Digital Indicators

K3HB Series

Distinct by Design,

Distinguished in Performance

K3HB-X

K3HB-H

K3HB-S

K3HB-V

Features

r

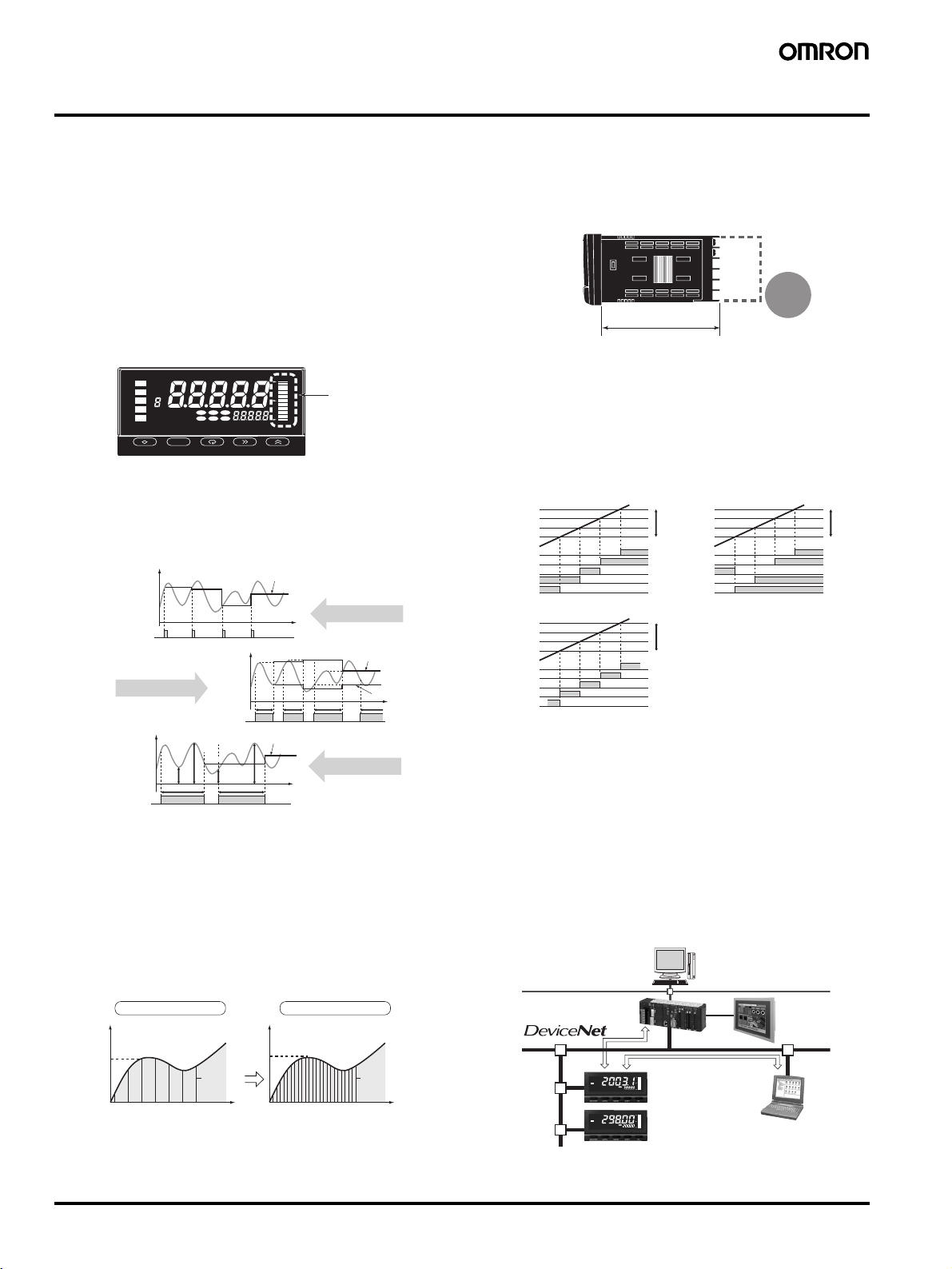

Red-Green Display Allows Easy Recognition

of Judgment Results

• The measurement value display can be set to switch between red and green in accordance with the status of comparative outputs. This means that the status can be

ascertained at a distance.

Position Meter Enables Easy Monitoring of

Operating Status Trends

• The present value with respect to the measurement or display range (full scale) can be viewed on a bar display. The

operating status can be grasped intuitively, allowing easy

judgement of levels and threshold values.

HH

Max

Min

H

P

L

LL

MAX/MIN

B

L

TG HH H

T-ZR

CMW

Zero

TLLL

Hold

UPSHIFTMODELEVEL

Position mete

Many Measurement and Discrimination

Functions Using External Event Input

• Offers a wide variety of application possibilities, such detection and judgement while synchronizing on an external signal.

Input

Measurement

OFF

TIMING

input

(b1−a1)

'a2

Sampling hold value

value

ON

Peak-to-peak value

'b2

(b2−a2)

Time

Time

Sampling

measurement

Peak hold value

Bottom hold value

Peak-to-peak hold

measurement

Time

Measurement value

TIMING

input

Peak/bottom hold

measurement

Input

Measurement value

TIMING

input

OFF

Input

OFF

ON

ON

b1

a1

High-speed Sampling at 50 Times per Second

(20 ms)

• Provides an input sampling cycle at least three times faster

than earlier models (12.5 times faster for temperature input

models) at 50 times/second (see note). In addition to improved response times for judgement output and transfer

output, average processing can be used to increase the stability of measurements.

Note: The K3HB-S Linear Sensor Indicator features high-speed re-

sponse of 2,000 times/second.

Sampling at 15 times/second Sampling at 50 times/second

Short Body with Depth of Only 95 mm (from

Behind the Front Panel)

• A short body of only 95 mm (see note) contributes to the development of slimmer and smaller control panels and installations.

27%

shorter

than earlier

Depth: 95 mm (See note.)

(The depth is 100 mm when mounted to the terminal cover.)

Note: Depth of DeviceNet models is 97 mm.

models

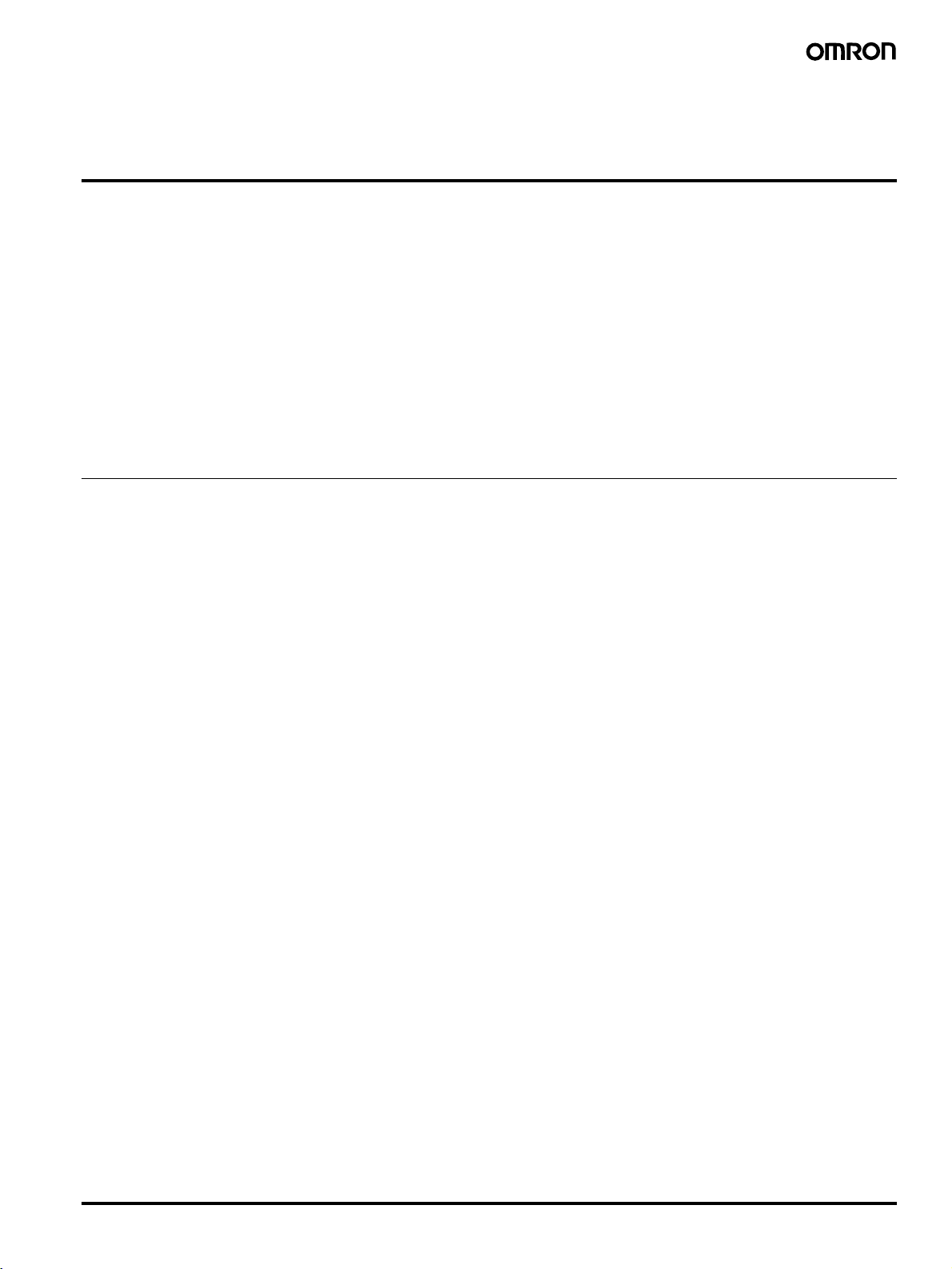

Select a Comparative Output Pattern to Suit

the Discrimination or Control Application

• The output pattern for comparative outputs can be selected.

In addition to high/low comparison with set values, output

based on level changes is also possible. (Use the type of output pattern appropriate for the application.)

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Output HH

Output H

Output PASS

Output L

Output LL

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Output HH

Output H

Output PASS

Output L

Output LL

Standard Output

Zone Output

Measurement

value

Higher

Lower

ON

OFF

Measurement

value

Higher

Lower

ON

OFF

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Output HH

Output H

Output PASS

Output L

Output LL

Level Output

Note: The HH, H, L, or LL outputs must be set in that order for the

zone outputs to output correctly.

(This is because the comparative set values and outputs for

standard and level outputs are in a 1-to-1 relationship, whereas

the meaning of zone outputs depends on the settings of all the

comparative set values.)

Measurement

value

Higher

Lower

ON

OFF

Lineup Includes DeviceNet Models Enabling

High-speed Data Communications with PLCs

without Special Programming

• DeviceNet compliance enables high-speed data transmission by allocating setting and monitoring parameters in the

I/O memory of the PLC. This capability greatly reduces labor

spent in developing communications programs.

Ethernet

DeviceNet

Master

Peak value

Time

100

Timing of

internal

sampling

0

Time

P

Zero

P

Zero

96

Timing of

internal

sampling

2 Digital Indicators K3HB Series (Analog Input Series)

H

K3HB

Digital Indicators

DeviceNet

Configurator

Note: The applications provided in this catalog are intended as reference only. Do not attempt to use any of them in real systems without first con-

firming machine and device functions and safety. For applications that require safety, ensure that there is sufficient leeway in ratings and

performances, install fail-safe measures, and take any other safety measures required by the application. In addition, contact your nearest

OMRON representative and confirm specifications.

K3HB-series Product Lineup

■ K3HB-X Process Indicator (page 4)

Indicates Measurements for Voltage/Current Signals

• DC Voltage Input Type: K3HB-XVD

(±199.99 V, ±19.999 V, ±1.9999 V, 1.0000 to 5.0000 V)

• DC Current Input Type: K3HB-XAD

(±199.99 mA, ±19.999 mA, ±1.9999 mA, 4.000 to 20.000 mA)

• AC Voltage Input Type: K3HB-XVA

(0.0 to 400.0 V, 0.00 to 199.99 V, 0.000 to 19.999 V, 0.0000 to 1.9999 V)

• AC Current Input Type: K3HB-XAA

(0.000 to 10.000 A, 0.0000 to 1.9999 A, 0.00 to 199.99 mA, 0.000 to

19.999 mA)

■ K3HB-V Weighing Indicator (page 8)

Digital Indicators K3HB Series (Analog Input Series) 3

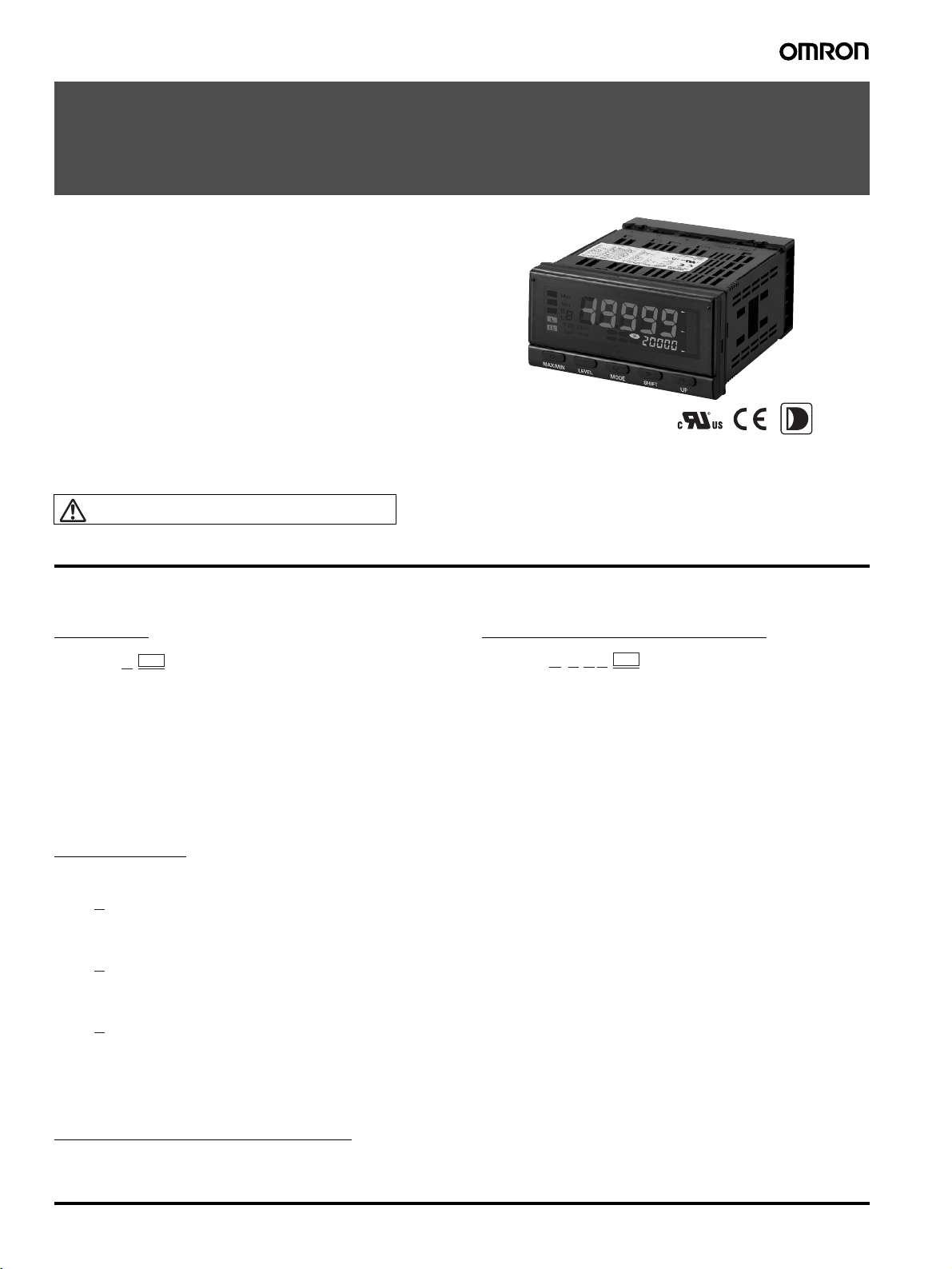

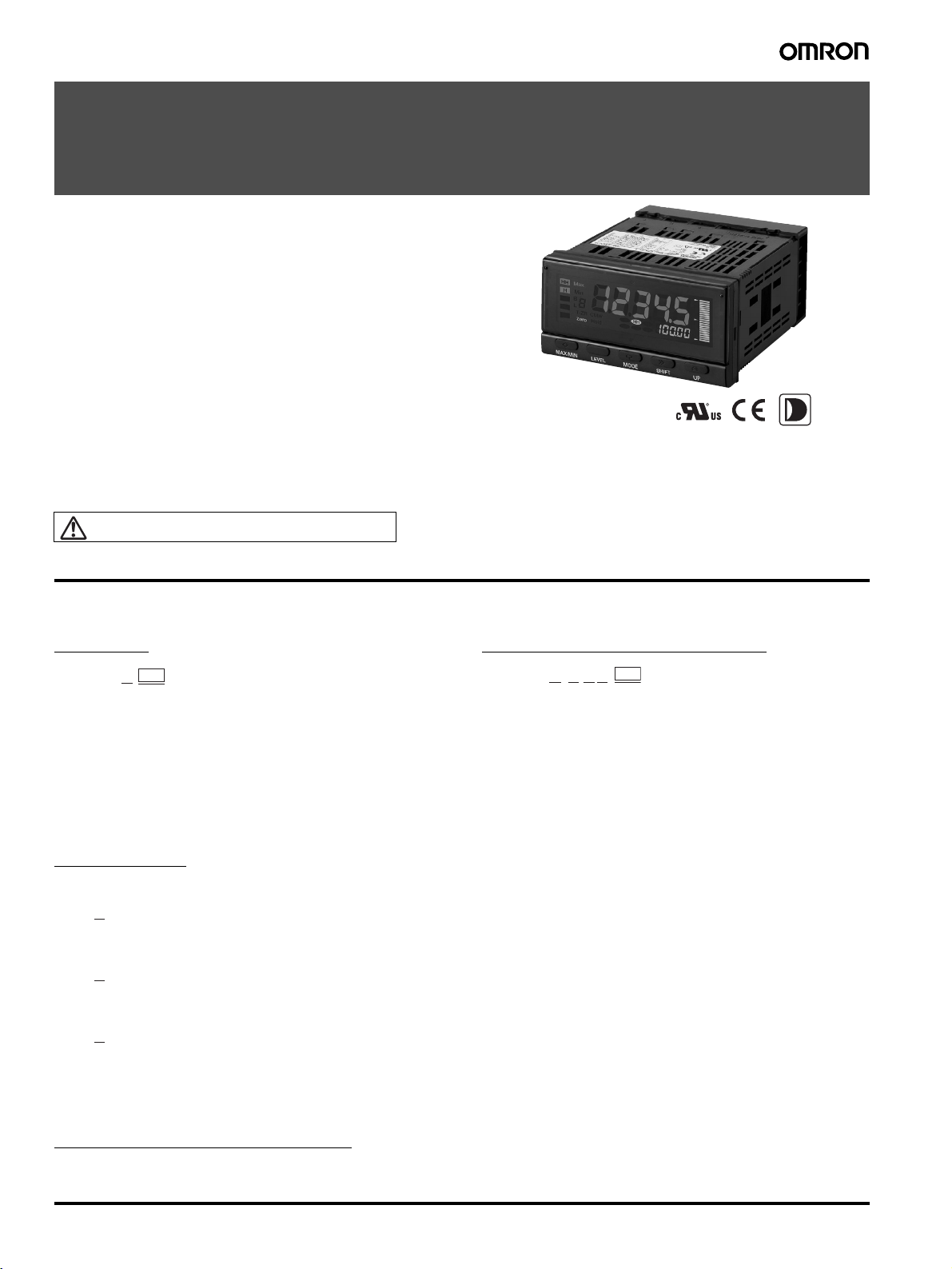

Process Indicator

K3HB-X

A Process Indicator Ideal for Discriminating and

Displaying Measurements for Voltage/Current

Signals

• Easy recognition of judgement results using color display that can be

switched between red and green.

• Equipped with a position meter for monitoring operating status trends.

• External event input allows use in various measurement and discrimination applications.

• Series expanded to include DeviceNet models.

• Shor t body with depth of only 95 mm (from behind the front panel), or

97 mm for DeviceNet models.

• UL certification approval (Certification Mark License).

• CE Marking conformance by third party assessment body.

• Water-resistant enclosure conforms to NEMA 4X (equivalent to IP66).

• Capable of high-speed sampling at 50 times per second (20 ms)

• Easy-to-set two-point scaling allows conversion and display of any userset values.

Refer to Precautions on page 30.

Model Number Structure

■ Model Number Legend

Base Units and Optional Boards can be ordered individually or as sets.

Base Units

K3HB-X@

1. Input Sensor Codes

VD: DC voltage input

AD: DC current input

VA: AC voltage input

AA: AC current input

5. Supply Voltage

100-240 VAC: 100 to 240 VAC

24 VAC/VDC: 24 VAC/VDC

Optional Board

Sensor Power Supply/Output Boards

K33-@

2

Relay/Transistor Output Boards

K34-@

3

Event Input Boards

K35-@

4

Note: 1. CPA can be combined with relay outputs only.

2. Only one of the following can be used by each Digital Indicator:

5

1

RS-232C/RS-485 communications, a linear output, or DeviceNet communications.

Base Units with Optional Boards

K3HB-X@-@@@

1234

2. Sensor Power Supply/Output Type Codes

None: None

CPA: Relay output (PASS: SPDT) + Sensor power supply

L1A: Linear current output (DC0(4) − 20 mA) + Sensor power supply

L2A: Linear voltage output (DC0(1) − 5 V, 0 to 10 V) + Sensor power supply

A: Sensor power supply (12 VDC +/−10%, 80 mA)

FLK1A: Communications (RS-232C) + Sensor power supply

FLK3A: Communications (RS-485) + Sensor power supply

3. Relay/Transistor Output Type Codes

None: None

C1: Relay contact (H/L: SPDT each)

C2: Relay contact (HH/H/LL/L: SPST-NO each)

T1: Transistor (NPN open collector: HH/H/PASS/L/LL)

T2: Transistor (PNP open collector: HH/H/PASS/L/LL)

BCD: BCD output + transistor output (NPN open collector: HH/H/PASS/L/

DRT: DeviceNet (See note 2.)

4. Event input Type Codes

None: None

1: 5 points (M3 ter minal blocks) NPN open collector

2: 8 points (10-pin MIL connector) NPN open collector

3: 5 points (M3 terminal blocks) PNP open collector

4: 8 points (10-pin MIL connector) PNP open collector

(12 VDC +/−10%, 80 mA) (See note 1.)

(12 VDC +/−10%, 80 mA) (See note 2.)

(12 VDC +/−10%, 80 mA) (See note 2.)

(12 VDC +/−10%, 80 mA) (See note 2.)

(12 VDC +/−10%, 80 mA) (See note 2.)

LL)

5

Accessories (Sold Separately)

K32-DICN: Special Cable (for event inputs, with 8-pin connector)

K32-BCD: Special BCD Output Cable

4 Process Indicator K3HB-X

Specifications

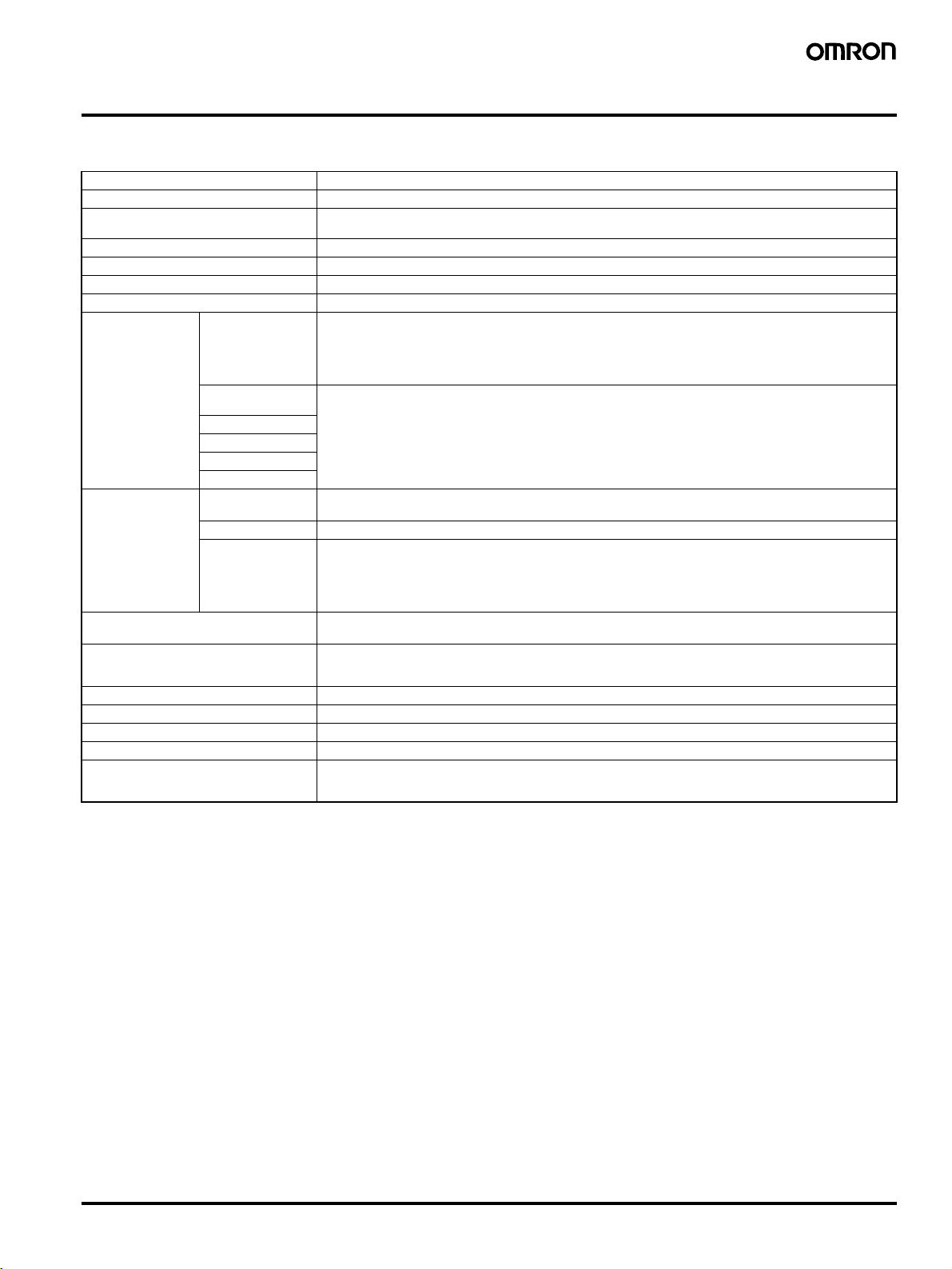

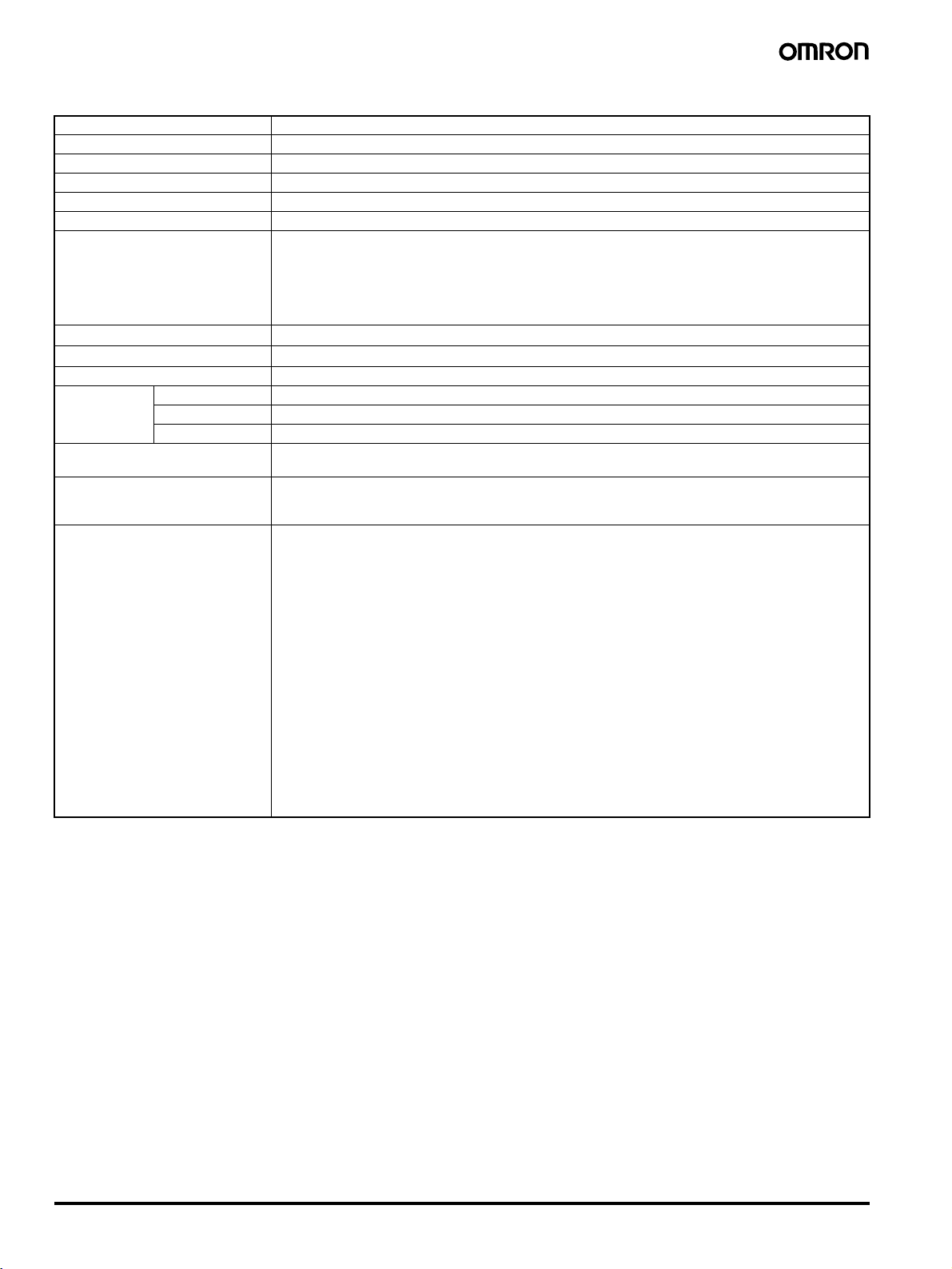

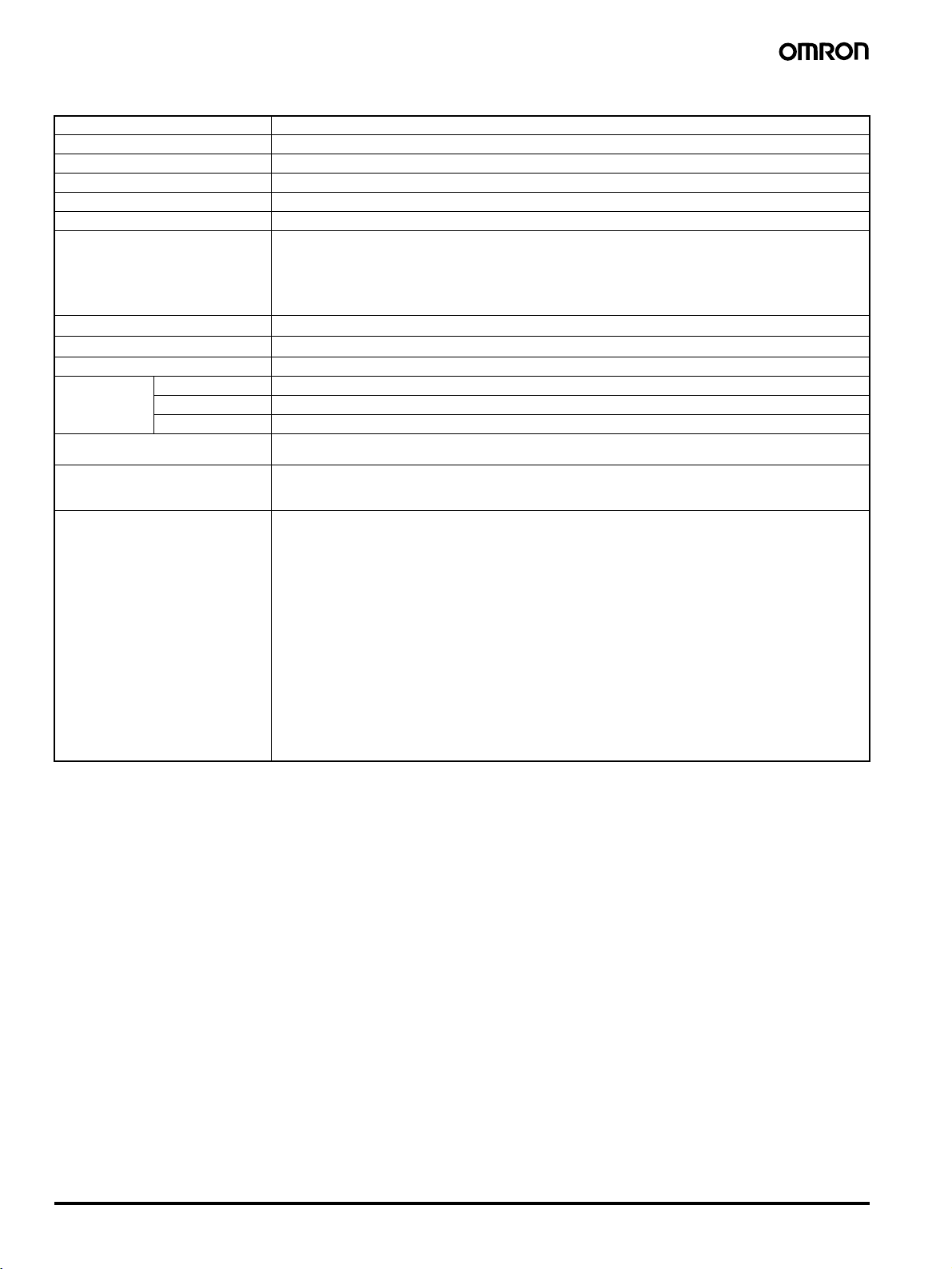

■ Ratings

Power supply voltage 100 to 240 VAC (50/60 Hz), 24 VAC/VDC, DeviceNet power supply: 24 VDC

Allowable power supply voltage range 85% to 110% of the rated power supply voltage, DeviceNet power supply: 11 to 25 VDC

Power consumption

(See note 1.)

Current consumption DeviceNet power supply: 50 mA max. (24 VDC)

Input DC voltage, DC current, AC voltage, AC current

A/D conversion method Delta-Sigma method

External power supply See Sensor Power Supply/Output Type Codes

Event inputs (See

note 2.)

Output ratings (depends on the model)

Display method Negative LCD (backlit LED) display

Main functions Scaling function, measurement operation selection, averaging, previous average value comparison, forced-ze-

Ambient operating temperature

Ambient operating humidity 25% to 85%

Storage temperature

Altitude 2,000 m max.

Accessories Watertight packing, 2 fixtures, terminal cover, unit stickers, instruction manual. DeviceNet models also include

Timing input NPN open collector or no-voltage contact signal

Startup compensation timer input

Hold input

Reset input

Forced-zero input

Bank input

Relay output 250 VAC, 30 VDC, 5 A (resistive load)

Transistor output Maximum load voltage: 24 VDC, Maximum load current: 50 mA, Leakage current: 100

Linear output Linear output 0 to 20 mA DC, 4 to 20 mA:

Note: 1. DC power supply models require a control power supply capacity of approximately 1 A per Unit when power is turned ON. Particular

attention is required when using two or more DC power supply models. The OMRON S8VS-series DC Power Supply Unit is recommended.

2. PNP input types are also available.

3. For K3HB-series DeviceNet models, use only the DeviceNet Connector included with the product. The crimp terminals provided are for

Thin Cables.

100 to 240 V: 18 VA max. (max. load)

24 VAC/DC: 11 VA/7 W max. (max. load)

ON residual voltage: 3 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 1.5 mA max.

NPN open collector or no-voltage contact signal

ON residual voltage: 2 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 0.1 mA max.

Mechanical life expectancy: 5,000,000 operations, Electrical life expectancy: 100,000 operations

Load: 500

Linear output 0 to 5 VDC, 1 to 5 VDC, 0 to 10 VDC:

Load: 5 k

(1 V or less: ±0.15 V; not output for 0 V or less)

7-segment digital display (Character height: PV: 14.2 mm (green/red); SV: 4.9 mm (green)

ro, zero-limit, output hysteresis, output OFF delay, output test, teaching, display value selection, display color

selection, key protection, bank selection, display refresh period, maximum/minimum hold, reset

−10 to 55°C (with no icing or condensation)

−25 to 65°C (with no icing or condensation)

a DeviceNet connector (Hirose HR31-5.08P-5SC(01)) and crimp terminals (Hirose HR31-SC-121) (See note

3.)

Ω: 17 mA max.

Ω: 4 mA max.

µA max.

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Process Indicator K3HB-X 5

■ Characteristics

Display range −19,999 to 99,999

Sampling period 20 ms (50 times/second)

Comparative output response time DC input: 100 ms max.; AC input: 300 ms max.

Linear output response time DC input: 150 ms max.; AC input: 420 ms max.

Insulation resistance 20 M

Dielectric strength 2,300 VAC for 1 min between external terminals and case

Noise immunity 100 to 240 VAC models:

Vibration resistance

Shock resistance

Weight Approx. 300 g (Base Unit only)

Degree of

protection

Memory protection EEPROM (non-volatile memory)

Applicable standards UL61010C-1, CSA C22.2 No. 1010.1 (evaluated by UL)

EMC EMI: EN61326+A1 industrial applications

Front panel Conforms to NEMA 4X for indoor use (equivalent to IP66)

Rear case IP20

Ter min als IP00 + finger protection (VDE0106/100)

Ω min. (at 500 VDC)

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

24 VAC/VDC models:

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

Frequency: 10 to 55 Hz; Acceleration: 50 m/s

2

150 m/s

Number of rewrites: 100,000

EN61010-1 (IEC61010-1): Pollution degree 2/Overvoltage category II

EN61326: 1997, A1: 1998, A2: 2001

Electromagnetic radiation interference

Terminal interference voltage

EMS: EN61326+A1 industrial applications

Electrostatic Discharge Immunity

Radiated Electromagnetic Field Immunity

Electrical Fast Transient/Burst Immunity

Surge Immunity

Conducted Disturbance Immunity

Voltage Dips and Interruptions Immunity

(100 m/s2 for relay outputs) 3 times each in 3 axes, 6 directions

CISPR 11 Group 1, Class A: CISPRL16-1/-2

CISPR 11 Group 1, Class A: CISPRL16-1/-2

EN61000-4-2: 4 kV (contact), 8 kV (in air)

EN61000-4-3: 10 V/m 1 kHz sine wave amplitude modulation (80 MHz to 1 GHz)

EN61000-4-4: 2 kV (power line), 1 kV (I/O signal line)

EN61000-4-5: 1 kV with line (power line), 2 kV with ground (power line)

EN61000-4-6: 3 V (0.15 to 80 MHz)

EN61000-4-11: 0.5 cycle, 0

°/180°, 100% (rated voltage)

2

, 10 sweeps of 5 min each in X, Y, and Z directions

µs/100 ns)

µs/100 ns)

6 Process Indicator K3HB-X

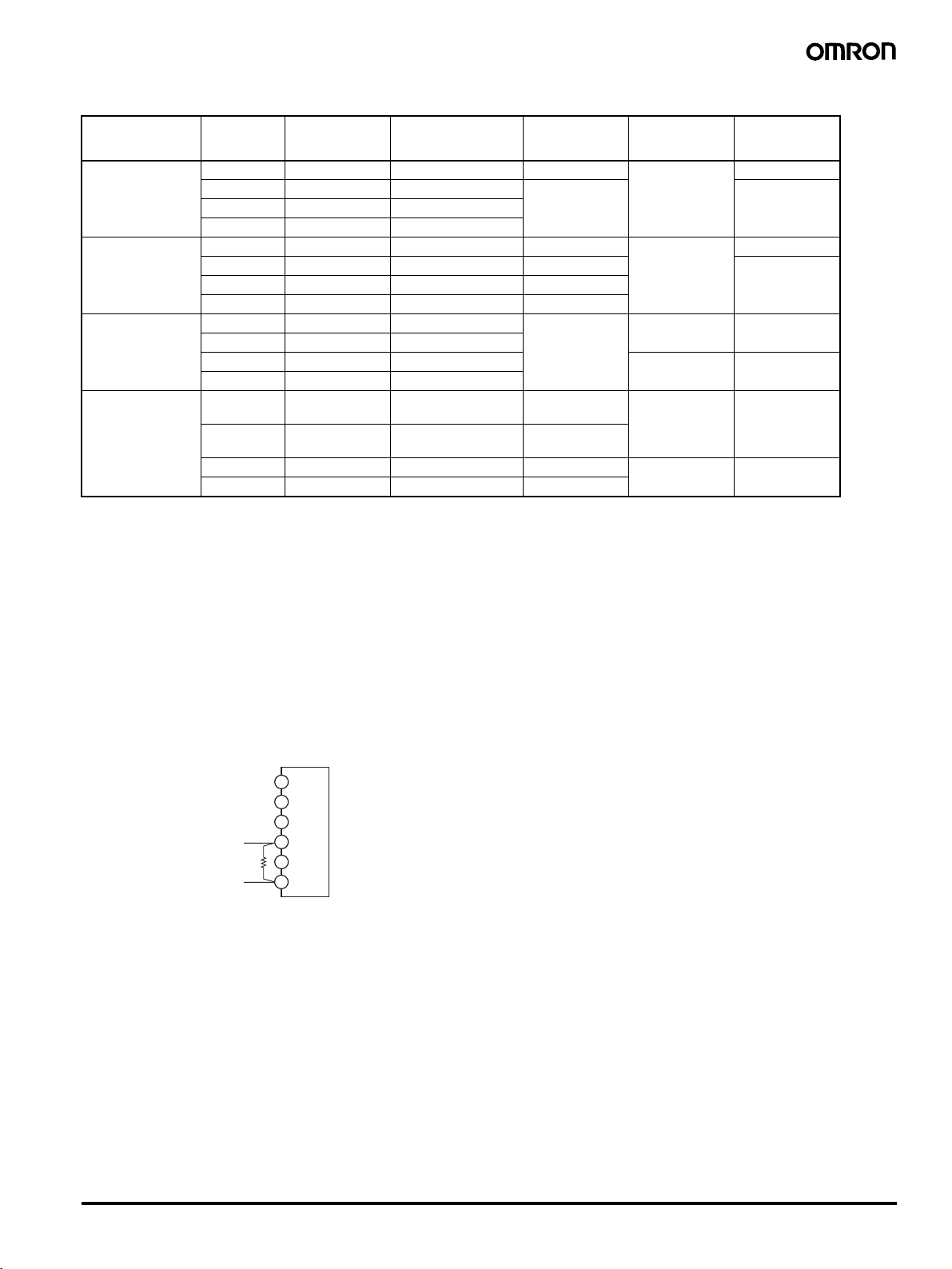

■ Input Range (Measurement Range and Accuracy) CAT II

Input type Range Set value Measurement range Input

impedance

Accuracy Allowable

instantaneous

overload (30 s)

K3HB-XVD

DC voltage

A a Ud ±199.99 V 10 M

B b Ud ±19.999 V 1 M

Ω min. ±0.1%rdg ± 1

Ω min. ±200 V

digit max.

±400 V

C c Ud ±1.9999 V

D d Ud 1.0000 to 5.0000 V

K3HB-XAD

DC current

K3HB-XVA

AC voltage

(See note 4.)

K3HB-XAA

AC current

A a ad ±199.99 mA 1

B b ad ±19.999 mA 10

C c ad ±1.9999 mA 33

D d ad 4.000 to 20.000 mA 10

A a Ua 0.0 to 400.0 V 1 M

B b Ua 0.00 to 199.99 V

Ω max. ±0.1%rdg ± 1

Ω max. ±200 mA

digit max.

Ω max.

Ω max.

Ω min. ±0.3%rdg ± 5

digits max.

C c Ua 0.000 to 19.999 V ±0.5%rdg ± 10

D d Ua 0.0000 to 1.9999 V

A a aa 0.000 to 10.000 A (0.5 VA CT)

(See note 3.)

digits max.

±0.5%rdg ± 20

digits max.

±400 mA

700 V

400 V

20 A

B b aa 0.0000 to 1.9999 A (0.5 VA CT)

(See note 3.)

C c aa 0.00 to 199.99 mA 1

D d aa 0.000 to 19.999 mA 10

Ω max. ±0.5%rdg ± 10

Ω max.

digits max.

2 A

Note: 1. The accuracy is for an input frequency range of 40 Hz to 1 kHz (except for AD current input A and B ranges) and an ambient temperature

of 23 ±5

°C. The error, however, increases below 10% of the maximum input value.

DC voltage input (all ranges): 10% or less of max. input = ±0.15% FS

DC current input (all ranges): 10% or less of max. input = ±0.1% FS

AC voltage input (A: 0.0 to 400.0 V): 10% or less of max. input = ±0.15% FS

AC voltage input (B: 0.00 to 199.99 V): 10% or less of max. input = ±0.2% FS

AC voltage input (C: 0.000 to 19.999 V; D: 0.0000 to 1.9999 V): 10% or less of max. input = ±1.0% FS

AC current input (A: 0.000 to 10.000 A): 10% or less of max. input = ±0.25% FS

AC current input (B: 0.0000 to 1.9999 A): 10% or less of max. input = ±0.5% FS

AC current input, (C: 0.00 to 199.99 mA; D: 0.000 to 19.999 A): 10% or less of max. input = ±0.15% FS

When DC voltage input models are used with a ±1.9999 V range, make sure that the connections between input terminals are not open.

If the input terminals are open, the display will show large variations. Connect resistance of approximately 1 M

Ω between the input ter-

minals if they are open.

2. The letters “rdg” mean “reading” and refer to the input error.

3. The value (0.5 VA CT) is the VA consumption of the internal CT (current transformer).

E2

+

−

1 MΩ

E3

E4

E5

E6

COM

±1.9999 V

4. The K3HB-XVA@@ complies with UL standards when the applied input voltage is within the range 0 to 150 VAC.

If the input voltage is higher than 150 VAC, install an external transformer or take other measures to drop the voltage to 150 VAC or lower.

Process Indicator K3HB-X 7

Weighing Indicator

K3HB-V

An Ideal Indicator for OK/NG Judgements in

Automated and Picking Machines, Measuring

Factors such as Pressure, Load, Torque, and

Weight Using Load Cell Signal Input.

• Easy recognition of judgement results using color display that can be

switched between red and green.

• Equipped with a position meter for monitoring operating status trends.

• External event input allows use in various measurement and discrimination applications.

• Series expanded to include DeviceNet models.

• Shor t body with depth of only 95 mm (from behind the front panel), or

97 mm for DeviceNet models.

• UL certification approval (Certification Mark License).

• CE Marking conformance by third party assessment body.

• Water-resistant enclosure conforms to NEMA 4X (equivalent to IP66).

• Capable of high-speed sampling at 50 times per second (20 ms)

• Easy-to-set two-point scaling allows conversion and display of any userset values.

Refer to Precautions on page 30.

Model Number Structure

■ Model Number Legend

Base Units and Optional Boards can be ordered individually or as sets.

Base Units

K3HB-V@

1. Input Sensor Codes

LC: Load cell input (DC low-voltage input)

5. Supply Voltage

100-240 VAC: 100 to 240 VAC

24 VAC/VDC: 24 VAC/VDC

Optional Board

Sensor Power Supply/Output Boards

K33-@

Relay/Transistor Output Boards

K34-@

Event Input Boards

K35-@

Note: 1. CPB can be combined with relay outputs only.

Accessories (Sold Separately)

K32-DICN: Special Cable (for event inputs, with 8-pin connector)

K32-BCD: Special BCD Output Cable

1

5

2

3

4

2. Only one of the following can be used by each Digital Indicator:

RS-232C/RS-485 communications, a linear output, or DeviceNet communications.

Base Units with Optional Boards

K3HB-V@-@@@

1234

2. Sensor Power Supply/Output Type Codes

None: None

CPB: Relay output (PASS: SPDT) + Sensor power supply

L1B: Linear current output (DC0(4)

L2B: Linear voltage output (DC0(1)

B: Sensor power supply (10 VDC +/

FLK1B: Communications (RS-232C) + Sensor power supply

FLK3B: Communications (RS-485) + Sensor power supply

3. Relay/Transistor Output Type Codes

None: None

C1: Relay contact (H/L: SPDT each)

C2: Relay contact (HH/H/LL/L: SPST-NO each)

T1: Transistor (NPN open collector: HH/H/PASS/L/LL)

T2: Transistor (PNP open collector: HH/H/PASS/L/LL)

BCD: BCD output + transistor output (NPN open collector: HH/H/PASS/L/

DRT: DeviceNet (See note 2.)

4. Event input Type Codes

None: None

1: 5 points (M3 ter minal blocks) NPN open collector

2: 8 points (10-pin MIL connector) NPN open collector

3: 5 points (M3 terminal blocks) PNP open collector

4: 8 points (10-pin MIL connector) PNP open collector

(10 VDC +/

(10 VDC +/

(10 VDC +/

(10 VDC +/

(10 VDC +/

LL)

5

−5%, 100 mA) (See note 1.)

−5%, 100 mA) (See note 2.)

−5%, 100 mA) (See note 2.)

−5%, 100 mA) (See note 2.)

−5%, 100 mA) (See note 2.)

− 20 mA) + Sensor power supply

− 5 V, 0 to 10 V) + Sensor power supply

−5%, 100 mA)

8 Weighing Indicator K3HB-V

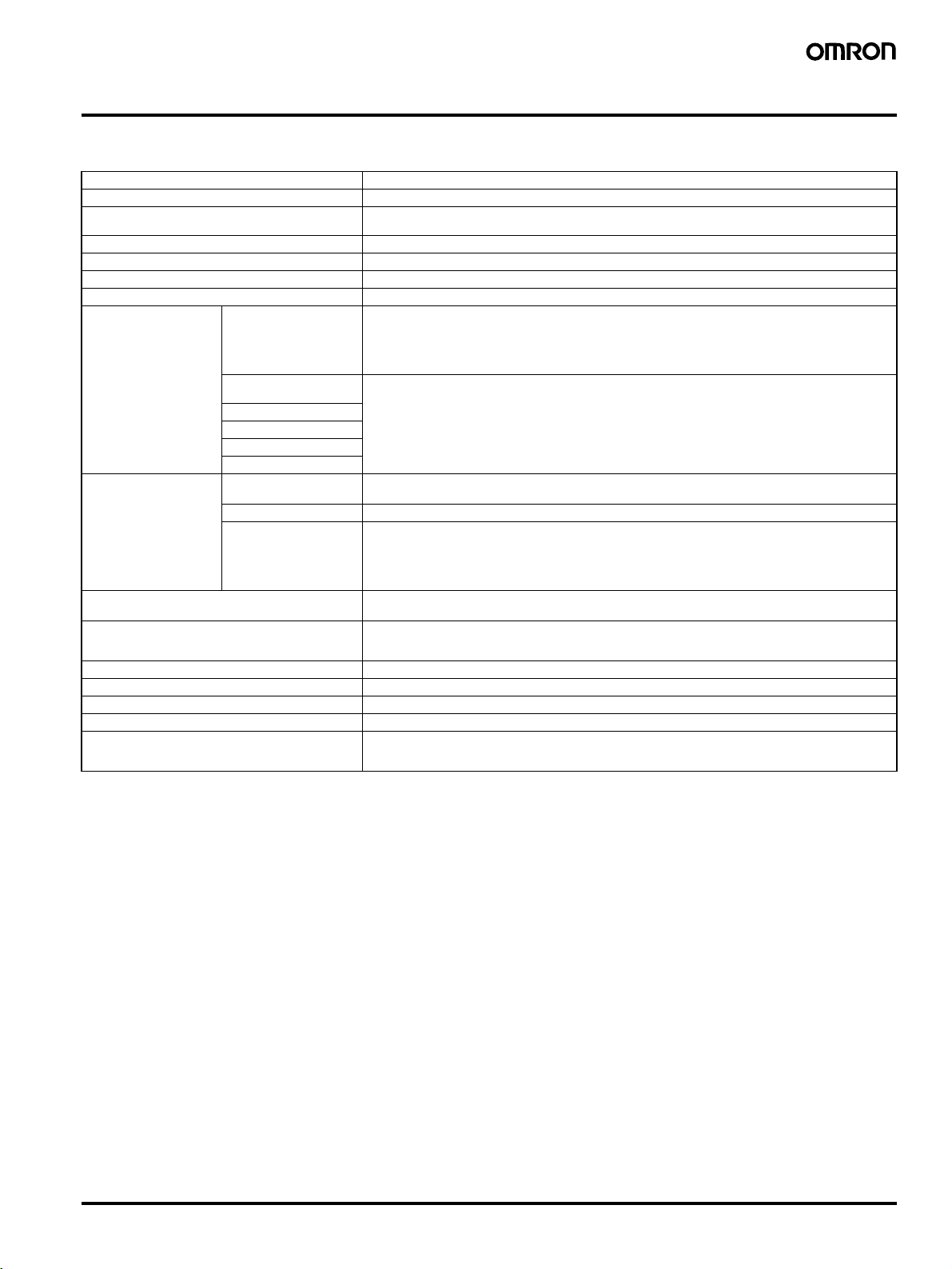

Specifications

■ Ratings

Power supply voltage 100 to 240 VAC (50/60 Hz), 24 VAC/VDC, DeviceNet power supply: 24 VDC

Allowable power supply voltage range 85% to 110% of the rated power supply voltage, DeviceNet power supply: 11 to 25 VDC

Power consumption

(See note 1.)

Current consumption DeviceNet power supply: 50 mA max. (24 VDC)

Input DC voltage

A/D conversion method Delta-Sigma method

External power supply See Sensor Power Supply/Output Type Codes

Event inputs

(See note 2.)

Output ratings (depends

on the model)

Display method Negative LCD (backlit LED) display

Main functions Scaling function, measurement operation selection, averaging, previous average value comparison, forced-

Ambient operating temperature

Ambient operating humidity 25% to 85%

Storage temperature −25 to 65°C (with no icing or condensation)

Altitude 2,000 m max.

Accessories Watertight packing, 2 fixtures, ter minal cover, unit stickers, operation manual. DeviceNet models also include

Timing input NPN open collector or no-voltage contact signal

Startup compensation

timer input

Hold input

Reset input

Forced-zero input

Bank input

Relay output 250 VAC, 30 VDC, 5 A (resistive load)

Transistor output Maximum load voltage: 24 VDC, Maximum load current: 50 mA, Leakage current: 100

Linear output Linear output 0 to 20 mA DC, 4 to 20 mA:

Note: 1. DC power supply models require a control power supply capacity of approximately 1 A per Unit when power is turned ON. Particular

attention is required when using two or more DC power supply models. The OMRON S8VS-series DC Power Supply Unit is recommended.

2. PNP input types are also available.

3. For K3HB-series DeviceNet models, use only the DeviceNet Connector included with the product. The crimp terminals provided are for

Thin Cables.

100 to 240 V: 18 VA max. (max. load)

24 VAC/DC: 11 VA/7 W max. (max. load)

ON residual voltage: 3 V max.

ON current at 0 Ω: 17 mA max.

Max. applied voltage: 30 VDC max.

OFF leakage current: 1.5 mA max.

NPN open collector or no-voltage contact signal

ON residual voltage: 2 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 0.1 mA max.

Mechanical life expectancy: 5,000,000 operations, Electrical life expectancy: 100,000 operations

Load: 500

Linear output 0 to 5 VDC, 1 to 5 VDC, 0 to 10 VDC:

Load: 5 k

(1 V or less: ±0.15 V; not output for 0 V or less)

7-segment digital display (Character height: PV: 14.2 mm (green/red); SV: 4.9 mm (green)

zero, zero-limit, output hysteresis, output OFF delay, output test, teaching, display value selection, display

color selection, key protection, bank selection, display refresh period, maximum/minimum hold, reset

−10 to 55°C (with no icing or condensation)

a DeviceNet connector (Hirose HR31-5.08P-5SC(01)) and crimp terminals (Hirose HR31-SC-121) (See note

3.)

Ω: 4 mA max.

µA max.

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Weighing Indicator K3HB-V 9

■ Characteristics

Display range −19,999 to 99,999

Sampling period 20 ms (50 times/second)

Comparative output response time 100 ms max.

Linear output response time 150 ms max.

Insulation resistance 20 M

Dielectric strength 2,300 VAC for 1 min between external terminals and case

Noise immunity 100 to 240 VAC models:

Vibration resistance

Shock resistance

Weight Approx. 300 g (Base Unit only)

Degree of

protection

Memory protection EEPROM (non-volatile memory)

Applicable standards UL61010C-1, CSA C22.2 No. 1010.1 (evaluated by UL)

EMC EMI: EN61326+A1 industrial applications

Front panel Conforms to NEMA 4X for indoor use (equivalent to IP66)

Rear case IP20

Ter min als IP00 + finger protection (VDE0106/100)

Ω min. (at 500 VDC)

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

24 VAC/VDC models:

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

Frequency: 10 to 55 Hz; Acceleration: 50 m/s

2

150 m/s

Number of rewrites: 100,000

EN61010-1 (IEC61010-1): Pollution degree 2/Overvoltage category II

EN61326: 1997, A1: 1998, A2: 2001

Electromagnetic radiation interference

Terminal interference voltage

EMS: EN61326+A1 industrial applications

Electrostatic Discharge Immunity

Radiated Electromagnetic Field Immunity

Electrical Fast Transient/Burst Immunity

Surge Immunity

Conducted Disturbance Immunity

Voltage Dips and Interruptions Immunity

(100 m/s2 for relay outputs) 3 times each in 3 axes, 6 directions

CISPR 11 Group 1, Class A: CISPRL16-1/-2

CISPR 11 Group 1, Class A: CISPRL16-1/-2

EN61000-4-2: 4 kV (contact), 8 kV (in air)

EN61000-4-3: 10 V/m 1 kHz sine wave amplitude modulation (80 MHz to 1 GHz)

EN61000-4-4: 2 kV (power line), 1 kV (I/O signal line)

EN61000-4-5: 1 kV with line (power line), 2 kV with ground (power line)

EN61000-4-6: 3 V (0.15 to 80 MHz)

EN61000-4-11: 0.5 cycle, 0

°/180°, 100% (rated voltage)

2

, 10 sweeps of 5 min each in X, Y, and Z directions

µs/100 ns)

µs/100 ns)

10 Weighing Indicator K3HB-V

■ Input Ranges (Measurement Range and Accuracy)

Input type Range Set value Measurement range Input impedance Accuracy Allowable

K3HB-VLC

Load Cell, mV

A a Ud 0.00 to 199.99 mV 1 M

Ω min. ±0.1%rdg ± 1 digit max. ±200 V

B b Ud 0.000 to 19.999 mV ±0.1%rdg ± 5 digits max.

C c Ud ±100.00 mV ±0.1%rdg ± 3 digits max.

D d Ud ±199.99 mV ±0.1%rdg ± 1 digit max.

Note: 1. The accuracy is for an ambient temperature of 23±5°C. For all ranges,10% or less of max. input ±0.1% FS.

2. The letters “rdg” mean “reading.”

Input type a lc b lc c lc d lc

(mV)

Connected

terminals

200.000

150.000

100.000

50.000

0.00

−50.00

−100.00

−150.00

−200.00

E2 E6 E3 E6 E4 E6 E5 E6

199.99 199.99

100.00

19.999

0.00 0.000

−100.00

−199.99

The area shown in dark shading indicates the factory setting.

instantaneous

overload (30 s)

■ Load Cell Wiring Example ■ Scaling Example Using Range A

Indicated on the K3HB-V as 0 to 49N in the load cell specifications

(rated load 49N, recommended applied voltage 10 V, rated output 2

mV/V) (See note.)

Display value

49 N

20 mV

Scaling values:

inp.a1=000.00

dsp.a1=00000

inp.a2=020.00

dsp.a2=49000

dp decimal point position: 00.000

Input value

Note: 2 mV/V indicates a load cell output of 2 mV for 1 V applied volt-

age for the rated load (when using a load of 1 N). When the applied voltage is 10 V, the load cell output is 20 mV (2 mV × 10).

B5

B6

B

E

E2

E3

E4

E5

E6

+10 V

+

−

0 V

+OUT

+IN

Load cell

−IN

−OUT

Weighing Indicator K3HB-V 11

Temperature Indicator

K3HB-H

New High-speed, High-precision Temperature

Indicator

• Easy recognition of judgement results using color display that can be

switched between red and green.

• Equipped with a position meter for monitoring operating status trends.

• External event input allows use in various measurement and discrimination applications.

• Series expanded to include DeviceNet models.

• Shor t body with depth of only 95 mm (from behind the front panel), or

97 mm for DeviceNet models.

• UL certification approval (Certification Mark License).

• CE Marking conformance by third party assessment body.

• Water-resistant enclosure conforms to NEMA 4X (equivalent to IP66).

• Capable of high-speed sampling at 50 times per second (20 ms).

• High-resolution of 0.01

input. Thermocouple sensor inputs also support a resolution of 0.1

for all ranges.

• Temperature input shift is easily set using two points.

Refer to Precautions on page 30.

Model Number Structure

°C with platinum-resistance thermometer Pt100

°C

■ Model Number Legend

Base Units and Optional Boards can be ordered individually or as sets.

Base Units

K3HB-H@

1. Input Sensor Codes

TA: Temperature input

5. Supply Voltage

100-240 VAC: 100 to 240 VAC

24 VAC/VDC: 24 VAC/VDC

Optional Board

Sensor Power Supply/Output Boards

K33-@

Relay/Transistor Output Boards

K34-@

Event Input Boards

K35-@

Note: 1. CPA can be combined with relay outputs only.

15

Thermocouple input/Platinum-resistance thermometer input

2

3

4

2. Only one of the following can be used by each Digital Indicator:

RS-232C/RS-485 communications, a linear output, or DeviceNet communications.

Base Units with Optional Boards

K3HB-H@-@@@

1234

2. Sensor Power Supply/Output Type Codes

None: None

CPA: Relay output (PASS: SPDT) + Sensor power supply

(12 VDC +/−10%, 80 mA) (See note 1.)

L1A: Linear current output (DC0(4) − 20 mA) + Sensor power supply

(12 VDC +/−10%, 80 mA) (See note 2.)

L2A: Linear voltage output (DC0(1) − 5 V, 0 to 10 V) + Sensor power supply

(12 VDC +/−10%, 80 mA) (See note 2.)

A: Sensor power supply (12 VDC +/−10%, 80 mA)

FLK1A: Communications (RS-232C) + Sensor power supply

(12 VDC +/−10%, 80 mA) (See note 2.)

FLK3A: Communications (RS-485) + Sensor power supply

(12 VDC +/−10%, 80 mA) (See note 2.)

3. Relay/Transistor Output Type Codes

None: None

C1: Relay contact (H/L: SPDT each)

C2: Relay contact (HH/H/LL/L: SPST-NO each)

T1: Transistor (NPN open collector: HH/H/PASS/L/LL)

T2: Transistor (PNP open collector: HH/H/PASS/L/LL)

BCD: BCD output + transistor output (NPN open collector: HH/H/PASS/

L/LL)

DRT: DeviceNet (See note 2.)

4. Event input Type Codes

None: None

1: 5 points (M3 terminal blocks) NPN open collector

2: 8 points (10-pin MIL connector) NPN open collector

3: 5 points (M3 terminal blocks) PNP open collector

4: 8 points (10-pin MIL connector) PNP open collector

5

Accessories (Sold Separately)

K32-DICN: Special Cable (for event inputs, with 8-pin connector)

K32-BCD: Special BCD Output Cable

12 Temperature Indicator K3HB-H

Specifications

■ Ratings

Power supply voltage 100 to 240 VAC (50/60 Hz), 24 VAC/VDC, DeviceNet power supply: 24 VDC

Allowable power supply voltage range 85% to 110% of the rated power supply voltage, DeviceNet power supply: 11 to 25 VDC

Power consumption

(See note 1.)

Current consumption DeviceNet power supply: 50 mA max. (24 VDC)

Input Platinum-resistance thermometer: Pt100

A/D conversion method Delta-Sigma method

External power supply See Sensor Power Supply/Output Type Codes

Event inputs

(See note 2.)

Output ratings

(depends on the

model)

Display method Negative LCD (backlit LED) display

Main functions Scaling function, measurement operation selection, averaging, previous average value comparison, zero-limit,

Ambient operating temperature

Timing input NPN open collector or no-voltage contact signal

Startup compensation timer input

Hold input

Reset input

Bank input

Relay output 250 VAC, 30 VDC, 5 A (resistive load)

Transistor output Maximum load voltage: 24 VDC, Maximum load current: 50 mA, Leakage current: 100

Linear output Linear output 0 to 20 mA DC, 4 to 20 mA:

100 to 240 V: 18 VA max. (max. load)

24 VAC/DC: 11 VA/7 W max. (max. load)

Thermocouple: K, J, T, E, L, U, N, R, S, B, W

ON residual voltage: 3 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 1.5 mA max.

NPN open collector or no-voltage contact signal

ON residual voltage: 2 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 0.1 mA max.

Mechanical life expectancy: 5,000,000 operations, Electrical life expectancy: 100,000 operations

Load: 500

Linear output 0 to 5 VDC, 1 to 5 VDC, 0 to 10 VDC:

Load: 5 k

(1 V or less: ±0.15 V; not output for 0 V or less)

7-segment digital display (Character height: PV: 14.2 mm (green/red); SV: 4.9 mm (green)

output hysteresis, output OFF delay, output test, display value selection, display color selection, key protection,

bank selection, display refresh period, maximum/minimum hold, reset

−10 to 55°

Ω: 17 mA max.

Ω: 4 mA max.

µA max.

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Note: 1. DC power supply models require a control power supply capacity of approximately 1 A per Unit when power is turned ON. Particular attention is

required when using two or more DC power supply models. The OMRON S8VS-series DC Power Supply Unit is recommended.

2. PNP input types are also available.

3. For K3HB-series DeviceNet models, use only the DeviceNet Connector included with the product. The crimp terminals provided are for Thin Ca-

bles.

Temperature Indicator K3HB-H 13

■ Characteristics

Display range

Accuracy Thermocouple input: (±0.3% PV or ±1

Sampling period 20 ms (50 times/second)

Comparative output response time Platinum-resistance thermometer input range: 120 ms max.

Linear output response time Platinum-resistance thermometer input range: 170 ms max.

Insulation resistance 20 M

Dielectric strength 2,300 VAC for 1 min between external terminals and case

Noise immunity 100 to 240 VAC models:

Vibration resistance

Shock resistance

Weight Approx. 300 g (Base Unit only)

Degree of protection

Memory protection EEPROM (non-volatile memory)

Applicable standards UL61010C-1, CSA C22.2 No. 1010.1 (evaluated by UL)

EMC EMI: EN61326+A1 industrial applications

Note: K, T, N (–100°C or less): ±2°C ±1 digit max.

U, L: ±2

B (400

R, S (200

W: (±0.3% PV or ±3

Front panel Conforms to NEMA 4X for indoor use (equivalent to IP66)

Rear case IP20

Ter min als IP00 + finger protection (VDE0106/100)

°C ±1 digit max.

°C max.): Nothing specified.

°C max.): ±3°C ±1 digit max.

°C whichever is larger) ±1 digit max.

−19,999 to 99,999

Platinum resistance thermometer input: (±0.2% PV or ±0.8

Thermocouple input range: 180 ms max.

Thermocouple input range: 230 ms max.

Ω min. (at 500 VDC)

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

24 VAC/VDC models:

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

Frequency: 10 to 55 Hz; Acceleration: 50 m/s

2

150 m/s

Number of rewrites: 100,000

EN61010-1 (IEC61010-1): Pollution degree 2/Overvoltage category II

EN61326: 1997, A1: 1998, A2: 2001

Electromagnetic radiation interference

Terminal interference voltage

EMS: EN61326+A1 industrial applications

Electrostatic Discharge Immunity

Radiated Electromagnetic Field Immunity

Electrical Fast Transient/Burst Immunity

Surge Immunity

Conducted Disturbance Immunity

Voltage Dips and Interruptions Immunity

(100 m/s2 for relay outputs) 3 times each in 3 axes, 6 directions

CISPR 11 Group 1, Class A: CISPRL16-1/-2

CISPR 11 Group 1, Class A: CISPRL16-1/-2

EN61000-4-2: 4 kV (contact), 8 kV (in air)

EN61000-4-3: 10 V/m 1 kHz sine wave amplitude modulation (80 MHz to 1 GHz)

EN61000-4-4: 2 kV (power line), 1 kV (I/O signal line)

EN61000-4-5: 1 kV with line (power line), 2 kV with ground (power line)

EN61000-4-6: 3 V (0.15 to 80 MHz)

EN61000-4-11: 0.5 cycle, 0

°C, whichever is larger) ± 1 digit max. (See note.)

2

, 10 sweeps of 5 min each in X, Y, and Z directions

°/180°, 100% (rated voltage)

°C, whichever is larger) ± 1 digit max.

µs/100 ns)

µs/100 ns)

14 Temperature Indicator K3HB-H

■ Input Ranges

Platinum-resistance Thermometer/Thermocouple

Input type Platinum-

Name Pt100 K J T E L U N R S B W

Connected

terminals

Te m perature

range

(

°C)

Setting code 0-pt 1-pt 2-k 3-k 4-j 5-j 6-t 7-e 8-l 9-u 10-n 11-r 12-s 13-b 14-w

Minimum

setting unit

(comparative

set value)

resistance

thermometer

E4 E5 E6 E5 E6

2300

1800

1300

850.0 850.0 850.0

900

800

700

600

400

200

100

0

−100

−200

150.00

−150.00

−200.0

0.1

°C0.01°C0.1°C

1300.0 1300.0

500.0 600.0

400.0 400.0 400.0

−20.0 −100.0 −20.0 −100.0

−200.0 −200.0 −200.0 −200.0

Thermocouple

(W/Re

5-26)

2300.0

1700.0 1700.0 1800.0

100.0

0.0 0.0 0.0 0.0

The range shown in dark shading indicates the factory setting.

Celsius/Fahrenheit Correlation Values and Setting/Specified Ranges

Input type Setting range Indication range

°C °F °C °F

Pt100 (1)

Pt100 (2)

K (1)

K (2)

J (1)

J (2)

T

E

L

U

N

R

S

B

W

−200.0 to 850.0 −300.0 to 1500.0 −305.0 to 955.0 −480.0 to 1680.0

−150.00 to 150.00 −199.99 to 300.00 −180.00 to 180.00 −199.99 to 350.00

−200.0 to 1300.0 −300.0 to 2300.0 −350.0 to 1450.0 −560.0 to 2560.0

−20.0 to 500.0 0.0 to 900.0 −72.0 to 552.0 −90.0 to 990.0

−100.0 to 850.0 −100.0 to 1500.0 −195.0 to 945.0 −260.0 to 1660.0

−20.0 to 400.0 0.0 to 750.0 −62.0 to 442.0 −75.0 to 825.0

−200.0 to 400.0 −300.0 to 700.0 −260.0 to 460.0 −400.0 to 800.0

0.0 to 600.0 0.0 to 1100.0 −60.0 to 660.0 −110.0 to 1210.0

−100.0 to 850.0 −100.0 to 1500.0 −195.0 to 945.0 −260.0 to 1660.0

−200.0 to 400.0 −300.0 to 700.0 −260.0 to 460.0 −400.0 to 800.0

−200.0 to 1300.0 −300.0 to 2300.0 −350.0 to 1450.0 −560.0 to 2560.0

0.0 to 1700.0 0.0 to 3000.0 −170.0 to 1870.0 −300.0 to 3300.0

0.0 to 1700.0 0.0 to 3000.0 −170.0 to 1870.0 −300.0 to 3300.0

100.0 to 1800.0 300.0 to 3200.0 −70.0 to 1970.0 10.0 to 3490.0

0.0 to 2300.0 0.0 to 4100.0 −230.0 to 2530.0 −410.0 to 4510.0

Temperature Indicator K3HB-H 15

Linear Sensor Indicator

K3HB-S

A Linear Sensor Indicator Capable of High-speed

Response at 2,000 Times per Second

• Effective for high-speed measurement and discrimination with a sampling period of 0.5 ms and output response time of 1 ms max.

• Easy recognition of judgement results using color display that can be

switched between red and green.

• Equipped with a position meter that represents measured amounts and

relative positions.

• Zero calibration can be performed easily with the forced zero function.

• Series expanded to include DeviceNet models.

• Shor t body with depth of only 95 mm (from behind the front panel), or

97 mm for DeviceNet models.

• UL certification approval (Certification Mark License).

• CE Marking conformance by third party assessment body.

• Water-resistant enclosure conforms to NEMA 4X (equivalent to IP66).

Refer to Precautions on page 30.

Model Number Structure

■ Model Number Legend

Base Units and Optional Boards can be ordered individually or as sets.

Base Units

Base Units with Optional Boards

K3HB-S@

1

5

1. Input Sensor Codes

SD: DC Process input

5. Supply Voltage

100-240 VAC: 100 to 240 VAC

24 VAC/VDC: 24 VAC/VDC

Optional Board

Sensor Power Supply/Output Boards

K33-@

2

Relay/Transistor Output Boards

K34-@

3

Event Input Boards

K35-@

4

Note: 1. CPA can be combined with relay outputs only.

2. Only one of the following can be used by each Digital Indicator:

RS-232C/RS-485 communications, a linear output, or DeviceNet communications.

K3HB-S@-@@@

1234

2. Sensor Power Supply/Output Type Codes

None: None

CPA: Relay output (PASS: SPDT) + Sensor power supply

L1A: Linear current output (DC0(4)

L2A: Linear voltage output (DC0(1)

A: Sensor power supply (12 VDC +/

FLK1A: Communications (RS-232C) + Sensor power supply

FLK3A: Communications (RS-485) + Sensor power supply

3. Relay/Transistor Output Type Codes

None: None

C1: Relay contact (H/L: SPDT each)

C2: Relay contact (HH/H/LL/L: SPST-NO each)

T1: Transistor (NPN open collector: HH/H/PASS/L/LL)

T2: Transistor (PNP open collector: HH/H/PASS/L/LL)

BCD: BCD output + transistor output (NPN open collector: HH/H/PASS/L/

DRT: DeviceNet (See note 2.)

4. Event input Type Codes

None: None

1: 5 points (M3 ter minal blocks) NPN open collector

2: 8 points (10-pin MIL connector) NPN open collector

3: 5 points (M3 terminal blocks) PNP open collector

4: 8 points (10-pin MIL connector) PNP open collector

(12 VDC +/

(12 VDC +/

(12 VDC +/

(12 VDC +/

(12 VDC +/

LL)

5

−10%, 80 mA) (See note 1.)

−10%, 80 mA) (See note 2.)

−10%, 80 mA) (See note 2.)

−10%, 80 mA) (See note 2.)

−10%, 80 mA) (See note 2.)

− 20 mA) + Sensor power supply

− 5 V, 0 to 10 V) + Sensor power supply

−10%, 80 mA)

Accessories (Sold Separately)

K32-DICN: Special Cable (for event inputs, with 8-pin connector)

K32-BCD: Special BCD Output Cable

16 Linear Sensor Indicator K3HB-S

Specifications

■ Ratings

Power supply voltage

Allowable power supply voltage range

Power consumption

(See note 1.)

Current consumption DeviceNet power supply: 50 mA max. (24 VDC)

Input DC voltage/current

A/D conversion method Sequential comparison system

External power supply See Sensor Power Supply/Output Type Codes

Event inputs

(See note 2.)

Output ratings (depends on the model)

Display method Negative LCD (backlit LED) display

Main functions Scaling function, 2-input calculation function, measurement operation selection, averaging, previous average value

Ambient operating temperature

Ambient operating humidity 25% to 85%

Storage temperature

Altitude

Timing input NPN open collector or no-voltage contact signal

Startup compensation timer input

Hold input

Reset input

Forced-zero input

Bank input

Relay output 250 VAC, 30 VDC, 5 A (resistive load)

Transistor output Maximum load voltage: 24 VDC, Maximum load current: 50 mA, Leakage current: 100

Linear output Linear output 0 to 20 mA DC, 4 to 20 mA:

100 to 240 VAC (50/60 Hz),

85% to 110% of the rated power supply voltage,

100 to 240 V: 18 VA max. (max. load)

24 VAC/DC: 11 VA/7 W max. (max. load)

ON residual voltage: 3 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 1.5 mA max.

NPN open collector or no-voltage contact signal

ON residual voltage: 2 V max.

ON current at 0

Max. applied voltage: 30 VDC max.

OFF leakage current: 0.1 mA max.

Mechanical life expectancy: 5,000,000 operations, Electrical life expectancy: 100,000 operations

Load: 500

Linear output 0 to 5 VDC, 1 to 5 VDC, 0 to 10 VDC:

Load: 5 k

(1 V or less: ±0.15 V; not output for 0 V or less)

7-segment digital display (Character height: PV: 14.2 mm (green/red); SV: 4.9 mm (green)

comparison, forced-zero, zero-limit, output hysteresis, output OFF delay, output test, teaching, display value selection,

display color selection, key protection, bank selection, display refresh period, maximum/minimum hold, reset

−10 to 55°C (with no icing or condensation)

−25 to 65°C (with no icing or condensation)

Ω: 17 mA max.

Ω: 4 mA max.

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

24 VAC/VDC, DeviceNet power supply: 24 VDC

DeviceNet power supply: 11 to 25 VDC

µA max.

Note: 1. DC power supply models require a control power supply capacity of approximately 1 A per Unit when power is turned ON. Particular

attention is required when using two or more DC power supply models. The OMRON S8VS-series DC Power Supply Unit is recommended.

2. PNP input types are also available.

3. For K3HB-series DeviceNet models, use only the DeviceNet Connector included with the product. The crimp terminals provided are for

Thin Cables.

Linear Sensor Indicator K3HB-S 17

■ Characteristics

Display range −19,999 to 99,999

Sampling period One input: 0.5 ms; Two inputs: 1.0 ms

Comparative output response

times (transistor

outputs)

Linear output response time

Insulation resistance 20 M

Dielectric strength 2,300 VAC for 1 min between external terminals and case

Noise immunity 100 to 240 VAC models:

Vibration resistance

Shock resistance

Weight Approx. 300 g (Base Unit only)

Degree of protection

Memory protection EEPROM (non-volatile memory)

Applicable standards UL61010C-1, CSA C22.2 No. 1010.1(evaluated by UL)

EMC EMI: EN61326+A1 industrial applications

One input OFF to ON: 1 ms max., ON to OFF: 1.5 ms max.

Two inputs OFF to ON: 2 ms max., ON to OFF: 2.5 ms max.

One input 51 ms max.

Two inputs 52 ms max.

Ω min. (at 500 VDC)

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

24 VAC/VDC models:

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1

Frequency: 10 to 55 Hz; Acceleration: 50 m/s

2

150 m/s

(100 m/s2 for relay outputs) 3 times each in 3 axes, 6 directions

Front panel Conforms to NEMA 4X for indoor use (equivalent to IP66)

Rear case IP20

Terminals IP00 + finger protection (VDE0106/100)

Number of rewrites: 100,000

EN61010-1 (IEC61010-1): Pollution degree 2/Overvoltage category II

EN61326: 1997, A1: 1998, A2: 2001

Electromagnetic radiation interference

CISPR 11 Group 1, Class A: CISPRL16-1/-2

Terminal interference voltage

CISPR 11 Group 1, Class A: CISPRL16-1/-2

EMS: EN61326+A1 industrial applications

Electrostatic Discharge Immunity

EN61000-4-2: 4 kV (contact), 8 kV (in air)

Radiated Electromagnetic Field Immunity

EN61000-4-3: 10 V/m 1 kHz sine wave amplitude modulation (80 MHz to 1 GHz)

Electrical Fast Transient/Burst Immunity

EN61000-4-4: 2 kV (power line), 1 kV (I/O signal line)

Surge Immunity

EN61000-4-5: 1 kV with line (power line), 2 kV with ground (power line)

Conducted Disturbance Immunity

EN61000-4-6: 3 V (0.15 to 80 MHz)

Voltage Dips and Interruptions Immunity

EN61000-4-11: 0.5 cycle, 0

°/180°, 100% (rated voltage)

2

, 10 sweeps of 5 min each in X, Y, and Z directions

µs/100 ns)

µs/100 ns)

■ Input Ranges (Measurement Ranges and Accuracy)

Input Input type Measurement range Indication range Input

K3HB-SSD

DC voltage/current

input

0 to 20 mA 0.000 to 20.000 mA

−2.000 to 22.000 mA 120 Ω max. One input:

4 to 20 mA 4.000 to 20.000 mA 2.000 to 22.000 mA

0 to 5 V 0.000 to 5.000 V

−0.500 to 5.500 mA 1 MΩ min. ±10 V

1 to 5 V 1.000 to 5.000 V 0.500 to 5.500 V

±5 V ±5.000 V ± 5.500 V

±10 V ±10.000 V ± 11.000 V ±14.5 V

Note: The accuracy is for an ambient temperature of 23±5°C.

18 Linear Sensor Indicator K3HB-S

impedance

Accuracy

(at 23

±5°C)

±0.1% F.S.

±1 digit max.

Two inputs:

±0.2% F.S.

±1 digit max.

Maximum

absolute rated

input

±31 mA

Input type DC current input Input type DC voltage input

Connected terminals 0-20 4-20 Connected terminals 0-5 1-5 5 10

Input A in-ta Input A in-ta

Input B in-tb Input B in-tb

DC current

range (mA)

24.000

22.000 22.000 DC voltage

20.000

16.000

12.000

8.000

4.000

0.000

−4.000

−2.000

E2 E3 E4 E3

E1 E3 E5 E3

range (V)

2.000

10.000

5.000

0.000

−5.000

−10.000

5.500 5.500 5.500

−0.500 0.500

11.000

−5.500

−11.000

The range shown in dark shading indicates the factory setting.

Sampling and Comparative Output Response Times

The K3HB-S sampling and comparative output response times depend on the calculation methods, timing hold type, and, for simple averaging, the

averaging times. Refer to the following description for details.

■ Output Refresh Period

The K3HB-S repeats input reads, calculation, and judgement output

processing. The output refresh period differs depending on whether

there are one or two inputs, as outlined below.

One Input

0.5 ms

Input

↓

Input A

or

Input B

Input read

Output

refresh

Two inputs

0.5 ms

Input

↓

Input A

or

Input B

Input read

Output

refresh

0.5 ms

Input

↓

↓

Output

Every 0.5 ms

Every 0.5 ms

0.5 ms

Input

Output

Input A: Every 1 ms

Input B: Every 1 ms

Every 0.5 ms

Input

↓

↓

Output

Input

↓

↓

Output

0.5 ms

0.5 ms

Input

↓

↓

Output

Input

Output

Input

↓

↓

Output

Input

↓

↓

Output

Input

↓

↓

Output

Input

Output

Input

↓

↓

Output

■ Output Response Time

The comparative output response time is the sum of the data processing time and the output (relay or transistor) response time.

One Input

0.5 ms 0.5 ms

R

Two Inputs

0.5 ms 0.5 ms 0.5 ms 0.5 ms

R R RR

Note: For transistor outputs:

For relay outputs:

0.5 ms

Data processing time

R R

R Output response time

(See note.)

Data processing time

R Output response time

(See note.)

For one input: OFF to ON 1 ms and ON to OFF 1.5 ms

For two inputs: OFF to ON 2 ms and ON to OFF 2.5 ms

The relay operation time of 15 ms is added to the transistor

output response times.

Linear Sensor Indicator K3HB-S 19

Common Specifications

■ Event Input Ratings

Input type S-TMR, HOLD, RESET, ZERO, BANK1, BANK2,

Contact ON: 1 k

No-contact ON residual voltage: 2 V max.

Ω max., OFF: 100 kΩ min. ---

OFF leakage current: 0.1 mA max.

Load current: 4 mA max.

Maximum applied voltage: 30 VDC max.

BANK4

ON residual voltage: 3 V max.

OFF leakage current: 1.5 mA max.

Load current: 17 mA max.

Maximum applied voltage: 30 VDC max.

■ Output Ratings

Contact Output Transistor Output

Item Resistive loads

Rated load 5 A at 250 VAC

Rated through

current

Mechanical life

expectancy

Electrical life

expectancy

(250 VAC, cos

30 VDC, L/R=0 ms)

5 A at 30 VDC

5A

5,000,000 operations

100,000 operations

φ=1;

Linear Output

Item 0 to 20 mA 4 to 20 mA 0 to 5 V 1 to 5 V 0 to 10 V

Allowable load impedance 500

Resolution Approx. 10,000

Output error ±0.5%FS

Ω max. 5 kΩ min.

Inductive loads

(250 VAC, closed

circuit, cos

30 VDC, L/R=7 ms)

1 A at 250 VAC

1 A at 30 VDC

φ=0.4;

Maximum load voltage 24 VDC

Maximum load current 50 mA

Leakage current 100

TIMING

µA max.

Serial Communications Output

Item RS-232C, RS-485

Communications method Half duplex

Synchronization method Start-stop synchronization

Baud rate 9,600, 19,200, or 38,400 bps

Transmission code ASCII

Data length 7 bits or 8 bits

Stop bit length 2 bits or 1 bit

Error detection Vertical parity and FCS

Parity check Odd, even

Note: For details on serial and DeviceNet communications, refer to

the Digital Indicator K3HB Communications User's Manual

(Cat.No. N129).

BCD Output I/O Ratings

(Input Signal Logic: Negative)

I/O signal name Item Rating

Inputs REQUEST

HOLD

MAX

MIN

RESET

Outputs DATA

POLARITY

OVER

DATA VALI D

RUN

HH

H

PA SS

L

LL

Note: For details on serial and DeviceNet communications, refer to

the Digital Indicator K3HB Communications User's Manual

(Cat.No. N129).

Input signal No-voltage

Input current for

no-voltage input

Signal

ON voltage 1.5 V max.

level

OFF voltage 3 V min.

Maximum load

voltage

Maximum load

current

Leakage current 100

Maximum load

voltage

Maximum load

current

Leakage current 100

contact input

10 mA

24 VDC

10 mA

µA max.

24 VDC

50 mA

µA max.

20 Digital Indicators K3HB-X/-V/-H/-S

DeviceNet Communications

Communications protocol Conforms to DeviceNet

Supported communications

Connection methods Combination of multi-drop and T-branch connections (for trunk and drop lines)

Baud rate DeviceNet: 500, 250, or 125 Kbps (automatic follow-up)

Communications media Special 5-wire cable (2 signal lines, 2 power supply lines, 1 shield line)

Communications distance

Communications power supply 24-VDC DeviceNet power supply

Allowable voltage fluctuation range 11 to 25-VDC DeviceNet power supply

Current consumption 50 mA max. (24 VDC)

Maximum number of nodes 64 (DeviceNet Configurator is counted as one node when connected)

Maximum number of slaves 63

Error control checks CRC errors

DeviceNet power supply Supplied from DeviceNet communications connector

Remote I/O communications Master-Slave connection (polling, bit-strobe, COS, cyclic)

Conforms to DeviceNet communications standards.

I/O allocations Allocate any I/O data using the Configurator.

Allocate any data, such as DeviceNet-specific parameters and variable area for Digital

Indicators.

Input area: 2 blocks, 60 words max.

Output area: 1 block, 29 words max.

(The first word in the area is always allocated for the Output Execution Enabled Flags.)

Message communications Explicit message communications

CompoWay/F communications commands can be executed (using explicit message

communications)

Baud rate Network length

(max.)

Drop line length

(max.)

500 Kbps 100 m (100 m) 6 m 39 m

250 Kbps 100 m

6 m 78 m

(250 m)

125 Kbps 100 m

6 m 156 m

(500 m)

The values in parentheses are for Thick Cable.

Total drop line

length (max.)

■ Internal Block Diagram

Analog input

BCD I/O

Event input

Linear output

Sensor power

supply

Input

circuit

BCD

• Input circuit

• Output circuit

• Transistor

output circuit

Digital input

circuit

Linear output

circuit

Filter

V

O

ADC

EEP-ROM

Drive

circuit

Micro-

Waveform

shaping circuit

Drive

circuit

Power supply circuit (isolated)

Power supply

computer

Keys

Indications

COM

Transistor

output

Relay output

DeviceNet

Communications

Drive

circuit

Drive

X

circuit

Drive

circuit

Drive

circuit

DD

V

DeviceNet

circuit

Communi-

cations

driver

V

V

O

DC-DC

Converter (isolated)

Digital Indicators K3HB-X/-V/-H/-S 21

■ Power Supply Derating Curve for Sensor (Reference Value)

With 12 V

With 10 V

Max. current (mA)

140

120

100

80

60

40

20

0

−20 −100 102030405060

Ambient temperature (°C)

1

Max. current (mA)

140

120

100

80

60

40

20

0

−20 −100 102030405060

Ambient temperature (°C)

1

Note: 1. The above values are for standard mounting. The derating curve differs depending on the mounting conditions.

2. Do not use the Sensor outside of the derating area (i.e., do not use it in the area labeled A in the above graphics). Doing so may occa-

sionally cause deterioration or damage to internal components.

■ Component Names and Functions

Max/Min status indicator

Turns ON when the maximum value or minimum value is

displayed in the RUN level.

PV display

Displays PVs, maximum values,

minimum values, parameter

names, and error names.

Level/bank display

In RUN level, displays the bank if the bank function is

ON. (Turns OFF if the bank function is OFF.)

In other levels, displays the current level.

Comparative output

status indicators

Display the status of comparative outputs.

Status indicators

Display

Turns ON when the tare zero function is

executed. Turns OFF if it is not executed or

T-ZR

is cleared.

Turns ON when the forced-zero function is

Zero

executed. Turns OFF if it is not executed or

is cleared. (Excluding the K3HB-H.)

Turns ON/OFF when hold input turns

Hold

ON/OFF.

Function

HH

H

P

L

LL

MAX/MIN

Max

Min

L

T-ZR

Zero

TG HH H

CMW

TLLL

Hold

UPMODELEVEL

SHIFT

Position meter

Displays the position of the PV with

respect to a desired scale.

SV display

Displays SV and monitor values.

SV display status indicators

Display Function

Turns ON when the timing signal turns

ON. Otherwise OFF.

TG

Turns ON when parameters for which

teaching can be performed are

T

displayed.

In RUN level, turn ON when the

HH, H,

comparative set values HH, H, L, and

L, LL

LL are displayed.

MAX/MIN Key LEVEL Key MODE Key SHIFT Key UP Key

Used to switch the

display between the

PV, maximum value,

and minimum value and

to reset the maximum

and minimum values.

Used to switch level.

Used to switch the

parameters displayed.

Used to change

parameter settings.

When changing a set

value, this key is used

to move along the

digits.

When changing a set value,

this key is used to change

the actual value.

When a measurement value

is displayed, this key is

used to execute or clear the

forced-zero function or to

execute teaching.

22 Digital Indicators K3HB-X/-V/-H/-S

■ BCD Output Timing Chart

A REQUEST signal from a Programmable Controller or other external device is required to read BCD data.

Single Sampling Data Output

20-ms pulse min. (50 ms max.)

REQ.

MAX.MIN.

DATA

DATA

VALID

The data is set in approximately 30 ms from the rising edge of the

REQUEST signal and the DATA VALID signal is output.

When reading the data from a Programmable Controller, start

reading the data when the DATA VALID signal turns ON.

The DATA VALID signal will turn OFF 40 ms later, and the data will

turn OFF 16 ms after that.

All data "High" All data "High"

Approx.

30 ms

K3HB

(1)

K3HB

(2)

K3HB

(3)

DATA (including POL and

OVER) and DATA VALID

can be used in a wired OR.

RUN, HH, H, PASS, L, and

LL are always output, with or

without a REQUEST signal.

Do not used a wired OR

connect for these signals.

Data

40 ms

Programmable

Controller

16 ms

REQ. (1)

REQ. (2)

REQ. (3)

DATA

DATA

VALID

Note: Leave 20 ms min. between DATA VALID turning OFF and the REQUEST signal.

Continuous Data Output

REQ.

MAX.MIN.

DATA

All data "High"

DATA

VALID

Approx.

30 ms

Measurement data is output every 64 ms while the REQUEST signal

remains ON.

Note: If HOLD is executed when switching between data 1 and data

2, either data 1 or data 2 is output depending on the timing of

the hold signal. The data will not go LOW.

(1) (2) (3)

(See note.) (See note.)

Data 1 Data 2

40 ms 40 ms

(See note.)

24 ms 24 ms

64 ms 64 ms

Programmable Controller Connection Example

Digital Indicator

+5 V

240 Ω

240 Ω

Connector pin No. (See note.)

1.COMMON

2.1

3.2

10°

4.4

5.8

23.DATA VALID

24.RUN

25.COMMON

26.REQUEST

240 Ω

30.RESET

240 Ω

31.POLARITY

(+/− polarity)

SYSMAC Programmable Controller

DC Input Unit

COM

IN

IN

IN

IN

IN

IN

Transistor Output Unit

OUT

OUT

COM

(0 V)

24 VDC

+24 V

DC power

supply

0 V

Internal circuit

Internal circuit

Internal circuit

Note: The BCD output connector pin number is the D-sub connector pin number when

the BCD Output Cable (sold separately) is connected. This number differs from

the pin number for the Digital Indicator narrow pitch connector (manufactured by

Honda Tsushin Kogyo Co., Ltd.).

Display Unit Connection Example

Digital Indicator

Connector pin No. (See note.)

1.COMMON

2.1

3.2

10°

4.4

5.8

23.DATA VALID

24.RUN

1

To 10

2

To 10

+5 V

240 Ω

240 Ω

240 Ω

240 Ω

25.COMMON

26.REQUEST

30.RESET

31.POLARITY

(+/− polarity)

Shortcircuit

V

V

B

A

D

C

O

O

LE

DP

8

M7E-01D@N2, 01H@N2

<M7E Digital Display Unit>

D

8

V

V

B

B

C

A

A

D

C

O

O

LE

LE

DP

DP

8

SEC

Refer to the following User's Manual for application precautions and other information required when using the Digital Indicator:

K3HB-S/-X/-V/-H Digital Indicator User's Manual (Cat. No. N128)

The manual can be downloaded from the following site in PDF format: OMRON Industrial Web http://www.fa.omron.co.jp

Digital Indicators K3HB-X/-V/-H/-S 23

■

24 Digital Indicators K3HB-X/-V/-H/-S

E Analog Input

(

)

D

Process Indicator

K3HB-X

AC voltage only

E1

A, B

N/C

E2

N/C

A

E3

C

B

E4

D

C

E5

N/C

D

E6

COM

COM

D Event Input

Models with Terminal Blocks

<K35-1><K35-3>

D1

TIMING

D2

S-TMR

D3

HOLD

D4

RESET

D5

ZERO

D6

COM

Models with Connectors

<K35-2><K35-4>

1: TIMING

3: HOLD

5: ZERO

7: BANK4

9: BANK1

• Applicable Connector (Sold separately)

XG4M-1030 (OMRON)

• Special Cable (Sold separately)

K32-DICN (OMRON)

(XG4M-1030 with 3 m cable)

2: S-TMR

2

1

4: RESET

6: COM

8: BANK2

10

9

10: COM

Weighing Indicator

K3HB-V

E1

N/C

E2

A

E3

B

E4

C

E5

D

E6

COM

Temperature Indicator

K3HB-H

E1

E2

N/C

E3

A

E4

Pt

E5

B

TC

E6

COM

+

B'

Linear Sensor Indicator

Current input

Voltage input

• Use terminal pin D6 as the common terminal.

• Use NPN open collector or no-voltage contacts for event input.

PNP types are also available.

4.7 kΩ

3.9 kΩ

12 V

TIMING

COM

D1

D6

S-TMR: D2

HOLD: D3

RESET: D4

ZERO: D5

COM

D6

K3HB-S

N/C

560 Ω

750 Ω

E1

E2

E3

E4

E5

E6

12 V

Input B

Input A

COM

Input A

Input B

BCD Output Cable

Model Shape Pin arrangement

K32-BCD

K3HB end

38 mm 46.5 mm

Cover: HDR-E50LPA5

(manufactured by Honda Tsushin Co., Ltd)

Connector: HDR-E50MAG1

(manufactured by Honda Tsushin Co., Ltd)

300 mm

D-sub connector (37-pin female)

Cover: 17JE-37H-1A (manufactured by DDK)

Connector: Equivalent to 17JE-13370-02

(manufactured by DDK)

Stand: 17L-002A

Connected device end

(PLC, display device, etc.)

manufactured by DDK

COMMON

1

20

4

4

2

10

1

21

8

3

2

0

22

10

4

4

5

8

6

1

7

7

2

1

10

8

4

9

8

10

1

11

2

2

10

12

4

13

8

14

1

15

2

3

10

16

4

17

8

18

1

4

10

19

2

OVER

23

DATA VALI

24

RUN

25

COMMON

26

REQUEST

27

MAX REQ.

28

MIN REQ.

29

HOLD

30

RESET

31

POLARITY

32

HH

33

H

34

PASS

35

L

36

LL

37

COMMON

Note: The BCD Output Cable has a D-sub plug. Cover: 17JE-37H-1A (manufactured by DDK); Connector: equivalent to 17JE-23370-02 (D1) (manufactured by DDK)

Special Cable (for Event Inputs with 8-pin Connector)

Model Appearance Wiring

K32-DICN

910

12

Cable marking

3,000 mm

(3 m)

Pin No.

1

2

3

4

5

6

7

8

9

10

Signal name

N/C

S-TMR

HOLD

RESET

N/C

COM

BANK4

BANK2

BANK1

COM

Digital Indicators K3HB-X/-V/-H/-S 25

■ Main Functions

e

e

Measurement

Input Calculation

S

• Two input circuits are provided. The input ranges for these circuits

can be set independently. For example, one can be set to 4 to 20

mA and the other can be set to 1 to 5 V.

• In addition to calculations such as K (constant)–A (input for one circuit), it is possible to perform calculations based on the inputs for

both circuits, such as A+B and A–B, making it possible to perform

thickness measurement and level-difference measurement using

displacement and length-measuring sensors.

Timing Hold

X V H S

Normal

• Continuously performs measurement and always outputs based on

comparative results.

Input

H comparative set value

Measurement value

Time

H output

Peak Hold/Bottom Hold

• Measures the maximum (or minimum) value in a specified period.

Input

Measurement value

ON

TIMING

input

OFF

Peak hold value

Bottom hold value

Time

A

K

K−A

Sampling Hold

• Holds the measurement at the rising edge of the TIMING signal.

Input

Measurement value

ON

TIMING

input

OFF

Sampling hold valu

Time

Peak-to-peak Hold

• Measures the difference between the maximum and minimum val-

ues in a specified period.

Input

Measurement value

ON

TIMING

input

OFF

(b1−a1)

b1

a1

'a2

Peak-to-peak value

(b2−a2)

'b2

Time

Scaling Average Processing

Scaling converts input signals in any way required before displaying

them. The values can be manipulated by shifting, inverting, or +/–

reversing.

Display value

Display value 2

(

dsp.a2

Display value 1

(

dsp.a1

)

)

Input value 1

Input value 2

(inp.a1)

(inp.a2)

(Scaling) (Reverse scaling)

Display value

Display value 2

Display value 1

Input value

Teaching

Settings for scaling can be made using the present measurement

values instead of inputting values with the SHIFT and UP Keys. This

is a convenient function for making the settings while monitoring the

operating status.

Standby Sequence

X V S X V H S

Turns the comparative output OFF until the measurement value

enters the PASS range.

Average processing of input signals with extreme changes or noise

smooths out the display and makes control stable.

(

dsp.a2

)

(

dsp.a1

)

Input value 2

X V S

X V H S

(

inp.a2

)

Input value 1

(

inp.a1

Input valu

)

Previous Average Value Comparison

Slight changes can be removed from input signals to detect only

extreme changes.

Temperature Input Shift

Shifts the temperature input value.

Supported Models

The models that support the functions shown here are indicated by symbols as follows:

K3HB-X

X

K3HB-V

V

K3HB-H

H

K3HB-S

S

X V H S

H

26 Digital Indicators K3HB-X/-V/-H/-S

■ Input Compensation/Display

Forced-zero

Forces the present value to 0. (Convenient for setting reference values or deducting tares for weight measurement.)

Tare Z e ro

Shifts the current value measured with a forced zero to 0 again. It is

possible to measure two or more compounds separately and then, by

releasing the tare zero and forced-zero, measure the combined total.

Zero-trimming

Compensates for mild fluctuations in input signals due to factors

such as sensor temperature drift, based on OK (PASS) data at measurement. (This function can be used with sampling hold, peak hold,

or bottom hold.)

Zero-limit

Changes the display value to 0 for input values less than the set

value. It is enabled in normal mode only. (This function can be used,

for example, to stop negative values being displayed or to eliminate

flickering and minor inconsistencies near 0.)

Display

X V S

V S

X V H S

X V H S

The current display value can be selected from the present value, the

maximum value, and the minimum value.

It is possible to specify (i.e., restrict) the values that the smallest displayed digit can change by. For example, if the setting is 2, the smallest digit will only take the values 0, 2, 4, 6, or 8 and if the setting is 5,

it will only take the values 0 or 5. If the setting is 10, it will only take

the value of 0.

Zero-limit

setting

Input

Display Refresh Period

The display refresh period can be lengthened to reduce flickering

and thereby make the display easier to read.

Display Color Selection

Values can be displayed in either red or green. With comparative output models, the display color can also be set to change according to

the status of comparative outputs (e.g., green to red or red to green).

X

Digital Indicators K3HB-X/-V/-H/-S 27

■ Output

e

Comparative Output Pattern

X V H S

The output pattern for comparative outputs can be selected. In addition to high/low comparison with set values, output based on level

changes is also possible. (Use the type of output pattern appropriate

for the application.)

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Output HH

Output H

Output PASS

Output L

Output LL

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Output HH

Output H

Output PASS

Output L

Output LL

Output Logic

Standard Output

Zone Output

Measurement

value

Higher

Lower

ON

OFF

Measurement

value

Higher

Lower

ON

OFF

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Output HH

Output H

Output PASS

Output L

Output LL

Level Output

X V H S

Measurement

Reverses the output operation of comparative outputs for comparative results.

value

ON

OFF

Higher

Lower

Hysteresis

X V H S

Prevents comparative output chattering when the measurement

value fluctuates slightly near the set value.

Example: Comparative Output Pattern (Standard Output)

Comparative set value H

Comparative set value L

Comparative output H

Comparative output L

Startup Compensation Timer

Hysteresis

Hysteresis

X V H S

Measurement can be stopped for a set time using external input.

Input

H comparative set value

Tim

H output

H input

PASS Output Change

Startup compensation time

set time

X V H S

Comparative results other than PASS and error signals can be output

from the PASS output terminal.

■ Dimensions

101.2

91

96

Terminal cover (included)

Character Size for Main Display (mm)

PV display SV display

14.2

100

(112)

12

1.3

48

7.6

95*

2

*DeviceNet models: 97 mm

Terminal: M3, Terminal Cover: Accessory

3.5

4.9

44.8

Panel Cutout Dimensions

75 min.

+0.8

92

0

120 min.

45

+0.6

0

28 Digital Indicators K3HB-X/-V/-H/-S

■ Wiring Precautions