Page 1

Industrial PC Platform

NY-series

Industrial Monitor

User's Manual

NYM15W

NYM15W

NYM12W

NYM12W-C106£

-C100£

-C106£

-C100£

Industrial Monitor

W554-E2-03

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or other-

wise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover

because OMRON is constantly striving to improve its high-quality products, the information contained

in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publica-

tion.

,

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the Industrial Monitor.

This manual contains information that is necessary to use the Industrial Monitor (hereafter also named

as Monitor). Please read this manual and make sure you understand the functionality and perform-

ance of the Monitor before attempting to use it.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing Factory Automation systems.

• Personnel in charge of designing Factory Automation systems.

• Personnel in charge of installing and maintaining Factory Automation systems.

• Personnel in charge of managing Factory Automation systems and facilities.

Introduction

Applicable Products

This manual covers the following Industrial Monitor products:

Industrial Monitor, 15.4 inch

Industrial Monitor, 12.1 inch

Additional Information

Refer to 1-4 Product Configuration on page

Product Model

NYM15W-C100£

NYM15W-C106£

NYM12W-C100£

NYM12W-C106£

1 - 5 for configuration details.

NY-series Industrial Monitor User's Manual (W554)

1

Page 4

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience

Applicable Products ......................................................................................................................................... 1

Manual Information.................................................................................................. 7

Page Structure.................................................................................................................................................7

Special Information .......................................................................................................................................... 8

Terms and Conditions Agreement.......................................................................... 9

Warranty and Limitations of Liability ................................................................................................................ 9

Application Considerations ............................................................................................................................10

Disclaimers ....................................................................................................................................................10

Safety Precautions................................................................................................. 11

Definition of Precautionary Information.......................................................................................................... 11

Symbols ......................................................................................................................................................... 11

Warnings........................................................................................................................................................ 12

Cautions......................................................................................................................................................... 13

...........................................................................................................................................1

Precautions for Safe Use ...................................................................................... 14

Disassembly, Dropping, Mounting, Installation and Storage .........................................................................14

Wiring............................................................................................................................................................. 14

Power Supply Design and Turning ON/OFF the Power Supply.....................................................................15

Operation ....................................................................................................................................................... 15

Cleaning, Maintenance and Disposal ............................................................................................................16

Precautions for Correct Use ................................................................................. 17

Storage, Installation and Mounting ................................................................................................................17

Wiring............................................................................................................................................................. 17

Actual Operation and Operation ....................................................................................................................17

Cleaning and Maintenance ............................................................................................................................ 18

Regulations and Standards .................................................................................. 19

Conformance to EU Directives ......................................................................................................................19

Conformance to KC Standards......................................................................................................................20

Conformance to UL and CSA Standards.......................................................................................................20

Related Manuals..................................................................................................... 21

Related Industrial PC Manuals ......................................................................................................................21

Related Industrial PC Without Operating System Manuals ...........................................................................21

Related IPC Machine Controller Manuals...................................................................................................... 22

Related IPC RTOS Controller Manuals .........................................................................................................23

Related IPC Programmable Multi Axis Controller Manuals ...........................................................................23

Terminology and Abbreviations ........................................................................... 24

Industrial PC Platform ...................................................................................................................................24

Hardware ......................................................................................................................................................24

Software......................................................................................................................................................... 24

Revision History..................................................................................................... 25

Sections in this Manual ......................................................................................... 27

2

NY-series Industrial Monitor User's Manual (W554)

Page 5

Section 1 Overview

1-1 Intended Use ........................................................................................................................1 - 2

1-2

Hardware Features...............................................................................................................1 - 3

1-3 ID Information Label ............................................................................................................1 - 4

1-4 Product Configuration.........................................................................................................1 - 5

1-5 Industrial PC Platform Overview ........................................................................................1 - 6

1-5-1 Industrial Monitor ......................................................................................................................1 - 6

1-5-2 Industrial Box PC .....................................................................................................................1 - 7

1-5-3 Industrial Panel PC ..................................................................................................................1 - 7

Section 2 Hardware

2-1 Component Names and Functions.....................................................................................2 - 2

2-1-1

2-1-2 Bottom of the Industrial Monitor ................................................................................................2 - 3

2-2 LED Indicators......................................................................................................................2 - 4

2-2-1 Logo LED ..................................................................................................................................2 - 5

2-2-2 Status LED Indicator .................................................................................................................2 - 5

2-3 Connectors ........................................................................................................................... 2 - 6

2-3-1 Power Connector ......................................................................................................................2 - 6

2-3-2 DVI-D Connector (Optional) ......................................................................................................2 - 7

2-3-3 NY Monitor Link Connector (Optional) ......................................................................................2 - 7

2-3-4 USB Type-A Connector.............................................................................................................2 - 8

2-3-5 USB Type-B Connector (Optional)............................................................................................2 - 9

2-4 Optional Hardware ............................................................................................................. 2 - 10

2-4-1 DVI Cables ..............................................................................................................................2 - 10

2-4-2 USB Type-A to USB Type-B Cables .......................................................................................2 - 11

2-4-3 NY Monitor Link Cables ..........................................................................................................2 - 12

2-4-4 Power Supply ..........................................................................................................................2 - 13

Front and Top of the Industrial Monitor .....................................................................................2 - 2

CONTENTS

Section 3 Software

3-1 Operating Systems ..............................................................................................................3 - 2

3-1-1 Touch Functionality ...................................................................................................................3 - 2

3-1-2 Determine Your Version of the Windows Operating Systems ...................................................3 - 3

3-2 Support Software ................................................................................................................. 3 - 4

3-2-1 Overview IPC Support Software for Windows...........................................................................3 - 4

3-2-2 Industrial Monitor Utility ............................................................................................................3 - 5

3-2-3 Industrial Monitor Brightness Utility ..........................................................................................3 - 8

3-2-4 Industrial PC Tray Utility .........................................................................................................3 - 10

3-3 Software for Developers....................................................................................................3 - 13

3-3-1 Overview IPC Developer Software for Windows.....................................................................3 - 13

3-3-2 Industrial Monitor API .............................................................................................................3 - 14

Section 4 Specifications

4-1 General Specifications .......................................................................................................4 - 2

4-1-1

4-1-2 General Electrical Specifications...............................................................................................4 - 3

4-2 Connector Specifications ...................................................................................................4 - 4

4-2-1 Power Connector Specifications ...............................................................................................4 - 4

4-2-2 DVI-D Connector Specifications................................................................................................4 - 5

Dimensions and Weight ............................................................................................................4 - 2

NY-series Industrial Monitor User's Manual (W554)

3

Page 6

CONTENTS

4-2-3 NY Monitor Link Connector Specifications................................................................................4 - 7

4-2-4

4-2-5 USB Type-B Connector Specifications....................................................................................4 - 10

USB Type-A Connector Specifications......................................................................................4 - 9

4-3 Display Specifications....................................................................................................... 4 - 11

4-4 Environmental Specifications...........................................................................................4 - 12

4-4-1 Operation Environment Specifications ....................................................................................4 - 12

4-4-2 Temperature and Humidity Specifications...............................................................................4 - 13

4-4-3 Recycling Specifications .........................................................................................................4 - 14

Section 5 Installation

5-1 Unpack .................................................................................................................................. 5 - 2

5-1-1

5-1-2 Items Supplied ..........................................................................................................................5 - 3

5-2 Mount ....................................................................................................................................5 - 4

5-2-1 Installation Method in Control Panels........................................................................................5 - 4

5-2-2 Product Orientation ...................................................................................................................5 - 5

5-2-3 Temperature ..............................................................................................................................5 - 6

5-2-4 Humidity ....................................................................................................................................5 - 8

5-2-5 Vibration and Shock ..................................................................................................................5 - 8

5-2-6 Atmosphere...............................................................................................................................5 - 9

5-2-7 Electrical Environment ..............................................................................................................5 - 9

5-2-8 Prepare the Mounting Surface ................................................................................................5 - 14

5-2-9 Mount the Industrial Monitor....................................................................................................5 - 16

5-3 Wire .....................................................................................................................................5 - 17

5-3-1 Ground ....................................................................................................................................5 - 17

5-3-2 Wire the Power Connector ......................................................................................................5 - 24

5-4 Connect...............................................................................................................................5 - 26

5-4-1 Connector Identification ..........................................................................................................5 - 26

5-4-2 Connection Procedure ............................................................................................................5 - 27

5-5 Initial Power ON .................................................................................................................5 - 28

5-5-1 Initial Power ON Procedure.....................................................................................................5 - 28

Unpack Procedure ....................................................................................................................5 - 2

Section 6 Operating Procedures

6-1 Touchscreen Operation.......................................................................................................6 - 2

6-2

Power ON / Power OFF / Standby.......................................................................................6 - 3

6-3 Support Software and Product Information .....................................................................6 - 4

6-4 React to Product Messages ................................................................................................ 6 - 5

Section 7 Maintenance

7-1 Preventive Maintenance ...................................................................................................... 7 - 2

7-1-1 Preventive Maintenance Schedule............................................................................................7 - 2

7-1-2 Clean the Touchscreen Surface ................................................................................................7 - 3

7-1-3 Clean the Monitor......................................................................................................................7 - 3

7-1-4 Check the Gasket Seal .............................................................................................................7 - 4

7-1-5 Keep Software Updated ............................................................................................................7 - 4

7-2 Corrective Maintenance ......................................................................................................7 - 5

7-2-1 Warning and Error Messages....................................................................................................7 - 5

7-2-2 Windows Event Viewer..............................................................................................................7 - 5

7-2-3 Correct Display Functionality when Nothing is Displayed .........................................................7 - 8

7-2-4 Correct Touchscreen Functionality............................................................................................7 - 9

4

NY-series Industrial Monitor User's Manual (W554)

Page 7

Index

CONTENTS

NY-series Industrial Monitor User's Manual (W554)

5

Page 8

CONTENTS

6

NY-series Industrial Monitor User's Manual (W554)

Page 9

Manual Information

A

B

C

E

F

B

C

H

5 Installation

5 - 3

N

Y-series User's Manual (W555)

5-1 Unpack

5

5-1-1 Unpack Procedure

G

5-1

Unpack

This section provides details on how to unpack the Industrial Panel PC.

5-1-1

Unpack Procedure

1 Check the package for damage.

If there is any visible damage:

• Take photos of the package and save them.

• Inform your supplier immediately.

2 Open the package.

Ensure not to damage the contents.

3 Ensure that all items are present.

Additional Information

Refer to 5-1-2 Items Supplied with the Product

for the items supplied.

This section provides information about this manual.

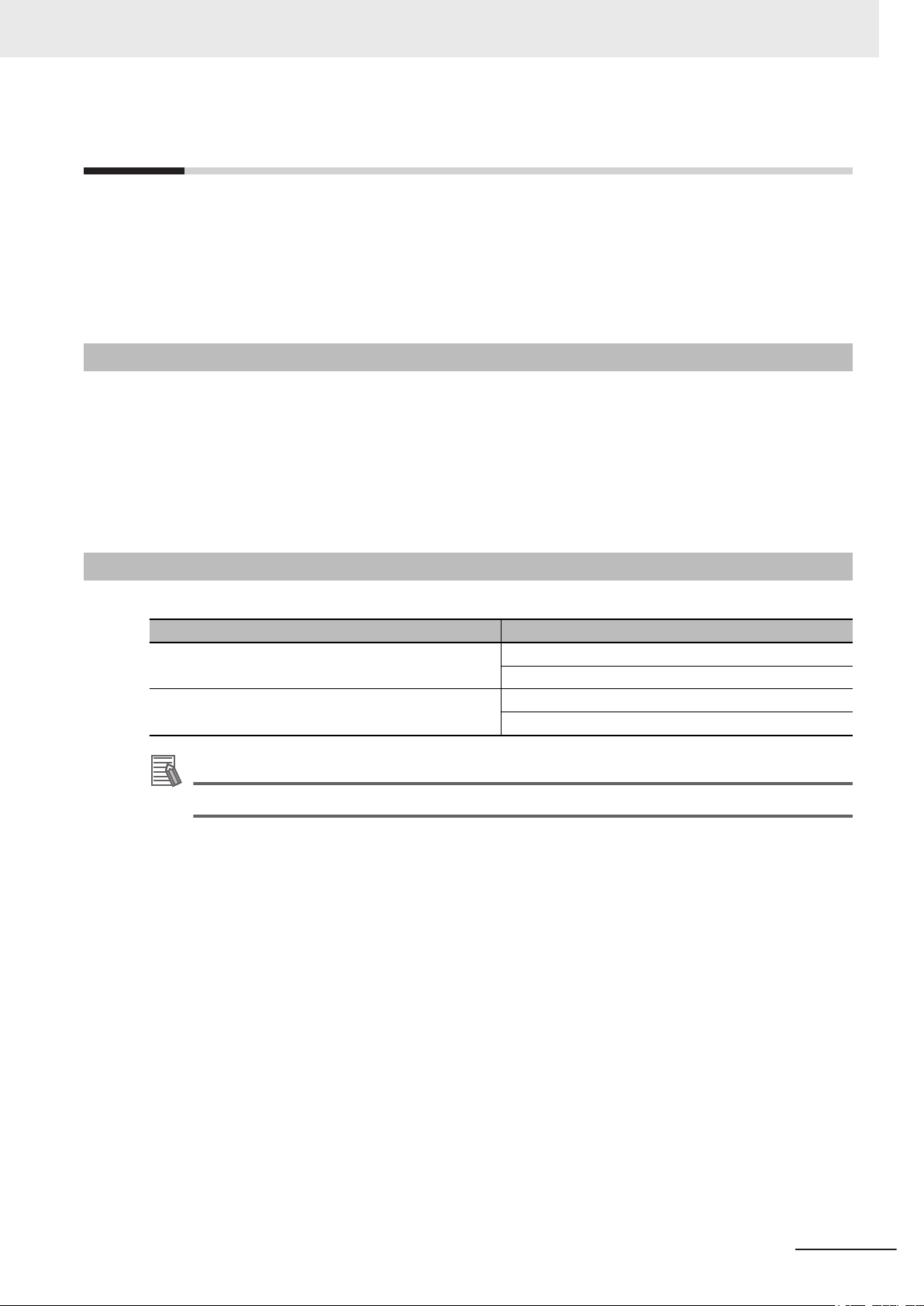

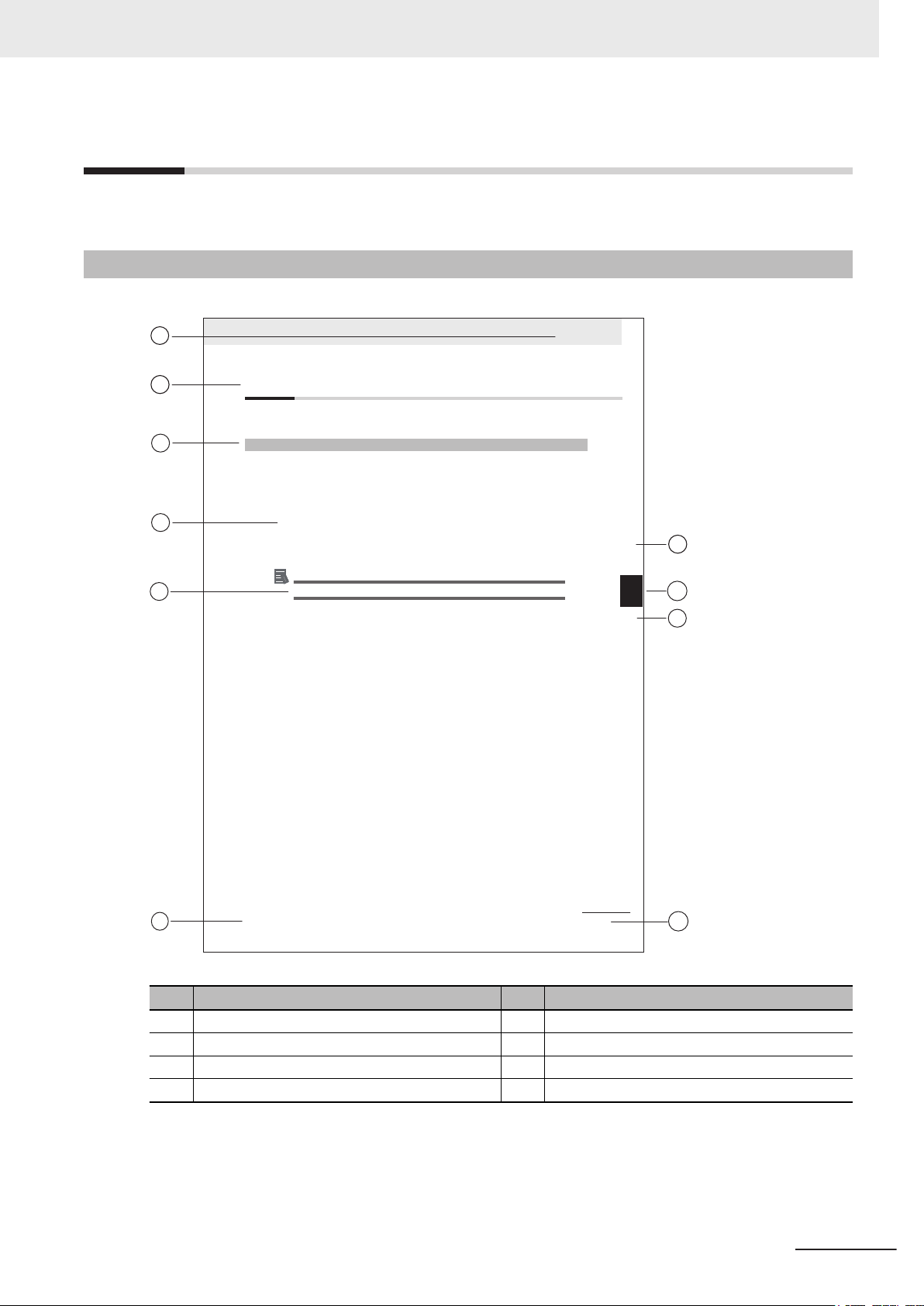

Page Structure

The following page structure is used in this manual.

Manual Information

Note: This illustration is provided as a sample. It will not literally appear in this manual.

Item Explanation Item Explanation

A Level 1 heading E Special Information

B Level 2 heading F Manual name

C Level 3 heading G Page tab with the number of the main section

D Step in a procedure H Page number

NY-series Industrial Monitor User's Manual (W554)

7

Page 10

Manual Information

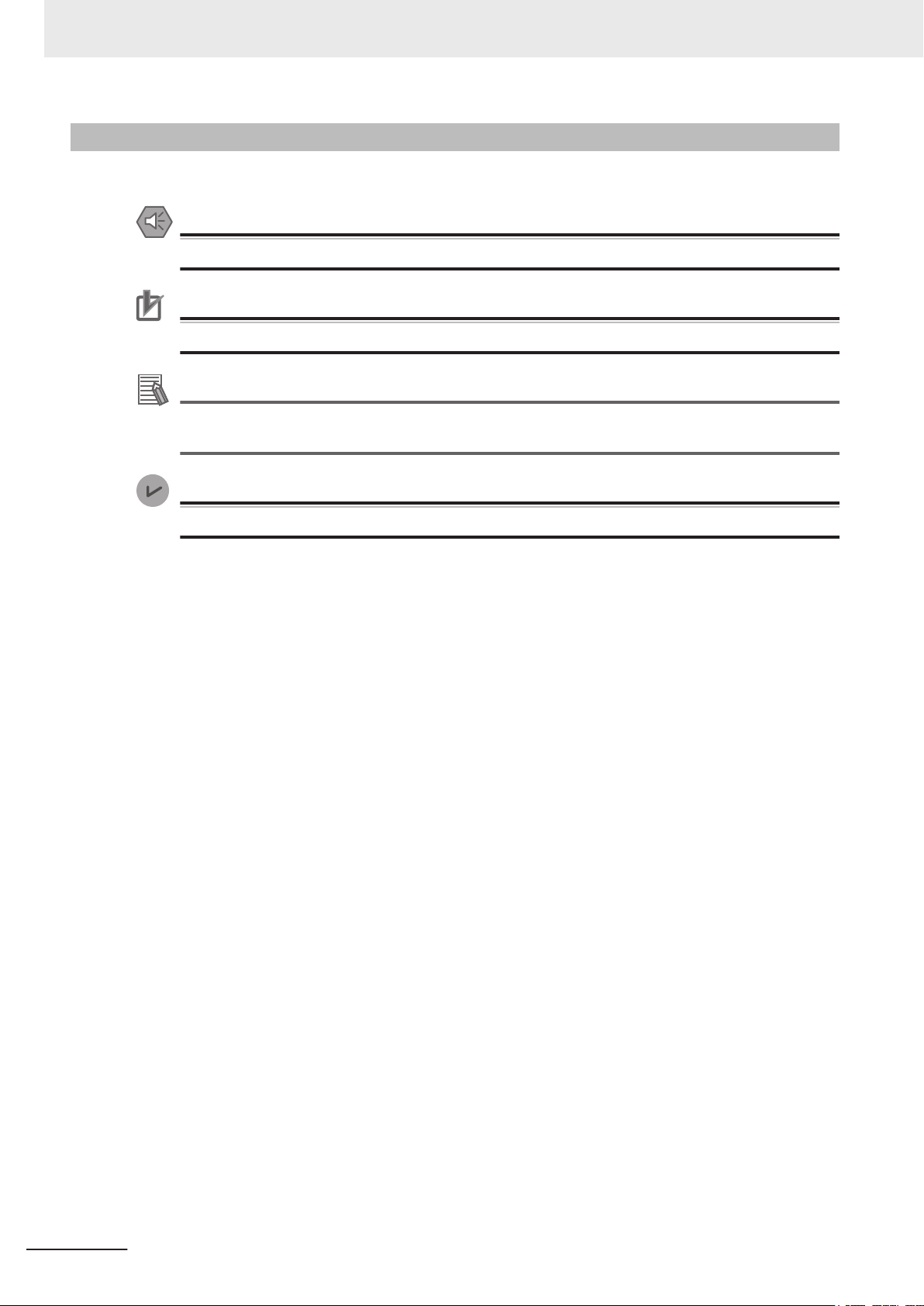

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier

Version Information

.

Information on differences in specifications and functionality between different versions.

8

NY-series Industrial Monitor User's Manual (W554)

Page 11

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty and Limitations of Liability

Warranty

• Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workman-

ship for a period of twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, expressed or implied.

• Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

• Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products un-

less Omron’s analysis confirms that the Products were properly handled, stored, installed and main-

tained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any

Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in combination

with any electrical or electronic components, circuits, system assemblies or any other materials or

substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitations of Liability

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY. Further, in no event shall liability of Omron Com-

panies exceed the individual price of the Product on which liability is asserted.

NY-series Industrial Monitor User's Manual (W554)

9

Page 12

Terms and Conditions Agreement

Application Considerations

Suitability for Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND IN-

STALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

’s application or use of the Product. At Buy-

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

. It may represent the result of

, some specifications of the Product may

10

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever

, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NY-series Industrial Monitor User's Manual (W554)

Page 13

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the Industrial Monitor. The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoid-

WARNING

Caution

ed, could result in death or serious injury

may be severe property damage.

Indicates a potentially hazardous situation which, if not avoid-

ed, may result in minor or moderate injury

Safety Precautions

. Additionally, there

, or property damage.

Symbols

The circle and slash symbol indicates operations that you must not do. The

specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly

The triangle symbol indicates precautions (including warnings). The specific

operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings). The specific

operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do. The specific

operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

.

NY-series Industrial Monitor User's Manual (W554)

11

Page 14

Safety Precautions

Warnings

Ensure that installation and post-installation checks are performed by personnel in charge who possess a thorough understanding of the machinery

to be installed.

Do not use the input functions of the touchscreen in applications that involve

human life, in applications that may result in serious injury

stop switches.

Water or other liquid present on the touchscreen surface may create false

touch behavior and unexpected operation. Wipe away liquid on the

touchscreen before operation.

Disassembly and Dropping

WARNING

, or for emergency

Do not attempt to disassemble, repair, or modify the product in any way. Doing so may result in malfunction or fire.

Installation

Always connect to a ground of 100 Ω or less when installing the product.

12

NY-series Industrial Monitor User's Manual (W554)

Page 15

Cautions

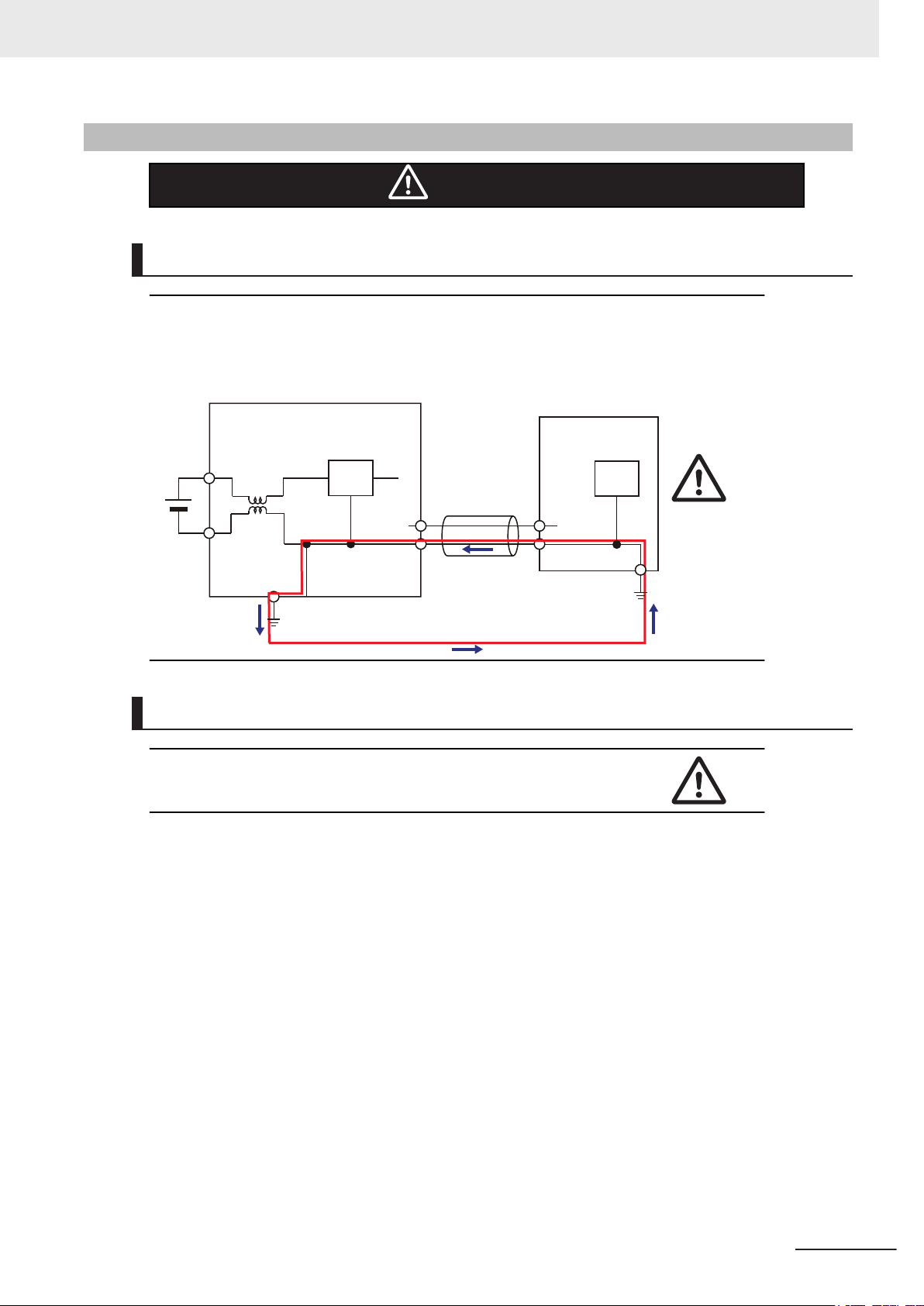

Industrial PC Platform Product

Non-isolated

Device

Non-isolated

Interface

24 VDC

0 VDC

Wiring

The product has an internal non-isolated DC power supply. Circuit ground (0

VDC) and frame ground are connected together. When connecting a nonisolated device or a non-isolated interface to the product, take appropriate

actions to avoid communication failures or damage to the mentioned ports.

Safety Precautions

Caution

Operation

When using a system with multiple touchscreens, multiple users can perform simultaneous operations. Make sure that this can not result in unintended actions.

NY-series Industrial Monitor User's Manual (W554)

13

Page 16

Precautions for Safe Use

Precautions for Safe Use

Disassembly, Dropping, Mounting, Installation and Storage

• Do not drop the product or subject it to abnormal vibration or shock. Doing so may result in product

malfunction or burning.

• When unpacking, check carefully for any external scratches or other damages. Also, shake the

product gently and check for any abnormal sound.

• Always use the devices specified in the relevant manual.

• The product must be installed in a control panel.

• Always install equipment that is included in the product specifications. Not doing so may result in

failure or malfunction.

• Install the product in the correct orientation and temperature according to the specifications in the

manual to prevent overheating. Not doing so may result in malfunction.

• When connecting peripheral devices to the product, ensure sufficient countermeasures against

noise and static electricity during installation of the peripheral devices.

• The mounting panel must be between 1.6 and 6.0 mm thick. Tighten the Mounting Brackets evenly

to a torque of 0.6 N·m to maintain water and dust resistance. If the tightening torque exceeds the

specified value, or the tightening is not even, deformation of the front panel may occur. Additionally,

make sure the panel is not dirty or warped and that it is strong enough to hold the product.

• Do not let metal particles enter the product when preparing the panel. Do not allow wire clippings,

shavings, or other foreign material to enter any product. Otherwise, the product burning, failure, or

malfunction may occur. Cover the product or take other suitable countermeasures, especially during

wiring work.

Wiring

• Follow the instructions in the manual to correctly perform connector wiring and insertion. Double-

• Always ensure connectors and cables are completely locked in place to prevent accidental discon-

• Do not bend or pull the cables beyond normal limit. Do not place heavy objects on top of the cables

• Always use power supply wires with sufficient wire diameters to prevent voltage drop and burning.

• Use a power cable with a conductor cross-section of 0.2 mm2 to 2.5 mm2. Remove 7 mm of sheath

• Be sure that all mounting bracket screws and cable connector screws are tightened to the torque

• Use crimp terminals for wiring.

• Observe the following precautions to prevent broken wires.

check all wiring and connector insertion before turning ON the power supply.

nection.

or other wiring lines. Doing so may break the cables.

Make sure that the current capacity of the wire is sufficient. Otherwise, excessive heat may be gen-

erated. When cross-wiring terminals, the total current for all the terminals will flow in the wire. When

wiring cross-overs, make sure that the current capacity of each of the wires is not exceeded.

before connecting the wires.

specified in the relevant manuals. The loose screws may result in fire or malfunction.

• When you remove the sheath, be careful not to damage the conductor.

• Connect the conductor without twisting the wires.

• Do not weld the conductors. Doing so may cause the wires to break with vibration.

14

NY-series Industrial Monitor User's Manual (W554)

Page 17

Precautions for Safe Use

• Emergency stop circuits, interlock circuit, limit circuits, and similar safety measures must be provid-

ed in external control circuits.

•

For an NY Monitor Link connection, always follow the cable type and connection method specifica-

tions in the manual. Otherwise, communications may be faulty.

Power Supply Design and Turning ON/OFF the Power Supply

• Always use a power supply that provides power within the rated range.

Do not perform a dielectric strength test.

•

• Power ON after the DVI cable is connected between the host PC and the product.

• Power ON after the NY Monitor Link cable is connected between the host PC and the product.

• Always check the power supply and power connections before applying power. Incorrect power con-

nections can damage the product or cause burning.

• Always turn OFF the power supply to system before you attempt any of the following.

• Connecting cables

• Connecting or disconnecting the connectors

• Use a DC power supply with a slight voltage fluctuation that will provide a stable output even if the

input is momentarily interrupted for 10 ms. Use a DC power supply with reinforced insulation or dou-

ble insulation. The rated power supply voltage of the product is 24 VDC with an allowable range of

19.2 to 28.8 VDC.

• Do not turn ON the power supply to the product when a part of a human body or a conductive object

is touching the surface of the touchscreen. Doing so will cause the touchscreen functionality to be

disabled. Remove the conductive object and cycle the power supply to restore the touchscreen

functionality.

Operation

• Do not carry out the following operations when accessing a USB device or an SD Memory Card.

Turn OFF the power supply of the product.

•

• Press the power button of the host PC.

• Remove a USB device.

• Confirm the safety of the system before using the touch panel.

• Signals from the touchscreen may not be entered if the touchscreen is pressed consecutively at

high speed. Only move on to the next operation after confirming that the product has detected the

previous input of the touchscreen.

• Do not accidentally press the touchscreen when the backlight is not lit or when the display does not

appear. Confirm the safety of the system before pressing the touchscreen.

• Do not use hard or pointed objects to operate or scrub the touchscreen, otherwise the surface of the

touchscreen may be damaged.

• Before you connect a computer to the product, disconnect the power supply plug of the computer

from the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG

terminal has the same electrical potential on the product. A difference in electrical potential between

the computer and the product may cause failure or malfunction.

• In systems with multiple screens in extended view, an interruption in the video signal of one screen

will cause all windows on that screen to be moved to the primary screen. Make sure that this situa-

tion is properly handled.

NY-series Industrial Monitor User's Manual (W554)

15

Page 18

Precautions for Safe Use

Cleaning, Maintenance and Disposal

• Periodically check the installation conditions in applications where the product is subject to contact

with oil or water

• As the rubber gasket will deteriorate, shrink, or harden depending on the operating environment, pe-

riodical inspection is necessary.

.

16

NY-series Industrial Monitor User's Manual (W554)

Page 19

Precautions for Correct Use

Storage, Installation and Mounting

• Do not operate or store the product in the following locations. Operation may stop or malfunctions

may occur.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil or chemicals

• Locations subject to shock or vibration

• Locations outdoors subject to direct wind and rain

• Locations subject to strong ultraviolet light

• Take appropriate and sufficient countermeasures when installing the product in the following loca-

tions

• Locations subject to strong, high-frequency noise

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power lines

• Always touch a grounded piece of metal to discharge static electricity from your body before starting

an installation or maintenance procedure.

• The backlight has a finite life and if that is exceeded, the product may fail or malfunction. Check the

brightness periodically and if necessary, replace the product.

Precautions for Correct Use

Wiring

• Always ensure the rated supply voltage is connected to the product.

• Do not use cables exceeding the maximum specified length. Doing so may cause malfunction.

• Do not connect an AC power supply to the DC power connector.

• Never ground the 24 VDC side of the power supply. This may cause a short circuit.

Actual Operation and Operation

• The touchscreen supports 5 simultaneous touches. When the number of touches is exceeded, not

all touch points will be detected.

• The capacitive touchscreen reacts to contact on its surface. Accidental touching the surface of the

touchscreen may cause unintended behavior.

• You can operate the touchscreen even when you wear some gloves. Confirm that you can correctly

operate the touchscreen while wearing gloves prior to actual operation.

NY-series Industrial Monitor User's Manual (W554)

17

Page 20

Precautions for Correct Use

Cleaning and Maintenance

• Do not use corrosive substances to clean the product.

Turn OFF the product or disable the touchscreen for cleaning with water.

•

18

NY-series Industrial Monitor User's Manual (W554)

Page 21

Regulations and Standards

Conformance to EU Directives

The Industrial Monitor complies with EU Directives. To ensure that the machine or device in which the

Industrial Monitor is used complies with EU Directives, the following precautions must be observed:

• The Industrial Monitor must be installed within a control panel.

• The Industrial Monitor that complies with EU Directives also conforms to the Common Emission

Standard. Radiated emission characteristics (10-m regulations) may vary depending on the configu-

ration of the control panel used, other devices connected to the control panel, wiring, and other con-

ditions. You must therefore confirm that the overall machine or equipment in which the Industrial

Monitor is used complies with EU Directives.

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference. If radio interference occurs, the user may be required to take appropriate meas-

ures.

Regulations and Standards

Applicable Directive

EMC Directive

EMC Directive

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have been

checked for conformity to EMC standards.

Applicable EMC (Electromagnetic Compatibility) standards are as follows:

• EMS (Electromagnetic Susceptibility): EN 61131-2

• EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations)

Whether the products conform to the standards in the system used by the customer, however, must be

checked by the customer. EMC-related performance of the OMRON devices that comply with EU Di-

rectives will vary depending on the configuration, wiring, and other conditions of the equipment or con-

trol panel on which the OMRON devices are installed. The customer must, therefore, perform the final

check to confirm that devices and the overall machine conform to EMC standards.

NY-series Industrial Monitor User's Manual (W554)

19

Page 22

Regulations and Standards

Conformance to KC Standards

Observe the following precaution if you use Industrial PC Platform products in Korea.

Class A Device (Broadcasting Communications Device for Office Use).

This device obtained EMC registration for of

other than homes.

Sellers and/or users need to take note of this.

fice use (Class A), and it is intended to be used in places

Conformance to UL and CSA Standards

Some Industrial PC Platform products comply with UL and CSA standards. If you use a product that

complies with UL or CSA standards and must apply those standards to your machinery or devices,

refer to this manual. This manual provides the application conditions for complying with the standards.

If the product is used in a manner not specified in the Instruction Sheet or in the product manuals then

the protection provided by the equipment may be impaired.

20

NY-series Industrial Monitor User's Manual (W554)

Page 23

Related Manuals

The following manuals are related. Use these manuals for reference.

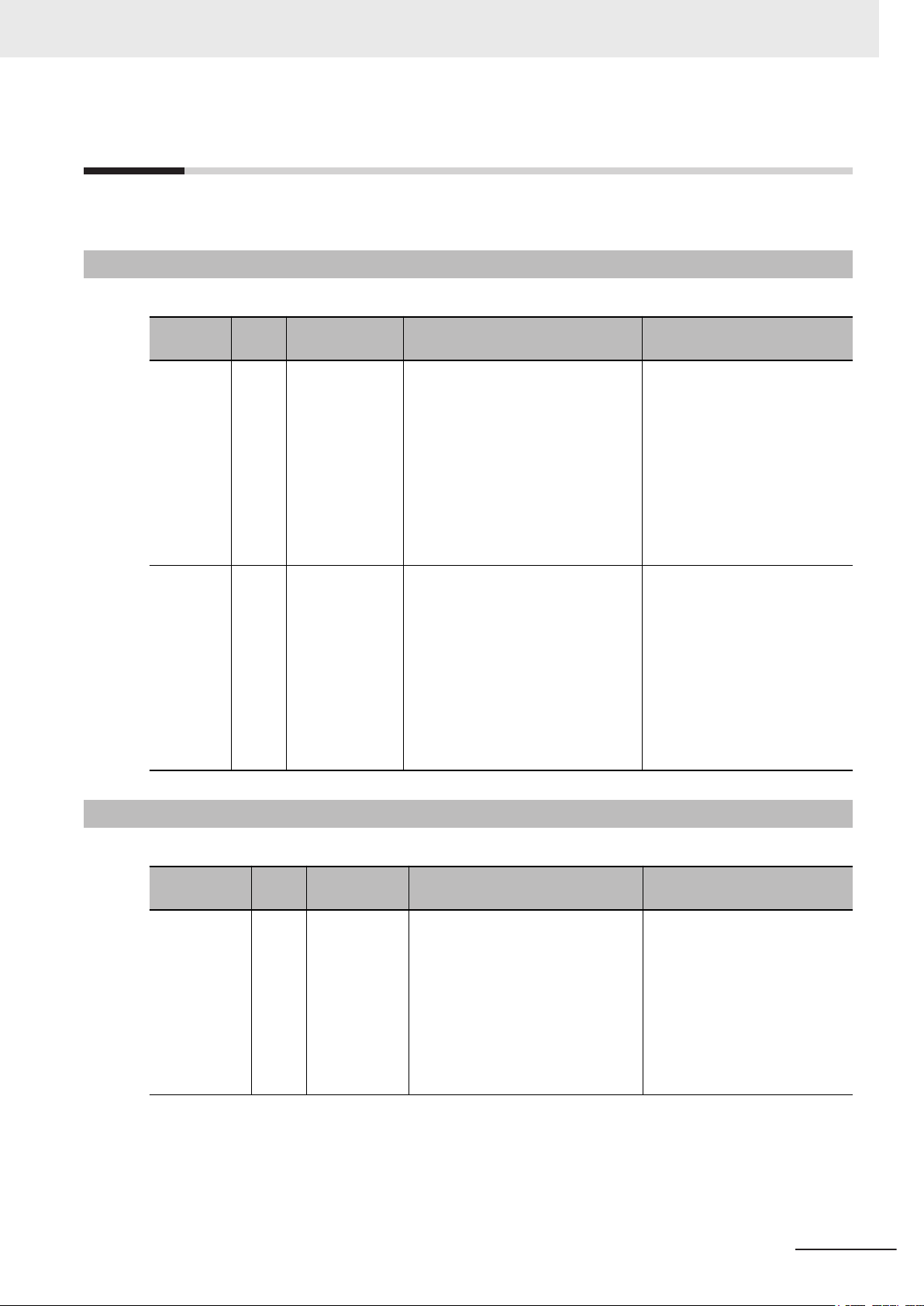

Related Industrial PC Manuals

This table contains the related manuals of other Industrial PC products.

Related Manuals

Manual

name

Industrial

Box PC

’s

User

Manual

Industrial

Panel PC

User

’s

Manual

Cat.

No.

W553

W555

Model numbers Application Description

• NYB17-£1£

££

• NYB25-£1£

££

• NYB1C-£1£

££

Learning all basic information about

the Industrial Box PC. This includes

introductory information with features, hardware overview, software

overview, specifications, mounting,

wiring, connecting, operating and

maintaining the Industrial Box PC.

An introduction to the Industrial

Box PC is provided along with

the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

• NYP17-£1£

££

• NYP25-£1£

££

• NYP1C-£1£

££

Learning all basic information about

the Industrial Panel PC. This includes introductory information with

features, hardware overview, software overview, specifications,

mounting, wiring, connecting, operating and maintaining the Industrial

Panel PC.

An introduction to the Industrial

Panel PC is provided along with

the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

Related Industrial PC Without Operating System Manuals

This table contains the related manuals of other Industrial PC products.

Manual name

Industrial Box

PC without

Operating

System User’s Manual

Cat.

No.

W586

Model num-

bers

• NYB17-

£100£

• NYB25-

£100£

• NYB1C-

£100£

Application Description

Learning all basic information about

the Industrial Box PC. This includes

introductory information with features, hardware overview, specifications, mounting, wiring, connecting, operating and maintaining the

Industrial Box PC.

An introduction to the Industrial

Box PC is provided along with

the following information:

• Overview

• Hardware

• Specifications

• Installation

• Operating Procedures

• Maintenance

NY-series Industrial Monitor User's Manual (W554)

21

Page 24

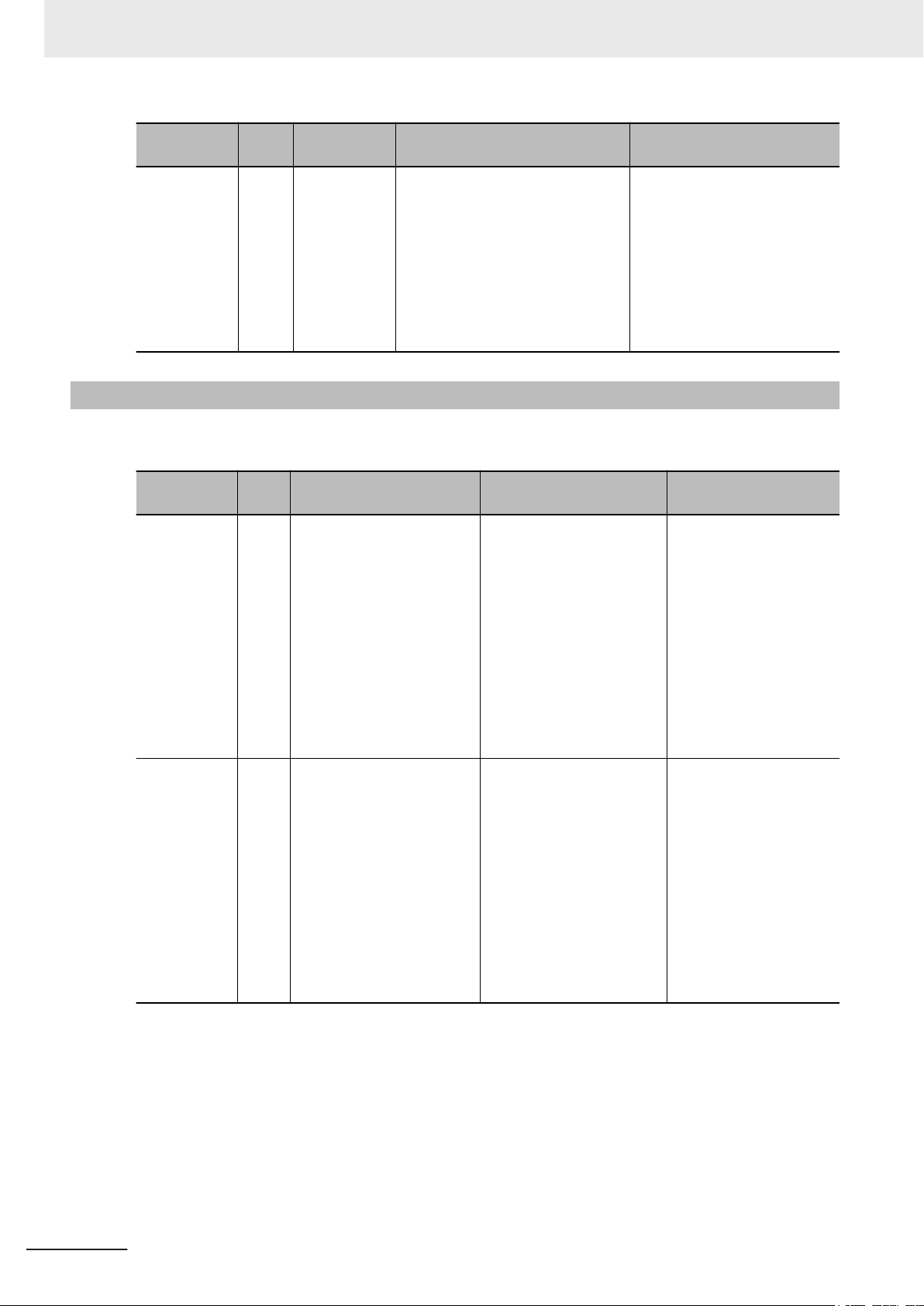

Related Manuals

Manual name

Industrial

Panel PC

without Operating System

’s Manual

User

Cat.

No.

W587

Model num-

bers

• NYP17-

£100£

• NYP25-

£100£

• NYP1C-

£100£

Application Description

Learning all basic information about

the Industrial Panel PC. This includes introductory information with

features, hardware overview, specifications, mounting, wiring, connecting, operating and maintaining

the Industrial Panel PC.

Related IPC Machine Controller Manuals

This table contains the related manuals of other Industrial PC with Machine Automation Control Soft-

ware products.

Manual name

Industrial Box

PC with Machine Automation Control Software

Industrial Box

PC

Hardware Us-

’s Manual

er

Industrial

Panel PC with

Machine Automation Control Software

Industrial

Panel PC

Hardware User

’s Manual

Cat.

No.

W556

W557

Model numbers Application Description

NY512-£1£££-1£13£

£X

• NY532-1£00-1

£0

11£13£

• NY532-1£00-112£13£

£0

Learning all basic hardware

information about the Industrial Box PC with Machine

Automation Control Software Industrial Box PC.

This includes introductory

information with features,

hardware overview, specifications, mounting, wiring,

connecting, operating and

maintaining the Box PC.

Learning all basic hardware

information about the

trial Panel PC with Machine

Automation Control Software Industrial Panel PC.

This includes introductory

information with features,

hardware overview, specifications, mounting, wiring,

connecting, operating and

maintaining the Panel PC.

An introduction to the Industrial

Panel PC is provided along

with the following information:

• Overview

• Hardware

• Specifications

• Installation

• Operating Procedures

• Maintenance

An introduction to the Industrial Box PC with Machine Automation Control

Software Box PC is provided along with the following information:

• Overview

• Hardware

• Specifications

• Installation

• Operating Procedures

• Maintenance

An introduction to the In-

Indus-

dustrial Panel PC with

Machine Automation

Control Software Panel

PC is provided along with

the following information:

• Overview

• Hardware

• Specifications

• Installation

• Operating Procedures

• Maintenance

22

NY-series Industrial Monitor User's Manual (W554)

Page 25

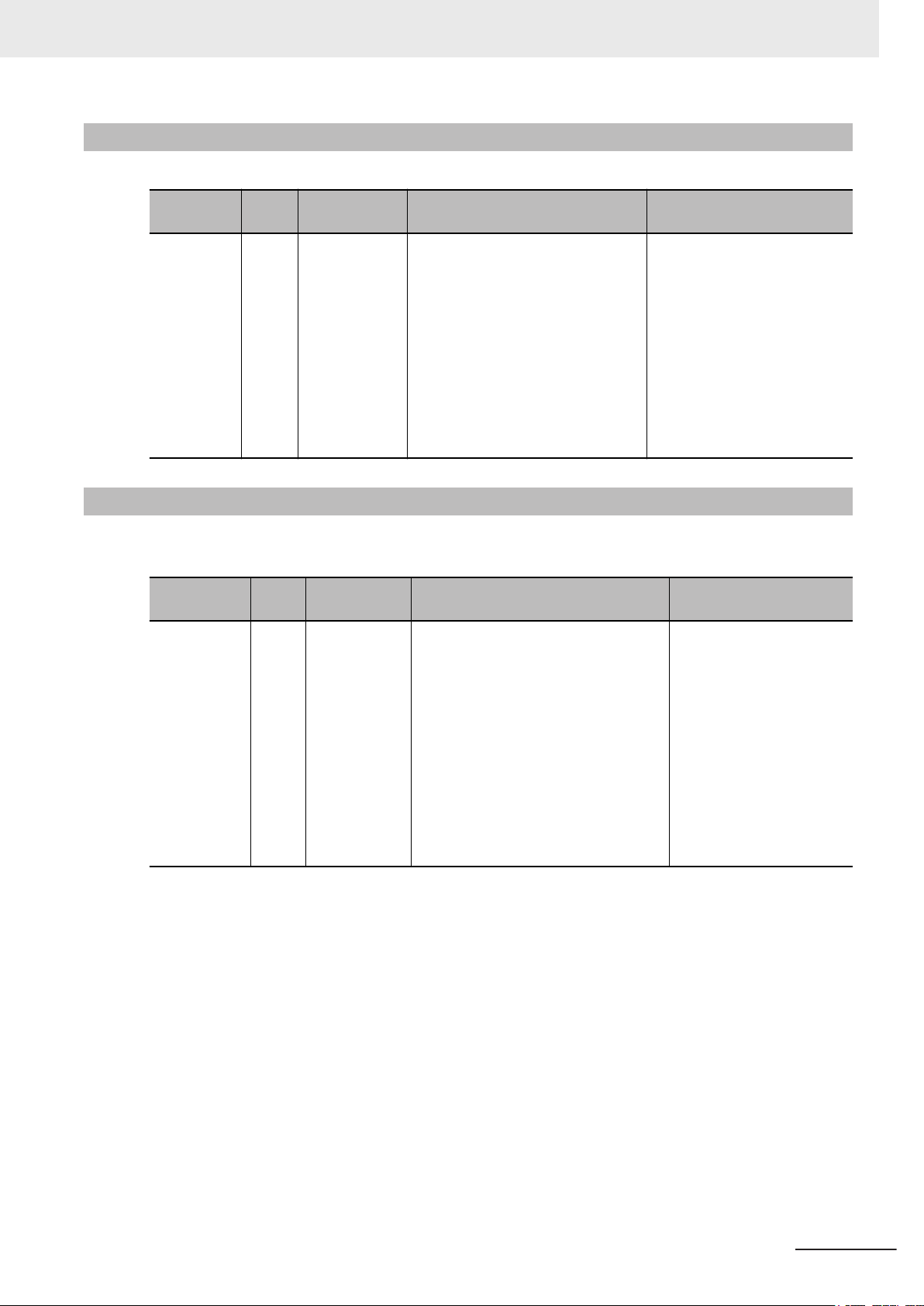

Related IPC RTOS Controller Manuals

This table contains the related manuals of other Industrial PC with RTOS Controller products.

Related Manuals

Manual

name

Industrial

PC with

TOS Con-

R

troller User’s

Manual

Cat.

No.

W581

Model num-

bers

• NY512-A

£00-1XX

£13££X

Application Description

Learning all basic information about

the Industrial PC with RTOS Controller. This includes introductory information with features, hardware

overview, software overview, specifications, mounting, wiring, connecting, operating and maintaining the

Industrial PC with RTOS Controller.

An introduction to the Industrial

PC with RTOS Controller is

provided along with the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

Related IPC Programmable Multi Axis Controller Manuals

This table contains the related manuals of other Industrial PC with Programmable Multi Axis Controller

products.

Manual

name

Industrial PC

with Programmable Multi

Axis Controller Hardware

’s Man-

User

ual

Cat.

No.

W580

Model num-

bers

• NY512-A

£00-1XX

£13££X

Application Description

Learning all basic information about the

Industrial PC with Programmable Multi

Axis Controller. This includes introductory information with features, hardware overview, software overview,

specifications, mounting, wiring, connecting, operating and maintaining the

Industrial PC with Programmable Multi

Axis Controller. Mainly hardware information is provided.

An introduction to the Industrial PC with RTOS

Controller is provided along

with the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

NY-series Industrial Monitor User's Manual (W554)

23

Page 26

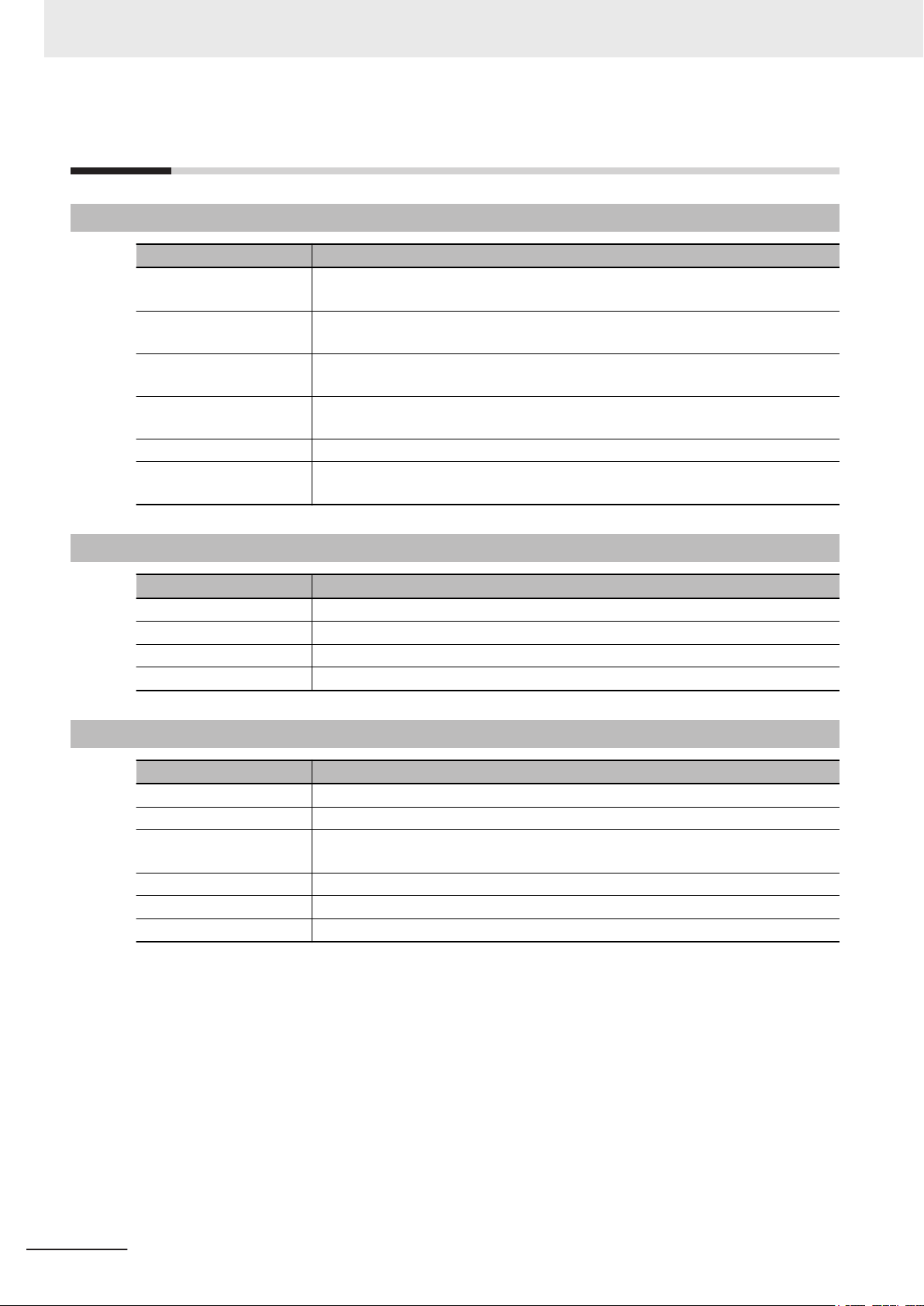

Terminology and Abbreviations

Terminology and Abbreviations

Industrial PC Platform

Term / Abbreviation Description

Industrial PC Platform An integrated range of OMRON products designed for use in any industrial applica-

tion that will benefit from advanced PC technology

Industrial Monitor An industrial monitor with a touchscreen as the user interface designed to work in

industrial environments

Industrial Panel PC An industrial PC with an integrated touchscreen monitor designed to work in indus-

trial environments

Industrial Box PC A box-shaped industrial PC including an OS designed to work in industrial environ-

ments

IPC Industrial PC

Sysmac OMRON’s brand name of the product family for the industrial automation equip-

ment

Hardware

Term / Abbreviation Description

DVI Digital Visual Interface

DVI-D A Digital Visual Interface with only Digital signals

NYML NY Monitor Link interface with video signals and USB signals

USB Universal Serial Bus

Software

Term / Abbreviation Description

API Application Programming Interface

Developer Any person involved with software development

Merge module A module providing a standard method by which developers deliver shared Win-

OS Operating System

SDK Software Development Kit

Windows The Windows Operating System

dows Installer components and setup logic to their applications

24

NY-series Industrial Monitor User's Manual (W554)

Page 27

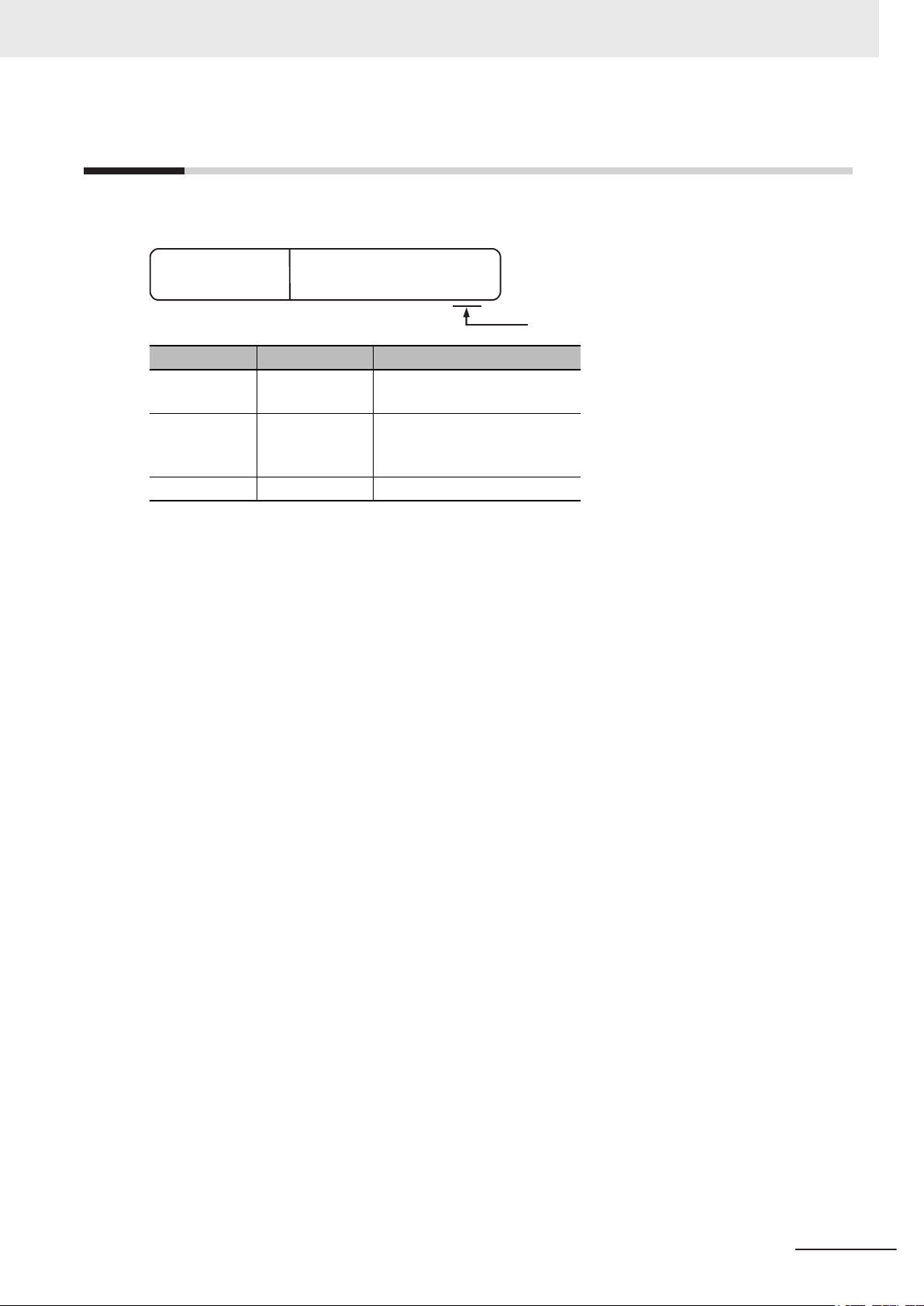

Revision History

W554-E2-03

Cat. No.

Revision code

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

03 June 2017

02 December 2016

01 September 2016 First release

Revision History

• Added NY Monitor Link

• Minor modifications

• UL implementation

• KC Standard implementation

• Minor modifications

NY-series Industrial Monitor User's Manual (W554)

25

Page 28

Revision History

26

NY-series Industrial Monitor User's Manual (W554)

Page 29

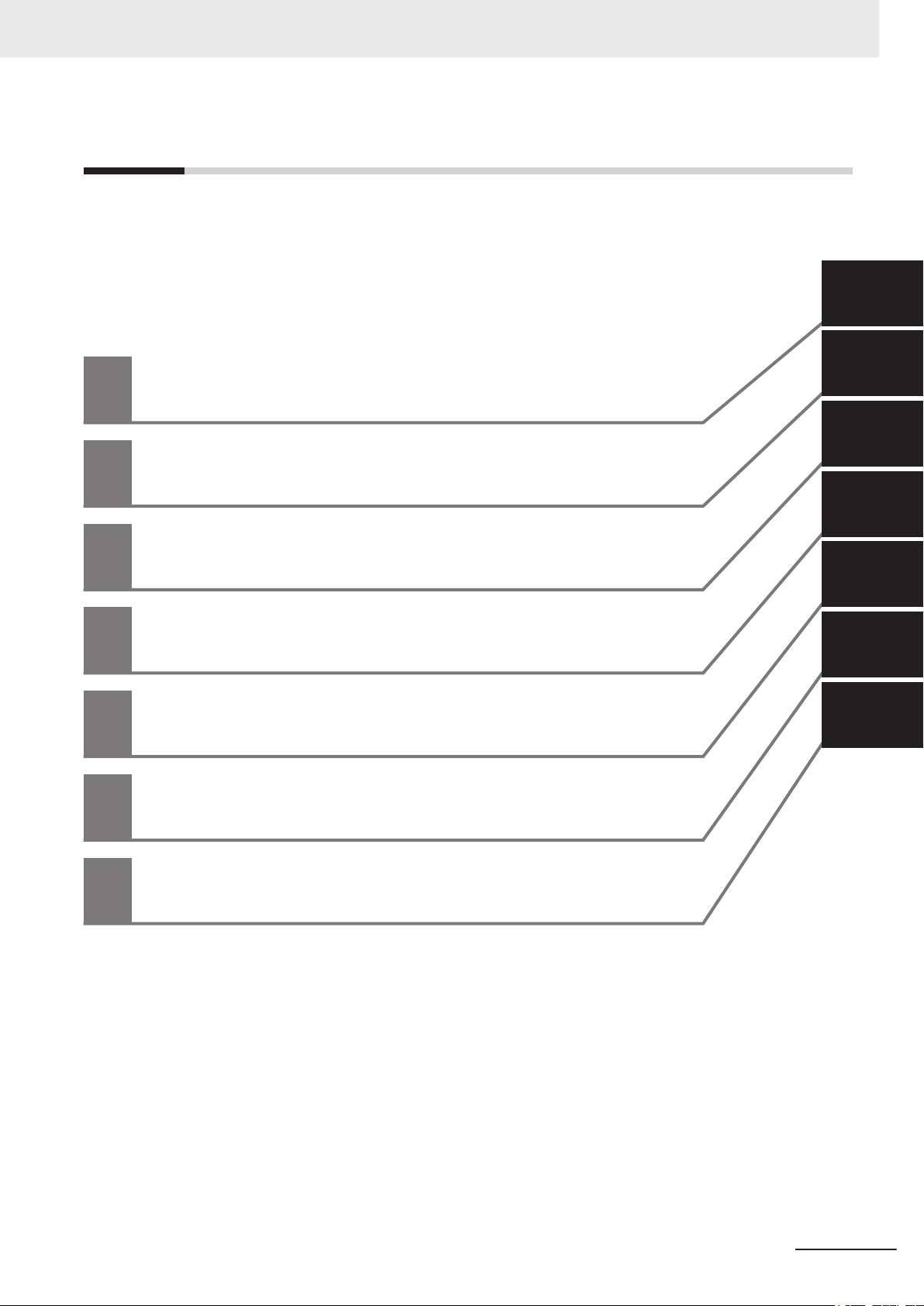

Sections in this Manual

Operating Procedures

Specifications

Installation

Software

Hardware

Overview

1

2

3

4

5

6

1

2

3

4

6

5

1

7

7

Maintenance

A

Sections in this Manual

NY-series Industrial Monitor User's Manual (W554)

27

Page 30

Sections in this Manual

28

NY-series Industrial Monitor User's Manual (W554)

Page 31

Overview

This section provides general information about the Industrial Monitor.

1-1

1-2 Hardware Features....................................................................................... 1 - 3

1-3 ID Information Label..................................................................................... 1 - 4

1-4 Product Configuration ................................................................................. 1 - 5

1-5 Industrial PC Platform Overview ................................................................ 1 - 6

1

Intended Use................................................................................................. 1 - 2

1-5-1 Industrial Monitor ......................................................................................... 1 - 6

1-5-2 Industrial Box PC ......................................................................................... 1 - 7

1-5-3 Industrial Panel PC ...................................................................................... 1 - 7

1

NY-series Industrial Monitor User's Manual (W554)

1 - 1

Page 32

1 Overview

1-1

Intended Use

The Industrial Monitor is intended to be used as a display and touch interface for the Industrial PC

Platform variants. The Industrial Monitor allows the user to interact through touch interactions on the

LCD display.

Users of the Industrial Monitor are able to set the brightness settings of both the LCD backlight and

the indicator LEDs. This allows the monitor to be configured for the required installation environment.

The Industrial Monitor additionally includes a USB hub to allow USB slave devices to be added at the

monitor location. Peripheral components such as a keyboard, mouse, or camera can be attached to

the monitor and used to control or be controlled by the operating system of the connected Industrial

PC.

1 - 2

NY-series Industrial Monitor User's Manual (W554)

Page 33

1 Overview

1-2 Hardware Features

1-2

Hardware Features

Depending on the product configuration the Industrial Monitor provides the following hardware fea-

tures.

• LCD touchscreen

The LCD touchscreen provides high functionality for your PC interface.

The high resolution and a high brightness provide clarity and high visibility.

• Multi-touch functionality

Up to 5 simultaneous touches are supported for complex functions.

• Backlit Logo

The standard product logo is OMRON. Check your sales representative for the possibilities to cus-

tomize the product logo. The product logo is provided with a controllable backlight to increase visibil-

ity.

• Status LED Indicator

The Monitor includes one multi-color LED indicator on the front of the product. The brightness of the

LED indicator is adjustable.

• Brightness control

Use the Monitor Utilities to control the Monitor's LCD brightness.

• DVI-D visual interface

The video interface for the Monitor is provided with a DVI connector for connection to the host PC.

• USB Type-B port for host PC

The USB Type-B port supports USB2.0 specifications. This port allows the host PC to communicate

with multiple internal USB devices within the Monitor as well as external devices connected to the

two USB Type-A ports. This communication includes the touchscreen functionality.

• NY Monitor Link interface

The combination of a video interface and a data connection using an NY Monitor Link cable. This

interface supports a touchscreen monitor connection over a distance up to 100 meter.

• USB Type-A ports for slave devices

Two USB Type-A ports are available for connection to external USB devices such as a keyboard,

mouse, camera, memory sticks, or other peripheral hardware.

1

NY-series Industrial Monitor User's Manual (W554)

1 - 3

Page 34

CUSTOM ID

D

OMRON Corporation Kyoto, 600-8530 JAPAN MADE IN THE NETHERLAND

S

INDUSTRIAL MONITOR

B

A

EF

C

NYM

1 Overview

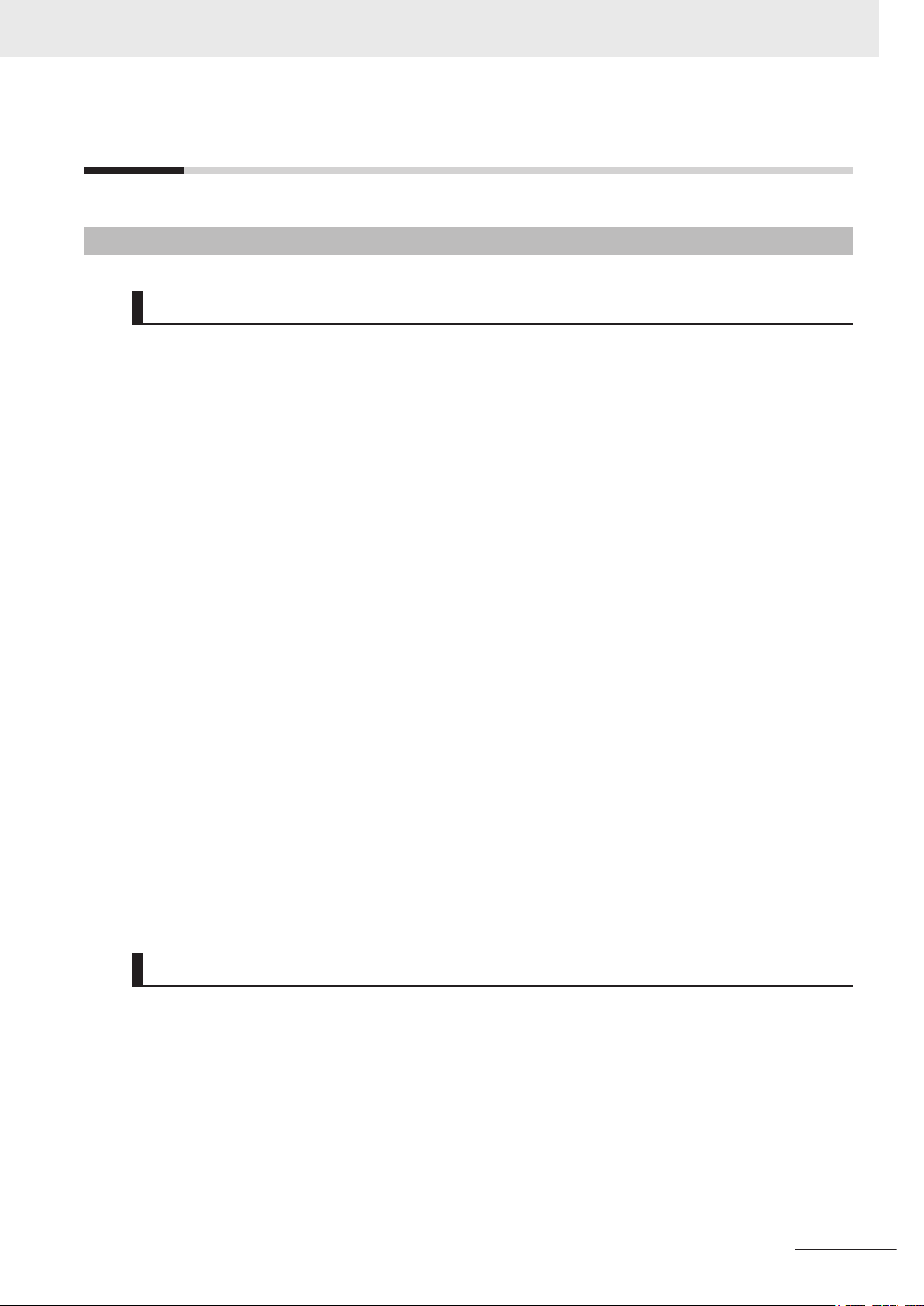

1-3

ID Information Label

The ID information label contains relevant information of your Industrial Monitor.

Item Name Description

A Product name Industrial Monitor

B

C Power rating Power rating details

D Custom ID

E Standards and QR

F LOT number and

*1. Refer to 1-4 Product Configuration on page

*1

Model

(Optional)

code

serial number

Model and configuration details

A custom ID [NYC£££-££££££££]

Only for Industrial Monitor

The applicable standards and a QR code for OMRON internal use

Production details, consisting of:

• The lot number of the Industrial Monitor

DDMYY with Month number 1 to 9 for January to September, X for October, Y

for November, and Z for December.

£: For use by OMRON

s and Industrial Panel PCs with a custom logo *1.

in the format DDMYY£.

• Serial number (4 digits)

1 - 5 for model details.

Additional Information

Refer to 2-1-1 Front and T

label location.

1 - 4

op of the Industrial Monitor on page 2 - 2 for the ID information

NY-series Industrial Monitor User's Manual (W554)

Page 35

N Y M

1

2 3 4 5 6 7 8

1 Overview

1-4 Product Configuration

1-4

Product Configuration

This section provides an overview of the product configurations available for the Industrial Monitor.

The product configuration is visible in the model-type that is mentioned on the ID information label of

the Monitor.

The structure of the model-type is: NYM£££-£££££.

Each item in the model-type has a specific meaning.

Item Description Option

1 Series name NYM: NY- series Industrial Monitor

2 Display size

(diagonal)

3 Display ratio W: Wide

4 Touchscreen C: Projected Capacitive Touch type

5 Frame type 1: Aluminum frame, black

6 Design 0: Standard

7 Build-in options 0: None

8 Logo 0: OMRON

12: 12.1 inches

15: 15.4 inches

6: NY Monitor Link

2: Customization

1

NY-series Industrial Monitor User's Manual (W554)

1 - 5

Page 36

1 Overview

1-5

1-5-1

Industrial PC Platform Overview

The Industrial PC Platform is an integrated range of products designed for use in a variety of industrial

applications that will benefit from advanced PC technology. The range is scalable, robust and reliable,

and is suitable for use with both standard operating system software and proprietary programs for ma-

chine control and automation.

In line with OMRON’s established quality standards, each element in the Industrial PC Platform, rang-

ing from the standalone Industrial Box PC to the touchscreen Industrial Monitor, is engineered with

long-life components and built to the most advanced design standards.

The following sections introduce Industrial PC Platform products.

Industrial Monitor

The Industrial Monitor is of key importance at the interface between operator and system. The Indus-

trial Monitor is efficient, effective and highly visible with an attractive design.

Using smart algorithms, the touch controller determines the exact location of each touch for precise

control as well as detecting abnormal or illegal actions to protect misuse or false touches.

1 - 6

NY-series Industrial Monitor User's Manual (W554)

Page 37

1 Overview

1-5 Industrial PC Platform Over-

1-5-2

Industrial Box PC

The Industrial Box PC is designed to meet the specific needs of the industrial environment. Design

simplification and future-proof architecture minimize the risk of failure. In addition, new PC features

can be seamlessly incorporated, without the need for wholesale redesign.

view

1

1-5-2 Industrial Box PC

1-5-3

Industrial Panel PC

The Industrial Panel PC intelligently combines the functionality of the Industrial Box PC and Industrial

Monitor

and reliable operation in industrial environments.

. No cables are used between the two components, which ensures optimal signal distribution

NY-series Industrial Monitor User's Manual (W554)

1 - 7

Page 38

1 Overview

1 - 8

NY-series Industrial Monitor User's Manual (W554)

Page 39

2

2

Hardware

This section provides an overview of the hardware of the Industrial Monitor.

2-1

2-2 LED Indicators.............................................................................................. 2 - 4

2-3 Connectors ...................................................................................................2 - 6

2-4 Optional Hardware .....................................................................................2 - 10

Component Names and Functions............................................................. 2 - 2

2-1-1 Front and Top of the Industrial Monitor ......................................................... 2 - 2

2-1-2 Bottom of the Industrial Monitor.................................................................... 2 - 3

2-2-1 Logo LED...................................................................................................... 2 - 5

2-2-2 Status LED Indicator..................................................................................... 2 - 5

2-3-1 Power Connector .......................................................................................... 2 - 6

2-3-2 DVI-D Connector (Optional).......................................................................... 2 - 7

2-3-3 NY Monitor Link Connector (Optional).......................................................... 2 - 7

2-3-4 USB Type-A Connector ................................................................................ 2 - 8

2-3-5 USB Type-B Connector (Optional)................................................................ 2 - 9

2-4-1 DVI Cables.................................................................................................. 2 - 10

2-4-2 USB Type-A to USB Type-B Cables ............................................................2 - 11

2-4-3 NY Monitor Link Cables .............................................................................. 2 - 12

2-4-4 Power Supply.............................................................................................. 2 - 13

NY-series Industrial Monitor User's Manual (W554)

2 - 1

Page 40

B

D

A

C

2 Hardware

2-1

2-1-1

Component Names and Functions

This section shows views of the Industrial Monitor with information about all items.

Front and Top of the Industrial Monitor

This section shows the component names and functions for the front and top of the Industrial Monitor.

Item Name Description

A Logo Backlit logo with adjustable brightness

B Status LED Indicator Multi-colored LED to indicate power and connection status with adjustable

C ID Information Label Label containing Model ID., LOT No. and other product specific information.

D Touchscreen Multi-touch LCD display

brightness

Refer to 1-3 ID Information Label on page 1 - 4 for label details.

2 - 2

NY-series Industrial Monitor User's Manual (W554)

Page 41

A

B

C

D

F

E

A

G

C

F

E

2 Hardware

2-1 Component Names and Functions

2-1-2

Bottom of the Industrial Monitor

The monitor is available with a DVI-D connector and with an NYML connector.

For both versions all items on the bottom of the Industrial Monitor

Monitor with DVI-D connector Monitor with NYML connector

are identified here.

2

2-1-2 Bottom of the Industrial Monitor

Item Name Description

A Power Supply Connector 24 VDC power supply input connector

B

C USB Type-A

D USB Type-B

E Mounting Brackets 8 retractable mounting brackets to secure the Industrial Monitor on a

F Ground Terminal Terminal connection for grounding of the Industrial Monitor

G

*1. Refer to 1-4 Product Configuration on page

DVI-D Connector

Connectors

Connector

NYML Connector

*1

*1

DVI-D dual link connector for host video connection

2 USB connectors to connect external USB slave devices

USB connector for connection with the host PC

Only for Industrial Monitor

mounting surface

NY Monitor Link connector for video and USB communication with the

host PC

1 - 5 for model details.

s with a DVI-D connector.

NY-series Industrial Monitor User's Manual (W554)

2 - 3

Page 42

B

A

2 Hardware

2-2

LED Indicators

The Industrial Monitor has two LED indicators on the front of the product.

Item LED Description

A Logo LED LED to backlight the logo

B Status Indicator LED Indicates the operating condition of the Industrial Monitor.

2 - 4

NY-series Industrial Monitor User's Manual (W554)

Page 43

2 Hardware

2-2-1

2-2-2

Logo LED

The Logo LED brightness can be changed with the Industrial Monitor Utility.

Additional Information

The Logo LED brightness is adjustable.

Refer to Industrial Monitor Utility

The Industrial Monitor Utility information is available:

• For products NYM£ in the section Software in this manual.

• For products NYP£ in the section Support Software in this manual.

• For products NY5£ in the NY-series IPC Machine Controller Industrial Panel PC / Industrial

Box PC Setup User’s Manual (Cat. No. W568)

for brightness details.

Status LED Indicator

The Status LED indicator provides information about the operating condition of the Industrial Monitor.

Color Status Meaning

None Not lit The Status LED is not lit in following situations:

• The 24 VDC power is not supplied.

• Normal operation

Green Blinking The Status LED is blinking in following situations:

• The host PC is in standby mode.

• The host PC power is not supplied.

• The DVI cable or the NY Monitor Link cable is not connected.

Red Lit The Status LED is lit with maximum brightness in following situations:

• Power supply defective

• Monitor internal hardware error

2-2 LED Indicators

2

2-2-1 Logo LED

Additional Information

The Status LED indicator's brightness is adjustable.

Refer to Industrial Monitor Brightness Utility

on page 3 - 8 for brightness details.

NY-series Industrial Monitor User's Manual (W554)

2 - 5

Page 44

2 Hardware

2-3

2-3-1

Connectors

This section gives an overview of the available connectors for the Industrial Monitor.

Power Connector

The power connector on the Monitor is used to supply 24 VDC power to the Monitor.

The power connector is supplied with the Monitor.

Additional Information

• Refer to 4-2-1 Power Connector Specifications on page 4 - 4 for specifications.

•

Refer to 5-3-2 Wire the Power Connector on page 5 - 24 for wiring details.

• Refer to 5-4 Connect on page 5 - 26 for connection details.

2 - 6

NY-series Industrial Monitor User's Manual (W554)

Page 45

2 Hardware

2-3-2

DVI-D Connector (Optional)

Depending on the product configuration this DVI-D Connector is available.

The Digital V

isual Interface (DVI-D) connector connects a digital video source to the Industrial Monitor.

Additional Information

2-3 Connectors

2

2-3-2 DVI-D Connector (Optional)

2-3-3

• Refer to Product Configuration for configuration details.

•

Refer to 4-2-2 DVI-D Connector Specifications on page 4 - 5 for specifications.

• Refer to 5-4 Connect on page 5 - 26 for connection details.

NY Monitor Link Connector (Optional)

Depending on the product configuration this NY Monitor Link connector is available.

The NY Monitor Link interface connector connects an OMRON

Monitor.

Industrial PC to the OMRON Industrial

Industrial PC Industrial Monitor

NY-series Industrial Monitor User's Manual (W554)

2 - 7

Page 46

2 Hardware

Additional Information

2-3-4

• Refer to 1-4 Product Configuration on page

• Refer to 4-2-3 NY Monitor Link Connector Specifications on page 4 - 7 for specifications.

• Refer to 5-4 Connect on page 5 - 26 for connection details.

1 - 5 for configuration details.

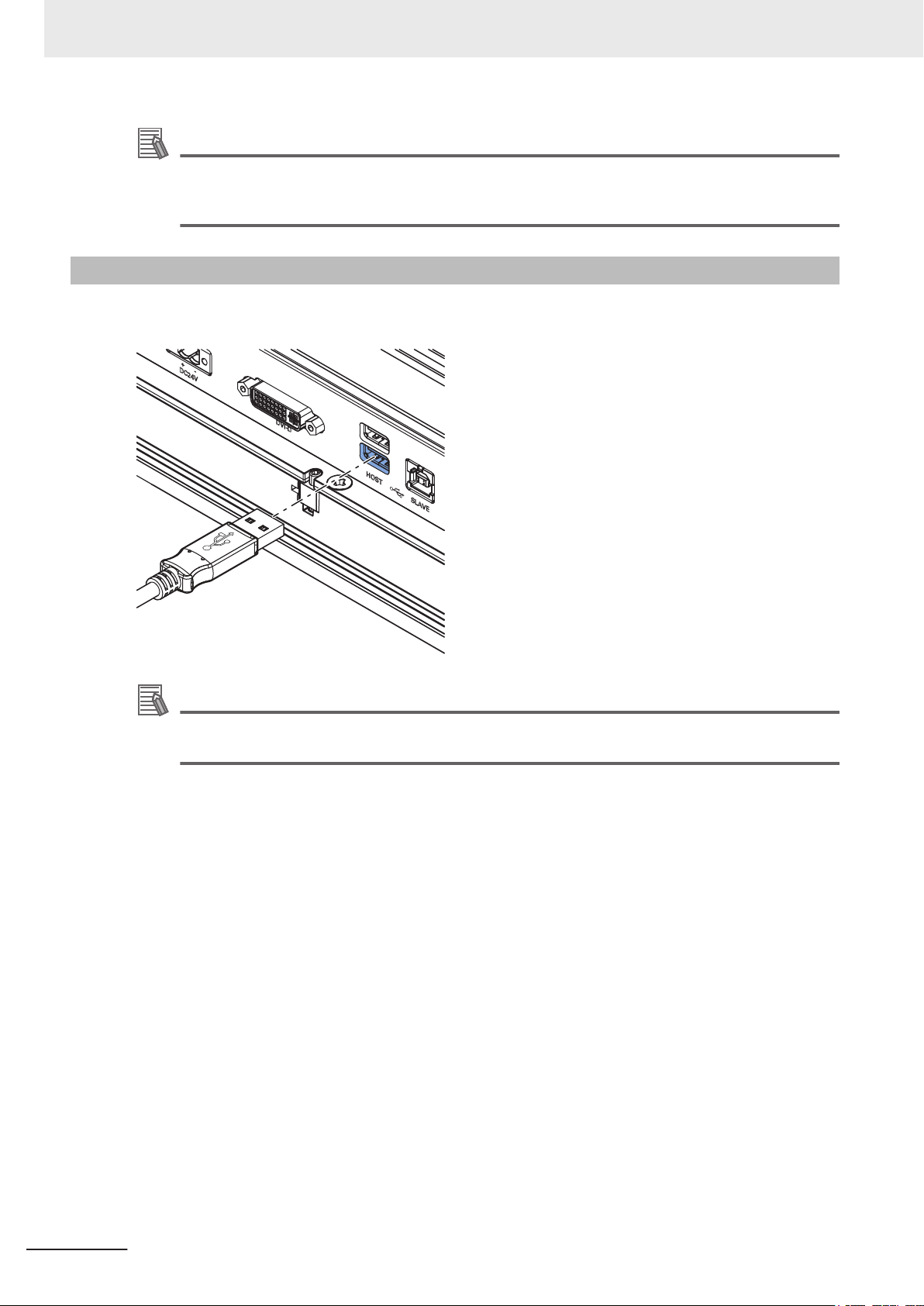

USB Type-A Connector

The Universal Serial Bus (USB) Type-A connectors provide a connection point on the Industrial Moni-

tor for USB slave devices.

Additional Information

• Refer to 4-2-4 USB T

• Refer to 5-4 Connect on page 5 - 26 for connection details.

ype-A Connector Specifications on page 4 - 9 for specifications.

2 - 8

NY-series Industrial Monitor User's Manual (W554)

Page 47

2 Hardware

2-3-5

USB Type-B Connector (Optional)

This USB Type-B connector is only available for product configurations without NY Monitor Link.

The Universal Serial Bus (USB) T

connector to the host PC. The host PC uses this interface to access the internal touchscreen functions

as well as external devices plugged into the USB Type-A connectors.

ype-B connector connects an Industrial Monitor that has a DVI-D

2-3 Connectors

2

2-3-5 USB Type-B Connector (Optional)

Additional Information

• Refer to Product Configuration for configuration details.

•

Refer to 4-2-5 USB Type-B Connector Specifications on page 4 - 10 for specifications.

• Refer to 5-4 Connect on page 5 - 26 for connection details.

NY-series Industrial Monitor User's Manual (W554)

2 - 9

Page 48

90 mm

2 Hardware

2-4

2-4-1

Optional Hardware

The following optional hardware is available for the Industrial Monitor.

DVI Cables

DVI cable details are provided below.

OMRON is not responsible for the operation or performance of any other brand of DVI cable.

Model Appearance Cable length Specifications

NY000AC00 2M

NY000AC00 5M

DVI Cable Clearance

The DVI cable requires a minimum clearance of 90 mm from the connector entry to prevent excessive

strain on the connector and cable assembly

2 m

5 m

• Supports DVI-D

• Minimum bend radius: 36 mm

.

2 - 10

NY-series Industrial Monitor User's Manual (W554)

Page 49

60 mm

2 Hardware

2-4-2

USB Type-A to USB Type-B Cables

USB Type-A to USB Type-B cable details are provided below.

OMRON is not responsible for the operation or performance of any other brand of USB T

Type-B cable.

Model Appearance Cable length Specifications

FH-VUAB 2M 2 m

FH-VUAB 5M 5 m

• USB 2.0

• Minimum bend radius: 25 mm

ype-A to USB

USB Type-A to USB Type-B Cable Clearance

The USB Type-A to USB Type-B cable requires a minimum clearance of 60 mm from the connector

entry to prevent excessive strain on the connector and cable assembly

.

2-4 Optional Hardware

2

2-4-2 USB Type-A to USB Type-B Cables

NY-series Industrial Monitor User's Manual (W554)

2 - 11

Page 50

2 Hardware

2-4-3

NY Monitor Link Cables

The following table lists the recommended cables and connectors for the NY Monitor Link cable.

Intra cabinet or

Application

Maximum length 25 m 100 m 100 m

Manufacturer Lapp Lapp Lapp

Cable type 2170196 2170614 2170466

Category type Cat 6A Cat 7 Cat 6A

Cable sheath Halogen free Halogen free Halogen free

Conductor pairs/size/type 4 x 2 x AWG23/1 4 x 2 x AWG23/1 4 x 2 x AWG22/1

Overall shielding Aluminum foil Copper braid Copper braid

Pair shielding Aluminum foil Aluminum foil Aluminum foil

Maximum outer diameter 7.6 mm 7.7 mm 9.0 mm

Maximum bending radius of cable in a

fixed position

Maximum temperature for a cable in a

fixed position

RJ45 connectors Manufacturer Stewart Connector Stewart Connector Lapp

Partnumber SS39200-027 or

Connector length 30 mm 30 mm 50 mm

light industrial en-

vironment

31 mm 31 mm 90 mm

60°C 60°C 80°C

SS39200-030

Inter cabinet

SS39200-027 or

SS39200-030

Inter cabinet and

harsh industrial

environment

21700600 (T568A)

or 21700601

(T568B)

Additional Information

When making cables, connect the shield to the connectors at both ends.

NY Monitor Link Cable Clearance

The NY Monitor Link cable requires a minimum clearance from the connector entry to prevent exces-

sive strain on the connector and cable assembly

The minimum clearance consists of the sum of:

• Connector length

• Maximum bending radius of cable in a fixed position

.

2 - 12

NY-series Industrial Monitor User's Manual (W554)

Page 51

2 Hardware

2-4-4

Power Supply

Details for the recommended power supply are provided below.

OMRON is not responsible for the operation or performance of any other power supply

Model Appearance Specifications

S8VK-G£££24

Additional Information