Omron NYB - 3 Series, NYB - 4 Series, NYB - 1 Series, NYB - 0 Series, NYB - 2 Series Operating Manual

...Page 1

Industrial PC Platform

NY-series

Industrial PC

Operating Systems and Software Utilities Manual

NYB££NYB££-££1

NYB££-££2

NYB££-££3

NYB££-££4

NYP££-££0

NYP££-££1

NYP££-££2

NYP££-££3

NYP££-££4

££0

W616-E2-02

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or other-

wise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information contained

in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publica-

tion.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

• CFAST is a registered trademark of CompactFlash Association.

• Intel, the Intel Logo, Celeron and Intel Core are trademarks of Intel Corporation in the U.S. and/or

other countries.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the Industrial PC.

This manual contains information that is necessary to use the Industrial PC (hereafter also named as

IPC). Please read this manual and make sure you understand the functionality and performance of the

IPC before attempting to use it.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of software pro-

gramming (a software engineer or the equivalent).

• Personnel in charge of introducing Factory Automation systems.

• Personnel in charge of designing Factory Automation systems.

• Personnel in charge of software design for Factory Automation systems.

• Personnel in charge of installing and maintaining and programming Factory Automation systems.

• Personnel in charge of managing Factory Automation systems and facilities.

Introduction

Applicable Products

This manual covers following Industrial PC products:

Industrial Box PC

Industrial Panel PC

Additional Information

Refer to 1-4 Product Configuration on page 1-5 for configuration details.

Product Model

NYB££

NYP££

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

1

Page 4

Introduction

2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 5

Sections in this Manual

Operating Procedures

Specifications

Installation

Software

System Configurations

Overview

1

2

3

4

5

6

1

2

3

4

6

5

1

7

7

Appendices

Maintenance

A

A

Sections in this Manual

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3

Page 6

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products

Sections in this Manual ........................................................................................... 3

Manual Information.................................................................................................. 7

Page Structure.................................................................................................................................................7

Special Information .......................................................................................................................................... 8

Terms and Conditions Agreement.......................................................................... 9

Warranty and Limitations of Liability ................................................................................................................ 9

Application Considerations ............................................................................................................................10

Disclaimers ....................................................................................................................................................11

Safety Precautions................................................................................................. 12

.........................................................................................................................................1

Precautions for Safe Use ...................................................................................... 13

Precautions for Correct Use ................................................................................. 14

Regulations and Standards .................................................................................. 15

Conformance to EU Directives ......................................................................................................................15

Conformance to KC Certification ...................................................................................................................16

Conformance to UL and CSA Standards.......................................................................................................16

Software Licenses and Copyrights ................................................................................................................16

Related Manuals..................................................................................................... 17

Related Industrial PC Manuals ......................................................................................................................17

Industrial Monitor Manual ..............................................................................................................................17

Terminology and Abbreviations ........................................................................... 18

Industrial PC Platform ...................................................................................................................................18

Software......................................................................................................................................................... 18

Hardware ......................................................................................................................................................19

Revision History..................................................................................................... 20

Section 1 Overview

1-1 Intended Use .........................................................................................................................1-2

1-2 Software Features

1-3 ID Information Label ..............................................................................................................1-4

1-4 Product Configuration...........................................................................................................1-5

1-4-1 Product Configuration Box PC ....................................................................................................1-5

1-4-2 Product Configuration Panel PC .................................................................................................1-7

1-5 Overall Setup Procedure .......................................................................................................1-9

4

..................................................................................................................1-3

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 7

Section 2 System Configurations

2-1 Configuration for NYB and NYP ...........................................................................................2-2

Section 3 Software

3-1 Windows Operating System .................................................................................................3-3

3-1-1 Determine Y

3-2 Overview IPC Support Software for Windows ....................................................................3-4

3-3 Industrial PC Support Utility ................................................................................................ 3-5

3-3-1 Industrial PC Support Utility Overview ........................................................................................3-6

3-3-2 Product Information Tab .............................................................................................................3-7

3-3-3 System Status Tab ......................................................................................................................3-8

3-3-4 Machine Controller Tabs .............................................................................................................3-9

3-3-5 Compatibility................................................................................................................................3-9

3-3-6 Installation ...................................................................................................................................3-9

3-3-7 Startup.........................................................................................................................................3-9

3-3-8 Logging .....................................................................................................................................3-10

3-4 Industrial Monitor Utility ..................................................................................................... 3-11

3-4-1 Industrial Monitor Utility Overview............................................................................................. 3-11

3-4-2 Compatibility..............................................................................................................................3-15

3-4-3 Installation .................................................................................................................................3-15

3-4-4 Startup.......................................................................................................................................3-15

3-4-5 Configuration.............................................................................................................................3-16

3-4-6 Messages..................................................................................................................................3-16

3-4-7 Logging .....................................................................................................................................3-16

3-5 Industrial Monitor Brightness Utility .................................................................................3-17

3-5-1 Industrial Monitor Brightness Utility ..........................................................................................3-17

3-5-2 Compatibility..............................................................................................................................3-17

3-5-3 Installation .................................................................................................................................3-18

3-5-4 Startup.......................................................................................................................................3-18

3-5-5 Configuration.............................................................................................................................3-18

3-5-6 Logging .....................................................................................................................................3-18

3-6 Rescue Disk Creator............................................................................................................3-19

3-6-1 Rescue Disk Creator Overview .................................................................................................3-19

3-6-2 Compatibility..............................................................................................................................3-20

3-6-3 Installation .................................................................................................................................3-20

3-6-4 Startup.......................................................................................................................................3-21

3-6-5 Messages..................................................................................................................................3-21

3-7 Industrial PC Tray Utility ....................................................................................................3-25

3-7-1 Industrial PC Tray Utility Overview............................................................................................3-25

3-7-2 Features ....................................................................................................................................3-25

3-7-3 Menu .........................................................................................................................................3-26

3-7-4 About the Industrial PC Tray Utility ...........................................................................................3-26

3-7-5 Status Indicators on Icons.........................................................................................................3-27

3-7-6 Compatibility..............................................................................................................................3-27

3-7-7 Installation .................................................................................................................................3-27

3-7-8 Startup.......................................................................................................................................3-28

3-8 Power Attendant Lite Utility ................................................................................................ 3-29

3-8-1 Power Attendant Lite Utility Overview .......................................................................................3-29

3-8-2 Features ....................................................................................................................................3-29

3-8-3 Compatibility..............................................................................................................................3-29

3-8-4 Installation .................................................................................................................................3-30

3-8-5 Configuration.............................................................................................................................3-30

3-9 Software for Developers......................................................................................................3-32

3-9-1 Overview IPC Developer Software for Windows.......................................................................3-32

3-9-2 Industrial PC System API .........................................................................................................3-33

3-9-3 Industrial Monitor API ...............................................................................................................3-34

our Version of the Windows Operating Systems .....................................................3-3

CONTENTS

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

5

Page 8

CONTENTS

Section 4 Specifications

4-1 Software Specifications .......................................................................................................4-2

4-1-1 A

4-1-2 Supported Languages.................................................................................................................4-3

vailable Windows Operating Systems.......................................................................................4-2

Section 5 Installation

5-1 Install Software ......................................................................................................................5-2

5-1-1 Internet Browser

5-1-2 Firewall........................................................................................................................................5-3

5-1-3 Anti-virus Software ......................................................................................................................5-3

5-1-4 Drivers and Custom Software .....................................................................................................5-4

5-1-5 Activate Windows........................................................................................................................5-4

5-1-6 Customize Windows....................................................................................................................5-4

5-2 Install Support Software........................................................................................................5-5

5-2-1 Overview IPC Support Software for Installation ..........................................................................5-5

5-3 Create Backup and Repair Media ......................................................................................... 5-6

..........................................................................................................................5-2

Section 6 Operating Procedures

6-1 React to Product Messages .................................................................................................. 6-2

6-2 React to Windows Messages................................................................................................6-3

Section 7 Maintenance

7-1 Preventive Maintenance ........................................................................................................7-2

7-1-1 Preventive Maintenance Schedule

7-1-2 Keep Software Updated ..............................................................................................................7-2

7-1-3 Create Backup and Repair Data .................................................................................................7-3

7-1-4 Check the Storage Device Status .............................................................................................7-15

7-1-5 Check the Backup and Repair Media........................................................................................7-17

7-2 Corrective Maintenance ......................................................................................................7-19

7-2-1 Warning and Error Messages....................................................................................................7-19

7-2-2 Restore and Repair Data ..........................................................................................................7-20

7-2-3 Allocate a Drive in Windows......................................................................................................7-28

7-2-4 Windows Event Viewer..............................................................................................................7-29

7-2-5 Windows Low on Memory .........................................................................................................7-31

7-2-6 Windows Blue Screens .............................................................................................................7-32

7-2-7 Correct Display Functionality when Nothing is Displayed .........................................................7-32

7-2-8 Correct Touchscreen Functionality............................................................................................7-33

..............................................................................................7-2

Appendices

A-1 Customize Windows ............................................................................................................. A-2

A-1-1 Enhanced W

A-1-2 File-Based Write Filter................................................................................................................ A-3

A-1-3 Unified Write Filter...................................................................................................................... A-5

A-1-4 Trusted Platform Module............................................................................................................ A-6

Index

6

rite Filter................................................................................................................. A-2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 9

Manual Information

A

B

C

E

F

B

C

H

5 Installation

5 - 3

NY

-series User's Manual (W555)

5-1 Unpack

5

5-1-1 Unpack Procedure

G

5-1

Unpack

This section provides details on how to unpack the Industrial Panel PC.

5-1-1

Unpack Procedure

1 Check the package for damage.

If there is any visible damage:

• Take photos of the package and save them.

• Inform your supplier immediately.

2 Open the package.

Ensure not to damage the contents.

3 Ensure that all items are present.

Additional Information

Refer to 5-1-2 Items Supplied with the Product

for the items supplied.

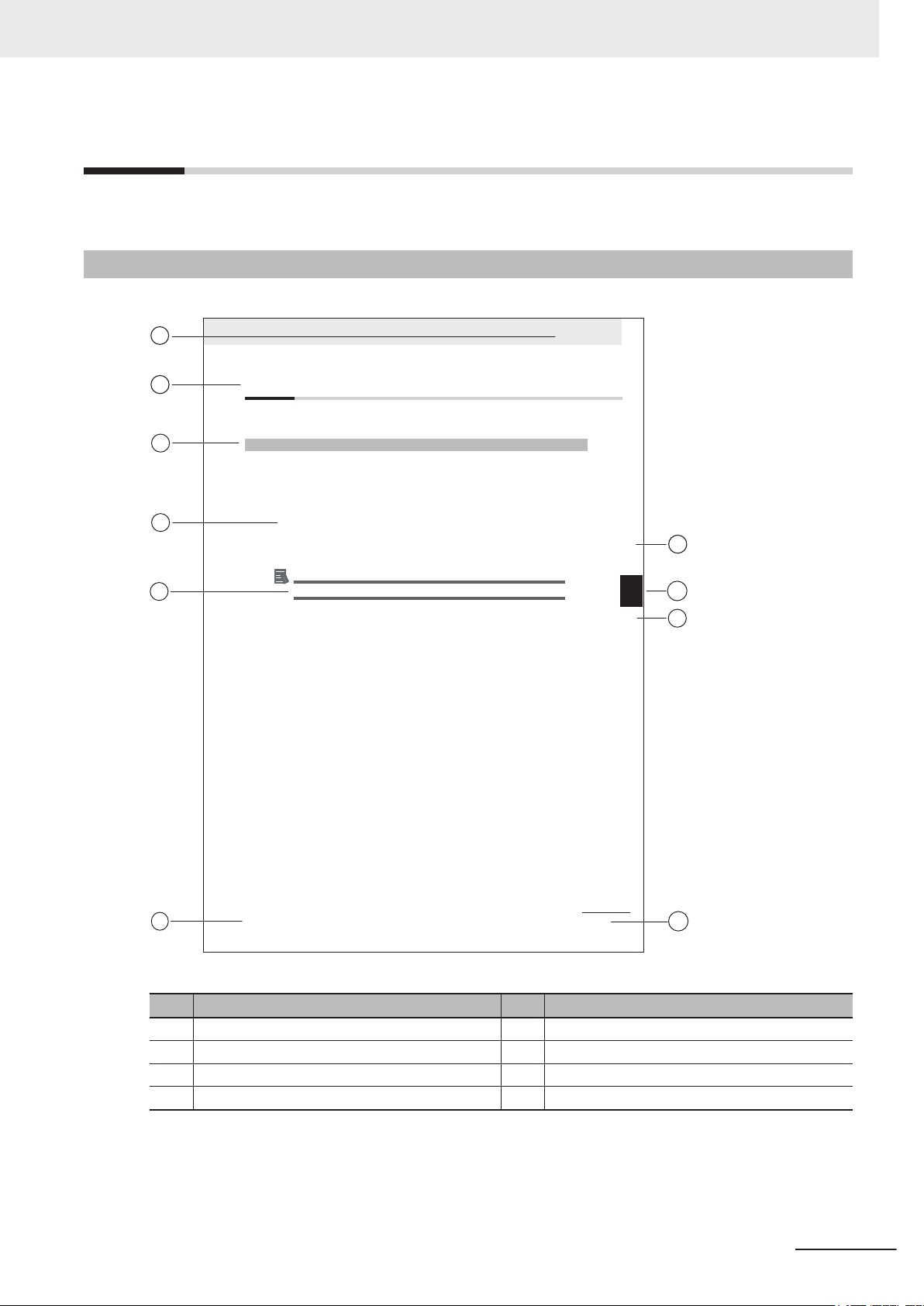

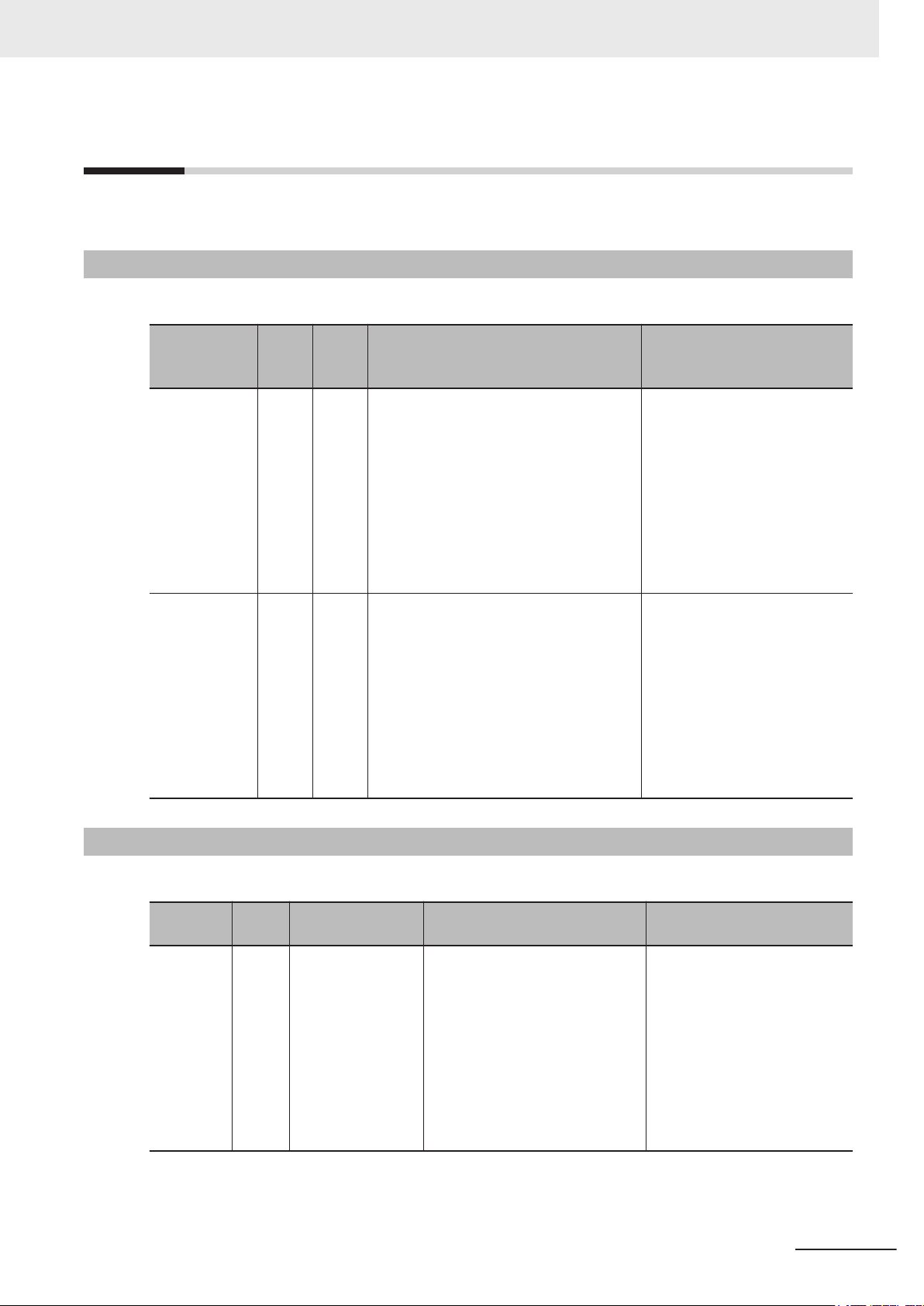

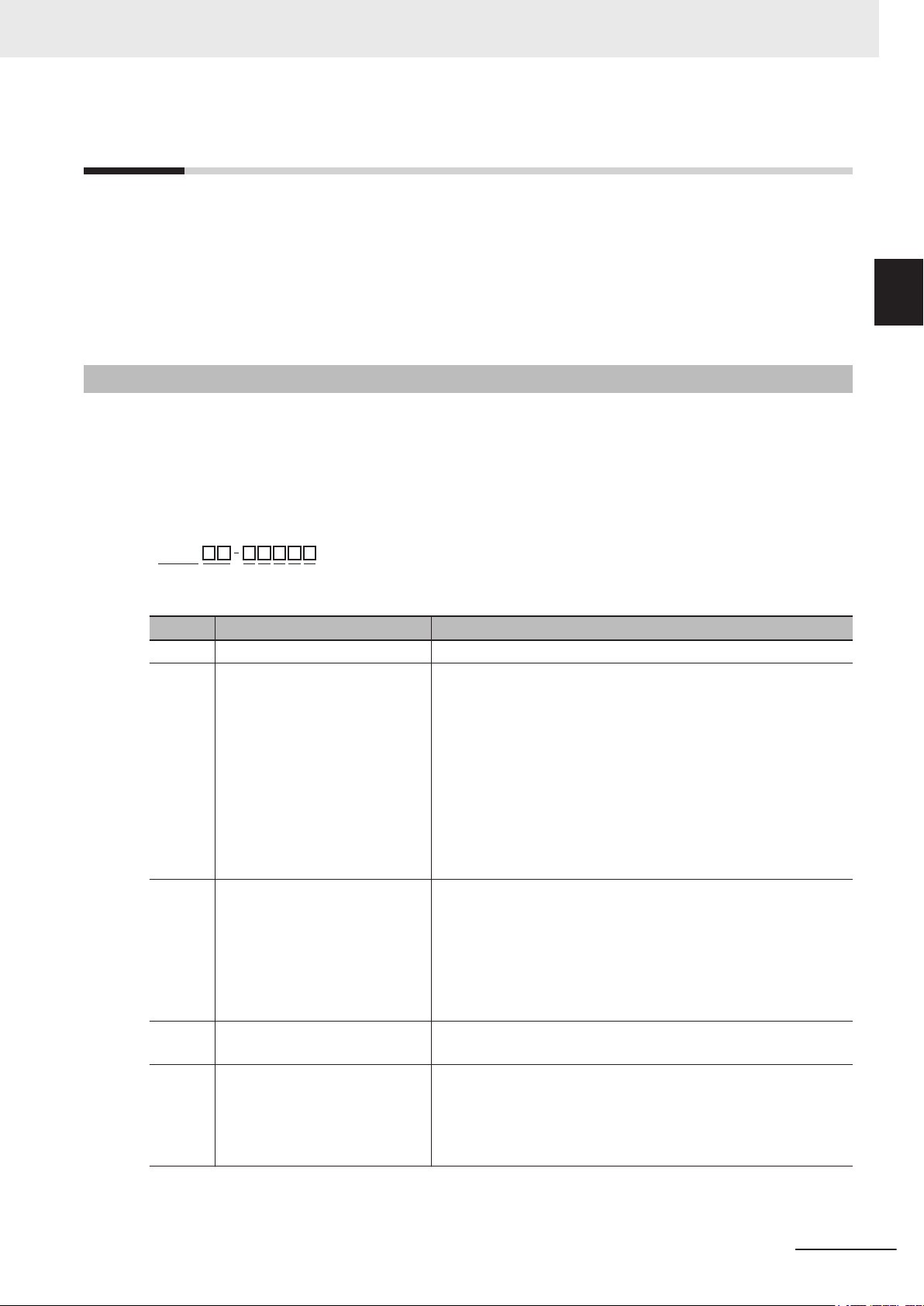

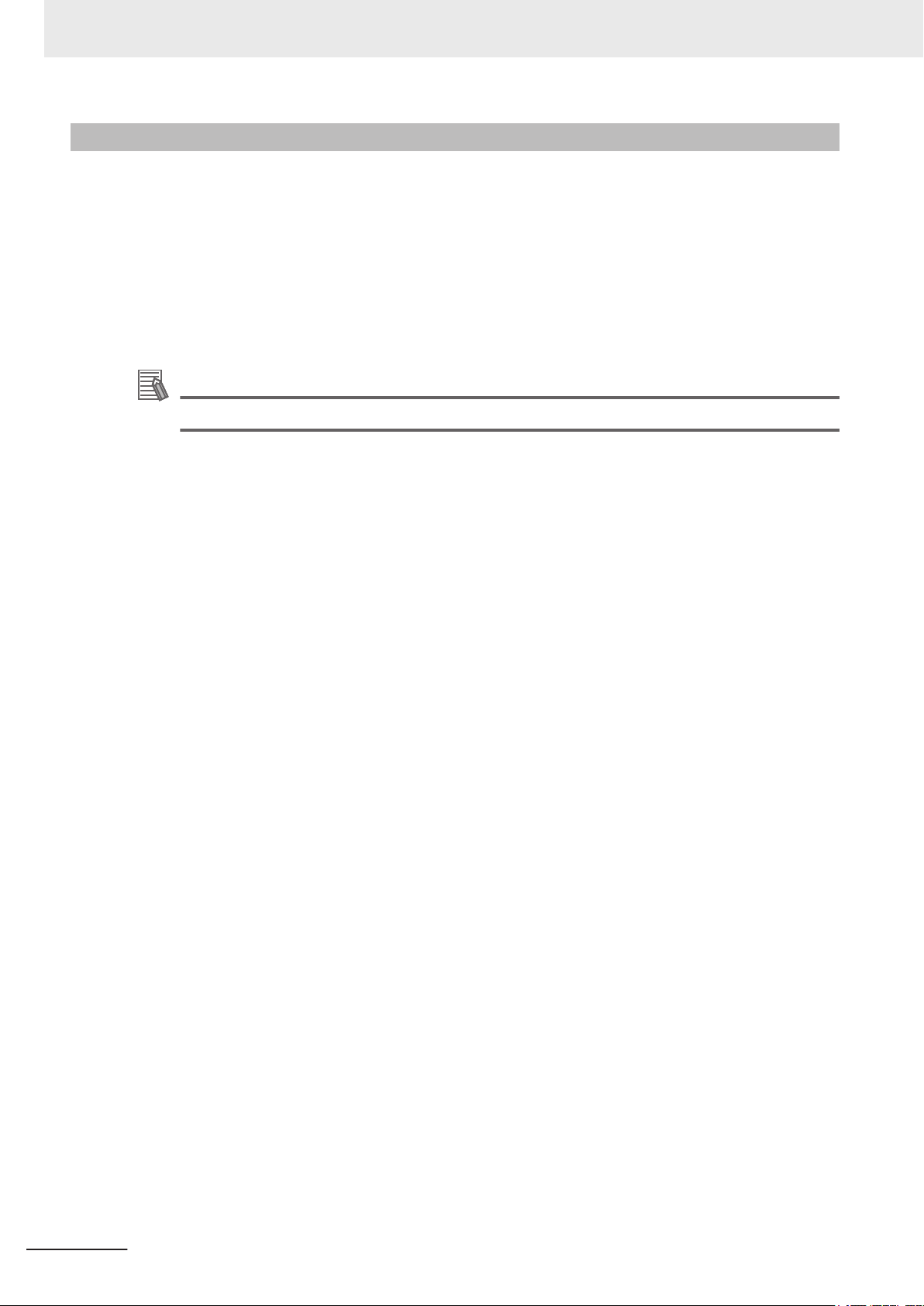

This section provides information about this manual.

Page Structure

The following page structure is used in this manual.

Manual Information

Note: This illustration is provided as a sample. It will not literally appear in this manual.

Item Explanation Item Explanation

A Level 1 heading E Special Information

B Level 2 heading F Manual name

C Level 3 heading G Page tab with the number of the main section

D Step in a procedure H Page number

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

7

Page 10

Manual Information

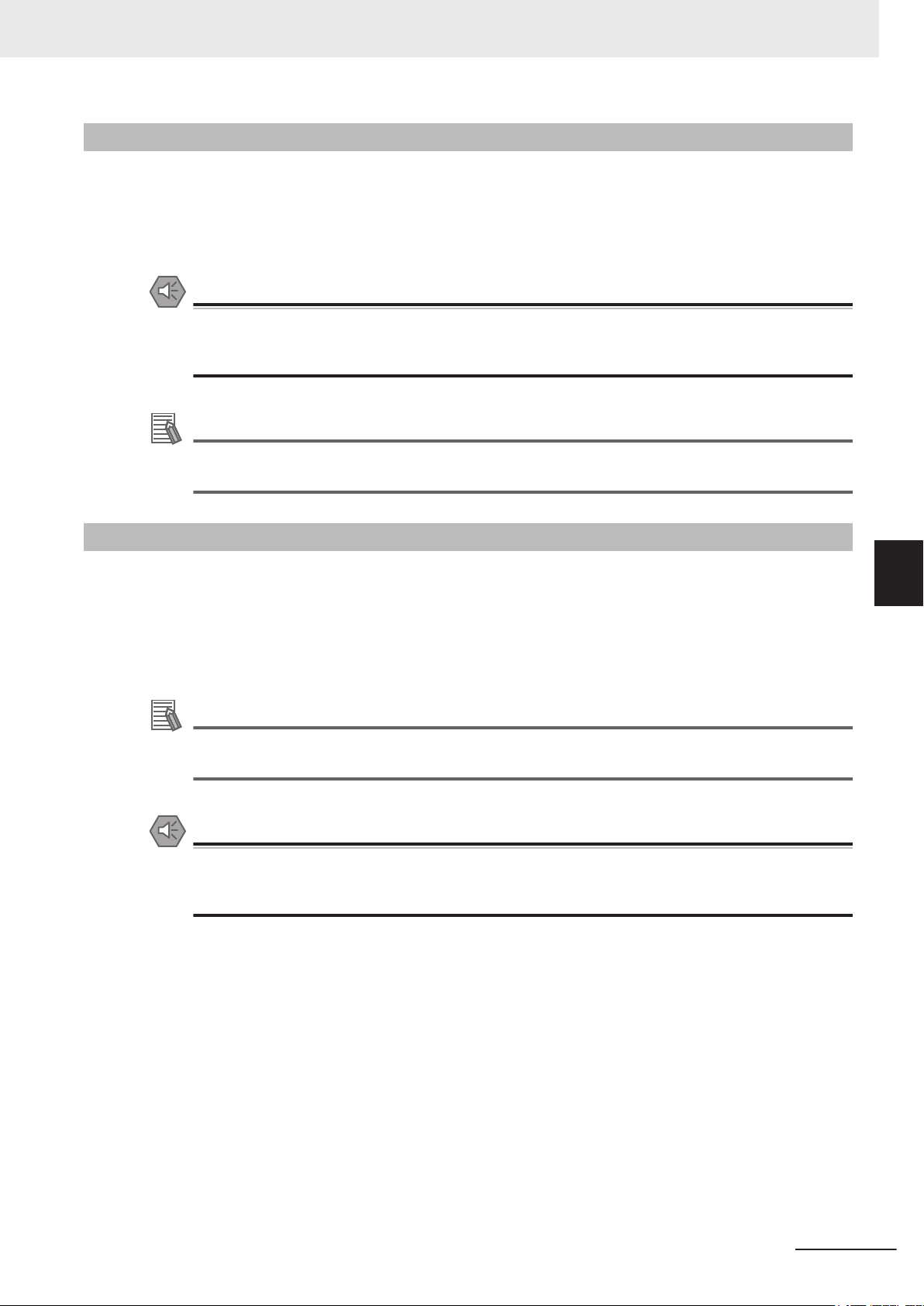

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Information on differences in specifications and functionality between different versions.

8

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 11

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty and Limitations of Liability

WARRANTY

• The warranty period for the Software is one year from the date of purchase, unless otherwise

specifically agreed.

• If the User discovers defect of the Software (substantial non-conformity with the manual), and return

it to OMRON within the above warranty period, OMRON will replace the Software without charge by

offering media or download from OMRON’s website. And if the User discovers defect of media

which is attributable to OMRON and return it to OMRON within the above warranty period, OMRON

will replace defective media without charge. If OMRON is unable to replace defective media or

correct the Software, the liability of OMRON and the User’s remedy shall be limited to the refund of

the license fee paid to OMRON for the Software.

LIMITATION OF LIABILITY

• THE ABOVE WARRANTY SHALL CONSTITUTE THE USER’S SOLE AND EXCLUSIVE

REMEDIES AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR

FITNESS FOR PARTICULAR PURPOSE. IN NO EVENT, OMRON WILL BE LIABLE FOR ANY

LOST PROFITS OR OTHER INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF USE OF THE SOFTWARE.

• OMRON SHALL HAVE NO LIABILITY FOR DEFECT OF THE SOFTWARE BASED ON

MODIFICATION OR ALTERNATION TO THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

OMRON SHALL NOT BE RESPONSIBLE AND/OR LIABLE FOR ANY LOSS, DAMAGE, OR

EXPENSES DIRECTLY OR INDIRECTLY RESULTING FROM THE INFECTION OF OMRON

PRODUCTS, ANY SOFTWARE INSTALLED THEREON OR ANY COMPUTER EQUIPMENT,

COMPUTER PROGRAMS, NETWORKS, DATABASES OR OTHER PROPRIETARY MATERIAL

CONNECTED THERETO BY DISTRIBUTED DENIAL OF SERVICE ATTACK, COMPUTER

VIRUSES, OTHER TECHNOLOGICALLY HARMFUL MATERIAL AND/OR UNAUTHORIZED

ACCESS.

• OMRON SHALL HAVE NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

9

Page 12

Terms and Conditions Agreement

Application Considerations

APPLICABLE CONDITIONS

A USER SHALL NOT USE THE SOFTWARE FOR ANY PURPOSE THAT IS NOT PROVIDED IN

THIS MANUAL OR IN A RELATED HARDW

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness

of the particular Product with respect to Buyer

application responsibility in all cases.

ARE USER'S MANUAL.

’s application, product or system. Buyer shall take

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Programmable Products

• Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

• Omron Companies shall not be responsible for the operation of the user accessible operating sys-

tem (e.g. Windows, Linux), or any consequence thereof.

10

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 13

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’

formance is subject to the Omron’s Warranty and Limitations of Liability.

s test conditions, and the user must correlate it to actual application requirements. Actual per-

Change in Software Specifications

The software specifications and accessories may be changed at any time based on improvements and

other reasons.

Terms and Conditions Agreement

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

11

Page 14

Safety Precautions

Safety Precautions

For NYB£ and NYP£ refer to the following manuals:

• NY-series Industrial Box PC Hardware User

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W555)

’s Manual (Cat. No. W553)

12

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 15

Precautions for Safe Use

For NYB£ and NYP£ refer to the following manuals:

• NY-series Industrial Box PC Hardware User

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W555)

’s Manual (Cat. No. W553)

Precautions for Safe Use

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

13

Page 16

Precautions for Correct Use

Precautions for Correct Use

For NYB£ and NYP£ refer to the following manuals:

• NY-series Industrial Box PC Hardware User

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W555)

’s Manual (Cat. No. W553)

14

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 17

Regulations and Standards

Conformance to EU Directives

The Industrial PC complies with EU Directives. To ensure that the machine or device in which the In-

dustrial PC is used complies with EU Directives, the following precautions must be observed:

• The Industrial PC must be installed within a control panel.

• The Industrial PC that complies with EU Directives also conforms to the Common Emission Stand-

ard. Radiated emission characteristics (10-m regulations) may vary depending on the configuration

of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment in which the Industrial PC is used

complies with EU Directives.

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference. If radio interference occurs, the user may be required to take appropriate meas-

ures.

Regulations and Standards

Applicable Directive

EMC Directive

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

15

Page 18

Regulations and Standards

Conformance to KC Certification

When you use this product in South Korea, observe the following precautions.

This product meets the electromagnetic compatibility requirements for business use. There is a risk of

radio interference when this product is used in home.

Conformance to UL and CSA Standards

Some Industrial PC Platform products comply with UL and CSA standards. If you use a product that

complies with UL or CSA standards and must apply those standards to your machinery or devices,

refer to this manual. This manual provides the application conditions for complying with the standards.

If the product is used in a manner not specified in the Instruction Sheet or in the product manuals then

the protection provided by the equipment may be impaired.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associat-

ed with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

16

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 19

Related Manuals

The following manuals are related. Use these manuals for reference.

Related Industrial PC Manuals

This table contains the related manuals of Industrial PC products.

Related Manuals

Manual name

NY-series Industrial Box

PC Hardware

’

s Manual

User

(Cat. No.

W553)

NY-series Industrial Panel

PC Hardware

User’

s Manual

(Cat. No.

W555)

Cat.

No.

W553 NYB Learning all basic information about the

W555 NYP Learning all basic information about the

Model

num-

bers

Application Description

Industrial Box PC. This includes introductory information with features, hardware

overview, software overview, specifications, mounting, wiring, connecting, operating and maintaining the Industrial Box

PC.

Mainly hardware information is provided.

Industrial Panel PC. This includes introductory information with features, hardware overview, software overview, specifications, mounting, wiring, connecting, operating and maintaining the Industrial

Panel PC.

Mainly hardware information is provided.

An introduction to the Industrial

Box PC is provided along with

the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

An introduction to the Industrial

Panel PC is provided along with

the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

Industrial Monitor Manual

This table contains the related manual of the Industrial Monitor.

Manual

name

Industrial

Monitor

User’

s

Manual

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Cat.

No.

W554

Model numbers Application Description

• NYM12W-C1

££

• NYM15W-C1£

££

• NYM19W-C1£

££

Learning all basic information

£

about the Industrial Monitor

includes introductory information

with features, hardware overview,

specifications, mounting, wiring,

connecting, operating and maintaining the Industrial Monitor.

. This

An introduction to the Industrial

Monitor is provided along with

the following information:

• Overview

• Hardware

• Software

• Specifications

• Installation

• Operating Procedures

• Maintenance

17

Page 20

Terminology and Abbreviations

Terminology and Abbreviations

Industrial PC Platform

Term / Abbreviation Description

Industrial PC Platform An integrated range of OMRON products designed for use in any industrial applica-

tion that will benefit from advanced PC technology

Industrial Monitor An industrial monitor with a touchscreen as the user interface designed to work in

industrial environments

Industrial Panel PC An industrial PC with an integrated touchscreen monitor designed to work in indus-

trial environments

Industrial Box PC A box-shaped industrial PC including an OS designed to work in industrial environ-

ments

IPC Industrial PC

Sysmac OMRON’s brand name of the product family for the industrial automation equip-

ment

Software

Term / Abbreviation Description

ACPI Advanced Configuration and Power Interface protocol for operating systems

API Application Programming Interface

BIOS Basic Input Output System. The first software run by a PC when powered on.

Developer Any person involved with the development of software

DST Daylight Saving Time

EWF Enhanced Write Filter

FBWF File-Based Write Filter

IIoT Industrial Internet of Things

Linux An open source Operating System

MBR Master Boot Record

Merge module A module providing a standard method by which developers deliver shared Win-

MSDN Microsoft Developer Network

NUI Natural User Interface

OS Operating System

PLC Programmable Logic Controller

RTOS Realtime Operating System

SDK Software Development Kit

TCP/IP Transmission Control Protocol / Internet Protocol, a core member of the Internet

TPM Trusted Platform Module

VxWorks A Realtime Operating System designed by Wind River

Windows An Operating System designed by Microsoft

dows installer components and setup logic to their applications

protocol suite

18

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 21

Hardware

Term / Abbreviation Description

BMC Board Management Controller

CFast An SSD CFast storage device

CPU A Central Processing Unit is the hardware within a computer that executes the in-

DVI Digital Visual Interface

DVI-D A Digital Visual Interface with only Digital signals

DVI-I A Digital Visual Interface with Analog and Digital signals

Ethernet A network communication protocol used in TCP/IP network

HDD A Hard Disk Drive storage device

HMI A Human Machine Interface that facilitates machine operation and control

iMLC Industrial Multi-Level Cell type of SSD storage device

NYML NY Monitor Link interface with video signals and USB signals

PCIe The PCI Express is a high-speed computer bus standard called Peripheral Compo-

PoE Power over Ethernet

SATA The Serial AT Attachment is a serial bus interface primarily used with mass storage

SLC Single-Level Cell type of SSD storage device

SO-DIMM Small Outline Dual Inline Memory Module

SSD A Solid State Drive storage device

USB Universal Serial Bus

Terminology and Abbreviations

structions of a computer program

nent Interconnect Express

devices such as hard disk drives

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

19

Page 22

W616-E2-02

Cat. No.

Revision code

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

02 July 2019 Updated Conformance to KC certification

01 May 2019

• First release of this software manual for Industrial PCs

NY

• All hardware information for the Box PC is available in

trial Box PC Hardware User’s Manual (Cat. No. W553)

• All hardware information for the Panel PC is available in NY-series In-

dustrial Panel PC Hardware User’s Manual (Cat. No. W555).

-series Indus-

20

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 23

Overview

This section provides general information about the Industrial PC.

1

1

1-1 Intended Use

1-2 Software Features ..........................................................................................1-3

1-3 ID Information Label....................................................................................... 1-4

1-4 Product Configuration ................................................................................... 1-5

1-4-1 Product Configuration Box PC........................................................................ 1-5

1-4-2 Product Configuration Panel PC..................................................................... 1-7

1-5 Overall Setup Procedure ...............................................................................1-9

.................................................................................................. 1-2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

1-1

Page 24

1 Overview

1-1

Intended Use

The Industrial PC is intended to be used in factory automation environments. This Industrial PC can

be configured with Windows, Linux or a realtime operating system (RTOS). Software utilties extend

the functionality and support the functional integration in custom software. It can be used with third

party software to serve as a powerful PC platform.

A user can access the Industrial PC for control, configuration and supervisory operations.

The Industrial PC can easily be integrated in manufacturing innovations like big data, NUI and IIoT.

The Industrial PC has a compact design that offers flexibility, expandability and easy maintenance for

applications in factory automation environments.

1-2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 25

1 Overview

1-2 Software Features

1-2

Software Features

The Industrial PC provides the following software features:

• Operating Systems

The system can be delivered with and without an operating system.

• Software Utilities

A range of software utilities extends the functionality of the Industrial PC.

There are software utilities that provide:

• functional support like brightness adjustments.

• operator support like messages for the operator.

• technical support like status details for diagnosing and resolving problems.

• APIs for developers

Several APIs allow software developers to implement functionality of the Industrial PC in a custom

program.

1

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

1-3

Page 26

1 Overview

1-3

ID Information Label

The ID information label contains the product configuration and other details on the specific configura-

tion of your Industrial PC.

For NYB£ and NYP£ refer to the following manuals:

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W553)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W555)

1-4

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 27

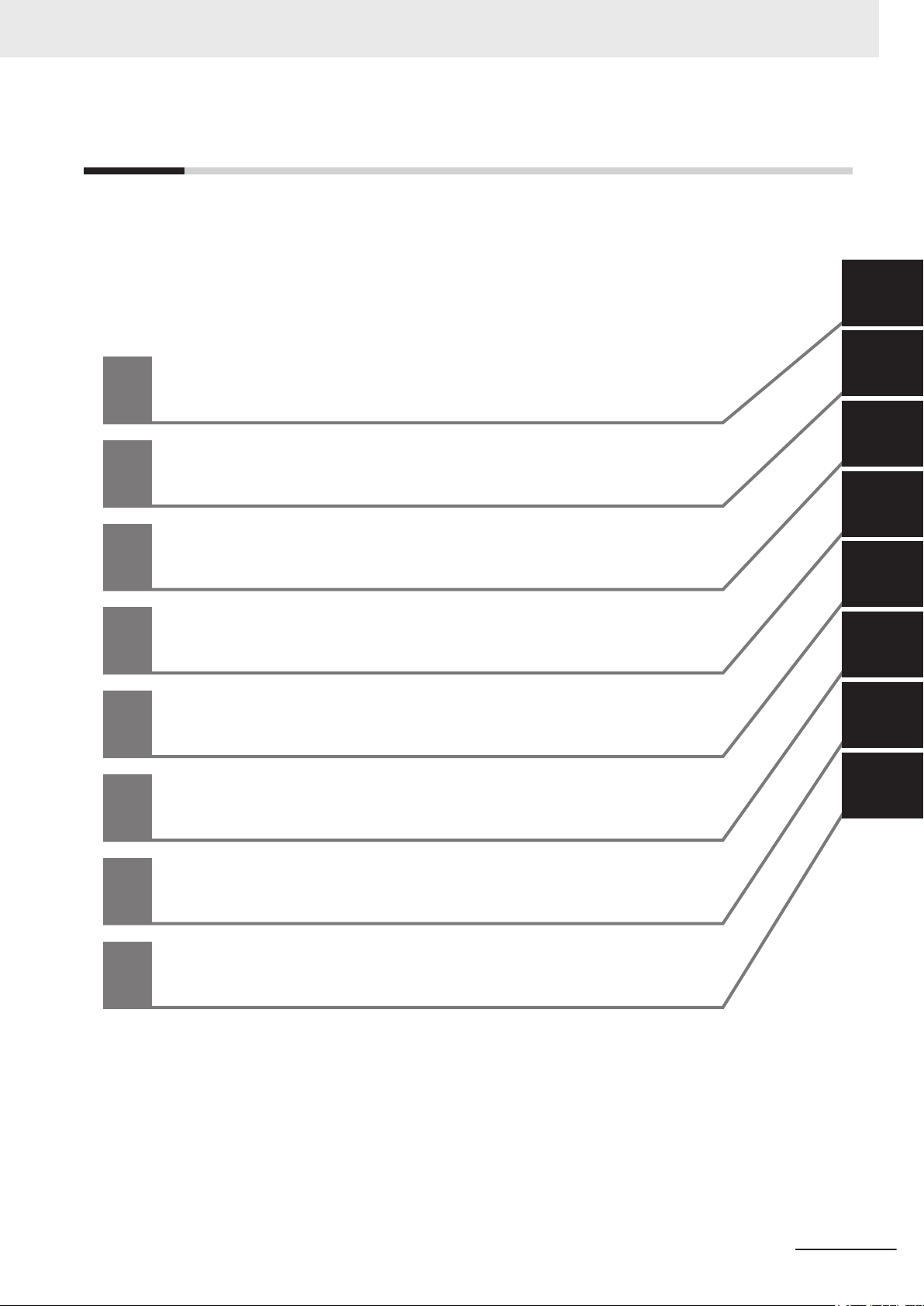

N Y B

1 2

3 4 5 6 7

1 Overview

1-4 Product Configuration

1-4

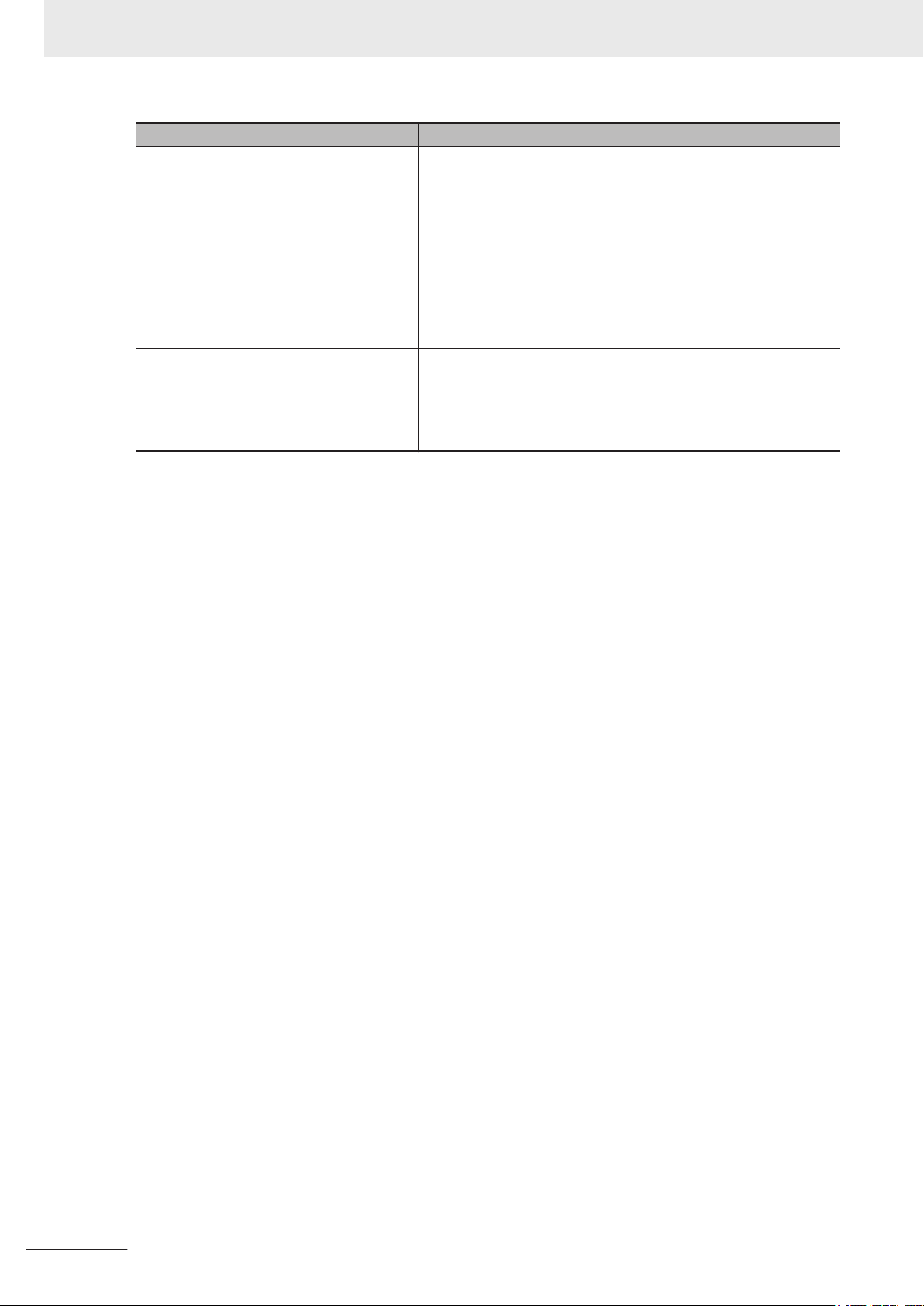

1-4-1

Product Configuration

This section provides an overview of the product configurations available for the Industrial PCs.

The product configuration is visible in the model-ID that is mentioned on the ID information label of the

Industrial PC.

Refer to 1-4-1 Product Configuration Box PC on page 1-5 for Industrial Box PC details.

Refer to 1-4-2 Product Configuration Panel PC on page 1-7 for Industrial Panel PC details.

Product Configuration Box PC

This section provides an overview of the product configurations available for the Industrial Box PC.

The product configuration is visible in the model-ID that is mentioned on the ID information label of the

product.

The structure of the model-ID is: NYB££-£££££.

Each item in the model-ID has a specific meaning.

1

1-4-1 Product Configuration Box PC

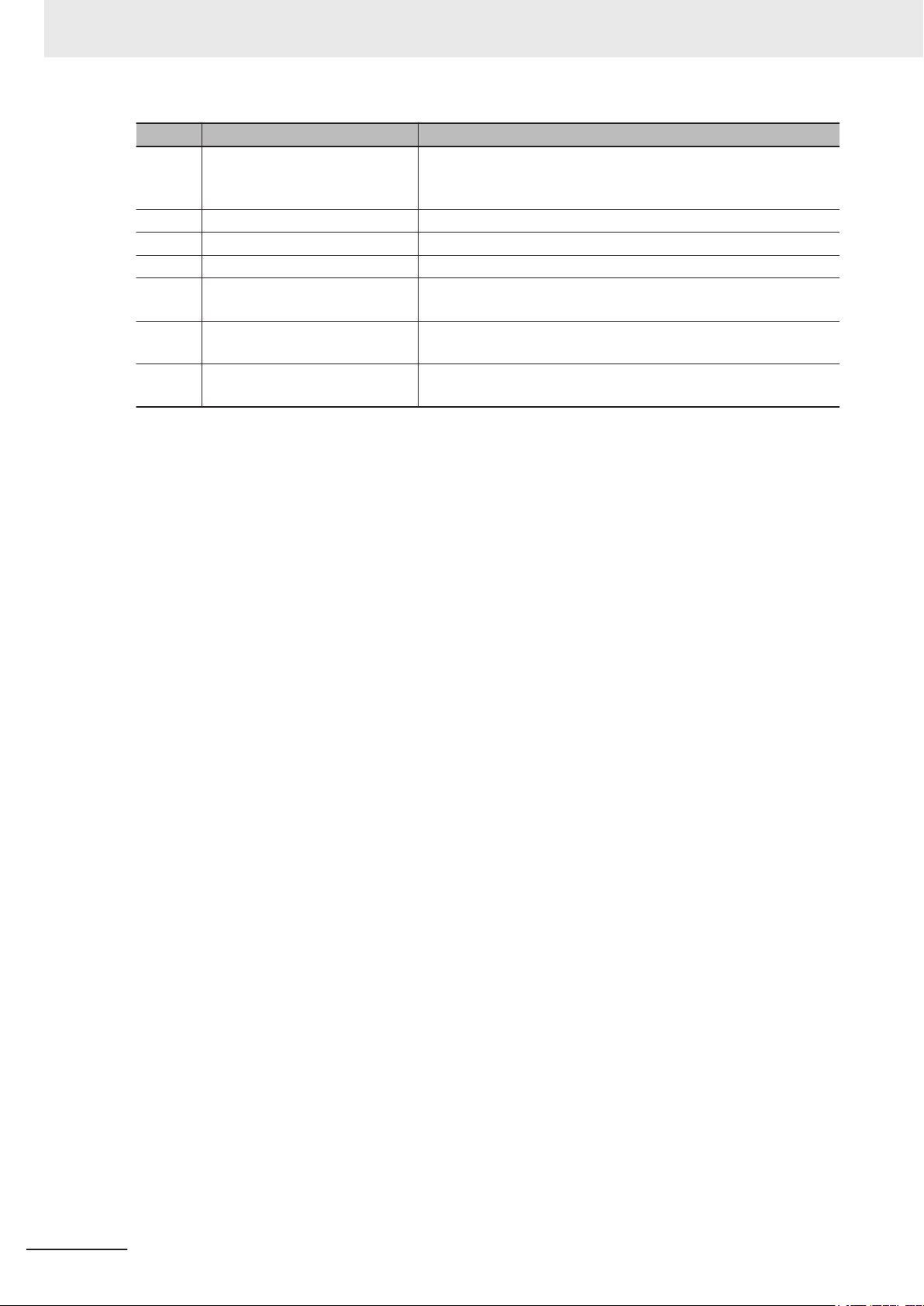

Item Description Option / Description

1 Series name NYB: NY- series Industrial Box PC

2 Processor

3 Main memory 1: 2 GB, non-ECC

4 Expansion slots 0: None

5 Operating system 0: No Operating System

1C: Intel® Celeron® 2980U, 4th generation CPU

1E: Intel® Xeon® E3-1515M v5

6th generation CPU with active cooling

17: Intel®

2A: Intel® Atom® x5-E3940

2C: Intel® Celeron® 3965U, 7th generation CPU

25: Intel® Core™ i5-4300U, 4th generation CPU

35: Intel® Core™ i5-7300U, 7th generation CPU

2: 4 GB, non-ECC

3: 8 GB, non-ECC

4: 16 GB, non-ECC

5: 32 GB, non-ECC

C: 8 GB, ECC

D: 16 GB, ECC

1: 1 PCIe slot

1: Windows Embedded Standard 7 - 32 bit

2: Windows Embedded Standard 7 - 64 bit

3: Windows 10 IoT Enterprise 2016 L

4: Windows 10 IoT Enterprise 2019 L

Core™ i7-4700EQ,

4th generation CPU with active cooling

TSB - 64 bit

TSC - 64 bit

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

1-5

Page 28

1 Overview

6 Storage 5: 64 GB, CFast iMLC

7 Optional interface 0: None

Item Description Option / Description

6: 128 GB, CFast iMLC

7: 256 GB, CFast iMLC

8: 32 GB, SSD SLC

9: 64 GB, SSD SLC

C: 320 GB, HDD

D: 500 GB, HDD

E: 1 TB, HDD

K: 128 GB, SSD iMLC

M: 500 GB, SSD iMLC

1: RS-232C

2: DVI-D

6: NY Monitor Link

9: Gb Ethernet

1-6

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 29

N Y P

1 2

3 4 5 6 7 8 9

10 11 12 13 14

1 Overview

1-4 Product Configuration

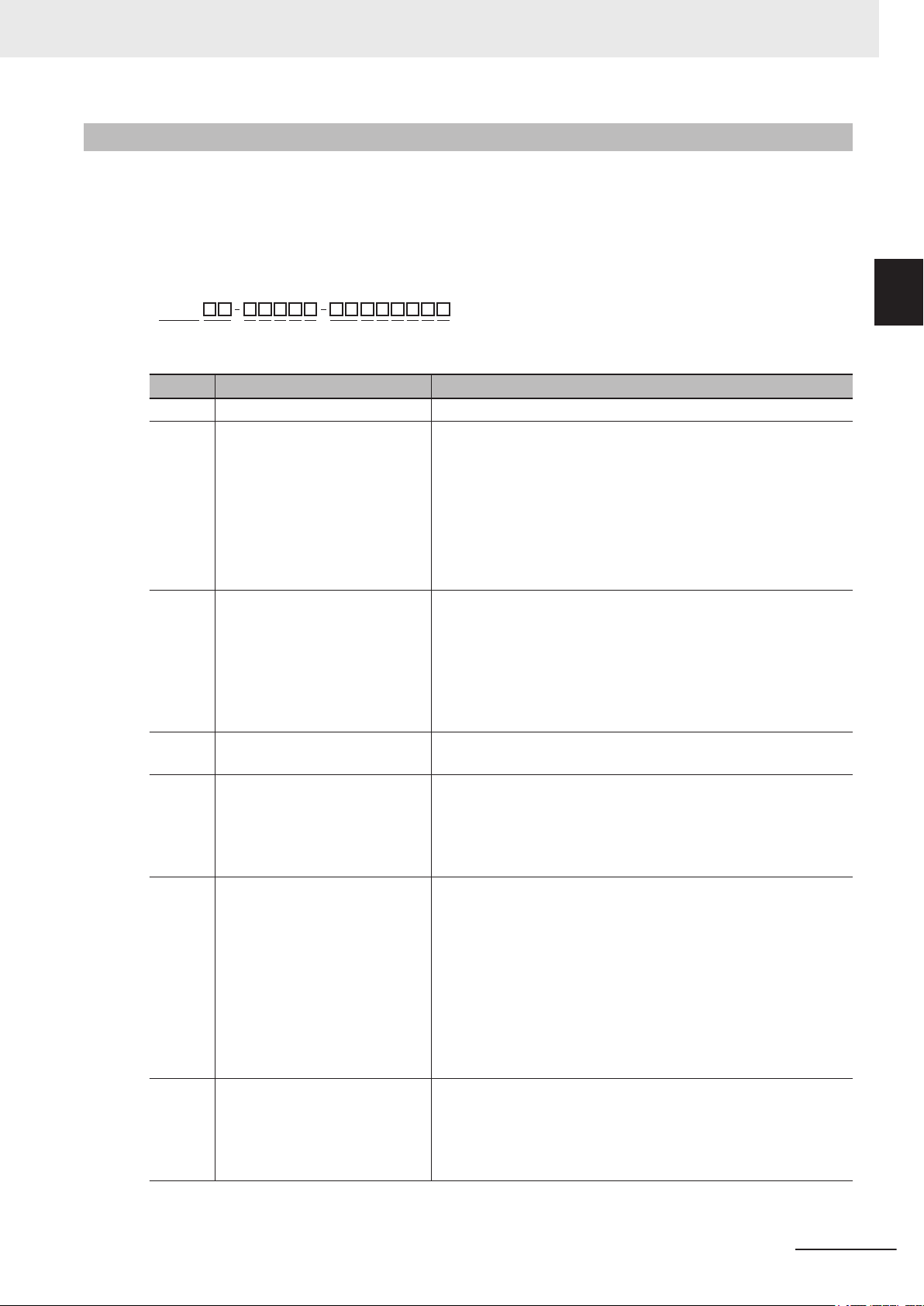

1-4-2

Product Configuration Panel PC

This section provides an overview of the product configurations available for the Industrial Panel PC.

The product configuration is visible in the model-ID that is mentioned on the ID information label of the

IPC.

The structure of the model-ID is: NYP££-£££££-££££££££.

Each item in the model-ID has a specific meaning.

Item Description Option / Description

1 Series name NYP: NY- series Industrial Panel PC

2 Processor

3 Main memory 1: 2 GB, non-ECC

4 Expansion slots 0: None

5 Operating system 0: No Operating System

6 Storage 5: 64 GB, CFast iMLC

7 Optional interface 0: None

1C: Intel® Celeron® 2980U, 4th generation CPU

17: Intel® Core™ i7-4700EQ,

4th generation CPU with active cooling

2A: Intel® Atom® x5-E3940

2C: Intel® Celeron®

25: Intel® Core™ i5-4300U, 4th generation CPU

35: Intel® Core™ i5-7300U, 7th generation CPU

2: 4 GB, non-ECC

3: 8 GB, non-ECC

4: 16 GB, non-ECC

5: 32 GB, non-ECC

C: 8 GB, ECC

D: 16 GB, ECC

1: 1 PCIe slot

1: Windows Embedded Standard 7 - 32 bit

2: Windows Embedded Standard 7 - 64 bit

3: Windows 10 IoT Enterprise 2016 L

4: Windows 10 IoT Enterprise 2019 L

6: 128 GB, CFast iMLC

7: 256 GB, CFast iMLC

8: 32 GB, SSD SLC

9: 64 GB, SSD SLC

C: 320 GB, HDD

D: 500 GB, HDD

E: 1 TB, HDD

K: 128 GB, SSD iMLC

M: 500 GB, SSD iMLC

1: RS-232C

2: DVI-D

6: NY Monitor Link

9: Gb Ethernet

3965U, 7th generation CPU

TSB - 64 bit

TSC - 64 bit

1

1-4-2 Product Configuration Panel PC

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

1-7

Page 30

1 Overview

8 Display size

9 Display ratio W: Wide

10 Touchscreen C: Projected Capacitive Touch type

11 Frame type 1: Panel mounted

12 Material finish 0: Aluminum, painted black

13 Built-in options 0: None

14 Logo 0: OMRON

Item Description Option / Description

12: 12.1 inch model, 1280 x 800 pixels, 24 bit full color

(diagonal)

15: 15.4 inch model, 1280 x 800 pixels, 24 bit full color

19: 18.5 inch model, 1920 x 1080 pixels, 24 bit full color

1: Aluminum, Nickel plated

6: NY Monitor Link

2: Customization

1-8

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 31

1 Overview

1-5 Overall Setup Procedure

1-5

Overall Setup Procedure

This section gives the overall setup procedure for the Industrial PC.

This manual presents this information in the same order as the following setup procedure.

To setup the Industrial PC:

1 Familiarize yourself with the Industrial PC

• Refer to the sections Overview and Hardware of the Hardware manual.

For NYB

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W553)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W555)

• Refer to the information in this manual.

Specifically refer to the sections:

• Section 2 System Configurations on page 2-1

• Section 3 Software on page 3-1

• Section 4 Specifications on page 4-1

2 Install the IPC Hardware

Perform the procedures that are required to use the

nection with peripheral devices including a UPS.

Refer to the section Installation in the Hardware manual..

£ and NYP£ refer to the following manuals:

Industrial PC

such as installation, and con-

1

3 Setup the IPC

Install and configure the operating system, the software support utilities and the UPS software.

Item Remark Reference

Operating system settings Follow the procedure for 'First

time startup'

UPS settings Make the required UPS settings The applicable UPS Manual

Industrial Monitor settings Adjust the brightness and con-

trast of the monitor

The applicable Hardware Manual, see step 1.

3-4 Industrial Monitor Utility on

page 3-1

1

4 Operate the IPC

Use the operating procedures to operate the Industrial PC

Refer to the sections Operating Procedures in this manual and in the Hardware manual.

The setup of the Industrial PC is finished.

The section 'Maintenance' contains preventive and corrective maintenance information.

Refer to the section Maintenance in this manual and in the Hardware manual.

.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

1-9

Page 32

1 Overview

1-10

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 33

2

2

System Configurations

This section provides an overview of the system configurations for the Industrial PC.

2-1 Configuration for NYB and NYP

.................................................................... 2-2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

2-1

Page 34

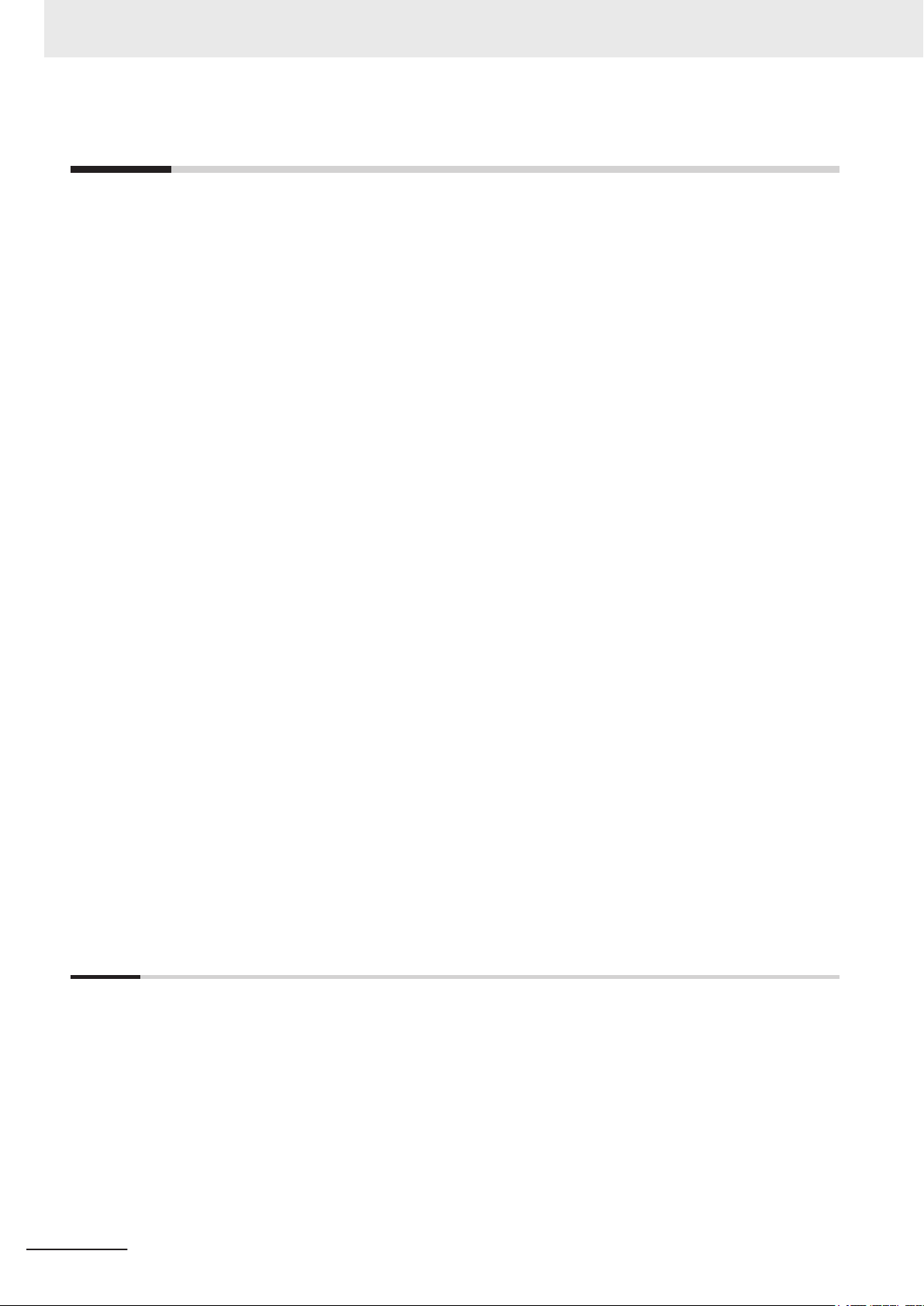

NYB and NYP-series IPC

Ethernet

SD Memory

Card

PCIe Card

HDD / SSD

RS-232C

DVI USB

Ports

NYML

Operating System

&

Software Utilities

&

APIs

2 System Configurations

2-1

Configuration for NYB and NYP

The Industrial PC supports the following software configurations.

The operating system is the foundation for your software environment. The operating system manages

the IPC hardware and supplies an interface for the users.

Refer to 3-1 Windows Operating System on page 3-3 for details.

Support software is a collection of software utilities to support and extend the functionality of your In-

dustrial PC.

Refer to 3-2 Overview IPC Support Software for Windows on page 3-4 for details.

APIs are available for software developers that want to implement PC functionality in custom software

applications.

Refer to 3-9 Software for Developers on page 3-32 for details.

2-2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 35

Software

3

3

This section provides software information for the Industrial PC.

3-1 W

3-2 Overview IPC Support Software for Windows............................................. 3-4

3-3 Industrial PC Support Utility ........................................................................3-5

3-4 Industrial Monitor Utility ............................................................................. 3-11

3-5 Industrial Monitor Brightness Utility ......................................................... 3-17

3-6 Rescue Disk Creator ....................................................................................3-19

3-7 Industrial PC Tray Utility ............................................................................. 3-25

indows Operating System.......................................................................... 3-3

3-1-1 Determine Your Version of the Windows Operating Systems......................... 3-3

3-3-1 Industrial PC Support Utility Overview............................................................ 3-6

3-3-2 Product Information Tab................................................................................. 3-7

3-3-3 System Status Tab.......................................................................................... 3-8

3-3-4 Machine Controller Tabs ................................................................................. 3-9

3-3-5 Compatibility ................................................................................................... 3-9

3-3-6 Installation....................................................................................................... 3-9

3-3-7 Startup ............................................................................................................ 3-9

3-3-8 Logging ......................................................................................................... 3-10

3-4-1 Industrial Monitor Utility Overview .................................................................3-11

3-4-2 Compatibility ................................................................................................. 3-15

3-4-3 Installation..................................................................................................... 3-15

3-4-4 Startup .......................................................................................................... 3-15

3-4-5 Configuration ................................................................................................ 3-16

3-4-6 Messages ..................................................................................................... 3-16

3-4-7 Logging ......................................................................................................... 3-16

3-5-1 Industrial Monitor Brightness Utility ............................................................. 3-17

3-5-2 Compatibility ................................................................................................. 3-17

3-5-3 Installation..................................................................................................... 3-18

3-5-4 Startup .......................................................................................................... 3-18

3-5-5 Configuration ................................................................................................ 3-18

3-5-6 Logging ......................................................................................................... 3-18

3-6-1 Rescue Disk Creator Overview..................................................................... 3-19

3-6-2 Compatibility ................................................................................................. 3-20

3-6-3 Installation..................................................................................................... 3-20

3-6-4 Startup .......................................................................................................... 3-21

3-6-5 Messages ..................................................................................................... 3-21

3-7-1 Industrial PC Tray Utility Overview ............................................................... 3-25

3-7-2 Features........................................................................................................ 3-25

3-7-3 Menu............................................................................................................. 3-26

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-1

Page 36

3 Software

3-7-4 About the Industrial PC Tray Utility............................................................... 3-26

3-7-5 Status Indicators on Icons ............................................................................ 3-27

3-7-6 Compatibility ................................................................................................. 3-27

3-7-7 Installation..................................................................................................... 3-27

3-7-8 Startup .......................................................................................................... 3-28

3-8 Power Attendant Lite Utility ........................................................................3-29

3-8-1 Power Attendant Lite Utility Overview........................................................... 3-29

3-8-2 Features........................................................................................................ 3-29

3-8-3 Compatibility ................................................................................................. 3-29

3-8-4 Installation..................................................................................................... 3-30

3-8-5 Configuration ................................................................................................ 3-30

3-9 Software for Developers.............................................................................. 3-32

3-9-1 Overview IPC Developer Software for Windows .......................................... 3-32

3-9-2 Industrial PC System API ............................................................................ 3-33

3-9-3 Industrial Monitor API .................................................................................. 3-34

3-2

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 37

3 Software

3-1

3-1-1

Windows Operating System

This section provides an overview of Windows Operating System information.

Determine Your Version of the Windows Operating Systems

This section provides methods to find version details of your Windows Operating System.

Windows 7

Windows 7 is only compatible with 4th generation CPUs.

Refer to 1-4-2 Product Configuration Panel PC on page 1-7 for CPU details.

T

o determine your version of the Windows Operating System:

1 Select the Start Button.

2 Enter System Information in the search box.

3-1 Windows Operating System

3

3-1-1 Determine Your Version of the Windows Operating Systems

3 Select System Information in the pop-up that appears.

Windows 10

To determine your version of the Windows Operating System:

1 Select the Search Button.

2 Enter System Information in the search box.

3 Select System Information in the pop-up that appears.

An overview of your System Information will appear

details.

, including the Windows Operating System

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-3

Page 38

3 Software

3-2

Overview IPC Support Software for Windows

This section gives an overview of the software utilities available for all Industrial PC Platform products

with a Windows operating system.

Product Software utility

Industrial Monitor Industrial Monitor Utility

*1

Industrial Monitor Brightness Utility

Industrial PC T

Industrial Box PC Industrial PC Support Utility

Industrial PC T

Rescue Disk Creator

Industrial Panel PC Industrial Monitor Utility

Industrial Monitor Brightness Utility

Industrial PC Support Utility

Industrial PC T

Rescue Disk Creator

*1. Included in the Industrial Monitor Utility installer

*2. Included in the Industrial PC Support Utility installer

*3. Together with the Industrial PC Tray Utility also Microsoft .NET Framework 4.6 is installed.

ray Utility

ray Utility

ray Utility

*1*2*3

*2*3

*1

*1*2*3

*1

Select and download the required utilities from the OMRON website.

Additional Information

An internet connection is required to install support software.

3-4

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 39

3 Software

3-3

Industrial PC Support Utility

This section provides an overview of the Industrial PC Support Utility.

3-3 Industrial PC Support Utility

3

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-5

Page 40

G

EDB

A

C

F

3 Software

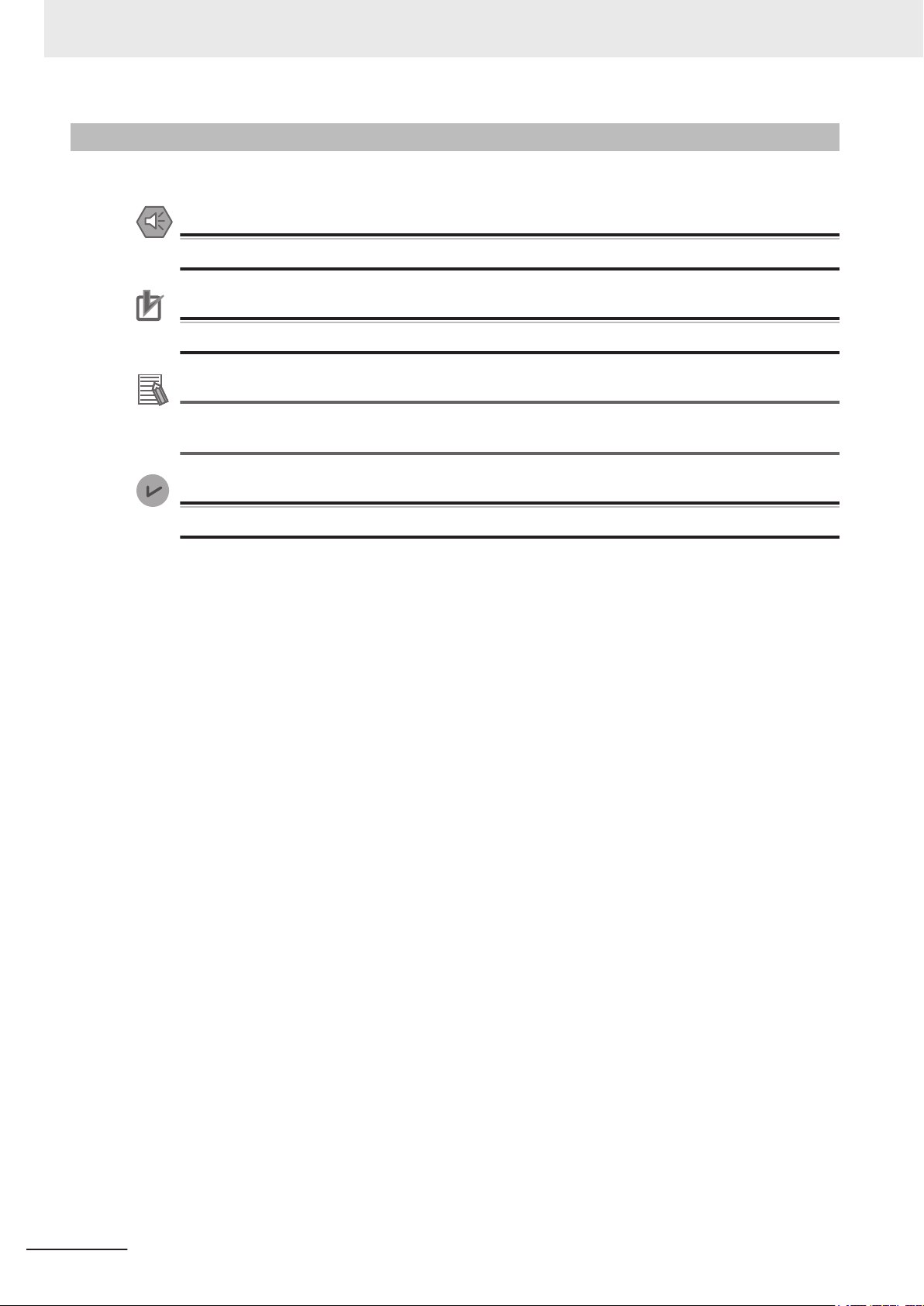

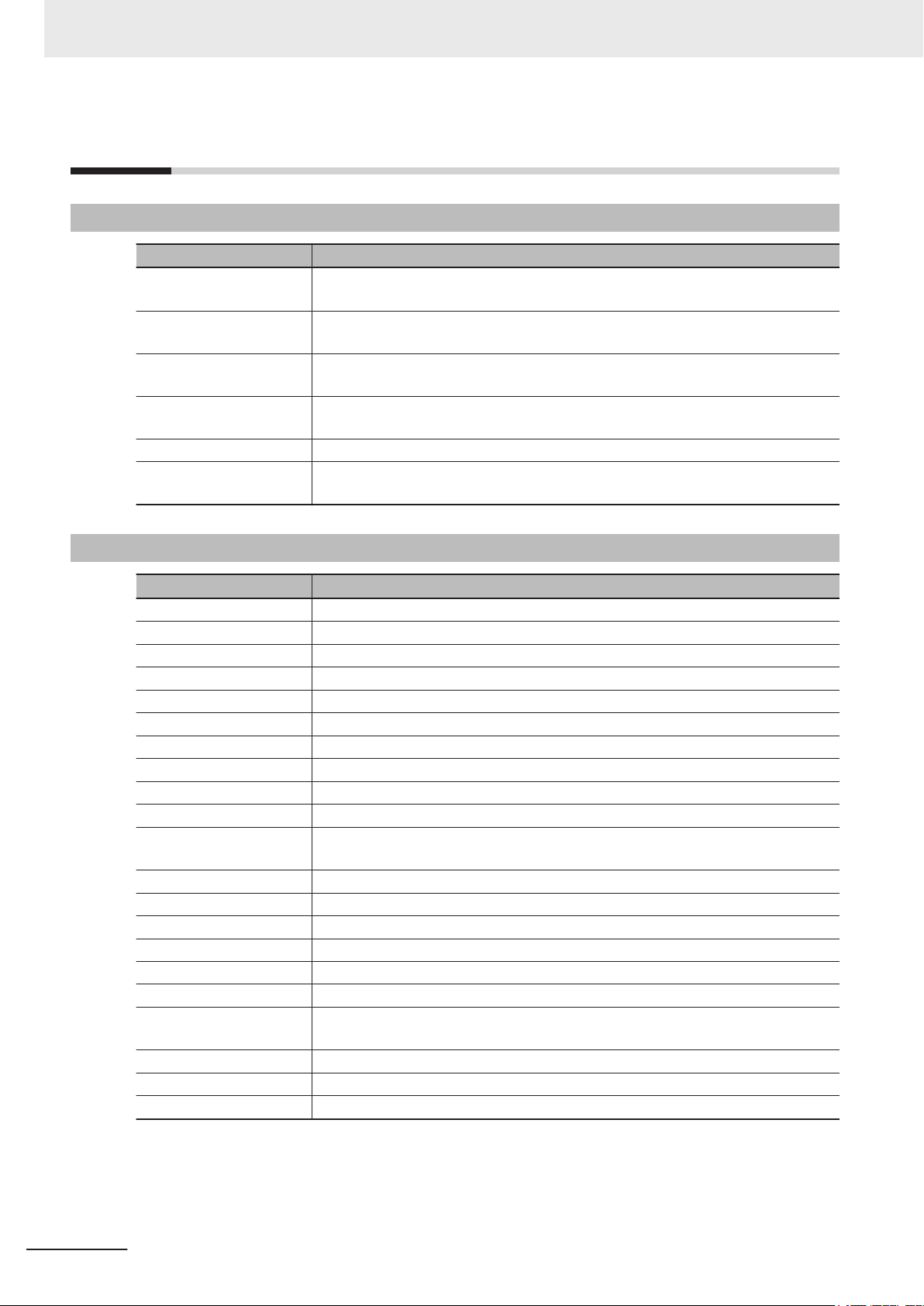

3-3-1

Industrial PC Support Utility Overview

The Industrial PC Support Utility is a software utility to assist in diagnosing and resolving problems of

the Industrial PC.

Item Description Details

A Production Data Tab

B System Status Tab

C Machine Controller Tabs A series of tabs that is only availabel for an Industrial PC with Machine

D Tab details Details of the selected Tab page.

E Language Selector Select to display and choose the UI language of the Industrial PC Support

F Close Button Close the Industrial PC Support Utility.

G Update Screen Button Use this button to retrieve updated values from the Industrial PC.

Select to display Production Data details in the Tab details area

Refer to 3-3-2 Product Information Tab on page 3-7

Select to display System Status details in the Tab details area

Refer to 3-3-3 System Status Tab on page 3-8 for details.

Automation Control Software. Refer to

page 3-9 for details.

Utility.

.

for details.

.

3-3-4 Machine Controller Tabs on

3-6

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 41

3 Software

3-3-2

Product Information Tab

The Production Data tab displays generic Industrial PC information. These are e.g. Model name, Lot

number

trial PC Support Utility and Industrial PC System API).

, Serial number

, Hardware version, BIOS version, BMC version, and software versions (Indus-

3-3 Industrial PC Support Utility

3

3-3-2 Product Information Tab

• Model Name is the configuration code of this model.

Refer to 1-4-2 Product Configuration Panel PC on page 1-7 for details.

•

BMC Version is the firmware version of the Board Management Controller.

Values are not updated automatically. Select the Update Screen Button to display the latest values.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-7

Page 42

3 Software

3-3-3

System Status Tab

The System Status tab displays actual states and diagnostic information like internal temperature, fan

revolution, battery and power supply status.

A status that requires attention is indicated with a red bar

.

Item Description

Internal Temperature The average CPU temperature.

Fan Revolution

*1

The actual rotation speed for each fan in revolutions per minute (r/min).

• First number = rotation speed of fan located closest to Power button.

• Second number = rotation speed of fan located closest to battery.

Fan Status

*2

The target speed for the fans is dynamically set based on the CPU temperature. The

target speed is compared with the actual fan speed.

indicates both fans are running on the target speed.

• OK

• Low revolution speed indicates one or both fans do not reach the target speed.

Clean the fans and replace the Fan Unit if the problem persists.

Battery Status The battery status.

• OK indicates the battery is full.

• Low indicates the battery voltage is low. Replace the battery.

Power Supply The power supply status is determined by the UPS and reported to the IPC via the I/O

connector.

• NormalPowerSupply indicates the IPC is powered by the 24V power supply.

• UPS Power Supply indicates that there is no power from the 24V power supply

and the IPC runs on battery power from the UPS.

*1. The Fan Revolution will always show 0 (r/min) / 0 (r/min) for fanless models

Refer to 1-4-2 Product Configuration Panel PC on page 1-7 for fan details.

*2. The Fan Status will always show OK for fanless models

3-8

Values are not updated automatically. Select the Update Screen Button to display the latest values.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 43

3 Software

3-3-4

3-3-5

3-3-6

Machine Controller Tabs

The Industrial PC with Machine Automation Control Software has additional tabs available.

Examples are:

Controller Status, to display operation mode and current errors.

•

•

Controller Operation, to change operating mode or backup / restore the controller.

• Network Setting, to display and change network settings

• Virtual SD Memory Card Settings, to change the Virtual SD Memory Card Settings. .

These Machine Controller tabs are only relevant for an Industrial PC with Machine Automation Control

Software. Refer to NY-series IPC Machine Controller Industrial Panel PC / Industrial Box PC Setup

User’s Manual (Cat. No. W568) for details.

Compatibility

This software utility can be used on an IPC with Windows 7 or higher.

Installation

The Industrial PC Support Utility is pre-installed on the Industrial PC if it comes with a Windows oper-

ating system installed.

Download the

Industrial PC Support Utility

the OMRON website if reinstallation is required.

from

3-3 Industrial PC Support Utility

3

3-3-4 Machine Controller Tabs

3-3-7

Startup

The Industrial PC Support Utility can be started from:

Windows Start Menu

•

Select

• Industrial PC Tray Utility

• Windows desktop shortcut

OMRON and then Industrial PC Support Utility.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-9

Page 44

3 Software

3-3-8

Logging

There is logging in the Windows event log of the following utilities:

Industrial Monitor Utility

•

In the Windows Event V

• Industrial Monitor Brightness Utility

In the Windows Event Viewer filter for event source IndMonService.

• Industrial PC Support Utility

In the Windows Event Viewer filter for event source IPCServiceHost or OMRON Industrial PC

Support Utility.

Additional Information

Refer to 7-2-4 Windows Event V

iewer filter for event source IndMonService.

iewer on page 7-29 for the logged messages.

3-10

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 45

A

E

F

G

I

J

H

B

C

D

3 Software

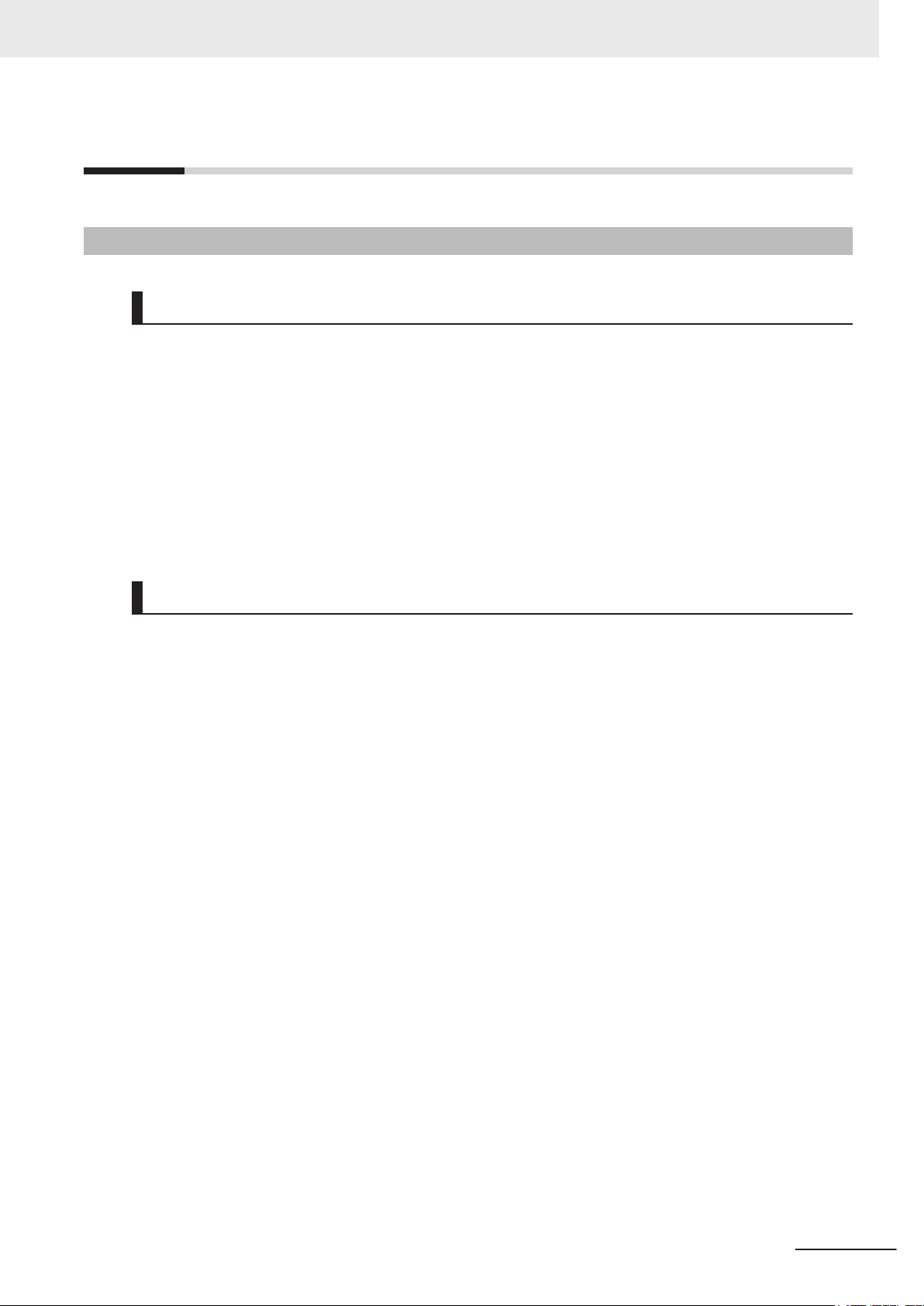

3-4

3-4-1

Industrial Monitor Utility

This section provides an overview of the Industrial Monitor Utility.

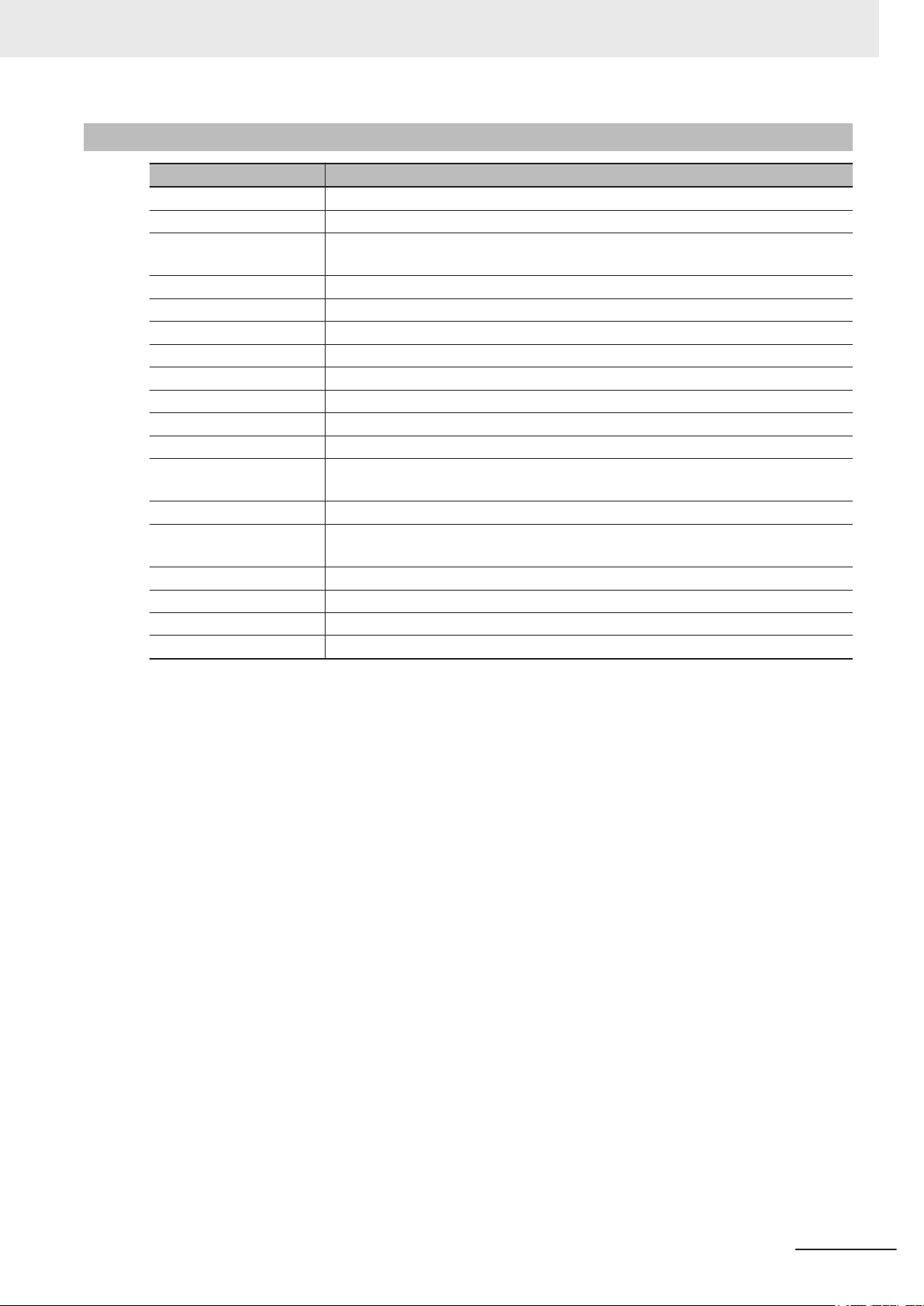

Industrial Monitor Utility Overview

The Industrial Monitor Utility provides a user interface to control settings and display details of con-

nected Industrial Monitors.

3-4 Industrial Monitor Utility

3

3-4-1 Industrial Monitor Utility Overview

Item Description Details

A Connected Monitors

Product Information Provides details of the selected Industrial Monitor.

B

Version Information Provides version details of Industrial Monitor Utility software and firmware

C

D Monitor Settings Provides several setting adjustments to control the operation of the selected

Backlight Brightness Ad-

E

justment

F Logo Brightness Adjust-

ment

G Status Brightness Adjust-

ment

Touch Input Settings Provides details about the touch settings.

H

*2

I Advanced Settings Provides access to defaults and relevant Windows settings.

J Standard windows but-

tons

*1. The Industrial Monitor Utility scans the connected USB devices and shows a list of connected monitors. If an

Industrial Monitor is not connected with the USB cable, it will not be found.

Shows a list of the connected Industrial Monitors.*1 Select one

Monitor in the list to display the Monitor Details. When selected the LED Indicators of the selected monitor will flash during 3 seconds.

Refer to Product Information on page 3-12 for details.

details of the connected monitor.

Refer to

Industrial Monitor.

Use the slider to control the brightness of the selected Industrial Monitor.

Use the slider to control the brightness of the Logo LED.

Use the slider to control the brightness of the Status LED Indicator on the

monitor.

Refer to Touch Input Settings

Refer to Advanced Settings on page

Version Information on page 3-12 for details.

on page 3-13 for details.

3-14 for details.

Industrial

• OK button. Applies changes and closes the window

• Cancel button. Exits the utility

• Apply button. Applies the changes,

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-11

Page 46

3 Software

*2. With a very low backlight brightness setting (15%-0%) the displayed information might not be visible in an envi-

The Product Information part supplies details of the selected connected monitor.

ronment with high ambient light conditions. This prevents brightness adjustments with the Industrial Monitor Utility.

Additional Information

To adjust the backlight brightness when the brightness setting is set too low:

• Bring the IPC in a low ambient light environment

• Lighten the display with a bright flashlight

Product Information

Version Information

The Version Information part supplies version details of the software and of the selected monitor.

Software details:

• The version of the Industrial Monitor Utility

The version of the Industrial Monitor API

•

Monitor details:

• The Hardware version of the monitor

• The version of the Firmware Software installed on the monitor

• The version of the Touch Firmware installed on the monitor

3-12

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 47

3 Software

Touch Input Settings

The Touch Input Settings display the actual settings.

• Point

Set to Single the monitor accepts only one touch point.

Set to Multiple allows more touch points simultaneously.

Water Detection

•

When enabled then a message will appear to inform the user when water is detected.

When disabled then no message will appear when water is detected.

• Mouse Emulation

When mouse emulation is enabled the Point setting is disabled and Press and Hold is enabled.

When mouse emulation is disabled the Point setting is enabled and the Press and Hold is disabled.

3-4 Industrial Monitor Utility

3

3-4-1 Industrial Monitor Utility Overview

Additional Information

Do not activate mouse emulation when using multiple industrial monitors in combination with

extended mode.

• Press and Hold

When enabled then a right-click mouse action occurs when holding a touch.

When disabled then holding the touch does not trigger the right-click mouse action.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-13

Page 48

3 Software

Advanced settings gives access to the factory settings and shortcuts to relevant Window settings.

• Restore Factory Defaults button

•

• Pen and Touch

Advanced Settings

Resets all settings of the Industrial Monitor

Tablet PC Settings

Opens the ‘Tablet PC Settings’-dialog of Windows.

Opens the ‘Pen and Touch’-dialog of Windows.

to the factory defaults.

3-14

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 49

3 Software

3-4-2

3-4-3

Compatibility

This monitor utility can be used on any PC that is connected to an OMRON Industrial Monitor.

This monitor utility can be used with:

Windows 10

•

•

Windows 7

Additional Information

This monitor utility does not support 3rd party monitors.

Installation

The Industrial Monitor Utility is pre-installed on the Industrial PC if it comes with a Windows operating

system installed.

Download the

another Industrial PC.

The Industrial Monitor Utility is installed onto Windows, and can be accessed via the Windows start

menu and the

trial PC Tray Utility.

Industrial Monitor Utility

Industrial PC Tray Utility. Installing the Industrial Monitor Utility will also install the Indus-

the OMRON website for reinstallation or for installation on

from

3-4 Industrial Monitor Utility

3

3-4-2 Compatibility

3-4-4

Additional Information

Refer to 3-7 Industrial PC Tray Utility

on page 3-25 for Industrial PC Tray Utility details.

Startup

The Industrial Monitor Utility can be started from:

Windows Start Menu.

•

Select

• Industrial PC Tray Utility

Omron and then Industrial Monitor Utility.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

3-15

Page 50

3 Software

3-4-5

3-4-6

Configuration

The Industrial Monitor Utility can be configured with following options:

Configuration item Description

Language Follows the Windows language configuration when that language is supported for the

Industrial Monitor Utility. The default language English (EN-US) will be used if the language configured in Windows is not supported.

Monitor identification

If enabled, the Status LED indicator on the selected Industrial Monitor will flash for 3

seconds.

To enable:

Open the Windows registry key HKEY_LOCAL_MACHINE\SOFTWARE

1.

\Wow6432Node\Omron\IPC\MonitorConfiguration

2. Set the registry value Indicate to value True.

Messages

The Industrial Monitor Utility can use the Industrial PC Tray Utility to display following messages:

Message

type

Info Connected A new monitor connected

Warning Not Connected Monitor disconnected

Warning Video Disconnected DVI cable disconnected or NY Monitor Link

Warning Serial number: x

Water detected on a monitor

ouch may be rejected

T

Warning No Signal DVI cable connected but no signal detected

Message Description

• USB cable connected

• Monitor powered ON

• USB cable disconnected

• Monitor powered OFF

cable disconnected

Water is detected on monitor x

3-4-7

3-16

Logging

There is logging in the Windows event log of the following utilities:

• Industrial Monitor Utility

In the Windows Event V

• Industrial Monitor Brightness Utility

In the Windows Event Viewer filter for event source IndMonService.

• Industrial PC Support Utility

In the Windows Event Viewer filter for event source IPCServiceHost or OMRON Industrial PC

Support Utility.

Additional Information

Refer to 7-2-4 Windows Event V

iewer filter for event source IndMonService.

iewer on page 7-29 for the logged messages.

NY-series Industrial PC Operating Systems and Software Utilities Manual (W616)

Page 51

A

B

3 Software

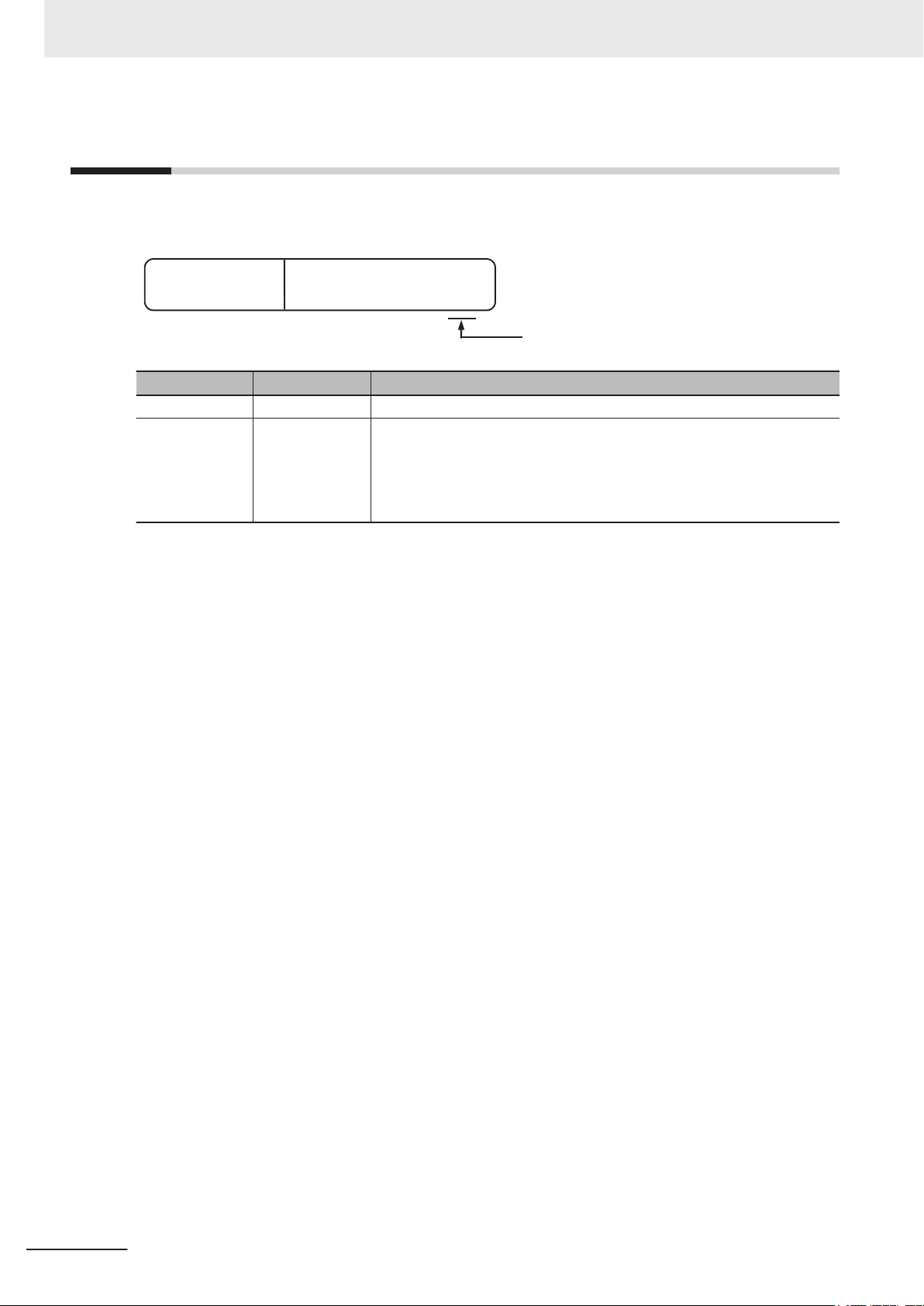

3-5

3-5-1

Industrial Monitor Brightness Utility

This section provides an overview of the Industrial Monitor Brightness Utility.

Industrial Monitor Brightness Utility

The Industrial Monitor Brightness Utility is a software utility that allows you to control the brightness of

the screen backlight of all connected Industrial Monitors.

3-5 Industrial Monitor Brightness Utility

3

3-5-1 Industrial Monitor Brightness Utility

3-5-2

Item Description Details

A Backlight brightness slider Use the slider to control the display brightness of all connected Industrial

Monitors.

B Industrial Monitor Utility Button to start the Industrial Monitor Utility.

With a very low backlight brightness setting (15%-0%) the displayed information might not be visible in

an environment with high ambient light conditions. This prevents brightness adjustments with the In-

dustrial Monitor Brightness Utility

Additional Information

To adjust the backlight brightness when the brightness setting is set too low:

• Bring the IPC in a low ambient light environment

Lighten the display with a bright flashlight

•

.

Compatibility

This monitor utility can be used on any PC that is connected to an OMRON Industrial Monitor.

This monitor utility can be used with:

• Windows 10

Windows 7

•