Omron NY532-1500, NY512-1500, NY532-1400, NY512-1400, NY512-1300 Reference Manual

...

Industrial PC Platform

NY-series

Motion Control Instructions

Reference Manual

NY532-1500

NY532-1400

NY532-1300

NY512-1500

NY512-1400

NY512-1300

W561-E1-01

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the USA and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Introduction

Thank you for purchasing an NY-series IPC Machine Controller Industrial Panel PC / Industrial Box PC.

This manual provides a collective term of Industrial Panel PC and Industrial Box PC which are applicable products as the NY-series Industrial PC. This manual also provides the range of devices that are

directly controlled by the Controller functions embedded the Real-Time OS in the NY-series Industrial

PC as the Controller.

This manual describes the motion control instructions. Please be sure you sufficiently understand the

operations and handling procedures, and use the Motion Control Function Module (abbreviated as “MC

Function Module”) correctly.

Use this manual together with the user’s manuals for the NY-series Controller.

When you have finished reading this manual, keep it in a safe location where it will be readily available

for future use.

Intended Audience

Introduction

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Applicable Products

This manual covers the following products.

NY-series IPC Machine Controller Industrial Panel PC

• NY532-15

• NY532-14

• NY532-13

NY-series IPC Machine Controller Industrial Box PC

• NY512-15

• NY512-14

• NY512-13

Part of the specifications and restrictions for the Industrial PC are given in other manuals. Refer to Relevant Manuals on page 2 and Related Manuals on page 23.

NY-series Motion Control Instructions Reference Manual (W561)

1

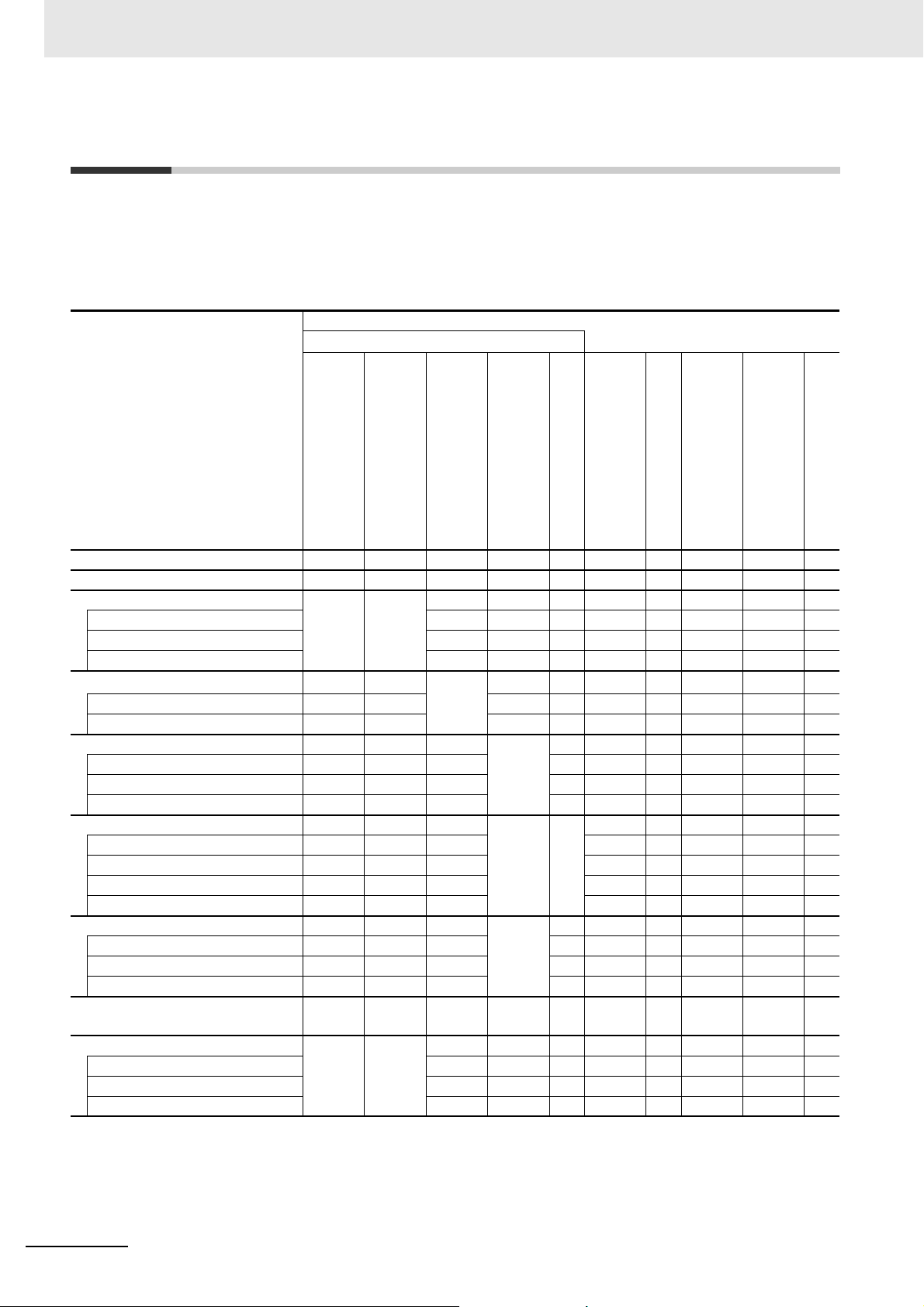

Relevant Manuals

Relevant Manuals

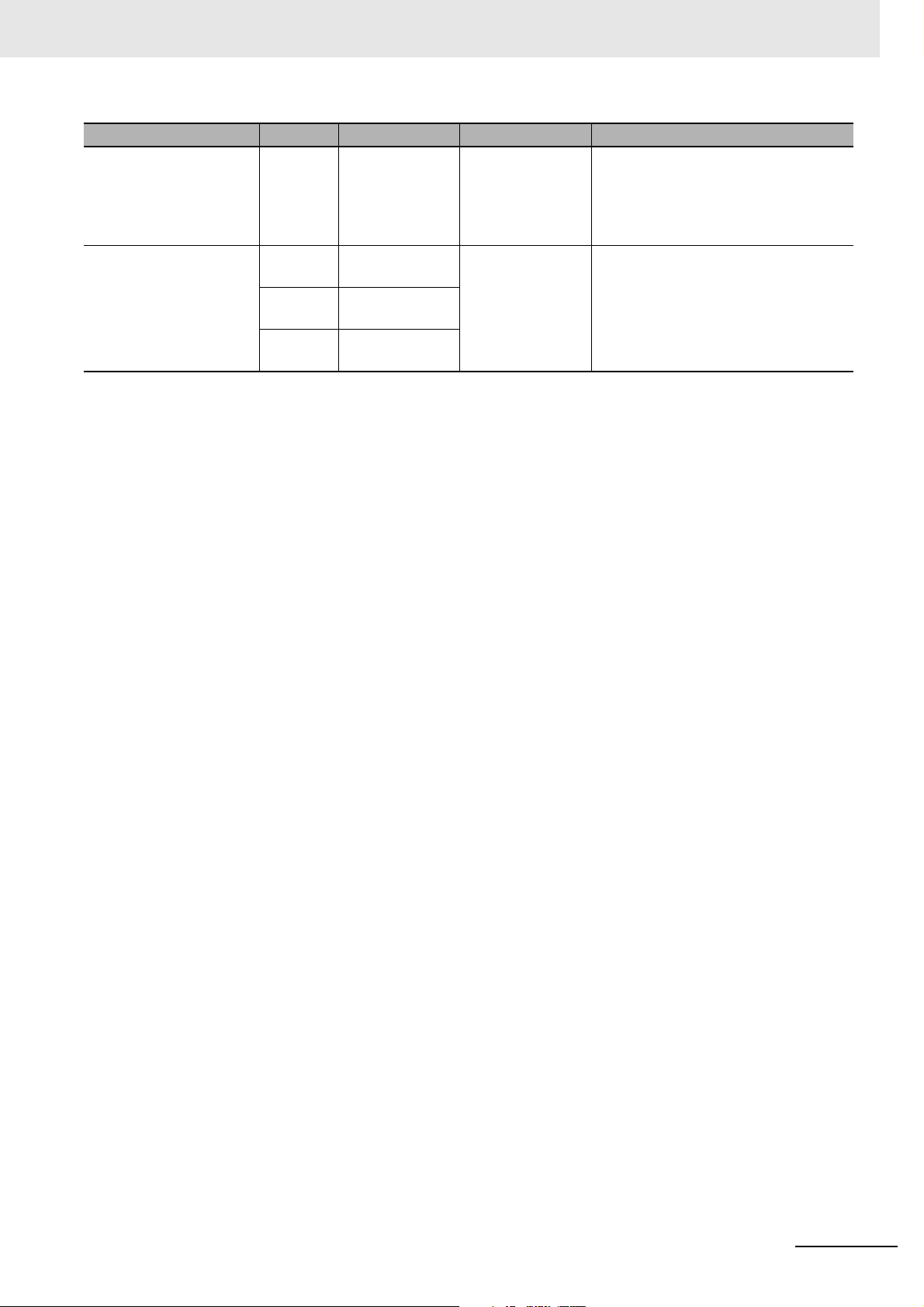

The following table provides the relevant manuals for NY-series Controller.

Read all of the manuals that are relevant to your system configuration and application before you use

NY-series Controller.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac Stu-

dio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

NY-series IPC Machine Controller

Industrial Panel PC

Hardware User’s Manual

Purpose of use

Basic information

NY-series IPC Machine Controller

Industrial Box PC

Hardware User’s Manual

Industrial Panel PC / Industrial Box PC

Setup User's Manual

Manual

NY-series IPC Machine Controller

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Software User’s Manual

Instructions Reference Manual

NY-series

Motion Control User's Manual

Industrial Panel PC / Industrial Box PC

NY-series IPC Machine Controller

NY-series Motion Control

Instructions Reference Manual

NY-series IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherCAT Port User’s Manual

Built-in EtherNet/IP Port User's Manual

Industrial Panel PC / Industrial Box PC

NY-series IPC Machine Controller

NY-series

Troubleshooting Manual

Introduction to NY-series Panel PCs {

Introduction to NY-series Box PCs {

Setting devices and hardware

Using motion control {

Using EtherCAT {

Using EtherNet/IP {

Making setup

Making initial settings

Preparing to use Controllers

Software settings

Using motion control {

Using EtherCAT {

Using EtherNet/IP {

Writing the user program

Using motion control {{

Using EtherCAT {

Using EtherNet/IP {

Programming error processing {

Testing operation and debugging

Using motion control {

Using EtherCAT {

Using EtherNet/IP {

Learning about error management and

corrections

Maintenance

Using motion control {

Using EtherCAT {

Using EtherNet/IP {

*1

*2

{{

{

{

{{

{

{{

{

*1 Refer to the NY-series Industrial Panel PC / Industrial Box PC Setup User’s Manual (Cat. No. W568) for how to set up and

how to use the utilities on Windows.

*2 Refer to the NY-series Troubleshooting Manual (Cat. No. W564) for the error management concepts and an overview of

the error items.

2

NY-series Motion Control Instructions Reference Manual (W561)

Manual Structure

Some of the instructions described in this manual are common to NJ/NX-series as well. Therefore, note

the following conditions.

Manual Structure

• With the NY-series Controller, use the primary periodic task and priority-16 periodic task. You cannot

use the priority-5 periodic task.

• Use _MC_AX[*] when using the Axis Variable name of the system-defined variable. You cannot use

_MC1_AX[*] and _MC2_AX[*].

• Use _MC_GRP[*] when using the Axes Group Variable name of the system-defined variable. You

cannot use _MC1_GRP[*] and _MC2_GRP[*].

• In explanation of the instructions, replace the term “CPU Unit” with “NY-series Controller.”

• The unit version of the NY-series Controller is 1.12 or later.

NY-series Motion Control Instructions Reference Manual (W561)

3

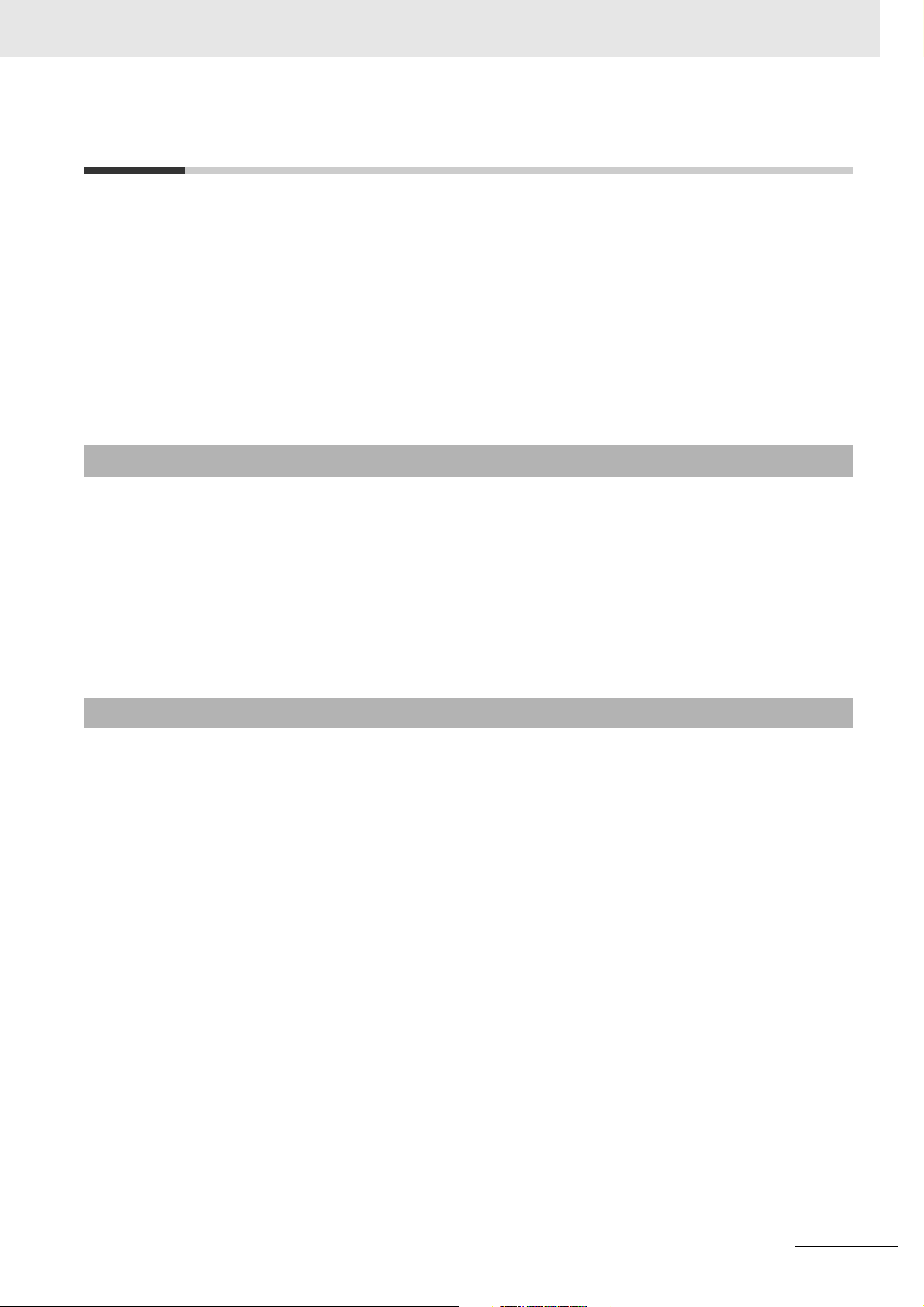

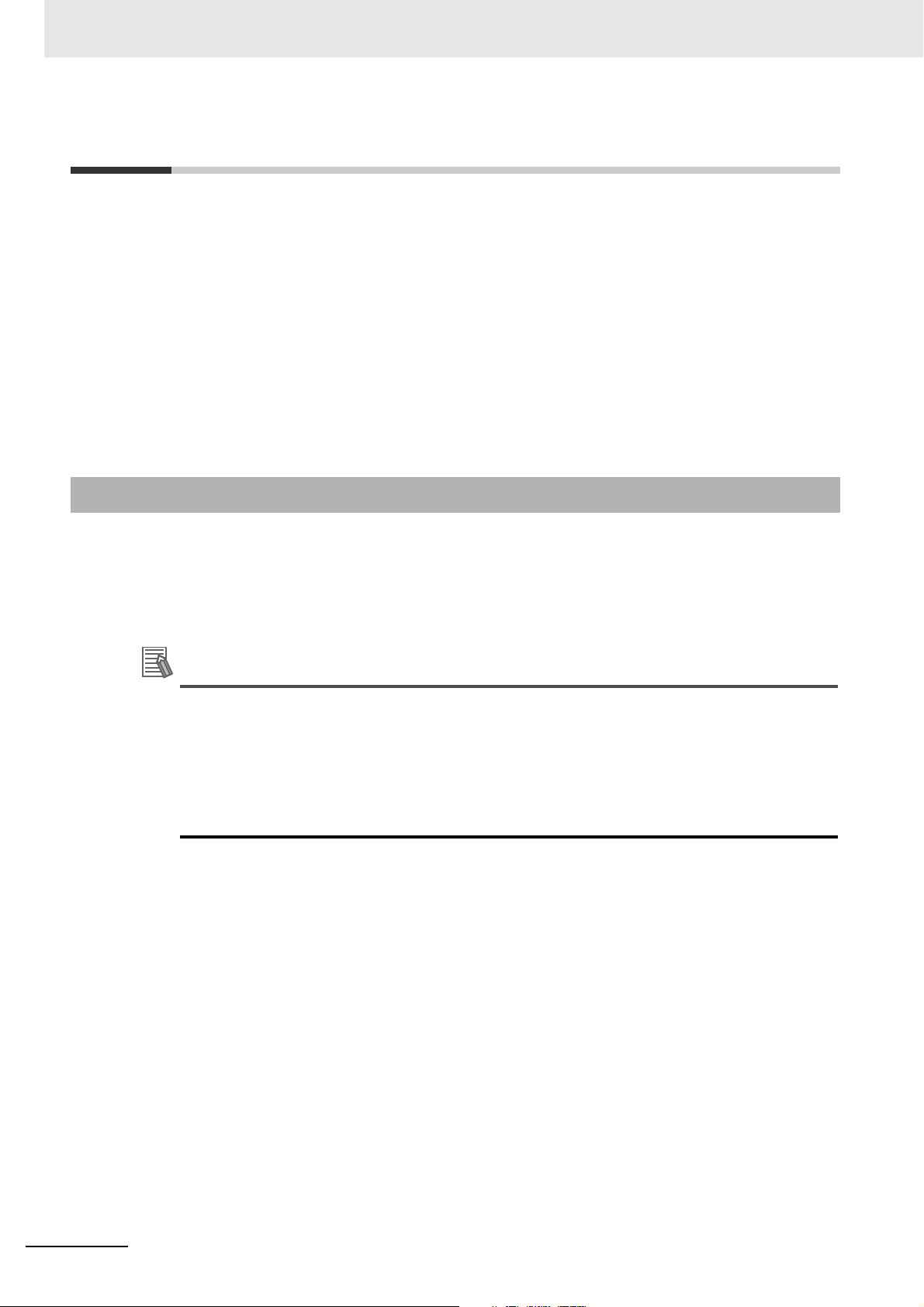

Manual Structure

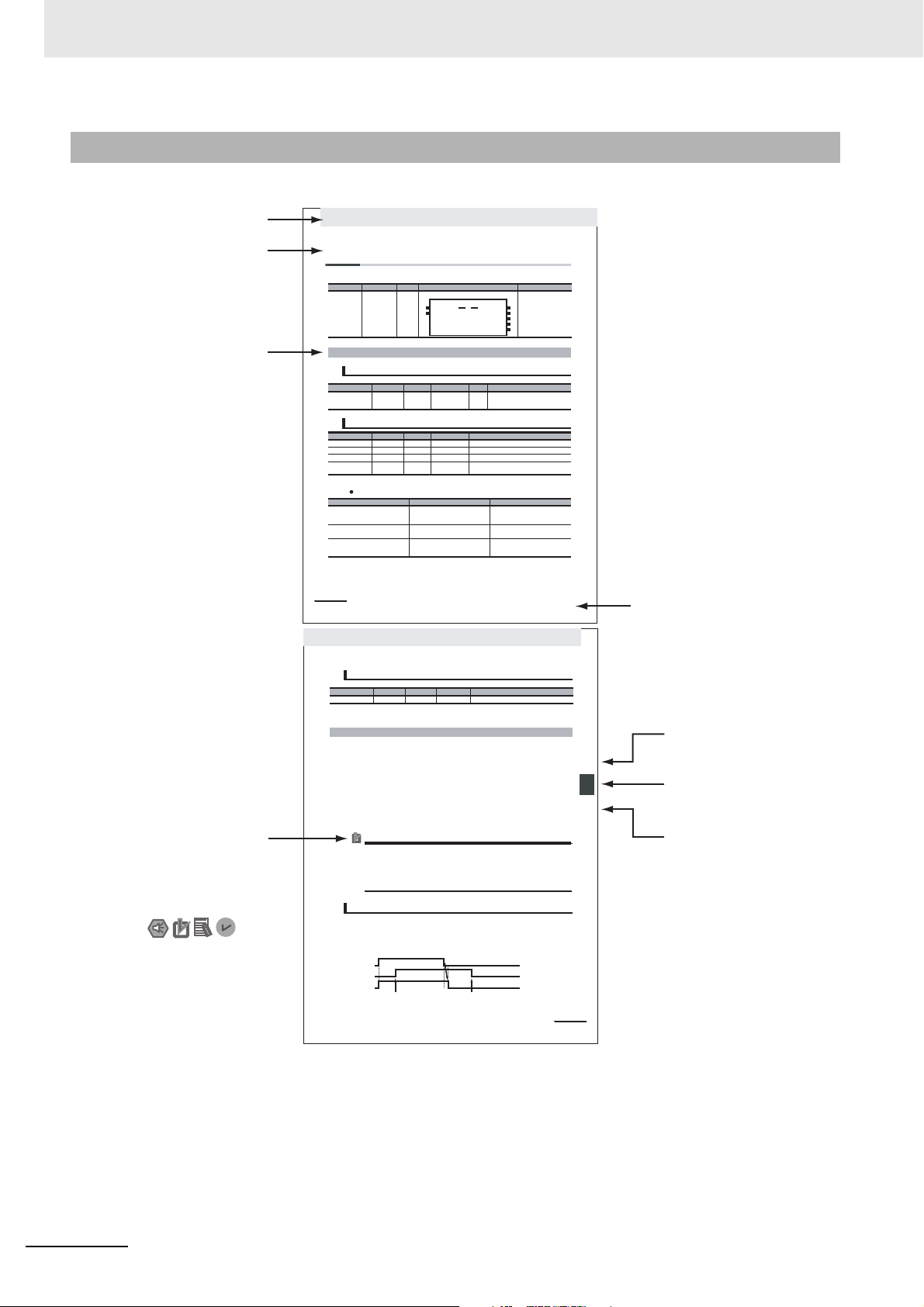

Manual name

Special information

Icons indicate

precautions, additional

information, or reference

information.

Note: This page is for illustration only. It does not represent a specific page in this manual.

Level-1 section heading

Level-2 section heading

Level-1 section number

Level-3 section heading

The level-1 section number

is given.

The level-2 section heading

is given.

The level-3 section heading

is given.

3 Axis Command Instructions

3-2

NJ-series Motion Control Instructions Reference Manual (W508)

MC_Power

The MC_Power instruction makes a Servo Drive ready to operate.

*Refer to A-1 Error Codes.

Output Variable Update Timing

Instruction Name FB /FUN Graphic expression ST expression

MC_Power Power Servo FB MC_Power_instance (

Axis :=parameter,

Enable :=parameter,

Status =>parameter,

Busy =>parameter,

Error =>parameter,

ErrorID =>parameter

);

Vari able s

Input Variables

Name Meaning Data type Valid range Default Description

Enable Enable BOOL TRUE or FALSE FALSE The device is ready for operation when

Enable is TRUE, and not ready when it is

FALSE .

Output Variables

Name Meaning Data type Valid ra nge Description

Status Servo ON BOOL TRUE or FALSE TRUE when the device is ready for operation.

Busy Executing B OOL TRUE or FALSE TRUE when the instruction is acknowledged.

Error Error BOOL TRUE or FALSE TRUE while there is an error.

ErrorID Error Code WORD

*

Contains the error code when an error occurs.

A value of 16#0000 indicates normal execution.

Name Timing for changing to TRUE Timing for changing to FALSE

Status When the specified axis becomes

ready for operation.

• When operation ready status for the

specified axis is cleared.

• When Error changes to TRUE.

Busy When Enable changes to TRUE. • When Enable changes to FALSE.

• When Error changes to TRUE.

Error When there is an error in the execution

conditions or input parameters for the

instruction.

When the error is cleared.

MC_Power_instance

Error

Axis Axis

Enable Status

Busy

MC_Power

ErrorID

3-3

3 Axis Command Instructions

NJ-series Motion Control Instructions Reference Manual (W508)

rewoP_CM

3

noitcnuF

* Specify an Axis Variable that was created in the Axis Basic Settings of the Sysmac Studio. (The default axis variable names

are MC_Axis***.)

• When Enable changes to TRUE, the axis specified by Axis is made ready to operate.

You can control the axis when it is ready to operate.

• When Enable changes to FALSE, the ready status is cleared for the axis specified by Axis.

You cannot control the axis after the ready status is cleared because it will not acknowledge operation commands. Also, an error occurs if a motion command is executed for an axis for which the

ready status is cleared. You can execute the MC_Power (Power Servo) and MC_Reset (Reset Axis

Error) instructions even for axes that are not ready.

• You can use this instruction to disable the operation of axes while they are in motion. In this case,

CommandAborted will change to TRUE. Output of the operation command will stop and the axis will

not longer be ready for operation.

• If home is not defined for a Servomotor with an absolute encoder, compensation is performed using

the absolute encoder home offset to define home when the axis is ready to operate.

For details on the absolute encoder home offset, refer to the NJ-series CPU Unit Motion Control

User’s Manual (Cat. No. W507).

Precautions for Correct UsePrecautions for Correct Use

• You can use this instruction for servo axes and virtual servo axes. If the instruction is used for

encoder axes or virtual encoder axes, an error will occur.

• Executing this Instruction for the Master Axis of Synchronized Control

When master axis operation is disabled for a vertical axis, the position of the master axis may

change rapidly. This may cause the motion of the slave axis to change rapidly. Take suitable

measures to prevent the slave axis from moving rapidly, such as applying a brake to the master axis or leaving master axis operation enabled until after synchronized control is completed.

• When Enable changes to TRUE, Busy (Executing) changes to TRUE to indicate that the instruction

was acknowledged.

• After the axis becomes ready for operation, Status (Servo ON) changes to TRUE.

• When Enable changes to FALSE, Busy (Executing) changes to FALSE. Status (Servo ON) changes

to FALSE when ready status is cleared. Status (Servo ON) outputs the axis ready status regardless

of whether Enable is TRUE or FALSE.

In-Out Variables

Name Meaning Data type Valid range Description

Axis Axis _sAXIS_REF ---

Specify the axis.

*

Function

Timing Charts

Enable

Status

Busy

The specified axis becomes

ready for operation.

Ready status is cleared for the

specified axis.

Level-2 section heading

Level-3 section heading

Page Structure

The following page structure is used in this manual.

4

NY-series Motion Control Instructions Reference Manual (W561)

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Information on differences in specifications and functionality for Controller with different unit versions

and for different versions of the Sysmac Studio are given.

Manual Structure

Note References are provided to more detailed or related information.

NY-series Motion Control Instructions Reference Manual (W561)

5

Manual Structure

6

NY-series Motion Control Instructions Reference Manual (W561)

1

2

3

4

5

A

I

1

2

3

4

5

A

I

Introduction to Motion Control Instructions

Variables and Instructions

Axis Command Instructions

Axes Group Instructions

Common Command Instructions

Appendices

Index

Sections in this Manual

Sections in this Manual

NY-series Motion Control Instructions Reference Manual (W561)

7

Sections in this Manual

8

NY-series Motion Control Instructions Reference Manual (W561)

CONTENTS

CONTENTS

Introduction............................................................................................................... 1

Relevant Manuals...................................................................................................... 2

Manual Structure ...................................................................................................... 3

Sections in this Manual............................................................................................ 7

Terms and Conditions Agreement ........................................................................ 15

Safety Precautions ................................................................................................. 17

Precautions for Safe Use ....................................................................................... 18

Precautions for Correct Use .................................................................................. 19

Regulations and Standards ................................................................................... 20

Versions................................................................................................................... 21

Related Manuals ..................................................................................................... 23

Revision History ..................................................................................................... 26

Section 1 Introduction to Motion Control Instructions

1-1 Motion Control Instructions.................................................................................................... 1-2

Function Blocks for PLCopen® Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Overview of Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Precautions for Master and Auxiliary Axes in Synchronized Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-2 Basic Information on Motion Control Instructions ............................................................... 1-8

Motion Control Instruction Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Languages for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Motion Control Instruction Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Multi-execution of Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Online Editing of Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Changes in the Operating Mode of the NY-series Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Section 2 Variables and Instructions

2-1 Variables................................................................................................................................... 2-2

MC Common Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Axis Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Axes Group Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Input Variables for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Output Variables for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

In-Out Variables for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2-2 Instructions ............................................................................................................................ 2-30

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Axis Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Axes Group Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-3 PDO Mapping ......................................................................................................................... 2-34

Required Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Objects Required for Specific Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

NY-series Motion Control Instructions Reference Manual (W561)

9

CONTENTS

Section 3 Axis Command Instructions

MC_Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

MC_MoveJog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

MC_Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

MC_HomeWithParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

MC_Move . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

MC_MoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Sample Programming 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Sample Programming 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

MC_MoveRelative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

MC_MoveVelocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-85

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

MC_MoveZeroPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

MC_MoveFeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-105

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-106

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-122

MC_Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-133

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-133

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-134

MC_ImmediateStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-142

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-142

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-143

MC_SetPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-147

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-147

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-148

MC_SetOverride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-153

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-153

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-154

MC_ResetFollowingError . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-158

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-158

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-159

MC_CamIn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-165

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-165

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-169

Sample Programming 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-192

Sample Programming 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-203

MC_CamOut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-219

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-219

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-220

MC_GearIn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-224

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-224

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-226

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-233

10

NY-series Motion Control Instructions Reference Manual (W561)

CONTENTS

MC_GearInPos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-243

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-243

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-246

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-254

MC_GearOut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-264

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-264

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-266

MC_MoveLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-269

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-269

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-272

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-282

MC_CombineAxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-292

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-292

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-295

MC_Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-304

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-304

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-306

MC_TorqueControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-312

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-312

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-314

MC_SetTorqueLimit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-323

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-323

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-324

MC_ZoneSwitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-330

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-330

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-332

MC_TouchProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-336

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-336

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-339

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-351

MC_AbortTrigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-358

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-358

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-360

MC_AxesObserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-363

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-363

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-365

MC_SyncMoveVelocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-369

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-369

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-371

MC_SyncMoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-379

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-379

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-381

MC_Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-386

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-386

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-387

MC_ChangeAxisUse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-390

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-390

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-391

MC_DigitalCamSwitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-394

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-395

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-396

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-406

MC_TimeStampToPos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-413

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-413

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-414

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-417

MC_SyncOffsetPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-425

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-425

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-427

NY-series Motion Control Instructions Reference Manual (W561)

11

CONTENTS

Section 4 Axes Group Instructions

MC_GroupEnable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

MC_GroupDisable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

MC_MoveLinear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

MC_MoveLinearAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

MC_MoveLinearRelative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

MC_MoveCircular2D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

MC_GroupStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

MC_GroupImmediateStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

MC_GroupSetOverride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

MC_GroupReadPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

MC_ChangeAxesInGroup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

MC_GroupSyncMoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-93

MC_GroupReset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

Section 5 Common Command Instructions

MC_SetCamTableProperty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

MC_SaveCamTable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

MC_Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

MC_GenerateCamTable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

MC_WriteAxisParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

12

NY-series Motion Control Instructions Reference Manual (W561)

CONTENTS

MC_ReadAxisParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-62

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

Appendices

A-1 Instructions for Which Multi-execution Is Supported ..........................................................A-2

A-1-1 Axis and Axes Group Status ....................................................................................................... A-3

A-1-2 State Transitions and Instructions for which Multi-execution Is Supported.................................A-5

A-2 Connecting to NX Units ........................................................................................................A-10

Index

NY-series Motion Control Instructions Reference Manual (W561)

13

14

CONTENTS

NY-series Motion Control Instructions Reference Manual (W561)

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

z Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

z Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

z Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

NY-series Motion Control Instructions Reference Manual (W561)

15

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

16

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NY-series Motion Control Instructions Reference Manual (W561)

Safety Precautions

Refer to the following manuals for safety precautions.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

• NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No. W558)

Safety Precautions

NY-series Motion Control Instructions Reference Manual (W561)

17

Precautions for Safe Use

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

• NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No. W558)

18

NY-series Motion Control Instructions Reference Manual (W561)

Precautions for Correct Use

Refer to the following manuals for precautions for correct use.

• NY-series Industrial Box PC Hardware User’s Manual (Cat. No. W556)

• NY-series Industrial Panel PC Hardware User’s Manual (Cat. No. W557)

• NY-series Industrial Panel PC / Industrial Box PC Software User’s Manual (Cat. No. W558)

Precautions for Correct Use

NY-series Motion Control Instructions Reference Manual (W561)

19

Regulations and Standards

Regulations and Standards

Conformance to EU Directives

Applicable Directives

•EMC Directives

Concepts

z EMC Directive

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EU

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform the

final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations)

*

z Conformance to EU Directives

The NY-series Controllers comply with EU Directives. To ensure that the machine or device in which

the NY-series Controller is used complies with EU Directives, the Controller must be installed as follows:

• The NY-series Controller must be installed within a control panel.

• You must use the power supply in SELV specifications for the DC power supplies connected to DC

Power Supply Units and I/O Units.

• NY-series Controllers that comply with EU Directives also conform to the Common Emission Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EU Directives.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

20

NY-series Motion Control Instructions Reference Manual (W561)

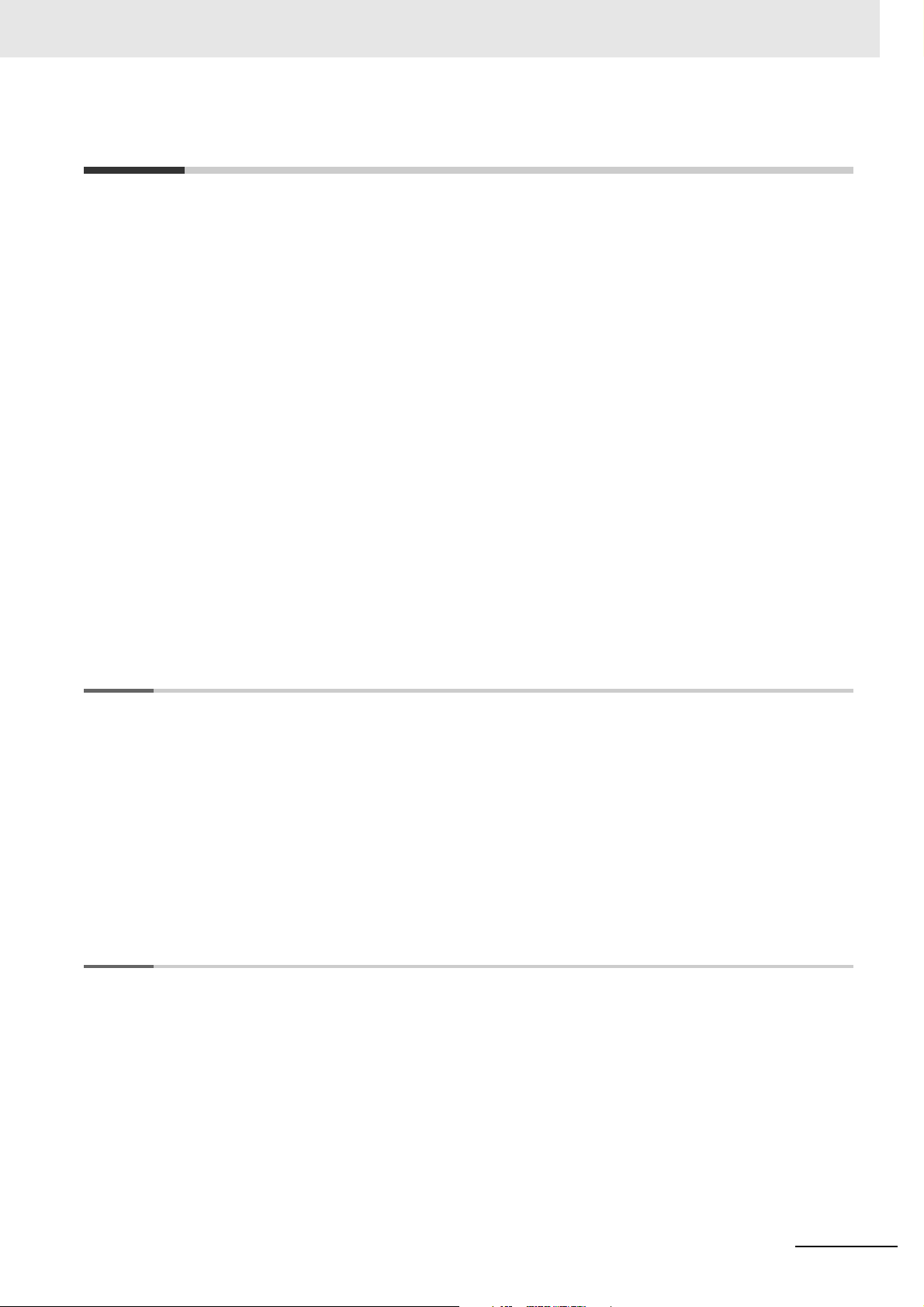

Versions

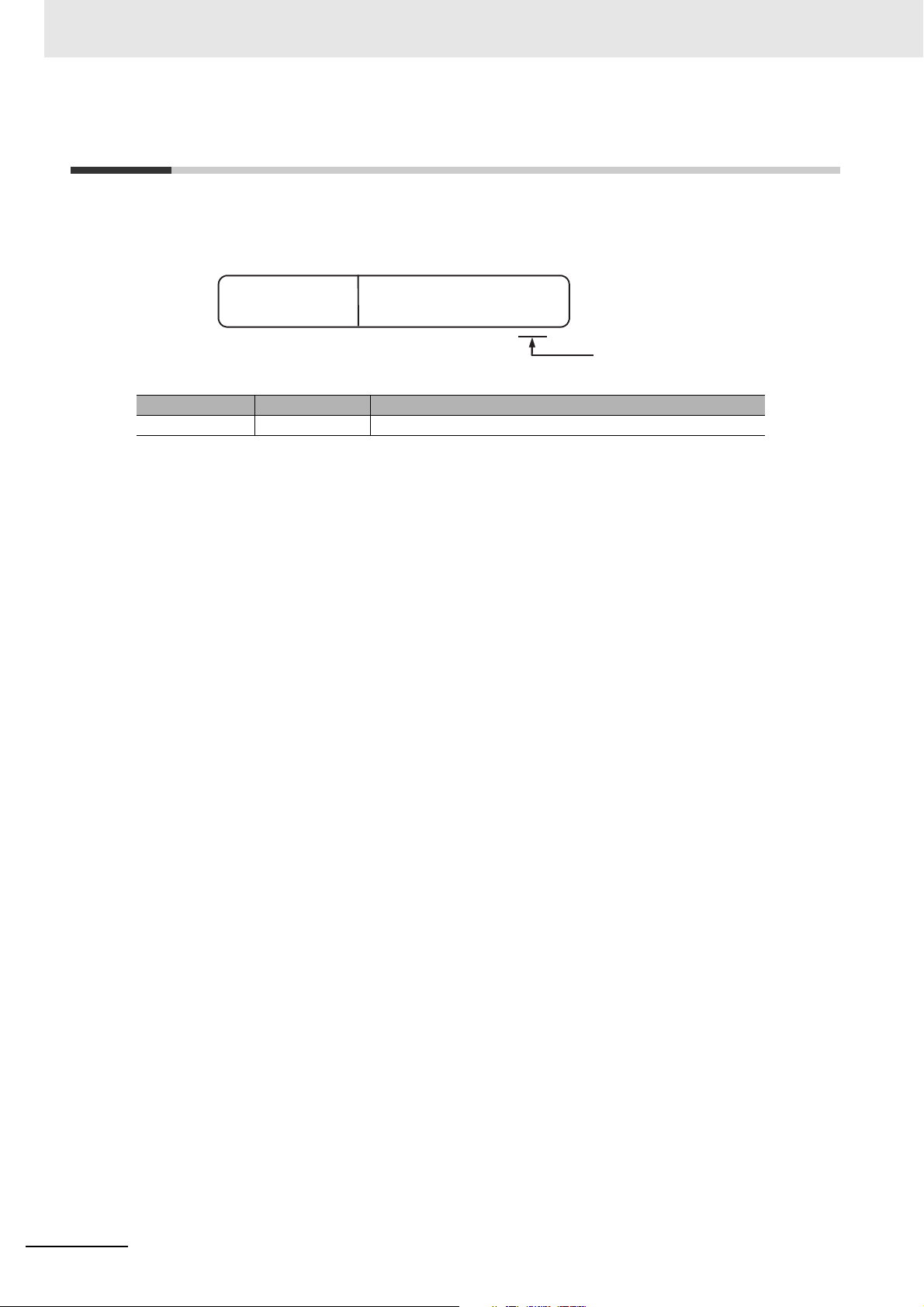

ID information indication

Unit version

Ver.1.

Hardware revisions and unit versions are used to manage the hardware and software in NY-series Controllers and EtherCAT slaves. The hardware revision or unit version is updated each time there is a

change in hardware or software specifications. Even when two Units or EtherCAT slaves have the same

model number, they will have functional or performance differences if they have different hardware revisions or unit versions.

Checking Versions

You can check versions on the ID information indications or with the Sysmac Studio.

Checking Unit Versions on ID Information Indications

The unit version is given on the ID information indication on the back side of the product.

The ID information on an NY-series NY52-1 Controller is shown below.

Versions

Checking Unit Versions with the Sysmac Studio

You can use the Sysmac Studio to check unit versions. The procedure is different for Units and for EtherCAT slaves.

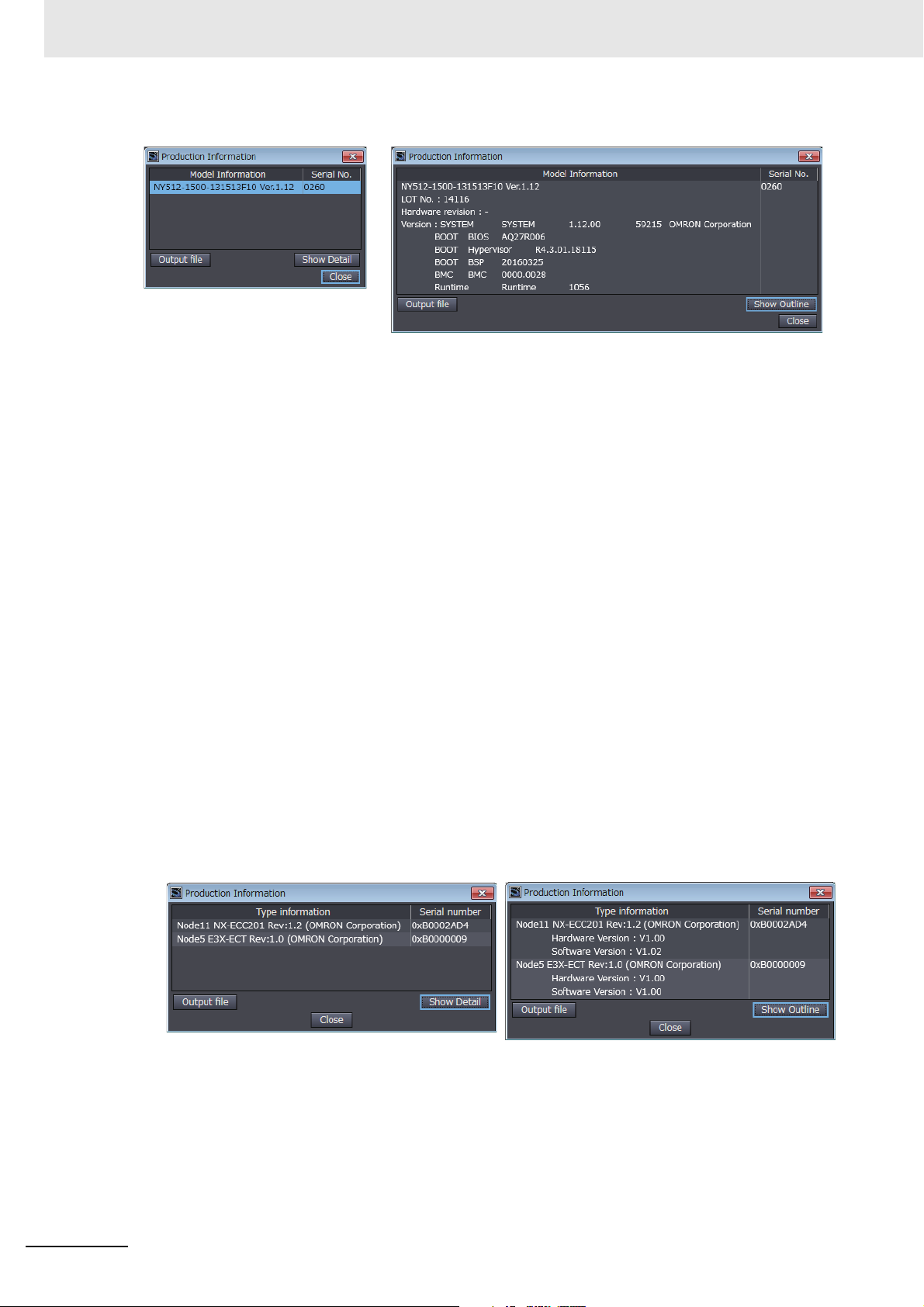

z Checking the Unit Version of an NY-series Controller

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can only do this for the Controller.

• Right-click CPU Rack under Configurations and Setup − CPU/Expansion Racks in the Multiv-

iew Explorer and select Production Information.

The Production Information Dialog Box is displayed.

z Changing Information Displayed in Production Information Dialog Box

Click the Show Detail or Show Outline Button at the lower right of the Production Information Dialog Box.

The view will change between the production information details and outline.

NY-series Motion Control Instructions Reference Manual (W561)

21

Versions

Outline View Detail View

The information that is displayed is different for the Outline View and Detail View. The Detail View

displays the unit version, hardware revision, and other versions. The Outline View displays only the

unit version.

z Checking the Unit Version of an EtherCAT Slave

You can use the Production Information while the Sysmac Studio is online to check the unit version

of an EtherCAT slave. Use the following procedure to check the unit version.

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or, right-

click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displayed.

2 Right-click the master on the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.

The unit version is displayed after “Rev.”

z Changing Information Displayed in Production Information Dialog Box

Click the Show Detail or Show Outline Button at the lower right of the Production Information Dialog Box.

The view will change between the production information details and outline.

22

Outline View Detail View

NY-series Motion Control Instructions Reference Manual (W561)

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NY-series

IPC Machine Controller

Industrial Panel PC

Hardware

User’s Manual

NY-series

IPC Machine Controller

Industrial Box PC

Hardware

User’s Manual

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Setup

User’s Manual

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Software

User’s Manual

NY-series

Instructions

Reference Manual

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Motion Control

User’s Manual

NY-series

Motion Co

Reference Manual

ntro

l Instructions

W557 NY532-1 Learning the basic

specifications of the

NY-series Industrial

Panel PCs, including

introductory information, designing, installation, and

maintenance.

Mainly hardware

information is provided.

W556 NY512-1 Learning the basic

specifications of the

NY-series Industrial

Box PCs, including

introductory information, designing, installation, and

maintenance.

Mainly hardware

information is provided.

W568 NY532-1

NY512-1

W558 NY532-1

NY512-1

W560 NY532-1

NY512-1

W559 NY532-1

NY512-1

W561 NY532-1

NY512-1

Learning about initial

setting of the NYseries Industrial PCs

and how to prepare

the Controller.

Learning how to program and set up the

Controller functions

of an NY-series

Industrial PC.

Learning detailed

specifications on the

basic instructions of

the NY-series Industrial PC.

Learning about

motion control settings and programming concepts of an

NY-series Industrial

PC.

Learning about the

specifications of the

motion control

instructions of an NYseries Industrial PC.

An introduction to the entire NY-series system

is provided along with the following information on the Industrial Panel PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NY-series system

is provided along with the following information on the Industrial Box PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided on an

introduction to the entire NY-series system.

• Two OS systems

• Initial settings

• Industrial PC Support Utility

• NYCompolet

• Industrial PC API

• Backup and recovery

The following information is provided on the

NY-series Controller functions.

• Controller operation

• Controller features

• Controller settings

• Programming based on IEC 61131-3 language specifications

The instructions in the instruction set (IEC

61131-3 specifications) are described.

The settings and operation of the Controller

and programming concepts for motion control

are described.

The motion control instructions are

described.

Related Manuals

NY-series Motion Control Instructions Reference Manual (W561)

23

Related Manuals

Manual name Cat. No. Model numbers Application Description

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherCAT® Port

User’s Manual

NY-series

IPC Machine Controller

Industrial Panel PC / Industrial Box PC

Built-in EtherNet/IP™ Port

User’s Manual

NY-series

Troubleshooting

Manual

Sysmac Studio Version 1

Operation Manual

NX-series

EtherCAT® Coupler Unit

User’s Manual

NX-series NX Units User’s

Manuals

NX-series Data

Reference Manual

GX-series EtherCAT Slave

Units User’s Manual

W562 NY532-1

NY512-1

W563 NY532-1

NY512-1

W564 NY532-1

NY512-1

W504 SYSMAC

W519 NX-ECC Learning how to use

W521 NX-ID

W522 NX-AD

W523 NX-PD1

W524 NX-EC0

W525 NX- Referring to the list of

W488 GX-ID

-SE2

NX-IA

NX-OC

NX-OD

NX-DA

NX-TS

NX-PF0

NX-PC0

NX-TBX

ECS

NX-

NX-

PG0

GX-OD

GX-OC

GX-MD

GX-AD

GX-DA

GX-EC

XWT-ID

XWT-OD

Using the built-in EtherCAT port in an NYseries Industrial PC.

Using the built-in EtherNet/IP port in an

NY-series Industrial

PC.

Learning about the

errors that may be

detected in an NYseries Industrial PC.

Learning about the

operating procedures and functions

of the Sysmac Studio.

an NX-series EtherCAT Coupler Unit and

EtherCAT Slave Terminals.

Learning how to use

NX Units.

data required for NXseries unit system

configuration.

Learning how to use

the EtherCAT remote

I/O terminals.

Information on the built-in EtherCAT port is

provided.

This manual provides an introduction and

provides information on the configuration,

features, and setup.

Information on the built-in EtherNet/IP port is

provided.

Information is provided on the basic setup,

tag data links, and other features.

Concepts on managing errors that may be

detected in an NY-series Controller and information on individual errors are described.

Describes the operating procedures of the

Sysmac Studio.

The following items are described: the overall

system and configuration methods of an EtherCAT Slave Terminal (which consists of an

NX-series EtherCAT Coupler Unit and NX

Units), and information on hardware, setup,

and functions to set up, control, and monitor

NX Units through EtherCAT.

Describe the hardware, setup methods, and

functions of the NX Units.

Manuals are available for the following Units.

Digital I/O Units, Analog I/O Units, System

Units, and Position Interface Units.

Provides the list of data required for system

configuration including the power consumption and weight of each NX-series Unit.

Describes the hardware, setup methods, and

functions of the EtherCAT remote I/O terminals.

24

NY-series Motion Control Instructions Reference Manual (W561)

Manual name Cat. No. Model numbers Application Description

AC Servomotors/Servo

Drives 1S-series with Built-in

EtherCAT® Communications

User’s Manual

AC Servomotors/Servo

Drives G5-series with Built-in

EtherCAT® Communications

User’s Manual

I586 R88M-1

R88D-1SN-ECT

I573 R88M-K

R88D-KN-ECT-R

I576 R88M-K

R88D-KN-ECT

I577 R88L-EC-

R88D-KN-ECT-L

Learning how to use

the Servomotors/Servo Drives

with built-in EtherCAT Communications.

Learning how to use

the Servomotors/Servo Drives

with built-in EtherCAT Communications.

Describes the hardware, setup methods and

functions of the Servomotors/Servo Drives

with built-in EtherCAT Communications.

Describes the hardware, setup methods and

functions of the Servomotors/Servo Drives

with built-in EtherCAT Communications.

The linear motor type model and the model

dedicated for position controls are available in

G5-series.

Related Manuals

NY-series Motion Control Instructions Reference Manual (W561)

25

Revision History

W561-E1-01

Revision code

Cat. No.

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 September 2016 Original production

26

NY-series Motion Control Instructions Reference Manual (W561)

Introduction to Motion Control

Instructions

This section gives an introduction to motion control instructions supported by NY-series

Controllers.

1-1 Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Basic Information on Motion Control Instructions . . . . . . . . . . . . . . . . . . . 1-8

1

NY-series Motion Control Instructions Reference Manual (W561)

1-1

1 Introduction to Motion Control Instructions

Additional Information

1-1 Motion Control Instructions

Motion control instructions are used in the user program to execute motion controls for an NY-series

Controller. These instructions are defined as function blocks.

The motion control instructions of the MC Function Module are based on the technical specifications of

®

function blocks for PLCopen

There are two types of motion control instructions: PLCopen

are unique to the MC Function Module. This section provides an overview of the PLCopen

control function blocks and motion control instructions.

For details on motion control instructions, refer to the NY-series Industrial Panel PC / Industrial Box PC

Motion Control User’s Manual (Cat. No. W559).

Refer to the NX-series Position Interface Units User’s Manual (Cat. No. W524) for information on using

the NX-series Position Interface Units.

motion control.

®

-defined instructions and instructions that

®

motion

Function Blocks for PLCopen® Motion Control

®

PLCopen

specified in IEC 61131-3 (JIS B 3503). Single-axis positioning, electronic cams, and multi-axes coordinated control are defined along with basic procedures for executing instructions.

By using PLCopen

hardware dependence. Costs for training and support are also reduced.

standardizes motion control function blocks to define a program interface for the languages

®

motion control function blocks, programming can be more easily reused without

PLCopen

PLCopen® is a promotion body for IEC 61131-3 that has its headquarters in Europe and a worldwide membership structure. IEC 61131-3 is an international standard for PLC programming.

PLCopen

that have concerns related to the Japanese market.

• The website of headquarters of PLCopen

®

®

Japan is the promotion committee for the Japanese market and consists of members

®

in Europe is http://www.plcopen.org/.

1-2

NY-series Motion Control Instructions Reference Manual (W561)

Loading...

Loading...