Page 1

Machine Automation Controller

NX-series

Safety Control Unit

User's Manual

NX-SL££££

NX-SI££££

NX-SO££££

Safety Control Unit

Z930-E1-13

Page 2

NOTE

(1) All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or

otherwise, without the prior written permission of OMRON.

(2) No patent liability is assumed with respect to the use of the information contained herein.

Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON as-

(3)

sumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained

in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and V

trademarks of Microsoft Corporation in the United States and other countries.

• EtherCAT

GmbH, Germany.

• Safety over EtherCAT

Automation GmbH, Germany.

®

is registered trademark and patented technology, licensed by Beckhoff Automation

®

is a registered trademark and a patented technology licensed by Beckhoff

isual Basic are either registered trademarks or

• ODVA, CIP, CompoNet, DeviceNet, EtherNet/IP, and CIP Safety are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

Copyrights

• Microsoft product screen shots reprinted with permission from Microsoft Corporation.

• This product incorporates certain third party software. The license and copyright information associ-

ated with this software is available at http://www

.fa.omron.co.jp/nj_info_e/.

Page 3

Introduction

Thank you for purchasing an NX-series Safety Control Unit.

This manual contains information that is necessary to use the NX-series Safety Control Unit.

Please read this manual and make sure you understand the functionality and performance of the Unit

before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

• Personnel with the qualifications, authority, and responsibility for providing safety at each phase of

the lifecycle of the machine: design, installation, operation, maintenance, and disposal.

• Personnel with a knowledge of functional safety.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Introduction

Applicable Products

This manual covers the following products.

• NX-series Safety Control Units

NX-SL££££

NX-SI££££

NX-SO££££

Note that this manual provides information for using an NX-series Safety Control Unit described above

together with an NJ/NX-series CPU Unit, an EtherCAT Coupler Unit, or with an EtherNet/IP Coupler

Unit. When you use it with an NX-CSG320 Communication Control Unit, refer to the NX-series Safety

Control Unit / Communication Control Unit User's Manual (Cat. No. Z395).

NX-series Safety Control Unit User's Manual (Z930)

1

Page 4

Introduction

2

NX-series Safety Control Unit User's Manual (Z930)

Page 5

Sections in this Manual

1 10

2

3

4

5

6

7

8

9

1

10

2

3

11

12

4

13

5 A

6 I

8

9

Overview

Specifications

Safety Unit Restore

Installation and Wiring

Safety Control Unit

Operation

Programming

12

Troubleshooting

System Configuration

and Setup

11

Safety Data Logging

A

Appendices

I

Index

13

Inspection and

Maintenance

Checking Operation and Actual Operation

Calculating Safety Reaction Times

Communications Load

7

Sections in this Manual

NX-series Safety Control Unit User's Manual (Z930)

3

Page 6

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products

Sections in this Manual ........................................................................................... 3

Relevant Manuals................................................................................................... 11

Manual Structure.................................................................................................... 13

Page Structure...............................................................................................................................................13

Special Information ........................................................................................................................................ 14

Precaution on Terminology ............................................................................................................................14

Terms and Conditions Agreement........................................................................ 15

Warranty, Limitations of Liability ....................................................................................................................15

Application Considerations ............................................................................................................................16

Disclaimers ....................................................................................................................................................16

.........................................................................................................................................1

Safety Precautions................................................................................................. 18

Definition of Precautionary Information..........................................................................................................18

Symbols ......................................................................................................................................................... 18

Warnings........................................................................................................................................................19

Precautions for Safe Use ...................................................................................... 24

Precautions for Correct Use ................................................................................. 29

Regulations and Standards .................................................................................. 31

Conformance to EU Directives ......................................................................................................................31

Conformance to EN ISO 13849-1 and EN 62061..........................................................................................32

Conformance to UL and CSA Standards.......................................................................................................33

Conformance to Shipbuilding Standards .......................................................................................................33

Conformance to KC Certification ...................................................................................................................33

Unit Versions.......................................................................................................... 35

Unit Versions..................................................................................................................................................35

Unit Versions of Units and Sysmac Studio Versions......................................................................................36

Related Manuals..................................................................................................... 37

Terminology............................................................................................................ 39

Revision History..................................................................................................... 42

Section 1 Overview

1-1 Introduction and Features...................................................................................................1 - 2

1-1-1 Overview of Safety Control Unit

1-1-2 Features of Safety Control Unit.................................................................................................1 - 5

1-2 System Configuration and Configuration Devices ........................................................... 1 - 8

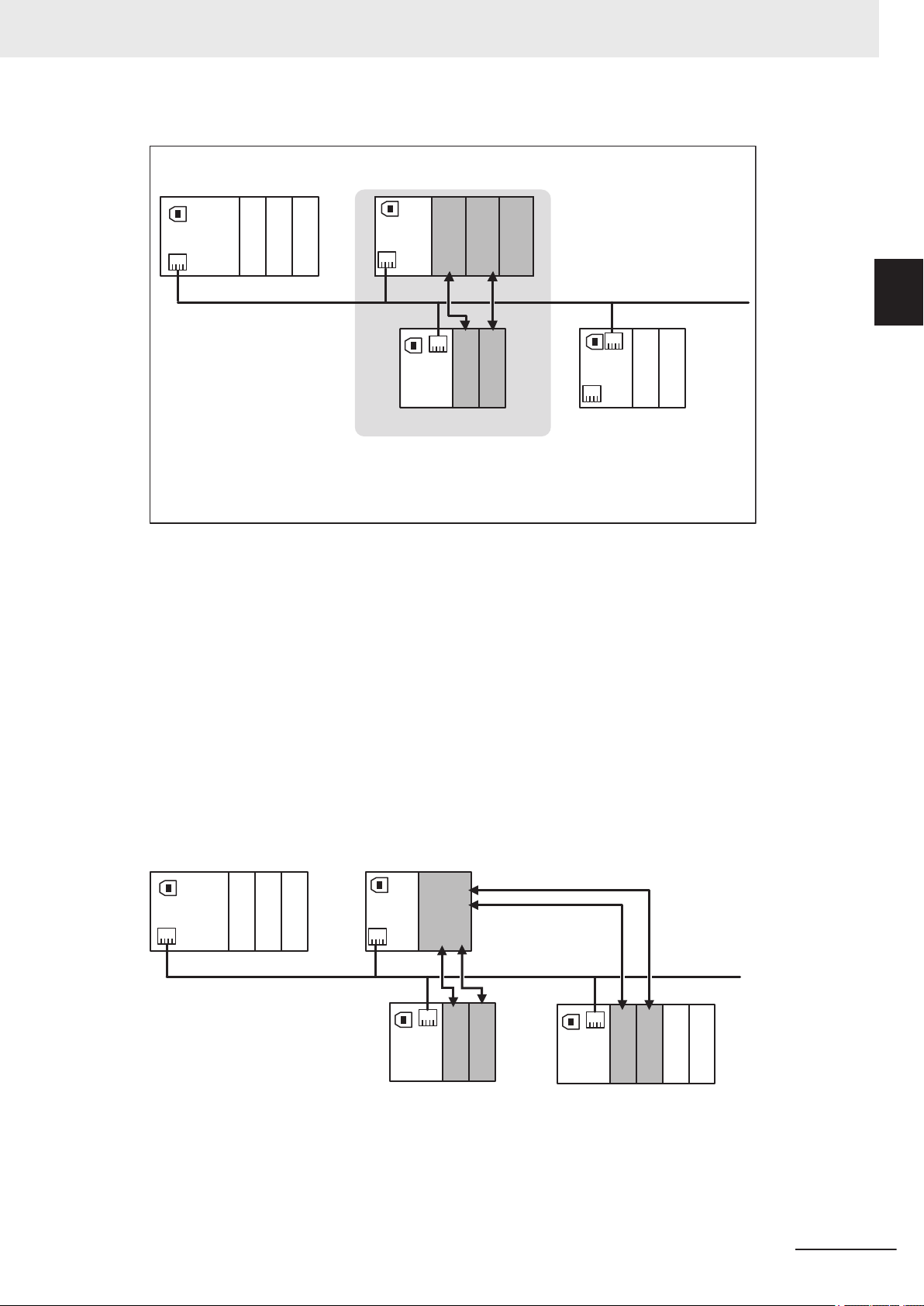

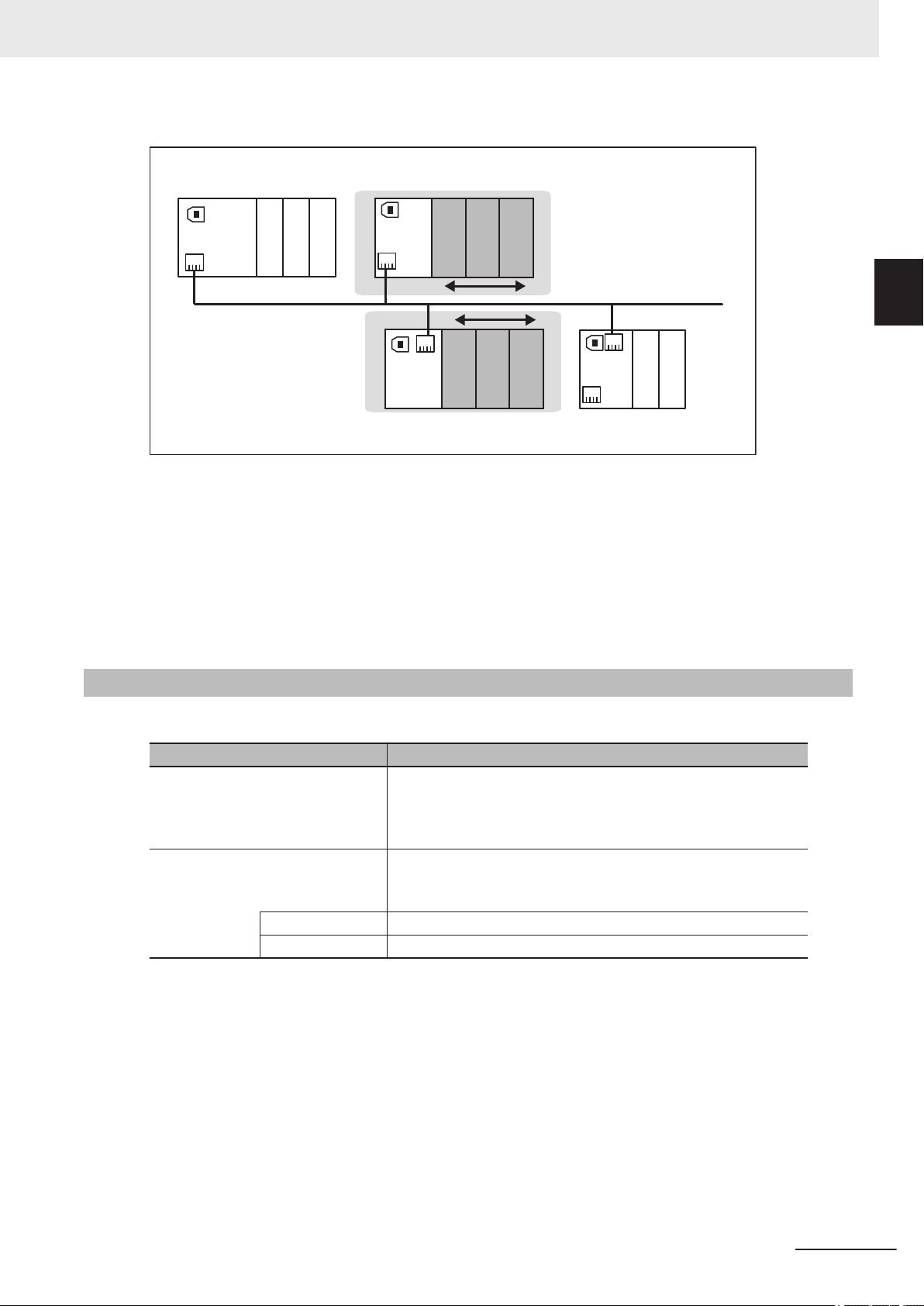

1-2-1 Safety Control System Configuration on NX bus of CPU Unit or EtherCAT Network ...............1 - 8

1-2-2 Safety Control System Configuration on EtherNet/IP Network ...............................................1 - 10

1-2-3 Standalone Safety Control System Configuration...................................................................1 - 10

4

................................................................................................1 - 2

NX-series Safety Control Unit User's Manual (Z930)

Page 7

1-2-4 Types of Safety Control Unit ...................................................................................................1 - 11

1-3 Support Software

1-3-1 Applicable Support Software...................................................................................................1 - 12

1-3-2 Connection Method and Procedures for EtherCAT Coupler Units ..........................................1 - 12

1-3-3 Connection Method and Procedures for EtherNet/IP Coupler Units .......................................1 - 14

...............................................................................................................1 - 12

1-4 Commissioning Procedures .............................................................................................1 - 15

1-4-1 Overall Procedure ...................................................................................................................1 - 15

1-4-2 Detailed Procedures................................................................................................................1 - 16

Section 2 Specifications

2-1 Safety CPU Unit....................................................................................................................2 - 2

2-1-1 Models and Specifications

2-1-2 Part Names and Functions........................................................................................................2 - 8

2-1-3 Indicators.................................................................................................................................2 - 10

2-2 Safety Input Unit ................................................................................................................2 - 16

2-2-1 Models and Specifications ......................................................................................................2 - 16

2-2-2 Part Names and Functions......................................................................................................2 - 22

2-2-3 Indicators.................................................................................................................................2 - 24

2-3 Safety Output Unit .............................................................................................................2 - 28

2-3-1 Models and Specifications ......................................................................................................2 - 28

2-3-2 Part Names and Functions......................................................................................................2 - 35

2-3-3 Indicators.................................................................................................................................2 - 38

2-4 PFH......................................................................................................................................2 - 41

CONTENTS

........................................................................................................2 - 2

Section 3 Installation and Wiring

3-1 Installing Units .....................................................................................................................3 - 2

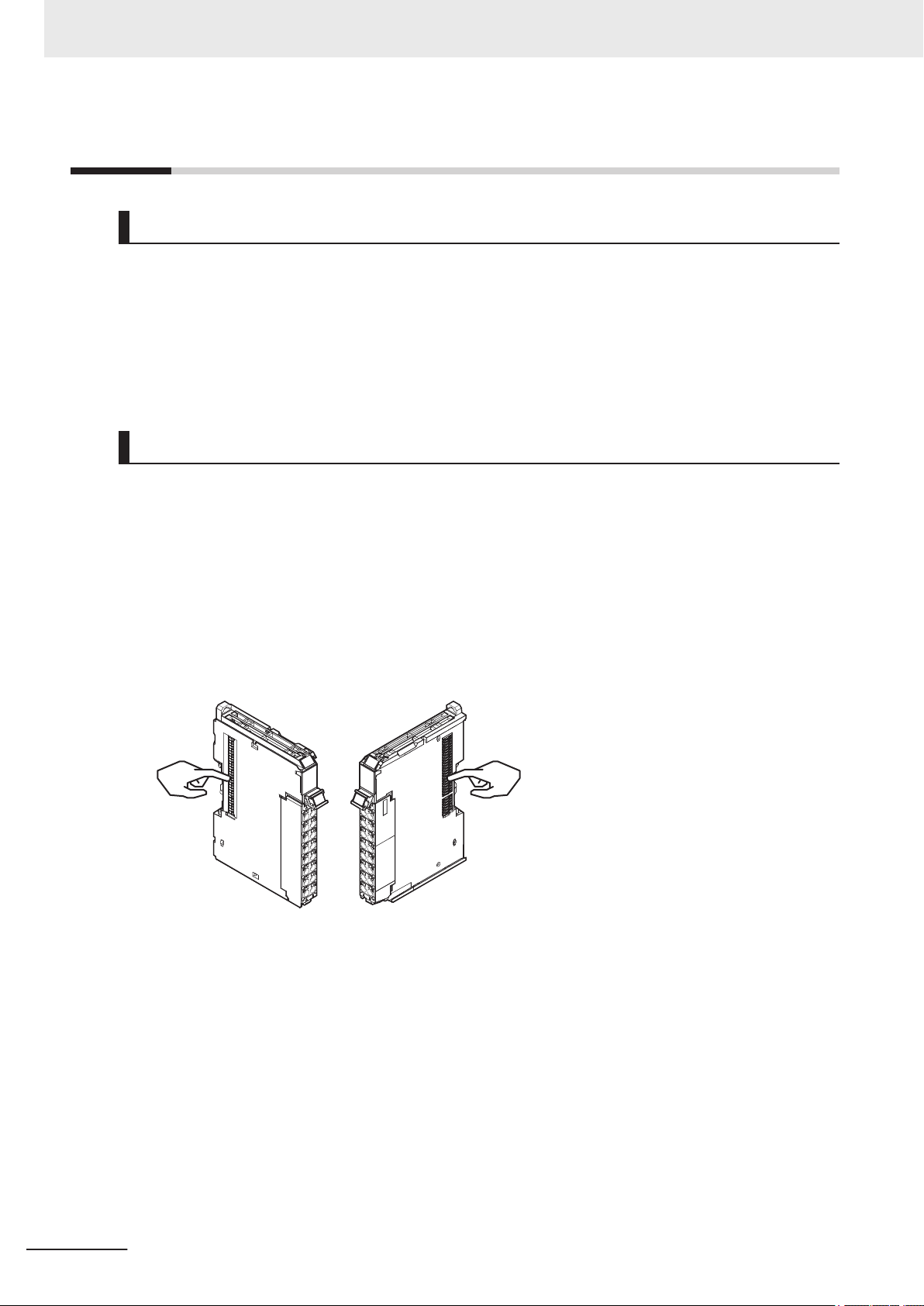

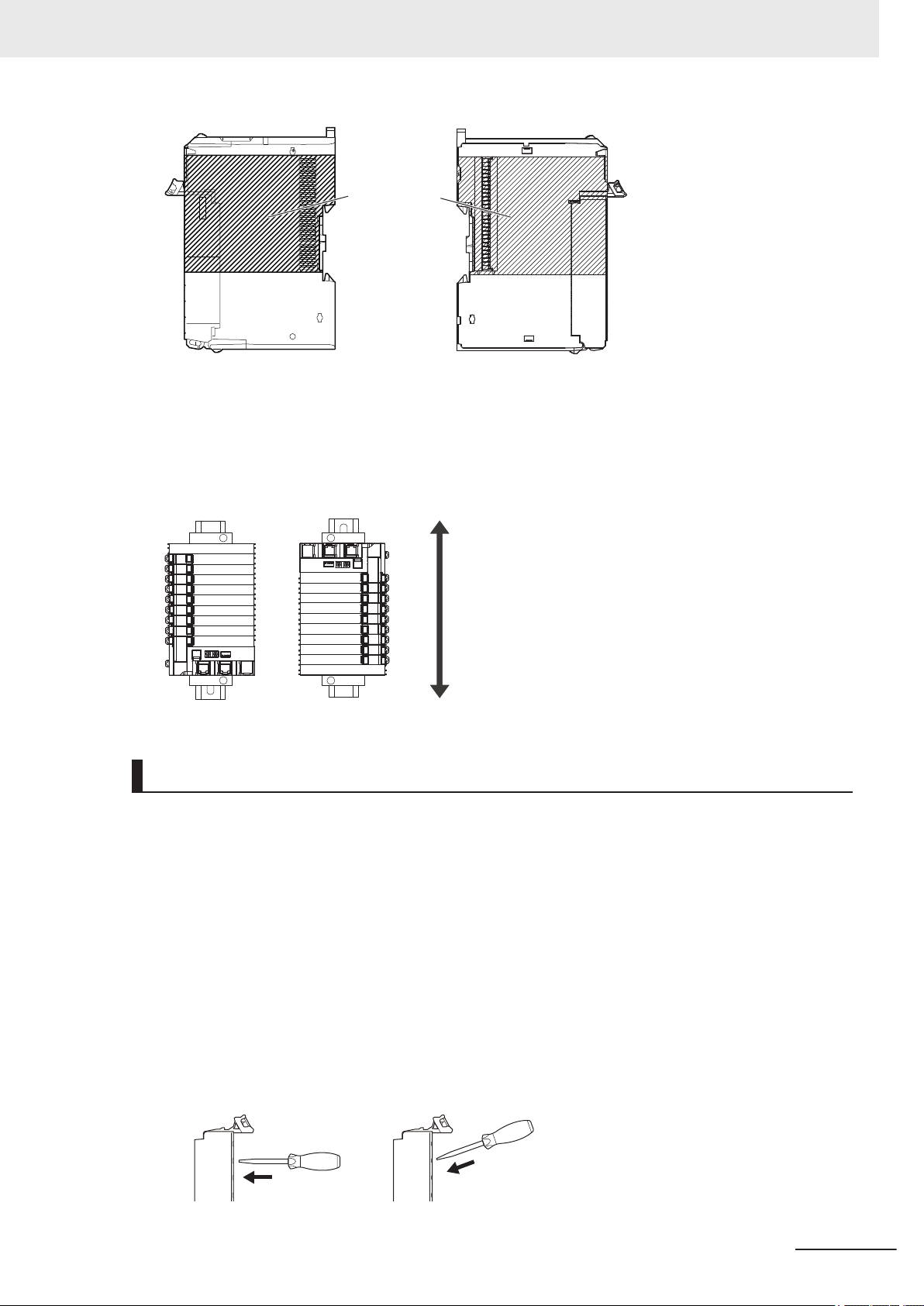

3-1-1 Installing NX Units

3-1-2 Attaching Markers .....................................................................................................................3 - 4

3-1-3 Removing Units.........................................................................................................................3 - 5

3-1-4 Installation Orientation ..............................................................................................................3 - 6

.....................................................................................................................3 - 2

3-2 Power Supply Types and Wiring ........................................................................................3 - 8

3-2-1 Applications of I/O Power Supply and Supply Methods ............................................................3 - 8

3-2-2 Calculating the Total Current Consumption from I/O Power Supply .........................................3 - 9

3-3 Wiring the Terminals..........................................................................................................3 - 10

3-3-1 Wiring to the Screwless Clamping Terminal Blocks ................................................................3 - 10

3-3-2 Checking Wiring ......................................................................................................................3 - 23

Section 4 Safety Control Unit Operation

4-1 Relationship between Units and Types of Communications...........................................4 - 2

4-1-1 Safety Control System on CPU Rack or EtherCAT Network.....................................................4 - 2

4-1-2 Safety Control System on EtherNet/IP Network........................................................................4 - 4

4-1-3 Standalone Safety Control System ...........................................................................................4 - 6

4-2 I/O System ............................................................................................................................4 - 8

4-2-1 Relationship between the Types of Signals and the Types of Communications.......................4 - 8

4-2-2 Safety Data Types and Standard Data Types...........................................................................4 - 8

4-2-3 Specifying Safety Data Types and Standard Data Types .........................................................4 - 9

4-3 Safety I/O Function ............................................................................................................4 - 10

4-3-1 Safety Input Function ..............................................................................................................4 - 10

4-3-2 Safety Output Function ...........................................................................................................4 - 32

NX-series Safety Control Unit User's Manual (Z930)

5

Page 8

CONTENTS

Section 5 System Configuration and Setup

5-1 Configuration and Setup Procedures ................................................................................5 - 2

5-2 Part Names and Functions of the Sysmac Studio W

5-3 Controller Configuration and Setup of the Safety Control Units ....................................5 - 5

5-3-1 Procedures for Creating the Controller Configuration for Safety Control ..................................5 - 6

5-3-2 Setting and Viewing the Safety Control Unit Settings ...............................................................5 - 9

5-3-3 Procedure to Change the Model of the Safety Control Unit ....................................................5 - 10

5-4 Setting Up the Safety Process Data Communications...................................................5 - 12

5-4-1 Setting Up the FSoE Communications....................................................................................5 - 12

5-4-2 Setting Up the CIP Safety Communications ...........................................................................5 - 13

5-4-3 Calculating the Number of Connections..................................................................................5 - 20

5-5 Safety I/O Functions ..........................................................................................................5 - 23

5-6 Registering Device Variables............................................................................................5 - 26

5-7 Exposing Variables to Standard Controllers...................................................................5 - 30

5-7-1 Exposing Global Variables ......................................................................................................5 - 30

5-7-2 Setting Exposed Variables ......................................................................................................5 - 31

5-7-3 Safety CPU Unit Status...........................................................................................................5 - 35

5-7-4 I/O Ports for Safety I/O Units...................................................................................................5 - 36

5-7-5 I/O Refreshing Method ............................................................................................................5 - 36

5-8 Setting Standard Process Data Communications ..........................................................5 - 37

5-8-1 Using an CPU Unit or EtherCAT Coupler Unit ........................................................................5 - 37

5-8-2 Using an EtherNet/IP Coupler Unit .........................................................................................5 - 37

5-9 Exporting/Importing Settings Data...................................................................................5 - 39

5-9-1 Exporting/Importing the Settings for the Entire Slave Terminal...............................................5 - 39

5-9-2 Exporting/Importing the Settings for All the NX Units on a CPU Rack or Slave Terminal.......5 - 41

5-9-3 Exporting/Importing Data for Individual Safety CPU Unit........................................................5 - 42

indow .............................................5 - 3

Section 6 Programming

6-1 POUs (Program Organization Units) .................................................................................. 6 - 3

6-1-1 POU

6-1-2 Overview of the Three Types of POUs......................................................................................6 - 3

6-1-3 Differences between Programs, Functions, and Function Blocks.............................................6 - 4

6-1-4 Details on Programs..................................................................................................................6 - 5

6-1-5 Details on Function Blocks........................................................................................................6 - 6

6-1-6 Details on Functions................................................................................................................6 - 10

6-1-7 Instructions..............................................................................................................................6 - 11

6-2 Variables .............................................................................................................................6 - 12

6-2-1 Variables..................................................................................................................................6 - 12

6-2-2 Types of Variables ...................................................................................................................6 - 12

6-2-3 Type of User-defined Variable .................................................................................................6 - 12

6-2-4 Attributes of Variables .............................................................................................................6 - 13

6-2-5 Data Type................................................................................................................................6 - 14

6-2-6 Variable Attributes Other Than Data Type...............................................................................6 - 16

6-2-7 Function Block Instances ........................................................................................................6 - 17

6-2-8 Restrictions on Variable Names and Other Safety Program-related Names...........................6 - 17

6-3 Constants (Literals) ...........................................................................................................6 - 19

6-3-1 Constants ................................................................................................................................6 - 19

6-3-2 Types of Constants .................................................................................................................6 - 19

6-4 Programming Languages..................................................................................................6 - 21

6-4-1 Programming Languages........................................................................................................6 - 21

6-4-2 FBD Language ........................................................................................................................6 - 21

6-5 Programming Operations..................................................................................................6 - 26

6-5-1 Programming Layer on the Sysmac Studio.............................................................................6 - 26

..........................................................................................................................................6 - 3

6

NX-series Safety Control Unit User's Manual (Z930)

Page 9

CONTENTS

6-5-2 Registering POUs ...................................................................................................................6 - 27

6-5-3 Registering V

6-5-4 FBD Programming ..................................................................................................................6 - 41

6-5-5 Function Block Conversion for Programs................................................................................6 - 60

6-5-6 Building ..................................................................................................................................6 - 61

6-5-7 Searching and Replacing ........................................................................................................6 - 63

6-5-8 Safety Task Settings................................................................................................................6 - 66

6-6 Automatic Programming ................................................................................................... 6 - 68

6-6-1 Generation Algorithms for Automatic Programming................................................................6 - 68

6-6-2 Automatic Programming Settings............................................................................................6 - 71

6-6-3 Automatic Programming Execution Procedure .......................................................................6 - 74

6-7 Monitoring Memory Usage for Safety Control Unit ........................................................6 - 77

6-8 Offline Debugging..............................................................................................................6 - 79

6-8-1 Offline Safety Program Debugging..........................................................................................6 - 79

6-8-2 Monitoring ...............................................................................................................................6 - 82

6-8-3 Controlling BOOL Variables, Changing Present Values, and Using Forced Refreshing.........6 - 82

6-8-4 Setting the Initial Values of Variables......................................................................................6 - 82

6-8-5 Feedback Settings ..................................................................................................................6 - 83

6-8-6 Simple Automatic Test.............................................................................................................6 - 84

ariables ..............................................................................................................6 - 36

Section 7 Checking Operation and Actual Operation

7-1 Procedures before Operation and Transferring the Required Data................................7 - 3

7-1-1 Commissioning Procedure

7-1-2 Data That You Must Transfer before Operation and Data Transfer Procedures .......................7 - 4

7-2 Transferring the Configuration Information ...................................................................... 7 - 7

7-2-1 Overview ...................................................................................................................................7 - 7

7-2-2 Transfer Procedure for a Connection to NJ/NX-series CPU Unit..............................................7 - 8

7-2-3 Transfer Procedure for a Connection to Communications Coupler Unit ...................................7 - 8

7-3 Operating Modes of the Safety CPU Unit ........................................................................7 - 11

7-3-1 Startup Operating Mode and Changing the Operating Mode.................................................. 7 - 11

7-3-2 Operation When Changing Operating Mode...........................................................................7 - 13

7-3-3 Executable Functions in Each Mode of the Safety CPU Unit..................................................7 - 14

7-4 Changing to DEBUG Mode................................................................................................7 - 17

7-5 Checking External Device Wiring.....................................................................................7 - 20

7-5-1 Overview of Functions for Checking Wiring ............................................................................7 - 20

7-5-2 Monitoring Safety I/O Units .....................................................................................................7 - 20

7-5-3 Troubleshooting Safety I/O Terminals .....................................................................................7 - 24

7-5-4 Clear All Memory Operation for Safety I/O Units ....................................................................7 - 25

7-6 Functions for Checking Operation...................................................................................7 - 27

7-6-1 Overview of Functions for Checking Operation.......................................................................7 - 27

7-6-2 Starting and Stopping the Safety Programs in DEBUG Mode ................................................7 - 27

7-6-3 Monitoring Variables in the FBD Editor ...................................................................................7 - 28

7-6-4 Monitoring Variables in a Watch Tab Page..............................................................................7 - 29

7-6-5 Controlling BOOL Variables, Changing Present Values, and Using Forced Refreshing.........7 - 31

7-7 Online Functional Test ......................................................................................................7 - 40

7-7-1 Online Functional Test Settings...............................................................................................7 - 40

7-7-2 Online Functional Test Execution Procedure ..........................................................................7 - 44

7-8 Node Name .........................................................................................................................7 - 50

7-9 Security Settings................................................................................................................7 - 51

7-9-1 Setting the Safety Password ...................................................................................................7 - 51

7-9-2 Data Protection .......................................................................................................................7 - 52

7-10 Performing Safety Validation and Operation...................................................................7 - 56

7-10-1 Performing Safety Validation...................................................................................................7 - 56

7-10-2 Changing to RUN Mode ..........................................................................................................7 - 57

7-10-3 Changing to PROGRAM Mode ...............................................................................................7 - 58

........................................................................................................7 - 3

NX-series Safety Control Unit User's Manual (Z930)

7

Page 10

CONTENTS

7-11 Uploading Configuration Information and Safety Application Data .............................7 - 60

7-11-1

7-11-2 Uploading Data for a Connection to an NJ/NX-series CPU Unit.............................................7 - 60

7-11-3 Uploading Data for a Connection to a Communications Coupler Unit ....................................7 - 61

Outline.....................................................................................................................................7 - 60

7-12 Transferring Safety Application Data...............................................................................7 - 63

7-13 Monitoring Controller Status ............................................................................................7 - 64

7-14 Restarting and Clearing All Memory ................................................................................ 7 - 66

7-14-1 Restarting................................................................................................................................7 - 66

7-14-2 Clear All Memory Operation....................................................................................................7 - 67

Section 8 Calculating Safety Reaction Times

8-1 Safety Reaction Time...........................................................................................................8 - 2

8-1-1 Calculating the Safety Reaction T

8-1-2 Verifying Safety Reaction Times ...............................................................................................8 - 4

8-2 Safety Task ...........................................................................................................................8 - 5

8-2-1 Safety Task................................................................................................................................8 - 5

8-2-2 Operation of Safety Task...........................................................................................................8 - 5

8-2-3 Minimum Safety Task Period.....................................................................................................8 - 5

8-2-4 Setting the Safety Task Period..................................................................................................8 - 7

8-3 FSoE Watchdog Timer.........................................................................................................8 - 9

8-3-1 FSoE Watchdog Timers ............................................................................................................8 - 9

8-3-2 Checking FSoE Watchdog Timers ............................................................................................8 - 9

8-3-3 Settings for FSoE Watchdog Timers .......................................................................................8 - 10

8-3-4 Changing FSoE Watchdog Timers..........................................................................................8 - 10

8-4 EPI (Data Packet Interval).................................................................................................. 8 - 11

8-4-1 Changing the EPI .................................................................................................................... 8 - 11

8-4-2 EPI Restrictions....................................................................................................................... 8 - 11

ime .......................................................................................8 - 2

Section 9 Communications Load

9-1 Adjusting the Communications Load ................................................................................9 - 2

9-1-1 Checking Bandwidth Usage for T

9-1-2 Checking the Device Bandwidth Usage of the CIP Safety Routing ..........................................9 - 4

9-1-3 Relationship between the Number of Packets Used per Second and Packet Intervals............9 - 5

9-1-4 Adjusting the Device Bandwidth Usage ....................................................................................9 - 5

ag Data Links ........................................................................9 - 3

Section 10 Safety Unit Restore

10-1 Safety Unit Restore............................................................................................................10 - 2

10-1-1 Generate Safety Unit Restore File Function ...........................................................................10 - 2

10-1-2 Safety Unit Restore Function ..................................................................................................10 - 3

10-1-3 Specifications of a Safety Unit Restore File ............................................................................10 - 6

Section 11 Safety Data Logging

11-1 Outline of the Safety Data Logging Function.................................................................. 11 - 2

Creating a Safety Data Logging Settings File with the Sysmac Studio........................ 11 - 4

11-2

11-3 Safety Data Logging Operation Procedure .....................................................................11 - 6

11-4 Checking the Logging Status ........................................................................................... 11 - 7

11-4-1 Checking the Seven-segment Indicator ..................................................................................11 - 7

11-4-2 Checking with System-defined Variables ................................................................................11 - 7

8

NX-series Safety Control Unit User's Manual (Z930)

Page 11

11-5 Log File Specifications......................................................................................................11 - 8

Section 12 Troubleshooting

12-1 How to Check for Errors....................................................................................................12 - 2

12-2 Checking for Errors with the Indicators

12-2-1 Troubleshooting the Main Errors in the Safety CPU Unit........................................................12 - 3

12-2-2 Troubleshooting the Main Errors in the Safety I/O Units.......................................................12 - 11

12-3 Checking for Errors with the Sysmac Studio................................................................12 - 14

12-3-1 Checking for Errors from the Sysmac Studio ........................................................................12 - 14

12-3-2 Types of Errors......................................................................................................................12 - 15

12-3-3 Event Codes for Errors and Troubleshooting Procedures.....................................................12 - 17

12-3-4 Error Descriptions .................................................................................................................12 - 31

12-4 Resetting Errors...............................................................................................................12 - 90

12-5 Troubleshooting Flow When Errors Occur....................................................................12 - 91

CONTENTS

..........................................................................12 - 3

Section 13 Inspection and Maintenance

13-1 Cleaning and Inspection ...................................................................................................13 - 2

13-1-1 Cleaning

13-1-2 Periodic Inspections ................................................................................................................13 - 2

..................................................................................................................................13 - 2

13-2 Maintenance Procedures ..................................................................................................13 - 5

13-2-1 Replacing the Safety CPU Unit ...............................................................................................13 - 5

13-2-2 Replacing Safety I/O Units ......................................................................................................13 - 7

Appendices

A-1 Dimensions.......................................................................................................................... A - 3

A-1-1 Safety CPU Unit ....................................................................................................................... A - 3

A-1-2 Safety I/O Units ........................................................................................................................ A - 4

A-2 NX Objects ........................................................................................................................... A - 5

A-2-1 Format of NX Object Descriptions............................................................................................ A - 5

A-2-2 Safety CPU Unit (NX-SL3300/NX-SL3500) ............................................................................. A - 5

A-2-3 Safety CPU Unit (NX-SL5500/NX-SL5700) ............................................................................. A - 7

A-2-4 NX-SID800 Safety Input Unit ..................................................................................................A - 11

A-2-5 NX-SIH400 Safety Input Unit ................................................................................................. A - 16

A-2-6 NX-SOD400 Safety Output Unit............................................................................................. A - 21

A-2-7 NX-SOH200 Safety Output Unit............................................................................................. A - 25

A-3 Application Examples....................................................................................................... A - 30

A-3-1 Emergency Stop Pushbutton Switches .................................................................................. A - 30

A-3-2 Safety Doors .......................................................................................................................... A - 32

A-3-3 Safety Laser Scanners........................................................................................................... A - 36

A-3-4 Safety Door Switches with Magnetic Locks and Key Selector Switches................................ A - 39

A-3-5 Enable Switches..................................................................................................................... A - 43

A-3-6 Two-hand Switches................................................................................................................ A - 47

A-3-7 D40A Non-contact Door Switches.......................................................................................... A - 50

A-3-8 D40Z Non-contact Door Switches.......................................................................................... A - 53

A-3-9 Safety Mats and Safety Light Curtains................................................................................... A - 56

A-3-10 Safety Edges.......................................................................................................................... A - 61

A-3-11 Single Beam Safety Sensor ................................................................................................... A - 63

A-3-12 Multi-axis Servo Drives (STO)................................................................................................ A - 66

A-4 Change Tracking ............................................................................................................... A - 70

A-5 Safety CPU Unit Status..................................................................................................... A - 72

A-5-1 NX-SL3300/NX-SL3500 ......................................................................................................... A - 72

A-5-2 NX-SL5500/NX-SL5700 ......................................................................................................... A - 72

NX-series Safety Control Unit User's Manual (Z930)

9

Page 12

CONTENTS

A-6 I/O Ports of Safety I/O Units ............................................................................................. A - 74

A-7 CIP Response Codes ........................................................................................................ A - 81

A-8 Icon list for Safety Slave Unit Parameters ...................................................................... A - 86

A-9 Calculating I/O Sizes for CPU Rack or Slave Terminals................................................ A - 93

A-10 Printing .............................................................................................................................. A - 94

A-11 List of Screwless Clamping Terminal Block Models ..................................................... A - 96

A-12 I/O Response Times for Communications between NX Units on EtherNet/IP

A-13 Units That Support Communications between NX Units ............................................ A - 100

A-14 Checking the Signature Code on the Seven-segment Indicator ................................ A - 101

A-15 Execution Scenarios for the Simple Automatic Test................................................... A - 102

A-16 Differences in Checking Operation between the Simulator and Safety CPU Unit.... A - 104

A-17 Version Information ........................................................................................................ A - 105

A-6-1 NX-SIH400 Safety Input Unit

A-6-2 NX-SID800 Safety Input Unit ................................................................................................. A - 76

A-6-3 NX-SOH200 Safety Output Unit............................................................................................. A - 77

A-6-4 NX-SOD400 Safety Output Unit............................................................................................. A - 78

A-7-1 General Status Codes............................................................................................................ A - 81

A-7-2 Extended Status Codes ......................................................................................................... A - 83

A-8-1 External Device Icons for Input Devices ................................................................................ A - 86

A-8-2 Contact Icons for Input Devices ............................................................................................. A - 89

A-8-3 External Device Icons for Output Devices.............................................................................. A - 91

A-8-4 Contact Icons for Output Devices .......................................................................................... A - 92

A-10-1 Selecting the Items to Print .................................................................................................... A - 94

A-10-2 Items that are Printed............................................................................................................. A - 94

A-11-1 Model Notation ....................................................................................................................... A - 96

A-11-2 List of Terminal Block Models................................................................................................. A - 96

................................................................................................. A - 74

Slave Terminals................................................................................................................. A - 98

A-17-1 Relationship between Unit Versions and Sysmac Studio Versions...................................... A - 105

A-17-2 Functions That Were Added or Changed for Each Version ................................................. A - 109

Index

10

NX-series Safety Control Unit User's Manual (Z930)

Page 13

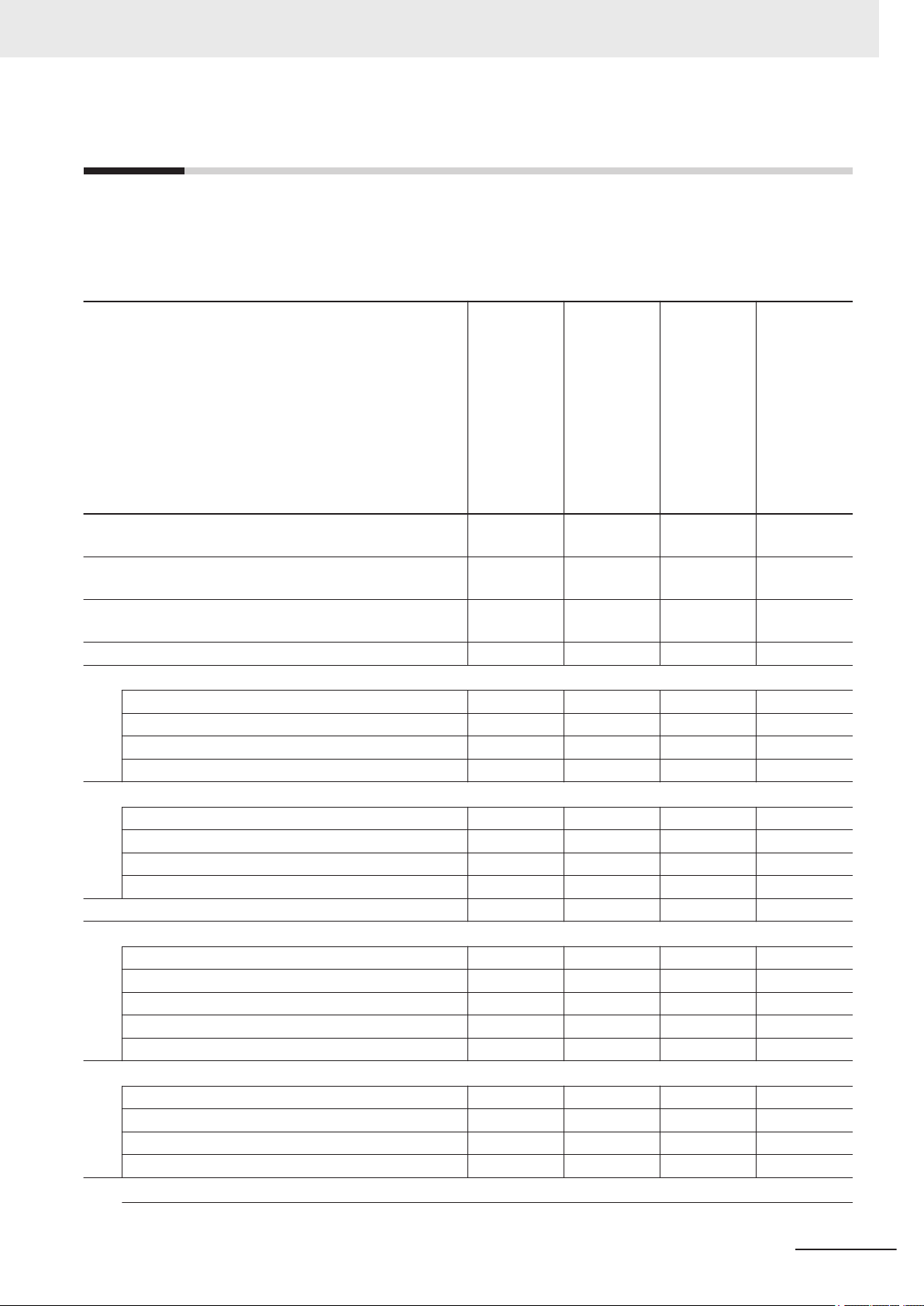

Relevant Manuals

The following table provides the relevant manuals for this product. Read all of the manuals that are

relevant to your system configuration and application before you use the product.

Most operations on this product are performed from the Sysmac Studio Automation Software. For details on the Sysmac Studio, refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

Purpose of use

NX-series

Safety Control Unit

User's Manual

User's Manual

Relevant Manuals

NX-series

Safety Control Unit /

Communication Control Unit

NX-series

Communication Control Unit

Built-in Function User's Manual

NX-series

Safety Control Unit

Instructions Reference Manual

Building a safety control system integrated with NJ/NX-series CPU Units

Building a standalone safety control system with

EtherNet/IP Coupler Units

Building a safety network control system with Communication Control Units

Introduction to Safety Control Unit

Setting devices and hardware

NX-SL5£££ Safety CPU Unit

NX-SL3£££ Safety CPU Unit

NX-SI££££ and NX-SO££££ Safety I/O Units

NX-CSG£££ Communication Control Unit

Software settings

NX-SL5£££ Safety CPU Unit

NX-SL3£££ Safety CPU Unit

NX-SI££££ and NX-SO££££ Safety I/O Units

NX-CSG£££ Communication Control Unit

Creating safety programs

Testing operation and debugging

Safety programs

Safety process data communications

Safety I/O functions

Tag data links

Built-in functions for Communication Control Unit

Learning about error corrections

NX-SL5£££ Safety CPU Unit

NX-SL3£££ Safety CPU Unit

NX-SI££££ and NX-SO££££ Safety I/O Units

NX-CSG£££ Communication Control Unit

Maintenance

l

l

l

l l

l l

l

l l

l

l l

l

l l

l l

l l l

l l l

l l

l l

l

l l

l l l

l l

l l

l

NX-series Safety Control Unit User's Manual (Z930)

11

Page 14

Relevant Manuals

Purpose of use

NX-series

Safety Control Unit

User's Manual

User's Manual

NX-series

Safety Control Unit /

Communication Control Unit

NX-series

Communication Control Unit

Built-in Function User's Manual

NX-series

Safety Control Unit

Instructions Reference Manual

NX-SL5£££ Safety CPU Unit

NX-SL3£££ Safety CPU Unit

NX-SI££££ and NX-SO££££ Safety I/O Units

NX-CSG£££ Communication Control Unit

l l

l

l l

l

12

NX-series Safety Control Unit User's Manual (Z930)

Page 15

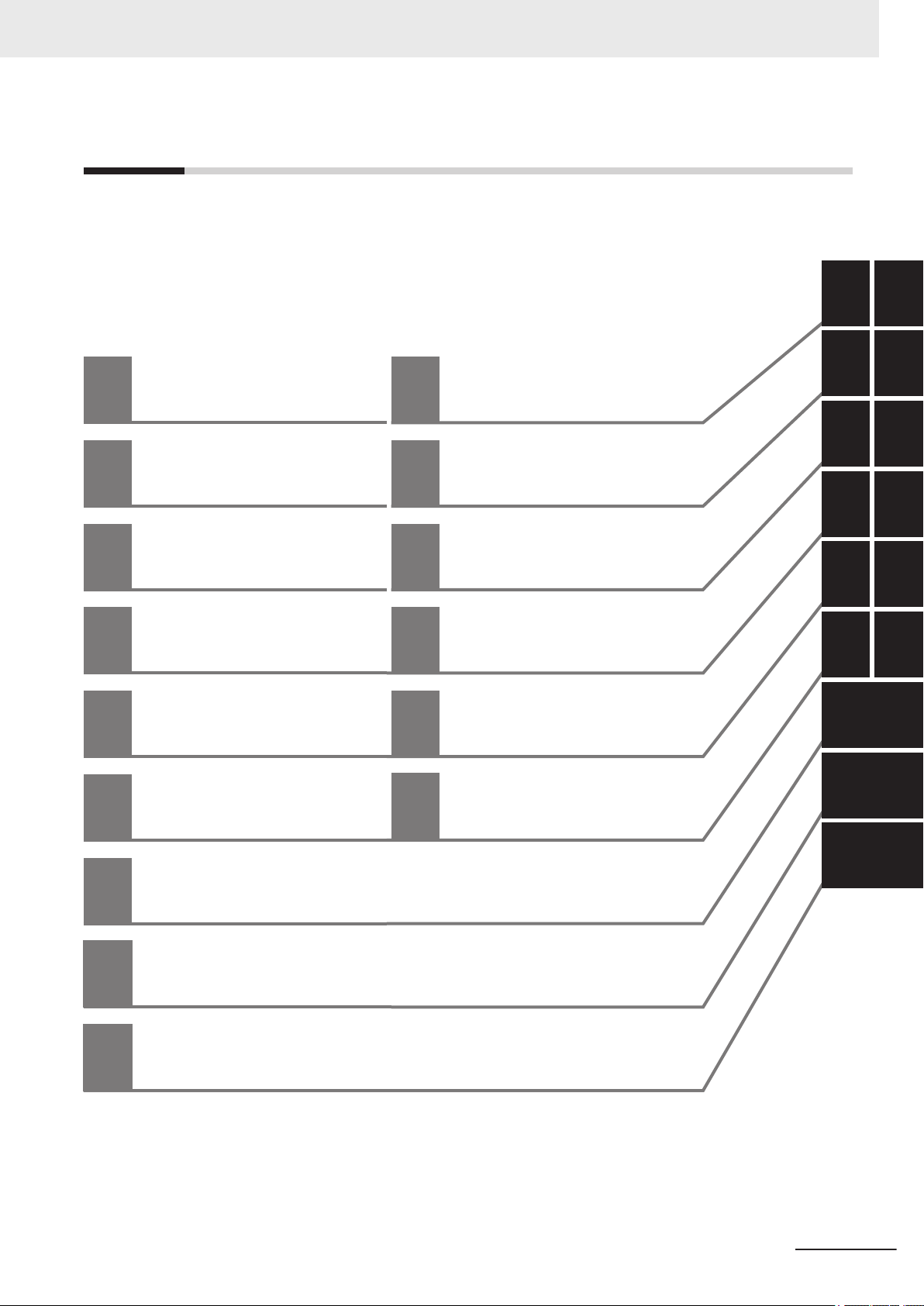

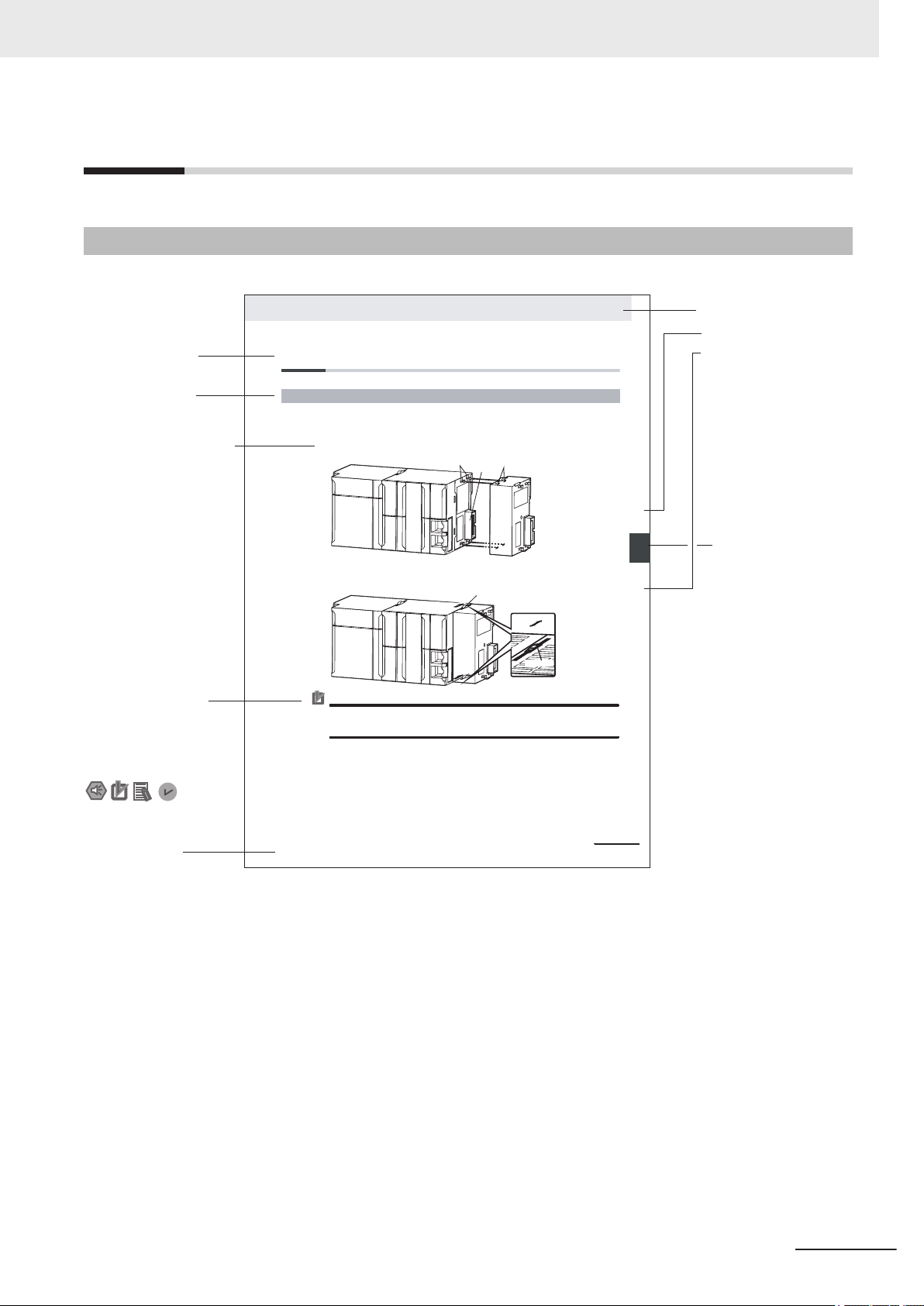

Manual Structure

4-9

4 Installation and Wir

ing

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the conn ectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

The sliders on the tops and bottoms of the Power Supply Unit, C

PU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Page Structure

The following page structure is used in this manual.

Manual Structure

NX-series Safety Control Unit User's Manual (Z930)

13

Page 16

RightLeft

Up

Down

Manual Structure

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Information on dif

and for dif

ferent versions of the Sysmac Studio is given.

ferences in specifications and functionality for Controller with different unit versions

Precaution on Terminology

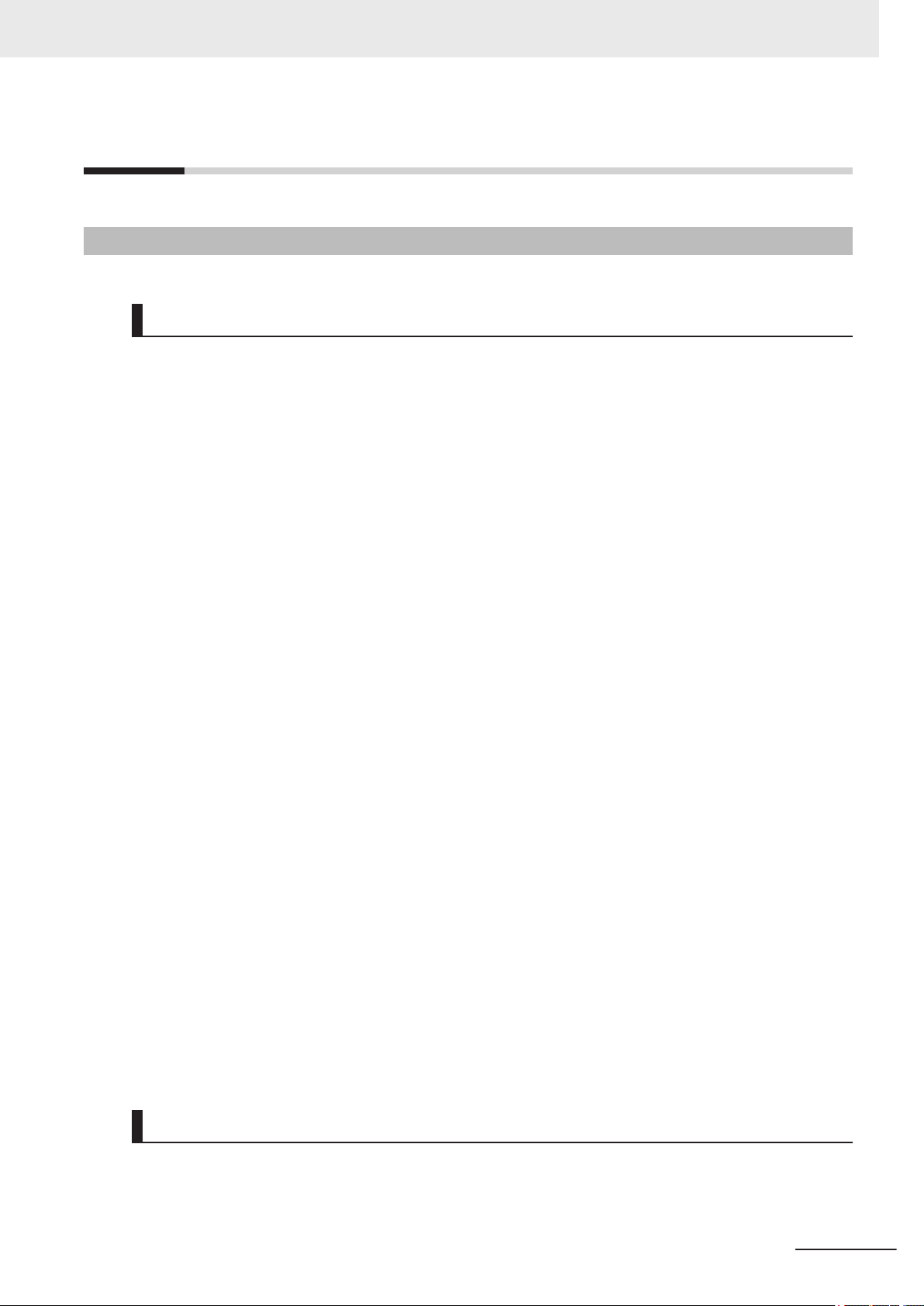

In this manual, the directions in relation to the Units are given in the following figure, which shows upright installation.

14

NX-series Safety Control Unit User's Manual (Z930)

Page 17

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

l

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

l

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

l

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

NX-series Safety Control Unit User's Manual (Z930)

15

Page 18

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

, NEGLIGENCE OR STRICT LIABILITY.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

s application or use of the Product. At Buy-

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’

formance is subject to the Omron’s Warranty and Limitations of Liability.

s test conditions, and the user must correlate it to actual application requirements. Actual per-

16

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may

NX-series Safety Control Unit User's Manual (Z930)

Page 19

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NX-series Safety Control Unit User's Manual (Z930)

17

Page 20

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Additionally, there may be severe property

damage.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate

injury, or property damage.

WARNING

Ca

ution

Safety Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the NX-series Safety Control Unit. The safety precautions that are provided are extremely important to

safety. Always read and heed the information provided in all safety precautions.

The following notation is used.

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

.

18

NX-series Safety Control Unit User's Manual (Z930)

Page 21

Warnings

WARNING

Serious injury may possibly occur due to loss of required safety functions.

When building the system, observe the following warnings to ensure the integrity of the safety-related

components.

Setting Up a Risk Assessment System

The process of selecting these products should include the development and execution of a risk assessment system early in the design development stage to help identify

potential dangers in your equipment and optimize safety product selection.

Related International Standards:

• ISO 12100 General Principles for Design - Risk Assessment and Risk Reduction

Safety Precautions

Protective Measure

When developing a safety system for the equipment and devices that use safety products, make every effort to understand and conform to the entire series of international

and industry standards available, such as the examples given below

Related International Standards:

• ISO 12100 General Principles for Design - Risk Assessment and Risk Reduction

• IEC 60204-1 Electrical Equipment of Machines - Part 1: General Requirements

• ISO 13849-1, -2 Safety-related Parts of Control Systems

• ISO 14119 Interlocking Devices Associated with Guards - Principles for Design and

Selection

• IEC/TS 62046 Application of Protective Equipment to Detect the Presence of Persons

• IEC 62061 Functional Safety of Safety-related Electrical, Electronic and Programmable Electronic Control Systems

• IEC 61508 Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems

.

Role of Safety Products

Safety products incorporate standardized safety functions and mechanisms, but the

benefits of these functions and mechanisms are designed to attain their full potential

only within properly designed safety-related systems. Make sure you fully understand

all functions and mechanisms, and use that understanding to develop systems that will

ensure optimal usage.

Related International Standards:

• ISO 141

Selection

• ISO 13857 Safety Distances to Prevent Hazard Zones being Reached by Upper and

Lower Limbs

19 Interlocking Devices Associated with Guards - Principles for Design and

NX-series Safety Control Unit User's Manual (Z930)

19

Page 22

Safety Precautions

Installing Safety Products

Qualified engineers must develop your safety-related system and install safety products in devices and equipment. Prior to machine commissioning verify through testing

that the safety products works as expected.

Related International Standards:

• ISO 12100 General Principles for Design - Risk Assessment and Risk Reduction

IEC 60204-1 Electrical Equipment of Machines - Part 1: General Requirements

•

• ISO 13849-1, -2 Safety-related Parts of Control Systems

• ISO 14119 Interlocking Devices Associated with Guards - Principles for Design and

Selection

• IEC 62061 Functional Safety of Safety-related Electrical, Electronic and Programmable Electronic Control Systems

• IEC 61508 Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems

Observing Laws and Regulations

Safety products must conform to pertinent laws, regulations, and standards. Make sure

that they are installed and used in accordance with the laws, regulations, and standards of the country where the devices and equipment incorporating these products are

distributed.

Observing Usage Precautions

Carefully read the specifications and precautions as well as all items in the Instruction

Manual for your safety product to learn appropriate usage procedures. Any deviation

from instructions will lead to unexpected device or equipment failure not anticipated by

the safety-related system.

Transferring Devices and Equipment

When transferring devices and equipment, be sure to retain one copy of the Instruction

Manual and supply another copy with the device or equipment so the person receiving

it will have no problems with operation and maintenance.

Related International Standards:

• ISO 12100 General Principles for Design - Risk Assessment and Risk Reduction

•

IEC 60204-1 Electrical Equipment of Machines - Part 1: General Requirements

• ISO 13849-1, -2 Safety-related Parts of Control Systems

• IEC 62061 Functional Safety of Safety-related Electrical, Electronic and Programmable Electronic Control Systems

• IEC 61508 Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems

20

Design

NX-series Safety Control Unit User's Manual (Z930)

Page 23

Safety Precautions

Confirm that the calculated reaction times meet the required specifications for all safety

chains.

Serious injury may possibly occur due to loss of required safety functions.

All safety devices and components that are connected to an NX-series Safety Control

Unit must be selected and used to meet the required level of safety and the relevant

safety category.

Serious injury may possibly occur due to loss of required safety functions.

Do not use indicators on the NX-series Safety Control Units for safety operations.

Serious injury may possibly occur due to loss of required safety functions.

Check during the import of the program that the CRC of the program is correct.

Serious injury may possibly occur due to loss of required safety functions.

Check during the import of the user defined function that the CRC of the imported function block is correct.

Serious injury may possibly occur due to loss of required safety functions.

Do not use non-safety signals, including tag data links, explicit messages, and exposed variables, as safety signals.

Serious injury may possibly occur due to loss of required safety functions.

If you select “Only Open” for the Open Type setting, make sure to verify that the originator/target have correct configurations.

Serious injury may possibly occur due to loss of required safety functions.

Before connecting an NX Series Safety Control Unit to the network, clear the previous

settings.

Serious injury may possibly occur due to loss of required safety functions.

Debugging

Before you perform safety validation of the safety programs, complete debugging of

the safety programs.

Otherwise, the Safety CPU Unit will start with safety programs that are not fully debugged and may cause serious personal injury.

Make sure that the area around the system is safe before you change the operating

mode, change present values, or execute forced refreshing. The outputs may operate

and may cause serious injury.

Make sure that the area around the system is safe before you start the system operation while the online functional test is in progress. The outputs may operate and may

cause serious injury.

Testing Operation

Before you start the system, perform user testing to make sure that all safety devices

operate correctly

Serious injury may possibly occur due to loss of required safety functions.

NX-series Safety Control Unit User's Manual (Z930)

. The safety signature is validated upon completion of the user testing.

21

Page 24

Safety Precautions

After you perform safety validation, check items for safety validation printed out to confirm Safety Control Units are correctly configured.

Although the Simulator and Simple Automatic Test simulate the operation of the Safety

CPU Unit, there are differences from the Safety CPU Unit in operation and timing. Always confirm operation on the actual equipment before you operate the equipment.

Accidents may occur if the controlled system performs unexpected operation.

Wiring

Wire the safety input and output lines so that they do not touch other lines.

Serious injury may possibly occur due to loss of required safety functions.

Wire the Safety Control Unit properly so that 24-VDC lines do not touch output lines

accidentally or unintentionally.

Serious injury may possibly occur due to loss of required safety functions.

Wire the safety output lines and 24-VDC lines so that ground faults will not cause the

loads to turn ON.

Serious injury may possibly occur due to loss of required safety functions.

The wiring information that is displayed on the Sysmac Studio is for reference only and

may dif

forming suitable wiring.

Serious injury may possibly occur due to loss of required safety functions.

fer from the actual wiring diagrams. Always confirm the actual wiring and per-

During Power Supply

Do not touch any of the terminals or terminal blocks while the power is being supplied.

Doing so may result in electric shock.

Do not attempt to take any Unit apart.

In particular, high-voltage parts are present in Units that supply power while power is supplied or

immediately after power is turned OFF

There are sharp parts inside the Unit that may cause injury.

. Touching any of these parts may result in electric shock.

Replacing Units

When replacing a Safety Control Unit, confirm that the model of the Unit is correct,

confirm that the Unit and terminal block mounting positions are correct, configure the

replacement Unit suitably, and confirm that the Unit operates correctly

.

Voltage and Current Inputs

Make sure that the voltages and currents that are input to the Units and slaves are

within the specified ranges.

Inputting voltages or currents that are outside of the specified ranges may cause accidents or fire.

22

NX-series Safety Control Unit User's Manual (Z930)

Page 25

Safety Precautions

Transferring

Always confirm safety at the destination before you transfer the unit configuration information, parameters, set values, or other data from tools such as the Sysmac Studio.

The devices or machines may perform unexpected operation regardless of the operating mode of the Controller.

Restoring Data

When you restore the Safety CPU Unit, confirm that the safety signature for the restored programs is correct. Serious injury may possibly occur due to loss of required

safety functions.

NX-series Safety Control Unit User's Manual (Z930)

23

Page 26

Example: NX Unit (12 mm width)

N

G NG

Precautions for Safe Use

Precautions for Safe Use

Transporting

• Do not attempt to disassemble, repair, or modify any Units. Doing so may result in malfunction or

fire.

• Do not drop any Unit or subject it to abnormal vibration or shock. Doing so may result in Unit malfunction or burning.

• When transporting any Unit, use the special packing box for it. Also, do not subject the Unit to excessive vibration or shock during transportation.

Mounting

• Always turn OFF the power supply before mounting a Unit. If the power supply is not OFF, the Unit

may malfunction or may be damaged.

• Mount terminal blocks and connectors only after checking the mounting location carefully. Be sure

that the terminal blocks, expansion cables, and other items with locking devices are properly locked

into place.

• Do not apply labels or tape to the Unit. When the Units are installed or removed, adhesive or scraps

may adhere to the pins in the NX bus connector, which may result in malfunctions.

• Do not touch the pins in the NX bus connector on the Unit. Dirt may adhere to the pins in the NX bus

connector, which may result in malfunctions.

• Do not write on the an NX Unit with ink within the restricted region that is shown in the following

figure. Also do not get this area dirty. When the Unit is installed or removed, ink or dirt may adhere

to the pins in the NX bus connector, which may result in malfunctions in the Controller.

Refer to the user's manual of the CPU Unit or Communications Coupler Unit to be connected for

details on the restricted region of the CPU Unit or Communications Coupler Unit.

24

NX-series Safety Control Unit User's Manual (Z930)

Page 27

Restricted region

(shaded portion)

Upper

Lower

NG OK

Precautions for Safe Use

• For the installation orientations in the following figure, support the cables, e.g., with a duct, so that

the End Plate on the bottom is not subjected to the weight of the cables. The weight of the cables

may cause the bottom End Plate to slide downward so that the Slave Terminal is no longer secured

to the DIN T

rack, which may result in malfunctions.

Wiring

• Follow the instructions in this manual to correctly perform wiring.

• Double-check all switch settings to make sure that they are correct before turning ON the power

.

supply

• Use the correct wiring parts and tools when you wire the system. Otherwise, cables may be disconnected to cause short-circuit or wire breakage.

• Do not pull on the cables or bend the cables beyond their natural limit. Do not place any heavy objects on the cables or other wiring lines. Doing so may severe the cables.

• When wiring or installing the Units, do not allow metal fragments to enter the Units.

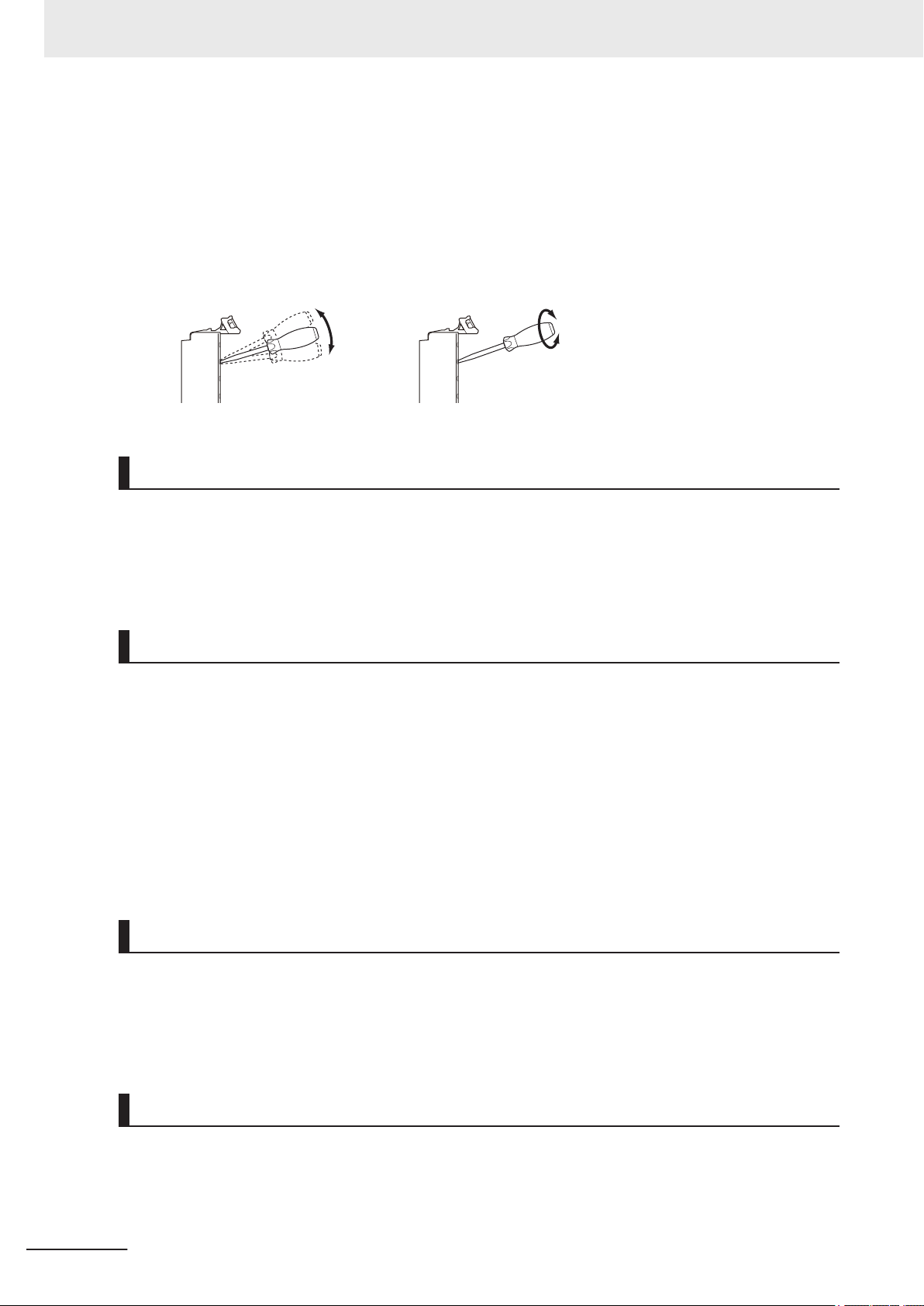

• Do not press the flat-blade screwdriver straight into the release hole on the screwless clamping terminal block. Doing so may damage the terminal block.

NX-series Safety Control Unit User's Manual (Z930)

25

Page 28

NG NG

Precautions for Safe Use

• When you insert a flat-blade screwdriver into a release hole on the screwless clamping terminal

block, press the screwdriver down with a force of 30 N or less. Applying excessive force may damage the terminal block.

• Do not tilt or twist the flat-blade screwdriver while it is pressed into the release hole on the screwless

clamping terminal block. Doing so may damage the terminal block.

Power Supply Design

• Use the I/O power supply capacity within the range that is given in the Unit specifications.

• Provide suitable power supply capacity according to the reference manuals.

•

Use the power supply voltage that is specified in the related manuals.

• Do not apply voltages that exceed the rated value to any Input Unit.

Debugging

• With forced refreshing, the values of variables are overwritten with specified values and then the

safety programs are executed. If forced refreshing is used for variables that give the results of program processing, the variables will first take the specified values, but they will then be overwritten by

the safety program.

• Depending on the dif

• After you clear the memory, the Controller operates in the same way as immediately after you create

the system configuration with the Controller in the factory default condition.

• Verify that the safety communications with a remote node will be established in the debug mode of

the Safety CPU Unit.

ference in the forced status, the control system may operate unexpectedly.

Turning ON the Power Supply or Restarting after Safety Validation

• Remember that if safety validation is successful, the next time the Safety CPU Unit is started, it will

automatically start in RUN mode.

• When you download the parameters for the NJ/NX-series CPU Units, the Communications Coupler

Unit and NX Units, the Safety CPU Unit automatically restarts.

Turning ON the Power Supply

• Double-check all wiring connections and switch settings to make sure that they are correct before

turning ON the power supply. Use the correct wiring parts and tools when you wire the system.

26

NX-series Safety Control Unit User's Manual (Z930)

Page 29

Precautions for Safe Use

• Make sure that the voltages and currents that are input to the Units and slaves are within the specified ranges. Inputting voltages or currents that are outside of the specified ranges may damage the

Units or slaves or cause fire.

Actual Operation

• The relevant Units will maintain the safe states for I/O data with safety connections after an error is

detected in safety process data communications. However, when the cause of the error is removed,

safety process data communications will recover automatically

If you need to prevent equipment from restarting when safety process data communications recover

automatically, implement suitable restart conditions in the user program.

.

Turning OFF the Power Supply

• Do not disconnect the cable or turn OFF the power supply to the Controller or a Slave Terminal

when downloading data or the user program from the Support Software.

• Always turn OFF the external power supply to the Units before attempting any of the following.

a)

Mounting or removing an NX Unit.

b) Assembling Units

c) Setting DIP switches or rotary switches

d) Connecting or wiring cables

e) Attaching or removing terminal blocks or connectors

The Power Supply Unit may continue to supply power to the Controller for a few seconds after the

power supply turns OFF. The UNIT PWR and I/O PWR indicators are lit during this time. Confirm

that the UNIT PWR and the I/O PWR indicators are not lit before you perform any of the above actions.

General Communications

• Do not exceed the ranges that are given in the specifications for the communications distance and

number of connected Units.

• Refer to the user