Page 1

Daily Time Switch

H5L

Weekly Control with a Large Time Display

Easy Programming with Large Display and Interactive

Functions.

• Easy operation with five keys.

• Up to 24 steps of ON/OFF operations can be set.

• Power supply freely selectable from 100 to 240 VAC.

• Memory protection during power failure for up to 10 years.

• Certified for UL and CSA safety standards.

• The same setting can be used for multiple-day operation and

timer operation.

Refer to Safety Precautions for All Timers.

Refer to Safety Precautions on page 12

CSM_H5L_DS_E_2_2

96 mm

96 mm

For the most recent information on models that have been certified for

safety standards, refer to your OMRON website.

Ordering Information

Wiring Backup power supply function for memory

Screw terminals Provided (approx. 10 years at 25°C) 24 (Each ON or OFF is considered to be one step.) H5L-A

protection

No. of program steps Model

Specifications

■ Time Ranges

Rated time Time setting range Time division

24 hrs x 7 days 00:00 to 23:59 1 min

■ Ratings

Rated supply voltage 100 to 240 VAC (50/60 Hz)

Operating voltage range 85% to 110% of rated supply voltage

Power consumption Approx. 4 VA at 240 VAC

Control outputs 15 A at 250 VAC, resistive load at 50°C

12 A at 250 VAC, resistive load at 55°C

Minimum applied load: 100 mA at 5 VDC (failure level: P, reference value)

1

Page 2

H5L

■ Characteristics

Accuracy of operating time ±0.01% ±0.05 s max. (see note 1)

Setting error

Influence of voltage

Influence of temperature

Time accuracy ±15 s per month (at 25°C)

Insulation resistance 100 MΩ min.

Dielectric strength 2,000 VAC, 50/60 Hz for 1 min (between current-carrying terminals and exposed non-current-carrying

Vibration resistance Destruction: 10 to 55 Hz with 0.75-mm double amplitude

Shock resistance

Ambient temperature Operating: –10°C to 55°C

Ambient humidity Operating: 35% to 85%

Life expectancy 100,000 operations min. (15 A at 250 VAC, resistive load)

Approved standards UL (File No. E52800), CSA (File No. LR22310)

Weight Approx. 350 g

Note: The overall error, which includes repeat accuracy, setting error, and variations due to changes in voltage and temperature, is ±0.01% or

±0.05 s max. The accuracy of ±0.01% also indicates the error in the time interval of the set time.

metal parts and between control power supply circuit and contact control output circuits)

1,000 VAC, 50/60 Hz for 1 min (between non-continuous contacts)

Malfunction: 10 to 55 Hz with 0.5-mm double amplitude

2

Destruction: 300 m/s

Malfunction: 100 m/s

(approx. 30G)

2

(approx. 10G)

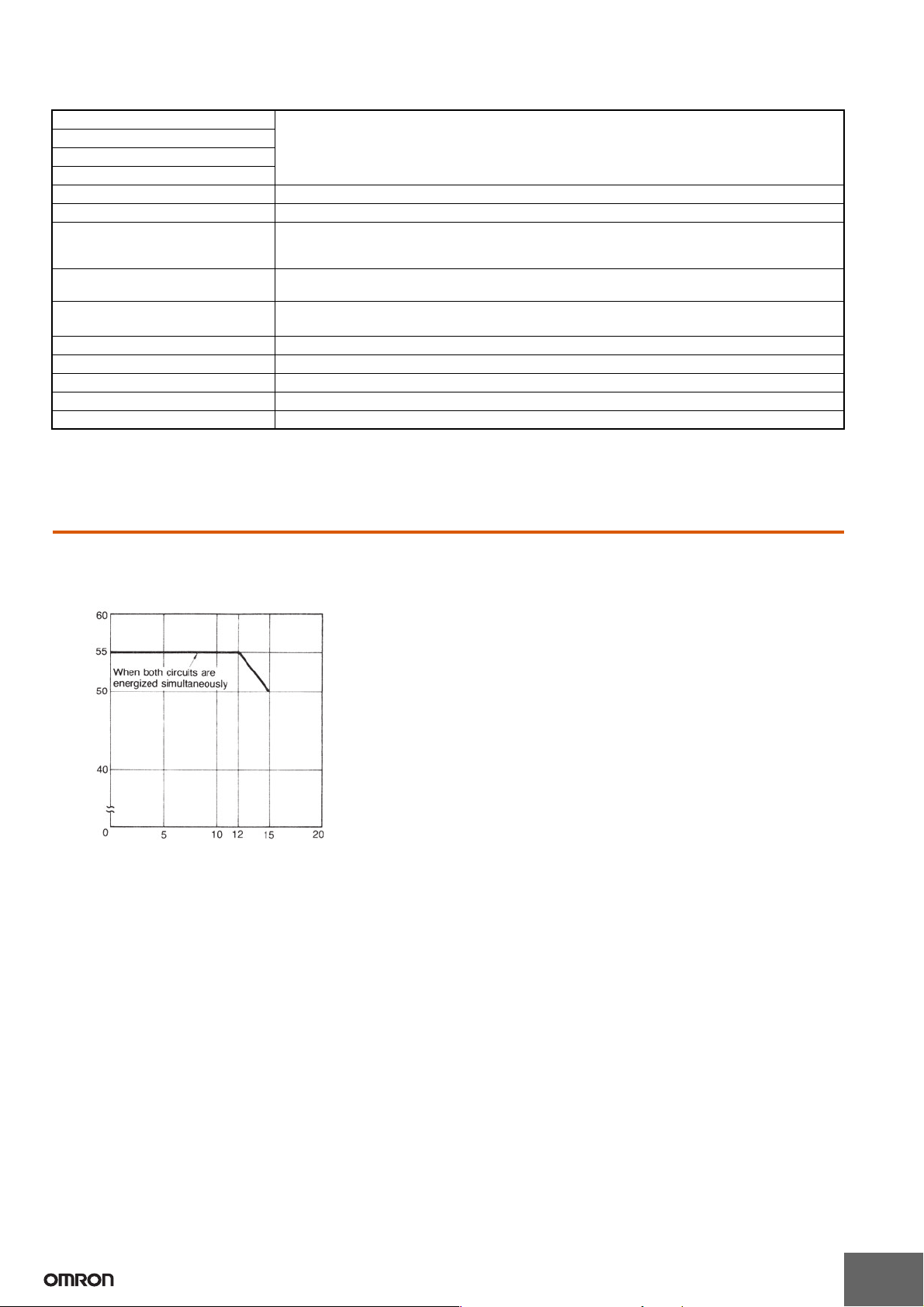

Engineering Data

Ambient Operating Temperature and Carry Current

Note that the upper limit of the ambient operating temperature

lowers when a large carry current is being applies as shown below.

Upper limit of ambient temperature (°C)

Carry current AC/DC (A)

2

Page 3

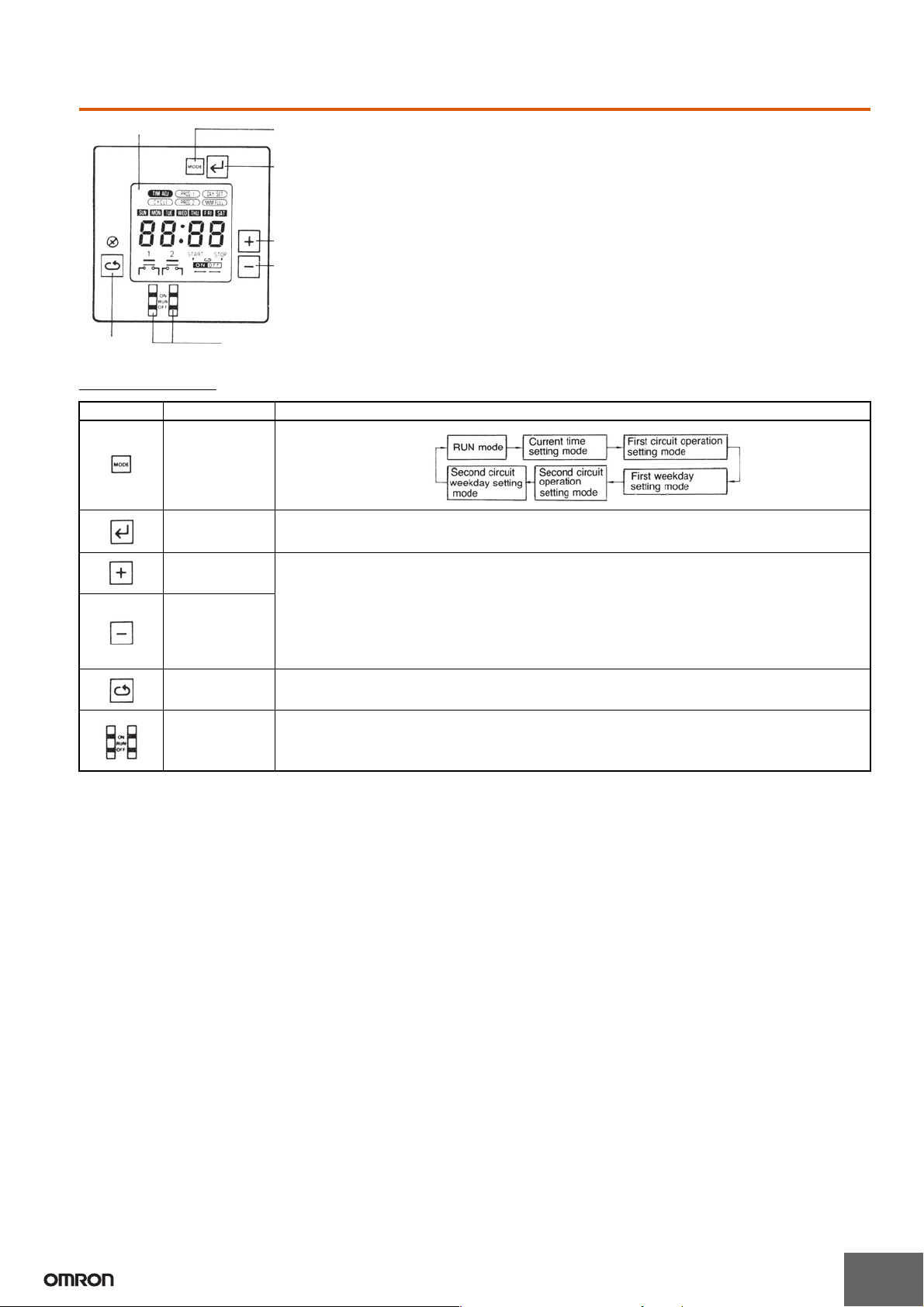

Nomenclature

H5L

LCD

Cycle Key Manual override switch

Mode Key

Write Key

Plus Key

Minus Key

Note: This figure shows the LCD section with all display items

being displayed on the screen.

Key Operation

Key Name Function

Mode Key

Write Key To write the set data using the Plus and/or Minus Key.

Plus Key Changes “day of week” while setting day of week.

Minus Key

Cycle Key Specifies the cycle program. Pressing this key twice causes the set cycle program to be cleared.

Changes program mode

Reads out the set program.

Changes “hours” or “minutes” while setting current time.

When the Plus Key is held down, the displayed digit increments continuously; when the Minus Key is held

down, it decrements continuously.

When specifying output.

The Plus Key specifies output ON while the Minus Key specifies output OFF.

Note that if the same key is pressed twice, the output specification becomes invalid; neither ON nor OFF is

set.

Manual override

switch

ON: Turns ON output regardless of program

RUN: Executes program

OFF: Turns OFF output regardless of program

First and second circuit can be operated independently.

3

Page 4

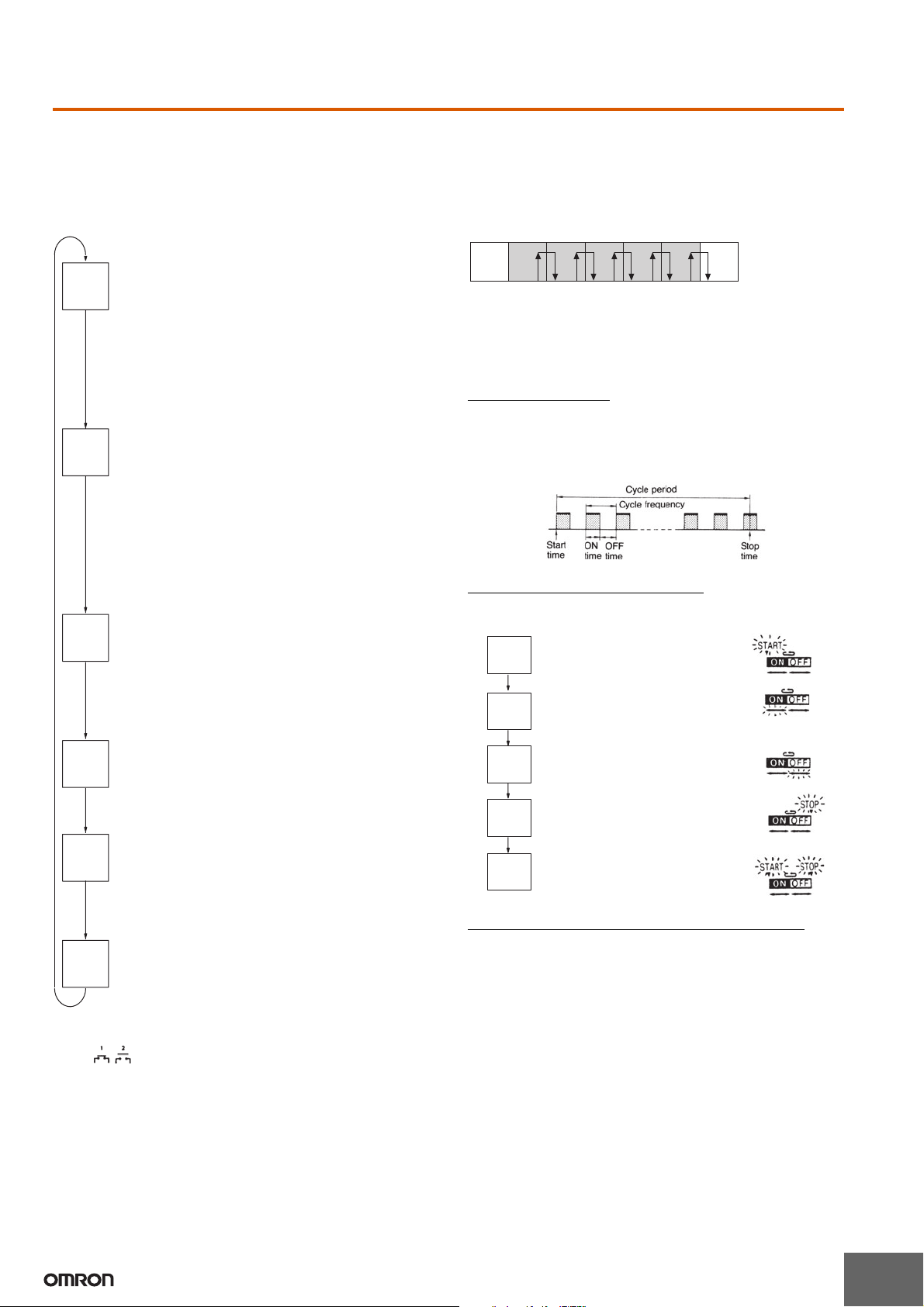

Operation

■ Programming

H5L

The H5L Weekly Timer has the following six program modes. Use

the Mode Key to change the modes. Use the Write Key, Plus Key,

Minus Key, and Cycle Key for programming in each mode.

Mode Change Sequence Programming Details

Current

time

setting

First

circuit

operation

setting

First

circuit

weekday

setting

To set the current time in the order of "day of week",

"hour" and "minute".

1. Press the Mode Key for longer than 1 s to put

the H5L in "TIM ADJ" mode.

2. Set "DAY OF WEEK" using the Plus and/or

Minus Keys. Then press the Write Key to

write the set weekday.

3. Set "hour" using the Plus and/or Minus Keys.

Then press the Write Key to write the set

hour.

4. Set "minute" using Plus and/or Minus Keys.

Then press the Write Key to write the set

minute.

To specify first circuit operation in the order of

"hour", "minute", and "output ON or OFF"

1. Press the Mode Key to put the H5L in "PROG

1" mode.

2. Set "hour" using the Plus and/or Minus Keys.

Then press the Write Key to write the set

hour.Set minute" using the Plus and/or Minus

Keys. Then press the Write Key to write the set

minute.

3. Specify "ON" or "OFF" of output using the Plus

or Minus Key and press the Write Key to write

the set output specification.

In this manner, set ON time and OFF

time as many times as necessary.

To set for each weekday whether the program for the first

circuit set in the previous step is to be executed or not.

1. Press the Mode Key to put the H5L in "PROG 1"

"DAY SET" mode.

2. Press the Plus Key to run the first circuit and

press the Minus Key for it not to run.

3. Press the Write Key to change day of week.

Repeat steps 2 and 3 for Sunday to Saturday.

Setting Multiple-day Operation

Example for Turning ON Circuit 1 Every Day from Monday to Friday

at 11:50 pm and Turning Circuit 1 OFF at 3:00 am the Next Morning

Sun Mon

Tue Wed Thu Fri Sat

23:50 3:00

1. Use the procedure First circuit operation setting given at the left to

set the ON time to 23:50 and the OFF time to 3:00.

2. Use the procedure First circuit weekday setting given at the left to

set Monday, Tuesday, Wednesday, Thursday, and Friday.

Cycle Program

In the H5L, the cycle program can be used to repeat ON and OFF of

output for a certain period in a predetermined cycle. A cycle program

consists of the following four steps:

Start time, ON time, OFF time, Stop time

Setting A Cycle Program

Set the four steps of the cycle program in the following procedure.

Setting

start

time

Setting

ON

time

Set the "hour" and "minute" of start

time using the Plus and/or Minus Key.

Set the ON time of the cycle frequency

in the order of "hour" and "minute".

Second

circuit

operation

setting

Second

circuit

weekday

setting

RUN

Note: The H5L operates in accordance with the program already set

To specify second circuit operation in the order of "hour",

"minute", and "output ON or OFF"

1. Press the Mode Key to put the H5L in "PROG 2"

mode.

2. Proceed with the settings in the same manner as in

the first circuit operation setting above.

To set for each weekday whether the program for the

second circuit set in the previous steps is to be executed

or not.

1. Press the Mode Key to put the H5L in "PROG 2" "DAY

SET" mode.

2. Proceed with the settings in the same manner as in

the first circuit operation setting above.

Run the H5L using the set program. In RUN mode, the

current time and output status are displayed but the

operation mode is not displayed. After starting the H5L, the

colon between the hour" and minute" blinks to indicate

that time count is in execution.

even while another program is being set. The output status display

( etc.) during programming displays the setting being

programmed. Therefore, note that the output status displayed on

the LCD may not agree with the actual output status.

Setting

OFF

time

Setting

stop

time

Normal

program

mode

Set the OFF time of the cycle frequency

in the order of "hour" and "minute".

Set the stop time of the cycle program.

On completing settings for the four

steps, the H5L returns automatically

to normal program mode.

Cautions on Using Cycle Programs

1. When the current time is included within the set cycle period, the

cycle operation starts (output turns ON) on completing the cycle

program setting (when stop time is written).

2. When any of the following occurs during a cycle period, the cycle

operation restarts from output ON.

Recovery after power failure

Current time adjustment

Change of start or stop time of the cycle program during

operation. For this reason, if the cycle programs for the first and

second circuits are set in such a manner that outputs 1 and 2

have a phase difference, note that the phase difference is

changed when any of the conditions above occur as shown in the

example below. (Therefore, it is recommended that cycle

programs are used sequentially.)

4

Page 5

Recovery after

power failure

H5L

Note: Refer to "Programming

Example".

3. The cycle period (from start time to stop time) does not need to

be a multiple of the cycle frequency (ON time plus OFF time). The

cycle period can be set within a range of 1 min to 24 hrs.

4. ON time as well as OFF time can be set within a range of 1 min to

23 hrs 59 min.

Output 1 and 2 start

simultaneously

5

Page 6

Deleting Programming

1. Deleting from Normal Operation Programs (ON Time/OFF

Time)

Call up the output display for the program to be deleted by

pressing the Write Key. The minus sign (–) for the output point will

flash.

Next, change the display to disable the output using the Plus and

Minus Keys. For NC contacts, press the Plus Key and for NO

contacts, press the Minus Key. The connecting bar above the

contacts will disappear and the display will flash to indicate that

the output has been displayed. If the Write Key is pressed at this

time, the step will be deleted.

2. Deleting from Cyclic Programs

Four steps will be simultaneously deleted from the cyclic program

if the program is called up and then the Cycle and Write Keys are

pressed in order. The start time display will remain, but the

program will be deleted.

■ LCD Display

LCD Display (Display Example in Each Mode)

Since the H5L employs interactive programming, the program mode and setting data are displayed on the LCD.

Display Mode Display data Display Mode Display data

RUN Current day of week:

Monday

Current time:10:11

First circuit: OFF

Second circuit: ON

Second

operation time

setting

H5L

The second circuit turns ON

Sunday to Thursday

(operation by the set

program is executed). It

turns OFF on Friday and

Saturday (operation by the

set program stops).

Current time

setting

First operation

time setting

First weekday

setting

Note: Meaning of output status indications

:Output ON, ; Output OFF, : Invalid (if an invalid instruction is written to a step, that step will be cleared.)

Current day of week:

Tu e sd a y

Current time: 9:31

The first circuit turns on at

8:15

The first circuit turns OFF

on Sunday and Saturday

(operation by the set

program stops). It turns ON

Monday to Friday (operation

by the set program is

executed).

Second

Weekday

setting

Cycle Program

setting

Memory over Indicates that all 24

■ Programming Example

Be sure to create a timing chart before programming.

The second circuit turns ON

Sunday to Thursday

(operation by the set

program is executed). It

turns OFF on Friday and

Saturday (operation by the

set program stops).

The first circuit starts cycle

operation at 1:10 (for

details, refer to Cycle

Program).

program steps have been

written (on writing the 24th

step, the data set for the first

step is displayed on the

LCD).

Operating Timing Chart

First Circuit

Second Circuit

6

Page 7

H5L

Example

ON and OFF Programs

Cyclic Programs

In this example, the first circuit is programmed to turn ON at 7:40 and OFF at 19:30. This circuit is operated from Monday through Friday and

stopped on Saturday and Sunday.

The second circuit is cyclically operated with each parameter set as follows:

Start time: 6:50

ON time: 5 min

OFF time: 20 min

Stop time: 20:30

The second circuit is stopped from operating on Sunday and operated from Monday through Saturday. The current time is assumed to be 11:15

a.m. on Tuesday.

Writing Program

Even while being programmed, the timer generates output according to the previous program. If you don’t want an unexpected operation of output

relay, turn on (or off) the manual switch.

In the figure, the indicators and digits shown in are blinking.

1. Setting Current Time

To set the current time, "day of the week", "hour", and "minute" must be specified.

First, turn on the power to the H5L.

The contents of the memory are cleared on power-up and the TIM ADJ indicator is displayed as

shown on the left.As an example, set the time to 11:15 on Tuesday.

Start by setting the day of the week. The blinking indicator indicates the parameter that can be set.

Set the current day of the week to Tuesday by pressing the Plus or Minus Key.

When "TUE" is displayed, press the Write Key to store the current day of the week in memory. The

"hour" indicator will begin to flash and the day of the week" indicator will stop flashing.

Set the current hour to 11 by pressing the Plus or Minus Key, followed by the Write Key.

At this time, the "minute" indicator will blink. Set the current minute to 15 by pressing the Plus or

Minus Key, followed by the Write Key.

This completes the current time setting.

7

Page 8

2. First Circuit Operation Setting

To program the operation of the first circuit, "hour", "minute", and "output" must be specified.

Press the Mode Key to place the H5L into PROG 1 mode. The display will be as shown on the left.

Since the first circuit is to be turned ON at 7:40, set the "hour" to 7 by pressing the Plus or Minus

Key and then store it in memory by using the Write Key.

The "minute" will start blinking. Set it to 40 by using the Plus or Minus Key and store it in memory

by pressing the Write Key.

Now, the output status indicator will blink. Set the output to the ON state with the Plus Key

followed by the Write Key.

(If the Plus Key is pressed twice at this time, the display will give an invalid indication, and if the

Write Key is pressed, this program will be deleted.)

The display returns to the initial state as shown on the left and waits for the next program command to be input.

Since the first circuit should be turned OFF at 19:30, set the hour to 19 and the minute to 30 by

using the Plus or Minus Key and then the Write Key.

H5L

The output status indicator starts blinking. Set the output to the OFF state using the Minus Key and

store it in memory by pressing the Write Key.

The display returns to the initial state and waits for the next program command to be input. Now let us turn

to the setting of the "day of the week".

3. Fist Circuit Day-of-the-week Setting

By pressing the Mode Key, place the H5L into DAY SET mode.

The display will be as shown on the left.

Press the Plus Key to operate the first circuit on a particular day of the week and press the Minus Key to stop it.

The reverse video (i.e., white characters on a black background) of the day-of-the-week indicators means that

the first circuit is operated on that day. The day on which circuit operation is stopped is indicated by bold

indicators. Initially, the circuit is set to operates on all the days of the week and the SUN indicator blinks.

In this example, since circuit operation is to be stopped on Sunday, select SUN and press the Minus Key, then

store the setting in memory by pressing the Write Key.

The MON indicator will start blinking. Press the Write Key, until the SAT indicator blinks.

Since the first circuit is not to be operated on Saturday, press the Minus Key followed by the Write Key.

The SUN indicator will start blinking again. This completes the setting of all the days of the week for the

first circuit.

8

Page 9

4. Second Circuit Operation Setting

Press the Mode Key to place the H5L into PROG 2 mode. The display appears as shown on the left.

In this example, as the second circuit is to be cyclically operated, specify the cycle program by

pressing the Cycle Key.

Select the start time by setting the hour to 6 and the minute to 50 using pressing the Plus or Minus Key.

Write each set value by pressing the Write Key.

The timer will now wait for you to set the ON time (5 min in this example).

Press the Write Key to select 0 hrs, then use the Plus or Minus Keys followed by the Write Key to select 5 min.

The timer will now wait for the OFF time to be set (20 min in this example).

H5L

Press the Write Key to select 0 hrs, then use the Plus or Minus Keys followed by the Write Key to select 20 min.

The timer will now wait for the cyclic circuit operation stop time to be set (20:30 in this example).

Set the hour to 20 using the Plus or Minus Keys, then press the Write Key. Set the minutes to 30 and press the

Write Key again.

The programming of the cyclic operation is now complete. The timer will wait for input of a new program as shown.

We will now have to set the day of the week for the second circuit.

5. Second Circuit Day-of-the Week Setting

Press the Mode Key to place the H5L into PROG 2, DAY WET mode. Initially, all days of the week are selected

(shown by reverse video) and the SUN indicator will be flashing.

In our example, the second circuit is to be operated on all days except Sunday. To inhibit Sunday operation,

press the Minus Key while the SUN indicator is flashing. The circuit will now be operated only from Monday to

Saturday.

All of the parameters have now been programmed for this example. Press the Mode Key to place the timer

into RUN mode. The display will be as shown (assuming five minutes have elapsed while programming). The

output status indicators indicate the status of each of the circuit.

Note: Set manual override switches 1 and 2 to RUN.

9

Page 10

Dimensions

Note: All units are in millimeters unless otherwise indicated.

H5L-A

6

96

12

Panel CutoutDimensions Mounting Bracket (Included)

H5L

96

14.5

56.5

42

4

35.3 91.9

M3.5

terminal

screws

Dimensions

59.8 (See note 1)

68.5 (See note 2)

Note: 1. When using mounting track

PFP-100N or PFP-50N.

2. When using mounting track

PFP-100N2.

Panel CutoutDimensions Mounting Bracket (Included)

Two, M4 taps

Mounting bracket

Panel

10

Page 11

■ Accessories (Order Separately)

Front Cover

Y92A-96A

Mounting Track (Meets DIN EN 50022)

PFP-100N/PFP-50N

H5L

16

42

(See note)

PFP-100N2

PFP-100N 1 m

PFP-50N 50 cm

PFP-100N2 1 m

(See note 2)

Twelve,-25 × 4.5 elliptic holes (See note 2)

(See note)

(See note)

Installation

■ Connections

Connect the power supply between terminals A and B, the load for

the first circuit between terminals G and H, and the load for the

second circuit between terminals E and F. Terminals C and D are

no connects.

Note: 1. This dimension is 15 mm on both ends in the

case of the PFP-100N but on one end in the

case of the PFP-50N.

2. The length l of each mounting track is shown

in this table.

3. A total of twelve 25 × 4.5 elliptic holes are

provided, with six holes cut from each end of

the track at a pitch of 10 mm between holes.

Note: To each load, connect the power supply for load.

11

Page 12

Safety Precautions

Refer to Safety Precautions for All Timers.

!CAUTION

Tighten terminal screws to the specified torque of approx.

0.8 N·m (maximum torque: 0.98 N·m). Loose screws may

occasionally cause fires or malfunction.

The Time Switch contains a lithium battery (explosionproof). Do not disassemble the Time Switch, deform the

Time Switch under pressure, heat the Time Switch to

above 100°C, or incinerate the Time Switch. Doing any of

these may result in fire or battery rupture.

■ Precautions for Safe Use

Observe all of the following precautions to maintain safety.

1. The Time Switch is not waterproof or oil resistant. Do not use it in

locations subject to water or oil.

2. Use the following wire to wire the Time Switch: 600-V vinylinsulated wire (solid wire or twisted wire, copper), 14 to 24 AWG

3. Do not connect more than two crimp terminals to each Time

Switch terminal.

4. None of the Time Switch components are user-replaceable,

including the battery.

H5L

Surface Mounting

• Use a straight mounting bracket to surface mount the unit.

Track Mounting

• Hook the upper part on the rear surface to the upper edge of the

mounting track and press the unit down.

(1) (2)

■ Precautions for Correct Use

Be sure that the capacity of the power supply is large enough,

otherwise the Time Switch may not start due to the inrush current

(approx. 3 A) that flows for an instant when the power to the Time

Switch is turned ON.

ON Current and Ambient Temperature

(Reference Values)

If the ON current is too large, the upper limit to the ambient operating

temperature must be reduced as shown in the following diagram.

60

55

Both circuits ON simultaneously

50

40

Upper limit to ambient operating temperature (°C)

5010121520

ON Current (A AC or DC)

• To remove the Timer Switch from the DIN Track, pull

down on the yellow lever at the back of the Timer

Switch.

Wiring

Wiring From the Rear

• Perform wiring from the rear of

the unit when the unit is flush

mounted.

Wiring From the Front

• Perform wiring from the front of

the unit when the unit is track

or surface mounted.

Yellow lever

M3.5

terminal screws

Mounting Dimensions

Flush Mounting

• Use a U-shaped mounting bracket to flush mount the unit.

Wiring Procedure

1. Loosen the screw on the left

side of the front.

2. Slide the upper part of the unit

approx. 15 mm upward.

3. After the terminals appear,

perform wiring.

4. Return the upper part of the

unit to the original position and

tighten the screw.

Note: Screw tightening torque: 0.98 N·m max.

12

Page 13

H5L

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

In the interest of product improvement, specifications are subject to change without notice.

13

Page 14

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified)

from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the

products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or government regulations.

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the

result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2012 All Right Reserved.

2012.8

Loading...

Loading...