Page 1

Industrial PC Platform

NY-series

IPC Machine Controller

Industrial Box PC

Hardware User's Manual

NY512-1500-1XX£13££X

NY512-1400-1XX£13££X

NY512-1300-1XX£13££X

Industrial Box PC

W556-E2-04

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or other-

wise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information contained

in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publica-

tion.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Windows, Visual Basic and V

soft Corporation in the USA and other countries.

isual Studio are either registered trademarks or trademarks of Micro-

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

• Intel, the Intel Logo, Celeron and Intel Core are trademarks or registered trademarks of Intel Corpo-

ration or its subsidiaries in the USA and other countries.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the IPC Machine Controller.

This manual contains information that is necessary to use the IPC Machine Controller. Please read

this manual and make sure you understand the functionality and performance of the Box PC before

attempting to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Part of the specifications and restrictions for the IPC Machine Controller are available in other man-

uals.

Refer to Relevant Manuals on page 2 and Related Manuals on page 32.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing Factory Automation systems.

• Personnel in charge of designing Factory Automation systems.

• Personnel in charge of installing and maintaining Factory Automation systems.

• Personnel in charge of managing Factory Automation systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3.

Introduction

Applicable Products

This manual covers following Industrial Box PC with Machine Automation Control Software configura-

tions:

NY512-1500-1XX£13££X

NY512-1400-1XX£13££X

NY512-1300-1XX£13££X

Additional Information

Refer to 1-4 Product Configuration on page

1 - 6 for configuration details.

NY-series Industrial Box PC Hardware User's Manual (W556)

1

Page 4

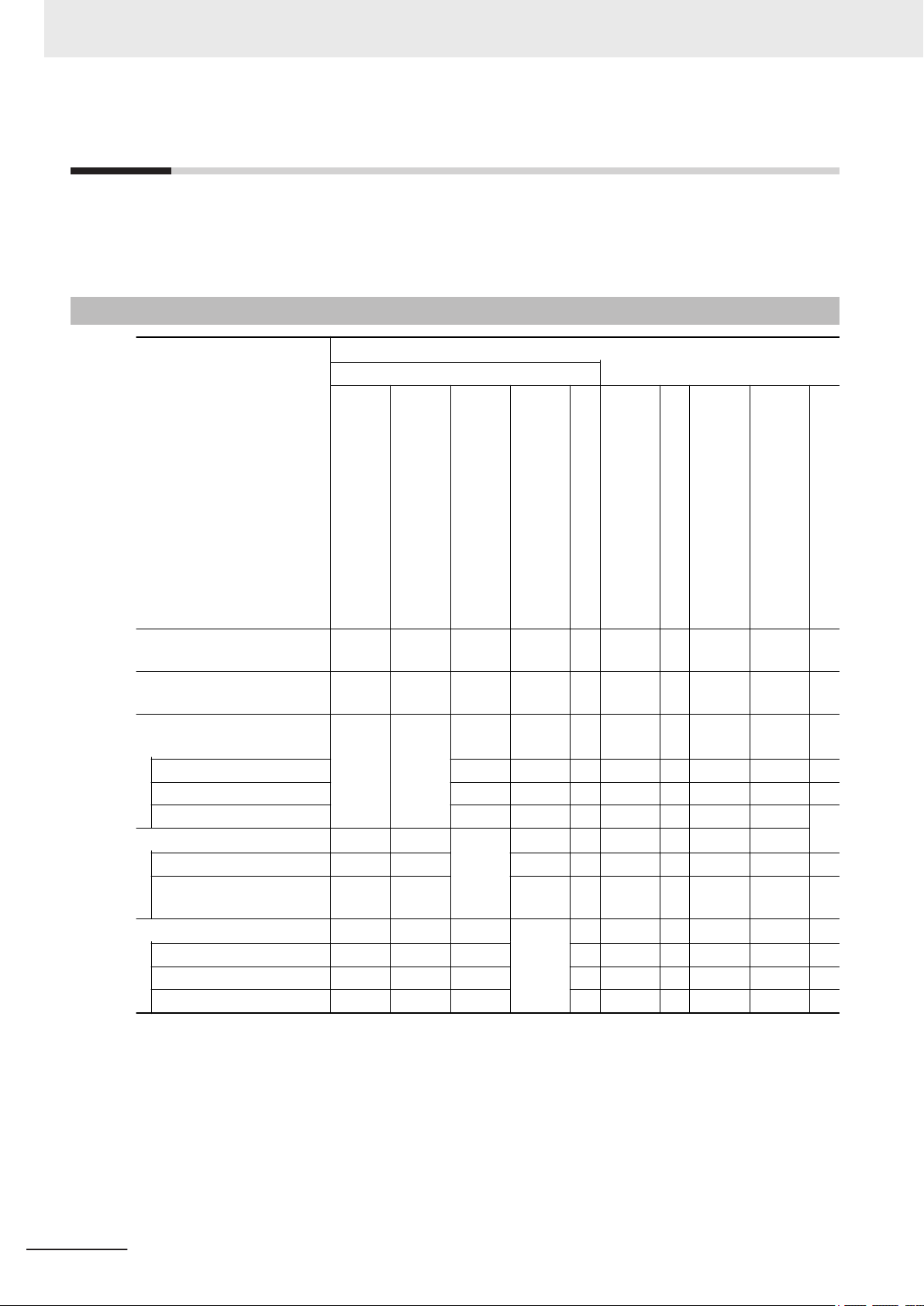

Relevant Manuals

Relevant Manuals

The following sections provide the relevant manuals for the IPC Machine Controller.

Read all of the manuals that are relevant to your system configuration and application before you use

the IPC Machine Controller.

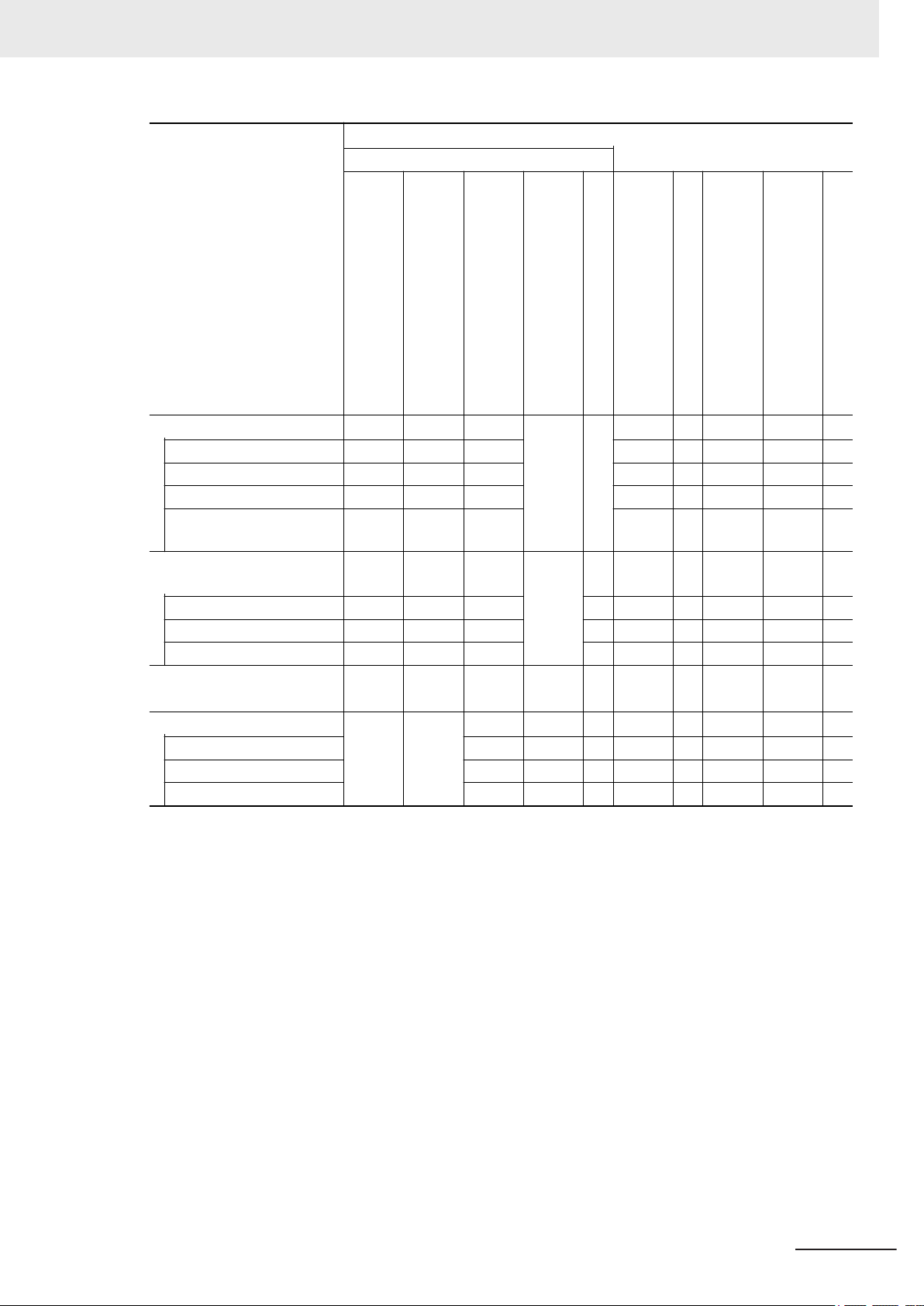

Overview Relevant Manuals

Basic Information

Industrial Panel PC

Hardware User's Manual

Purpose of use

NY-series

IPC Machine Controller

NY-series

IPC Machine Controller

Industrial Box PC

Hardware User's Manual

IPC Machine Controller

Industrial Panel PC

Setup User's Manual

/ Industrial Box PC

Manual

NY-series

NY-series

IPC Machine Controller

Industrial Panel PC

Software User's Manual

/ Industrial Box PC

NY-series

Instructions Reference Manual

Motion Control User's Manual

NY-series

IPC Machine Controller

Industrial Panel PC

/ Industrial Box PC

NY-series Motion Control

Instructions Reference Manual

NY-series

IPC Machine Controller

Industrial Panel PC

Built-in EtherCAT Port User's Manual

/ Industrial Box PC

NY-series

IPC Machine Controller

Industrial Panel PC

Built-in EtherNet/IP Port User's Manual

/ Industrial Box PC

NY-series

T

roubleshooting Manual

Introduction to NY-series

Panel PC

Introduction to NY-series Box

PC

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Making setup

Making initial settings

Preparing to use Controllers

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

l

l l

l

l

l

l

l

l

l

l

l

2

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 5

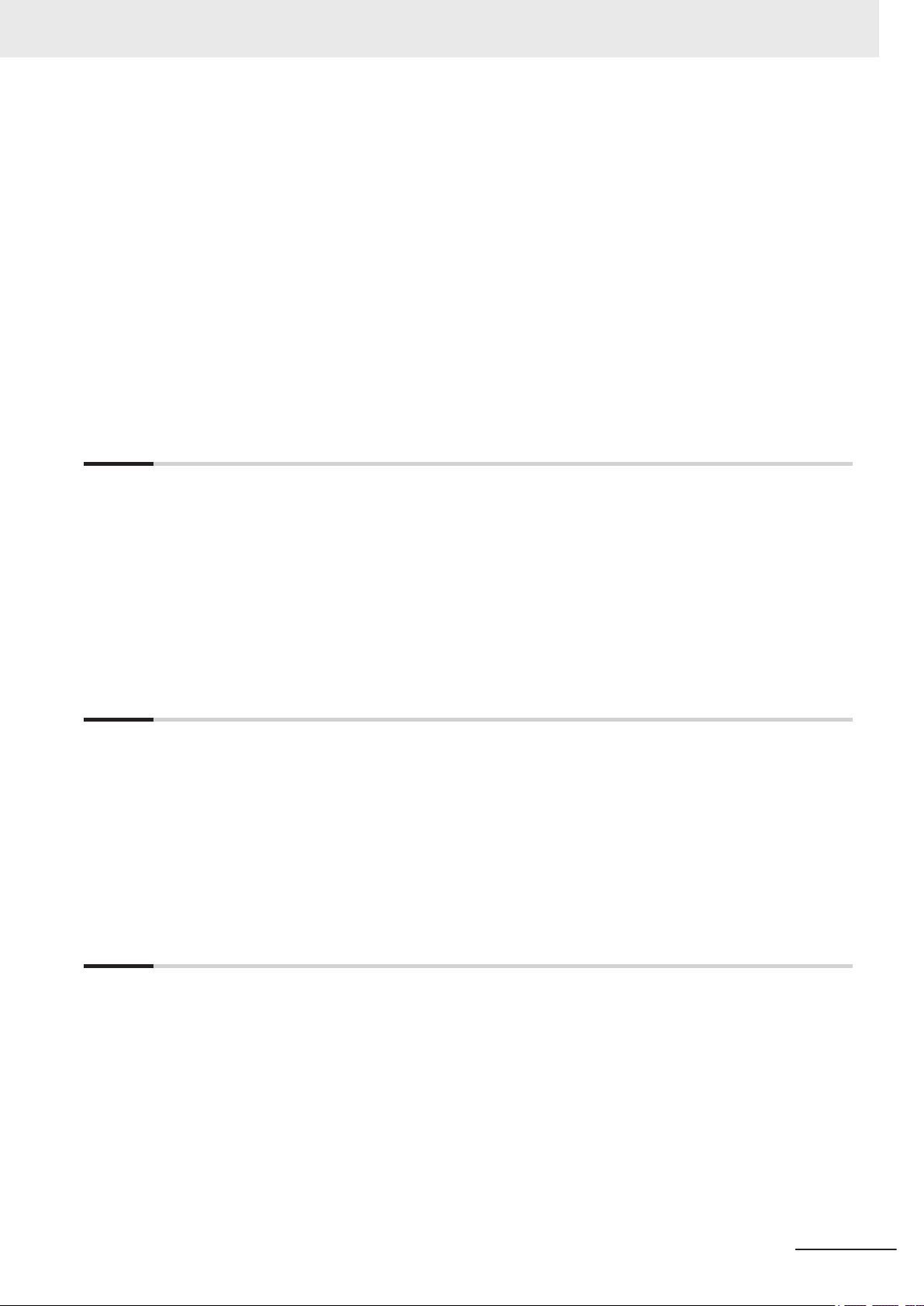

Basic Information

NY-series

IPC Machine Controller

Industrial Panel PC

Hardware User's Manual

NY-series

IPC Machine Controller

Industrial Box PC

Hardware User's Manual

Industrial Panel PC / Industrial Box PC

Setup User's Manual

Manual

NY-series

IPC Machine Controller

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Software User's Manual

NY-series

Instructions Reference Manual

Motion Control User's Manual

Relevant Manuals

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

NY-series Motion Control

Instructions Reference Manual

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherCA

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherNet/IP Port User's Manual

NY-series

Troubleshooting Manul

Purpose of use

Writing the user program

Using motion control

Using EtherCAT

Using EtherNet/IP

Programming error processing

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Learning about error man-

agement and corrections

Maintenance

Using motion control

Using EtherCAT

Using EtherNet/IP

*1. Refer to the NY

overview of the error items. Refer to the manuals that are indicated with triangles for details on errors for the

corresponding Units.

*1

-series Troubleshooting Manual (Cat. No. W564) for the error management concepts and an

p p p p p p l

l l

l

l l

l

l l

l

l

T Port User's Manual

l

l

l

l

l

l

l

NY-series Industrial Box PC Hardware User's Manual (W556)

3

Page 6

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience

Applicable Products ......................................................................................................................................... 1

Relevant Manuals..................................................................................................... 2

Overview Relevant Manuals ............................................................................................................................ 2

Manual Information.................................................................................................. 9

Page Structure.................................................................................................................................................9

Special Information ........................................................................................................................................ 10

Terms and Conditions Agreement........................................................................ 11

Warranty and Limitations of Liability .............................................................................................................. 11

Application Considerations ............................................................................................................................12

Disclaimers ....................................................................................................................................................12

...........................................................................................................................................1

Safety Precautions................................................................................................. 14

Definition of Precautionary Information.......................................................................................................... 14

Symbols ......................................................................................................................................................... 14

Warnings........................................................................................................................................................ 15

Cautions......................................................................................................................................................... 17

Precautions for Safe Use ...................................................................................... 18

Disassembly, Dropping, Mounting, Installation and Storage .........................................................................18

Wiring............................................................................................................................................................. 18

Power Supply Design and Turning ON/OFF the Power Supply.....................................................................18

Actual Operation ............................................................................................................................................ 19

Operation ....................................................................................................................................................... 19

General Communications ..............................................................................................................................20

EtherNet/IP Communications ........................................................................................................................20

EtherCAT Communications............................................................................................................................20

Motion Control ...............................................................................................................................................21

Restoring Data...............................................................................................................................................22

Battery Replacement .....................................................................................................................................22

Product Replacement ....................................................................................................................................23

Cleaning, Maintenance and Disposal ............................................................................................................23

Precautions for Correct Use ................................................................................. 24

Storage, Installation and Mounting ................................................................................................................24

Wiring............................................................................................................................................................. 24

Actual Operation and Operation ....................................................................................................................25

Error Processing ............................................................................................................................................ 25

Restoring Data...............................................................................................................................................26

Task Settings .................................................................................................................................................26

Motion Control ...............................................................................................................................................26

EtherCAT Communications............................................................................................................................26

Battery Replacement .....................................................................................................................................26

SD Memory Cards .........................................................................................................................................27

Regulations and Standards .................................................................................. 28

Conformance to EU Directives ......................................................................................................................28

Conformance to KC Standards......................................................................................................................29

Conformance to UL and CSA Standards.......................................................................................................29

Software Licenses and Copyrights ................................................................................................................29

Versions.................................................................................................................. 30

Check Unit Versions ......................................................................................................................................30

4

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 7

CONTENTS

Check Hardware Revision .............................................................................................................................30

Related Manuals

Related IPC Machine Controller Manuals...................................................................................................... 32

Related Products Manuals............................................................................................................................. 34

..................................................................................................... 32

Terminology and Abbreviations ........................................................................... 35

Industrial PC Platform ...................................................................................................................................35

Hardware ......................................................................................................................................................35

Software......................................................................................................................................................... 36

Revision History..................................................................................................... 37

Sections in this Manual ......................................................................................... 39

Section 1 Introduction to the Industrial Box PC

1-1 Intended Use ........................................................................................................................1 - 2

1-2

Features ................................................................................................................................ 1 - 3

1-2-1 Hardware Features ...................................................................................................................1 - 3

1-2-2 Machine Controller Software Features......................................................................................1 - 4

1-3 ID Information Label ............................................................................................................1 - 5

1-3-1 Label with Controller License (Optional) ...................................................................................1 - 5

1-4 Product Configuration.........................................................................................................1 - 6

1-5 Overall Operating Procedure..............................................................................................1 - 7

Section 2 System Configurations

2-1 Basic Configurations...........................................................................................................2 - 2

2-2

EtherCAT Network Configuration.......................................................................................2 - 3

2-2-1 Related EtherCAT Hardware.....................................................................................................2 - 4

2-3 EtherNet/IP Network Configuration....................................................................................2 - 5

2-3-1 Related EtherNet/IP Hardware..................................................................................................2 - 5

2-4 Connection with the Sysmac Studio..................................................................................2 - 7

2-4-1 Configurations That Allow Online Connections.........................................................................2 - 7

2-4-2 Configurations That Do Not Allow Online Connections.............................................................2 - 8

Section 3 Hardware Overview

3-1 Component Names and Functions.....................................................................................3 - 3

3-1-1 Front and Top of the Industrial Box PC .....................................................................................3 - 3

3-1-2 Back of the Industrial Box PC ...................................................................................................3 - 6

3-2 LED Indicators......................................................................................................................3 - 7

3-2-1 PWR LED Indicator ...................................................................................................................3 - 7

3-2-2 ERR LED Indicator....................................................................................................................3 - 8

3-2-3 HDD LED Indicator....................................................................................................................3 - 8

3-2-4 RUN LED Indicator....................................................................................................................3 - 8

3-3 Power Button........................................................................................................................3 - 9

3-4 Drive Bays ..........................................................................................................................3 - 10

3-5 SD Memory Card Slot ........................................................................................................3 - 11

3-6 PCIe Card Slot....................................................................................................................3 - 12

NY-series Industrial Box PC Hardware User's Manual (W556)

5

Page 8

CONTENTS

3-7 Connectors.........................................................................................................................3 - 13

3-8 Spare Parts.........................................................................................................................3 - 18

3-9 Optional Hardware.............................................................................................................3 - 20

3-7-1

3-7-2 I/O Connector..........................................................................................................................3 - 13

3-7-3 USB Connectors .....................................................................................................................3 - 14

3-7-4 Ethernet Connectors ...............................................................................................................3 - 15

3-7-5 DVI Connector.........................................................................................................................3 - 15

3-7-6 RS-232C Connector (Optional) ...............................................................................................3 - 16

3-7-7 DVI-D Connector (Optional) ....................................................................................................3 - 16

3-7-8 NY Monitor Link Connector (Optional) ....................................................................................3 - 17

3-8-1 Battery.....................................................................................................................................3 - 18

3-8-2 Fan Unit...................................................................................................................................3 - 18

3-8-3 Accessory Kit ..........................................................................................................................3 - 19

3-9-1 Mounting Brackets ..................................................................................................................3 - 20

3-9-2 SD Memory Cards...................................................................................................................3 - 20

3-9-3 USB Flash Drives....................................................................................................................3 - 21

3-9-4 Storage Devices......................................................................................................................3 - 21

3-9-5 DVI Cables ..............................................................................................................................3 - 22

3-9-6 USB Type-A to USB Type-B Cables .......................................................................................3 - 22

3-9-7 NY Monitor Link Cables ..........................................................................................................3 - 23

3-9-8 Industrial Monitor ....................................................................................................................3 - 24

3-9-9 Power Supply ..........................................................................................................................3 - 24

3-9-10 UPS.........................................................................................................................................3 - 25

3-9-11 UPS Communication Cable ....................................................................................................3 - 25

Power Connector ....................................................................................................................3 - 13

Section 4 Specifications

4-1 General Specifications ....................................................................................................... 4 - 2

4-1-1

4-1-2 General Electrical Specifications...............................................................................................4 - 3

4-1-3 Power Consumption Specifications...........................................................................................4 - 3

4-1-4 CPU Specifications ...................................................................................................................4 - 4

4-1-5 Memory Specifications ..............................................................................................................4 - 4

4-1-6 Storage Device Specifications ..................................................................................................4 - 5

4-1-7 PCIe Card Specifications ..........................................................................................................4 - 7

4-1-8 Bracket Specifications...............................................................................................................4 - 8

4-2 Connector Specifications ...................................................................................................4 - 9

4-2-1 Power Connector Specifications ...............................................................................................4 - 9

4-2-2 I/O Connector Specifications...................................................................................................4 - 10

4-2-3 USB Connector Specifications ................................................................................................4 - 14

4-2-4 Ethernet Connector Specifications..........................................................................................4 - 15

4-2-5 DVI Connector Specifications .................................................................................................4 - 19

4-2-6 DVI-D Connector Specifications..............................................................................................4 - 20

4-2-7 RS-232C Connector Specifications.........................................................................................4 - 21

4-2-8 NY Monitor Link Connector Specifications..............................................................................4 - 21

4-3 Environmental Specifications...........................................................................................4 - 23

4-3-1 Operation Environment Specifications ....................................................................................4 - 23

4-3-2 Temperature and Humidity Specifications...............................................................................4 - 24

4-3-3 Recycling Specifications .........................................................................................................4 - 26

Dimensions and Weight ............................................................................................................4 - 2

Section 5 Installation

5-1 Unpack..................................................................................................................................5 - 2

5-1-1

5-1-2 Items Supplied ..........................................................................................................................5 - 3

5-2 Install Options......................................................................................................................5 - 5

5-2-1 Install a Drive ............................................................................................................................5 - 5

6

Unpack Procedure ....................................................................................................................5 - 2

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 9

CONTENTS

5-2-2 Install the PCIe Card .................................................................................................................5 - 9

5-3

Mount ..................................................................................................................................5 - 14

5-3-1 Installation Method in Control Panels......................................................................................5 - 14

5-3-2 Product Orientation .................................................................................................................5 - 15

5-3-3 Temperature ............................................................................................................................5 - 15

5-3-4 Humidity ..................................................................................................................................5 - 18

5-3-5 Vibration and Shock ................................................................................................................5 - 18

5-3-6 Atmosphere.............................................................................................................................5 - 19

5-3-7 Electrical Environment ............................................................................................................5 - 19

5-3-8 Book Mount Procedure ...........................................................................................................5 - 24

5-3-9 Wall Mount Procedure.............................................................................................................5 - 25

5-4 Wire .....................................................................................................................................5 - 26

5-4-1 Wiring Warnings and Cautions................................................................................................5 - 26

5-4-2 Ground ....................................................................................................................................5 - 27

5-4-3 Wire the Power Connector ......................................................................................................5 - 34

5-4-4 Wire the I/O Connector ...........................................................................................................5 - 37

5-5 Connect...............................................................................................................................5 - 40

5-5-1 Connector Identification ..........................................................................................................5 - 41

5-5-2 Connection Procedure ............................................................................................................5 - 42

5-5-3 Ethernet Connection Procedure..............................................................................................5 - 44

5-5-4 Connect UPS ..........................................................................................................................5 - 45

5-6 Initial Power ON .................................................................................................................5 - 48

5-6-1 Initial Power ON Procedure.....................................................................................................5 - 48

Section 6 Operating Procedures

6-1 Power ON..............................................................................................................................6 - 2

6-1-1

6-1-2 Power ON Using the Power ON/OFF Input...............................................................................6 - 2

6-1-3 Power ON Using Safe Mode .....................................................................................................6 - 3

6-1-4 Auto Power ON .........................................................................................................................6 - 3

Power ON Using the Power Button...........................................................................................6 - 2

6-2 Power OFF............................................................................................................................6 - 4

6-2-1 Power OFF Using the Power Button .........................................................................................6 - 4

6-2-2 Power OFF Using the Power ON/OFF Input.............................................................................6 - 4

6-2-3 Forced Power OFF Using the Power Button.............................................................................6 - 5

Section 7 Maintenance

7-1 Preventive Maintenance......................................................................................................7 - 2

7-1-1

7-1-2 Clean the Box PC......................................................................................................................7 - 3

7-2 Corrective Maintenance ......................................................................................................7 - 4

7-2-1 Remove the Cover ....................................................................................................................7 - 4

7-2-2 Replace the Fan Unit ................................................................................................................7 - 5

7-2-3 Replace the Battery...................................................................................................................7 - 7

7-2-4 Replace a Drive.........................................................................................................................7 - 9

7-2-5 Replace the PCIe Card ...........................................................................................................7 - 14

Preventive Maintenance Schedule............................................................................................7 - 2

Appendices

A-1 BIOS ..................................................................................................................................... A - 2

A-1-1 BIOS Overview......................................................................................................................... A - 2

A-1-2 BIOS - Main.............................................................................................................................. A - 4

A-1-3 BIOS - Advanced ..................................................................................................................... A - 5

A-1-4 BIOS - Chipset ......................................................................................................................... A - 8

A-1-5 BIOS - Boot .............................................................................................................................. A - 9

NY-series Industrial Box PC Hardware User's Manual (W556)

7

Page 10

CONTENTS

A-2 Allocate a Drive in Windows ............................................................................................ A - 11

A-3 DVI Connector Pin Details................................................................................................ A - 12

A-4 RS-232C Connector Pin Details....................................................................................... A - 15

Index

A-1-6 BIOS - Security ...................................................................................................................... A - 10

A-1-7

A-3-1 DVI-I Connector Pin Details ................................................................................................... A - 12

A-3-2 DVI-D Connector Pin Details.................................................................................................. A - 13

BIOS - Save & Exit................................................................................................................. A - 10

8

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 11

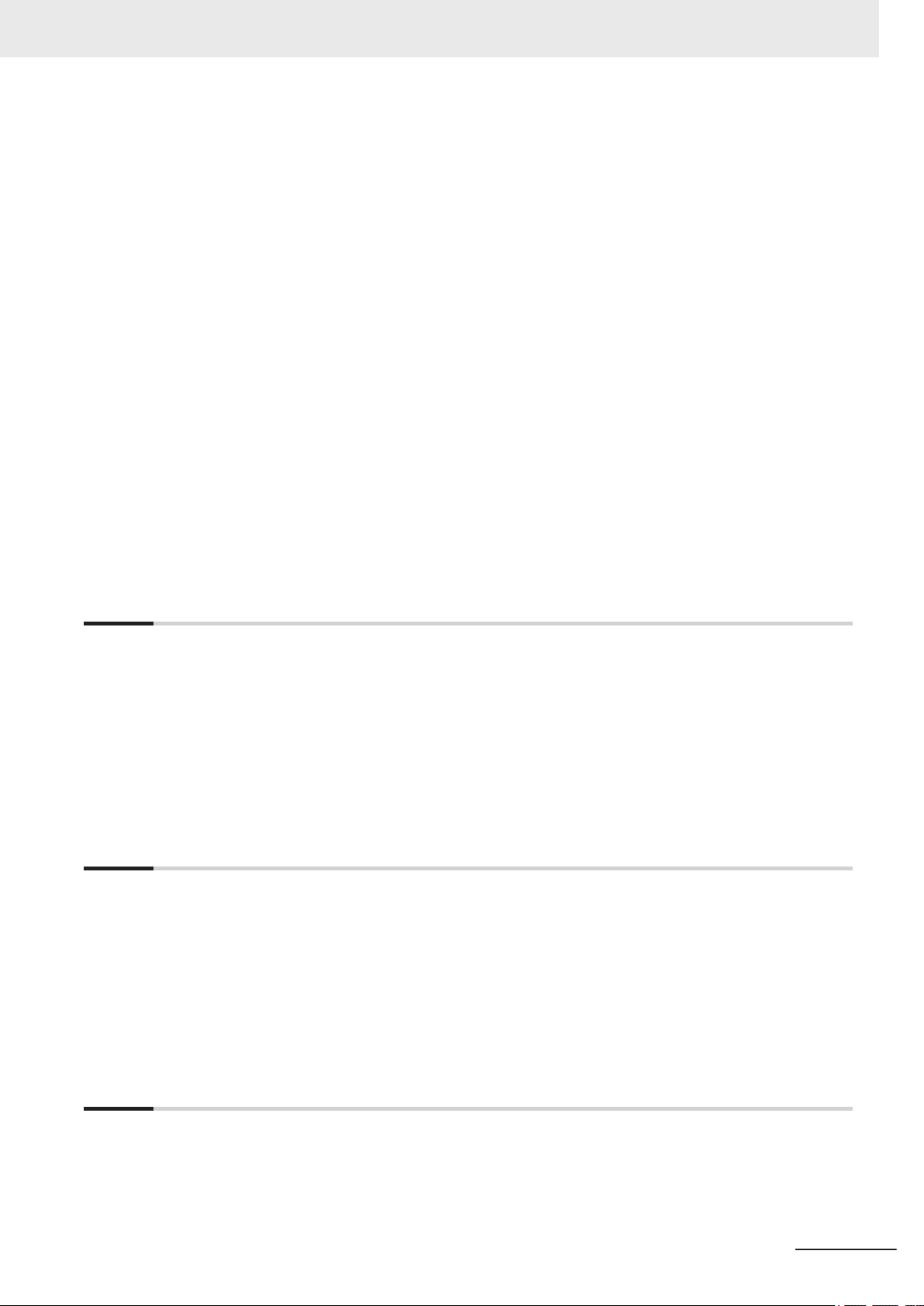

Manual Information

A

B

C

E

F

B

C

H

5 Installation

5 - 3

N

Y-series User's Manual (W555)

5-1 Unpack

5

5-1-1 Unpack Procedure

G

5-1

Unpack

This section provides details on how to unpack the Industrial Panel PC.

5-1-1

Unpack Procedure

1 Check the package for damage.

If there is any visible damage:

• Take photos of the package and save them.

• Inform your supplier immediately.

2 Open the package.

Ensure not to damage the contents.

3 Ensure that all items are present.

Additional Information

Refer to 5-1-2 Items Supplied with the Product

for the items supplied.

This section provides information about this manual.

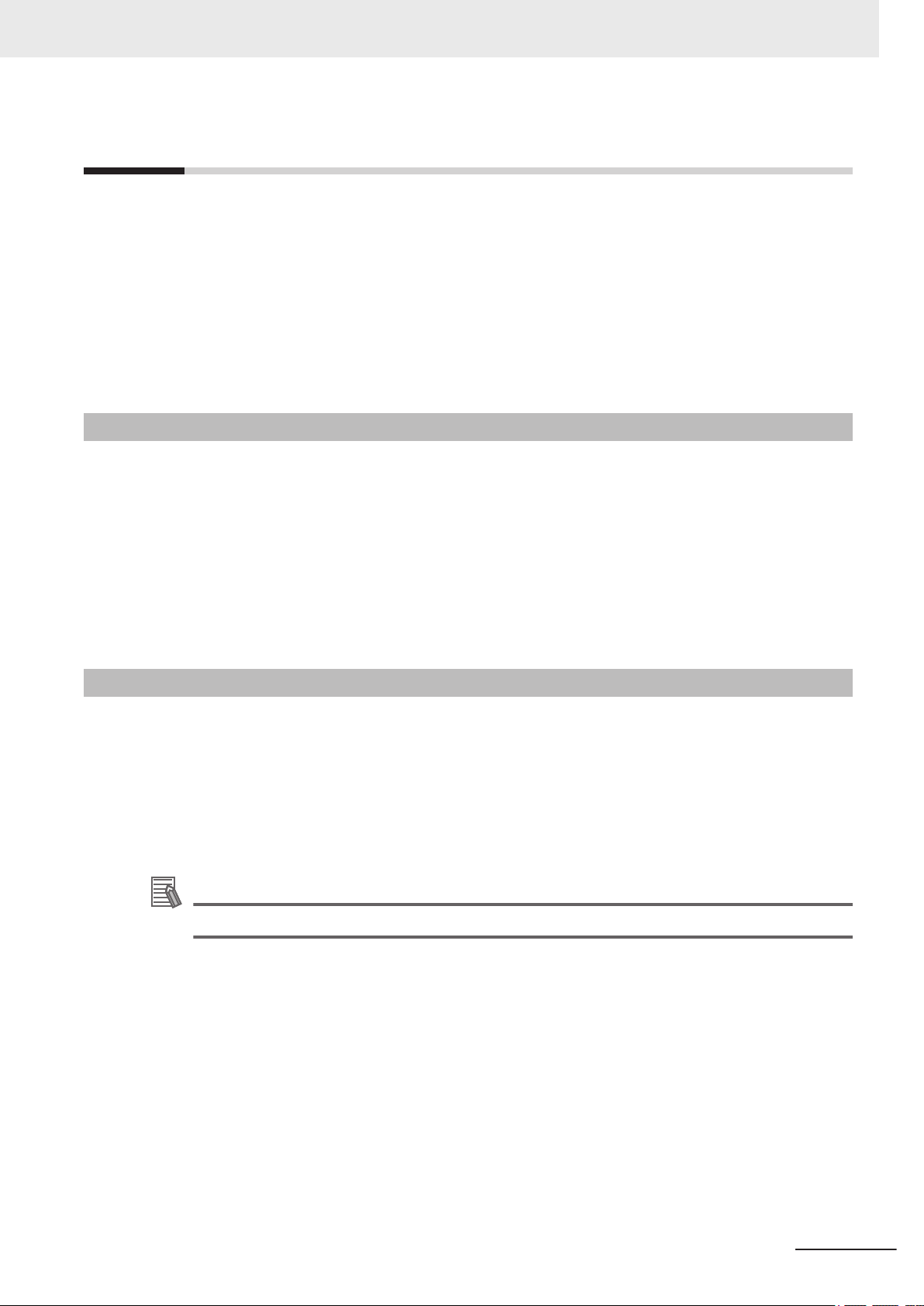

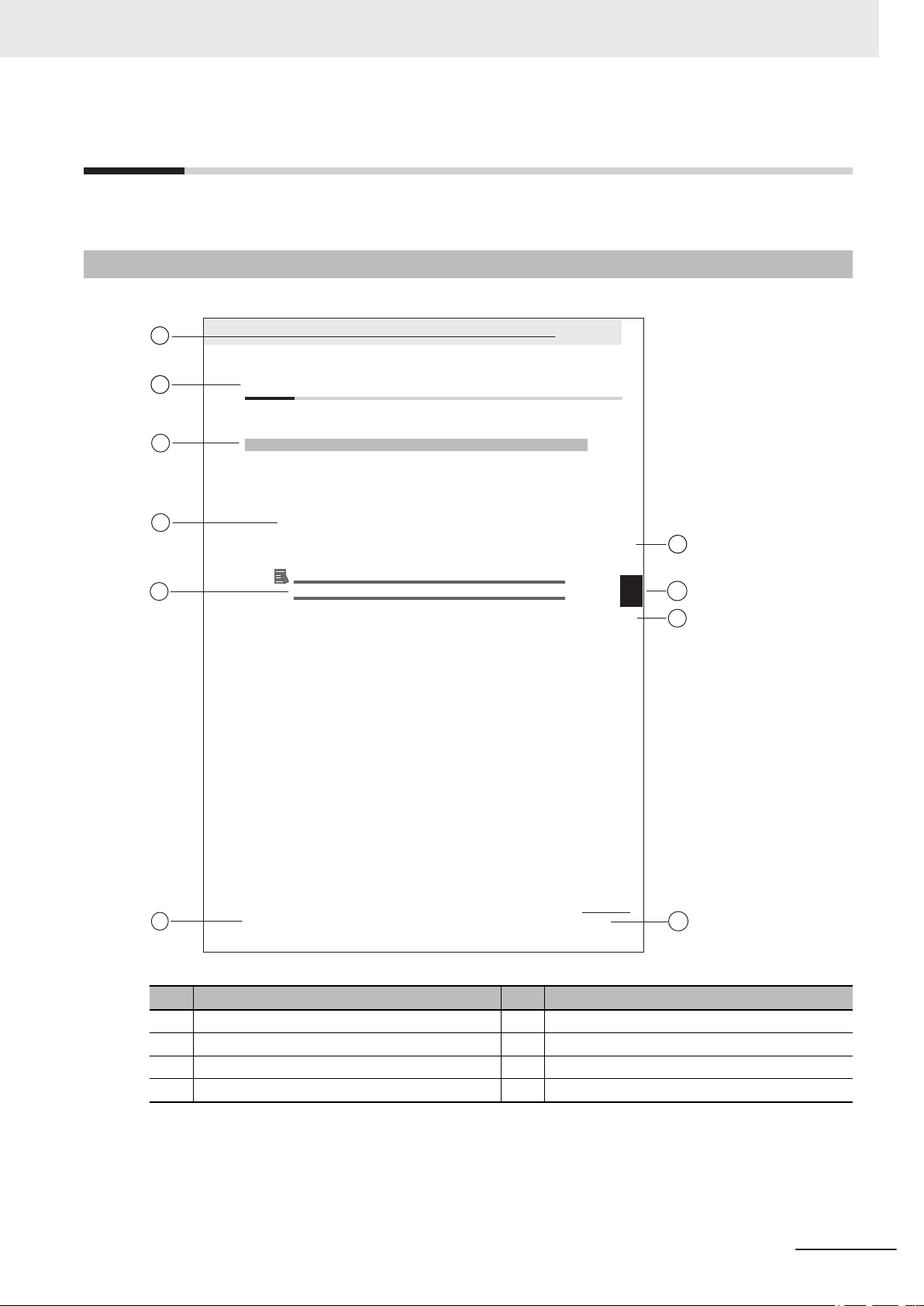

Page Structure

The following page structure is used in this manual.

Manual Information

Note: This illustration is provided as a sample. It will not literally appear in this manual.

Item Explanation Item Explanation

A Level 1 heading E Special Information

B Level 2 heading F Manual name

C Level 3 heading G Page tab with the number of the main section

D Step in a procedure H Page number

NY-series Industrial Box PC Hardware User's Manual (W556)

9

Page 12

Manual Information

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier

Version Information

.

Information on differences in specifications and functionality between different versions.

10

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 13

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty and Limitations of Liability

Warranty

• Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workman-

ship for a period of twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, expressed or implied.

• Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

• Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products un-

less Omron’s analysis confirms that the Products were properly handled, stored, installed and main-

tained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any

Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in combination

with any electrical or electronic components, circuits, system assemblies or any other materials or

substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitations of Liability

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY. Further, in no event shall liability of Omron Com-

panies exceed the individual price of the Product on which liability is asserted.

NY-series Industrial Box PC Hardware User's Manual (W556)

11

Page 14

Terms and Conditions Agreement

Application Considerations

Suitability for Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND IN-

STALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

’s application or use of the Product. At Buy-

Programmable Products

• Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

•

Omron Companies shall not be responsible for the operation of the user accessible operating sys-

tem (e.g. Windows, Linux), or any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

. It may represent the result of

12

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

NY-series Industrial Box PC Hardware User's Manual (W556)

, some specifications of the Product may

Page 15

Terms and Conditions Agreement

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever

, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NY-series Industrial Box PC Hardware User's Manual (W556)

13

Page 16

Safety Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the IPC Machine Controller. The safety precautions that are provided are extremely important to safe-

ty.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoid-

WARNING

Caution

ed, could result in death or serious injury

may be severe property damage.

Indicates a potentially hazardous situation which, if not avoid-

ed, may result in minor or moderate injury

. Additionally, there

, or property damage.

Symbols

The circle and slash symbol indicates operations that you must not do. The

specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly

The triangle symbol indicates precautions (including warnings). The specific

operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings). The specific

operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do. The specific

operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

.

14

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 17

Warnings

Disassembly and Dropping

Do not attempt to disassemble, repair, or modify the product in any way. Doing so may result in malfunction or fire.

Installation

Always connect to a ground of 100 Ω or less when installing the product.

Safety Precautions

WARNING

Ensure that installation and post-installation checks of the product are performed by personnel in charge who possess a thorough understanding of

the machinery to be installed.

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if

an abnormality occurs due to malfunction of the product or due to other external factors af

dents due to incorrect operation.

Emergency stop circuits, interlock circuit, limit circuits, and similar safety

measures must be provided in external control circuits.

The product will turn OFF all outputs from Output Units in the following cases. The slaves will operate according to the settings in the slaves.

• If an error occurs in the power supply

• If a CPU watchdog timer error or CPU reset occurs

• If a major fault level Controller error occurs

• While the product is on standby until RUN mode is entered after the pow-

er is turned ON

• If a system initialization error occurs

External safety measures must be provided to ensure safe operation of the

system in such cases.

If external power supplies for slaves or other devices are overloaded or

short-circuited, the voltage will drop, outputs will turn OFF

may be unable to read inputs. Provide external safety measures in controls

with monitoring of external power supply voltage as required so that the system operates safely in such a case.

Unintended behavior may occur when an error occurs in internal memory of

the product. As a countermeasure for such problems, external safety measures must be provided to ensure safe operation of the system.

fecting operation. Not doing so may result in serious acci-

, and the system

NY-series Industrial Box PC Hardware User's Manual (W556)

15

Page 18

Safety Precautions

Provide measures in the communications system and user program to ensure safety in the overall system even if errors or malfunctions occur in data

link communications or remote I/O communications.

If there is interference in remote I/O communications or if a major fault level

error occurs, output status will depend on the products that are used. Confirm the operation that will occur when there is interference in communications or a major fault level error

of the settings in the slaves and Units.

The use of an uninterruptible power supply (UPS) allows normal operation

to continue even if a momentary power failure occurs, possibly resulting in

the reception of an erroneous signal from an external device affected by the

momentary power failure. Take external fail-safe measures. Where necessary, monitor the power supply voltage on the system for external devices

and use it as an interlock condition.

Downloading

, and implement safety measures. Adjust all

Always confirm safety at the destination before you transfer a user program,

configuration data, setup data, or device variables from the Sysmac Studio.

The devices or machines may perform unexpected operation regardless of

the operating mode of the product.

Actual Operation

Check the user program, data, and parameter settings for proper execution

before you use them for actual operation.

Security setting adjustments should only be performed by the engineer in

charge that possesses a thorough understanding of the security settings.

Selecting non-recommended security settings can put your system at risk.

Changing BIOS information is only allowed for the engineer in charge that

possesses a thorough understanding of the BIOS settings because it can

change the behavior of the product.

16

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 19

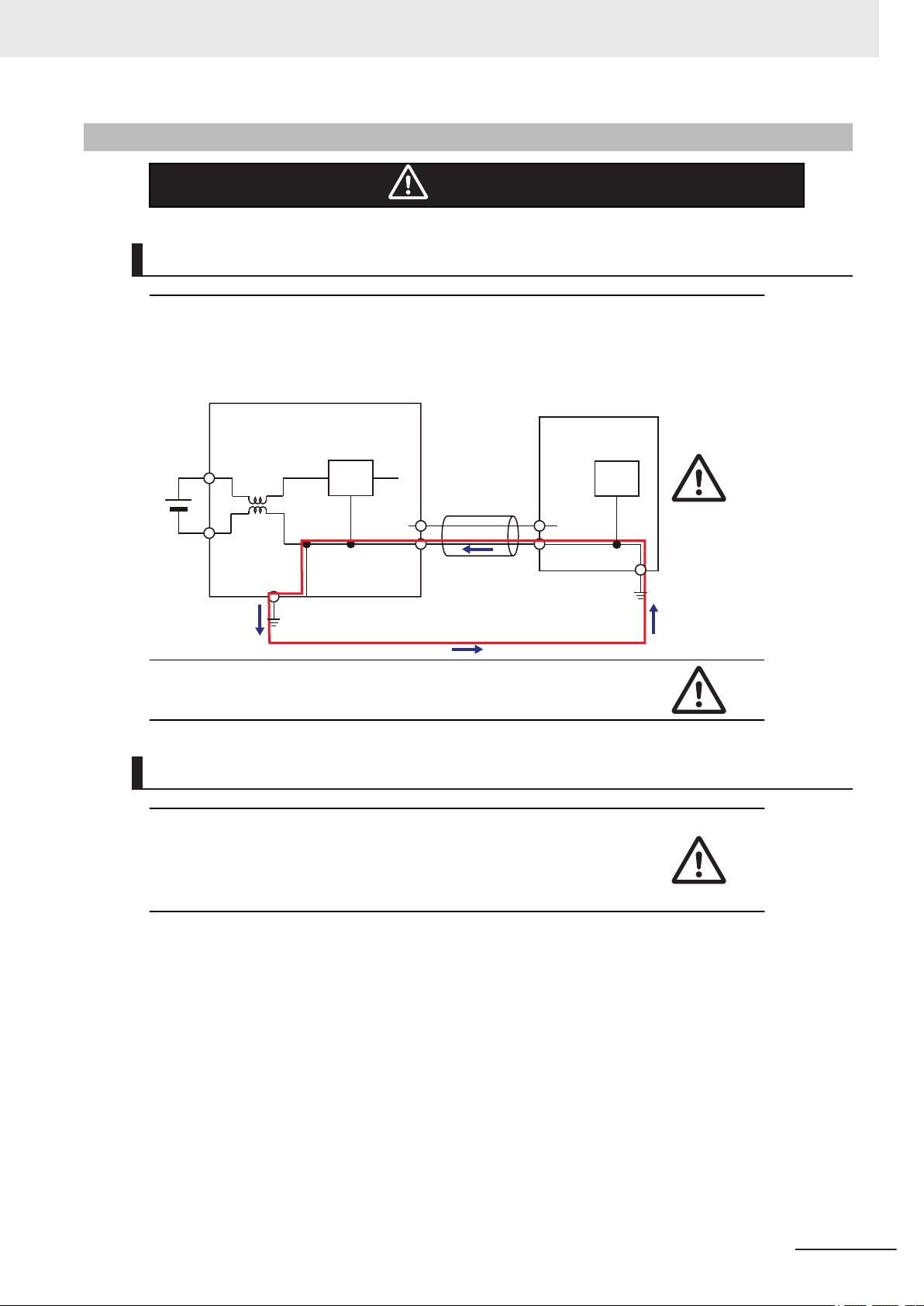

Cautions

Industrial PC Platform Product

Non-isolated

Device

Non-isolated

Interface

24 VDC

0 VDC

Wiring

The product has an internal non-isolated DC power supply. Circuit ground (0

VDC) and frame ground are connected together. When connecting a nonisolated device or a non-isolated interface to the product, take appropriate

actions to avoid communication failures or damage to the mentioned ports.

Safety Precautions

Caution

Never ground the 24 VDC side of the power supply. This may cause a short

circuit.

Online Editing

Execute online editing only after confirming that no adverse effects will be

caused by deviations in the timing of I/O. If you perform online editing, the

task execution time may exceed the task period, I/O may not be refreshed

with external devices, input signals may not be read, and output timing may

change.

NY-series Industrial Box PC Hardware User's Manual (W556)

17

Page 20

Precautions for Safe Use

Precautions for Safe Use

Disassembly, Dropping, Mounting, Installation and Storage

• Do not drop the product or subject it to abnormal vibration or shock. Doing so may result in product

malfunction or burning.

• When unpacking, check carefully for any external scratches or other damages. Also, shake the

product gently and check for any abnormal sound.

• Always use the devices specified in the relevant manual.

• The product must be installed in a control panel.

• Always install equipment that is included in the product specifications. Not doing so may result in

failure or malfunction.

• If the storage period exceeds 6 months, check the performance of the Fan Unit before production

starts.

• Install the product in the correct orientation and temperature according to the specifications in the

manual to prevent overheating. Not doing so may result in malfunction.

• When connecting peripheral devices to the product, ensure sufficient countermeasures against

noise and static electricity during installation of the peripheral devices.

Wiring

• Follow the instructions in the manual to correctly perform connector wiring and insertion. Double-

• Always ensure connectors, cables, PCIe Cards and Storage devices are completely locked in place

• Before you connect a computer to the product, disconnect the power supply plug of the computer

• Do not bend or pull the cables beyond normal limit. Do not place heavy objects on top of the cables

• Always use power supply wires with sufficient wire diameters to prevent voltage drop and burning.

• Be sure that all mounting bracket screws and cable connector screws are tightened to the torque

• Use crimp terminals for wiring.

• For an NY Monitor Link connection, always follow the cable type and connection method specifica-

check all wiring and connector insertion before turning ON the power supply.

to prevent accidental disconnection.

from the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG

terminal has the same electrical potential as the product. A difference in electrical potential between

the computer and the product may cause failure or malfunction.

or other wiring lines. Doing so may break the cables.

Make sure that the current capacity of the wire is sufficient. Otherwise, excessive heat may be gen-

erated. When cross-wiring terminals, the total current for all the terminals will flow in the wire. When

wiring cross-overs, make sure that the current capacity of each of the wires is not exceeded.

specified in the relevant manuals. The loose screws may result in fire or malfunction.

tions in the manual. Otherwise, communications may be faulty.

Power Supply Design and Turning ON/OFF the Power Supply

• Always use a power supply that provides power within the rated range in the manual.

• Do not perform a dielectric strength test.

18

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 21

Precautions for Safe Use

• Always use the recommended uninterruptable power supply (UPS) to prevent data loss and other

system file integrity issues caused by unexpected power interruption. Back up the system files in the

planned way to prevent data loss and other system file integrity issues caused by incorrect opera-

tion.

•

Use an Omron S8BA UPS with the correct revision number to prevent improper system shutdown.

• It takes up to approximately 10 to 20 s to enter RUN mode after the power is turned ON. The out-

puts during this time behave according to the slave or Output Unit specifications. Implement fail-safe

circuits so that external devices do not operate incorrectly.

• Power ON after the DVI or NY Monitor Link cable is connected between the product and an external

monitor.

• Always check the power supply and power connections before applying power. Incorrect power con-

nections can damage the product or cause burning.

• Always turn OFF the power supply to system before you attempt any of the following.

• Inserting or removing PCIe Cards

• Connecting cables

• Connecting or disconnecting the connectors

• Wiring the system

• Replacing or removing the HDD/SSD

• Replacing the Battery

• Replacing the Fan Unit

Actual Operation

• Choose a OS password that is not obvious to prevent unauthorized access.

Remember the OS user name and password. The product is inaccessible without it.

•

• Before operating the system , please make sure the appropriate software is installed and config-

ured. Doing so may prevent unexpected operation.

• Install all updates and ensure the browser stays up-to-date.

• Install all updates and ensure the firewall stays up-to-date.

• Make sure that your OS environment is protected against malicious software and viruses.

• Install all updates and ensure virus definitions stay up-to-date.

• Do not remove the fan cover while the power is ON. Contact with a rotating fan may result in injury.

• Virtual memory settings can affect the performance of the system. Disable the paging file after in-

stallation of applications or updates.

• Correctly perform wiring and setting, and ensure that the shutdown by the UPS can be executed.

Operation

• Confirm that no adverse effect will occur in the system before you attempt any of following.

Changing the operating mode of the product (including changing the setting of the Startup Mode)

•

• Changing the user program or settings

• Changing set values or present values

• Forced refreshing

• Do not carry out the following operations when accessing a USB device or an SD Memory Card.

• Turn OFF the power supply of the product.

• Press the Power Button of the product.

• Remove a USB device or SD memory card.

NY-series Industrial Box PC Hardware User's Manual (W556)

19

Page 22

Precautions for Safe Use

• If two different function modules are used together, such as when you see PCIe connected board

and EtherCA

that safety is maintained in the controlled system if one of the function modules stops. The relevant

outputs will behave according to the slave or Output Unit specifications if a partial fault level error

occurs in one of the function modules.

• Do not attempt to remove or touch the fan unit while the product is powered ON or immediately after

the power supply is turned OFF. If you attempt to replace the fan unit then, there is a risk of personal

injury due to hot or rotating parts.

• Press the power button for several seconds to force the product shutdown. Always back up files in

the planned way to prevent data loss or system file corruption.

• Do not touch any product housing when power is being supplied or immediately after the power sup-

ply is turned OFF. Doing so may result in burn injury.

• Always confirm safety at the connected equipment before you perform the following operations

when the device output hold configuration is set to enable. The equipment may operate unexpected-

ly because the last status for outputs is retained.

• Changing the operating mode of the product

• When downloaded

T slaves, take suitable measures in the user program and external controls to ensure

General Communications

• Unexpected operation may result if inappropriate data link tables are set. Even if appropriate data

link tables have been set, confirm that the controlled system will not be adversely af

you transfer the data link tables. The data links start automatically after the data link tables are

transferred.

• Separate the machine network segment from the office network to avoid communication failures.

EtherNet/IP Communications

• Make sure that the communications distance, number of nodes connected, and method of connec-

tion for EtherNet/IP are within specifications. Do not connect EtherNet/IP communications to Ether-

T or other networks. An overload may cause the network to fail or malfunction.

CA

• All related EtherNet/IP nodes are reset when you transfer settings for the built-in EtherNet/IP port

(including IP addresses and tag data links settings). The settings can only be enabled after the re-

set. Confirm that the system will not be adversely affected by resetting nodes before you transfer the

settings.

• If EtherNet/IP tag data links (cyclic communications) are used with a repeating hub, the communica-

tions load on the network will increase. This will increase collisions and may prevent stable commu-

nications. Do not use repeating hubs on networks where tag data links are used. Use an Ethernet

switch instead.

fected before

EtherCAT Communications

• Malfunctions or unexpected operation may occur for some combinations of EtherCAT revisions of

the master and slaves. If you disable the revision check in the network settings, use the Sysmac

Studio to check the slave revision settings in the master and the actual slave revisions, and then

make sure that functionality is compatible in the slave manuals or other references. Y

the actual slave revisions from the Sysmac Studio or on slave nameplates.

20

ou can check

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 23

Precautions for Safe Use

• If the Fail-soft Operation parameter is set to stop operation, process data communications will stop

for all slaves when an EtherCA

Drive will operate according to the Servo Drive specifications. Make sure that the Fail-soft Operation

parameter setting results in safe operation when a device error occurs.

• If noise occurs or an EtherCAT slave is disconnected from the network, any current communications

frames may be lost. If frames are lost, slave I/O data is not communicated, and unintended opera-

tion may occur. The slave outputs will behave according to the slave specifications. Refer to the

manual for the slave. If a noise countermeasure or slave replacement is required, perform the fol-

lowing processing.

• Program the Input Data Invalid system-defined variable as an interlock condition in the user pro-

gram.

• Set the PDO communications timeout detection count setting in the EtherCAT master to at least 2.

Refer to the NY-series IPC Machine Controller Industrial Panel PC / Industrial Box PC Built-in

EtherCAT Port User’s Manual (Cat. No. W562) for details.

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables in the user program to confirm that communications are es-

tablished before attempting control operations.

• When an EtherCAT slave is disconnected or disabled, communications will stop and control of the

outputs will be lost not only for the disconnected slave, but for all slaves connected after it. Confirm

that the system will not be adversely affected before you disconnect or disable a slave.

• You cannot use standard Ethernet hubs or repeater hubs with EtherCAT communications. If you use

one of these, a major fault level error or other error may occur.

• Always use the specified EtherCAT slave cables. If you use any other cable, the EtherCAT master

or the EtherCAT slaves may detect an error and one of the following may occur.

• Continuous refreshing of process data communications will not be possible.

• Continuous refreshing of process data communications will not end during the set cycle.

T communications error is detected in a slave. At that time, the Servo

Motion Control

• The motor is stopped if communications are interrupted between the Sysmac Studio and the product

during an MC T

curely and confirm that the system will not be adversely affected before you perform an MC Test

Run.

• The positive drive prohibit input (POT), negative drive prohibit input (NOT), and home proximity in-

put (DEC) of the Servo Drive are used by the MC Function Module as the positive limit input, nega-

tive limit input, and home proximity input. Make sure that the signal widths for all of these input sig-

nals are longer than the control period of the MC Function Module. If the input signal widths are

shorter than the control period, the MC Function Module may not be able to detect the input signals,

resulting in incorrect operation.

• Always execute the Save Cam Table instruction if you change any of the cam data from the user

program in the CPU Unit or from the Sysmac Studio. If the cam data is not saved, the previous con-

dition will be restored when the power is turned ON again, possibly causing unexpected machine

operation.

• Confirm the axis number carefully before you perform an MC Test Run.

• Use the NX_AryDOutTimeStamp (Write Digital Output Array with Specified Time Stamp) instruction

only after you confirm that InOperation from the MC_DigitalCamSwitch (Enable Digital Cam Switch)

instruction is TRUE.

est Run. Connect the communications cable between the computer and product se-

NY-series Industrial Box PC Hardware User's Manual (W556)

21

Page 24

FirstOnPosition LastOnPosition

OnCompensation

FirstOnPosition

after compensation

FirstOnPosition LastOnPosition

OffCompensation

LastOnPosition

after compensation

Precautions for Safe Use

• Always use the axis at a constant velocity for the MC_DigitalCamSwitch (Enable Digital Cam

Switch) instruction.

If you set the Count Mode to Rotary Mode, the following operation will occur if you use OnCompen-

sation

• If the value of OnCompensation or OffCompensation is equivalent to the time for half a rotation or

• If the value of OnCompensation results in exceeding LastOnPosition, the output timing will be un-

• If the value of OffCompensation results in exceeding FirstOnPosition, the output timing will be un-

or OffCompensation and the axis velocity changes abruptly.

more, InOperation will be FALSE.

stable.

stable.

Restoring Data

• The absolute encoder home offsets are backed up with a non-volatile memory in the product as ab-

solute encoder information. If any of the following conditions is met, clear the absolute encoder

home of

fsets from the list of data items to restore, and then restore the data. Then, define the abso-

lute encoder home again. If you do not define home, unintended operation of the controlled system

may occur.

• The Servomotor or Servo Drive was changed since the data was backed up.

• The absolute encoder was set up after the data was backed up.

• The absolute data for the absolute encoder was lost.

• You can partially or cannot at all back up, restore, or compare data of the settings depending on

slaves and Units. Also, you cannot back up, restore, or compare data for disabled slaves or Units.

After you restore data, sufficiently confirm that operation is correct before you start actual operation.

Battery Replacement

• Dispose of any Battery that has been dropped on the floor or otherwise subjected to excessive

shock. Batteries that have been subjected to shock may leak if they are used.

UL standards require that only an experienced engineer replace the Battery. Make sure that an ex-

•

perienced engineer is in charge of Battery replacement.

• The Battery may leak, rupture, heat, or ignite. Never short-circuit, charge, disassemble, heat, or in-

cinerate the Battery or subject it to strong shock.

22

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 25

Product Replacement

• Make sure that the required data, including the user program, configurations, settings and variables

is transferred to a product that was replaced and to externally connected devices before restarting

operation.

Be sure to include the tag data link settings and routing tables, which are stored in the product.

Cleaning, Maintenance and Disposal

• Do not use corrosive substances to clean the product. Doing so may result in the failure or malfunc-

tion.

Dispose of the product and batteries according to local ordinances as they apply.

•

• The following information must be displayed for all products that contain primary lithium batteries

with a perchlorate content of 6 ppb or higher when shipped to or transported through the State of

California, USA.

Perchlorate Material - special handling may apply

See http://www.dtsc.ca.gov/hazardouswaste/perchlorate.

• The product contains a lithium battery with a perchlorate content of 6ppb or higher. When exporting

an end product containing the product to or shipping through California, USA, label all packing and

shipping containers appropriately.

Precautions for Safe Use

.

NY-series Industrial Box PC Hardware User's Manual (W556)

23

Page 26

Precautions for Correct Use

Precautions for Correct Use

Storage, Installation and Mounting

• Do not operate or store the product in the following locations. Operation may stop or malfunctions

may occur.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil or chemicals

• Locations subject to shock or vibration

• Locations outdoors subject to direct wind and rain

• Locations subject to strong ultraviolet light

• Always install the product with sufficient surrounding space to allow for adequate heat dissipation

and cooling effect.

• Take appropriate and sufficient countermeasures when installing the product in the following loca-

tions

• Locations subject to strong, high-frequency noise

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power lines

• Always touch a grounded piece of metal to discharge static electricity from your body before starting

an installation or maintenance procedure.

• Insert USB devices and PCIe devices correctly to avoid the burning, failure or malfunction.

• Execute a backup of the product before PCIe addition or replacement. Be sure that the PCIe device

works correctly before you use them for actual operation. PCIe devices and their related software

may cause an OS boot failure or crash.

• Ensure the selected operating system supports ACPI to enable operating system shutdown using

the power button.

• Download the enhanced Video Driver from the OMRON Download Center and install it on the Indus-

trial PC.

Wiring

24

• Always ensure the rated supply voltage is connected to the product.

• Do not allow wire clippings, shavings, or other foreign material to enter the product. Otherwise, burn-

ing, failure, or malfunction may occur. Cover the product or take other suitable countermeasures, es-

pecially during wiring work.

• Do not use cables exceeding the maximum specified length. Doing so may cause malfunction.

• Do not connect an AC power supply to the DC power connector.

• Observe the following precautions to prevent broken wires.

• When you remove the sheath, be careful not to damage the conductor.

• Connect the conductor without twisting the wires.

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 27

• Do not weld the conductors. Doing so may cause the wires to break with vibration.

Actual Operation and Operation

• After an OS update or a peripheral device driver update for the product is executed, the product be-

havior might be dif

• Ensure the fan is operational to provide adequate cooling while the power is turned ON.

• HDD and SSD storage devices, SD Memory Cards, power buttons, fan units and batteries have fi-

nite lives and if those are exceeded, the product may fail or malfunction.

• Always monitor the fan status. If a fan is used beyond its service life, the Low Revolution Speed

warning message is displayed and the product overheating may occur.

• Always monitor the battery warning message. When a battery has low voltage, the system time will

be lost.

• Do not reset or power OFF the product while the password is being changed. If you fail to save the

password there is a possibility that the project will not work.

• Always confirm safety at the connected equipment before you reset Controller errors with an event

level of partial fault or higher from the EtherCAT master Function Module. When the Error is reset,

all slaves that were in any state other than Operational state due to a Controller error with an event

level of partial fault or higher (in which output are disabled) will go to Operational state and the out-

puts will be enabled. Before you reset all errors or restart a slave, confirm that no Controller errors

with an event level of partial fault have occurred for the EtherCAT Master Function Module.

• The functions that are supported depend on the unit version of the product. The version of Sysmac

Studio that supports the functions that were added for an upgrade is also required to use those func-

tions. Refer to Version Information for NY-series Controllers for the relationship between the unit

versions of the controller and the Sysmac Studio versions, and for the functions that are supported

by each unit version.

• If the product experiences a sudden loss of power or disconnecting the cable while saving a setting

or transfer of data is underway, the changes may not be stored and unexpected behavior may occur.

• Ensure that available software checks are performed by personnel in charge who possess a thor-

ough understanding of the software.

• Always create a Rescue Disk using the Rescue Disk Utility and restore to recover the HDD/SSD

configuration if necessary.

• Confirm the device output hold configuration before you change the operating mode of the product

or execute the download.

ferent. Confirm that operation is correct before you start actual operation.

Precautions for Correct Use

Error Processing

• In applications that use the results of instructions that read the error status, consider the effect on

the system when errors are detected and program error processing accordingly

the detection of a minor error, such as Battery replacement during operation, can affect the system

depending on how the user program is written.

• If you change the event level of a Controller error, the output status when the error occurs may also

change. Confirm safety before you change an event level.

NY-series Industrial Box PC Hardware User's Manual (W556)

. For example, even

25

Page 28

Precautions for Correct Use

Restoring Data

• When you edit the restore command file, do not change anything in the file except for the “yes” and

“no” specifications for the selectable data groups. If you change anything else in the file, the Control-

ler may perform unexpected operation when you restore the data.

Task Settings

• If a Task Period Exceeded error occurs, shorten the programs to fit in the task period or increase the

setting of the task period.

Motion Control

• Before you start an MC Test Run, make sure that the operation parameters are set correctly.

Do not download motion control settings during an MC Test Run.

•

EtherCAT Communications

• Set the Servo Drives to stop operation if an error occurs in EtherCAT communications between the

Controller and a Servo Drive.

If you need to disconnect the cable from an EtherCAT slave during operation, first disconnect the

•

software connection to the EtherCAT slave or disable the EtherCAT slave and all of the EtherCAT

slaves that are connected after it.

• Make sure that all of the slaves to be restored are participating in the network before you reset a

Network Configuration Verification Error, Process Data Communications Error, or Link OFF Error in

the EtherCAT Master Function Module. If any slave is not participating when any of these errors is

reset, the EtherCAT Master Function Module may access slave with a different node address than

the specified node address or the error may not be reset correctly.

• Make sure that the communications distance, number of devices connected, and method of connec-

tion for EtherCAT are within specifications. Do not connect EtherCAT communications to

EtherNet/IP, a standard in-house LAN, or other networks. An overload may cause the network to fail

or malfunction.

• After you transfer the user program, the product is restarted and communications with the EtherCAT

slaves are cut off. During that period, the slave outputs behave according to the slave specifications.

The time that communications are cut off depends on the EtherCAT network configuration. Before

you transfer the user program, confirm that the system will not be adversely affected.

Battery Replacement

• Turn ON the power after replacing the battery for a product that has been unused for an extended

period of time. Leaving the product unused without turning ON the power even once after the battery

is replaced may result in a shorter battery life.

Make sure to use a battery of the correct type, install the battery properly.

•

• Apply power for at least five minutes before changing the battery. Mount a new battery within five

minutes after turning OFF the power supply. If power is not supplied for at least five minutes, the

clock data may be lost. Check the clock data after changing the battery.

26

NY-series Industrial Box PC Hardware User's Manual (W556)

Page 29

SD Memory Cards

• Insert an SD Memory Card completely and ensure it is in place.

Precautions for Correct Use