Page 1

Cat. No. I571-E1-01

USER’S MANUAL

OMNUC G5 SERIES

R88M-K@

(AC Servomotors)

R88D-KT

(AC Servo Drives)

AC SERVOMOTORS/SERVO DRIVES

Page 2

Trademarks and Copyrights

•

Product names and system names in this manual are trademarks or registered trademarks of their

respective companies.

© OMRON, 2009

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 3

Introduction

Thank you for purchasing the OMNUC G5 Series. This user's manual explains how to install and

wire the OMNUC G5 Series, set parameters needed to operate the G5 Series, and remedies to be

taken and inspection methods to be used should problems occur.

Intended Readers

This manual is intended for the following individuals.

Those having electrical knowledge (certified electricians or individuals having equivalent or more

knowledge) and also being qualified for one of the following:

Those in charge of introducing FA equipment

Those designing FA systems

Those managing FA sites

Notes

This manual contains the information you need to know to correctly use the OMNUC G5 Series and

peripheral equipment.

Before using the OMNUC G5 Series, read through this manual and gain a full understanding of the

information provided herein.

After you finished reading the manual, keep it in a convenient place so that the manual can be

referenced at any time.

Make sure this manual will also get to the end-user.

Introduction

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

1

Page 4

Items Requiring Acknowledgment

Items Requiring Acknowledgment

1. Terms of Warranty

(1) Warranty period

The warranty period of this product is 1 year after its purchase or delivery to the specified

location.

(2) Scope of warranty

If the product fails during the above warranty period due to design, material or

workmanship, we will provide a replacement unit or repair the faulty product free of

charge at the location where you purchased the product.

Take note, however, that the following failures are excluded from the scope of warranty.

a) Failure due to use or handling of the product in any condition or environment not

specified in the catalog, operation manual, etc.

b) Failure not caused by this product

c) Failure caused by any modification or repair not carried out by OMRON

d) Failure caused by any use not intended for this product

e) Failure that could not be predicted with the level of science and technology available

when the product was shipped from OMRON

f) Failure caused by a natural disaster or any other reason for which OMRON is not held

responsible

Take note that this warranty applies to the product itself, and losses induced by a failure

of the product are excluded from the scope of warranty.

2. Limited Liability

(1) OMRON shall not assume any responsibility whatsoever for any special damage, indirect

damage or passive damage arising from this product.

(2) OMRON shall not assume any responsibility for programming done by individuals not

belonging to OMRON, if the product is programmable, or outcomes of such programming.

3. Conditions for Intended Application

(1) If this product is combined with other product, the customer must check the standards and

regulations applicable to such combination. The customer must also check the compatibility

of this product with any system, machinery or device used by the customer. If the above

actions are not taken, OMRON shall not assume any responsibility regarding the

compatibility of this product.

(2) If the product is used in the following applications, consult your OMRON sales representative

to check the necessary items according to the specification sheet, etc. Also make sure the

product is used within the specified ratings and performance ranges with an ample margin

and implement safety measures, such as designing a safety circuit, to minimize danger

should the product fail.

a) Used in any outdoor application, application subject to potential chemical

contamination or electrical interference, or in any condition or environment not

specified in the catalog, operation manual, etc.

b) Nuclear power control equipment, incineration equipment, railway, aircraft and vehicle

equipment, medical machinery, entertainment machinery, safety system or any other

device controlled by an administrative agency or industry regulation

c) System, machinery or device that may threaten human life or property

d) Gas, water or electricity supply system, system operated continuously for 24 hours or

any other equipment requiring high reliability

e) Any other application where a high level of safety corresponding to a) to d) above is

required

(3) If the customer wishes to use this product in any application that may threaten human life or

property, be sure to confirm beforehand that the entire system is designed in such a way to

notify dangers or ensure the necessary level of safety via design redundancy, and that the

product is wired and installed appropriately in the system according to the intended

2

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 5

Items Requiring Acknowledgment

application.

(4) Sample applications explained in the catalog, etc. are provided for reference purposes only.

When adopting any of these samples, check the function and safety of each equipment or

device.

(5) Understand all prohibited items and notes on use provided herein, so that this product will be

used correctly and that customers or third parties will not suffer unexpected losses.

4. Specification Change

The product specifications and accessories explained in the catalog, operation manual, etc.

are subject to change, if necessary, for the reasons of improvement, etc. Contact your

OMRON sales representative to check the actual specifications of this product.

5. Scope of Service

The price of this product excludes costs of service such as dispatching engineers.

If you have any request regarding service, consult your OMRON sales representative.

6. Scope of Application

The above paragraphs are based on the assumption that this product is traded and used in

Japan.

If you wish to trade or use this product outside Japan, consult your OMRON sales

representative.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

3

Page 6

Safety Precautions Document

Safty Points

Precautions for Correct Use

Reference

Danger

Caution

When an incorrect handling can lead to a dangerous

situation, which may result in a minor or moderate

injury, and when only a property damage may occur

When an incorrect handling can lead to a dangerous

situation, which may result in death or serious injury

Or, when a serious property damage may occur

Safety Precautions Document

So that the OMNUC G5-Series Servomotor and Servo Drive and peripheral equipment are used safely and correctly,

be sure to peruse this Safety Precautions document section and the mai n text before using the product in o rder to

learn all items you should know regarding the equipment as well as all safety information and precautions.

Make an arrangement so that this manual also gets to the end-user of this product.

After reading this manual, keep it with you at all times.

Explanation of Display

The precautions explained in this section describe important information regarding safety and must be followed without fail.

The display of precautions used in this manual and their meanings are explained below.

Even those items denoted by the caution symbol may lead to a serious outcome depending on the

situation. Accordingly, be sure to observe all safety precautions.

This symbol indicates an item you should perform or avoid in order to use the product safely.

This symbol indicates an item you should perform or avoid in order to prevent inoperative,

malfunction or any negative effect on performance or function.

This symbol indicates an item that helps deepen your understanding of the product or other useful tip.

Explanation of Symbols

Example of symbols

This symbol indicates danger and caution.

The specific instruction is described using an illustration or text inside or near .

The symbol shown to the left indicates "beware of electric shock".

4

This symbol indicates a prohibited item (item you must not do).

The specific instruction is described using an illustration or text inside or near .

The symbol shown to the left indicates "disassembly prohibited".

This symbol indicates a compulsory item (item that must be done).

The specific instruction is described using an illustration or text inside or near .

The symbol shown to the left indicates "grounding required".

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 7

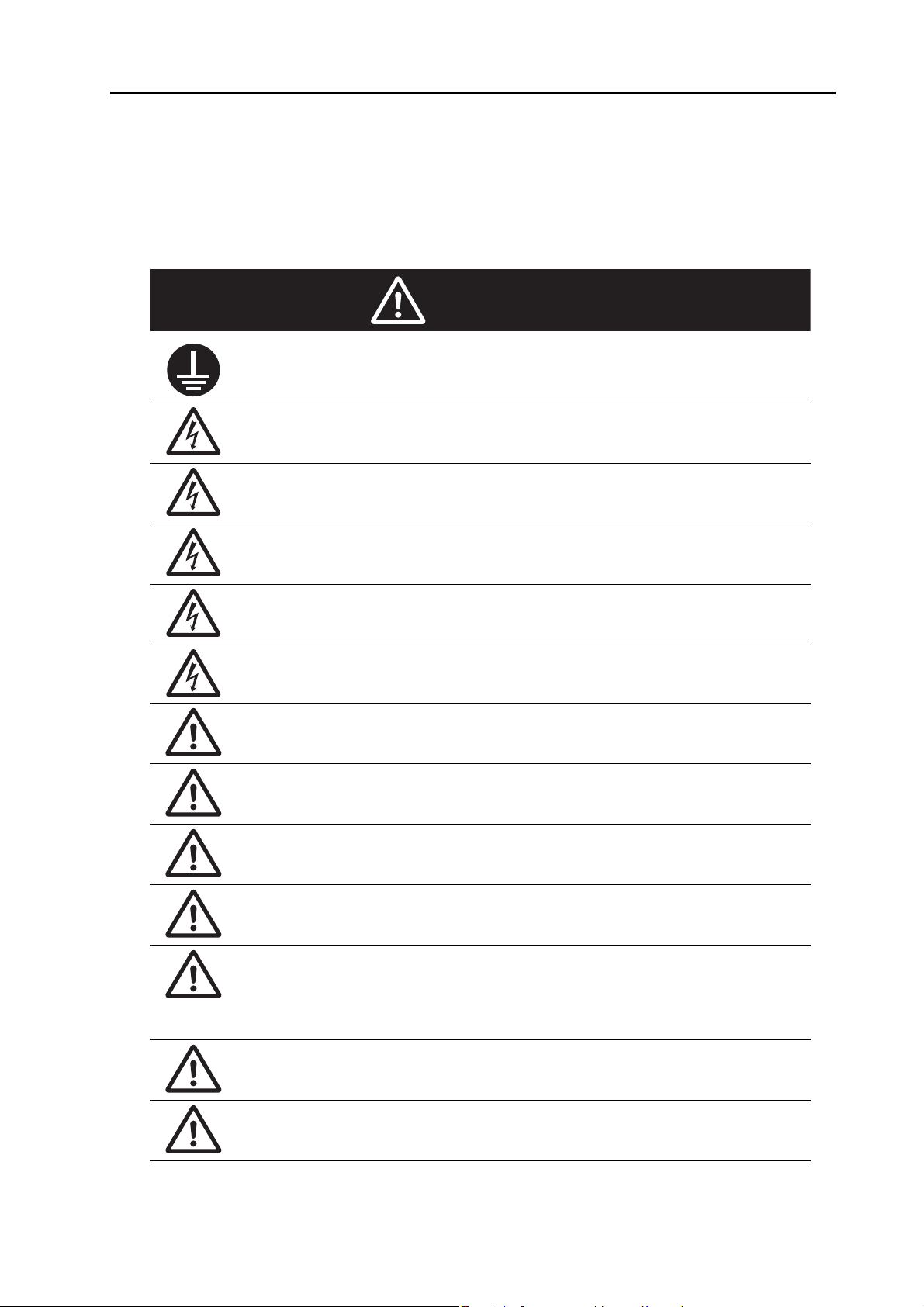

Safety Precautions Document

Danger

For Safe Use of This Product

Illustrations contained in this manual sometimes depict conditions without covers and safety shields for the

purpose of showing the details. When using this product, be sure to install the covers and shields as specified

and use the product according to this manual.

If the product has been stored for an extended period of time, contact your OMRON sales representative.

Be sure to ground the frame ground terminals of the driver and motor to 100 Ω or less.

Electric shock may result.

Never touch the parts inside the driver.

Electric shock may result.

While the power is supplied, do not remove the front cover, terminal covers, cables and

options.

Electric shock may result.

Installation, operation and maintenance or inspection by unauthorized personnel is

prohibited.

Electric shock or injury may result.

Before carrying out wiring or inspection, turn OFF the power supply and wait for at least 15

minutes.

Electric shock may result.

Do not damage, pull, stress strongly or pinch the cables or place heavy articles on them.

Electric shock, stopping of product operation or burn damage may result.

Never touch the rotating part of the motor during operation.

Injury may result.

Never modify the product.

Injury or equipment damage may result.

Install a stopping device on the machine side to ensure safety.

* The holding brake is not a stopping device to ensure safety.

Injury may result.

Install an immediate stop device externally to the machine so that the operation can be

stopped and the power supply cut off immediately.

Injury may result.

When the power is restored after a momentary power interruption, the machine may restart

suddenly. Never come close to the machine.

* Implement remedies to ensure safety of people nearby even when the machine is

restarted.

Injury may result.

After an earthquake, be sure to conduct safety checks.

Electric shock, injury or fire may result.

Never drive the motor using an external drive source.

Fire may result.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

5

Page 8

Safety Precautions Document

Caution

Do not place flammable materials near the motor, driver or Regeneration Resistor.

Fire may result.

Install the motor, driver and Regeneration Resistor to non-flammable mate rials such as

metals.

Fire may result.

When you perform a system configuration using the safety function, be sure to fully

understand the relevant safety standards and the descriptions in the operation manual, and

apply them to the system design.

Injury or damage may result.

Do not use the cable when it is laying in oil or water.

Electric shock, injury or fire may result.

Never connect a commercial power supply directly to the motor.

Fire or failure may result.

Danger

Do not perform wiring or any operation with wet hands.

Electric shock, injury or fire may result.

Do not touch the key grooves with bare hands if a motor with shaft-end key grooves is being

used.

Injury may result.

Use the motor and driver in the specified combination.

Fire or equipment damage may result.

Do not store or install the product in the following environment:

Location subject to direct sunlight

Location where the ambient temperature exceeds the specified level

Location where the relative humidity exceeds the specified level

Location subject to condensation due to the rapid temperature change

Location subject to corrosive or flammable gases

Location subject to higher levels of dust, salt content or iron dust

Location subject to splashes of water, oil, chemicals, etc.

Location where the product may receive vibration or impact directly

Installing or storing the product in these locations may result in fire, electric shock or

equipment damage.

The driver radiator, Regeneration Resistor, motor, etc. may become hot while the power is

supplied or remain hot for a while even after the power supply is cut off. Never touch these

components.

A burn injury may result.

6

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 9

Storage and Transportation

Caution

When transporting the product, do not hold it by the cables or motor shaft.

Injury or failure may result.

Do not overload the products. (Follow the instruction on the product label.)

Injury or failure may result.

Use the motor eye-bolts only when transporting the motor.

Do not use them to transport the machine.

Injury or failure may result.

Safety Precautions Document

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

7

Page 10

Safety Precautions Document

Caution

Installation and Wiring

Do not step on the product or place heavy articles on it.

Injury may result.

Do not block the intake or exhaust openings. Do not allow foreign objects to enter the

product.

Fire may result.

Be sure to observe the mounting direction.

Failure may result.

Provide the specified clearance between the driver and the inner surface of the control panel

or other equipment.

Fire or failure may result.

Do not apply strong impact on the motor shaft or driver.

Failure may result.

Wire the cables correctly and securely.

Runaway motor, injury or failure may result.

Securely tighten the unit mounting screws, terminal block screws and cable screws.

Failure may result.

Use crimp terminals for wiring.

If simple twisted wires are connected directly to the protective ground terminal, fire may

result.

Only use the power supply voltage specified in this manual.

Burn damage may result.

In locations where the power supply infrastructure is poor, make sure the rated voltage can

be supplied.

Equipment damage may result.

Provide safety measures, such as a breaker, to protect against short circuiting of external

wiring.

Fire may result.

If the product is used in the following locations, provide sufficient shielding measures.

Location where noise generates due to static electricity, etc.

Location where a strong electric or magnetic field generates

Location where exposure to radioactivity may occur

Location where power supply lines are running nearby

Using the product in these locations may result in equipment damage.

Connect an immediate stop relay in series with the brake control relay.

Injury or failure may result.

When connecting the battery, make sure the correct polarity is connected.

Battery damage or explosion may result.

8

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 11

Operation and Adjustment

Caution

Caution

Conduct a test operation after confirming that the equipment is not affected.

Equipment damage may result.

Before operating the product in an actual environment, check if it operates correctly based

on the parameters you have set.

Equipment damage may result.

Never adjust or set parameters to extreme values, as it will make the operation unstable.

Injury may result.

Separate the motor from the mechanical system and check its operation before installing the

motor to the machine.

Injury may result.

If an alarm generated, remove the cause of the alarm and ensure safety, and then reset the

alarm and restart the operation.

Injury may result.

Do not use the built-in brake of the motor for normal braking operation.

Failure may result.

Safety Precautions Document

Do not operate the Servomotor when an excessive load inertia is installed.

Failure may result.

Install safety devices to preven t idle running or lock of the electromagnetic brake or the gear

head, or leakage of grease from the gear head.

Injury, damage or taint damage may result.

If the driver fails, cut off the power supply to the driver on the power supply side.

Fire may result.

Do not turn ON and OFF the main driver power supply frequently.

Failure may result.

Maintenance and Inspection

After replacing the unit, transfer to the new unit all data needed to resume operation, before

restarting the operation.

Equipment damage may result.

Never repair the product by disassembling it.

Electric shock or injury may result.

Be sure to turn OFF the power supply when the unit is not going to be used for a prolonged

period of time.

Injury may result.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

9

Page 12

Safety Precautions Document

Warning label display location

(R88D-KTA5L)

Location of Warning Label

This product bears a warning label at the following location to provide handling warnings.

When handling the product, be sure to observe the instructions provided on this label.

Instructions on Warning Label

Disposal

When disposing of the battery, insulate it using tape, etc. and dispose of it by following the

applicable ordinance of your local government.

Dispose of the product as an industrial waste.

10

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 13

Items to Check after Unpacking

Items to Check after Unpacking

After unpacking, check the following items.

Is this the model you ordered?

Is there any damage sustained during shipment?

Accessories of This Product

Safety Precautions document x 1 copy

Connectors, mounting screws, etc. other than those in the table below are not supplied. They must

be prepared by the customer.

If any item is missing or a problem is found such as Servo Drive damage, contact the OMRON

dealer or sales office where you purchased your product.

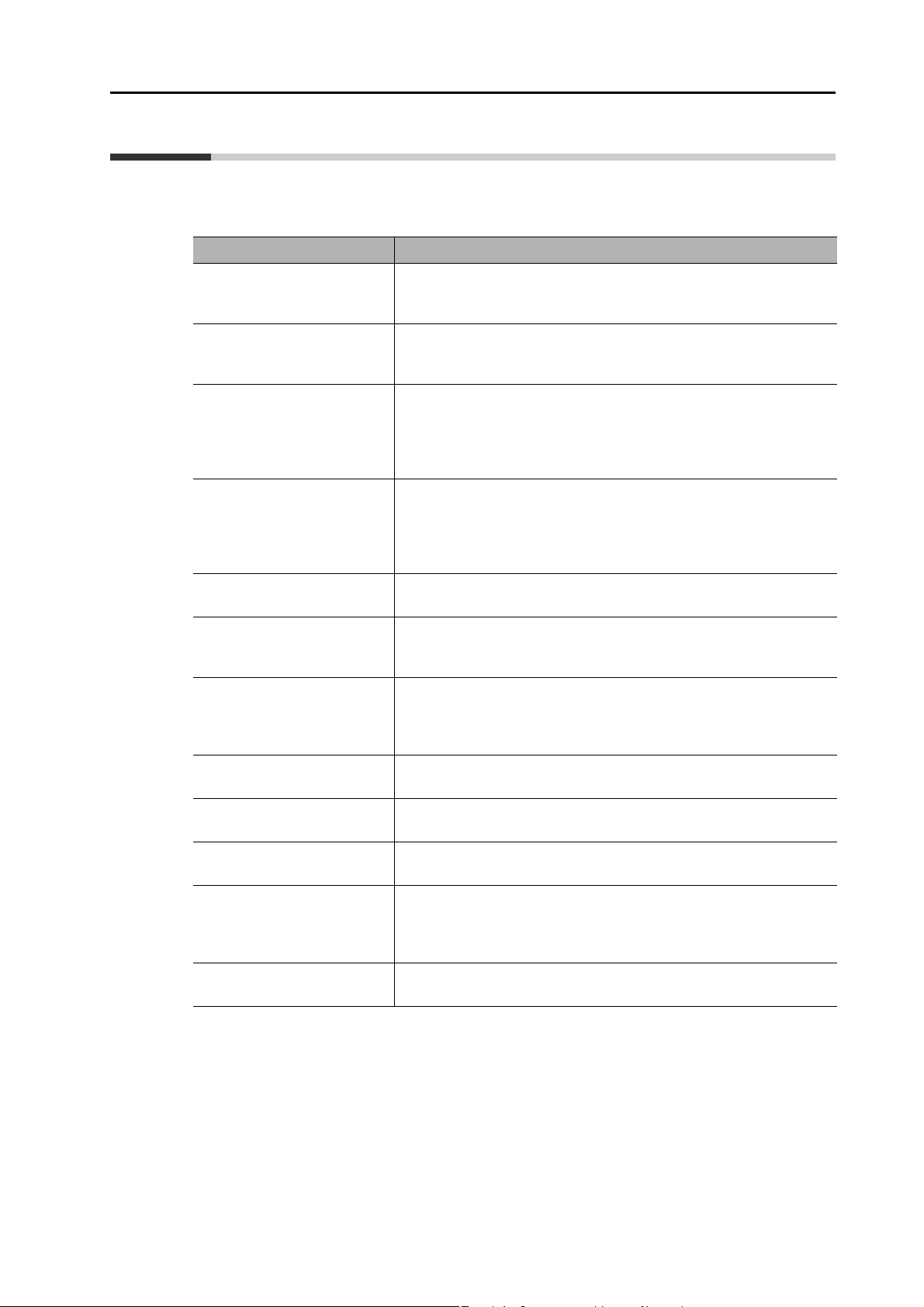

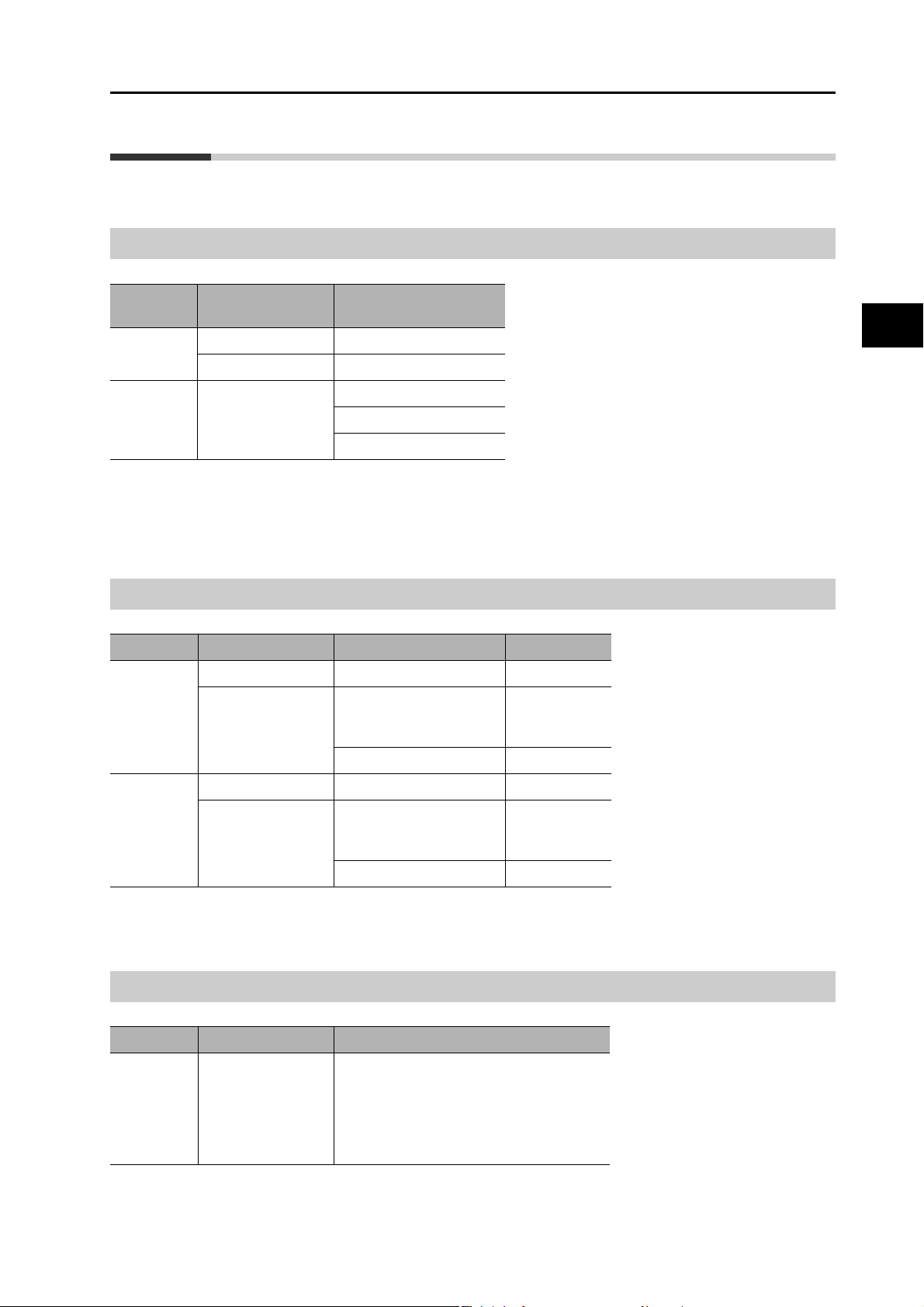

Specifications

Single-

phase 100

VAC

Single-

phase/3-

phase 200

VAC

3-phase

200 VAC

3-phase

400 VAC

50 W

100 W

200 W

400 W

100 W

200 W

400 W

750 W

1 kW

1.5

kW

2 kW

3 kW

5 kW

600 W

1 kW

1.5

kW

2 kW

Main power

supply

connector

Control power

supply

connector

Motor

connector

Included

− Included

Included

Regeneration

Resistor

connector

Open

software

Safety

bypass

connector

3 kW

− Included

5 kW

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

11

Page 14

Manual Revision History

Manual Revision History

The manual revision symbol is an alphabet appended at the end of the manual number found in the

bottom left-hand corner of the front or back cover.

Example

I571-E1-01

Revision symbol

Revision

symbol

01 September 2009 First print

Revision date Description of revision and revised page

12

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 15

Structure of This Document

This manual consists of the following chapters.

Read the necessary chapter or chapters referring to below.

Structure of This Document

Outline

Features and

Chapter 1

Chapter 2

Chapter 3 Specifications

Chapter 4 System Design

Chapter 5

Chapter 6

Chapter 7 Safety Function

Chapter 8

Chapter 9 Operation

System

Configuration

Standard Models

and External

Dimensions

BASIC

CONTROL mode

Applied

Functions

Parameters

Details

This chapter explains the features of this product, name of each part,

and applicable EC directives and UL standards.

This chapter explains the models of Servo Drive, Servomotor, and

peripheral equipment, as well as the external dimensions and

mounting dimensions.

This chapter explains the general specifications, characteristics,

connector specifications and I/O circuits of the Servo Drive, general

specifications, characteristics, encoder specifications of the

Servomotor, and all other specifications including those of peripheral

equipment.

This chapter explains the installation conditions, wiring methods

including wiring conforming to EMC directives and regenerative energy

calculation methods regarding the Servo Drive, Servomotor and

Decelerator, as well as the performance of External Regeneration

Resistors, and so on.

This chapter explains an outline of operations available in various

CONTROL modes and explains the contents of setting.

This chapter gives outline of applied functions such as damping

control, electronic gears, gain switching and disturbance observer, and

explains the contents of setting.

This function stops the motor based on a signal from a Safety

Controller or safety sensor.

An outline of the function is explained together with operation and

connection examples.

This chapter explains the set value and contents of setting of each

parameter.

This chapter explains the operating procedures and how to operate in

each mode.

Chapter 10

Chapter 11

Chapter 12 Appendix

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Adjustment

Functions

Error and

Maintenance

This chapter explains the functions, setting methods and items to note

regarding various gain adjustments.

This chapter explains the items to check when problems occur, error

diagnosis using the alarm LED display and measures, error diagnosis

based on the operating condition and measures, and periodic

maintenance.

This chapter provides connection examples using OMRON's PLC and

Position Controller, as well as a list of parameters.

13

Page 16

Table Of Contents

Introduction......................................................................................1

Items Requiring Acknowledgment...................................................2

Safety Precautions Document.........................................................4

Items to Check after Unpacking.......................................................11

Manual Revision History..................................................................12

Structure of This Document.............................................................13

Chapter1 Features and System Configuration

1-1 Outline ................................................................................................1-1

1-2 System Configuration .........................................................................1-2

1-3 Names and Functions.........................................................................1-3

1-4 System Block Diagrams......................................................................1-5

1-5 Applicable Standards..........................................................................1-6

Chapter2 Standard Models and External Dimensions

2-1 Servo System Configuration...............................................................2-1

2-2 How to Read Model............................................................................2-3

2-3 Standard Model List............................................................................2-5

2-4 External and Mounting Dimensions....................................................2-22

2-5 EMC Filter Dimensions.......................................................................2-54

Chapter3 Specifications

3-1 Driver Specifications...........................................................................3-1

3-2 Overload Characteristics (Electronic Thermal Function) ....................3-53

3-3 Motor Specifications ...........................................................................3-54

3-4 Cable and Connector Specifications...................................................3-78

3-5 Servo Relay Units and Cable Specifications ......................................3-106

3-6 External Regeneration Resistor Specifications...................................3-136

3-7 EMC Filter Specifications....................................................................3-138

Chapter4 System Design

4-1 Installation Conditions.........................................................................4-1

4-2 Wiring..................................................................................................4-7

4-3 Wiring Conforming to EMC Directives................................................4-21

4-4 Regenerative Energy Absorption........................................................4-37

Chapter5 BASIC CONTROL Mode

5-1 Position Control ..................................................................................5-1

5-2 Speed Control.....................................................................................5-6

5-3 Torque Control....................................................................................5-12

5-4 Internally Set Speed Control...............................................................5-17

5-5 Switching Control................................................................................5-20

5-6 Full Closing Control ............................................................................5-23

14

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 17

Table Of Contents

Chapter6 Applied Functions

6-1 Damping Control.................................................................................6-1

6-2 Adaptive Filter.....................................................................................6-5

6-3 Notch Filter.........................................................................................6-7

6-4 Electronic Gear Function.................................................................... 6-10

6-5 Encoder Dividing Function.................................................................. 6-13

6-6 Brake Interlock....................................................................................6-18

6-7 Gain Switching Function.....................................................................6-23

6-8 Torque Limit........................................................................................6-31

6-9 Sequence I/O Signal...........................................................................6-34

6-10 Forward and Reverse Drive Prohibition Functions............................. 6-40

6-11 Disturbance Observer Function..........................................................6-43

6-12 Gain Switching 3 Function..................................................................6-45

6-13 Friction Torque Compensation Function ............................................6-46

6-14 Inertia Ratio Switching Function......................................................... 6-48

6-15 Hybrid Vibration Suppression Function.............................................. 6-49

6-16 Feed-forward Function .......................................................................6-50

6-17 Instantaneous Speed Observer Function........................................... 6-54

Chapter7 Safety Function

7-1 Safe Torque OFF (STO) Function......................................................7-1

7-2 Operation Example.............................................................................7-4

7-3 Connection Examples.........................................................................7-6

Chapter8 Parameters Details

8-1 Basic Parameters...............................................................................8-1

8-2 Gain Parameters ................................................................................8-9

8-3 Vibration Suppression Parameters.....................................................8-20

8-4 Analog Control Parameters................................................................ 8-25

8-5 Interface Monitor Setting Parameters................................................. 8-36

8-6 Extended Parameters......................................................................... 8-46

8-7 Special Parameters............................................................................8-59

Chapter9 Operation

9-1 Operational Procedure .......................................................................9-1

9-2 Preparing for Operation...................................................................... 9-2

9-3 Using the Front Display......................................................................9-6

9-4 Setting the Mode ................................................................................9-7

9-5 Trial Operation....................................................................................9-33

Chapter10 Adjustment Functions

10-1 Gain Adjustment.................................................................................10-1

10-2 Realtime Autotuning...........................................................................10-3

10-3 Manual Tuning....................................................................................10-10

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

15

Page 18

Table Of Contents

Chapter11 Error and Maintenance

11-1 Error Processing.................................................................................11-1

11-2 Warning List........................................................................................11-4

11-3 Alarm List............................................................................................11-5

11-4 Troubleshooting..................................................................................11-9

11-5 Periodic Maintenance......................................................................... 11-20

Chapter12 Appendix

12-1 Connection Examples.........................................................................12-1

12-2 Parameter List....................................................................................12-11

Index

16

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 19

Features and System Configuration

This chapter explains the features of this product, name of each part, and

applicable EC directives and UL standards.

1-1 Outline...........................................................................1-1

Outline of the OMNUC G5 Series...................................................1-1

Features of the OMNUC G5 Series ................................................1-1

1-2 System Configuration..................................................1-2

1-3 Names and Functions..................................................1-3

Driver Part Names ..........................................................................1-3

Driver Functions..............................................................................1-4

1-4 System Block Diagrams...............................................1-5

1-5 Applicable Standards...................................................1-6

EC Directives..................................................................................1-6

UL and cUL Standards....................................................................1-6

Functional Safety............................................................................1-6

1

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 20

1

1-1 Outline

1-1 Outline

Outline of the OMNUC G5 Series

With the OMNUC G5 Series, you can perform full closing control in addition to position control,

speed control and torque control.

Various models are available supporting wide-ranging motor capacities from 50 W to 5 kW and input

power supplies from 100 to 400 V. You will surely find a model that best suits your application.

Motors with high-resolution 20-bit incremental encoders and 17-bit absolute/incremental

encoders are available as standard models.

The OMNUC G5 Series features realtime autotuning function and adaptive filter function that

automatically perform complicated gain adjus tments. A notch filter can also be aut omatically

set to suppress machine vibration by reducing machine resonance during operation.

The damping control function of the Servomotor and Servo Drive realizes stable stopping

performance in a mechanism which vibrates because of the low rigidity of the load.

Features of the OMNUC G5 Series

The OMNUC G5 Series has the following features.

7 Possible CONTROL modes Switching

You can switch among 7 CONTROL modes including the following: (1) position control, (2)

speed control, (3) torque control, (4) position and speed control, (5) position and torque control,

(6) speed and torque control, (7) full closing control. Desired modes can be selected with the

flexible driver according to your need. A single driver supports various applications.

Features and System Configuration

Achievement of Accurate Positioning by Full Closing Control

Feedbacks from the external scale connected to the motor are used to accurately control positions.

Accordingly, position control is not affected by deviation caused by ball screws or temperature.

Wide Range of Power Supplies to Match Any Necessity

The OMNUC G5 Series now has models supporting 400 V for use with large equipment, at

overseas facilities and in wide-ranging applications and environment. Since the utilization ratio

of facility equipment also increases, the TCO (Total Cost of Ownership) will come down.

Safe Torque OFF (STO) Function to Ensure Safety

You can cut off the motor current to stop the motor based on a signal from an immediate stop

button or other safety equipment. In addition to the conventional stop method based on a

control signal, the STO function that permits direct stopping without a need to involve the

control circuit provides the immediate stop from 2 systems, thereby enhancin g safety.

1-1

Suppressing Vibration of Low-rigidity Mechanisms during Acceleration/Deceleration

The damping control function suppresses vibration of low-rigidity mechanisms or devices

whose tips tend to vibrate.

2 vibration filters are provided to enable switching the vibration frequency automatically

according to the rotation direction and also via an external signal. In addition, the settings can

be made easily merely by just setting the vibration frequency and filter values, and you are

assured of stable operation even if the set values are inappropriate.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 21

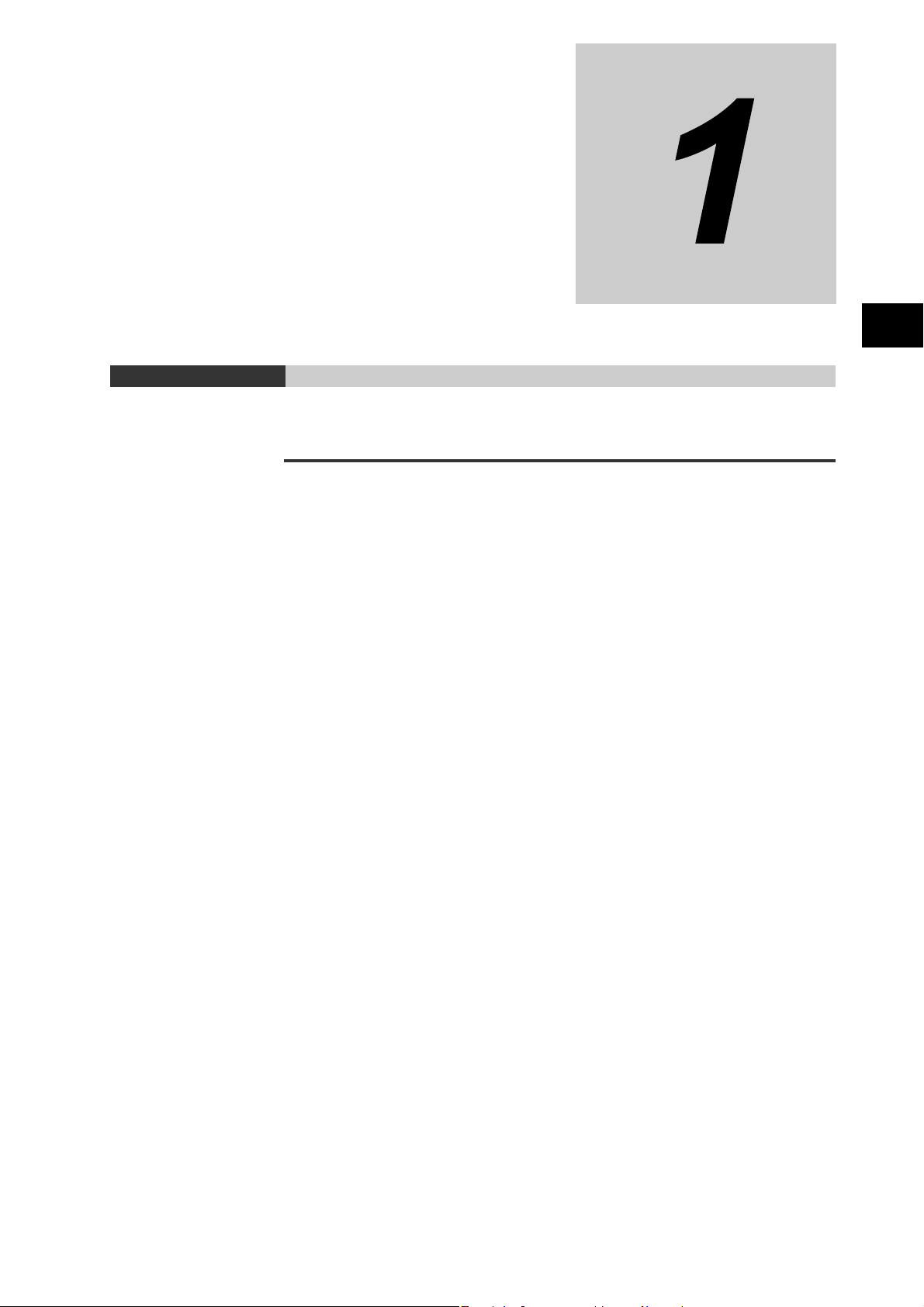

1-2 System Configuration

OMNUC G5 Series

AC Servomotor

R88D-KTx

OMNUC G5 Series

AC Servomotor

R88M-Kx

INC ABS

Pulse train

Analog

voltage

SYSMAC + Position Control Unit (Pulse Train Output Type)

Programmable

Controller

SYSMAC CJ/CS

Position Control Unit

CJ1W-NC113/213/413

CJ1W-NC133/233/433

CJ1W-NC214/414

CJ1W-NC234/434

CS1W-NC113/213/413

CS1W-NC133/233/433

C200HW-NC113/213/413

Flexible Motion Controller

FQM1-MMA22

FQM1-MMP22

Controller (Voltage Output Type)

Programmable

Controller

SYSMAC CS

Motion Control Unit

CS1W-MC221/421 (-V1)

PA202

POWER

INPUT

AC100

-240V

L2/N

L1

NC

NC

PERIPHERAL

ERR/ALM

RUN

INH

COMM

PRPHL

CONTROLLER

CJ1G-CPU44

SYSMAC

PROGRAMMABLE

PORT

OPEN

BUSY

MCPWR

MACH

x10

1

x10

0

No.

NC414

CN1

CN2

RUN

A1

1

2

B1

A2

B2

A3

3 4

B3

A4

B4

AS

BS

SYNC

ERC

ERH

AXIS1AXIS2

CN3 CN4

AXIS2 AXIS1

1-2 System Configuration

1

Features and System Configuration

The following units support a motor with absolute encoder:

CJ1W-NC214/414

CJ1W-NC234/434

CS1W-MC221/421 (-V1)

FQM1-MMA22

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

1-2

Page 22

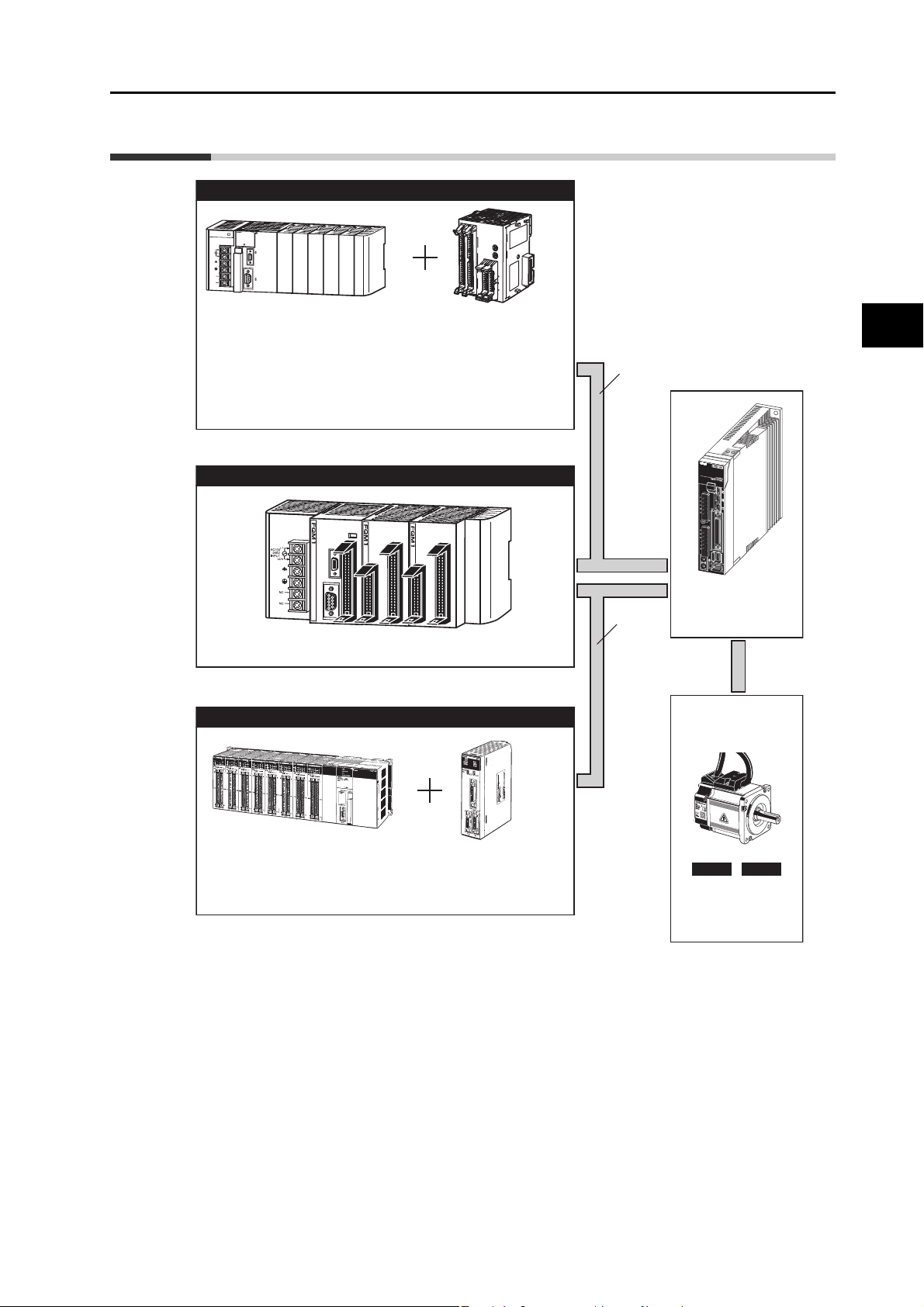

1

Display area

Operation area

USB connector (CN7)

Expansion connector (CN3)

Monitor connector (CN5)

Motor connection

terminals (U, V and W)

Control circuit

power supply terminals

(L1C and L2C)

Main circuit

power supply terminals

(L1, L2, and L3)

External Regeneration

Resistor connection

terminals (B1, B2 and B3)

Protective ground terminals

Control I/O connector (CN1)

Safety connector (CN8)

External scale connector (CN4)

Encoder connector (CN2)

Charge lamp

1-3 Names and Functions

1-3 Names and Functions

Driver Part Names

Features and System Configuration

1-3

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 23

Driver Functions

Display Area

A 6-digit 7-segment LED display shows the driver status, alarm codes, parameters, and other

information.

1-3 Names and Functions

Operation Area

Monitors the parameter setting and driver condition.

Charge Lamp

Lits when the main circuit power supply is turned ON.

Control I/O Connector (CN1)

Used for command input signals and I/O signals.

Encoder Connector (CN2)

Connector for the encoder installed in the Servomotor.

Expansion Connector (CN3)

A spare connector for expansion. Do not connect anything.

1

Features and System Configuration

External Scale Connector (CN4)

Connector for an encoder signal used during full closing control.

Monitor Connector (CN5)

2 analog outputs to monitor values like motor rotation speed, torque command value, etc.

USB Connector (CN7)

Communications connector for the computer.

Safety Connector (CN8)

Connector for the safety devices.

If no safety device is used, keep the factory-set safety bypass connector installed.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

1-4

Page 24

1-4 System Block Diagrams

1-4 System Block Diagrams

1

L1

L2

L3

L1C

L2C

CN A

FUSE

FUSE

GR

GR

FUSE

15 V

G1

5 V

3.3 V

2.5 V

1.5 V

E5 V

±12 V

G2

+

−

+

−

SW power

supply main

circuit control

Internal

control power

supply

Voltage

detection

Relay

drive

Regeneration

control

MPU&ASIC

Position, speed and torque calculation control area

• PWM control

Overcurrent

detection

Gate drive

Internal Regeneration

Resistor R88D-KT10H

or more only

Current detection

Display and

setting circuit

area

CN B

B1

B2

B3

U

V

W

GR

Cooling fan

Features and System Configuration

R88D-KT10H or more only

CN1

Control

interface

CN2 CN4 CN5 CN7

Encoder

External

scale

Analog

monitor

CN8

USB Safety

1-5

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 25

1-5 Applicable Standards

EC Directives

1-5 Applicable Standards

EC

directive

Low voltage

command

EMC

directives

Note. To conform to EMC directives, the Servo Motor and Servo Drive must be installed under the conditions described

in "4-3 Wiring Conforming to EMC Directives" (P.4-21).

Product Applicable standards

AC Servo Drive EN 61800-5-1

AC Servomotor EN60034-1/-5

AC Servo Drive

AC Servomotor

EN 55011 class A group 1

IEC61800-3

EN61000-6-2

UL and cUL Standards

Standard Product Applicable standards File number

UL

standards

CSA

standards

AC Servo Drive UL508C E179149

AC Servomotor UL1004-1

[100 V, 200 V]

3,000 r/min 50 to 750 W

UL1004 E179189

AC Servo Drive CSA22.2 No. 14 E179149

AC Servomotor CSA22.2 No. 100

[100 V, 200 V]

3,000 r/min 50 to 750 W

E331224

E331224

1

Features and System Configuration

CSA22.2 No. 100 E179189

Functional Safety

Standard Product Applicable standards

Functional

safety

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

AC Servo Drive EN954-1 (Category 3)

ISO13849-1 (Performance level D)

EN61508 (SIL2)

EN62061 (SIL2)

EV61800-5-2 (STO)

IEC61326-3-1 (SIL2)

1-6

Page 26

Page 27

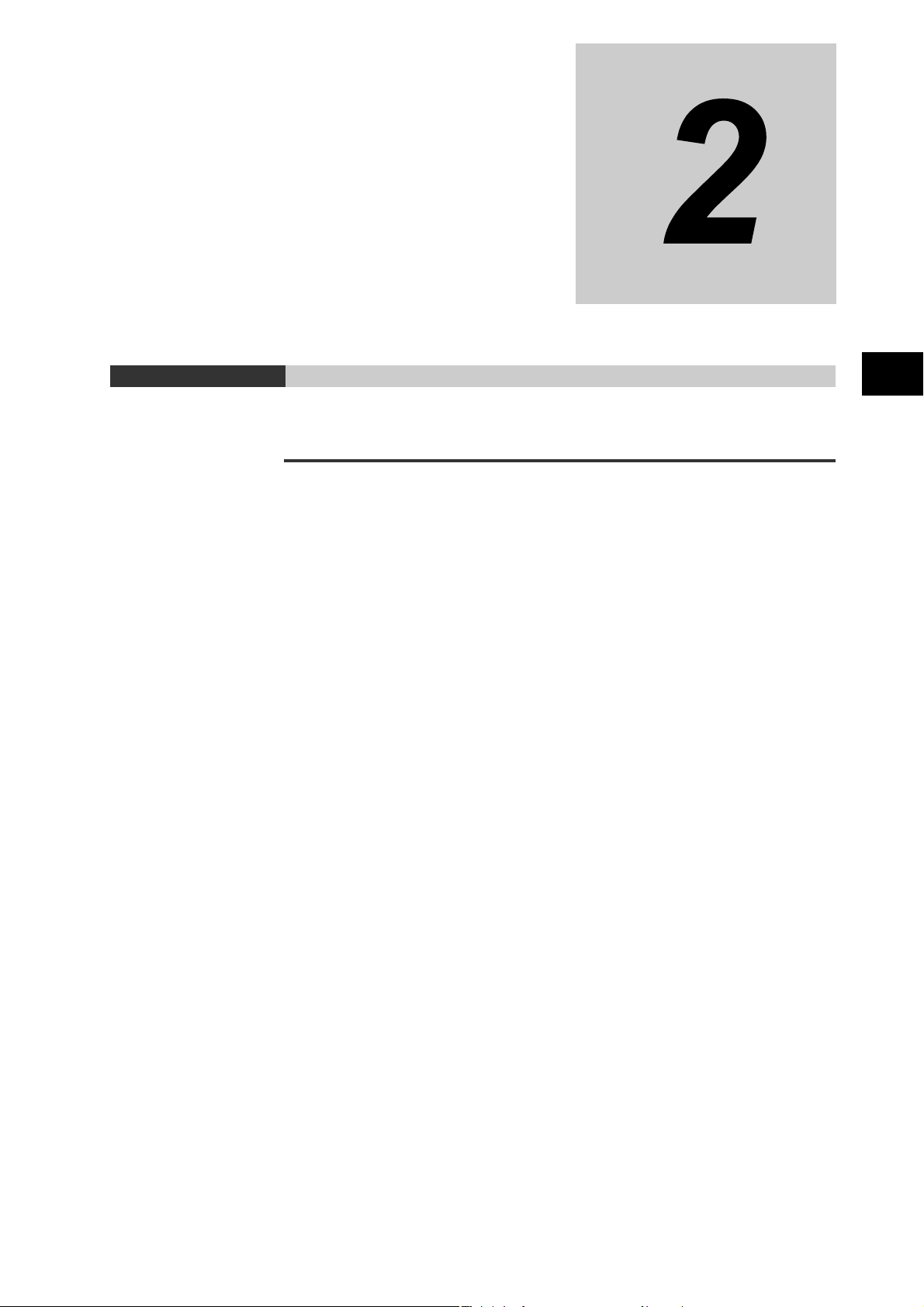

Standard Models and External Dimensions

2

This chapter explains the models of Servo Drive, Servomotor, and peripheral

equipment, as well as the external dimensions and mounting dimensions.

2-1 Servo System Configuration .......................................2-1

2-2 How to Read Model.......................................................2-3

Servo Drive.....................................................................................2-3

Servomotor .....................................................................................2-4

2-3 Standard Model List .....................................................2-5

Servo Drive Model List....................................................................2-5

Servomotor Model List....................................................................2-6

Servo Drive and Servomotor Combination List.............................2-10

Peripheral Equipment and Cable Model List.................................2-12

2-4 External and Mounting Dimensions..........................2-22

Servo Drive Dimensions ...............................................................2-22

Servomotor Dimensions................................................................2-34

External Regeneration Resistor Dimensions ................................2-53

2-5 EMC Filter Dimensions...............................................2-54

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 28

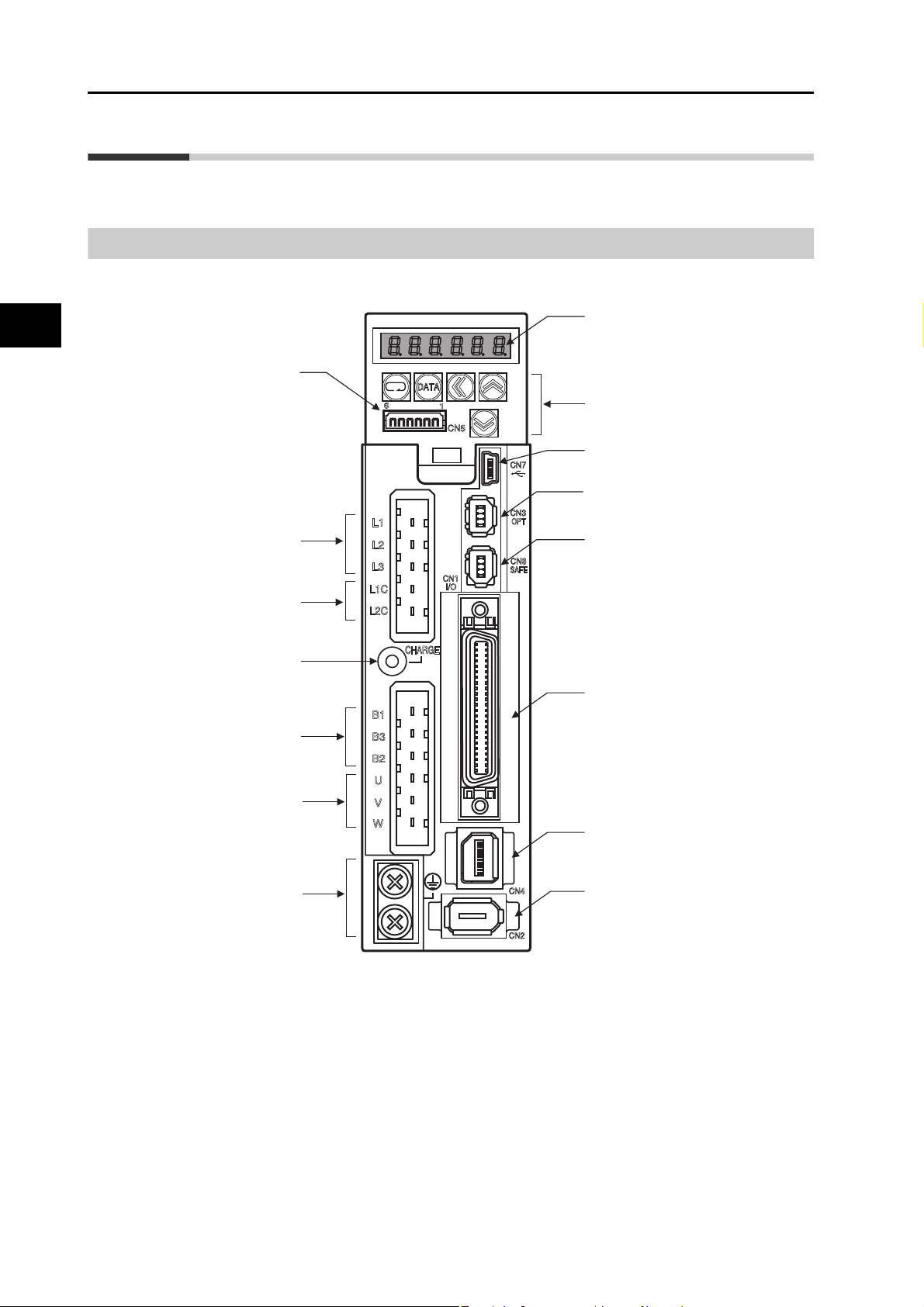

2

Controller

Flexible Motion Controller

SYSMAC + Controller (Analog output type)

Position Control UnitCPU Unit

Pulse Train CommandsAnalog Commands

Pulse Train Commands/Feedback Signals

External Signal

External Signal

Analog Commands/Feedback Signals

Pulse Train Commands

Programmable

Controller

SYSMAC CJ2

High-speed type

Position Control Unit (NC)

CJ1W-NC214/414

CJ1W-NC234/434

Standard type

Programmable

Controller

SYSMAC CJ1/CS1

Position Control Unit (NC)

CJ1W-NC@@3 CS1W-NC@@3

C200HW-NC@@3

CP1H/CP1L

CJ1M-CPU2

@

FQM1-MMA22

(Analog output)

FQM1-MMP22

(Pulse train output)

Motion Control Unit (MC)

CS1W-MC221/421 (-V1)

Programmable Controller

SYSMAC CS1

Available to build the Absolute System.

Built-in pulse

I/O function type

Built-in pulse

I/O function type

XW2Z-@-B@

XW2B-@XW2Z-@-A@

XW2Z-@-B@

Servo Drive Cable

XW2Z-@-A@

Position Control Unit Cable (NC)

XW2Z-@@@J-G@

Direct connection cable for CJ1W-NC@@4

R88A-CPG

Control Cables (for Motion Control Unit)

•

CX-One FA Integrated

Tool Package

Including CX-Programmer

and CX-Position

and CX-Motion

Support Software

•

CX-One FA Integrated

Tool Package

(Including CX-Drive)

•

CX-Drive

WS02-DRVC1

Support Software

XW2B-80J7-12A

Servo Relay Units (for FQM1)

INC

servo

1

ABS _C

W

-

0

19

Servo Drive Cable

Servo Relay Unit

Position Control Unit Cable (NC)

XW2Z-@@@J-B24XW2@-50G@

Connector-Terminal Block Conversion Units and Cable

XW2Z-@X

Connector Terminal Block Conversion Unit

Position Control Unit Cable

XW2@-20G@

MACH

x10

1

x10

0

No.

NC41

4

CN1

CN2

RUN

A1

1

2

B1

A

2

B2

A

3

34

B3

A

4

B

4

A

S

BS

SYNC

ERC

ERH

AXIS1

AXIS2

CN3 CN4

AXIS2 AXIS1

PERIFHER

AL

ERR/ALM

RUN

INH

COMM

PRPHL

CONTROLLER

CJ1G-CPU4

4

SYSM

AC

PROGRAMMABLE

PORT

O

PE

N

BU

SY

M

C

PW

R

PERIPHERAL

ERR/

ALM

RUN

INH

COMM

BKUP

PRP

HL

CONTROLLE

R

CPU64

CJ2H

SYSM

AC

PROGRAMM

ABLE

PORT

OPE

N

BU

S

Y

M

C

PW

R

NC113

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

RUN

ERC

ERH

X

MACH

No.

10

1

10

0

20

1

1

20

X

CN1

2-1 Servo System Configuration

2-1 Servo System Configuration

Standard Models and External Dimensions

2-1

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 29

2-1 Servo System Configuration

Servo Drive

Peripheral Devices

•

Reactors

3G3AX-DL

3G3AX-AL

•

External

Regeneration

Resistors

R88A-RR

External scale

AC Servomotors

Decelerators

• OMNUC G5 Series driver

R88D-KT

• OMNUC G5 Series motor

R88M-K

Motor power signals

Feedback Signals

Power Cables

•

Without Brake

R88A-CA@@@@@S

•

With Brake

R88A-CA@@@@@B

•

Without Brake

R88A-CA@@@@@SR

•

With Brake

R88A-CA@@@@@BR

•

Standard Cables

•

Robot Cable

Encoder Cables

•

Standard Cables

R88A-CRK@@@@@

Brake Cables (50 to 750 W max.)

•

Standard Cables

R88A-CAKA@@@B

•

Robot Cable

R88A-CAKA@@@BR

•

Robot Cable

R88A-CRK@@@@@R

USB

communications

Absolute Encoder Battery Cable

* Not required if a battery is connected to

the control connector (CN1).

(One Battery is included with Servo

Drivers with model numbers ending

in “BS.”)

R88A-CRGD0R3C (-BS)

100 VAC

200 VAC

400 VAC

3,000 r/min

2,000 r/min

1,000 r/min

2

Standard Models and External Dimensions

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-2

Page 30

2-2 How to Read Model

2-2 How to Read Model

Servo Drive

The Servo Drive model can be identified by the Servo Drive type, applicable Servomotor

capacity, power supply voltage, etc.

R88D-KT01H

2

OMNUC G5 Series

Servomotor

Driver Type

: Pulse/analog typeT

Maximum Applicable Servomotor Capacity

: 50 W

A5

01

: 100 W

02

: 200 W

04

: 400 W

08

: 750 W

10

: 1 kW

15

: 1.5 kW

20

: 2 kW

30

: 3 kW

50

: 5 kW

Power Supply Voltage

: 100 VAC

L

: 200 VAC

H

: 400 VAC

F

Standard Models and External Dimensions

2-3

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 31

Servomotor

OMNUC G5 Series Servomotor

Motor Type

Blank: Cylinder type

Servomotor Capacity

050

: 50 W

100

: 100 W

200

: 200 W

400

: 400 W

600

: 600 W

750

: 750 W

900

: 900 W

1K0

: 1 kW

1K5

: 1.5 kW

2K0

: 2 kW

3K0

: 3 kW

4K0

: 4 kW

5K0

: 5 kW

2-2 How to Read Model

R88M-KP10030H-BOS2

2

Standard Models and External Dimensions

Rated Rotation Speed

10

: 1,000 r/min

20

: 2,000 r/min

30

: 3,000 r/min

Applied V oltage

F

: 400 VAC (incremental encoder specifications)

H

: 200 VAC (incremental encoder specifications)

L

: 100 VAC (incremental encoder specifications)

C

: 400 VAC (absolute encoder specifications)

T

: 200 VAC (absolute encoder specifications)

S

: 100 VAC (absolute encoder specifications)

Options

No

: Straight shaft

B

: With brake

O

: With oil seal

S2

: With key

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-4

Page 32

2

2-3 Standard Model List

2-3 Standard Model List

Servo Drive Model List

Specifications Model

Single-phase 100 VAC 50 W R88D-KTA5L

100 W R88D-KT01L

200 W R88D-KT02L

400 W R88D-KT04L

Single-phase/3-phase 200 VAC 100 W R88D-KT01H

200 W R88D-KT02H

400 W R88D-KT04H

Standard Models and External Dimensions

750 W R88D-KT08H

1 kW R88D-KT10H

1.5 kW R88D-KT15H

3-phase 200 VAC 2 kW R88D-KT20H

3 kW R88D-KT30H

5 kW R88D-KT50H

3-phase 400 VAC 600 W R88D-KT06F

1 kW R88D-KT10F

1.5 kW R88D-KT15F

2 kW R88D-KT20F

3 kW R88D-KT30F

5 kW R88D-KT50F

2-5

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 33

Servomotor Model List

Without brakes

3,000-r/min motors

Specifications

50 W R88M-K05030H R88M-K05030H-S2 R88M-K05030T R88M-K05030T-S2

100 W R88M-K10030L R88M-K10030L-S2 R88M-K10030S R88M-K10030S-S2

100 V

200 W R88M-K20030L R88M-K20030L-S2 R88M-K20030S R88M-K20030S-S2

400 W R88M-K40030L R88M-K40030L-S2 R88M-K40030S R88M-K40030S-S2

50 W R88M-K05030H R88M-K05030H-S2 R88M-K05030T R88M-K05030T-S2

With incremental encoder With absolute encoder

Straight shaft

without key

Straight shaft

with key and tap

Model

2-3 Standard Model List

Straight shaft

without key

Straight shaft

with key and tap

2

Standard Models and External Dimensions

100 W R88M-K10030H R88M-K10030H-S2 R88M-K10030T R88M-K10030T-S2

200 W R88M-K20030H R88M-K20030H-S2 R88M-K20030T R88M-K20030T-S2

400 W R88M-K40030H R88M-K40030H-S2 R88M-K40030T R88M-K40030T-S2

750 W R88M-K75030H R88M-K75030H-S2 R88M-K75030T R88M-K75030T-S2

200 V

400 V

1 kW R88M-K1K030H R88M-K1K030H-S2 R88M-K1K030T R88M-K1K030T-S2

1.5 kW R88M-K1K530H R88M-K1K53 0H-S2 R88M-K1K530T R88M-K1K530T-S2

2 kW R88M-K2K030H R88M-K2K030H-S2 R88M-K2K030T R88M-K2K030T-S2

3 kW R88M-K3K030H R88M-K3K030H-S2 R88M-K3K030T R88M-K3K030T-S2

4 kW R88M-K4K030H R88M-K4K030H-S2 R88M-K4K030T R88M-K4K030T-S2

5 kW R88M-K5K030H R88M-K5K030H-S2 R88M-K5K030T R88M-K5K030T-S2

750 W R88M-K75030F R88M-K75030F-S2 R88M-K75030C R88M-K75030C-S2

1 kW R88M-K1K030F R88M-K1K030F-S2 R88M-K1K030C R88M-K1K030C-S2

1.5 kW R88M-K1K530F R88M-K1K530F-S2 R88M-K1K530C R88M-K1K530C-S2

2 kW R88M-K2K030F R88M-K2K030F-S2 R88M-K2K030C R88M-K2K030C-S2

3 kW R88M-K3K030F R88M-K3K030F-S2 R88M-K3K030C R88M-K3K030C-S2

4 kW R88M-K4K030F R88M-K4K030F-S2 R88M-K4K030C R88M-K4K030C-S2

5 kW R88M-K5K030F R88M-K5K030F-S2 R88M-K5K030C R88M-K5K030C-S2

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-6

Page 34

2-3 Standard Model List

With brakes

Model

2

Specifications

50 W R88M-K05030H-B R88M-K05030H-BS2 R88M-K05030T-B R88M-K05030T-BS2

100 V

200 V

100 W R88M-K10030L-B R88M-K10030L-BS2 R88M-K10030S-B R88M-K10030S-BS2

200 W R88M-K20030L-B R88M-K20030L-BS2 R88M-K20030S-B R88M-K20030S-BS2

400 W R88M-K40030L-B R88M-K40030L-BS2 R88M-K40030S-B R88M-K40030S-BS2

50 W R88M-K05030H-B R88M-K05030H-BS2 R88M-K05030T-B R88M-K05030T-BS2

100 W R88M-K10030H-B R88M-K10030H-BS2 R88M-K10030T-B R88M-K10030T-BS2

200 W R88M-K20030H-B R88M-K20030H-BS2 R88M-K20030T-B R88M-K20030T-BS2

400 W R88M-K40030H-B R88M-K40030H-BS2 R88M-K40030T-B R88M-K40030T-BS2

750 W R88M-K75030H-B R88M-K75030H-BS2 R88M-K75030T-B R88M-K75030T-BS2

1 kW R88M-K1K030H-B R88M-K1K030H-BS2 R88M-K1K030T-B R88M-K1K030T-BS2

1.5 kW R88M-K1K530H-B R88M-K1K530H-BS2 R88M-K1K530T-B R88M-K1K530T-BS2

2 kW R88M-K2K030H-B R88M-K2K030H-BS2 R88M-K2K030T-B R88M-K2K030T-BS2

3 kW R88M-K3K030H-B R88M-K3K030H-BS2 R88M-K3K030T-B R88M-K3K030T-BS2

4 kW R88M-K4K030H-B R88M-K4K030H-BS2 R88M-K4K030T-B R88M-K4K030T-BS2

5 kW R88M-K5K030H-B R88M-K5K030H-BS2 R88M-K5K030T-B R88M-K5K030T-BS2

With incremental encoder With absolute encoder

Straight shaft

without key

Straight shaft

with key and tap

Straight shaft

without key

Straight shaft

with key and tap

Standard Models and External Dimensions

750 W R88M-K75030F-B R88M-K75030F-BS2 R88M-K75030C-B R88M-K75030C -BS2

1 kW R88M-K1K030F-B R88M-K1K030F-BS2 R88M-K1K030C-B R88M-K1K030C-BS2

1.5 kW R88M-K1K530F-B R88M-K1K530F-BS2 R88M-K1K530C-B R88M-K1K530C-BS2

400 V

Note. Models with oil seals are also available.

2 kW R88M-K2K030F-B R88M-K2K030F-BS2 R88M-K2K030C-B R88M-K2K030C-BS2

3 kW R88M-K3K030F-B R88M-K3K030F-BS2 R88M-K3K030C-B R88M-K3K030C-BS2

4 kW R88M-K4K030F-B R88M-K4K030F-BS2 R88M-K4K030C-B R88M-K4K030C-BS2

5 kW R88M-K5K030F-B R88M-K5K030F-BS2 R88M-K5K030C-B R88M-K5K030C-BS2

2-7

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 35

2,000-r/min Motors

Without brakes

With brakes

Specifications

1 kW R88M-K1K020H R88M-K1K020H-S2 R88M-K1K020T R88M-K1K020T-S2

1.5 kW R88M-K1K520H R88M-K1K52 0H-S2 R88M-K1K520T R88M-K1K520T-S2

2 kW R88M-K2K020H R88M-K2K020H-S2 R88M-K2K020T R88M-K2K020T-S2

200 V

3 kW R88M-K3K020H R88M-K3K020H-S2 R88M-K3K020T R88M-K3K020T-S2

2-3 Standard Model List

Model

With incremental encoder With absolute encoder

Straight shaft

without key

Straight shaft

with key and tap

Straight shaft

without key

Straight shaft

with key and tap

4 kW R88M-K4K020H R88M-K4K020H-S2 R88M-K4K020T R88M-K4K020T-S2

5 kW R88M-K5K020H R88M-K5K020H-S2 R88M-K5K020T R88M-K5K020T-S2

400 W R88M-K40020F R88M-K40020F-S2 R88M-K40020C R88M-K40020C-BS2

600 W R88M-K60020F R88M-K60020F-S2 R88M-K60020C R88M-K60020C-BS2

1 kW R88M-K1K020F R88M-K1K020F-S2 R88M-K1K020C R88M-K1K020C-S2

1.5 kW R88M-K1K520F R88M-K1K520F-S2 R88M-K1K520C R88M-K1K520C-S2

400 V

2 kW R88M-K2K020F R88M-K2K020F-S2 R88M-K2K020C R88M-K2K020C-S2

3 kW R88M-K3K020F R88M-K3K020F-S2 R88M-K3K020C R88M-K3K020C-S2

4 kW R88M-K4K020F R88M-K4K020F-S2 R88M-K4K020C R88M-K4K020C-S2

5 kW R88M-K5K020F R88M-K5K020F-S2 R88M-K5K020C R88M-K5K020C-S2

1 kW R88M-K1K020H-B R88M-K1K020H-BS2 R88M-K1K020T-B R88M-K1K020T -BS2

1.5 kW R88M-K1K520H-B R88M-K1K520H-BS2 R88M-K1K520T-B R88M-K1K520T-BS2

2 kW R88M-K2K020H-B R88M-K2K020H-BS2 R88M-K2K020T-B R88M-K2K020T -BS2

200 V

3 kW R88M-K3K020H-B R88M-K3K020H-BS2 R88M-K3K020T-B R88M-K3K020T -BS2

4 kW R88M-K4K020H-B R88M-K4K020H-BS2 R88M-K4K020T-B R88M-K4K020T -BS2

5 kW R88M-K5K020H-B R88M-K5K020H-BS2 R88M-K5K020T-B R88M-K5K020T -BS2

400 W R88M-K40020F-B R88M-K40020F-BS2 R88M-K40020C-B R88M-K40020C-BS2

600 W R88M-K60020F-B R88M-K60020F-BS2 R88M-K60020C-B R88M-K60020C-BS2

1 kW R88M-K1K020F-B R88M-K1K020F-BS2 R88M-K1K020C-B R88M-K1K020C-BS2

1.5 kW R88M-K1K520F-B R88M-K1K520F-BS2 R88M-K1K520C-B R88M-K1K520C-BS2

400 V

2 kW R88M-K2K020F-B R88M-K2K020F-BS2 R88M-K2K020C-B R88M-K2K020C-BS2

3 kW R88M-K3K020F-B R88M-K3K020F-BS2 R88M-K3K020C-B R88M-K3K020C-BS2

4 kW R88M-K4K020F-B R88M-K4K020F-BS2 R88M-K4K020C-B R88M-K4K020C-BS2

2

Standard Models and External Dimensions

5 kW R88M-K5K020F-B R88M-K5K020F-BS2 R88M-K5K020C-B R88M-K5K020C-BS2

Note. Models with oil seals are also available.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-8

Page 36

2-3 Standard Model List

Without brakes

With brakes

1,000-r/min Motors

Model

2

Specifications

900 kW R88M-K90010H R88M-K90010H-S2 R88M-K90010T R88M-K90010T-S2

200 V

400 V

200 V

400 V

Note. Models with oil seals are also available.

2 kW R88M-K2K010H R88M-K2K010H-S2 R88M-K2K010T R88M-K2K010T-S2

3 kW R88M-K3K010H R88M-K3K010H-S2 R88M-K3K010T R88M-K3K010T-S2

900 kW R88M-K90010F R88M-K90010F-S2 R88M-K90010C R88M-K90010C-S2

2 kW R88M-K2K010F R88M-K2K010F-S2 R88M-K2K010C R88M-K2K010C-S2

3 kW R88M-K3K010F R88M-K3K010F-S2 R88M-K3K010C R88M-K3K010C-S2

900 kW R88M-K90010H-B R88M-K90010H-BS2 R88M-K90010T-B R88M-K90010T-BS2

2 kW R88M-K2K010H-B R88M-K2K010H-BS2 R88M-K2K010T-B R88M-K2K010T-BS2

3 kW R88M-K3K010H-B R88M-K3K010H-BS2 R88M-K3K010T-B R88M-K3K010T-BS2

900 kW R88M-K90010F-B R88M-K90010F-BS2 R88M-K90010C-B R88M-K90010C-BS2

2 kW R88M-K2K010F-B R88M-K2K010F-BS2 R88M-K2K010C-B R88M-K2K010C-BS2

3 kW R88M-K3K010F-B R88M-K3K010F-BS2 R88M-K3K010C-B R88M-K3K010C-BS2

With incremental encoder With absolute encoder

Straight shaft

without key

Straight shaft

with key and tap

Straight shaft

without key

Straight shaft

with key and tap

Standard Models and External Dimensions

2-9

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 37

Servo Drive and Servomotor Combination List

The tables in this section show the possible combinations of OMNUC G5 Series Servo Drives

and Servomotors. The Servomotors and Servo Drives can only be used in the listed

combinations.

-x at the end of the motor mo del num ber is for option s, such as the s haft typ e, brak e, oil seal

and key.

3,000-r/min Motors and Drivers

2-3 Standard Model List

Voltage

Single-phase

100 V

Single-phase/

3-phase 100 V

Single-phase/

3-phase 200 V

3-phase 200 V

Servomotor

Rated

output

50 W R88M-K05030H-x R88M-K05030T-x R88D-KT A 5L

100 W R88M-K10030L-x R88M-K10030S-x R88D-KT01L

200 W R88M-K20030L-x R88M-K20030S-x R88D-KT02L

400 W R88M-K40030L-x R88M-K40030S-x R88D-KT04L

50 W R88M-K05030H-x R88M-K05030T-x R88D-KT 01H

100 W R88M-K10030H-x R88M-K10030T-x R88D-KT01H

200 W R88M-K20030H-x R88M-K20030T-x R88D-KT02H

400 W R88M-K40030H-x R88M-K40030T-x R88D-KT04H

750 W R88M-K75030H-x R88M-K75030T-x R88D-KT08H

1 kW R88M-K1K030H-x R88M-K1K030T-x R88D-KT15H

1.5 kW R88M-K1K530H-x R88M-K1K530T-x R88D-KT15H

2 kW R88M-K2K030H-x R88M-K2K030T-x R88D-KT20H

3 kW R88M-K3K030H-x R88M-K3K030T-x R88D-KT30H

5 kW R88M-K5K030H-x R88M-K5K030T-x R88D-KT50H

750 W R88M-K75030F-x R88M-K75030C-x R88D-KT10F

With incremental

encoder

With absolute

encoder

Servo Drive

2

Standard Models and External Dimensions

1 kW R88M-K1K030F-x R88M-K1K030C-x R88D-KT15F

1.5 kW R88M-K1K530F-x R88M-K1K530C-x R88D-KT15F

3-phase 400 V

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2 kW R88M-K2K030F-x R88M-K2K030C-x R88D-KT20F

3 kW R88M-K3K030F-x R88M-K3K030C-x R88D-KT30F

4 kW R88M-K4K030F-x R88M-K4K030C-x R88D-KT50F

5 kW R88M-K5K030F-x R88M-K5K030C-x R88D-KT50F

2-10

Page 38

2-3 Standard Model List

2,000-r/min Motors and Drivers

Voltage

Single-phase/

3-phase 200 V

3-phase 200 V

Servomotor

Rated

output

1 kW R88M-K1K020H-x R88M-K1K020T-x R88D-KT10H

1.5 kW R88M-K1K520H-x R88M-K1K520T-x R88D-KT15H

2 kW R88M-K2K020H-x R88M-K2K020T-x R88D-KT20H

3 kW R88M-K3K020H-x R88M-K3K020T-x R88D-KT30H

4 kW R88M-K4K020H-x R88M-K4K020T-x R88D-KT50H

With incremental

encoder

With absolute

encoder

Servo Drive

2

Standard Models and External Dimensions

5 kW R88M-K5K020H-x R88M-K5K020T-x R88D-KT50H

400 W R88M-K40020F-x R88M-K40020C-x R88D-KT06F

600 W R88M-K60020F-x R88M-K60020C-x R88D-KT06F

1 kW R88M-K1K020F-x R88M-K1K020C-x R88D-KT10F

3-phase 400 V

1.5 kW R88M-K1K520F-x R88M-K1K520C-x R88D-KT15F

2 kW R88M-K2K020F-x R88M-K2K020C-x R88D-KT20F

3 kW R88M-K3K020F-x R88M-K3K020C-x R88D-KT30F

4 kW R88M-K4K020F-x R88M-K4K020C-x R88D-KT50F

5 kW R88M-K5K020F-x R88M-K5K020C-x R88D-KT50F

1,000-r/min Motors and Drivers

Voltage

Single-

phase/3-

phase 200 V

3-phase

200 V

Single-

phase/3-

phase 400 V

Rated

output

900 W R88M-K90010H-x R88M-K90010T-x R88D-KT15H

2 kW R88M-K2K010H-x R88M-K2K010T-x R88D-KT30H

3 kW R88M-K3K010H-x R88M-K3K010T-x R88D-KT50H

900 W R88M-K90010F-x R88M-K90010C-x R88D-KT15F

With incremental

encoder

Servomotor

Servo Drive

With absolute encoder

2-11

3-phase

400 V

2 kW R88M-K2K010F-x R88M-K2K010C-x R88D-KT30F

3 kW R88M-K3K010F-x R88M-K3K010C-x R88D-KT50F

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 39

Peripheral Equipment and Cable Model List

Encoder Cables (Non-Flexible Cables)

Specifications Model

[100 V and 200 V]

For 3,000-r/min motors of 50 to 750 W

(for both absolute encoders and incremental encoders)

2-3 Standard Model List

3 m R88A-CRKA003C

5 m R88A-CRKA005C

10 m R88A-CRKA010C

15 m R88A-CRKA015C

20 m R88A-CRKA020C

30 m R88A-CRKA030C

40 m R88A-CRKA040C

50 m R88A-CRKA050C

2

Standard Models and External Dimensions

[100 V and 200 V]

3,000-r/min motors of 1.0 kW or more

For 2,000-r/min motors

For 1,000-r/min motors

[400 V]

For 3,000-r/min motors

For 2,000-r/min motors

For 1,000-r/min motors

3 m R88A-CRKC003N

5 m R88A-CRKC005N

10 m R88A-CRKC010N

15 m R88A-CRKC015N

20 m R88A-CRKC020N

30 m R88A-CRKC030N

40 m R88A-CRKC040N

50 m R88A-CRKC050N

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-12

Page 40

2-3 Standard Model List

Motor Power Cables (Non-Flexible Cables)

[100 V and 200 V]

For 3,000-r/min motors of 50 to 750 W

Specifications

Model

For motor without

brake

3 m R88A-CAKA003S −

5 m R88A-CAKA005S −

10 m R88A-CAKA010S −

15 m R88A-CAKA015S −

For motor with brake

2

Standard Models and External Dimensions

[200 V]

For 3,000-r/min motors of 1 to 2 kW

For 2,000-r/min motors of 1 to 2 kW

For 1,000-r/min motors of 900 W

[400 V]

For 3,000-r/min motors of 750 W to 2 kW

For 2,000-r/min motors of 400 W to 2 kW

For 1,000-r/min motors of 900 W

For 3,000-r/min motors of 3 to 5 kW

For 2,000-r/min motors of 3 to 5 kW

For 1,000-r/min motors of 2 to 3 kW

20 m R88A-CAKA020S −

30 m R88A-CAKA030S −

40 m R88A-CAKA040S −

50 m R88A-CAKA050S −

3 m R88A-CAGB003S R88A-CAGB003B

5 m R88A-CAGB005S R88A-CAGB005B

10 m R88A-CAGB010S R88A-CAGB010B

15 m R88A-CAGB015S R88A-CAGB015B

20 m R88A-CAGB020S R88A-CAGB020B

30 m R88A-CAGB030S R88A-CAGB030B

40 m R88A-CAGB040S R88A-CAGB040B

50 m R88A-CAGB050S R88A-CAGB050B

3 m R88A-CAGB003S R88A-CAKF003B

5 m R88A-CAGB005S R88A-CAKF005B

10 m R88A-CAGB010S R88A-CAKF010B

15 m R88A-CAGB015S R88A-CAKF015B

20 m R88A-CAGB020S R88A-CAKF020B

30 m R88A-CAGB030S R88A-CAKF030B

40 m R88A-CAGB040S R88A-CAKF040B

50 m R88A-CAGB050S R88A-CAKF050B

3 m R88A-CAGD003S R88A-CAGD003B

5 m R88A-CAGD005S R88A-CAGD005B

10 m R88A-CAGD010S R88A-CAGD010B

2-13

15 m R88A-CAGD015S R88A-CAGD015B

20 m R88A-CAGD020S R88A-CAGD020B

30 m R88A-CAGD030S R88A-CAGD030B

40 m R88A-CAGD040S R88A-CAGD040B

50 m R88A-CAGD050S R88A-CAGD050B

Note.There are separate connectors for power and brakes for 100 V and 200 V 3,000-r/min motors of 50

to 750 W. Therefore, when a motor with a brake is used, it will require both a power cable for a motor

without a brake and a brake cable.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 41

Brake Cables (Non-Flexible Cables)

Specifications Model

2-3 Standard Model List

[100 V and 200 V]

For 3,000-r/min motors of 50 to 750 W

Encoder Cables (Non-Flexible Cables)

Specifications Model

[100 V and 200 V]

For 3,000-r/min motors of 50 to 750 W

(for both absolute encoders and incremental encoders)

3 m R88A-CAKA003B

5 m R88A-CAKA005B

10 m R88A-CAKA010B

15 m R88A-CAKA015B

20 m R88A-CAKA020B

30 m R88A-CAKA030B

40 m R88A-CAKA040B

50 m R88A-CAKA050B

3 m R88A-CRKA003CR

5 m R88A-CRKA005CR

10 m R88A-CRKA010CR

15 m R88A-CRKA015CR

20 m R88A-CRKA020CR

2

Standard Models and External Dimensions

[100 V and 200 V]

3,000-r/min motors of 1.0 kW or more

For 2,000-r/min motors

For 1,000-r/min motors

[400 V]

For 3,000-r/min motors

For 2,000-r/min motors

For 1,000-r/min motors

30 m R88A-CRKA030CR

40 m R88A-CRKA040CR

50 m R88A-CRKA050CR

3 m R88A-CRKC003NR

5 m R88A-CRKC005NR

10 m R88A-CRKC010NR

15 m R88A-CRKC015NR

20 m R88A-CRKC020NR

30 m R88A-CRKC030NR

40 m R88A-CRKC040NR

50 m R88A-CRKC050NR

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-14

Page 42

2-3 Standard Model List

Motor Power Cables (Non-Flexible Cables)

[100 V and 200 V]

For 3,000-r/min motors of 50 to 750 W

Specifications

Model

For motor without

brake

3 m R88A-CAKA003SR −

5 m R88A-CAKA005SR −

10 m R88A-CAKA010SR −

15 m R88A-CAKA015SR −

For motor with brake

2

Standard Models and External Dimensions

[200 V]

For 3,000-r/min motors of 1 to 2 kW

For 2,000-r/min motors of 1 to 2 kW

For 1,000-r/min motors of 900 W

[400 V]

For 3,000-r/min motors of 750 W to 2 kW

For 2,000-r/min motors of 400 W to 2 kW

For 1,000-r/min motors of 900 W

For 3,000-r/min motors of 3 to 5 kW

For 2,000-r/min motors of 3 to 5 kW

For 1,000-r/min motors of 2 to 3 kW

20 m R88A-CAKA020SR −

30 m R88A-CAKA030SR −

40 m R88A-CAKA040SR −

50 m R88A-CAKA050SR −

3 m R88A-CAGB003SR R88A-CAGB003BR

5 m R88A-CAGB005SR R88A-CAGB005BR

10 m R88A-CAGB010SR R88A-CAGB010BR

15 m R88A-CAGB015SR R88A-CAGB015BR

20 m R88A-CAGB020SR R88A-CAGB020BR

30 m R88A-CAGB030SR R88A-CAGB030BR

40 m R88A-CAGB040SR R88A-CAGB040BR

50 m R88A-CAGB050SR R88A-CAGB050BR

3 m R88A-CAGB003SR R88A-CAKF003BR

5 m R88A-CAGB005SR R88A-CAKF005BR

10 m R88A-CAGB010SR R88A-CAKF010BR

15 m R88A-CAGB015SR R88A-CAKF015BR

20 m R88A-CAGB020SR R88A-CAKF020BR

30 m R88A-CAGB030SR R88A-CAKF030BR

40 m R88A-CAGB040SR R88A-CAKF040BR

50 m R88A-CAGB050SR R88A-CAKF050BR

3 m R88A-CAGD003SR R88A-CAGD003BR

5 m R88A-CAGD005SR R88A-CAGD005BR

10 m R88A-CAGD010SR R88A-CAGD010BR

2-15

15 m R88A-CAGD015SR R88A-CAGD015BR

20 m R88A-CAGD020SR R88A-CAGD020BR

30 m R88A-CAGD030SR R88A-CAGD030BR

40 m R88A-CAGD040SR R88A-CAGD040BR

50 m R88A-CAGD050SR R88A-CAGD050BR

Note.There are separate connectors for power and brakes for 100 V and 200 V 3,000-r/min motors of 50

to 750 W. Therefore, when a motor with a brake is used, it will require both a power cable for a motor

without a brake and a brake cable.

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 43

Brake Cables (Non-Flexible Cables)

Specifications Model

2-3 Standard Model List

[100 V and 200 V]

For 3,000-r/min motors of 50 to 750 W

3 m R88A-CAKA003BR

5 m R88A-CAKA005BR

10 m R88A-CAKA010BR

15 m R88A-CAKA015BR

20 m R88A-CAKA020BR

30 m R88A-CAKA030BR

40 m R88A-CAKA040BR

50 m R88A-CAKA050BR

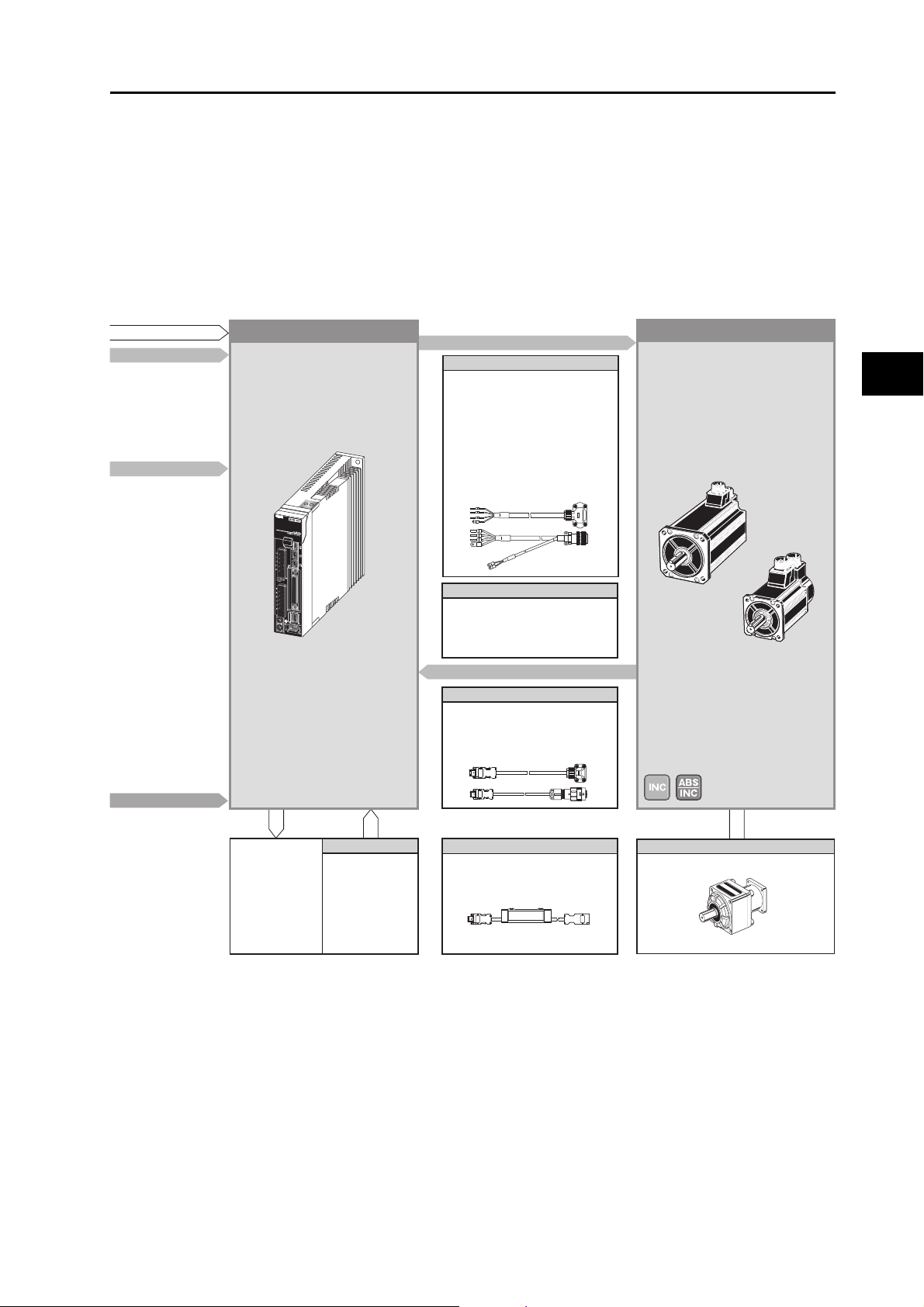

Absolute Encoder Battery Cables

Specifications Model

ABS battery cable (battery not supplied) 0.3 m R88A-CRGD0R3C

ABS battery cable (R88A-BAT01G battery × 1 supplied)

0.3 m

R88A-CRGD0R3C-BS

Analog Monitor Cable

2

Standard Models and External Dimensions

Specifications Model

Analog monitor cable 1 m R88A-CMK001S

Absolute Encoder Backup Battery

Specifications Model

2,000 mA•h 3.6 V R88A-BAT01G

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-16

Page 44

2-3 Standard Model List

Connectors

Specifications Model

2

Motor connector for encoder cable [100 V and 200 V]

For 3,000-r/min of 50 to 750 W

[100 V and 200 V]

For 3,000-r/min of 1 to 5 kW

For 2,000 r/min, 1,000 r/min

[400 V]

For 3,000 r/min, 2,000 r/min and

1,000 r/min

Control I/O connector (CN1) R88A-CNU11C

Encoder connector (CN2) R88A-CNW01R

External scale connector (CN4) R88A-CNK41L

Safety connector (CN8) R88A-CNK81S

Power cable connector (for 750 W max.) R88A-CNK11A

Brake cable connector (for 750 W max.) R88A-CNK11B

R88A-CNK02R

R88A-CNK04R

Standard Models and External Dimensions

2-17

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

Page 45

Servo Relay Units (for CN1)

Specifications Model

2-3 Standard Model List

Servo Relay Unit For CS1W-NC113/-NC133

For CJ1W-NC113/-NC133

For C200HW-NC113

For CS1W-NC213/-NC413/-NC233/-NC433

For CJ1W-NC213/-NC413/-NC233/-NC433

For C200HW-NC213/-NC413

For CJ1M-CPU21/-CPU22/-CPU23 XW2B-20J6-8A

For FQM1-MMA22

For FQM1-MMP22

For CQM1-CPU43-V1

For CQM1H-PLB21

Servo Relay Unit Cables for Servo Drives

Specifications Model

Servo Drive cables For PCU (XW2B-xJ6-xB)

For CQM1 (XW2B-20J6-3B)

For CJM1

(XW2B-20J6-8A/XW2B-40J6-9A)

XW2B-20J6-1B

XW2B-40J6-2B

XW2B-40J6-9A

XW2B-80J7-12A

XW2B-20J6-3B

1 m XW2Z-100J-B25

2 m XW2Z-200J-B25

1 m XW2Z-100J-B31

2 m XW2Z-200J-B31

2

Standard Models and External Dimensions

For FQM1-MMA22

(XW2B-80J7-12A)

For FQM1-MMP22

(XW2B-80J7-12A)

1 m XW2Z-100J-B27

2 m XW2Z-200J-B27

1 m XW2Z-100J-B26

2 m XW2Z-200J-B26

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

2-18

Page 46

2-3 Standard Model List

Servo Relay Unit Cables for Position Control Units

Specifications Model

For CQM1H-PLB21 (XW2B-20J6-3B) 0.5 m XW2Z-050J-A3

1 m XW2Z-100J-A3

For CS1W-NC113, C200HW-NC113 (XW2B20J6-1B)

For CS1W-NC213/-NC413, C200HW-NC213/NC413 (XW2B-20J6-2B)

0.5 m XW2Z-050J-A6

1 m XW2Z-100J-A6

0.5 m XW2Z-050J-A7

1 m XW2Z-100J-A7

2

Standard Models and External Dimensions

Position Control Unit

cables

For CS1W-NC133 (XW2B-20J6-1B) 0.5 m XW2Z-050J-A10

1 m XW2Z-100J-A10

For CS1W-NC233/-NC433 (XW2B-20J6-2B) 0.5 m XW2Z-050J-A11

1 m XW2Z-100J-A11

For CJ1W-NC113 (XW2B-20J6-1B) 0.5 m XW2Z-050J-A14

1 m XW2Z-100J-A14

For CJ1W-NC213/-NC413 (XW2B-20J6-2B) 0.5 m XW2Z-050J-A15

1 m XW2Z-100J-A15

For CJ1W-NC133 (XW2B-20J6-1B) 0.5 m XW2Z-050J-A18

1 m XW2Z-100J-A18

For CJ1W-NC233/-NC433 (XW2B-20J6-2B) 0.5 m XW2Z-050J-A19

1 m XW2Z-100J-A19

For CJ1M-CPU21/-CPU22/-CPU23 (XW2B20J6-8A/XW2B-40J6-9A)

For FQM1-MMA22

(XW2B-80J7-12A)

General I/O 0.5 m XW2Z-050J-A28

Special I/O 0.5 m XW2Z-050J-A31

0.5 m XW2Z-050J-A33

1 m XW2Z-100J-A33

1 m XW2Z-100J-A28

2 m XW2Z-200J-A28

1 m XW2Z-100J-A31

2 m XW2Z-200J-A31

2-19

For FQM1-MMP22

(XW2B-80J7-12A)

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

General I/O 0.5 m XW2Z-050J-A28

1 m XW2Z-100J-A28

2 m XW2Z-200J-A28

Special I/O 0.5 m XW2Z-050J-A30

1 m XW2Z-100J-A30

2 m XW2Z-200J-A30

Page 47

Control Cables

2-3 Standard Model List

Specifications Model

Specified cables for Position Control Unit

(line-driver output for 1 axis)

CJ1W-NC234/-NC434

Specified cables for Position Control Unit

(open collector output for 1 axis)

CJ1W-NC214/-NC414

Specified cables for Position Control Unit

(line-driver output for 2 axes)

CJ1W-NC234/-NC434

Specified cables for Position Control Unit

(open collector output for 2 axes)

CJ1W-NC214/-NC414

Specified cables for Motion Control Unit (for 1 axis)

CS1W-MC221-V1/-MC421-V1

Specified cables for Motion Control Unit (for 2 axes)

CS1W-MC221-V1/-MC421-V1

1 m XW2Z-100J-G9

5 m XW2Z-500J-G9

10 m XW2Z-10MJ-G9

1 m XW2Z-100J-G13

XW2Z-300J-G13

3 m

1 m XW2Z-100J-G13

5 m XW2Z-500J-G1

10 m XW2Z-10MJ-G1

1 m XW2Z-100J-G5

XW2Z-300J-G5

3 m

1 m R88A-CPG001M1

2 m R88A-CPG002M1

3 m R88A-CPG003M1

5 m R88A-CPG005M1

1 m R88A-CPG001M2

2 m R88A-CPG002M2

3 m R88A-CPG003M2

5 m R88A-CPG005M2

2

Standard Models and External Dimensions

General control cables (with connector on one end) 1 m R88A-CPG001S

2 m R88A-CPG002S

Connector-terminal block cables 1 m XW2Z-100J-B24

2 m XW2Z-200J-B24

Connector-terminal block M3 screw type XW2B-50G4

M3.5 screw type XW2B-50G5

M3 screw type XW2D-50G6

External Regeneration Resistors

Specifications Model