Page 1

Cat. No. W342-E1-14

SYSMAC CS/CJ/CP Series

SYSMAC One NSJ Series

Communications Commands

REFERENCE MANUAL

Page 2

Page 3

SYSMAC CS/CJ/CP Series

CS1G/H-CPU@@H

CS1G/H-CPU@@-EV1

CS1D-CPU@@H

CS1D-CPU@@S

CS1W-SCB@@-V1

CS1W-SCU@@-V1

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ1H-CPU@@H-R

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1G-CPU@@

CJ1M-CPU@@

CJ1W-SCU@@-V1

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

CP1L-M/L@@@-@

CP1E-E@@D@-@

CP1E-N@@D@-@

SYSMAC One NSJ Series

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Communications Commands

Reference Manual

Revised July 2009

Page 4

iv

Page 5

Notice:

f

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this

manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also

capitalized when it refers to an OMRON product, regardless of whether or not

it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON

products, often means “word” and is abbreviated “Wd” in documentation in

this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

© OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

The following headings appear in the left column of the manual to help you

locate different types of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

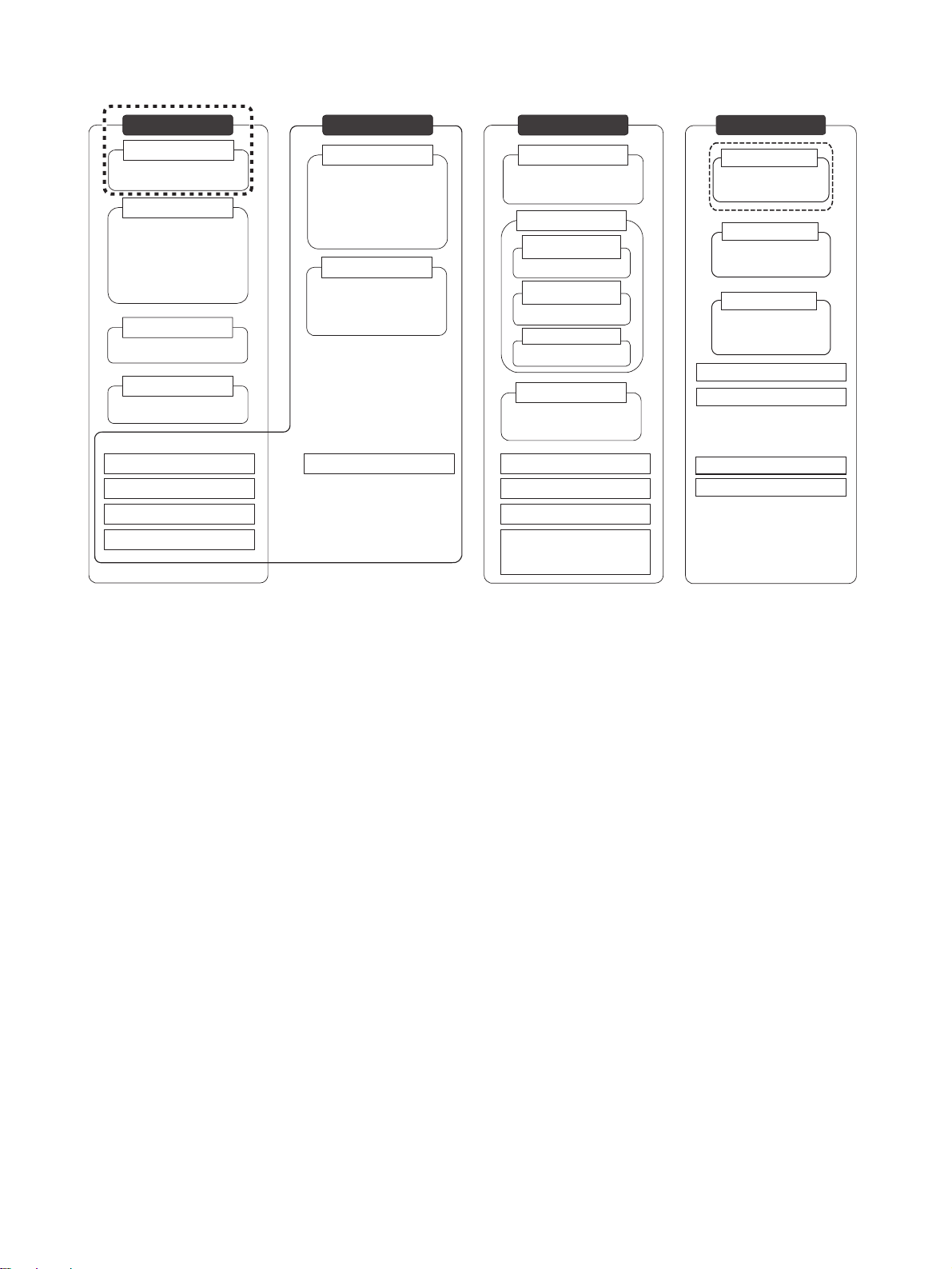

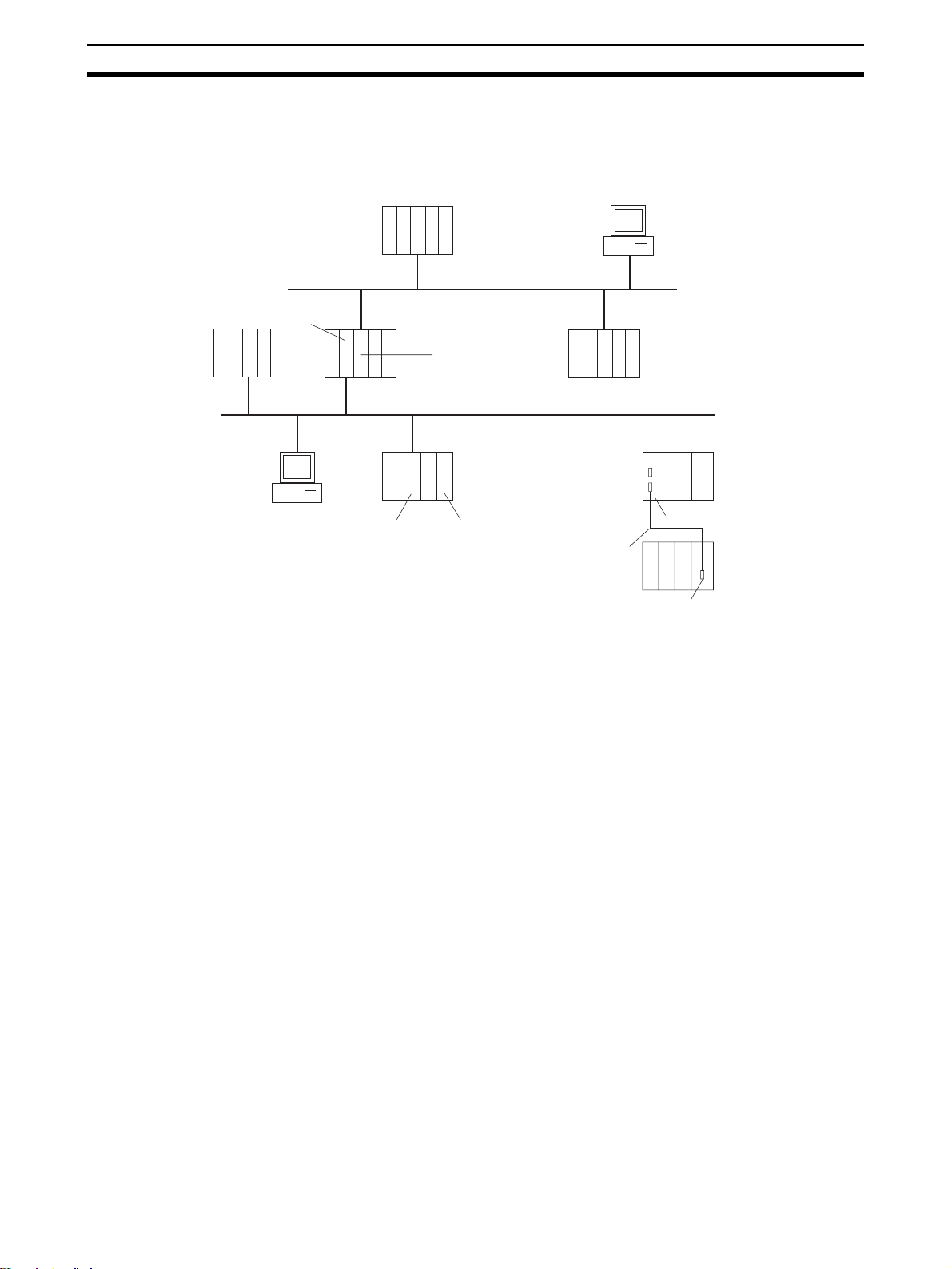

CJ Series

CJ2 CPU Units

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ1-H CPU Units

CJ1H-CPU@@H-R

CJ1H-CPU@@H

CJ1G-CPU@@H

CJ1G-CPU@@P

(Loop CPU Units)

CJ1M CPU Units

CJ1M-CPU@@

CJ1 CPU Units

CJ1G-CPU@@

NSJ Series

NSJ Controllers

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

NSJ Controllers

NSJ5-TQ@@(B)-M3D

NSJ5-SQ@@(B)-M3D

NSJ8-TV@@(B)-M3D

CS Series

CS1-H CPU Units

CS1H-CPU@@H

CS1G-CPU@@H

CS1D CPU Units

CS1D CPU Units for

Duplex Systems

CS1D-CPU@@H

CS1D CPU Units for

Simplex Systems

CS1D-CPU@@S

CS1D Process-control CPU Units

CS1D-CPU@@P

CS1 CPU Units

CS1H-CPU@@(-V)

CS1G-CPU@@ (-V)

CP Series

CP1E CPU Units

CP1E-E@@D@-@*2

CP1E-N@@D@-@*3

CP1L CPU Units

CP1L-L @@D@-@

CP1L-M@@D@-@

CP1H CPU Units

CP1H-X@@D@-@

CP1H-XA@@D@-@

CP1H-Y@@DT-D

CP-series Expansion I/O Units

CP-series Expansion Units

CJ-series Basic I/O Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

CJ-series Power Supply Units

NSJ-series Expansion Units

CS-series Basic I/O Units

CS-series Special I/O Units

CS-series CPU Bus Units

CS-series Power Supply Units

Note: A special Power Supply Unit

must be used for CS1D CPU Units.

CJ-series Special I/O Units*1

CJ-series CPU Bus Units*1

*1 Can only be used with the CP1H CPU unit.

*2 Indicated as "E-type" in some parts of this manual.

*3 Indicated as "N-type" in some parts of this manual.

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview of Communications Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 C-mode Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-3 FINS Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Overview of C-mode Commands . . . . . . . . . . . . . . . . . . . . . 7

2-1 C-mode Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2-2 Command/Response Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-3 Application Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-4 Precautions when Reusing Programs from Earlier Models . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION 3

Overview of FINS Commands. . . . . . . . . . . . . . . . . . . . . . . . 27

3-1 FINS Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-2 Using FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-3 FINS Command and Response Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-4 Settings for Sending FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-5 FINS Commands with Host Link Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-6 Serial Gateway Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-7 Communications Frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

SECTION 4

C-mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4-1 C-mode Command List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4-2 End Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4-3 C-mode Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

SECTION 5

FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

5-1 Command Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

5-2 Designating Command Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5-3 FINS Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

vii

Page 8

viii

Page 9

About this Manual:

This manual describes the C-series (Host Link) and FINS communications commands used with CS/

CJ-series and CP-series Programmable Controllers (PLCs) and NSJ Controllers, and includes the

sections described below.

Please read this manual and all related manuals listed in the following table and be sure you understand information provided before attempting to design or implement communications for CS/CJ-series

or CP-series Programmable Controllers (PLCs) or NSJ Controllers.

Name Cat. No. Contents

SYSMAC CS/CJ/CP/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1H-CPU@@H-R,

CJ1G-CPU@@, CJ1M-CPU@@, CJ1G-CPU@@P,

CJ1G/H-CPU@@H, CJ2H-CPU6@-EIP, CJ2H-CPU6@,

CS1W-SCU@@-V1, CS1W-SCB@@-V1, CJ1W-SCU@@-V1,

CP1H-X@@@@-@, CP1H-XA@@@@-@, CP1H-Y@@@@-@,

CP1L-M/L@@@-@, CP1E-E@@D@-@,

CP1E-N@@D@-@, NSJ@-@@@@(B)-G5D,

NSJ@-@@@@(B)-M3D

Communications Commands Reference Manual

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H, CS1DCPU@@H, CS1D-CPU@@S, CJ2H-CPU6@-EIP, CJ2HCPU6@, CJ1H-CPU@@H-R, CJ1G-CPU@@, CJ1MCPU@@, CJ1G-CPU@@P, C J 1G /H -C P U @@H, NSJ@-

@@@@(B)-G5D, NSJ@-@@@@(B)-M3D

Programmable Controllers Instructions Reference Manual

SYSMAC CS/CJ/NSJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1G-CPU@@,

CJ1M-CPU@@, CJ1G-CPU@@

NSJ@-@@@@(B)Programmable Controllers Programming Manual

SYSMAC CS Series

CS1D-CPU@@H CPU Units

CS1D-CPU@@S CPU Units

CS1D-DPL01 Duplex Unit

CS1D-PA207R Power Supply Unit

Duplex System Operation Manual

SYSMAC CS Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CJ Series

CJ1G-CPU@@, CJ1M-CPU@@, CJ1G-CPU@@P, CJ 1G / H CPU@@H

Programmable Controllers Operation Manual

SYSMAC CJ Series

CJ1M-CPU@@

Built-in I/O Operation Manual

G5D, NSJ@-@@@@(B)-M3D

P, CJ 1G /H - C P U @@H,

W342 Describes the communications commands used

with CS-series, CJ-series, and CP-series PLCs

and NSJ Controllers. (This manual)

W474 Describes the ladder diagram programming

instructions supported by CS/CJ-series PLCs and

NSJ Controllers.

W394 This manual describes programming and other

methods to use the functions of the CS/CJ-series

PLCs and NSJ Controllers.

W405 Provides an outline of and describes the design,

installation, maintenance, and other basic operations for a Duplex System based on CS1D CPU

Units.

W339 Provides an outlines of and describes the design,

installation, maintenance, and other basic operations for the CS-series PLCs.

W393 Provides an outlines of and describes the design,

installation, maintenance, and other basic operations for the CJ-series PLCs.

W395 Describes the functions of the built-in I/O for

CJ1M CPU Units.

ix

Page 10

Name Cat. No. Contents

SYSMAC CJ Series CJ2H-CPU6@-EIP, CJ2H-CPU6@

CPU Unit Software User’s Manual

SYSMAC CJ Series CJ2H-CPU6@-EIP, CJ2H-CPU6@

CPU Unit Hardware User’s Manual

SYSMAC CS/CJ Series CS1W-EIP21, CJ1W-EIP21,

CJ2H-CPU6@-EIP

EtherNet/IP Units Operation Manual

SYSMAC One NSJ Series

NSJ5-TQ@@(B)-G5D, NSJ5-SQ@@(B)-G5D, NSJ8TV@@(B)-G5D, NSJ10-TV@@(B)-G5D, NSJ12-TS@@(B)-

G5D, NSJ5-TQ@@(B)-M3D, NSJ5-SQ@@(B)-M3D, NSJ8-

TV@@(B)-M3D, NSJW-ETN21, NSJW-CLK21-V1, NSJWIC101

NSJ Controllers Operation Manual

SYSMAC CP Series

CP1H-X40D@-@, CP1H-XA40D@-@,

CP1H-Y20DT-D

CP1H CPU Unit Operation Manual

SYSMAC CP Series

CP1H-X@@@@-@, CP1H-XA@@@@-@,

CP1H-Y@@@@-

CP1H CPU Uni

SYSMAC CP Series

CP1L-L10D@-@,

CP1L-L14D@-@,

CP1L-L20D@-@,

CP1L-M30D@-@,

CP1L-M40D@-@,

CP1L-M60D@-@

CP1L CPU Unit Operation Manual

SYSMAC CP Series CP1E CPU Unit Hardware User's

Manual

CP1E-E@@D@-@

CP1E-N@@D@-@

@

t Programming Manual

W473 Describes the following for CJ2 CPU Units:

• CPU Unit operation

• Internal memory

• Programming

• Settings

• Function built into the CPU Unit

Also refer to the Hardware User's Manual (W472)

W472 Describes the following for CJ2 CPU Units:

• Overview and features

• Basic system configuration

• Part nomenclature and functions

• Mounting and setting procedure

• Remedies for errors

Also refer to the Software User's Manual (W473)

W465 Describes the built-in EtherNet/IP port and Ether-

Net/IP Units.

Describes basic settings, tag data links, FINS

communication, and other functions.

W452 Provides basic specifications on NSJ Controllers,

including an overview, designing, installation, and

maintenance.

W450 Provides basic specifications on CP-series CP1H

PLCs, including an overview, designing, installation, and maintenance.

W451 Provides information on programming CP-series

PLCs.

W462 Provides basic specifications on CP-series CP1L

PLCs, including an overview, designing, installation, and maintenance.

W479 Describes the following information for CP1E

PLCs.

• Overview and features

• Basic system configuration

• Part names and functions

• Installation and settings

• Troubleshooting

x

Page 11

Name Cat. No. Contents

SYSMAC CP Series CP1E CPU Unit Software User's

Manual

CP1E-E@@D@-@

CP1E-N@@D@-@

SYSMAC CP Series CP1E CPU Unit Instructions

Reference Manual

CP1E-E@@D@-@

CP1E-N@@D@-@

SYSMAC CXONE-AL@@C-V@/AL@@D-V@

CX-One FA Integrated Tool Package Setup Manual

SYSMAC

CXONE-AL@@C-V@/, CXONE-AL@@D-V@, CS/CJ/CP/

NSJ Series

CX-Integrator Operation Manual

SYSMAC

WS02-CX@@-V@

CX-Programmer Operation Manual

SYSMAC CX-Programmer

WS02-CX@@-V@

Operation Manual: Function Blocks/Structured Text

SYSMAC

WS02-CX@@-V@

CX-Programmer Operation Manual: SFC

W480 Describes the following information for CP1E

PLCs.

• CPU Unit operation

• Internal memory

• Programming

• Settings

• CPU Unit built-in functions

• Interrupts

• High-speed counter inputs

• Pulse outputs

• Serial communications

• Other functions

W483 Describes each programming instruction in detail.

W463 Provides an overview of the CX-One FA Inte-

grated Tool Package and CX-One installation procedures.

W464 Describes setting and monitoring networks.

W446 Describes operating procedures for the CX-Pro-

grammer Support Software running on a Windows computer.

W447 Describes specifications and procedures required

to use function blocks/structured text.

W469 Describes specifications and procedures required

to use SFC programming functions.

Section 1 introduces the C-mode commands and FINS commands, and explains the relationship

between them.

Section 2 provides an overview of C-mode commands.

Section 3 provides an overview of FINS commands.

Section 4 provides detailed descriptions of the C-mode commands.

Section 5 provides detailed descriptions of the FINS commands.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xi

Page 12

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xii

Page 13

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xiii

Page 14

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiv

Page 15

PRECAUTIONS

This section provides general precautions for using the CS/CJ-series Programmable Controllers (PLCs) and related devices.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

xv

Page 16

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

xvi

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

Page 17

Safety Precautions 3

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V-DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!Caution Confirm safety before transferring data files stored in the file memory (Mem-

ory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a

peripheral tool. Otherwise, the devices connected to the output unit may malfunction regardless of the operation mode of the CPU Unit.

!Caution Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Serious accidents may

result from abnormal operation if proper measures are not provided.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution The CS1-H, CJ1-H, CJ1M, or CS1D CPU Unit automatically backs up the

user program and parameter data to flash memory when these are written to

the CPU Unit. I/O memory (including the DM, EM, and HR Areas), however, is

not written to flash memory. The DM, EM, and HR Areas can be held during

power interruptions with a battery. If there is a battery error, the contents of

these areas may not be accurate after a power interruption. If the contents of

the DM, EM, and HR Areas are used to control external outputs, prevent inappropriate outputs from being made whenever the Battery Error Flag (A402.04)

is ON.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

xvii

Page 18

Operating Environment Precautions 4

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. Loose screws may result in burning

or malfunction.

!Caution Do not touch the Power Supply Unit when power is being supplied or immedi-

ately after the power supply is turned OFF. The Power Supply Unit will be hot

and you may be burned.

!Caution Be careful when connecting personal computers or other peripheral devices

to a PLC to which is mounted a non-insulated Unit (CS1W-CLK12/52(-V1) or

CS1W-ETN01) connected to an external power supply. A short-circuit will be

created if the 24 V side of the external power supply is grounded and the 0 V

side of the peripheral device is grounded. When connecting a peripheral

device to this type of PLC, either ground the 0 V side of the external power

supply or do not ground the external power supply at all.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xviii

Page 19

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the PLC System.

• You must use the CX-Programmer (programming software that runs on

Windows) if you need to program more than one task. A Programming

Console can be used to program only one cyclic task plus interrupt tasks.

A Programming Console can, however, be used to edit multitask programs originally created with the CX-Programmer.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a class-3 ground (to 100 Ω or less) when installing the

Units. Not connecting to a class-3 ground may result in electric shock.

• A class-3 ground (to 100 Ω or less) must be installed when connecting the

GR and LG terminals on the Power Supply Unit.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Inner Boards, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• The user program and parameter area data in the CS1-H, CS1D, CJ1-H,

and CJ1M CPU Units are backed up in the built-in flash memory. The

BKUP indicator will light on the front of the CPU Unit when the backup

operation is in progress. Do not turn OFF the power supply to the CPU

Unit when the BKUP indicator is lit. The data will not be backed up if

power is turned OFF.

• When using a CS-series CS1 CPU Unit for the first time, install the

CS1W-BAT01 Battery provided with the Unit and clear all memory areas

from a Programming Device before starting to program. (Not required for

CS1-H, CJ1, CJ1-H, CJ1M, or CS1D CPU Units.)

• When using the internal clock for a CS-series CS1 CPU Unit, turn ON

power after installing the battery and set the clock from a Programming

Device or using the DATE(735) instruction. The clock will not start until the

time has been set. (Not required for CS1-H, CJ1, CJ1-H, CJ1M, or CS1D

CPU Units.)

• When using a CS1-H, CJ1, CJ1-H, CJ1M, or CS1D CPU Unit, the PLC

Setup is set to specify using the mode set on the Programming Console,

and a Programming Console is not connected, the CPU Unit will start in

RUN mode. This is the default setting in the PLC Setup. A CS1 CPU Unit

will start in PROGRAM mode under the same conditions.

xix

Page 20

Application Precautions 5

• When creating an AUTOEXEC.IOM file from a Programming Device (a

Programming Console or the CX-Programmer) to automatically transfer

data at startup, set the first write address to D20000 and be sure that the

size of data written does not exceed the size of the DM Area. When the

data file is read from the Memory Card at startup, data will be written in

the CPU Unit starting at D20000 even if another address was set when

the AUTOEXEC.IOM file was created. Also, if the DM Area is exceeded

(which is possible when the CX-Programmer is used), the remaining data

will be written to the EM Area.

• Always turn ON power to the PLC before turning ON power to the control

system. If the PLC power supply is turned ON after the control power supply, temporary errors may result in control system signals because the

output terminals on DC Output Units and other Units will momentarily turn

ON when power is turned ON to the PLC.

• Fail-safe measures must be taken by the customer to ensure safety in the

event that outputs from Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Do not turn OFF the power supply to the PLC when data is being transferred. In particular, do not turn OFF the power supply when reading or

writing a Memory Card. Also, do not remove the Memory Card when the

BUSY indicator is lit. To remove a Memory Card, first press the memory

card power supply switch and then wait for the BUSY indicator to go out

before removing the Memory Card.

• If the I/O Hold Bit is turned ON, the outputs from the PLC will not be

turned OFF and will maintain their previous status when the PLC is

switched from RUN or MONITOR mode to PROGRAM mode. Make sure

that the external loads will not produce dangerous conditions when this

occurs. (When operation stops for a fatal error, including those produced

with the FALS(007) instruction, all outputs from Output Unit will be turned

OFF and only the internal output status will be maintained.)

• The contents of the DM, EM, and HR Areas in the CPU Unit are backed

up by a Battery. If the Battery voltage drops, this data may be lost. Provide

countermeasures in the program using the Battery Error Flag (A402.04)

to re-initialize data or take other actions if the Battery voltage drops.

• When supplying power at 200 to 240 VAC for CS-series PLCs, always

remove the metal jumper from the voltage selector terminals. The product

will be destroyed if 200 to 240 VAC is supplied while the metal jumper is

attached.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

xx

Page 21

Application Precautions 5

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Separate the line ground terminal (LG) from the functional ground terminal (GR) on the Power Supply Unit before performing withstand voltage

tests or insulation resistance tests. Not doing so may result in burning.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

• With CS-series PLCs, be sure that all the Unit and Backplane mounting

screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Wire all connections correctly.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the

startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• Do not use commercially available RS-232C personal computer cables.

Always use the special cables listed in this manual or make cables

xxi

Page 22

Application Precautions 5

according to manual specifications. Using commercially available cables

may damage the external devices or CPU Unit.

• Never connect pin 6 (5-V power supply) on the RS-232C port on the CPU

Unit to any device other than an NT-AL001 or CJ1W-CIF11 Adapter. The

external device or the CPU Unit may be damaged.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in malfunction or damage.

• When transporting or storing circuit boards, cover them in antistatic material to protect them from static electricity and maintain the proper storage

temperature to protect the LSIs, ICs, and other components.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handled improperly.

• Do not short the battery terminals or charge, disassemble, heat, or incinerate the battery. Do not subject the battery to strong shocks. Doing any

of these may result in leakage, rupture, heat generation, or ignition of the

battery. Dispose of any battery that has been dropped on the floor or otherwise subjected to excessive shock. Batteries that have been subjected

to shock may leak if they are used.

• UL standards required that batteries be replaced only by experienced

technicians. Do not allow unqualified persons to replace batteries.

• Dispose of the product and batteries according to local ordinances as

they apply. Have qualified specialists properly dispose of used batteries

as industrial waste.

• With a CJ-series PLC, the sliders on the tops and bottoms of the Power

Supply Unit, CPU Unit, I/O Units, Special I/O Units, and CPU Bus Units

must be completely locked (until they click into place). The Unit may not

operate properly if the sliders are not locked in place.

• With a CJ-series PLC, always connect the End Plate to the Unit on the

right end of the PLC. The PLC will not operate properly without the End

Plate.

• Unexpected operation may result if inappropriate data link tables or

parameters are set. Even if appropriate data link tables and parameters

have been set, confirm that the controlled system will not be adversely

affected before starting or stopping data links.

• CPU Bus Units will be restarted when routing tables are transferred from

a Programming Device to the CPU Unit. Restarting these Units is required

to read and enable the new routing tables. Confirm that the system will

not be adversely affected before allowing the CPU Bus Units to be reset.

xxii

Page 23

SECTION 1

Introduction

This section introduces the C-mode commands and FINS commands, and explains the relationship between them.

1-1 Overview of Communications Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 C-mode Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 FINS Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1

Page 24

Overview of Communications Commands Section 1-1

1-1 Overview of Communications Commands

Communications Commands Addressed to CS/CJ/CP/NSJ-series Units

A CS/CJ/CP-series CPU Unit or NSJ Controller can receive the following

communications commands.

C-mode commands via Host Link

Communications commands

FINS commands

C-mode Commands C-mode commands are specialized Host Link communications commands.

They are issued by a host computer and sent to a CPU Unit. The devices that

can be connected for serial communications are the CPU Unit, a Serial Communications Unit, and a Serial Communications Board.

FINS Commands FINS commands are message service communications commands. They do

not depend on a particular transmission path. They can be used for communications on various networks (Controller Link, Ethernet, etc.) and for serial

communications (Host Link). They can be issued from a CPU Unit, Special I/O

Unit, or host computer, and they can also be sent to any of these. The specific

commands that can be sent depend on the destination.

This manual explains commands sent to CS/CJ/CP-series CPU Units and

NSJ Controllers, when the commands are issued from a CPU Unit or a host

computer connected by Host Link.

Via CMND(490)/SEND(090)/RECV(098)

Via Host Link

Note When the source of the commands is a CPU Unit, the FINS commands are

sent by means of CMND(490)/SEND(090)/RECV(098). When the source is a

host computer, the FINS commands are issued using Host Link protocol.

1-2 C-mode Commands

The following table lists the C-mode (Host Link) commands. For details, refer

to SECTION 4 C-mode Commands.

Type Header

I/O memory

reading

code

RR CIO AREA READ Reads the specified number of words beginning with the

RL LR AREA READ Reads the specified number of words beginning with the

RH HR AREA READ Reads the specified number of words beginning with the

RC TIMER/COUNTER PV READ Reads the specified number of words of the timer/counter

RG TIMER/COUNTER STATUS

READ

RD DM AREA READ Reads the specified number of words beginning with the

RJ AR AREA READ Reads the specified number of words beginning with the

RE EM AREA READ Reads the specified number of words beginning with the

Name Function

designated CIO word.

designated LR word.

designated HR word.

PV beginning with the designated word.

Reads the specified number of words of the timer/counter

status beginning with the designated word.

designated DM word.

designated AR word.

designated EM word.

2

Page 25

C-mode Commands Section 1-2

Type Header

I/O memory

writing

Timer/counter SV

reading

Timer/counter SV

changing

CPU Unit status MS STATUS READ Reads the CPU Unit’s operating conditions (operating

Forced

set/reset

PLC model code

reading

Testing TS TEST Returns, just as it is, a single block that was sent from the

Program area

accessing

code

WR CIO AREA WRITE Writes the specified data in word units beginning with the

WL LR AREA WRITE Writes the specified data in word units beginning with the

WH HR AREA WRITE Writes the specified data in word units beginning with the

WC TIMER/COUNTER PV WRITE Writes the specified timer/counter PV data in word units

WD DM AREA WRITE Writes the specified data in word units beginning with the

WJ AR AREA WRITE Writes the specified data in word units beginning with the

WE EM AREA WRITE Writes the specified data in word units beginning with the

R# TIMER/COUNTER SV READ 1Reads in four digits BCD the constant SV that is written as

R$ TIMER/COUNTER SV READ 2Finds the specified timer/counter instruction, beginning

R% TIMER/COUNTER SV READ 3Finds the specified timer/counter instruction, beginning

W# TIMER/COUNTER SV

CHANGE 1

W$ TIMER/COUNTER SV

CHANGE 2

W% TIMER/COUNTER SV

CHANGE 3

SC STATUS CHANGE Changes the CPU Unit’s operating mode.

MF ERROR READ Reads the CPU Unit’s error information (i.e., all fatal or

KS FORCED SET Forcibly sets one designated bit.

KR FORCED RESET Forcibly resets one designated bit.

FK MULTIPLE FORCED

SET/RESET

KC FORCED SET/RESET CAN-

CEL

MM PLC MODEL READ Reads the model code of the CPU Unit.

RP PROGRAM READ Reads, in one batch, the contents of the CPU Unit’s user

WP PROGRAM WRITE Writes into the CPU Unit’s user program area the

Name Function

designated CIO word.

designated LR word.

designated HR word.

beginning with the designated word.

designated DM word.

designated AR word.

designated EM word.

an operand of the designated timer/counter instruction.

with the designated program address, and reads the constant SV in four digits or the word in which the SV is

stored.

with the designated program address, and reads the constant SV in four digits (BCD) or the word in which the SV

is stored.

Changes the SV of the specified timer/counter instruction

to a new constant SV.

Finds the specified timer/counter instruction, beginning

with the designated program address in the user program,

and changes the constant SV in four digits (BCD) or the

word in which the SV is stored to a new constant SV or

storage word.

Finds the specified timer/counter instruction, beginning

with the designated program address in the user program,

and changes the constant SV in four digits (BCD) or the

word in which the SV is stored to a new constant SV or

storage word.

mode, forced set/reset status, and fatal errors).

non-fatal errors currently in effect).

Forcibly sets/resets/cancels multiple designated bits.

Cancels all forced set/reset status.

host computer.

program at the machine language (object) level.

machine language (object) sent from the host computer.

3

Page 26

FINS Commands Section 1-3

Type Header

I/O table creation MI I/O TABLE CREATE Creates an I/O table with the contents of the actual I/O

I/O memory area

registration and

reading

Host Link communications

processing

code

QQMR REGISTER I/O MEMORY Registers the I/O memory words or bits that are to be

QQIR READ I/O MEMORY Reads the registered I/O memory words/bits all at once.

XZ ABORT (command only) Aborts the operation being performed by a Host Link com-

** INITIALIZE (command only) Initializes the transfer control procedures for all Host Link

IC Undefined command

(response only)

Name Function

configuration.

read.

mand, and then returns to the initial status.

Units.

This is the response when the command header code

cannot be decoded.

1-3 FINS Commands

The following table lists the FINS commands. For details, refer to SECTION 5

FINS Commands.

Type Command

I/O memory area

access

Parameter area

access

Program area

access

Operating mode

changes

Machine configuration reading

Status reading 06 01 CPU UNIT STATUS READ Reads the status of the CPU Unit.

Time data access 07 01 CLOCK READ Reads the present year, month, date,

code

MR SR

01 01 MEMORY AREA READ Reads the contents of consecutive I/O mem-

01 02 MEMORY AREA WRITE (See

note.)

01 03 MEMORY AREA FILL (See note.) Writes the same data to the specified range

01 04 MULTIPLE MEMORY AREA READ Reads the contents of specified non-consec-

01 05 MEMORY AREA TRANSFER (See

note.)

02 01 PARAMETER AREA READ Reads the contents of consecutive parame-

02 02 PARAMETER AREA WRITE (See

note.)

02 03 PARAMETER AREA FILL (CLEAR)

(See note.)

03 06 PROGRAM AREA READ Reads the UM (User Memory) area.

03 07 PROGRAM AREA WRITE (See

note.)

03 08 PROGRAM AREA CLEAR (See

note.)

04 01 RUN (See note.) Changes the CPU Unit’s operating mode to

04 02 STOP (See note.) Changes the CPU Unit’s operating mode to

05 01 CPU UNIT DATA READ Reads CPU Unit data.

05 02 CONNECTION DATA READ Reads the model numbers of the device cor-

06 20 CYCLE TIME READ Reads the maximum, minimum, and average

07 02 CLOCK WRITE (See note.) Changes the present year, month, date,

Name Function

ory area words.

Writes the contents of consecutive I/O mem-

ory area words.

of I/O memory area words.

utive I/O memory area words.

Copies the contents of consecutive I/O mem-

ory area words to another I/O memory area.

ter area words.

Writes the contents of consecutive parame-

ter area words.

Clears the specified range of parameter area

words.

Writes to the UM (User Memory) area.

Clears a specified range of the UM (User

Memory) area.

RUN or MONITOR.

PROGRAM.

responding to addresses.

cycle time.

minute, second, and day of the week.

minute, second, or day of the week.

4

Page 27

FINS Commands Section 1-3

Type Command

Message display 09 20 MESSAGE READ/CLEAR Reads and clears messages, and reads

Access rights 0C 01 ACCESS RIGHT ACQUIRE (See

Error log 21 01 ERROR CLEAR (See note.) Clears errors or error messages.

FINS write access

log

File memory 22 01 FILE NAME READ Reads file device data.

Debugging 23 01 FORCED SET/RESET (See note.) Force-sets or force-resets bits, or releases

code

MR SR

note.)

0C 02 ACCESS RIGHT FORCED

ACQUIRE

0C 03 ACCESS RIGHT RELEASE Releases the access right that has been

21 02 ERROR LOG READ Reads the error log.

21 03 ERROR LOG CLEAR (See note.) Clears all error log records.

21 40 FINS WRITE ACCESS LOG READ The CPU Unit automatically keeps a log of

21 41 FINS WRITE ACCESS LOG

CLEAR (See note.)

22 02 SINGLE FILE READ Reads a specified length of file data from a

22 03 SINGLE FILE WRITE (See note.) Writes a specified length of file data from a

22 04 FILE MEMORY FORMAT (See

note.)

22 05 FILE DELETE (See note.) Deletes specified files stored in the file

22 07 FILE COPY (See note.) Copies files from one file device to another

22 08 FILE NAME CHANGE (See note.) Changes a file name.

22 0A MEMORY AREA–FILE TRANSFER

(See note.)

22 0B PARAMETER AREA–FILE TRANS-

FER (See note.)

22 0C PROGRAM AREA–FILE TRANS-

FER (See note.)

22 15 DIRECTORY CREATE/DELETE

(See note.)

22 20 MEMORY CASSETTE TRANS-

FER (CP1H/CP1L CPU Units only)

23 02 FORCED SET/RESET CANCEL

(See note.)

Name Function

FAL/FALS messages.

Acquires the access right as long as no other

device holds it.

Acquires the access right even if another

device already holds it.

acquire.

any access for FINS write commands. This

command reads this log.

Clears the FINS write access log.

specified position within a single file.

specified position within a single file.

Formats (initializes) the file device.

device.

file device in the same system.

Transfers or compares data between the I/O

memory area and the file device.

Transfers or compares data between the

parameter area and the file device.

Transfers or compares data between the UM

(User Memory) area and the file device.

Creates or deletes a directory.

Transfers and verifies data between a Memory Cassette and the CPU Unit.

force-set status.

Cancels all bits that have been force-set or

force-reset.

Note These commands will not be accepted and an end code of 2102 hex (cannot

write due to protection) will be returned if the Write Protection from FINS

Commands Sent to CPU Units via Networks option is selected in the PLC

Setup for a CS/CJ-series CPU Unit with unit version 2.0 or later, for a CPseries CPU Unit, or for an NSJ Controller.

5

Page 28

FINS Commands Section 1-3

6

Page 29

Overview of C-mode Commands

This section provides an overview of C-mode (Host Link) commands.

2-1 C-mode Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Command/Response Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-3 Application Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-4 Precautions when Reusing Programs from Earlier Models . . . . . . . . . . . . . . 15

2-4-1 C-series Host Link Units with 1:N Host Link Format Selected . . . . 15

2-4-2 C-series Host Link Units with 1:1 Host Link Format Selected . . . . 20

2-4-3 C-mode Command Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SECTION 2

7

Page 30

C-mode Commands Section 2-1

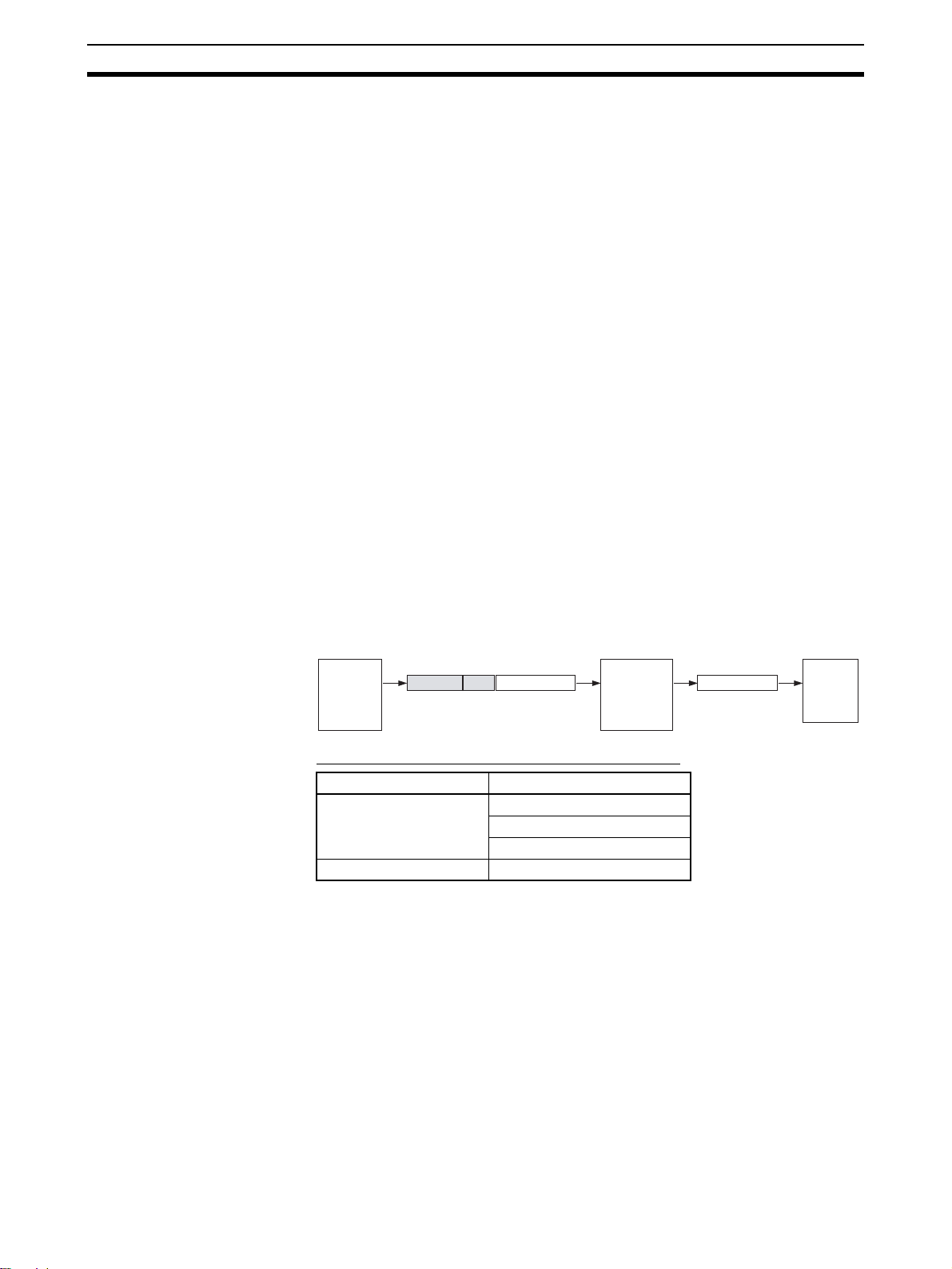

2-1 C-mode Commands

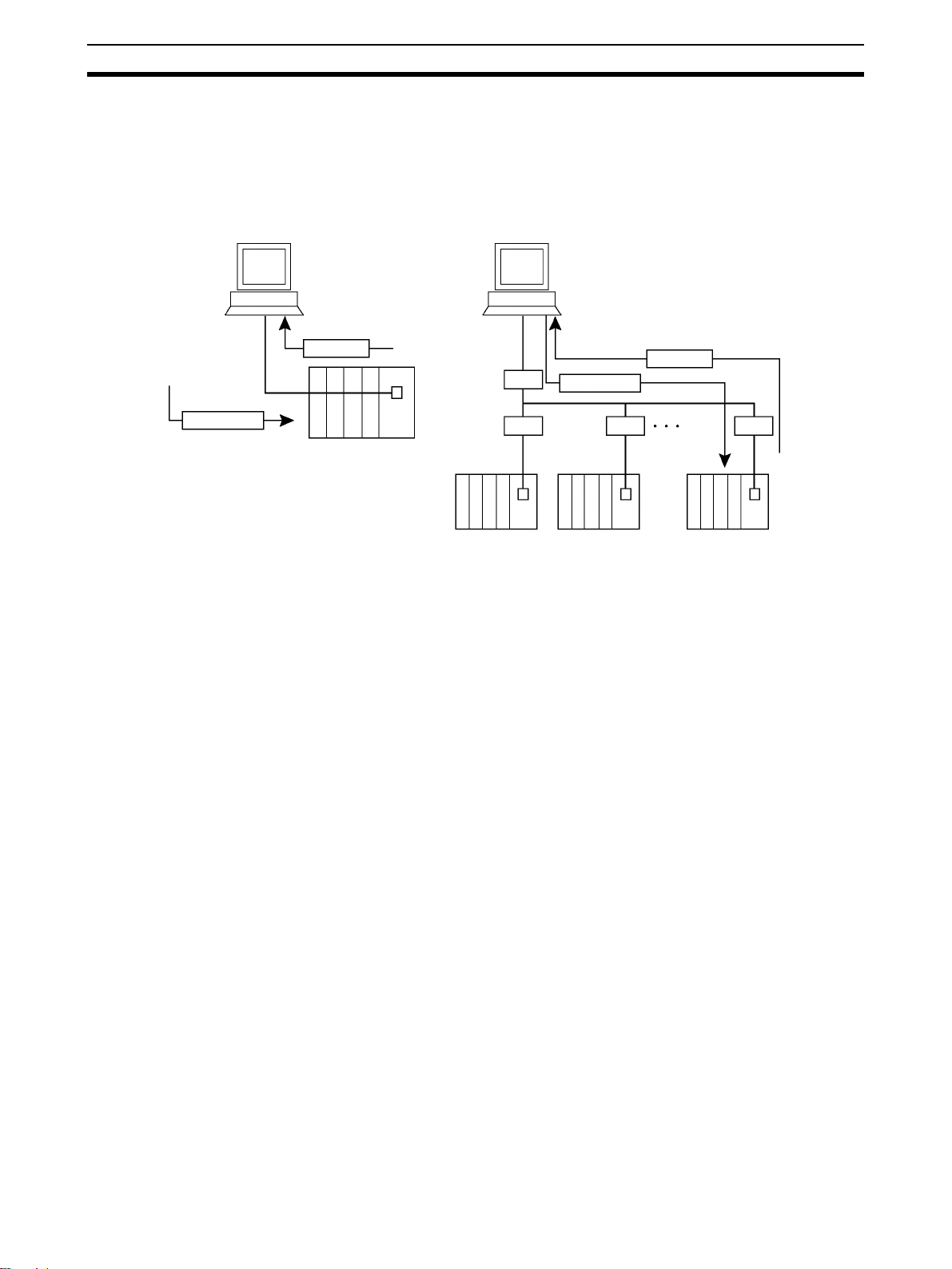

C-mode (Host Link) commands form a command/response system for serial

communications (Host Link Mode) to perform various control operations

between a CPU Unit and a host computer directly connected to it. These

operations include reading from and writing to I/O memory, changing operating modes, executing forced set and forced reset operations, and so on.

C-mode command

Response

C-mode command

Response

Note 1. There are two Host Link formats: the 1:N Host Link (with N ≥ 1) and the 1:1

Host Link.

• The 1:1 Host Link is the earlier Host Link format supported by C-series

PLCs, such as the C200H, C1000H, and C2000H.

• The built-in peripheral and RS-232C ports of CS/CJ-series CPU Units,

built-in serial ports of N-type CP1E CPU Units, serial port C on NSJ

Controllers, and serial ports 1 and 2 on the Option Board for CP-series

CPU Units support only the 1:N Host Link format. When a Serial Communications Board or Unit (version 1.2 or later) is being used, a 1:1

Host Link program created for a C-series PLC (C200H/C1000H/

C2000H) can be reused by selecting the Host Link 1:1 format.

In this manual, the term “Host Link” generally indicates the 1:N Host Link.

2. Unlike FINS commands, C-mode commands can only be addressed to a

CPU Unit, and they cannot be used for message service outside of the local network. They cannot be used for functions such as file operations.

C-mode (Host Link) commands can be sent from a host computer connected

to a CS/CJ-series Host Link Unit. Up to 32 PLCs (Host Link Units) can be connected to a single host computer. For identification, each Host Link Unit is

assigned a unit number from 0 to 31.

The length of a single unit of a command or response exchange is called a

“frame.” A single frame contains a maximum of 131 characters of data. Characters are sent and received as ASCII.

Note For a CS/CJ-series PLC, a “Host Link Unit” can be the CPU Unit, a Serial

Communications Unit, or a Serial Communications Board.

A maximum of 30 words of data can be transferred for the first command

frame and a maximum of 31 words of data can be transferred for other command frames when reading or writing word data in I/O memory. When reading/writing more than 30 words of data, the data transfer will be processed in

multiple transmissions, with 30 words in the first and up to 31 words in each of

8

Page 31

Command/Response Formats Section 2-2

)

the following transmissions until the number of words set in the command has

been processed.

The frame formats for Host Link commands sent from a host computer and

responses returned by the PLC receiving the commands are explained in the

following section.

2-2 Command/Response Formats

Single-frame Commands If a command is not more than 131 characters long, communications can be

completed by sending a single command frame. This is called a “single-frame

command.”

Command Frame Format

Terminator

Header code

Unit number (BCD)

Te xt

FCS

• @: Must be attached at the beginning of the command.

• Unit number: Set in BCD from 0 to 31 for each Host Link Unit.

• Header code: Specified in two characters.

• Text: Set parameters corresponding to command code.

• FCS: Calculate 2-character FCS (frame check sequence) at host

computer. For details on calculating FCS, refer to FCS Cal-

culations later in this section.

• Terminator: Set “*” and CR (CHR$(13)) as two characters to indicate

the end of the command.

Single-frame Response If a response is not more than 131 characters long, the communications can

be completed by returning one response frame. This is called a “single-frame

response.”

Response Frame Format

Header code

Unit number (BCD

End code (hexadecimal)

Te xt

FCS

• @: Must be attached at the beginning of the response.

• Unit number: Set in BCD from 0 to 31 for each Host Link Unit.

• Header code: The command code that was received is returned.

• End code: The results (error status, etc.) of command execution is

returned.

• Text: Returned only if there is read data.

Terminator

9

Page 32

Command/Response Formats Section 2-2

• FCS: The 2-character FCS (frame check sequence) is returned.

• Terminator: Two characters indicating the end of the command, “*” and

CR (CHR$(13)), are returned.

Error Response Formant If a reception error or an error in executing the command occurs, a response

is returned with no text.

Terminator

FCS

End code (hexadecimal)

Header code

Unit number (BCD)

Partitioned Commands If a command is longer than 131 characters, the command’s text is partitioned

by sending a delimiter [CR code, CHR$(13)] instead of a terminator at the end

of each command frame until the last one. A terminator is sent at the end of

the last frame. The procedure is given below for three command frames.

Note When sending command frames for writing (WR, WL, WC, WD, etc.), be care-

ful not to partition into separate frames data that is to be written into the same

word.

1,2,3... 1. From the host computer, attach a delimiter (CR) at the end of command

frame 1 and send the frame.

2. When the PLC receives this delimiter (CR), it will return only a delimiter

(CR) to the host computer.

3. From the host computer, attach a delimiter (CR) at the end of command

frame 2 and send the frame.

4. When the PLC receives this delimiter (CR), it will return only a delimiter

(CR) to the host computer.

5. From the host computer, attach a terminator (*CR) at the end of command

frame 3 and send the frame.

6. When the PLC receives this terminator (*CR), it will return the response

format with a terminator (*CR) attached to the end.

10

Page 33

Command/Response Formats Section 2-2

p

The following diagram shows the command format when there are more than

131 characters.

Command frame 1 Command frame 2 Command frame 3

Host

Computer

Header code

@Unit number

PLC

Te xt

FCS

Delimiter

128 characters max. 128 characters max.

Delimiter

FCS

Te xt

Delimiter

Delimiter

FCS

Te xt

Terminator

Te xt

FCS

Terminator

Header code

@Unit number

End code

Res

onse frame

Note A “delimiter” is a CR code [CHR$(13)] sent as a single character to indicate

the middle of a command or response.

Partitioned Responses If a response is more than 131 characters long, the response from the PLC is

partitioned by returning a delimiter (CR code, CHR$(13)) instead of a terminator at the end of each frame until the last one. A terminator is returned at the

end of the last frame.

In the following example procedure, the response is partitioned into three

frames.

1,2,3... 1. When the PLC receives the command frame from the host computer, it re-

turns response frame 1 with a delimiter (CR) at the end to the host computer.

2. Only a delimiter (CR) is sent from the host computer to the PLC.

3. When the PLC receives this delimiter (CR), it returns response frame 2

with a delimiter (CR) at the end to the host computer.

4. Only a delimiter (CR) is sent from the host computer to the PLC.

5. When the PLC receives this delimiter (CR), it returns response frame 3

with a terminator (*CR) at the end to the host computer.

11

Page 34

Command/Response Formats Section 2-2

The following diagram shows the response format when there are more than

131 characters.

Command frame

Te xt

FCS

Header code

Host computer

@Unit number

131 characters max.

Terminator

Delimiter

Delimiter

PLC

Te xt

End code

Header code

@Unit number

Response frame 1

FCS

Delimiter

Te xt

FCS

Delimiter

Response frame 2

128 characters max. 128 characters max.

Te xt

FCS

Terminator

Response frame 3

Note 1. Frames in partitioned commands or responses must have not more than

128 characters including the delimiter/terminator.

2. Delimiters from the host computer are detected by the presence of a CR

code. The delimiter will be detected even if there is data in front of it.

12

Page 35

Command/Response Formats Section 2-2

FCS Calculations The PLC calculates the FCS (Frame Check Sequence) value for each com-

mand frame it receives, and it checks for errors by comparing that value with

the FCS value sent with the command frame. The host computer must calculate the FCS value when sending a command frame.

Also, when checking for errors in response frames, the host computer must

calculate the FCS value for each response frame it receives and compare that

value to the FCS value sent in the response frame.

Header code

Unit number

FCS calculation range

ASCII

Code

@ 40 0100 0000

EOR

1 31 0011 0001

EOR

0 30 0011 0000

EOR

R 52 0101 0010

1 31 0011 0001

0100 0010

Calculation result

(See note.)

4 Hex

Te xt

•

•

•

Note The FCS is an 8-bit value converted into two ASCII characters. The 8-bit

value is the result of an exclusive OR sequentially performed between each

character in a transmission, from the first character in the frame to the last

character of the text in that frame. Non-ASCII data, however, may sometimes

be sent in the text data. If the data length is 7 bits, the leftmost bit of each

character is masked before the FCS is calculated.

2 Hex

Terminator

FCS

The value is converted to hexadecimal

and handled as ASCII.

13

Page 36

Application Example Section 2-3

2-3 Application Example

Sending a Host Link Command from a Host Computer

In this example program, a Host Link command is sent from a host computer

and a response is received.

10 ’CS1 SAMPLE PROGRAM FOR EXCEPTION

20 CLOSE

30 CLS

40 OPEN “COM:E73”AS#1

50 *KEYIIN

60 INPUT ”DATA

70 IF S$=””THEN GOTO 190

80 PRINT ”SEND DATA=”;S$

90 ST$=S$

100 INPUT ”SEND OK? Y or N?=”,BS

110 IF B$=”Y” THEN GOTO 130 ELSE GOTO *KEYIN

120 S$=ST$

130 PRINT #T,S$ Sends command to PLC.

140 INPUT #1,R$ Receives command from PLC.

150 PRINT ”RECV DATA=”;R$

160 IF MID$(R$,4,2)=”EX”THEN GOTO 210 Identifies command.

170 IF RIGHT$(R$,1)<>”*”THEN S$=””:GOTO 130

180 GOTO *KEYIN

190 CLOSE 1

200 END

210 PRINT ”EXCEPTION!!DATA”

220 GOTO 140

–”,S

Explanation

1,2,3... 1. The host computer’s transmission/reception program is started up, and the

Host Link command is input.

2. The Host Link command that was input is sent to the PLC, and the data

that is received is displayed on the screen.

Note The example program up to this point does not include an error processing

routine in case reception is not normal (e.g., if there is no FCS). Include error

processing routines when creating an actual program.

400 *FCSCHCK

410 L=LEN(RESPONSE$) Transmission/reception data

420 Q=0:FCSCK$=””

430 A$=RIGHT$(RESPONSE$,1)

440 PRINT RESPONSE$,A$,L

450 IF A$=”*”THEN LENGS=LEN(RESPONSE$)

ELSE LENGS=LEN(RESPONSE$)

460 FCSP$=MID$(RESPONSE$,LENGS+1,2) FCS data that is received

470 FOR I=1 TO LENGS Number of characters in FCS calculation

480 Q=ASC(MID$(RESPONSE$1,1))XOR Q

490 NEXT 1

500 FCSD$=HEX$(Q)

510 IF LEN(FCSD$) =1 THEN FCSD$=”0”+FCSD$ FCS calculation result

520 IF FCSD$<>FCSP$ THEN FCSCK$=”ERR”

530 PRINT ”FCSD$=”;FCSD$,”FCSP$=”;FCSP$,”FCSCK$=”;FCSCK$

Normal FCS reception: “ ” (space); abnormal FCS reception: “ERR”

540 RETURN

–2

–3

14

Page 37

Precautions when Reusing Programs from Earlier Models Section 2-4

2-4 Precautions when Reusing Programs from Earlier Models

Observe the following precautions when reusing host computer programs created for communications with C-series Host Link Units.

2-4-1 C-series Host Link Units with 1:N Host Link Format Selected

Using the CPU Unit's Built-in Peripheral Port or RS-232C Port

Number of Data Words per Frame

When I/O memory data is read with the following commands, the number of

data words in each response frame is different for a C-series Host Link Unit

compared to the built-in peripheral and RS-232C ports on CS/CJ-series CPU

Units, serial port C on NSJ Controllers, built-in serial ports of N-type CP1E

CPU Units, and serial ports 1 and 2 on the Option Board for CP-series CPU

Units.

With a C-series Host Link Unit, the first frame can contain up to 29 words of

data (text) and the following frames can contain up to 30 words of data (text).

With the built-in peripheral and RS-232C ports on CS/CJ-series CPU Units,

serial port C on NSJ Controllers, built-in serial ports of N-type CP1E CPU

Units, and serial ports 1 and 2 on the Option Board for CP-series CPU Units,

the first frame can contain up to 30 words of data (text) and the following

frames can contain up to 31 words of data (text).

Header code Name

RR CIO AREA READ

RL LR AREA READ

RH HR AREA READ

RC TIMER/COUNTER PV READ

RG TIMER/COUNTER STATUS READ

Note: The number of data words per response frame is different

for the RG command than for the other C-mode commands.

For details, see the table Words per Frame for C-mode RG

Command below.

RD DM AREA READ

RJ AR AREA READ

Because the Units do not have the same number of words per response

frame, the data may not be read properly if a host computer program originally

used with a C-series Host Link Unit is reused with a CS-series CPU Unit, CJseries CPU Unit, CP-series CPU Unit, or NSJ Controller. In this case, be sure

to edit the host computer program so that it is compatible with the frame format.

Note Serial Communications Boards and Units with version numbers 1.2 and later

are equipped with a Host Link model compatibility selection function that

changes the Host Link function's specifications to match the frame format of

other Units in the Host Link. It is not necessary to edit an existing program if

the Host Link model compatibility selection function is set to match the Host

Link format used in the program. For details, see Using a Serial Communica-

tions Board or Unit with Version Number 1.2 or Later below.

15

Page 38

Precautions when Reusing Programs from Earlier Models Section 2-4

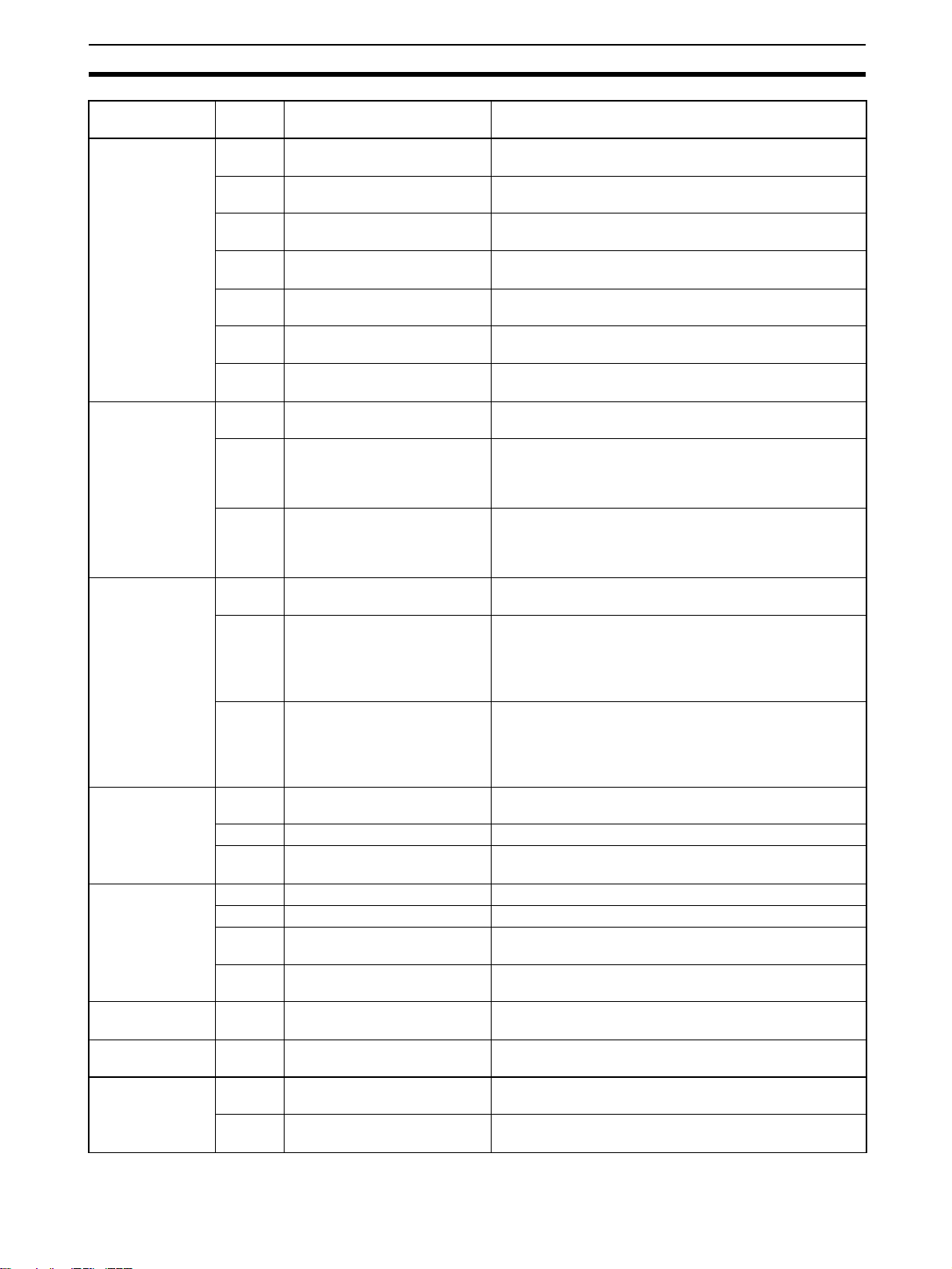

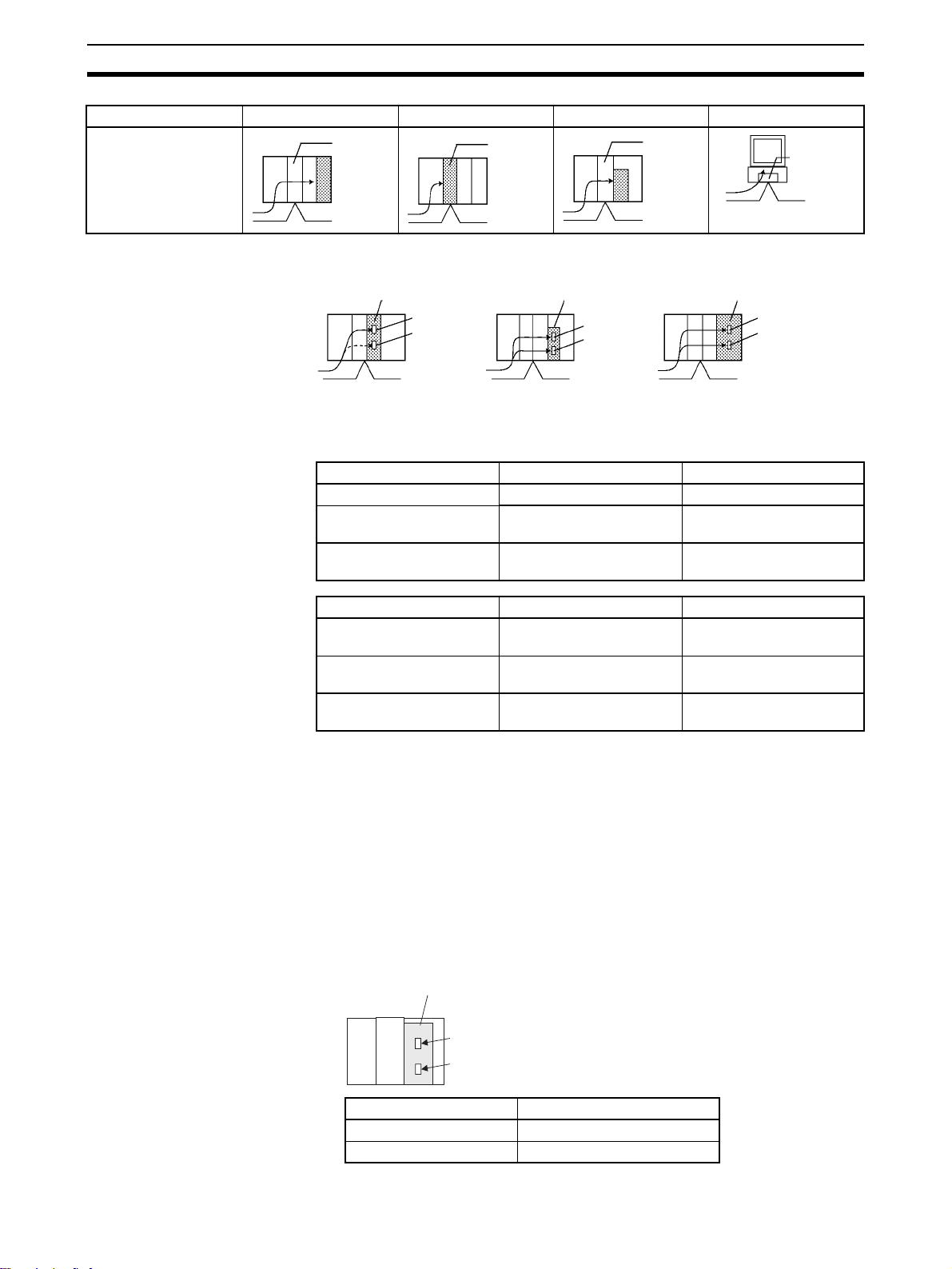

Words per Frame for C-mode Commands (Except RG Command)

Units C Series CS/CJ Series CVM1 and CV Series Data words per frame

C-series

Host Link

Units

Other

Boards and

Units

C200H-LK101/LK201/

LK202 Host Link Units

C500-LK103/LK203

Host Link Units

3G2A5-LK101/LK201

Host Link Units

3G2A6-LK101/LK201/

LK202 Host Link Units

SRM1 built-in ports

CPM1 built-in ports

CPM1A built-in ports

CQM1-CPU

ports

C200HS-CPU

in ports

C200HX/HG/HE-

CPU

C200HW-COM@@

Communications Board

ports

@@ built-in

@@ built-

@@ built-in ports

st

frame

1

--- --- 29 words 30 words

CS2H-CPU

built-in ports

CS1G/H-CPU

built-in ports

CS1G/H-CPU

built-in ports

CS1D-CPU

in ports

CJ1G/H-CPU

built-in ports

CJ1G-CPU@@ built-in

ports

CJ1M-CPU@@ built-in

ports

CS1W-SCB21-V1/

41-V1 (unit version:

Pre-Ver. 1.2) Serial

Communications Board

ports

CS1W-SCU21-V1 (unit

version: Pre-Ver. 1.2)

Serial Communications Unit ports

CJ1W-SCU21/41 (unit

version: Pre-Ver. 1.2)

Serial Communications Unit ports

@@(-EIP)

@@H

@@-EV1

@@H built-

@@H

CVM1-CPU

ports

CV-CPU

ports

CV500-LK201 Host

Link Unit

@@ built-in

@@ built-in

30 words 31 words

Other frames

16

Page 39

Precautions when Reusing Programs from Earlier Models Section 2-4

Words per Frame for C-mode RG Command

Units C Series CS/CJ Series CVM1 and CV Series Data words per frame

C-series

Host Link

Units

Other

Boards and

Units

C200H-LK101/LK201/

LK202 Host Link Units

C500-LK103/LK203

Host Link Units

3G2A5-LK101/LK201

Host Link Units

3G2A6-LK101/LK201/

LK202 Host Link Units

SRM1 built-in ports

CPM1 built-in ports

CPM1A built-in ports

CQM1-CPU

ports

CQM1H-CPU

in ports

CQM1H-SCB

in ports

C200HX/HG/HE-

CPU

C200HW-COM

Communications Board

ports

@@ built-in

@@ built-

@@ built-

@@ built-in ports

@@

st

frame

1

--- --- 89 words 89 words

--- --- 89 words 60 words

CS2H-CPU@@(-EIP)

built-in ports

CS1G/H-CPU

built-in ports

CS1G/H-CPU

built-in ports

CS1D-CPU

in ports

CJ1G/H-CPU

built-in ports

CJ1G-CPU@@ built-in

ports

CJ1M-CPU

ports

CS1W-SCB21-V1/41V1 (unit version: PreVer. 1.2) Serial Communications Board

ports

CS1W-SCU21-V1 (unit

version: Pre-Ver. 1.2)

Serial Communications Unit ports

CJ1W-SCU21/41 (unit

version: Pre-Ver. 1.2)

Serial Communications Unit ports

@@H

@@-EV1

@@H built-

@@H

@@ built-in

CVM1-CPU

ports

CV-CPU

ports

CV500-LK201 Host

Link Unit

@@ built-in

@@ built-in

121 words 125 words

Other frames

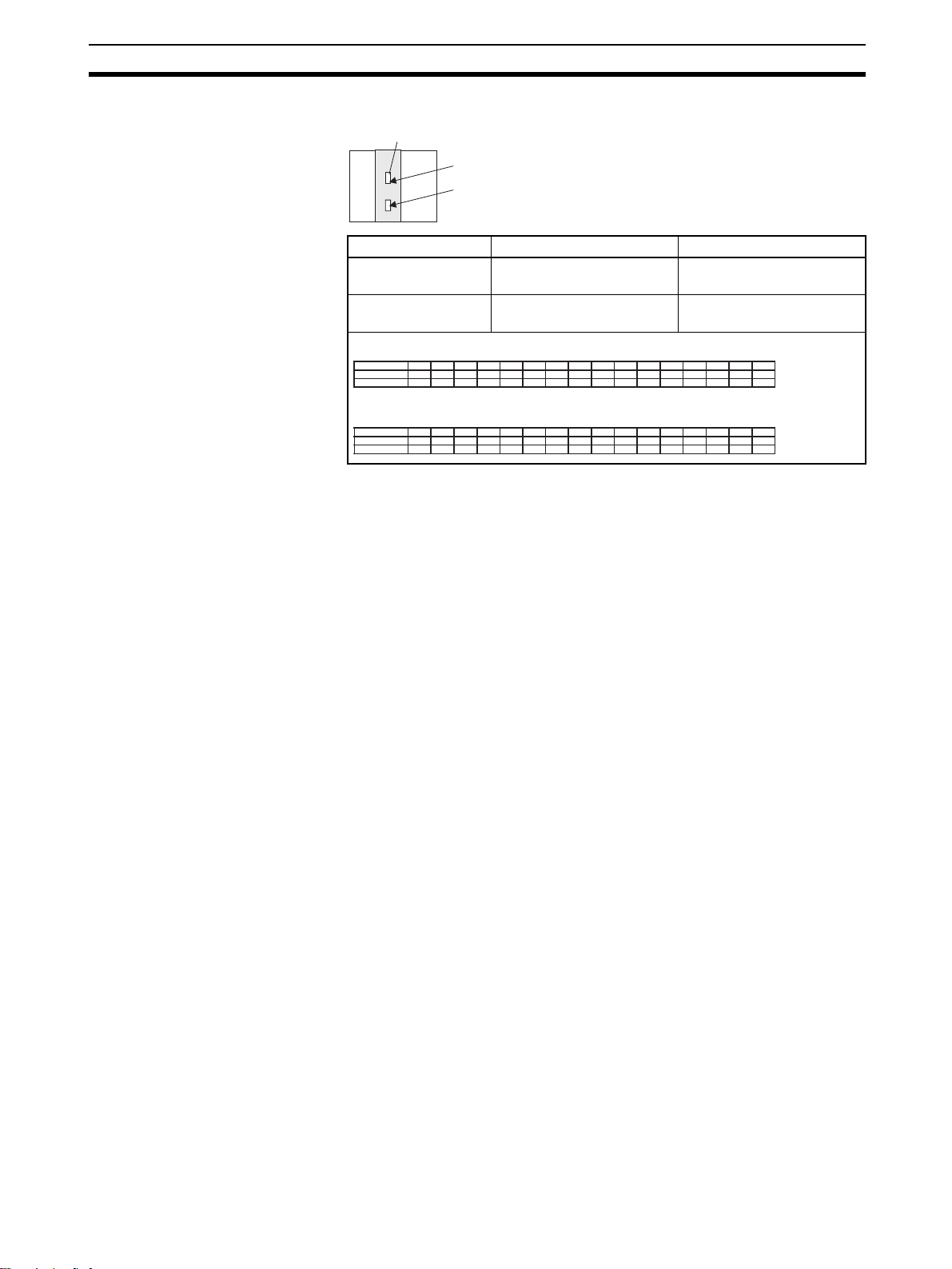

Note There are several exceptions to the number of words per frame values shown

in the table above:

The following responses are returned when reading 246 words of Timer/

Counter Completion Flags through CS/CJ-series CPU Unit built-in ports, CS/

CJ-series Serial Communications Units/Boards, C200HX/HG/HE CPU Unit

built-in ports, or C200HS CPU Unit built-in ports.

1st frame 2nd frame 3rd frame

121 words 124 words 1 word

The second-to-last frame contains 124 data words and the last frame contains

1 word. This also applies when the number of words is 246 + a multiple of 125

(i.e., 371 words, 496 words, 621 words, etc.).

The following responses are returned when reading 121 words of Timer/

Counter Completion Flags through CS/CJ-series Unit built-in ports.

st

1

frame 2nd frame

120 words 1 word

17

Page 40

Precautions when Reusing Programs from Earlier Models Section 2-4

The following responses are returned when reading 121 words or 246 words

through CVM1 and CV-series CPU Unit built-in ports or CVM1/CV-series Host

Link Units.

Number of Words = 121

1st frame 2nd frame

121 words 0 words (terminator only)

Number of Words = 246

st

frame 2nd frame 3rd frame

1

121 words 125 words 0 words (terminator only)

The second-to-last frame contains 125 data words and the last frame contains

the terminator only. This also applies when the number of words is 246 + a