Omron R88D-KN04H-ECT-L, R88D-KN01H-ECT-L, R88D-KN08H-ECT-L, R88D-KN10H-ECT-L, R88D-KN06F-ECT-L User Manual

...Page 1

AC SERVOMOTORS/SERVO DRIVES

G5-series WITH BUIL T-IN

EtherCAT® COMMUNICATIONS

Linear Motor Type

User’s Manual

R88L-EC- (Linear Motors)

R88D-KN-ECT-L (AC Servo Drives)

I577-E1-04

Page 2

© OMRON, 2011

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON

is constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

Page 3

Introduction

Thank you for purchasing a G5-series Servo Drive. This manual explains how to install and wire the

Servo Drive, set parameters needed to operate the Servo Drive, an d remedies to be taken and

inspection methods to be used in case that problems occur.

Intended Readers

This manual is intended for the following individuals.

Those who have electrical knowledge (certified electricians or individuals who have equivalent

knowledge) and also are qualified for one of the following:

• Introducing FA equipment

• Designing FA systems

• Managing FA sites

Introduction

Notice

This manual contains information you need to know to correctly use the Servo Drive and peripheral

equipment.

Before using the Servo Drive, read this manual and gain a full understanding of the information

provided herein.

After you finished reading this manual, keep it in a convenient place so that it can be referenced at any

time.

Make sure this manual is delivered to the end user.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

1

Page 4

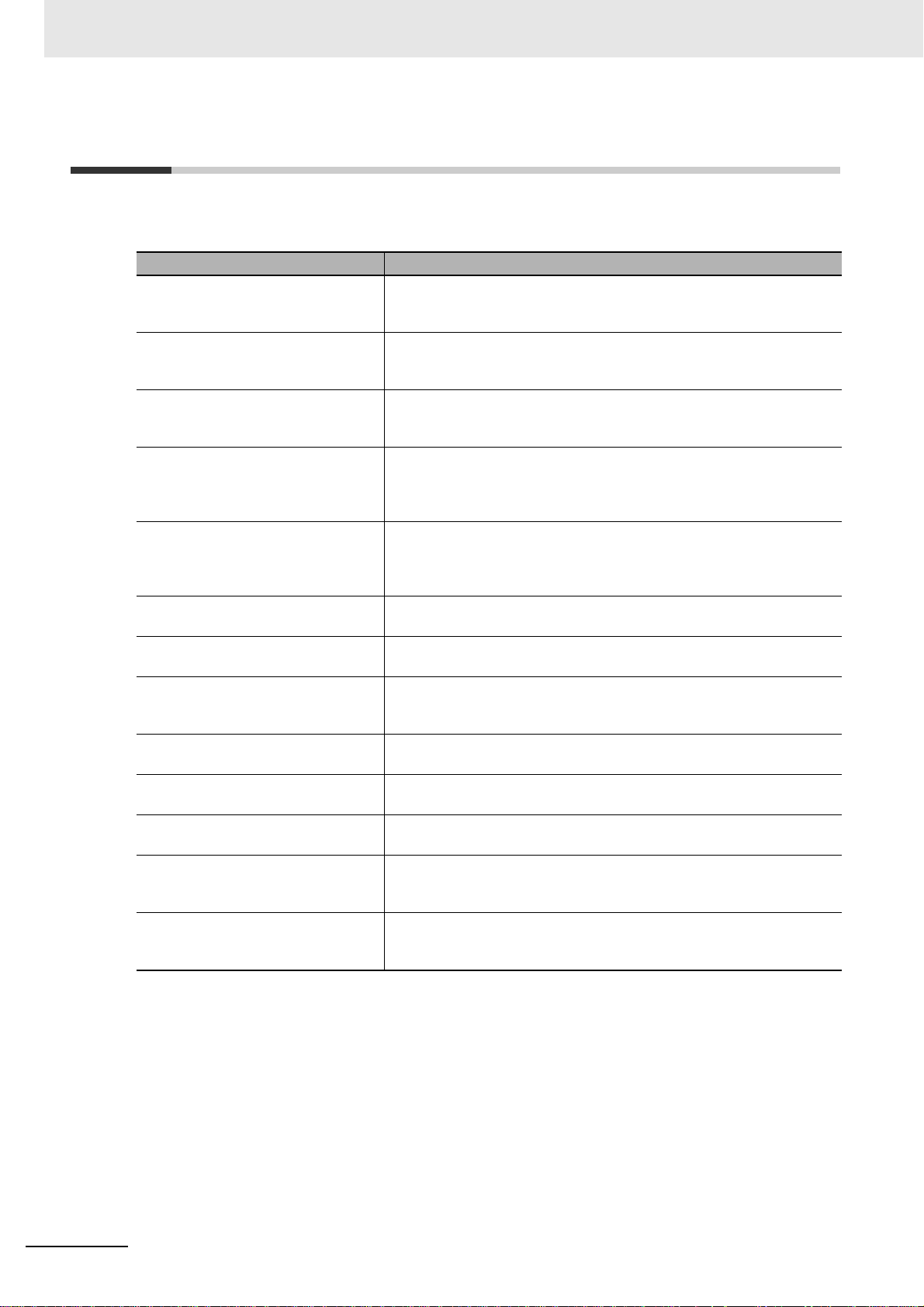

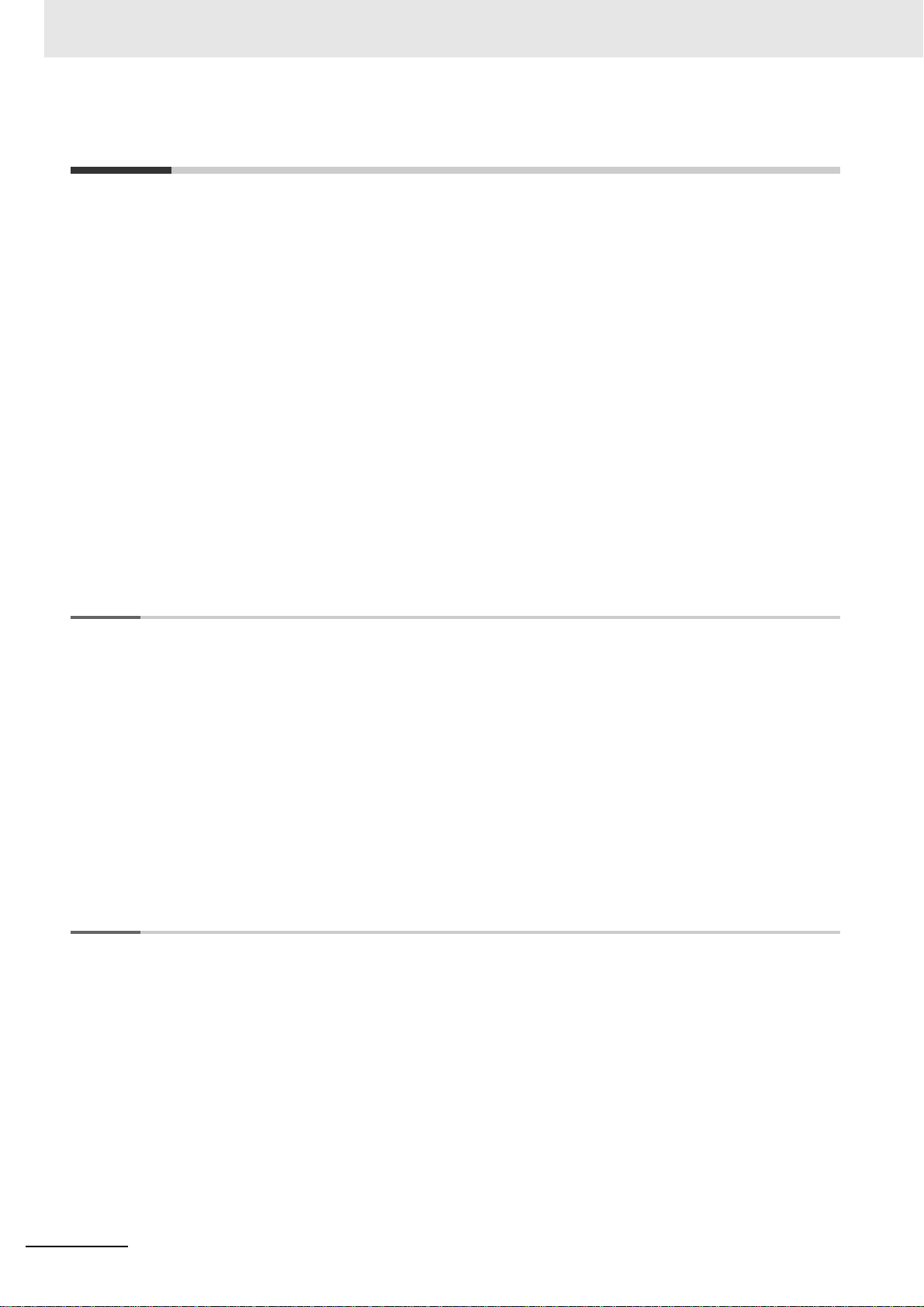

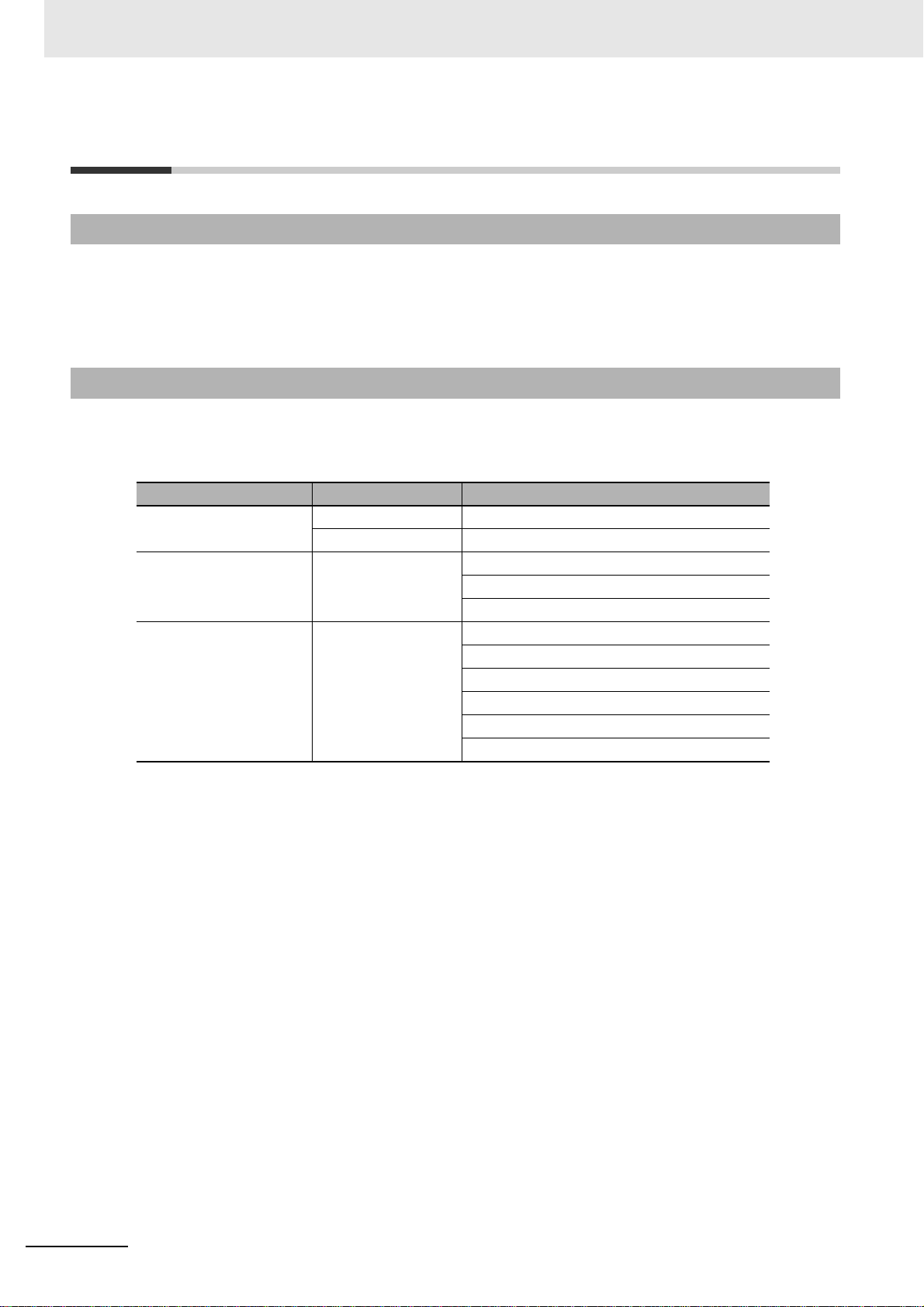

Manual Configuration

Manual Configuration

This manual consists of the following sections.

Section 1 Features and

System

Configuration

Section 2 Models and

External

Dimensions

Section 3 Specifications This section provides the general specifications, characteristics,

Section 4 System Design This section explains the installation conditions, wiring methods which

Section 5 EtherCAT

Communications

Section 6 Basic Control

Functions

Section 7 Applied Functions This section outlines the applied functions such as the electronic gear

Section 8 Safety Function This function stops the motor based on a signal from a safety controller

Section 9 Servo Parameter

Objects

Section 10 Operation This section explains the operating procedures and how to operate in

Section 11 Adjustment

Functions

Section 12 Troubleshooting

and Maintenance

Appendices The appendices provide the explanation for the profile that is used to

This section explains the features of the Servo Drive and name of each

part.

This section explains the models of Servo Drive, Linear Motors, and

peripheral devices, and provides the external dime nsions and mounting

dimensions.

connector specifications, I/O circuits of the Servo Drives and Linear

Motors, as well as specifications of other peripheral devices.

include wiring conforming to EMC directives, and regenerative energy

calculation methods for the Servo Drive and Linear Motor, and also

describes the performance of External Regeneration Resistors.

This section describes EtherCAT communications under the assumption that

the G5-series Servo Drive is connected to the Machine Automation Controller

NJ-series (Model: NJ301(Model: CJ1W-NC281/NC481/NC881/NCF81/NC482/NC882/NCF82).

This section outlines basic control functions, and explains the settings.

and gain switching, and explains the settings.

or safety sensor. An outline of the function is given together with

operation and connection examples.

This section explains the settings of each object.

each mode.

This section explains the functions, setting methods, and items to note

regarding various gain adjustments.

This section describes the items to check when problems occur,

troubleshooting using the error displays, troubleshooting based on the

operating conditions, and periodic maintenance.

control the Servo Drive, lists of objects, Sysmac error status codes, and

other information.

Outline

/NJ501-

) or Position Control Unit

2

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 5

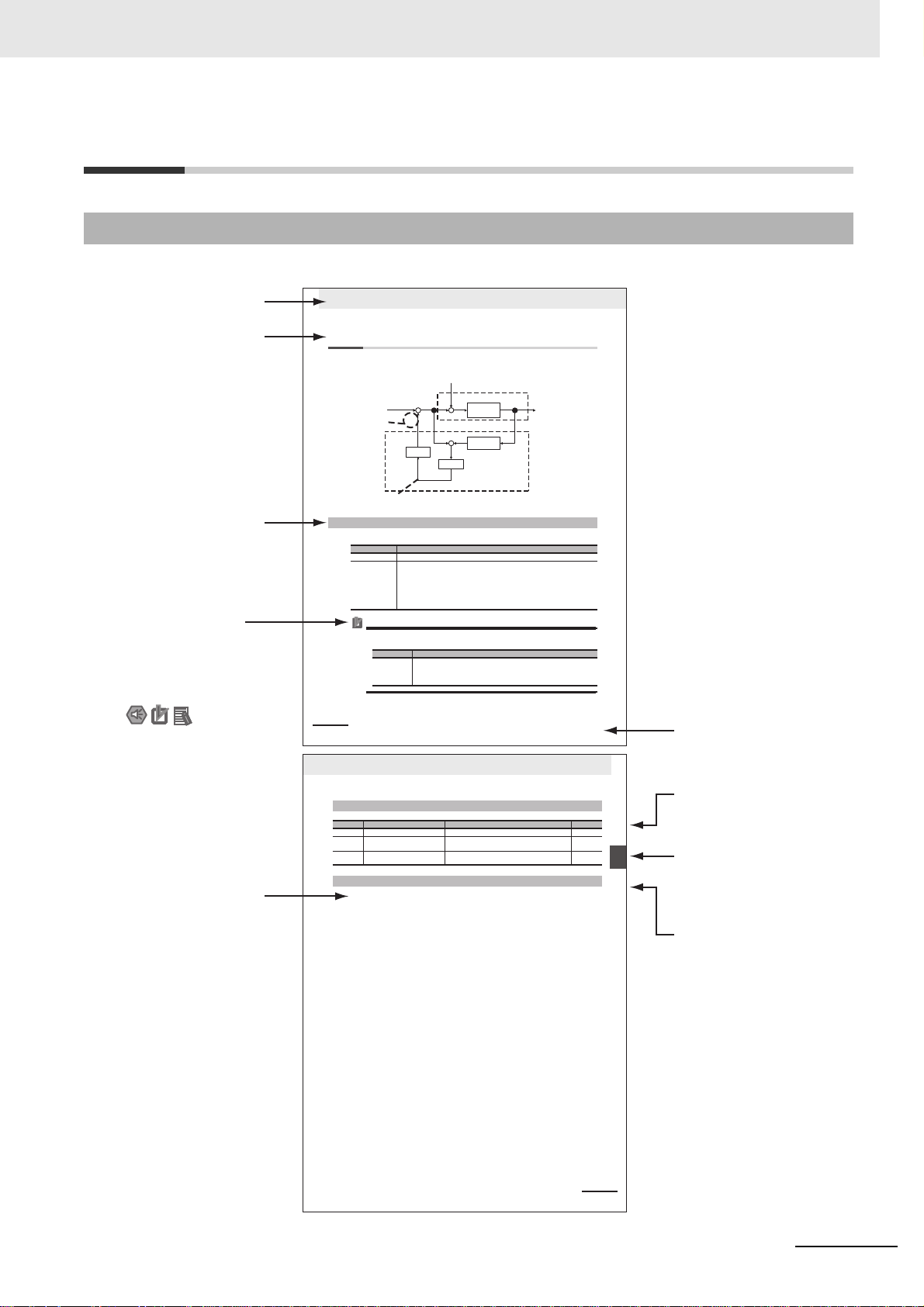

Manual Structure

11 Adjustment Functions

11-26

11-8 Disturbance Observer Function

You can use the disturbance force value estimated with the disturbance observer to lower the effect of

the disturbance force and reduce vibration.

The disturbance observer function can be used in the following situations.

Precautions for Correct UsePrecautions for Correct Use

The disturbance observer function may not work properly under the c onditions described in the

following table.

11-8-1 Operating Conditions

Conditions

Operating mode Position control Mode, speed control

Others • When Servo is ON.

• When elements other than control parameters, such as the force limit, are set correctly

and there is no trouble with the motor's normal (The setting of 3002 hex is “0”.).

• When realtime a utotuning function is disabled operation.

•

When instantaneous speed observer function is disabled (The setting of 361 0 he x bi t 0 is “0”.).

progress.

• Dis turbance obse rver operation is disabled wh en magnetic pole position estimation is in

Conditions under which the adaptive filter does not operate properly

Load condition • If there is a resonance point below the cut-off frequency estimated by the distur-

bance observer

• If a large amount of high-frequency elements is found in the disturbance force

• If the the external encoder resolution is low

Motor+load

+

−

Load model

+ −

Filter

Gain

+

+

Disturbance observer

Add to the

direction that

negates the

disturbance

Setting with

3623 hex

Set with 3624 hex

Disturbance force

Estimation value

Disturbance force

Force command

Internal force command

Motor Speed

G5 Series AC ServoDrives With Built-in EtherCAT Communications, Linear Motor Type

11-27

11 Adjustment Functions

revresbO ecnabrutsiD 8-11

noitcnuF

11

sgnitteS gniriuqeR stcejbO

2-8-11

1

Set the Function Expansion Setting (3610 hex).

Set whether to enable or disable the disturbance observer in bit 1.

0: Disabled

1: Enabled

Set the operating conditions for enabling the function in bit 2.

0: Enabled at all time

1: Enabled only when gain 1 is selected

2

Set the Disturbance Observer Filter Setting (3624 hex).

Set a small value for the Disturbance Force Compensation Gain (3623 hex). Change the value

in the Disturbance Observer Filter Setting (3624 hex) from a large value gradually to a smaller

one. The smaller the value set in the Disturbance Observer Filter Setting (3624 he x) , t he l e s s

the lag you will have during disturbance force estimation. This has advantages in effectively

controlling the influence of disturbance, but results in a large operation noise. Consider the

balance between the advantage and disadvantage when setting this value.

3

Set the Disturbance Torque Compensation Gain (3623 hex).

After you set the Disturbance Observer Filter Setting (3624 hex), increase the value of the

Disturbance Force Compensation Gain (3623 hex) from a small value to a large value. The

larger the value set on the Disturbance Torque Compensation Gain (3623 hex) is, the more

effective control over the disturbance influence can be obtained. But the larger the value is, the

larger the operation noise will be. Set this object in combination with the Disturbance Observer

Filter Setting (3624 hex) to achieve balanced settings.

11-8-2 Objects Requiring Settings

Index Name Description Reference

3610 hex Function Expansion Settings Set the bits related to the disturbance observer. page 9-44

3623 hex Disturbance Force Compensation

Gain

Set the compensation gain for disturbance force. page 9-46

3624 hex Disturbance Observer Filter Setting Set the filter time constant for disturbance force

compensation.

page 9-46

11-8-3 Operating Procedure

G5 Series AC ServoDrives With Built-in EtherCAT Communications, Linear Motor Type

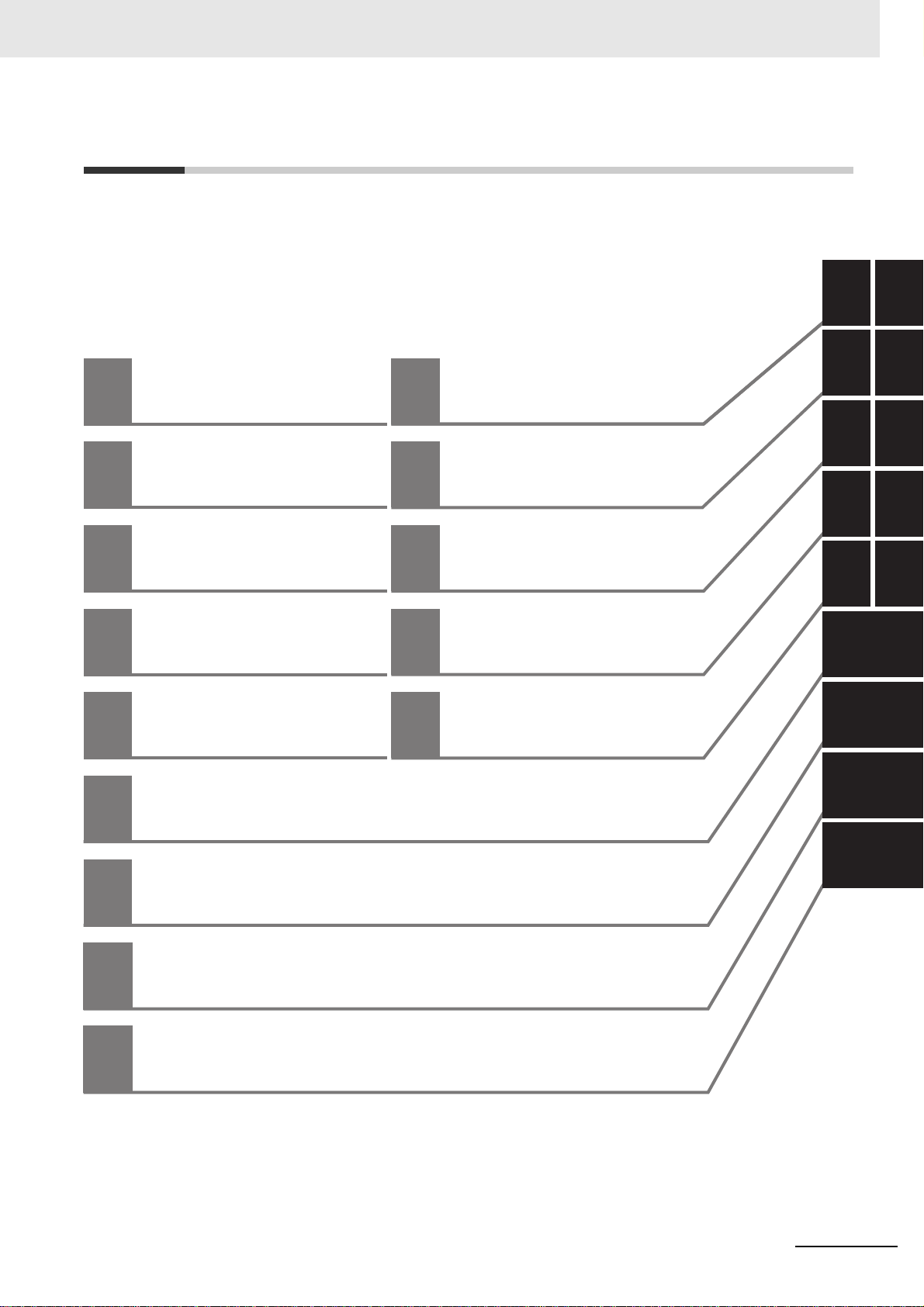

Level 2 heading

Level 3 heading

Level 1 heading

Manual Name

Level 2 heading

Section Number of

Level 1 heading

Level 3 heading

Shows which section

the content of the current

page belongs to.

Shows which sub-section

the content of the current

page belongs to.

Shows which paragraph

the content of the current

page belongs to.

Note, Supplementary

Information, Reference Target

A note, supplementary

information, reference target,

etc. are provided with

difference icons.

Operation Steps

Describes

the operation steps.

Page Structure and Symbol Icons

The following page structure and symbol icons are used in this manual.

Manual Structure

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Note The above page is only a sample for illustrative purposes. It is not the actual content of the manual.

3

Page 6

Manual Structure

Precautions for Safe Use

Precautions for Correct UsePrecautions for Correct Use

Additional Information

Special Information

Special information in this manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions on what to do and what not to do to ensure proper operation an d performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Terms and Expressions Used for the Linear Motor

In this manual, the term “Linear Motor” is defined as an OMRON product that consists of a Motor Coil

Unit (the coil on the primary side) and a Magnet Track (the magnets on the secondary side).

In addition to these components, constr u ctin g a Lin ea r Mot or syste m also requires the following parts,

which are built into a component called the “Linear Slider.”

• Motor Coil Unit (the coil on the primary side)

• Magnet Track (the magnets on the secondary side)

• External encoder

• Linear guide

• Chassis

*1 Not available from OMRON.

*1

Because a Linear Motor provides a linear movement, terms or expressions different from rotary motors

are used.

Example

Rotary Linear

Torque [N·m] Force [N]

Rotation speed [r/min] Speed [mm/s]

Inertia [kg·m

*1

*1

2

] Mass [kg]

2

However, for object names with respect to the CiA 402 Drive Profile and the terms used for the Safe

Torque OFF (STO) function, the manual uses the word “torque” for conformance with the relevant

standards.

Read “torque” as “force” when using these object names.

4

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 7

1

10

2

11

3

12

4A

5

6

7

8

9

1

10

2

11

3

12

4A

5I

6

7

8

9

Features and System

Configuration

Operation

Models and External

Dimensions

Adjustment Functions

Specifications

Troubleshooting and

Maintenance

System Design Appendices

I

Index

EtherCAT

Communications

Basic Control Functions

Applied Functions

Safety Function

Servo Parameter Objects

Sections in this Manual

Sections in this Manual

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

5

Page 8

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Manual Configuration ...............................................................................................2

Manual Structure.......................................................................................................3

Sections in this Manual ............................................................................................5

CONTENTS ................................................................................................................6

Terms and Conditions Agreement.........................................................................12

Safety Precautions..................................................................................................14

Regulations and Standards....................................................................................24

Items to Check after Unpacking.............................................................................27

Revision History......................................................................................................30

Section 1 Features and System Configuration

1-1 Outline......................................................................................................................................1-2

1-1-1 Features of G5-series Servo Drives............................................................................................1-2

1-1-2 What is EtherCAT?.....................................................................................................................1-3

1-1-3 Object Dictionary.........................................................................................................................1-3

1-2 System Configuration............. .... ... ... ....................................... ... ............................................ 1-4

1-3 Names and Functions............................................................................................................. 1-6

1-3-1 Servo Drive Part Names ...................................................................... .......................................1-6

1-3-2 Servo Drive Functions......................................................... ... ..................................... ... .............1-7

1-4 System Block Diagram................................ ... ... ....................................... ... ............................ 1-8

1-5 Unit Versions .........................................................................................................................1-12

1-5-1 Confirmation Method.................................................................................................................1-12

1-5-2 Unit Versions........................................................................................... ... ... ............................1-12

Section 2 Models and External Dimensions

2-1 Servo System Configuration..................................................................................................2-2

2-2 How to Read Model Numbers................................................................................................. 2-4

2-2-1 Servo Drive ..................................................................................................... ... .........................2-4

2-2-2 Linear Motor..................................................... ... .. ..................................... ... ..............................2-5

2-3 Model Tables............................................................................................................................ 2-7

2-3-1 Servo Drive Model Table.............................................................................................................2-7

2-3-2 Linear Motor Model Table...........................................................................................................2-7

2-3-3 Servo Drive and Linear Motor Combination Tables....................................................................2-8

2-3-4 Cable and Peripheral Device Model Tables..............................................................................2-10

2-4 External and Mounting Dimensions..................................................................................... 2-12

2-4-1 Servo Drive Dimensions.................................................................. .. ........................................2-12

2-4-2 Linear Motor Dimensions............................................... .................................... ... ... .................2-20

2-4-3 External Regeneration Resistor Dimensions ............................................................................2-27

2-4-4 Reactor Dimensions........................................................................................... ... ... .................2-28

2-4-5 Mounting Bracket Dimensions ..................................................................................................2-31

6

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 9

CONTENTS

Section 3 Specifications

3-1 Servo Drive Specifications.....................................................................................................3-2

3-1-1 General Specifications................................................................................................................ 3-2

3-1-2 Characteristics............................................................................................................................ 3-3

3-1-3 EtherCAT Communications Specifications................................................................................. 3-5

3-1-4 EtherCAT Communications Connector Specifications (RJ45).................................................... 3-5

3-1-5 Control I/O Specifications (CN1).................................................................................................3-6

3-1-6 Control Input Circuits..................................................................................................................3-8

3-1-7 Control Input Details...................................................................... ... .......................................... 3-9

3-1-8 Control Output Circuits............................................................. ... .. ........................................... 3-11

3-1-9 Control Output Details ..............................................................................................................3-12

3-1-10 External Encoder Specifications...............................................................................................3-16

3-1-11 External Encoder Connector Specifications (CN4)...................................................................3-17

3-1-12 Analog Monitor Connector Specifications (CN5) ................................................................... ...3-21

3-1-13 USB Connector Specifications (CN7).......................................................................................3-22

3-1-14 Safety Connector Specifications (CN8)....................................................................................3-22

3-2 Overload Characteristics (Electronic Thermal Function).................................................. 3-25

3-3 Linear Motor Specifications ................................................................................................. 3-28

3-3-1 General Specifications of Iron-core Linear Motors ................................................................... 3-28

3-3-2 Performance Specifications of Iron-core Linear Motors............................................................3-29

3-3-3 Iron-core Linear Motor Speed - Force Characteristics.............................................................. 3-32

3-3-4 Temperature Sensor Specifications of Iron-core Linear Motors............................................... 3-35

3-3-5 General Specifications of Ironless Linear Motors..................................................................... 3-36

3-3-6 Performance Specifications of Ironless Linear Motors ............................................................. 3-36

3-3-7 Ironless Linear Motor Speed - Force Characteristics ............................................................... 3-39

3-3-8 Temperature Sensor Specifications of Ironless Linear Motors.................................................3-44

3-3-9 Cable Specifications................................................................................................................. 3-45

3-4 Cable and Connector Specifications................................................................................... 3-46

3-4-1 Resistance to Bending of Robot Cable........................................ ............................... .. ............ 3-46

3-4-2 External Encoder Cable Specifications..................................................................................... 3-47

3-4-3 Connector Specifications..........................................................................................................3-48

3-4-4 EtherCAT Communications Cable Specifications..................................................................... 3-49

3-4-5 Analog Monitor Cable Specifications........................................................................................3-52

3-4-6 Control Cable Specifications............................ .................................... ... .................................. 3-53

3-5 External Regeneration Resistor Specifications.................................................................. 3-58

3-6 Reactor Specifications.......................................................................................................... 3-59

Section 4 System Design

4-1 Installation Conditions............................................................................................................ 4-2

4-1-1 Installation Conditions.................................................................................................................4-2

4-1-2 Iron-core Linear Motor Installation Conditions............................................................................ 4-4

4-1-3 Ironless Linear Motor Installation Conditions............................................................................ 4-10

4-2 Wiring ..................................................................................................................................... 4-14

4-2-1 Peripheral Equipment Connection Examples ........................................................................... 4-14

4-2-2 Main Circuit and Linear Motor Connections........................... ..................................... .. ............ 4-18

4-2-3 Terminal Block Wire Sizes........................................................................................................ 4-22

4-2-4 Terminal Block Wiring Procedure.............................................................................................4-24

4-3 Wiring Conforming to EMC Directives ................................................................................ 4-26

4-3-1 100-VAC and 200-VAC Input Servo Drive Models...................................................................4-26

4-3-2 400-VAC Input Servo Drive Models..........................................................................................4-27

4-4 Noise Reduction.................................................................................................................... 4-29

4-4-1 Wiring Method........................................................................................................................... 4-29

4-4-2 Selecting Connection Components ..........................................................................................4-33

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

7

Page 10

CONTENTS

4-5 Regenerative Energy Absorption......................................................................................... 4-47

4-5-1 Calculating the Regenerative Energy........................................................................................4-47

4-5-2 Servo Drive Regeneration Absorption Capacity........................................................................4-49

4-5-3 Regenerative Energy Absorption with an External Regeneration Resistor ...............................4-50

4-5-4 Connecting an External Regeneration Resistor........................................................................4-51

Section 5 EtherCAT Communications

5-1 Display Area and Settings......................................................................................................5-2

5-1-1 Node Address Setting.................................................................................................................5-2

5-1-2 Status Indicators .........................................................................................................................5-3

5-2 Structure of the CAN Application Protocol over EtherCAT................................................. 5-4

5-3 EtherCAT State Machine......................................................................................................... 5-5

5-4 Process Data Objects (PDOs) ................................................................................................ 5-6

5-4-1 PDO Mapping Settings................................................................................................................5-6

5-4-2 Sync Manager PDO Assignment Settings ..................................................................................5-7

5-4-3 Fixed PDO Mapping.......................................................... .. ..................................... ... ... .............5-7

5-4-4 Variable PDO Mapping ..................................................................... ..........................................5-9

5-4-5 Multiple PDO Mapping..............................................................................................................5-10

5-5 Service Data Objects (SDOs)................................................................................................ 5-12

5-6 Synchronization with Distributed Clocks............................................................................ 5-13

5-7 Emergency Messages...........................................................................................................5-14

5-8 Sysmac Device Features ...................................................................................................... 5-15

Section 6 Basic Control Functions

6-1 Cyclic Synchronous Position Mode.......................................................................................6-2

6-1-1 Related Objects...........................................................................................................................6-3

6-1-2 Block Diagram for Position Control Mode...................................................................................6-4

6-2 Cyclic Synchronous Velocity Mode.......................................................................................6-5

6-2-1 Related Objects...........................................................................................................................6-6

6-2-2 Objects Requiring Settings..........................................................................................................6-6

6-2-3 Related Functions.......................................................................................................................6-6

6-2-4 Block Diagram for Speed Control Mode...................................................................................... 6-7

6-3 Cyclic Synchronous Torque Mode......................................................................................... 6-8

6-3-1 Related Objects...........................................................................................................................6-9

6-3-2 Objects Requiring Settings..........................................................................................................6-9

6-3-3 Related Functions.....................................................................................................................6-10

6-3-4 Block Diagram for Force Control Mode.....................................................................................6-10

6-4 Profile Position Mode . .... ...................................... .... ...................................... .... ... ................6-11

6-4-1 Related Objects.........................................................................................................................6-12

6-4-2 Description of Function.............................................................................................................6-13

6-4-3 Controlword (6040 hex) in Profile Position Mode................................................................ ... ...6-14

6-4-4 Statusword (6041 hex) in Profile Position Mode.......................................................................6-14

6-5 Homing Mode.........................................................................................................................6-15

6-6 Connecting with OMRON Controllers.................................................................................. 6-16

Section 7 Applied Functions

7-1 Sequence I/O Signals.............................................................................................................. 7-2

7-1-1 Input Signals ...............................................................................................................................7-2

7-1-2 Output Signals.............................................................................................................................7-5

7-2 Positive and Negative Drive Prohibition Functions....... .... ... ... ... ... .... ... ... ... .... ... ... ... ....... ... .. 7-8

8

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 11

CONTENTS

7-3 Overrun Protection................................................................................................................ 7-11

7-3-1 Operating Conditions................................................................................................................ 7-11

7-3-2 Objects Requiring Settings....................................................................................................... 7-11

7-3-3 Operation Example............................................... ... .................................... ... .......................... 7-12

7-4 Backlash Compensation....................................................................................................... 7-13

7-5 Brake Interlock....................................................................................................................... 7-15

7-5-1 Objects Requiring Settings....................................................................................................... 7-15

7-5-2 Operation Timing.......................................... .................................... ... ... ..................................7-16

7-6 Electronic Gear Function...................................................................................................... 7-20

7-6-1 Objects Requiring Settings....................................................................................................... 7-20

7-6-2 Operation Example............................................... ... .................................... ... .......................... 7-21

7-7 Force Limit Switching........................................................................................................... 7-22

7-7-1 Operating Conditions................................................................................................................ 7-22

7-7-2 Objects Requiring Settings....................................................................................................... 7-22

7-8 Soft Start ............................................... .... ... ... ... ....................................... ... .......................... 7-24

7-8-1 Objects Requiring Settings....................................................................................................... 7-24

7-8-2 Soft Start Acceleration or Deceleration Time.......................................... ... .. .............................7-24

7-8-3 S-curve Acceleration or Deceleration Time .............................................................................. 7-25

7-9 Gain Switching Function ......................................................................................................7-26

7-9-1 Objects Requiring Settings....................................................................................................... 7-26

7-9-2 Gain Switching Based on the Control Mode.............................................................................7-28

7-9-3 Diagrams of Gain Switching Setting. ........................................................................................7-31

7-9-4 Position Gain Switching Time (3119 hex).................................................................................7-36

7-10 Gain Switching 3 Function ...................................................................................................7-37

7-10-1 Operating Conditions................................................................................................................ 7-37

7-10-2 Objects Requiring Settings....................................................................................................... 7-37

7-10-3 Operation Example.................................................. .................................... ... .......................... 7-37

7-11 Touch Probe Function (Latch Function) ....................................................... ... ... ... ... .... ... ... 7-39

7-11-1 Objects Requiring Settings....................................................................................................... 7-39

7-11-2 Trigger Signal Settings.............................................................................................................7-39

7-11-3 Operation Sequences............................................................................................................... 7-40

Section 8 Safety Function

8-1 Safe Torque OFF Function ................................................................................ ... ... ...............8-2

8-1-1 Safety Input Signals......................................................... ... ..................................... ... ................ 8-3

8-1-2 External Device Monitor (EDM) Output Signal ...........................................................................8-4

8-1-3 Relationship Between Safety Input Signals and EDM Output Signal......................................... 8-4

8-2 Operation Example......... ... ... ....................................... ... ....................................... ... ... ............ 8-5

8-3 Connection Example............................................................................................................... 8-7

Section 9 Servo Parameter Objects

9-1 Basic Settings.......................................................................................................................... 9-2

9-2 Gain Settings ........................................................................................................................... 9-7

9-3 Vibration Suppression Settings........................................................................................... 9-18

9-4 Analog Control Objects ........................................................................................................9-25

9-5 Interface Monitor Settings.................................................................................................... 9-30

9-6 Extended Objects..................... ... ... ... ....................................... ... .......................................... 9-41

9-7 Special Objects...................................................................................................................... 9-47

9-8 Linear Motor Objects............................................................................. ... ............................. 9-61

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

9

Page 12

CONTENTS

Section 10 Operation

10-1 Operational Procedure.......................................................................................................... 10-2

10-2 Preparing for Operation........................................................................................................10-4

10-2-1 Items to Check Before Turning ON the Power Supply..............................................................10-4

10-2-2 Turning ON the Power Supply..................................................................................................10-6

10-2-3 Checking the Displays................................ ..................................... .. ........................................10-6

10-2-4 Preparing the Linear Motor for Operation .................................................................................10-8

10-3 Linear Motor Setup.............................................................................................................. 10-13

10-3-1 Outline of Linear Motor Setup.................................................................................................10-14

10-3-2 Operation from the CX-Drive...................................................................................................10-14

10-3-3 Connection from the CX-Drive via Network ............................................................................10-23

10-3-4 Connection from the Sysmac Studio via Network...................................................................10-25

10-4 Trial Operation..................................................................................................................... 10-27

10-4-1 Preparations for Trial Operation..............................................................................................10-27

10-4-2 Trial Operation via USB Communications from the CX-Drive.................................................10-28

10-4-3 Setup via Network............................................... .. ..................................... ... ............... ...........10-28

Section 11 Adjustment Functions

11-1 Analog Monitor .................................. ... ... .... ... ... ... .... ...................................... .... ...................11-2

11-2 Gain Adjustment.................................................................................................................... 11-5

11-2-1 Purpose of the Gain Adjustment...............................................................................................11-5

11-2-2 Gain Adjustment Methods.........................................................................................................11-5

11-2-3 Gain Adjustment Procedure.............................................. .................................... ... ... ..............11-6

11-3 Realtime Autotuning .............................................................................................................11-7

11-3-1 Operating Conditions ................................................................................................................11-8

11-3-2 Objects Requiring Settings........................................................................................................11-8

11-3-3 Setting Realtime Autotuning......................................................................................................11-9

11-3-4 Setting Machine Rigidity..........................................................................................................11-10

11-3-5 Objects to Be Updated................................................ ... .................................... ... ... ...............11-12

11-4 Manual Tuning .....................................................................................................................11-15

11-4-1 Preparation for Manual Tuning................................................................................................11-15

11-4-2 Position Control Mode Adjustment..........................................................................................11-16

11-5 Damping Control ............ ..................................................................................................... 11-17

11-5-1 Operating Conditions ..............................................................................................................11-17

11-5-2 Objects Requiring Settings......................................................................................................11-18

11-5-3 Operating Procedure...............................................................................................................11-19

11-6 Adaptive Filter .... ... ....................................... ... ....................................... ... ... ........................ 11-21

11-6-1 Operating Conditions ..............................................................................................................11-22

11-6-2 Objects Requiring Settings......................................................................................................11-22

11-6-3 Objects to Be Set Automatically..............................................................................................11-23

11-6-4 Operating Procedure...............................................................................................................11-23

11-7 Notch Filters......................................................................................................................... 11-24

11-7-1 Objects Requiring Settings......................................................................................................11-25

11-7-2 Notch Filter Width and Depth............................................ .. ..................................... ... ............11-26

11-8 Disturbance Observer Function......................................................................................... 11-28

11-8-1 Operating Conditions ..............................................................................................................11-28

11-8-2 Objects Requiring Settings......................................................................................................11-29

11-8-3 Operating Procedure...............................................................................................................11-29

11-9 Friction Force Compensation Function.............................................................................11-30

11-9-1 Operating Conditions ..............................................................................................................11-30

11-9-2 Objects Requiring Settings......................................................................................................11-30

11-9-3 Operating Procedure...............................................................................................................11-31

10

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 13

CONTENTS

11-10Feed-forward Function...................... ... .... ... ... ... .... ...... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... . ... 11-32

11-10-1 Objects Requiring Settings ..................................................................................................... 11-32

11-10-2 Operating Procedure .............................. ... .................................... ... ...................................... 11-33

11-11Instantaneous Speed Observer Function ......................................................................... 11-35

11-11-1 Operating Conditions..............................................................................................................11-35

11-11-2 Objects Requiring Settings ..................................................................................................... 11-36

11-11-3 Operating Procedure .............................. ... .................................... ... ...................................... 11-36

Section 12 Troubleshooting and Maintenance

12-1 Actions for Problems .................................................. ... .... ... ... ....................................... ...... 12-2

12-1-1 Preliminary Checks When a Problem Occurs...........................................................................12-2

12-1-2 Precautions When a Problem Occurs.......................................................................................12-3

12-1-3 Replacing the Linear Motor or Servo Drive...............................................................................12-3

12-2 Warnings ................................................................................................................................ 12-5

12-2-1 Related Objects........................................................................................................................ 12-5

12-2-2 Warning List............................................................................................... .. ............................. 12-6

12-3 Errors...................................................................................................................................... 12-9

12-3-1 Error List................................................................................................................................... 12-9

12-3-2 Immediate Stop Operation at Errors.......................................................................................12-11

12-4 Troubleshooting .................................................................................................................. 12-13

12-4-1 Troubleshooting with Error Displays.......................................................................................12-13

12-4-2 Troubleshooting with the AL Status Code.............................................................................. 12-27

12-4-3 Troubleshooting Using the Operation State............................................................................ 12-28

12-5 Periodic Maintenance.......................................................................................................... 12-35

12-5-1 Linear Slider Life Expectancy................................................................................................. 12-35

12-5-2 Servo Drive Life Expectancy................................................................................................... 12-36

Appendices

A-1 CiA402 Drive Profile ................................................. ... ... .... ... ... ... ............................................A-2

A-1-1 Controlling the State Machine of the Servo Drive.......................................................................A-2

A-1-2 Modes of Operation..................................................................... .. .............................................A-4

A-1-3 Communications Cycles and Corresponding Modes of Operation........................................ ... ..A-5

A-1-4 Modes of Operation and Applied Functions................................................................................A-6

A-1-5 Changing the Mode of Operation................................................................................................A-7

A-1-6 Homing Mode Specifications....................................................................................................A-15

A-1-7 Object Dictionary......................................................................................................................A-22

A-1-8 Communication Objects............................................................................................................A-25

A-1-9 PDO Mapping Objects..............................................................................................................A-31

A-1-10 Sync Manager Communication Objects ...................................................................................A-44

A-1-11 Manufacturer Specific Objects..................................................................................................A-49

A-1-12 Servo Drive Profile Objects.......................................................................................................A-55

A-2 Object List..............................................................................................................................A-77

A-3 Sysmac Error Status Codes .................................................................................................A-95

A-3-1 Error Table................................................................................................................................A-95

A-3-2 Error Description.....................................................................................................................A-109

A-4 Response Time in EtherCAT Process Data Communications ........................................A-167

A-4-1 Input Response Time..............................................................................................................A-167

A-4-2 Output Response Time............................................ ... ... .................................... ... ..................A-168

A-5 EtherCAT Terminology .......................................................................................................A-169

Index

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

11

Page 14

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

z Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and

workmanship for a period of twelve months from the date of sale by Omron (or such other period

expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

z Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

z Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s electi on, to (i) replace (in the form origin ally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an

amount equal to the purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, repair, indemnity or any other claims or expenses rega rding the

Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate

modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from

the use of Products in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or

information given orally or in writing, are not to be construed as an amendment or addition to the

above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

12

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 15

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness

of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time b ased on improve ments and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

13

Page 16

Safety Precautions

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury, or property damage.

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Additionally, there may be severe property damage.

DANGER

Caution

Safety Precautions

To ensure that the G5-series Servo Drive and Servomotor as well as peripheral equipment are used safely

and correctly, be sure to read this Safety Precautions section and the main text before using the product.

Learn all items you should know before use, regarding the equipment as well as the required safety

information and precautions.

Make an arrangement so that this manual also gets to the end user of this product.

After reading this manual, keep it in a convenient place so that it can be referenced at any time.

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

G5-series Servo Drives and Servomotors.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The display of precautions used in this manual and their meanings are explained below.

Explanation of Symbols

This symbol indicates a prohibited item.

The specific instruction is indicated using an illustration inside and text.

The symbol shown to the left indicates “disassembly prohibited.”

This symbol indicates a compulsory item.

The specific instruction is indicated using an illustration inside and text.

The symbol shown to the left indicates “grounding required.”

14

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration inside and text.

The symbol shown to the left indicates “beware of electric shock.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration inside

The symbol shown to the left indicates the “risk of hot surface.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration inside and text.

The symbol shown to the left indicates the “risk of fire.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration inside

The symbol shown to the left indicates a “general precaution.”

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

and text.

and text.

Page 17

Precautions for Safe Use of This Product

DANGER

• Illustrations contained in this manual sometimes depict conditions without covers and safety shields

for the purpose of showing the details.

When using this product, be sure to install the covers and shields as specified and use the product

according to this manual.

• If the product has been stored for an extended period of time, contact your OMRON sales

representative.

Be sure to ground the frame ground terminals and ground wires for the Servo Drive and

Motor with 100 VAC or 200 VAC to 100 Ω or less, and for the Servo Drive and Motor with

400 VAC to 10 Ω or less.

Electric shock may result.

Never touch the parts inside the Servo Drive or the cable ends of the Motor Coil Unit.

Electric shock may result.

Safety Precautions

Do not remove the front cover, terminal covers, cables, or optional items while the power is

being supplied.

Doing so may result in electric shock.

Installation, operation and maintenance or inspection by unauthorized personnel is

prohibited.

Electric shock or injury may result.

Before carrying out wiring or inspection, turn OFF the main circuit power and wait for at

least 15 minutes.

Electric shock may result.

Install the Servo Drive and Motor before wiring.

Improper grounding may result in electrical shock.

Do not damage, pull, or put excessive stress or heavy objects on the cables.

Doing so may cause electric shock, malfunction, or burning.

Do not use the cable when it is laying in oil or water.

Electric shock, injury, or fire may result.

Do not perform wiring or any operation with wet hands.

Electric shock, injury, or fire may result.

Do not touch the Servo Drive radiator, Regeneration Resistor, or Motor while the power is

supplied or for a while after the power is turned OFF becuse they get hot.

Fire or a burn injury may result.

Use the Motor and Servo Drive in a specified combination.

Fire or equipment damage may result.

Never connect a power supply directly to the Motor.

Fire or failure may result.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

15

Page 18

Safety Precautions

Do not enter the operating area during operation.

Injury may result.

Never modify the Servo Drive.

Injury or equipment damage may result.

Install a stopping device on the machine to ensure safety.

* The holding brake is not a stopping device to ensure safety.

Injury may result.

Install an immediate stop device externally to the machine so that the operation can be

stopped and the power supply is cut off immediately.

Injury may result.

When the power is restored after a momentary power interruption, the machine may restart

suddenly. Never come close to the machine when restoring power.

* Implement measures to ensure safety of people nearby even when the machine is

restarted.

Injury may result.

After an earthquake, be sure to conduct safety checks.

Electric shock, injury, or fire may result.

Never drive the Motor using an external drive source.

Fire may result.

Do not place flammable materials near the Motor, Servo Drive, or Regeneration Resistor.

Fire may result.

Install the Motor, Servo Drive, and Regeneration Resistor on non-flammable materials such

as metals.

Fire may result.

When constructing a system that includes safety functions, be sure you understand the

relevant safety standards and all related information in user documentation, and design the

system to comply with the standards.

Not doing so may result in injury or equipment damage.

If the motor is not controlled, it may not be possible to maintain the stop.

To ensure safety, install a stop device. Risk of equipment damage and human injury.

Do not handle objects made of magnetic materials ne ar the Linear Motor. Use nonmagnetic

tools when performing installation or other work on the Linear Moto r.

The objects may be attracted by the magnetic field of the Linear Motor and you may be

caught between the motor parts, resulting in injury.

People using a pacemaker or other electronic medical device must stay away from the

linear motor.

A powerful magnetic field is generated by the stator and powered needle.

This may cause malfunctioning of electronic devices.

When shipping or transporting the Magnet Track, be sure to display that the content is a

strong magnetic product.

Medical electronics such as cardiac pacemakers may malfunction or injury may result.

Do not put the product into the fire.

Burst or gas may occur and injury may result.

16

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 19

Safety Precautions

Caution

Do not store or install the Servo Drive in the following locations:

• Location subject to direct sunlight

• Location where the ambient temperature exceeds the specified level

• Location where the relative humidity exceeds the specified level

• Location subject to condensation due to rapid temperature changes

• Location subject to corrosive or flammable gases

• Location subject to high levels of dust, salt content, or iron dust

• Location subject to splashes of water, oil, chemicals, etc.

• Location where the Servo Drive may receive vib ration or impact directly

Installing or storing the Servo Drive in these locations may result in fire, electric shock, or

equipment damage.

The magnetic attraction force always affects between the Motor Coil Unit and Magnet Track

even when the power supply is turned OFF. Design a machine which supports the

magnetic attraction force and provides enough rigidity to maintain the accuracy.

Malfunction or failure may result.

Design a machine with consideration of the magnetic attraction force.

Malfunction or failure may result.

Do not hit the Motor Coil Unit against the stopper. Design the configuration so that the table

mounted on the Motor Coil Unit hits against the stopper.

Equipment damage may result.

Do not apply strong impact on the product.

Failure may result.

Prevent adhesion of foreign objects to the product.

Malfunction may result.

You cannot use the Linear Motor because its magnetic pole cannot be detected in an

unbalanced load such as vertical axis.

If the magnetic pole cannot be detected, an error may occur and the Linear Motor may be in

the free-run status.

Injury or equipment damage may result.

The protective structure of the Linear Motor is IP00. Take necessary measures to prevent

dust, oil, etc.

Failure may result.

Ensure that the Linear Slider has a sufficient rigidity.

Equipment damage or malfunction may result.

Provide appropriate safety measures to prevent crashes, etc. if you design a system which

cooperates multiple motor coil units such as multi-head or tandem.

Equipment damage may result.

Do not bring electronic devices, magnetic recording media, or other articles that may be

affected by magnetism (clocks, computers, measuring instruments, magnetic cards, IC

cards, etc.) near the linear motor.

This may cause malfunctioning or equipment damage.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

17

Page 20

Safety Precautions

Storage and Transportation

When transporting the Motor Coil Unit, do not hold the cable.

Injury or equipment damage may result.

When transporting the Magnet Track, do not hold the cover to protect the magnet.

Injury or equipment damage may result.

Do not overload the product. (Follow the instructions on the product label.)

Injury or failure may result.

Be sure to store the product as packed in the same packing as delivered.

Injury or equipment damage may result.

Caution

When transporting or storing the magnet track, pack the product in the same condition as

delivered or cover the magnetic side by 30 mm or more thick material such as high density

plastics. (Be sure to provide more than 60 mm of thickness.)

Equipment damage may result.

The magnetic body (Motor Coil Unit, other Magnet Track or tools) generates attractive force

by Magnet Track. Be careful about the ambient environment when and after disassembling

the Linear Motor, and handling the Magnet Track.

Injury such as getting one’s hand caught in the Linear Motor or equipment damage may

result.

When lifting a 15 kW or higher Servo Drive du ring moving or installation, always have two

people lift the product by grasping a metal part.

Do not grasp a plastic part.

Injury or failure may result.

18

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 21

Installation and Wiring

Caution

Provide the specified clearance between the Servo Drive and the inner surface of the

control panel or other equipment.

Fire or failure may result.

Use crimp terminals to wire screw type terminal blocks. Do not connect bare stranded wires

directly to terminals blocks.

Fire may result.

Provide safety measures, such as a breaker, to protect against short circuiting of external

wiring.

Fire may result.

Do not step on the Servo Drive or place heavy articles on it.

Injury may result.

Safety Precautions

Be sure to observe the mounting direction.

Failure may result.

Wire the cables correctly and securely.

Runaway motor, injury, or failure may result.

Tighten the mounting screws, terminal block screws, and cable screws for the product to

the specified torque.

Failure may result.

Use non-magnetic mounting screws. Note also that the depth of any mounted screw is less

than the effective thread depth.

Equipment damage may result.

Be sure to wire the motor coil unit cable fixedly.

Equipment damage may result.

For wiring between the Motor Coil Unit cable and the Servo Drive, use a robot cable.

Equipment damage may result.

Be sure to securely fix the Linear Motor to the machine.

The Linear Motor may come off during operation and equipment damage may result.

When installing the Linear Motor, match the center of gravity of the motor coil unit and load.

Malfunction or equipment damage may result by the increase of the running loa d.

Install linear guides with great caution to comply with the gap specification of the motor coil

unit and magnet track. (If the gap is small, the running load by the friction will increase in

proportion to the magnetic attraction force.)

Malfunction may result.

Do not allow foreign objects to enter between the Motor Coil Unit and Magnet Track.

Equipment damage or malfunction may result.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

19

Page 22

Safety Precautions

Set a parameter to operate the Motor and external encoder in the same direction.

Malfunction or equipment damage may result.

When installing more than one Magnet Track, set the mounting screw accumulative pitch

tolerance within ± 0.2 mm.

Malfunction may result.

Use the specified screws for the tap holes of Motor Coil Unit. The tap holes are used to

install the Motor Coil Unit.

Equipment damage may result.

Use all tap holes of Motor Coil Unit and threaded holes of Magnet Track to install the Linear

Motor.

Equipment damage may result.

Always use the power supply voltage specified in the User’s Manual.

An incorrect voltage may result in malfunction or burning.

Take appropriate measures to ensure that the specified power with the rated voltage is

supplied.

Be particularly careful in locations where the power supply is unstable.

An incorrect power supply may result in failure.

Connect the Servo Drive to the Motor without a contactor, etc.

Malfunction or equipment damage may result.

Take appropriate and sufficient countermeasures to provide shielding when installing

systems in the following locations.

Not doing so may result in failure.

• Locati ons subject to static electricity or other forms of noise.

• Locati ons subject to strong electromagnetic fields and magnetic fields.

• Locati ons subject to possible exposure to radioactivity.

• Locati ons close to power supplies.

Do not use the Linear Motor in the location sub j ect to magnetic powders such as iron

filings.

They may adhere to the Linear Motor and failure may result.

Connect an emergency stop (immediate stop) relay in series with the brake control relay.

Injury or failure may result.

20

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 23

Operation and Adjustment

Caution

If the Servo Drive fails, cut off the power supply to the Servo Drive.

Fire may result.

Do not block the intake or exhaust openings.

Do not allow foreign objects to enter the Servo Drive.

Fire may result.

Conduct a test operation after confirming that the equipment is not affected.

Equipment damage may result.

Check any newly set parameters and software switch settings for proper execution before

actually using them.

Not doing so may result in equipment damage.

Never adjust or set parameters to extreme values, because it will make the operation

unstable.

Injury may result.

Separate the Motor from the mechanical system and check its operation before installing

the Motor to the machine.

Injury may result.

If the magnetic body is near the Linear Motor, the cogging will occur and affect the

performance.

Malfunction or equipment damage may result.

If an error occurs, remove the cause of the error and ensure safety, and then reset the

alarm and restart the operation.

Injury may result.

Do not operate the Motor connected to an excessive load mass.

Failure may result.

Safety Precautions

Do not turn ON and OFF the main Servo Drive power supply frequently.

Failure may result.

Install equipment to prevent crash and reduce shock.

Crash against the stroke edge may occur depending on stopping distance and equipment

damage may result.

If a problem occurs in serial communications during a test operation, you have no means to

stop the Motor.

Install external hardware to ensure that the Motor can be stopped at any time.

Before transferring parameters or data from the CX-Drive and Sysmac Studio to any other

node, check the safety around the target node.

Injury may result.

Check the axis (shaft) number before operating with the CX-Drive and Sysmac Studio.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

21

Page 24

Safety Precautions

Maintenance and Inspection

Do not attempt to disassemble, repair, or modify the Servomotor or Servo Drive.

Any attempt to do so may result in electric shock or other injury.

After replacing the Servo Drive, transfer to the new Servo Drive all data needed to resume

operation, before restarting operation.

Equipment damage may result.

Turn OFF the power supply when not using the Servomotor or Servo Drive for a long period

of time.

Not doing so may result in injury or malfunction.

Design the system to stop for at least ten minutes after the dynamic brake operates.

If it is used under more conditions, the dynamic brake may break and the brake may not

operate.

Caution

22

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

Page 25

Safety Precautions

VOLTAGE

100~120V

1Ø 3Ø

0-120V

INPUT OUTPUT

PHASE

2.6A

50/60Hz

0~500.0Hz

1.7A

100W

A09080004

FREQ

POWER

OMRON Corporation

MADE IN JAPAN

SERIAL No.

F L C

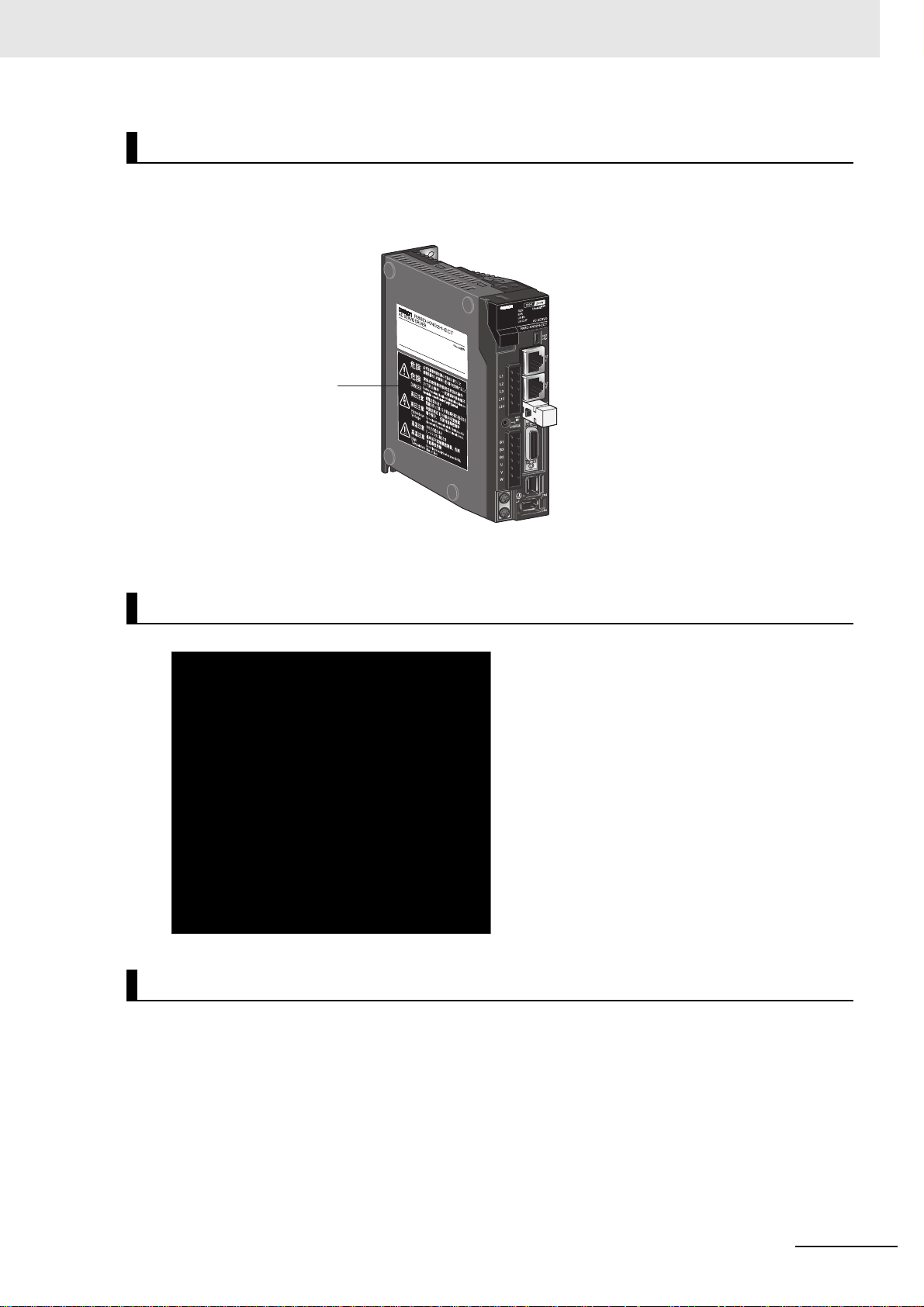

Location of Warning Label

(R88D-KN02H-ECT-L)

Location of Warning Label

The Servo Drive bears a warning label at the following location to provide handling warnings.

When handling the Servo Drive, be sure to observe the instructions provided on this label.

Instructions on Warning Label

Disposal

• Dispose of the Servo Drive as industrial waste.

• When disposing of the battery, insulate it using tape and dispose of it by following the applicable

ordinance of your local government.

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

23

Page 26

Regulations and Standards

Regulations and Standards

Overseas Use

To export (or provide to nonresident aliens) any part of this product that falls under the category of

goods (or technologies) for which an export certifica te or license is ma ndato ry accordi ng to the For eign

Exchange and Foreign Trade Control Law of Japan, an export certificate or license (or service

transaction approval) according to this law is required.

Conformance to EC Directives

For the G5-series Servo Drive which is an EC-compliant product, it is the user’s responsibility to check

and ensure the compliance of the equipment and the entire system with the applicable EC Directives.

EC Directive Product Applicable standards

Low Voltage Directive AC Servo Drives EN61800-5-1

Linear Motor EN60034-1

EMC Directive AC Servo Drives EN55011 classA group1

EN61000-6-2

EN61800-3