Page 1

Thank you for choosing this OMNUC FND-X-series product.

This manual provides details on the installation, wiring, troubleshooting, and maintenance of

OMNUC

FND-X-series

products along with parameter settings for the operation of the products.

S Make

S Retain this manual for future reference.

S This

S Specifications and functions may change without notice to improve product performance.

S Forward

sure that actual users of this product will read this manual thoroughly and handle and operate the prod

uct with care.

manual describes the specifications

sume that nothing described in this manual is possible.

and reverse rotation of AC Servomotors described

the

output shaft of the motor as follows: counterclockwise rotation is forward and clockwise rotation is reverse.

and functions of the product and relations with other products. As

in this manual are defined as looking at the end of

General Instructions

1. Refer to Precautions first and carefully read and be sure to understand the information provided.

2. Familiarize

motor and Servo Driver for proper use.

3. The

Servomotor

4. We

recommend that you add the following precautions to any instruction manuals you prepare for

the system into which the product is being installed.

S Precautions on the dangers of high-voltage equipment.

S Precautions on touching the terminals of the product even after power has been turned OFF.

(These terminals are live even with the power turned OFF.)

5. Do

not perform withstand voltage

internal components.

6. Servomotors

hand and to consider the operating environment and other conditions affecting the service life.

7. Do not set any parameter not described in this manual, otherwise the Servomotor or Servo Driver

may malfunction. Contact your OMRON representatives if you have any inquiry.

yourself with this manual

and Servo Driver must be wired and operated by experts in electrical engineering.

and Servo Drivers have a finite service life. Be sure to keep replacement products on

and understand the functions and performance of the Servo

or other megameter tests on the product. Doing so may damage

-

-

-

NOTICE

Before using the product under the following conditions, consult your OMRON representatives, make

sure

that the ratings and performance characteristics of the product are good enough for the systems,

machines,

mechanisms.

1. Conditions not described in the manual.

2. The application of the product to nuclear control systems, railroad systems, aviation systems, ve-

3. The

or equipment, and be sure to provide the systems, machines, or equipment with double safety

hicles, combustion systems, medical equipment, amusement machines, or safety equipment.

application of the product to systems,

on human life and property if they are used improperly.

machines, or equipment that may have a serious influence

Items to Check After Unpacking

Check the following items after removing the product from the package:

S Has the correct product been delivered (i.e., the correct model number and specifications)?

S Has the product been damaged in shipping?

The product is provided with Safety Precautions Sheets. No connectors or mounting screws are

provided.

Page 2

USER’S MANUAL

OMNUC FND-X SERIES

MODELS FND-Xj (DIO Type)

FND-Xj-SRT (CompoBus/S Type)

POSITION DRIVERS

Page 3

No. 6182

OMRON Corporation

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

1

Page 4

No. 6182

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

2

Page 5

No. 6182

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

3

Page 6

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates

!

or serious injury.

WARNING Indicates

!

or serious injury.

Caution Indicates

!

or moderate injury, or property damage.

an imminently hazardous situation which, if not avoided, will

a potentially hazardous situation which, if not avoided, could result in death

a potentially hazardous situation which, if not avoided, may result in minor

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name

of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products,

often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation

for anything else.

result in death

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for dam

ages resulting from the use of the information contained in this publication.

, because

-

Page 7

General Precautions

Observe the following precautions when using the OMNUC Position Drivers and peripheral

devices.

This manual may include illustrations of the product with protective covers removed in order

to describe the components of the product in detail. Make sure that these protective covers

are on the product before use.

Consult your OMRON representative when using the product after a long period of storage.

WARNING Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

!

WARNING Always

!

to

in electric shock.

WARNING Do

!

items while the power is being supplied. Doing so may result in electric shock.

WARNING Operation,

!

Not doing so may result in operation stoppage, burning of the product, electric

shock, or injury.

WARNING Wiring

!

supply. Doing so may result in electric shock.

WARNING Do

!

Doing so may result in electric shock.

WARNING Do not touch the rotating parts of the Servomotor under operation. Doing so may

!

result in injury.

WARNING Do

!

connect the frame ground terminals of the Servo Driver and the Servomotor

a class-3 ground (to 100 Ω or less). Not connecting to

not remove the front cover

maintenance, or inspection must be performed by authorized personnel.

or inspection must be performed

not damage, pull on, apply stress to, place heavy objects on, or pinch the cables.

not modify the product. Doing so may result in injury or damage to the

, terminal covers, cables, Parameter Units, or optional

at least 1 minute after turning of

a class-3 ground may result

f the power

product.

Caution Use the Servomotors and Servo Drivers in a specified combination. Not doing so

!

may result in fire or damage to the products.

Caution Do

!

Caution Do not touch the Servo Driver radiator, regenerative resistor, or Servomotor while

!

not store or install the product in the following places. Doing so may result in elec

tric shock, fire or damage to the product.

S Locations subject to direct sunlight.

S Locations subject to temperatures or humidity outside the range specified in the

specifications.

S Locations

S Locations subject to corrosive or flammable gases.

S Locations subject to dust (especially iron dust) or salts.

S Locations subject to shock or vibration.

S Locations subject to exposure to water, oil, or chemicals.

the

power is being supplied or soon after the power is turned of

in a skin burn due to the hot surface.

subject to condensation as the result of severe changes in

f. Doing

temperature.

so may result

-

Page 8

Storage and Transportation Precautions

Caution Do not hold by the cables or motor shaft while transporting the product. Doing so

!

may result in injury or malfunction.

Caution Do

!

Caution Use

!

not place any load exceeding the figure indicated on the product.

result in injury or malfunction.

the motor eye-bolts

porting the machinery may result in injury or malfunction.

only for transporting the Servomotor

Installation and Wiring Precautions

Caution Do

!

Caution Do

!

Caution Be

!

Caution Provide

!

not step on or place a heavy object on the

not cover the inlet or outlet ports and prevent any foreign objects from entering

the product. Doing so may result in fire.

sure to install the product in the correct direction. Not doing so may result in mal

function.

the specified clearances between the Servo Driver and the

with other devices. Not doing so may result in fire or malfunction.

Doing so may

. Using them for trans

product. Doing so may result in injury

control panel or

-

.

-

Caution Do not apply any strong impact. Doing so may result in malfunction.

!

Caution Be sure to wire correctly and securely. Not doing so may result in motor runaway,

!

injury, or malfunction.

Caution Be

!

Caution Use crimp terminals for wiring. Do not connect bare stranded wires directly to the

!

Caution Use

!

Caution Take

!

Caution Install

!

sure to firmly tighten the screws fixing the product,

Not doing so may result in malfunction.

terminal block. Doing so may result in fire.

the power supply voltages specified in this manual. Not doing so may result in

burning.

appropriate

is

supplied. Be particularly careful in places where the power supply is unstable. Not

doing so may result in damage to the product.

external breakers and take other safety measures against short-circuiting in

external wiring. Not doing so may result in fire.

measures to ensure that the specified power with the rated voltage

the terminal block, and cables.

Page 9

Caution Provide an appropriate stopping device on the machine side to secure safety. (A

!

holding

injury.

brake is not a stopping device

for securing safety

.) Not doing so may result in

Caution Provide

!

operation and power interruption. Not doing so may result in injury.

Caution Take

!

lowing locations. Not doing so may result in equipment damage.

S Locations subject to static electricity or other forms of noise.

S Locations subject to strong electromagnetic fields and magnetic fields.

S Locations subject to possible exposure to radioactivity.

S Locations close to power supplies.

an external emergency stopping device that allows an instantaneous stop

appropriate and suf

ficient

countermeasures when installing systems in the fol

Operation and Adjustment Precautions

Caution Confirm that no adverse effect will occur in the system before performing the test

!

operation. Not doing so may result in equipment damage.

Caution Check

!

Not doing so may result in equipment damage.

Caution Do not make any extreme adjustments or setting changes. Doing so may result in

!

unstable operation and injury.

the newly

set parameters for proper execution before actually running them.

of

-

Caution Separate the Servomotor from the machine, check for proper operation, and then

!

connect to the machine. Not doing so may cause injury.

Caution When an alarm occurs, remove the cause, reset the alarm after confirming safety,

!

and then resume operation. Not doing so may result in injury.

Caution Do

!

Caution Do

!

not come close to the machine immediately after resetting

terruption to avoid an unexpected restart. (Take appropriate measures to secure

safety against an unexpected restart.) Doing so may result in injury.

not use the built-in brake

result in malfunction.

of the Servomotor for ordinary braking. Doing so may

momentary power in

Maintenance and Inspection Precautions

WARNING Do not attempt to take the Unit apart or repair. Doing either of these may result in

!

electrical shock or injury.

Caution Resume

!

quired for operation. Not doing so may result in equipment damage.

operation only after transferring to the new Unit the

contents of the data re

-

-

Page 10

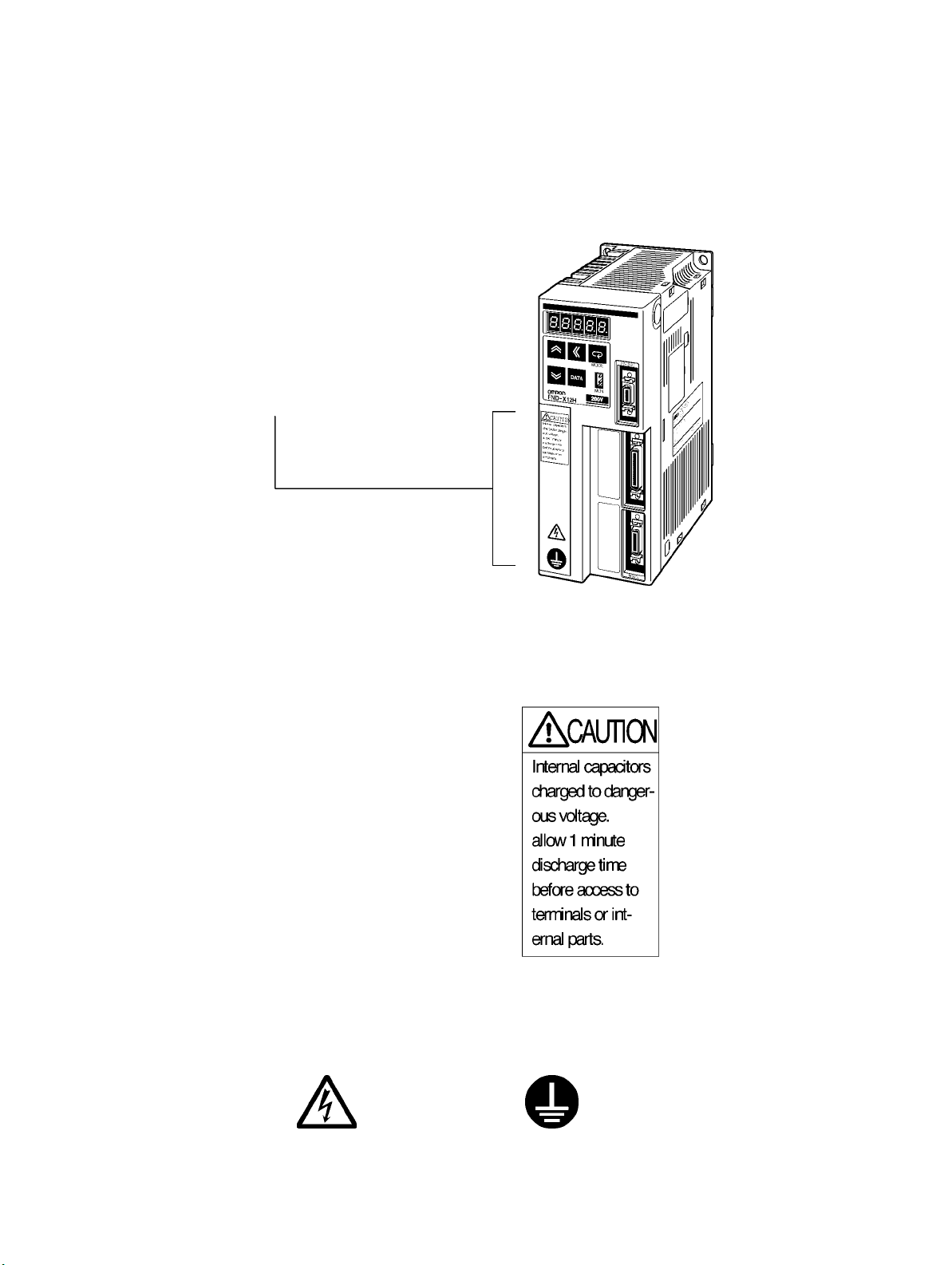

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to

follow the instructions given there.

Warning

labels

Warning Labels

Warning

label 1

W

arning label 2

May cause electric shock.

Connect to a ground of 100

Ω or less.

Page 11

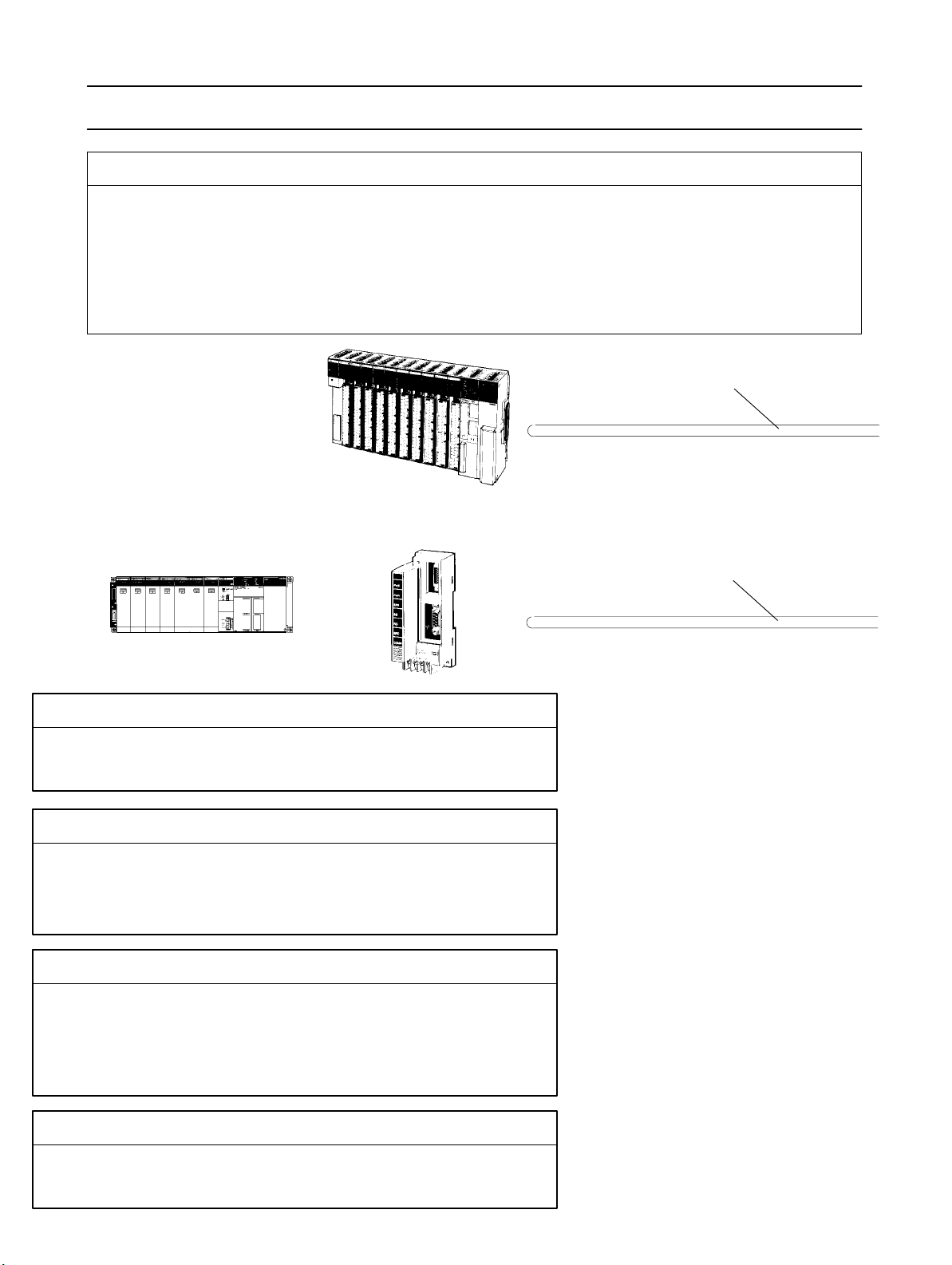

VISUAL INDEX

For users who wish to begin operations quickly.

- The

OMNUC FND-X-series Position Driver allows motor test operation

and motor without connecting the controller. Read

play

,

properly set the motor model code, and then operate the

Check Mode

Do not connect any load (machines) when performing test operation. Perform test operation

only after confirming that no adverse effects will be caused by test operation.

.

3-2 Turning ON Power and Checking Dis-

motor according to

SYSMAC C/CV

Programmable Controller

I/O signals

SYSMAC C200H-HX/HG/HE

or CQM1 Programmable

Controller

SRM1-C01/-C02

Master Controller

Section 6 CompoBus/S Specifications

CompoBus/S signals

only by wiring the driver

3-8-2System

5-3-1 General Control

Cable Specifications

Initial Operation (Starting)

- 3-1 Operation Procedure

- 3-2Turning ON Power and Checking Displays

Function Settings (Parameter Settings)

- 3-4 Setting Functions: User Parameters (H Parameters)

- 3-5 Position Control Settings (PTP Parameters)

- 3-6 Setting Positioning Data (PTP Data, Direct Input)

Trial Operation and Adjustments

- 3-8-1 Trial Operation Procedure

- 3-8-2 System Check Mode

- 3-9-1 Auto-tuning

- 3-9-2 Manually Adjusting Gain

Troubleshooting

- 4-4 Protection and Diagnosis

- 4-5 Troubleshooting

Page 12

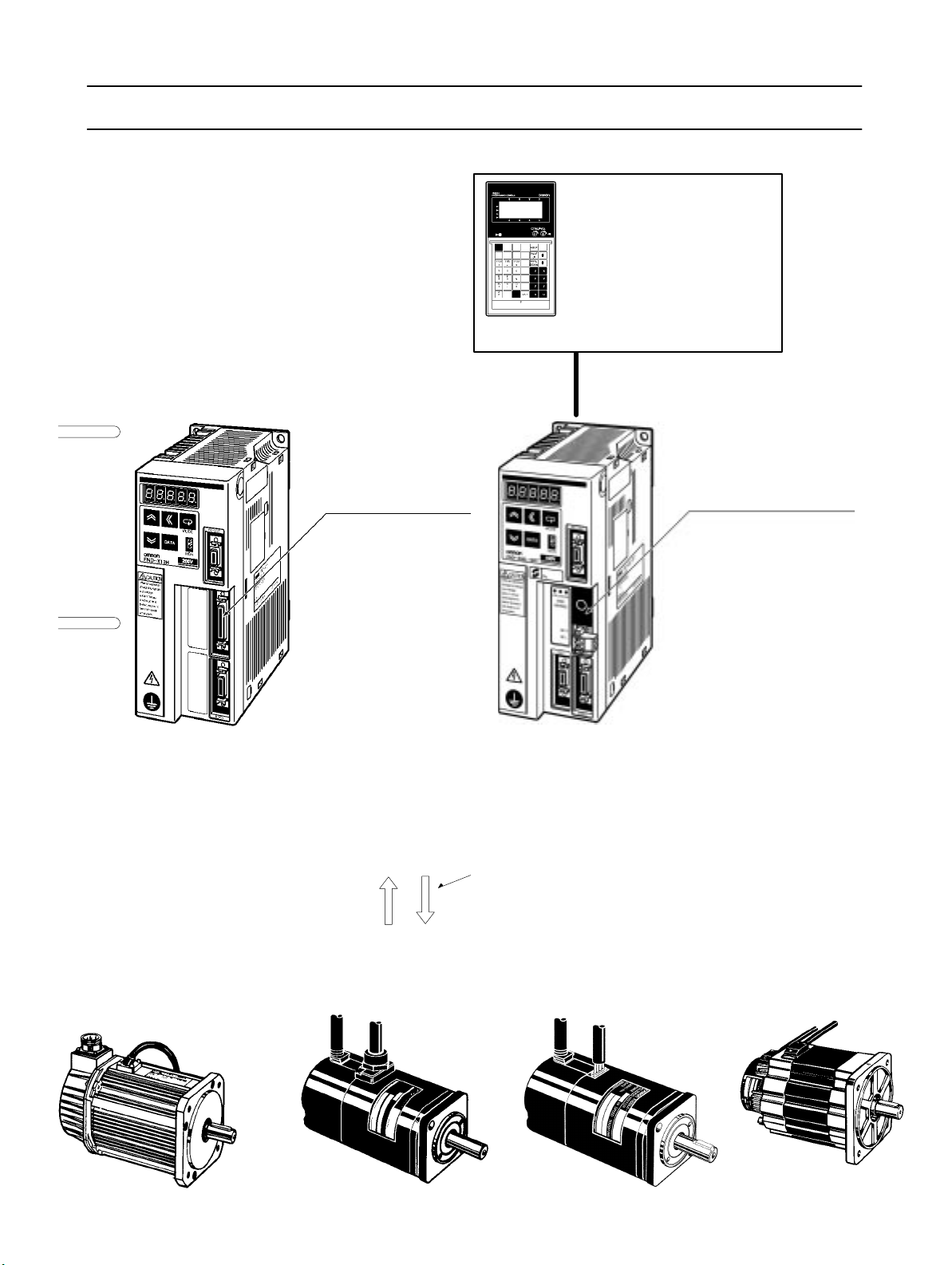

OMNUC FND-X Series

Teaching Box

CVM1-PRO01 Teaching Box

ROM Cassette:

CVM1-MP702

(Common for MC Units and

Position Drivers)

CVM1-MP703

For details refer to Cat. No. W354-E1.

RS-422 Teaching Box connections cable

OMNUC FND-X-series Position Drivers

2-2-2 Control Circuitry

Terminal Wiring

DIO Type

200 V: FND-XjjH

100 V: FND-XjjL

5-1 Position Driver Specifications

2-2-3 Wiring Terminal Blocks

3-3-3 Mode Details

6-3 Connecting a CompoBus/S

System

CompoBus/S Type

200 V: FND-XjjH-SRT

100 V: FND-XjjL-SRT

OMNUC M-series

AC Servomotors

1200

r/min: 200 to 1.8 kW with Resolver

2000 r/min: 200 to 2.2 kW with Resolver

4000 r/min: 60 to 2 kW with Resolver

OMNUC U-series

AC Servomotors

3000 r/min: 30 to 2 kW with

Incremental Encoder

3000 r/min: 30 to 2 kW with

Absolute Encoder

5-3 Cable Specifications

Encoder/Resolver signalsPower signals

OMNUC U-UE-series

AC Servomotors

3000

r/min: 100 to 750 W with

Incremental Encoder

OMNUC H-series

AC Servomotors

3000 r/min: 50 to 1

Incremental Encoder

100 W with

Page 13

Table of Contents

Chapter 1. Introduction .

1-1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Nomenclature and Key Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Supported Standards and Supporting Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Standards Supported by Position Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Standards Supported by AC Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

3-1 Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Turning ON Power and Checking Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Using the Display Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Setting Functions: User Parameters (H Parameters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Position Control Settings (PTP Parameters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Setting Positioning Data (PTP Data, Direct Input) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Operational Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Design and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 External Dimensions (Unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Control Circuitry Terminal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Wiring Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Wiring for Noise Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-5 Wiring Products Conforming to EMC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-6 Peripheral Device Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-7 Battery Wiring and Encoder Setup for Absolute Encoder . . . . . . . . . . . . . . . . . . . . . .

3. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Items to Check Before Turning ON the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Turning ON the Power and Checking the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Key Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 Modes and Mode Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-3 Mode Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-4 CompoBus/S Communications Display and Setting Panel . . . . . . . . . . . . . . . . . . . . .

3-4-1 Setting User Parameters and H Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-2 User Parameter and H Parameter Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4-3 User Parameter and H Parameter Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-1 Setting PTP Parameters (PP-01 to PP-26) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-2 PTP Parameters (PP-01 to PP-26) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-3 PTP Parameter Details (PP-01 to PP-26) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-1 Setting PTP Data (When UP-01 is 11 or 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-2 Setting Direct Input (When UP-01 is 13 or 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-3 PTP Data (Pd01jj to Pd64j) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-4 PTP Data Details (Pdjjj) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-1 Origin Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-2 Origin Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-3 Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-4 Point Positioning (UP-01: 11 or 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7-5 Direct Positioning (UP-01: 13 or 14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-1 Trial Operation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8-2 System Check Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 14

Table of Contents

3-9 Making Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9-1 Auto-tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9-2 Manually Adjusting Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9-3 Adjustment Parameter Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Regenerative Energy Absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10-1 Calculating Regenerative Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10-2 Position Driver Absorbable Regenerative Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10-3 Regenerative Energy Absorption by Regeneration Resistor . . . . . . . . . . . . . . . . . . . .

Chapter

4-1 Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Check Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Protection and Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

5-1 Position Driver Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Servomotor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-1 I/O Signal Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-2 Countermeasures to Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-3 CompoBus/S-type Position Driver Protective and Diagnostic Functions . . . . . . . . . .

4-4-4 Overload Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4-5 Alarm Output and Clearing Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5-1 Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5-2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5-3 Replacing the Position Driver and the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5-4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-1 General Specifications (Common to DIO, CompoBus/S) . . . . . . . . . . . . . . . . . . . . . .

5-1-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-3 I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-1 U-series 30-W to 750-W Servomotors (INC/ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-2 U-UE-series Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-3 U-series 1-kW to 2-kW Servomotors (INC/ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-4 H-series Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-5 M-series Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-1 General Control Cables (DIO Position Drivers Only) . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-2 Connector Terminal Board Conversion Unit Cables (DIO Position Drivers Only) . . .

5-3-3 External Control Signal Connecting Cables (CompoBus/S Position Drivers Only) . .

5-3-4 Encoder Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-5 Resolver Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-6 Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

6-1 CompoBus/S Configuration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 CompoBus/S Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Connecting a CompoBus/S System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. CompoBus/S Specifications. . . . . . . . . . . . . . . . . . . . . . . . .

Page 15

Table of Contents

Chapter 7. Appendices .

7-1 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Parameter Settings Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 16

1

Chapter 1

Introduction

1-1 Functions

1-2 Nomenclature and Key Operations

1-3 Supported Standards and Supporting Models

Page 17

Introduction Chapter 1

1-1 Functions

OMRON’s FND-X Position Drivers are servo drivers with built-in positioner functions

that control AC servomotors according to positioning data.

H FND-X-Series Models

There are two types of FND-X Position Drivers, according to the type of control signals used.

Control signals Model

DIO FND-XjjH/FND-XjjL

CompoBus/S FND-XjjH-SRT/FND-XjjL-SRT

Up to eight CompoBus/S Position

output points. Two-wire communications are used, reducing system wiring. High-speed communications are also achieved, with a communications cycle time of 0.5 or 0.8 ms.

Note Only the high-speed communications mode is available with the FND-X.

Drivers can be connected to one Master Unit for 128 input and 128

H International Standards: EC Directives and UL/cUL Standards

Position

UL/cUL

forming to directives/standards, use U-series Servomotors that also conform to the require directives/standards.

Drivers manufactured beginning April 1999 are available that conform to EC directives

standards, making it easier to conform

to these standards in the overall system. When con

and

H Applicable Servomotor Models

The following AC Servomotors can be connected to FND-X-series Position Drivers.

• OMNUC U Series (30 to 750 W)

Servomotors Conforming to UL/cUL Standards

With incremental encoders: R88M-UjjjjjHA-j

With absolute encoders: R88M-UjjjjjTA-j

Servomotors Conforming to EC Directives

With incremental encoders: R88M-UjjjjjVA-j

With absolute encoder: R88M-UjjjjjXA-j

-

• OMNUC U Series (1 to 2 kW)

Servomotors Not Conforming to Standards

With incremental encoder: R88M-UjjjjjH-j

With absolute encoder: R88M-UjjjjjT-j

Servomotors Conforming to EC Directives

With incremental encoder: R88M-UjjjjjV-j

With absolute encoder: R88M-UjjjjjX-j

• OMNUC U-UE Series (100 to 750 W)

Servomotors Not Conforming to Standards

With incremental encoder: R88M-UEjjjjjH-j

Servomotors Conforming to EC Directives

With incremental encoder: R88M-UEjjjjjV-j

1-2

Page 18

g

,

50/60 Hz

,

,

,

,

,

,

,

,

,

,

,

Introduction Chapter 1

• OMNUC H (50 to 1,100 W) Series (with incremental encoder): R88M-Hjjjjj-j

• OMNUC M (60 to 2,200 W) Series (with resolver): R88M-Mjjjjj-j

Note H-series and M-series models do not conform to the EC Directives and UL/cUL standards.

• The

following

models are available with dif

ferent output capacities, and are arranged according to in

put power supply.

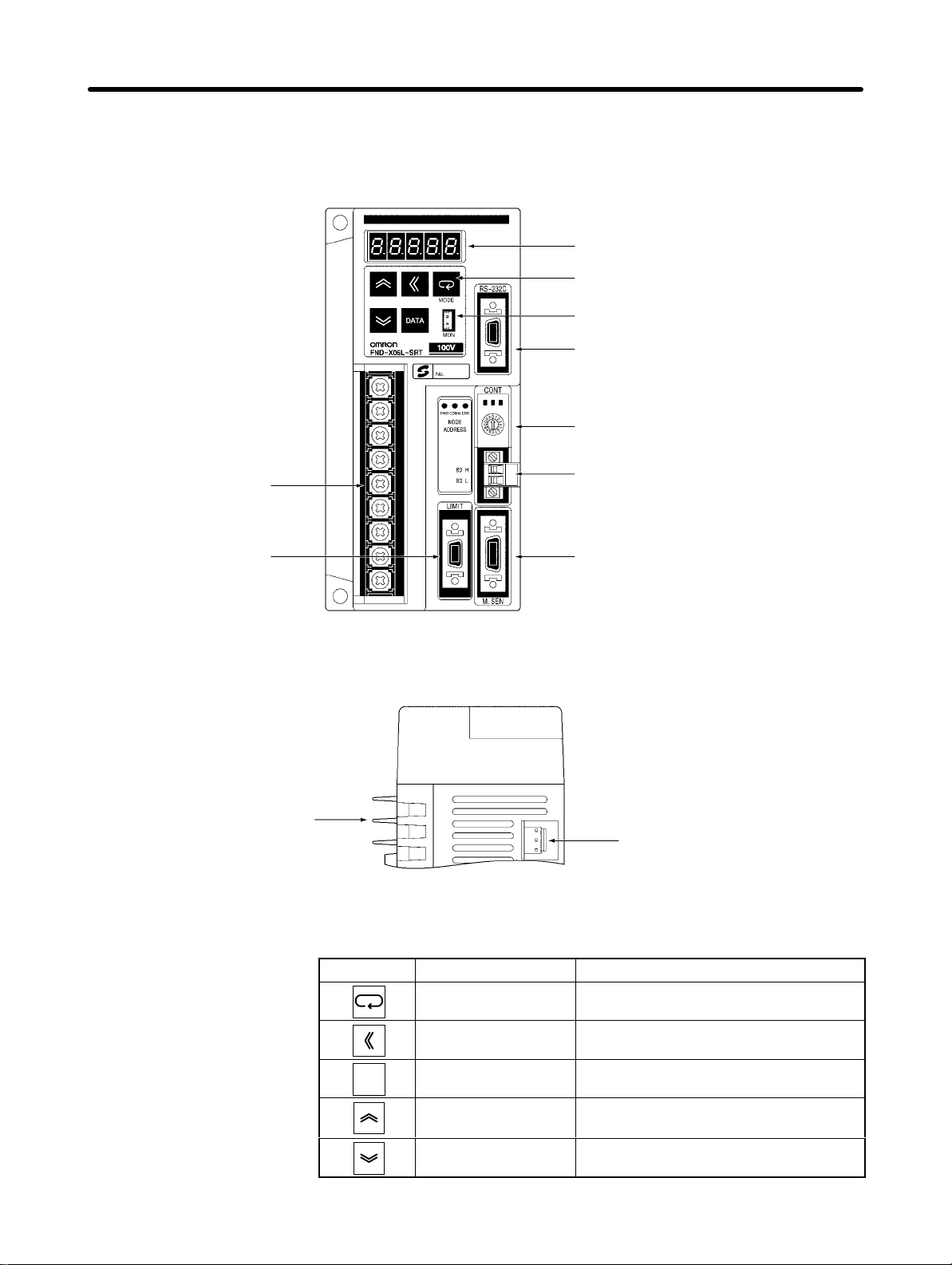

D Position Driver and AC Servomotor Combinations

Position

Input power

supply

Single-phase

200/240 (170 to

264) V

AC at

Driver

Model Series Model Output

FND-X06H-j U

U-UE R88M-UE10030j-S1 100 W 3,000 r/min

H

FND-X12H-j U

U-UE

H

M

FND-X25H-j U

U-UE R88M-UE75030j-S1 750 W 3,000 r/min

H

M

R88M-U03030jA 30 W

R88M-U05030jA 50 W

R88M-U10030jA 100 W

R88M-H05030 50 W

R88M-H10030 100 W

R88M-U20030jA 200 W

R88M-U40030jA 400 W

R88M-UE20030j-S1 200 W

R88M-UE40030j-S1 400 W

R88M-H20030 200 W

R88M-H30030 300 W

R88M-M06040 60 W

R88M-M12040 120 W

R88M-M20040 200 W

R88M-M40040 400 W

R88M-M20020 200 W

R88M-M40020 400 W

R88M-M20012 200 W

R88M-M40012 400 W

R88M-U75030jA 750 W

R88M-U1K030j 1000 W

R88M-H50030 500 W

R88M-H75030 750 W

R88M-H1K130 1100 W

R88M-M70040 700 W

R88M-M1K140 1100 W

R88M-M70020 700 W

R88M-M1K120 1100 W

R88M-M70012 700 W 1,200 r/min

Applicable AC Servomotor

-

Rated r/min

capacity

3,000 r/min

3,000 r/min

3,000 r/min

3,000 r/min

3,000 r/min

4,000 r/min

2,000 r/min

1,200 r/min

3,000 r/min

3,000 r/min

4,000 r/min

2,000 r/min

1-3

Page 19

50/60 Hz

g

,

50/60 Hz

,

,

Introduction Chapter 1

Position

Input power

supply

Three-phase

200/240 (170 to

264) V

AC at

Single-phase

100/115 (85 to

127) V

AC at

Driver

FND-X50H-j U

FND-X06L-j U

FND-X12L-j

Applicable AC Servomotor

ModelSeriesModel

capacity

R88M-U1K530j 1500 W

R88M-U2K030j 2000 W

M

U-UE R88M-UE10030j-S1 100 W 3,000 r/min

H

U R88M-U20030jA 200 W 3,000 r/min

U-UE R88M-UE20030j-S1 200 W 3,000 r/min

H R88M-H20030 200 W 3,000 r/min

M

R88M-M2K040 2000 W 4000 r/min

R88M-M1K820 1800 W

R88M-M2K220 2200 W

R88M-M1K112 1100 W

R88M-M1K412 1400 W

R88M-M1K812 1800 W

R88M-U03030jA 30 W

R88M-U05030jA 50 W

R88M-U10030jA 100 W

R88M-H05030 50 W

R88M-H10030 100 W

R88M-M06040 60 W

R88M-M12040 120 W

R88M-M20040 200 W

R88M-M20020 200 W 2,000 r/min

R88M-M20012 200 W 1,200 r/min

Rated r/minOutput

3000 r/min

2000 r/min

1200 r/min

3,000 r/min

3,000 r/min

4,000 r/min

Note 1. Even

when a U-series or U-UE-series

Position Driver

put

, a 200-V

Servomotor is used in combination with a100-V

AC Servomotor must be used. A 100-V

AC-in-

AC Servomotor cannot be

connected.

Note 2. Straight-axis servomotors are available either with or without a key or brake. In the above

table, the Servomotors have the following features.

U-series Straight axis without brake, without key

U-series UE models Straight axis without brake, with key (not available without key)

H-series Straight axis without brake, with key

M-series Straight axis without brake, with key (“A” cut for small-capacity)

Note 3. Motor control is enabled by setting the user parameter UP-02 of the Position Driver.

Note 4. U-series

UE-type and H-series Servomotors can

be used only with Position Driver software

version 4.01 (September 1997) or later.

U-series 1-kW to 2-kW Servomotors and M-series 1.1-kW to 2.2-kW Servomotors can be

used only with Position Driver software version 4.04 (April 1999) or later.

1-4

Page 20

Introduction Chapter 1

H Servomotor Features and Selection Standards

Any

FND-X-series Position Driver can be

selection, take the following points into consideration.

D Servomotor Features

U/UE Series

S Compact size, high-speed response

S High resolution (except for UE type)

S Absolute encoder system can be configured (except for UE type).

H Series

S High resolution

S High application load inertia (less than 10 times the rotary inertia)

S Usable in systems with comparatively low mechanical rigidity.

M Series

S High application load inertia (less than 10 times the rotary inertia)

freely selected according to the application. When making the

S Usable in systems with comparatively low mechanical rigidity.

S High output torque in a low-rotation motor

S Up to a maximum of 50 meters between Servomotor and Servo Driver.

D Motor Selection Standards (Reference)

Drive system type Low inertia High inertia

Ball screw direct connection U, U-UE, H, M U, U-UE, H, M

Turntable direct connection U, U-UE, H, M U, U-UE, H, M

Feeder (direct connection) U, U-UE, H, M U, U-UE, H, M

Harmonic drive U, U-UE, H, M H, M

Chain drive U, U-UE, H, M H, M

Belt drive U, U-UE, H, M H, M

Rack & pinion U, U-UE, H, M H, M

Note “Low

inertia” means that the motor axis conversion inertia is approximately 0 to 5 times the

inertia

for U-series and U-series UE-type Servomotors.

“High inertia” means that the motor axis conversion inertia is approximately 5 to 10 times the

rotary

inertia for U-series and U-series UE-type Servomotors.

for H-series and M-series Servomotors, and approximately 0 to

inertia for H-series and M-series Servomotors, and approximately 15 to 30 times the rotary

15 times the rotary inertia

rotary

H Position Control Functions

D Pulse Rate Setting Function

Pulse

rate setting makes it possible to set positioning data (i.e., positions and speeds) according to the

mechanical axis.

1-5

Page 21

Introduction Chapter 1

D Control Mode

The

following four types of control modes are available to the Position Driver: PTP

control

rect I/O signal input.

modes with the internal point data preset in the Position Driver and these same modes with di

D Internal Point Data

• A maximum of 64 points of data (Pd01j to Pd64j) can be set internally in the Position Driver.

• Positions can be set within a range between –39,999,999 to 39,999,999 with the absolute or incre-

mental value specified.

D Positioning Data Instruction by Direct Input

Eight-point

lowing ranges into the Position Driver.

Position Setting Range: –39,999,999 to 39,999,999 (with incremental or absolute setting)

Speed Setting Range: 1% to 100% (override setting with respect to reference speed)

input and input timing signals are used to

input position data and speed data within the fol

D Position Compensation Function

This

function executes

feeder control is used.

backlash compensation when PTP control is used, and slip compensation when

control and feeder

-

-

D Acceleration/Deceleration Function

•

Either linear (trapezoidal) acceleration or deceleration time or

celeration

and deceleration.

• The

ors smoothly or achieve feeder control with minimal feeder slippage.

or deceleration time can be selected. In addition,

S-shaped acceleration/deceleration function makes it possible, for example, to start up convey

S-shaped (primary low-pass filter) ac

dif

ferent times can be set for acceleration

D Stop Methods

• The stop method for when the STOP signal is turned OFF can be selected with PP-24.

Free-running stop: Motor power supply turned OFF.

Deceleration stop: Servo-lock

Error counter reset stop: Servo-lock

counter reset.

• The

stop method of the Position Driver in the case of overrun or software limit signal detection can be

selected with PP-25.

Overrun: Servo free-running stop with the alarm AL38 turned ON or servo-

lock stop.

Software limit detection: Servo-lock

after the operation decelerates to a stop in preset time.

after an immediate deceleration to a stop with the error

stop with or without alarms AL34 and AL35 turned ON.

-

-

H Teaching Functions

D Position Teaching

The

Position Driver has a teaching function that enables the Position Driver stop the mechanical axis

with

an external force

data automatically as part of PTP data.

1-6

by going into servo-free status or JOG operation and to take up the stop position

Page 22

Introduction Chapter 1

D Mechanical Origin Teaching

An

optional position can be specified as the mechanical origin by moving the position to the mechanical

origin and teaching after the completion of origin search.

H Motor Control Functions

D Motor Type and Capacity Selection by Motor Code

A motor type and capacity can be selected by setting UP-02 to the corresponding motor code.

D Auto-tuning Function

• The

Position

Driver,

turning

ity and characteristics of the machine load.

• The auto-tuning function makes it possible to save system startup time.

H Programming Devices

Driver has an auto-tuning function. If a machine and motor are connected to the Position

this function makes it possible

the motor and enables the automatic gain control of

to check the capacity and characteristics of the machine load by

the Position Driver according to the capac

-

D Teaching Box: CVM1-PRO01 + ROM Cassette

The Teaching Box provides for easy operation, including the following:

Position Driver status monitoring

Parameter editing and transfer

Teaching

Jogging

Positioning to specified points

Autotuning

Note Refer to the

CVM1-PRO01 Teaching Box Operation Manual (W354)

D OMNUC FND-X Series Monitoring Software

TheOMNUC

vides for easy operation, including the following:

Position Driver status monitoring

Parameter editing and transfer

Speed and current waveform displays

Autotuning

FND-X Series Monitoring Software runs on an IBM PC/A

T or compatible computer and

H Monitor Functions

for more information.

pro-

D Monitor Mode

The

motor speed, present value, reference value,

rent,

ef

fective load factor, electronic thermal value, electrical angle, and regenerative absorption rate

can be monitored on the front panel of the Position Driver in this mode.

position deviation value, machine speed, motor cur

D Check Mode

The

I/O

signal status, alarm details, alarm history

of the Position Driver in this mode.

, and software version are displayed on the front panel

-

1-7

Page 23

Introduction Chapter 1

H Protection and Self-diagnostic Functions

D Hardware Protection

The

Position Driver is protected from overcurrent,

ure, overcurrent (soft), speed amplifier saturation, and overload damage.

D Mechanical System Protection

The

mechanical system is protected from damage resulting

soft limit overflows, coordinate counter overflows, or overrun.

D Parameter Setting-related Errors

The Position Driver detects parameter setting errors.

D Detector-related Errors

Resolver

absolute

absolute encoder absolute failure, absolute encoder overspeed failure, encoder data failure, and encoder initialization failure.

wire burnout, resolver failure, encoder wire disconnection, encoder communications

encoder backup

failure, absolute encoder checksum failure, absolute encoder battery failure,

overvoltage, low voltage, abnormal power

from overspeed, error counter overflows,

, clock fail

failure,

-

D Position-related Errors

BCD data, indefinite PV, and PTP data non-setting errors.

H Test Functions

D Motor Test Function

The

Position Driver has a motor test function that makes it possible to easily check whether a motor is

connected

trolled with the operation keys and the motor speed can be set in UP-29. The motor speed is set to

50 r/min before shipping.

D Sequential Output Test Function

The

Position Driver has a sequential output test function that makes it possible

host controller is connected to the Position Driver. This function makes it possible to turn any output

terminal ON or OFF with the operation keys.

to the Position Driver

. When this function is enabled, the motor rotation direction can be con

to easily check whether a

-

1-8

Page 24

Introduction Chapter 1

1-2 Nomenclature and Key Operations

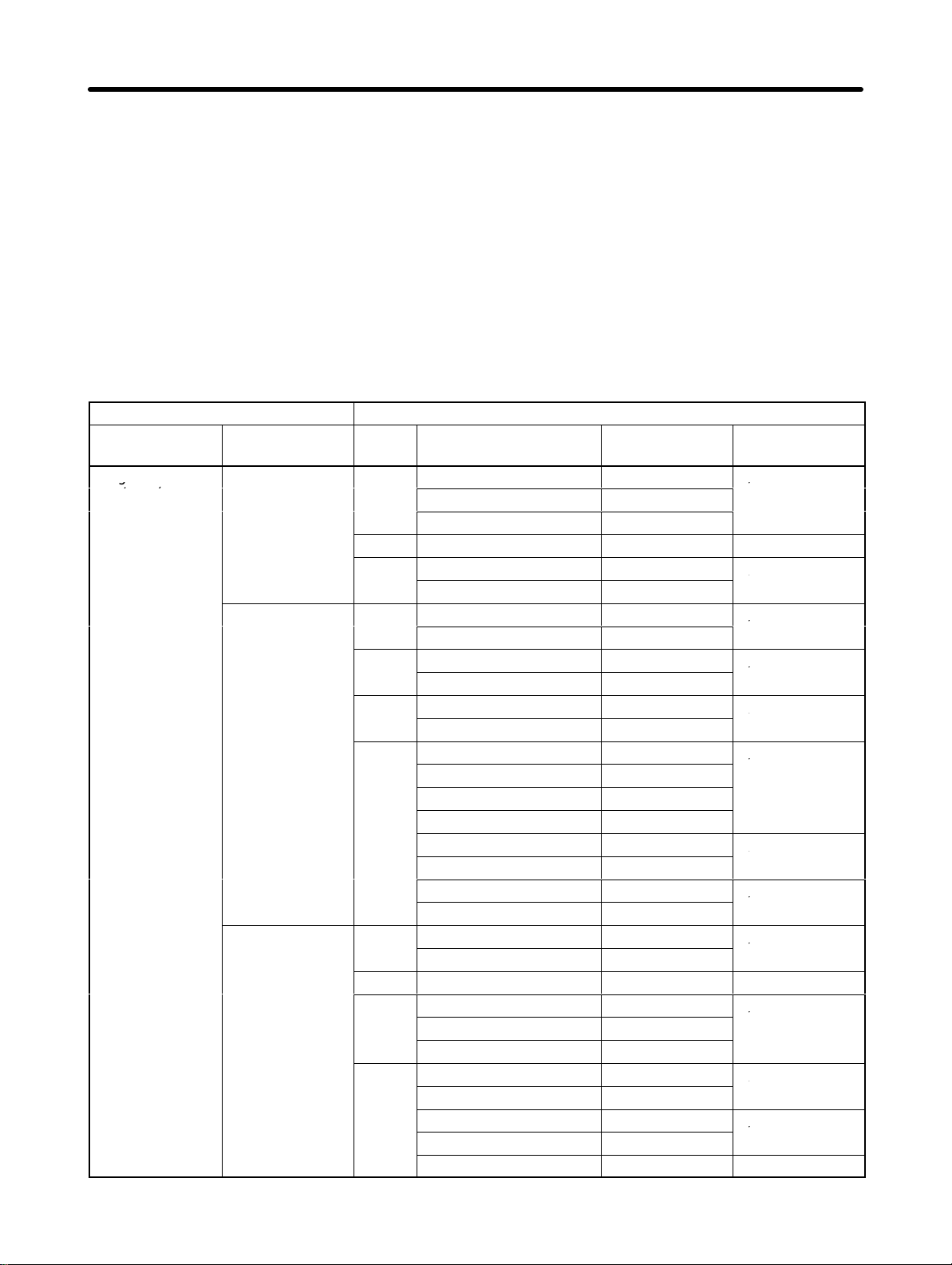

D DIO Position Drivers

Front View

Display

(5-digit, 7-segment LEDs)

Operation Keys (5 keys)

Monitor Output Terminal

CN5 (RS-232C)

Communications

Connector

CN1 (CONT)

Control Signal

Terminal

Block

Connector

Bottom View

Radiation

fin

H Key Operations

CN2 (M.SEN)

Motor Sensor

Connector

CN6

BAT

Connector

Key Name Main function

Mode Key Changes the Position Driver’s mode.

Shift Key

Shifts the operation column to the left.

DATA

Data Key Saves the set data.

Increment Key Increments the parameter address or

data value.

Decrement Key Decrements the parameter address or

data value.

1-9

Page 25

Introduction Chapter 1

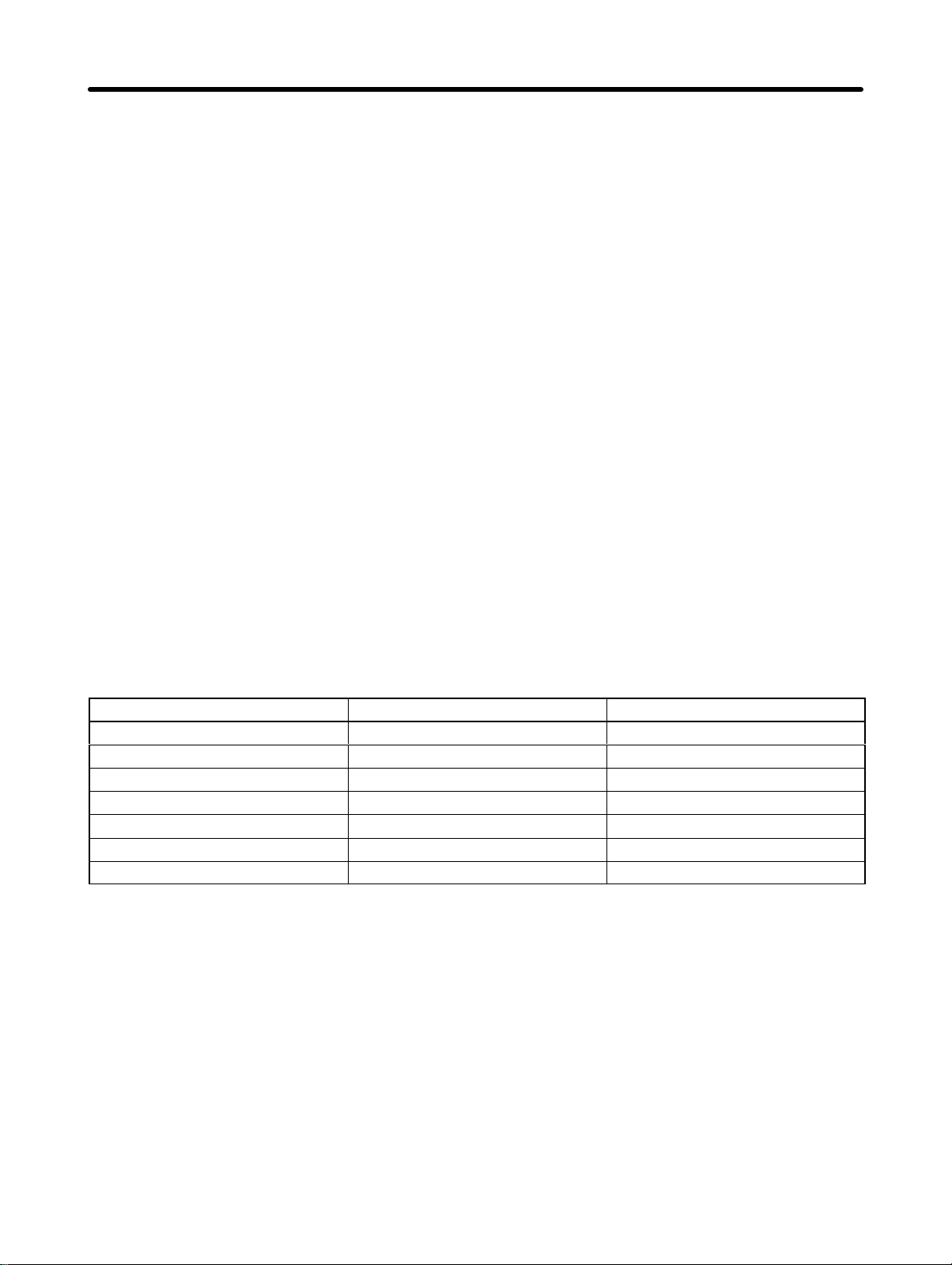

D CompoBus/S Position Drivers

Front View

Display

(5-digit, 7-segment LEDs)

Operation Keys (5 keys)

Monitor Output Terminal

CN5 (RS-232C)

Communications

Connector

Node Address

Setting Switch

CN4 (LIMIT)

External control

signal connector

Bottom View

Terminal

Block

Radiation

CN1 (CONT)

Control Signal

Connector

CN2 (M.SEN)

Motor Sensor

Connector

fin

CN6

BAT Connector

H Key Operations

1-10

Key Name Main function

Mode Key Changes the Position Driver’s mode.

DATA

Shift Key

Data Key Saves the set data.

Shifts the operation column to the left.

Increment Key Increments the parameter address or

data value.

Decrement Key Decrements the parameter address or

data value.

Page 26

Introduction Chapter 1

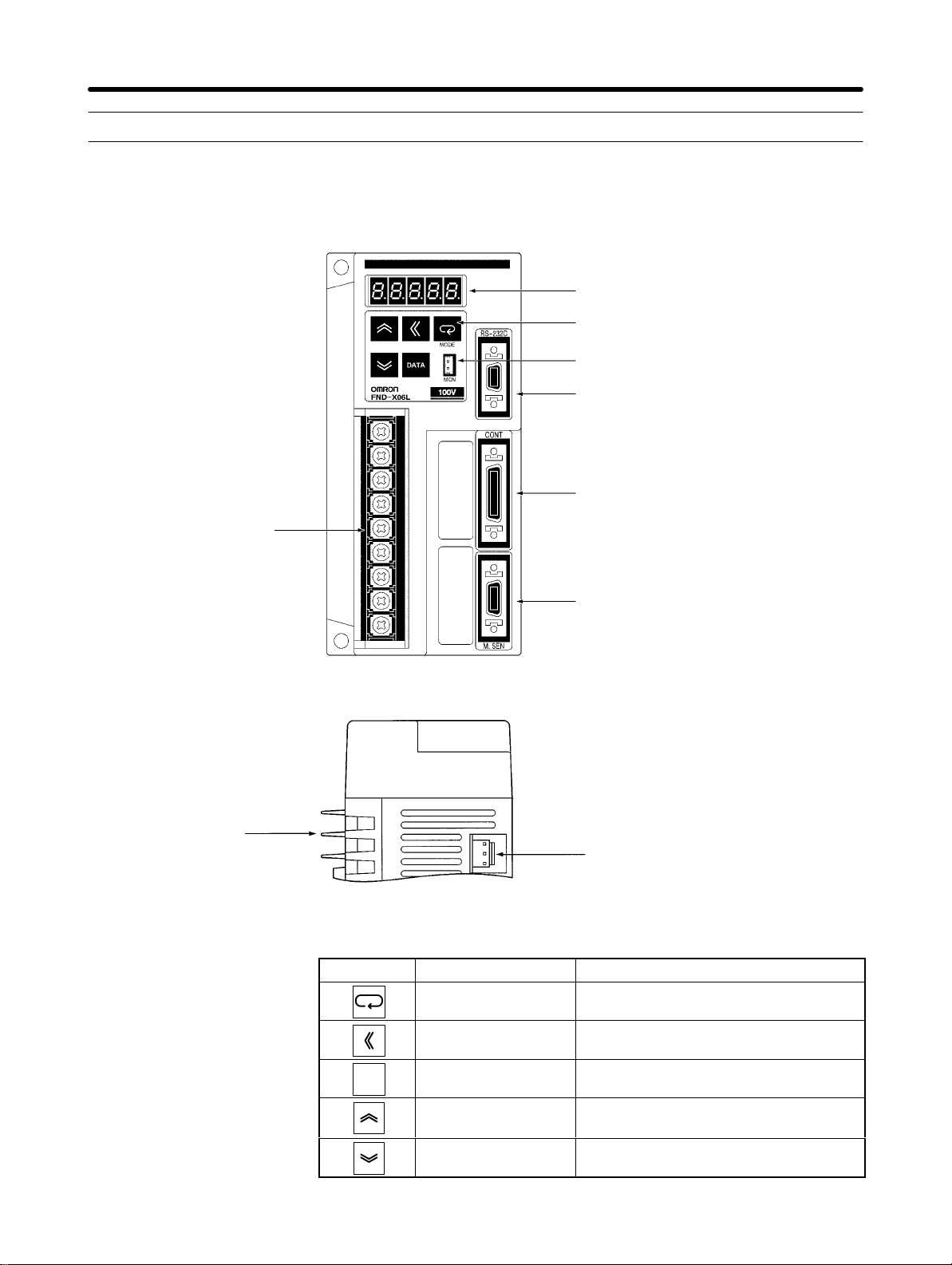

1-3 Supported Standards and Supporting Models

1-3-1 Standards Supported by Position Drivers

Standard Supported standard File No. Remarks

UL/cUL UL508C E179149 Electrical power conversion devices

EC

Low-voltage Directive EN50178 --- Industrial product specifications

EMC Directive

EN55011 class A

group 1

EN61000-4 --- Electromagnetic compatibility and immunity

--- Radio interference limits and measurement

methods for radio frequency devices for industrial, scientific, and medical applications

Note All Position Drivers in the FND-X Series conform to UL/cUL standards and EC directives.

1-3-2 Standards Supported by AC Servomotors

Standard Supported standard File No. Remarks

UL/cUL

EC

Low-voltage Directive IEC34-1, -5, -8, -9 --- Rotating electric devices

EMC Directive

UL1004 E179189 Electric motors

cUL C22.2 No. 100 E179189 Motors and generators

EN55011 class A

group 1

EN61000-4 --- Electromagnetic compatibility and immunity

--- Radio interference limits and measurement

methods for radio frequency devices for industrial, scientific, and medical applications

H Servomotors Conforming to UL/cUL Standards

Power supply AC Servomotors Encoder

200 VAC R88M-Ujjj30HA-j (30 to 750 W) Incremental encoder

200 VAC R88M-Ujjj30TA-j (30 to 750 W) Absolute encoder

Note Servomotors manufactured beginning in May 1998 conform to UL/cUL standards.

H Servomotors Conforming EC Directives

Power supply AC Servomotors Encoder

200 VAC R88M-Ujjj30VA-j (30 to 750 W) Incremental encoder

200 VAC R88M-Ujjj30XA-j (30 to 750 W) Absolute encoder

200 VAC R88M-UEjjj30V-j (100 to 750 W) Incremental encoder

200 VAC R88M-Ujjj30V-j (1 to 2 kW) Incremental encoder

200 VAC R88M-Ujjj30X-j (1 to 2 kW) Absolute encoder

Note The Servomotors must be wired as described in

2-2 Wiring

to conform to the EMC Directive.

1-11

Page 27

2

Chapter 2

Design and Installation

2-1 Installation

2-2 Wiring

Page 28

Design and Installation Chapter 2

2-1 Installation

2-1-1 External Dimensions (Unit: mm)

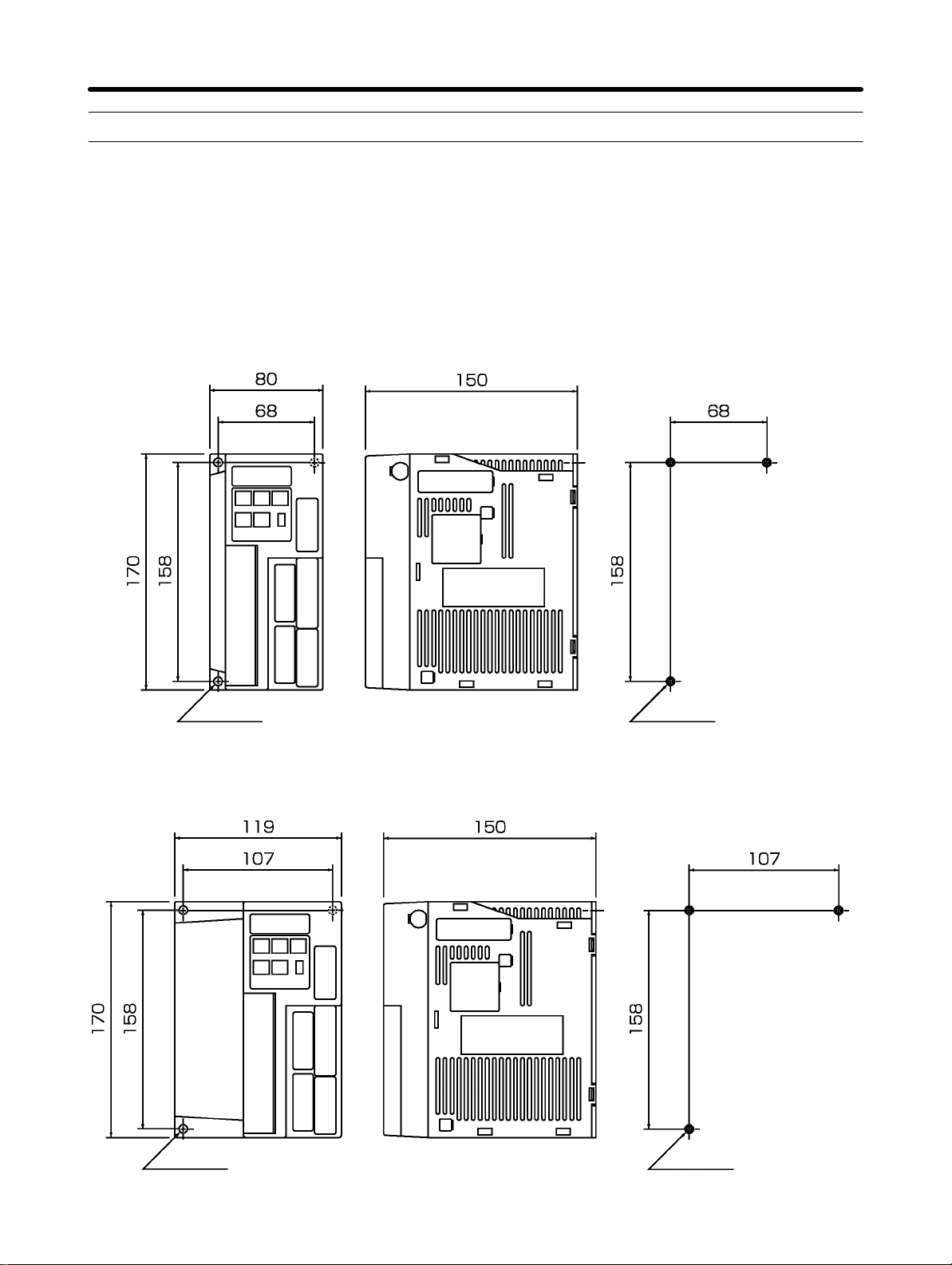

H DIO and CompoBus/S Position Drivers

D 200-VAC FND-X06H-j/-X12H-j

100-VAC FND-X06L-j/-X12L-j

Mounting Dimensions

Three,

6 dia.

D 200-VAC FND-X25H-j

Three,

6 dia.

Three, M5

Mounting Dimensions

Three, M5

2-2

Page 29

Design and Installation Chapter 2

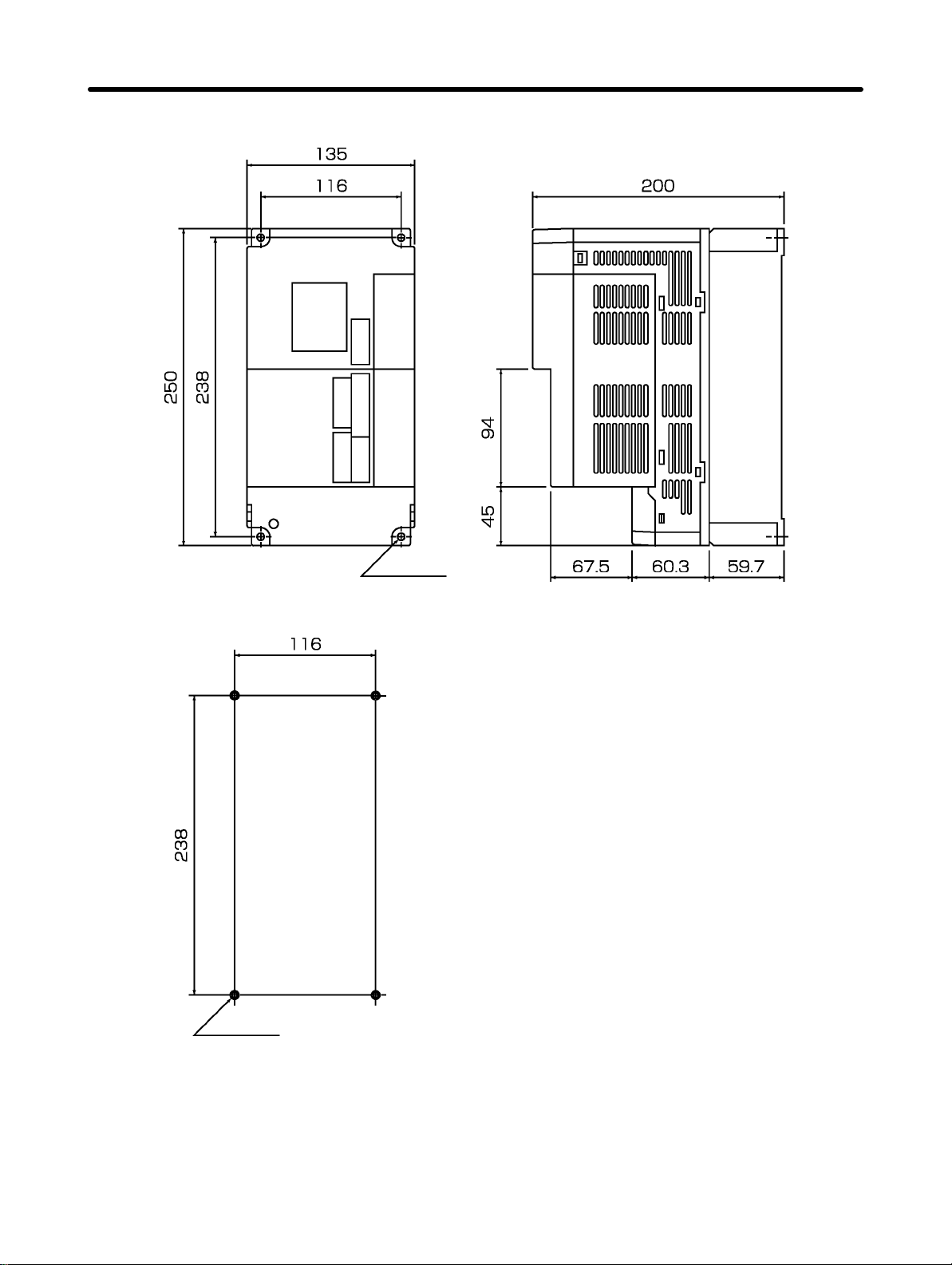

D 200-VAC FND-X50H-j

Mounting Dimensions

Four

, M5

Four,

6 dia.

2-3

Page 30

Design and Installation Chapter 2

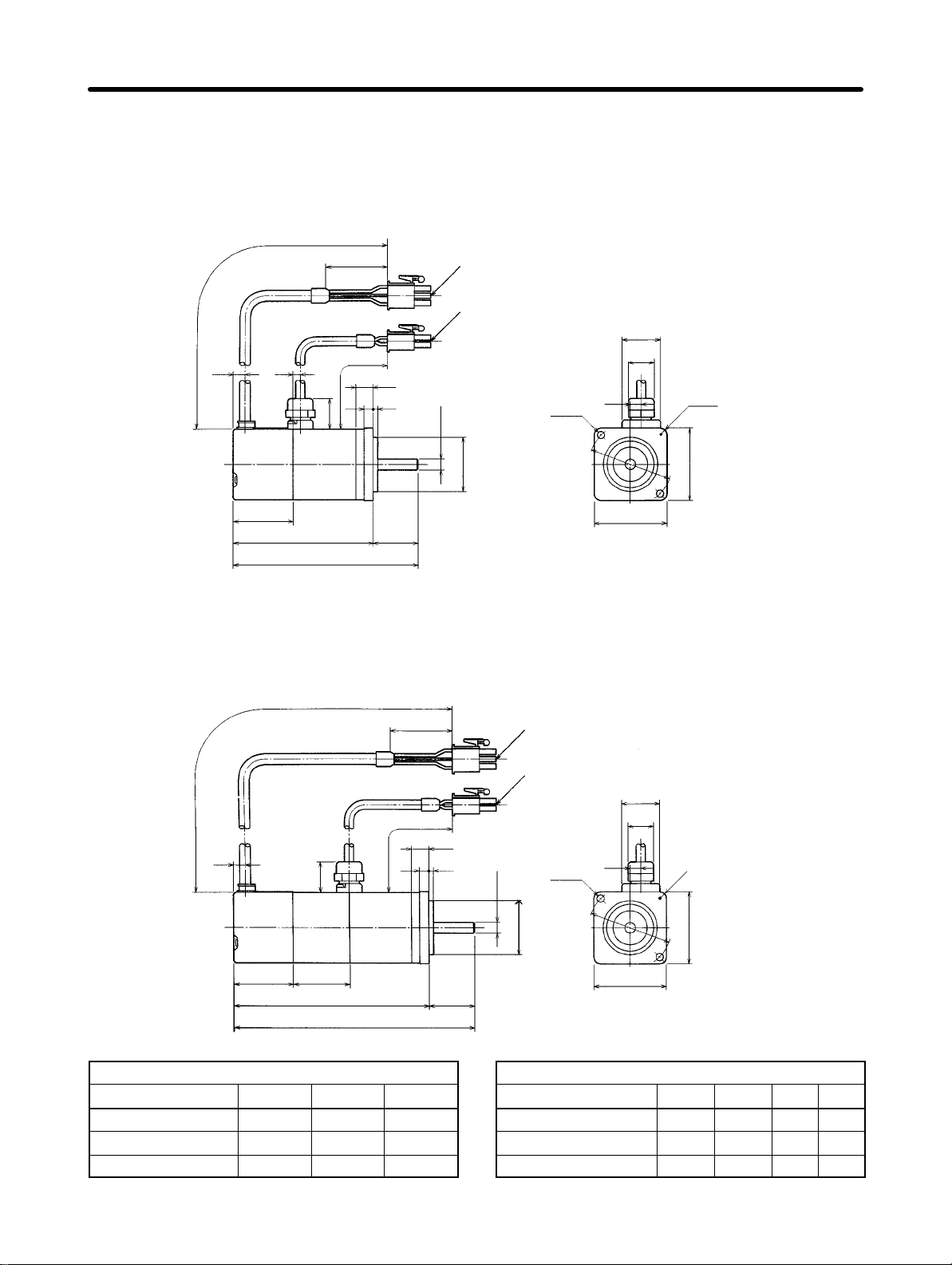

H OMNUC U-Series AC Servomotors with Incremental Encoders

(U-INC 30 to 750 W) Conforming to UL/cUL

D 30-W/50-W/100-W Standard Models (Without Brakes):

R88M-U03030HA, R88M-U05030HA, R88M-U10030HA

300±30

6.5 6

17

35

300±30

5

9.5

2.5

Encoder adapter

Motor plug

6h6 dia.

30h7 dia.

Two,

4.3 dia.

46

dia.

18

14

dia.

6

Four, R3.7

40

33

LL 25

L

D 30-W/50-W/100-W Models with Brakes:

R88M-U03030HA-B, R88M-U05030HA-B, R88M-U10030HA-B

300±30

6.5

35

300±30

9.5

2.55

17

33 LB

25LL

L

Encoder adapter

Motor plug

Two,

4.3 dia.

6h6 dia.

30h7 dia.

46

dia.

40

21

14

dia.

4

40

Four, R3.7

40

Standard Models (Without Brakes)

Model L LL S

R88M-U03030HA 94.5 69.5 6

R88M-U05030HA 102.0 77.0 6

R88M-U10030HA 119.5 94.5 8

2-4

Models with Brakes

Model L LL LB S

R88M-U03030HA-B 126 101 31.5 6

R88M-U05030HA-B 133.5 108.5 31.5 6

R88M-U10030HA-B 160 135 40.5 8

Page 31

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Incremental Encoders

(U-INC 30 to 750 W) Conforming to UL/cUL (Contd.)

D 200-W/400-W Standard Models (Without Brakes):

R88M-U20030HA, R88M-U40030HA

300±30

5.2 7

35

300±30

12

17

63

Encoder adapter

Motor plug

Four,

5.5 dia.

14h6 dia.

70

dia.

50h7 dia.

21

14

dia.

Four, R5.3

60

34

LL 30

L

D 200-W/400-W Models with Brakes:

R88M-U20030HA-B, R88M-U40030HA-B

5.2 5.5 7

17

300±30

35

300±30

12

63

60

Encoder adapter

Motor plug

14

Four,

5.5

dia.

14h6 dia.

70 dia.

50h7 dia.

21

dia.

Four, R5.3

60

34 39.5

LL 30

L

Standard Models (Without Brakes)

Model L LL

R88M-U20030HA 126.5 96.5

R88M-U40030HA 154.5 124.5

60

Models with Brakes

Model L LL

R88M-U20030HA-B 166 136

R88M-U40030HA-B 194 164

2-5

Page 32

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Incremental Encoders

(U-INC 30 to 750 W) Conforming to UL/cUL (Contd.)

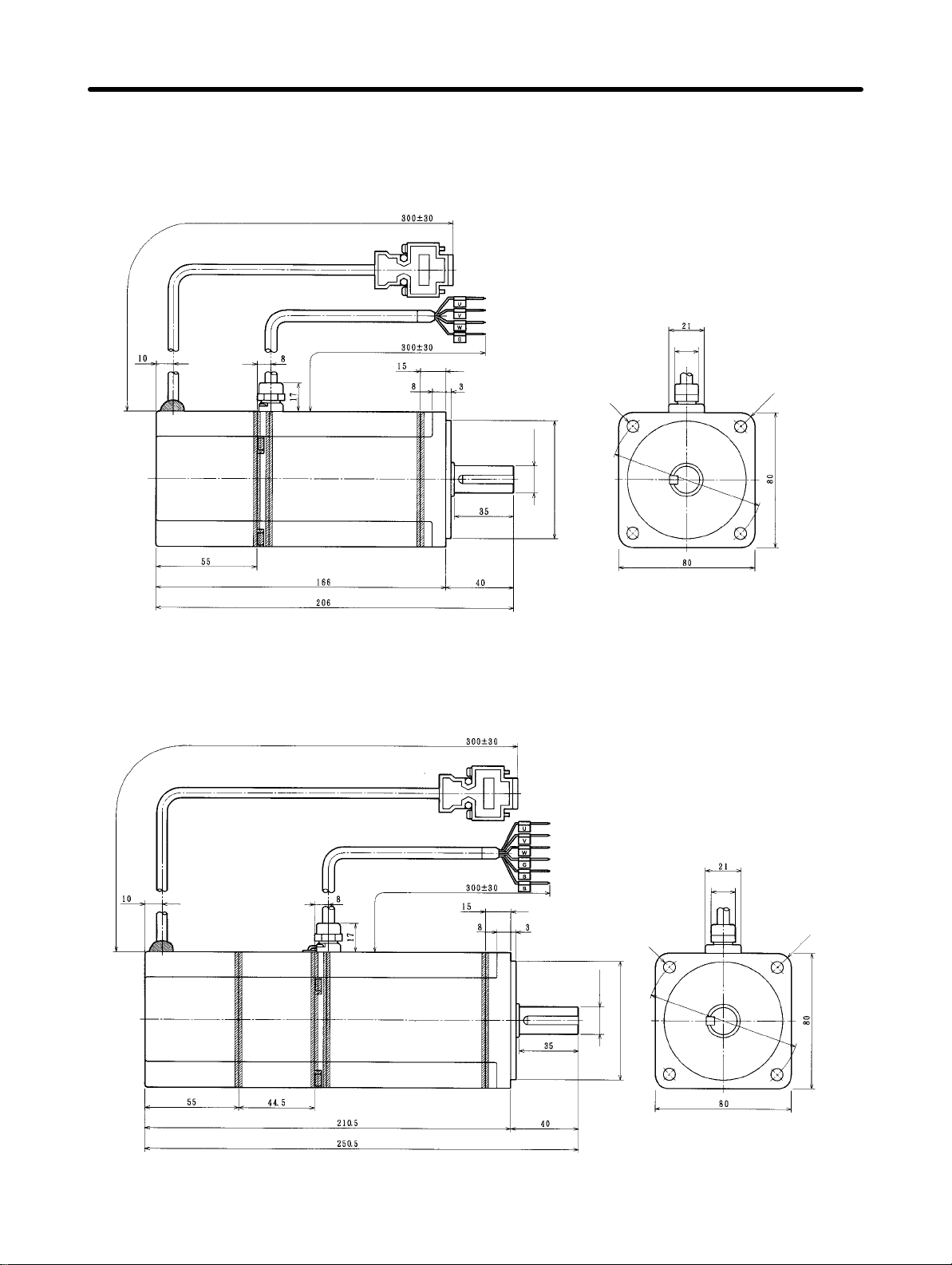

D 750-W Standard Models (Without Brakes): R88M-U75030HA

300±30

35

85.2

17

300±30

15

83

Encoder adapter

Motor plug

Four,

7 dia.

21

14 dia.

Four, R8.2

16h6 dia.

35

34

145 40

185

D 750-W Models with Brakes: R88M-U75030HA-B

300±30

35

85.2

17

300±30

15

83

90 dia.

70h7 dia.

Encoder adapter

Motor plug

Four,

7 dia.

80

80

21

14 dia.

Four, R8.2

2-6

34 44.5

189.5 40

229.5

16h6 dia.

35

90 dia.

80

70h7 dia.

80

Page 33

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Incremental Encoders

(U-INC 30 to 750 W) Conforming to EC Directives

D 30-W/50-W/100-W Standard Models (Without Brakes):

R88M-U03030VA-S1, R88M-U05030VA-S1, R88M-U10030VA-S1

14 dia.

Two,

4.3 dia.

Sh6 dia.

46 dia.

30h7 dia.

D 30-W/50-W/100-W Models with Brakes:

R88M-U03030VA-BS1, R88M-U05030VA-BS1, R88M-U10030VA-BS1

14 dia.

Two,

4.3 dia.

Sh6 dia.

Four, R3.7

Four, R3.7

Standard Models (Without Brakes)

Model L LL S

R88M-U03030VA-S1 94.5 69.5 6

R88M-U05030VA-S1 102.0 77.0 6

R88M-U10030VA-S1 119.5 94.5 8

46 dia.

30h7 dia.

Models with Brakes

Model L LL LB S

R88M-U03030VA-BS1 126 101 31.5 6

R88M-U05030VA-BS1 133.5 108.5 31.5 6

R88M-U10030VA-BS1 160 135 40.5 8

2-7

Page 34

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Incremental Encoders

(U-INC 30 to 750 W) Conforming to EC Directives (Contd.)

D 200-W/400-W Standard Models (Without Brakes):

R88M-U20030VA-S1, R88M-U40030VA-S1

14 dia.

D 200-W/400-W Models with Brakes:

R88M-U20030VA-BS1, R88M-U40030VA-BS1

14h6 dia.

50h7 dia.

Four,

5.5 dia.

70 dia.

Four, R5.3

14 dia.

Standard Models (Without Brakes)

Model L LL

R88M-U20030VA-S1 126.5 96.5

R88M-U40030VA-S1 154.5 124.5

2-8

Four,

14h6 dia.

50h7 dia.

5.5 dia.

70 dia.

Four, R5.3

Models with Brakes

Model L LL

R88M-U20030VA-BS1 166 136

R88M-U40030VA-BS1 194 164

Page 35

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Incremental Encoders

(U-INC 30 to 750 W) Conforming to EC Directives (Contd.)

D 750-W Standard Models (Without Brakes): R88M-U75030VA-S1

14 dia.

Four,

16h6 dia.

70h7 dia.

D 750-W Models with Brakes: R88M-U75030VA-BS1

7 dia.

90 dia.

Four, R8.2

Four,

16h6 dia.

70h7 dia.

14 dia.

Four, R8.2

7 dia.

90 dia.

2-9

Page 36

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders

(U-ABS 30 to 750 W) Conforming to UL/cUL

D 30-W/50-W/100-W Standard Models (Without Brakes):

R88M-U03030TA, R88M-U05030TA, R88M-U10030TA

Encoder adapter

Motor plug

14 dia.

Four

, R3.7

53

dia.

Sh6 dia.

30h7 dia.

Two,

4.3 dia.

46 dia.

D 30-W/50-W/100-W Models with Brakes:

R88M-U03030TA-B, R88M-U05030TA-B, R88M-U10030TA-B

Encoder adapter

Motor plug

53

dia.

Standard Models (Without Brakes)

Model L LL S

R88M-U03030TA 117.5 92.5 6

R88M-U05030TA 125 100 6

R88M-U10030TA 142.5 117.5 8

Sh6 dia.

30h7 dia.

R88M-U03030TA-B 149 124 31.5 6

R88M-U05030TA-B 156.5 131.5 31.5 6

R88M-U10030TA-B 183 158 40.5 8

Two,

Model L LL LB S

14

dia.

4.3 dia.

46 dia.

Models with Brakes

Four

, R3.7

2-10

Page 37

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders

(U-ABS 30 to 750 W) Conforming to UL/cUL (Contd.)

D 200-W/400-W Standard Models (Without Brakes):

R88M-U20030TA, R88M-U40030TA

Encoder adapter

Motor plug

14

dia.

D 200-W/400-W Models with Brakes:

R88M-U20030TA-B, R88M-U40030TA-B

14h6 dia.

14h6 dia.

Four

, 5.5.dia.

70 dia.

50h7 dia.

Encoder adapter

Motor plug

Four

, 5.5.dia.

Four,

R5.3

14

dia.

Four,

R5.3

Standard Models (Without Brakes)

Model L LL

R88M-U20030TA 147.5 117.5

R88M-U40030TA 175.5 145.5

70 dia.

50h7 dia.

Models with Brakes

Model L LL

R88M-U20030TA-B 187 157

R88M-U40030TA-B 215 185

2-11

Page 38

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders

(U-ABS 30 to 750 W) Conforming to UL/cUL (Contd.)

D 750-W Standard Models (Without Brakes): R88M-U75030TA

Encoder adapter

Motor plug

14

dia.

Four,

Four

, 7 dia.

R8.2

16h6 dia.

D 750-W Models with Brakes: R88M-U75030TA-B

90 dia.

70h7 dia.

Encoder adapter

Motor plug

Four

, 7 dia.

14

dia.

Four,

R8.2

2-12

16h6 dia.

90 dia.

70h7 dia.

Page 39

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders

(U-ABS 30 to 750 W) Conforming to EC Directives

D 30-W/50-W/100-W Standard Models (Without Brakes):

R88M-U03030XA-S1, R88M-U05030XA-S1, R88M-U10030XA-S1

14 dia.

Two,

4.3 dia.

53 dia.

Sh6 dia.

30h7 dia.

46 dia.

D 30-W/50-W/100-W Models with Brakes:

R88M-U03030XA-BS1, R88M-U05030XA-BS1, R88M-U10030XA-BS1

Two,

4.3 dia.

Sh6 dia.

46 dia.

53

dia.

30h7 dia.

Four, R3.7

14 dia.

Four, R3.7

Standard Models (Without Brakes)

Model L LL S

R88M-U03030XA-S1 117.5 92.5 6

R88M-U05030XA-S1 125 100 6

R88M-U10030XA-S1 142.5 117.5 8

Models with Brakes

Model L LL LB S

R88M-U03030XA-BS1 149 124 31.5 6

R88M-U05030XA-BS1 156.5 131.5 31.5 6

R88M-U10030XA-BS1 183 158 40.5 8

2-13

Page 40

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders

(U-ABS 30 to 750 W) Conforming to EC Directives (Contd.)

D 200-W/400-W Standard Models (Without Brakes):

R88M-U20030XA-S1, R88M-U40030XA-S1

14 dia.

Four,

5.5 dia.

14h6 dia.

70 dia.

50h7 dia.

Four, R5.3

D 200-W/400-W Models with Brakes:

R88M-U20030XA-BS1, R88M-U40030XA-BS1

14h6 dia.

50h7 dia.

Four,

70 dia.

5.5 dia.

14 dia.

Four, R5.3

Standard Models (Without Brakes)

Model L LL

R88M-U20030XA-S1 147.5 117.5

R88M-U40030XA-S1 175.5 145.5

2-14

Models with Brakes

Model L LL

R88M-U20030XA-BS1 187 157

R88M-U40030XA-BS1 215 185

Page 41

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders

(U-ABS, 30 to 750 W) Conforming to EC Directives (Contd.)

D 750-W Standard Models (Without Brakes): R88M-U75030XA-S1

14 dia.

16h6 dia.

D 750-W Models with Brakes: R88M-U75030XA-BS1

Four,

90 dia.

70h7 dia.

7 dia.

Four, R8.2

Four,

16h6 dia.

14 dia.

Four, R8.2

7 dia.

90 dia.

70h7 dia.

2-15

Page 42

Design and Installation Chapter 2

H U-Series AC Servomotor Shaft Dimensions with Keys

(U-INC, U-ABS, 30 to 750 W)

Standard U-series AC Servomotors do not have keys on the shafts. The shaft dimensions of motors

keys are shown below

with

ber. Key slots are based on JIS B1301-1976.

D 30-W/50-W Models

Standard: R88M-U03030j-S1, R88M-U05030j-S1

With Brakes: R88M-U03030j-BS1, R88M-U05030j-BS1

D 100-W Models

Standard: R88M-U10030j-S1

With Brakes: R88M-U10030j-BS1

. Motors with keys are indicated by adding “-S1” to the end of

14

14

Dia.:

Dia.:

6h6

8h6

2

1.2

2

1.8

3

the model num

-

3

D 200-W/400-W Models

Standard: R88M-U20030j-S1, R88M-U40030j-S1

With Brakes: R88M-U20030j-BS1, R88M-U40030j-BS1

20

Dia.:

14h6

5

5

D 750-W Models

Standard: R88M-U75030j-S1

With Brakes: R88M-U75030j-BS1

30

Dia.:

16h6

5

5

3

3

2-16

Page 43

Design and Installation Chapter 2

H OMNUC U-UE-Series AC Servomotors with Incremental Encoders (UE)

Not Conforming to Any Standards

D 100-W Standard Models (Without Brakes): R88M-UE10030H-S1

Encoder adapter

Motor plug

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

Two, 4.3 dia.

8h6 dia.

46 dia.

30h7 dia.

Four, R3.7

8h6 dia.

D 100-W Models with Brakes: R88M-UE10030H-BS1

Encoder adapter

Motor plug

Two, 4.3 dia.

8h6 dia.

46 dia.

30h7 dia.

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

Four, R3.7

8h6 dia.

2-17

Page 44

Design and Installation Chapter 2

H OMNUC U-UE-Series AC Servomotors with Incremental Encoders (UE)

(Contd.)

D 200-W/400-W Standard Models (Without Brakes):

R88M-UE20030H-S1, R88M-UE40030H-S1

Encoder adapter

Motor plug

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

Four, 5.5 dia.

14h6 dia.

70 dia.

50h7 dia.

Four, R5.3

14h6 dia.

D 200-W/400-W Models with Brakes:

R88M-UE20030H-BS1, R88M-UE40030H-BS1

Standard Models (Without Brakes)

Model L LL

R88M-UE20030H-S1 126.5 96.5

R88M-UE40030H-S1 154.5 124.5

Encoder adapter

Motor plug

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

Four, 5.5 dia. Four, R5.3

14h6 dia.

70 dia.

50h7 dia.

Models with Brakes

Model L LL

R88M-UE20030H-BS1 166 136

R88M-UE40030H-BS1 194 164

14h6 dia.

2-18

Page 45

Design and Installation Chapter 2

H OMNUC U-UE-Series AC Servomotors with Incremental Encoders (UE)

Not Conforming to Any Standards (Contd.)

D 750-W Standard Models (Without Brakes): R88M-UE75030H-S1

Encoder adapter

Motor plug

Four, 7 dia.

90 dia.

16h6 dia.

70h7 dia.

D 750-W Models with Brakes: R88M-UE75030H-BS1

Encoder adapter

Motor plug

Four, 7 dia.

Four, R8.2

16h6 dia.

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

Four, R8.2

90 dia.

16h6 dia.

70h7 dia.

16h6 dia.

Shaft end dimensions

Key slot dimensions, conform to

JIS B1301-1976.

2-19

Page 46

Design and Installation Chapter 2

H OMNUC U-UE-Series AC Servomotors with Incremental Encoders (UE)

Conforming to EC Directives

D 100-W Standard Models (Without Brakes): R88M-UE10030V-S1

14 dia.

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

8h6 dia.

8h6 dia.

30h7 dia.

Two, 4.3 dia.

46 dia.

Four, R3.7

D 100-W Models with Brakes: R88M-UE10030V-BS1

Two, 4.3 dia.

8h6 dia.

46 dia.

30h7 dia.

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

8h6 dia.

14 dia.

Four, R3.7

2-20

Page 47

Design and Installation Chapter 2

H OMNUC U-UE-Series AC Servomotors with Incremental Encoders (UE)

Conforming to EC Directives (Contd.)

D 200-W/400-W Standard Models (Without Brakes):

R88M-UE20030V-S1, R88M-UE40030V-S1

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

14h6 dia.

14 dia.

14h6 dia.

50h7 dia.

D 200-W/400-W Models with Brakes:

R88M-UE20030V-BS1, R88M-UE40030V-BS1

Four, 5.5 dia.

70 dia.

14 dia.

Four, R5.3

Shaft end dimensions

Key slot dimensions, conform to

JIS B1301-1976.

14h6 dia.

Standard Models (Without Brakes)

Model L LL

R88M-UE20030V-S1 126.5 96.5

R88M-UE40030V-S1 154.5 124.5

Four, 5.5 dia.

14h6 dia.

70 dia.

50h7 dia.

Four, R5.3

Models with Brakes

Model L LL

R88M-UE20030V-BS1 166 136

R88M-UE40030V-BS1 194 164

2-21

Page 48

Design and Installation Chapter 2

H OMNUC U-UE-Series AC Servomotors with Incremental Encoders (UE)

Conforming to EC Directives (Contd.)

D 750-W Standard Models (Without Brakes): R88M-UE75030V-S1

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

14 dia.

Four, 7 dia.

16h6 dia.

90 dia.

70h7 dia.

16h6 dia.

Four, R8.2

D 750-W Models with Brakes: R88M-UE75030V-BS1

16h6 dia.

Four, 7 dia.

70h7 dia.

Shaft end dimensions

Key slot dimensions, conform to JIS B1301-1976.

16h6 dia.

14 dia.

Four, R8.2

90 dia.

2-22

Page 49

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Incremental Encoders (U-INC

1 to 2 kW)

D 1.0-kW/1.5-kW/2.0-kW Standard Models (Without Brakes)

Not Conforming to Any Standards: R88M-U1K030H/-U1K530H/-U2K030H

Conforming to EC Directives: R88M-U1K030V-S1/-U1K530V-S1/-U2K030V-S1

24h6 dia.

95h7 dia.

130 dia.

115 dia.

Four, 7 dia.

D 1.0-kW/1.5-kW/2.0-kW Models With Brakes

Not Conforming to Any Standards: R88M-U1K030H-B/-U1K530H-B/-U2K030H-B

Conforming to EC Directives: R88M-U1K030V-BS1/-U1K530V-BS1/-U2K030V-BS1

24h6 dia.

95h7 dia.

130 dia.

115 dia.

Four, 7 dia.

Standard Models (Without Brakes)

Model L LL

R88M-U1K030j 194 149

R88M-U1K530j 220 175

R88M-U2K030j 243 198

R88M-U1K030j-Bj 238 193

R88M-U1K530j-Bj 264 219

R88M-U2K030j-Bj 287 242

Models with Brakes

Model L LL

Note Servomotors with model numbers ending in “S1” have straight shafts with keys. Refer to

2-25 U-Series AC Servomotor Shaft Dimensions with Keys

for key dimensions.

page

2-23

Page 50

Design and Installation Chapter 2

H OMNUC U-Series AC Servomotors with Absolute Encoders (U-ABS

1 to 2 kW)

D 1.0-kW/1.5-kW/2.0-kW Standard Models (Without Brakes)

Not Conforming to Any Standards: R88M-U1K030T/-U1K530T/-U2K030T

Conforming to EC Directives: R88M-U1K030X-S1/-U1K530X-S1/-U2K030X-S1

24h6 dia.

95h7 dia.

130 dia.

115 dia.

Four, 7 dia.

D 1.0-kW/1.5-kW/2.0-kW Models With Brakes

Not Conforming to Any Standards: R88M-U1K030T-B/-U1K530T-B/-U2K030T-B

Conforming to EC Directives: R88M-U1K030X-BS1/-U1K530X-BS1/-U2K030X-BS1

24h6 dia.

95h7 dia.

130 dia.

115 dia.

Four, 7 dia.

Standard Models (Without Brakes)

Model L LL

R88M-U1K030j 208 163

R88M-U1K530j 234 189

R88M-U2K030j 257 212

R88M-U1K030j-Bj 252 207

R88M-U1K530j-Bj 278 233

R88M-U2K030j-Bj 301 256

Models with Brakes

Model L LL

Note Servomotors with model numbers ending in “S1” have straight shafts with keys. Refer to

2-25 U-Series AC Servomotor Shaft Dimensions with Keys

for key dimensions.

2-24

page

Page 51

Design and Installation Chapter 2

H U-Series AC Servomotor Shaft Dimensions with Keys

(U-INC, U-ABS, 1 to 2 kW)

Standard U-series AC Servomotors do not have keys on the shafts. The shaft dimensions of motors

keys are shown below

with

ber. Key slots are based on JIS B1301-1976.

D 1.0-kW/1.5-kW/2.0-kW Models

Standard: R88M-U1K030j-S1, R88M-U1K530j-S1, R88M-U2K030j-S1

With Brakes: R88M-U1K030j-BS1, R88M-U1K530j-BS1, R88M-U2K030j-BS1

. Motors with keys are indicated by adding “-S1” to the end of

24h6 dia.

M8 with effective

depth of 16

the model num

-

2-25

Page 52

Design and Installation Chapter 2

H OMNUC H-Series AC Servomotor with Incremental Encoder (H)

D 50-W/100-W Standard Models (Without Brakes): R88M-H05030, R88M-H10030

D 50-W/100-W Models with Brakes: R88M-H05030-B, R88M-H10030-B

Four, R4

93 dia. max.

63 dia.

50

0

ć0.025

Ădia.

80±0.2 dia.

Four, 5 dia.

Standard Models (Without Brakes)

Model L1 L2 L3

R88M-H05030 (50 W) 53.5 99 45.5

R88M-H10030 (100 W) 63.5 109 45.5

66 66±0.4

Models With Brakes

Model L1 L2 L3

R88M-H05030-B (50 W) 84.5 130 45.5

R88M-H10030-B (100 W) 94.5 140 45.5

8

ć0.009

0

Ădia.

D 200-W/300-W Standard Models (Without Brakes): R88M-H20030, R88M-H30030

D 200-W/300-W Models with Brakes: R88M-H20030-B, R88M-H30030-B

Four, R10

0

14

Ădia.

ć0.011

77 dia.

107 dia. max.

0

70

Ădia.

ć0.03

90±0.2 dia.

Four, 6 dia.

Standard Models (Without Brakes)

Model L1 L2 L3

R88M-H20030 (200 W) 77 123.5 46.5

R88M-H30030 (300 W) 89 135.5 46.5

2-26

80 80±0.4

Models With Brakes

Model L1 L2 L3

R88M-H20030-B (200 W) 107.5 154 46.5

R88M-H30030-B (300 W) 119.5 166 46.5

Page 53

Design and Installation Chapter 2

H OMNUC H-Series AC Servomotors with Incremental Encoders (H)

(Contd.)

D 500-W/750-W/1100-W Standard Models (Without Brakes):

R88M-H50030, R88M-H75030, R88M-H1K130

D 500-W/750-W/1100-W Models with Brakes:

R88M-H50030-B, R88M-H75030-B, R88M-H1K130-B

Four, R15

162 dia. max.

77 dia.

Shaft

Dimensions

R88M-H50030/-H50030-B

R88M-H75030/-H75030-B

0

16

Ădia.

ć0.011

Shaft Dimensions

R88M-H1K130/-H1K130-B

0

19

Ădia.

ć0.013

110

0

ć0.035

Ădia.

130±0.2 dia.

Four, 9 dia.

Standard Models (Without Brakes)

Model L1 L2 L3

R88M-H50030 (500 W) 107.5 154.0 46.5

R88M-H75030 (750 W) 126.0 172.5 46.5

R88M-H1K130 (1100 W) 144.5 191.0 46.5

Models With Brakes

Model L1 L2 L3

R88M-H50030-B (500 W) 148.5 195.0 46.5

R88M-H75030-B (750 W) 167.0 213.5 46.5

R88M-H1K130-B (1100 W) 185.5 232.0 46.5

2-27

Page 54

Design and Installation Chapter 2

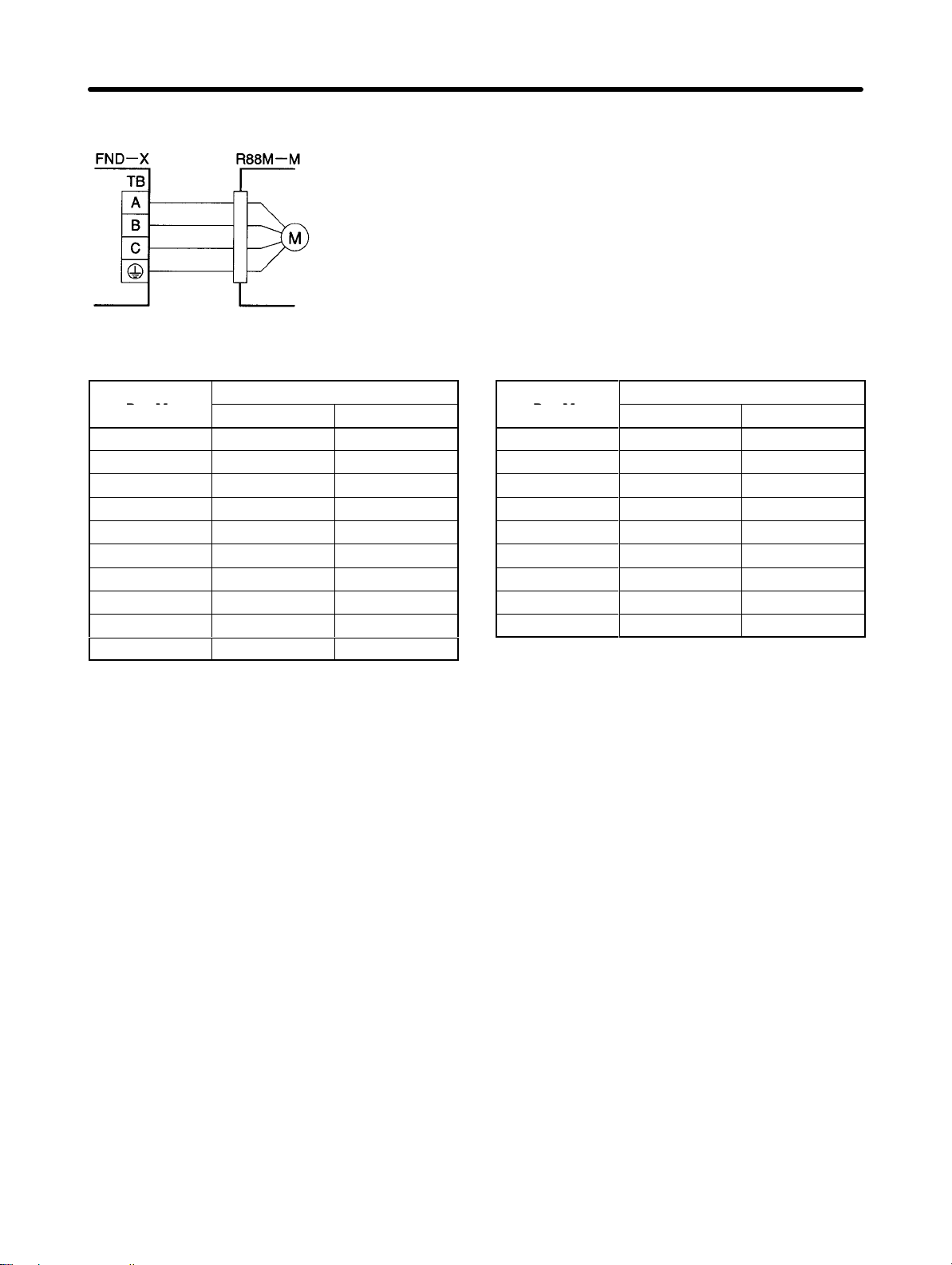

H OMNUC M-Series AC Servomotors with Resolvers (M)

D 60-W/120-W (4,000 r/min) Standard Models (Without Brakes): R88M-M06040,

R88M-M12040

7.4 dia.

8h6 dia.

50h7 dia.

…

Four,

5 dia.

D 60-W/120-W (4,000 r/min) Models with Brakes: R88M-M06040-B, R88M-M12040-B

7.4 dia.

8h6 dia.

50h7 dia.

°

°

Four,

5 dia.

Standard Models (Without Brakes)

Model L LL LM

R88M-M06040 150 120 85

R88M-M12040 175 145 110

D Shaft End Dimensions

2-28

Models with Brakes

Model LX LY LM

R88M-M06040-B 184 154 85

R88M-M12040-B 209 179 110

Page 55

Design and Installation Chapter 2

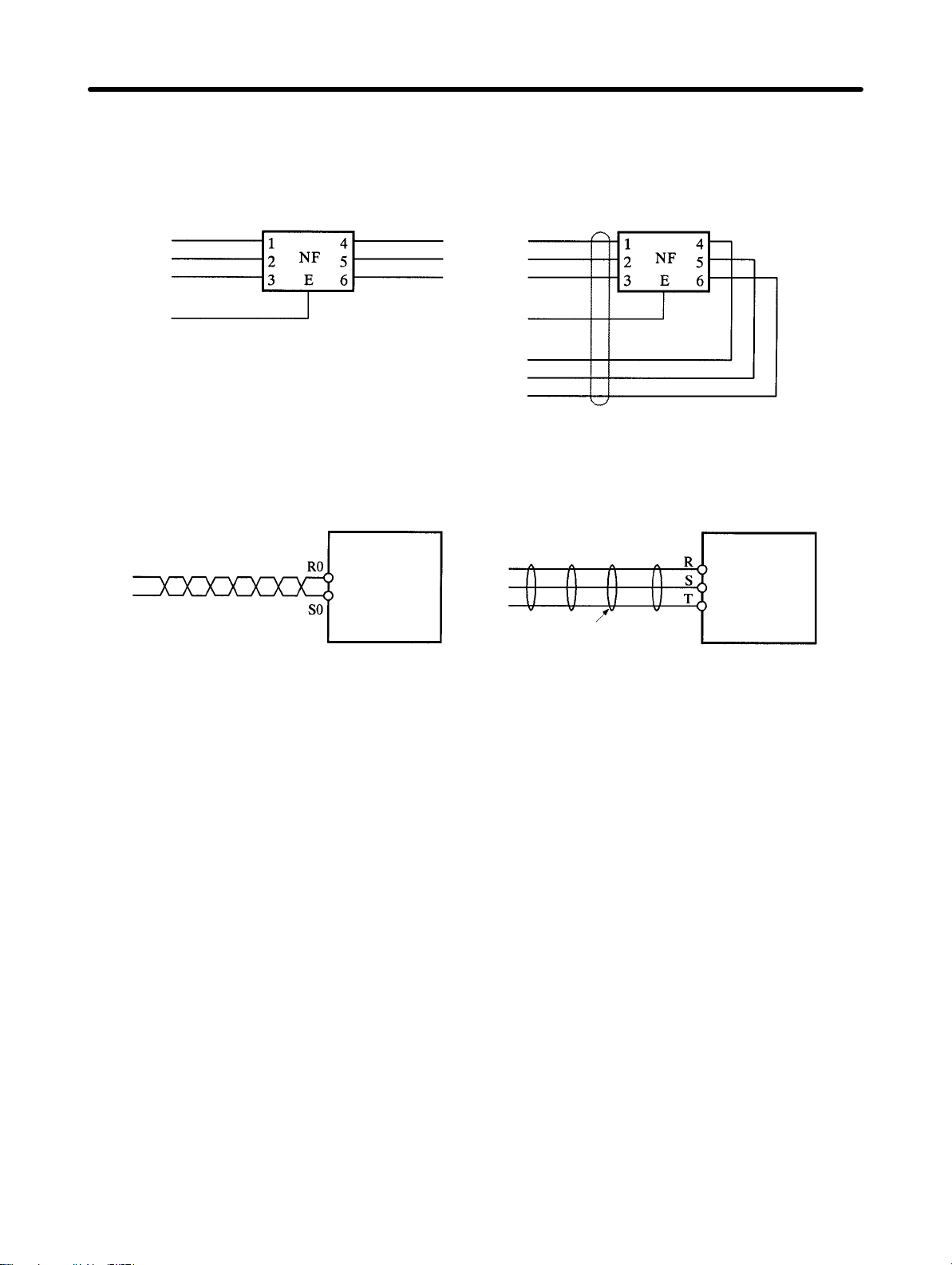

H OMNUC M-Series AC Servomotors with Resolvers (M) (Contd.)

D 200-W (2,000 r/min) Standard Models (Without Brakes): R88M-M20020

D 200-W/400-W (4,000 r/min) Standard Models: R88M-M20040, R88M-40040

7.4 dia.

14h6 dia.

100±0.2 dia

80h7 dia.

Four, 7dia.

D 200-W (2,000 r/min) Models with Brakes: R88M-M20020-B

D 200-W/400-W (4,000 r/min) Models with Brakes: R88M-M20040-B, R88M-M40040-B