Page 1

Machine Automation Controller

NX-series

Safety Control Unit

Instructions Reference Manual

NX-SL

Z931-E1-04

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• Safety over EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing Machine Automation Controller NX-series Safety Control Units.

This manual contains information that is necessary to use the NX-series Safety Control Units. Please

read this manual and make sure you understand the functionality and performance of the NX-series

Safety Control Units before you attempt to use them in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

• Personnel with the qualifications, authority, and responsibility for providing safety at each phase of

the lifecycle of the machine: design, installation, operation, maintenance, and disposal.

• Personnel with a knowledge of functional safety.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

Introduction

Applicable Products

This manual covers the following products.

• NX-series Safety Control Units

NX-SL

NX-series Safety Control Unit Instructions Reference Manual (Z931)

1

Page 4

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Applicable Products..................................................................................................................................... 1

Relevant Manuals .....................................................................................................7

Manual Structure ......................................................................................................8

Page Structure............................................................................................................................................. 8

Special Information...................................................................................................................................... 9

Terms and Conditions Agreement........................................................................10

Warranty, Limitations of Liability ................................................................................................................ 10

Application Considerations ........................................................................................................................ 11

Disclaimers ................................................................................................................................................ 11

Safety Precautions .................................................................................................13

Precautions for Safe Use.......................................................................................14

Precautions for Correct Use..................................................................................15

Regulations and Standards...................................................................................16

Conformance to EC Directives .................................................................................................................. 16

Conformance to EN ISO 13849-1 and EN 62061...................................................................................... 17

Conformance to UL and CSA Standards ................................................................................................... 17

Conformance to KC Standards.................................................................................................................. 18

Software Licenses and Copyrights ............................................................................................................ 18

Unit Versions ..........................................................................................................19

Unit Versions.............................................................................................................................................. 19

Unit Versions and Sysmac Studio Versions............................................................................................... 21

Unit Version Notation ................................................................................................................................. 21

Related Manuals .....................................................................................................22

Terminology ............................................................................................................23

Revision History .....................................................................................................24

Sections in this Manual .........................................................................................25

Section 1 Introduction to Instructions for Safety Control Units and

Interpreting Instruction Descriptions

1-1 Types of Instructions............................................................................................................. 1-2

1-2 Interpreting Instruction Descriptions .................................................................................. 1-3

1-2-1 Items ...........................................................................................................................................1-3

1-2-2 Safety Data Types and Standard Data Types ............................................................................. 1-4

1-2-3 Valid Ranges and Default Values of Variables ............................................................................ 1-4

1-2-4 Timer Set Values .........................................................................................................................1-5

2

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 5

Section 2 Standard Functions

Table of Standard Functions ....................................................................................................2-2

Execution Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

JUMP and LABEL.................................................................................................................... 2-6

RETURN.................................................................................................................................. 2-8

Data Type Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

BOOL_TO_INT...................................................................................................................... 2-12

BOOL_TO_DINT ...................................................................................................................2-13

BOOL_TO_TIME ...................................................................................................................2-14

BOOL_TO_WORD ................................................................................................................ 2-15

BYTE_TO_INT ...................................................................................................................... 2-16

BYTE_TO_DINT.................................................................................................................... 2-17

WORD_TO_INT ....................................................................................................................2-18

WORD_TO_DINT.................................................................................................................. 2-20

DWORD_TO_DINT ............................................................................................................... 2-21

BYTE_TO_TIME.................................................................................................................... 2-23

WORD_TO_TIME.................................................................................................................. 2-24

DWORD_TO_TIME ............................................................................................................... 2-25

BYTE_TO_WORD................................................................................................................. 2-26

WORD_TO_BYTE................................................................................................................. 2-27

WORD_TO_DWORD ............................................................................................................ 2-28

DINT_TO_BOOL ...................................................................................................................2-29

INT_TO_BOOL...................................................................................................................... 2-30

DINT_TO_BYTE.................................................................................................................... 2-31

DINT_TO_DWORD ............................................................................................................... 2-32

DINT_TO_WORD.................................................................................................................. 2-34

INT_TO_BYTE ...................................................................................................................... 2-35

INT_TO_DWORD.................................................................................................................. 2-36

INT_TO_WORD ....................................................................................................................2-38

DINT_TO_INT ....................................................................................................................... 2-40

INT_TO_DINT ....................................................................................................................... 2-41

DINT_TO_TIME..................................................................................................................... 2-42

INT_TO_TIME ....................................................................................................................... 2-43

TIME_TO_BOOL ...................................................................................................................2-44

TIME_TO_BYTE..................................................................................................................

TIME_T

TIME_TO_WORD.................................................................................................................. 2-47

TIME_TO_DINT..................................................................................................................... 2-48

TIME_TO_INT ....................................................................................................................... 2-49

WORD_TO_BOOL ................................................................................................................ 2-50

Boolean Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

AND, OR, and XOR...............................................................................................................2-52

NOT ....................................................................................................................................... 2-54

_DWORD ............................................................................................................... 2-46

O

CONTENTS

.. 2-45

NX-series Safety Control Unit Instructions Reference Manual (Z931)

3

Page 6

CONTENTS

Math Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

ADD ....................................................................................................................................... 2-56

SUB ....................................................................................................................................... 2-58

MUL ....................................................................................................................................... 2-60

DIV......................................................................................................................................... 2-62

Comparison Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

EQ ......................................................................................................................................... 2-66

NE.......................................................................................................................................... 2-67

LT, LE, GT, and GE ................................................................................................................ 2-68

Selection Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

SEL........................................................................................................................................ 2-72

MUX....................................................................................................................................... 2-74

Section 3 Safety Standard Function Blocks

Safety Standard Function Block Instructions ........................................................................... 3-2

SF_CTD................................................................................................................................... 3-3

SF_CTU................................................................................................................................... 3-5

SF_CTUD ................................................................................................................................ 3-7

SF_F_TRIG ........................................................................................................................... 3-10

SF_R_TRIG........................................................................................................................... 3-11

SF_RS ................................................................................................................................... 3-12

SF_SR ................................................................................................................................... 3-13

SF_TOF................................................................................................................................. 3-14

SF_TON................................................................................................................................. 3-16

SF_TP ................................................................................................................................... 3-18

Section 4 Safety Function Blocks

General Rules for Safety Function Blocks............................................................................... 4-2

Safety Function Block Instructions .......................................................................................... 4-8

SF_Antivalent .......................................................................................................................... 4-9

SF_EDM ................................................................................................................................ 4-15

SF_EmergencyStop...............................................................................................................4-23

SF_EnableSwitch .................................................................................................................. 4-30

SF_Equivalent ....................................................................................................................... 4-36

SF_ESPE .............................................................................................................................. 4-42

SF_GuardLocking.................................................................................................................. 4-49

SF_GuardMonitoring .............................................................................................................4-55

SF_ModeSelector.................................................................................................................. 4-61

SF_MutingPar........................................................................................................................ 4-70

SF_MutingPar_2Sensor ........................................................................................................ 4-82

SF_MutingSeq....................................................................................................................... 4-91

SF_OutControl..................................................................................................................... 4-101

SF_SafetyRequest .............................................................................................................. 4-107

4

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 7

Index 2

CONTENTS

SF_TestableSafetySensor................................................................................................... 4-113

SF_TwoHandControlTypeII ................................................................................................. 4-124

SF_TwoHandControlTypeIII ................................................................................................ 4-129

NX-series Safety Control Unit Instructions Reference Manual (Z931)

5

Page 8

CONTENTS

6

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 9

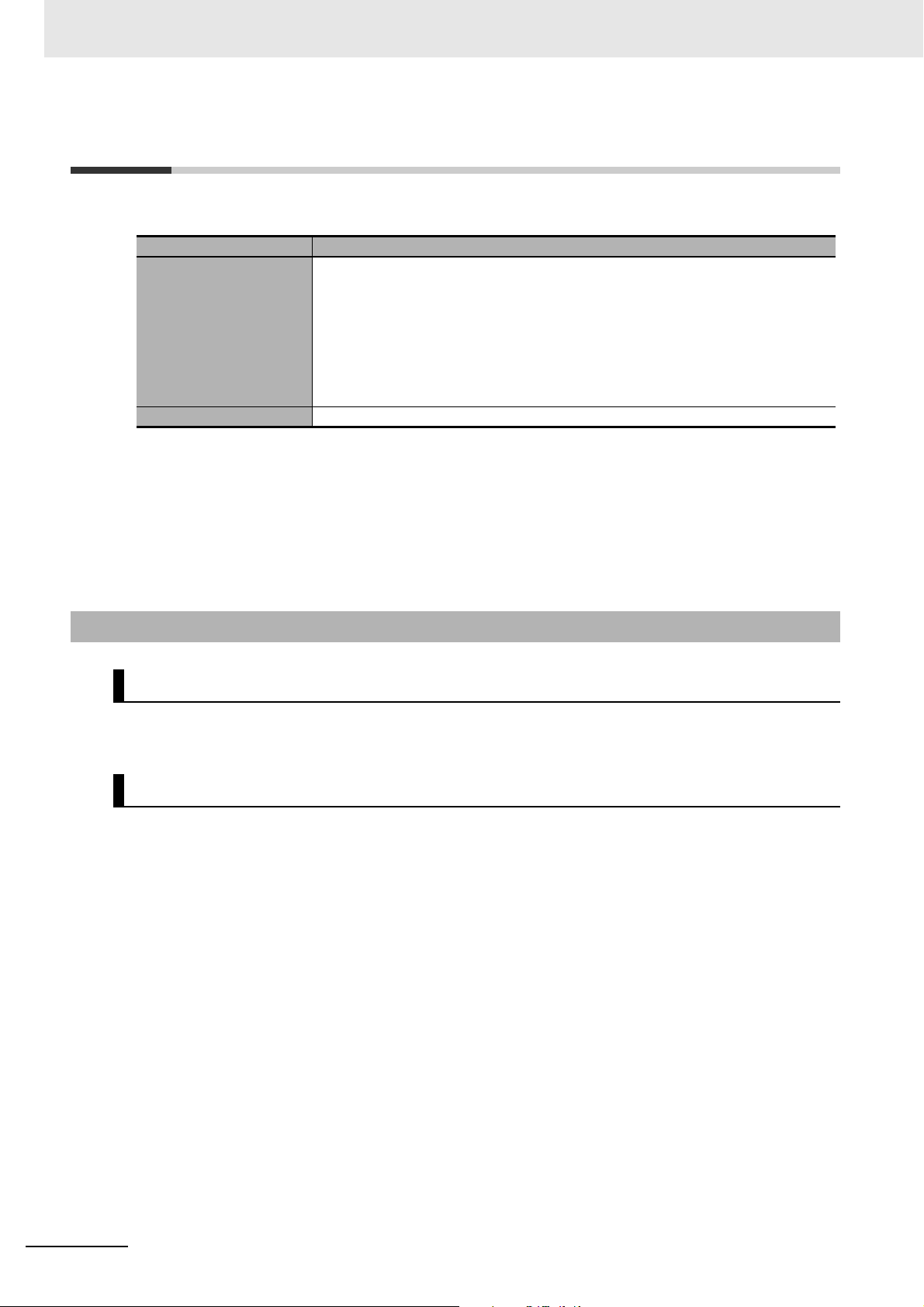

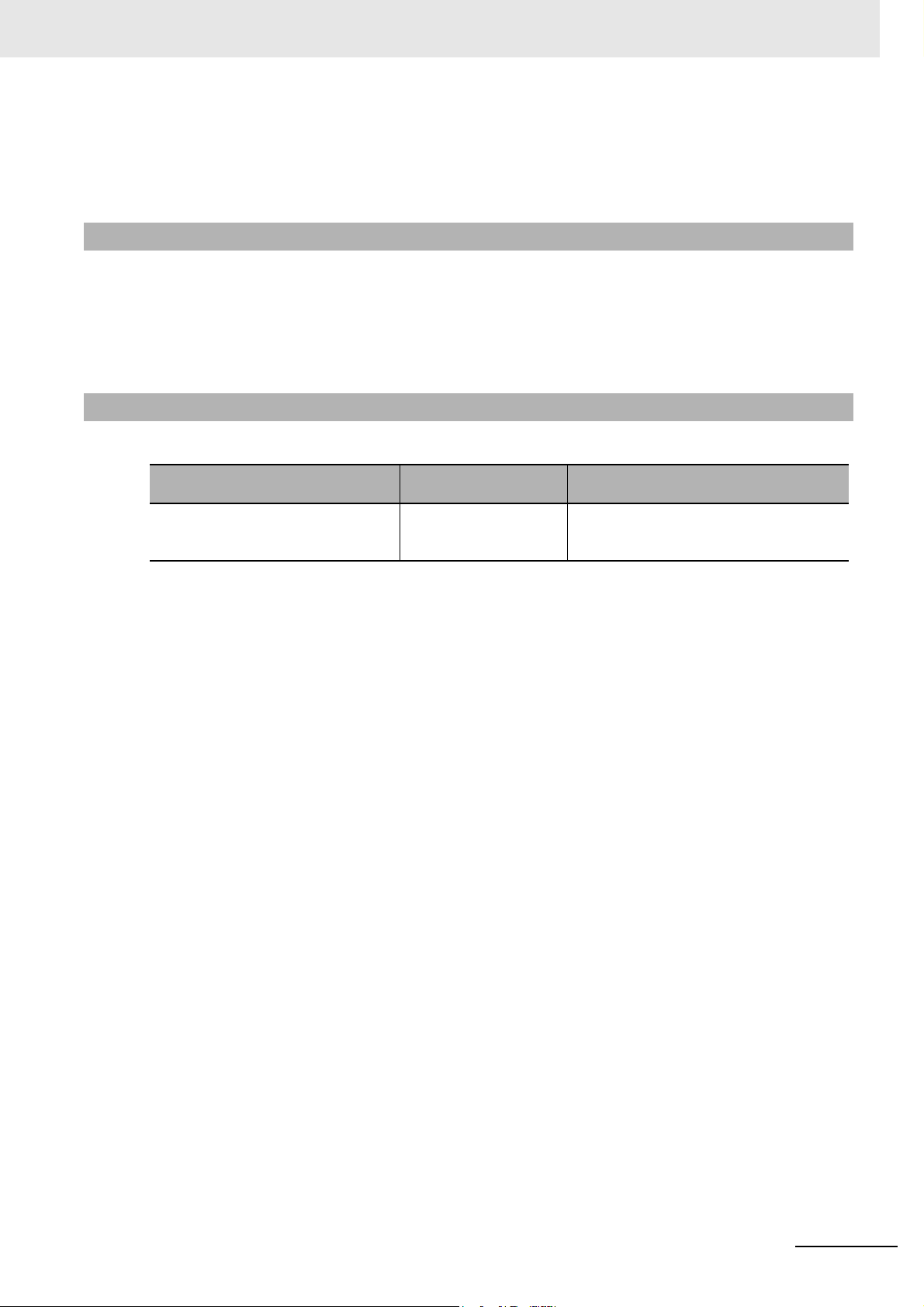

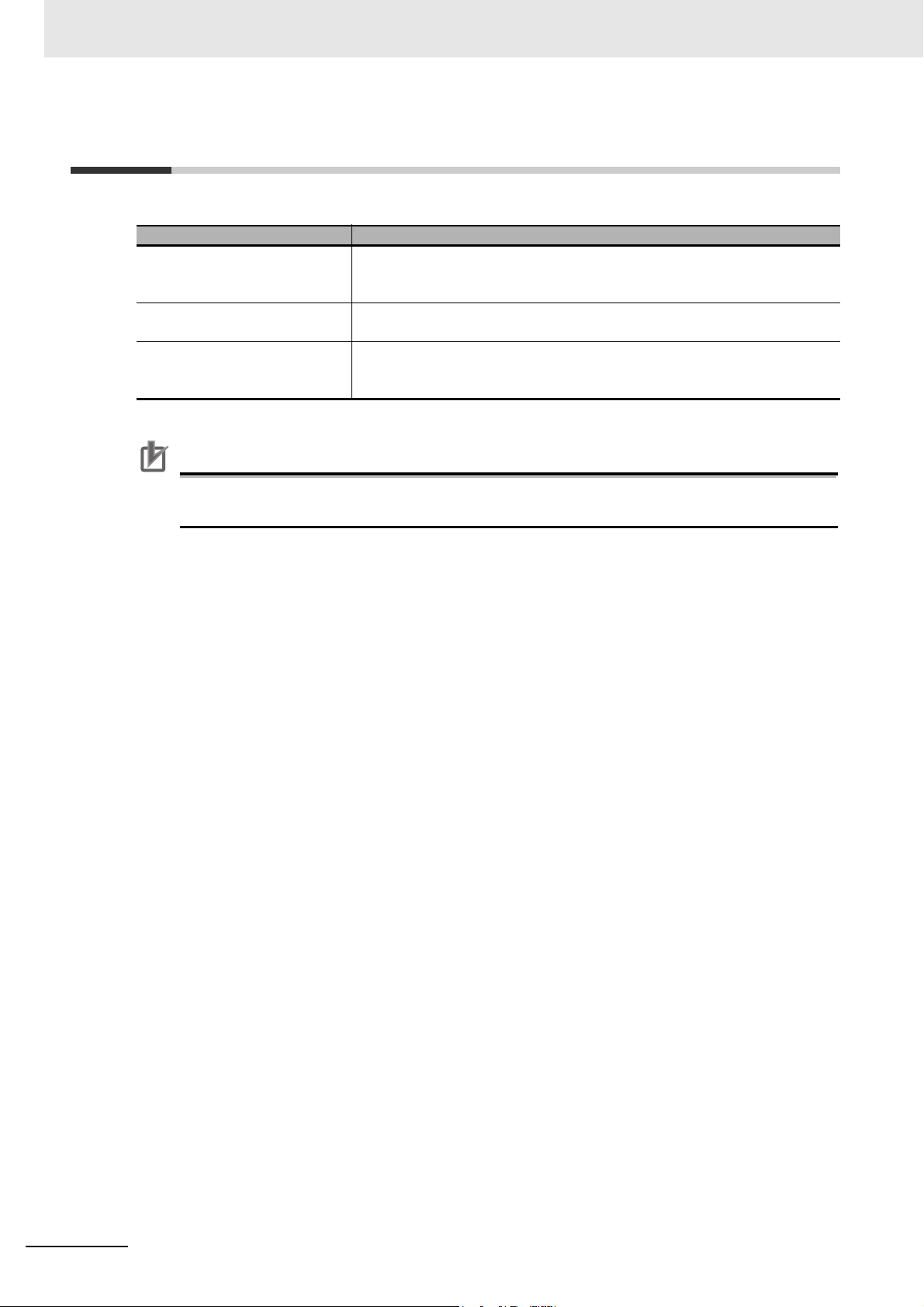

Relevant Manuals

The information for this product is divided between two manuals as shown in the following table.

Read all of the manuals that are relevant to your system configuration and application before you use

the product. Most operations are performed from the Sysmac Studio Automation Software.

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Relevant Manuals

Purpose of use

Learning about Safety Control Units

Mounting, installing, and making hard-

ware settings for Safety Control Units

Making software settings for Safety

Control Units

Creating safety programs

Verifying and debugging safety programs

Troubleshooting Safety Control Units

Maintaining Safety Control Units

NX-series Safety Control Unit

User’s Manual

NX-series Safety Control Unit

Instructions Reference Manual

NX-series Safety Control Unit Instructions Reference Manual (Z931)

7

Page 10

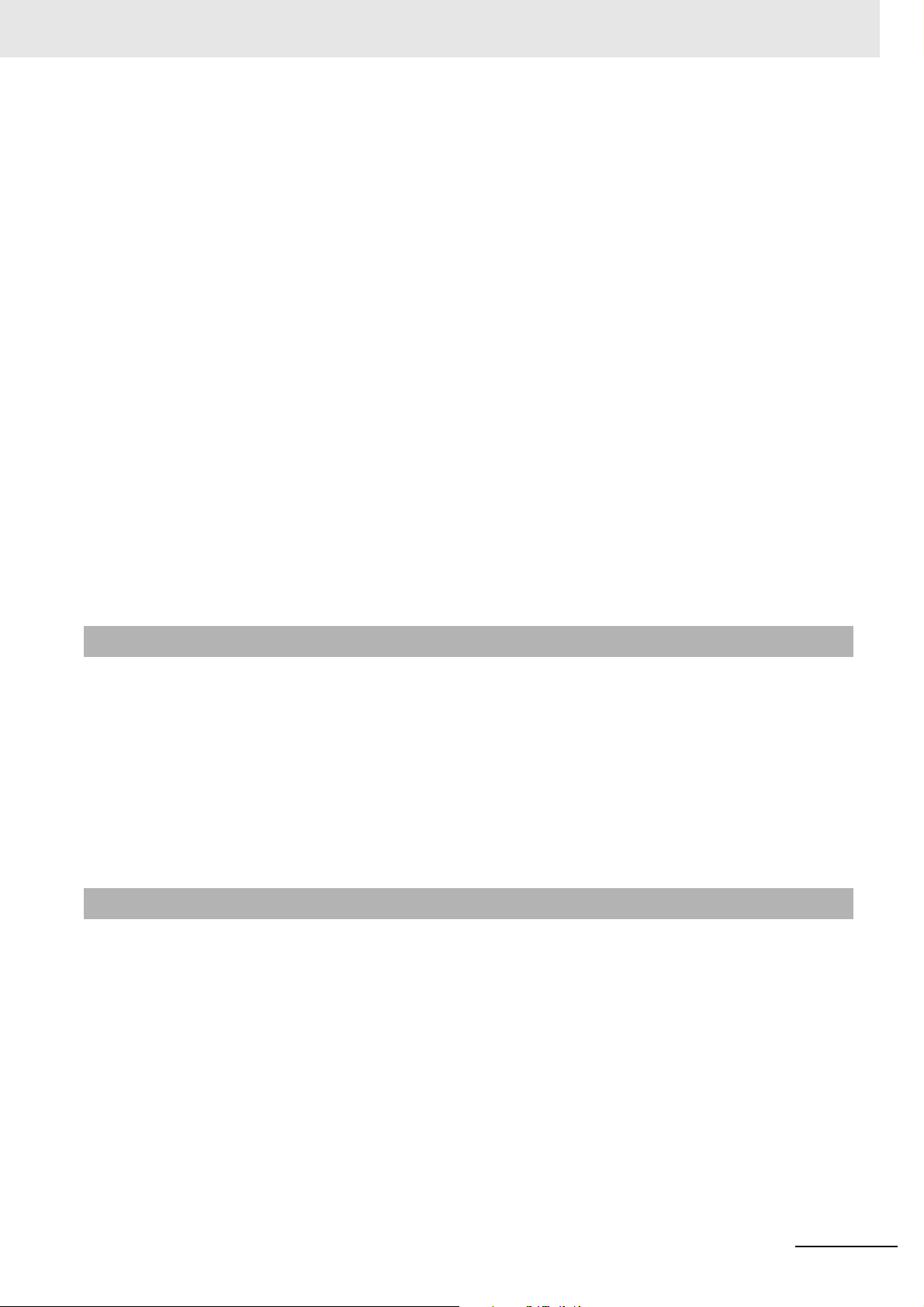

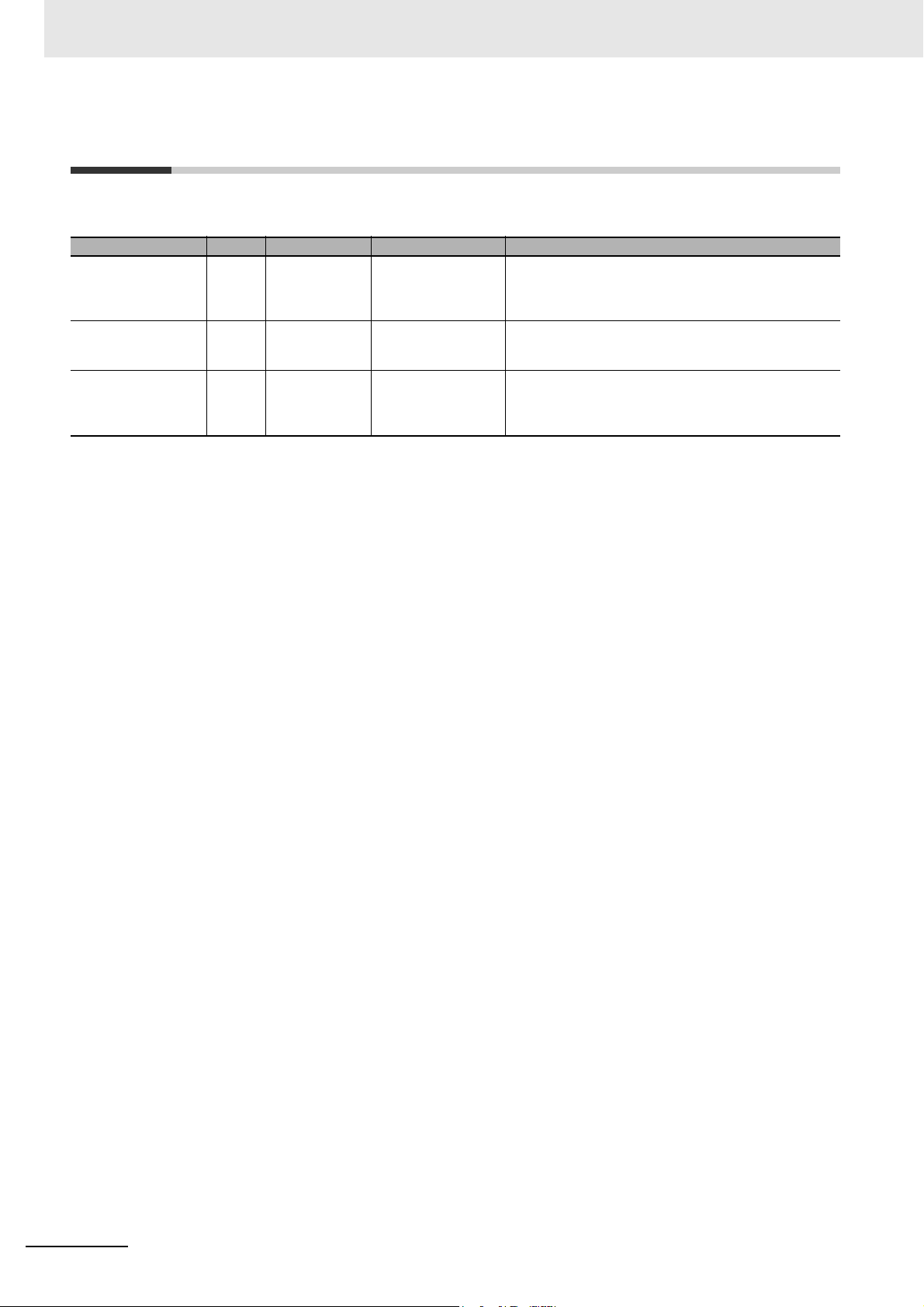

Manual Structure

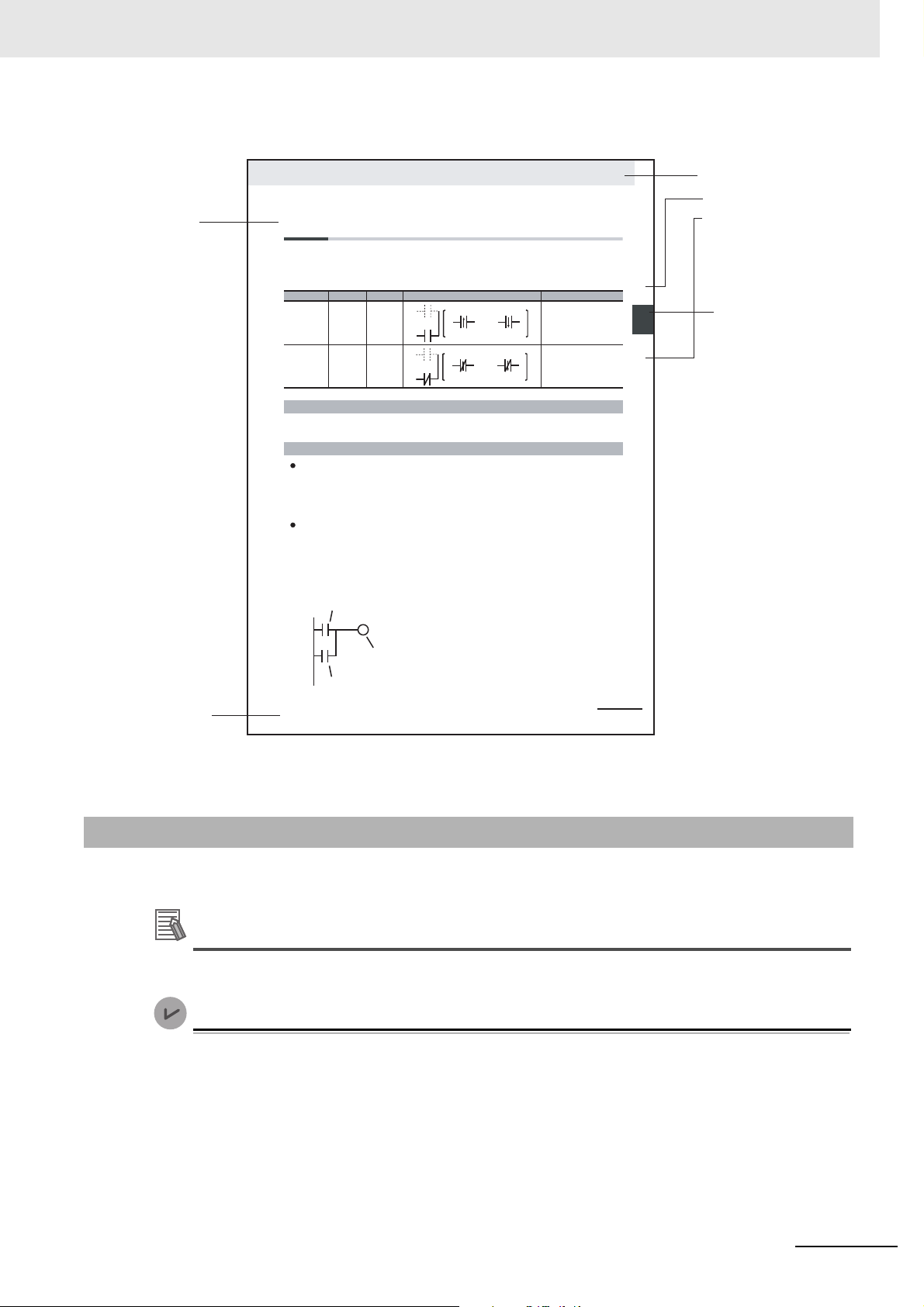

Level-2 heading

Level-2

heading

Manual name

Level-1

section number

Gives the number

of the section.

This page is for illustration only. It may not literally appear in this manual.

snoitcurtsnI margaiD reddaL

2

2-13

NJ-series Instructions Reference Manual (W502)

Ladder Diagram Instructions

Instruction Name Page

LD and LDN Load/

Load NOT

2-14

AND and ANDN AND/

AND NOT

2-16

OR and ORN OR/

OR NOT

2-18

Out and OutNot Output/

Output NOT

2-20

Manual Structure

Page Structure

The following page structure is used in this manual.

8

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 11

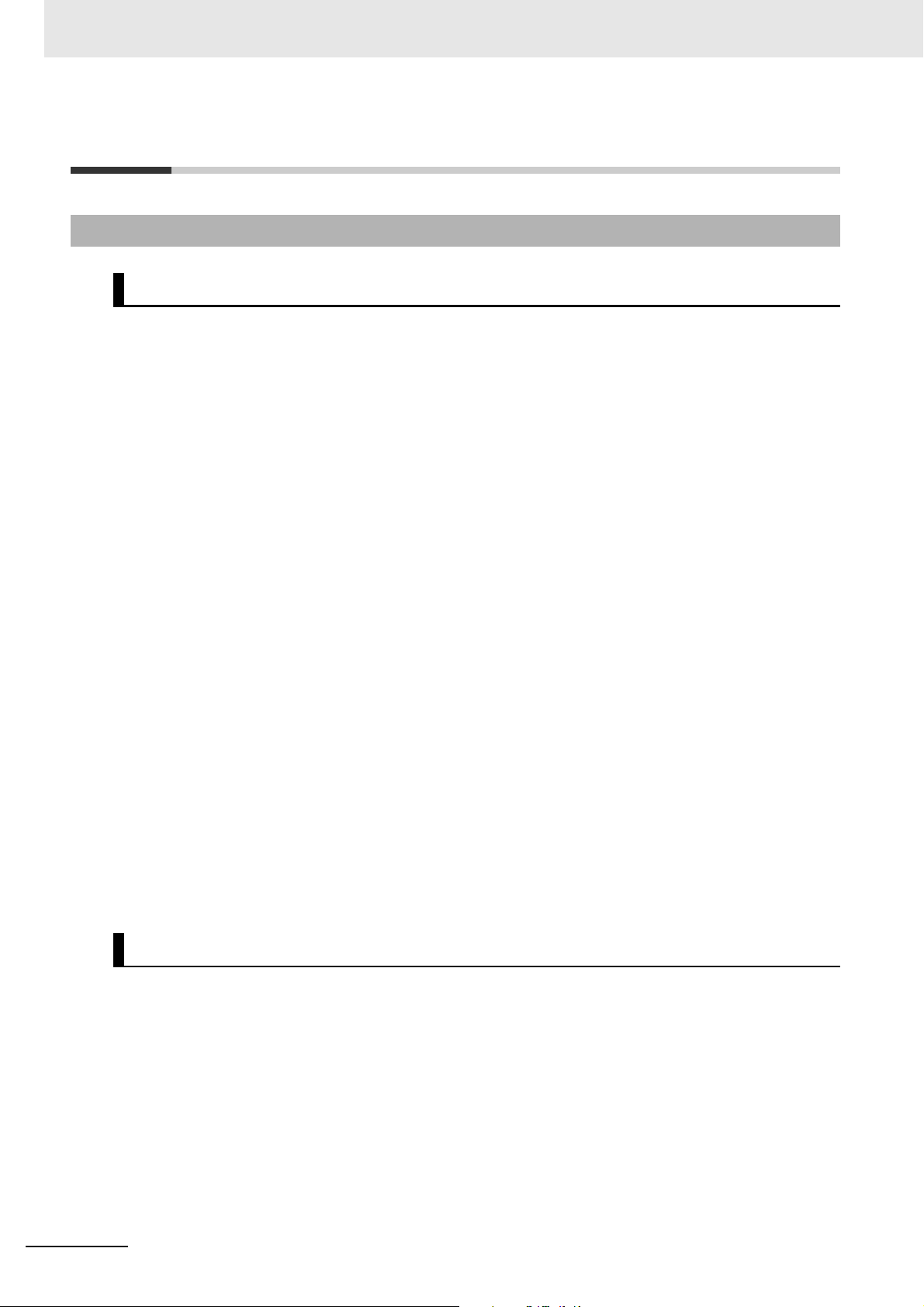

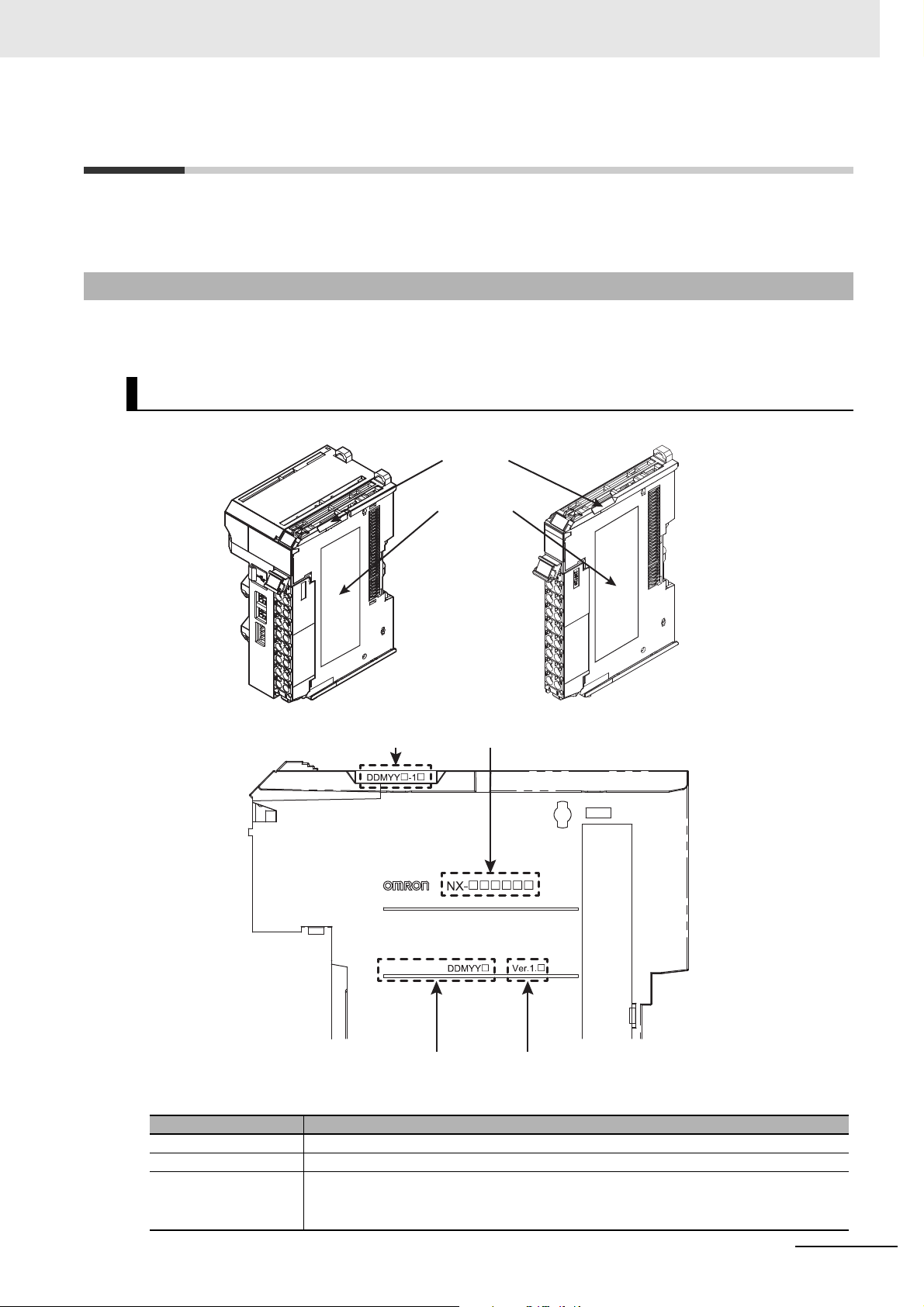

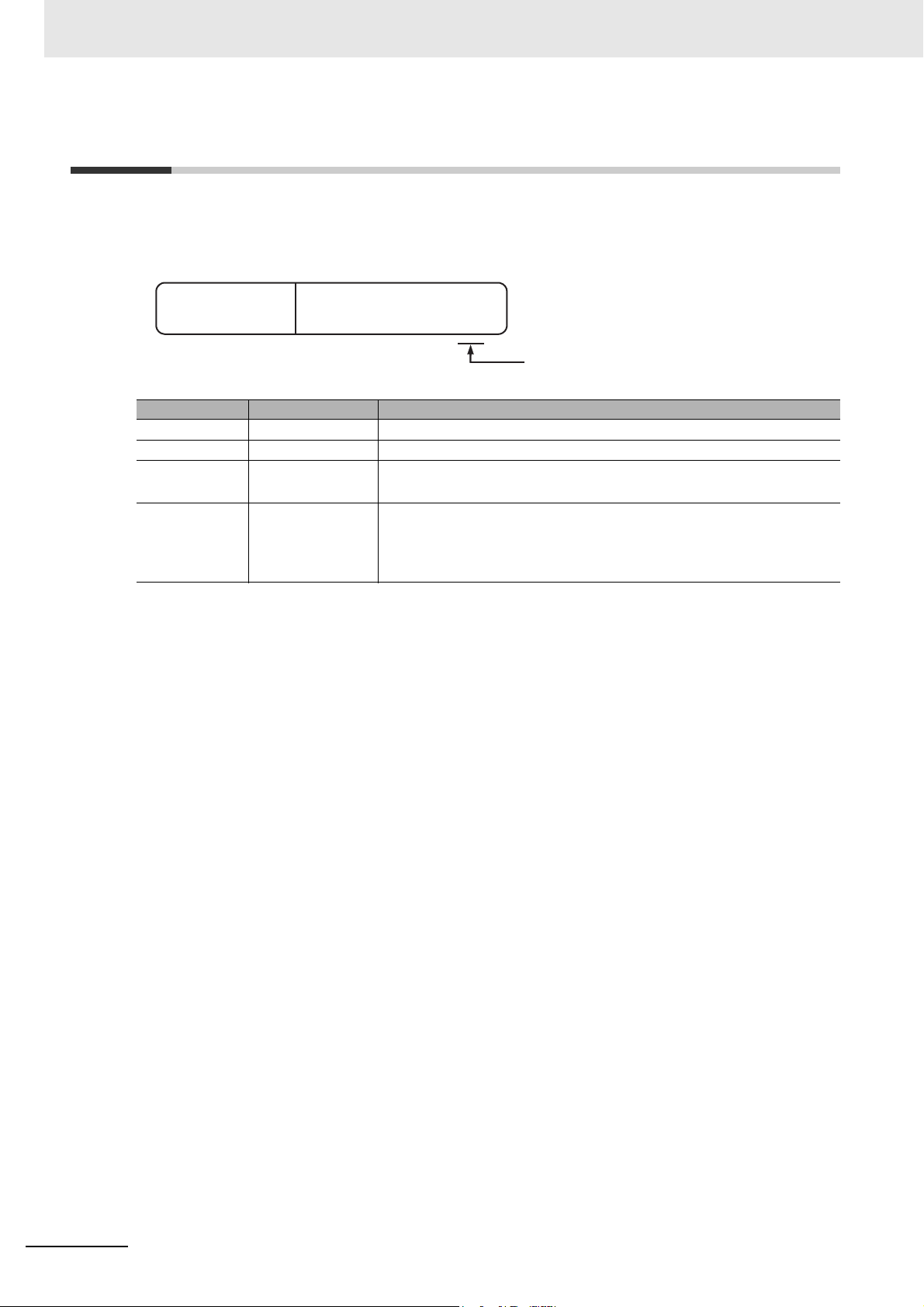

Manual Structure

Additional Information

Version Information

2-17

2 Instruction Descriptions

NJ-series Instructions Reference Manual (W502)

s

no

itcu

rt

s

n

I

m

a

r

ga

iD

re

dd

aL

2

N

RO dn

a

RO

OR and ORN

None

OR

The OR instruction takes the logical OR of the value of a specified BOOL variable and the execution

condition and outputs it to the next instruction. Use the OR instruction for a NO bit connected in parallel

with the previous instruction. Use the OR instruction to configure a logical OR between an NO bit and

one of the following : a LD or LDN instruction connected directly to the bus bar, or the logic block starting

with a LD or LDN instruction and ending with the instruction immediately before the OR instruction.

ORN

The ORN instruction takes the logical OR of the inverse of the value of a specified BOOL variable and

the execution condition and outputs it to the next instruction. Use the ORN instruction for a NC bit connected in parallel with the previous instruction. Use the ORN instruction to configure a logical OR

between an NC bit and one of the following: a LD or LDN instruction connected directly to the bus bar,

or the logic block starting with a LD or LDN instruction and ending with the instruction immediately

before the ORN instruction.

The following figure shows a programming example of the OR instruction. It takes the logical OR of variable A and variable B and outputs it to variable C.

OR: Takes the logical OR of the value of a BOOL variable and the execution condition.

ORN: Takes the logical OR of the inverse of the value of a BOOL variable and the execution condi-

tion.

Instruction Name FB/FUN Graphic expression ST expression

OR OR --- result:=vBool1 OR vBool2;

ORN OR NOT --- result:=vBool1 OR NOT

vBool2;

Variables

Function

Vari abl e

Downward

differentiation

Upward

differentiation

Vari abl e

Vari abl e

Vari abl e

Vari abl e

Vari abl e

Downward

differentiation

Upward

differentiation

Vari abl e

Downward

differentiation

Upward

differentiation

Vari abl e

Vari abl e

Vari abl e

Vari abl e

Vari abl e

Downward

differentiation

Upward

differentiation

B

A

C

LD instruction

Out instruction

OR instruction

Level-3

heading

Level-1

section number

Gives the number

of the section.

Level-1 heading

Level-2 heading

Level-3 heading

Manual name

This page is for illustration only. It may not literally appear in this manual.

Give the current

headings.

Special Information

Special information in this manual is classified as follows:

References are provided to more detailed or related information.

Information on differences in specifications and functionality for CPU Units and EtherCAT Coupler Units with different unit versions and for different versions of the Sysmac Studio is given.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

9

Page 12

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

10

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 13

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

11

Page 14

Terms and Conditions Agreement

12

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 15

Safety Precautions

Refer to the following manual for safety precautions.

• NX-series Safety Control Unit User’s Manual (Cat No. Z930)

Safety Precautions

NX-series Safety Control Unit Instructions Reference Manual (Z931)

13

Page 16

Precautions for Safe Use

Precautions for Safe Use

Refer to the following manual for precautions for the safe use of the Safety Control Unit.

• NX-series Safety Control Unit User’s Manual (Cat No. Z930)

14

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 17

Precautions for Correct Use

Refer to the following manual for precautions for the correct use of the Safety Control Unit.

• NX-series Safety Control Unit User’s Manual (Cat No. Z930)

Precautions for Correct Use

NX-series Safety Control Unit Instructions Reference Manual (Z931)

15

Page 18

Regulations and Standards

Regulations and Standards

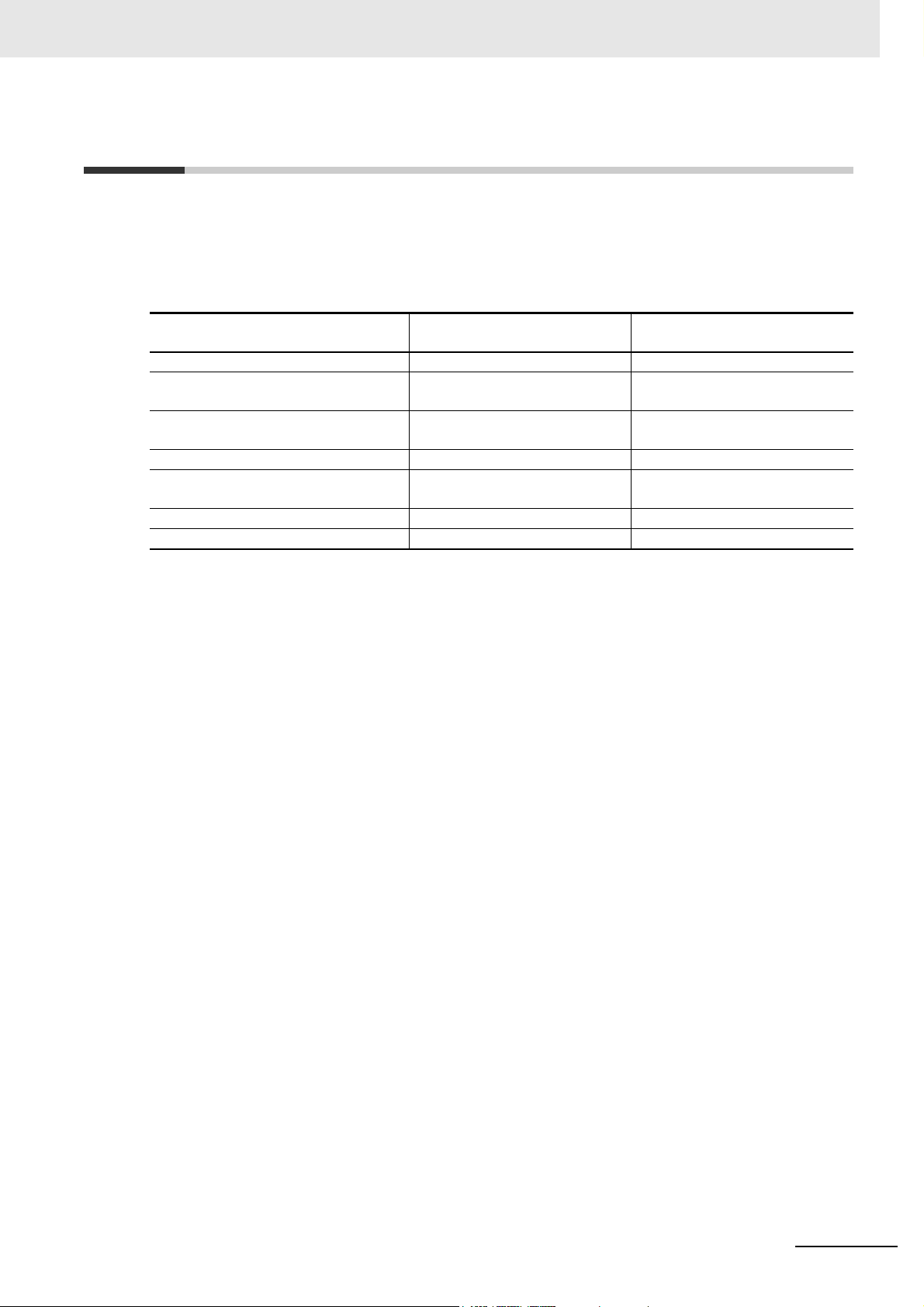

The NX-series Safety Control Units are certified for the following standards.

Certification body Standards

• EN ISO 13849-1:2008 + AC:2009

• EN ISO 13849-2:2012

• IEC 61508 parts 1-7:2010

TÜV Rheinland

UL • cULus: Listed (UL508) and ANSI/ISA 12.12.01

*1. Certification was received for applications in which OMRON FSoE devices are connected to each other.

The NX-series Safety Control Units allow you to build a safety control system that meets the following

standards.

• Requirements for SIL 3 (Safety Integrity Level 3) in IEC 61508, EN 62061 (Functional Safety of

Electrical/Electronic/Programmable Electronic Safety-related Systems)

• Requirements for PLe (Performance Level e) and for safety category 4 in EN ISO 13849-1

*1

• EN 62061:2005

• EN 61131-2:2007

• EN ISO 13850:2008

• EN 60204-1:2006 + A1:2009 + AC:2010

• EN 61000-6-2:2005

• EN 61000-6-4:2007

•NFPA 79:2012

• ANSI RIA 15.06-1999

• ANSI B11.19-2010

• UL1998

• IEC 61326-3-1:2008

The NX-series Safety Control Units are also registered for C-Tick and KC compliance.

Conformance to EC Directives

Applicable Directives

• EMC Directive

• Machinery Directive

Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*1

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

16

*1. Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations).

Machinery Directive

The Machinery Directive demands that the safety components that are used to provide safety for the

relevant machinery are used according to the required levels of safety.

The applicable directives are EN ISO 13849-1:2008 and EN 62061 SIL CL3.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 19

Regulations and Standards

Conformance to EC Directives

The NX-series Units comply with EC Directives. To ensure that the machine or device in which the

NX-series Units are used complies with EC Directives, the following precautions must be observed.

• The NX-series Units must be installed within a metallic control cabinet.

• You must meet the following conditions for the DC power supplies that are connected as the Unit

power supplies and I/O power supplies for the NX-series Units.

(a) Use reinforced insulation or double insulation.

(b) Ensure an output hold time of 20 ms min.

(c) Use an SELV power supply that meets the requirements of IEC/EN 60950-1 and EN

50178.

Do not allow the power supply cable length to exceed 3 m.

We recommend that you use the OMRON S8JX-series Power Supplies. EMC standard compliance was confirmed for the recommended Power Supplies.

• NX-series Units that comply with EC Directives also conform to the Common Emission Standard

(EN 61131-2). Radiated emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions.

You must therefore confirm that the overall machine or equipment in which the NX-series Units

are used complies with EC Directives.

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference. If radio interference occurs, the user may be required to take appropriate measures.

Conformance to EN ISO 13849-1 and EN 62061

International standards EN ISO 13849-1 and EN 62061 demand that process controls be in place for

the creation of safety-related software when building a safety control system that uses Safety Control

Units. The process control must ensure that the software is easy to read, understand, test, and maintain

to avoid system failures during each phase (i.e., general software design, safety circuit system design,

and software upgrades) of the software design lifecycle.

This means that process controls must also be in place for the design and development of safety software, such as for equipment and machinery that use function blocks that are provided by the Safety

Control Units.

It is the customer’s responsibility to conform with all standards.

Conformance to UL and CSA Standards

The NX-series Safety Control Units comply with the following UL and CSA standards. The application

conditions for standard compliance are defined. Refer to the Instruction Sheet that is provided with

each Unit before application.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

17

Page 20

Regulations and Standards

Conformance to KC Standards

Observe the following precaution if you use NX-series Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated

with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

18

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 21

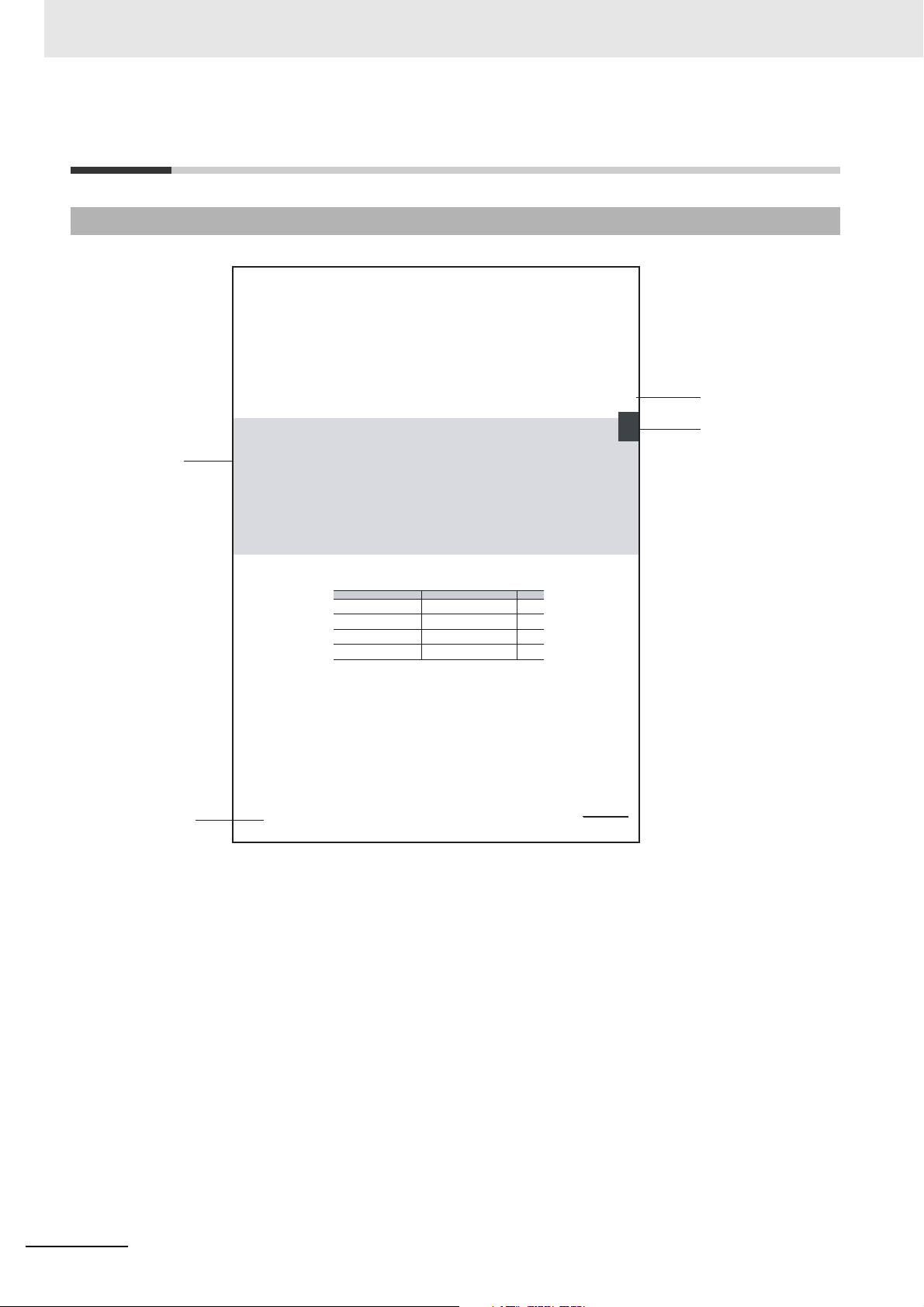

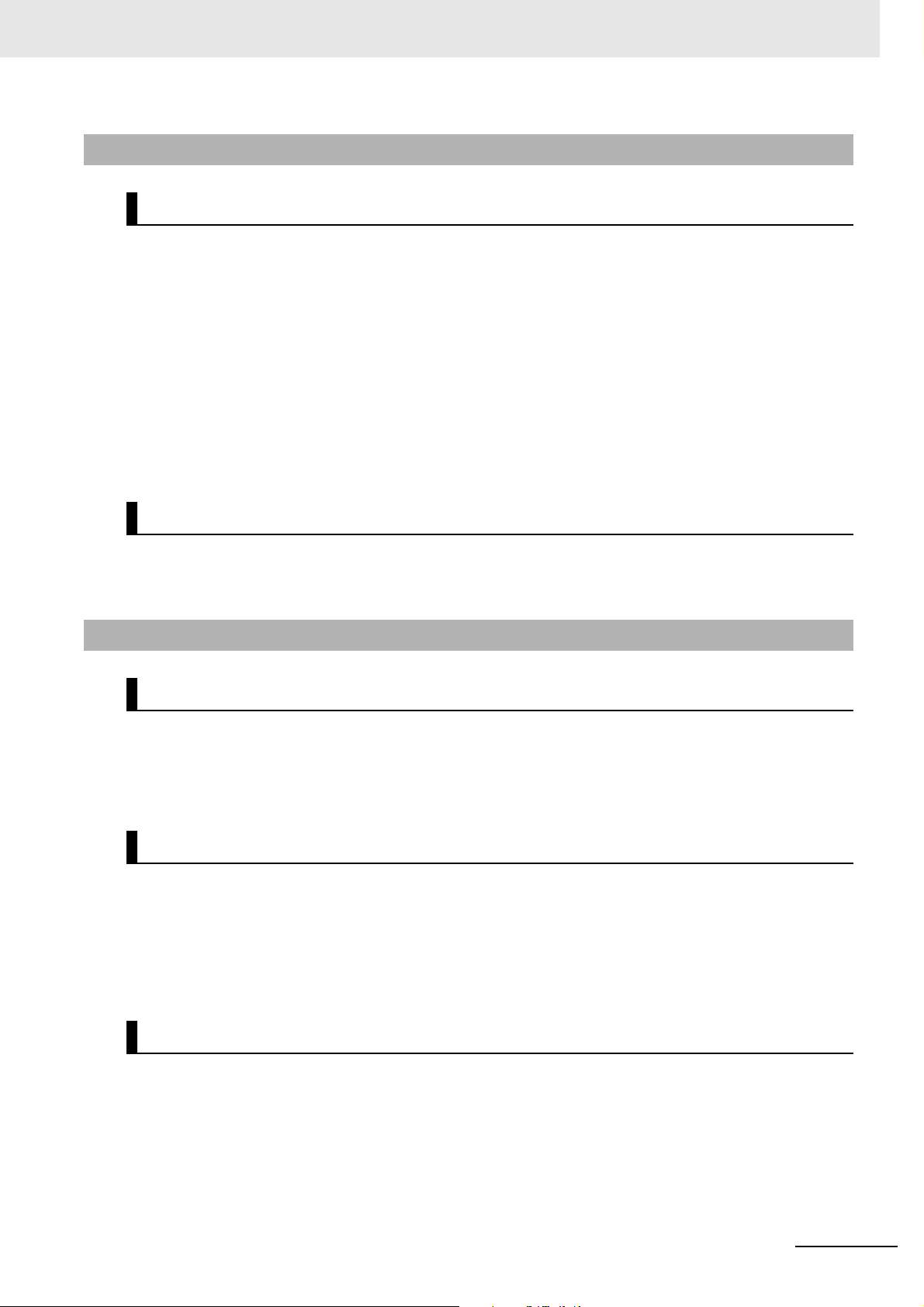

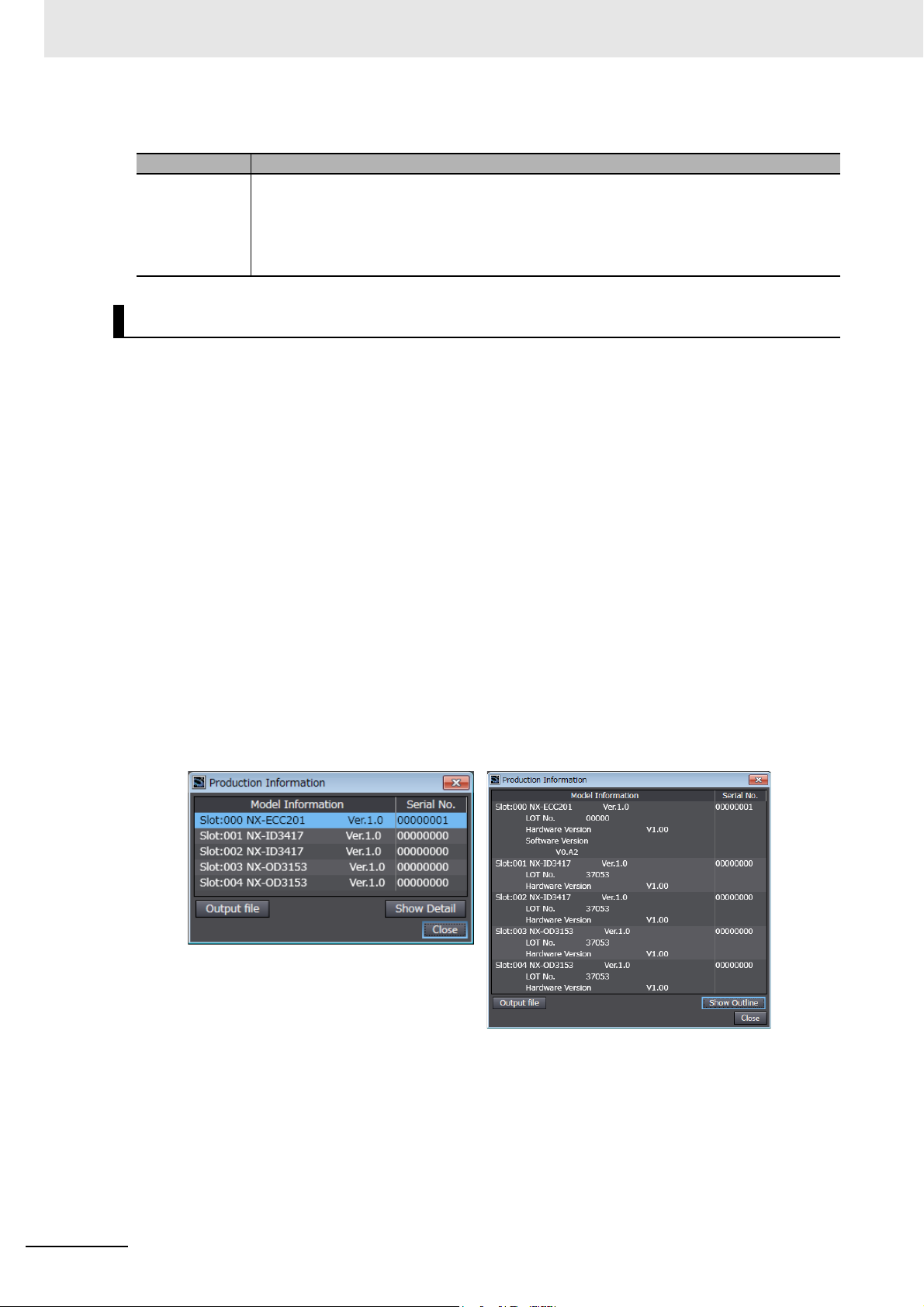

Unit Versions

Notched

area

Unit

specifications

LOT No.

Unit version

Lot number

Unit model number

Lot number and unit version

This section describes the notation that is used for unit versions, the confirmation method for unit versions, and the relationship between unit versions and Sysmac Studio versions.

Unit Versions

A “unit version” has been introduced to manage the Units in the NX Series according to differences in

functionality accompanying Unit upgrades.

Notation of Unit Versions on Products

The unit version is given with the Unit specifications on the side of the Unit or in the notched area.

Unit Versions

The following information is provided in the Unit specifications on the Unit.

Unit model number Gives the model of the Unit.

Unit version Gives the unit version of the Unit.

Lot number Gives the lot number of the Unit.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Name Function

DDMYY: Lot number, : Used by OMRON.

“M” gives the month (1 to 9: January to September, X: October, Y: November, Z: December)

19

Page 22

Unit Versions

The following information is provided in the notched area on the Unit.

Name Function

Lot number and

unit version

Confirming Unit Versions with the Sysmac Studio

You can use the Unit Production Information on the Sysmac Studio to check the unit versions EtherCAT

Coupler Unit and NX Units.

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer, and then

double-click the EtherCAT Coupler Unit. Or, right-click the EtherCAT Coupler Unit and select

Edit from the menu.

The Edit Slave Terminal Configuration Tab Page is displayed.

Gives the lot number and unit version of the Unit.

• DDMYY: Lot number, : Used by OMRON.

“M” gives the month (1 to 9: January to September, X: October, Y: November, Z: December)

•1: Unit version

The decimal portion of the unit version is omitted. (It is provided in the Unit specifications.)

You can also display the Edit Slave Terminal Configuration Tab Page with any of the following

operations.

Double-click EtherCAT under Configurations and Setup in the Multiview Explorer, right-click

the EtherCAT Coupler Unit in the EtherCAT Configuration Edit Tab Page, and select Edit Slave

Terminal Configuration.

Or, select the EtherCAT Coupler Unit on the EtherCAT Configuration Edit Tab Page click the

Edit Slave Terminal Configuration Button.

2 Go online.

3 Right-click the EtherCAT Coupler Unit and select Display Production Information from the

menu.

The Production Information Dialog Box is displayed.

20

Simple Display

Detailed Display

In this example, “Ver.1.0” is displayed next to the Unit model.

The following items are displayed.

• Slot number

• Unit model number

• Unit version

• Serial number

• Lot number

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 23

• Hardware version

• Software version

The software version is displayed only for Units that contain software.

Unit Versions and Sysmac Studio Versions

The functions that are supported depend on the unit version of the Unit. The version of Sysmac Studio

that supports the functions that were added for an upgrade is also required to use those functions.

Refer to the NX-series Safety Control Unit User’s Manual (Cat. No. Z930) for the relationship between

the unit versions of the CPU Units and the Sysmac Studio versions, and for the functions that are supported by each unit version.

Unit Version Notation

In this User’s Manual, unit versions are specified as shown in the following table.

Unit Versions

Unit version in Unit specifications

on the product

Ver. 1. or later Unit version 1.0 or later Unless unit versions are specified, the infor-

Notation in this manual Remarks

mation in this manual applies to all unit versions.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

21

Page 24

Related Manuals

Related Manuals

The following manuals are related. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NX-series Safety Control Unit Instructions

Reference Manual

NX-series Safety Control Unit User’s Manual

Sysmac Studio Version 1 Operation Manual

Z931 NX-SL Learning about the

Z930 NX-SL

W504 SYSMAC-

NX-SI

NX-SO

SE2

specifications of

instructions for the

Safety CPU Unit.

Learning how to use

NX-series Safety

Control Units.

Learning about the

operating procedures

and functions of the

Sysmac Studio.

The instructions for the Safety CPU Unit are described.

When programming, use this manual together with the

NX-series Safety Control Unit User’s Manual (Cat. No.

Z930).

The hardware, setup methods, and functions of the

NX-series Safety Control Unit are described.

Describes the operating procedures of the Sysmac Studio.

22

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 25

Terminology

Refer to the NX-series Safety Control Unit User’s Manual (Cat. No. Z930) for the definitions of terms

that are used in this manual.

Terminology

NX-series Safety Control Unit Instructions Reference Manual (Z931)

23

Page 26

Revision History

Cat. No.

Z931-E1-04

Revision code

Revision History

A manual revision code appears as a suffix to the catalog number at the bottom left of the front and

back covers of the manual.

Revision code Date Revised content

01 June 2013 Original production

02 September 2013 Corrected mistakes.

03 December 2013 Added information on timer set values.

04 April 2016 • Changed Section 2 Other Standard Instructions to Selection Instruc-

Corrected mistakes.

tions.

• Added DigitalCode (decimal) to FB-specific Error Codes and FB-spe-

cific State Codes tables in Section 4 Safety Function Blocks.

24

NX-series Safety Control Unit Instructions Reference Manual (Z931)

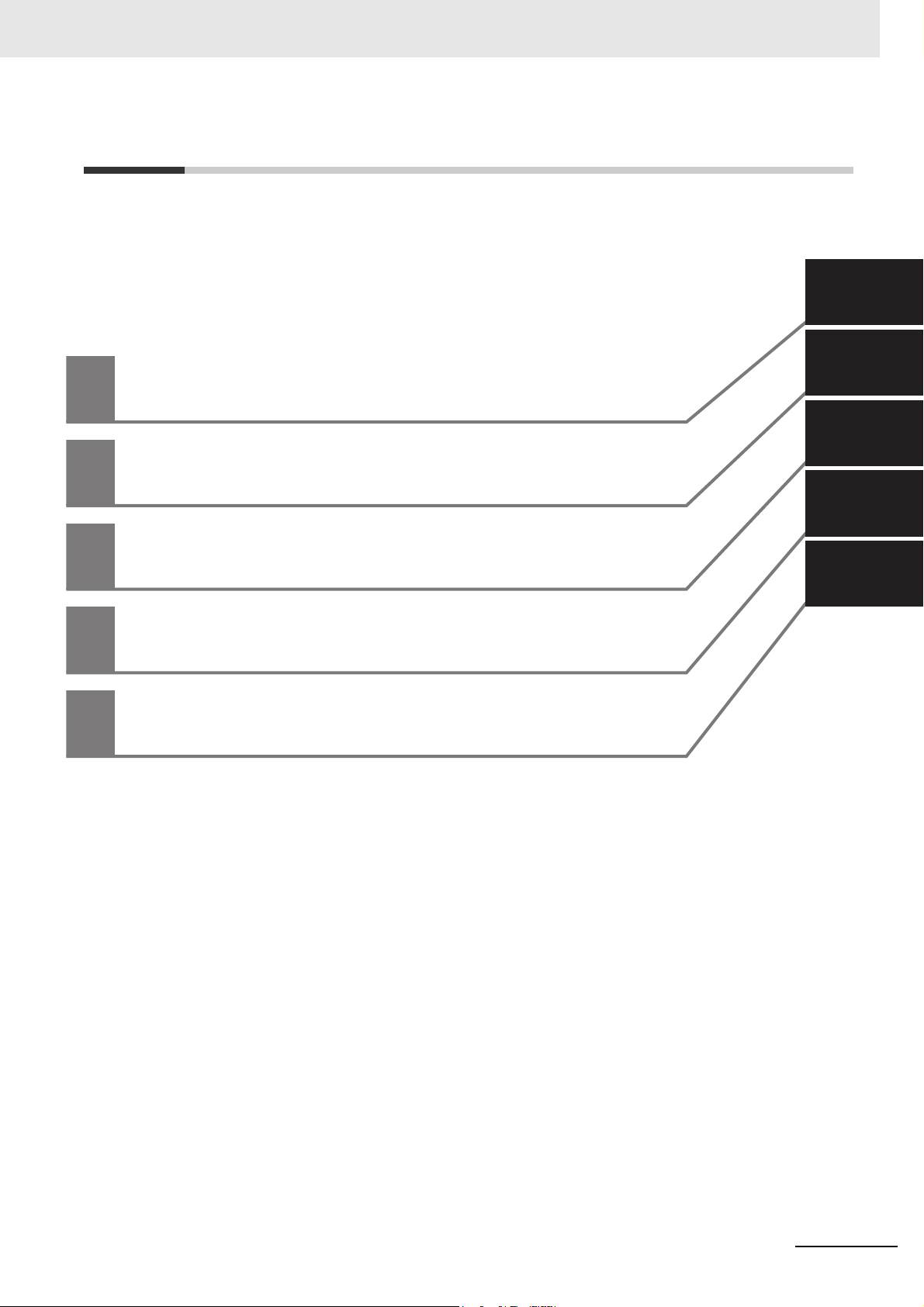

Page 27

1

2

3

4

3

4

1

2

Introduction to Instructions for Safety Control Units and

Interpreting Instruction Descriptions

Standard Functions

Safety Standard Function Blocks

Safety Function Blocks

I

I

Index

Sections in this Manual

Sections in this Manual

NX-series Safety Control Unit Instructions Reference Manual (Z931)

25

Page 28

Sections in this Manual

26

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 29

1

Introduction to Instructions for Safety

Control Units and Interpreting Instruction

This section provides an introduction to the instructions for Safety Control Units and

tells how to interpret the instruction descriptions.

1-1 Types of Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Interpreting Instruction Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2-1 Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2-2 Safety Data Types and Standard Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-3 Valid Ranges and Default Values of Variables . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-4 Timer Set Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

NX-series Safety Control Unit Instructions Reference Manual (Z931)

1 - 1

Page 30

1 Introduction to Instructions for Safety Control Units and Interpreting Instruction Descriptions

Precautions for Correct Use

1-1 Types of Instructions

The following three types of instructions can be used with the Safety Control Units.

Type Description

Standard functions These function instructions do not use safety data. They include program

execution control instructions, data type conversion instructions, Boolean

operation instructions, math instructions, comparison instructions, etc.

Safety standard function blocks These function block instructions use safety data. They include counter

instructions, up/down trigger instructions, timer instructions, etc.

Safety function blocks These function block instructions use safety data and are based on the safety

standards defined by PLCopen. They include an antivalent instruction, emergency stop instruction, etc.

Instruction specifications are provided starting from section 2.

Some of the instructions have the same names as the instructions that are supported by the

NJ-series CPU Units. Operating specifications, however, are different.

1 - 2

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 31

1 Introduction to Instructions for Safety Control Units and Interpreting Instruction Descriptions

Instance specification

Input variable

name

Output variable

name

ADD

Instruction word

SF_CTU

CU

SF_CTU_instance

RESET

PV

Q

CV

Example for a FUN

Instruction

Example for a FB

Instruction

1-2 Interpreting Instruction Descriptions

The notation that is used to describe instructions is explained in this section.

1-2-1 Items

The following items are provided. The order of the items is not the same for all instructions. If there are

items that are specific to one type of instruction, they are explained in the section for each instruction

type.

Item Description

Instruction The instruction word is given.

Name The name of the instruction is given.

FB/FUN Whether the instruction is a function block (FB) instruction or a function (FUN) instruction

is given.

Graphic expression The figure that represents the instruction in a function block diagram is given.

1-2 Interpreting Instruction

Descriptions

1

1-2-1 Items

Variables • Variable

Instance specification: An instance of an instruction is indicated by “XX_instance” above a

FB instruction. You must assign an instance name to any instance of an instruction that

you specify.

The input variable or output variable is given.

•Name

The name of the variable is given.

Example: Up-counter

• I/O

Whether the variable is an input variable or output variable is given.

• Description

The meaning of the variable and any restrictions are given.

• Valid range

The range that the variable can take is given. “Depends on data type” indicates that the

valid range of the variable depends on the data type that you use. The valid ranges of

the data types are given later in this section.

•Default

The specified default value is automatically used for the variable if you do not assign a

parameter to the instruction before it is executed. “---” indicates the following:

Input variables: The default value of the data type of the input variable is assigned. The

default values of the data types are given later in this section.

Output variables: Default values are not set.

• Data type

The data type of the variable is given. Broadly speaking, there are two classifications of

data types: safety signals and non-safety signals. These two classifications of data

types are described later.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

1 - 3

Page 32

1 Introduction to Instructions for Safety Control Units and Interpreting Instruction Descriptions

Item Description

Function The function of the instruction is described.

Additional Informa-

tion

Precautions for Correct Use

Additional information on the function of the instruction is provided. This includes related

instructions and helpful information for application of the instruction.

Precautions for application of the instruction are given. The conditions under which errors

occur for the instruction are also given here.

1-2-2 Safety Data Types and Standard Data Types

The Safety Control Unit classifies the following two data types to distinguish between safety signals and

standard signals.

• Safety data types: These data types represent signals related to safety control.

• Standard data types: These data types represent signals related to standard control.

The safety data type variables are prefixed with the “SAFE” before the name of the standard data type,

as in SAFEBOOL and SAFEBYTE.

You can input a signal for a safety data type variable to a standard data type variable. You cannot input

a signal for a standard data type variable to a safety data type variable. A building error will occur.

1-2-3 Valid Ranges and Default Values of Variables

The valid range of a variable indicates the range of values that variable can take. The default value of a

variable indicates the value that is assigned to an input variable when the instruction is executed without a parameter assigned to the input variable. These values are defined for each data type. If specific

values are not given for an instruction, then the valid ranges and default values of the data types are

applied. These variables are indicated by “depends on data type” in the valid range column of the table

that describes the variables and by “---” in the input variable default column. The valid ranges and

default values of the data types are given in the following tables.

Classification

Boolean

Bit strings

Integers

Durations

Safety/standard

data type

Standard data

type

Safety data type SAFEBOOL

Standard data

type

Safety data type SAFEBYTE

Standard data

type

Safety data type SAFEWORD

Standard data

type

Safety data type SAFEDWORD

Standard data

type

Safety data type SAFEINT

Standard data

type

Safety data type SAFEDINT

Standard data

type

Safety data type SAFETIME

Data type Range of values Default

BOOL

BYTE

WORD

DWORD

INT

DINT

TIME

TRUE or FALSE FALSE

byte#16#00 to byte#16#FF byte#16#00

word#16#0000 to

word#16#FFFF

dword#16#00000000 to

dword#16#FFFFFFFF

int#−32768 to int#32767 int#0

dint#-2147483648 to

dint#2147483647

t#0ms to t#2147483647ms

and t#0d0h0m0s0ms to

t#24d20h31m23s647ms

word#16#0000

dword#16#00000000

dint#0

t#0s

1 - 4

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 33

1 Introduction to Instructions for Safety Control Units and Interpreting Instruction Descriptions

Precautions for Correct Use

1-2-4 Timer Set Values

Time set values, such as those for DiscrepancyTime or the OFF-Delay Timer instruction, operate in

increments of the safety task period.

The timer error is +1 safety task period. Every safety task period, a timer value is checked to see if it

has reached the set time. If the timer value reaches the set time immediately after this check, the time

is delayed by one safety task period.

Examples are provided below.

1-2 Interpreting Instruction

Descriptions

1

When the OFF-Delay Timer Instruction Is Set to 500 ms and the Safety Task

Period Is Set to 16 ms

The timer will time out 512 ms (16 ms × 32) after the safety task is started.

When the OFF-Delay Timer Instruction Is Set to 500 ms and the Safety Task

Period Is Set to 20 ms

The timer will time out 520 ms (20 ms × 26) after the safety task is started. Care is required because

the timer will not operate at 500 ms.

Refer to the NX-series Safety Control Unit User’s Manual (Cat. No. Z930) for details on the safety task

period.

The time when an OFF-Delay Timer instruction times out can affect the safety reaction times.

1-2-4 Timer Set Values

NX-series Safety Control Unit Instructions Reference Manual (Z931)

1 - 5

Page 34

1 Introduction to Instructions for Safety Control Units and Interpreting Instruction Descriptions

1 - 6

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 35

Standard Functions

This section gives the specifications of the standard functions that you can use for

NX-series Safety Control Units.

Table of Standard Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Execution Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Data Type Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Boolean Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Math Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Comparison Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

Selection Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

2

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 1

Page 36

2 Standard Functions

Table of Standard Functions

Type Instruction Name Description Page

Execution control Jump Jump Moves processing to the

jump destination specified

by a label.

Return Return Returns control to the pro-

cess that called the POU

without executing any processing after RETURN.

Data type

conversion

Boolean to

integer

Boolean to

duration

Boolean to bit

string

Bit string to integer

Bit string to

duration

Bit string to bit

string

BOOL_TO_INT Convert

BOOL to INT

BOOL_TO_DINT Convert

BOOL to

DINT

BOOL_TO_TIME Convert

BOOL to

TIME

BOOL_TO_WORD Convert

BOOL to

WORD

BYTE_TO_INT Convert

BYTE to INT

BYTE_TO_DINT Convert

BYTE to

DINT

WORD_TO_INT Convert

WORD to

INT

WORD_TO_DINT Convert

WORD to

DINT

DWORD_TO_DINT Convert

DWORD to

DINT

BYTE_TO_TIME Convert

BYTE to

TIME

WORD_TO_TIME Convert

WORD to

TIME

DWORD_TO_TIME Convert

DWORD to

TIME

BYTE_TO _WORD Convert

BYTE to

WORD

WORD_TO_BYTE Convert

WORD to

BYTE

WORD_TO_DWORD Convert

WORD to

DWORD

Converts a BOOL variable

to an INT variable.

Converts a BOOL variable

to a DINT variable.

Converts a BOOL variable

to a TIME variable.

Converts a BOOL variable

to a WORD variable.

Converts a BYTE variable to

an INT variable.

Converts a BYTE variable to

a DINT variable.

Converts a WORD variable

to an INT variable.

Converts a WORD variable

to a DINT variable.

Converts a DWORD variable to a DINT variable.

Converts a BYTE variable to

a TIME variable.

Converts a WORD variable

to a TIME variable.

Converts a DWORD variable to a TIME variable.

Converts a BYTE variable to

a WORD variable.

Converts a WORD variable

to a BYTE variable.

Converts a WORD variable

to a DWORD variable.

P. 2 -6

P. 2 -8

P. 2-12

P. 2-13

P. 2-14

P. 2-15

P. 2-16

P. 2-17

P. 2-18

P. 2-20

P. 2-21

P. 2-23

P. 2-24

P. 2-25

P. 2-26

P. 2-27

P. 2-28

2 - 2

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 37

Data type

conversion

2 Standard Functions

Type Instruction Name Description Page

Integer to

Boolean

Integer to bit

string

Integer to integer DINT_TO_INT Convert

Integer to

duration

Duration to

Boolean

Duration to bit

string

Duration to

integer

Bit string to

Boolean

DINT_TO_BOOL Convert

DINT to

BOOL

INT_TO_BOOL Convert INT

to BOOL

DINT_TO_BYTE Convert

DINT to

BYTE

DINT_TO_DWORD Convert

DINT to

DWORD

DINT_TO_WORD Convert

DINT to

WORD

INT_TO_BYTE Convert INT

to BYTE

INT_TO_DWORD Convert INT

to DWORD

INT_TO_WORD Convert INT

to WORD

DINT to INT

INT_TO_DINT Convert INT

to DINT

DINT_TO_TIME Convert

DINT to

TIME

INT_TO_TIME Convert INT

to TIME

TIME_TO_BOOL Convert

TIME to

BOOL

TIME_TO_BYTE Convert

TIME to

BYTE

TIME_TO_DWORD Convert

TIME to

DWORD

TIME_TO_WORD Convert

TIME to

WORD

TIME_TO_DINT Convert

TIME to

DINT

TIME_TO_INT Convert

TIME to INT

WORD_TO_BOOL Convert

WORD to

BOOL

Converts a DINT variable to

a BOOL variable.

Converts an INT variable to

a BOOL variable.

Converts a DINT variable to

a BYTE variable.

Converts a DINT variable to

a DWORD variable.

Converts a DINT variable to

a WORD variable.

Converts an INT variable to

a BYTE variable.

Converts an INT variable to

a DWORD variable.

Converts an INT variable to

a WORD variable.

Converts a DINT variable to

an INT variable.

Converts an INT variable to

a DINT variable.

Converts a DINT variable to

a TIME variable.

Converts an INT variable to

a TIME variable.

Converts a TIME variable to

a BOOL variable.

Converts a TIME variable to

a BYTE variable.

Converts a TIME variable to

a DWORD variable.

Converts a TIME variable to

a WORD variable.

Converts a TIME variable to

a DINT variable.

Converts a TIME variable to

an

INT variable.

Converts a WORD variable

to a BOOL variable.

P. 2 -2 9

P. 2 -3 0

P. 2 -3 1

P. 2 -3 2

P. 2 -3 4

P. 2 -3 5

P. 2 -3 6

P. 2 -3 8

P. 2 -4 0

P. 2 -4 1

P. 2 -4 2

P. 2 -4 3

P. 2 -4 4

P. 2 -4 5

P. 2 -4 6

P. 2 -4 7

P. 2 -4 8

P. 2 -4 9

P. 2 -5 0

2

Table of Standard Functions

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 3

Page 38

2 Standard Functions

Type Instruction Name Description Page

Boolean operations AND Logical AND Performs a logical AND on

multiple Boolean variables.

OR Logical OR Performs a logical OR on

multiple Boolean variables.

XOR Exclusive

logical OR

NOT Bit Reversal Reverses the value of a

Math ADD Addition Adds integers or durations. P. 2-56

SUB Subtraction Subtracts integers or dura-

MUL Multiplication Multiplies integers or a dura-

DIV Division Divides integers or a dura-

Comparison EQ Equal Determines if the values of

NE Not Equal Determines if the values of

LT Less Than Performs a less than com-

LE Less Than

Or Equal

GT Greater

Than

GE Greater

Than Or

Equal

Selection SEL Bit Selection Selects one of two selec-

MUX Multiplexer Selects one of multiple

Performs an exclusive logical OR on multiple Boolean

variables.

Boolean bit.

tions.

tion.

tion.

two variables are equivalent.

two variables are not equivalent.

parison between two values.

Performs a less than or

equal comparison between

two values.

Performs a greater than

comparison between two

values.

Performs a greater than or

equal comparison between

two values.

tions.

selections.

P. 2-52

P. 2-52

P. 2-52

P. 2-54

P. 2-58

P. 2-60

P. 2-62

P. 2-66

P. 2-67

P. 2-68

P. 2-68

P. 2-68

P. 2-68

P. 2-72

P. 2-74

2 - 4

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 39

Execution Control Instructions

Type Instruction Name Description Page

Execution control Jump Jump Moves processing to the

jump destination specified

by a label.

Return Return Returns control to the pro-

cess that called the POU

without executing any processing after RETURN.

2

P. 2 -6

P. 2 -8

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 5

Page 40

2 Standard Functions

Label

Label:

Programming A

Not executed due

to JUMP instruction.

ExecutionNetwork

4

Step1:

1

Programming A

3

Programming C

5

Programming D

2

Programming B

BOOL output

Step1:

FALSE Output from Programming B

Network

TRUE Output from Programming B

4

Step1:

1

5

Programming D

2

Programming B

BOOL output

Step1:

3

Programming C

Execution

JUMP and LABEL

This function moves processing to the jump destination specified by a label.

Instruction Name FB/FUN Graphic expression

JUMP Jump FUN

LABEL Label FUN

Variables

There are no variables for these instructions.

Function

When the execution condition is TRUE, the JUMP instruction moves processing to the jump destination

specified by a label in the program.

The label can be any text string.

The following figure shows a programming example. This example uses the text string Step1 as the

label.

When the JUMP instruction is executed, processing moves to the location marked Step1. In this example, programming C between the JUMP instruction and the label is not executed. The outputs in programming C retain the values that they had just before the JUMP instruction was executed.

2 - 6

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 41

Additional Information

• You cannot jump upward in the networks.

• You can use the same label as the jump destination for more than one JUMP instruction.

• You can set only a label in a network, or you can set both programming and a label in a network.

Precautions for Correct Use

• You must use either a BOOL or SAFEBOOL execution condition for the JUMP instruction.

If you connect an execution condition with any other data type, a building error will occur.

• You cannot omit labels. If you omit a label, a building error will occur.

• Place the JUMP instruction and label in the same POU.

• Programming between the JUMP instruction and the label is not executed when the JUMP instruction

is executed. The outputs retain the values that they had just before the JUMP instruction was executed.

2 Standard Functions

Execution Control Instructions

2

JUMP and LABEL

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 7

Page 42

2 Standard Functions

Not executed due to

RETURN instruction.

Not executed due to

RETURN instruction.

Network

1

Programming A

3

Programming C

4

Programming D

FALSE Output from Programming B

Network

TRUE Output from Programming B

1

Programming A

Programming B

BOOL output

2

RETURN

2

Programming B

BOOL output

RETURN

3

Programming C

4

Programming D

Execution Execution

RETURN

This function returns control to the process that called the POU without executing any processing after

RETURN.

Instruction Name FB/FUN Graphic expression

RETURN Return FUN

Variables

There are no variables for these instructions.

Function

RETURN

When the execution condition is TRUE, control is returned to the location that called the POU without

executing any processing after RETURN.

The following figure shows a programming example. When the RETURN instruction is executed in the

example, programming C and D that follow it are not executed. The outputs in programming C and D

retain the values that they had just before the RETURN instruction was executed.

Precautions for Correct Use

• You must use either a BOOL or SAFEBOOL execution condition for the RETURN instruction.

If you connect an execution condition with any other data type, a building error will occur.

• If you use this instruction too often, the flow of processing will be difficult to understand. Use it with

caution.

• Programming after the RETURN instruction is not executed when the RETURN instruction is executed. The outputs retain the values that they had just before the RETURN instruction was executed.

2 - 8

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 43

Data type

conversion

Data Type Conversion Instructions

Type Instruction Name Description Page

Boolean to

integer

Boolean to

duration

Boolean to bit

string

BOOL_TO_INT Convert

BOOL to INT

BOOL_TO_DINT Convert

BOOL to

DINT

BOOL_TO_TIME Convert

BOOL to

TIME

BOOL_TO_WORD Convert

BOOL to

WORD

Converts a BOOL variable

to an INT variable.

Converts a BOOL variable

to a DINT variable.

Converts a BOOL variable

to a TIME variable.

Converts a BOOL variable

to a WORD variable.

2

P. 2 -1 2

P. 2 -1 3

P. 2 -1 4

P. 2 -1 5

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 9

Page 44

2 Standard Functions

Type Instruction Name Description Page

Data type

conversion

Bit string to integer

Bit string to

duration

Bit string to bit

string

Integer to

Boolean

Integer to bit

string

Integer to integer DINT_TO_INT Convert

BYTE_TO_INT Convert

BYTE to INT

BYTE_TO_DINT Convert

BYTE to

DINT

WORD_TO_INT Convert

WORD to

INT

WORD_TO_DINT Convert

WORD to

DINT

DWORD_TO_DINT Convert

DWORD to

DINT

BYTE_TO_TIME Convert

BYTE to

TIME

WORD_TO_TIME Convert

WORD to

TIME

DWORD_TO_TIME Convert

DWORD to

TIME

BYTE_TO _WORD Convert

BYTE to

WORD

WORD_TO_BYTE Convert

WORD to

BYTE

WORD_TO_DWORD Convert

WORD to

DWORD

DINT_TO_BOOL Convert

DINT to

BOOL

INT_TO_BOOL Convert INT

to BOOL

DINT_TO_BYTE Convert

DINT to

BYTE

DINT_TO_DWORD Convert

DINT to

DWORD

DINT_TO_WORD Convert

DINT to

WORD

INT_TO_BYTE Convert INT

to BYTE

INT_TO_DWORD Convert INT

to DWORD

O_WORD Convert INT

INT_T

to WORD

DINT to INT

INT_TO_DINT Convert INT

to DINT

Converts a BYTE variable to

an INT variable.

Converts a BYTE variable to

a DINT variable.

Converts a WORD variable

to an INT variable.

Converts a WORD variable

to a DINT variable.

Converts a DWORD variable to a DINT variable.

Converts a BYTE variable to

a TIME variable.

Converts a WORD variable

to a TIME variable.

Converts a DWORD variable to a TIME variable.

Converts a BYTE variable to

a WORD variable.

Converts a WORD variable

to a BYTE variable.

Converts a WORD variable

to a DWORD variable.

Converts a DINT variable to

a BOOL variable.

Converts an INT variable to

a BOOL variable.

Converts a DINT variable to

a BYTE variable.

Converts a DINT variable to

a DWORD variable.

Converts a DINT variable to

a WORD variable.

Converts an INT variable to

a BYTE variable.

Converts an INT variable to

a DWORD variable.

Converts an INT variable to

a WORD variable.

Converts a DINT variable to

an INT variable.

Converts an INT variable to

a DINT variable.

P. 2-16

P. 2-17

P. 2-18

P. 2-20

P. 2-21

P. 2-23

P. 2-24

P. 2-25

P. 2-26

P. 2-27

P. 2-28

P. 2-29

P. 2-30

P. 2-31

P. 2-32

P. 2-34

P. 2-35

P

. 2-36

P. 2-38

P. 2-40

P. 2-41

2 - 10

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 45

Data type

conversion

2 Standard Functions

Type Instruction Name Description Page

Integer to

duration

Duration to

Boolean

Duration to bit

string

Duration to

integer

Bit string to

Boolean

DINT_TO_TIME Convert

DINT to

TIME

INT_TO_TIME Convert INT

to TIME

TIME_TO_BOOL Convert

TIME to

BOOL

TIME_TO_BYTE Convert

TIME to

BYTE

TIME_TO_DWORD Convert

TIME to

DWORD

TIME_TO_WORD Convert

TIME to

WORD

TIME_TO_DINT Convert

TIME to

DINT

TIME_TO_INT Convert

TIME to INT

WORD_TO_BOOL Convert

WORD to

BOOL

Converts a DINT variable to

a TIME variable.

Converts an INT variable to

a TIME variable.

Converts a TIME variable to

a BOOL variable.

Converts a TIME variable to

a BYTE variable.

Converts a TIME variable to

a DWORD variable.

Converts a TIME variable to

a WORD variable.

Converts a TIME variable to

a DINT variable.

Converts a TIME variable to

an INT variable.

Converts a WORD variable

to a BOOL variable.

P. 2 -4 2

P. 2 -4 3

P. 2 -4 4

P. 2 -4 5

P. 2 -4 6

P. 2 -4 7

P. 2 -4 8

P. 2 -4 9

P. 2 -5 0

Data Type Conversion Instructions

2

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 11

Page 46

2 Standard Functions

BOOL_TO_INT

BOOL_TO_INT

This function converts a BOOL variable to an INT variable.

Instruction Name FB/FUN Graphic expression

BOOL_TO_INT Convert BOOL to

INT

Variables

Name I/O Description Valid range Default

In Data to con-

vert

Out Conversion

result

If you omit an input or output parameter, a building error will occur.

Input Data to con-

Output Conversion

FUN

TRUE or FALSE FALSE

vert

INT#0 or INT#1 INT#0

result

Boolean Bit strings Integers Durations

BOOL

In OK OK

Out OK OK

SAFEBOOL

BYTE

SAFEBYTE

WORD

SAFEWORD

DWORD

SAFEDWORD

INT

Function

This function converts BOOL data In to INT data Out.

If the value of In is FALSE, the value of Out is INT#0.

If the value of In is TRUE, the value of Out is INT#1.

Additional Information

To check for INT data, refer to INT_TO_BOOL.

SAFEINT

DINT

SAFEDINT

TIME

SAFETIME

Precautions for Correct Use

• The input condition depends on whether the output is safety data or standard data. If the condition is

not met, a building error will occur.

• If you set a safety data type variable for the output terminal, set a safety data type variable for the

input terminal as well.

• If you set a standard data type variable for the output terminal, you can set either a safety data type

variable or a standard data type variable for the input terminal.

2 - 12

NX-series Safety Control Unit Instructions Reference Manual (Z931)

Page 47

BOOL_TO_DINT

This function converts a BOOL variable to a DINT variable.

Instruction Name FB/FUN Graphic expression

BOOL_TO_DINT Convert BOOL to

DINT

FUN

2 Standard Functions

Data Type Conversion Instructions

BOOL_TO_DINT

Variables

Name I/O Description Valid range Default

In Data to con-

vert

Out Conversion

result

If you omit an input or output parameter, a building error will occur.

Boolean Bit strings Integers Durations

BOOL

In OK OK

Out OK OK

SAFEBOOL

Input Data to con-

Output Conversion

BYTE

SAFEBYTE

WORD

vert

result

SAFEWORD

DWORD

TRUE or FALSE FALSE

DINT#0 or DINT#1 DINT#0

SAFEDWORD

INT

SAFEINT

DINT

Function

This function converts BOOL data In to DINT data Out.

SAFEDINT

TIME

2

BOOL_TO_DINT

SAFETIME

If the value of In is FALSE, the value of Out is DINT#0.

If the value of In is TRUE, the value of Out is DINT#1.

Additional Information

To check for DINT data, refer to DINT_TO_BOOL.

Precautions for Correct Use

• The input condition depends on whether the output is safety data or standard data. If the condition is

not met, a building error will occur.

• If you set a safety data type variable for the output terminal, set a safety data type variable for the

input terminal as well.

• If you set a standard data type variable for the output terminal, you can set either a safety data type

variable or a standard data type variable for the input terminal.

NX-series Safety Control Unit Instructions Reference Manual (Z931)

2 - 13

Page 48

2 Standard Functions

BOOL_TO_TIME

BOOL_TO_TIME

This function converts a BOOL variable to a TIME variable.

Instruction Name FB/FUN Graphic expression

BOOL_TO_TIME Convert BOOL to

TIME

Variables

Name I/O Description Valid range Default

In Data to con-

vert

Out Conversion

result

If you omit an input or output parameter, a building error will occur.

Input Data to con-

Output Duration T#0ms or T#1ms T#0ms

FUN

vert

TRUE or FALSE FALSE

Boolean Bit strings Integers Durations

BOOL

In OK OK

Out OK OK