Page 1

SJDE-@APA-OY

A

A

Junma Pulse servo drive

A new concept in drive simplicity

Save space, save time

• Ultra compact drive size reduces panel space

• Tuning-less technology, no gain parameters need to

be set

• Peak torque 300% of nominal for 3 seconds

• High response, high speed, high torque and high

accuracy

• Fully “Parameter-less” just plug and run

• Position resolution of 10,000 steps per revolution

Ratings

• 230 VAC Single-phase 100 W to 750 W (2.39 Nm)

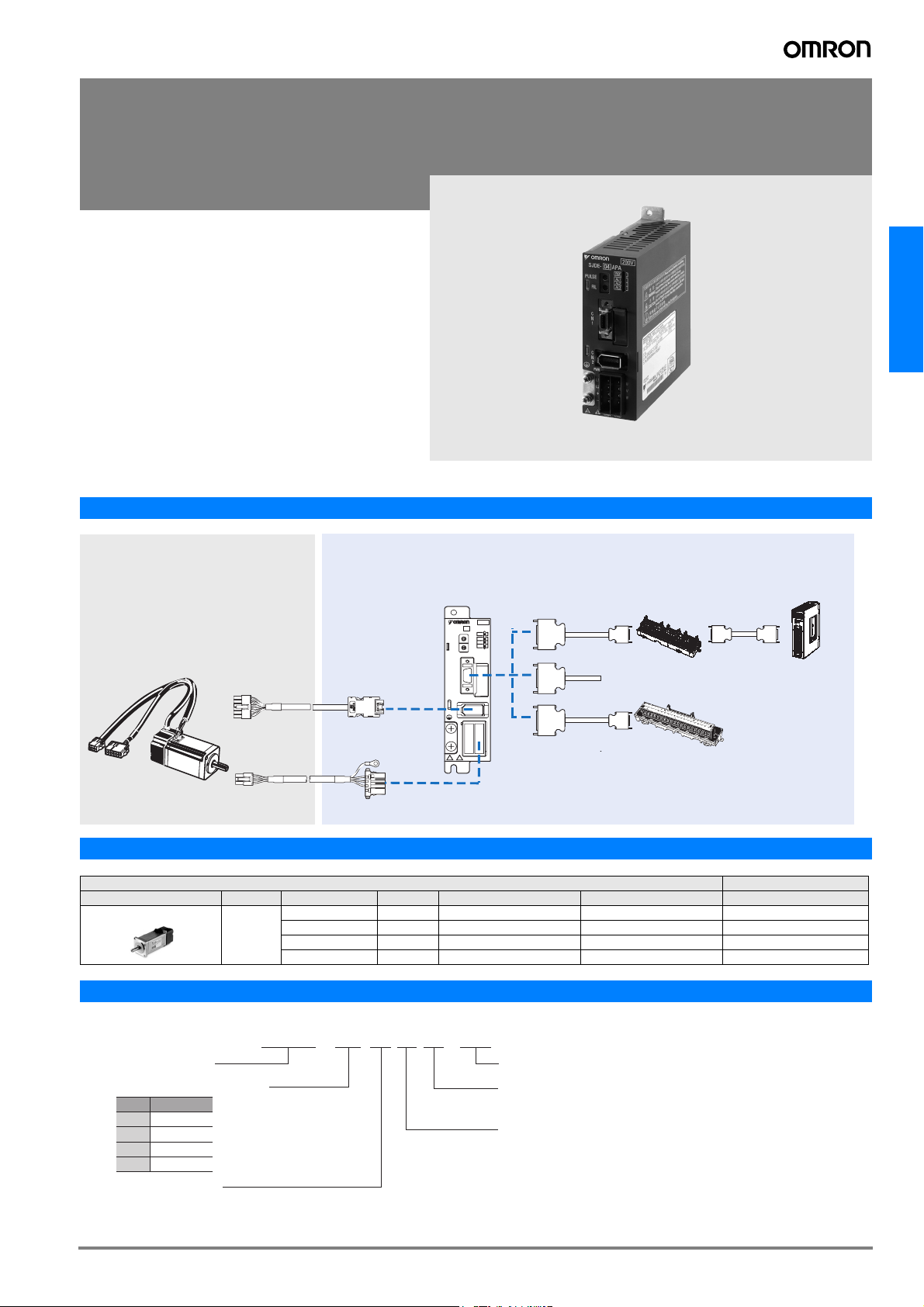

System Configuration

Junma PULSE Servo Drive Configuration

AC Servo systems

Junma Pulse

Servo Drive

200V

SJDE- 02 APA-OY

REF

D

C

B

E

A

F

9

0

8

1

AL1

7

PULSE

2

6

3

5

4

AL2

D

C

B

E

A

F

AL3

9

0

8

1

7

2

FIL

6

3

5

Junma Servo Motor

3,000 rpm

(100-750 W)

Encoder cable

Power cable

4

C

N

1

C

N

2

PWR

U

L1

V

L2

W

+

-

CNA CNB

Connector terminal block

Position control

unit

General purpose controller

(with pulse output)

Servomotor / Servo Drive Combination

Junma Servomotor Junma servo drive

-1

SJME- (3000 min

) 200 V 0.318 Nm 100 W SJME-01AMB41-OY SJME-01AMB4C-OY SJDE-01APA-OY

Voltage Rated Torque Capacity Model without brake Model with brake Pulse Control

0.637 Nm 200 W SJME-02AMB41-OY SJME-02AMB4C-OY SJDE-02APA-OY

1.27 Nm 400 W SJME-04AMB41-OY SJME-04AMB4C-OY SJDE-04APA-OY

2.39 Nm 750 W SJME-08AMB41-OY SJME-08AMB4C-OY SJDE-08APA-OY

Servo Drive Type Designation

SJDE - 02 A P A - OY

JUNMA servo drive

pplicable servomotor capacity

Output (W)

Code

100

01

200

02

400

04

750

08

Power supply voltage

: 200 VAC

OMRON YASKAWA Motion Control BV

Design revision

A: Standard

Control Interface specification

N: MECHATROLINK-II

P: Pulse train input

169Junma Pulse servo drive

Page 2

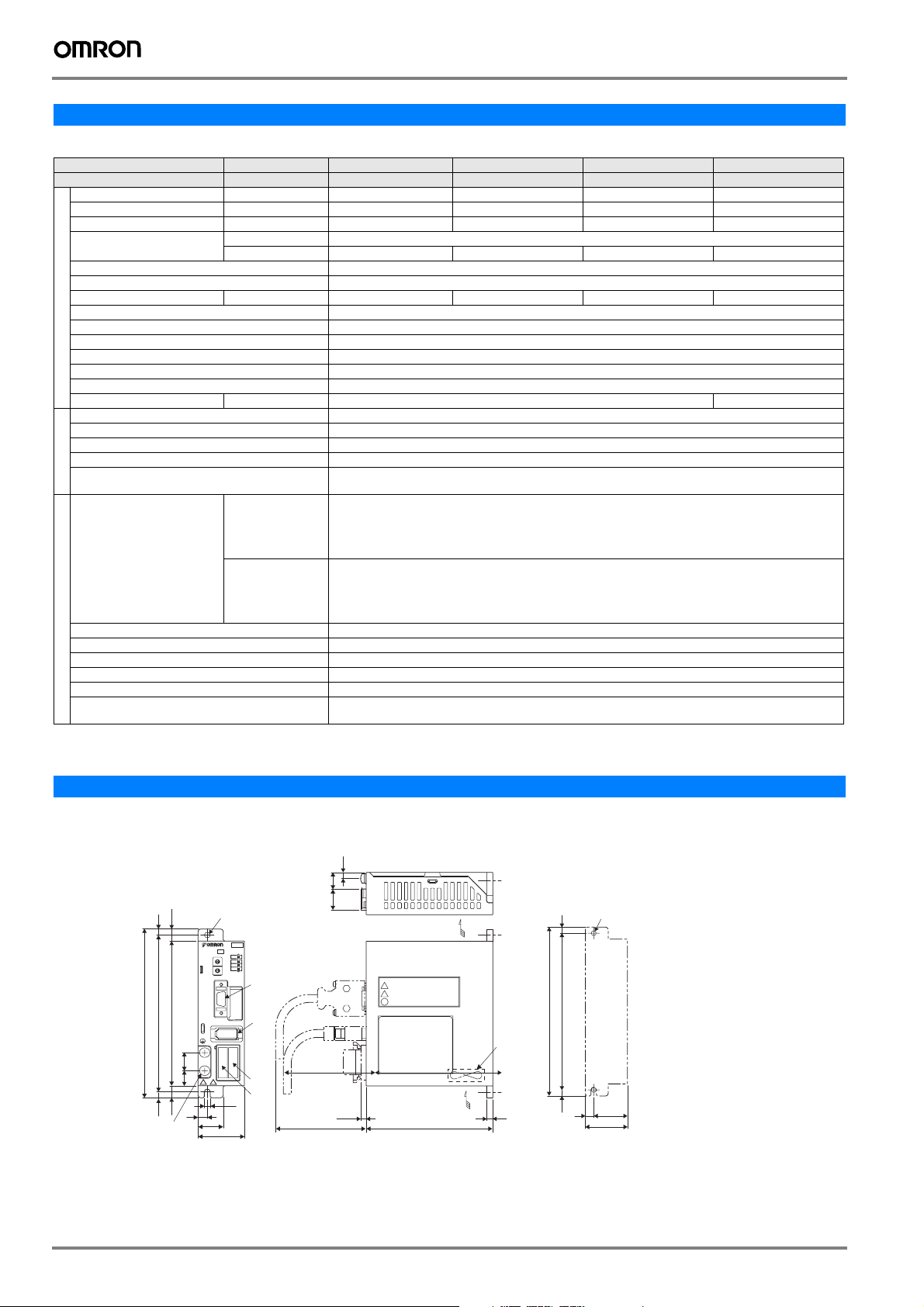

Servo Drive Specifications

Junma Pulse Servo Drives

Servo Drive Type SJDE- @ 01APA-OY 02APA-OY 04APA-OY 08APA-OY

Applicable servomotor SJME-@ 01A@ 02A@ 04A@ 08A@

Max. Applicable Motor capacity W 100 200 400 750

Continuous output current Arms 0.84 1.1 2.0 3.7

Max. output current Arms 2.5 3.3 6.0 11.1

Input power supply

(Main circuit and control circuit)

Control Method PWM control, sine wave current drive system

Feedback Analogue incremental encoder (10000 steps per revolution)

Allowable load inertia

*1

Usage / storage temperature 0 to +55° C / -20 to 70° C

Usage / storage humidity 90%RH or less (non-condensing)

Basic specifications

Altitude 1000 m or less above sea level

Vibration/shock Resistance 4.9m/s

Configuration Base mounted

Cooling method Forced cooling (built-in fan)

Approx. mass kg 0.5 1.0

Dynamic brake (DB) Operated at main power OFF, servo alarm, servo OFF.(OFF after motor stops; ON when motor power is off.)

Regenerative processing Optional (If the regenerated energy is too large, install a regenerative unit JUSP-RG08D)

LED display 5 (PWE, REF, AL1, AL2, AL3)

Reference filter Select one of eight levels with FIL switch

Protection Speed errors, overload, encoder errors, voltage errors, overcurrents, disablement of the built-in cooling fan,

Built-in functions

Input signal for reference

Designated pulse type and

pulse resolution with PULSE

switch.

Clear input signal Clears the positioning error when turned ON

I/O Signals

Servo ON input signal Turns the servomotor ON or OFF

Alarm output signal OFF if an alarm occurs. (Note: OFF for 2s when power is turned ON)

Brake output signal External signal to control brakes. Turn ON to release the brake

Positioning completed output signal ON if the current position is equal to the reference position ±10 pulses.External signal to control brakes.

Origin output signal ON if the motor is at the origin. (Width: 1/500 rev)

Voltage Single-phase, 200 to 230 VAC, + 10 to -15% (50/60 Hz)

Capacity KVA 0.40 0.75 1.2 2.2

kg⋅m

2

-4

0.6 × 10

2

(0.5G) / 19.6m/s2 (2G)

3.0 × 10

-4

5.0 × 10

-4

10.0 × 10

system errors

Pulse type Select one of the following signals:

1. CCW + CW

2. Sign + pulse train

3. CCW + CW (logic reversal)

4. Sign + pulse train (logic reversal)

Pulse resolution Select one of the following signals:

1. 1000 pulses/rev (Open collector/line driver) 75 kpps max.

2. 2500 pulses/rev (Open collector/line driver) 187.5 kpps max.

3. 5000 pulses/rev (Line driver) 375 kpps max.

4. 10000 pulses/rev (Line driver) 750 kpps max.

(Note:Use the pulse edge that changes the signal from OFF to ON)

-4

Note: *1. Value without external regeneration unit

Dimensions

Junma pulse control servo drives

SJDE-01, 02APA-OY (200V, 100 to 200W)

15

12.5

4.5 dia.holes

SJDE- 02 APA-OY

D

C

B

E

A

F

9

0

8

1

7

PULSE

2

6

3

5

4

D

C

B

E

A

F

9

0

8

1

7

2

FIL

6

3

5

4

C

N

1

C

N

2

PWR

L1

L2

+

-

CNA CNB

4.5

7

19

35

200V

REF

AL1

AL2

AL3

CN1

CN2

U

V

W

CNB

CNA

(75)

10

5

130

120

140

(5)

(10)

Ground Terminal

2-M4 screws

(14)

(17)

(5)

(4.5)

AIR FLOW

AIR FLOW

105

Cooling fan

5

Mounting Hole Diagram

2-M4 screw holes

5

)

140

130 ± 0.5

Mounting pitch

(

(5)

(28)

7

35

Approx. mass : 0.5 kg

Units in mm

170 AC Servo Systems

Page 3

SJDE-04APA-OY (200V, 400W)

5

10

130

140

120

(5)

(10)

Ground Terminal

2-M4 screws

15

12.5

4.5 dia.holes

SJDE- 04 APA-OY

D

C

B

E

A

F

9

0

8

1

7

PULSE

2

6

3

5

4

D

C

B

E

A

F

9

0

8

1

7

2

FIL

6

3

5

4

C

N

1

C

N

2

PWR

L1

L2

+

-

CNA CNB

4.5

7

19

40

200V

REF

AL1

AL2

AL3

CN1

CN2

U

V

W

CNB

CNA

SJDE-08APA-OY (200V, 800W)

(75)

(14)(17)

(44)(17)

(5)

(4.5)

(35)

AIR FLOW

AIR FLOW

105

Cooling fan

5

Mounting Hole Diagram

5130 ± 0.5

)

140

Mounting pitch

(

(5)

7

2-M4 mounting holes

Visible outline

Approx. mass : 0.5 kg

(33)

40

AC Servo systems

Units in mm

17

4.5 dia.holes

SJDE- 08 APA-OY

D

C

B

E

A

F

9

0

8

1

7

PULSE

2

6

3

5

4

D

C

B

E

A

F

9

0

8

1

7

2

FIL

6

3

5

4

C

N

1

C

N

2

PWR

L1

L2

+

-

CNA CNB

4.5

70

200V

REF

AL1

AL2

AL3

CN1

CN2

U

V

W

CNB

CNA

140

130 5(5)

Ground Terminal

2-M4 screws

10(10) 120

12.5 15

14 30

Ordering Information

Junma Pulse Servo Drive Configuration

(Refer to servo motor chapter)

A

Junma Servo Motor

3,000 rpm

(100-750 W)

D

Encoder cable

Power cable

C

(75)

(4.5)

Filter

Junma Pulse

B

Servo Drive

PULSE

J

K

AIR FLOW

AIR FLOW

145

SJDE- 02 APA-OY

D

C

B

E

A

F

9

0

8

1

7

2

6

3

5

4

D

C

B

E

A

F

9

0

8

1

7

2

FIL

6

3

5

4

C

N

1

C

N

2

PWR

L1

L2

+

-

CNA CNB

200V

REF

AL1

AL2

AL3

U

V

W

Cooling fan

5

F

H

I

Mounting Hole Diagram

5

)

140

130 ± 0.5

Mounting pitch

(

(5)

141730

2-M4 mounting holes

Visible outline

Approx. mass : 1 kg

(13)

70

E

G

I

Connector terminal block

General purpose controller

(with pulse output)

Units in mm

Position control

unit

Junma Pulse servo drive 171

Page 4

Servomotors and Servo drives

Symbol Specifications A Servomotor model B Servo drive model

Voltage Encoder and Design Rated Torque Capacity Pulse Control

AB

1 Phase

200 VAC

Analogue Incremental

Encoder

Straight shaft with key

Without brake 0.318 Nm 100 W SJME-01AMB41-OY SJDE-01APA-OY

0.637 Nm 200 W SJME-02AMB41-OY SJDE-02APA-OY

1.27 Nm 400 W SJME-04AMB41-OY SJDE-04APA-OY

2.39 Nm 750 W SJME-08AMB41-OY SJDE-08APA-OY

With brake 0.318 Nm 100 W SJME-01AMB4C-OY SJDE-01APA-OY

0.637 Nm 200 W SJME-02AMB4C-OY SJDE-02APA-OY

1.27 Nm 400 W SJME-04AMB4C-OY SJDE-04APA-OY

2.39 Nm 750 W SJME-08AMB4C-OY SJDE-08APA-OY

Control cables (for CN1) Filters

Symbol Name Compatible units Model

E

F

G

H

I

Servo relay

unit

Cable to

servo drive

Cable to position

control unit

Control cable

Connector

terminal

block cable

Connector

terminal

block

Units: CS1W-NC113/133,

CJ1W-NC113/133,

C200HW-NC113

Units:

CS1W-NC213/233/413/433,

CJ1W-NC213/233/413/433,

C200HW-NC213/413

Units: CQM1H-PLB21 and

CQM1-CPU43-V1

Use with

CJ1M-CPU21/22/23

For the servo relay unit

XW2B-@@J6-@B,

XW2B-20J6-8A,

XW2B-40J6-9A

CQM1H-PLB21 and

CQM1-CPU43-V1

CS1W-NC113 and

C200HW-NC113

CS1W-NC213/413 and

C200HW-NC213/413

CS1W-NC133 0.5 m XW2Z-050J-A12

CS1W-NC233/433 0.5 m XW2Z-050J-A13

CJ1W-NC113 0.5 m XW2Z-050J-A16

CJ1W-NC213/413 0.5 m XW2Z-050J-A17

CJ1W-NC133 0.5 m XW2Z-050J-A20

CS1W-NC233/433 0.5 m XW2Z-050J-A21

CJ1M-CPU21/22/23 0.5 m XW2Z-050J-A26

For general-purpose controllers

For general-purpose

controllers

- XW2B-20J6-1B

(1 axis)

- XW2B-40J6-2B

(2 axes)

- XW2B-20J6-3B

(1 axis)

- XW2B-20J6-8A

(1 axis)

- XW2B-40J6-9A

(2 axes)

1 m XW2Z-100J-B17

2 m XW2Z-200J-B17

0.5 m XW2Z-050J-A3

1 m XW2Z-100J-A3

0.5 m XW2Z-050J-A8

1 m XW2Z-100J-A8

0.5 m XW2Z-050J-A9

1 m XW2Z-100J-A9

1 m XW2Z-100J-A12

1 m XW2Z-100J-A13

1 m XW2Z-100J-A16

1 m XW2Z-100J-A17

1 m XW2Z-100J-A20

1 m XW2Z-100J-A21

1 m XW2Z-100J-A26

1 m R7A-CPZ001S

or JZSP-CHI003-01

2 m R7A-CPZ002S

or JZSP-CHI003-02

3 m JZSP-CHI003-03

1 m XW2Z-100J-B19

2 m XW2Z-200J-B19

- XW2B-20G5

Symbol Applicable servo

J

drive

SJDE-01APA-OY

SJDE-02APA-OY

SJDE-04APA-OY

SJDE-08APA-OY 9A 1.7 mA R7A-FIZP109-BE

Rated

Leakage

current

current

5A 1.7 mA 250 VAC

Rated

voltage

1- phase

Filter model

R7A-FIZP105-BE

Regenerative Unit Model (Option)

Symbol Specifications Model (Omron) Model (Yaskawa)

K

External regenerative unit

(Optional)

R88A-RG08UA JUSP-RG08D

Connectors

Specification Model (Omron) Model (Yaskawa)

Control I/O connector (for CN1) R7A-CNA01R JZSP-CHI9-1

Power input connector (for CNB).

(Included in drive the box)

R7A-CNZ01P JZSP-CHG9-1

Power and encoder cables

Note: CD Refer to the Junma servo motor section for motor cables or connec-

tors selection

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I71E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

172 AC Servo Systems

Loading...

Loading...