Page 1

P122-E1-01

Machine A utomation Contr oller NX1P

Practices Guide

for NX1P Programming

NX1P2-[][][][]

SYSMAC-SE20[][]

Page 2

All rights reserved. No part of this publication may be repr oduced, stored in a retrieval system, or

Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and

© OMRON, 2017

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or

otherwise, without the prio r w r it t en per m iss ion of OMRON.

No patent liability is assume d with respect to the use of the i nf ormation contained herein. M or eover,

because OMRON is constantly striving to improve its high-quality produc t s, t he information

contained in this guide is subject to change w it hout notice. Every pr ecaution has been taken in the

preparation of this guide. Nev er t hel es s, O MRON assumes no responsibility for errors or om issions.

Neither is any liab i lity assumed for damages resulting from the use o f the information contained in

Trademarks

•

other countries for OMRON factory automation pr oducts.

• Windows is either a register ed trademark or tradem ar k of Microsoft Corporati on in the United States

and/or other countries.

• EtherCAT

GmbH, Germany

• EtherNet/IP™ is a trademark of ODVA.

• Celeron, Intel, and Intel Core are the trademarks of Intel Corporation in the USA and other countries.

• Microsoft product screen shot(s) reprinted with permission from Microso ft C orporation.

Other company names an d pr oduct names in this document ar e t he t r ademarks or registered

trademarks of their respective companies.

®

is a registered t r ademark and patented technology, licensed by Beckho f f Automation

2

Page 3

Introduction

Precautions for Correct Use

performance.

Additional Information

This information is provided to increase understanding or make operation easier.

Thank you for purchasing an NX -series NX1P2 CPU Unit and the Sysmac Studio.

This NX1P Programming Practic es G uide for Beginners (her eafter referred to as “this G uide”)

describes the differenc es i n progra mm ing b etw een t he NX1 P a nd trad itio nal c ontr ollers a nd th e

programming procedures using the Sysmac Studio that are required to use an NX 1P2 CPU

Unit for the first time. Y ou can perform the procedures t hat ar e pr esented in this Guide to

quickly gain a basic underst anding of the NX1P2 CPU Units and the Sysmac Studio. This

Guide does not contain safety information and other det ai ls t hat ar e r equired for actual use.

Thoroughly read and under s t and t he manuals for all of the devices t hat ar e used in this Guide

to ensure that the system is used safely. Review the entire c ont ents of these materia ls,

including all safety precautions, precautions for safe use, and precautions for correct use.

For the startup and operating ins t r uct i ons for motion control, re fer t o t he NJ/NX-series Star tup

Guide for Motion Control (Cat. No. W514).

Intended Audience

This Guide is intended for the following personnel, who must al so have knowledge of elect r ical

systems (an electrical eng ineer or the equivalent).

• Personnel in charge of int r oducing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of in s t alling and maintaining F A systems

Applicable Products

This Guide covers the foll ow ing products.

• NX1P2 CPU Units of NX -series Machine Automat ion Controllers

• Automation Software Sy sm ac Studio

Special Information

The icons that are used in this G uid e ar e described below.

Precautions on what to do and what not to do to ensure proper operation and

Additional informat ion to read as required.

3

Page 4

Terms and Condit ions Agreement

Warranty, Limitations of Liability

Warranties

• Exclusi ve Warranty

Omron’s exclusive warranty is that the Products will be fre e from defects in mater ials and

workmanship for a perio d of twelve months from the dat e of sale by Omron (or such other

period expressed in writing b

• Limitations

OMRON MAK ES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTAB I L ITY OR FITNESS FOR A PARTICULAR PURPOSE

OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED

THAT THE PRO DUCTS WILL SUITABLY M EET THE REQUIREMENTS O F THEIR

INTENDED USE.

Omron further disclaims a l l w ar r ant ies and responsibility of any type for claims or expenses

based on infringement by t he Pr oducts or otherwise of any intellectual property r ight.

• Buyer Remedy

Omron’s sole obligation hereunder shall be, at O mron’s election, to (i) replace (in the form

originally shipped with Buy er r espons i bl e for labor charges for removal or r eplacement thereof)

the non-complying Product, (ii) repair the no n-complying Product, or ( iii) repay or credit Buyer

an amount equal to the purchase price of the non-complying Product; provided that in no event

shall Omron be respons ibl e for w ar r ant y, repair, indemnity or any other claims or expenses

regarding the Products unless Omron’s analysis con firms that the Products wer e pr oper ly

handled, stored, installed and maintained and not subject t o c ont amination, abuse, misuse or

inappropriate modification. Return of any Product s by Buyer must be approved in writing by

Omron before shipment. O mron Companies shall not be li abl e for the suitability or unsuitability

or the results from the use of Products in combination with any electrical or elec t r onic

components, circuits, sy stem ass e mblies or a ny ot her mat eria ls or substances or environ ment s.

Any advice, recommend at ions or information given oral ly or in writing, are not t o be cons t r ued

as an amendment or addition to t he above warranty.

See http://www.omron.com/global/ or contact your Omron representat iv e for published

information.

y Omron). Omron disclaims all other warranties, express or implied.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in

Product on which liability is a s s

4

no event shall liability of Omron Companies exceed the individual price of the

erted.

Page 5

Application Consider at ions

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product,

machine, system, or other application or use. Buyer shall be solely responsible for determining

appropriateness of the par t icular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED

TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall n ot be r esponsible for the user’s pro gramming of a programma bl e

Product, or any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catal ogs and other materials is pr ovided as a

guide for the user in d eter min ing s uitabi lity and do es not con st itute a w ar ranty . It may represent

the result of Omron’s test c onditions, and the user mu st c orr elate it to actual applicatio n

requirements. Actual performanc e is subject to the Omron’s Warranty and Limitations o f

Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on i mprovements

and other reasons. It is ou r prac tice t o ch ange part n umber s wh en p ubli shed ra tings or feat ure s

are changed, or when significant construction changes are made. However, some

specifications of the Prod uct may be changed witho ut any notice. When in doubt, special part

numbers may be assigned t o fix or est ablish key specifications for your application. P lease

consult with your Omron’s r epr esent ative at any time to confirm actual specifi cat ions of

purchased Product.

5

Page 6

Errors and Omissions

Information presented by Omron Co mpan ies h as been checked an d is be liev ed to be acc urate ;

however, no responsibi lity is assumed for clerical, t ypogr aphical or proofreadin g er r or s or

omissions.

Automation Software Sysmac Studio

WARRANTY

• The warranty period for the Software is one year from the date of purchase, unles s

otherwise specifically agreed.

• If the User discovers defe ct of t he Software (substantial n on-conformity with the m anual),

and return it to OMRON within the above warranty period, OMRON will replace the Softw are

without charge by offering media or download fro m OMRON’s website. And if the User

discovers defect of medi a w hich is attributable to OMRON and return it to OMRO N w ithin

the above warranty period, OMRON wi ll replace defective media w ithout c harge. If OMRON

is unable to replace defectiv e media or correct the Softw ar e, the liability of OMRON and the

User’s remedy shall be lim ited to the refund of the license f ee paid to OMRON for the

Software.

LIMITATION OF LIABILITY

• THE ABOVE WARRA NT Y SHALL CO NSTITUTE THE USE R ’S SOL E AND E X CL USI VE

REMEDIES AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. IN NO EVENT,

OMRON WILL BE LIABLE FOR ANY LOST PROFITS OR OTHER I NDIRECT,

INCIDENTAL , SPECIAL O R CONSEQUENTIAL DAMAGES

• ARISING OUT OF USE OF T HE SOFTWARE. OMRON SHALL HAVE NO L IABILITY FOR

DEFECT OF THE SOFTWARE BASED ON MODIFICATION OR ALTERNATION TO THE

SOFTWARE BY THE USER OR ANY THIRD PARTY.

• OMRON SHALL HAVE NO LI ABILITY FOR SOFTWARE DE VELOPED BY THE USER OR

ANY THIRD PARTY BAS ED ON THE SOFTWARE O R ANY CONSEQUENCE THEREOF.

APPLICABLE CONDITIONS

USER SHALL NOT USE THE SOFTWARE FOR THE PURPOSE THAT IS NOT PROVIDED

IN THE ATTACHED USER MANUAL.

CHANGE IN SPECIFICATION

The software specificat ion s and accessories may be chang ed at any time based on

improvements and other reasons.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate;

however, no responsibi lity is assumed for clerical, t ypogr aphical, or proofread i ng er r or s, or

omissions.

6

Page 7

Precautions

• When building a system, check the specification s for all devices and equipment that will

make up the system and make sur e t hat the OMRON product s ar e used well within their

rated specifications and performances. Sa fet y measures, such as sa fety circuits, must be

implemented in order to m inim ize the risks in the event of a ma lf unction.

• Thoroughly read and understand the manuals for al l devices and equipment t hat w il l make

up the system to ensure that t he s ystem is used safely. Review t he ent ir e contents of these

materials, including a ll sa f ety precautions, precaut ions for safe use, and preca ut ions for

correct use.

• Confirm all regulations, standards, and restrict io ns t hat t he system must adhere to.

Software Licenses and Copyrights

This product incorporate s cer t ain t hird party software. The l ice ns e and copyright information

associated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

7

Page 8

Related Manuals

provided.

W501).

The followings are the ma nuals related to this manual. Use these manuals for refere nce.

Manual name Cat. No. Model Application Description

NX-series

NX1P2 CPU Unit

Hardware User's

Manual

W578 NX1P2- □□□□ Learning the basic

specifications of the

NX1P2 CPU Units,

including introductory

information,

designing, installation,

and maintenance.

Mainly hardware

information is

An introduction t o the entire NX1P2

system is provi ded along with the

following inform ation on the CPU Unit.

• Features and system c onfiguration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

NX-series

NX1P2 CPU Unit

Built-in I/O and

Option Board

User's Manual

NJ/NX-series

CPU Unit

Software User’s

Manual

NJ/NX-series

Instructions

Reference Manual

W579 NX1P2- □□□□ Learning about the

details of func tions

only for an NX-series

NX1P2 CPU Unit and

an introduction of

functions for an

NJ/NX-series CPU

Unit.

W501 NX701- □□□□

NJ501- □□□□

NJ301- □□□□

NJ101- □□□□

NX1P2- □□□□

W502 NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NX1P2-□□□□

Learning how to

program and set up

an NJ/NX-series CP U

Unit.

Mainly software

information is

provided.

Learning detaile d

specificati ons on the

basic instruct ions of

an NJ/NX-series CP U

Unit.

Of the functions for an NX1P2 CPU

Unit, the following information is

provided.

• Built-in I/O

• Serial Communications Option Boards

• Analog I/O Option Boards

An introduction of following functions for

an NJ/NX-series CPU Unit is also

provided.

• Motion control functions

• EtherNet/I P communications functions

• EtherCAT communications func tions

The following information on a

Controller built with an NJ/NX-series

CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial setting

• Programming b ased on IEC 61131-3

language specifications

Use this manual together with the

NX-series NX1P2 CPU Uni t Hardware

User's Manual (Cat. No. W578).

The instructions in the instruction set

(IEC 61131-3 specifications) are

described. When programming, use this

manual together with the NJ-series CPU

Unit Hardware User's Manual (Cat. No.

W500) and NJ/NX-series CPU Unit

Software User' s M anual (Cat. No.

NJ/NX-series

CPU Unit

Motion Control

User’s Manual

8

W507 NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NX1P2-□□□□

Learning about

motion control

settings and

programming

concepts.

The settings and operation of the CPU

Unit and programming concepts for

motion control are described. Use this

manual together with the NJ-series CPU

Unit Hardware User's Manual (Cat. No.

W500) and NJ/NX-series CPU Unit

Software User' s M anual (Cat. No.

W501).

Page 9

Manual name Cat. No. Model Application Description

W507).

W501).

Sysmac Studio.

NJ/NX-series

Motion Control

Instructions

Reference Manual

W508 NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NX1P2-□□□□

Learning about the

specifications of the

motion control

instructions.

The motion control instructions are

described. When programming, use this

manual together with the NJ-series CPU

Unit Hardware User's Manual (Cat. No.

W500), NJ/NX-series C P U U nit

Software User' s M anual (Cat. No.

W501),and NJ/NX-series CPU Unit

Motion Control Us er’s Manual (Cat. No.

NJ/NX-series

CPU Unit

Built-in

EtherCAT

User’s Manual

NJ/NX-series

CPU Unit

Built-in

EtherNet/IP Port

User’s Manual

NJ/NX-series

Troubleshooting

Manual

Sysmac Studio

Version 1

Operation Manual

Port

W505 NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NX1P2-□□□□

W506 NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NX1P2-□□□□

W503 NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

NX1P2-□□□□

W504 SYSMAC-SE2 □□□

Using the built-in

EtherCAT port on an

NJ/NX-series CPU

Unit.

Using the built-in

EtherNet/IP port on an

NJ/NX-series CPU

Unit.

Learning about the

errors that may be

detected in an

NJ/NX-series

Controller.

Learning about the

operating procedures

and functions of the

Information on the bui lt-in EtherCAT

port is provided. This manual provides

an introduction an d information on the

configuration, features, and set up. Use

this manual together with the NJ-series

CPU Unit Hardware User's Manual (Cat.

No. W500) and NJ/NX-series CPU Unit

Software User' s M anual (Cat. No.

W501).

Information on the bui lt-in EtherNet/IP

port is provided. Information on t he

basic setup, tag dat a links, and other

features is provided. Use this manual

together with the NJ-series CPU Unit

Hardware User's Manual (Cat. No.

W500) and NJ/NX-series CPU Unit

Software User' s M anual (Cat. No.

Concepts on managing errors that may

be detected in an NJ/NX-series

Controller and inf ormation on individual

errors are described. Use this manual

together with the NJ-series CPU Unit

Hardware User's Manual (Cat. No.

W500) and NJ/NX-series CPU Unit

Software User' s M anual (Cat. No.

W501).

The operating proced ures of the

Sysmac Studio is described.

NJ/NX-series

Startup Guide for

Motion Control

W514 NX1P2-□□□□

NX701-□□□□

NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

SYSMAC-SE20□□

R88M-1□

R88D-1SN□-ECT

Learning startup

procedures and

Sysmac Studio

operating procedures

for someone that will

use NJ/NX series

motion control

functions for the first

time.

The operations fr om hardware

assembly through d ebugging for axis

parameter settings, simple one-axis

positioning, and two-axis linear

interpolation ar e described.

9

Page 10

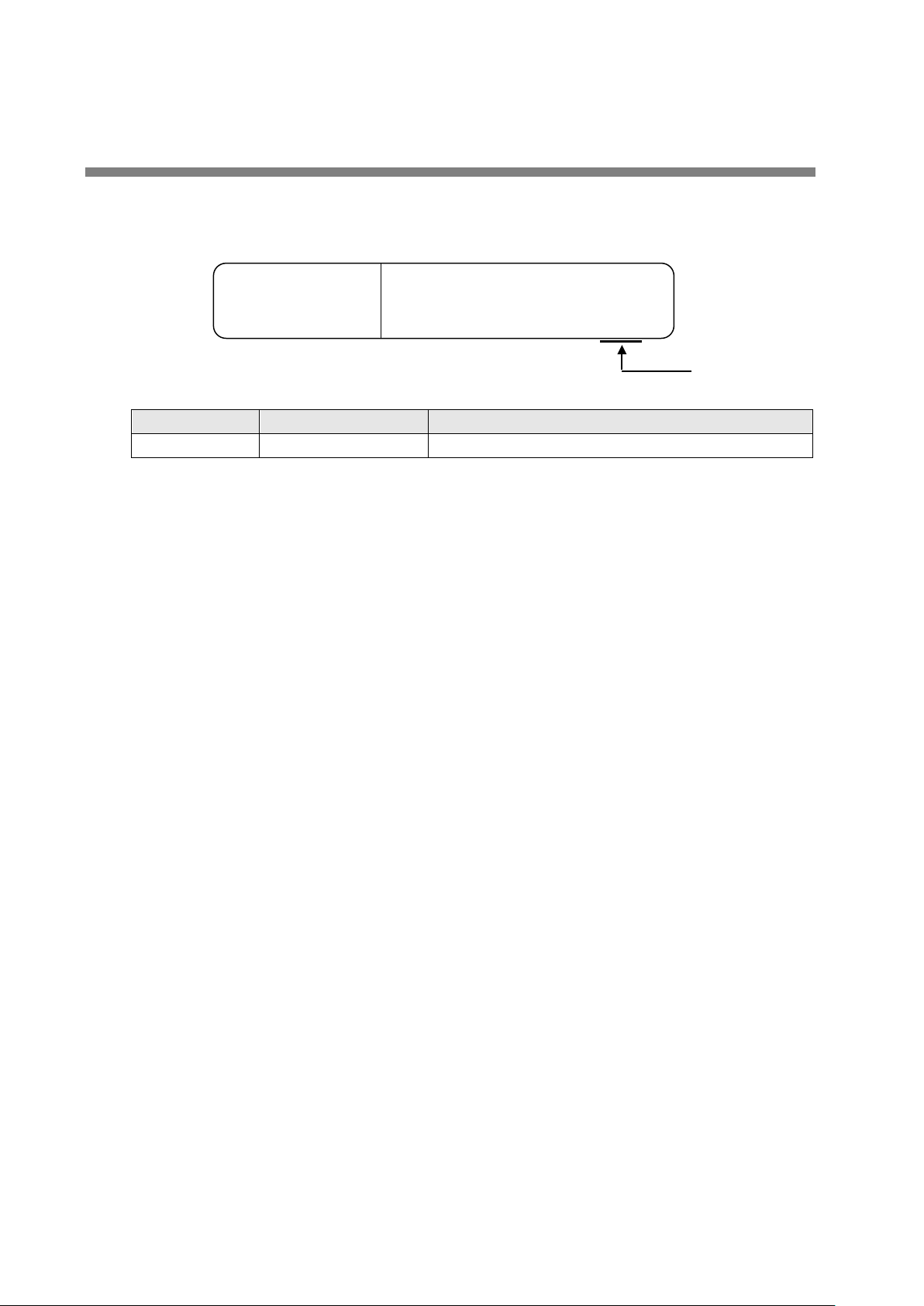

Revision History

Revision code

Date

Revised content

01

September 2017

Original production

P122-E1-01

Revision code

A manual revision code appears as a suffix to t he catalog number on the front and bac k covers

of the manual.

10

Page 11

CONTENTS

Introduction ...............................................................................................................3

Terms and Conditions Agreement ............................................................................4

Precautions ...............................................................................................................7

Related Manuals .......................................................................................................8

Revision History ..................................................................................................... 10

1 Programming the NX1P .......................................................... 14

1-1 Overview .......................................................................................................... 15

1-2 Features of NX1P Progr a mming ..................................................................... 16

1-2-1 Challenges in Development and Solutions Using the NX1P ............. 16

1-2-2 Easy to Add Programs ....................................................................... 17

1-2-3 Easy Motion Programming ................................................................ 18

1-2-4 Structured Text Language for Easy Mathematical Processing ......... 19

1-3 Programm ing with Variables ............................................................................ 20

1-3-1 Programming the NX1P ..................................................................... 20

1-3-2 Data Types ........................................................................................ 23

1-3-3 Benefit of Using Data Types .............................................................. 24

1-3-4 International Standard IEC 61131-3 .................................................. 25

1-4 Programming Software .................................................................................... 26

1-4-1 Programming Software Sysmac Studio ............................................. 26

1-4-2 Simulations ........................................................................................ 27

2 Before You Begin .................................................................... 28

2-1 System Configuration and Devices ................................................................. 29

2-1-1 Overview ............................................................................................ 29

2-1-2 Wiring ................................................................................................. 30

2-2 Installing the Sysmac Studio............................................................................ 32

2-2-1 Installing the Sysmac Studio ............................................................. 32

2-2-2 Requirements for Installation ............................................................. 32

3 Ladder Programming .............................................................. 33

3-1 Programming with the Sysmac Studio............................................................. 35

3-1-1 Programming Procedure ................................................................... 35

3-1-2 Creating a Project .............................................................................. 35

11

Page 12

3-2 Parts of the Sysmac Studio Window ................................................................37

3-2-1 Screen for Configurations and Setup ................................................ 37

3-2-2 Screen for Programming.................................................................... 37

3-3 Assignin g Variables to Terminals .....................................................................38

3-3-1 Variable Names for Terminal Numbers ............................................. 38

3-3-2 I/O Map Setting .................................................................................. 39

3-3-3 Checking Wiring ................................................................................. 41

3-4 Ladder Programming ........................................................................................42

3-4-1 Inserting Circuit Parts ........................................................................ 42

3-4-2 Keyboard Mapping ............................................................................. 42

3-4-3 Rules .................................................................................................. 43

3-5 Example of a Basic Ladder Program ................................................................44

3-5-1 Practice of Programming a Ladder Diagram ..................................... 44

3-5-2 Writing the Algorithm ......................................................................... 45

3-5-3 Program Check .................................................................................. 47

3-5-4 Saving the Program ........................................................................... 48

3-5-5 Checking Operation on the NX1P ..................................................... 49

3-5-6 Checking Operation on the Simulator ................................................ 50

3-5-7 Example of a Program Error (Offline) ................................................ 52

3-5-8 Example of an Error Occurred During Operation .............................. 52

3-6 Example of a Ladder Program Using a Ti m er I ns t r uct ion ................................53

3-6-1 Self-holding Rung .............................................................................. 53

3-6-2 On-Delay Timer (TON) Instruction ..................................................... 54

3-6-3 Exercise: Energy Saving Es c alator ................................................... 58

3-6-4 Checking the Operation of the Program ............................................ 59

3-6-5 Checking the Operation of the Program (Watch Tab Page) .............. 60

3-7 Example of a Ladder Program Using Date and Time ......................................62

3-7-1 Programming the NX1P Using Date and Time .................................. 62

3-7-2 Exercise: Continuous Operating Time of Escalator ........................... 62

3-8 Fundame nt als of Programming to Red uce Develo pme nt Time .......................66

3-8-1 POUs (Program Organization Units) ................................................. 66

3-8-2 Programs and Execution Priorities (Tasks) ....................................... 66

3-8-3 Functions (FUNs) and Function Blocks (FBs) ................................... 68

3-8-4 Sections ............................................................................................. 69

3-8-5 Types of Variables ............................................................................. 70

4 Creating Programs to Handle Data..........................................73

4-1 Variables Use d for Data Processing ................................................................74

4-1-1 Arrays................................................................................................. 74

12

4-2 Programming Exercise .....................................................................................75

4-2-1 Application Example .......................................................................... 75

4-2-2 Programming ..................................................................................... 75

4-2-3 Creating a Project .............................................................................. 76

4-2-4 Configuring Analog Option Board Settings ........................................ 77

4-2-5 Assigning Variables to the Option Board and Input Terminal............ 77

4-2-6 Program Example .............................................................................. 78

Page 13

4-2-7 Creating an Array .............................................................................. 79

4-2-8 Entering Programming Code ............................................................. 80

4-2-9 Checking the Operation of the Program ............................................ 81

4-2-10 Referring Values of Array Variables .................................................. 83

5 Motion FB Programming ......................................................... 84

5-1 Motion FB Programming .................................................................................. 85

5-1-1 Motion FB Programming .................................................................... 85

5-1-2 Programming Procedure ................................................................... 85

5-2 Adding a Servo Drive and Setting t he Parameters ......................................... 86

5-2-1 Registering a Servo Drive.................................................................. 86

5-2-2 Registering the Axis ........................................................................... 87

5-2-3 Setting the Axis Parameters .............................................................. 87

5-3 Creating a Progra m ......................................................................................... 89

5-3-1 Overview of the Ladder Program ...................................................... 89

5-3-2 Motion FBs to Use ............................................................................. 89

5-3-3 Writing the Ladder Program .............................................................. 90

5-4 Data Tracing .................................................................................................... 93

5-4-1 Checking the Operation with Data Traces ......................................... 93

5-5 3D Simulation ................................................................................................... 95

5-5-1 Starting 3D Simulation ....................................................................... 95

6 ST Programming ..................................................................... 97

6-1 Overview of ST Programming ......................................................................... 98

6-1-1 Advantages of ST Language ............................................................. 98

6-1-2 ST Programs Including Constructs .................................................... 98

6-1-3 Structure of ST and Example ............................................................ 99

6-1-4 Operators ........................................................................................... 99

6-2 NX1P Program ming in ST ............................................................................. 100

6-2-1 Writing an ST Program for NX1P .................................................... 100

6-3 ST Programming Exercise ............................................................................. 101

6-3-1 Exercise of Numerical Calculation Programming ............................ 101

6-3-2 Programming Procedures................................................................ 102

6-3-3 Checking the Program ..................................................................... 104

6-3-4 Checking the Operation of the ST Program .................................... 104

13

Page 14

1

1 Programmi ng the NX 1P

This section describes the fund amental elements of progr amming an NX1P

Machine Automation Controller .

1-1 Overview ....................................................................................................... 1-15

1-2 Features of NX1P Progr a mming .................................................................. 1-16

1-2-1 Challenges in Development and Solutions Using the NX1P ......... 1-16

1-2-2 Easy to Add Programs ................................................................... 1-17

1-2-3 Easy Motion Programming ............................................................ 1-18

1-2-4 Structured Text Language for Easy Mathematical Processing ..... 1-19

1-3 Programm ing with Variables ......................................................................... 1-20

1-3-1 Programming the NX1P ................................................................. 1-20

1-3-2 Data Types .................................................................................... 1-23

1-3-3 Benefit of Using Data Types .......................................................... 1-24

1-3-4 International Standard IEC 61131-3 .............................................. 1-25

1-4 Programming Software ................................................................................. 1-26

1-4-1 Programming Software Sysmac Studio ......................................... 1-26

1-4-2 Simulations .................................................................................... 1-27

14

Page 15

1-1 Overview

Push-In Plus

The photo below shows a n NX 1P 2 CPU Unit. Push-In Plus terminal blocks are used to

connect a power supply a nd I / O devices.

EtherCAT and EtherNet/IP ports are built in.

terminal

block

Features

1. The built-in EtherCAT port and adv anc ed mot ion c ont rol ma ke mach ine s fast er and more

precise

• Up to four axes of motion control. Electronic cams a nd interpo lation incr ease mach ine

speed and precision

• EtherCAT simplifies the wiring to up to eight servo systems including for single-axis

position control

2. Networks for IoT

• EtherNet/IP enables communications with a host PC and data links bet w een

NJ/NX-series Co nt r ol lers and CJ-series PLCs

3. Push-In Plus terminal blocks

• Push-In Plus connection reduces w iri ng t ime when a control panel is built

The environment for progr am m in g t he NX 1P makes developm ent f as t er and easier.

This Guide describes the feat ur es of NX1P programming and how to program the NX1P

using the Sysmac Studio.

15

Page 16

1-2 Features of NX1P Programming

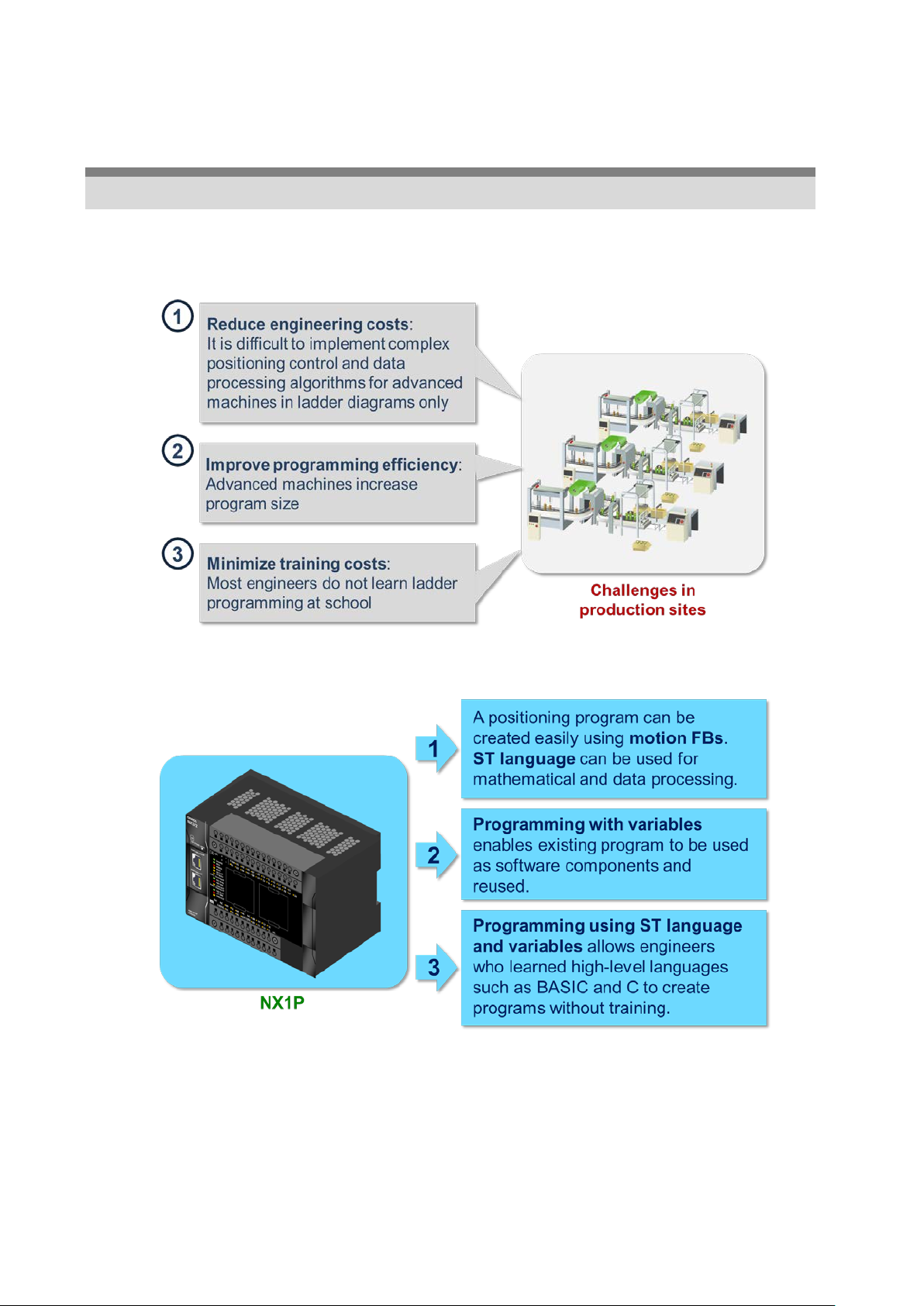

1-2-1 Challenges in Devel opm e nt a nd S olutions Us ing the NX1P

As manufacturers need to improve productivity and qua lity, machines are getting more

advanced and more complex. Engineers are facing challenges such as reducing

engineering costs, improving programming effic ien cy, and minimizing train in g c ost s.

The NX1P can offer soluti ons t o each challenge.

The next section gives more det ailed explanation about pr ogr amming the NX1P.

16

Page 17

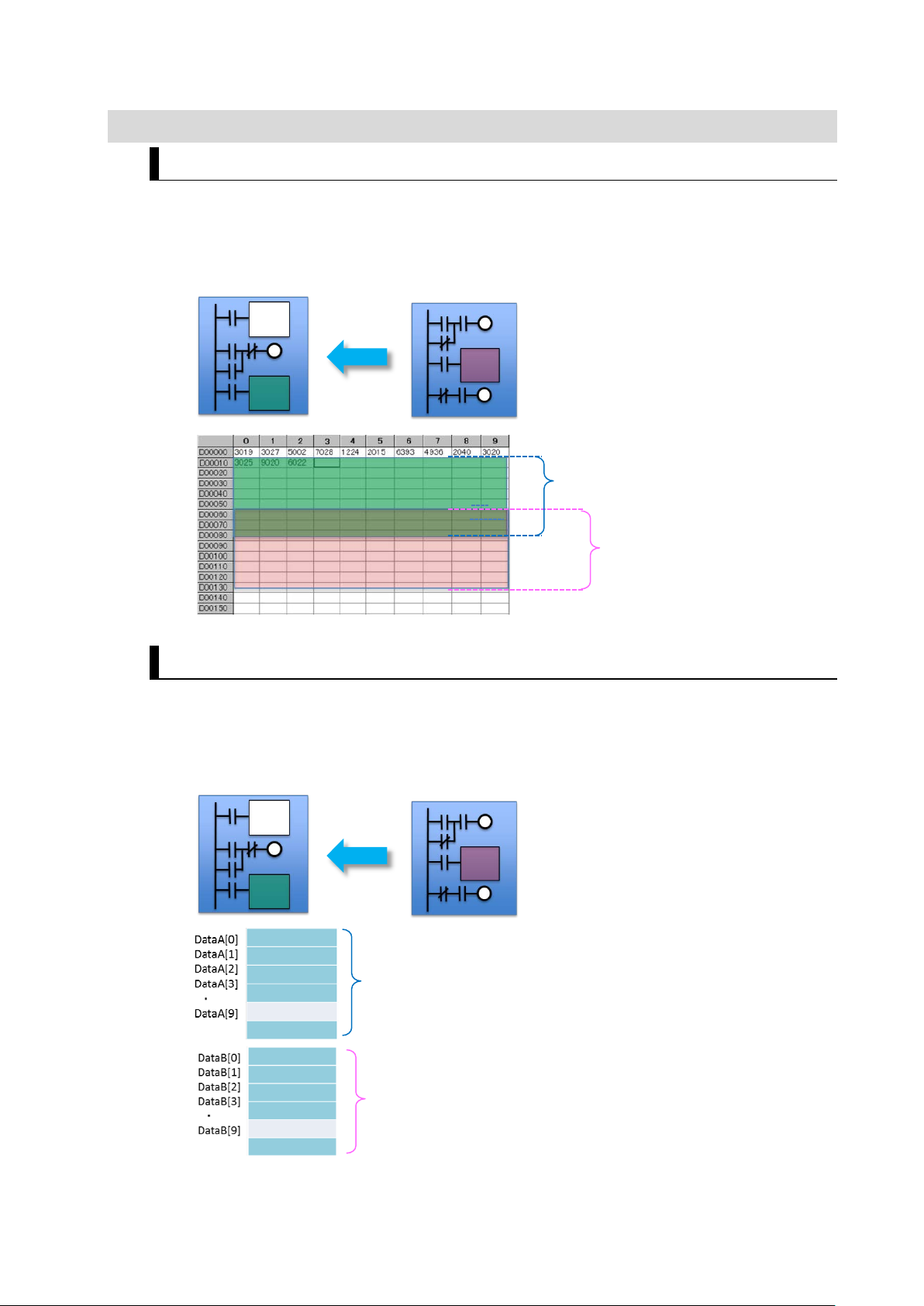

1-2-2 Easy to Add Programs

Memory area used for

Memory area used for

Memory area allocated for

Memory area allocated for

Previously

When adding a program, the user neede d t o check whether the I/O addresses and memory

area used for the additional program had already been used. If they were used,

modifications and debugg ing w ere requ ired. These t asks redu ced d ev elopmen t productiv ity .

Existing program Program to add (reused)

existing program

The same area is used

Programming the NX1P

When a program is reuse d, the NX1P automatically allo cat es memory addresses in t he

memory area for variables. The user does not need to worry about addresses when add ing or

modifying the program. Debugging time can also be reduced.

Existing program Program to add (reused)

variables of existing program

program to add

variables of program to add

17

Page 18

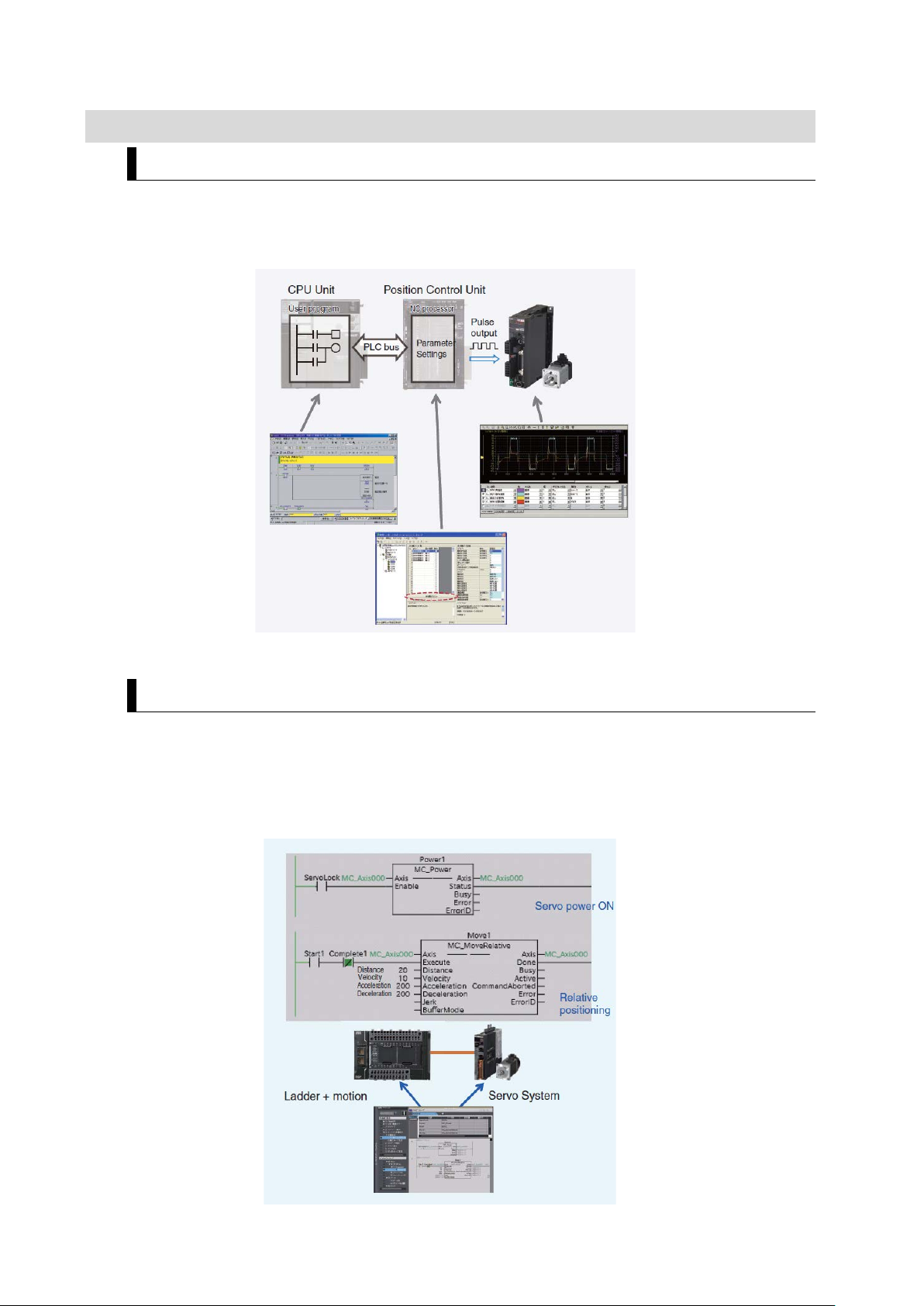

1-2-3 Easy Motion Programming

Previously

The traditional PLC (e.g., CJ2) used three different software applications for Position Control

Unit settings, ladder programming, and Servo Sy s t em sett i ngs . The user had to create a

program while monitorin g and t uning the settings.

Programming the NX1P

Operations such as turning ON the Servo, homing, and positioning can be de scr ibed in one

program by using motion FBs.

Processes are executed from top to bottom, which ma kes t he program easy to read.

The Sysmac Studio integrating ladder programming, motion, and Servo configuration

facilitates positioning control. Simple monitoring and modification!

18

Page 19

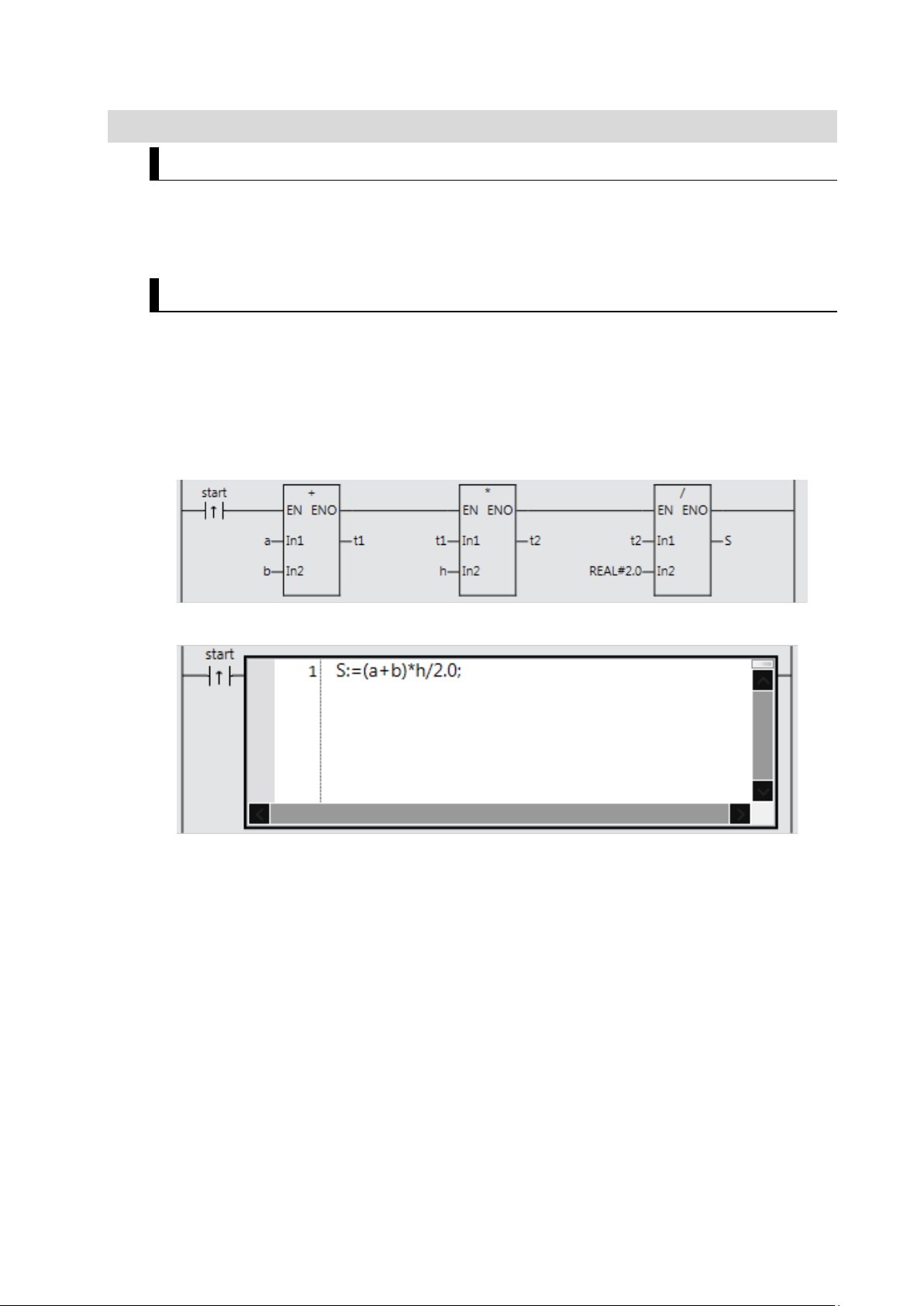

1-2-4 Structured Text Language for Easy Mathematical Processing

Structured Text Language

The structured text (ST) la nguage is a high-level structur ed language, similar to Pascal. I t is

ideal for mathematical processing and nested conditional branching that are difficult to write

in ladder diagrams.

Features of ST Language

You can create easy to read progr ams by using two different program m in g languages,

ladder diagram language f or sequence control and ST language for mathematical

processing.

Example: Calculating the area of a trapezoid

(Top length + bottom lengt h) * height / 2

The ST language simplifie s t his cod e.

You can use ST as an element in a l adder diagram or create a pr ogr am in ST only.

ST is ideal for:

1. Arithmetic operations an d fun c t io n c al culation

+, -, *, /, SIN, COS, TAN, etc.

2. Loop and condition constructs

IF THEN, FOR NEXT, etc.

3. Text string processing

Joining, extracting, searching, and replacing text st rings

The next section gives more det ailed explanation about pr ogr amming with variables.

19

Page 20

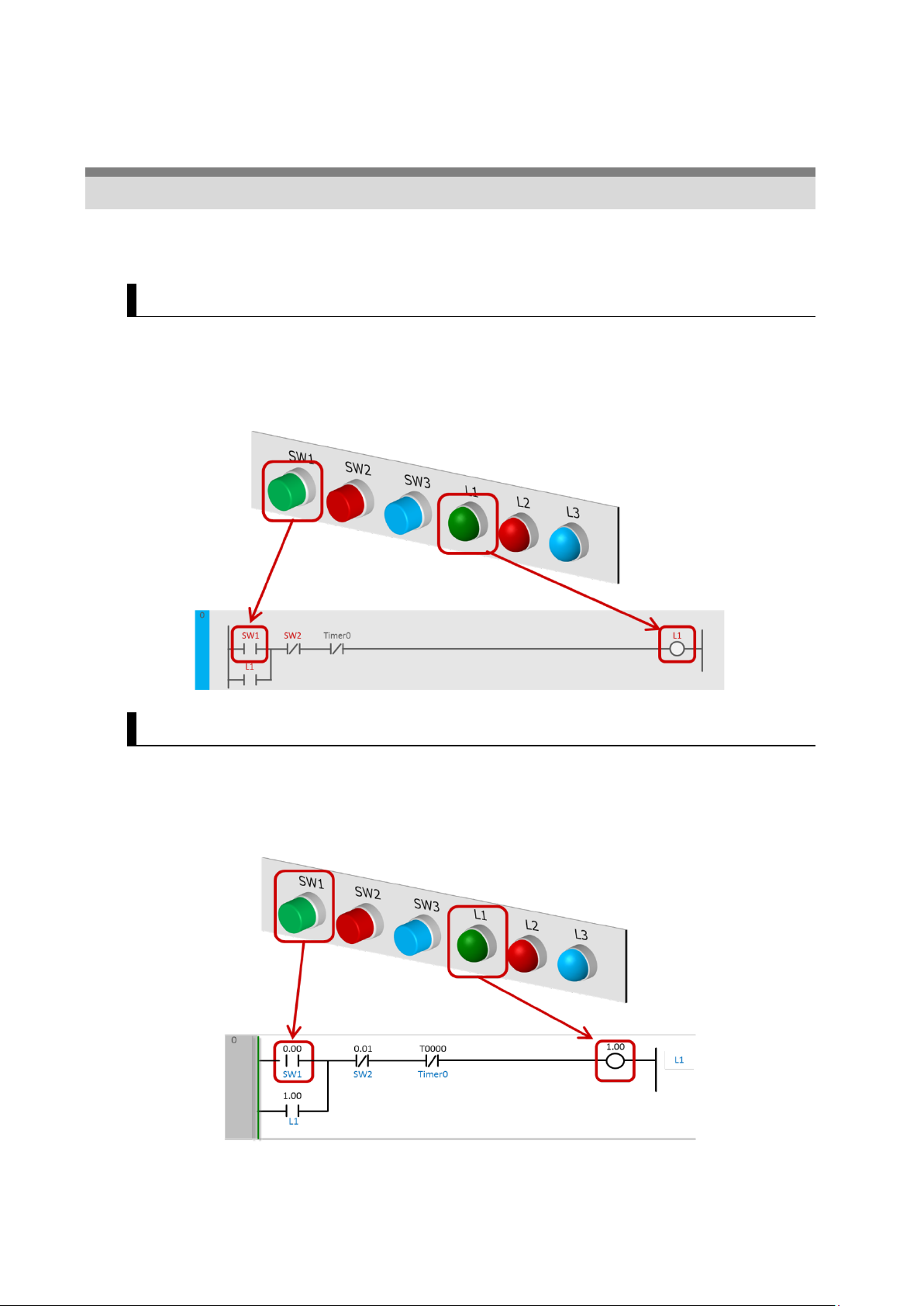

1-3 Programming with Variables

1-3-1 Programming the NX1P

Variables are names defined by the user. They are used for programming t he NX 1P

although addresses are used for the CJ2 and other traditional PLCs.

Programming the NX1P

Programming with variables eliminates the need to remember addresses and makes

programming faster and easier.

Programming with variables means that you can cr eat e pr ogr ams using the names on your

control panel or touchscreen as shown below.

Programming Traditional PLCs

I/O numbers and timer nu mb er s ( 0. 00 and T0000 shown in the figure below) are used to

program traditional PLCs such as CJ2.

For most PLCs, comment s can be added to the numbers in order to easily understand what

the numbers mean. Omro n calls the comment “I/O comment”.

20

Page 21

Difference between Programming with Addresses and with Variables

CJ2 program example

NX1P program example

NX1P

I/O Map

This section shows the difference between two prog r am m in g m et hods.

The CJ2 program (created with the CX-Programmer ) and NX 1P program (created with t he

Sysmac Studio) are show n below.

Two programs shown above were written to perform t he sam e operation.

To program the NX1P, ea ch v ariable (e. g., SW1 and L1) must be ass igned in the I/O Map to

the corresponding input / out put t er m inal to which the physical device is connected.

Variables used in the progr am ar e li nked with actual I/O ( input/output terminals of the NX1 P

in this example). You can change I/O assignments by simply changing the terminal number

in the I/O Map. The benefit of programmi ng w it h variables is that there is no need to change

the program itself.

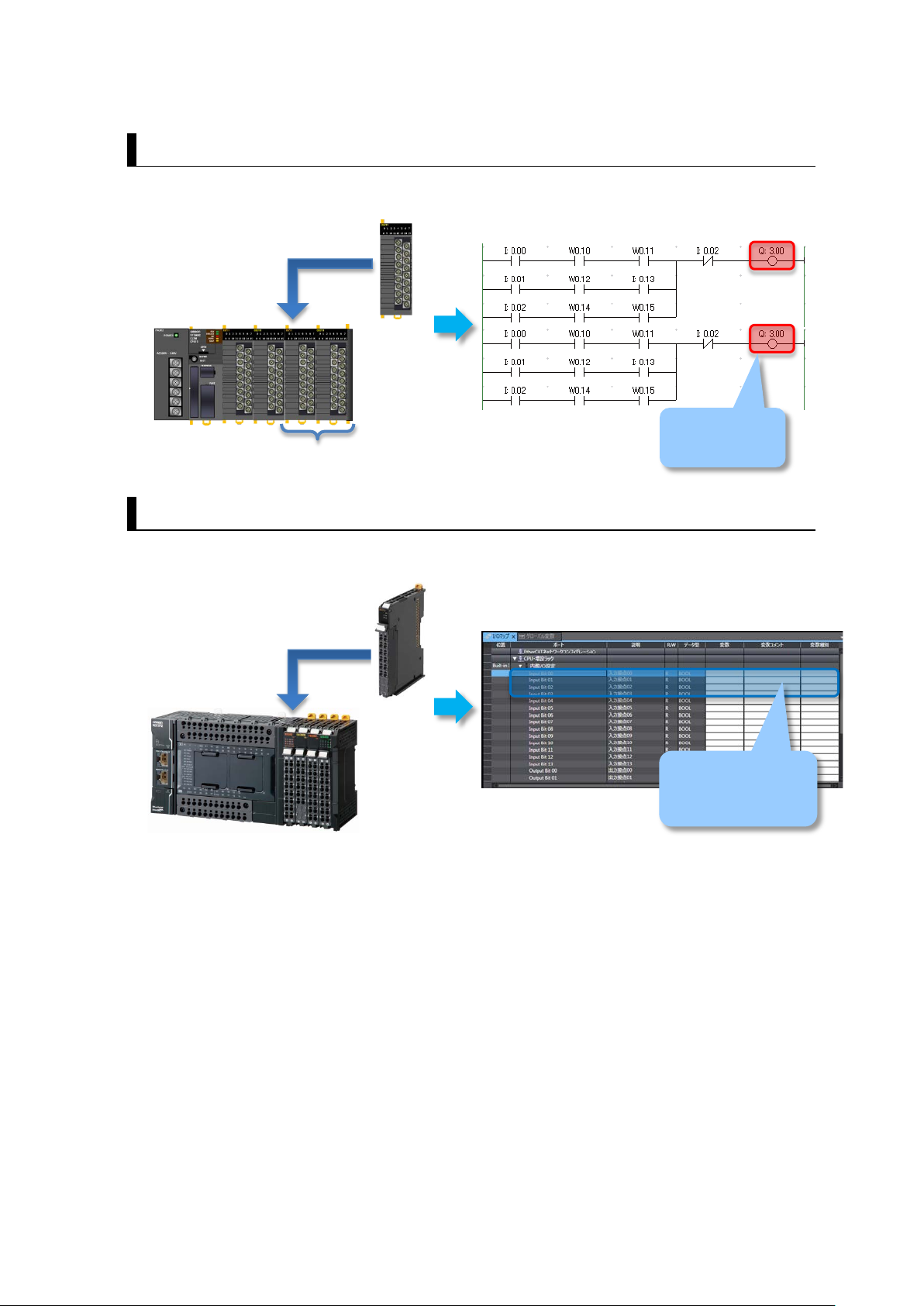

21

Page 22

Addresses are changed

Adding

a Unit

Change all related

Adding

a Unit

Just assign the device

I/O Map for NX1P

Previously

When changing the Unit conf iguration, you had to change addresses in the ladder program

because the addresses assigned to the I/O channels were changed.

addresses in the

ladder program

Programming the NX1P

Even when adding Units, you just assign variables to new I /O ports in the I/O Map without

changing the program.

variables to the I/O

ports of the added

Unit

22

Page 23

1-3-2 Data Types

Classification

Used for

Data type

Range of values

Notation

Boolean

ON/OFF status

BOOL

0 to 1

INT

-32768 to +32767

+30000, -20000

DINT

-2147483648 to

+2147483647

+12345678, -20000000

UINT

0 to 65535

60000

UDINT

0 to 4294967295

20000000

Floating-point

Real number

REAL

Single-precision

floating-point values

0.15625

LREAL

Double-precision

floating-point values

1.0000000000000002

Text string

Text string

HMI

STRING

Text strings (UTF-8)

‘OMRON’

using the name

real number, and text string) of data

For example, you define a variable called L1 (meaning the 1st lamp). It is clear that L1

contains ON/OFF data be caus e L1 is a lamp.

However, if you define a variab le called Data1, Data1 may contain a decimal num ber ,

decimal point number, or text string.

The data type defines the type of data that is expressed by a variable.

A variable is a container for dat a w ith a name and data type.

Variable = (Name) + (Data type)

Examples of Data Types

Programming

Defines the range and type (e.g., integer,

The table below lists the data types used for the NX1P. Th e BO O L dat a t ype is used for

ON/OFF data, the INT data t ype for decimal integers, and the STRING data type for text

strings.

Although both the INT and DIN T dat a t ypes represent decimal integers, they have differe nt

ranges of values.

The WORD data type for bit st r ing s , t he DA TE_AND_TIME data type for date and time, and

other data types can also be used.

・1 or 0

・TRUE or FALSE

Decimal

number

(integer)

number

of inputs and

outputs

Numeric

operation

Signed

Unsigned

displayed on

Approx. 2,000 bytes

‘Failure rate’

23

Page 24

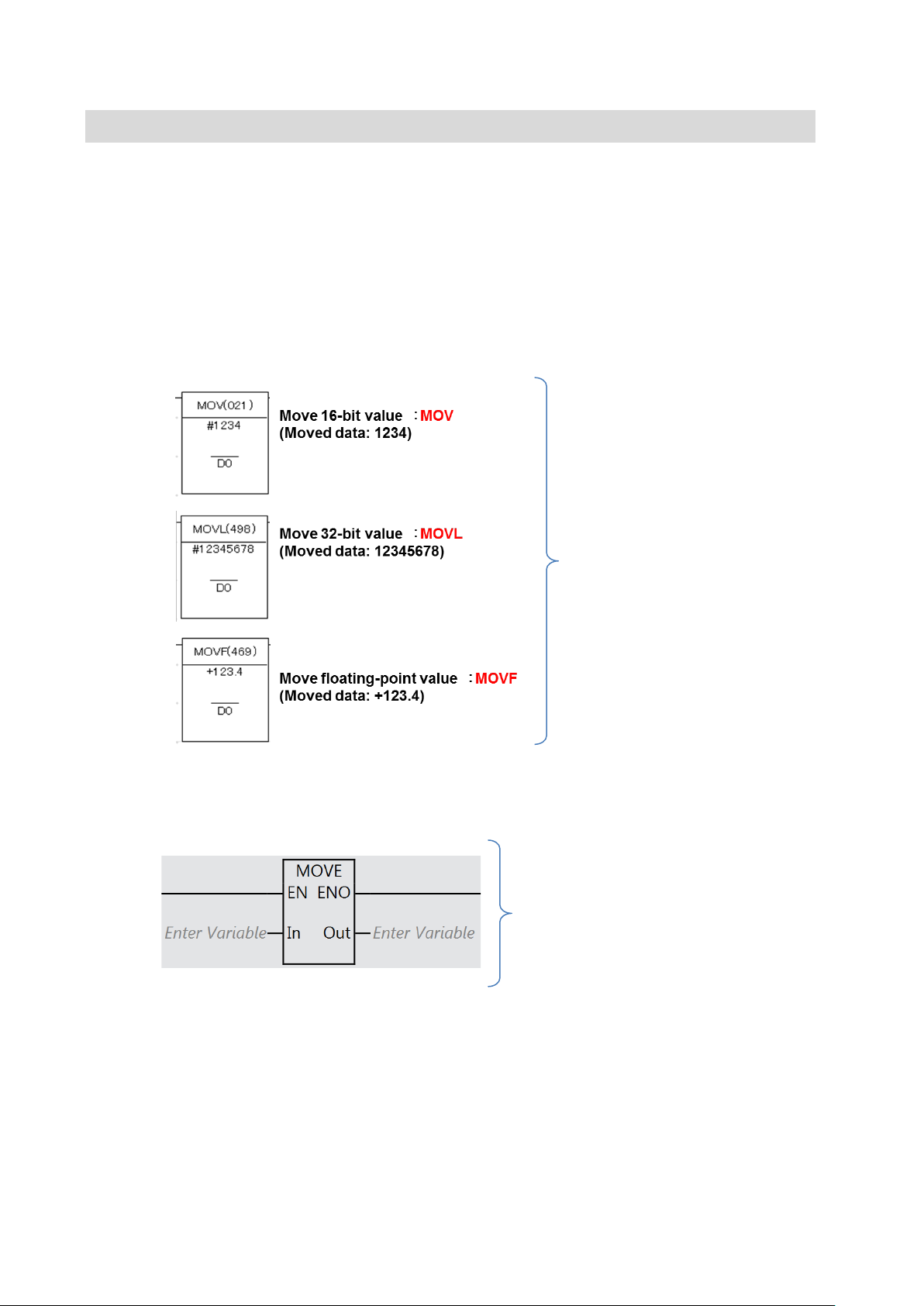

1-3-3 Benefit of Usi ng Data Types

● CJ2 or traditional PLC

● NX1P

MOV, MOVL, M OV F , etc.

Move floating-point value ⇒ REAL

When special instructio ns are used for a traditional PLC such as CJ2, different instr uct ions

must be used for different types of data.

With the NX1P, operands of sp ec i al instructions are specified with variables. As the

variables contain data types, there is no need to use differ ent instructions for differ ent dat a

types.

Even when the data length is cha nged from 16 bits to 32 bits, all you have to do is change

the data type. You don’t need t o change the program or allocate memory.

Different special instructions for

different types or lengths of data.

24

MOVE instruction only.

The concepts of “progra m m ing w ith variables” and “dat a types” based on the inter nat ional

standard IEC 61131-3 are rapidly spreading.

Specify the appropriate data types for

move source In and move destination

Out when the type or length of data is

changed.

Move 16-bit value ⇒ INT

Move 32-bit value ⇒ DINT

Page 25

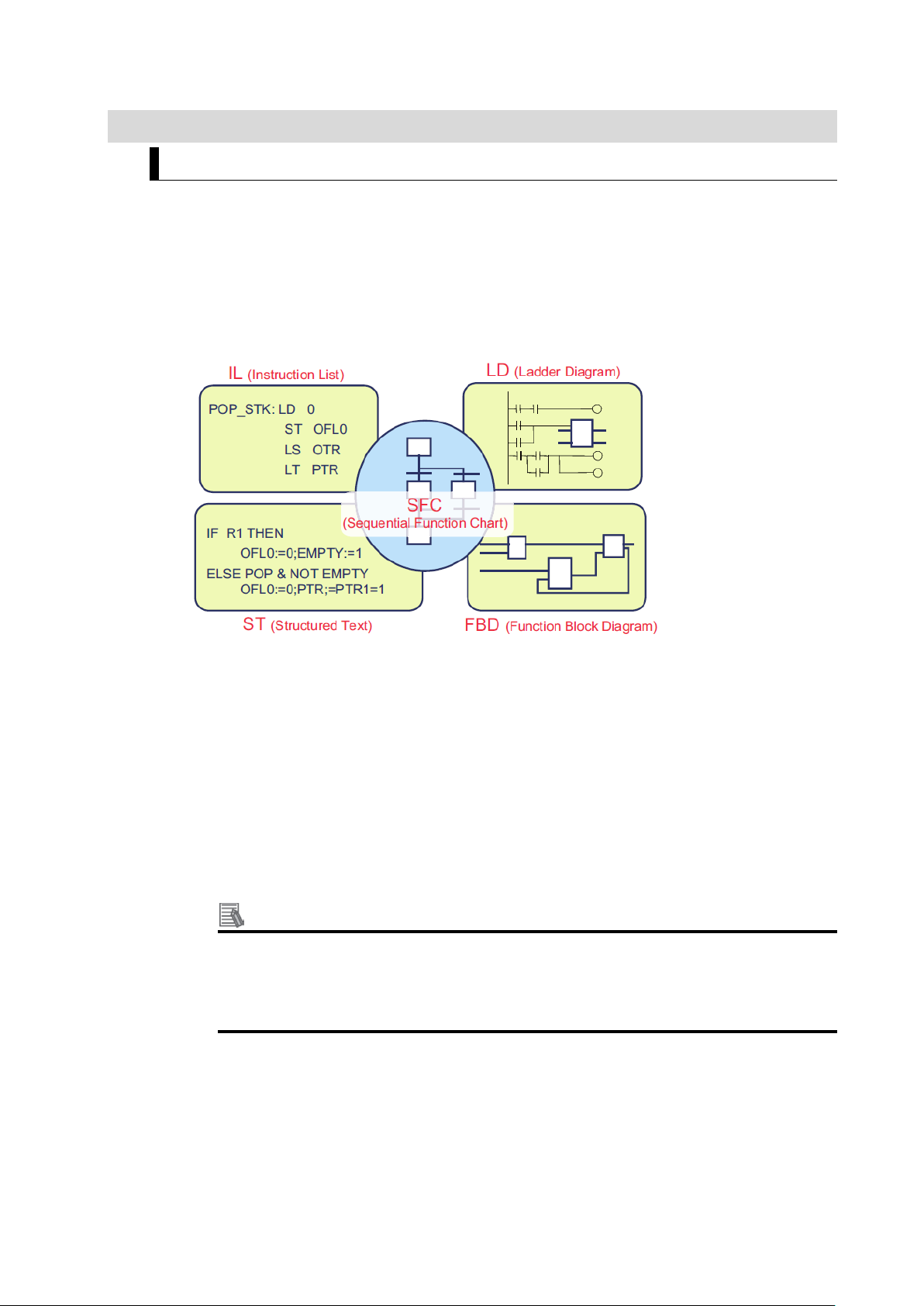

1-3-4 International Standard IEC 61131-3

IEC 61131-3

IEC 61131-3*1 is an international standard that i s in it ially published in 1993.

• Manufacturer and hardware-independent

• Reusable software components

• Five programming languages for a variet y of purposes and skill levels

*1. IEC (International Electrotechnical Commission)

Five programming langu ages according to IEC 61131-3

• IL (Instruction List): A low-level text language similar to assembly

• LD (Ladder Diagram): A graphical language written in a form similar to electrical circuits

• ST (Structured Text): A high-level structur ed language similar to Pasc al

• FBD (Function Block Diagram):

A graphical language to descr ibe the function as a set of ele mentary blocks

• SFC (Sequential Function Chart):

A graphical language used to program processes that c an be split into steps

The NX1P supports LD and ST.

Adoption of the IEC 61131-3 standard

The adoption of the IEC 61131-3 standard is widespr ead from Europe and North

America to Asia.

The NX1P support progra mm ing lan guages b ased on IEC 6 113 1-3. Engineers can be

trained easily thanks to familiar programming languages.

25

Page 26

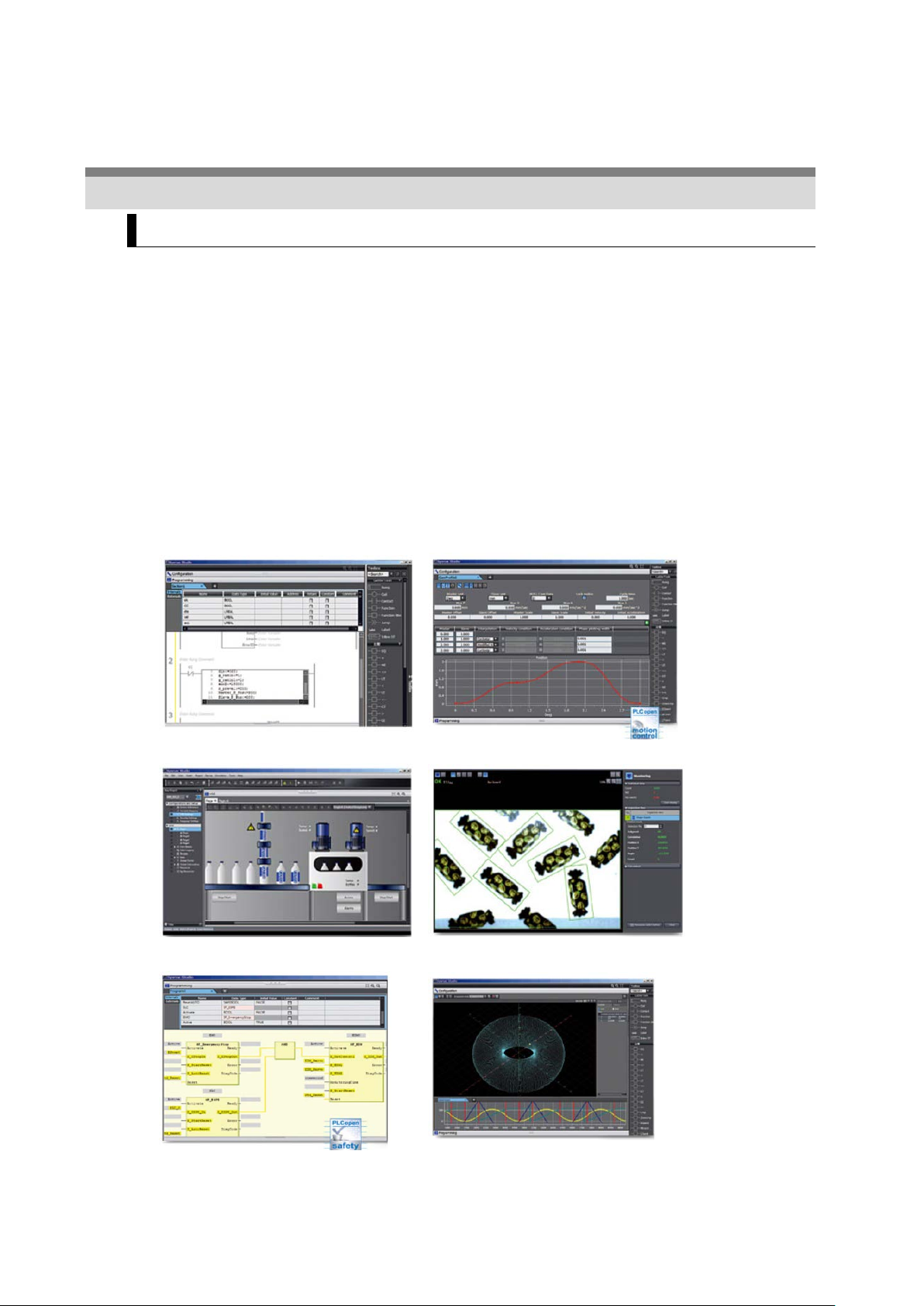

1-4 Programming Software

1-4-1 Programming Sof tware Sysmac Studio

The Sysmac Studio

The Sysmac Studio provides an integr ated dev elopme nt environ ment to configure, program,

debug, and maintain NJ/N X-series Machine Auto ma t ion Controllers.

Features

1. One software integrates configuration, progra m m in g and monitoring

2. Programming with variables. Supports the ladder and ST languages and FBs

based on IEC 61131-3

3. PLCopen function blocks f or easy programming of complex motion profiles, and

Cam Editor for quick implementation of cam motion profiles

4. Integrated simulation and debugging

Motion trajectories in 3D can be pr e-tested, and simulati on of programs can be

performed. This reduces set-up and tuning time.

*1. ST language (Structured Text language), FB (Function Block)

Programming Motion control

HMI Vision sensors

Safety Simulation

*1

26

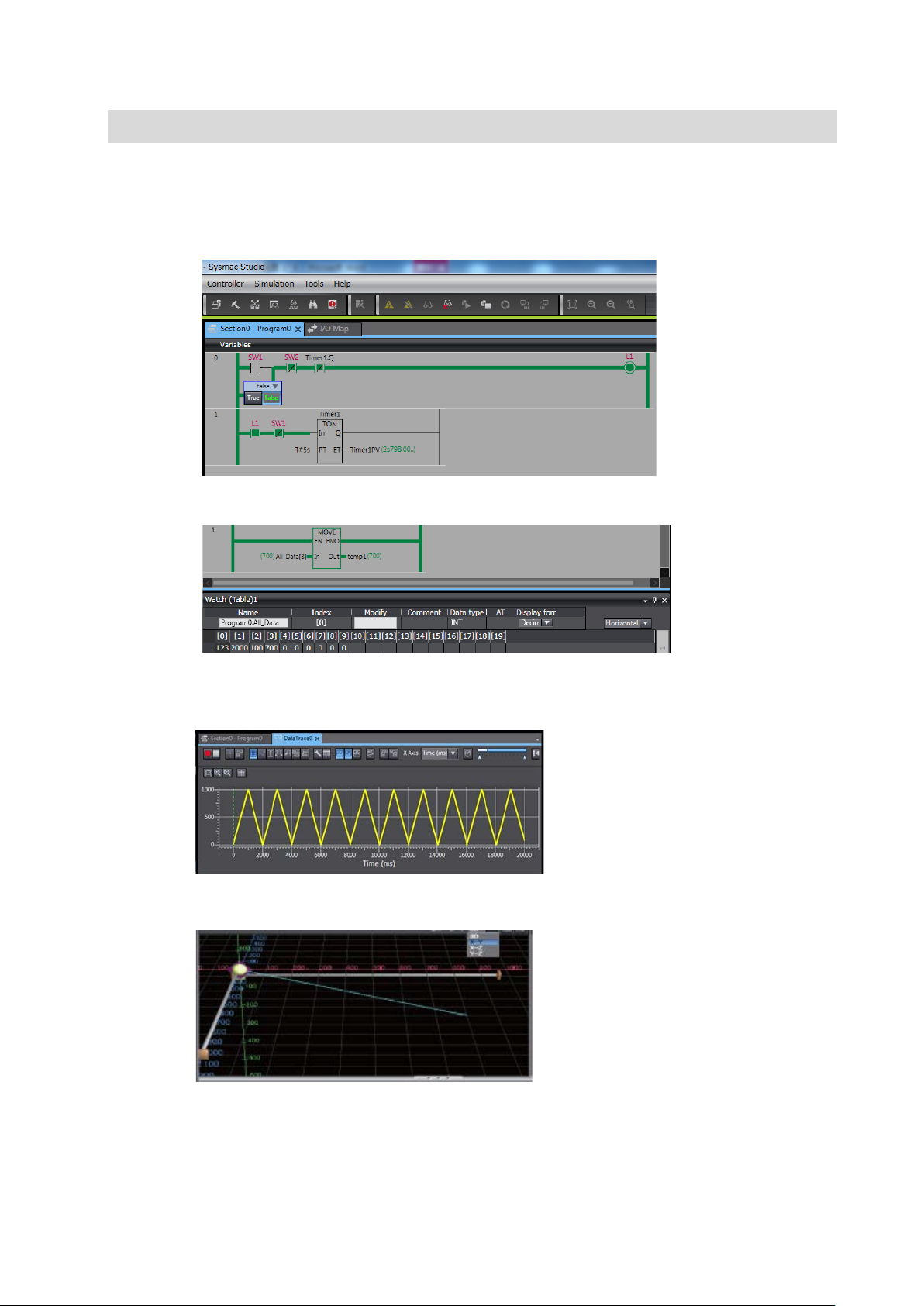

Page 27

1-4-2 Simulations

The Sysmac Studio provides a variety of simulations.

The Simulator in the Sysm ac Studio all ows you to t est progra ms without connect ing physic al

devices.

1. Check the operations of a pr ogr am

2. Monitor variables in the Watch Tab Page without conn ecting devices

3. Check a motion program by viewing the changes of positio ns and velocities sampled

by data tracing

4. Check motion trajector i es by performing 3D motion monitoring, without con nect ing

physical devices

27

Page 28

2

2 Before You B egin

This section describes the pr ocess of hardware mounting a nd w iring and the

installation of the Sysmac St udio.

2-1 System Conf igurat ion and Devices .............................................................. 2-29

2-1-1 Overview ........................................................................................ 2-29

2-1-2 Wiring ............................................................................................. 2-30

2-2 Installing the Sysmac Studio ........................................................................ 2-32

2-2-1 Installing the Sysmac Studio ......................................................... 2-32

2-2-2 Requirements for Installation ......................................................... 2-32

28

Page 29

2-1 System Configuration and Devices

Version 1.17 or higher

(1 license)

Pushbutton Switch

Indicator

Power Supply

A22NL etc.

M22N etc.

S8VK-S06024 etc.

2-1-1 Overview

Connect a Power Supply , Pushbut t on Switches, and Indicator s t o t he NX1P and create a

ladder program in Section 3 Ladder Programming.

Automation Software

Sysmac Studio

Standard Edition

SYSMAC-SE200D

(DVD only)

SYSMAC-SE201L

The physical devices such as NX1P, Pushbutton Switches, and Indicators w i ll hel p you

understand programming conce pts.

Even if there is no physica l device, you can check operatio n using the Simulator in the

Sysmac Studio.

Section 4, 5, and 6 explain about simulations.

Machine Automation

Controller

NX1P

NX1P2-□□□□ -

Ethernet cable

(100Base-TX/10Base-T)

29

Page 30

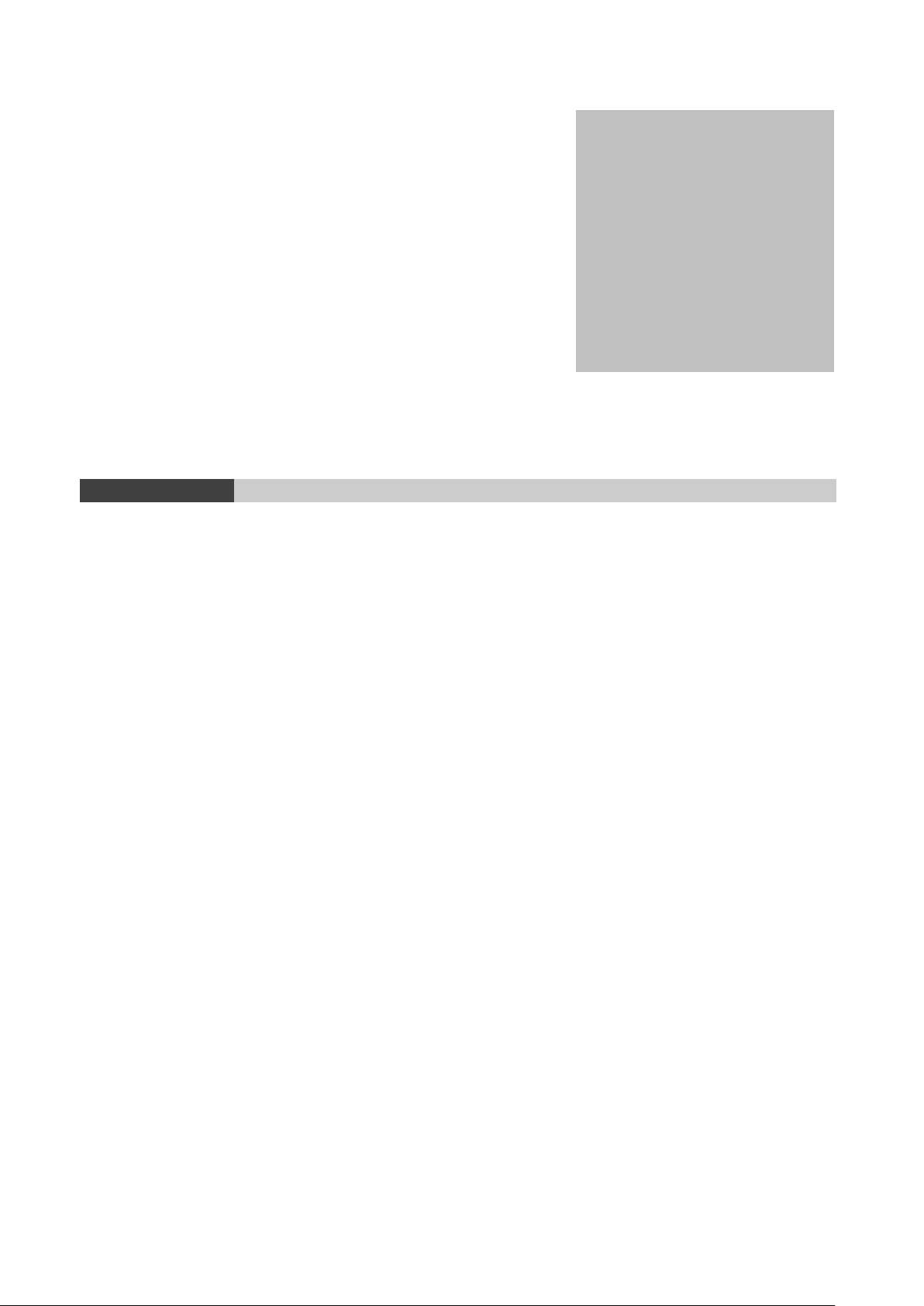

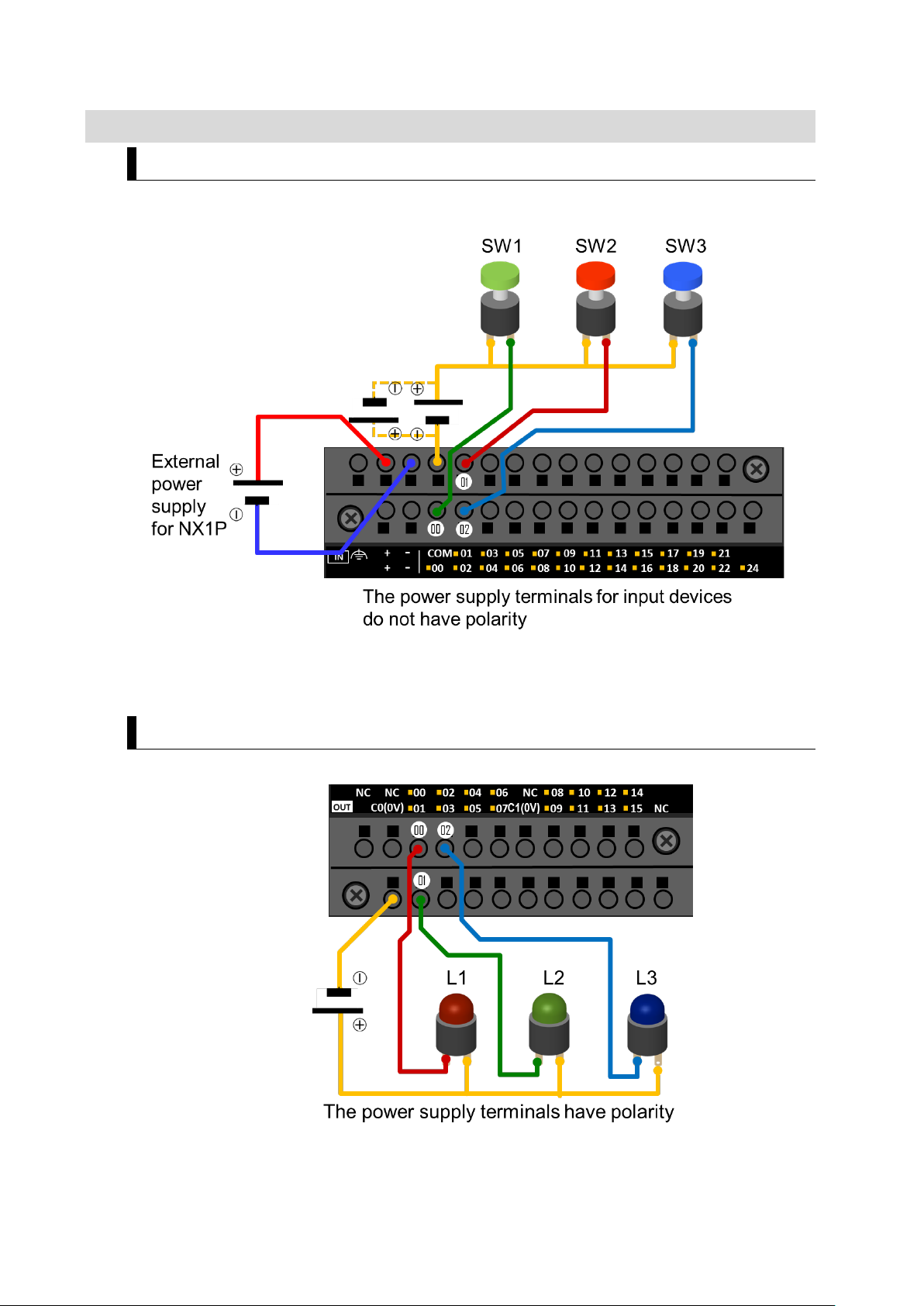

2-1-2 Wiring

Wiring Pushbutton Switches

Wire Pushbutton Switches to the NX1P as shown below.

Wiring Indicators

30

Page 31

Push-In Plus Terminal Blocks

Held securely with

Flat-blade

Remove the

A push-in terminal block allows you to connect wires (e.g. ferrule) by just pushing t hem in.

Reducing wiring work can gr eatly reduce the time required to build control panels.

Push-In Plus Terminal Blocks were independently developed by Omron for ea s ier w ire

insertion and firmer wire holding ability than standard push-in terminal blocks.

You can connect and re m ove a wire (solid or ferrule) t o/ from a Push-In Plus Terminal Blo ck

by following the procedure below. (Refer to the manual for connection and removal of a

stranded wire)

■ Connecting a wire

Just push the wire into the ter minal b lock until stopping. When connecting a stranded wire,

use a ferrule, or insert the wire after loosenin g t he clamp spring with a tool and then remove

the tool.

■ Removing a wire

Press a flat-blade screwdriver diag onally into the release hole to l oosen the clamp spring

and then remove the wire. Re mov e t he f lat-blade screwdriver.

screwdriver

clam p sprin g

screwdriver

31

Page 32

2-2 Installing the Sysmac Studio

OS

CPU

RAM

Display

colors

equivalent

colors

2-2-1 Installing the Sysmac Studio

The Sysmac Studio is the support software to config ur e, pr ogr am, debug, and simulate

NJ/NX-series Co nt r ol lers .

Use the following procedure to install the Sysmac Studio on your computer.

1. Set the Sysmac Studio installation disk into the DVD-ROM drive.

The setup program is start ed auto mat ically and th e Se lect Set up La nguage Dialo g Box is

displayed.

2. Select the language to use, and then click the OK Button.

The Sysmac Studio Setup Wizard is started.

3. Follow the wizard to install the Sysma c St udio.

4. Restart your computer after the Sy s ma c St udio has been success ful ly inst alled.

2-2-2 Requirements for Installation

The system requirements for t he Sysmac Studio are giv en in the f ollowing table.

Windows 7

32-bit or 64-bit edition

Windows 8

32-bit or 64-bit edition

Windows 8.1

32-bit or 64-bit edition

Windows 10

32-bit or 64-bit edition

Precautions for Correct Use

When the CX-One version 4 or lower has been installed, uninstall it before installing

the Sysmac Studio.

Minimum IBM AT or compatible with

Recommended IBM AT or compatible with

®

Intel

Celeron® processor 540

(1.8 GHz)

®

Intel

Core™ i5 M520

processor (2.4 G Hz) or the

2 GB XGA

1,024 x 768

16 million

4 GB

min.

WXGA

1,280 × 800

16 million

32

Page 33

3

3 Ladder Programming

3-6-1 Self-holding Rung .......................................................................... 3-53

This section describes how to writ e ladder pr ograms using the Sys mac Studio.

3-1 Programm ing with the Sysmac Stud io ......................................................... 3-35

3-1-1 Programming Procedure................................................................ 3-35

3-1-2 Creating a Project .......................................................................... 3-35

3-2 Parts of the Sysmac Studio Window ............................................................ 3-37

3-2-1 Screen for Configurations and Setup ............................................ 3-37

3-2-2 Screen for Programming................................................................ 3-37

3-3 Assignin g Variables to Terminals ................................................................. 3-38

3-3-1 Variable Names for Terminal Numbers ......................................... 3-38

3-3-2 I/O Map Setting .............................................................................. 3-39

3-3-3 Checking Wiring ............................................................................. 3-41

3-4 Ladder Programming .................................................................................... 3-42

3-4-1 Inserting Circuit Parts .................................................................... 3-42

3-4-2 Keyboard Mapping ......................................................................... 3-42

3-4-3 Rules .............................................................................................. 3-43

3-5 Example of a Basic Ladder Program ............................................................ 3-44

3-5-1 Practice of Programming a Ladder Diagram ................................. 3-44

3-5-2 Writing the Algorithm ..................................................................... 3-45

3-5-3 Program Check .............................................................................. 3-47

3-5-4 Saving the Program ....................................................................... 3-48

3-5-5 Checking Operation on the NX1P ................................................. 3-49

3-5-6 Checking Operation on the Simulator ............................................ 3-50

3-5-7 Example of a Program Error (Offline) ............................................ 3-52

3-5-8 Example of an Error Occurred During Operation .......................... 3-52

3-6 Example of a Ladder Program Using a Ti m er I nst r uc t ion ............................ 3-53

33

Page 34

3-6-2

3-6-3 Exercise: Energy Saving Es c alator ............................................... 3-58

3-6-4 Checking the Operation of the Program ........................................ 3-59

3-6-5 Checking the Operation of the Program (Watch Tab Page) .......... 3-60

3-7 Example of a Ladder Program Using Date and Time .................................. 3-62

3-7-1 Programming the NX1P Using Date and Time .............................. 3-62

3-7-2 Exercise: Continuous Operating Time of Escalator ....................... 3-62

3-8 Fundame ntals of Progra mming to Reduc e Develo pme nt Time ................... 3-66

3-8-1 POUs (Program Organization Units) ............................................. 3-66

3-8-2 Programs and Execution Priorities (Tasks) ................................... 3-66

3-8-3 Functions (FUNs) and Function Blocks (FBs) ............................... 3-68

3-8-4 Sections ......................................................................................... 3-69

3-8-5 Types of Variables ......................................................................... 3-70

On-Delay Timer (TON) Instruction ................................................. 3-54

34

Page 35

3-1 Programming with the Sysmac

Connecting NX1P to debug program using physical devices

Assigning variables to connected I/O devices in I/O Map

Programming

Creating a project

Studio

3-1-1 Programming Procedure

This section describes how to create a simple ladder pr ogr am using pushbutton s w itc hes and

lamps.

The overall programming procedure is given below.

3-1-2 Creating a Proje c t

1. Start the Sysmac Studio.

2. Enter the project name.

Select NX1P2, 9024DT/1140DT for the device parameter and 1.13 (version indicated on th e

NX1P) for the version parameter, and t hen click the Create Button.

35

Page 36

Right-click

The following window is displayed.

Additional Information

You can change the model, version, and other propert ies after cr eating a project file.

36

Page 37

3-2 Parts of the Sysmac Studio Window

and Setup

Toolbox

Programming

Edit Pane

Pane

to set up

create programs

assistant tools

3-2-1 Screen for Configurations and Setup

Configurations

Multiview

Explorer

3-2-2 Screen for Programming

1. Select an item

2. Make settings or

Simulation

3. Use as setup

37

Page 38

3-3 Assigning Variables to Terminals

3-3-1 Variable Names for Ter m inal Numbers

Although Pushbutton Switches and Indicators are physically connected to t he input and output

terminals of the NX1P, they cannot be used for programm ing now.

In order to create a program usin g t he c onnected devices (I/ O ) , you need t o assign variable

names for the numbers of termina ls to which devices are conne ct ed.

Any name can be assigne d. Names r elated to t he dev ice type or processin g are reco mmended.

For example, you can use “SW1” for a Pushbutton Switch co nnected to the input t erminal 00 of

the NX1P because “SW1” is its na me on the n amep lat e in the contro l pa nel. This makes it easy

to identify the device.

38

Page 39

3-3-2 I/O Map Setting

Variable

name

Variable

name

Input bit 01

Input bit 02

Set variables for terminals.

I/O map setting means that variables used for a progra m are assigned to terminals (called “I/O

ports” in the Sysmac Stud i o) of t he NX 1P to which devices (I/ O ) ar e connected.

1. Double-click I/O Map under Configurations and Set up on the Multiview Exp lorer . The I/O

Map is displayed.

As the NX1P is selected f or the dev ice, al l input/ out put t ermina ls (I/ O port s: I nput Bit 00 et c.)

of the NX1P are displayed in the I/O Map.

2. Double-click an I/O port to enter a variable name.

Set variable names for input / out put terminals as shown below.

Variable names for input t er m inals Variable names for output termina ls

Terminal No. R/W

Input bit 00

*1. SW means a switch (Pushbutton Switch).

*2. L means a lamp (Indicator).

R SW1*1 BOOL Output bit 00 R L1*2 BOOL

R SW2 BOOL Output bit 01 R L2 BOOL

R SW3 BOOL Output bit 02 R L3 BOOL

Data type Terminal No. R/W

Data type

3. Enter “SW1” in the Variable Column of Input Bit 00.

39

Page 40

4. In the same way, set SW2 and SW3 for Input Bit 01 and 02 and L1 to L3 for Output Bit 00 t o

02.

The variable names have been linked with the terminal numbers.

40

Page 41

3-3-3 Checking Wiring

Go online

Transfer to Controller

1. Connect the NX1P to the computer (Sysmac Stud io) via an Ethernet cable.

2.

Go online, and then transfer t he I/O map settings to the NX1P.

3. Change the operating mode to PROGR AM mode to prevent the progra m fro m being

executed while checking I/O wiring.

Change to PROGRAM mode

4. Press the Pushbutton Switches to c heck whether the values o f the input bits change in the

I/O Map.

5.

Select the I/O port. Right-click and select Set or Reset from the menu to chec k whet her the

Indicator turns ON or OFF.

41

Page 42

Operation

Shortcut keys

Reference (Shortcut key in CX-Programmer)

C

Entering an N.C. input

/

Same key

W

Entering an OR with an N. C . input

X

Same key * Different cursor position

O

Entering a NOT output

Q

Same key

F

Calling a functi on

I

Different key * First letter of instruction

R

Inserting a rung above the cursor

Shift + R

3-4 Ladder Programming

3-4-1 Inserting Circ uit Parts

Inserting a Program Input or Output in an AND Structure

Shortcut key: Select a connecting line a nd pr es s t he shortcut key

Example: N.O. Input - C Key, output - O Key

Toolbox: Drag a c ircuit part from the Toolbox

Right-click: Right-cl ick a conn ect ing line a nd s elect Ins ert Inp ut or Insert Output from the

Menu.

Inserting a Program Input in an OR Structure

Shortcut key: Select an input and press t he W Key. (The N.O. input is ins er t ed in an OR

structure)

Drag and drop: Drag the c onnecting line and select a circuit part from the pop-up menu

Inserting a Rung

Shortcut key: Select the start of a rung and pres s t he R Key.

Right-click: Right-click a rung and select Insert rung above or I nse r t r ung below.

3-4-2 Keyboard Mapping

The following table lists th e shor tcut keys that you can use when creating ladder programs.

Entering an N.O. input

Entering an OR with an N. O . input

Entering an output

Calling a functi on block

Inserting a rung below the cursor

* Select Keyboard Mapping R efer ence from the Help Menu to display the Keyboard Mapping Reference.

Same key * C or L in CX-Programmer

Same key * Different cursor position

Same key

Same key * F for both FUN and FB

Same key

42

Page 43

3-4-3 Rules

You Can

With the NX1P, you can progr am a ladder diagra m that cannot be progr ammed with the CJ2 or

other traditional PLC.

You can insert an output without inserting an input. (Always ON Flag is not required)

Functions and function blo c ks can also be inserted wit hout inserting an input.

You can connect outputs, fun c t io ns , and function blocks in series .

You Cannot

You cannot set a rung without any circuit parts.

You cannot set a rung with only one input.

You cannot connect any item other than output after an out put.

43

Page 44

FULL

AVAILABLE

3-5 Example of a Basic Ladder Program

3-5-1 Practice of Progr amming a Ladder Diagram

[Exercise] Coin Operated Parking Space

Three cars can be parked in t he parking space. Crea t e a pr ogr am to turn ON the FULL lamp

(L3 (red lamp)) if the parking lot s are ful l and turn ON the AVAILABLE la mp (L 1 (green la mp)) if

one or more parking lots are available.

SW1, SW2, and SW3 are used as sens or s to detect presence of cars.

Completed program

44

Page 45

3-5-2 Writing the Algorithm

1. Click POUs under Programming in the Multiview Explorer.

Programs, Functions, and Function Blocks are d isplayed under POUs.

2. Double-click Section0 under Programs - Program0.

The Ladder Editor is displayed.

3. Write a ladder program on the Ladder Editor.

Additional Information

When a new ladder program is create d, Sectio n0 wi ll be mar ked with a red ! mark ( ).

This mark means that the program contains an error. I t w ill disappear when the program

is written correctly.

45

Page 46

S と入力し、変数リストから SW1 を

選択して、[Enter]キーを押す。

コメントが必要なければ、

[Enter]

Right-click

Enter “s”. Select SW1 from

Enter

Just press the Enter Key

comments

(1) Insert a program input in an AND structure

Insert an input and enter the variable name.

1. Press the C Key or right-click a connecting line and select Insert I nput from the

Menu.

the variable list and press the

Key

if you do not enter any

In the same way insert circuit parts as shown below.

2. To insert an output, press the O Key or r ight-click a connecting line and select Insert

Output from the Men u.

(2) Insert a rung below.

1. Select the start of a rung and press the R Key, or right-clic k a rung and select Insert

rung below.

(3) Insert a program input in an OR struct ur e

1. Insert an N.C. input and an output.

Insert an N.C. input by pre s sin g the / Key and then insert an output.

46

Page 47

2. Inset an N.C. input in an OR structure. Select SW1 and press the X Key, or dr ag t he

Drag the connecting line

from the start point

to

the end point

connecting line from the start point to the end point and sel ec t N.C. Input from the

menu.

3. Insert another N.C. Input in the same way.

The program is completed.

3-5-3 Program Check

1. Select Check All Progra m s from the Project Menu.

Warnings and errors

are displayed

47

Page 48

Save

Export

Start page.

The project is Saved as a file.

2. Modify the program if an error is found.

The results of the progra m ch eck are displayed in the Build Ta b Page.

Modify the program if an error is fou nd.

3-5-4 Saving the Program

1. Save and export the project file before taking the next step.

Select Save from the File Menu.

2. Select Export from the File Menu. Enter a file name and export the file to the desktop.

< Useful function >

Double-click the line of the err or t o

jump to the location of the er ror

Additional Information Difference between Save and Export

The project is saved in the defa ult

folder. The user does not need t o

know where the project is saved.

To open the

saved project,

click Open

Project on the

To open the saved

project,

double-click the

file icon or Click

Import on the

Start page.

48

Page 49

3-5-5 Checking Opera tion on the NX 1 P

Connect the NX1P and the Sysmac Studio and download the project (all data includin g t he

program) from the Sysma c Studio to the NX1P to check operat i on.

1. Connect the NX1P to the computer (Sy smac Studio) via an Ethernet cable.

2. Go online.

Start the Sysmac Studio and go online with the NX1P.

3. Download the project.

Click the Transfer to Controller Button.

Transfer to Controller

49

Page 50

4. Change the operating mode to RUN mode.

Check the Controller Stat us Pane. If the mode is PROGRAM mode, change the oper at ing

mode to RUN mode.

Change to RUN mode

5. Check operation.

Turn ON and OFF the SW1, S W2, and SW3 to check whether the AVAIL ABLE lamp (L1)

and FULL lamp (L3) turn ON and OFF.

3-5-6 Checking Opera tion on the Simulator

You can check operation usin g t he Simulator in the Sysmac Studio, without connecting the

NX1P (offline debugging).

1. Select Run from the Simulation Menu to start t he Si mu lat or .

2. The Simulator is started and connected after displaying some messages.

50

Page 51

3. Double-click the input. You can change the value between True ( O N) and False (O FF) to

debug the program, instea d of pressing the physical swit ch.

4. Select Stop from the Simulation Menu to stop the Simulator.

51

Page 52

Marked with a red line or red ! mark

Displays a description

of the error

Button to display the details

Displays status of NX1P

3-5-7 Example of a Program Err or ( O ffline)

Delete the variable name “SW1” of input SW1 offline. Select Check All Programs from the

Project Menu. Errors are disp lay ed in the Build Tab Page.

3-5-8 Example of an Error Oc c urred During Operation

Click the Troubleshooting Button (!) in the toolbar when an error occurs. The example below

shows a verification error that occurs when the NX1 W-CI F01 Serial Communi cat ions Option

Board is not connected physically but is connected on t he Sysmac Studio.

* Double-click Option Board Set tings under Configurations and Setup - Controller Setup to configure the

Option Board settings.

Press the Display Switch

52

Page 53

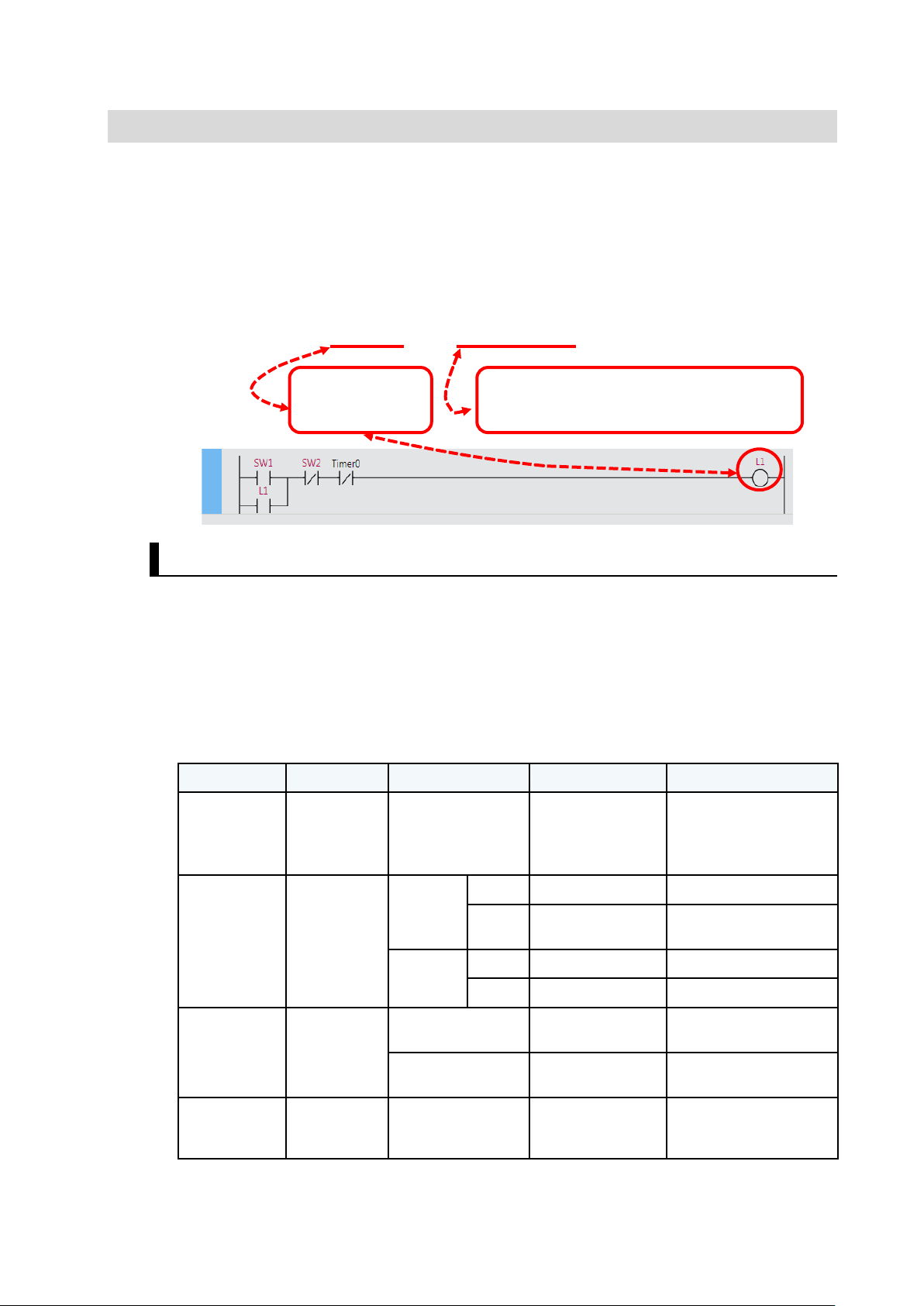

3-6 Example of a Ladder Program Using

a Timer Instruction

3-6-1 Self-holding Rung

Create a self-holding rung to turn ON L1 when SW1 is pressed and stay lit until SW2 is

pressed.

1. Create the program offline.

2. Delete the program created in 3-5 Example of a Basi c Ladder Program.

Right-click the rung numbers to delete while holding down the Ctrl Key. Press the Delete

Key.

Self-holding rung

Although the ladder progr am is delet ed, t he I/O Map settings are not deleted and r emain t he

same as those configured in 3-3-2 I/O Map Setting.

3. Create the following rungs.

4. Click the SW1 input, and then press the W Key to in s er t L1 in an OR structure.

53

Page 54

the Instructions Reference

Point

5. Click the connecting line to insert an N.C. I nput . Pr ess the / Key and enter “SW2”.

6.

The self-holding rung is cr eat ed.

3-6-2 On-Delay Timer (TON) Ins tr uc t ion

Create a rung to turn ON L2 in five sec onds after SW1 is pressed.

Rung to add

(1) Refer to the help for details of the TON instruction

• Select Instruction Reference - Timer - TON from the Help Menu.

Select an instruction and

press the F1 Key to display

54

Page 55

Additional Information

Data

Data

Durations

TIME

64

8 bytes

T#-9223372036854.775808ms

T#12d3h3s

TIME#25h_3m

Difference between the TON instruction for the NX 1P and the TIM instruction for the

traditional PLC

The TON instruction chan ges t i mer output Q to TRUE when t he set t ime PT elapses after

timer input In changes to TRUE.

The timer is reset when In changes t o FALSE. Elapsed time ET changes to 0 and Q

changes to FALSE.

(2) Input the set time

Specify a TIME data variable for the input paramete r PT when inputting the se t t ime.

For example, input “T#10.12s” to set to 10.12 secon ds.

Classification

type

size

bits

Alignment Range of values Notation

(T#-106751d_23h_47m_16s_

854.775808ms) to

T#+9223372036854.775807ms

(T#+106751d_23h_47m_16s_

854.775807ms)

T#3s56ms

TIME#6d_10m

TIME#16d_5h_3m_4s

T#12d3.5h

T#10.12s

T#61m5s (Equivalent to T#1h1m5s)

55

Page 56

Adding a rung using the On-Delay Timer instruction

1. Insert a rung below.

Right-click the existing rung and select Insert r ung below, or select t he st ar t of a rung

and press the R Key.

2. A rung is inserted below.

3. Insert the N.O. input L1 as shown below.

4. Search for the TON instruction in the Toolbox on the right of the window or select TON in

the Timer in the Toolbox.

5. Add the TON instruction by dragging it from the Toolbox.

* You can also insert the TON instr uc t i on by right-clicking the d esired location, selecting

Insert Function Block from the menu, and entering “TON”.

56

Page 57

6. The TON instruction is inserted.

7. Enter the instance name of the TON instruction.

Click Enter Function Block and enter “Timer1”.

8. Set the parameters.

PT: T#5s

ET: Timer1PV

9. Insert an output that changes to TRUE when Timer1 times out.

Enter “L2” for the variable name.

57

Page 58

3-6-3 Exercise: Energy Saving Escalator

This section explains the operat i on of the TON instruction.

This escalator does not move until someone approa ches it . When a person passes in front of

the sensor (SW1), the mot or ( L1) starts. In or der to save energy, the motor sto ps in five

seconds after the last person pa ss es.

Tips

(1) Modify the created program.

(2) Insert an N.C. Input for timer out put in the r ung to stop the motor. Ther e ar e two N.C.

input methods

① Specify timer output as a work bit (e.g., Timer1UP).

② Use Timer1.Q that represents t he out put status of the timer instruct io n.

(3) Modify so as to reset the timer whe n a per son passes.

Add an N.C. Input (Timer1UP) in the first rung to stop L1 (the motor of the escalator in this

example) when Timer1UP changes to TRUE. Add a nother N.C. Input (SW1) to reset the

present value of the TON ins t r uct ion. The program is completed.

■ Example (Output Timer1UP for when Timer1 times out)

58

Page 59

■ Example (Using Timer1.Q)

Present value of Timer1

L1 lamp

Go

online

Transfer to Controller

Enter “Timer1” and “.” (dot). A list of possible candidates is

displayed.

The list shows that Timer1 has four data: In (input signal), PT

(set time), Q (timer completion flag), and ET (elapsed time).

3-6-4 Checking the Opera t ion of the Program

Check the operation of the pr ogr am.

1. Connect the NX1P to the computer (Sy smac Studio) via an Ethernet cable.

2. Go online, and then transfer the program to the NX1P.

3.

Change input SW1 (passing person) to TRU E. O utput L1 (lamp 1) chang es t o TR U E and

variable Timer1PV (present value of Timer1) is incremented as time elapses.

4. Change input SW1 to FALSE, and check that variable Timer1PV is reset.

5. Change input SW2 (stop button of the escalator) to TRU E, and check that output L1

changes to FALSE and var iab le Timer1PV is reset.

6. Change input SW1 to TRUE. Check that output L1 automatically changes to FALSE and

variable Timer1PV is reset in five seconds after nothing is done.

59

Page 60

● Checking the operation using the Simulator

1. Select Run from the Simulation Menu to start t he Si mu lat or .

2. Double-click the input. You can change the value between True ( O N) and False (OFF) to

debug the programs, inste ad of pressing the physical switc h.

3-6-5 Checking the Opera t ion of the Program (Watch Tab Page)

You can also check the operation of the program in the Watch Tab Page.

Monitoring can be performed online on the NX1P or of fl ine with the Simulator in the same way.

1.

Select Watch Tab Page from the View Menu. The Watch Tab Page is display ed at the

bottom of the window.

2. Click the Watch Tab Page 1 Tab.

60

Page 61

3. Click the Variables Bar at the top of the window. The variabl e t abl e appears. Select the

Drag

Drag

variable to monitor from the variables (external v ar iables and internal variab les) used in the

program and drag it to the Watch Tab Page.

Register Timer1 by dragging it to the Watch Tab Page.

Click the ▼ mark, and check that data (ti mer st ar t flag (In), timer set value (PT), timer

present value (ET), and t imer completion flag (Q)) contained in Timer1 can be monitored.

4. Select the variable to monitor in the Ladder Editor and drag it to the Watch Ta b Page.

Register SW1 by dragging it t o t he Watch Tab Page.

5. Execute the program. You can monitor t he values.

Go offline before taking th e next s t ep.

6.

Save and export the projec t file.

• Select Save from the File Menu.

• Select Export from the File Menu to export the file to the desktop.

61

Page 62

3-7 Example of a Ladder Program Using

Date and Time

3-7-1 Programming the NX1P Us ing Date and Time

For example, best before date and time that is 30 hours from production is printed on boxed

lunch.

A program is required to

acquire date and time of product ion and

calculate the best before date and time by adding

30 hours to the acquired date and t ime

Programming with variabl es uses DAT E_ AND_TI M E data (year, month, day, hour, minute, and

second), TIME data, and instructions to perf orm calculations eas ily .

3-7-2 Exercise: Conti nuous Operating Time of Escalator

Create a program to meas ur e t ime by using the program creat ed i n 3-6-3 Exercise: Energy

Saving Escalator.

[Exercise] Acquire current time and calculate elapse d t ime

Measure continuous operating time of the escalator (continuous O N time of L1). Create a

program to subtract time of day when L1 turns OFF from ti m e of d ay when L1 turns ON.

Tips

(1) Use the GetTime function to acquire current ti me.

(2) Use the SUB_DT_DT function to subtract date and time.

(3) The SUB_DT_DT function returns TIME data.

62

Page 63

Add code to the progra m cr eat ed in 3-6-3 Exercise: Energy Saving Escalator.

1. Insert a rung below.

Right-click the rung 1 and select Insert rung bel ow, or select the start of a rung and press

the R Key.

2. Set upward differentiation for L1.

Press the C Key, or right-click a connecting line and select Ins e r t Input from the Menu to

insert an input. Press the @ Key, or right-click the input and select Diff Up from the menu.

3. Insert the GetTime function to acquire date and time when L1 cha nges to TRUE.

Press the I Key and enter “GetTime” as the func t io n name

Enter “StartTime” as the output variable name.

4. In the same way create another rung to execut e t he GetTime function when L1 changes to

FALSE.

To set downward different iation, press the % Key, or right-click the input and select Diff

Down from the menu.

63

Page 64

5. Insert the GetTime function and enter “EndTime” as the output variable na m e.

6. Insert the SUB_DT_DT (Subtract Dat e and Time) instruct ion to s ubtract StartTime from

EndTime.

Enter “LapTime” as the output variable name.

7. Click the Variables Bar at the top of the window to check the varia ble table.

StartTime and EndTime are registered as DATE_AND_TIME (date and time) data and

LapTime as TIME (durations) data.

The data types are automat ically set according to the used instructions.

64

Page 65

8. Execute the program.

Transfer the program to th e NX 1P or change the operating mode to RUN mode to us e t he

Simulator in the Sysmac Studio.

9. Click the Watch Tab Page 1 Tab.

Select StartTime, EndTime, and LapTime in the variable table and drag them to the Watch

Tab Page. Change the value of input SW1 from False to True and chec k th e value of

variable LapTime. The value of variable LapTime shows the time from wh en output L1

changes to TRUE to when output L1 changes to FA LS E.

Drag

10. Go of fline before taking the next step. Save an d export the project file.

65

Page 66

3-8 Fundamentals of Programming to