OMRON R88M-1L, R88D-1SN User Manual

AC Servomotors/Servo Drives

1S-series with Built-in

EtherCAT® Communications

User’s Manual

R88M-1L/-1M (AC Servomotors)

R88D-1SN-ECT (AC Servo Drives)

I586-E1-12

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• Safety over EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Introduction

Thank you for purchasing a 1S-series Servo Drive. This User’s Manual describes the installation and

wiring methods of the 1S-series Servo Drives and parameter setting method which is required for the

operation, as well as troubleshooting and inspection methods.

Intended Audience

This User’s Manual is intended for the following personnel, who must also have electrical knowledge

(certified electricians or individuals who have equivalent knowledge).

• Personnel in charge of introducing the FA equipment

• Personnel in charge of designing the FA systems

• Personnel in charge of installing and connecting the FA equipment

• Personnel in charge of managing the FA systems and facilities

Introduction

Notice

This User’s Manual contains information you need to know to correctly use the 1S-series Servo Drives

and peripheral equipment.

Before using the Servo Drive, read this User’s Manual and gain a full understanding of the information

provided herein.

After you finished reading this User’s Manual, keep it in a convenient place so that it can be referenced

at any time.

Make sure this User’s Manual is delivered to the end user.

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

1

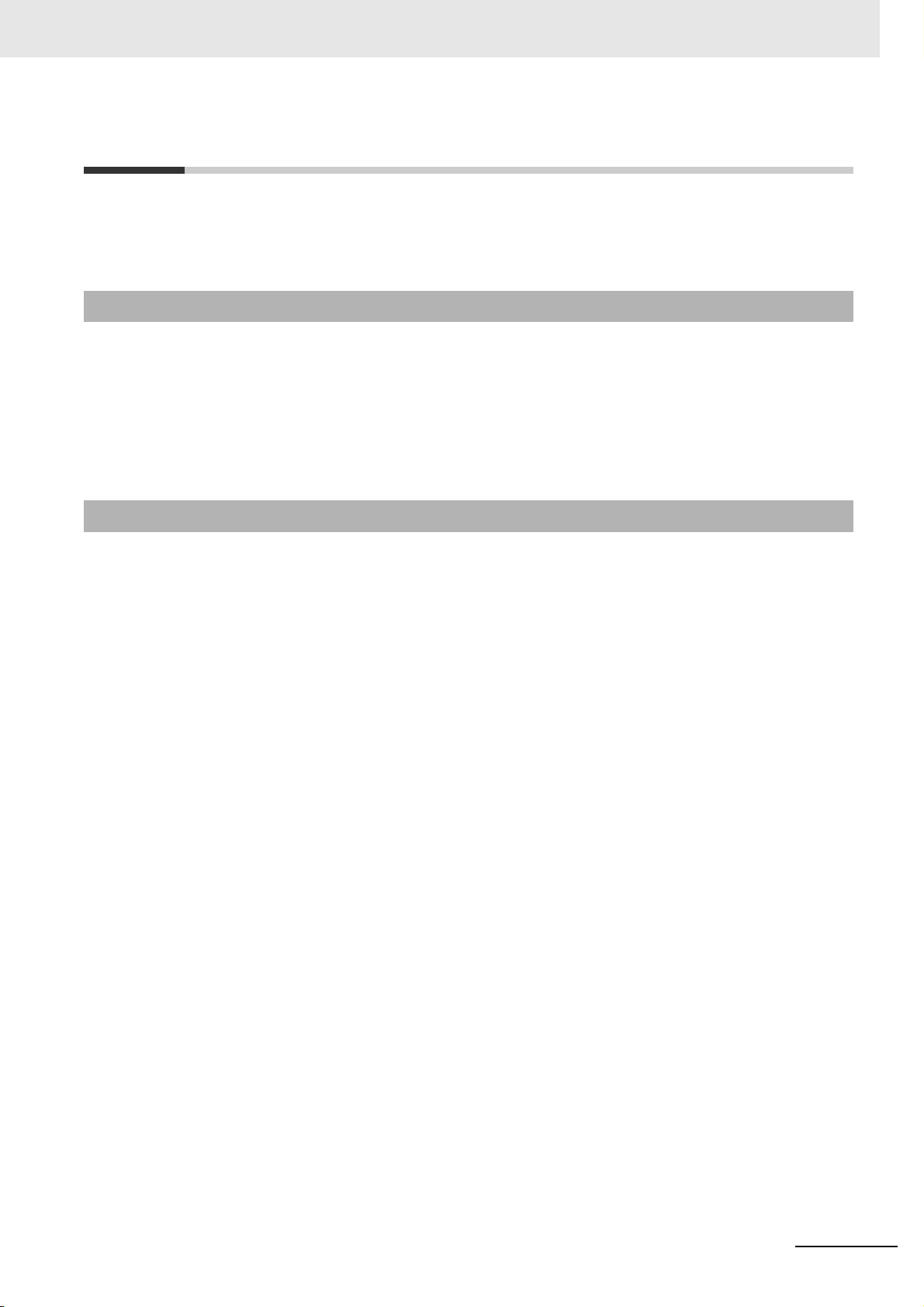

Manual Structure

7 Applied Functions

7 - 30

1S-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

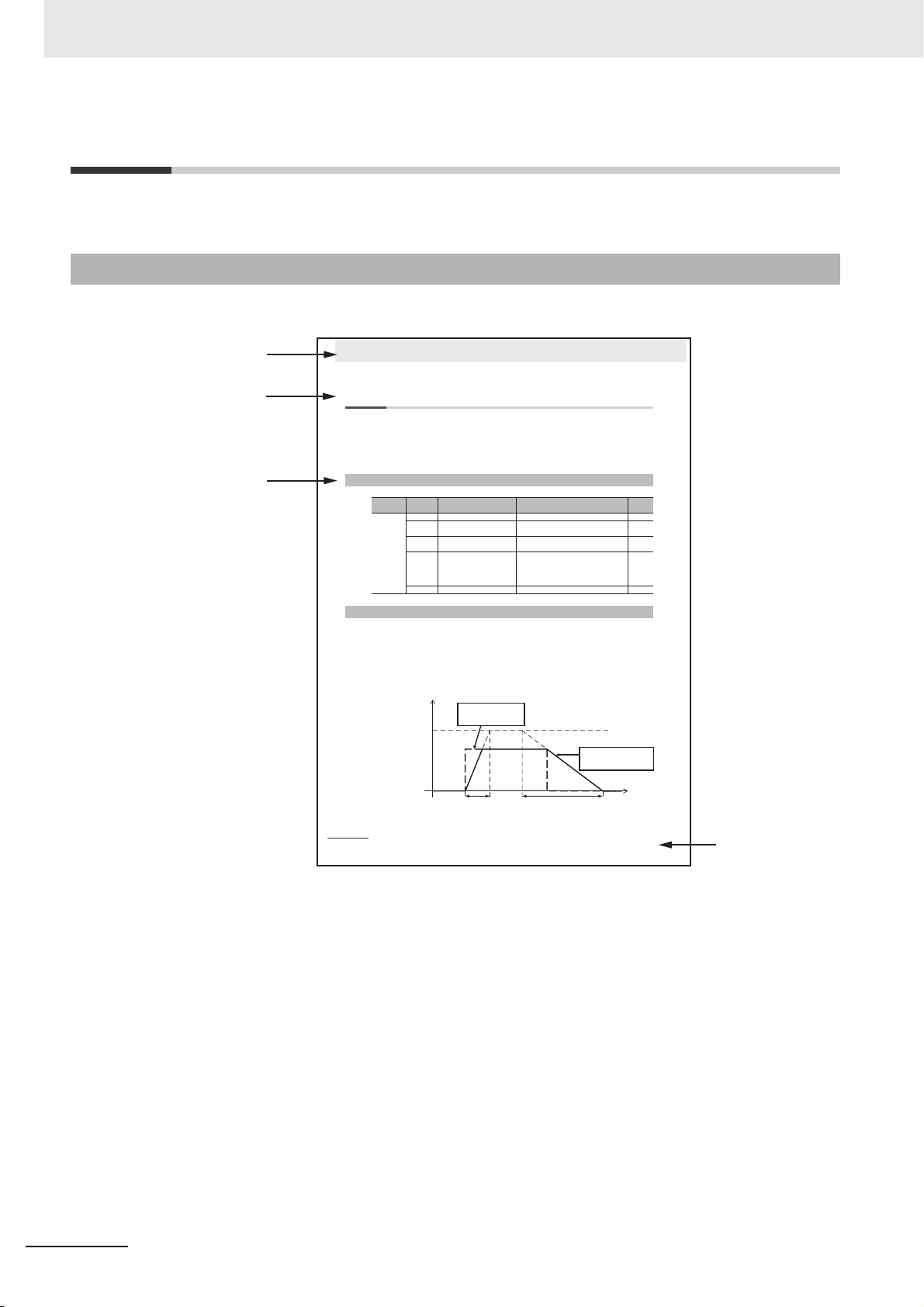

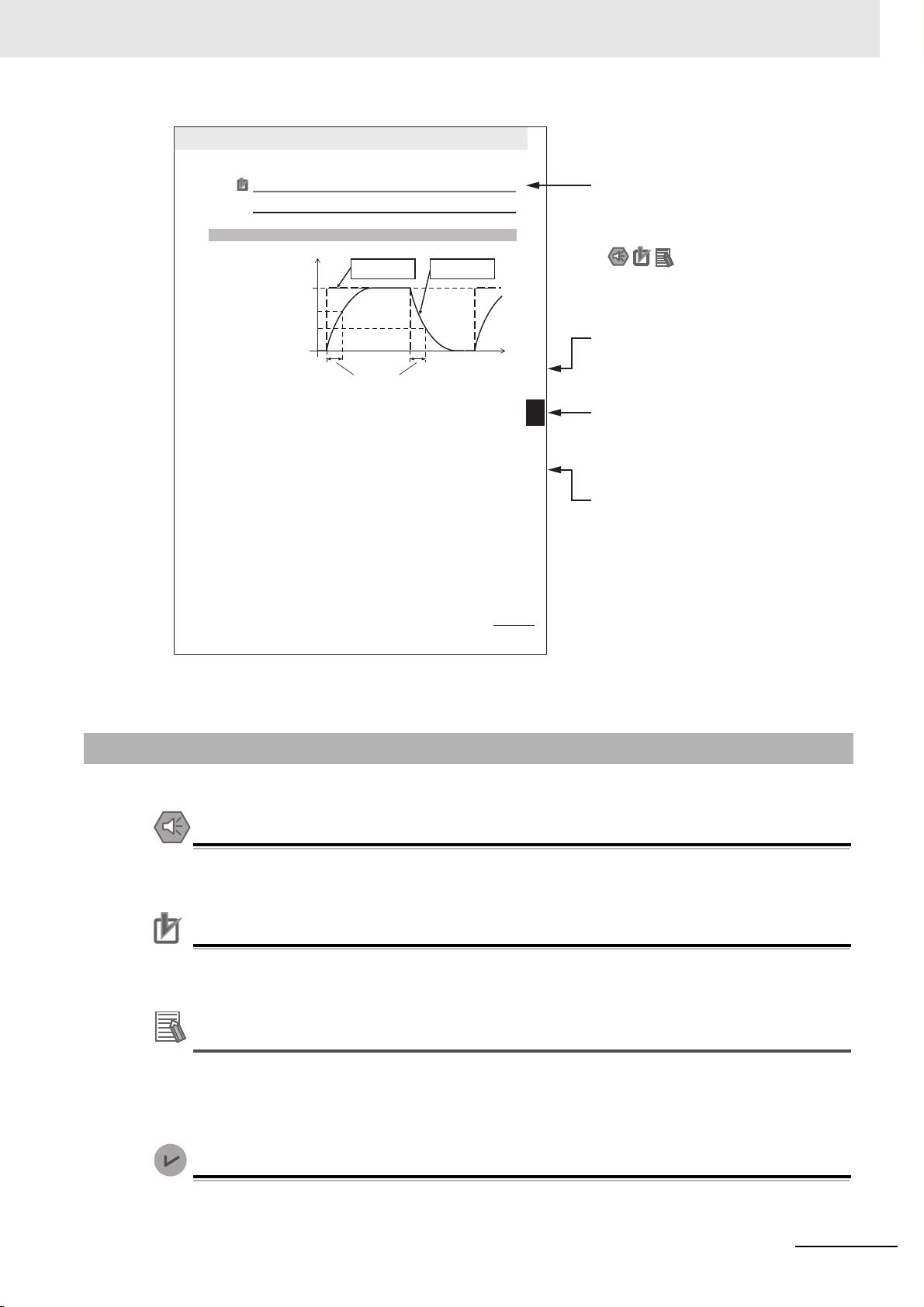

7-9 Soft Start Function

This function sets the acceleration and deceleration against the velocity command input inside the

Servo Drive and uses these values for speed control.

With this function, soft starts are possible when the step rotation velocity commands are input. To

reduce any impacts made by acceleration changes, you can also use the velocity command filter

(first-order lag).

For a step velocity command input, set the time until the velocity command reaches 1,000 r/min in

Acceleration Time.

Similarly, set the time until the velocity command slows from 1,000 r/min down to 0 r/min in Deceleration Time.

Acceleration Time (ms) = Vc/1,000 r/min × Acceleration Time × 0.1 ms

Deceleration Time (ms) = Vc/1,000 r/min × Deceleration Time × 0.1 ms

7-9-1 Objects Requiring Settings

Index

(hex)

Subindex

(hex)

Name Description

Refer-

ence

3021

–

Velocity Command Filter

–

P. 9 -1 9

01 Acceleration Time Sets the acceleration time during accelera-

tion.

P. 9 -1 9

02 Deceleration Time Sets the deceleration time during decelera-

tion.

P. 9 -1 9

03 IIR Filter Enable Selects whether to enable or disable the

IIR filter in the velocity command filter.

0: Disabled

1: Enabled

P. 9 -2 0

04 Filter Cutoff Frequency Sets the cutoff frequency for the IIR filter. P. 9-20

7-9-2 Soft Start Acceleration/Deceleration Time

Time

Velocity command [r/min]

Acceleration Time × 0.1 ms Deceleration Time × 0.1 ms

1,000 [r/min]

Velocity command before

acceleration control

(step type command)

Velocity command after

acceleration control

(trapezoidal type command)

Level 1

heading

Level 2

heading

Level 3

heading

Manual name

Manual Structure

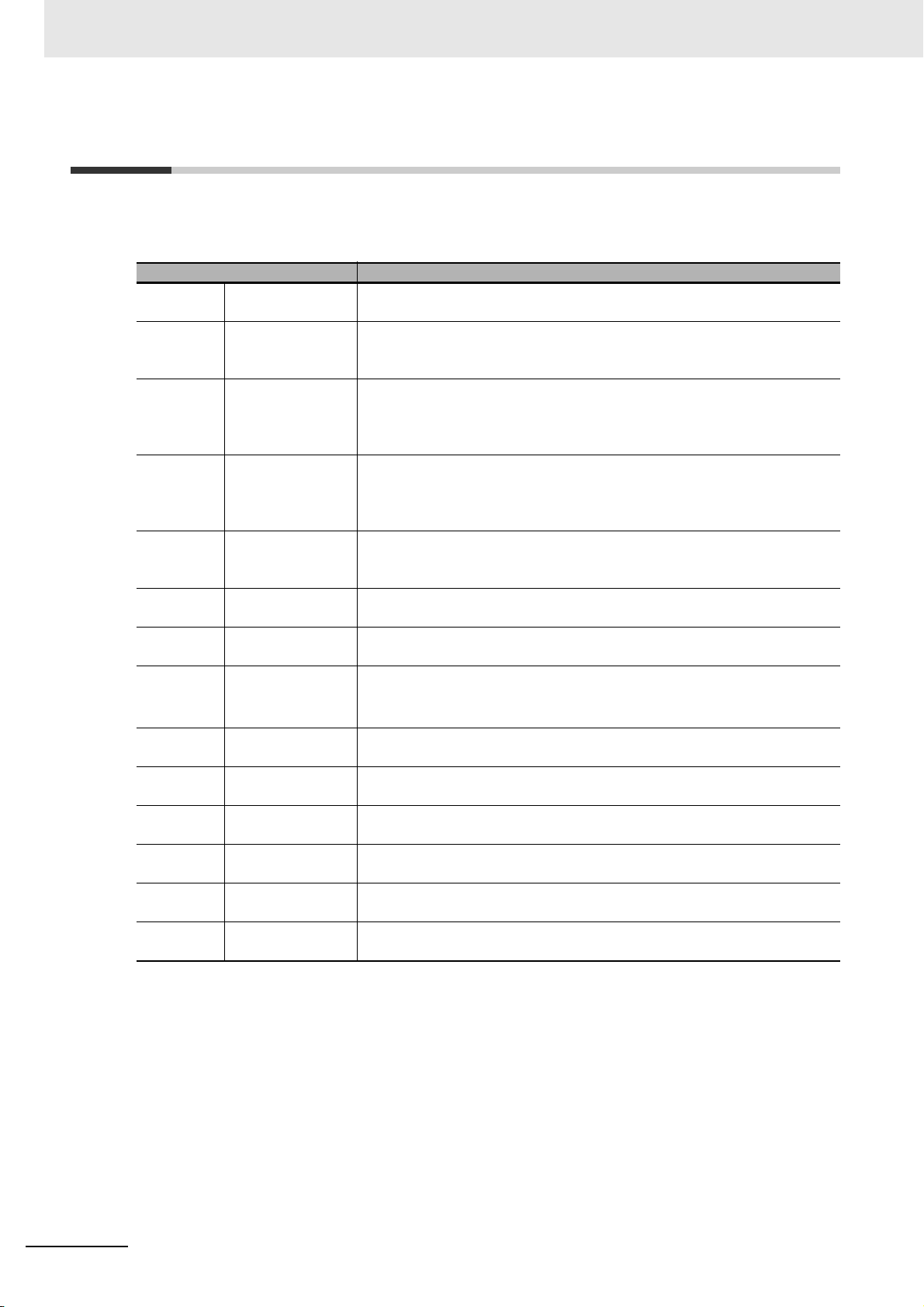

This section explains the page structure and symbol icons.

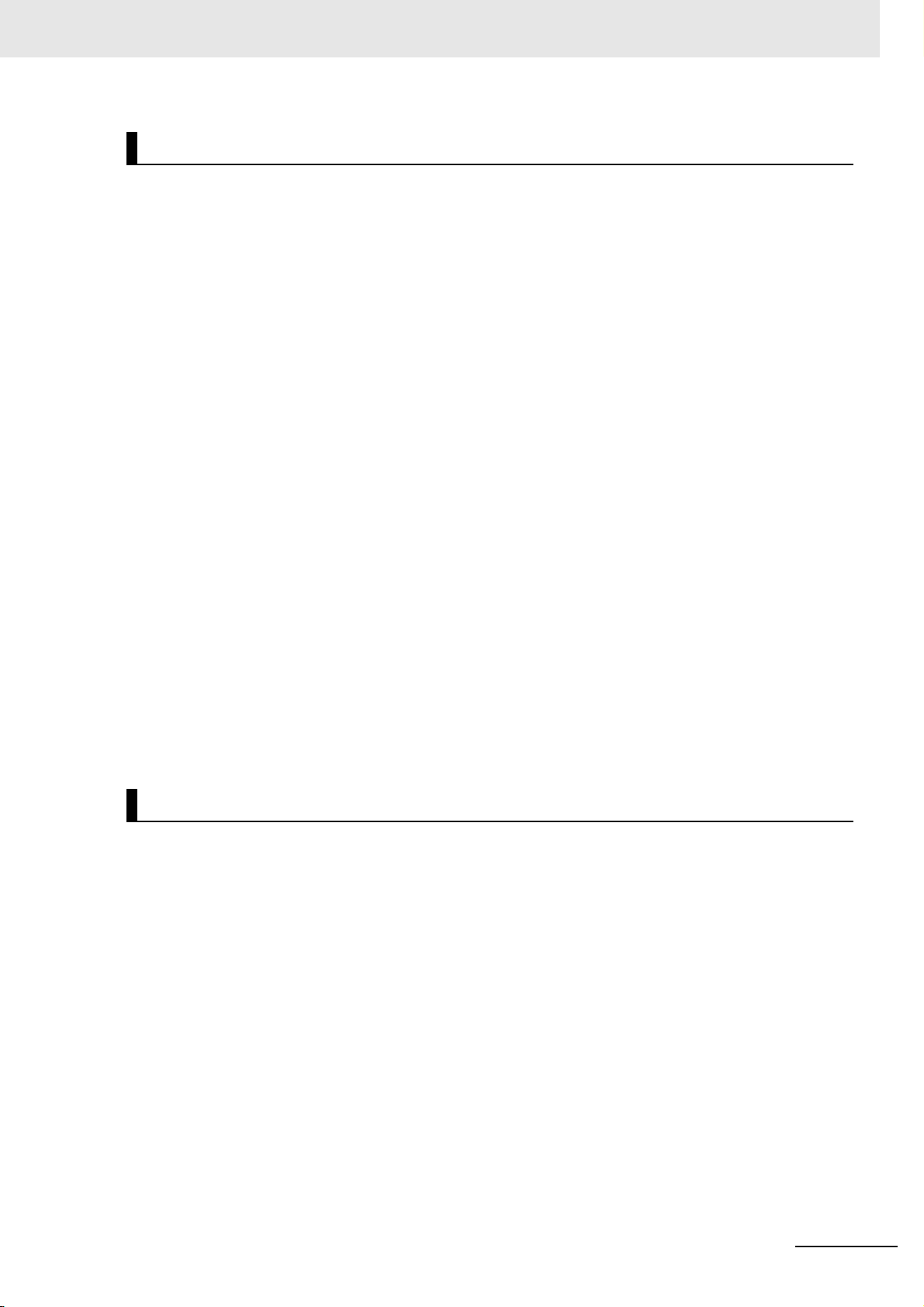

Page Structure

The following page structure is used in this manual.

Note The above page is only a sample for illustrative purposes. It is not the actual content of this User’s Manual.

2

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Version Information

7 - 31

7 Applied Functions

1S-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

7-9 Soft Start Function

7

7-9-3 Velocity Command Filter (First-order Lag)

Precautions for Correct Use

Do not set the Acceleration Time and the Deceleration Time when the position loop structure

with a host controller is used.

The velocity command filter (first-order lag) is an IIR filter used for speed commands.

7-9-3 Velocity Command Filter (First-order Lag)

Vc × 0.632

(s)

Vc × 0.368

Time

Velocity command [r/min]

Target velocity

Target velocity

Target velocity

Velocity command

before filter process

Velocity command

after filter process

1/(2π × Filter Cutoff Frequency)

Icons indicate precautions,

additional information, or

reference information.

Special information

Level 2 heading

Gives the current heading.

Page tab

Gives the number of

the main section.

Level 3 heading

Gives the current heading.

Manual Structure

Note This illustration is provided only as a sample. It may not literally appear in this manual.

Special Information

Special information in this manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Information on differences in specifications and functionality for Servo Drives with different unit

versions and for different versions of the Sysmac Studio is given.

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

3

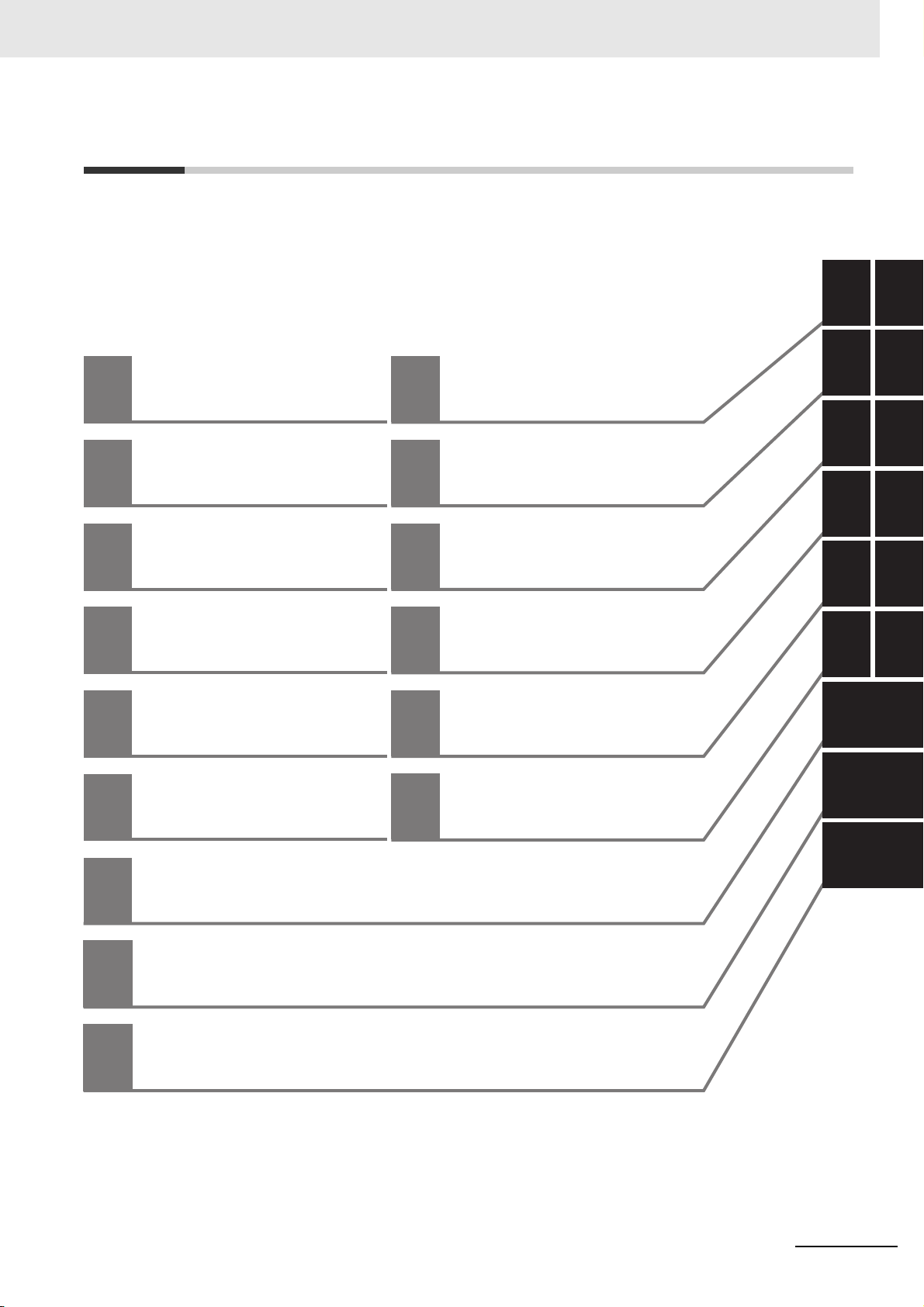

Manual Configuration

Manual Configuration

This User’s Manual consists of the following sections.

Read the necessary section or sections by reference to the following table.

Section Outline

Section 1

Section 2

Section 3 Specifications

Section 4

Section 5

Section 6

Section 7 Applied Functions

Section 8 Safety Function

Section 9

Section 10 Operation

Section 11

Section 12 Troubleshooting

Section 13

Appendices

Features and System Configuration

Models and External Dimensions

Configuration and

Wiring

EtherCAT Communications

Basic Control

Functions

Details on Servo

Parameters

Adjustment Functions

Maintenance and

Inspection

This section explains the features of the Servo Drive and name of each part.

This section explains the models of Servo Drives, Servomotors, Decelerators, and peripheral devices, and provides the external dimensions and

mounting dimensions.

This section provides the general specifications, characteristics, connector

specifications, and I/O circuits of the Servo Drives as well as the general

specifications, characteristics, encoder specifications of the Servomotors

and other peripheral devices.

This section explains the conditions for installing Servo Drives, Servomotors,

and Decelerators, the wiring methods including wiring conforming to EMC

Directives, the regenerative energy calculation methods, as well as the performance of External Regeneration Resistors.

This section explains EtherCAT communications under the assumption that

the Servo Drive is connected to a Machine Automation Controller

NJ/NX-series CPU Unit or Position Control Unit (Model: CJ1W-NC8)

This section explains the outline and settings of basic control functions.

This section provides the outline and settings of the applied functions such

as electronic gear and gain switching.

This function stops the motor based on a signal from a safety controller.

This section provides the outline of the function and examples of operation

and connection.

This section explains the details on each servo parameter, including the set

values, settings, and the display.

This section provides the operational procedure and explains how to operate

in each mode.

This section explains the functions, setting methods, and items to note

regarding adjustments.

This section explains the items to check when problems occur, and troubleshooting by the use of error displays or operation state.

This section explains maintenance and inspection of the Servomotors and

Servo Drives.

The appendices provide explanation for the profile that is used to control the

Servo Drive, lists of objects, and Sysmac error status codes.

4

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

1

10

2

11

3

4

13

5

6

7

8

9

1

10

2

11

12

3

4

13

5A

6 I

7

8

9

A

I

Features and System

Configuration

Models and External

Dimensions

Operation

Specifications

Adjustment Functions

12

Troubleshooting

Configuration and

Wiring

Maintenance and

Inspection

EtherCAT

Communications

Appendices

Applied Functions

Basic Control

Functions

Index

Safety Function

Details on Servo Parameters

Sections in this Manual

Sections in this Manual

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

5

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Manual Structure ......................................................................................................2

Manual Configuration ..............................................................................................4

Sections in this Manual ...........................................................................................5

Terms and Conditions Agreement ........................................................................16

Safety Precautions .................................................................................................18

Items to Check After Unpacking ...........................................................................29

Related Manuals .....................................................................................................40

Terminology ............................................................................................................43

Revision History .....................................................................................................45

Section 1 Features and System Configuration

1-1 Outline .................................................................................................................................. 1-2

1-1-1 Features of 1S-series Servo Drives.......................................................................................... 1-2

1-1-2 EtherCAT ..................................................................................................................................1-3

1-1-3 Object Dictionary ......................................................................................................................1-4

1-2 System Configuration .........................................................................................................1-5

1-3 Names and Functions ......................................................................................................... 1-6

1-3-1 Servo Drive Part Names ...........................................................................................................1-6

1-3-2 Servo Drive Functions ............................................................................................................1-13

1-3-3 Servomotor Part Names .........................................................................................................1-16

1-3-4 Servomotor Functions.............................................................................................................1-18

1-3-5 Shield Clamp Part Names ......................................................................................................1-19

1-4 System Block Diagram...................................................................................................... 1-20

1-5 Applicable Standards........................................................................................................ 1-28

1-5-1 EU Directives ..........................................................................................................................1-28

1-5-2 UL and cUL Standards............................................................................................................1-29

1-5-3 Korean Radio Regulations (KC) .............................................................................................1-30

1-5-4 SEMI F47................................................................................................................................1-30

1-5-5 Australian EMC Labeling Requirements (RCM) .....................................................................1-31

1-5-6 EAC Requirements .................................................................................................................1-31

1-6 Unit Versions...................................................................................................................... 1-32

1-6-1 Confirmation Method ..............................................................................................................1-32

1-6-2 Unit Versions and Sysmac Studio Versions............................................................................1-32

1-7 Procedures to Start Operation ......................................................................................... 1-33

1-7-1 Overall Procedure...................................................................................................................1-33

1-7-2 Procedure Details ...................................................................................................................1-35

Section 2 Models and External Dimensions

2-1 Servo System Configuration .............................................................................................. 2-2

6

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

CONTENTS

2-2 How to Read Model Numbers............................................................................................. 2-4

2-2-1 Servo Drive............................................................................................................................... 2-4

2-2-2 Servomotor............................................................................................................................... 2-5

2-2-3 Encoder Cable.......................................................................................................................... 2-6

2-2-4 Motor Power Cable without Brake Wire ................................................................................... 2-7

2-2-5 Motor Power Cable with Brake Wire ........................................................................................ 2-8

2-2-6 Decelerator............................................................................................................................... 2-9

2-3 Model Tables...................................................................................................................... 2-11

2-3-1 Servo Drive Model Table .........................................................................................................2-11

2-3-2 Servomotor Model Tables....................................................................................................... 2-12

2-3-3 Servo Drive and Servomotor Combination Tables.................................................................. 2-17

2-3-4 Decelerator Model Tables....................................................................................................... 2-19

2-3-5 Servomotor and Decelerator Combination Tables.................................................................. 2-23

2-3-6 Cable and Connector Model Tables ....................................................................................... 2-25

2-3-7 External Regeneration Resistor and External Regeneration Resistance Unit

Model Tables .......................................................................................................................... 2-33

2-3-8 External Dynamic Brake Resistor Model Table ...................................................................... 2-34

2-3-9 Reactor Model Table............................................................................................................... 2-34

2-3-10 Noise Filter Model Table......................................................................................................... 2-35

2-4 External and Mounting Dimensions ................................................................................ 2-36

2-4-1 Servo Drive Dimensions......................................................................................................... 2-36

2-4-2 Servomotor Dimensions......................................................................................................... 2-43

2-4-3 Cable Outlet Direction ............................................................................................................ 2-99

2-4-4 Cable Wiring Dimension for a Case of Motor Installing........................................................ 2-100

2-4-5 Decelerator Dimensions....................................................................................................... 2-102

2-4-6 Dimensions of External Regeneration Resistors and External Regeneration

Resistance Units ...................................................................................................................2-119

2-4-7 Dimensions of External Dynamic Brake Resistors ............................................................... 2-120

2-4-8 Reactor Dimensions ............................................................................................................. 2-121

2-4-9 Noise Filter Dimensions ....................................................................................................... 2-130

Section 3 Specifications

3-1 Servo Drive Specifications ................................................................................................. 3-3

3-1-1 General Specifications ............................................................................................................. 3-3

3-1-2 Characteristics.......................................................................................................................... 3-5

3-1-3 EtherCAT Communications Specifications ............................................................................. 3-13

3-1-4 Main Circuit and Motor Connections ...................................................................................... 3-14

3-1-5 Control I/O Connector (CN1) Specifications........................................................................... 3-27

3-1-6 Control Input Circuits.............................................................................................................. 3-30

3-1-7 Control Input Details............................................................................................................... 3-30

3-1-8 Control Output Circuits........................................................................................................... 3-31

3-1-9 Control Output Details............................................................................................................ 3-32

3-1-10 Encoder Pulse Output Specifications ..................................................................................... 3-32

3-1-11 Safety I/O Specifications ........................................................................................................ 3-33

3-1-12 Brake Interlock Connector (CN12) Specifications .................................................................. 3-35

3-1-13 Encoder Connector (CN2) Specifications............................................................................... 3-35

3-1-14 EtherCAT Communications Connector (RJ45) Specifications................................................ 3-36

3-1-15 USB Connector (CN7) Specifications..................................................................................... 3-36

3-1-16 Power ON Sequence.............................................................................................................. 3-37

3-1-17 Overload Characteristics (Electronic Thermal Function) ........................................................ 3-38

3-2 Servomotor Specifications ............................................................................................... 3-43

3-2-1 General Specifications ........................................................................................................... 3-43

3-2-2 Encoder Specifications........................................................................................................... 3-44

3-2-3 Characteristics........................................................................................................................ 3-45

3-3 Decelerator Specifications ............................................................................................... 3-70

3-4 Cable and Connector Specifications ............................................................................... 3-77

3-4-1 Encoder Cable Specifications ................................................................................................ 3-77

3-4-2 Motor Power Cable Specifications ......................................................................................... 3-84

3-4-3 Combination of Power Cable and Extension Cable ..............................................................3-117

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

7

CONTENTS

3-5 Specifications of External Regeneration Resistors and External Regeneration

3-6 External Dynamic Brake Resistor .................................................................................. 3-132

3-7 Reactor Specifications.................................................................................................... 3-133

3-8 Noise Filter Specifications.............................................................................................. 3-135

3-4-4 Resistance to Bending of Flexible Cable.............................................................................. 3-118

3-4-5 Connector Specifications ......................................................................................................3-120

3-4-6 EtherCAT Communications Cable Specifications .................................................................3-124

Resistance Units.............................................................................................................. 3-127

3-5-1 General Specifications..........................................................................................................3-127

3-5-2 Characteristics......................................................................................................................3-128

3-5-3 External Regeneration Resistance Unit Specifications......................................................... 3-130

3-6-1 General Specifications..........................................................................................................3-132

3-6-2 Characteristics......................................................................................................................3-132

3-7-1 General Specifications..........................................................................................................3-133

3-7-2 Characteristics......................................................................................................................3-133

3-7-3 Terminal Block Specifications ...............................................................................................3-134

3-8-1 General Specifications..........................................................................................................3-135

3-8-2 Characteristics......................................................................................................................3-136

3-8-3 Terminal Block Specifications ...............................................................................................3-137

Section 4 Configuration and Wiring

4-1 Installation Conditions........................................................................................................ 4-2

4-1-1 Servo Drive Installation Conditions...........................................................................................4-2

4-1-2 Servomotor Installation Conditions ...........................................................................................4-7

4-1-3 Decelerator Installation Conditions ......................................................................................... 4-11

4-1-4 External Regeneration Resistor and External Regeneration Resistance Unit

Installation Conditions.............................................................................................................4-14

4-1-5 Footprint-type Noise Filter Installation Conditions ..................................................................4-15

4-1-6 External Dynamic Brake Resistor Installation Condition.........................................................4-16

4-2 Wiring ................................................................................................................................. 4-17

4-2-1 Peripheral Equipment Connection Examples .........................................................................4-18

4-2-2 Procedure for Wiring Terminal Block and Procedure for Mounting Shield Clamp

to Servo Drive.........................................................................................................................4-34

4-2-3 Connector Attachment Procedure...........................................................................................4-40

4-2-4 Procedure for Change of Cable Outlet Direction for Connector Type M23 or M40.................4-44

4-2-5 Terminal Block Wiring Procedure for Footprint-type Noise Filter ............................................4-46

4-3 Wiring Conforming to EMC Directives ............................................................................ 4-47

4-3-1 Peripheral Equipment Connection Examples .........................................................................4-48

4-3-2 Selecting Connection Component ..........................................................................................4-62

4-4 Regenerative Energy Absorption..................................................................................... 4-72

4-4-1 Calculating the Regenerative Energy .....................................................................................4-72

4-4-2 Servo Drive Regeneration Absorption Capacity .....................................................................4-75

4-4-3 Regenerative Energy Absorption by an External Regeneration Resistance Device............... 4-76

4-4-4 Connecting an External Regeneration Resistor......................................................................4-77

4-5 Adjustment for Large Load Inertia................................................................................... 4-78

4-6 Machine Accuracy for Servomotor .................................................................................. 4-79

Section 5 EtherCAT Communications

5-1 Display Area and Settings .................................................................................................. 5-2

5-1-1 Node Address Setting...............................................................................................................5-2

5-1-2 Status Indicators.......................................................................................................................5-3

5-2 Structure of the CAN Application Protocol over EtherCAT ............................................. 5-5

5-3 EtherCAT State Machine ..................................................................................................... 5-6

8

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

5-4 Process Data Objects (PDOs) ............................................................................................ 5-7

5-4-1 PDO Mapping Settings............................................................................................................. 5-7

5-4-2 Sync Manager PDO Assignment Settings................................................................................ 5-8

5-4-3 Fixed PDO Mapping................................................................................................................. 5-8

5-4-4 Variable PDO Mapping............................................................................................................5-11

5-4-5 Sync Manager PDO Mapping Assignment Settings ............................................................... 5-12

5-5 Service Data Objects (SDOs)............................................................................................ 5-13

5-6 Synchronization Mode and Communications Cycle ...................................................... 5-14

5-6-1 Distributed Clock (DC) Mode.................................................................................................. 5-14

5-6-2 Free-Run Mode ...................................................................................................................... 5-14

5-7 Emergency Messages ....................................................................................................... 5-15

5-8 Sysmac Device Features .................................................................................................. 5-16

Section 6 Basic Control Functions

6-1 Outline of Control Functions.............................................................................................. 6-2

6-1-1 Basic Control and Control Methods.......................................................................................... 6-2

6-1-2 Control Method......................................................................................................................... 6-3

6-2 Control Blocks ..................................................................................................................... 6-5

6-2-1 Block Diagram for Position Control .......................................................................................... 6-5

6-2-2 Block Diagram for Velocity Control........................................................................................... 6-7

6-2-3 Block Diagram for Torque Control ............................................................................................ 6-9

6-3 Cyclic Synchronous Position Mode ................................................................................ 6-10

6-4 Cyclic Synchronous Velocity Mode................................................................................. 6-12

CONTENTS

6-5 Cyclic Synchronous Torque Mode................................................................................... 6-14

6-6 Profile Position Mode........................................................................................................6-16

6-7 Profile Velocity Mode ........................................................................................................6-21

6-8 Homing Mode..................................................................................................................... 6-24

6-9 Connecting with OMRON Controllers.............................................................................. 6-25

Section 7 Applied Functions

7-1 General-purpose Input Signals .......................................................................................... 7-3

7-1-1 Objects Requiring Settings....................................................................................................... 7-4

7-1-2 Default Setting.......................................................................................................................... 7-6

7-1-3 Function Input Details............................................................................................................... 7-7

7-2 General-purpose Output Signals ....................................................................................... 7-8

7-2-1 Objects Requiring Settings....................................................................................................... 7-8

7-2-2 Default Setting........................................................................................................................ 7-10

7-2-3 Function Output Details...........................................................................................................7-11

7-3 Drive Prohibition Functions ............................................................................................. 7-15

7-3-1 Objects Requiring Settings..................................................................................................... 7-15

7-3-2 Description of Operation......................................................................................................... 7-16

7-4 Software Position Limit Functions .................................................................................. 7-17

7-4-1 Operating Conditions.............................................................................................................. 7-17

7-4-2 Objects Requiring Settings..................................................................................................... 7-17

7-4-3 Description of Operation......................................................................................................... 7-18

7-5 Backlash Compensation................................................................................................... 7-20

7-5-1 Operating Conditions.............................................................................................................. 7-20

7-5-2 Objects Requiring Settings..................................................................................................... 7-20

7-5-3 Description of Operation......................................................................................................... 7-21

7-6 Brake Interlock................................................................................................................... 7-22

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

9

CONTENTS

7-7 Electronic Gear Function.................................................................................................. 7-29

7-8 Torque Limit Switching ..................................................................................................... 7-31

7-9 Soft Start ............................................................................................................................ 7-33

7-10 Gain Switching Function .................................................................................................. 7-35

7-11 Touch Probe Function (Latch Function).......................................................................... 7-39

7-12 Encoder Dividing Pulse Output Function ....................................................................... 7-43

7-13 Dynamic Brake................................................................................................................... 7-46

7-6-1 Objects Requiring Settings .....................................................................................................7-22

7-6-2 Description of Operation.........................................................................................................7-24

7-6-3 Operation Timing ....................................................................................................................7-25

7-7-1 Objects Requiring Settings .....................................................................................................7-29

7-7-2 Operation Example .................................................................................................................7-30

7-8-1 Operating Conditions ..............................................................................................................7-31

7-8-2 Objects Requiring Settings .....................................................................................................7-31

7-8-3 Torque Limit Switching Method...............................................................................................7-32

7-9-1 Objects Requiring Settings .....................................................................................................7-33

7-9-2 Soft Start Acceleration/Deceleration Time..............................................................................7-33

7-9-3 Velocity Command First-order Lag Filter ................................................................................7-34

7-10-1 Objects Requiring Settings .....................................................................................................7-35

7-10-2 Mode Selection .......................................................................................................................7-37

7-10-3 Gain Switching in Position Control..........................................................................................7-38

7-11-1 Related Objects ......................................................................................................................7-39

7-11-2 Trigger Signal Settings............................................................................................................7-41

7-11-3 Operation Sequence...............................................................................................................7-42

7-12-1 Objects Requiring Settings .....................................................................................................7-44

7-12-2 Dividing Ratio..........................................................................................................................7-44

7-12-3 Output Reverse Selection.......................................................................................................7-45

7-12-4 Z-phase Output.......................................................................................................................7-45

7-13-1 Operating Conditions ..............................................................................................................7-46

7-13-2 Objects Requiring Settings .....................................................................................................7-46

7-13-3 Description of Operation .........................................................................................................7-47

Section 8 Safety Function

8-1 Safe Torque OFF Function.................................................................................................. 8-2

8-2 STO Function via Safety Input Signals.............................................................................. 8-4

8-2-1 I/O Signal Specifications...........................................................................................................8-4

8-2-2 Operation Example ...................................................................................................................8-6

8-2-3 Connection Example.................................................................................................................8-7

8-3 STO Function via EtherCAT Communications................................................................ 8-10

8-3-1 Connection and Setting ..........................................................................................................8-10

8-3-2 Operation Example .................................................................................................................8-12

8-3-3 Connection Example...............................................................................................................8-14

Section 9 Details on Servo Parameters

9-1 Object Description Format ................................................................................................. 9-4

9-2 Common Control Objects ................................................................................................... 9-6

9-2-1 3000 hex: Basic Functions........................................................................................................9-6

9-2-2 3001 hex: Machine .................................................................................................................9-12

9-2-3 3002 hex: Optimized Parameters ...........................................................................................9-13

9-2-4 3010 hex: Position Command.................................................................................................9-15

9-2-5 3011 hex: Position Command Filter ........................................................................................9-17

9-2-6 3012 hex: Damping Control....................................................................................................9-18

9-2-7 3013 hex: Damping Filter 1.....................................................................................................9-19

9-2-8 3014 hex: Damping Filter 2.....................................................................................................9-20

10

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

CONTENTS

9-2-9 3020 hex: Velocity Command................................................................................................. 9-22

9-2-10 3021 hex: Velocity Command Filter........................................................................................9-23

9-2-11 3030 hex: Torque Command .................................................................................................. 9-24

9-2-12 3031 hex: Velocity Limit in Torque Control ............................................................................. 9-24

9-2-13 3040 hex: Profile Command................................................................................................... 9-25

9-2-14 3041 hex: Command Dividing Function ................................................................................. 9-26

9-3 Control Method Objects.................................................................................................... 9-28

9-3-1 3112 hex: ODF Velocity Feed-forward.................................................................................... 9-28

9-3-2 3113 hex: ODF Torque Feed-forward..................................................................................... 9-29

9-3-3 3120 hex: TDF Position Control ............................................................................................. 9-30

9-3-4 3121 hex: TDF Velocity Control.............................................................................................. 9-31

9-4 Control Loop Objects........................................................................................................ 9-33

9-4-1 3210 hex: Internal Position Command ................................................................................... 9-33

9-4-2 3211 hex: Position Detection .................................................................................................. 9-34

9-4-3 3212 hex: Gain Switching in Position Control ........................................................................ 9-34

9-4-4 3213 hex: 1st Position Control Gain.......................................................................................9-35

9-4-5 3214 hex: 2nd Position Control Gain...................................................................................... 9-36

9-4-6 3220 hex: Internal Velocity Command.................................................................................... 9-36

9-4-7 3221 hex: Velocity Detection.................................................................................................. 9-37

9-4-8 3222 hex: Gain Switching in Velocity Control......................................................................... 9-38

9-4-9 3223 hex: 1st Velocity Control Gain .......................................................................................9-38

9-4-10 3224 hex: 2nd Velocity Control Gain ......................................................................................9-39

9-4-11 3230 hex: Internal Torque Command ..................................................................................... 9-40

9-4-12 3231 hex: Torque Detection.................................................................................................... 9-40

9-4-13 3232 hex: Filter Switching in Torque Control.......................................................................... 9-40

3233

9-4-14

9-4-15 3234 hex: 2nd Torque Command Filter .................................................................................. 9-42

9-5 Torque Output Setting Objects ........................................................................................ 9-43

9-5-1 3310 hex: Torque Compensation............................................................................................ 9-43

9-5-2 3320 hex: Adaptive Notch Filter ............................................................................................. 9-45

9-5-3 3321 hex: 1st Notch Filter ...................................................................................................... 9-46

9-5-4 3322 hex: 2nd Notch Filter ..................................................................................................... 9-48

9-5-5 3323 hex: 3rd Notch Filter ...................................................................................................... 9-50

9-5-6 3324 hex: 4th Notch Filter ...................................................................................................... 9-52

9-5-7 3330 hex: Torque Limit ........................................................................................................... 9-54

9-6 Homing Objects ................................................................................................................. 9-56

9-7 Applied Function Objects ................................................................................................. 9-60

9-7-1 3B10 hex: Drive Prohibition.................................................................................................... 9-60

9-7-2 3B11 hex: Software Position Limit .......................................................................................... 9-61

9-7-3 3B20 hex: Stop Selection....................................................................................................... 9-63

9-7-4 3B21 hex: Deceleration Stop.................................................................................................. 9-67

9-7-5 3B30 hex: Touch Probe 1....................................................................................................... 9-67

9-7-6 3B31 hex: Touch Probe 2....................................................................................................... 9-70

9-7-7 3B40 hex: Zone Notification 1 ................................................................................................ 9-71

9-7-8 3B41 hex: Zone Notification 2 ................................................................................................ 9-72

9-7-9 3B50 hex: Position Detection Function .................................................................................. 9-73

9-7-10 3B51 hex: Positioning Completion Notification....................................................................... 9-73

9-7-11 3B52 hex: Positioning Completion Notification 2.................................................................... 9-74

9-7-12 3B60 hex: Speed Detection Function..................................................................................... 9-75

9-7-13 3B70 hex: Vibration Detection................................................................................................ 9-76

9-7-14 3B71 hex: Runaway Detection ............................................................................................... 9-77

9-7-15 3B80 hex: Load Characteristic Estimation ............................................................................. 9-78

9-8 Error- and Warning-related Objects................................................................................. 9-81

9-8-1 4000 hex: Error Full Code ...................................................................................................... 9-81

9-8-2 4020 hex: Warning Customization.......................................................................................... 9-82

9-8-3 4021 hex: Warning Output 1 Setting ...................................................................................... 9-85

9-8-4 4022 hex: Warning Output 2 Setting ...................................................................................... 9-86

9-8-5 4030 hex: Information Customization..................................................................................... 9-87

9-9 Monitoring-related Objects............................................................................................... 9-88

9-9-1 4110 hex: Monitor Data via PDO ............................................................................................9-88

9-9-2 4120 hex: EtherCAT Communications Error Count ................................................................ 9-89

hex: 1st Torque Command Filter ................................................................................... 9-41

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

11

CONTENTS

9-10 Display-related Objects.....................................................................................................9-97

9-11 Power Device-related Objects .......................................................................................... 9-98

9-12 External Device-related Objects..................................................................................... 9-101

9-13 Encoder-related Objects ................................................................................................. 9-104

9-14 I/O-related Objects........................................................................................................... 9-107

9-15 General-purpose Input Setting Objects......................................................................... 9-116

9-16 General-purpose Output Setting Objects...................................................................... 9-123

9-9-3 4130 hex: Safety Status Monitor.............................................................................................9-89

9-9-4 4131 hex: Safety Command Monitor 1 ...................................................................................9-91

9-9-5 4132 hex: Safety Command Monitor 2 ...................................................................................9-92

9-9-6 4140 hex: Lifetime Information ...............................................................................................9-93

9-9-7 4150 hex: Overload ................................................................................................................9-95

9-11-1 4310 hex: Regeneration .........................................................................................................9-98

9-11-2 4320 hex: Main Circuit Power Supply.....................................................................................9-99

9-12-1 4410 hex: Motor Identity .......................................................................................................9-101

9-12-2 4412 hex: Motor Advanced Setting.......................................................................................9-102

9-14-1 4600 hex: I/O Monitor ...........................................................................................................9-107

9-14-2 4601 hex: Function Input ......................................................................................................9-108

9-14-3 4602 hex: Function Output ................................................................................................... 9-110

9-14-4 4604 hex: Control Input Change Count .................................................................................9-111

9-14-5 4605 hex: Control Output Change Count ............................................................................. 9-112

9-14-6 4610 hex: Brake Interlock Output .........................................................................................9-113

9-14-7 4620 hex: Encoder Dividing Pulse Output ............................................................................ 9-114

9-15-1 Setting................................................................................................................................... 9-116

9-15-2 4630 hex: Positive Drive Prohibition Input............................................................................ 9-117

9-15-3 4631 hex: Negative Drive Prohibition Input .......................................................................... 9-117

9-15-4 4632 hex: External Latch Input 1 .......................................................................................... 9-117

9-15-5 4633 hex: External Latch Input 2 .......................................................................................... 9-118

9-15-6 4634 hex: Home Proximity Input...........................................................................................9-118

9-15-7 4635 hex: Positive Torque Limit Input................................................................................... 9-118

9-15-8 4636 hex: Negative Torque Limit Input ................................................................................. 9-119

9-15-9 4637 hex: Error Stop Input.................................................................................................... 9-119

9-15-10 4638 hex: Monitor Input 1 ..................................................................................................... 9-119

9-15-11 4639 hex: Monitor Input 2 .....................................................................................................9-120

9-15-12 463A hex: Monitor Input 3.....................................................................................................9-120

9-15-13 463B hex: Monitor Input 4.....................................................................................................9-120

9-15-14 463C hex: Monitor Input 5 ....................................................................................................9-121

9-15-15 463D hex: Monitor Input 6 ....................................................................................................9-121

9-15-16 463E hex: Monitor Input 7.....................................................................................................9-121

9-15-17 463F hex: Monitor Input 8.....................................................................................................9-122

9-16-1 Setting...................................................................................................................................9-123

9-16-2 4650 hex: Error Output .........................................................................................................9-124

9-16-3 4651 hex: Servo Ready Output ............................................................................................9-124

9-16-4 4652 hex: Positioning Completion Output 1 .........................................................................9-124

9-16-5 4653 hex: Positioning Completion Output 2 .........................................................................9-125

9-16-6 4654 hex: Velocity Attainment Detection Output...................................................................9-125

9-16-7 4655 hex: Torque Limit Output..............................................................................................9-125

9-16-8 4656 hex: Zero Speed Detection Output ..............................................................................9-126

9-16-9 4657 hex: Velocity Conformity Output ..................................................................................9-126

9-16-10 4658 hex: Warning Output 1.................................................................................................9-126

9-16-11 4659 hex: Warning Output 2.................................................................................................9-127

9-16-12 465A hex: Velocity Limiting Output....................................................................................... 9-127

9-16-13 465B hex: Error Clear Attribute Output.................................................................................9-127

9-16-14 465C hex: Remote Output 1 .................................................................................................9-128

9-16-15 465D hex: Remote Output 2 .................................................................................................9-128

9-16-16 465E hex: Remote Output 3 .................................................................................................9-128

9-16-17 465F hex: Zone Notification Output 1 ...................................................................................9-129

9-16-18 4660 hex: Zone Notification Output 2 ...................................................................................9-129

9-16-19 4661 hex: Position Command Status Output........................................................................9-129

9-16-20 4662 hex: Distribution Completed Output.............................................................................9-130

9-16-21 4663 hex: External Brake Interlock Output ...........................................................................9-130

12

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

Section 10 Operation

10-1 Operational Procedure...................................................................................................... 10-2

10-2 Preparing for Operation .................................................................................................... 10-3

10-2-1 Items to Check Before Turning ON the Power Supply ........................................................... 10-3

10-2-2 Turning ON the Power Supply................................................................................................ 10-4

10-2-3 Checking the Displays............................................................................................................ 10-5

10-2-4 Absolute Encoder Setup......................................................................................................... 10-7

10-2-5 Setting Up an Absolute Encoder from the Sysmac Studio ..................................................... 10-7

10-3 Test Run ............................................................................................................................. 10-8

10-3-1 Preparations for Test Run....................................................................................................... 10-8

10-3-2 Test Run via USB Communications from the Sysmac Studio ................................................ 10-9

Section 11 Adjustment Functions

11-1 Outline of Adjustment Functions..................................................................................... 11-3

11-1-1 Adjustment Methods................................................................................................................11-3

11-1-2 Adjustment Procedure.............................................................................................................11-4

11-2 Easy Tuning ....................................................................................................................... 11-6

11-2-1 Objects That Are Set ...............................................................................................................11-6

11-2-2 Executing Easy Tuning............................................................................................................11-8

11-3 Advanced Tuning............................................................................................................... 11-9

11-3-1 Objects That Are Set ...............................................................................................................11-9

11-3-2 Executing Advanced Tuning ..................................................................................................11-10

11-4 Manual Tuning ..................................................................................................................11-11

11-4-1 Objects That Are Set .............................................................................................................11-11

11-4-2 Executing Manual Tuning......................................................................................................11-11

11-5 Data Trace ........................................................................................................................ 11-12

11-6 FFT .................................................................................................................................... 11-13

CONTENTS

11-7 Damping Control ............................................................................................................. 11-14

11-7-1 Objects Requiring Settings....................................................................................................11-14

11-7-2 Operating Procedure .............................................................................................................11-16

11-7-3 Setting Frequency with Sysmac Studio.................................................................................11-17

11-8 Load Characteristic Estimation...................................................................................... 11-18

11-8-1 Objects Requiring Settings....................................................................................................11-19

11-8-2 Setting Load Characteristic Estimation Function...................................................................11-20

11-9 Adaptive Notch Filter ...................................................................................................... 11-21

11-9-1 Objects Requiring Settings....................................................................................................11-21

11-9-2 Operating Procedure .............................................................................................................11-22

11-10 Notch Filters..................................................................................................................... 11-23

11-10-1 Objects Requiring Settings....................................................................................................11-24

11-10-2 Notch Filter Width and Depth ................................................................................................11-25

11-11 Friction Torque Compensation Function ...................................................................... 11-26

11-11-1 Operating Conditions.............................................................................................................11-26

11-11-2 Objects Requiring Settings....................................................................................................11-26

11-11-3 Operation Example................................................................................................................11-27

11-12 Feed-forward Function.................................................................................................... 11-29

11-12-1 Feed-forward Control in TDF Control ....................................................................................11-29

11-12-2 Feed-forward Control in ODF Control ...................................................................................11-31

Section 12 Troubleshooting

12-1 Actions for Problems ........................................................................................................12-2

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

13

CONTENTS

12-1-1 Preliminary Checks When a Problem Occurs.........................................................................12-2

12-1-2 Precautions When a Problem Occurs.....................................................................................12-3

12-1-3 Replacing the Servomotor or Servo Drive ..............................................................................12-4

12-2 Warnings ............................................................................................................................ 12-6

12-2-1 Related Objects ......................................................................................................................12-6

12-2-2 Warning List ............................................................................................................................12-8

12-3 Errors................................................................................................................................ 12-10

12-3-1 Error List ...............................................................................................................................12-10

12-3-2 Deceleration Stop Operation at Errors..................................................................................12-13

12-4 Information....................................................................................................................... 12-14

12-4-1 Related Objects ....................................................................................................................12-14

12-4-2 Information List .....................................................................................................................12-14

12-5 Troubleshooting .............................................................................................................. 12-15

12-5-1 Troubleshooting Using Error Displays ..................................................................................12-16

12-5-2 Troubleshooting Using AL Status Codes ..............................................................................12-38

12-5-3 Troubleshooting Using the Operation State..........................................................................12-42

Section 13 Maintenance and Inspection

13-1 Periodic Maintenance........................................................................................................ 13-2

13-2 Servo Drive Lifetime.......................................................................................................... 13-3

13-3 Servomotor Lifetime.......................................................................................................... 13-4

Appendices

A-1 CiA 402 Drive Profile ..........................................................................................................A-2

A-2 CoE Objects ......................................................................................................................A-12

A-3 Object List .........................................................................................................................A-68

A-1-1 Controlling the State Machine of the Servo Drive .....................................................................A-2

A-1-2 Modes of Operation ..................................................................................................................A-4

A-1-3 Modes of Operation and Applied/Adjustment Functions...........................................................A-5

A-1-4 Changing the Mode of Operation..............................................................................................A-5

A-1-5 Homing Mode Specifications ....................................................................................................A-7

A-2-1 Object Dictionary Area............................................................................................................A-12

A-2-2 Data Type................................................................................................................................A-12

A-2-3 Object Description Format ......................................................................................................A-13

A-2-4 Communication Objects..........................................................................................................A-14

A-2-5 PDO Mapping Objects............................................................................................................A-20

A-2-6 Sync Manager Communication Objects .................................................................................A-35

A-2-7 Manufacturer Specific Objects................................................................................................A-38

A-2-8 Servo Drive Profile Object ......................................................................................................A-41

A-2-9 Safety Function Objects..........................................................................................................A-64

Index

14

A-4 Sysmac Error Status Codes ..........................................................................................A-100

A-4-1 Error List ...............................................................................................................................A-100

A-4-2 Error Descriptions.................................................................................................................A-112

A-5 Response Time in EtherCAT Process Data Communications....................................A-177

A-5-1 Input Response Time............................................................................................................A-177

A-5-2 Output Response Time.........................................................................................................A-177

A-6 Version Information........................................................................................................A-178

A-6-1 Relationship between Unit Versions and Sysmac Studio Versions ......................................A-178

A-6-2 Functions That Were Added or Changed for Each Unit Version...........................................A-180

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

CONTENTS

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

15

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

16

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings