Page 1

OS32C-DM Safety Laser Scanner with EtherNet/IP

This addendum is to be used in conjunction with the

OS32C User’s Manual (P/N 99863-0010 or Manual No. Z296-E1)

P/N 99863-0060 Rev.G

Cat. No. Z336-E1-07

Page 2

Original Detailed Instructions

Introduction

Thank you for purchasing the OS32C Safety Laser Scanner (herein after referred to as the "OS32C" ).

This is the instruction Manual describing how to connect the OS32C-xxx-DM to devices in EtherNet/IP systems and confirm the

connection.

This addendum is to be used in conjunction with the Safety Laser Scanner OS32C Series User’s Manual (Z296-E1) (herein after

referred to as the "OS32C User’s Manual".)

Always take into account the following points when using the OS32C:

Make sure OS32C is handled by a "Responsible Person" who is well aware of and familiar with the machine to be installed.

The term "Responsible Person" used in this Instruction Manual means the person qualified, authorized and responsible to secure

"safety" in each process of the design, installation, operation, maintenance services and disposition of the machine.

It is assumed that the OS32C will be used properly according to the installation environment, performance and function of the machine.

A responsible Person should conduct a risk assessment of the machine and determine the suitability of this product before installation.

Read this Manual thoroughly and understand its contents.

Trademarks

• Windows, Windows XP, Windows 7, Windows 8.1 and Windows 10 are either registered trademarks or trademarks of Microsoft

Corporation in the USA and other countries.

• ODVA, EtherNet/IP

•

Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

• Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

TM

, DeviceNetTM, ControlNetTM, CIPTM and CIP SafetyTM are trademarks of ODVA, Inc.

Page 3

Introduction

Terms and Conditions Agreement

Warranties.

(a) Exclusive Warranty. Omron's exclusive warranty is that the Products will be free from defects in materials and

workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in writing

by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NON-

INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS.

BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on infringement by the

Products or otherwise of any intellectual property right. (c) Buyer Remedy. Omron's sole obligation hereunder shall be, at

Omron's election, to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an

amount equal to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible

for warranty, repair, indemnity or any other claims or expenses regarding the Products unless Omron's analysis confirms

that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse

or inappropriate modification. Return of any Products by Buyer must be approved in writing by Omron before shipment.

Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other materials or

substances or environments. Any advice, recommendations or information given orally or in writing, are not to be

construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/

or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is

asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer's application or use of the Product. At Buyer's request, Omron will provide

applicable third party certification documents identifying ratings and limitations of use which apply to the Product. This

information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the

end product, machine, system, or other application or use. Buyer shall be solely responsible for determining

appropriateness of the particular Product with respect to Buyer's application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN

LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS

THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED

USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user's programming of a programmable Product, or any consequence

thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in

determining suitability and does not constitute a warranty. It may represent the result of Omron's test conditions, and the

OS32C with EtherNet/IP & Measurement Data Addendum

ii

Page 4

user must correlate it to actual application requirements. Actual performance is subject to the Omron's Warranty and

Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our

practice to change part numbers when published ratings or features are changed, or when significant construction

changes are made. However, some specifications of the Product may be changed without any notice. When in doubt,

special part numbers may be assigned to fix or establish key specifications for your application. Please consult with your

Omron's representative at any time to confirm actual specifications of purchased Product.

PATENTS

Elements of the electronics and optics essential to meet the specifications and performance standards of Omron controls

are covered by one or more of the following U.S. Patents Numbers: 6,665,621; 6,753,776; 6,493,653; 6,587,811;

7,965,384. Additional patents pending.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility

is assumed for clerical, typographical or proofreading errors or omissions.

Introduction

OS32C with EtherNet/IP & Measurement Data Addendum

E

iii

Page 5

Introduction

Safety Precautions

The Alert symbols and their meanings ensure safe use of the products

In order to use the OS32C safely, the precautions listed in this manual are indicated by alert symbols. The

descriptions must be followed. Failure to follow all precautions and alerts may result in an unsafe installation

or operation.

The following indications and symbols are used.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or moderate injury, or

may result in serious injury or death. Additionally, there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or moderate injury, or

there may be property damage.

Meanings of Alert Symbols

Indicates prohibited actions.

Indicates mandatory actions.

Alert Statements in this Manual

System and zone status parameters monitored over EtherNet/IP are to be used for diagnostic

purposes only, and must not be used in safety-critical functions.

Measurement data monitored over EtherNet/IP are to be used for diagnostic purposes only, and

must not be used in safety-critical functions.

iv

Ensure the measurement report configuration matches the expected measurement data format.

OS32C with EtherNet/IP & Measurement Data Addendum

Page 6

Contens

Contents

1. Introduction .................................................................................................................................................. 1

2. Range Data Accuracy .................................................................................................................................. 2

3. Laser Scanner Setup ................................................................................................................................... 3

4. EtherNet/IP Input Assembly Data ................................................................................................................ 4

4.1 Table 1: EtherNet/IP Data Types ........................................................................................................... 5

4.2 Table 2: Input Assembly 100 and Vendor Object 112 (32bytes), System Status .................................. 5

4.3 Table 3: Input Assembly 101 (296 bytes), System & Detection Status.................................................. 7

4.4 Table 4: Output Assembly 113 and Vendor Object 115 (104 bytes),

Measurement Report Configuration for Input Assembly 102 & 103 .................................................... 9

4.5 Table 5: Output Assembly 114 (108 bytes), Measurement Report Configuration

for Input Assembly 104 & 105............................................................................................................ 11

4.6 Table 6 : Output Assembly 115 (316 bytes), Measurement Report Configuration

for Input Assembly 106 through 111 .................................................................................................. 13

4.7 Table 7 : Output Assembly 112, 116-120 I/O Connection Triggers ..................................................... 16

4.8 Table 8: Common Measurement Report Header Format (56 bytes) ................................................... 18

4.9 Table 9: Input Assembly 102 and Vendor Specific Object 114 (max. 1410 bytes) .............................. 20

4.10 Table 10: Input Assembly 103 and Vendor Specific Object 116 (max. 1410 bytes) .......................... 20

4.11 Table 11: Vendor Specific Object 117 (max. 2764 bytes).................................................................. 20

4.12 Table 12: Input Assembly 104 (max. 960 bytes)................................................................................ 21

4.13 Table 13: Input Assembly 105 (max. 960 bytes)................................................................................ 21

4.14 Table 14: Input Assembly 106 (max. 554 bytes)................................................................................ 21

4.15 Table 15: Input Assembly 107 (max. 554 bytes)................................................................................ 21

4.16 Table 16: Input Assembly 108 (max. 454 bytes)................................................................................ 22

4.17 Table 17: Input Assembly 109 (max. 454 bytes)................................................................................ 22

4.18 Table 18: Input Assembly 110 (max. 358 bytes)................................................................................ 22

4.19 Table 19: Input Assembly 111 (max. 358 bytes)................................................................................ 22

4.20 Data Refresh Rate (Expected Packet Rate) ...................................................................................... 22

4.21 Active Warning Zone Set Selection ................................................................................................... 23

Introduction

5. Installing the OS32C EDS file .................................................................................................................... 24

6. Establishing a connection with Omron CJ2................................................................................................ 25

6.1 Setting up the EtherNet/IP Network ..................................................................................................... 25

6.2 Setting up EtherNet/IP Tags for the CJ2.............................................................................................. 25

6.3 Downloading EtherNet/IP Configuration to the CJ2 ............................................................................. 30

7. Establishing a connection with Omron NJ.................................................................................................. 32

7.1 NJ5 MAC EtherNet/IP Adapter Setup .................................................................................................. 32

7.2 Setting up tags in the NJ Controller ..................................................................................................... 32

7.3 Setting Tags into Global Variable Section ........................................................................................... 34

7.4 Exporting Tags to Network Configurator .............................................................................................. 35

7.5 Configuring the EtherNet/IP Network................................................................................................... 35

7.6 Downloading EtherNet/IP Configuration to the NJ ............................................................................... 37

8. Setup for multiple OS32Cs or multiple PLCs ............................................................................................. 40

8.1 One PLC Polling Multiple OS32Cs ...................................................................................................... 40

8.2 Multiple PLCs Polling One OS32C ............................................................................................

9.

Establishing communications wit

9.1 EtherNet/IP Command Protocol........................................................................................................... 46

h a computer based device .................................................................... 46

OS32C with EtherNet/IP & Measurement Data Addendum

.......... 43

E

iii

Page 7

Introduction

Contents

9.1.1 Table 10: EtherNet/IP Datagram Header - Command Format...................................................... 46

9.2 EtherNet/IP Command List .................................................................................................................. 46

9.2.1 Table 11: EtherNet/IP Command List ........................................................................................... 46

9.2.2 Table 12: EtherNet/IP Status Error Code List ............................................................................... 47

9.3 EtherNet/IP Command Specific Data................................................................................................... 47

9.3.1 Table 13: EtherNet/IP Common Packet Format (CPF)................................................................. 47

9.4 EtherNet/IP Commands ....................................................................................................................... 48

9.4.1 List Identity Command .................................................................................................................. 48

9.4.2 Table 14: List Identity Command Request.................................................................................... 48

9.4.3 Table 15: List Identity Command Reply ........................................................................................ 48

9.4.4 Table 16: EtherNet/IP Identity Object Parameters ........................................................................ 49

9.4.5 Register Scanner Session Command........................................................................................... 49

9.4.6 Table 17: Register Session Command Request........................................................................... 49

9.4.7 Table 18: Register Session Command Reply ............................................................................... 49

9.4.8 Un-Register Scanner Session Command ..................................................................................... 50

9.4.9 Table 19: Un-Register Session Command Request ..................................................................... 51

9.4.10 SendRRData Command ............................................................................................................. 51

9.4.11 Table 20: SendRRData Command Request............................................................................... 51

9.4.12 Table 21: Get Single Attribute Service Code Request CPF Data ............................................... 51

9.4.13 Table 22: SendRRData Command Reply to a Get Single Attribute Request ............................. 52

9.4.14 Table 23: Set Single Attribute Service Code Request CPF Data ............................................... 52

9.4.15 Table 24: SendRRData Command Reply to a Set Single Attribute Request .............................. 53

9.4.16 Table 25: Large Forward Open Request Encapsulation Packet................................................. 54

9.4.17 Table 26: SendRRData Command Reply to a Large Forward Open Request ........................... 55

9.4.18 Table 27: UDP I/O connection packet......................................................................................... 56

9.4.19 Table 28: Forward Close Request Encapsulation Packet........................................................... 57

9.4.20 Table 29: SendRRData Command Reply to a Forward Close Request ..................................... 58

10. Application Examples............................................................................................................................... 59

10.1 Runtime Monitoring using Explicit TCP/IP Request/Reply Messages ............................................... 59

10.1.1 Network Configuration ................................................................................................................ 59

10.1.2 Computer/PLC Configuration & Process Control Example......................................................... 59

10.2 Runtime Monitoring using an Implicit UDP I/O Connection ............................................................... 67

10.2.1 Network Configuration ................................................................................................................ 67

10.2.2 Computer/PLC Configuration & Process Control Example......................................................... 67

11. Revision History ....................................................................................................................................... 72

iv

OS32C with EtherNet/IP & Measurement Data Addendum

Page 8

Introduction

1. Introduction

The OS32C-xxx-DM Safety Laser Scanner with EtherNet/IP and Measurement Data allows the laser scanner

to be monitored by products that adhere to the ODVA guidelines for EtherNet/IP communications. The OS32C

with EtherNet/IP functions as an EtherNet/IP target (slave) device to the products that function as EtherNet/IP

originator (master) devices. Multiple EtherNet/IP master devices can be set up to monitor a single OS32C and

a single EtherNet/IP master can be set up to monitor multiple OS32Cs.

The OS32C-xxx-DM Safety Laser Scanner provides an EtherNet/IP communication interface for monitoring

system status and range measurement data. EtherNet/IP is a communication system suitable for use in

industrial environments. EtherNet/IP allows industrial devices to exchange time-critical application

information. These devices include simple I/O devices such as sensors/actuators, as well as complex control

devices such as robots, programmable logic controllers, welders, and process controllers. EtherNet/IP uses

CIP (Common Industrial Protocol), the common network, transport and application layers also shared by

ControlNet and DeviceNet. EtherNet/IP then makes use of standard Ethernet and TCP/IP technology to

transport CIP communications packets. The result is a common, open application layer on top of open and

highly popular Ethernet and TCP/IP protocols. EtherNet/IP provides a producer/consumer model for the

exchange of time-critical control data. The producer/consumer model allows the exchange of application

information between a sending device (e.g., the producer) and many receiving devices (e.g., the consumers)

without the need to send the data multiple times to multiple destinations. For EtherNet/IP, this is accomplished

by making use of the CIP network and transport layers along with IP Multicast technology. Many EtherNet/IP

devices can receive the same produced piece of application information from a single producing device.

EtherNet/IP makes use of standard IEEE 802.3 technology; there are no non-standard additions that attempt

to improve determinism. Rather, EtherNet/IP recommends the use of commercial switch technology, with 100

Mbps bandwidth and full-duplex operation, to provide for more deterministic performance.

Introduction

The OS32C with EtherNet/IP uses standard EtherNet/IP communications and does not use CIP Safety

protocols. Therefore, communication data from this device must not be used for functional safety. EtherNet/IP

communications with this laser scanner are for non-safety monitoring and changing non-safety warning

zone(s) purposes only. EtherNet/IP originator products are able to monitor the OS32C's detection zone state,

input & output status, configuration checksum values, and more. Full details of the OS32C's produced data

assembly can be found in this document, along with detailed instructions for establishing communications

between commonly used PLCs and the OS32C. General information for setting up communication

connections between the OS32C and a computer based device is also provided in this document.

A data measurement demo tool for the PC is available on the Omron website at www.omron247.com. This

demo tool is a C++ application that allows a user to view information such as system status, zone status,

range measurement, and more from the OS32C without the need for a PLC. Also available on the website

are data application function blocks for PLC programs. Users can use or modify these function blocks for their

own PLC programs. One such function block is a "configuration" function block which allows users to choose

the amount of data they would like to receive from the OS32C by specifying parameters such as the number

of beams and number of scans. "Object detection" function blocks are also available to help users process

the data they receive from the scanner.

OS32C with EtherNet/IP & Measurement Data Addendum

E

1

Page 9

Introduction

Range Data Accuracy

2. Range Data Accuracy

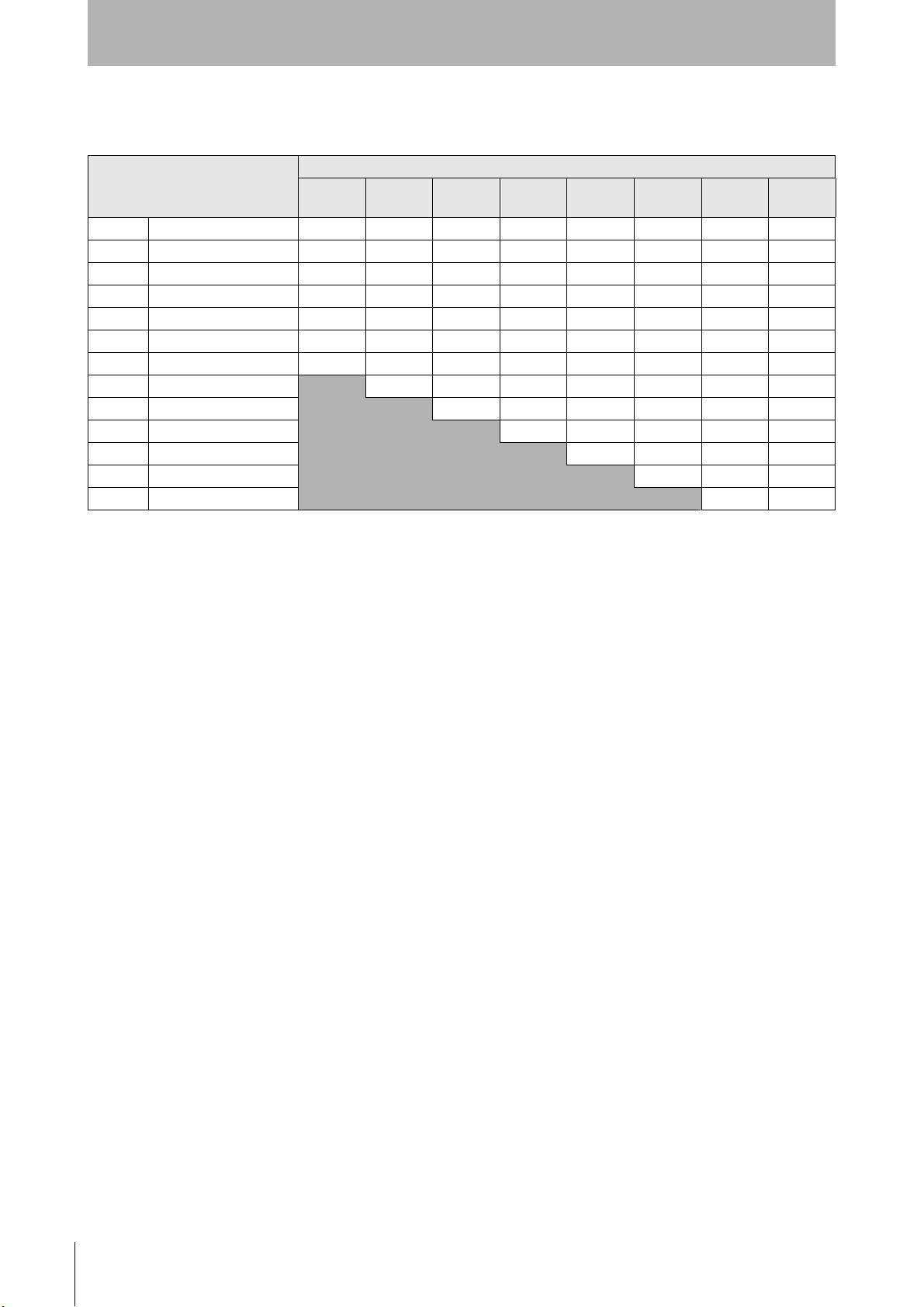

Estimated 1δ random error in mm (A) for given target reflectivity *2

Range

(mm)

250

500

1000

2000

3000

4000

5000

7500

10000

20000

30000

40000

50000

Recommended Minimum

Reflector Width (mm)*1

70 20 10 10 10 10 10 10 10

70 20 10 10 10 10 10 10 10

70 20 10 10 10 10 10 10 10

70 20 20 10 10 10 10 10 10

70 20 20 10 10 10 10 10 10

70 20 20 20 20 20 20 20 20

80 30 20 20 20 20 20 20 20

120

150

300

450

600

750

1.8% 5% 10%

40 20 20 20 20 20 20

40 20 20 20 20 20

40 20 20 20 20

Outside recommended range*3

25% 50% 75% 100%

30 30 30 30

30 30 30

40 40

Retro

(330/sr)

*1. Reflector Height should be between 300mm to 1000mm depending on application and range.

*2. To apply A toward a maximum expected error, use the formula n*A+B, where n corresponds to the desired

multiplier for s (1, 2, 3 etc.), and B is the maximum systematic error of 30mm. If there are reflectors in the

background of the target, refer to Table 7-2 in the OS32C user manual. Other error factors could arise

depending on other measurement conditions such as objects in close proximity to the beam path.

*3. Maximum range can vary depending on desired measurement accuracy, and can also be affected by

environmental conditions (e.g. smoke), window and/or target cleanliness.

For non-safety applications a value of 1 sigma can be used to determine the range accuracy of the OS32C-

DM, so the following calculation can be used in this case.

Range accuracy = (n * A) + B; where n = 1σ (sigma), A = random error and B = systematic error.

For example, at a range of 1000 mm with a reflectivity of 50%, the following range accuracy can be expected:

Using these attribute values and the value from the table, A = 10 mm and B is 30 mm, the range accuracy at

1000 mm with 50% reflectivity = (10 mm) + 30 mm = +- 40 mm.

2

OS32C with EtherNet/IP & Measurement Data Addendum

Page 10

Laser Scanner Setup

3. Laser Scanner Setup

Aside from changing the IP address settings of the OS32C, no configuration changes are required to establish

communications between the OS32C and an EtherNet/IP master device.

To change the OS32C configuration, including the IP address settings, refer to Chapter 3 of the OS32C Safety

Laser Scanner manual.

For OS32C wiring diagrams, refer to Chapter 5 of the OS32C Safety Laser Scanner manual.

Introduction

OS32C with EtherNet/IP & Measurement Data Addendum

E

3

Page 11

Introduction

EtherNet/IP Input Assembly Data

4. EtherNet/IP Input Assembly Data

The OS32C has twelve standard input assembly objects and four vendor specific objects as described below:

• Input Assembly Object 100 (32 bytes) and Vendor Specific Object 112 provide system status data.

• Input Assembly Object 101 (296 bytes) provides both system status and zone status data.

• Input Assembly Object 102 (up to 1410 bytes) and Vendor Specific Object 114 provide both system

status and range measurement data.

• Input Assembly Object 103 (up to 1410 bytes) and Vendor Specific Object 116 provide both system

status and reflectivity measurement data.

• Input Assembly Object 104 (up to 960 bytes) provides both system status and range measurement

data.

• Input Assembly Object 105 (up to 960 bytes) provides both system status and reflectivity

measurement data.

• Input Assembly Object 106 (up to 554 bytes) provides range measurement data.

• Input Assembly Object 107 (up to 554 bytes) provides reflectivity measurement data.

• Input Assembly Object 108 (up to 454 bytes) provides range measurement data.

• Input Assembly Object 109 (up to 454 bytes) provides reflectivity measurement data.

• Input Assembly Object 110 (up to 358 bytes) provides range measurement data.

• Input Assembly Object 111 (up to 358 bytes) provides reflectivity measurement data.

• Vendor Specific Object 117 (up to 2764 bytes) provides system status, range and reflectivity

measurement data.

Note: The term "Input Assembly" is from the originating devices perspective. PLCs and PC client software

applications are considered the originating devices from the OS32C's perspective.

The input assembly object data provided by the OS32C can be obtained by using either explicit TCP/IP

request/reply messages or by using implicit UDP I/O connections in order to receive the assembly data at a

specific repetitive interval. Vendor specific object data provided by the OS32C can be obtained by using

explicit TCP/IP request/reply messages at a rate defined by the software application. Data provided in

vendor specific objects 114, 116 and 117 are synchronous with the scan period of the OS32C (40 ms) and

can be used in applications requiring greater time precision. In firmware release 3.18 (3 dot 18) or later UDP/

IO messages are also synchronous with a multiple of the scan period (40, 80, 120 etc).

To read individual data attributes from the scanner, service code 14 (0x0E, Get Single Attribute) in a TCP

request/response explicit message can be used to obtain the data.

For example, sending the following parameters to the scanner will provide an unsigned 16-bit machine state

value:

Service code 14 (0x0E) // Get Single Attribute

Object class 112 (0x70) // Vendor Specific Object Number, System Status

Instance 1 (0x01) // Vendor Specific Instance

Attribute 4 (0x04), see additional attributes listed in the tables specified below.

To read the entire input assembly object data, service code 14 (0x0E, Get Single Attribute) can be used in a

TCP request/reply explicit message using the following parameters.

Service code 14 (0x0E) // Get Single Attribute

OS32C with EtherNet/IP & Measurement Data Addendum

4

Page 12

EtherNet/IP Input Assembly Data

Object class 4 (0x04) // Assembly Object Class

Instance 100 (0x64) // Input Assembly Object Number, System Status

Attribute 03 (0x03) // Input Assembly Object Data

To read the entire vendor specific object data, service code 14 (0x0E, Get Single Attribute) can be used in a

TCP request/reply explicit message using the following parameters.

Service code 14 (0x0E) // Get Single Attribute

Object class 114 (0x72) // Vendor Specific Object Number (Range Data)

Instance 1 (0x01) // Vendor Specific Instance

Attribute 03 (0x03) // Vendor Specific Object Data

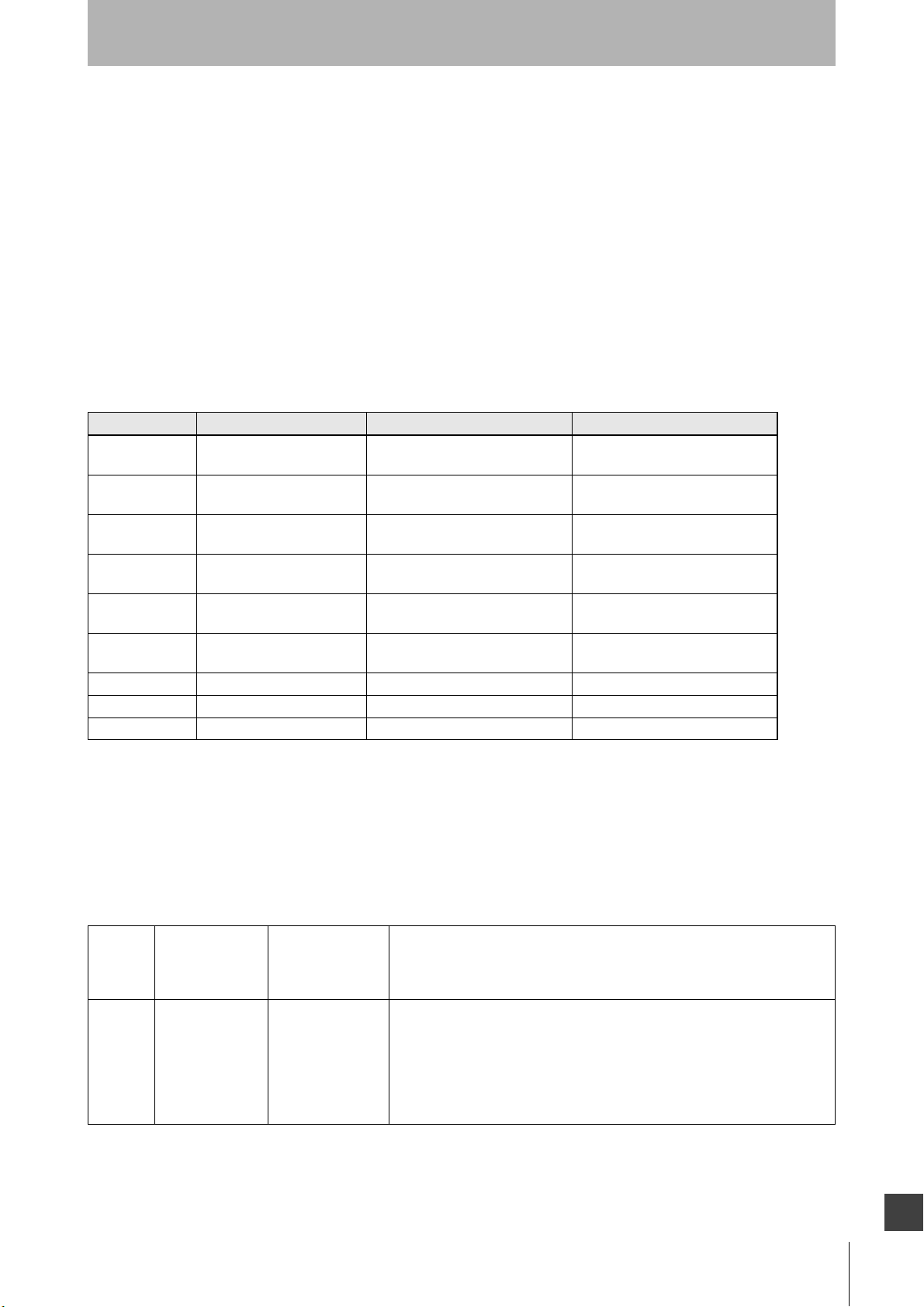

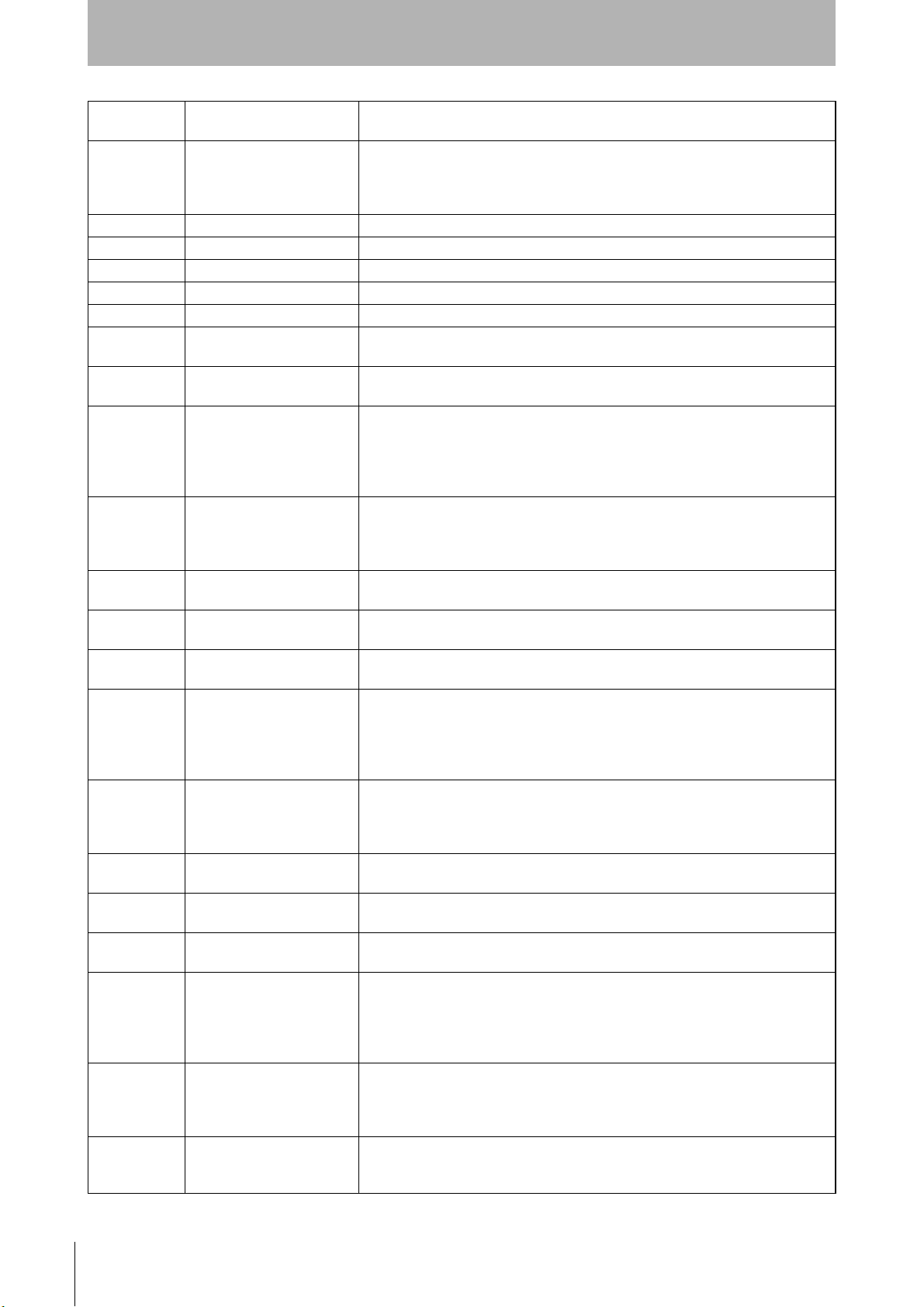

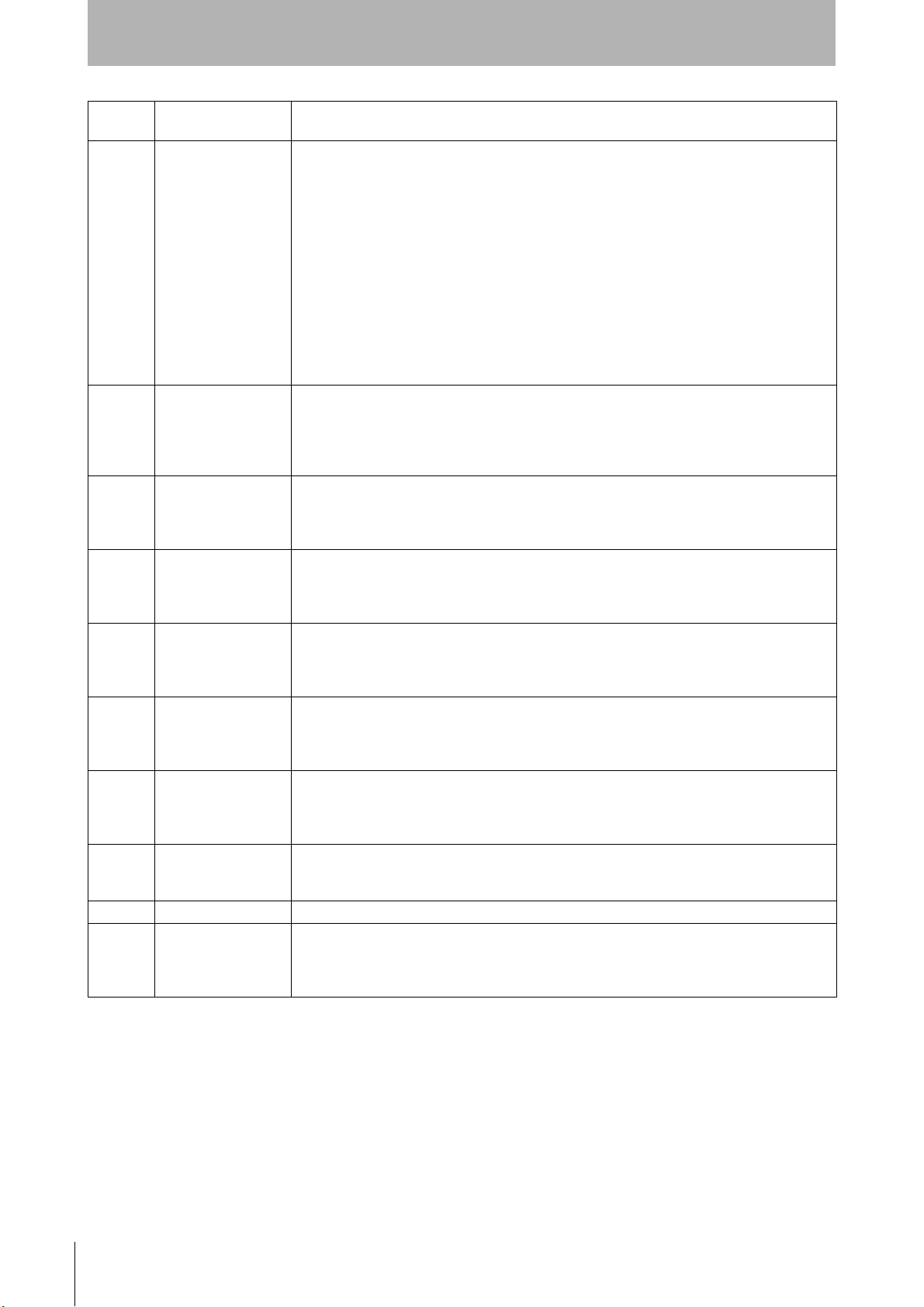

4.1 Table 1: EtherNet/IP Data Types

Keyword Description Minimum Maximum

SINT,

INT8

USINT,

UINT8

INT,

INT16

UINT,

UINT16

DINT,

INT32

UDINT,

UINT32

BYTE Bit string 8-bits 0 0xFF

WORD Bit string 16-bits 0 0xFFFF

DWORD Bit string 32-bits 0 0xFFFFFFFF

Short Integer -128 127

Unsigned Short Integer 0 255

Integer -32768 32767

Unsigned Integer 0 65535

Double Integer -2147483647 (-2

Unsigned Double Integer 0 4294967295 (2

31

) 2147483646 (231 - 1)

32)

Introduction

Input Assembly 100 listed in Table 2 below provides run-time system status information that can be

used to monitor the behavior and the current configuration of the scanner. Using an implicit UDP I/O

connection the scanner can be monitored at a repetition rate defined for the application.

4.2 Table 2: Input Assembly 100 and Vendor Object 112 (32bytes),

System Status

WORD #

(16-bit)

0

Description

Machine State

Data Type: UINT

16-bit

Vendor Specific

Object 0x70,

Instance 0x01

Attribute Number

4

Enumeration / Possible Values

POST = 0 // Power-on-self-test

STOP = 1 // Machine Stop, Protection Zone Violation

INTERLOCK = 2 // Start Interlock

RUN = 3 // Machine Run

STANDBY = 4 // System Standby.

CONFIGURE = 6 // Configuration process in session.

FAULT = 7 // System Faulted, OSSD's are OFF.

E

OS32C with EtherNet/IP & Measurement Data Addendum

5

Page 13

Introduction

EtherNet/IP Input Assembly Data

WORD #

(16-bit)

1

2

3

4

5

6

7

8

9

10

Description

Machine Stop

Reasons

Data Type: UINT

16-bit

Active Protection

Zone Set

Data Type: UINT

16-bit

Zone Inputs

Data Type: WORD

16-bit

Detection Zone

Status

Data Type: WORD

16-bit

Output Status

Data Type: WORD

16-bit

Input Status

Data Type: WORD

16-bit

Seven Segment

Display

Data Type: UINT

16-bit

Non-Safety

Configuration

Checksum Value

Data Type: UINT

16-bit

Safety

Configuration

Checksum Value

Data Type: UINT

16-bit

Active Warning

Zone Set

Data Type :

UINT 16-bit

V

endor Specific

Ob

Instance 0x01

Attribute Number

14 (0x0E),

NOTE: Words 11-15 are unused.

ject 0x70,

5

6

7

8

9

10 (0x0A)

11 ( 0 x 0 B)

12 (0x0C)

13 (0x0D)

Enumeration / Possible Values

DIRTY_WINDOW = 0 // Dirty window cause system to stop.

ZONE_SELECT_NUM_ACTIVE = 1 // Invalid zone inputs, with wrong number

of active inputs.

ZONE_SELECT_INVALID = 2 // Invalid zone inputs, with correct number

of active inputs.

QUALIFIED_ZONE_VIOLATION = 3 // Qualified protection zone violation.

STAND_BY_REQUEST = 4 // Stand-by requested.

RX_ERROR = 5 // Receiver error

TOO_CLEAN_WINDOW = 6 // Too clean window caused system to stop.

NOT IN MACHINE STOP_1 = 7 // System currently not in stop mode

SYSTEM FAULTED = 8 // The system faulted, check display code

NOT IN MACHINE STOP_2 = 9 // System currently not in stop mode.

AZS_01 = 0 (0x00)

…

AZS_70 = 69 (0x45)

INVALID AZS = 32,768 (0x8000)

Zinput 1 = bit 0

Zinput 2 = bit 1

Zinput 3 = bit 2

Zinput 4 = bit 3

Zinput 5 = bit 4

Zinput 6 = bit 5

Zinput 7 = bit 6

Zinput 8 = bit 7

Protection Zone = bit 0

Warning Zone #1 = bit 1

Warning Zone #2 = bit 2

Window Contamination = bit 3

OSSD Output = bit 0

Auxiliary Output = bit 1

Warning Output = bit 2

Standby Input = bit 0

Start Input = bit 1

EDM Input = bit 2

Digit Low followed by Digit High

Each Digit Displays 1 to 9 (0x01 to 0x09) for normal operation. 0x1B and 0x1B

for dashes "--" during machine stop operation.

16-bit Non-Safety Configuration CRC Value

16-bit Safety Configuration CRC Value

AZS_01 = 0 (0x00)

…

AZS_70 = 69 (0x45)

INVALID AZS = 32,768 (0x8000)

6

OS32C with EtherNet/IP & Measurement Data Addendum

Page 14

EtherNet/IP Input Assembly Data

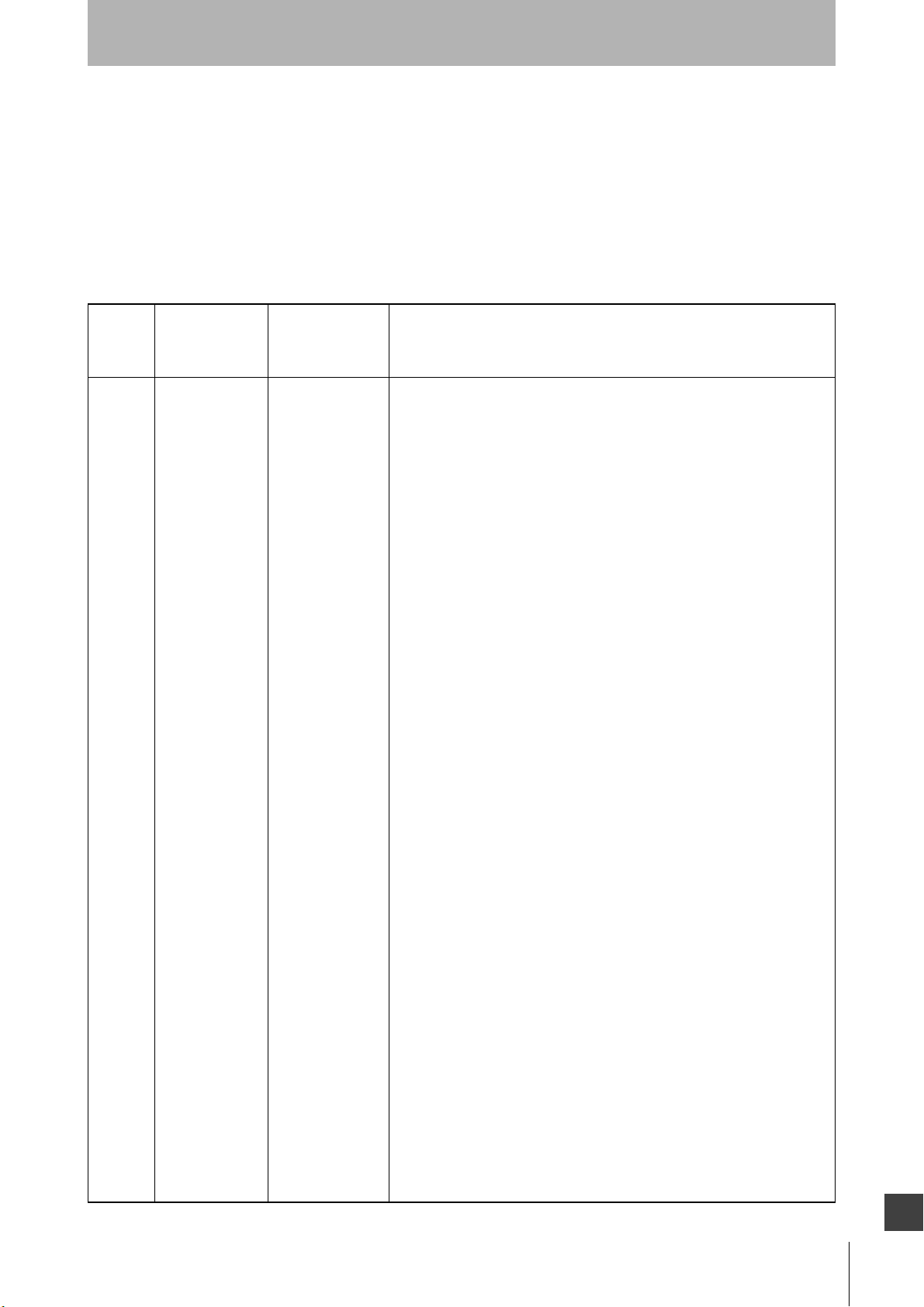

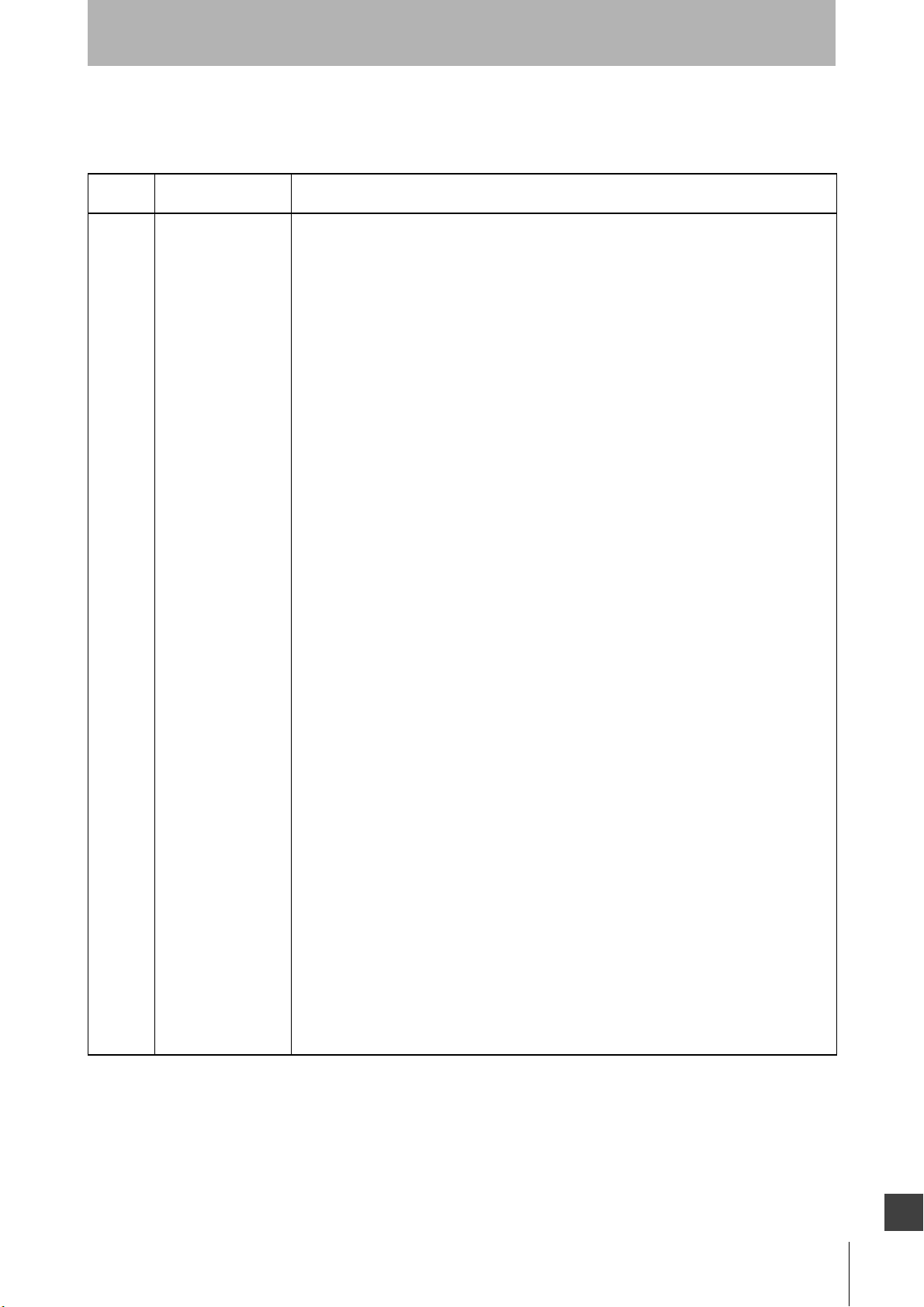

Input Assembly 101 listed in Table 3 below provides run-time system status plus, protection zone,

warning zone 1 and warning zone 2, detection status information. This information can be used to

monitor the behavior of the scanner as well as the detection zones of the scanner. Using an implicit

UDP I/O connection the scanner can be monitored at a repetition rate defined for the application.

4.3 Table 3: Input Assembly 101 (296 bytes), System & Detection Status

Introduction

WORD #

(16-bit)

0 Machine State

1 Machine Stop Reasons

2 Active Protection Zone Set

3 Zone Inputs

4 Detection Zone Status

5 Output Status

6 Input Status

7 Seven Segment Display

8

9

Attribute Description Data Field (16-bit)

Non-Safety Configuration

Checksum Value

Safety Configuration

Checksum Value

POST = 0 // Power-on-self-test

STOP = 1 // Machine Stop, Protection Zone Violation

INTERLOCK = 2 // Start Interlock

RUN = 3 // Machine Run

STANDBY = 4 // System Standby.

CONFIGURE = 6 // Configuration process in session.

FAULT = 7 // System Faulted, OSSD's are OFF.

DIRTY_WINDOW = 0 // Dirty window cause system to stop.

ZONE_SELECT_NUM_ACTIVE = 1 // Invalid zone inputs, with wrong number of

active inputs.

ZONE_SELECT_INVALID = 2 // Invalid zone inputs, with correct number of

active inputs.

QUALIFIED_ZONE_VIOLATION = 3 // Qualified protection zone violation.

STAND_BY_REQUEST = 4 // Stand-by requested.

RX_ERROR = 5 // Receiver error

TOO_CLEAN_WINDOW = 6 // Too clean window caused system to stop.

NOT IN MACHINE STOP_1 = 7 // System currently not in stop mode

SYSTEM FAULTED = 8 // The system faulted, check display code

NOT IN MACHINE STOP_2 = 9 // System currently not in stop mode

AZS_01 = 0 (0x00)

...

AZS_70 = 69 (0x45)

INVALID AZS = 32,768 (0x8000)

Zinput 1 = bit 0

Zinput 2 = bit 1

Zinput 3 = bit 2

Zinput 4 = bit 3

Zinput 5 = bit 4

Zinput 6 = bit 5

Zinput 7 = bit 6

Zinput 8 = bit 7

Protection Zone = bit 0

Warning Zone #1 = bit 1

Warning Zone #2 = bit 2

Window Contamination = bit 3

OSSD Output = bit 0

Auxiliary Output = bit 1

Warning Output = bit 2

Standby Input = bit 0

Start Input = bit 1

EDM Input = bit 2

Digit Low followed by Digit High

Each Digit Displays 1 to 9 (0x01 to 0x09) for normal operation. 0x1B and 0x1B for

dashes "--" during machine stop operation.

16-bit Non-Safety Configuration CRC Value

16-bit Safety Configuration CRC Value

OS32C with EtherNet/IP & Measurement Data Addendum

E

7

Page 15

Introduction

EtherNet/IP Input Assembly Data

WORD #

(16-bit)

10

11 Unused

12 Unused

13 Unused

14 Unused

15 Unused

16

17

18 through 57

58

59

60

61

62-101

102

103

104

105

106-145

146

147

Attribute Description Data Field (16-bit)

Active Warning Zone Set

Data Type: UINT 16-bit

Protection Zone Status

Beams #1 (Beams 1-16 )

Protection Zone Status

Beams #2 (Beams 17-32 )

Protection Zone Status

Beams #3 (Beam 33-48 )

Protection Zone Status

Beams #42 (Beams 653-672 )

Protection Zone Status

Beams #43 (Beams 673-688 )

Unused Zone Status Beams

#44 (Beams 689-704 )

Warning Zone #1 Status

Beams #1 (Beams 1-16 )

Warning Zone #1 Status

Beams #2 (Beams17-32 )

Warning Zone #1 Status

Beams #3 (Beam 33-48 )

Warning Zone #1 Status

Beams #42 (Beams 653-672 )

Warning Zone #1 Status

Beams #43 (Beams 672-688 )

Warning Zone #1 Status

Beams #44 (Beams 689-704 )

Warning Zone #2 Status

Beams #1 (Beams 1-16 )

Warning Zone #2 Status

Beams #2 (Beams17-32 )

Warning Zone #2 Status

Beams #3 (Beam 33-48 )

Warning Zone #2 Status

Beams #42 (Beams 653-672 )

Warning Zone #2 Status

Beams #43 (Beams 672-688 )

Warning Zone #2 Status

Beams #44 (Beams 689-704 )

AZS_01 = 0 (0x00)

…

AZS_70 = 69 (0x45)

INVALID AZS = 32,768 (0x8000)

For future use.

For future use.

For future use.

For future use.

For future use.

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Through

Beam status bit0 to bi16 (0 = Clear , 1 = Blocked)

Beam 678-688 unused.

Unused beams set to zero.

Note: Data used to maintain 16-bit word alignment.

Unused beams set to zero.

Note: Data used to maintain 32-bit alignment..

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Through

Beam status bit0 to bi16 (0 = Clear , 1 = Blocked)

Beam 678-688 unused.

Unused beams set to zero.

Note: Data used to maintain 16-bit word alignment.

Unused beams set to zero.

Note: Data used to maintain 32-bit alignment.

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Beam status bit0 to bit16 (0 = Clear , 1 = Blocked)

Through

Beam status bit0 to bi16 (0 = Clear , 1 = Blocked)

Beam 678-688 unused.

Unused beams set to zero.

Note: Data used to maintain 16-bit word alignment.

Unused beams set to zero.

Note: Data used to maintain 32-bit alignment.

8

OS32C with EtherNet/IP & Measurement Data Addendum

Page 16

EtherNet/IP Input Assembly Data

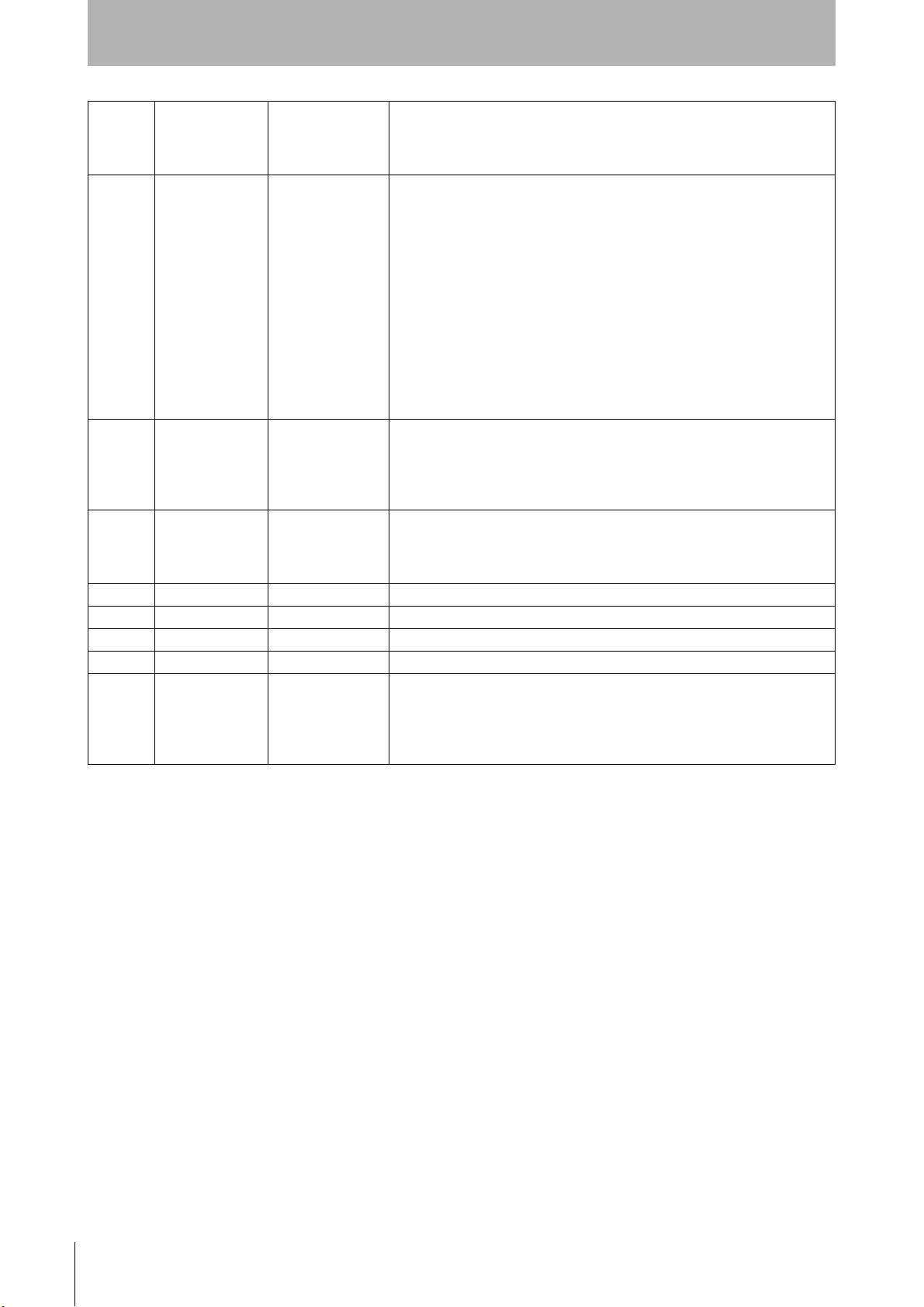

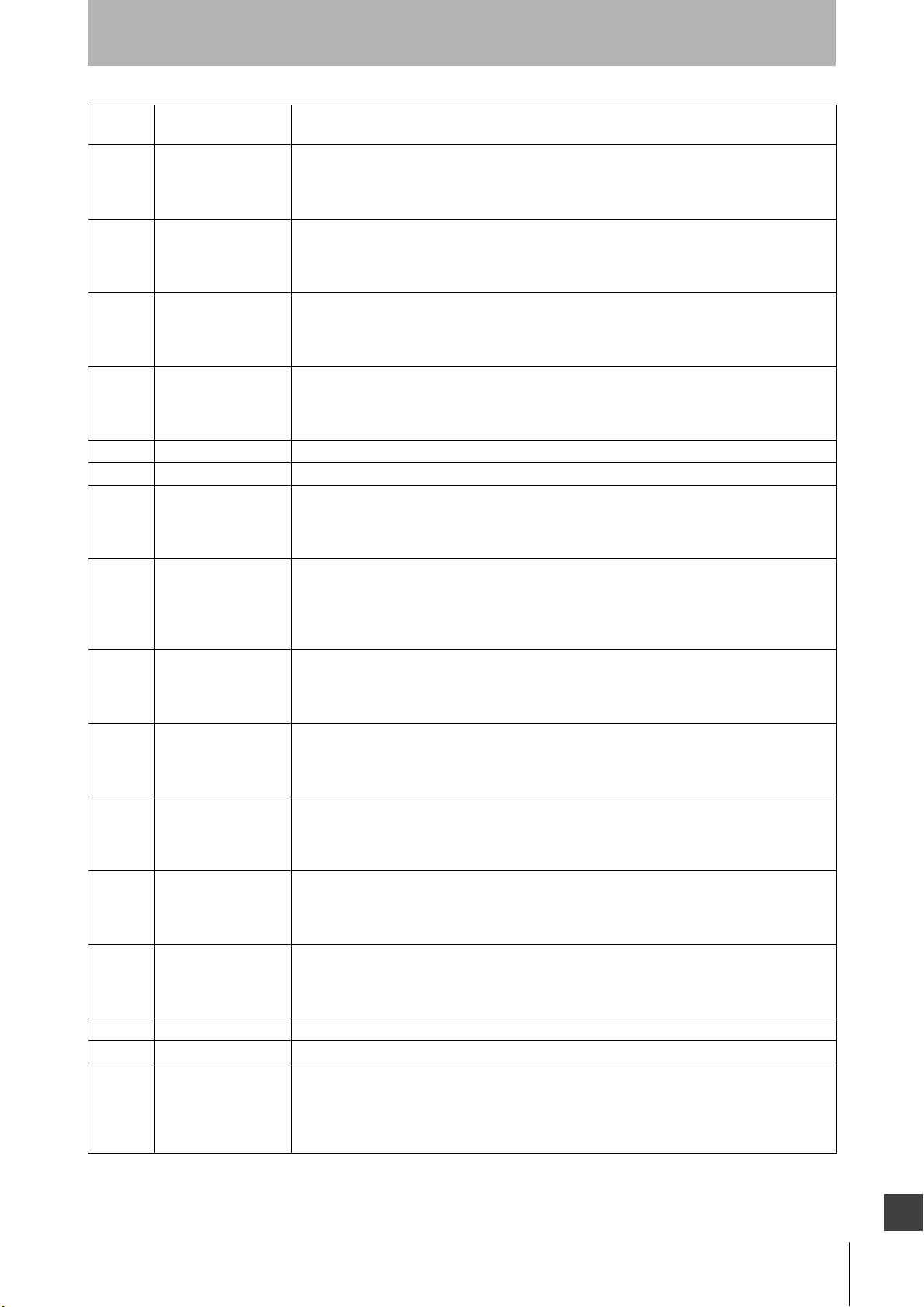

Output Assembly Object 113 and Vendor Specific Object 115 listed in Table 4 below are used to

configure the run-time measurement data that the scanner provides in input assembly objects 102 and

103 as well as vendor specific objects 114, 116 and 117. In output assembly 113 and vendor specific

115 objects the measurement report range and reflectivity formats as well as the individual beams to

be monitored can be selected using a beam report selection mask array.

4.4 Table 4: Output Assembly 113 and Vendor Object 115 (104 bytes),

Measurement Report Configuration for Input Assembly 102 & 103

Introduction

WORD #

(16-bit)

0

Description

Range Report

Format

Data Type: UINT

16-bit

Vendor Specific

Object x, Instance

y, Attribute

Number z

0x73, 1, 4

Enumeration / Possible Values

NO_TOF_MEASUREMENTS = 0,

// No time-of-flight measurements required.

RANGE_MEASURE_50M = 1, // default setting.

// Bit 0 to 15 (16-bit) distance measurement value (0 to 50,000 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0xFFFF = No Reflection.

RANGE_MEASURE_32M_PZ = 2,

// Bit 0 to 14 (15-bit) distance measurement value (0 to 32,766 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x7FFF = No Reflection.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_16M_WZ1PZ = 3,

// Bit 0 to 13 (14-bit) distance measurement value (0 to 16,382 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x3FFF = No Reflection.

// Bit 14: object detected (beam blocked) within the warning zone 1.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_8M_WZ2WZ1PZ = 4,

// Bit 0 to 12 (13-bit) distance measurement value (0 to 8,190 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x1FFF = No Reflection.

// Bit 13: object detected (beam blocked) within the warning zone 2.

// Bit 14: object detected (beam blocked) within the warning zone 1.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_TOF_4PS = 5

// Bit 0 to 15 (16-bit) TOF measurement value (0 to 65,534 x 4ps).

// Value of 0x0001 = Noisy Beam, Value of 0xFFFF = No Reflection.

RANGE_MEASURE_50M_W3BIT_ENCODED_TOT = 6,

// Bit 0 to 12 (13-bit) distance measurement value

// (0 to 50,000 millimeters, 50 meters with 8mm resolution).

// Bit 13 to 15 (3 bits) encoded reflectivity value (1/128 of measured value).

RANGE_MEASURE_32M_WZ2 = 7,

// Bit 0 to 14 (15-bit) distance measurement value (0 to 32,766 millimeters).

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

RANGE_MEASURE_16M_WZ1WZ2 = 8,

// Bit 0 to 13 (14-bit) distance measurement value (0 to 16,382 millimeters).

// Bit 14: measure value detected (beam blocked) within the warning zone 1.

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

RANGE_MEASURE_8M_PZWZ1WZ2 = 9,

// Bit 0 to 12 (13-bit) distance measurement value (0 to 8,190 millimeters).

// Bit 13: measure value detected (beam blocked) within protection zone.

// Bit 14: measure value detected (beam blocked) within the warning zone 1.

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

OS32C with EtherNet/IP & Measurement Data Addendum

E

9

Page 17

Introduction

EtherNet/IP Input Assembly Data

WORD #

(16-bit)

1

2

3

4 Unused. For future use.

5 Unused. For future use.

6 Unused. For future use.

7 Unused. For future use.

8 - 51

Description

Reflectivity Report

Format

Data Type: UINT

16-bit

Range Report

Mode

Data Type: UINT

16-bit

Active Warning

Zone Set Number

Data Type: UINT

16-bit

Beam Report

Selection Mask

Data Type: UINT

16-bit ARRAY[44]

Vendor Specific

Object x, Instance

y, Attribute

Number z

0x73, 1, 5

0x73,1,6

0x73,1,7

0x73, 1, 12 (0x0C)

NO_TOT_MEASUREMENTS = 0,

// No time-over-threshold measurements required.

REFLECTIVITY_MEASURE_TOT_ENCODED = 1, // default setting.

// Bit 0 to 9 (10-bit) TOT scaled value (0 to 1,000)

// Bit 10: unused.

// Bit 11: object detected (beam blocked) within the warning zone 2.

// Bit 12: object detected (beam blocked) within the warning zone 1.

// Bit 13: object detected (beam blocked) within protection zone.

// Bit 14: noisy beam detected.

// Bit 15: no reflection detected.

REFLECTIVITY_MEASURE_TOT_4PS = 2

// Bit 0 to 15 (16-bit) TOT measurement value (0 to 65,535 x 4ps).

REPORT_RANGE_ONLY = 0 (default),

// Assembly 102 Report Range Only.

REPORT_RANGE_AND_REFLECTIVITY = 1,

// Assembly 102 Report Range & Reflectivity.

Minimum Value: ZONE_1 = 0,

…

Maximum Value: ZONE_70 = 69.

Beam Report Selection Mask is used to define the reported beam

measurements in Assembly Input Objects 102, 103 & Vendor Specific Objects

114, 116 and 117.

Bit = 0, excluded from measurement report. // default setting.

Bit = 1, included in measurement reports.

Enumeration / Possible Values

10

OS32C with EtherNet/IP & Measurement Data Addendum

Page 18

EtherNet/IP Input Assembly Data

4.5 Table 5: Output Assembly 114 (108 bytes), Measurement Report

Configuration for Input Assembly 104 & 105

Introduction

Word #

(16-bit)

0

Description Enumeration / Possible Values

NO_TOF_MEASUREMENTS = 0,

// No time-of-flight measurements required.

RANGE_MEASURE_50M = 1, // default setting.

// Bit 0 to 15 (16-bit) distance measurement value (0 to 50,000 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0xFFFF = No Reflection.

RANGE_MEASURE_32M_PZ = 2,

// Bit 0 to 14 (15-bit) distance measurement value (0 to 32,766 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x7FFF = No Reflection.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_16M_WZ1PZ = 3,

// Bit 0 to 13 (14-bit) distance measurement value (0 to 16,382 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x3FFF = No Reflection.

// Bit 14: object detected (beam blocked) within the warning zone 1.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_8M_WZ2WZ1PZ = 4,

// Bit 0 to 12 (13-bit) distance measurement value (0 to 8,190 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x1FFF = No Reflection.

// Bit 13: object detected (beam blocked) within the warning zone 2.

// Bit 14: object detected (beam blocked) within the warning zone 1.

Range Report Format

Data Type: UINT

16-bit

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_TOF_4PS = 5

// Bit 0 to 15 (16-bit) TOF measurement value (0 to 65,534 x 4ps).

// Value of 0x0001 = Noisy Beam, Value of 0xFFFF = No Reflection.

RANGE_MEASURE_50M_W3BIT_ENCODED_TOT = 6,

// Bit 0 to 12 (13-bit) distance measurement value

// (0 to 50,000 millimeters, 50 meters with 8mm resolution).

// Bit 13 to 15 (3 bits) encoded reflectivity value (1/128 of measured value).

RANGE_MEASURE_32M_WZ2 = 7,

// Bit 0 to 14 (15-bit) distance measurement value (0 to 32,766 millimeters).

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

RANGE_MEASURE_16M_WZ1WZ2 = 8,

// Bit 0 to 13 (14-bit) distance measurement value (0 to 16,382 millimeters).

// Bit 14: measure value detected (beam blocked) within the warning zone 1.

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

RANGE_MEASURE_8M_PZWZ1WZ2 = 9,

// Bit 0 to 12 (13-bit) distance measurement value (0 to 8,190 millimeters).

// Bit 13: measure value detected (beam blocked) within protection zone.

// Bit 14: measure value detected (beam blocked) within the warning zone 1.

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

OS32C with EtherNet/IP & Measurement Data Addendum

E

11

Page 19

Introduction

EtherNet/IP Input Assembly Data

Word #

(16-bit)

1

2

3

4

5

6

7

8

9 Unused. For future use.

10- 53

Description Enumeration / Possible Values

NO_TOT_MEASUREMENTS = 0,

// No time-over-threshold measurements required.

REFLECTIVITY_MEASURE_TOT_ENCODED = 1, // default setting.

// Bit 0 to 9 (10-bit) TOT scaled value (0 to 1,000)

Reflectivity Report

Format

Data Type: UINT

16-bit

Range

Report Mode

Data Type: UINT

16-bit

Assembly 104 & 105

Enable User Tags

Data Type: UINT

16-bit

Assembly 104

User First Position Tag

Data Type: UINT

16-bit

Assembly 104

User Last Position Tag

Data Type: UINT

16-bit

Assembly 105

User First Position Tag

Data Type: UINT

16-bit

Assembly 105

User Last Position Tag

Data Type: UINT

16-bit

Active Warning Zone

Set Number

Data Type: UINT 16-bit

Beam Report Selection

Mask

Data Type: UINT

16-bit ARRAY[44]

// Bit 10: unused.

// Bit 11: object detected (beam blocked) within the warning zone 2.

// Bit 12: object detected (beam blocked) within the warning zone 1.

// Bit 13: object detected (beam blocked) within protection zone.

// Bit 14: noisy beam detected.

// Bit 15: no reflection detected.

REFLECTIVITY_MEASURE_TOT_4PS = 2

// Bit 0 to 15 (16-bit) TOT measurement value (0 to 65,535 x 4ps).

REPORT_RANGE_ONLY = 0,

// Report Range Only.

REPORT_RANGE_AND_REFLECTIVITY = 1,

// Report Range & Reflectivity.

Enable User Provided Tag Values for First & Last Positions of Input Assembly Data.

// Disable = 0 (default), Enable = 1

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

Minimum Value: ZONE_1 = 0,

Maximum Value: ZONE_70 = 69.

Beam Report Selection Mask is used to define the reported beam measurements in Assembly

Input Objects 104, 105.

Bit = 0, excluded from measurement report.

Bit = 1, included in measurement reports. // default setting.

12

OS32C with EtherNet/IP & Measurement Data Addendum

Page 20

EtherNet/IP Input Assembly Data

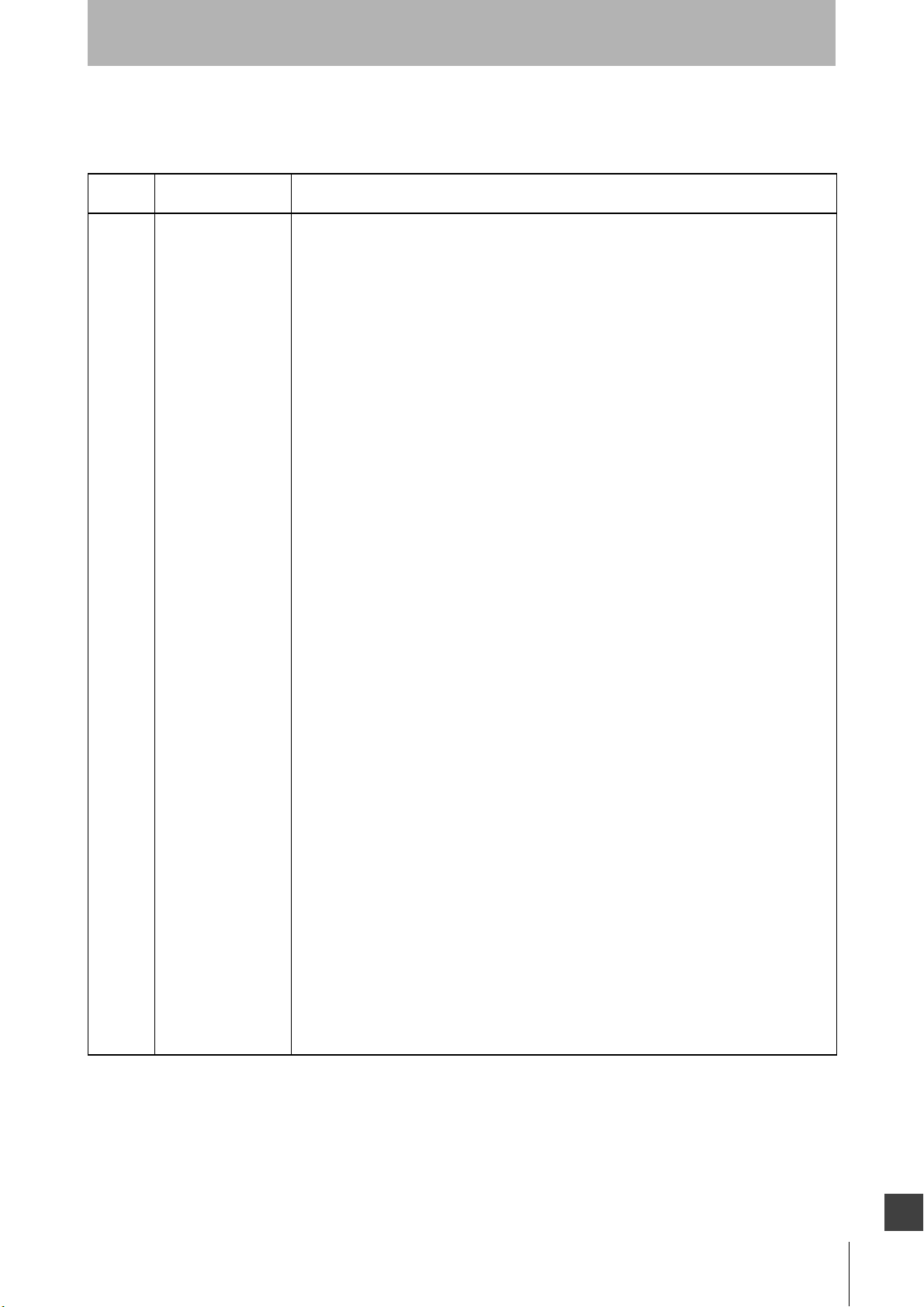

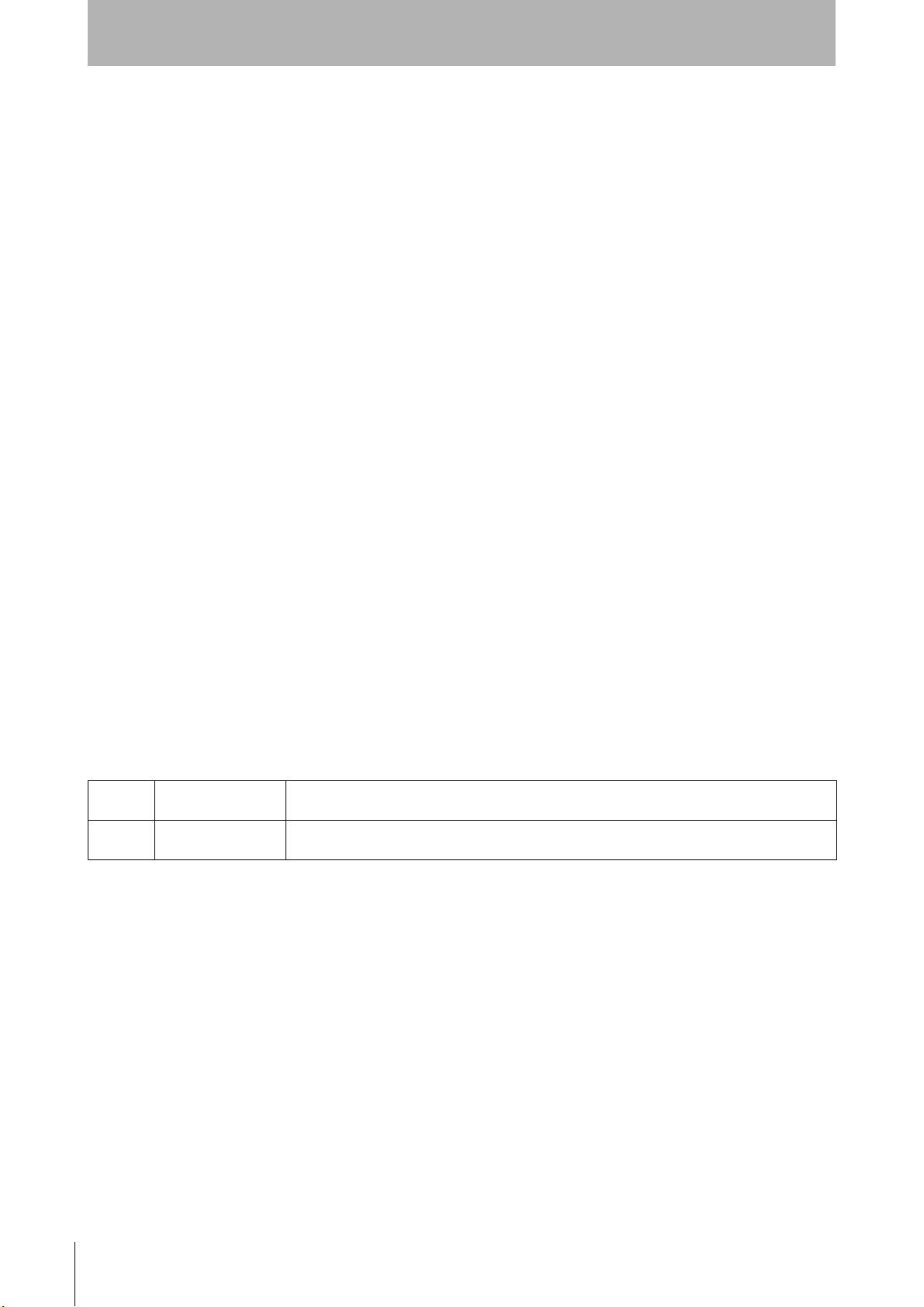

4.6 Table 6 : Output Assembly 115 (316 bytes), Measurement Report

Configuration for Input Assembly 106 through 111

Introduction

Word #

(16-bit)

0

Description Enumeration / Possible Values

NO_TOF_MEASUREMENTS = 0,

// No time-of-flight measurements required.

RANGE_MEASURE_50M = 1, // default setting.

// Bit 0 to 15 (16-bit) distance measurement value (0 to 50,000 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0xFFFF = No Reflection.

RANGE_MEASURE_32M_PZ = 2,

// Bit 0 to 14 (15-bit) distance measurement value (0 to 32,766 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x7FFF = No Reflection.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_16M_WZ1PZ = 3,

// Bit 0 to 13 (14-bit) distance measurement value (0 to 16,382 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x3FFF = No Reflection.

// Bit 14: object detected (beam blocked) within the warning zone 1.

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_8M_WZ2WZ1PZ = 4,

// Bit 0 to 12 (13-bit) distance measurement value (0 to 8,190 millimeters).

// Value of 0x0001 = Noisy Beam, Value of 0x1FFF = No Reflection.

// Bit 13: object detected (beam blocked) within the warning zone 2.

// Bit 14: object detected (beam blocked) within the warning zone 1.

Range Report Format

Data Type: UINT

16-bit

// Bit 15: object detected (beam blocked) within protection zone.

RANGE_MEASURE_TOF_4PS = 5

// Bit 0 to 15 (16-bit) TOF measurement value (0 to 65,534 x 4ps).

// Value of 0x0001 = Noisy Beam, Value of 0xFFFF = No Reflection.

RANGE_MEASURE_50M_W3BIT_ENCODED_TOT = 6,

// Bit 0 to 12 (13-bit) distance measurement value

// (0 to 50,000 millimeters, 50 meters with 8mm resolution).

// Bit 13 to 15 (3 bits) encoded reflectivity value (1/128 of measured value).

RANGE_MEASURE_32M_WZ2 = 7,

// Bit 0 to 14 (15-bit) distance measurement value (0 to 32,766 millimeters).

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

RANGE_MEASURE_16M_WZ1WZ2 = 8,

// Bit 0 to 13 (14-bit) distance measurement value (0 to 16,382 millimeters).

// Bit 14: measure value detected (beam blocked) within the warning zone 1.

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

RANGE_MEASURE_8M_PZWZ1WZ2 = 9,

// Bit 0 to 12 (13-bit) distance measurement value (0 to 8,190 millimeters).

// Bit 13: measure value detected (beam blocked) within protection zone.

// Bit 14: measure value detected (beam blocked) within the warning zone 1.

// Bit 15: measure value detected (beam blocked) within the warning zone 2.

OS32C with EtherNet/IP & Measurement Data Addendum

E

13

Page 21

Introduction

EtherNet/IP Input Assembly Data

Word #

(16-bit)

1

2

3

4

5

6

7

8

9 Unused. For future use.

10- 53

54

55

Description Enumeration / Possible Values

NO_TOT_MEASUREMENTS = 0,

// No time-over-threshold measurements required.

REFLECTIVITY_MEASURE_TOT_ENCODED = 1, // default setting.

// Bit 0 to 9 (10-bit) TOT scaled value (0 to 1,000)

Reflectivity Report

Format

Data Type: UINT

16-bit

Assembly 106 Range

Report Mode

Data Type: UINT

16-bit

Assembly 106 & 107

Enable User Tags

Data Type: UINT

16-bit

Assembly 106

User First Position Tag

Data Type: UINT

16-bit

Assembly 106

User Last Position Tag

Data Type: UINT

16-bit

Assembly 107

User First Position Tag

Data Type: UINT

16-bit

Assembly 107

User Last Position Tag

Data Type: UINT

16-bit

Active Warning Zone

Set Number

Data Type: UINT 16-bit

Beam Report Selection

Mask

Data Type: UINT

16-bit ARRAY[44]

Assembly 108 Range

Report Mode

Data Type: UINT

16-bit

Assembly 108 & 109

Enable User Tags

Data Type: UINT

16-bit

// Bit 10: unused.

// Bit 11: object detected (beam blocked) within the warning zone 2.

// Bit 12: object detected (beam blocked) within the warning zone 1.

// Bit 13: object detected (beam blocked) within protection zone.

// Bit 14: noisy beam detected.

// Bit 15: no reflection detected.

REFLECTIVITY_MEASURE_TOT_4PS = 2

// Bit 0 to 15 (16-bit) TOT measurement value (0 to 65,535 x 4ps).

REPORT_RANGE_ONLY = 0,

// Report Range Only.

REPORT_RANGE_AND_REFLECTIVITY = 1,

// Report Range & Reflectivity.

Enable User Provided Tag Values for First & Last Positions of Input Assembly Data.

// Disable = 0 (default), Enable = 1

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

Minimum Value: ZONE_1 = 0,

Maximum Value: ZONE_70 = 69.

Beam Report Selection Mask is used to define the reported beam measurements in Assembly

Input Objects 106, 107.

Bit = 0, excluded from measurement report.

Bit = 1, included in measurement reports. // default setting.

REPORT_RANGE_ONLY = 0,

// Report Range Only.

REPORT_RANGE_AND_REFLECTIVITY = 1,

// Report Range & Reflectivity.

Enable User Provided Tag Values for First & Last Positions of Input Assembly Data.

// Disable = 0 (default), Enable = 1

14

OS32C with EtherNet/IP & Measurement Data Addendum

Page 22

EtherNet/IP Input Assembly Data

Introduction

Word #

(16-bit)

56

57

58

59

60 Unused For future use.

61 Unused For future use.

62-105

106

107

108

109

110

111

112 Unused For future use.

113 Unused For future use.

114-157

Description Enumeration / Possible Values

Assembly 108

User First Position Tag

Data Type: UINT

16-bit

Assembly 108

User Last Position Tag

Data Type: UINT

16-bit

Assembly 109

User First Position Tag

Data Type: UINT

16-bit

Assembly 109

User Last Position Tag

Data Type: UINT

16-bit

Beam Report Selection

Mask

Data Type: UINT

16-bit ARRAY[44]

Assembly 110 Range

Report Mode

Data Type: UINT

16-bit

Assembly 110 & 111

Enable User Tags

Data Type: UINT

16-bit

Assembly 110

User First Position Tag

Data Type: UINT

16-bit

Assembly 110

User Last Position Tag

Data Type: UINT

16-bit

Assembly 111

User First Position Tag

Data Type: UINT

16-bit

Assembly 111

User Last Position Tag

Data Type: UINT

16-bit

Beam Report Selection

Mask

Data Type: UINT

16-bit ARRAY[44]

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

Beam Report Selection Mask is used to define the reported beam measurements in Assembly

Input Objects 108, 109.

Bit = 0, excluded from measurement report.

Bit = 1, included in measurement reports. // default setting.

REPORT_RANGE_ONLY = 0,

// Report Range Only.

REPORT_RANGE_AND_REFLECTIVITY = 1,

// Report Range & Reflectivity.

Enable User Provided Tag Values for First & Last Positions of Input Assembly Data.

// Disable = 0 (default), Enable = 1

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

User Provided Tag Value for First Position of Input Assembly Data.

User Provided Tag Value for Last Position of Input Assembly Data.

Beam Report Selection Mask is used to define the reported beam measurements in Assembly

Input Objects 110, 111.

Bit = 0, excluded from measurement report.

Bit = 1, included in measurement reports. // default setting.

The range report formats available in the configuration output assembly 113, 114 and 115 provide

options to receive range measurements in millimeters units, encoded detection zone bits and

OS32C with EtherNet/IP & Measurement Data Addendum

E

15

Page 23

Introduction

EtherNet/IP Input Assembly Data

millimeter units, or time-of-flight measurements in picoseconds. The encoded detection zone bits that

are provided by the scanner serve two purposes, 1) to provide fast detection of the location where

zone violations occur, and 2) so that the client application (PLC or PC) is not required to maintain the

same detection zone parameters that are already stored in the scanner. When encoded range

measurements are provided the measurement values can be separated from the detection zone bits

by using a binary mask for the selected format. When a measurement beam is noisy and does not

contain valid information the value returned is 1 (0x0001) and when there is no measurement of the

value the maximum value for the range report format is returned (i.e. for the RANGE_MEASURE_50M

format the returned value is 65535 (0xFFFF)). The range measurements are provided in input

assembly object 102, 104, 106, 108 and 110 as well as vendor specific object 114 and 117 which also

contains reflectivity measurements.

The reflectivity report formats available in the configuration output assembly 113, 114 and 115 provides

another option to receive reflectivity measurements in a scaled unit with encoded detection zone bits,

or time-over-threshold measurements in picoseconds. The encoded detection bits that are embedded

in the reflectivity measurements serve the same purpose as described above but provide an alternate

method for zone detection when long range measurements are required. The reflectivity

measurements are provided in input assembly object 103, 105, 107,109, and 111 as well as vendor

specific objects 116 and 117 which also contains range measurements.

Output Assembly 112 and 116 through 120 are single word assemblies which are used to keep a PLC

I/O connection alive for streaming any of the standard Input assemblies (100 through 111). The output

data of this assembly has no effect on the measurement report configuration and can be used to

trigger an alternate I/O connection. When the measurement report configuration, Output Assembly

113, is used to collect range measurement data for example, Output Assemblies 112, 116 through 120

can be used to create an alternate streaming connection in order to collect reflectivity data.

4.7 Table 7 : Output Assembly 112, 116-120 I/O Connection Triggers

Word #

(16-bit)

0

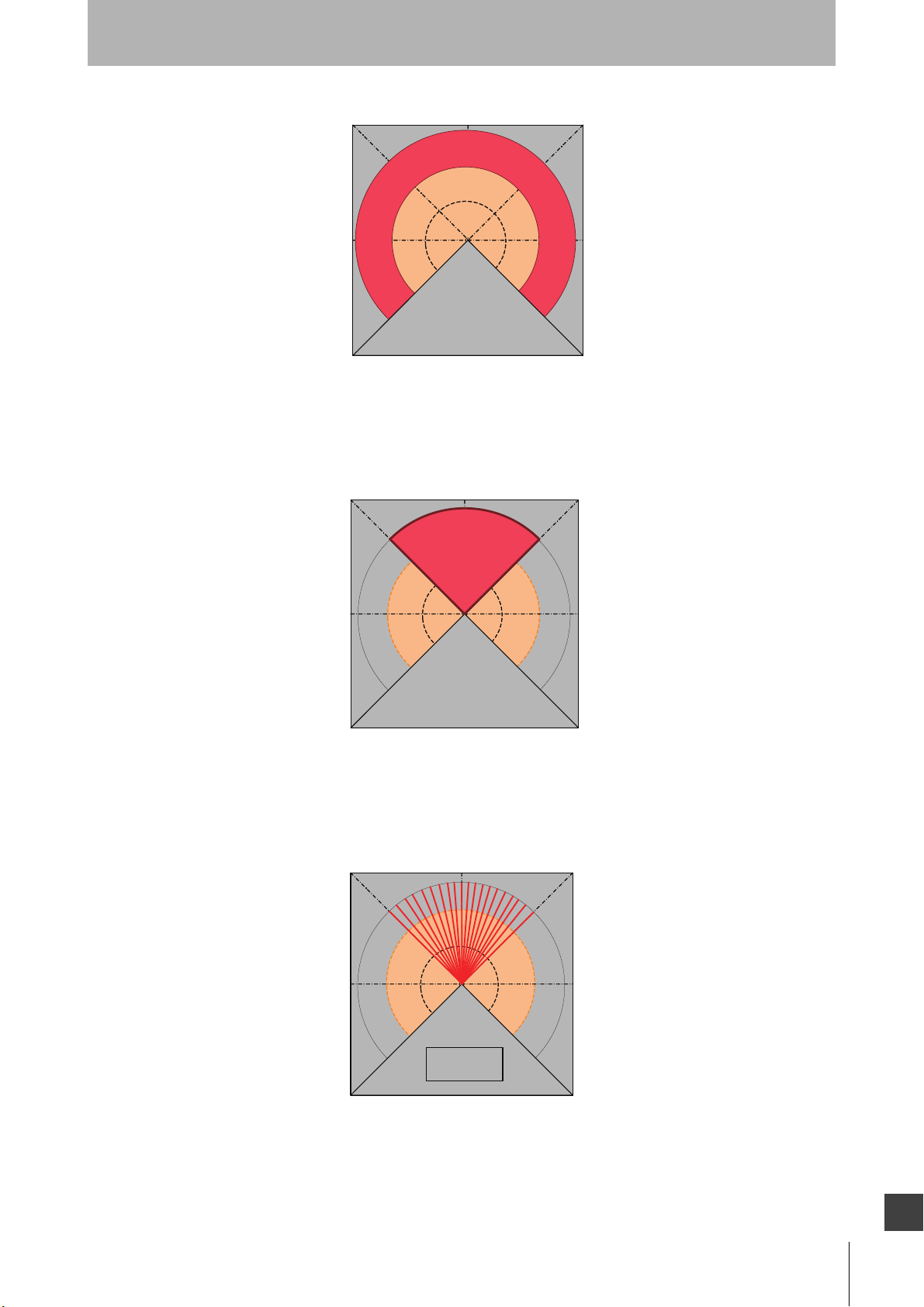

The OS32C uses a beam report selection mask to select the areas of interest. When defining the

required resolution and selected zones of interest, the beam report selection mask provides the

greatest flexibility for changing monitored zones during run-time. Figure 4-1 below shows the coverage

area when all beams are selected and each bit in the beam report selection mask is set to 1. Two

additional beams before and after the sensing field are provided to ensure the full safety region is

protected at all times. Therefore the true monitoring region coverage is from -0.4° to 270.4°.

Description Enumeration / Possible Values

Data Type: UINT

16-bit

Not used.

16

OS32C with EtherNet/IP & Measurement Data Addendum

Page 24

EtherNet/IP Input Assembly Data

-0.4° to 270.4°

Beam 0 thru 676

0.4° per beam

135º

0º

270º

135º

0º

270º

90° to 180°,

Beam 225 thru 450

0.4° per beam

135º

0º

270º

90° to 180°,

Beam 225 thru 450

2.0° per beam

Fig. 4-1 Beam Report Selection Mask, All Beams

Using the OS32C beam report selection mask smaller areas of interest can also be defined. For

example setting the selection bits 225 thru 450 in the beam report selection mask provides an area of

coverage from 90 to 180 degrees in the scan plane.

Introduction

Fig. 4-2 Beam Report Selection Mask, Beam 225 through 450

As shown in Figure 4-3 below, the beam report selection mask can also be used to reduce the amount

of data provided in the area of interest. For example setting every 5th beam in the selection bits 225

through 450 in the selection mask provides an area of coverage with a resolution of 2 degrees.

Fig. 4-3 Beam Report Selection Mask, Beam 225 through 450 with Low Resolution

OS32C with EtherNet/IP & Measurement Data Addendum

E

17

Page 25

Introduction

EtherNet/IP Input Assembly Data

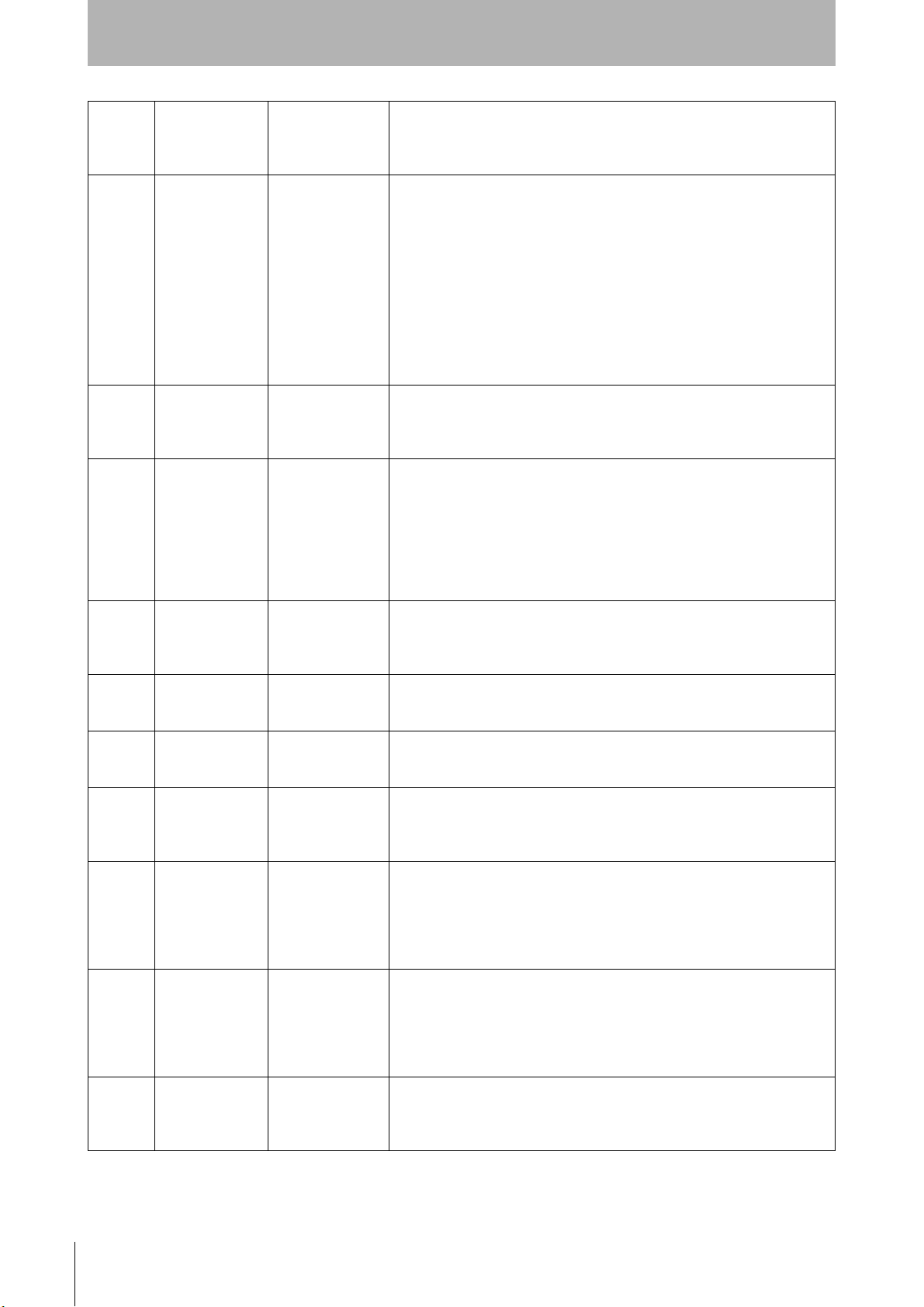

Input assembly objects 102 through 105 as well as vendor specific objects 114, 116 and 117 provide a

common measurement report header format in addition to the specific measurement data provided in

these assembly structures. Table 8 below shows the common measurement report header format.

Using explicit TCP/IP request/reply messages or an implicit UDP I/O connection for assembly objects

102 through 105 the scanner can be monitored at a repetition rate defined for the application.

4.8 Table 8: Common Measurement Report Header Format (56 bytes)

Word #

(16-bit)

0 & 1

2 & 3

4 & 5

6 & 7

8

9

10

11

Description

Scan Count

Data Type: UDINT

32-bit

Scan Rate

Data Type: UDINT

32-bit

Scan Time Stamp

Data Type: UDINT

32-bit

Scan Beam Period

Data Type: UDINT

32-bit

Machine State

Data Type: UINT

16-bit

Machine Stop

Reasons

Data Type: UINT

16-bit

Active Protection

Zone Set

Data Type: UINT

16-bit

Zone Inputs

Data Type: WORD

16-bit

Vendor Specific

Object x, Instance

y, Attribute

Number z

0x72, 1, 13 (0x0D)

0x72, 1, 14 (0x0E)

0x72, 1, 15 (0x0F)

0x72, 1, 16 (0x10)

0x70, 1, 4

0x70, 1, 5

0x70, 1, 6

0x70, 1, 7

Enumeration / Possible Values

0 to 4294967295 (2

39,000 us ± 500 us

0 to 4294967295 (2

42,777 to 43,888 ns

POST = 0 // Power-on-self-test

STOP = 1 // Machine Stop, Protection Zone Violation

INTERLOCK = 2 // Start Interlock

RUN = 3 // Machine Run

STANDBY = 4 // System Standby.

CONFIGURE = 6 // Configuration process in session.

FAULT = 7 // System Faulted, OSSD's are OFF.

DIRTY_WINDOW = 0 // Dirty window cause system to stop.

ZONE_SELECT_NUM_ACTIVE = 1 // Invalid zone inputs, with wrong number

of active inputs.

ZONE_SELECT_INVALID = 2 // Invalid zone inputs, with correct

number of active inputs.

QUALIFIED_ZONE_VIOLATION = 3 // Qualified protection zone violation.

STAND_BY_REQUEST = 4 // Stand-by requested.

RX_ERROR = 5 // Receiver error

TOO_CLEAN_WINDOW = 6 // Too clean window caused system to

stop.

NOT IN MACHINE STOP_1 = 7 // System currently not in stop mode

SYSTEM FAULTED = 8 // The system faulted, check display

code

NOT IN MACHINE STOP_2 = 9 // System currently not in stop mode

AZS_01 = 0 (0x00)

...

AZS_70 = 69 (0x45)

INVALID AZS = 32,768 (0x8000)

Zinput 1 = bit 0

Zinput 2 = bit 1

Zinput 3 = bit 2

Zinput 4 = bit 3

Zinput 5 = bit 4

Zinput 6 = bit 5

Zinput 7 = bit 6

Zinput 8 = bit 7

32

32

)

) us

18

OS32C with EtherNet/IP & Measurement Data Addendum

Page 26

EtherNet/IP Input Assembly Data

Introduction

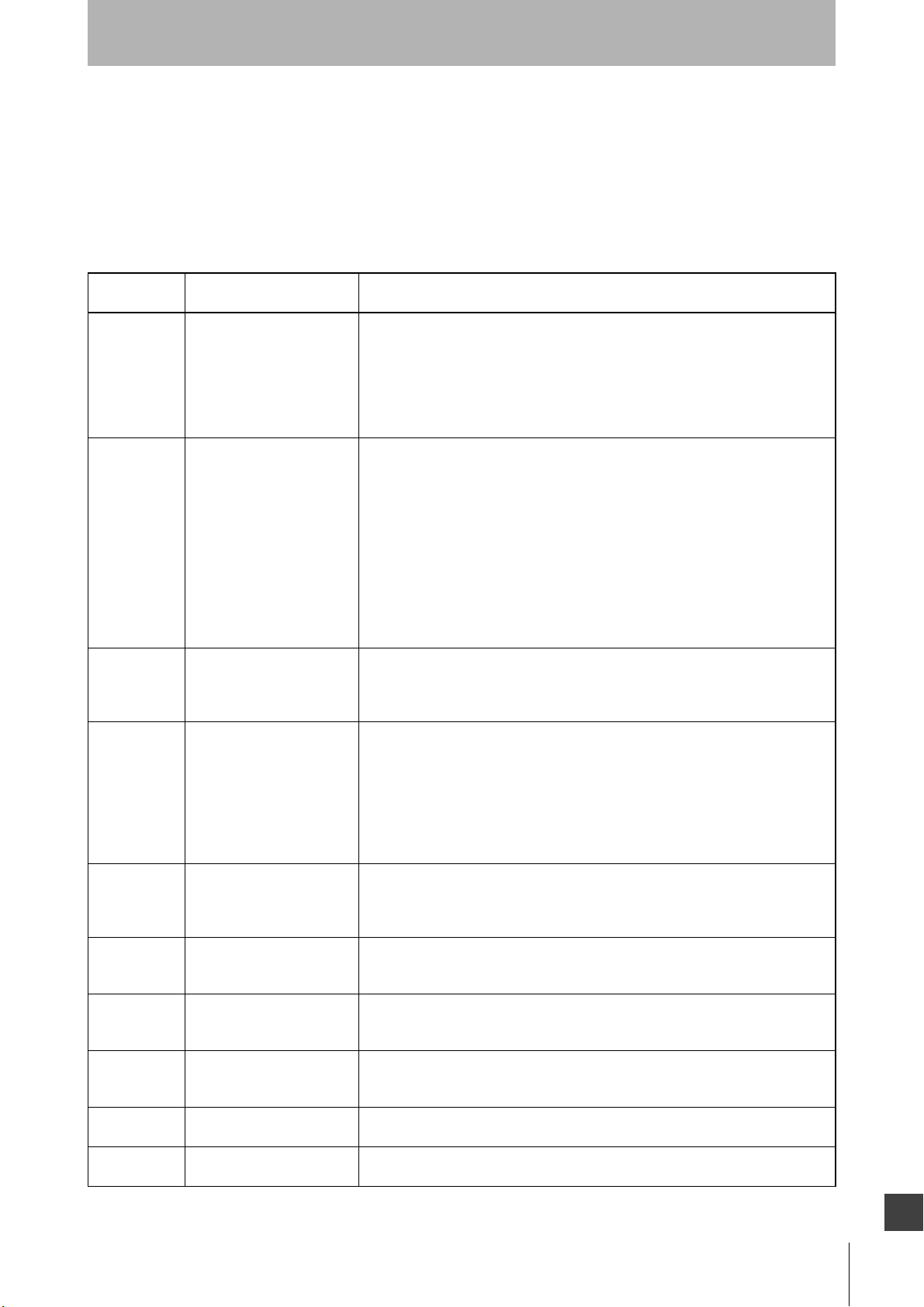

Word #

(16-bit)

12

13

14

15

16

17

18

19 Unused For future use.

20 Unused For future use.

21 Unused For future use.

22 Unused For future use.

23 Unused For future use.

24

25

26

27 Number of Beams 0x72, 1, 17 (0x11) Number of measurement beams in report.

Description

Detection Zone

Status

Data Type: WORD

16-bit

Output Status

Data Type: WORD

16-bit

Input Status

Data Type: WORD

16-bit

Seven Segment

Display

Data Type: UINT

16-bit

Non-Safety

Configuration

Checksum Value

Data Type: UINT

16-bit

Safety

Configuration

Checksum Value

Data Type: UINT

16-bit

Active Warning

Zone Set

Data Type : UINT

16-bit

Range Report

Format

Data Type: UINT

16-bit

Reflectivity Report

Format

Data Type: UINT

16-bit

Range Report

Mode

Data Type : UINT

16-bit

Vendor Specific

Object x, Instance

y, Attribute

Number z

0x70, 1, 8

0x70, 1, 9

0x70, 1, 10 (0x0A)

0x70, 1, 11 (0x0B)

0x70, 1, 12 (0x0C)

0x70, 1, 13 (0x0D)

0x70, 1, 14 (0x0E)

0x72, 1, 4

0x72, 1, 5

0x72, 1, 6 (0x06)

Enumeration / Possible Values

Protection Zone = bit 0

Warning Zone #1 = bit 1

Warning Zone #2 = bit 2

Window Contamination = bit 3

OSSD Output = bit 0

Auxiliary Output = bit 1

Warning Output = bit 2

StandBy Input = bit 0

Start Input = bit 1

EDM Input = bit 2

Digit Low followed by Digit High

Each Digit Displays 1 to 9 (0x01 to 0x09) for normal operation.

0x1B and 0x1B for dashes "--" during machine stop operation.

16-bit Non-Safety Configuration CRC Value

16-bit Safety Configuration CRC Value

AZS_01 = 0 (0x00)

…

AZS_70 = 69 (0x45)

INVALID AZS = 32,768 (0x8000)

Report format of range data

Report format of reflectivity data

REPORT_RANGE_ONLY = 0 (default),

// Assembly 102 Report Range Only.

REPORT_RANGE_AND_REFLECTIVITY = 1, // Assembly 102 Report Range &

Reflectivity.

OS32C with EtherNet/IP & Measurement Data Addendum

E

19

Page 27

Introduction

EtherNet/IP Input Assembly Data

In addition to the common measurement report header defined in Table 8, Input Assembly 102 and

Vendor Specific Object 114 includes range measurement data for the selected area of interest. Using

explicit TCP/IP request/reply messages or an implicit UDP I/O connection the scanner can be

monitored at a repetition rate defined for the application.

4.9 Table 9: Input Assembly 102 and Vendor Specific Object 114 (max.

1410 bytes)

Range measurement data, variable size.

Size selected using the beam report mask configuration. (1)

Array Size = Number of Beams included in measurement report header,

maximum size = 677.

28 - 704

Range (TOF)

data[]

UINT 16-bit

In addition to the common measurement report header defined in Table 8, Input Assembly 103

includes reflectivity measurement data for the selected area of interest. Using explicit TCP/IP request/

reply messages or an implicit UDP I/O connection the scanner can be monitored at a repetition rate

defined for the application.

4.10 Table 10: Input Assembly 103 and Vendor Specific Object 116 (max.

1410 bytes)

Reflectivity (TOT)

28 - 704

data[]

UINT 16-bit

In addition to the common measurement report header defined in Table 8, Vendor Specific Object 117

includes both range and reflectivity measurement data for the selected area of interest. Since UDP I/O

messages are limited to less than 1500 bytes this assembly can only be provided using explicit TCP/IP

request/reply messages. The scanner will respond to each request immediately after the next scan

period.

Reflectivity measurement data, variable size.

Size selected using the beam report mask configuration. (1)

Array Size = Number of Beams included in measurement report header,

maximum size = 677.

20

4.11 Table 11: Vendor Specific Object 117 (max. 2764 bytes)

Range (TOF)

28 - 704

705-1381

Note *1. See section Table 4: Output Assembly 113 and Vendor Object 115 (104 bytes), Measurement Report Configuration for Input

Assembly 102 & 103 for beam selection mask usage.

*2. Vendor Specific Assembly reports are synchronous with the scan period of the scanner.

data[]

UINT 16-bit

Reflectivity (TOT)

data[]

UINT 16-bit

OS32C with EtherNet/IP & Measurement Data Addendum

Range measurement data, variable size.

Size selected using the beam report mask configuration. *1. *2.

Array Size = Number of Beams included in measurement report header,

maximum size = 677.

Reflectivity measurement data, variable size.

Size selected using the beam report mask configuration. *1. *2.

Array Size = Number of Beams included in measurement report header,

maximum size = 677.

Page 28

EtherNet/IP Input Assembly Data

In addition to the common measurement report header defined in Table 8, Input Assembly 104

includes range measurement data for the selected area of interest. Using explicit TCP/IP request/reply

messages or an implicit UDP I/O connection the scanner can be monitored at a repetition rate defined

for the application.

4.12 Table 12: Input Assembly 104 (max. 960 bytes)

Introduction

Range (TOF)

28 - 479

* See Table 5: Output Assembly 114 (108 bytes), Measurement Report Configuration for Input Assembly 104 & 105 for beam selection

mask usage.

data[]

UINT 16-bit

Range measurement data, variable size.

Size selected using the beam report mask configuration. *

Array Size = Number of Beams included in measurement report header,

maximum size = 452 without tags.

In addition to the common measurement report header defined in Table 8, Input Assembly 105

includes reflectivity measurement data for the selected area of interest. Using explicit TCP/IP request/

reply messages or an implicit UDP I/O connection the scanner can be monitored at a repetition rate

defined for the application.

4.13 Table 13: Input Assembly 105 (max. 960 bytes)

Reflectivity (TOT)

28 - 479

* See Table 5: Output Assembly 114 (108 bytes), Measurement Report Configuration for Input Assembly 104 & 105 for beam selection

mask usage.

data[]

UINT 16-bit

Input Assembly 106 includes range measurement data for the selected area of interest. Using explicit

TCP/IP request/reply messages or an implicit UDP I/O connection the scanner can be monitored at a

repetition rate defined for the application.

Reflectivity measurement data, variable size.

Size selected using the beam report mask configuration. *

Array Size = Number of Beams included in measurement report header,

maximum size =452 without tags.

4.14 Table 14: Input Assembly 106 (max. 554 bytes)

Range (TOF)

0 - 276

* See Table 6 : Output Assembly 115 (316 bytes), Measurement Report Configuration for Input Assembly 106 through 111

data[]

UINT 16-bit

Input Assembly 107 includes reflectivity measurement data for the selected area of interest. Using

explicit TCP/IP request/reply messages or an implicit UDP I/O connection the scanner can be

monitored at a repetition rate defined for the application.

Range measurement data, variable size.

Size selected using the beam report mask configuration. *

Array Size = Number of Beams included in measurement report header,

maximum size = 277 without tags.

4.15 Table 15: Input Assembly 107 (max. 554 bytes)

Reflectivity measurement data, variable size.

Reflectivity (TOT)

0 - 276

* See Table 6 : Output Assembly 115 (316 bytes), Measurement Report Configuration for Input Assembly 106 through 111

data[]

UINT 16-bit

Size selected using the beam report mask configuration. *

Array Size = Number of Beams included in measurement report header,

maximum size =277 without tags.

OS32C with EtherNet/IP & Measurement Data Addendum

E

21

Page 29

Introduction

EtherNet/IP Input Assembly Data

Input Assembly 108 includes range measurement data for the selected area of interest. Using explicit

TCP/IP request/reply messages or an implicit UDP I/O connection the scanner can be monitored at a

repetition rate defined for the application.

4.16 Table 16: Input Assembly 108 (max. 454 bytes)

Range (TOF)

0 - 226

* See Table 6 : Output Assembly 115 (316 bytes), Measurement Report Configuration for Input Assembly 106 through 111

data[]

UINT 16-bit