-complying Product , ( ii) repair t he non-complying Product, or ( iii) repay or credit Buyer

an amount equal to the pur chase price of the non-complying Pr oduct; provided that in no event

shall Omron be respons ibl e for w ar r ant y, repair, indemnity or any other claims or expenses

regarding the Products unless Omron’s analysis confir ms that the Products were properly

handled, stored, installed and maintained and not subj ec t t o cont amination, abuse, misuse or

inappropriate modification. Return of any Products by Buyer must be approved in w r iting by

Omron before shipment. O mron Companies shall not be liable for the suitability or unsuit abi lity

or the results from the use of Products in combination w it h any electrical or electronic

components, circuits, system asse mblies or any other materials or substances or environ ments .

Any advice, recommend at ions or information given orally or in writing, are not to be construed

as an amendment or addition to t he above warranty.

See http://www.omron.com/global/

information.

Limitation on Liability; Etc

OMRON COMPANIES SHA L L NOT BE LIABLE FOR SPECI AL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMA GES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liabil ity of Omron Companies exceed t he i ndividual price of the

Product on which liability is asserted.

Suitability of Use

Omron Companies shall n ot be r esponsible for conformity w it h any standards, codes or

regulations which apply t o the combination of the Product in the Buyer’s application or us e of

the Product. At Buyer’s request, Omron will provide applicable third party certif ication

4

or contact your Omro n r epr esentative for published

Page 5

documents identifying rati ngs and limitations of use which apply t o the Product . This inform ation

by itself is not sufficient for a complete determination of the suitability of the P r oduc t in

combination with the end pr oduct , machine, system, or ot her appl ication or use. Buyer shall be

solely responsible for dete r m ini ng appropriateness of the part ic ular Product with respect to

Buyer’s application, pr oduct or system. Buyer shall ta ke application responsibility in all cases.

NEVER USE THE PRODUCT F OR AN APPLICATION INVOLVING S ERIOUS RISK TO LIFE

OR PROPERTY WIT HO U T ENSU RI NG TH A T THE SY ST EM AS A WHOLE H AS BE E N

DESIGNED TO ADDRES S THE RISKS, A ND THAT THE O MRON PROD UCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SY ST E M.

Programmable Products

Omron Companies shall n ot be r esponsible for the user’s programming of a programmable

Product, or any consequence thereof.

Performance Data

Data presented in Omron Company websites, catalogs and other materials is prov ided a s a

guide for the user in deter m in ing suitability and does not constitute a warranty. It may represent

the result of Omron’s test c onditions, and the user must cor r el at e it t o act ual application

requirements. Actual performance is subject to the O mron’s Warranty and Limitatio ns of

Liability

Change in Specificati on s

Product specifications and accessories may be changed at any time based on improvements

and other reasons. It is o ur practice to change par t numbers when published ratings or features

are changed, or when significant construction changes are made. However, some

specifications of the Product may be changed without any notice. When in doubt, speci al p ar t

numbers may be assigned to fix or establish key specificati ons f or your application. Please

consult with your Omron’s representative at any time t o c onf irm actual specifications of

purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading err or s or

omissions.

5

Page 6

Precautions

• When building a system, check the specifications for all devices and equipment that will make

up the system and make sur e t hat the OMRON products are used w el l w ithin their rated

specifications and performances. Safety measures, such as safety circuits, must be

implemented in order to m inim ize the risks in the event of a malfunction.

• Thoroughly read and understand the manuals for al l devices and equipment that w il l make up

the system to ensure that the system is used safely. Review the entire contents of these

manuals, including all saf ety precautions, prec aution s for safe use, and precau tions for corr ect

use.

• Confirm all regulations, standards, and restrictions that the system must ad here to.

• Check the user program f or pr oper execution before you use it for actual operation.

Trademarks

• Sysmac and SYSMAC are trademarks or reg ist er ed trademarks of OMRON Corporation in

Japan and other countries for O M RON factory automation product s.

• Windows is either registered trademarks or tradema rks o f M i c ros oft Corporation in the USA

and other countries.

• EtherCAT

GmbH, Germany.

• Microsoft product screen shot(s) reprinted with permission from Microsoft C orporation.

• Other company names and product names in this Guide are the trademarks or r egister ed

trademarks of their respe ctive companies.

Software Licenses and Copyrights

®

is registered tr ade mark and pat ented t echno logy, licensed by Beckhof f Automation

The NJ-series CPU Units and Sysmac Studio incorporate certain third party software. The

license and copyright infor mation associated with this softw ar e is available at

http://www.fa.omron.co.jp/nj_info_e/.

6

Page 7

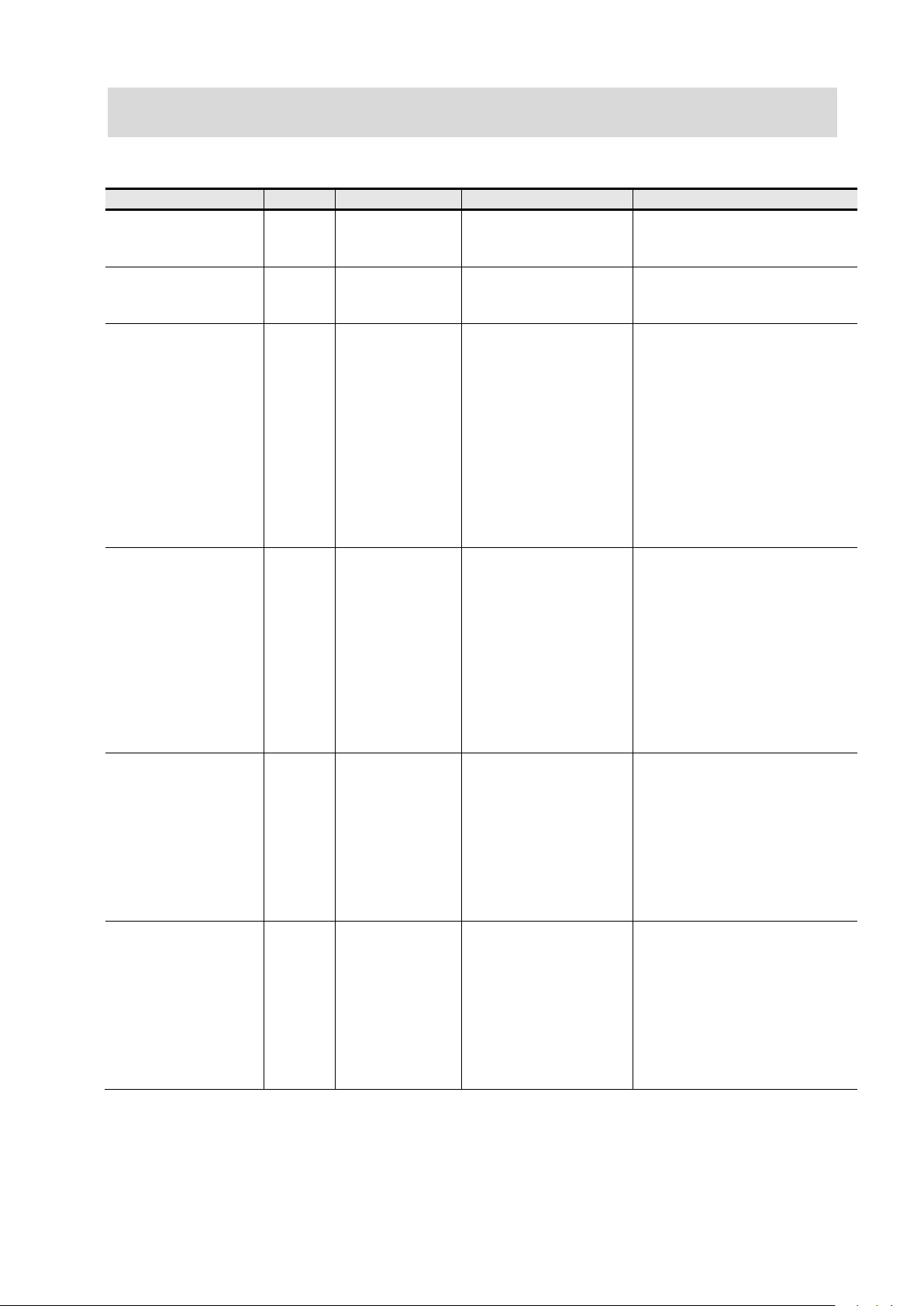

Related Manuals

The following manuals are related. Use these manuals for reference.

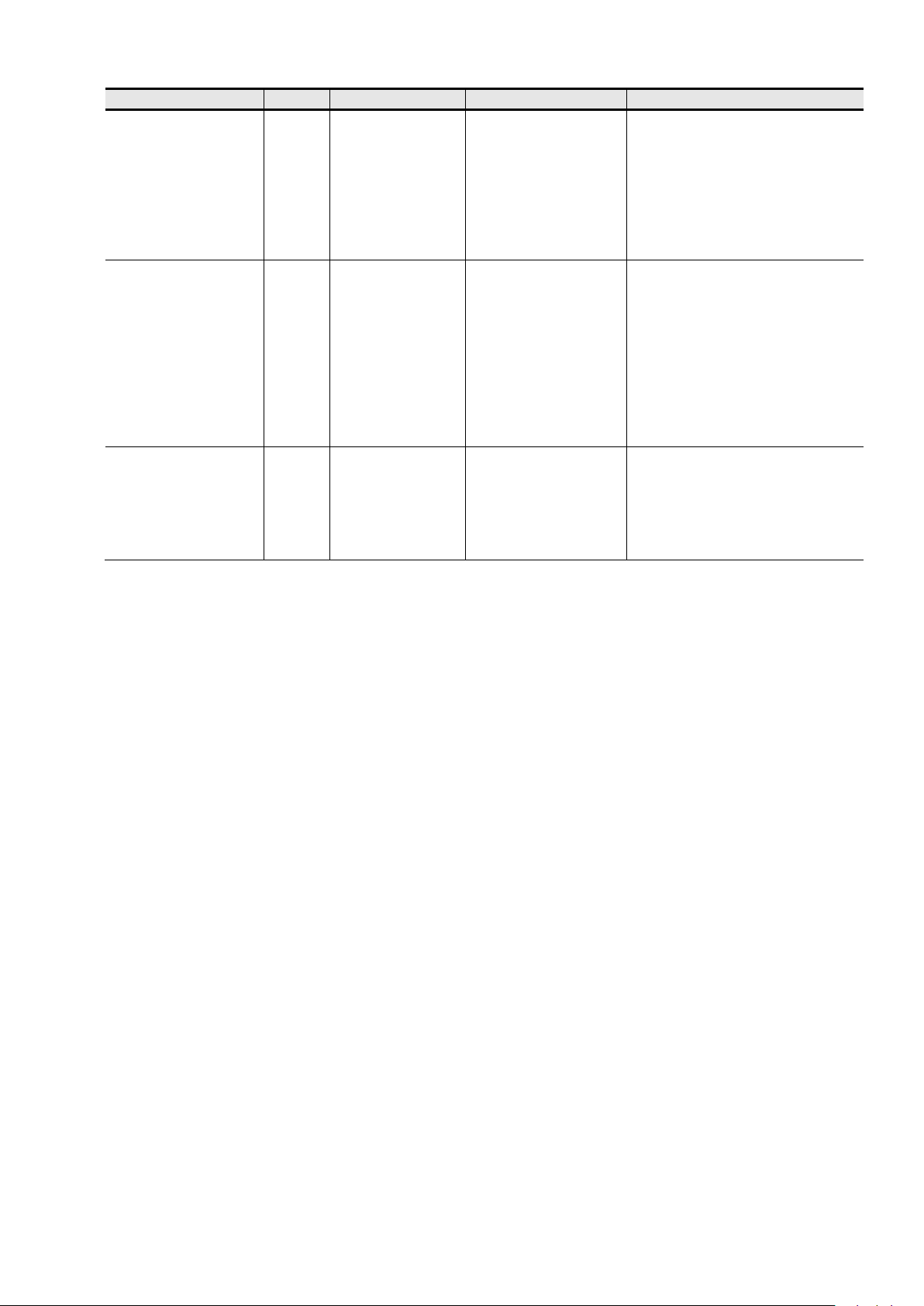

Manual name Cat. No. Model Application Description

Sysmac Studio Version 1

Operation Manual

Sysmac Studio Drive

Functions Operation

Manual

NJ-series CPU Unit

Hardware User´s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NJ/NX-series CPU Unit

Motion Control User's

Manual

NJ/NX-series Instructions

Reference Manual

W504 SYSMAC-SE2□□□ Learning about the operating

procedures and functions of

the Sysmac Studio.

I589-E1 SYSMAC-SE2□□□ Learning about the operating

procedures and functions of

the Sysmac Studio for Drives

W500 NJ501-□□□□

NJ301-□□□□

W501 NJ501-□□□□

NJ301-□□□□

W507 NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

W502 NJ501-□□□□

NJ301-□□□□

Learning the basic

specifications of the

NJ-series CPU Units,

including introductory

information, designing,

installation, and

maintenance.

Mainly hardware information

is provided.

Learning how to program and

set up an NJ/NX-series CPU

Unit.

Mainly software information is

provided.

Learning about motion

control settings and

programming concepts.

Learning detailed

specifications on the basic

instructions of an

NJ/NX-series CPU Unit.

Describes the operating procedures of

the Sysmac Studio.

Describes the operating procedures of

the Sysmac Studio to setup Drives

Provides an introduction to the entire

NJ-series system along with the

following information on the CPU Unit.

• Features and system configuration

• Overview

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the

NJ/NX-series CPU Unit Software

User's Manual (Cat. No. W501).

Provides the following information on a

Controller built with an NJ/NX-series

CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Language specifications and

programming based on IEC 61131-3

Use this manual together with the

NJ-series CPU Unit Hardware User's

Manual (Cat. No. W500).

Describes the settings and operation of

the CPU Unit and programming

concepts for motion control.

When programming, use this manual

together with the NJ-series CPU Unit

Hardware User's Manual (Cat . No .

W500) and NJ/NX-series CPU Unit

Software User's Manual (Cat. No.

W501).

Describes the instructions in the

instruction set (IEC 61131-3

specifications).

When programming, use this manual

together with the NJ-series CPU Unit

Hardware User's Manual (Cat . No .

W500) and NJ/NX-series CPU Unit

Software User's Manual (Cat. No.

W501).

7

Page 8

Manual name

Cat. No.

Model

Application

Description

NJ/NX-series Motion

Control Instructions

Reference Manual

NJ/NX-series

Troubleshooting Manual

W508 NJ501-□□□□

NJ301-□□□□

W503 NJ501-□□□□

NJ301-□□□□

Learning about the

specifications of the motion

control instructions that are

provided by OMRON.

Learning about the errors

that may be detected in an

NJ/NX-series Controller.

Describes the motion control instructions.

When programming, use this manual

together with the NJ-series CPU Unit

Hardware User's Manual (Cat . No .

W500), NJ/NX-series CPU Unit Software

User's Manual (Cat. No. W501), and

NJ/NX-series CPU Unit Motion Control

User's Manual (Cat. No. W507).

Describes concepts on managing errors

that may be detected in an NJ/NX-series

Controller and information on individual

errors.

Use this manual together with the

NJ-series CPU Unit Hardware User's

Manual (Cat. No. W500) and

NJ/NX-series CPU Unit Software User's

Manual (Cat. No. W501).

1S-series AC

Servomotors/Servo Drives

with Built-in EtherCAT

Communications User's

Manual

I586

R88D-1S□-ECT

R88M-1□

Learning detailed

specifications of a

1S-series Servo Drive.

Describes how to install and wire the

Servo Drive, set parameters needed to

operate the Servo Drive, and remedies to

be taken and inspection methods to be

used in case that problems occur.

8

Page 9

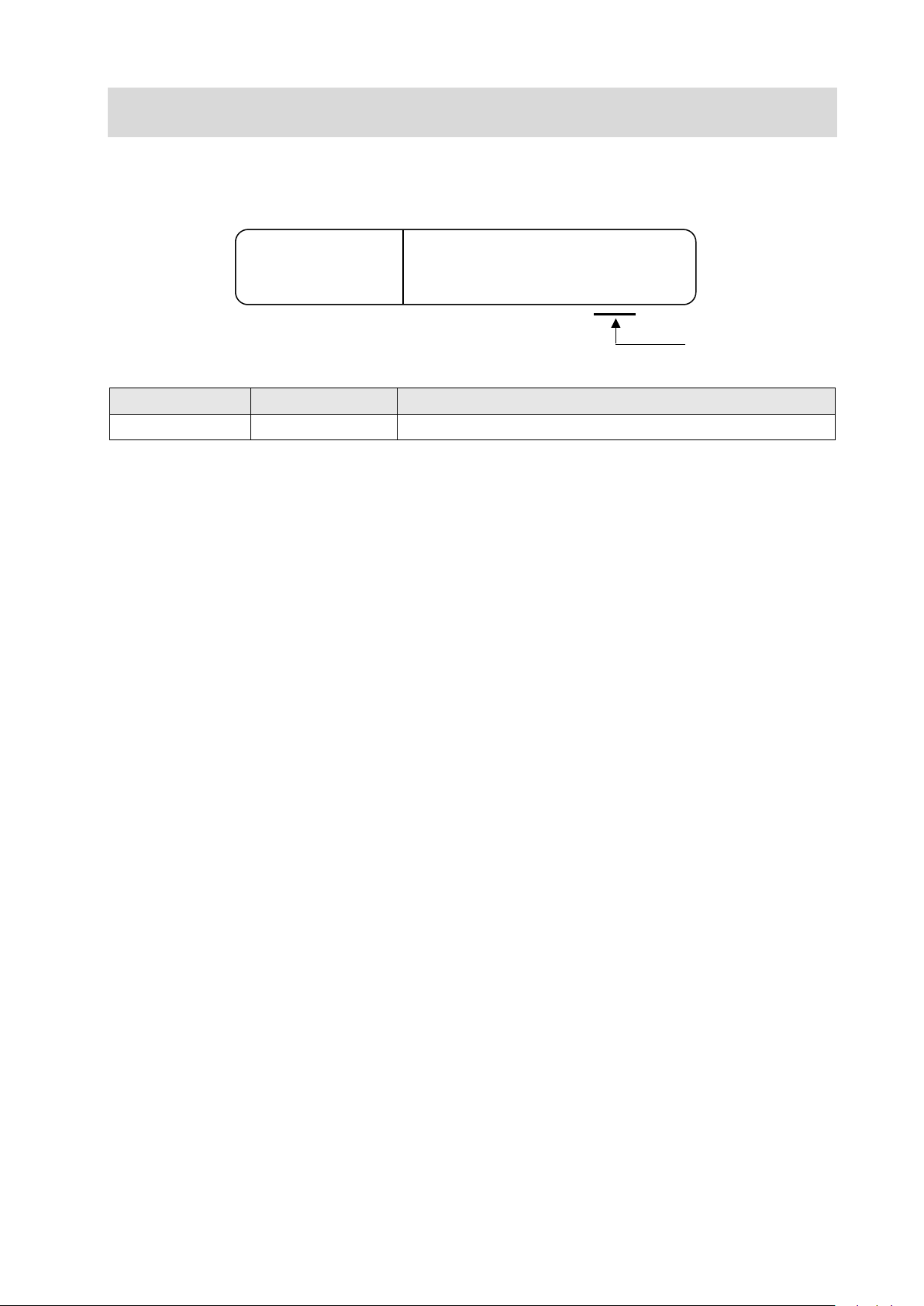

Revision History

Cat. No.

A manual revision code appears as a suffix to the catalog number on the front and back covers

of the manual.

Revision code Date Revised content

01 April 2017 Original production

I827-E1-01

Revision code

9

Page 10

CONTENTS

Introduction ······························································································ 3

Intended Audience ..................................................................................................... 3

Applicable Products ................................................................................................... 3

Special Information .................................................................................................... 3

T erms and Conditions Agreement ······························································· 4

Precautions ······························································································ 6

Trademarks ................................................................................................................ 6

Software Licenses and Copyrights ............................................................................ 6

Related Manuals ······················································································· 7

Revision History ······················································································· 9

1. Servo system configuration and peripheral pro ducts ···························· 11

1.1. Outline ............................................................................................................. 11

1.2. Servo System constructed in this guide .......................................................... 12

2. Before You Begin ·············································································· 14

2.1. Installin g the Sysmac Studio ........................................................................... 14

2.2. Assembl ing the Hardware ............................................................................... 15

2.3. Wiring the Device s .......................................................................................... 16

3. Performing setup ·············································································· 20

3.1. Two axis servo system operation .................................................................... 20

3.2. System s et up pr ocedures ............................................................................... 22

3.3. Creating pr oject with Auto connection ............................................................ 22

3.4 Creating the EtherCAT Network Configurati on ............................................... 24

3.5 Creating motion axes ...................................................................................... 26

3.6 Program making and transfer to the CPU Unit ............................................... 32

3.7 Drives and motors para m et er s set up .............................................................. 34

3.8 Easy Tuning (Multiple Driv es) ......................................................................... 38

ANNEX ··································································································· 44

A-1 Settings when control input signals are not wired ............................................ 44

A-2 Program making with st r uct ur ed text ................................................................ 51

10

Page 11

1. Servo system configuration and peripheral products

1.1. Outline

The 1S-series AC Servo Drives with Built-in EtherCAT communications support 100-Mbps EtherCAT .

When you use the 1S-series Servo Drive with a Machine Automation Controller NJ/NX-series CPU Unit,

you can construct a high-speed and sophisticated positioning control system.

Also, you need only one communications cable to connect the Servo Drive and the Controller. Therefore,

you can realize a position control system easily with reduced wiring effort.

With auto tuning, adaptive filter, notch filter, and damping control, you can set up a system that provides

stable operation by suppressing vibration in low-rigidity machines.

For machine composed with multiple 1S-series AC Servo Drives, Sysmac Studio provides a set of

functions to set-up and tune parameters with less effort.

Additional Inf or mation

For additional information about 1S servo drive, please refer to 1S-series AC Servomotors and Servo

Drives User’s Manual (with Built-in EtherCAT Communications) (Cat. No. I586)

11

Page 12

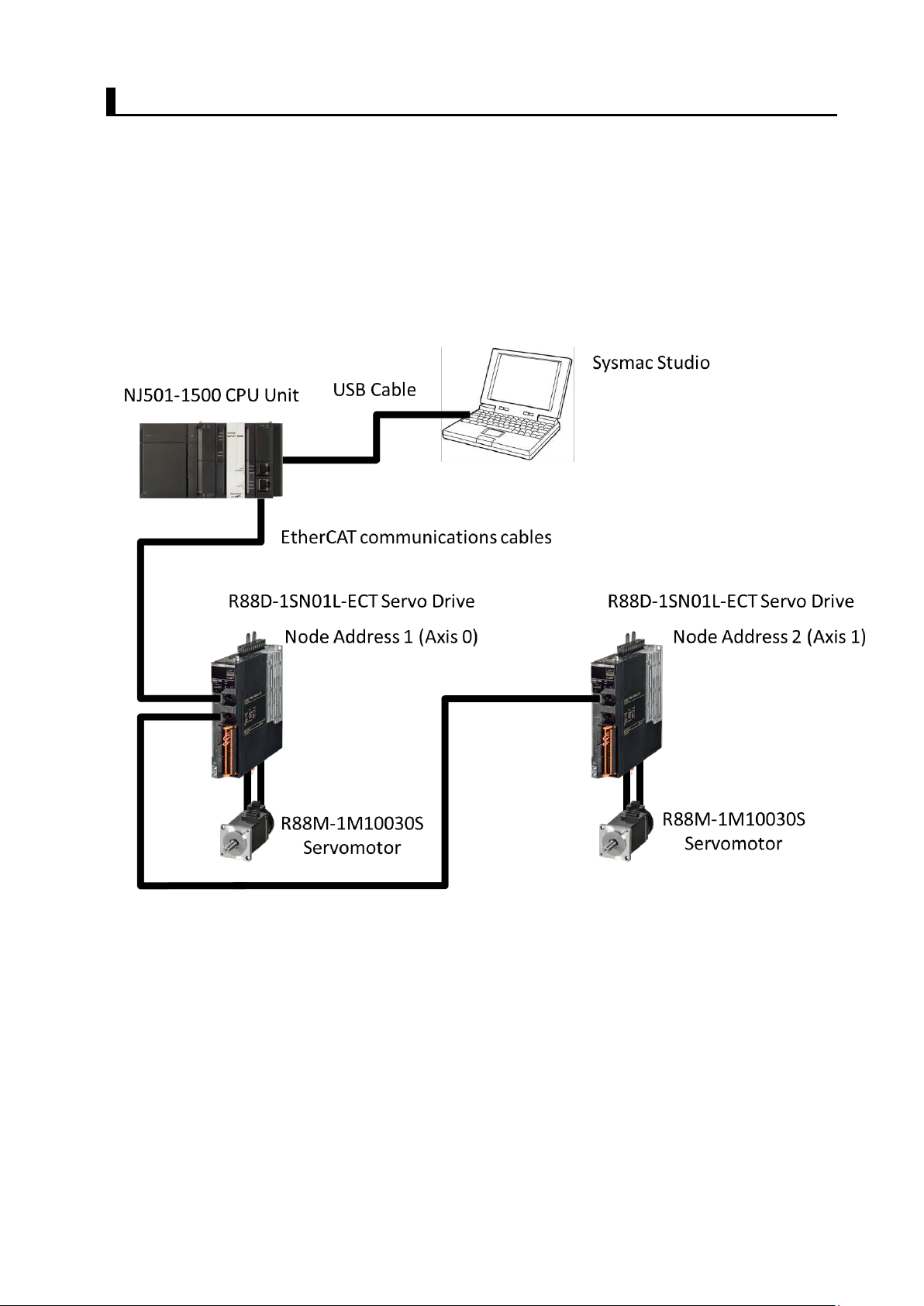

1.2. Servo System constructed in this guide

This 1S-series Startup Guide for multi-axis setup and tuning (hereafter referred to as “this Guide”) contains

instructions to set-up and tune an X-Y stage system composed of two 1S-series AC Servo Driv es.

The following figure shows the system configuration and devices that are used in this Guide.

The system configuration is shown in the following figure.

12

Page 13

in EtherCAT

Sysmac Studio Standard Edition

• Configuration device s

The models of the devices that are described in this Guide are given in the following table. When selecting

devices for an actual application, refer to the device manuals.

Device name Model Manual name

NJ-series CPU Unit NJ501-1500 NJ-series CPU Unit Hardware

NJ-series Power Supply Unit NJ-PA3001

EtherCAT communications cables XS5W-T421-CMD-K

AC Servo Drives R88D-1SN01L-ECT 1S-series AC Servomotors and

AC Servo Motors R88M-1M10030S

Power cables R88A-CA1A003S

Encoder Cables R88A-CR1A003C

User’s Manual (Cat. No. W500)

Servo Drives User’s Man ua l ( with

BuiltCommunications) (Cat. No. I586)

• Automation software

Product Number of license Model

None (DVD only) SYSMAC-SE200D

Versi on 1.18 or higher

1 license SYSMAC-SE201L

13

Page 14

2. Before You Begin

2.1. Installing the Sysmac Studio

The Sysmac Studio is the Support Software that you use for an NJ-series Controller. On it, you can set-up

the Controller configurations, parameters, and programs, and you can debug and simulate operation.

Install the Sysmac Studio on your computer.

Refer to the NJ-series Startup Guide for CPU Units (Cat. No. W513) for the procedure to install the

Sysmac Studio.

14

Page 15

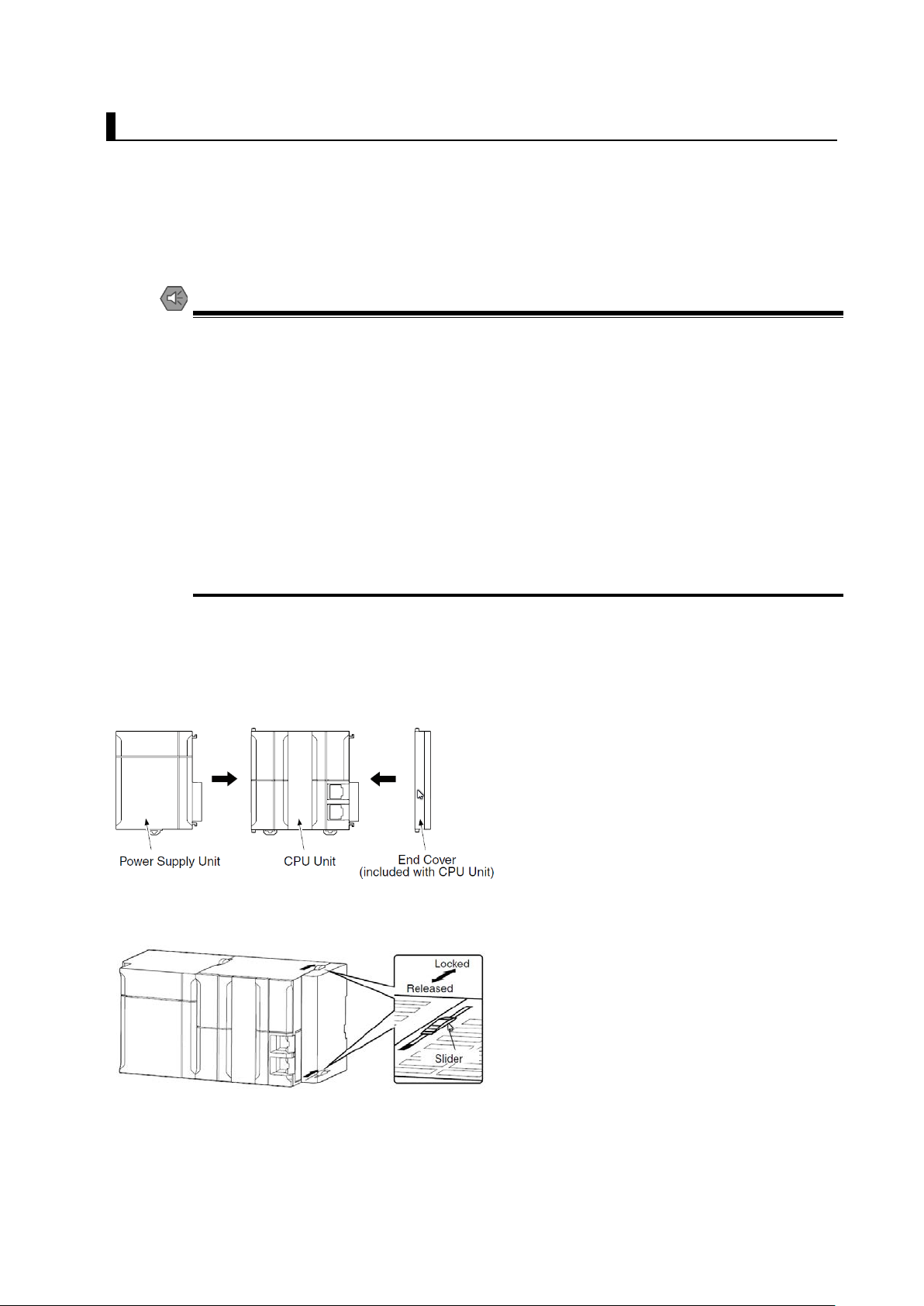

2.2. Assembling the Hardware

This section describes how to assemble the hardware used in the system.

This section gives an overview of the assembly procedures. Refer to the manuals for the devices that are

used in the system for detailed assembly procedures and safety precautions.

Mounting the Units

Connect the Power Supply Unit, CPU Unit, and End Cover.

Precautions for Safe Use

Always turn OFF the pow er s upply to the Controller and to the Servo Drives before you

attempt any of the followin g.

• Mounting or removing the CPU Unit and Other Units

• Assembling Racks

• Setting DIP switches or rotar y switches.

• Connecting cables or wiring the system

• Connecting or disconnecting the connectors

The Power Supply Unit cont inues to supply power to the Controller for up to several

seconds after the power s upply is turned OFF. The PWR indicator remains lit as long as

power is supplied. Ma ke sur e t hat the PWR indicator is not lit before you perform any of

the above operations.

After joining the connectors between the Units, use the sliders at the top and bottom of each Unit to lock

the Units together. Lock the sliders firmly into place.

15

Page 16

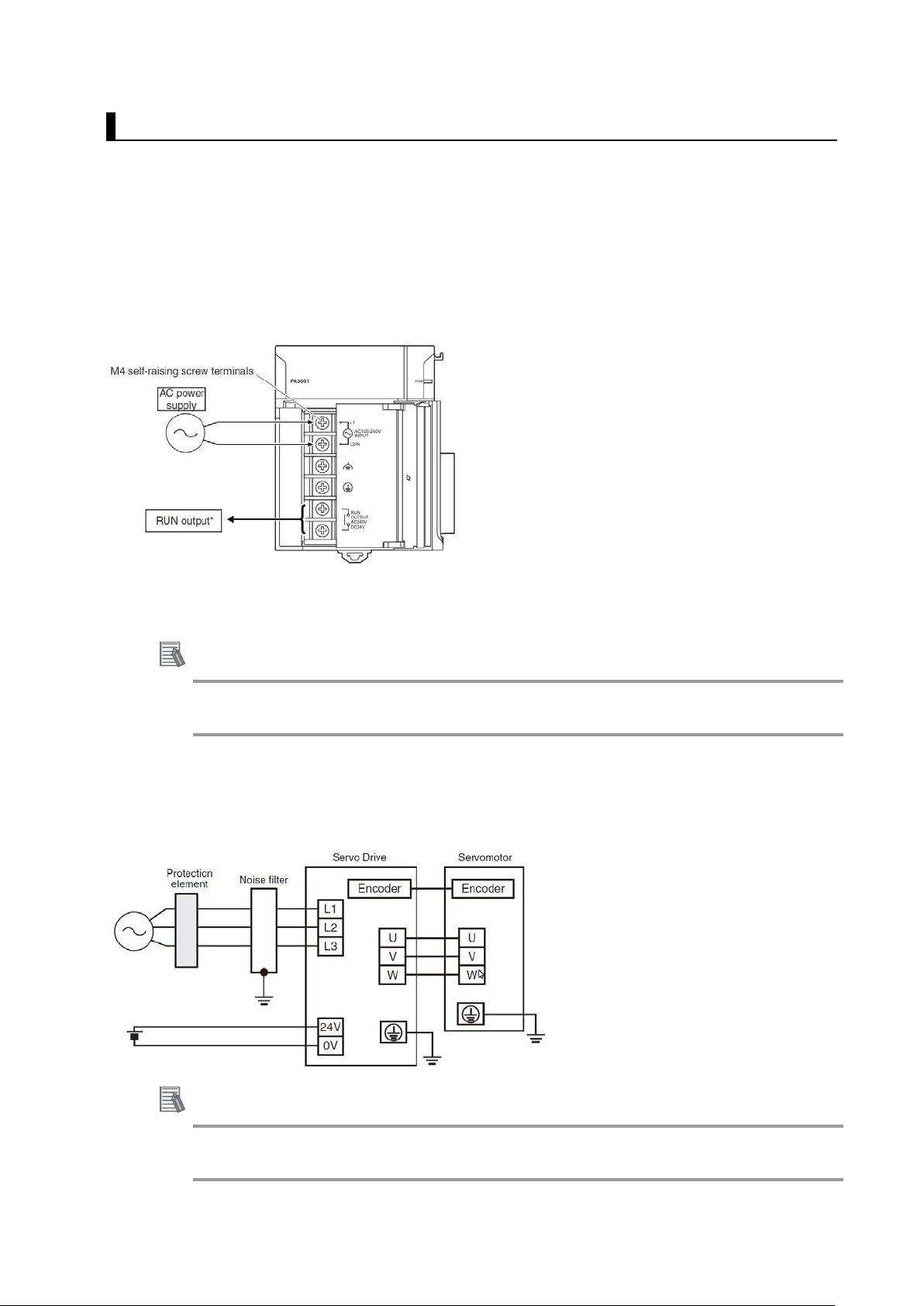

2.3. Wiring the Devices

This section describes how to wire the hardware devices.

This section gives an ov er v iew of the w irin g pro ced ur es. Re fer to th e manua ls for the dev ices t hat are

used in the system for detailed w iring procedures and safety precautions.

Wiring the Rack Power Supply Unit

Wire the Power Supply Unit to the power supply.

*The RUN output is ON when the CPU Unit is in RUN mode. It is OFF when the CPU

Unit is in PROGRAM mode or when a major fault level Controller error occurs.

Additional Inf or mation

This Guide uses an NJ-PA3001 AC Power Supply Unit. An NJ-PD3001 DC Power Supply Unit can also

be used.

Wiring the Servo Drive Power Supply

Wire the Servo Drives to the power supply as shown in the following figure.

16

Additional Inf or mation

For further details about wiring method, please r efer to 1S-series AC Servomotors and Servo Drives

User’s Manual (with Built-in EtherCAT Communications) (Cat. No. I586)

Page 17

Laying EtherCAT Communi cati ons Cables

Connect the EtherCAT slave communications cables between the built-in EtherCAT port on the CPU Unit

and the EtherCAT slaves as shown in the following figure.

Connect the communications cable from the built-in EtherCA T port to the input port on the first slave, and

then connect the communications cable to the next slave to the output port on the first slave.

Do not connect anything to the output port of the slave at the end of the network.

Setting the Node Addresses of the Servo Drives

Set the node addresses of the Servo Drives as shown below.

17

Page 18

Wiring the Servo Drives and the Servomotors

Wire the Servo Drives and the Servomotors as shown in the fol lowing figure.

18

Page 19

Wiring the Control Input Signals for the Servo Drives

When using the default Servo parameters, please wire the

Wire the control input signals for the Servo Drive using the R88A-CN101C Control I/ O connector

(CN1).

For details on wiring, refer t o the AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT

Communications User's Manual (Cat. No. I586).

immediate stop input (ESTOP), negative drive prohibit input

(NOT), and the positive drive prohibit input (POT).

*Control I/O Connector (CN1):

Used for command input signals, I/O signals, and as the safety device connector. The short-circuit wire is installed on

the safety signals before shipment.

Additional Inf or mation

• If you use the default Servo parameters, you must wire the immediate stop input, negative drive

prohibit input, and the positive drive prohibit input.

If these inputs are not wired, the CPU Unit will remain in the drive prohibit signal and emergency stop

signal detected state, and a minor fault level Controller error will occur. The minor fault level Controller

errors that will occur are an Immediate Stop Input Error and a Drive Prohibition Input Error. (The event

codes are 68220000 and 64E30000.)

• If the above signals are temporarily not wired while commissioning the system, you can temporarily

change the Servo parameters to prevent these errors from occurring in the CPU Unit.

Refer to A-1 Settings When Control Input Signals Are Not Wired

must change in this case.

for details on the settings that you

19

Page 20

3. Performing setup

3.1. Two axis servo system operation

This section describes the operation of two-axis Servo system that is set up in this Guide.

In this system, axis 0 and axis 1 are set up for an XY stage.

The mechanical configuration of axis 0 and axis 1 are as shown in the following table.

Item Axis 0 / Axis 1 mechanical configuration

Motor rated speed 3000 r/min

Ball screw pitch 10 mm

Encoder resolution 23 bits/rotation (8,338,608)

20

Page 21

The XY stage will repeatedly travel between two points using linear interpolation with a 2 seconds dwell

time after each movement.

Interpolation velocity: 250 mm/s

Acceleration rate: 8000 mm/s²

Deceleration rate: 8000 mm/s²

50 mm

Dwell time: 2 seconds

0 mm

The speed waveforms for axis 0 and axis 1 are shown below

Dwell time: 2 seconds

50 mm

21

Page 22

3.2. System setup procedures

1 Create a project with Auto connection

▼

2 Create the EtherCAT Network configuration

▼

3 Create motion axes

▼

4 Program making and transfer to the CPU U nit

▼

5 Drives and motors setup

▼

6 Multiple drive Easy tuning for gain adjustment

3.3. Creating project with Auto connection

Start the Sysmac Studio:

Select All Programs − OMRON − Sysmac Studio − Sysmac Studio from the Windows St art Menu.

Create a project in t he Sysmac Studio

1.

Click the Button in the Project window

2.

In the Connect to Device Dialog Box,

Click the button

22

Page 23

Sysmac Studio will browse and connect to the controller

This concludes the proce dure to create a project file w ith auto connection

Additional Inf or mation

For creating a project offl ine or specif ic proc edures please refer to the Sysmac Studio Version 1

Operation Manual (Cat. No. W504).

23

Page 24

Compare and Merge with Actual Network

3.4 Creating the EtherCAT Network Configuration

Two R88D-1SN01L-ECT Ser vo Drives are registered in the Et herCAT network configuration

1.

Double-click EtherCAT under Configurations and Setups in the Multiview Explorer.

The EtherCAT page is displayed in the Edit Pane.

2.

Right click on the Master and select

Configuration

24

Page 25

3. The Compare and Merge w it h Actual Network Configuration wind ow is displayed

e actual network

Click on Apply actual network configuration to apply th

configuration.

Click Apply to confirm:

A pop-up message confirmed the net w ork configuration.

Click the Close Button

Confirm the detected configuration and close the win dow

25

Page 26

Disconnect from the controller

3.5 Creating motion axes

This section describes how to add axes used to control Serv o Drives. A xes will be created bas ed on

detected Servo Drives.

1.

Right click on the Master and select Assign Drives to Axes

26

Confirm axes allocation by clicking the Yes Button

Confirm the list of Axes added and Click the Ok Button

Page 27

Right-click Axis Settings in the Multiview Explorer and select Axis setting table.

Axis number has been s et t o 0 and 1, A xis type to Servo axis and Output device 1 to

Node: 1 and Node: 2 on CH1 (Chan nel 1).

Project transfer to synchronize Sysmac Studio project and the CPU unit

2.

Click the Connect Button on the Toolbar

Click the Transfer to Controller Button on the Toolbar

Click the Execute Button to transfer the project from the computer to the CPU unit

27

Page 28

Click the Yes Button

The operating mode changes to PROGRAM mode, and the Sysmac Studio starts

transferring the project to the CPU Unit. During the transfer, a progress bar appears in the

Synchronize Pane.

After download completion, Click The Yes Button to switch to R UN m ode.

The transfer is completed, Cl ic k the Ok Button

28

Page 29

Apply Drive/Motor data to axis via network reading

3.

Right-click Axis Setti ngs in the Multiview Explorer and select Apply drive data to axis

settings.

Click the Yes Button to acquire data from the servo drive via EtherCAT Network

Applied axis settings are based on drive and motor data:

Command pulse count per motor rotation is set to 8,388,608 following the 23 bits

resolution of the motor.

Maximum velocity and Maximum jog velocity are set based on rated speed of the

motor.

Maximum positive torque limit and Max imum negative torque limit are set based

on drive/motor maximum torque limit.

Encoder type is set to Absolute encoder.

After confirmation, Click the Ok Button.

29

Page 30

Modification of axis settings to match the XY stage System

3. Disconnect from the Controller

Right-click Axis Settings in the Multiview Explorer and select Axis setting table.

Edit axis settings accordi ng to the XY stage ball screw system

Note: Alternatively, Unit conversion settings can also be modified before transferring the project; in

that case operation settin gs will be scaled based on mm units and drive data.

Adding Axes Group Settings

4.

Right-click Axes Group Settings under Configurations and Setup - Motion Control

Setup in the Multiview Explorer and select Add - Axes Group Settings from the

menu.

30

Page 31

An axes group is added to the M ultiview Explorer.

The new axes group is displayed as MC_Group000.

Right-click the group that you added in the Multiview Explorer and select Edit from the

menu.

The axes group settings are displayed on the Axes Group Basic Settings Display in the

Edit Pane.

Set the Axes Group Basic Settings f or axes group 0 as shown in the following figure.

This concludes the axes gr oup set tings.

31

Page 32

3.6 Program making and transfer t o the CPU Unit

Create the instructions to perform linear interpolation of two axes.

The following instructions are created. To do so, we will use axis v ar ia bles, an axes group, and

motion control instructions.

Rung 0: Axes Servo ON

Rung 1: Axes homing to zero position preset

Rung 2: Axis group enable

Rung 3: Absolute position assigned to input variables

Rung 4: Movement cycle (50mm>2s ec> 50mm>2sec repeating)

Please refer to A-2 Appendix for the equivalent Structur ed Text program example

Refer to the NJ/NX-series Startup Guide for CPU Units (Cat. No. W513) for details on how to create ladder

diagrams.

Precautions for Correct Use

The sample programming that is provided in this Guide inc lu des only the programming

that is required to operate the Servomotors. When programming ac t ual a pplications,

also program EtherC AT communications, device interlocks, I/O with ot her dev ices, and

other control procedures.

32

Page 33

Transfer to the CPU Unit

1.

Click the Connect Button on the Toolbar

2.

3.

Click the Transfer to Controller Button on the Toolbar

Click the Execute Button to transfer the project from t he com put er t o the CPU unit

Click the Yes Button

The operating mode changes to PROGRAM mode, and the Sysmac Studio starts

transferring the project to the CPU Unit. During the transfer, a progress bar appears in the

Synchronize Pane.

After download completion, Click The Yes Button to switch to RUN mode.

The transfer is completed, Cl ic k the Ok Button

33

Page 34

3.7 Drives and motors parameters setup

This section explains the procedure to setup parameters of drives and motors.

The absolute encoder must be set up the first time it is used, and when the rotation data is

initialized to 0.

1.

Right-click the Servo Drive and select Setup and Tuning from the menu.

2.

The Setup and Tuning Portal appears.

Click the Quick Parameter Setup and I/O Monitor Button.

The following dialog box a ppear s. Click the Yes Button.

The Motor and Encoder s et ting Page appears.

34

Page 35

3.

An Absolute Value Clear Error (error display number: 2701) will occur, and a dialog box

4.

Click the Launch Motor and Encoder view Button.

The Encoder Properties Tab Page appears.

Click the Clear system Button.

indicating "Restart the drive to complete the operation."

5.

Click the Yes Button.

The multiple rotation dat a of the absolute encoder is cleare d.

Return to the Wizard window.

35

Page 36

Check the motor rotation direction and modify settings if required

6. Adjust the motor rotation direction and transfer to t he dr ive

7.

Validate the motor operation

Apply the test run configurat ion, activate the Servo ON and in it iate t he movement

Note: In case of Error 87.00 ESTP input, please chec k your wiring connection o r disable the

error stop input (IN1) as explained in A-1 Settings When Control Input Signals Are Not Wired

details on the settings that you must change in this case.

36

for

Page 37

8.

the EtherCAT Slave Communication Error in the CPU Unit with

Click the Back to Portal Button

9.

Please repeat the same o per at ion for the node 2.

10. Following above procedure, drives have been restart ed t o apply Input settings.

Please Reset

Troubleshooting window.

Click on Reset All button

37

Page 38

3.8 Easy Tuning (Multiple Drives)

In this section we will explain h ow t o perform Easy tuning for multi pl e Drives simultaneously.

The Motion Controller wil l perf orm the motion profile.

Before running the program, be sure to place the XY system in the homing position required.

Confirm oper at ing mode of the CPU Unit is in RUN mode and t hen use control

BOOL variables (set/reset) to cont r ol t he m ot ion control instructions.

Double-click Section0 under Programming − POUs − Programs − Program0 in the Multiview

Explorer.

The ladder program is dis play ed in the Edit Pane.

Change the BOOL variables in the following order :

ServoLock changes to TRUE, Power 1 and Power 2 are executed.

Home changes to TRUE, Home1 and Home2 are executed. Axes position is now at zero position.

(Preset position is used)

GroupeEnable changes t o TRUE, Group1 is execut ed.

Start changes to TRUE.

Linear1 is executed and positioning is started for both axes. When the positioning for Linear1 is

completed, linear1 execution stops and Linear2 is executed. This operation is repeated with 2

seconds Dwell time betw een each movement.

38

Page 39

Perform the easy tuning (Multiple dri ves)

1.

Right-click Node1: R88D-1SN01L-ECT under Configurations and Setup -EtherCAT in

the Multiview Explorer, and select Setup and Tuning from the menu.

The Setup and Tuning Portal appears in Edit Pane

2.

Click the Easy Tuning Button under Tuning (Multiple Drives)

Select Drives to Tune and click the Ok Button

39

Page 40

3.

Tuning configuration

Select Simple mode and click Next

4.

Profile and criteria

The motion profile generator is the Motion Controller.

Adjust criteria to achieve t uni ng and click Next button

Precautions for Correct Use

The Load Characteristic E st imation function may not operate properly under the

following conditions. In such cases, s et t he r elated objects manually.

Load inertia

Load

Operation

Conditions that interfere with the Load Characteristic Estimation function

• If the load inertia is small, i.e. less than 3 times the rotor inertia or large, i.e. the

applicable load inertia or more

• If the load inertia changes easily

• If the machine rigidity is extrem ely low

• If there is a non-linear element (play), such as a backlash

• If the speed continues at lower than 100 r/min

• If the acceleration/dec el eration is 2,000 r/min/s or lower

• If the acceleration/dec el eration torque is small compared with the unbalanced load

and the friction torque

• If the speed or torque oscillates due to the high gain or small effect of each filter.

40

Page 41

5.

ain will be increased gradually until achieving the specified settling time. The positioning

window, specify the position deviation to determine that the positioning is completed. If it

Auto Tune Monitor

Click the Start Button

G

detects a vibration above the vibration detection level during tuning, an adjustment failure

will occur.

Criteria achieved, click th e Ok Button

Click the Next Button

41

Page 42

6.

Check Behavior

Click the Record Button

Monitor data will be traced and automatically scaled

Confirm the behavior and clic k the Next Button

42

Page 43

7.

Finish

Confirm new gain parame t er s and s ave to EEPROM

Click the Ok Button

The easy tuning wizard for mu lt ip le dr iv es is completed

Click the Finish Button

43

Page 44

ANNEX

A-1 Settings when control input signals are not wired

An error will occur in the CPU Unit if the Servo parameters for t he Ser vo Drive are left at their defau lt

values when the Servo Dri ve control input signals are not w ired. This is because the CPU Unit st ops

operation when a drive pr ohi bit or i m me di at e s t op signal is detected. The minor fault level Controller

errors that occur are as fol lows :

• Error Stop Input (Event code: 68220000)

• Drive Prohibition Input Er r or ( Event code: 64E30000)

This section describes how to temporarily change the Servo parameters to prevent t hes e er r ors from

occurring in the CPU Unit.

The procedure described here assume that a project with a Servo Drive registered to the EtherCAT

network configuration has been transferred to the CPU Unit and that the CPU Unit is currently online.

Perform the following befo r e you perform the procedures that ar e given in this section.

• Place the Sysmac Studio online with the CPU Unit.

• Transfer to the CPU Unit the project that contains the EtherCAT network configurat ion in which the

Servo Drives are register ed.

1.

Precautions for Correct Use

If the control input signals are not wired, it will not be possible to stop operation for limit

inputs or immediate stop inputs in the event that unexpect ed motor operation occurs.

Remove the coupling fro m the motor shaft or take ot her s uitable measures to prevent a

hazardous condition from occurring.

Right-click the Servo Drive and select Setup and Tuning from the menu.

44

The Setup and Tuning Portal appears.

Page 45

2.

Click the Quick Parameter Setup and I/O Monitor Button.

The following dialog box a ppears . Click the Yes Button.

The Motor and Encoder s et t ing P age appears.

3.

Click the Next Button

The Input Signals setting Page appears.

45

Page 46

5.

Change the signal allocation of the below listed input signal, and then click the Transfer to

Drive Button.

• Error Stop Input

• Positive Drive Prohibit Input

• Negative Drive Prohibit Input

The following dialog box a ppears . Click the Yes Button

The drive restarts and you ret ur n t o t he Input Signals setting Page.

6.

Click the Next Button

The Output Signals settin g Page appears

46

Page 47

7.

Click the Next Button

8. Please Set Node2: R88D-1SN01L-ECT(E002) in t he same way as Node1.

Please click to the Copy Settings Button

The Copy Settings window appears.

47

Page 48

9.

Check boxes and click the Execute button to start the procedure

Click the Yes Button to confirm the copy settings

Click the Yes Button to transfer settings to target driv e

48

The target drive is restarti ng

Page 49

Slave Communication Error in the CPU Unit with

Settings are now effe ctive in the target drive, click the Ok Button

Click the Close Button

Click the Finish Button

This concludes the proce dure to change Input settings of Nod e 1 and Node 2.

10. Following above procedure, drives have been rest arted to apply Input settings.

Please Reset the EtherCAT

Troubleshooting window.

Click on Reset All button

49

Page 50

Confirm the below message and lick on Yes button

Errors are now resetted

50

Page 51

A-2 Program making with structured text

Below is an alternative progr am to move the XY st age with st r uc t ur ed t ext .

Power1(Axis:=MC_Axis000, Enable:=ServoLock);

Power2(Axis:=MC_Axis001, Enable:=ServoLock);

Home1(Axis:=MC_Axis000, Execute:=Home);

Home2(Axis:=MC_Axis001, Execute:=Home);

Group1(AxesGroup: =MC_Group000, Exec ut e:= G roupEnable);

Distance1[0]:=0;

Distance1[1]:=0;

Distance2[0]:=50;

Distance2[1]:=50;

Dwell_Time1:=TIME#2s;

Dwell_Time2:=TIME#2s;

Dwell1(In:=Start AND NOT Complete, PT:=Dwell_Time1, Q=>Go_Linear1);

Dwell2(In:=Start AND NOT Complete AND MoveLinear1.Done, PT:=Dwell_Time2,

Q=>Go_Linear2);

MoveLinear1(Ax esGr oup:= M C _Gr oup 000, Execute:=Go_Linear1, Position:=Distance1,

Velocity:=250, Accel eration:=8000, Deceleration:=8000);

MoveLinear2(Ax esGr oup:= M C _Gr oup 000, Execute:=Go_Linear2, Position:=Distance2,

Velocity:=250, Acceleration:=8000, Deceleration:=8000, Done=>Complete);

51

Page 52

2017

Note:DonotusethisdocumenttooperatetheUnit.

I827-E1-01

0317 (0317)

Loading...

Loading...