Page 1

New Product

Digital Counter

H7CZ

Easy to Use and Easy to Read.

Basic Features

• Character height of 10 mm for better readability.

• Operation is simplified by the Up Key for each digit.

Safety and Reliability

• Power supply circuit and input circuits are isolated inside the

Counter.

• Set value limit function prevents unexpected operation of output

devices caused by setting mistakes.

• Output counter function helps in managing the service life of the

Counter or the load.

Other Features

• Waterproof, dust-proof structure (UL508 Type 4X and IP66).

• Key protection.

Refer to Safety Precautions on page 17.

For the most recent information on models that have been certified for

safety standards, refer to your OMRON website.

Features

Basic Features

Better Readability

Character Height of 10 mm with a Wide Viewing Angle.

Easy to read from the top,

bottom, and sides.

(actual size)

10 mm

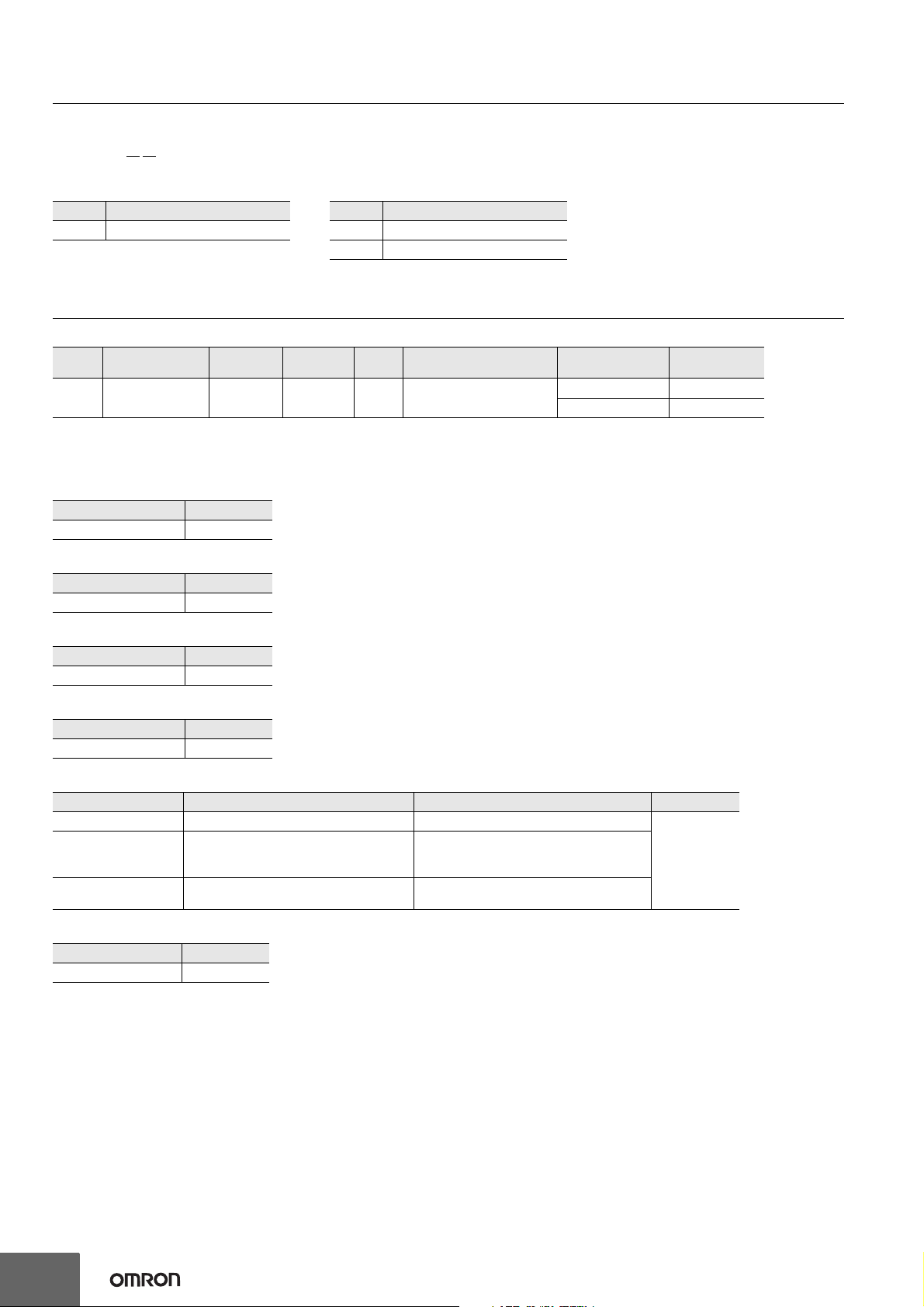

The Easiest Operation

Operation is simplified by the Up Key for

each digit.

Safety and Reliability

Isolated Power Supply and Input Circuits

Power supply circuit and input circuits are isolated inside the Counter.

Previous non-isolated counters had wiring restrictions and could be

damaged if wired incorrectly. The H7CZ removes these worries.

Clear

Confirmation

Set Value Limit

You can set an upper limit for the set value to prevent unexpected

operation of output devices caused by setting mistakes.

Setting the upper limit of the set

value enables worry-free operation.

For 1,000 pieces

No overflow

Output Counter

The output counter counts the number of times the output turns ON

(alarms can be displayed and the count can be monitored in

increments of 1,000 operations). This counter is useful in managing

the service life of the Counter or the load.

Other Features

Waterproof, Dust-proof Structure (UL508 Type

4X and IP66)

Worry-free application is possible in locations subject to water.

Note: When the Y92S-29 Waterproof Packing is used.

Key Protection

Select from any of seven protection patterns. Use the best one for the

application.

1

Page 2

H7CZ

Model Number Structure

Model Number Legend

H7CZ-L@@

12

1. External connections 2. Supply voltage

Symbol Meaning

8 8-pin socket

Symbol Meaning

None 100 to 240 VAC at 50/60 Hz

D1 12 to 24 VDC/24 VAC at 50/60 Hz

Ordering Information

List of Models

Type Configuration

H7CZ

Note: The functions that are provided depend on the model. Check detailed specifications before ordering.

• 1-stage preset

counter

External

connections

8-pin socket 1-stage 6 digits Contact output (SPDT)

Settings

Accessories (Order Separately)

Soft Cover

Model Page

Y92A-48F1 9

Display

digits

Outputs

Power supply

voltage

100 to 240 VAC H7CZ-L8

12 to 24 VDC/24 VAC H7CZ-L8D1

Model

Hard Cover

Model Page

Y92A-48 9

Flush Mounting Adapter

Model Page

Y92F-30 9

Waterproof Packing

Model Page

Y92S-29 9

Connection Sockets

Model Type Remarks Page

P2CF-08 Front-connecting Socket ---

P2CF-08-E Front-connecting Socket (Finger-safe Type)

P3G-08 Back-connecting Sockets

Round crimp terminals cannot be used on

Finger-safe Sockets.

Use forked crimp terminals.

A Y92A-48G Terminal Cover can be used with

the Socket to create a finger-safe construction.

Terminal Covers for P3G-08 Back-connecting Socket

Model Page

Y92A-48G 10

10

2

Page 3

H7CZ

H7CZ Multifunction Preset Counter

Specifications

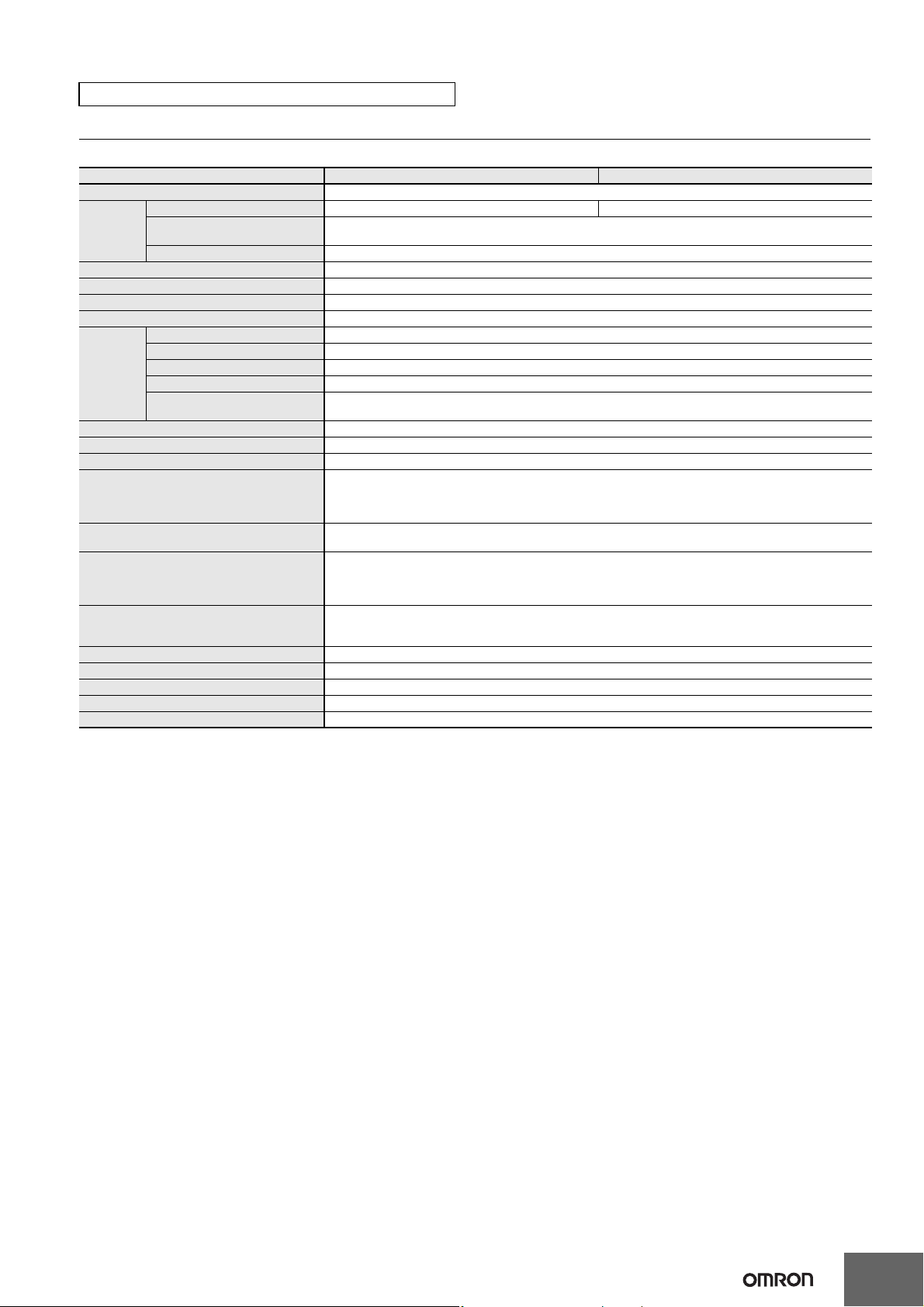

Ratings

Item Models H7CZ-L8 H7CZ-L8D1

Configuration 1-stage preset counter

Power supply voltage

Ratings

Mounting method Flush mounting or surface mounting

External connections 8-pin socket

Degree of protection IEC IP66, UL508 Type 4X (indoors) for panel surface only and only when Y92S-29 Waterproof Packing is used.

Input signals Count, Reset

Counter

Prescaling function Yes (0.001 to 99.999)

Decimal point adjustment Yes (rightmost 3 digits)

Sensor waiting time 290 ms max. (Control output is turned OFF and no input is accepted during sensor waiting time.)

Input method

Control output

Display

Digits

Memory backup EEPROM (overwrites: 100,000 times min.) that can store data for 10 years min.

Operating temperature range −10 to 55°C (−10 to 50°C if Counters are mounted side by side) (with no icing or condensation)

Storage temperature range −25 to 70°C (with no icing or condensation)

Operating humidity range 25% to 85%

Front panel color Light gray (5Y7/1)

*1. Do not use the output from an inverter as the power supply.The ripple must be 20% maximum for DC power.

*2. The display is lit only when the power is ON. Nothing is displayed when power is OFF.

Operating voltage fluctuation

range

Power consumption Approx. 9.4 VA at 100 to 240 VAC, Approx. 7.2 VA/4.7 W at 24 VAC/12 to 24 VDC

Maximum counting speed 30 Hz or 10 kHz (switchable) (ON/OFF ratio 1:1)

Input mode Increment, Decrement

Output mode N, F, C, R, K-1, P, Q, and A.

One-shot output time 0.01 to 99.99 s

Reset system

*2

*1

100 to 240 VAC, 50/60 Hz 24 VAC, 50/60 Hz or 12 to 24 VDC

85% to 110% of rated supply voltage (12 to 24 VDC: 90% to 110%)

External (minimum reset signal width: 1 ms or 20 ms, selectable), Manual, and Automatic reset (internal according

to C, R, P, and Q mode operation)

No-voltage inputs:

ON impedance: 1 kΩ max. (Leakage current: 12 mA at 0 Ω)

ON residual voltage: 3 V max.

OFF impedance: 100 kΩ min.

3 A at 250 VAC/30 VDC, resistive load (cosφ=1), Minimum applied load: 10 mA at 5 VDC (failure level: P, reference

value)

LCD

Character height

Count value: 10 mm

Set value: 6 mm

6 digits

−99999 to 999999

(−5 digits to +6 digits)

3

Page 4

H7CZ

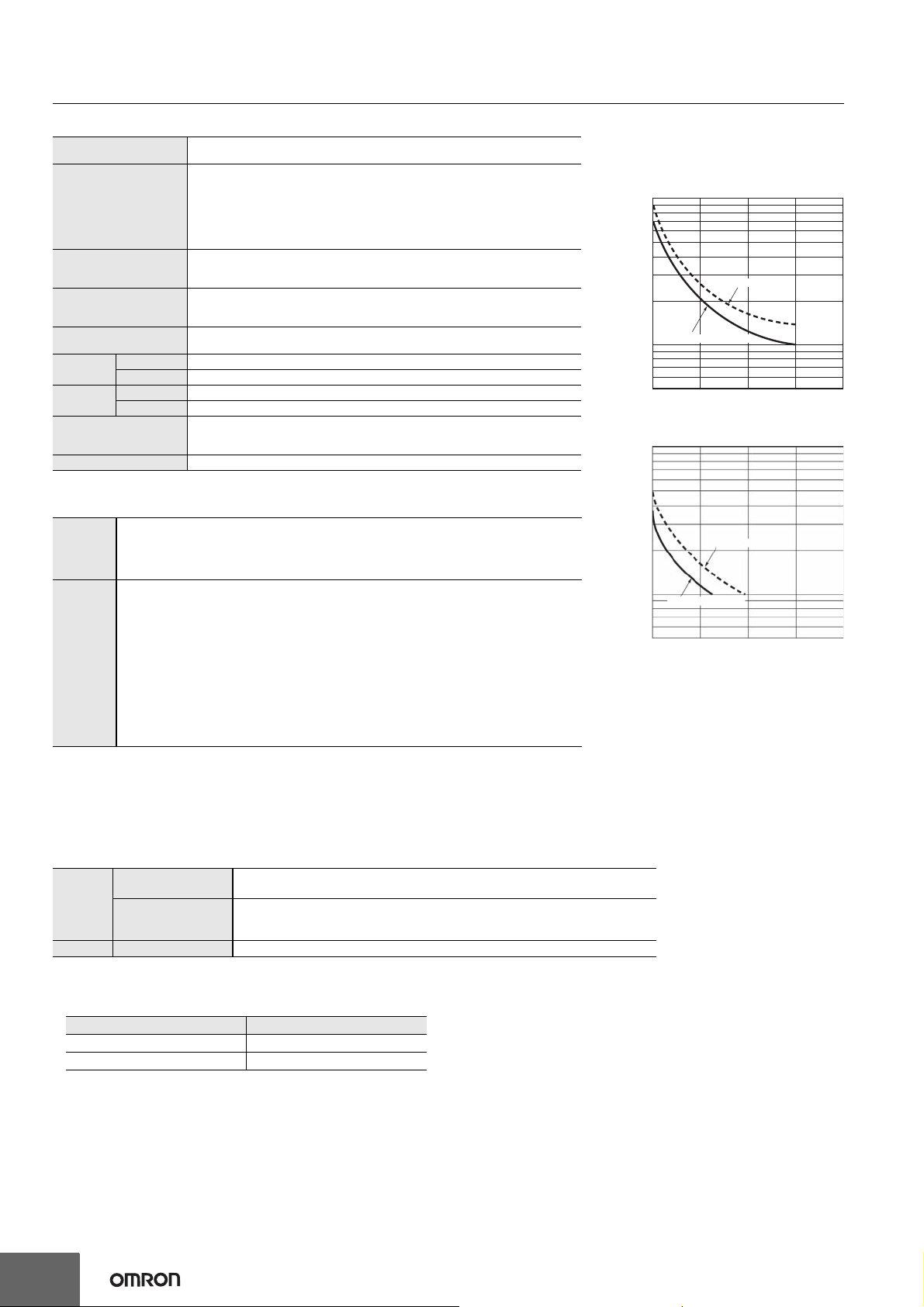

* Refer to the Life-test Curve.

Applicable Standards

*1. The following safety standards apply to H7CZ.

cUL (Listing): Applicable when an OMRON P2CF(-E) Socket is used.

cUR (Recognition): Applicable when any other socket is used.

*2. Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

Insulation resistance

100 MΩ min. (at 500 VDC) between current-carrying terminals and exposed noncurrent-carrying metal parts, and between non-continuous contacts

Dielectric strength

2,000 VAC, 50/60 Hz for 1 min between current-carrying metal parts and non-currentcarrying metal parts

2,000 VAC, 50/60 Hz for 1 min between power supply and input circuit (1,000 VAC for

24 VAC/12 to 24 VDC)

1,000 VAC, 50/60 Hz for 1 min between control output, power supply, and input circuit

(2,000 VAC)

1,000 VAC, 50/60 Hz for 1 min between non-continuous contacts

Impulse withstand voltage

3.0 kV between power terminals (1.0 kV for models with 24 VAC/12 to 24 VDC)

4.5 kV between current-carrying terminals and exposed non-current-carrying metal

parts (1.5 kV for models with 24 VAC/12 to 24 VDC)

Noise immunity

±1.5 kV between power terminals

±600 V between input terminals

Square-wave noise by noise simulator (pulse width: 100 ns/1 μs, 1-ns rise)

Static immunity

Malfunction: 8 kV

Destruction: 15 kV

Vibration

resistance

Destruction 10 to 55 Hz with 0.75-mm single amplitude each in three directions for 2 h each

Malfunction 10 to 55 Hz with 0.35-mm single amplitude each in three directions for 10 min each

Shock resistance

Destruction 300 m/s2 each in three directions

Malfunction 100 m/s2 each in three directions

Life expectancy

Mechanical: 10,000,000 operations min.

Electrical: 100,000 operations min. (3 A at 250 VAC, resistive load, ambient

temperature condition: 23°C)

*

Weight Approx. 100 g (Counter only)

Approved

safety

standards

cULus (or cURus): UL508/CSA C22.2 No. 14

*1

EN 61010-1 (IEC 61010-1): Pollution degree 2/overvoltage category II

B300 PILOT DUTY

1/4 HP 120 VAC, 1/3 HP, 240 VAC, 3 A resistive load

VDE0106/P100 (finger protection)

EMC

(EMI) EN61326-1

*2

Emission Enclosure: EN 55011 Group 1 class A

Emission AC mains: EN 55011 Group 1 class A

(EMS) EN61326-1

*2

Immunity ESD: EN 61000-4-2: 4 kV contact discharge;

8 kV air discharge

Immunity RF-interference: EN 61000-4-3: 10 V/m (Amplitude-modulated, 80 MHz to 1 GHz);

10 V/m (Pulse-modulated, 900 MHz ±5 MHz)

Immunity Conducted Disturbance: EN 61000-4-6: 10 V (0.15 to 80 MHz)

Immunity Burst: EN 61000-4-4: 2 kV power-line;

1 kV I/O signal-line

Immunity Surge: EN 61000-4-5: 1 kV line to lines (power and output lines);

2 kV line to ground (power and output lines)

Immunity Voltage Dip/Interruption: EN 61000-4-11: 0.5 cycle, 100% (rated voltage)

Life-test Curve (Reference

Values)

Resistive load

Inductive load

A current of 0.15 A max. can be switched at

125 VDC (cosφ=1) and current of 0.1 A max. can

be switched if L/R=7 ms. In both cases, a life of

100,000 operations can be expected.

1,000

700

500

300

100

70

50

Load current (A)

01 2 34

30 VDC (cosφ=1)

250 VAC (cosφ=1)

No. of operations (

×

10

3

)

Characteristics

)

1,000

3

10

×

700

500

I/O Functions

Using as a Counter

Inputs

Outputs OUT Outputs signals according to the specified output mode when a set value is reached.

*1. For information on operation of I/O functions, refer to page 14 and page 15.

*2. In elapsed time mode, the present value returns to 0; in remaining time mode, the present value returns to the set value.

• The following table shows the delay from when the reset signal is input until the output is turned OFF. (Reference values)

Minimum reset signal width Output delay time

4

*1

Count

Reset

• Reads counting signals.

• Increment and decrement inputs accepted.

• Resets present value and outputs.

• Counting cannot be performed during reset input.

• Reset indicator is lit while reset input is ON.

1 ms 0.8 to 1.2 ms

20 ms 15 to 25 ms

*2

300

No. of operations (

100

70

50

01 2 34

30 VDC (L/R=7 ms)

250 VAC (cosφ=1)

Load current (A)

Page 5

Connections

H7CZ

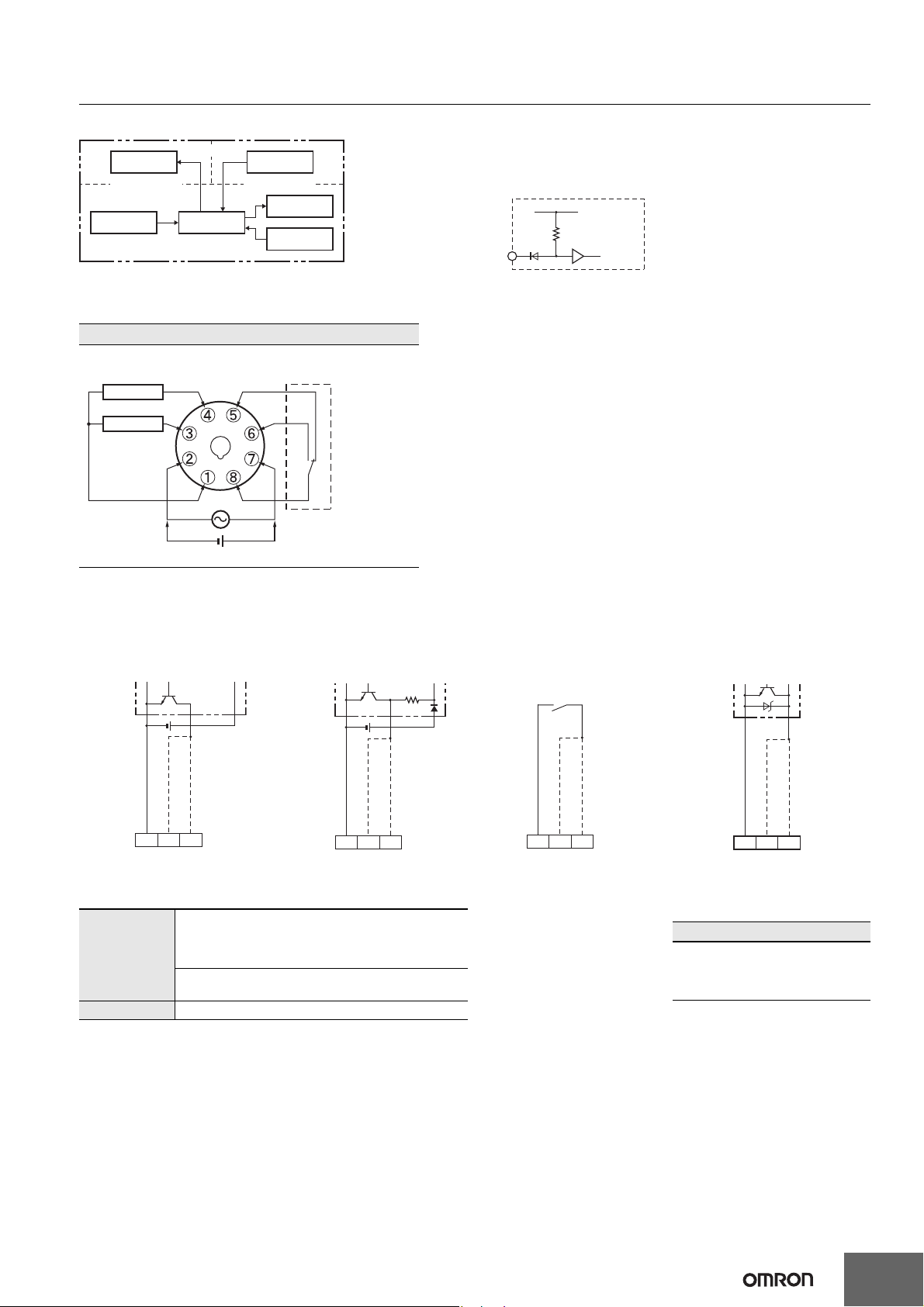

Block Diagram

Output circuit

(Basic insulation)

Input circuits

(Basic insulation)

Internal

control circuit

Power supply

circuit

(Basic insulation)

Display circuit

Key switch

circuit

Terminal Arrangement

Confirm that the power supply meets specifications before use.

H7CZ-L8/L8D1

1-stage Contact Output

Internal circuit

Count

Reset

Contact Output

0V

(+) (−)

Input Circuits

Count and Reset Input

No-voltage Inputs (NPN Inputs)

+14V

1 kΩ

IN

Internal

circuit

Input Connections

The inputs of the H7CZ-L8@ are no-voltage (short-circuit or open) inputs.

No-voltage Inputs (NPN Inputs)

Open Collector Voltage Output Contact Input DC Two-wire Sensor

PLC or

sensor

Reset input

Count input

0 V for inputs

134

Note: Operates with transistor ON.

No-voltage Input Signal Levels

Short-circuit level (transistor ON)

• Residual voltage: 3 V max.

No-contact input

Contact input Use contacts which can adequately switch 5 mA at 10 V.

Note: The DC voltage must be 30 VDC max.

• Impedance when ON: 1 kΩ max.

(The leakage current is approx. 12 mA when the impedance is 0 Ω.)

Open level (transistor OFF)

• Impedance when OFF: 100 kΩ min.

Sensor

Reset input

Count input

0 V for inputs

134

Note: Operates with transistor ON.

Reset input

Count input

0 V for inputs

134

Note: Operates with relay ON.

Reset input

0 V for inputs

134

Note: Operates with transistor ON.

Applicable Two-wire Sensor

• Leakage current: 1.5 mA max.

• Switching capacity: 5 mA min.

• Residual voltage: 3 VDC max.

• Operating voltage: 10 VDC

Count input

5

Page 6

H7CZ

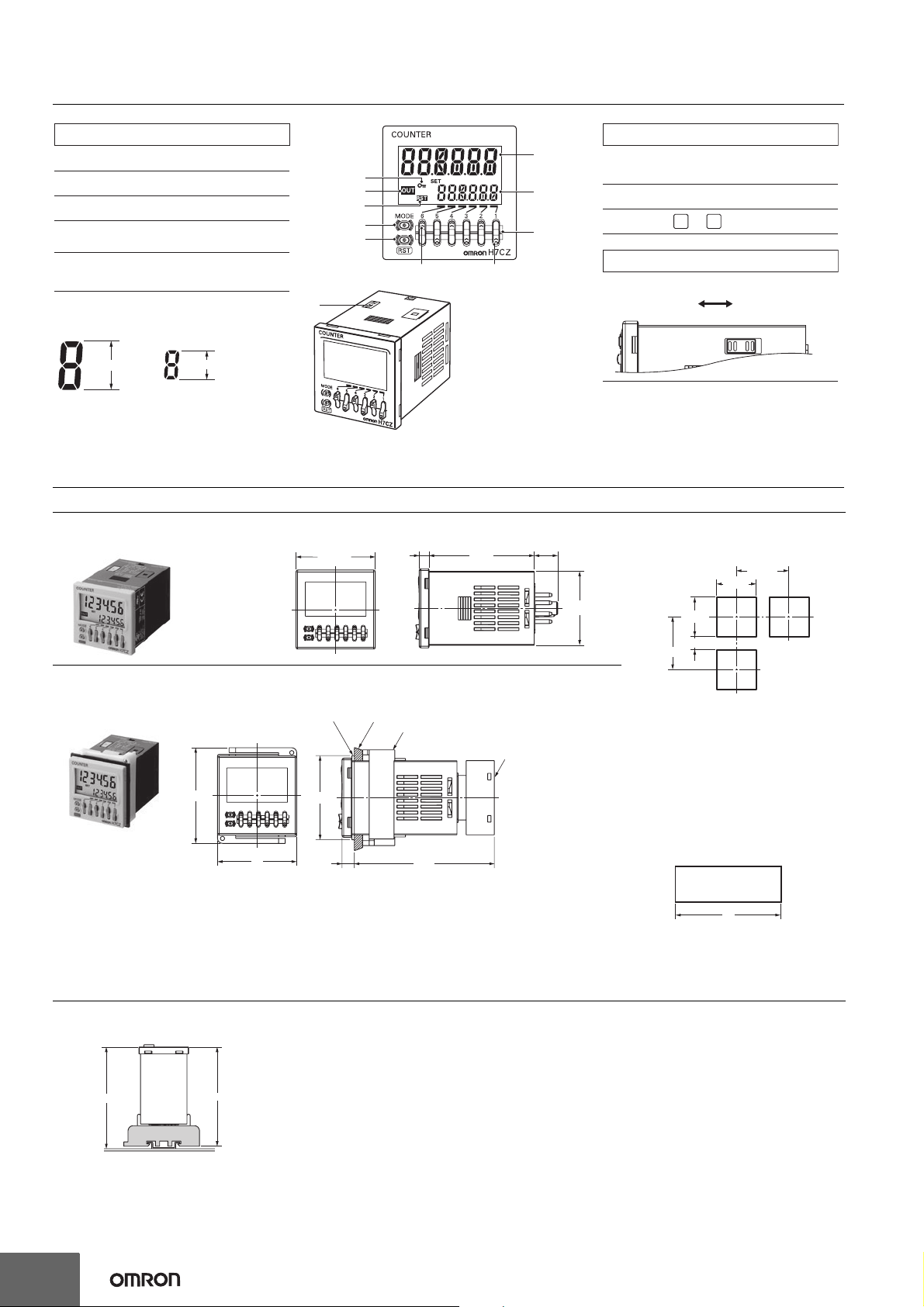

Nomenclature

Display Section

1. Key Protect Indicator

2. Control Output Indicator

3. Reset Indicator

4. Present Value (Main Display)

(Character height: 10 mm)

5. Set value (Sub-display)

(Character height: 6 mm)

Character Size

for Main Display

10 mm

Character Size

for Sub-display

6 mm

4

1

2

3

6

7

1st digit 6th digit

5

8

6. Mode Key

(Changes modes and setting items.)

7. Reset Key

8. Up Keys to

9. Key-protect Switch

9

(Default setting) OFF

Operation Keys

1 6

Switches

ON

(Disable)

(Enable)

Dimensions (Unit: mm)

Counters

H7CZ-L8/-L8D1 (Flush Mounting/Surface Mounting Models)

48 × 48

6

63.7

14.2

44.8×44.8

Panel Cutouts

Panel cutouts are as shown below. (according

to DIN43700).

60 min.

+

0.6

45

0

+

0.6

45

0

15 min.

60 min.

Dimensions with Flush Mounting Adapter

H7CZ-L8/-L8D1 (Adapter and Waterproof Packing Ordered Separately)

Waterproof Packing

58

48

(51)

Y92F-30 (order separately)

Pane lY92S-29 (order separately)

Flush Mounting Adapter

84.87.5

Dimensions with Front Connecting Socket

*

92.3

H7CZ

-L8@

90

P3G-08 (order

separately)

Back-connecting

Socket

Note: 1. The mounting panel thickness

should be 1 to 5 mm.

2. To allow easier operation, it is

recommended that Adapters be

mounted so that the gap between

sides with hooks is at least 15 mm

(i.e., with the panel cutouts

separated by at least 60 mm).

3. It is possible to horizontally mount

Timers side by side. Attach the

Flush Mounting Adapters so that

the surfaces without hooks are on

the sides of the Timers. If they are

mounted side-by-side, waterresistance will be lost.

n Units mounted

side by side

A

A=(48n−2.5)

With Y92A-48F1 attached.

A={48n−2.5+(n−1)×4}

With Y92A-48 attached.

A=(51n−5.5)

+1

−0

+1

−0

+1

−0

P2CF-08(-E) (order separately)

Front Connecting Socket

* These dimensions depend on the kind of DIN Track. (Reference value)

6

Page 7

Accessories (Order Separately)

Note: Depending on the operating environment, the condition

of resin products may deteriorate, and may shrink or

become harder. Therefore, it is recommended that resin

products are replaced regularly.

H7CZ

Soft Cover

Y92A-48F1

Hard Cover

Y92A-48

Protecting the Counter in Environments Subject to Oil

The H7CZ's panel surface is water-resistive (conforming to IP@6,

UL Type 4X) and so even if drops of water penetrate the gaps

between the keys, there will be no adverse effect on internal circuits.

If, however, there is a possibility of oil being present on the

operator's hands, use the Soft Cover. The Soft Cover ensures

protection equivalent to IP54F against oil. Do not, however, use the

H7CZ in locations where it would come in direct contact with oil.

Flush Mounting Adapter

Y92F-30

Order this Flush Mounting Adapter separately

if it is required.

Waterproof Packing

Y92S-29

The Waterproof Packing will deteriorate, harden, and shrink

depending on the application environment. To ensure maintaining the

IP@6, UL Type 4X waterproof level, periodically replace the

Waterproof Packing. The periodic replacement period will depend on

the application environment. You must confirm the proper

replacement period. Use 1 year or less as a guideline. If the

Waterproof Packing is not replaced periodically, the waterproof level

will not be maintained. It is not necessary to mount the Waterproof

Packing if waterproof construction is not required.

Order this Waterproof Packing

separately if it is required.

The Waterproof Packing can be used

to achieve IP66 protection.

7

Page 8

H7CZ

Connection Sockets

Front Connecting Socket

Model Dimensions

P2CF-08

Two, 4.5-dia. holes

50 max.

20.3 max.

Terminal arrangement

and internal connections

Mounting hole

dimensions

P2CF-08-E

(Finger Safe Terminal)

Eight, M3.5 x 7.5 sems screws

Two, 4.5-dia. holes

Eight, M3.5 x 7.5 set screws

P2CF-08-E

50 max.

40

10A250VAC

RESISTIVE

70 max.

4

7.8

±0.2

4365

70 max.

1278

4

7.8

3

21.5 max.

3

1.3

5

35.4

4.5

20.3

19

35.4

4.5

Note: Round crimp terminals cannot be used on Finger-safe Sockets. Use forked crimp terminals.

Back-connecting Sockets

Model Dimensions

P3G-08

45

27 dia.

45

4.9 17

Note: A Y92A-48G Terminal Cover can be used with the Socket to create a finger-safe construction.

Terminal arrangement

and internal connections

6 5 4 3

7 8 1 2

(Top View)

6543

7812

(Bottom View)

Two, M4 or 4.5-dia. holes

±0.2

40

Note: The Socket can

also be mounted

to DIN track.

Terminal Covers for P3G-08 Back-connecting Socket

Model Dimensions

Y92A-48G

34

Note: The Terminal Cover can be used with a Back-mounting Socket (P3G-08) to create a finger-safe construction.

Twelve, 6.4-dia. holes

Y92A-48G

UP

P C

47.4

47.7 × 47.7

16.5

24.6

48 × 48

27.6

8

Page 9

Optional Products for Track Mounting

H7CZ

Mounting Track

PFP-100N

PFP-50N

Mounting Track

PFP-100N2

End Plate

PFP-M

Spacer

PFP-S

4.5

4.5

15 25 2510

10

15 25 25

M4 × 8

pan head

screw

50

11.5

1,000 (500)*

1,000

10

M4 spring washer

5

25 25 1510

1025 25

10

16

12

7.3

15 (5)*

* The values shown in parentheses

are for the PFP-50N.

±

0.3

6.2

1.8

1

35.5 35.3

1.8

1.3

4.8

35

242735

±0.15

±0.3

1

±0.15

27

1

16

29.2

1.5

Note: Order Spacers in increments of 10.

44.3

34.8

16.5

9

Page 10

H7CZ

Operating Procedures

Setting Procedure Guide

Change to Function Setting Mode.

Power ON

*1

3 s min.

Run mode

*1. If the mode is switched to the function setting mode during operation, operation will continue.

*2. Changes made to settings in function setting mode are enabled for the first time when the mode is changed to run mode. Also,

when settings are changed, the counter is reset (present value initialized and output turned OFF) on returning to run mode.

Function

setting mode

*2

3 s min.

The characters displayed in reverse video are the default settings.

For details on operations and display in run mode, refer to page 13.

The display depends on the selected configuration.

Function Setting Mode

Input mode

(CNTM)

Output mode

(OUTM)

Output

time

(OTIM)

Counting

speed

(CNTS)

Reset input

signal width

(IFLT)

Decimal

point position

(DP)

• Set the input mode using the U Key.

down

up

(DOWN)(UP)

• Set the output mode using the U Key.

f

n

(N) (F) (C) (R) (K-1) (P) (Q) (A)

crk-1 p q a

• Set each digit using the individual U Key.

0.01 99.990.50

Note: Displayed only when the output mode is C, R, K-1, P, Q, or A.

(0.50 s) (99.99 s)(0.01 s)

• Set the counting speed using the U Key.

30hz

(30 Hz) (5 kHz)

• Set the Reset input signal width using the U Key.

1ms

20ms

(1 ms)(20 ms)

• Set the decimal point position using the U Key.

(No decimal

point)

(One digit after

decimal point)

(Two digits after

decimal point)

(Three digits after

decimal point)

10

Prescale

value

(PSCL)

To next pageFrom next page

• Set each digit using the individual U Key.

0.001

1.000

99.999

(99.999)(1.000)(0.001)

Page 11

H7CZ

page

From previous

page

To previous

Function Setting Mode

Set value

upper limit

(SL-H)

Key protect

level

(KYPT)

*3

Output ON

count alarm set

value/monitor

value

• Set each digit using the individual U Key.

9999991

(999999)(1)

• Set the key protect level using the U Key.

kp-1 kp-2 kp-3 kp-4 kp-5 kp-6 kp-7

(KP-1) (KP-2) (KP-3) (KP-4) (KP-5) (KP-6) (KP-7)

*3. Set each digit using the individual U Key.

Output

ON count

alarm set

value

Output

ON count

monitor

value

99990

(9999 × 1000 times)(0 × 1000 times)

Note: The monitor value is only displayed. It cannot be set.

11

Page 12

H7CZ

Explanation of Functions

Input Mode (cntm)

Set increment mode (UP) or decrement mode (DOWN) as the input

mode.

Output Mode (outm)

Set the way that control output for the present value is output. The

possible settings are N, F, C, R, K-1, P, Q, and A.

One-shot Output Time (otim)

Set the one-shot output time (0.01 to 99.99 s) for control output.

One-shot output can be used only when C, R, K-1, P, Q, or A is

selected as the output mode.

Counting Speed (cnts)

Set the maximum counting speed (30 Hz/5 kHz) for count inputs.

Reset Input Signal Width (iflt)

Set the reset input signal width (20 ms/1 ms) for reset inputs.

If contacts are used for the input signal, set the input signal width to

20 ms. Processing to eliminate chattering is performed for this setting.

Decimal Point Position (dp)

Decide the decimal point position for the present value.

Prescale Value (pscl)

Pulses input to the counter are converted according to the specified

prescale value.

(Setting range: 0.001 to 99.999 for 6-digit models.)

Example: To display the feed distance for systems that output 25

pulses for a feed length of 0.5 m in the form @@.@@ m:

1. Set the decimal point position to 2 decimal places.

2. Set the prescale value to 0.02 (0.5 ÷ 25).

Set Value Upper Limit (sl-h)

Set the upper limit for the set value when it is set in run mode.

The setting can be made from 1 to 999999 for 6-digit models.

Key Protect Level (kypt)

Set the key protect level.

Refer to Key Protect Level on page 16.

Output ON Count Alarm Set Value (on-a)

Set the alarm value for the output ON count.

The limit can be set to between 0

(9,999,000 times). Only the underlined values are set. The alarm will

be disabled if 0 is set.

If the total ON count of the output exceeds the alarm set value, e3

will be displayed on the Timer to indicate that the output ON count

alarm value was exceeded. Refer to Self-diagnostic Function on

page 16 for information on the e3 display.

× 1000 (0 times) and 9999 × 1000

Output ON Count Monitor Value (on-c)

The monitor value is only displayed. It cannot be set.

The output ON count will be 1,000 times the displayed value.

0.5 m

25 pulses

Encoder

• Observe the following points when setting a prescale value.

Set the set value to a value less than {Maximum countable value

− Prescale value}.

Example: If the prescale value is 1.25 and the counting range is

0.000 to 999.999, set the set value to a value less than 998.749

(= 999.999 − 1.25).

If the set value is set to a value greater than this, output will not turn

ON.

• Output will turn ON, however, if a present value overflow occurs

(FFFFFF).

Note: If the prescale value setting is incorrect, a counting error will

occur. Check that the settings are correct before using this

function.

12

Page 13

Operation in Run Mode

• Set values for each digit as required using the U Key.

Present value

Set value

• Present Value

Shows the present count value.

• Set Values

Set the set values.

When the present value reaches the set value, a signal

is output according to the specified output mode.

Input Modes and Present Value

I/O Functions for Counter Operation

UP (Increment) Mode DOWN (Decrement) Mode

Count input

H

L

Count input

H7CZ

H

L

4

Present value

1

0

0

* Counting starts when the count input is turned ON after turning ON the power.

3

2

n

n−1

Present value

0

n−2

n−3

n−4

Note: 1. The meaning of the H and L symbols in the tables is explained

below.

Symbol

Input method

H Short-circuit

L Open

No-voltage input

(NPN input)

13

Page 14

H7CZ

Input/Output Mode Settings

Self-holding

output

(The one-shot output time can be

set in the range 0.01 to 99.99s.)

One-shot

Output

mode

setting

N

F

C

Reset

999999

Set value

OUT

Reset

999999

Set value

OUT

Reset

999999

Set value

OUT

Input mode

UP DOWN

Operation after count

completion

The outputs and present

value display are held

0

until reset is input.

The present value

display continues to

increase/decrease.

0

0

The outputs are held until

reset is input.

As soon as the count

reaches SV, the present

value display returns to

the reset start status.

The present value display

does not show the

present value upon countup.

The outputs repeat oneshot operation.

R

K-1

Reset

999999

Set value

OUT

Reset

999999

Set value

OUT

The present value

display returns to the

reset start status after

0

the one-shot output time.

The outputs repeat oneshot operation.

The present value

display continues to

increase/decrease.

0

14

Page 15

Self-holding

output

(The one-shot output time can be

set in the range 0.01 to 99.99s.)

One-shot

H7CZ

Output

mode

setting

P

Q

A

Reset

999999

Set value

OUT

Reset

999999

Set value

Reset

999999

Set value

OUT

Input mode

UP DOWN

0

0

0

Operation after

count completion

The present value

display does not

change during the

one-shot output time

period, but the actual

count returns to the

reset start status.

The output will return

to one-shot mode.

The outputs repeat

one-shot operation.

The present value

continues to increase/

decrease for the oneshot output time, but

returns to the reset

start status after the

one-shot output time

has elapsed.

The outputs repeat

one-shot operation.

The present value

display and OUT selfholding output is held

until reset is input.

OUT

Note: 1. When the present value reaches 999999, it returns to 0.

2. Counting cannot be performed during reset input.

3. If reset is input while one-shot output is ON, one-shot output turns OFF.

4. If there is power failure while output is ON, output will turn ON again when the power supply has recovered.

For one-shot output, output will turn ON again for the duration of the output time setting once the power supply has recovered.

5. Do not use the counter function in applications where the count may be completed (again) while one-shot output is ON.

6. The setting range is 0 to 999,999.

15

Page 16

H7CZ

Key Protect Level

It is possible to prevent setting errors by prohibiting the use of certain operation keys by specifying the key protect level (KP-1 to KP-7) when the

key-protect switch is set to ON.

The key protect level is set in the function setting mode. The key protect indicator is lit when the key-protect switch is ON.

*

(Disabled)

* Factory-set to OFF

OFF

Key protect indicator

ON

(Enabled)

Level Description

KP-1

(default setting)

KP-2 Invalid Invalid Valid

KP-3 Invalid Valid Invalid

KP-4 Invalid Invalid Invalid

KP-5 Invalid Invalid Invalid

KP-6 Invalid Valid Valid

KP-7 Invalid Invalid Valid

Changing modes* Reset Key Up Keys

Invalid Valid Valid

Details

* Changing mode to function setting mode.

Self-diagnostic Function

The following displays will appear if an error occurs.

Main display Sub-display Description Output status Correction method Set value after reset

*1

-----

*1

fffff

e1 Not lit CPU error OFF

e2 Not lit Memory error (RAM) OFF Turn ON the power again. No change

e2 sum Memory error (EEPROM)

*4

e3

*1. Display flashes.(1-second cycles)

*2. This occurs if the present value or total count value falls below −99999.

*3. This includes times when the life of the EEPROM has expired.

*4. The normal display and e3 will appear alternately.

When the Reset Key is pressed, e3 will not be displayed even if the alarm set value is exceeded.

(Monitoring is possible, however, because the counter will continue without the output ON count being cleared.)

*5. This is displayed if the alarm value setting for either of the two outputs is exceeded if a model with two outputs is used.The total ON count will not be cleared by

using the Reset Key.

No change Present value underflow

No change Present value overflow No change

No change Output Counter Overflow No change Reset Key

*2

No change

*3

OFF Reset Key Factory setting

Either press the Reset Key or turn

ON reset input.

Either press the Reset Key or turn

ON reset input.

Either press the Reset Key or

reset the power supply.

*5

No change

No change

No change

No change

16

Page 17

Safety Precautions for All H7CZ Series (Common)

CAUTION

Do not allow pieces of metal, wire clippings, or fine

metallic shavings or fillings from installation to enter

the product. Doing so may occasionally result in

electric shock, fire, or malfunction.

Minor injury due to explosion may occasionally occur.

Do not use the Counter where subject to flammable or

explosive gas.

Fire may occasionally occur. Tighten the terminal

screws to the rated torque.

P2CF Socket terminals: 4.4 lb-in (0.5 N·m)

Minor injury due to electric shock may occasionally

occur. Do not touch any of the terminals while power

is being supplied. Be sure to mount the terminal cover

after wiring.

The life expectancy of the output relay varies

considerably according to its usage. Use the output

relay within its rated load and electrical life

expectancy. If the output relay is used beyond its life

expectancy, its contacts may become fused or there may be a

risk of fire. Also, be sure that the load current does not exceed

the rated load current and when using a heater, be sure to use a

thermal switch in the load circuit.

Minor electric shock, fire, or malfunction may

occasionally occur. Do not disassemble, modify, or

repair the Counter or touch internal components.

Precautions for Safe Use

• The panel surface of the H7CZ is water-resistant (conforming to

NEMA4, IP66, UL Type 4X (Indoor Use Only). To protect the

internal circuits from water penetration through the space between

the H7CZ and operating panel, waterproof packing is included.

Attach the Y92F-30 Adapter with sufficient pressure with the

reinforcing screws so that water does not penetrate the panel.

0.5 to 1 mm

It is recommended that the

space between the screw

head and the Adapter be

0.5 to 1 mm.

• When mounting the Counter to a panel, tighten the two mounting

screws alternately, a little at a time, so as to keep them at an equal

tightness. If the panel screws are tightened unequally, water may

enter the panel.

• Store the Counter at the specified temperature. If the Counter has

been stored at a temperature of less than

−10°C, allow the Counter to stand at room temperature for at least

3 hours before use.

• Mounting the Counter side-by-side may reduce the life

expectancies of internal components.

• Use the Counter within the specified ranges for the ambient

operating temperature and humidity.

• Do not use in the following locations:

• Locations subject to sudden or extreme changes in temperature.

• Locations where high humidity may result in condensation.

• Do not use the Counter outside of the rated ranges for vibration,

shock, water exposure, and oil exposure.

• Do not use this Counter in dusty environments, in locations where

corrosive gasses are present, or in locations subject to direct

sunlight.

• Install the Counter well away from any sources of static electricity,

such as pipes transporting molding materials, powders, or liquids.

• Internal elements may be destroyed if a voltage outside the rated

voltage range is applied.

• Be sure that polarity is correct when wiring the terminals.

• Separate the Counter from sources of noise, such as devices with

input signals from power lines carrying noise, and wiring for I/O

signals.

• Do not connect more than two crimp terminals to the same

terminal.

• Up to two wires of the same size and type can be inserted into a

single terminals.

• Use the specified wires for wiring. Applicable Wires: AWG 18 to

AWG 22, solid or twisted, copper

• Install a switch or circuit breaker that allows the operator to

immediately turn OFF the power, and label it to clearly indicate its

function.

• Approximately 14 V is output from the input terminals. Use a

sensor that contains a diode.

• Use a switch, relay, or other contact so that the rated power supply

voltage will be reached within 0.1 seconds. If the power supply

voltage is not reached quickly enough, the Counter may

malfunction or outputs may be unstable.

• Use a switch, relay, or other contact to turn the power supply OFF

instantaneously. Outputs may malfunction and memory errors may

occur if the power supply voltage is decreased gradually.

• When changing the set value during operation, because the H7CZ

uses a constant read-in system, output will turn ON if the set value

is equal to the present value.

• When changing the comparison value during operation, because

the H7CZ uses a constant read-in system, the output status will

change if the comparison value is changed to a value on the other

side of the present value.

• Do not use organic solvents (such as paint thinners or benzine),

strong alkali, or strong acids. They will damage the external finish.

• Confirm that indications are working normally, including the LCD.

The indicator, LCD, and resin parts may deteriorate more quickly

depending on the application environment, preventing normal

indications. Periodic inspection and replacement are required.

• The waterproof packing may deteriorate, shrink, or harden

depending on the application environment. Periodic inspection and

replacement are required.

H7CZ

Sensor

Diode

Input0 V

17

Page 18

H7CZ

Precautions for Correct Use

• An inrush current of approx. 10 A will flow for a short time when the

power supply is turned ON. If the capacity of the power supply is

not sufficient, the Counter may not start. Be sure to use a power

supply with sufficient capacity.

• Maintain voltage fluctuations in the power supply within the

specified operating voltage range.

• When turning the power ON and OFF, input signal reception is

possible, unstable, or impossible as shown in the diagram below.

Power

ON

supply

OFF

200 ms 5 ms0 to 90 ms 0 to 1 s

Input Impossible

• Inrush current generated by turning ON or OFF the power supply

may deteriorate contacts on the power supply circuit. Turn ON or

OFF to a device with the rated current of more than 10 A.

• If the prescale value setting is incorrect, a counting error will occur.

Check that the settings are correct before using this function.

• Make sure that all settings are appropriate for the application.

Unexpected operation resulting in property damage or accidents

may occur if the settings are not appropriate.

• Do not leave the Counter for long periods at a high temperature

with output current in the ON state. Doing so may result in the

premature deterioration of internal components (e.g., electrolytic

capacitors).

• EEPROM is used as backup memory when the power is

interrupted. The write life of the EEPROM is 100,000 writes. The

EEPROM is written at the following times:

• When the power supply is turned OFF

• When switching from Configuration Selection Mode or Function

Setting Mode to Run Mode

• Dispose of the product according to local ordinances as they apply.

Unstable

Poss ible

Unstable

Impossible

Conformance to EN/IEC Standards

• When conforming to EMC standards, refer to the information

provided in this datasheet for cable selection and other conditions.

• This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take

adequate measures to reduce interference.

• Basic insulation is provided between power supply and input

terminals, between power supply and output terminals, and

between input and output terminals.

• When double insulation or reinforced insulation is required, apply

double insulation or reinforced insulation as defined in IEC 60664

that is suitable for the maximum operating voltage with clearances

or solid insulation.

• Connect the input and output terminals to devices that do not have

any exposed charged parts.

18

Page 19

Warranty and Application Considerations

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have

any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS,

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer's application or use of the products.

Take all necessary steps to determine the suitability of the product for the systems, machines, and equipment with which it will

be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

Disclaimers

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons. Consult with

your OMRON representative at any time to confirm actual specifications of purchased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Page 20

OMRON Corporation Industrial Automation Company

Tokyo, JAPAN

Contact: www.ia.omron.com

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2009 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

CSM_7_3_0715

Cat. No. M082-E1-01

Printed in Japan

0709

Loading...

Loading...