Page 1

New Product

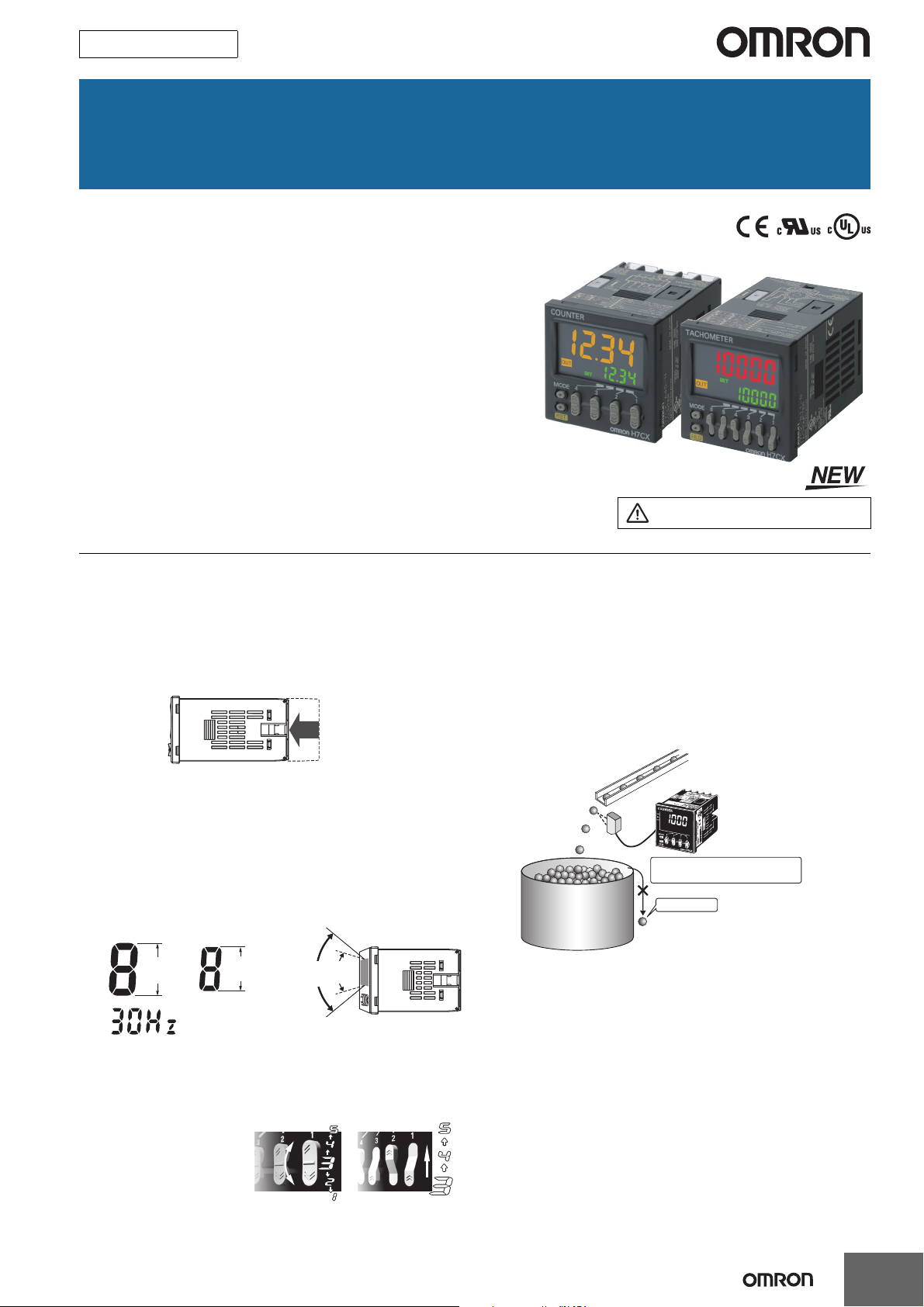

Multifunction Counter/Tachometer

H7CX-@-N

Ultra-compact Counter Provides More

Complete Functionality.

Basic Features

• Short body with depth of only 59 mm (for 12 to 24-VDC Models with Screw

Terminals).

• Better readability with character height of 12 mm on 4-digit models and 10 mm

on 6-digit models.

• The present value display characters can be switched between red, green, and

orange.

Safety and Reliability

• New set value limit and counter functions have been added.

Other Features

• Front Panel can be changed to white or light gray.

• Models with two independent tachometer inputs have been added to the series.

*1.For 100 to 240-VAC Models with Screw Terminals: 78 mm, Models with Sockets: 63.7 mm (case dimension).

*2.The H7CX-A11 and H7CX-R11 have only red characters.

*3.The Front Panel can be replaced with an optional Front Panel (except for Tachometer-only Models).

*1

*2

*3

Refer to Safety Precautions on page 52.

Features

Basic Features

Ultra Short Body

The body depth has been greatly reduced. Helps in making thinner

control panels.

12 to 24-VDC Models with Screw Terminals: 59 mm

100 to 240-VAC Models with Screw Terminals: 78 mm*

Models with Sockets: 63.7 mm (case dimension)

* Power supply circuit and input circuits are isolated for safety and reliability.

New models

Easier to Read

For better readability, the character height for the present value

display is 12 mm on models with 4 digits, the largest class in the

industry. The wide viewing angle and brightness provide excellent

visibility. The number of display segments has also been increased to

make settings easier to understand, and the present value display

can be switched between red, green, and orange so that output status

can be seen from a distance.

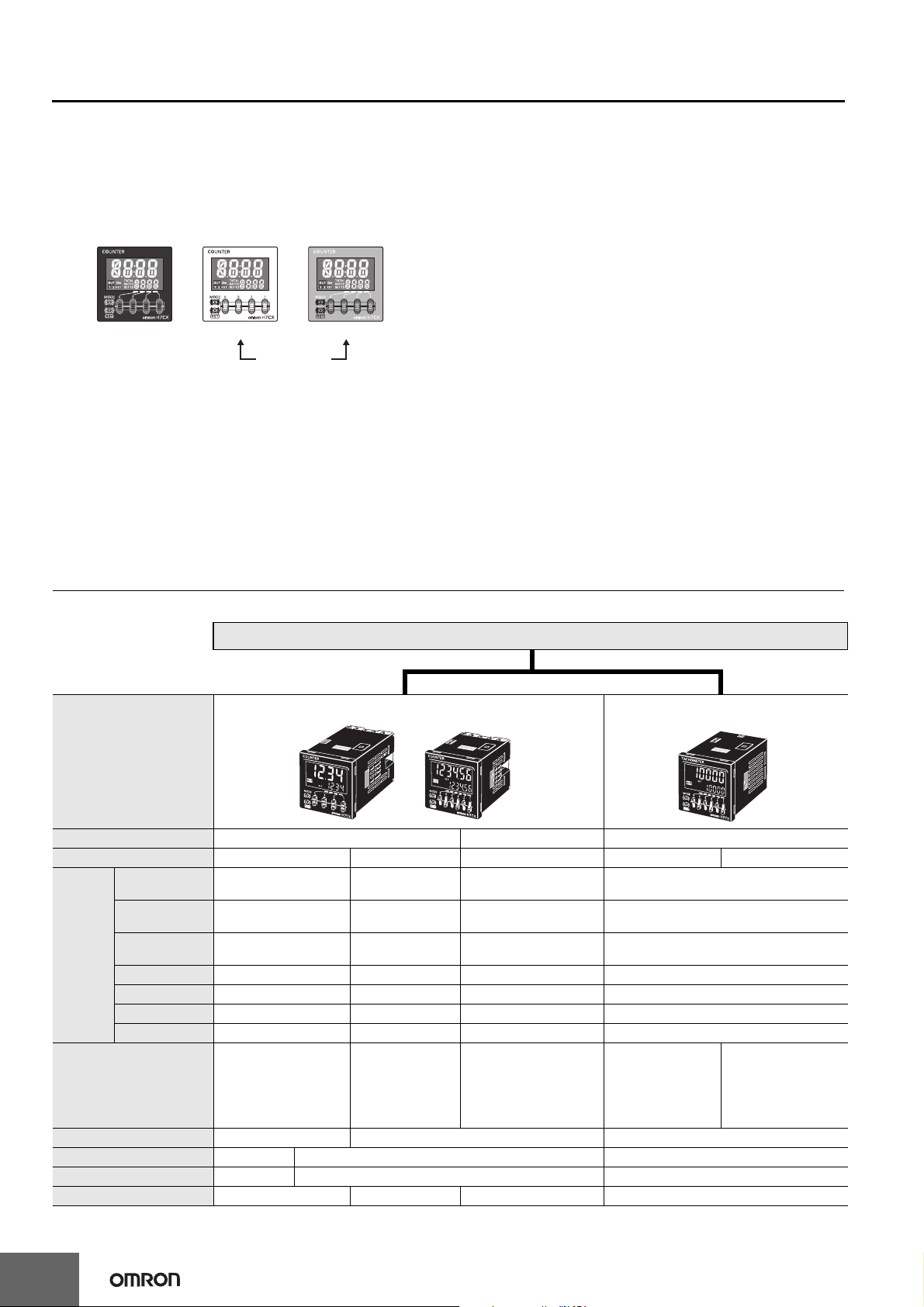

Model with 4 Digits Model with 6 Digits

12 mm

(actual size)

(Display example)

Note: The display color can be switched on all models except for the

H7CX-A11 and H7CX-R11.

10 mm

(actual size)

Previous

models

Previous

New

models

models

Easy to read from the top, bottom,

and sides!

Safety and Reliability

Isolated Power Supply and Input Circuits

Power supply circuit and input circuits are isolated inside the Counter/

Tachometer. Previous non-isolated counters had wiring restrictions

and could be damaged if wired incorrectly. The H7CX removes these

worries.

Note: Except 12 to 24-VDC models.

Set Value Limit

You can set an upper limit for the set value to prevent unexpected

operation of output devices caused by setting mistakes.

Setting the upper limit of the set

value enables worry-free operation.

For 1,000 pieces

Output Counter

The output counter counts the number of times the output turns ON

(alarms can be displayed and the count can be monitored in

increments of 1,000 operations). This counter is useful in managing

the service life of the Counter/Tachometer or the load.

No overflow

The Easiest Operation

Operation is simplified by the

Up/Down Key for each digit

on 4-digit models and Up

Key for each digit on 6-digit

models.

Model with 4 Digits Model with 6 Digits

1

Page 2

H7CX-@-N

Other Features

The front color can be changed simply by

replacing the Front Panel.

The Front Panel can be replaced with an optional Front Panel (sold

separately) with a different color to match the installation site. Select

from black, white, and light gray (except for models with tachometer

function only).

Black

(Standard)

White

Only the Front

Panel can be

replaced.

Universal NPN/PNP Input

DC 2-wire sensors can be connected for a wide range of input

devices.

Waterproof, Dust-proof Structure (UL508 Type

4X and IP66)

Worry-free application is possible in locations subject to water.

Note: When the Y92S-29 Waterproof Packing is used.

Light gray

Key Protection

Select from any of seven protection patterns. Use the best one for the

application.

New Functions

Many useful functions have been added, including a Twin Counter

Mode and many tachometer functions to handle even more

applications.

New Tachometer Functions

• Control with two independent inputs (independent measurements,

differential, absolute ratio, and error ratio)

• Peak/bottom hold function

• Output hysteresis setting

• Output OFF delay

• Switching the measurement method (pulse cycle/pulse width)

• Startup time

• Auto-zero time

• Averaging method/Number of averaging times

• AMD-compatible Mode

Model Number Structure

Model Configuration

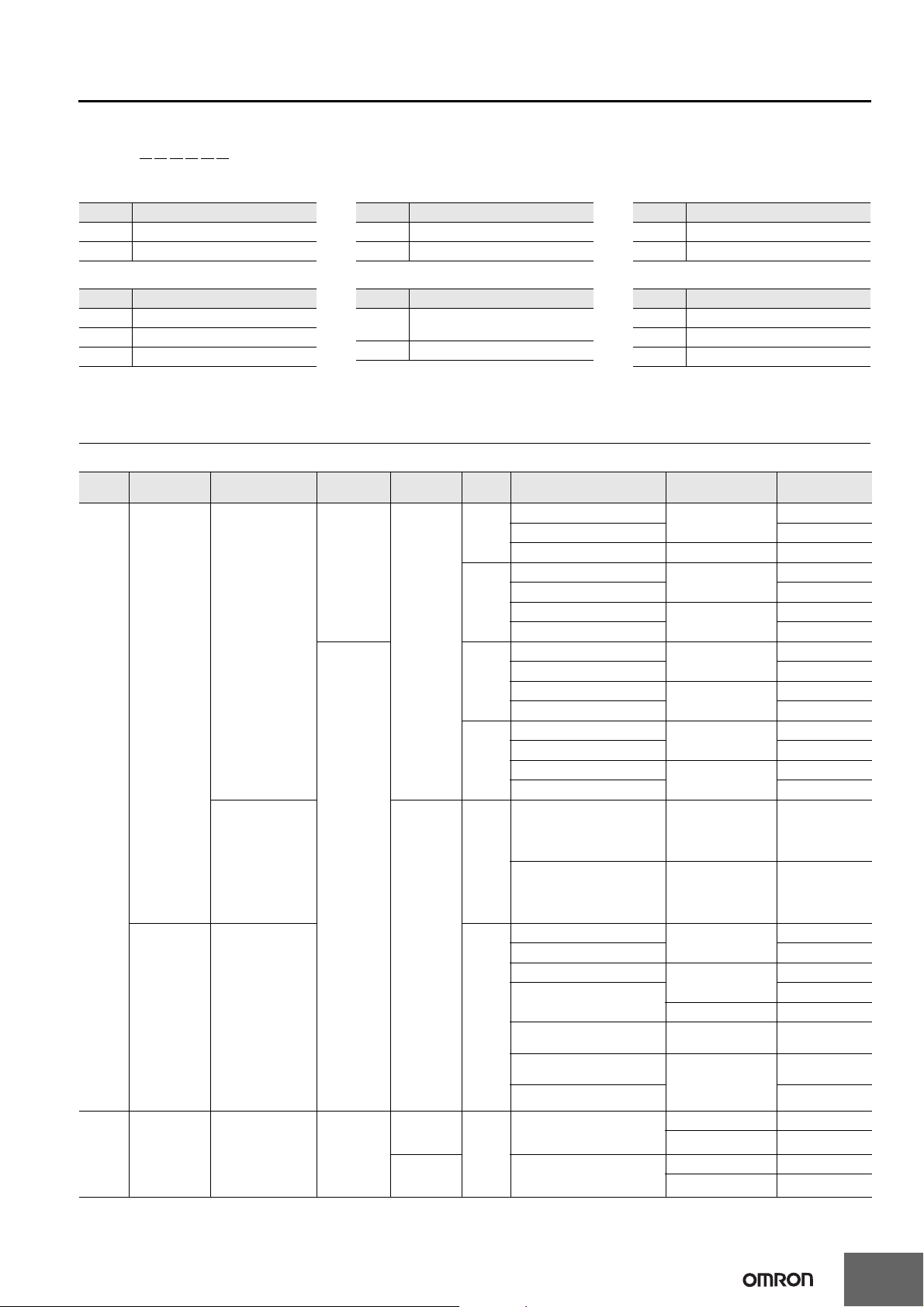

H7CX Series

H7CX-A-series Multifunction Preset Counter H7CX-R-series Digital Tachometer

Model

Classification Preset counter Preset counter/tachometer Tachometer

Model H7CX-A@-N H7CX-A4W@-N H7CX-AW@-N/-AU@-N H7CX-R11@-N H7CX-R11W@-N

1-stage preset

counter

2-stage preset

counter

Function

Tachometer input No No

Settings 1-stage 2-stage 1-stage

External connections 11-pin socket Screw terminals 11-pin socket

Display color of present value Red Red, green, or orange Red

Display digits 4 or 6 digits 4 digits 6 digits 6 digits

*1. Set the tachometer input mode from the function setting mode to switch to the tachometer function.

Total and preset

counter

Batch counter No Yes Yes No

Dual counter No Yes Yes No

Twin counter No Yes Yes No

Tachometer No No Yes

Yes Yes Yes No

No Yes Yes No

Yes Yes Yes No

*1

Yes

1 input or 2 inputs

(independent

measurements, differential,

absolute ratio value, and

error ratio value)

Yes

1 input

Yes

Yes

2 inputs (independent

measurement) only

2

Page 3

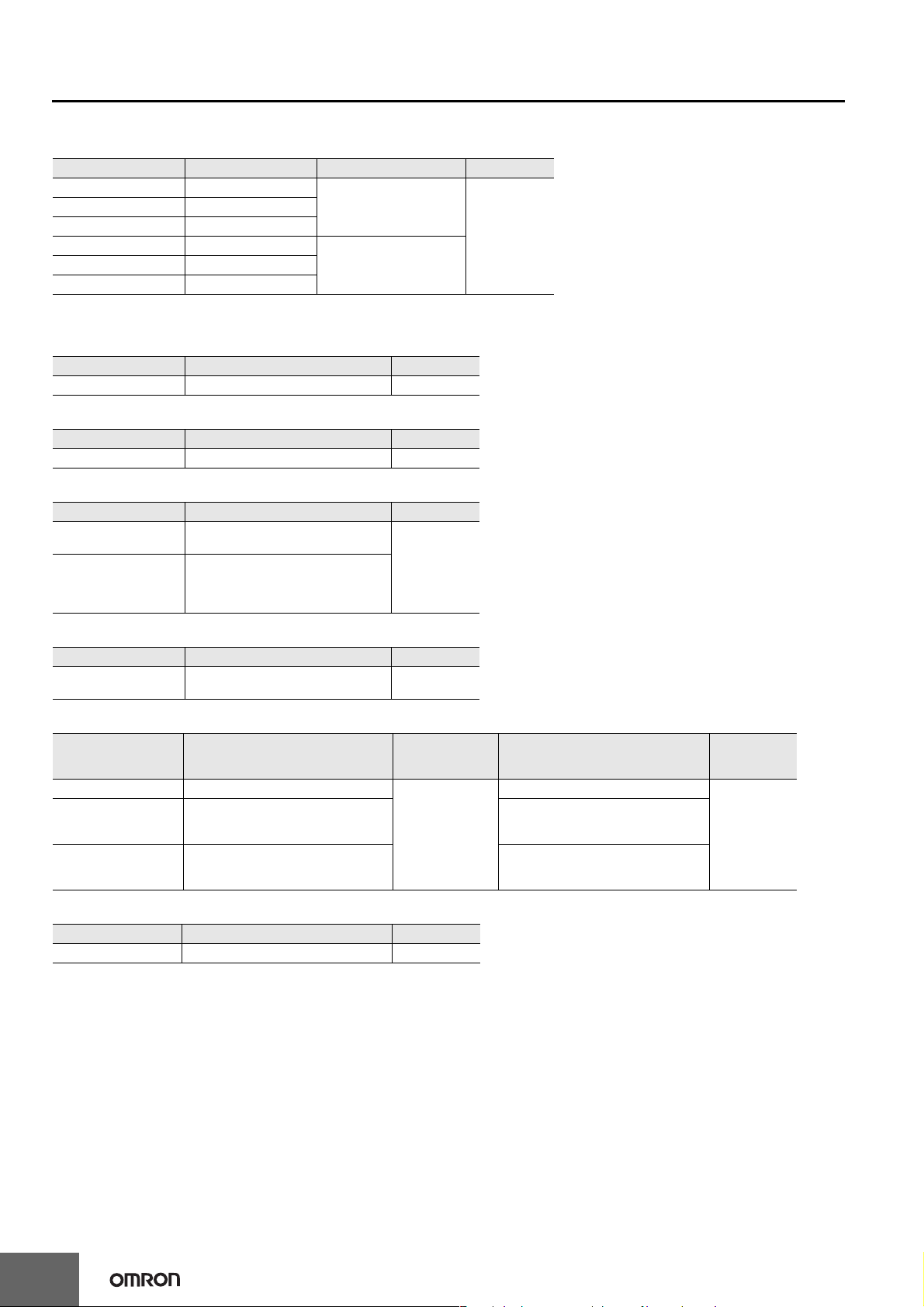

Model Number Legend (Not all possible combinations of functions are available.)

H7CX-@@@@@@-N

123 456

1. Type 2. External connections 3. Digits

Symbol Meaning

A Standard type

R Tachometer

4. Settings

Symbol Meaning

None 1-stage setting

U Factory-set to 1-stage setting

W Factory-set to 2-stage setting*

* The H7CX-R11W@ is a 1-stage (2 inputs and outputs)

rather than a 2-stage Counter.

Symbol Meaning

None Screw terminals

11 11-pin socket

Symbol Meaning

None 6 digits

4 4 digits

5. Output type 6. Supply voltage

Symbol Meaning

None

Contact output or contact output +

transistor output

S Transistor output

Symbol Meaning

None 100 to 240 VAC at 50/60 Hz

D 12 to 24 VDC

D1 12 to 24 VDC/24 VAC at 50/60 Hz

Ordering Information

List of Models

Type Classification Configuration

• 1-stage preset

counter

• Total and preset

counter

Preset counter

H7CX-A

Series

H7CX-R

Series

Preset counter/

Tachometer

Tachometer • Tachometer 11-pin socket

• 1-stage preset

counter

• 2-stage preset

counter

• Total and preset

counter

• Batch counter

• Dual counter

• Twin counter

• 1-stage preset

counter

• 2-stage preset

counter

• Total and preset

counter

• Batch counter

• Dual counter

• Twin counter

• Tachometer

External

connections

11-pin socket

Screw

terminals

Settings

1-stage

2-stage

1-stage

(1 input and

output)

1-stage

(2 inputs and

outputs)

Note: 1. The functions that are provided depend on the model. Check detailed specifications before ordering.

2. Refer to page page 37 and later for information on H7CX-R Tachometers.

Display

digits

4 digits

6 digits

4 digits

6 digits

4 digits

6 digits

6 digits

Outputs

Contact output (SPDT)

Transistor output (SPST) H7CX-A114S-N

Contact output (SPDT) 12 to 24 VDC/24 VAC H7CX-A114D1-N

Contact output (SPDT)

Transistor output (SPST) H7CX-A11S-N

Contact output (SPDT)

Transistor output (SPST) H7CX-A11SD1-N

Contact output (SPDT)

Transistor output (SPST) H7CX-A4S-N

Contact output (SPDT)

Transistor output (SPST) H7CX-A4SD-N

Contact output (SPDT)

Transistor output (SPST) H7CX-AS-N

Contact output (SPDT)

Transistor output (SPST) H7CX-ASD-N

Contact output (SPST + SPDT) 100 to 240 VAC H7CX-A4W-N

Transistor output (DPST) 12 to 24 VDC H7CX-A4WSD-N

Contact output (SPST + SPDT)

Transistor output (DPST) H7CX-AWS-N

Contact output (SPST + SPDT)

Transistor output (DPST)

Contact output (SPDT) +

Transistor output (SPST)

Contact output (SPDT) +

Transistor output (SPST)

Transistor output (DPST) H7CX-AUSD1-N

Contact output (SPDT)

Contact output (SPDT + SPST)

100 to 240 VAC

100 to 240 VAC

12 to 24 VDC/24 VAC

100 to 240 VAC

12 to 24 VDC

100 to 240 VAC

12 to 24 VDC

100 to 240 VAC

12 to 24 VDC/24 VAC

12 to 24 VDC H7CX-AWSD-N

100 to 240 VAC H7CX-AU-N

12 to 24 VDC/24 VAC

100 to 240 VAC H7CX-R11-N

12 to 24 VDC/24 VAC H7CX-R11D1-N

100 to 240 VAC H7CX-R11W-N

12 to 24 VDC/24 VAC H7CX-R11WD1-N

Power supply

voltage

H7CX-@-N

Model

H7CX-A114-N

H7CX-A11-N

H7CX-A11D1-N

H7CX-A4-N

H7CX-A4D-N

H7CX-A-N

H7CX-AD-N

H7CX-AW-N

H7CX-AWD1-N

H7CX-AWSD1-N

H7CX-AUD1-N

3

Page 4

H7CX-@-N

Accessories (Order Separately)

Front Panels (Replacement Part)

Model Color Applicable Counters Page

Y92P-CXC4G Light gray (5Y7/1) 4-digit Counter

Y92P-CXC4S White (5Y9.2/0.5)

Y92P-CXC4B Black (N1.5)

Y92P-CXC6G Light gray (5Y7/1) 6-digit Counter

Y92P-CXC6S White (5Y9.2/0.5)

Y92P-CXC6B Black (N1.5)

Note: 1. You can change the color of the Front Panel when mounting the Counter. The Counter is shipped with a black (N1.5) Front Panel.

2. "COUNTER" is printed on the front of Replacement Front Panels.

Soft Cover

Model Remarks Page

Y92A-48F1 --- 12

Hard Cover

Model Remarks Page

Y92A-48 --- 12

Flush Mounting Adapter

Model Remarks Page

Y92F-30

Y92F-45

Included with models with screw

terminals.

Use this Adapter to install the Counter/

Tachometer in a cutout previously made

for a DIN 72 × 72 mm device (panel

cutout: 68 × 68 mm).

12

12

Waterproof Packing

Model Remarks Page

Y92S-29

Included with models with screw

terminals.

12

Connection Sockets

Connectable

Model Classification

P2CF-11 Front-connecting Socket

P2CF-11-E

P3GA-11 Back-connecting Sockets

Front-connecting Socket (Finger-safe

Type)

Counter/

Tachometers

H7CX-@11@-N

Terminal Covers for P3GA-11 Back-connecting Socket

Model Remarks Page

Y92A-48G --- 13

Remarks Page

---

Round crimp terminals cannot be used on

Finger-safe Sockets.

Use forked crimp terminals.

A Y92A-48G Terminal Cover can be used

with the Socket to create a finger-safe

construction.

13

4

Page 5

H7CX-A@-N

H7CX-A@-N Multifunction Preset Counter

• Easy to check the output status from a long distance with changing

display colors

*1

(red, green, and orange).

• Includes total and preset counter, batch counter, dual counter, twin

counter, and tachometer.

*1. Not supported by the H7CX-A11@-N.

*2. The functions that can be selected depend on the model.

*2

Specifications

Ratings

Item Models H7CX-A114@-N H7CX-A11@-N H7CX-A4@-N H7CX-A@-N H7CX-A4W@-N H7CX-AW@-N/-AU@-N

Classification Preset counter

1-stage/2-stage preset

counter, total and preset

Configuration 1-stage preset counter, 1-stage preset counter with total counter (selectable)*1

Power supply

voltage*2

Ratings

Mounting method Flush mounting or surface mounting Flush mounting

External connections 11-pin socket Screw terminals

Degree of protection IEC IP66, UL508 Type 4X (indoors) for panel surface only and only when Y92S-29 Waterproof Packing is used.

Input signals CP1, CP2, reset, and total reset CP1, CP2, reset 1, and reset 2

Counter

Tachometer Refer to the separate table for tachometer function ratings.

Prescaling function Yes (0.001 to 9.999) Yes (0.001 to 99.999) Yes (0.001 to 9.999) Yes (0.001 to 99.999) Yes (0.001 to 9.999) Yes (0.001 to 99.999)

Decimal point adjustment Yes (rightmost 3 digits)

Sensor waiting time 290 ms max. (Control output is turned OFF and no input is accepted during sensor waiting time.)

Input method

External power supply 12 VDC (±10%), 100 mA (except for H7CX-A@D models) Refer to Precautions for Correct Use on page page 53 for details.

Control output

Display*4

Digits

Memory backup EEPROM (overwrites: 100,000 times min.) that can store data for 10 years min.

Operating temperature

range

Storage temperature range −25 to 70°C (with no icing or condensation)

Operating humidity range 25% to 85%

Case color Black (N1.5) (Optional Front Panels are available to change the Front Panel color to light gray or white.)

Attachments --- Flush mounting adapter, waterproof packing, terminal cover

*1. 1-stage preset counter and total counter functionality.

*2. Do not use the output from an inverter as the power supply.The ripple must be 20% maximum for DC power.

*3. A response of 10 kHz is possible if the response speed is 5 kHz and the 1-stage preset counter input mode is increment, decrement, or increment/

*4. The display is lit only when the power is ON. Nothing is displayed when power is OFF.

Operating voltage fluctuation

range

Power consumption

Maximum

counting speed

Input mode Increment, decrement, increment/decrement (UP/DOWN A (command input), UP/DOWN B (individual inputs), or UP/DOWN C (quadrature inputs))

Output mode N, F, C, R, K-1, P, Q, A, K-2, D, and L. N, F, C, R, K-1, P, Q, A, K-2, D, L, and H.

One-shot output time

Reset system External (minimum reset signal width: 1 ms or 20 ms, selectable), manual, and automatic reset (internal according to C, R, P, and Q mode operation)

decrement (command input).

• 100 to 240 VAC, 50/60 Hz

• 24 VAC, 50/60 Hz or 12 to 24 VDC

85% to 110% of rated supply voltage (12 to 24 VDC: 90% to 110%)

Approx. 9.4 VA at 100 to 240 VAC, Approx. 7.2 VA/4.7 W at 24 VAC/12 to 24 VDC, Approx. 3.7 W at 12 to 24 VDC

30 Hz or 5 kHz (switchable) (ON/OFF ratio 1:1)*3

*Common setting for CP1 and CP2

0.01 to 99.99 s

No-voltage inputs:

ON impedance: 1 kΩ max. (Leakage current: 12 mA at 0 Ω)

ON residual voltage: 3 V max.

OFF impedance: 100 kΩ min.

Voltage input:

High (logic) level: 4.5 to 30 VDC

Low (logic) level: 0 to 2 VDC (Input resistance: approx. 4.7 kΩ)

No-voltage input/voltage input (switchable)

• Contact output: 3 A at 250 VAC/30 VDC, resistive load (cosφ=1), Minimum applied load: 10 mA at 5 VDC (failure level: P, reference value)

• Transistor output: NPN open collector, 100 mA at 30 VDC, Residual voltage: 1.5 VDC max. (approx. 1 V), Leakage current: 0.1 mA max.

7-segment, negative

transmissive LCD

Character height

Count value: 12 mm

(red)

Set value: 6 mm (green)

4 digits

−999 to 9999

(−3 digits to +4 digits)

−10 to 55°C (−10 to 50°C if Counter/Tachometers are mounted side by side) (with no icing or condensation)

7-segment, negative

transmissive LCD

Character height

Count value: 10 mm

(red)

Set value: 6 mm (green)

6 digits

−99999 to 999999

(−5 digits to +6 digits)

• 100 to 240 VAC, 50/60 Hz

•12 to 24 VDC

7-segment, negative

transmissive LCD

Character height

Count value: 12 mm

(red, green, or orange

selectable)

Set value: 6 mm (green)

4 digits

−999 to 9999

(−3 digits to +4 digits)

7-segment, negative

transmissive LCD

Character height

Count value: 10 mm

(red, green, or orange

selectable)

Set value: 6 mm (green)

6 digits

−99999 to 999999

(−5 digits to +6 digits)

counter*1, batch

counter, dual counter,

and twin counter

(selectable)

7-segment, negative

transmissive LCD

Character height

Count value: 12 mm

(red, green, or orange

selectable)

Set value: 6 mm (green)

4 digits

−999 to 9999

(−3 digits to +4 digits)

Preset counter/

tachometer

1-stage/2-stage preset

counter, total and preset

counter*1, batch

counter, dual counter,

twin counter, and

tachometer (selectable)

• 100 to 240 VAC at 50/

60 Hz

• 24 VAC at 50/60 Hz or

12 to 24 VDC

• 12 to 24 VDC

7-segment, negative

transmissive LCD

Character height

Count value: 10 mm

(red, green, or orange

selectable)

Set value: 6 mm (green)

6 digits

−99999 to 999999

(−5 digits to +6 digits),

tachometer: 0 to 999999

Flush mounting adapter,

waterproof packing,

terminal cover, label for

DIP switch settings

5

Page 6

H7CX-A@-N

)

Tachometer Function Ratings

Model

H7CX-A114@-N

H7CX-A11@-N

H7CX-A4@-N

Item

Input mode

Pulse measurement method Periodic measurement Pulse width measurement

Maximum counting speed 30 Hz

Minimum input signal width --- --- 30 ms

Measuring ranges 0.01 to 30.00 Hz

Sampling period 200 ms min.

Measuring accuracy ±0.1% FS ±1 digit max. (at 23 ±5°C)

Output mode

Auto-zero time 0.1 to 999.9s

Startup time 0.0 to 99.9s

Averaging Simple averaging/moving averaging selectable, Processing: OFF, 2, 4, 8, or 16 times

Hold input Minimum input signal width: 20 ms

* An input OFF time of at least 20 ms is required.

H7CX-A@-N

H7CX-A4W@-N

No tachometer

functionality

Selectable from independent measurements for 1 or 2 inputs, differential input for 2 inputs, absolute ratio for 2 inputs, and

error ratio for 2 inputs.

1-input mode: 10 kHz

Other modes: 5 kHz

1-input mode: 0.01 to 10 kHz,

Other modes: 0.01 to 5 kHz

200 ms min. or continuous

selectable (minimum interval of 10

ms)

Input mode:

Not 2-input independent measurement: HI-LO, AREA, HI-HI, LO-LO

2-input independent measurement: HI-HI, LO-LO

Characteristics

Insulation resistance

Dielectric strength

Impulse withstand voltage

Noise immunity

Static immunity

Vibration

resistance

Shock resistance

Life expectancy

Weight Approx. 130 g (Counter only)

* Refer to the Life-test Curve.

Destruction 10 to 55 Hz with 0.75-mm single amplitude each in three directions for 2 h each

Malfunction 10 to 55 Hz with 0.35-mm single amplitude each in three directions for 10 min each

Destruction 300 m/s2 each in three directions

Malfunction 100 m/s2 each in three directions

100 MΩ min. (at 500 VDC) between current-carrying terminals and exposed non-

current-carrying metal parts, and between non-continuous contacts

2,000 VAC, 50/60 Hz for 1 min between current-carrying metal parts and noncurrent-carrying metal parts

2,000 VAC, 50/60 Hz for 1 min between power supply and input circuit for all models

except H7CX-@D@ (1,000 VAC for 24 VAC/12 to 24 VDC)

1,000 VAC (for H7CX-@SD@), 50/60 Hz for 1 min between control output, power

supply, and input circuit (2,000 VAC for models other than H7CX-@SD@)

1,000 VAC, 50/60 Hz for 1 min between non-continuous contacts

3.0 kV between power terminals (1.0 kV for models with 24 VAC/12 to 24 VDC or 12

to 24 VDC)

4.5 kV between current-carrying terminals and exposed non-current-carrying metal

parts (1.5 kV for models with 24 VAC/12 to 24 VDC or 12 to 24 VDC)

±1.5 kV between power terminals (±480 V for models with 12 to 24 VDC)

±600 V between input terminals

Square-wave noise by noise simulator (pulse width: 100 ns/1 µs, 1-ns rise)

Malfunction: 8 kV

Destruction: 15 kV

Mechanical: 10,000,000 operations min.

Electrical: 100,000 operations min. (3 A at 250 VAC, resistive load, ambient

temperature condition: 23°C)*

Applicable Standards

Approved

safety

standards

EMC

* The following safety standards apply to models with sockets (H7CX-A11@ or H7CX-A114@).

cUL (Listing): Applicable when an OMRON P2CF(-E) Socket is used.

cUR (Recognition): Applicable when any other socket is used.

cULus (or cURus): UL508/CSA C22.2 No. 14*

EN 61010-1 (IEC 61010-1): Pollution degree 2/overvoltage category II

B300 PILOT DUTY

1/4 HP 120 VAC, 1/3 HP, 240 VAC, 3 A resistive load

VDE0106/P100 (finger protection)

(EMI) EN61326

Emission Enclosure: EN 55011 Group 1 class A

Emission AC mains: EN 55011 Group 1 class A

(EMS) EN61326

Immunity ESD: EN 61000-4-2: 4 kV contact discharge;

Immunity RF-interference: EN 61000-4-3: 10 V/m (Amplitude-modulated, 80 MHz to 1

Immunity Conducted Disturbance: EN 61000-4-6: 10 V (0.15 to 80 MHz)

Immunity Burst: EN 61000-4-4: 2 kV power-line;

Immunity Surge: EN 61000-4-5: 1 kV line to lines (power and output lines);

Immunity Voltage Dip/Interruption: EN 61000-4-11: 0.5 cycle, 100% (rated voltage)

8 kV air discharge

GHz);

10 V/m (Pulse-modulated, 900 MHz ±5 MHz)

1 kV I/O signal-line

2 kV line to ground (power and output lines)

H7CX-AW@-N/-AU@-N

30 Hz

0.030 to 999999 s

Continuous (minimum interval of 10 ms)

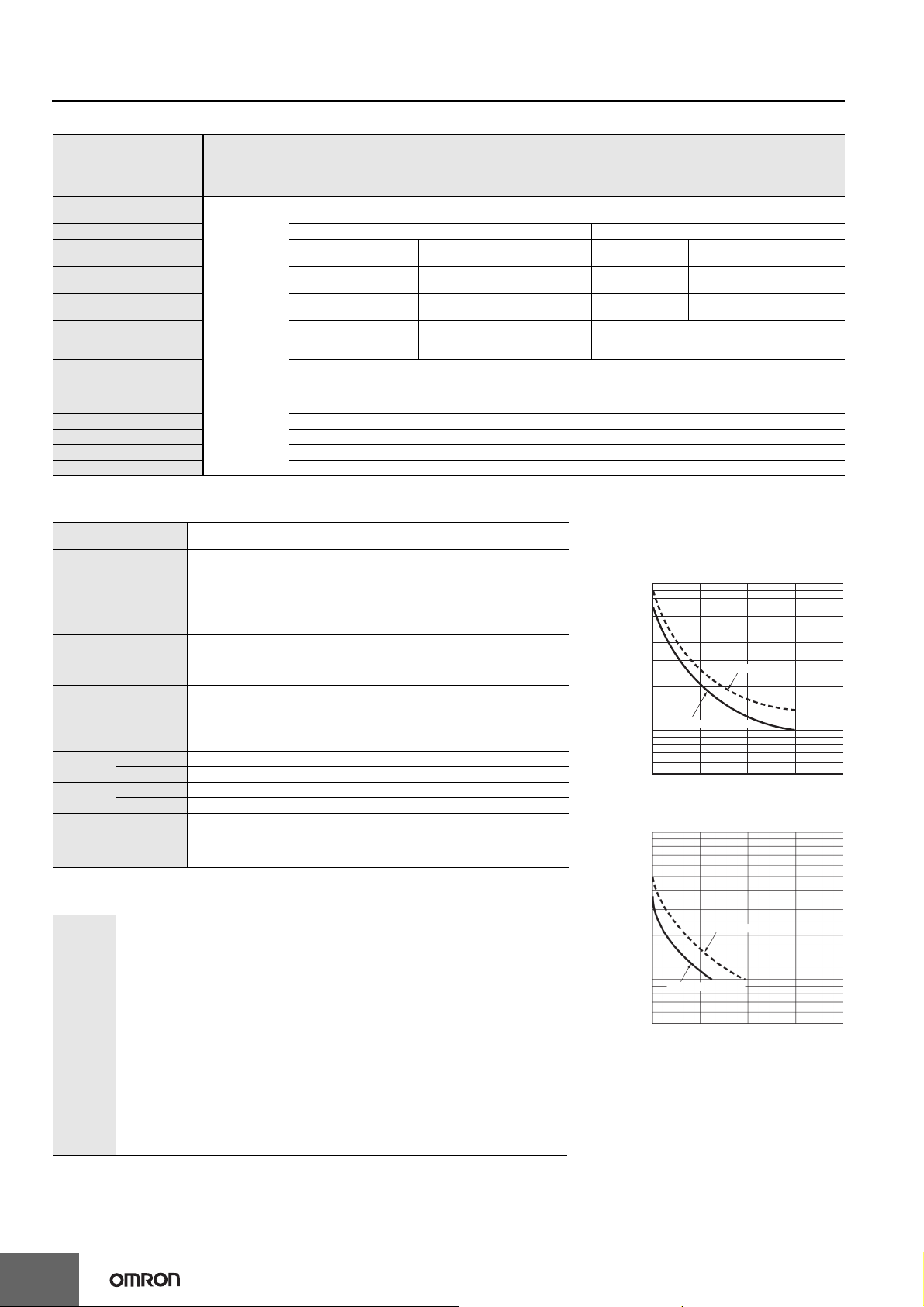

Life-test Curve (Reference

Values)

A current of 0.15 A max. can be switched at 125

VDC (cosφ=1) and current of 0.1 A max. can be

switched if L/R=7 ms. In both cases, a life of

100,000 operations can be expected.

*1

Resistive load

)

1,000

3

10

×

700

500

300

No. of operations (

250 VAC (cosφ=1)

100

70

50

01 2 34

Inductive load

)

1,000

3

10

×

700

500

300

No. of operations (

100

250 VAC (cosφ=1)

70

50

01 2 34

1-input mode: 10 kHz

Other modes: 5 kHz

1-input mode: 0.2 ms

Other modes: 0.4 ms*

1-input mode: 0.0002 to 99999 s

Other modes: 0.0004 to 99999 s

30 VDC (cosφ=1)

Load current (A

30 VDC (L/R=7 ms)

Load current (A)

6

Page 7

H7CX-A@-N

I/O Functions

Using as a Counter

CP1, CP2

Inputs

Reset/reset 1

Total reset or reset 2 The reset function depends on the selected configuration*3.

Outputs OUT1, OUT2 Outputs signals according to the specified output mode when a set value is reached.

*1. For information on operation of I/O functions, refer to pages page 22 to page 25.

*2. In increment mode or increment/decrement mode, the present value returns to 0; in decrement mode, the present value returns to the set value with 1-stage models,

and returns to set value 2 with 2-stage models.

*3. Reset operates as described in the following table. (The reset indicator will not be lit.)

Configuration Reset operation

1-stage/2-stage

preset counter

Total and preset

counter

Batch counter

Dual counter

Twin counter • Resets the CP2 present value.

• The following table shows the delay from when the reset signal is input until the output is turned OFF. (Reference values)

Minimum reset signal width Output delay time

1 ms 0.8 to 1.2 ms

20 ms 15 to 25 ms

*1

(1) In general (except for Dual Counter Mode)

• Reads counting signals.

• Increment, decrement, command, individual, and quadrature inputs accepted.

(2) When used as a dual counter or twin counter

• Reads CP1 count signals with CP1 input and CP2 count signals with CP2 input.

• Increment signals can be input.

(1) In general (except for Dual Counter Mode)

• Resets present value and outputs (OUT2 when using the batch counter)*2.

• Counting cannot be performed during reset/reset 1 input.

• Reset indicator is lit while reset input is ON.

(2) When used as a dual counter or twin counter.

• Resets the CP1 present value (to 0).

• Counting for CP1 input cannot be performed while the reset 1 input is ON.

• The reset indicator is lit while the reset 1 input is ON.

Does not operate (not used).

• Resets the total count value.

• The total count value is held at 0 while the total reset input is ON.

• Resets the batch count value and batch output (OUT1).

• The batch count value is held at 0 while the reset 2 input is ON.

• Resets the CP2 present value.

• Counting for CP2 input cannot be performed while the reset 2 input is ON.

Operating Procedures (Tachometer Function)

CP1, CP2 Reads counting signals. (The CP2 input can be used when the input mode is not 1-input mode.)

Inputs

Outputs OUT1, OUT2 Outputs signals according to the specified output mode when a set value is reached.

Reset/reset 1

• Holds the measurement value and outputs. (The reset 2 input can be used when the input mode

is 2-input independent measurement.)

• The reset indicator is lit when the value is being held.

7

Page 8

H7CX-A@-N

t

t

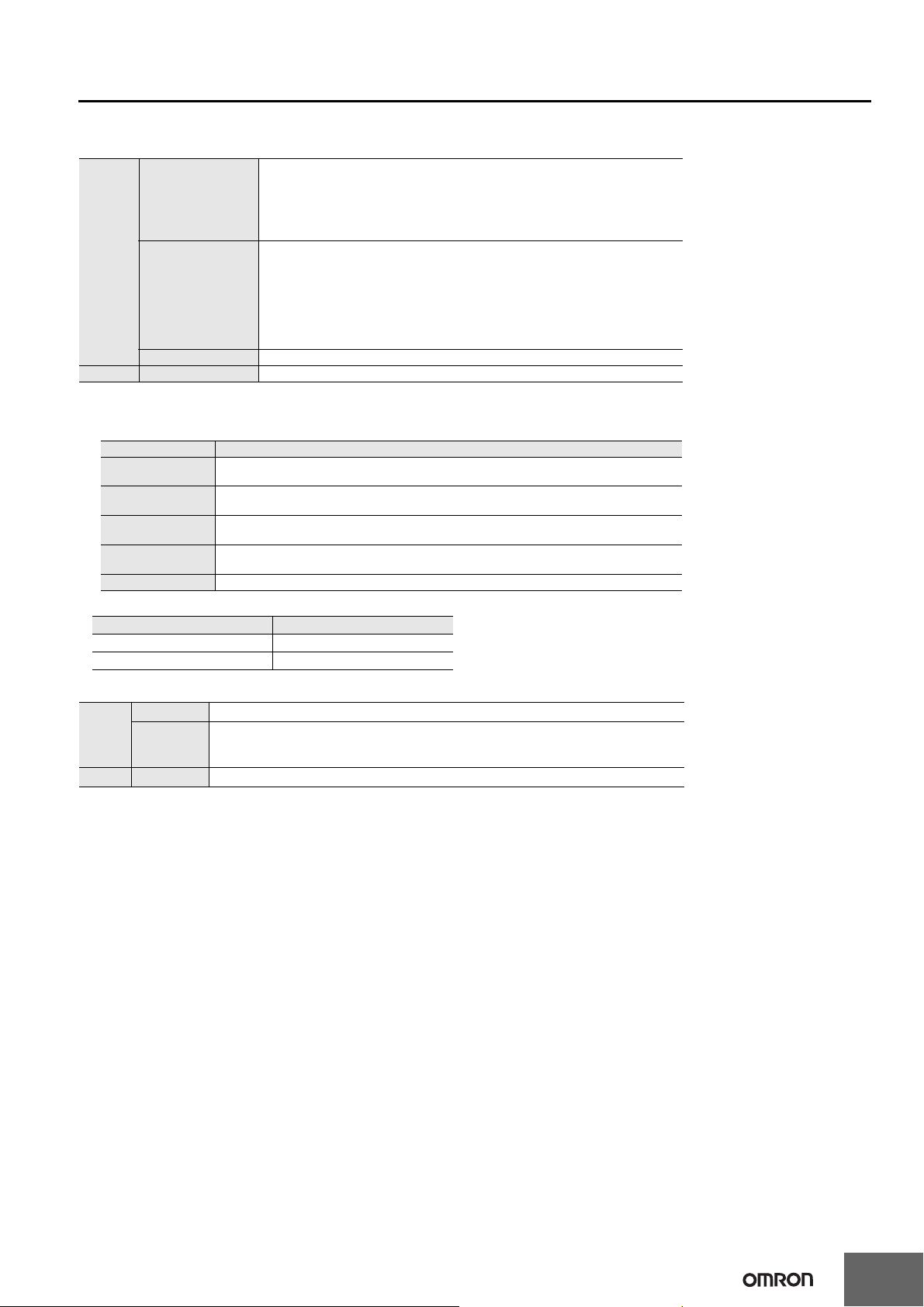

Connections

Terminal Arrangement

Confirm that the power supply meets specifications before use.

H7CX-A-N/-A4-N H7CX-AD-N/-A4D-N H7CX-AS-N/-A4S-N

1-stage Contact Output 1-stage Contact Output

1-stage Transistor Output

Reset

(+)

CP2

OUT

CP1

Total reset

(−)

Sensor

(+)

12 VDC

External

power supply

0 V

678910

11

12345

(−)

Sensor

(+)

12 VDC

External

power supply

CP1

CP2

Reset

0 V

678910

11

12345

OUT

Total reset

0 V

678910

12345

(−)

Terminals 1 and 6 are connected internally.

H7CX-ASD-N/-A4SD-N H7CX-AW-N/-A4W-N/-AWD1-N/-AU-N/-AUD1-N H7CX-AWS-N/-AWSD1-N/-AUSD1-N

1-stage Transistor Output

CP1

CP2

Reset

0 V

678910

12345

(+)(−)

Terminals 1 and 6 are connected internally.

Total reset

OUT

2-stage Contact Output 2-stage Transistor Output

CP1

(−)

Sensor

(+)

12 VDC

External

power supply

CP2

Reset 1

0 V

678910

11 12 13

12345

OUT2

(+)(−)

Reset 2

1

*

OUT1

1: “-AU@” Models

*

12 13

(−)

Sensor

(+)

12 VDC

External

power supply

*

Reset 1

0 V

678910

11 12 13

12345

(+)(−)

H7CX-AWSD-N/-A4WSD-N H7CX-A11-N/-A114-N/-A11D1-N/-A114D1-N H7CX-A11S-N/-A114S-N/-A11SD1-N

2-stage Transistor Output

1-stage Contact Output 1-stage Transistor Output

Reset

CP2

CP2

OUT2

OUT

CP1

CP1

Total reset

Reset 2

OUT1

CP1

CP2

Reset 1

0 V

678910

12 13

12345

(+)(−)

OUT2

Reset 2

OUT1

(−)

Sensor

(+)

Total reset

External

power supply

Terminals 1 and 6 are connected internally.

Transistor Output

• The transistor output of the H7CX is isolated from the internal

circuitry by a photocoupler, so the transistor output can be used as

both NPN and PNP output.

NPN Output PNP Output

Load

+

Power for load

+

Power for load

Load

Reset

CP1

CP2

12 VDC

0 V

Reset

CP1

(−)

Sensor

(+)

CP2

Total reset

0 V

12 VDC

External

power supply

6

5

7

4

3

8

9

2

10

1

11

(+)(−)

Internal circui

6

5

7

4

3

8

9

2

10

1

11

OUT

(+)

(−)

• The diode connected to the collector of the output transistor is used

to absorb inverted voltage that is generated when an inductive load

is connected to the H7CX.

Counter

Inductive

load

+

Power for load

Internal circui

OUT

8

Page 9

H7CX-A@-N

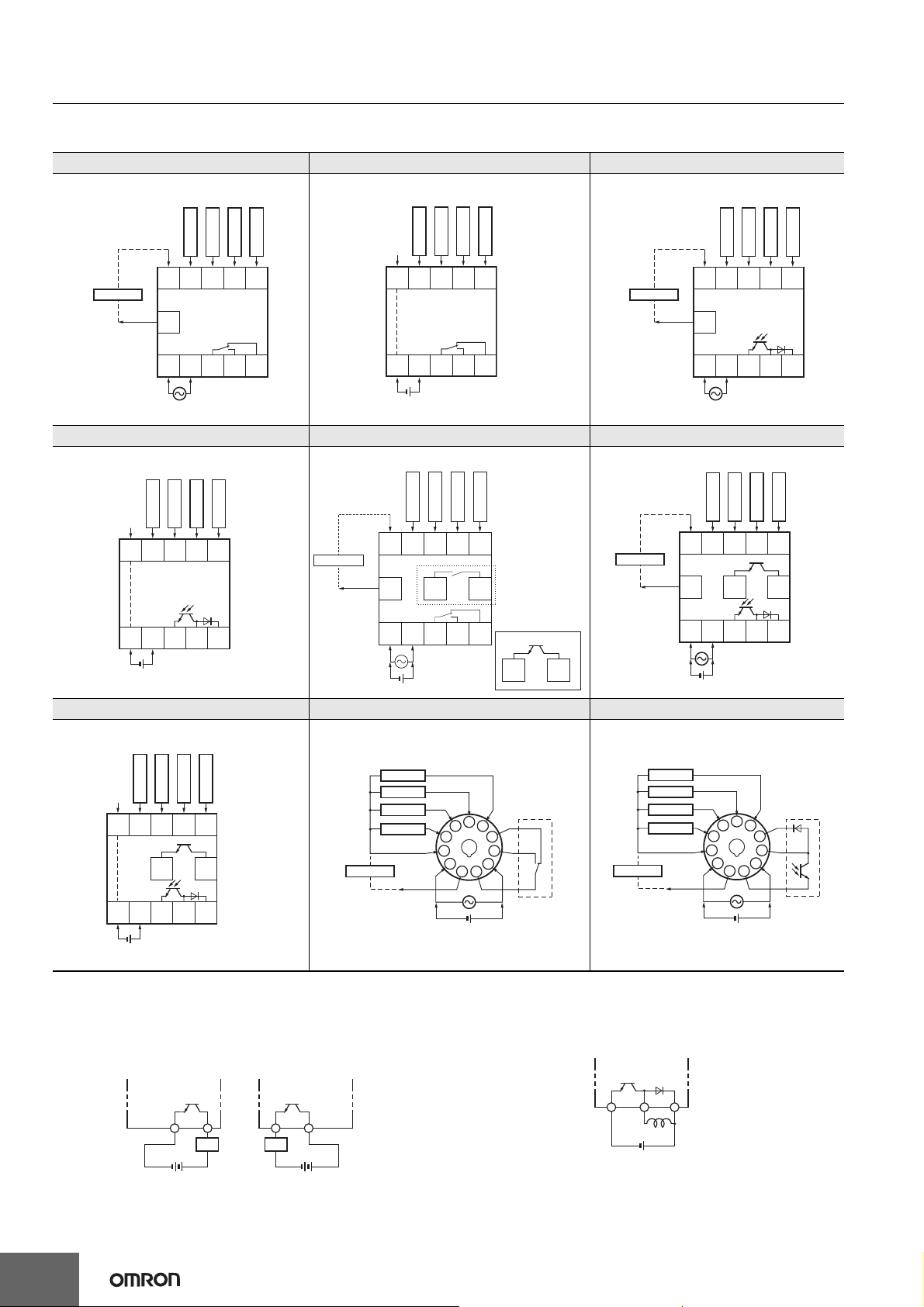

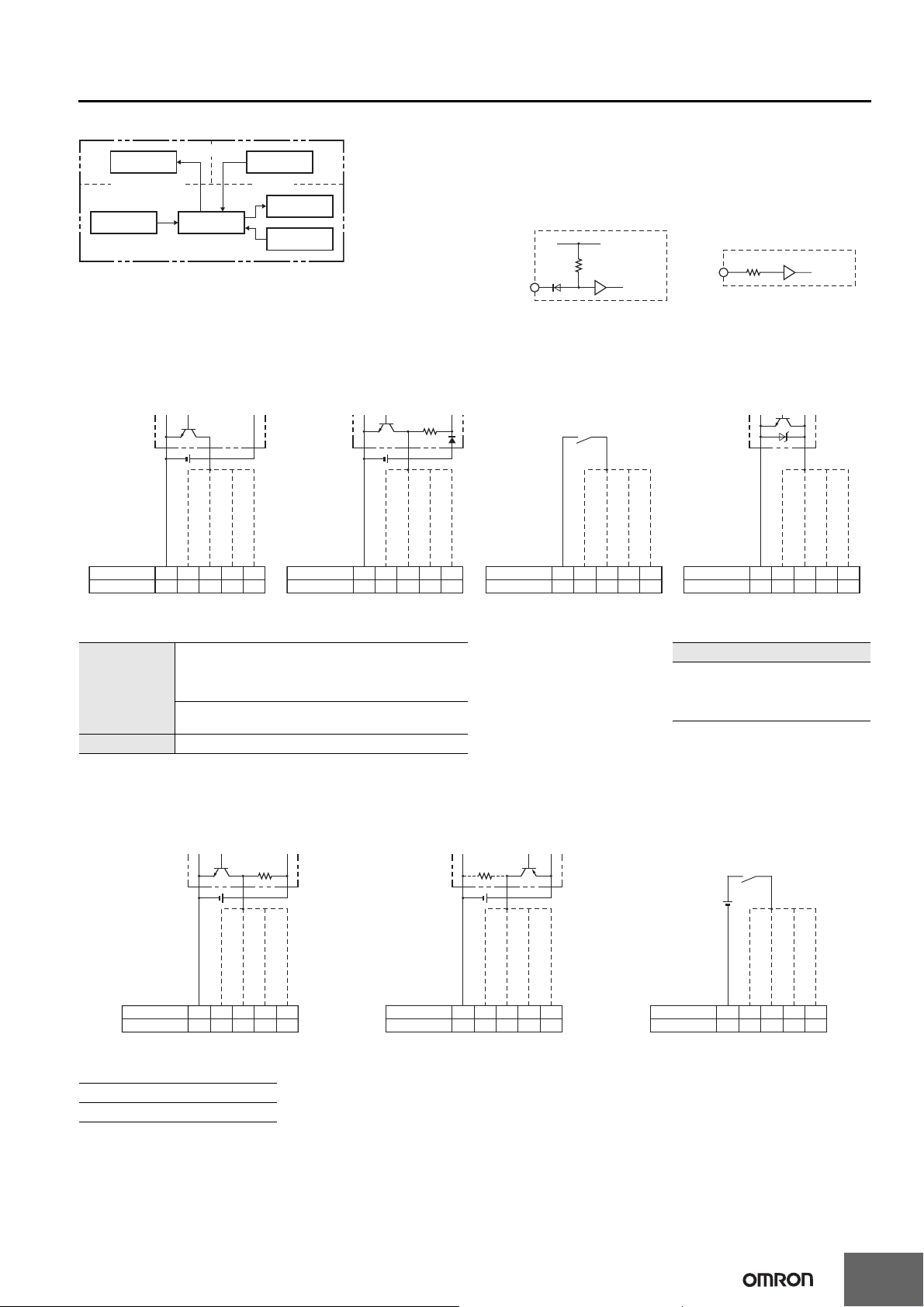

Block Diagram

Output circuit

(Basic insulation)

Input circuits

(Basic insulation)

Internal

control circuit

Note: All models except for H7CX-@D-N have basic insulation.

Power supply

circuit

(See note.)

Display circuit

Key switch

circuit

Input Circuits

CP1, CP2, Reset/Reset 1, and Total Reset/Reset 2

Input

No-voltage Inputs

(NPN Inputs)

+14V

1 kΩ

IN

Internal

circuit

Voltage Inputs (PNP Inputs)

Approx. 4.7 kΩ

IN

Input Connections

The inputs of the H7CX-@-N are no-voltage (short-circuit or open) inputs or voltage inputs.

No-voltage Inputs (NPN Inputs)

Open Collector Voltage Output Contact Input DC Two-wire Sensor

PLC or

sensor

0 V for inputs

Reset/reset 1 input

H7CX-A@

H7CX-A11@

Note: Operates with transistor ON.

678910

37564

CP2 input

CP1 input

Total reset/reset 2 input

Sensor

0 V for inputs

Reset/reset 1 input

H7CX-A@

H7CX-A11@

Note: Operates with transistor ON.

678910

37564

CP2 input

CP1 input

Total reset/reset 2 input

H7CX-A@

H7CX-A11@

Note: Operates with relay ON.

CP2 input

0 V for inputs

678910

37564

CP1 input

Reset/reset 1 input

Total reset/reset 2 input

H7CX-A@

H7CX-A11@

Note: Operates with transistor ON.

678910

37564

0 V for inputs

Internal

circuit

CP2 input

CP1 input

Reset/reset 1 input

Total reset/reset 2 input

No-voltage Input Signal Levels

Short-circuit level (transistor ON)

• Residual voltage: 3 V max.

No-contact input

• Impedance when ON: 1 kΩ max.

(The leakage current is approx. 12 mA when the impedance is 0 Ω.)

Open level (transistor OFF)

• Impedance when OFF: 100 kΩ min.

Contact input Use contacts which can adequately switch 5 mA at 10 V.

Note: The DC voltage must be 30 VDC max.

Voltage Inputs (PNP Inputs)

No-contact Input (NPN Transistor) No-contact Input (PNP Transistor) Contact Input

Sensor

CP2 input

0 V for inputs

H7CX-A@

H7CX-A11@

Note: Operates with transistor OFF.

678910

37564

CP1 input

Reset/reset 1 input

Total reset/reset 2 input

Voltage Input Signal Levels

High level (input ON): 4.5 to 30 VDC

Low level (input OFF): 0 to 2 VDC

Note: 1. The DC voltage must be 30 VDC max.

2. Input resistance: Approx. 4.7 kΩ

Sensor

0 V for inputs

Reset/reset 1 input

H7CX-A@

H7CX-A11@

Note: Operates with transistor ON.

678910

37564

CP1 input

CP2 input

Total reset/reset 2 input

H7CX-A@

H7CX-A11@

Note: Operates with relay ON.

Applicable Two-wire Sensor

• Leakage current: 1.5 mA max.

• Switching capacity: 5 mA min.

• Residual voltage: 3 VDC max.

• Operating voltage: 10 VDC

CP2 input

0 V for inputs

678910

37564

CP1 input

Reset/reset 1 input

Total reset/reset 2 input

9

Page 10

H7CX-A@-N

5

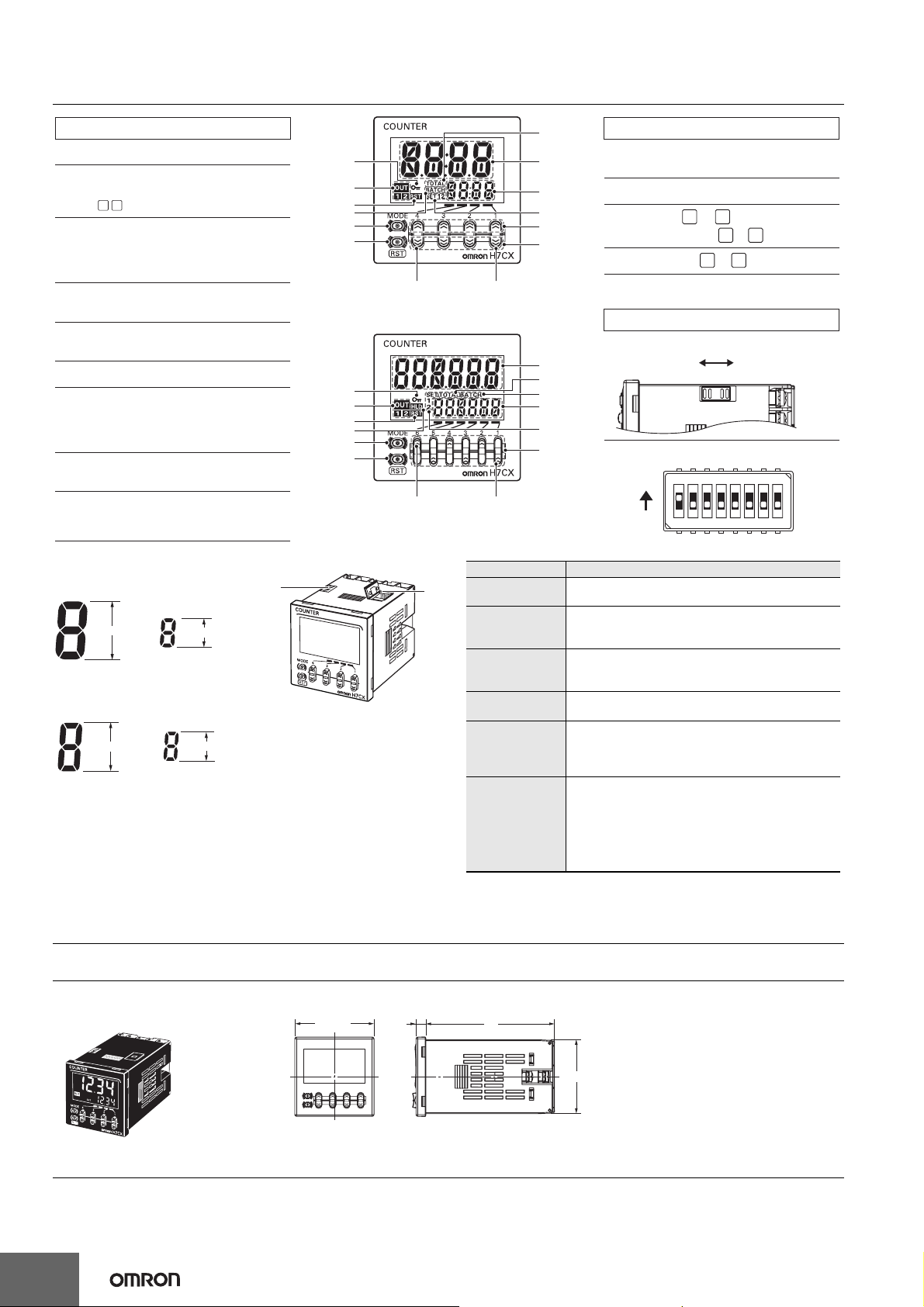

Nomenclature

Display Section

1. Key Protect Indicator (orange)

2. Control Output Indicator (orange)

OUT: (One-stage)

1 2

OUT: (Two-stage)

3. Reset Indicator (orange)

(Lit when the reset input (1) or Reset Key is ON.)

Displayed only when the configuration selection

mode is not tachometer mode.

4. Total Count Indicator

(Lit when the total count value is displayed.)

5. Batch Indicator

(Lit when the batch count value is displayed.)

6. Set Value 1, 2 Stage Indicator

7. Present Value (Main Display)

(Character height: 12 mm (6-digit: 10 mm), red*)

* Characters on models with screw terminals (H7CX-A11@)

can be switched between red, green, and orange.

8. Set value (Sub-display)

(Character height: 6 mm, green)

9. Hold Display (orange)

Displayed only when the configuration selection

mode is not tachometer mode.

Model with 4 Digits

Character Size

for Main Display

12 mm

Character Size

for Sub-display

6 mm

14

Model with 6 Digits

Character Size

for Main Display

10 mm

Character Size

for Sub-display

6 mm

1

2

3

5

10

11

(Front view of 4-digit model)

1

2

3

9

10

11

RST

(Front view of 6-digit model)

1

4

7

8

6

12

13

10. Mode Key

(Changes modes and setting items.)

11. Reset Key (See note.)

12. Up Keys to

(6-digit models: to )

13. Down Keys to

1st digit4th digit

Operation Keys

1

4

1 6

1 4

Switches

14. Key-protect Switch

7

4

5

8

6

12

1st digit6th digit

(Default setting) OFF

(Disable)

15. DIP Switch

ON

OFF

12345678

ON

(Enable)

Note: The reset functions depends on the selected configuration.

Configuration Reset operation

1-stage/2-stage

preset counter

Total and preset

counter

Batch counter

Dual counter

Twin counter

Tachometer

Resets the present value and outputs.

• Resets the present value and outputs.

• When the total count value is displayed, resets the

present value, the total count value, and outputs.

• Resets the present value and OUT2.

• When the batch count value is displayed, resets the

present value, the batch count value, and outputs.

Resets the CP1 present value, CP2 present value, dual

count value, and outputs.

Resets the CP1 present value and output 1 when the

CP1 present value is displayed.

Resets the CP2 present value and output 2 when the

CP2 present value is displayed.

Holds the measurement value and outputs (hold

function).

(When the input mode is 2-input independent

measurement, the CP1 measurement value display will

hold the CP1 measurement value and output 1 and the

CP2 measurement value display will hold the CP2

measurement value and output 2.)

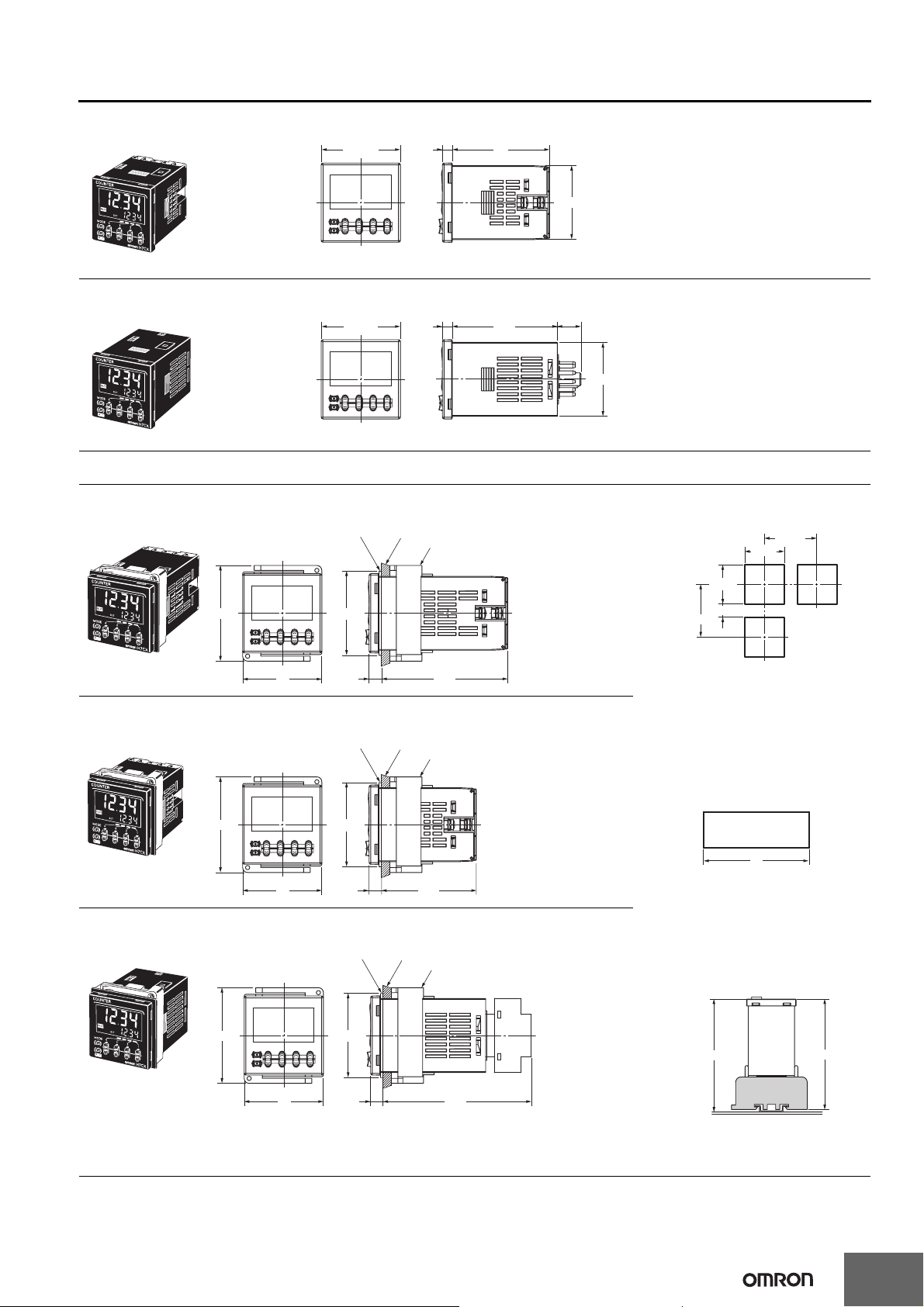

Dimensions (Unit: mm)

Counters

H7CX-A-N/-AS-N/-AW-N/-AWS-N/-AWD1-N/-AWSD1-N/-A4-N/-A4S-N/-A4W-N/-AU-N/-AUD1-N/-AUSD1-N

(Flush Mounting Models)

48 × 48

6

78

44.8 × 44.8

Note: M3.5 terminal screw (effective length: 6 mm)

10

Page 11

H7CX-A@-N

H7CX-AD-N/-ASD-N/-AWSD-N/-A4D-N/-A4SD-N/-A4WSD-N (Flush Mounting Models)

48 × 48

H7CX-A11-N/-A11S-N/-A11D1-N/-A11SD1-N/-A114-N/-A114S-N/-A114D1-N (Flush Mounting/Surface Mounting Models)

48 × 48

Dimensions with Flush Mounting Adapter

H7CX-A-N/-AS-N/-AW-N/-AWS-N/-AWD1-N/-AWSD1-N/-A4-N/-A4S-N/-A4W-N

(Provided with Adapter and Waterproof Packing)

Y92S-29 (provided)

Waterproof Packing

6

6

Y92F-30 (provided)

Panel

Flush Mounting Adapter

59

44.8 × 44.8

Note: M3.5 terminal screw (effective length: 6 mm)

63.7

14.4

44.8 × 44.8

Panel Cutouts

Panel cutouts are as shown below. (according

to DIN43700).

45

0

+

0.6

60 min.

58

48

(51)

76.57.5

H7CX-AD-N/-ASD-N/-AWSD-N/-A4D-N/-A4SD-N/-A4WSD-N

(Provided with Adapter and Waterproof Packing)

Panel

Y92S-29 (provided)

Waterproof Packing

58

48

(51)

7.5 57.5

Y92F-30 (provided)

Flush Mounting Adapter

H7CX-A11-N/-A11S-N/-A11D1-N/-A11SD1-N/-A114-N/-A114S-N/-A114D1-N

(Adapter and Waterproof Packing Ordered Separately)

Y92S-29 (order separately)

Waterproof Packing

Panel

Y92F-30 (order separately)

Flush Mounting Adapter

+

0.6

45

0

15 min.

60 min.

Note: 1. The mounting panel thickness

should be 1 to 5 mm.

2. To allow easier operation, it is

recommended that Adapters be

mounted so that the gap between

sides with hooks is at least 15 mm

(i.e., with the panel cutouts

separated by at least 60 mm).

3. It is possible to mount counters

side by side, but only in the

direction without the hooks. If they

are mounted side-by-side, waterresistance will be lost.

n Units mounted

side by side

A

A=(48n−2.5)

With Y92A-48F1 attached.

A={48n−2.5+(n−1)×4}

With Y92A-48 attached.

A=(51n−5.5)

+1

−0

+1

−0

+1

−0

Dimensions with Front

Connecting Socket

58

48

(51)

7.5 89.9

H7CX

103.2*

P2CF-11(-E) Front Connecting Socket

* These dimensions depend on the kind of DIN Track.

(Reference value)

-A11@

(order separately)

100.9

11

Page 12

H7CX-A@-N

G

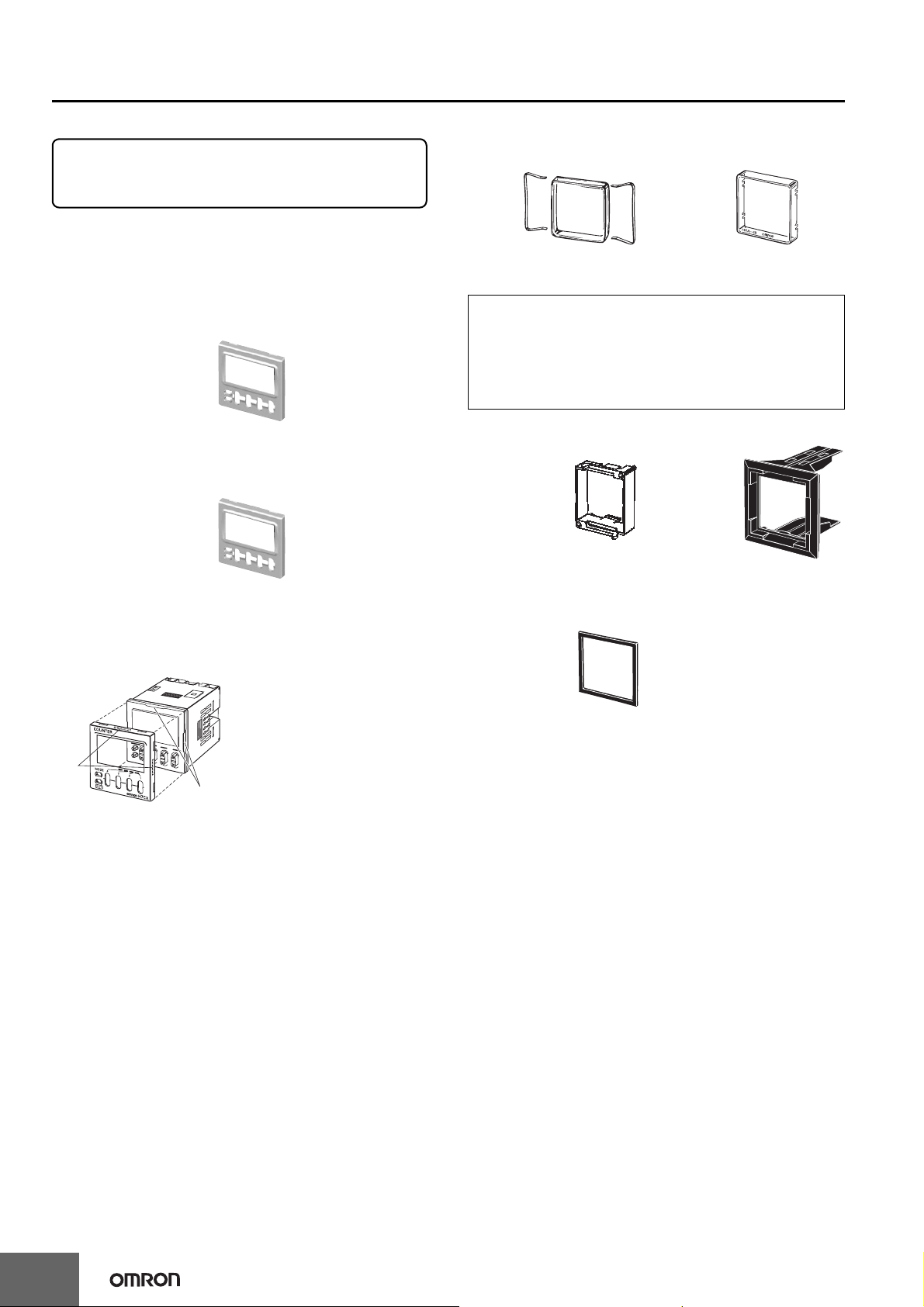

Accessories (Order Separately)

Note: Depending on the operating environment, the condition

of resin products may deteriorate, and may shrink or

become harder. Therefore, it is recommended that resin

products are replaced regularly.

Front Panel (Replacement Part)

You can change the color of the Front Panel when mounting the

Counter/Tachometer. The Counter/Tachometer is shipped with a

black (N1.5) Front Panel. "COUNTER" is printed on the front of

Replacement Front Panels.

Y92P-CXC4

4-digit Counter

Light gray (5Y7/1)

Y92P-CXC4S

4-digit Counter

White (5Y9.2/0.5)

Y92P-CXT4B

4-digit Counter

Black (N1.5)

Y92P-CXT6G

6-digit Counter

Light gray (5Y7/1)

Y92P-CXT6S

6-digit Counter

White (5Y9.2/0.5)

Y92P-CXT6B

6-digit Counter

Black (N1.5)

Replacement Method

The Front Panel is attached to the

Counter/Tachometer with tabs in

four locations. To remove the

Front Panel, open the tabs and

pull the Front Panel forward. To

attach the Front Panel, press it

Ta bs

onto the Counter/Tachometer so

that all four tabs lodge into the

grooves on the body of the

Grooves

Counter/Tachometer.

Soft Cover

Y92A-48F1

Hard Cover

Y92A-48

Protecting the Counter/Tachometer in Environments

Subject to Oil

The H7CX's panel surface is water-resistive (conforming to IP@6,

UL Type 4X) and so even if drops of water penetrate the gaps

between the keys, there will be no adverse effect on internal circuits.

If, however, there is a possibility of oil being present on the

operator's hands, use the Soft Cover. The Soft Cover ensures

protection equivalent to IP54F against oil. Do not, however, use the

H7CX in locations where it would come in direct contact with oil.

Flush Mounting Adapter

Y92F-30

Order the Flush

Mounting Adapter with

the following model

number separately if it

is lost or damaged.

Note: The

Waterproof

Packing is

included with

models with

screw

terminals.

Y92F-45

Use this Adapter to

install the Counter/

Tachometer in a

cutout previously

made for a DIN 72

× 72 mm device

(panel cutout: 68 ×

68 mm).

Waterproof Packing

Y92S-29

Note: The

Waterproof

Packing is

included with

models with

screw

terminals.

The Waterproof Packing will deteriorate, harden, and shrink

depending on the application environment. To ensure maintaining the

IP@6, UL Type 4X waterproof level, periodically replace the

Waterproof Packing. The periodic replacement period will depend on

the application environment. You must confirm the proper

replacement period. Use 1 year or less as a guideline. If the

Waterproof Packing is not replaced periodically, the waterproof level

will not be maintained. It is not necessary to mount the Waterproof

Packing if waterproof construction is not required.

Order the Waterproof Packing

separately if it is lost or damaged. The

Waterproof Packing can be used to

achieve IP66 protection.

12

Page 13

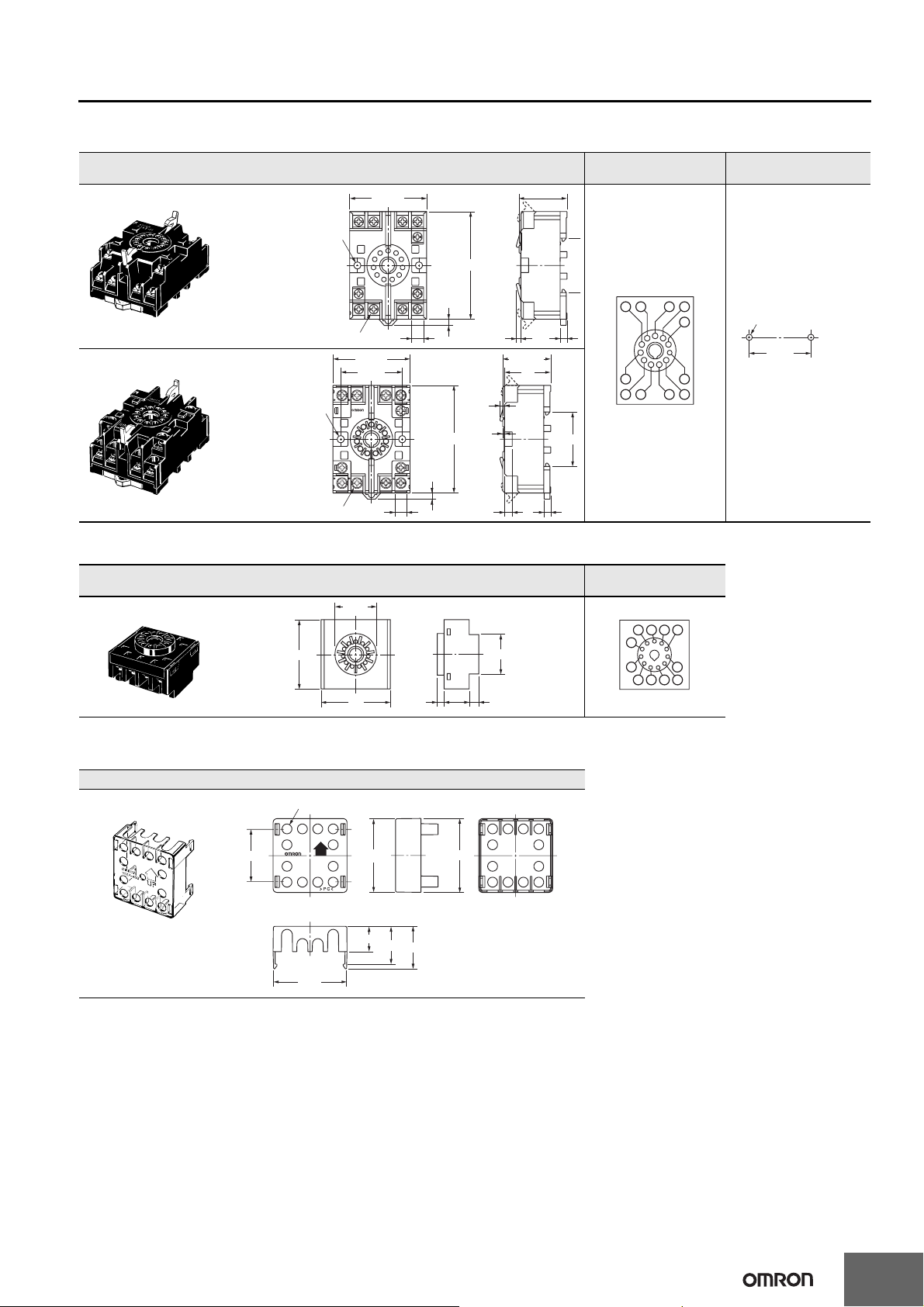

Connection Sockets

4

4

Front Connecting Socket

Model Dimensions

P2CF-11

Two, 4.5-dia. holes

50 max.

70 max.

31.2 max.

Terminal arrangement

and internal connections

H7CX-A@-N

Mounting hole

dimensions

4

4

3

12

7.8

70 max.

4

7.8

3

31.2 max.

30

3

1.2

5

35.

4.5

P2CF-11-E

(Finger-safe Type)

Eleven, M3.5 × 7.5 sems screws

Two, 4.5-dia. holes

Eleven, M3.5 × 7.5 set screws

7865

P2CF-11-E

9

10A250VAC

RESISTIVE

10 11

50 max.

±0.2

40

Note: Round crimp terminals cannot be used on Finger-safe Sockets. Use forked crimp terminals.

Back-connecting Sockets

Model Dimensions

P3GA-11

45

27 dia.

45

25.6

4.5

16.3

6.2

Note: A Y92A-48G Terminal Cover can be used with the Socket to create a finger-safe construction.

Terminal arrangement

and internal connections

8 7 6 5

9 3

10 11 1 2

(Top View)

876

5

4

3

9

101112

(Bottom View)

4

Two, M4 or 4.5-dia. holes

±0.2

40

Note: The Socket can

also be mounted

to DIN track.

Terminal Covers for P3GA-11 Back-connecting Socket

Model Dimensions

Y92A-48G

34

Note: The Terminal Cover can be used with a Back-mounting Socket (P3GA-11) to create a finger-safe construction.

Twelve, 6.4-dia. holes

Y92A-48G

UP

P C

47.4

47.7 × 47.7

16.5

24.6

48 × 48

27.6

13

Page 14

H7CX-A@-N

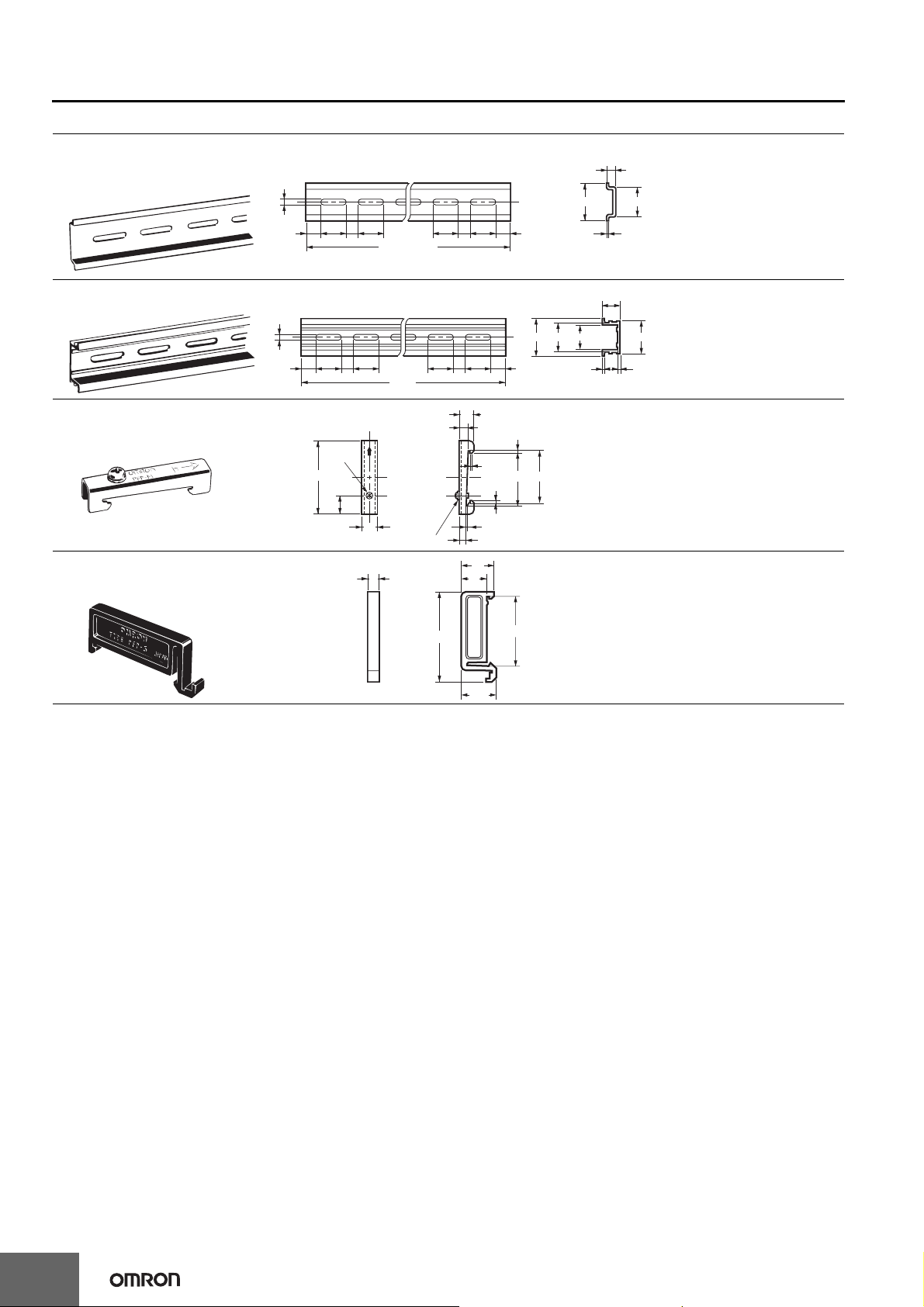

Optional Products for Track Mounting

Mounting Track

PFP-100N

PFP-50N

Mounting Track

PFP-100N2

End Plate

PFP-M

Spacer

PFP-S

4.5

4.5

15 25 2510

10

15 25 25

M4 × 8

pan head

screw

50

11.5

1,000 (500)*

1,000

10

M4 spring washer

5

25 25 1510

1025 25

10

16

12

7.3

15 (5)*

* The values shown in parentheses

are for the PFP-50N.

±

0.3

6.2

1.8

1

35.5 35.3

1.8

1.3

4.8

±0.15

±0.3

35

242735

1

±0.15

27

1

16

29.2

1.5

Note: Order Spacers in increments of 10.

44.3

34.8

16.5

14

Page 15

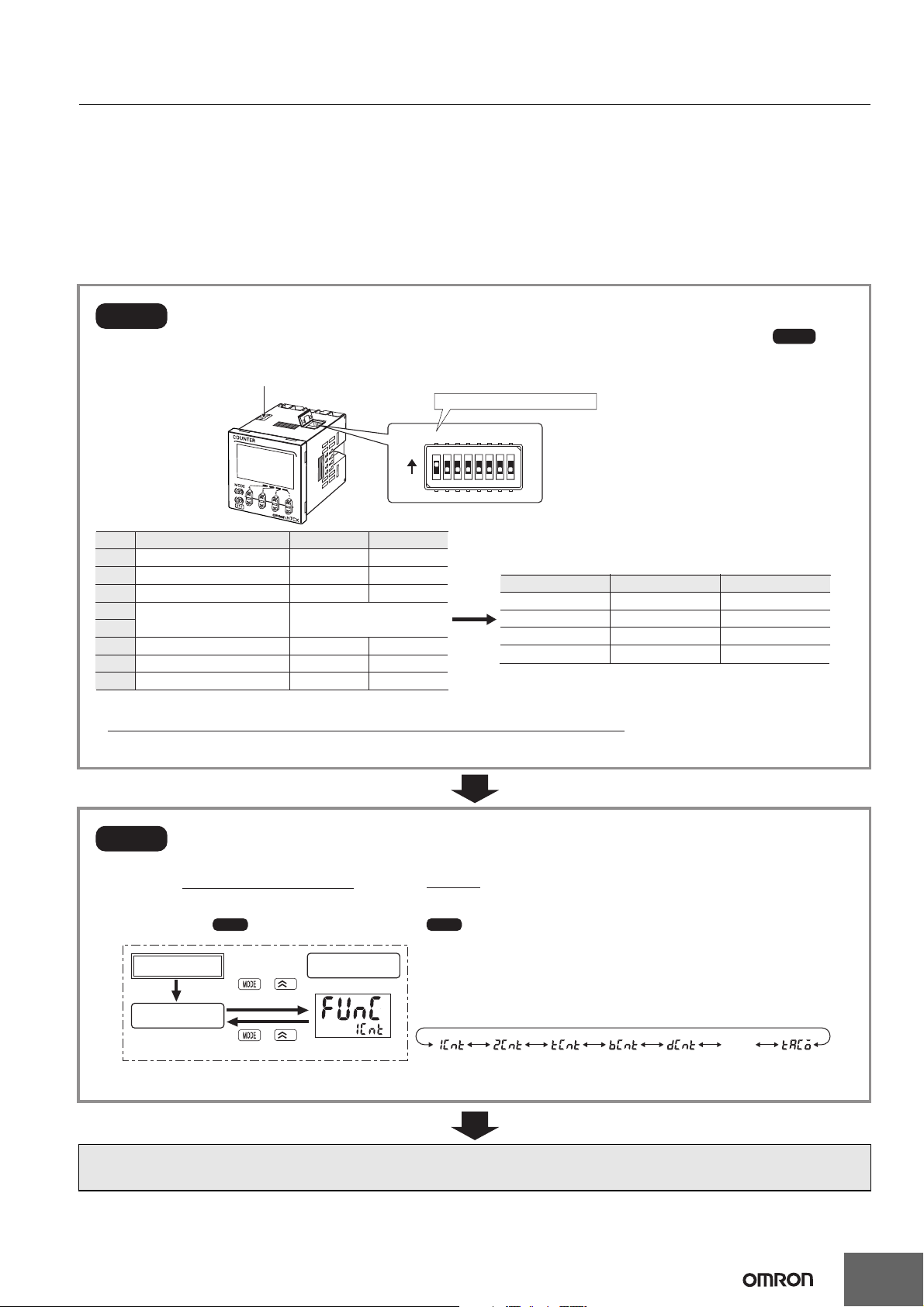

H7CX-A@-N

Operating Procedures

Setting Procedure Guide

Setting for Counter Operation

Use the following settings.

Setting for Tachometer Operation

Refer to page page 27.

* At the time of delivery, the H7CX is set to the 1-stage preset counter configuration. (2-stage models are set to the 2-stage preset counter configuration.) Refer to page page 35 for information

on switching models.

I/O Functions for Counter Operation

*

*

Counter

Step1

Set the basic parameters.

(If the desired I/O mode is not listed below or to set all parameters using the front panel keys, perform ,

Step3

below.)

Key-protect switch

Be sure to set pin 1 to ON.

ON

OFF

12345678

Item OFF ON

1

DIP switch settings

2

Counting speed

3

Input mode

4

Output mode

5

6

Output time 0.5 s 0.05 s

7

Minimum reset signal

8

Input selection

Note: All pins are factory-set to OFF.

Disabled Enabled

30 Hz 5 kHz

UP DOWN

Refer to the table on the right.

20 ms 1 ms

NPN PNP

OFF

ON

OFF

ON

OFF

OFF

ON

ON

Output modePin 5Pin 4

N

F

C

K-1

• When setting functions using the DIP switch, be sure to set pin 1 of the DIP switch to ON.

• DIP switch settings are effective when the power is turned ON again. (Perform DIP switch settings while the power is OFF.)

Step2

The H7CX-A@-N is a Counter that contains more than one functional counter.

When using the Counter in any mode other than the default mode*, use the following chart to enter

Configuration Selection Mode and set the functions that are suitable to the application.

* The default mode is 1-stage preset counter configuration (2-stage preset counter configuration for 2-stage models).

Step2 Step1

Note: can be performed first, followed by .

Power ON

Run mode

+

Hold down for 1 s min.

+

Hold down for 1 s min.

Configuration

selection mode

1

1

Select the function from Table 1 using the U (D) Key.

(1-stage

preset

counter)

Note:

(2-stage

preset

counter)

The configuration that can be selected depends on the model.

(Total and

preset counter)

(Batch

counter)

(Dual

counter)

After making DIP switch settings for basic operations, advanced functions can be added using the operation keys.

For details, refer to page page 16.

twn

(Twin

counter)

(Tachometer)

15

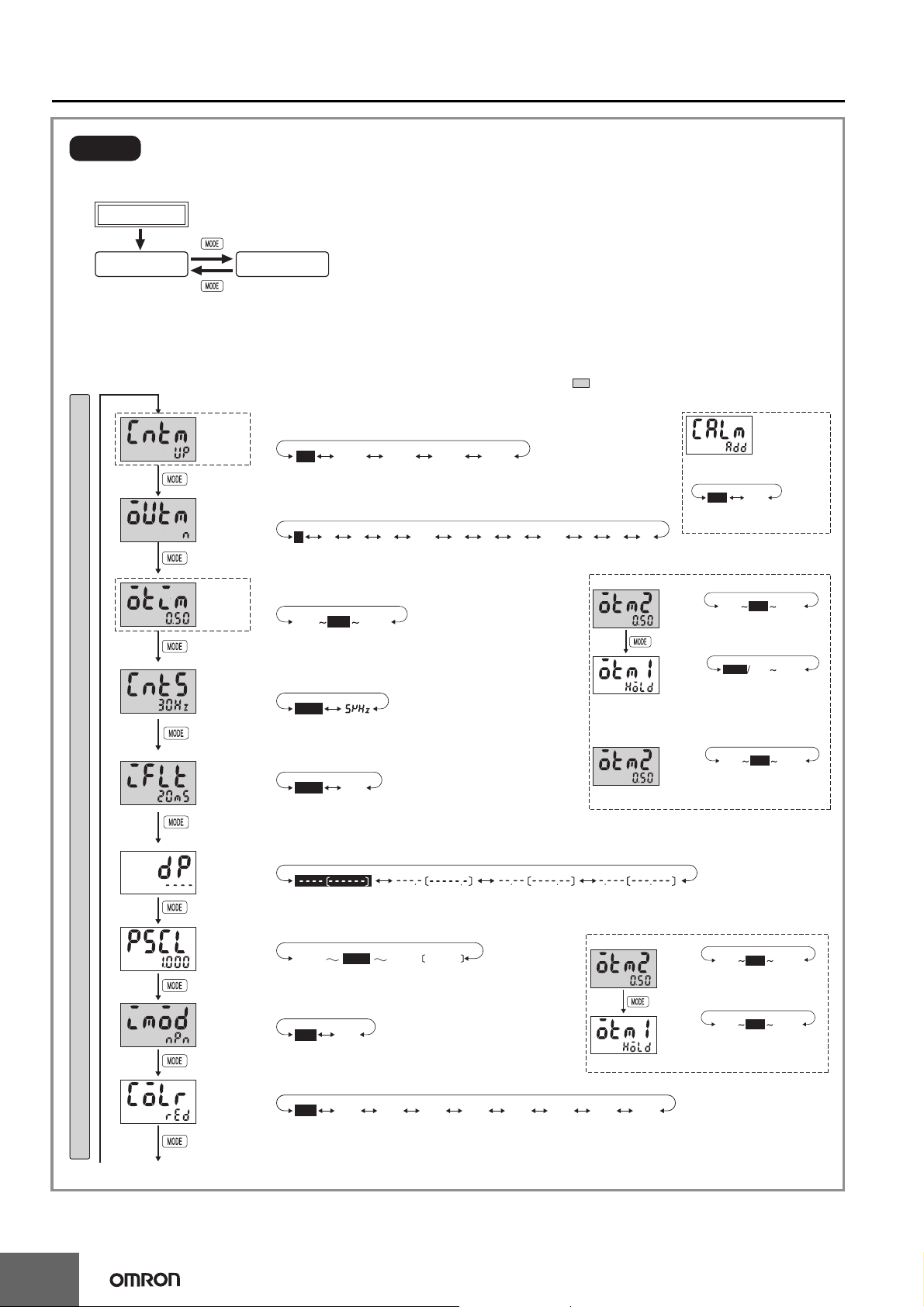

Page 16

H7CX-A@-N

Counter

Step3

Parameters that cannot be set with the DIP switch are set with the operation keys on the front panel.

Change to Function Setting Mode.

Power ON

*1

3 s min.

Run mode

setting mode

3 s min.

Function

*2

*1 If the mode is switched to the function setting mode during operation, operation will continue.

*2 Changes made to settings in function setting mode are enabled for the first time when the mode is changed to run mode. Also,

when settings are changed, the counter is reset (present value initialized and output turned OFF) on returning to run mode.

The characters displayed in reverse video are the default settings.

When performing settings with operation keys only, set pin1 of the DIP switch to OFF (factory setting).

If pin 1 of the DIP switch is set to ON, the setting items indicated by will not be displayed.

For 6-digit models, only U Keys are provided.

*3

Displays for 6-digit models are given in parentheses.

Input mode

(CNTM)

• Set the input mode using the U (D) Keys.

up

Note: Displayed only when Twin Counter Mode is not selected.

*5 Displayed for output modes other than K-2, D, L, and H only.

Output mode

(OUTM)

Output

time

(OTIM)

Counting

speed

(CNTS)

Reset input

signal width

(IFLT)

• Set the output mode using the U (D) Keys.

n

(N)

*6 Displayed only when the input mode is ud-a, ud-b, or ud-c.

*7

(Not displayed when the function is set to twn.)

• Set each digit using the individual U (D) Keys.

0.01 99.990.50

Note: Displayed only when the output mode is C, R, K-1, P, Q, A,

or K-2.

• Set the counting speed using the U (D) Keys.

30hz

(30 Hz) (5 kHz)

• Set the Reset input signal width using the U (D) Keys.

20ms

Function Setting Mode

For details on operations and display in run mode, refer to page page 20.

The display depends on the selected configuration.

*5

*5

down

(DOWN) (

f

(F) (C) (R) (K-1) (P) (Q) (A) (K-2) (D) (L) (H)

ud-a ud-b ud-c

UP/DOWN A)(UP/DOWN B)(UP/DOWN C

crk-1 k-2pqa dlh

)(UP)

*6 *6 *6 *6

*7 Set each digit using the individual U (D) Keys.

When using as a 2-stage preset counter

(0.50 s) (99.99 s)(0.01 s)

When using as a batch counter

1ms

(1 ms)(20 ms)

*3 When Using Dual Counter

Operation

Dual count

calculating

mode

• Set the dual count calculating

mode using the UD Keys.

(Addition) (Subtraction)

*4 Displayed only when the output mode is K-2,

D, L, or H.

One-shot

output 2

time

(OTM2)

Note: Displayed only when the

One-shot

output 1

time

(OTM1)

If the output time is 0.00, hold is displayed.

Note: Displayed for output modes

HOLD cannot be set when

One-shot

output 2

time

(OTM2)

Note: Displayed only when the

(ADD)

*4

subadd

0.50

0.01 99.99

(0.50 s) (99.99 s)(0.01 s)

output mode is C, R, K-1, P, Q,

A, or K-2.

hold 0.01 99.99

(0.01 s) (99.99 s)

(Outputs held)

other than D, L, and H.

the output mode is K-2.

0.01 0.50 99.99

(0.50 s) (99.99 s)(0.01 s)

output mode is C, R, K-1, P, Q,

A, or K-2.

16

Decimal

point position

(DP)

Prescale

value

(PSCL)

NPN/PNP

input mode

(IMOD)

Display color

(COLR)

• Set the decimal point position using the U (D) Keys.

(No decimal point)

(One digit after

decimal point)

(Two digits after

decimal point)

• Set each digit using the individual U (D) Keys.

0.001

1.000

(9.999)

99.9999.999

(99.999)(1.000)(0.001)

• Set the NPN/PNP input mode using the U (D) Keys.

pnpnpn

(PNP input)(NPN input)

• Set the display color using the U (D) Keys.

grnred org r-g g-r r-o o-r g-o o-g

(Red) (Green) (Orange)

(Red-green) (Green-red) (Red-orange) (Orange-red)

(Three digits after

decimal point)

*7 Set each digit using the individual U (D) Keys.

Twin Counter

(Green-orange) (Orange-green)

Output 2

output

time

(OTM2)

Note: Displayed only when the

Output 1

output

time

(OTM1)

Note: Displayed only when the

0.500.01 99.99

(0.50 s) (99.99 s)(0.01 s)

output mode is C, R, K-1, P,

Q, or A.

0.500.01 99.99

(0.50 s) (99.99 s)(0.01 s)

output mode is C, R, K-1, P,

Q, or A.

Note: Displayed for terminal-block models (except H7CX-A11@) only.

To next pageFrom next page

Page 17

H7CX-A@-N

Counter

page

From previous

page

To previous

Function Setting Mode

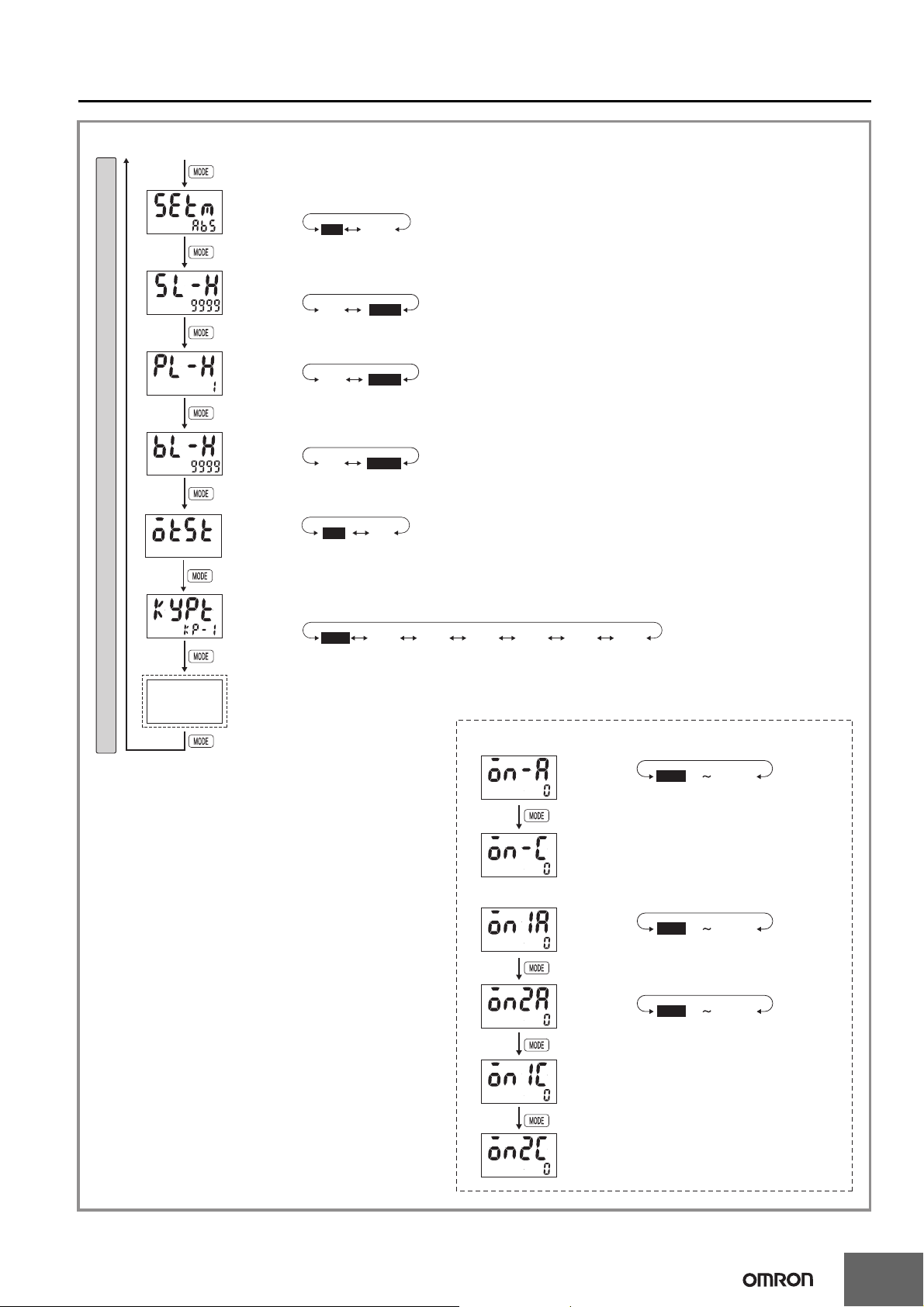

Absolute value

setting/forecast

value setting

(SETM)

Set value

upper limit

(SL-H)

Forecast

setting

upper limit

(PL-H)

Batch count

upper limit

(BL-H)

Output

allocation

change

Key protect

level

(KYPT)

*8

Output ON

count alarm set

value/monitor

value

• Make the absolute value setting and forecast setting using the U (D) Keys.

ofstabs

Note: Displayed only when the configuration selection mode is set to the 2-stage function 2cnt.

(OFST)(ABS)

• Set each digit using the individual U (D) Keys.

99991

Note: 1 to 999999 for 6-digit models

(9999)(1)

• Set each digit using the individual U (D) Keys.

99991

Note: 1 to 999999 for 6-digit models.

Note: Displayed only when the configuration selection mode is set to the 2-stage function 2cnt and a forecast value is set.

(9999)(1)

• Set each digit using the individual U (D) Keys.

99991

Note: 1 to 999999 for 6-digit models.

Note: Displayed only when the output mode is set to bcnt.

Note: Displayed only for "-AU@" models.

off: Output 1 = 12, 13, Output 2 = 3, 4, 5 on: Output 1 = 3, 4, 5, Output 2 = 12, 13

The numbers are the terminals numbers.

(9999)(1)

onoff

(ON)(OFF)

• Set the key protect level using the U (D) Keys.

kp-1 kp-2 kp-3 kp-4 kp-5

(KP-1) (KP-2) (KP-3) (KP-4) (KP-5) (KP-6) (KP-7)

*8 Set each digit using the individual U (D) Keys.

kp-6 kp-7

Procedure for Models Other than “-@W@” Models

Output

ON count

alarm set

value

Output

ON count

monitor

value

Note: The monitor value is only displayed. It cannot be set.

Procedure for “-@W@” Models

Output 1

(OUT1) ON

count alarm

set value

Output 2

(OUT2) ON

count alarm

set value

Output 1

(OUT1) ON

count monitor

value

Output 2

(OUT2) ON

count monitor

value

99990

(9999 × 1000 times)(0 × 1000 times)

99990

(9999 × 1000 times)(0 × 1000 times)

99990

(9999 × 1000 times)(0 × 1000 times)

Note: The monitor value is only displayed. It cannot be set.

Note: The monitor value is only displayed. It cannot be set.

17

Page 18

H7CX-A@-N

Counter

Explanation of Functions

Items marked with stars ★ can be set using the DIP switch.

Input Mode (cntm)★

Set increment mode (UP), decrement mode (DOWN), or one of the

increment/decrement modes (UP/DOWN A, UP/DOWN B, or UP/

DOWN C) as the input mode.

Input modes other than UP or DOWN modes cannot be set using the

DIP switch and so use the operation keys if other modes are required.

(For details on the operation of the input modes, refer to Input Modes

and Present Value on page page 21.)

Dual Count Calculating Mode ( calm)

When using as a dual counter, select either ADD (addition) or SUB

(subtraction) as the calculation method for the dual count value.

ADD: Dual count value = CP1 PV + CP2 PV

SUB: Dual count value = CP1 PV − CP2 PV

Output Mode (outm)★

Set the way that control output for the present value is output. The

possible settings are N, F, C, R, K-1, P, Q, A, K-2, D, L, and H.

Output modes other than N, F, C, or K-1 cannot be set using the DIP

switch and so use the operation keys if other modes are required. The

output modes that can be set vary with the model.

(For details on the operation of the output modes, refer to Input/

Output Mode Settings on page page 22.)

One-shot Output Time (otim)★

Set the one-shot output time (0.01 to 99.99 s) for control output.

One-shot output can be used only when C, R, K-1, P, Q, A, or K-2 is

selected as the output mode. Output times other than 0.5 s or 0.05 s

cannot be set with the DIP switch and so use the operation keys if

other settings are required.

One-shot Output 2 Time (otm2)★

Set the one-shot output time (0.01 to 99.99 s) for control output

(OUT2).

One-shot output can be used only when C, R, K-1, P, Q, A, or K-2 is

selected as the output mode. Output times other than 0.5 s or 0.05 s

cannot be set with the DIP switch and so use the operation keys if

other settings are required.

One-shot Output 1 Time (otm1)

Set the one-shot output time (0.01 to 99.99 s) for control output

(OUT1).

One-shot output can be used only when D, L, or H is selected as the

output mode.

If the output time is set to 0.00, hold is displayed, and outputs are

held.

Counting Speed (cnts)★

Set the maximum counting speed (30 Hz/5 kHz) for CP1 and CP2

inputs together.

If contacts are used for input signals, set the counting speed to 30 Hz.

Processing to eliminate chattering is performed for this setting.

Reset Input Signal Width (iflt)★

Set the reset input signal width (20 ms/1 ms) for reset/reset 1 and total

reset/reset 2 inputs together.

If contacts are used for the input signal, set the input signal width to

20 ms. Processing to eliminate chattering is performed for this setting.

Decimal Point Position (dp)

Decide the decimal point position for the present value, CP1/CP2

present values, set value (SV1, SV2), total count value, and dual

count set value.

Prescale Value (pscl)

Pulses input to the counter are converted according to the specified

prescale value.

(Setting range: 0.001 to 99.999 for 6-digit models and 0.001 to 9.999

for 4-digit models.)

Example: To display the feed distance for systems that output 25

pulses for a feed length of 0.5 m in the form @@.@@ m:

1. Set the decimal point position to 2 decimal places.

2. Set the prescale value to 0.02 (0.5 ÷ 25).

0.5 m

25 pulses

Encoder

• Observe the following points when setting a prescale value.

Set the set value to a value less than {Maximum countable value

− Prescale value}.

Example: If the prescale value is 1.25 and the counting range is

0.000 to 999.999, set the set value to a value less than 998.749

(= 999.999 − 1.25).

If the set value is set to a value greater than this, output will not turn

ON.

• Output will turn ON, however, if a present value overflow occurs

(FFFFFF or FFFF).

Note: If the prescale value setting is incorrect, a counting error will

occur. Check that the settings are correct before using this

function.

NPN/PNP Input Mode (imod)

Select either NPN input (no-voltage input) or PNP input (voltage

input) as the input format. When using a two-wire sensor, select NPN

input.

The same setting is used for all external inputs.

For details on input connections, refer to Input Connections on page

page 9.

Display Color (colr) (Displayed for terminal block models

(except H7CX-A11@) only.)

Set the color used for the present value.

Output OFF* Output ON*

red

grn

org

r-g

g-r

r-o

o-r

g-o

o-g

* Output 2 for 2-stage models.

With the twin counter, output 1 and output 2 will both turn OFF when

the output status is OFF. Either output 1 or output 2 will turn ON when

the output status is ON.

Red Green

Green Red

Red Orange

Orange Red

Green Orange

Orange Green

Red (fixed)

Green (fixed)

Orange (fixed)

18

Page 19

H7CX-A@-N

Counter

Absolute Value Setting/Forecast Value Setting (setm)

For the 2 count output mode, an absolute value setting (abs) or

forecast value setting (ofst) can be set for set value 1.

When a forecast value is set, specify the forecast value set value (i.e.,

the deviation for the set value).

The forecast output (output 1) turns ON when the present value

reaches the forecast value.

If the forecast set value is greater than or equal to the set value, the

forecast output (output 1) will turn ON as soon as counting starts.

Example: F Mode

Set value 2

Set value 1

0

Control output 1 (OUT1)

Control output 2 (OUT2)

If the forecast value setting is used, specify the set value 2 minus the

forecast value setting for set value 1.

Example: F Mode

Forecast set value

Forecast output (OUT1)

Set value

Forecast

value

0

Count value

Count value

Output ON Count Alarm Set Value (on-a)

Set the alarm value for the output ON count.

The limit can be set to between 0

× 1000 (0 times) and 9999 × 1000

(9,999,000 times). Only the underlined values are set. The alarm will

be disabled if 0 is set.

If the total ON count of the output exceeds the alarm set value, e3

will be displayed on the Timer to indicate that the output ON count

alarm value was exceeded. Refer to Self-diagnostic Function on page

page 36 for information on the e3 display.

ON Count Alarm Set Values for Outputs 1 and 2 (OUT1

and OUT2) (on1a and on2a)

Set the ON count alarm values for the outputs 1 and 2.

The limit can be set to between 0

× 1000 (0 times) and 9999 × 1000

(9,999,000 times). Only the underlined values are set. The alarm will

be disabled if 0 is set.

If the total ON count of instantaneous output 1 or 2 exceeds the alarm

set value, e3 will be displayed on the Timer to indicate that the output

ON count alarm value was exceeded. Refer to Self-diagnostic

Function on page page 36 for information on the e3 display.

Output ON Count Monitor Value (on-c)

The monitor value is only displayed. It cannot be set.

The output ON count will be 1,000 times the displayed value.

ON Count Monitor Values for Outputs 1 and 2 (OUT1 and

OUT2) (on1c and on2c)

The monitor value for output 1 or 2 is only displayed. It cannot be set.

The output ON count will be 1,000 times the displayed value.

Control output (OUT 2)

Set Value Upper Limit (sl-h)

Set the upper limit for the set value when it is set in run mode.

The setting can be made from 1 to 9999 for 4-digit models and from

1 to 999999 for 6-digit models.

Forecast Set Upper Limit (pl-h)

Set the upper limit for the forecast set value.

The setting can be made from 1 to 9999 for 4-digit models and from

1 to 999999 for 6-digit models.

Batch Count Upper Limit (bl-h)

Set the upper limit for the batch count value. The setting can be made

from 1 to 9999 for 4-digit models and from 1 to 999999 for 6-digit

models.

Output Allocation (otst)

When using an H7CX-AU@-N model as a 2-stage counter, the output

can be flexibly allocated to either stage 1 or 2.

The transistor output can be allocated to SV1 and the contact output

to SV2 or vice verse, as in the following tables.

H7CX-AU-N/-AUD1-N

Output 1 Output 2

off Transistor (12-13) Contact (3, 4, 5)

on Contact (3, 4, 5) Transistor (12-13)

H7CX-AUSD1-N

Output 1 Output 2

off Transistor (12-13) Transistor with diode (3, 4, 5)

on Transistor with diode (3, 4, 5) Transistor (12-13)

Key Protect Level (kypt)

Set the key protect level.

Refer to Key Protect Level on page page 36.

19

Page 20

H7CX-A@-N

Counter

Operation in Run Mode

I/O Functions for Counter Operation

• Set values for each digit as required using the U (D) Keys. (U Key only for 6-digit models.)

1-stage Preset Counter

Present value

Set value

2-stage Preset Counter with

Absolute Value Setting

Present value

Set value 1

Present value

Set value 2

• Present Value

Shows the present count value.

• Set Values (Set Value 1 and Set Value 2)

Set the set values.

When the present value reaches the set value (set

value 1 or set value 2), a signal is output according

to the specified output mode.

2-stage Preset Counter with

Forecast Value Setting

Present value

Set value

Present value

Forecast Set Value

• Present Value

Shows the present count value.

• Set Values

Set the set values.

• Forecast Set Value

Set the deviation for the set value.

Total and Preset Counter

Present value

Set value

Total count value

• Present Value/Set Value

Same as 1-stage preset counter.

• Total Count Value

Shows the present total count value.

Batch Counter

Present value

Set value

Batch count value

Batch count set value

• Present Value/Set Value

Same as 1-stage preset counter.

• Batch Count Value

Shows the number of times the count has been

completed for the present value.

• Batch Count Set Value

Set the batch count set value.

When the batch count value reaches the batch

count set value, batch output (OUT1) turns ON.

Dual Counter

Dual count value

Dual count

set value

CP1 present value

CP2 present value

• Dual Count Value

Shows the sum of the CP1 present value and

CP2 present value when the dual count

calculating mode is ADD and shows the value

obtained by subtracting the CP2 present

value from the CP1 present value when the

dual count calculating mode is SUB.

• Dual Count Set Value

Set the dual count set value.

When the dual count value reaches the dual

count set value, signals are output according

to the specified output mode.

• CP1/CP2 Present Value

Show the present count values for CP1 and

CP2 present values respectively.

Twin Counter

Present value 1

Set value 1

Present value 2

Set value 2

• Present Values 1 and 2

Shows the present count value 1 or 2.

• Set Values 1 and 2

Setting for present value 1 or 2.

20

Page 21

Input Modes and Present Value (See note 1.)

I/O Functions for Counter Operation

UP (Increment) Mode DOWN (Decrement) Mode

CP1: Count input; CP2: Prohibit (gate) input

H

CP1

L

H

CP2

L

Present value

2

1

0

A

must be greater than the minimum signal width. (See note 2.)

0

CP1: Prohibit (gate) input; CP2: Count input

H

*CP1

L

H

CP2

L

Present value

1

0

A

must be greater than the minimum signal width. (See note 2.)

* Counting starts when the CP1 is turned ON after turning ON the power.

0

A A

Prohibit

3

A A

Prohibit

2

5

4

5

4

3

H7CX-A@-N

CP1: Count input; CP2: Prohibit (gate) input

H

CP1

L

H

CP2

L

n

n−1

Present value

A

must be greater than the minimum signal width. (See note 2.)

0

n−2

CP1: Prohibit (gate) input; CP2: Count input

H

*CP1

L

H

CP2

L

n

n−1

Present value

A

must be greater than the minimum signal width. (See note 2.)

0

A A

Prohibit

n−3

A A

Prohibit

n−2

Counter

n−4

n−5

n−3

n−4

n−5

UP/DOWN A Command Input Mode UP/DOWN B Individual Input Mode

H

CP1

L

H

CP2

L

Present value

0

0

A

must be greater than the minimum signal width. (See note 2.)

2

1

A A

3

2

1

UP/DOWN C Quadrature Input Mode

H

CP1

L

B B B B

H

CP2

L

Present value

1

0

0

B

must be at least 1/2 the minimum signal width. (See note 2.)

3

2

2

1

H

CP1

L

H

CP2

L

3

2

Present value

1

0

0

3

2

2

11

3

2

Note: 1. If the configuration selection is set to dual counter, CP1 and

CP2 input will operate in the same way as the count input

(CP1) of UP (increment) mode.

A

2. must be greater than the minimum signal width and

B

must be at least 1/2 the minimum signal width.

If they are less, a count error of ±1 may occur.

3

2

3. The meaning of the H and L symbols in the tables is explained

below.

Symbol

Input method

H Short-circuit 4.5 to 30 VDC

L Open 0 to 2 VDC

Minimum signal width: 16.7 ms (when maximum counting speed = 30 Hz)

100 µs (when maximum counting speed = 5 kHz)

No-voltage input

(NPN input)

Voltage input (PNP

input)

21

Page 22

H7CX-A@-N

Counter

Input/Output Mode Settings

I/O Functions for Counter Operation

If a 1-stage model or 2-stage model is incorrectly used as twin counter, the operation for

output 2 will be performed. When using a 2-stage model as a 1-stage preset counter,

total and preset counter, or dual counter, OUT1 and OUT2 turn ON and OFF

simultaneously.

One-shot output from OUT1

Self-holding

output

Self-holding

output

One-shot

output from OUT2

(The one-shot output time can be

set in the range 0.01 to 99.99s.)

Output

mode

setting

N

F

C

R

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

Input mode

UP DOWN UP/DOWN A, B, C

Operation after count

completion

The outputs and present

value display are held

0

until reset/reset 1 is

input.

The present value

display continues to

0

increase/decrease.

The outputs are held until

reset/reset 1 is input.

As soon as the count

reaches SV, the present

value display returns to

the reset start status.

The present value display

does not show the

present value upon count-

0

up.

The outputs repeat oneshot operation.

OUT1 self-holding output

turns OFF after the OUT2

one-shot output time.

The OUT1 one-shot

output time is

independent of OUT2.

The present value

display returns to the

reset start status after

the one-shot output time.

The outputs repeat oneshot operation.

0

OUT1 self-holding output

turns OFF after the

OUT2 one-shot output

time.

The OUT1 one-shot

output time is

independent of OUT2.

22

K-1

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

The present value

display continues to

increase/decrease.

OUT1 self-holding output

turns OFF after the

0

OUT2 one-shot output

time.

The OUT1 one-shot

output time is

independent of OUT2.

Page 23

H7CX-A@-N

a

9

Counter

Output

mode

setting

P

Q

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

OUT1

OUT2

Input mode

UP DOWN UP/DOWN A, B, C

0

0

One-shot output from OUT1

Self-holding

output

Self-holding

output

One-shot

output from OUT2

The present value

display does not

change during the

one-shot output time

period, but the actual

count returns to the

reset start status.

The output will return

to one-shot mode.

The outputs repeat

one-shot operation.

OUT1 self-holding

output turns OFF after

the OUT2 one-shot

output time.

The OUT1 one-shot

output time is

independent of OUT2.

The present value

continues to increase/

decrease for the oneshot output time, but

returns to the reset

start status after the

one-shot output time

has elapsed.

The outputs repeat

one-shot operation.

OUT1 self-holding

output turns OFF after

the OUT2 one-shot

output time.

The OUT1 one-shot

output time is

independent of OUT2.

(The one-shot output time c

set in the range 0.01 to 99.

Operation after

count completion

Reset/

reset 1

999999

Set value 2

Set value 1

A

0

OUT1

OUT2

Note: 1. The full scale (FS) for H7CX 4-digit models is 9999.

2. When the present value reaches 999999, it returns to 0.

3. Counting cannot be performed during reset/reset 1 input.

4. If reset/reset 1 is input while one-shot output is ON, one-shot output turns OFF.

5. If there is power failure while output is ON, output will turn ON again when the power supply has recovered.

For one-shot output, output will turn ON again for the duration of the output time setting once the power supply has recovered.

6. Do not use the counter function in applications where the count may be completed (again) while one-shot output is ON.

7. The setting range is 0 to 999,999 (0 to 9,999 for 4-digit models).

The present value

display and OUT1

self-holding output is

held until reset/reset 1

is input.

OUT1 and OUT2 are

independent.

23

Page 24

H7CX-A@-N

Counter

Self-holding

output

Instantaneous

(equals) output

(The one-shot output time can be

set in the range 0.01 to 99.99s.)

One-shot

output

Output

mode

setting

K-2

D

L

Reset/

reset 1

999999

Set value 2

Set value 1

−99999

OUT1

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

−99999

OUT1

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

−99999

OUT1

Input mode

Operation after count completion

UP/DOWN A, B, C

The display continues to increase/

0

decrease until the overflow or

underflow value is reached.

One-shot output only.

The display continues to increase/

0

decrease until the overflow or

underflow value is reached.

The outputs are ON while the count is

equal.

The display continues to increase/

decrease until the overflow or

underflow value is reached.

0

OUT1 is held while the present value

is less than or equal to set value 1.

OUT2 is held while the present value

is greater than or equal to set value 2.

OUT2

Reset/

reset 1

999999

Set value 2

Set value 1

H

0

−99999

OUT1

OUT2

Note: 1. Counting cannot be performed during reset/reset 1 input.

2. If reset/reset 1 is input while one-shot output is ON, one-shot output turns OFF.

3. If there is power failure while output is ON, output will turn ON again when the power supply has recovered.

For one-shot output, output will turn ON again for the duration of the output time setting once the power supply has recovered.

4. Do not use the counter function in applications where the count may be completed (again) while one-shot output is ON.

5. The set value is from −99999 to 999999.

24

The display continues to increase/

decrease until the overflow or

underflow value is reached.

OUT1 is held while the present value

is greater than or equal to set value 1.

OUT2 is held while the present value

is greater than or equal to set value 2.

* H mode is available only when using a 6-

digit model as a 2-stage counter.

Page 25

H7CX-A@-N

Counter

Total and Preset Counter Operation