Page 1

=;76HULHV

&DW1R,((1

<5&;5RERW&RQWUROOHU

86(5¶60$18$/

6&$5$5RERWV

<5&;6HULHV

Page 2

Page 3

CONTENTS

Safety Instructions

1. Safety Information S-1

2. Signal words used in this manual S-2

3. Warning labels S-3

3.1 Warning labels S-3

3.1.1 Warning label messages on robot and controller S-3

3.1.2 Supplied warning labels S-6

3.2 Warning symbols S-7

4. Important precautions for each stage of the robot life cycle S-8

4.1 Precautions for using robots and controllers S-8

4.2 Design S-9

4.2.1 Precautions for robots S-9

4.2.2 Precautions for robot controllers S-9

4.3 Moving and installation S-10

4.3.1 Precautions for robots S-10

4.3.2 Precautions for robot controllers S-11

4.4 Safety measures S-13

4.4.1 Safety measures S-13

4.4.2 Installing a safety enclosure S-14

4.5 Operation S-15

4.5.1 Trial operation S-15

4.5.2 Automatic operation S-17

4.5.3 Precautions during operation S-17

4.6 Inspection and maintenance S-19

4.6.1 Before inspection and maintenance work S-19

4.6.2 Precautions during service work S-20

4.7 Disposal S-21

YRCX

User’s Manual

5. Emergency action when a person is caught by robot S-22

6. Cautionsregardingstrongmagneticelds S-22

7. Using the robot safely S-23

7.1 Movement range S-23

7.2 Robot protective functions S-24

7.3 Residual risk S-25

7.4 Special training for industrial robot operation S-25

7.5 KC mark S-26

7.5.1 EMC standards S-26

7.5.2 Examples of EMC countermeasures S-26

T-1

Page 4

CONTENTS

Warranty

Important information before reading this manual

Introduction i

About this manual i

Overview of the YRCX ii

Before using the robot controller (Be sure to read the following notes) iii

Chapter 1 Using the robot safely

1. Emergency action when a person is caught by robot 1-1

2. Emergency stop 1-2

2.1 Emergency stop release and alarm reset 1-2

3. Power-ON procedures 1-4

YRCX

User’s Manual

4. Usage environments 1-5

Chapter 2 System overview

1. I/O interface overview 2-1

1.1 Mainsystemconguration 2-1

1.2 AxiscongurationfortheYRCX 2-2

2. Name of each part and control system 2-3

2.1 YRCXexternalview 2-3

2.2 Controller system 2-4

3. Optional devices 2-5

3.1 Programming box 2-5

3.2 Basic key operation 2-5

3.3 Expansion I/O board 2-5

4. Basic sequence from installation to operation 2-6

Chapter 3 Installation

1. Transport, unpacking 3-1

T-2

2. Installing the robot controller 3-1

2.1 Installation conditions 3-1

2.2 Installation methods 3-2

Page 5

CONTENTS

3. Connecting to the power 3-3

3.1 Powersupplyandgroundterminals 3-3

3.2 ACpowerconnectorwiring 3-4

3.3 Consideringpowercapacityandgeneratedheatamount 3-5

3.4 Installing an external leakage breaker 3-6

3.4.1 Selecting condition 3-6

3.5 Installing a circuit protector 3-6

3.6 Installing an electromagnetic contactor 3-6

3.7 Installinganoiselter 3-7

3.8 Installing a surge absorber 3-7

4. Connecting the absolute battery 3-8

5. Robot connections 3-9

5.1 Connecting the robot cables 3-9

5.2 Noise countermeasures 3-10

6. Connecting the programming box 3-10

YRCX

User’s Manual

7. I/O connections 3-11

8. Connecting the regenerative shorting connector 3-11

9. Connecting the brake power supply 3-12

10. Precautions for cable routing and installation 3-12

10.1 Wiring methods 3-12

10.2 Methods of preventing malfunctions 3-13

11. Checking the robot controller operation 3-14

11.1 Controllerwiring 3-14

11.2 Wiring example of emergency stop circuit for operation check 3-15

11.3 Operation check 3-15

Chapter 4 I/O interface

1. I/O interface overview 4-1

1.1 ID settings 4-2

1.2 Powersupply 4-2

1.3 Powerconnectorwiringwork 4-3

1.4 Connector I/O signals 4-4

1.4.1 StandardspecicationI/Oconnectorsignallist 4-4

1.4.2 ExpandedspecicationI/Oconnectorsignallist 4-5

1.5 Connector pin assignment lists 4-6

1.5.1 StandardspecicationI/Oconnector 4-6

1.5.2 ExpandedspecicationI/Oconnector 4-6

T-3

Page 6

CONTENTS

1.6 Connector pin numbers 4-7

1.7 Typical input signal connection 4-7

1.8 Typical output signal connection 4-8

1.9 Dedicated input signal description 4-9

1.10 Dedicated output signal description 4-10

1.11 Dedicated I/O signal timing chart 4-12

1.11.1 From the controller power on to servo on 4-12

1.11.2 Controller emergency stop and servo on reset 4-13

1.11.3 Return-to -origin 4-14

1.11.4 Program reset and program execution 4-15

1.11.5 Stopping by program stop 4-16

1.12 General-purpose I/O signals 4-17

1.12.1 General-purpose input signals 4-17

1.12.2 General-purpose output signals 4-17

1.12.3 General-purpose output signal reset (off) 4-17

2. Ratings 4-18

2.1 Input 4-18

2.2 Output 4-18

YRCX

User’s Manual

3. Caution items 4-18

Chapter 5 SAFETY I/O interface

1. SAFETY I/O interface overview 5-1

1.1 Power 5-1

1.2 Connector I/O signals 5-1

1.3 Connectionexamplecombiningtheprogrammingboxwith

external emergency stop circuit 5-2

1.3.1 ConnectionexampleofcontrollerwithCEspecicationsandPBEX 5-2

1.4 Connections example of dedicated input signal 5-3

1.4.1 Emergencystopinputs(E-STOPRDY*,E-STOPCOM*) 5-3

1.4.2 AUTOmodeinputs(AUTO*+,AUTOCOM*) 5-3

1.5 Connection example of dedicated output signal 5-4

1.5.1 Emergencystopcontactoutputs(E-STOP*1,E-STOP*2) 5-4

1.5.2 Enableswitchcontactoutputs(ENABLE*1,ENABLE*2) 5-4

1.5.3 Motorpowerreadyoutputs(MPRDY*+,MPRDY*-) 5-5

Chapter 6 External communication interface

1. Overview 6-1

1.1 Communicationoverview 6-1

1.2 ONLINE and OFFLINE modes 6-2

1.3 Character code 6-3

T-4

Page 7

CONTENTS

2. RS-232C 6-4

2.1 Connectors and cables 6-4

2.2 Communicationspecications 6-5

2.3 Connections 6-5

2.4 Communication parameter setting 6-6

2.5 Communicationowcontrol 6-7

2.5.1 Flow control during transmit 6-7

2.5.2 Flow control during receive 6-7

2.6 Other caution items 6-7

3. Ethernet 6-8

3.1 Connectors and cables 6-9

3.2 Communicationspecications 6-11

3.3 Connections 6-12

3.4 Parameter setting on controller (server) 6-13

3.4.1 Setting the communication mode and parameters 6-14

3.4.2 Initializing communication parameters 6-14

3.5 System setting on personal computer (client) 6-15

3.5.1 SettingtheTCP/IPprotocol 6-15

3.6 Connection check using "Ping" 6-16

3.7 Communicationexampleusing"TELNET.EXE" 6-16

3.8 Appendix 6-17

3.8.1 Exampleofnetworksystemconguration 6-17

3.8.2 Glossary 6-20

YRCX

User’s Manual

4. General Ethernet port (GEP) 6-22

4.1 GEP parameter setting 6-22

4.2 GEP parameter setting method 6-23

4.3 Initializing communication parameters 6-24

Chapter 7 Controller system settings

1. Overview 7-1

2. History 7-1

3. Check 7-2

4. Property 7-2

4.1 Robot information 7-2

4.2 Option information 7-3

4.3 Clock 7-3

4.4 Version 7-3

4.5 Conguration 7-4

T-5

Page 8

CONTENTS

5. USB memory operation 7-4

5.1 Saving the data 7-4

5.2 Loading the data 7-5

6. Execution level 7-6

6.1 Changing the access level 7-6

7. Safety setting 7-7

8. Initialize 7-8

8.1 Initializing the data 7-8

8.2 Setting the clock 7-9

9. Generation 7-10

10. Parameters 7-10

10.1 Parameter setting conditions 7-10

10.2 Setting the parameters 7-10

10.3 Parameter list 7-12

10.4 Controller parameters 7-15

10.5 Robot parameters 7-17

10.6 Axis parameters 7-20

10.7 I/O parameters 7-27

10.8 Option board related parameters 7-29

YRCX

User’s Manual

Chapter 8 Periodic inspection

1. Before carrying out work 8-1

2. Maintenance parts 8-1

3. Periodic inspections 8-1

3.1 Daily inspections 8-1

3.2 Three-month inspections 8-2

4. Replacing the absolute battery 8-2

5. Replacing the memory battery 8-2

Chapter 9 Specications

1. Controller 9-1

1.1 Specications 9-1

1.2 Basic functions 9-2

1.3 Externalview 9-3

T-6

Page 9

CONTENTS

2. Programming box 9-4

2.1 Basicspecications 9-4

2.2 Externalview 9-4

Troubleshooting

1. Alarm messages A-1

1.1 Alarm messages related to the controller A-1

1.1.1 Alarm group number list A-3

1.1.2 Alarmclassicationnumberlist A-4

1.1.3 Warning number list A-4

[0]Operationmessages A-4

[ 1] System events A-5

[ 2] Alarm related to the robot operation A-7

[3]Alarmrelatedtotheprogramleoperation A-13

[ 4] Alarm related to the data input A-15

[ 5] Alarm related to the syntax of the robot language (compile) A-16

[ 6] Alarm related to the robot language execution A-23

[ 9] Alarm related to the memory A-33

[10] Alarm related to the environment and general hardware A-36

[12] Alarm related to the option board A-38

[14] Alarm related to the communication A-46

[17] Alarm related to the motor control A-49

[19]AlarmrelatedtotheYC-Link/E A-55

[21] Serious alarm related to software A-58

[22] Serious alarm related to hardware A-59

[26] Alarm related to the gripper A-62

[28]AlarmrelatedtothedriverI/F A-66

[ c] Warning A-67

1.2 Alarm messages related to the programming box A-68

YRCX

User’s Manual

2. Troubleshooting A-69

2.1 When trouble occurs A-69

2.2 Acquiring the alarm information A-70

2.2.1 Checking the alarm occurrence status A-70

2.2.2 Checking the alarm history A-70

2.3 Troubleshooting checkpoints A-71

2.3.1 Installation and power supply A-71

2.3.2 Robot operation A-72

2.3.3 I/O A-73

T-7

Page 10

Page 11

Safety Instructions

Contents

1. Safety Information S-1

2. Signal words used in this manual S-2

3. Warning labels S-3

3.1 Warning labels S-3

3.1.1 Warning label messages on robot and controller S-3

3.1.2 Supplied warning labels S-6

3.2 Warning symbols S-7

4. Important precautions for each stage of the robot life cycle

4.1 Precautions for using robots and controllers S-8

4.2 Design S-9

4.2.1 Precautions for robots S-9

4.2.2 Precautions for robot controllers S-9

4.3 Moving and installation S-10

4.3.1 Precautions for robots S-10

4.3.2 Precautions for robot controllers S-11

4.4 Safety measures S-13

4.4.1 Safety measures S-13

4.4.2 Installing a safety enclosure S-14

4.5 Operation S-15

4.5.1 Trial operation S-15

4.5.2 Automatic operation S-17

4.5.3 Precautions during operation S-17

4.6 Inspection and maintenance S-19

4.6.1 Before inspection and maintenance work S-19

4.6.2 Precautions during service work S-20

4.7 Disposal S-21

5.

Emergency action when a person is caught by robot

S-8

S-22

6. Cautions regarding strong magnetic fields S-22

Page 12

7. Using the robot safely S-23

7.1 Movement range S-23

7.2 Robot protective functions S-24

7.3 Residual risk S-25

7.4 Special training for industrial robot operation S-25

7.5 KC mark S-26

7.5.1 EMC standards S-26

7.5.2 Examples of EMC countermeasures S-26

Page 13

1. Safety Information

Industrial robots are highly programmable, mechanical devices that provide a large degree of freedom when

performing various manipulative tasks. To ensure safe and correct use of OMRON industrial robots and controllers*, carefully read and comply with the safety instructions and precautions in this "Safety Instructions"

guide. Failure to take necessary safety measures or incorrect handling may result in trouble or damage to the

robot and controller, and also may cause personal injury (to installation personnel, robot operator or service

personnel) including fatal accidents.

* The descriptions about the controller stated in this manual also include the contents of the robot driver.

Before using this product, read this manual and related manuals and take safety precautions to ensure correct handling.

The precautions listed in this manual relate to this product. To ensure safety of the user’s final system that includes OMRON robots, please take appropriate safety measures as required by the user’s individual system.

To use OMRON robots and controllers safely and correctly, always comply with the safety rules and instructions.

• For specific safety information and standards, refer to the applicable local regulations and comply with

the instructions.

• Warning labels attached to the robots are written in English, Japanese, Chinese and Korean. This manual

is available in English or Japanese (or some parts in Chinese). Unless the robot operators or service

personnel understand these languages, do not permit them to handle the robot.

• Cautions regarding the official language of EU countries

For equipment that will be installed in EU countries, the language used for the manuals, warning labels,

operation screen characters, and CE declarations is English only.

Warning labels only have pictograms or else include warning messages in English. In the latter case,

messages in Japanese or other languages might be added.

Safety Instructions

It is not possible to list all safety items in detail within the limited space of this manual. So please note that

it is essential that the user have a full knowledge of safety and also make correct judgments on safety procedures.

S-1

Page 14

Safety Instructions

2. Signal words used in this manual

This manual uses the following safety alert symbols and signal words to provide safety instructions that must

be observed and to describe handling precautions, prohibited actions, and compulsory actions. Make sure

you understand the meaning of each symbol and signal word and then read this manual.

DANGER

This indicates an immediately hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

This indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

This indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury, or

damage to the equipment.

NOTE

Explains the key point in the operation in a simple and clear manner.

S-2

Page 15

3. Warning labels

Warning labels shown below are attached to the robot body and controller to alert the operator to potential

hazards. To ensure correct use, read the warning labels and comply with the instructions.

3.1 Warning labels

WARNING

If warning labels are removed or difficult to see, then the necessary precautions may not be taken, resulting in an

accident.

• Do not remove, alter or stain the warning labels on the robot body.

• Do not allow warning labels to be hidden by devices installed on the robot by the user.

• Provide proper lighting so that the symbols and instructions on the warning labels can be clearly seen from

outside the safety enclosure.

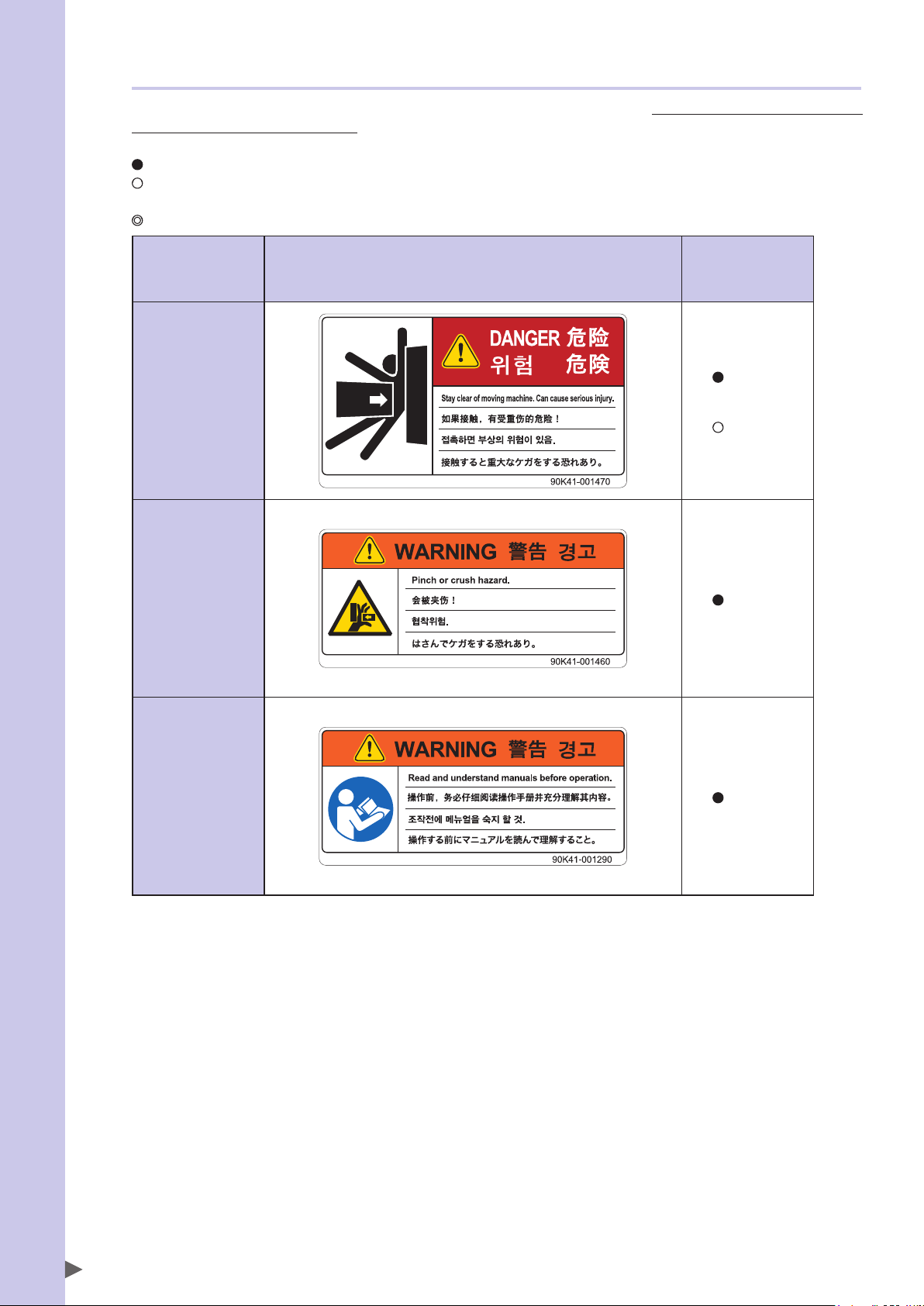

3.1.1 Warning label messages on robot and controller

Word messages on the danger, warning and caution labels are concise and brief instructions. For more specific

instructions, read and follow the "Instructions on this label" described on the right of each label shown below.

See “7.1 Movement range” for details on the robot’s movement range.

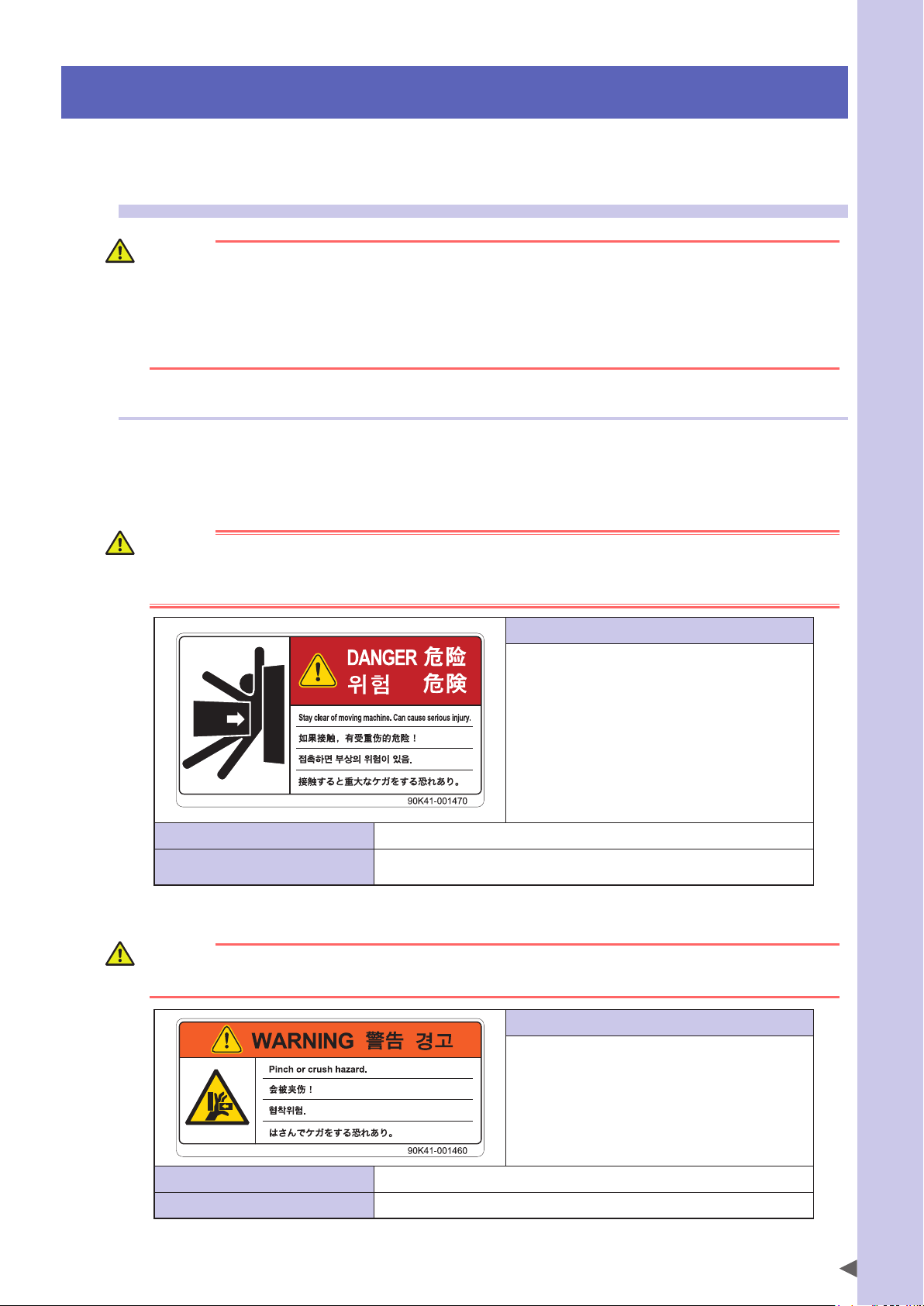

■Warning label 1

DANGER

Serious injury may result from contact with a moving robot.

• Keep outside of the robot safety enclosure during operation.

• Press the emergency stop button before entering the safety enclosure.

Safety Instructions

Potential hazard to human body

To avoid hazard

Serious injury may result from contact with a moving robot.

• Keep outside of the robot safety enclosure during operation.

• Press the emergency stop button before entering the safety enclosure.

■Warning label 2

WARNING

Moving parts can pinch or crush hands.

Keep hands away from the movable parts of the robot.

Instructions on this label

• Always install a safety enclosure to keep all persons

away from the robot movement range and prevent

injury from contacting the moving part of the robot.

Install an interlock that triggers emergency stop when

•

the door or gate of the safety enclosure is opened.

• The safety enclosure should be designed so that no

one can enter inside except from the door or gate

equipped with an interlock device.

• Warning label 1 that comes supplied with a robot

should be affixed to an easy-to-see location on the

door or gate of the safety enclosure.

90K41-001470

Instructions on this label

Use caution to prevent hands and fingers from being

pinched or crushed by the movable parts of the robot

when transporting or moving the robot or during

teaching.

Potential hazard to human body

To avoid hazard

Moving parts can pinch or crush hands.

Keep hands away from the movable parts of the robot.

90K41-001460

S-3

Page 16

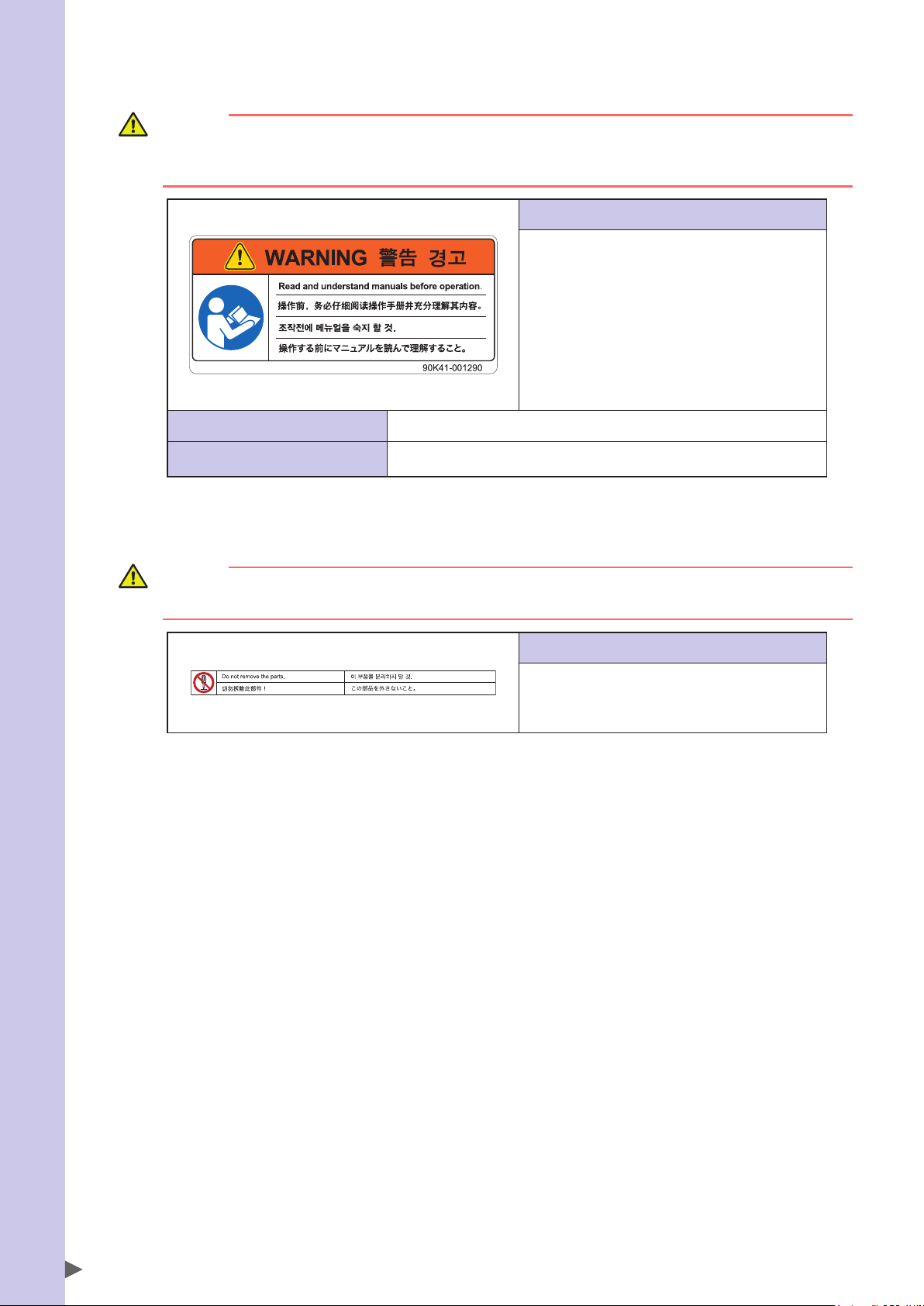

■Warning label 3

Safety Instructions

WARNING

Improper installation or operation may cause serious injury.

Before installing or operating the robot, read the manual and instructions on the warning labels and understand

the contents.

Instructions on this label

• Be sure to read the warning label and this manual

carefully to make you completely understand the

contents before attempting installation and operation

of the robot.

• Before starting the robot operation, even after you

have read through this manual, read again the

corresponding procedures and "Safety Instructions".

• Never install, adjust, inspect or service the robot in

any manner that does not comply with the

instructions in this manual.

Potential hazard to human body

To avoid hazard

Improper installation or operation may cause serious injury.

Before installing or operating the robot, read the manual and instructions on the

warning labels and understand the contents.

■Warning label 4

90K41-001290

CAUTION

Do not remove the parts on which Warning label 4 is attached.

Doing so may damage the ball screw.

Instructions on this label

The Z-axis ball screw will be damaged if the upper end

mechanical stopper on the Z-axis spline is removed or

moved. Never attempt to remove or move it.

90K41-001520

S-4

Page 17

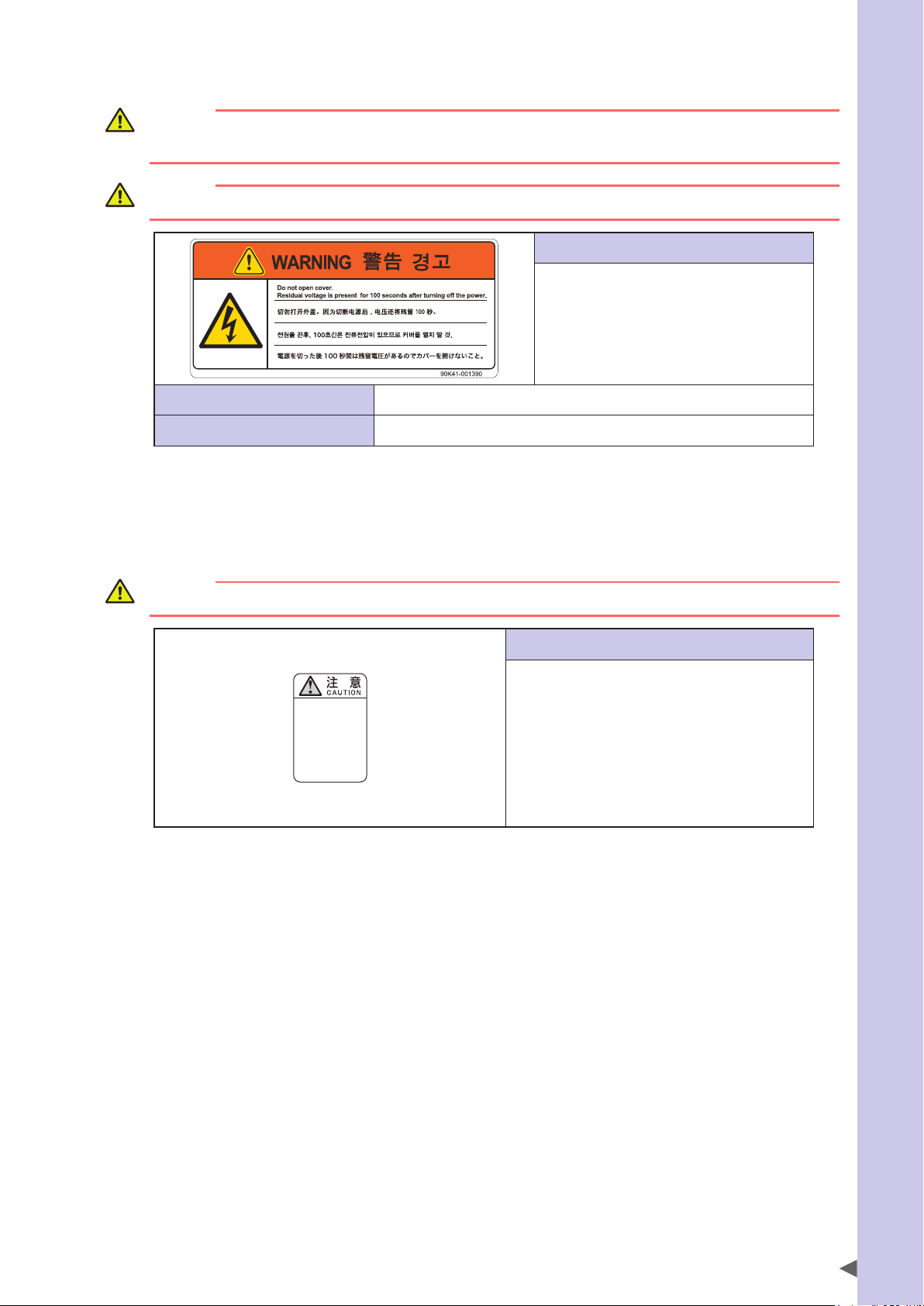

■Warning label 5 (YRCX/YRC controllers)

WARNING

These are precautions for OMRON and distributors' service personnel.

Customers must not attempt to open the covers.

WARNING

Wait at least 100 seconds after power-off before opening the covers.

Instructions on this label

• Wait at least 100 seconds after power-off

before opening the covers (*).

• Some parts in the controller still retain a high

voltage even after power-off, so electrical

shock may occur if those parts are touched.

Potential hazard to human body

To avoid hazard

Electrical shock

Wait at least 100 seconds after power-off before opening the covers (*).

* These are precautions for OMRON and distributors' service personnel. Customers must not attempt to open the covers.

90K41-001390

■Warning label 6 (Controller)*

* This label is attached to the front panel.

Safety Instructions

CAUTION

Refer to the manual.

取扱説明書参照

READ INSTRUCTION

MANUAL

Instructions on this label

This indicates important information that you must

know and is described in the manual.

Before using the controller, be sure to read the manual

thoroughly.

When adding external safety circuits or connecting a

power supply to the controller, read the manual

carefully and make checks before beginning the work.

Connectors have an orientation. Insert each connector

in the correct direction.

93005-X0-00

S-5

Page 18

3.1.2 Supplied warning labels

Safety Instructions

Some warning labels are not affixed to robots but included in the packing box. These warning labels should be

affixed to an easy-to-see location.

Warning label is attached to the robot body.

Warning label comes supplied with the robot and should be affixed to an easy-to-see location on the door or gate of the

safety enclosure.

Warning label comes supplied with the robot and should be affixed to an easy-to-see location.

SCARA robots

1

*

Warning label 1

Warning label 2

Warning label 3

*1: See "Part names" in each SCARA robot manual for label positions.

1

*

1

*

S-6

Page 19

3.2 Warning symbols

!

Warning symbols shown below are indicated on the robots and controllers to alert the operator to potential

hazards. To use the OMRON robot safely and correctly always follow the instructions and cautions indicated

by the symbols.

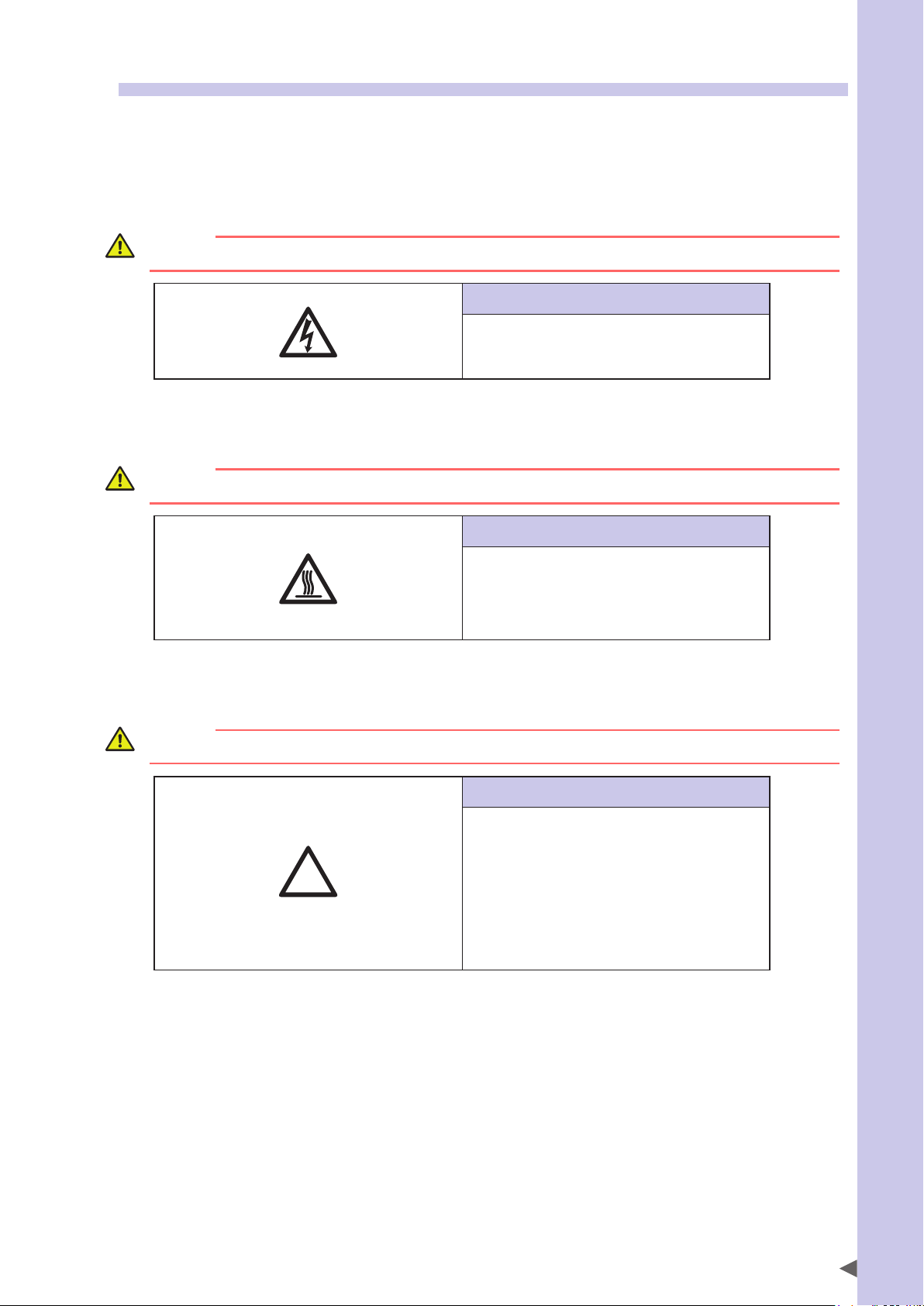

1. Electrical shock hazard symbol

WARNING

Touching the terminal block or connector may cause electrical shock, so use caution.

Instructions by this symbol

This indicates a high voltage is present.

Touching the terminal block or connector may cause

electrical shock.

93006-X0-00

2. High temperature hazard symbol

WARNING

Motors, heatsinks, and regenerative units become hot, so do not touch them.

Instructions by this symbol

Safety Instructions

3. Caution symbol

CAUTION

Always read the manual carefully before using the controller.

This indicates the area around this symbol may become

very hot.

Motors, heatsinks, and regenerative units become hot

during and shortly after operation. To avoid burns be

careful not to touch those sections.

93008-X0-00

Instructions by this symbol

This indicates important information that you must

know and is described in the manual.

Before using the controller, be sure to read the manual

thoroughly.

When adding external safety circuits or connecting a

power supply to the controller, read the manual

carefully and make checks before beginning the work.

Connectors must be attached while facing a certain

direction, so insert each connector in the correct

direction.

93007-X0-00

S-7

Page 20

Safety Instructions

4. Important precautions for each stage of the robot life cycle

This section describes major precautions that must be observed when using robots and controllers. Be sure to

carefully read and comply with all of these precautions even if there is no alert symbol shown.

4.1 Precautions for using robots and controllers

General precautions for using robots and controllers are described below.

1. Applications where robots cannot be used

OMRON robots and robot controllers are designed as general-purpose industrial equipment and cannot be used for the

following applications.

DANGER

OMRON robot controllers and robots are designed as general-purpose industrial equipment and cannot be used

for the following applications.

• In medical equipment systems which are critical to human life

• In systems that significantly affect society and the general public

• In equipment intended to carry or transport people

• In environments which are subject to vibration such as onboard ships and vehicles.

2. Qualification of operators/workers

Operators or persons who perform tasks for industrial robots (such as teaching, programming, movement check, inspection, adjustment, and repair) must receive appropriate training and also have the skills needed to perform the tasks

correctly and safely.

Those tasks must be performed by qualified persons who meet requirements established by local regulations and standards for industrial robots. They must also read the manual carefully and understand its contents before attempting the

robot operation or maintenance.

WARNING

• It is extremely hazardous for persons who do not have the above qualifications to perform tasks for industrial

robots.

• Adjustment and maintenance that require removing a cover must be performed by persons who have the

above qualifications. Any attempt to perform such tasks by an unqualified person may cause an accident

resulting in serious injury or death.

S-8

Page 21

4.2 Design

4.2.1 Precautions for robots

1. Restricting the robot moving speed

WARNING

Restriction on the robot moving speed is not a safety-related function.

To reduce the risk of collision between the robot and workers, the user must take the necessary protective

measures such as enable devices according to risk assessment by the user.

2. Restricting the movement range

See “7.1 Movement range” for details on the robot’s movement range.

WARNING

Soft limit function is not a safety-related function intended to protect the human body.

To restrict the robot movement range to protect the human body, use the mechanical stoppers installed in the

robot (or available as options).

CAUTION

If the robot moving at high speed collides with a mechanical stopper installed in the robot (or available as

option), the robot may be damaged.

3. Provide safety measures for end effector (gripper, etc.)

Safety Instructions

WARNING

• End effectors must be designed and manufactured so that they cause no hazards (such as a loose workpiece

or load) even if power (electricity, air pressure, etc.) is shut off or power fluctuations occur.

• If the object gripped by the end effector might possibly fly off or drop, then provide appropriate safety

protection taking into account the object size, weight, temperature, and chemical properties.

4. Provide adequate lighting

Provide enough lighting to ensure safety during work.

5. Install an operation status light

WARNING

Install a signal light (signal tower) at an easy-to-see position so that the operator will be aware of the robot stop

status (temporarily stopped, emergency stop, error stop, etc.).

4.2.2 Precautions for robot controllers

1. Emergency stop input terminal

DANGER

Each robot controller has an emergency stop input terminal to trigger emergency stop. Using this terminal, install

a safety circuit so that the system including the robot controller will work safely.

For the robot driver without emergency stop input terminal, construct a safety circuit including the emergency

stop function using an external circuit.

2. Maintain clearance

CAUTION

Do not bundle control lines or communication cables together or in close to the main power supply or power

lines. Usually separate these by at least 100mm. Failure to follow this instruction may cause malfunction due to

noise.

S-9

Page 22

4.3 Moving and installation

Safety Instructions

4.3.1 Precautions for robots

■Installation environment

1. Do not use in strong magnetic fields

WARNING

Do not use the robot near equipment or in locations that generate strong magnetic fields. The robot may BREAK

DOWN or malfunction if used in such locations.

2. Do not use in locations subject to possible electromagnetic interference, etc.

WARNING

Do not use the robot in locations subject to electromagnetic interference, electrostatic discharge or radio

frequency interference. The robot may malfunction if used in such locations creating hazardous situations.

3. Do not use in locations exposed to flammable gases

WARNING

• OMRON robots are not designed to be explosion-proof.

• Do not use the robots in locations exposed to explosive or inflammable gases, dust particles or liquid. Failure to

follow this instruction may cause serious accidents involving injury or death, or lead to fire.

■Moving

1. Use caution to prevent pinching or crushing of hands or fingers

WARNING

Moving parts can pinch or crush hands or fingers.

Keep hands away from the movable parts of the robot.

As instructed in Warning label 2, use caution to prevent hands or fingers from being pinched or crushed by movable parts

when transporting or moving the robot. For details on warning labels, see "3. Warning labels".

2. Take safety measures when moving robots

To ensure safety when moving a SCARA robot with an arm length of 500mm or more, use the eyebolts that come supplied

with the robot. Always refer to the robot user’s manual for details.

When moving other robots, please comply with the transport methods described in their respective user’s manuals.

3. Take measures to prevent the robot from falling

When moving the robot by lifting it with equipment such as a hoist or crane, wear personal protective gear and be

careful not to move the robot at higher than the required height.

Make sure that there are no persons on paths used for moving the robot.

WARNING

A robot falling from a high place and striking a worker may cause death or serious injury. When moving the

robot, wear personal protective gear such as helmets and make sure that no one is within the surrounding area.

■Installation

1. Protect electrical wiring and hydraulic/pneumatic hoses

Install a cover or similar item to protect the electrical wiring and hydraulic/pneumatic hoses from possible damage.

S-10

Page 23

■Wiring

1. Protective measures against electrical shock

WARNING

Always ground the robot to prevent electrical shock.

■Adjustment

1. Adjustment that requires removing a cover

WARNING

Adjustment by removing a cover require specialized technical knowledge and skills, and may also involve

hazards if attempted by an unskilled person. This adjustment must be performed only by persons who have the

required qualifications described in “2. Qualification of operators/workers” in section 4.1 of this “Safety Instructions”.

4.3.2 Precautions for robot controllers

■Installation environment

1. Installation environment

WARNING

OMRON robots are not designed to be explosion-proof. Do not use the robots and controllers in locations

exposed to explosive or inflammable gases, dust particles or liquid such as gasoline and solvents. Failure to

follow this instruction may cause serious accidents involving injury or death, and lead to fire.

Safety Instructions

WARNING

• Use the robot controller in locations that support the environmental conditions specified in this manual.

Operation outside the specified environmental range may cause electrical shock, fire, malfunction or product

damage or deterioration.

• The robot controller and programming box must be installed at a location that is outside the robot safety

enclosure yet where it is easy to operate and view robot movement.

• Install the robot controller in locations with enough space to perform work (teaching, inspection, etc.) safely.

Limited space not only makes it difficult to perform work but can also cause injury.

• Install the robot controller in a stable, level location and secure it firmly. Avoid installing the controller upside

down or in a tilted position.

• Provide sufficient clearance around the robot controller for good ventilation. Insufficient clearance may cause

malfunction, breakdown or fire.

■Installation

To install the robot controller, observe the installation conditions and method described in the manual.

1. Installation

WARNING

Securely tighten the screws to install the robot controller. If not securely tightened, the screws may come loose

causing the controller to drop.

2. Connections

WARNING

• Always shut off all phases of the power supply externally before starting installation or wiring work. Failure to do

this may cause electrical shock or product damage.

• Never directly touch conductive sections and electronic parts other than the connectors, rotary switches, and

DIP switches on the outside panel of the robot controller. Touching them may cause electrical shock or

breakdown.

• Securely install each cable connector into the receptacles or sockets. Poor connections may cause the

controller or robot to malfunction.

S-11

Page 24

■Wiring

Safety Instructions

1. Connection to robot controller

The controller parameters are preset at the factory before shipping to match the robot model. Check the specified robot

and controller combination, and connect them in the correct combination.

Since the software detects abnormal operation such as motor overloads, the controller parameters must be set correctly

to match the motor type used in the robot connected to the controller.

2. Wiring safety points

WARNING

Always shut off all phases of the power supply externally before starting installation or wiring work. Failure to do

this may cause electrical shock or product damage.

CAUTION

• Make sure that no foreign matter such as cutting chips or wire scraps get into the robot controller. Malfunction,

breakdown or fire may result if these penetrate inside.

• Do not apply excessive impacts or loads to the connectors when making cable connections. This might bend

the connector pins or damage the internal PC board.

• When using ferrite cores for noise elimination, be sure to fit them onto the power cable as close to the robot

controller and/or the robot as possible, to prevent malfunction caused by noise.

3. Wiring method

WARNING

Securely install the connectors into the robot controller and, when wiring the connectors, make the crimp,

press-contact or solder connections correctly using the tool specified by the connector manufacturer.

CAUTION

When disconnecting the cable from the robot controller, detach by gripping the connector itself and not by

tugging on the cable. Loosen the screws on the connector (if fastened with the screws), and then disconnect the

cable. Trying to detach by pulling on the cable itself may damage the connector or cables, and poor cable

contact will cause the controller or robot to malfunction.

4. Precautions for cable routing and installation

CAUTION

• Always store the cables connected to the robot controller in a conduit or clamp them securely in place. If the

cables are not stored in a conduit or properly clamped, excessive play or movement or mistakenly pulling on

the cable may damage the connector or cables, and poor cable contact will cause the controller or robot to

malfunction.

• Do not modify the cables and do not place any heavy objects on them. Handle them carefully to avoid

damage. Damaged cables may cause malfunction or electrical shock.

• If the cables connected to the robot controller may possibly become damaged, then protect them with a

cover, etc.

• Check that the control lines and communication cables are routed at a gap sufficiently away from main power

supply circuits and power lines, etc. Bundling them together with power lines or close to power lines may

cause faulty operation due to noise.

5. Protective measures against electrical shock

WARNING

Be sure to ground the ground terminals of the robot and controller. Poor grounding may cause electrical shock.

S-12

Page 25

4.4 Safety measures

4.4.1 Safety measures

1. Referring to warning labels and manual

WARNING

• Before starting installation or operation of the robot, be sure to read the warning labels and this manual, and

comply with the instructions.

• Never attempt any repair, parts replacement and modification unless described in this manual. These

tasks require specialized technical knowledge and skills and may also involve hazards. Please contact your

distributor for advice.

NOTE

For details on warning labels, see "3. Warning labels".

2. Draw up "work instructions" and make the operators/workers understand them

WARNING

Decide on "work instructions" in cases where personnel must work within the robot safety enclosure to perform

startup or maintenance work. Make sure the workers completely understand these "work instructions".

Decide on "work instructions" for the following items in cases where personnel must work within the robot safety

enclosure to perform teaching, maintenance or inspection tasks. Make sure the workers completely understand these

"work instructions".

1. Robot operating procedures needed for tasks such as startup procedures and handling switches

2. Robot speeds used during tasks such as teaching

3. Methods for workers to signal each other when two or more workers perform tasks

4. Steps that the worker should take when a problem or emergency occurs

5. Steps to take after the robot has come to a stop when the emergency stop device was triggered, including checks for

cancelling the problem or error state and safety checks in order to restart the robot.

6. In cases other than above, the following actions should be taken as needed to prevent hazardous situations due to

sudden or unexpected robot operation or faulty robot operation as listed below.

• Place a display sign on the operator panel

• Ensure the safety of workers performing tasks within the robot safety enclosure

• Clearly specify position and posture during work

Specify a position and posture where worker can constantly check robot movements and immediately move to

avoid trouble if an error/problem occurs

• Take noise prevention measures

• Use methods for signaling operators of related equipment

• Use methods to decide that an error has occurred and identify the type of error

Implement the "work instructions" according to the type of robot, installation location, and type of work task.

When drawing up the "work instructions", make an effort to include opinions from the workers involved, equipment

manufacturer technicians, and workplace safety consultants, etc.

Safety Instructions

3. Take safety measures

DANGER

• Never enter the robot movement range while the robot is operating or the main power is turned on. Failure to

follow this warning may cause serious accidents involving injury or death. Install a safety enclosure or a gate

interlock with an area sensor to keep all persons away from the robot movement range.

• When it is necessary to operate the robot while you are within the robot movement range such as for teaching

or maintenance/inspection tasks, always carry the programming box with you so that you can immediately

stop the robot operation in case of an abnormal or hazardous condition. Install an enable device in the

external safety circuit as needed. Also set the robot moving speed to 3% or less. Failure to follow these

instructions may cause serious accidents involving injury or death.

See “7.1 Movement range” for details on the robot’s movement range.

S-13

Page 26

Safety Instructions

WARNING

• During startup or maintenance tasks, display a sign "WORK IN PROGRESS" on the programming box and

operation panel in order to prevent anyone other than the person for that task from mistakenly operating the

start or selector switch. If needed, take other measures such as locking the cover on the operation panel.

• Always connect the robot and robot controller in the correct combination. Using them in an incorrect

combination may cause fire or breakdown.

4. Install system

When configuring an automated system using a robot, hazardous situations are more likely to occur from the automated

system than the robot itself. So the system manufacturer should install the necessary safety measures required for the

individual system. The system manufacturer should provide a proper manual for safe, correct operation and servicing of

the system.

WARNING

To check the robot controller operating status, refer to this manual and to related manuals. Design and install the

system including the robot controller so that it will always work safely.

5. Precautions for operation

WARNING

• Do not touch any electrical terminal. Directly touching these terminals may cause electrical shock, equipment

damage, and malfunction.

• Do not touch or operate the robot controller or programming box with wet hands. Touching or operating them

with wet hands may result in electrical shock or breakdown.

6. Do not disassemble and modify

WARNING

Never disassemble and modify any part in the robot, controller, and programming box. Do not open any cover.

Doing so may cause electrical shock, breakdown, malfunction, injury, or fire.

4.4.2 Installing a safety enclosure

Be sure to install a safety enclosure to keep anyone from entering within the movement range of the robot. The

safety enclosure will prevent the operator and other persons from coming in contact with moving parts of the

robot and suffering injury.

See “7.1 Movement range” for details on the robot’s movement range.

DANGER

Serious injury may result from contact with a moving robot.

• Keep outside of the robot safety enclosure during operation.

• Press the emergency stop button before entering the safety enclosure.

WARNING

• Install an interlock that triggers emergency stop when the door or gate of the safety enclosure is opened.

• The safety enclosure should be designed so that no one can enter inside except from the door or gate

equipped with an interlock device.

• Warning label 1 (See "3. Warning labels") that comes supplied with a robot should be affixed to an easy-to-see

location on the door or gate of the safety enclosure.

S-14

Page 27

4.5 Operation

When operating a robot, ignoring safety measures and checks may lead to serious accidents. Always take the

following safety measures and checks to ensure safe operation.

DANGER

Check the following points before starting robot operation.

• No one is within the robot safety enclosure.

• The programming unit is in the specified location.

• The robot and peripheral equipment are in good condition.

4.5.1 Trial operation

After installing, adjusting, inspecting, maintaining or repairing the robot, perform trial operation using the

following procedures.

1. If a safety enclosure has not yet been provided right after installing the robot:

Then rope off or chain off the movement range around the robot in place of the safety enclosure and observe the

following points.

See “7.1 Movement range” for details on the robot’s movement range.

DANGER

Place a "Robot is moving - KEEP AWAY!" sign to keep the operator or other personnel from entering within the

movement range of the robot.

Safety Instructions

WARNING

• Use sturdy, stable posts which will not fall over easily.

• The rope or chain should be easily visible to everyone around the robot.

2. Check the following points before turning on the controller.

• Is the robot securely and correctly installed?

• Are the electrical connections to the robot wired correctly?

• Are items such as air pressure correctly supplied?

• Is the robot correctly connected to peripheral equipment?

• Have safety measures (safety enclosure, etc.) been taken?

• Does the installation environment meet the specified standards?

3. After the controller is turned on, check the following points from outside the safety enclosure.

• Does the robot start, stop and enter the selected operation mode as intended?

• Does each axis move as intended within the soft limits?

• Does the end effector move as intended?

• Are the correct signals being sent to the end effector and peripheral equipment?

• Does emergency stop function?

• Are teaching and playback functions normal?

• Are the safety enclosure and interlocks functioning as intended?

S-15

Page 28

4. Working inside safety enclosures

Safety Instructions

Before starting work within the safety enclosure, always confirm from outside the enclosure that each protective

function is operating correctly (see the previous section 2.3).

DANGER

Never enter within the movement range while within the safety enclosure.

See “7.1 Movement range” for details on the robot’s movement range.

WARNING

When work is required within the safety enclosure, place a sign "Work in progress" in order to keep other persons

from operating the controller switch or operation panel.

WARNING

When work within the safety enclosure is required, always turn off the controller power except for the following

cases:

Exception

Work with power turned on, but robot in emergency stop

Origin position setting SCARA robots

Standard coordinate setting SCARA robots

Soft limit settings SCARA robots

Follow the precautions and procedure described in "Adjusting the

origin".

Follow the precautions and procedure described in "Setting the

standard coordinates".

Follow the precautions and procedure described in "Setting the soft

limits".

Work with power turned on

Teaching SCARA robots

Refer to "5. Teaching within safety enclosure" described below.

5. Teaching within the safety enclosure

When performing teaching within the safety enclosure, check or perform the following points from outside the safety

enclosure.

DANGER

Never enter within the movement range while within the safety enclosure.

See “7.1 Movement range” for details on the robot’s movement range.

WARNING

• Make a visual check to ensure that no hazards are present within the safety enclosure.

• Check that the programming box or handy terminal operates correctly.

• Check that no failures are found in the robot.

• Check that emergency stop works correctly.

• Select teaching mode and disable automatic operation.

S-16

Page 29

4.5.2 Automatic operation

Check the following points when operating the robot in AUTO mode. Observe the instructions below in cases

where an error occurs during automatic operation. Automatic operation described here includes all operations

in AUTO mode.

1. Checkpoints before starting automatic operation

Check the following points before starting automatic operation.

DANGER

• Check that no one is within the safety enclosure.

• Check the safety enclosure is securely installed with interlocks functional.

WARNING

• Check that the programming box / handy terminal and tools are in their specified locations.

• Check that the signal tower lamps or other alarm displays installed for the system are not lit or flashing,

indicating no error is occurring on the robot and peripheral devices.

2. During automatic operation and when errors occur

After automatic operation starts, check the operation status and the signal tower to ensure that the robot is in automatic

operation.

DANGER

Never enter the safety enclosure during automatic operation.

Safety Instructions

WARNING

If an error occurs in the robot or peripheral equipment, observe the following procedure before entering the

safety enclosure.

1) Press the emergency stop button to set the robot to emergency stop.

2) Place a sign on the start switch, indicating that the robot is being inspected in order to keep other persons from

restarting the robot.

4.5.3 Precautions during operation

1. When the robot is damaged or an abnormal condition occurs

WARNING

• If unusual odors, noise or smoke occur during operation, immediately turn off power to prevent possible

electrical shock, fire or breakdown. Stop using the robot and contact your distributor.

• If any of the following damage or abnormal conditions occurs the robot, then continuing to operate the robot

is dangerous. Immediately stop using the robot and contact your distributor.

Damage or abnormal condition Type of danger

Damage to machine harness or robot cable Electrical shock, robot malfunction

Damage to robot exterior Damaged parts fly off during robot operation

Abnormal robot operation (position deviation, vibration, etc.) Robot malfunction

Z-axis (vertical axis) or brake malfunction Z-axis unit falls off

2. High temperature hazard

WARNING

• Do not touch the robot controller and robot during operation. The robot controller and robot body are very hot

during operation, so burns may occur if these sections are touched.

• The motor and speed reduction gear casing are very hot shortly after operation, so burns may occur if these

are touched. Before touching those parts for inspections or servicing, turn off the controller, wait for a while and

check that their temperature has cooled.

S-17

Page 30

3. Use caution when releasing the Z-axis (vertical axis) brake

Safety Instructions

WARNING

The vertical axis will slide downward when the brake is released, causing a hazardous situation. Take adequate

safety measures in consideration by taking the weight and shape into account.

• Before releasing the brake after pressing the emergency stop button, place a support under the vertical axis so

that it will not slide down.

• Be careful not to let your body get caught between the vertical axis and the installation base when performing

tasks (direct teaching, etc.) with the brake released.

4. Be careful of Z-axis movement when the controller is turned off or emergency stop is triggered

(air-driven Z-axis)

WARNING

The Z-axis starts moving upward when power to the controller or PLC is turned off, the program is reset, emergency stop is triggered, or air is supplied to the solenoid valve for the Z-axis air cylinder.

• Do not let hands or fingers get caught and squeezed by robot parts moving along the Z-axis.

• Keep the usual robot position in mind so as to prevent the Z-axis from hanging up or binding on obstacles

during raising of the Z-axis except in case of emergency stop.

5. Take protective measures when the Z-axis interferes with peripheral equipment (air-driven Z-axis)

WARNING

When the Z-axis comes to a stop due to obstruction from peripheral equipment, the Z-axis may move suddenly

after the obstruction is removed, causing injury such as pinched or crushed hands.

• Turn off the controller and reduce the air pressure before attempting to remove the obstruction.

• Before reducing the air pressure, place a support under the Z-axis because the Z-axis will drop under its own

weight.

6. Be careful of Z-axis movement when air supply is stopped (air-driven Z-axis)

WARNING

The Z-axis will slide downward when the air pressure to the Z-axis air cylinder solenoid valve is reduced, creating

a hazardous situation.

Turn off the controller and place a support under the Z-axis before cutting off the air supply.

7. Make correct parameter settings

CAUTION

The robot must be operated with the correct tolerable moment of inertia and acceleration coefficients that

match the manipulator tip mass and moment of inertia. Failure to follow this instruction will lead to a premature

end to the drive unit service life, damage to robot parts, or cause residual vibration during positioning.

8. If the X-axis, Y-axis or R-axis rotation angle is small

CAUTION

If the X-axis, Y-axis or R-axis rotation angle is set smaller than 5 degrees, then it will always move within the same

position. This restricted position makes it difficult for an oil film to form on the joint support bearing, and so may

possibly damage the bearing. In this type of operation, add a range of motion so that the joint moves through 90

degrees or more, about 5 times a day.

S-18

Page 31

4.6 Inspection and maintenance

Always perform daily and periodic inspections and make a pre-operation check to ensure there are no problems with the robot and related equipment. If a problem or abnormality is found, then promptly repair it or

take other measures as necessary.

Keep a record of periodic inspections or repairs and store this record for at least 3 years.

4.6.1 Before inspection and maintenance work

1. Do not attempt any work or operation unless described in this manual.

Never attempt any work or operation unless described in this manual.

If an abnormal condition occurs, please be sure to contact your distributor. Our service personnel will take appropriate

action.

WARNING

Never attempt inspection, maintenance, repair, and part replacement unless described in this manual. These

tasks require specialized technical knowledge and skills and may also involve hazards. Please be sure to

contact your distributor for advice.

2. Precautions during repair and parts replacement

WARNING

When it is necessary to repair or replace parts of the robot or controller, please be sure to contact your distributor

and follow the instructions they provide. Inspection and maintenance of the robot or controller by an unskilled,

untrained person is extremely hazardous.

Safety Instructions

Adjustment, maintenance and parts replacement require specialized technical knowledge and skills, and also may

involve hazards. These tasks must be performed only by persons who have enough ability and qualifications required by

local laws and regulations.

WARNING

Adjustment and maintenance by removing a cover require specialized technical knowledge and skills, and may

also involve hazards if attempted by an unskilled person. This adjustment must be performed only by persons

who have the required qualifications described in “2. Qualification of operators/workers” in section 4.1 of this

“Safety Instructions”.

3. Shut off all phases of power supply

WARNING

Always shut off all phases of the power supply externally before cleaning the robot and controller or securely

tightening the terminal screws etc. Failure to do this may cause electrical shock or product damage or malfunction.

4. Allow a waiting time after power is shut off (Allow time for temperature and voltage to drop)

WARNING

• When performing maintenance or inspection of the robot controller under your distributor's instructions, wait at

least the time (*) specified for each controller after turning the power off. Some components in the robot

controller are very hot or still retain a high voltage shortly after operation, so burns or electrical shock may

occur if those parts are touched.

• The motor and speed reduction gear casing are very hot shortly after operation, so burns may occur if they are

touched. Before touching those parts for inspections or servicing, turn off the controller, wait for a while and

check that the temperature has cooled.

* For information on how long you should wait after turning the power off, see the user’s manual for each controller.

5. Precautions during inspection of controller

WARNING

• When you need to touch the terminals or connectors on the outside of the controller during inspection, always

first turn off the controller power switch and also the power source in order to prevent possible electrical shock.

• Do not disassemble the controller. Never touch any internal parts of the controller. Doing so may cause

breakdown, malfunction, injury, or fire.

S-19

Page 32

4.6.2 Precautions during service work

Safety Instructions

1. Be careful when removing the Z-axis motor

WARNING

The Z-axis will slide downward when the Z-axis motor is removed, causing a hazardous situation.

• Turn off the controller and place a support under the Z-axis before removing the Z-axis motor.

• Be careful not to let your body get caught by the driving unit of the Z-axis or between the Z-axis drive unit and

the installation base.

2. Do not remove the Z-axis upper limit mechanical stopper

CAUTION

Warning label 4 is attached to each SCARA robot. (For details on warning labels, see "3. Warning labels".)

Removing the upper limit mechanical stopper installed to the Z-axis spline or shifting its position will damage the

Z-axis ball screw. Never attempt to remove it.

3. Use caution when handling a robot that contains powerful magnets

WARNING

Powerful magnets are installed inside the robot. Do not disassemble the robot since this may cause injury.

Devices that may malfunction due to magnetic fields must be kept away from this robot.

See "6. Cautions regarding strong magnetic fields" for detailed information on strong magnetic fields.

4. Use the following caution items when disassembling or replacing the pneumatic equipment.

WARNING

Air or parts may fly outward if pneumatic equipment is disassembled or parts replaced while air is still supplied.

• Do service work after turning off the controller, reducing the air pressure, and exhausting the residual air from

the pneumatic equipment.

• Before reducing the air pressure, place a support stand under the Z-axis (2-axis robots with air driven Z-axis)

since it will drop under its own weight.

5. Use caution to avoid contact with the controller cooling fan

WARNING

• Touching the rotating fan may cause injury.

• If removing the fan cover, first turn off the controller and make sure the fan has stopped.

6. Precautions for robot controllers

CAUTION

• Back up the robot controller internal data on an external storage device. The robot controller internal data

(programs, point data, etc.) may be lost or deleted for unexpected reasons. Always make a backup of this data.

• Do not use thinner, benzene, or alcohol to wipe off the surface of the programming box. The surface sheet may

be damaged or printed letters or marks erased. Use a soft, dry cloth and gently wipe the surface.

• Do not use a hard or pointed object to press the keys on the programming box. Malfunction or breakdown

may result if the keys are damaged. Use your fingers to operate the keys.

S-20

Page 33

4.7 Disposal

When disposing of robots and related items, handle them carefully as industrial wastes. Use the correct

disposal method in compliance with your local regulations, or entrust disposal to a licensed industrial waste

disposal company.

1. Disposal of lithium batteries

When disposing of lithium batteries, use the correct disposal method in compliance with your local regulations, or

entrust disposal to a licensed industrial waste disposal company. We do not collect and dispose of the used batteries.

2. Disposal of packing boxes and materials

When disposing of packing boxes and materials, use the correct disposal method in compliance with your local regulations. We do not collect and dispose of the used packing boxes and materials.

3. Strong magnet

WARNING

Strong magnets are installed in the robot. Be careful when disposing of the robot.

See "6. Cautions regarding strong magnetic fields" for detailed information on strong magnetic fields.

Safety Instructions

S-21

Page 34

Safety Instructions

5. Emergency action when a person is caught by robot

If a person should get caught between the robot and a mechanical part such as the installation base, then

release the axis.

■Emergency action

Release the axis while referring to the following section in the manual for the robot controller.

Controller Refer to:

YRC

Section 1, "Emergency action when a person is caught by robot" in Chapter 1

YRCX

NOTE

Make a printout of the relevant page in the manual and post it a conspicuous location near the controller.

6. Cautions regarding strong magnetic fields

Some OMRON robots contain parts generating strong magnetic fields which may cause bodily injury, death,

or device malfunction. Always comply with the following instructions.

• Persons wearing ID cards, purses or wristwatches must keep away from the robot.

• Do not bring tools close to the magnet inside the robot.

S-22

Page 35

7. Using the robot safely

7.1 Movement range

When a tool or workpiece is attached to the robot manipulator tip, the actual movement range enlarges from

the movement range of the robot itself (Figure A) to include the areas taken up by movement of the tool and

workpiece attached to the manipulator tip (Figure B).

The actual movement range expands even further if the tool or workpiece is offset from the manipulator tip.

The movement range here is defined as the range of robot motion including all areas through which the robot

arms, the tool and workpiece attached to the manipulator tip, and the solenoid valves attached to the robot

arms move.

To make the robot motion easier to understand, the figures below only show the movement ranges of the tool

attachment section, tool, and workpiece.

Please note that during actual operation, the movement range includes all areas where the robot arms and any

other parts move along with the robot.

Movement range

Safety Instructions

Figure A: Movement range of robot itself

CAUTION

To make the robot motion easier to understand, the above figures only show the movement ranges of the tool

attachment section, tool, and workpiece. In actual operation, the movement range includes all areas where the

robot arms and any other parts move along with the robot.

Figure B: Movement range when tool and workpiece are attached

to manipulator tip

93009-X0-00

S-23

Page 36

7.2 Robot protective functions

Safety Instructions

Protective functions for OMRON robots are described below.

1. Overload detection

This function detects an overload applied to the motor and turns off the servo.

If an overload error occurs, take the following measures to avoid such errors:

1. Insert a timer in the program.

2. Reduce the acceleration.

2. Overheat detection

This function detects an abnormal temperature rise in the driver inside the controller and turns off the servo.

If an overheat error occurs, take the following measures to avoid the error:

1. Insert a timer in the program.

2. Reduce the acceleration.

3. Soft limits

Soft limits can be set on each axis to limit the working envelope in manual (jog) operation and automatic operation after

return-to-origin. The working envelope is the area limited by soft limits.

WARNING

Soft limit function is not a safety-related function intended to protect the human body.

To restrict the robot movement range to protect the human body, use the mechanical stoppers installed in the

robot (or available as options).

4. Mechanical stoppers

If the servo is turned off by emergency stop operation or protective function while the robot is moving, then these

mechanical stoppers prevent the axis from exceeding the movement range. The movement range is the area limited by the

mechanical stoppers.

• The X and Y axes have mechanical stoppers that are installed at both ends of the maximum movement

range. Some robot models have a standard feature that allows changing the mechanical stopper

SCARA robots

positions. On some other models, the mechanical stopper positions can also be changed by using

option parts.

• The Z-axis has a mechanical stopper at the upper end and lower end. The stopper positions can be

changed by using option parts.

• No mechanical stopper is provided on the R-axis.

WARNING

Axis movement does not stop immediately after the servo is turned off by emergency stop or other protective

functions, so use caution.

CAUTION

If the robot moving at high speed collides with a mechanical stopper installed in the robot (or available as

option), the robot may be damaged.

5. Z-axis (vertical axis) brake

An electromagnetic brake is installed on the Z-axis to prevent the Z-axis from sliding downward when the servo is OFF.

This brake is working when the controller is OFF or the Z-axis servo power is OFF even when the controller is ON. The

Z-axis brake can be released by the programming unit / handy terminal or by a command in the program when the

controller is ON.

WARNING

The vertical axis will slide downward when the brake is released, causing a hazardous situation. Take adequate

safety measures in consideration by taking the weight and shape into account.

•

Before releasing the brake after pressing the emergency stop button, place a support under the vertical axis so

that it will not slide down.

•

Be careful not to let your body get caught between the vertical axis and the installation base when performing

tasks (direct teaching, etc.) with the brake released.

S-24

Page 37

7.3 Residual risk

To ensure safe and correct use of OMRON robots and controllers, System integrators and/or end users implement machinery safety design that conforms to ISO12100.

Residual risks for OMRON robots and controllers are described in the DANGER or WARNING instructions

provided in each chapter and section. Read them carefully.

7.4 Special training for industrial robot operation

Operators or persons who handle the robot for tasks such as for teaching, programming, movement checks,

inspections, adjustments, and repairs must receive appropriate training and also have the skills needed to

perform the job correctly and safely. They must also read the manual carefully to understand its contents before

attempting the robot operation or maintenance.

Tasks related to industrial robots (teaching, programming, movement check, inspection, adjustment, repair,

etc.) must be performed by qualified persons who meet requirements established by local regulations and

safety standards for industrial robots.

Safety Instructions

Comparison of terms used in this manual with ISO

This manual ISO 10218-1 Note

Maximum movement range

Movement range

Working envelope

Within safety enclosure

See “7.1 Movement range” in for details on the robot’s movement range.

maximum space Area limited by mechanical stoppers.

restricted space Area limited by movable mechanical stoppers.

operational space Area limited by software limits.

safeguarded space

S-25

Page 38

7.5 KC mark

Safety Instructions

KC (Korean Certification) is a system based on the Korean Radio Law. Machineries designated with this system

are required to be registered as conformed certification or conformed registration, and to show KC marks.

Target products are prescribed by notification of the National Radio Research Agency (RRA).

7.5.1 EMC standards

■Cautions regarding compliance with KC mark

The OMRON robot-series product is one component that is incorporated into the customer's system (built-in equipment).

We decide models by single robot product (controller, robot and peripheral device) and conform them to the EMC

standards.

This does not therefore guarantee that the OMRON robot-series product conforms to the EMC standards if only the robot

is used independently. The customer who incorporates OMRON robot products into the customer's final system, which

will be shipped to or used in Korea, should verify that the overall system conforms to the EMC standards.

■KC mark

The OMRON robots (robots and controllers) are registered in the National Radio Research Agency (RRA) as conformed by

self-test and KC marks are affixed to the robots.

■Related standards

• Electromagnetic Compatibility (EMC)

■Information of conformity assessment

• Certification number list

Product Model name Certification number

Controller

Robot

• Applicant and manufacturer : OMRON

YRC MSIP-REM-Y3M-X240

YRCX MSIP-REM-Y3M-X340

SCARA robots MSIP-REM-Y3M-YK

7.5.2 Examples of EMC countermeasures

It is not necessary to take measures for ERCD and robots connecting to ERCD.

Examples of EMC countermeasures for single OMRON robot product are the same as those of CE marks.

Refer to countermeasures described in the related user's manual.

Furthermore, take proper countermeasures to conform customer's final system (overall system) to EMC

standards.

S-26

Page 39

Warranty

The OMRON robot and/or related product you have purchased are warranted against the defects or

malfunctions as described below.

■Warranty description

If a failure or breakdown occurs due to defects in materials or workmanship in the genuine parts constituting this

OMRON robot and/or related product within the warranty period, then OMRON shall supply free of charge the necessary

replacement/repair parts.

■Warranty period

The warranty period ends 24 months after the date of manufacturing as shown on the products.

■Exceptions to the warranty

This warranty will not apply in the following cases:

1. Fatigue arising due to the passage of time, natural wear and tear occurring during operation (natural fading of painted

or planted surfaces, deterioration of parts subject to wear, etc.)

2. Minor natural phenomena that do not affect the capabilities of the robot and/or related product (noise from computers,

motors, etc.)

3. Programs, point data and other internal data were changed or created by the user.

Warranty

Failures resulting from the following causes are not covered by warranty.

1. Damage due to earthquakes, storms, floods, thunderbolt, fire or any other natural or man-made disaster.

2. Troubles caused by procedures prohibited in this manual.

3. Modifications to the robot and/or related product not approved by OMRON or OMRON sales representative.

4. Use of any other than genuine parts and specified grease and lubricant.

5. Incorrect or inadequate maintenance and inspection.

6. Repairs by other than authorized dealers.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship

for a period of one year (or other period if specified) from date of sale by OMRON. OMRON MAKES

NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR

USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS

WILL SUITABLY MEET THE REQUERIMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS

OF PROFITS OR COMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WETHER SUCH

CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR OR OTHER CLAIMS REGARDING

THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY

HANDLED, STORED, INSTALLED AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE,

MISUSE OR INAPPROPIATE MODIFICATION OR REPAIR.

Page 40

Page 41

Important information before reading this manual

Introduction i

About this manual i

Overview of the YRCX ii

Before using the robot controller (Be sure to read the following notes) iii

Page 42

Page 43

Introduction

Our sincere thanks for your purchase of this OMRON robot controller.

Be sure to read this manual carefully as well as related manuals and comply with their instructions for using

the OMRON robot controller safely and correctly.

About this manual

Warnings and cautions listed in this manual relate to OMRON robot controllers. To ensure safety of the user's

final system that includes OMRON robots and controllers, please take appropriate safety measures as required

by the user's individual system.

Industrial robots are highly programmable machines that provide a large degree of freedom in movement.

To use OMRON robots and controllers safely and correctly, be sure to comply with the safety instructions and

precautions described in this manual.

Failure to take necessary safety measures or incorrect handling may result not only in trouble or damage to

the robot and controller, but also in serious accidents involving injury or death to personnel (robot installer,

operator, or service personnel). Observe the precautions given in each Chapter.

To use OMRON robots and controllers safely and correctly, first read "Safety Instructions" in this manual and

always comply with the safety rules and instructions.

Please note, however, this manual cannot cover all items regarding safety.

So it is extremely important that the operator or user have knowledge of safety and make correct decisions

regarding safety.

Important information before reading this manual

i

Page 44

Important information before reading this manual

Overview of the YRCX

The OMRON YRCX robot controllers were developed based on years of OMRON experience and proven

achievements in robotics and electronics. These controllers are specifically designed to operate OMRON

industrial robots efficiently and accurately.

Despite their compact size, the YRCX controllers operate efficiently as multi-axis controllers with a variety of

functions.

Major features and functions are:

1. Multi-task function

Up to 16 tasks* can be executed simultaneously by specifying the priority. However, low priority tasks are halted while

high priority tasks are running.

Programs are processed in parallel to efficiently perform various operations. Additionally, the operation efficiency of

the total robot system including peripheral units is greatly improved.

*Refer to "Multi-tasking" in the YRCX programming manual for more details on tasks.

2. Robot language

The YRCX series controller comes with a BASIC-like high-level robot language that conforms to the industrial robot

programming language SLIM*. This robot language allows easy programming even of complex movements such as

multi-task operations.

*Standard Language for Industrial Manipulators

3. Robot control

Up to four robots can be controlled.

Versatile motion functions are incorporated and these functions can be executed by multiple robots.

4. Applicable robots

Software servo control provides unit standardization.

The YRCX can be connected to almost all OMRON SCARA robots.

5. CE marking

The YRCX series robot controller is designed to conform to machinery directives and EMC (Electromagnetic compatibility)

directives as a OMRON robot series product.

For details about CE marking compliance, refer to the "Safety standards application guide". Additionally, to make the

system applicable to the CE marking, select the YRCX CE specifications.

This manual explains how to handle and operate the OMRON robot controllers correctly and effectively, as well

as I/O interface connections.

Read this manual carefully before installing and using the robot controller.

YRCX

Also refer to the separate

programming manual and robot user’s manual as needed.

ii

Page 45

Before using the robot controller (Be sure to read the following notes)

Duty (%) =

Operation time

Operation time+ Non-operation time

0

Important information before reading this manual

Please be sure to perform the following tasks before using the robot controller.