Page 1

Digital Daily Time Switch

H5F

Daily Time Control with Simple Operations

(Operation Day Selection Possible)

• Up to 12 ON/OFF operations (24 for pulse-output operation).

• Special holidays can be handled easily with the holiday setting

function.

• Adjustments f o r sudde n sch edule c hange s can be ma de eas ily

using output override and automatic return operation.

• The operation progr am can be che ck ed ea sily w ith the progra m

check function.

• Enables pulse output operation and summer time setting.

• Incorporates finger-safe terminals.

• Conforms to UL, CSA, and CE marking.

• Meets a variety of mounting requirements: flush mounting, surface mounting, and DIN track mounting.

Model Number Structure

■Model Number Lege nd

H5F-@B

12

1. Mounting method

None: Flush mounting

F: Surface mounting

K: Surface mounting/track mounting

2. Language

B: English

Ordering Information

■List of Models

Wiring Mounting method Model

Screw terminals Flush mounting H5F-B

Surface mounting H5F-FB

Surface mounting/track mounting H5F-KB

■Accessories (Order Separately)

Name Models

Soft cover Y92A-48F1

Hard cover For H5F-B Y92A-48

For H5F-FB/-KB Y92A-48E (See note 1.)

Flush Mounting Adapter (See note 2.) Y92F-30

Mounting Track 50 cm (l)

1 m (l)

1 m (l)

End Plate PFP-M

Spacer PFP-S

Note: 1. Supplied with H5F-KB model.

2. Supplied with H5F-B (flush-mounting) model.

´ 7.3 mm (t) PFP-50N

´ 7.3 mm (t) PFP-100N

´ 16 mm (t) PFP-100N2

Digital Daily Time Switch H5F 1

Page 2

Specifications

■Ratings

Rated supply voltage 100 to 240 VAC (50/60 Hz)

Operating voltage range 85% to 110% of rated supply voltage

Power consumption Approx. 2.4 VA at 264 VAC

Control outputs Contact output: SPST-NO, 15 A at 250 VAC, resistive load, 10 A at 24 VDC, resistive load

External connections Screw terminals (M3.5 screw)

Terminal screw tightening torque 0.98 to 1.17 N · m

■Characteristics

Accuracy of operating time ±0.01% ±0.05 s max. (see note 1)

Setting error

Influence of voltage

Influence of temperature

Cyclic error Monthly differen ce

Memory protection Continuous use: 5 years min. (at 25

Insulation resista nc e 100 M

Dielectric strength 2,000 V A C , 50/6 0 Hz f or 1 min (betw een curren t-carrying terminals and e xpos ed non-cu rrent-car rying metal parts and

Noise immunity 1.5 kV (between power terminals)

Vibration resistance Destruction:10 to 55 Hz with 0.375-mm single amplitude, four cycles each in three directions (8 minutes per cycle)

Shock resistance

Ambient temperature Operating:–10

Ambient humidity Operating: 35% to 85%

Life expectancy Mechanical (at 20

Approved safety standards UL508/Listing, CSA C22.2 No. 14, conforms to EN61010-1 (Pollution degr ee 2/overvoltage category II)

EMC (EMI) EN61326

Case color Light gray (Munsell 5Y7/1)

Weight H5F-B: approx. 115 g; H5F-KB: approx. 160 g; H5F-FB: approx. 130 g

Note: 1. The total error including the repeat accuracy, setting error, variation due to voltage change, and variation due to temperature change is

±0.01%±0.05 s max. ±0.01% also indicates an error in the time interval of a set time.

2. The total time when power is not being supplied.

Minimum applied load: 100 mA at 5 VDC (failure level: P, reference value)

NEMA A300 Pilot Duty, 1/3 HP at 120 VAC

±15 s (at 25°C)

(lithium ba tt ery)

W min. (between current-carrying t erminals and exposed non-current-carrying metal parts, between operating

power supply circui t and control output circuit and between non-continuous contacts )

between operating power supply circuit and control output circuit)

1,000 VAC, 50/60 Hz for 1 min (between non-continuous contacts)

Square-wave noise by noise simulator (pulse width: 100 ns/1

Malfunction:10 to 55 Hz with 0.25-mm single amplitude for 10 minutes eac h in three directions

Destruction:300 m/s

Malfunction:100 m/s

Storage: –25

100,000 operations min.

Electr ical (at 20

50,000 operations mi n. (15 A, 250 VAC, resistive load)

50,000 operations mi n. (1 HP, 250 VAC, motor load)

50,000 operations min. (10 A, 250 VAC, inductive load (cos

50,000 operations min. (100 W, 100 VAC, lamp load)

10,000 operations min. (300 W, 100 VAC, lamp load)

Conforms to VDE0106/P100 (finger protection).

Conforms to Electrical Appliance and Material Safety Law (for Japan)

Emission Enclosure: EN55011 Group 1 class A

Emission AC mains: EN55011 Group 1 class A

(EMS) EN61326

Immunity ESD: EN61000-4-2: 4 kV contact discharge (level 2)

Immunity RF-interference: EN61000-4-3: 10 V/m (Amplitude-modulated, 80 MHz to 1 GHz,

Immunity Conducted

Disturbance: EN61000-4-6: 10 V (0.15 to 80 MHz) (according to EN61000-6-2)

Immunity Burst: EN61000-4-4: 2 kV power-line (le vel 3)

Immunity Surge: EN61000-4-5: 1 kV line to lines (power and out put lines) (level 2) ;

Immunity Voltage Dip/Interrupti on: EN61000-4-11: 0.5 cycle, 100% (rat ed voltage)

Immunity Magnetic Power Field: EN61000-4-8: 30 A/m

2

3 times each in 6 directions

2

3 times each in 6 directions

°C to 55°C (with no icing)

°C to 65°C (with no icing)

°C):

°C):

°C); Power-interruption rate of 50%: 10 years min. (at 25°C) (see note 2)

ms, 1-ns rise)

f = 0.7))

8 kV air discharge (level 3)

1.4 to 2 GHz) (level 3)

1 kV I/O signal-line (le vel 4)

2 kV line to ground (power an d output lines) (level 3)

2 Digital Daily Time Switch H5F

Page 3

Connections

■Terminal Arrangement

Flush Mounting Models

H5F-B H5F-FB

(Rear View)

Power source

100 to 240 VAC

Load

Power supply

of load

Surface Mounting Models

(Front View)

H5FTIME SWITCH

SU MO TU WE TH FR SA

PM

3 00

OUT

ON

PM

POWER

OUT

ON

AUTO

OFF

Power source

100 to 240 VAC

5 00

PW

P

TMR/

MODE

CLR

P

m

/ WD

WRITE

dhSELECT

TESTHOLIDAY+1h

Load

Power supply

of load

Surface Mounting/Track Mounting Models

H5F-KB

(Front View)

H5FTIME SWITCH

SU MO TU WE TH FR SA

PM

3 00

ON

OUT

POWER

OUT

ON

AUTO

OFF

Power source

100 to 240 VAC

5 00

PM

PW

P

TMR/

MODE

SELECT

CLR

P

m

/ WD

h

WRITE

d

TESTHOLIDAY+1h

Load

Power supply

of load

Note: 1. The Time Switch uses M3.5 terminals.

2. The Time Switch output is no-voltage contact output. An external power supply is required to drive the load.

3. Applicable wire: 600-V vinyl-insulated wire (solid wire or twisted wire, copper), 14 to 24 AWG, 2 wires max. per terminal.

4. Applicable tightening torque: 0.98 to 1.17 N·m.

5. Recommended fuse: T2A, 250 VAC, time delay, low breaking capacity.

Operation

■Operation

Operation method Digital quartz

Time range 24 h

Operation 1. Daily operation (Multiple-day operation possible.)

Display 1. Day, hours (12-hour (am/pm) or 24-hour clock), minutes (0:00 to 11:59 a.m./ 0:00 to 11:59 p.m.,

Other func tions Program check function, summer time function

Number of circuits 1 independent circuit

Minimum setting unit 1 min

Minimum set interval 1 min

Number of operations that can be set 24 (see note)

Note: Up to 12 ON/OFF operations are possible per day. (For pulse-output operation, the number is 24.)

´ 7 days (Operation days can be specified.)

2. Pulse-output operation (Pulse width can be set in units of 1 s from 1 to 59 s and in units of 1min

from 1 to 60 min.)

3. Partial operation on specified day (One or some of the operations for certain days can also be

executed on other days.)

4. Forced ON/OFF operation

5. Holiday operation

6. Output override and automatic return operation

0:00 to 23:59)

2. Digital display by LCD. Character height: 8 mm

3. Digital display of present time and time schedules for operation

4. Timing chart display of present time and time schedules for operation

Digital Daily Time Switch H5F 3

Page 4

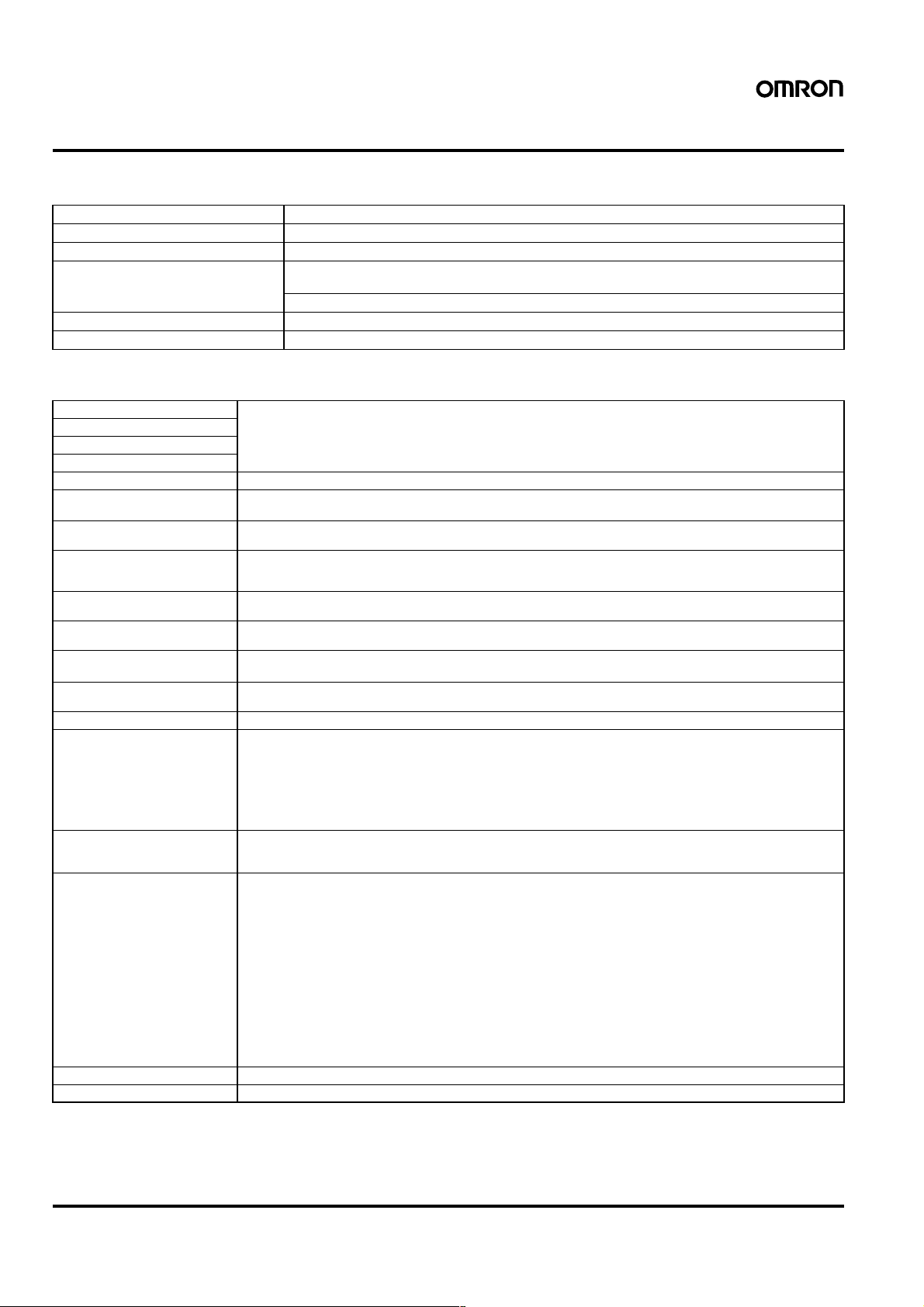

■Operation Function s

Timer operation (ON/OFF operation) Controls the output according to preset of ON and OFF times

• Minimum setting unit: 1 min

• Up to 12 ON/OFF operations are possible per day.

ON time

OFF time

Pulse-output operation Output turns ON for a fixed period (pulse width) at the set time.

Pulse width

ON time

• Pulse width: 1 to 59 s, or 1 to 60 min. (The same pulse width setting is used for all types of

output operation.)

• The pulse width can be set in units of 1 s or 1 min.

• Up to 24 pulse-output operations are possible per day.

Forced ON/OFF operation Forcibly turns ON/OFF the output by the output ON/OFF switch.

Override and automatic return operation Using the output ON/OFF switch and the Write Key, control output is held in the ON state until

Regular

program

Output

operation

Start of override and

automatic return operation

the next OFF time.

• It is also possible to hold the control output in the OFF state until the next ON time.

• Operation after the output turns OFF (or ON) will be based on the regular program.

• This function can be used with pulse-output operation.

Partial operation on specified day The Time Switch operates according to only some of the programs on a user-specified day.

(Convenient, for e xample, for executing a half-day operation on Saturday.)

• It is not possible to set operation to be executed only on the specified day.

• This function can be used with pulse-output operation.

Regular

program

Operation on

operation day

Operation on

specified day

Program 1

(special)

Program 2

Holiday setting It is possible to set a day in the present week as a holiday (i.e., a non-operation day: output

OFF regardless of the settings). When that day has passed, operation will continue according

to the regular program, and operation will be executed as normal on that day from the foll owing week

• This function can be used with pulse-output operation.

Regular

program

Operation in

present week

Operation from

next week

Operation on

operation day

Operation

on holiday

Note: B oth the timer operation and the pulse-output operation cannot be programmed together.

■Operation When Power Turn s OF F

1. The time and settings are backed up using a lithium battery.

2. The display stays ON but the output turns OFF.

3. Settings for all types of operation except override and automatic

return operation are possible.

4 Digital Daily Time Switch H5F

Page 5

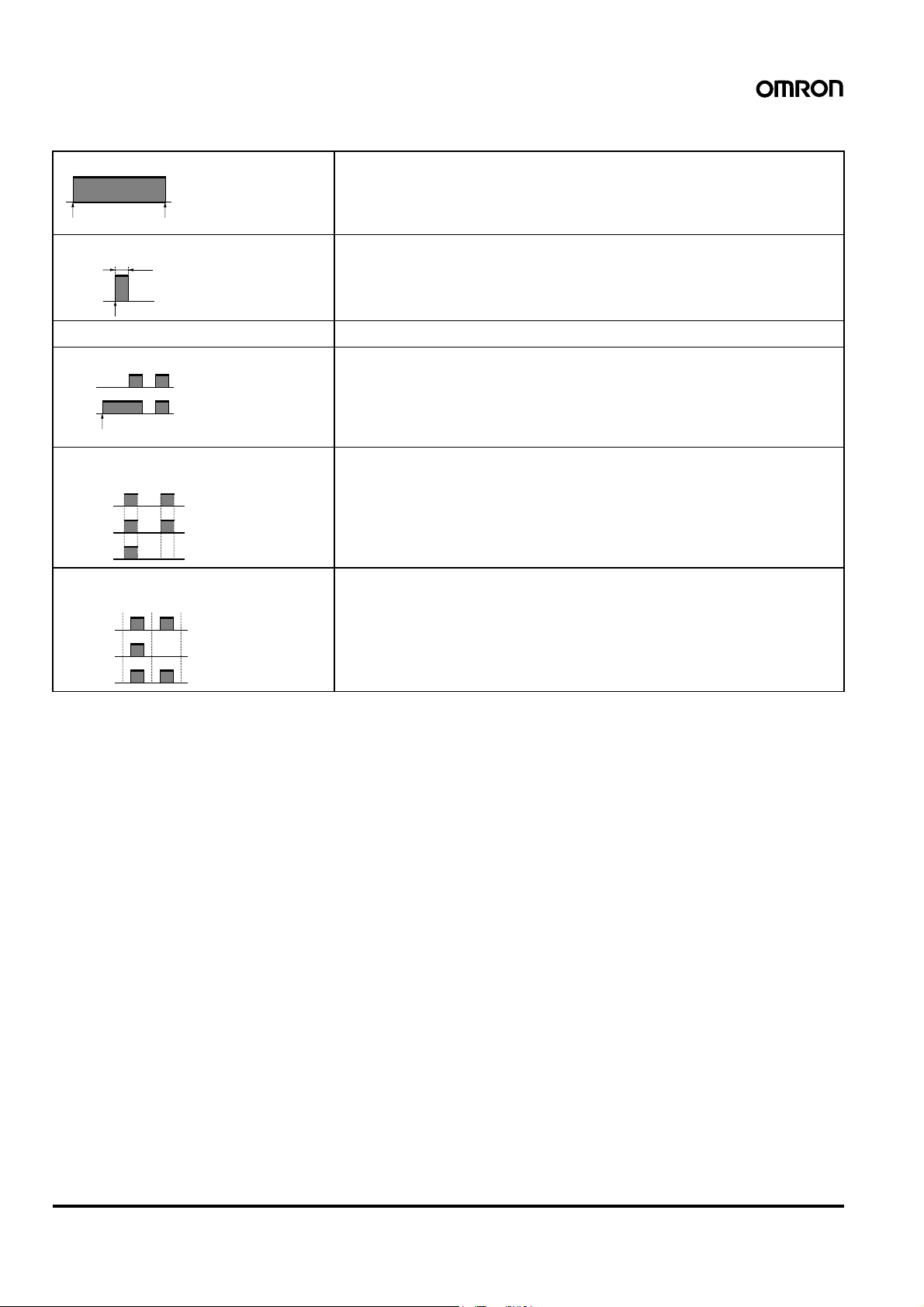

Nomenclature

Front Panel

(Actual Size)

H5FTIME SWITCH

SU MO TU WE TH FR SA

A Mode Key

OUT

P

I TMR/ Key

H Output ON/OFF

Switch

G CLR/+1h Key

No. Name Function

A Mode Key Switches between time adjustment mode, the operation setting modes, and run mode.

B h (Hour) Key Sets hours or switches between 12-hour (am/pm) and 24-hour display.

C Sets minutes or a pulse time width.

P

m/ WD (Minute/Pulse Time Width) Key

D Write Key Writes the set data to memory or confirms settings with the program check function.

E d/Test (Day Shift/Program Test) Key Moves the cursor to specify a day or starts the program check function.

F Select/Holiday Key Specifies or cancels a specified day or switches to holiday setting mode.

G CLR/+1h (Clear/Summer Time) Key Erases the set data and initializes the day of operation or sets/clears summer time.

H Output ON/OFF switch ON: Turns on the output regardless of the setting.

I Selects timer operation or pulse-output operation.

P

TMR/ (Timer/Pulse output) Key

POWER

OUT

ON

AUTO

OFF

TMR/

CLR

+1h

P

MODE

SELECT

HOLIDAY

B h Key

P

C m/ WD Key

D Write Key

E d/Test Key

TEST

P

m/

h

d

WD

WRITE

F Select/Holiday Key

AUTO: Turns on/off the output according to the setting.

OFF: Turns off the output regardless of the setting.

Override and automatic return operation can be executed by using this key in combination with the Write Key.

Display

Time Adjustment Mode Indicator

Displays the Present Time,

Operation Time, and Time Width

Output Indicator

Lit when control output is ON.

Power Indicator

Lit when power is supplied

to the Time Switch.

Pulse Operation Indicator

Lit: Pulse-output operation

Not lit: Timer operation

Present Day Indicator

Operation Day Indicator

SU MO TU WE TH FR SA

AM

PM

ON

PW

P

AM

PM

+1h

Lit: Operation day

Not lit: Non-operation day

Flashing: Specified operation day

S

s

m

Partial Operation on Specified Day Indicator

Pulse Width Unit Indicator

Summer Time Indicator

P

Lit when set to summer time.

Operation Setting Mode Indicator

Next Operation Indicators

Run mode: Displays the direction (i.e., ON or

Operation time setting mode: Displays the program number for

Holiday setting mode: Displays hday (hday) when the

Program check: Displays test (test) during

OFF) and time of the next output

operation.

the setting.

Time Switch is in holiday setting

mode.

program check.

Digital Daily Time Switch H5F 5

Page 6

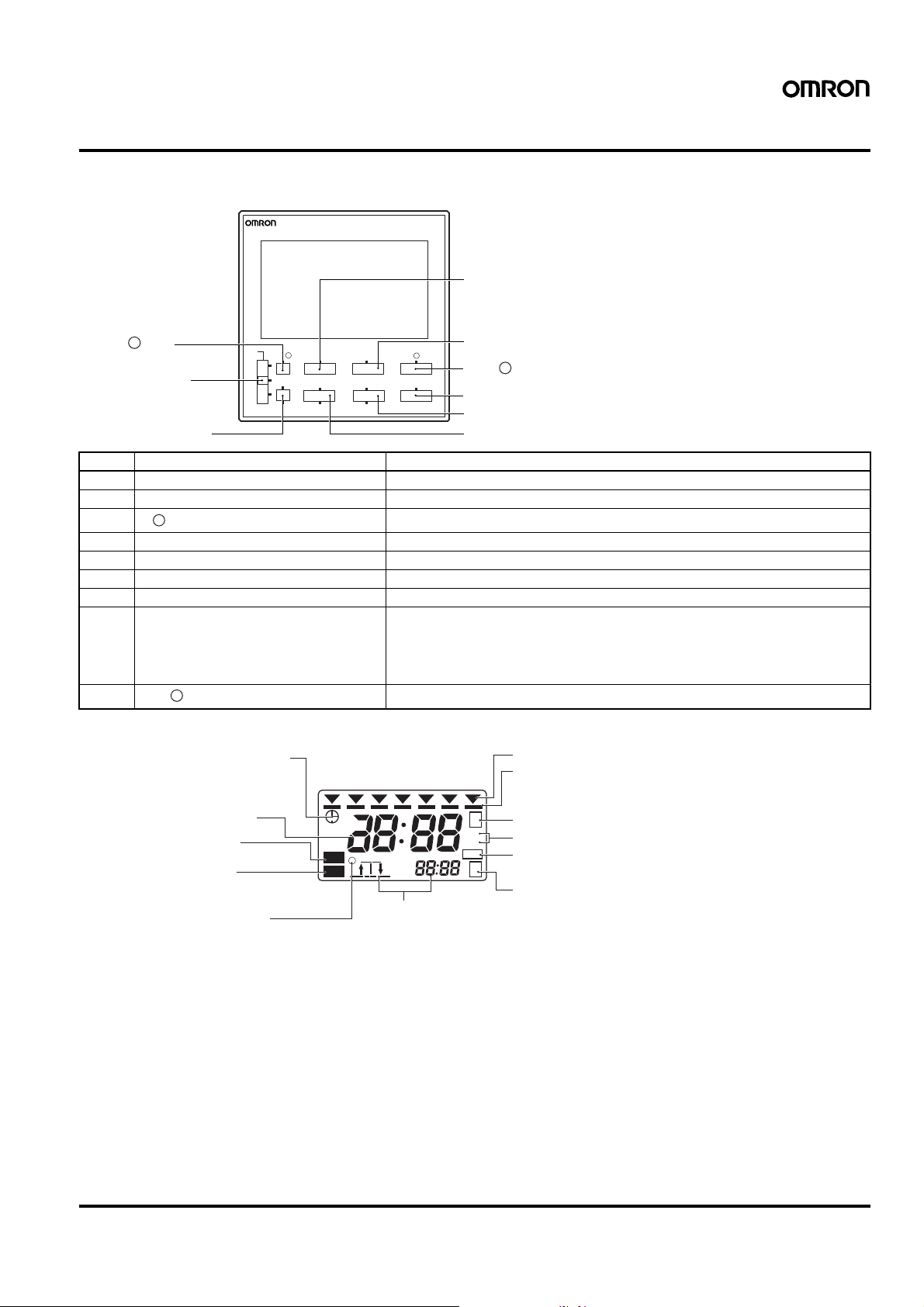

Dimensions

Note: A ll units are in millimeters unless otherwise indicated.

H5F-B (provided with Y92F-30 Flush Mounting Adap te r)

(Flush Mounting)

H5F

T

IM

E S

W

ITC

H

SU

M

O

T

U

W

E

TH

FR

S

A

P

M

3

OUT

00

O

N

P

O

W

E

R

P

W

P

M

5

0

0

OUT

T

M

R

/

P

MOD

E

h

ON

m/ WD

AUTO

OFF

P

CLR

SE

LECT

d

SET

+1h

HOLIDAY

TEST

48

H5F-FB

(Surface Mounting)

H5F

T

I

M

E

S

W

IT

C

H

S

U

M

O

T

U

W

E

T

H

F

R

S

A

P

M

3

O

U

00

T

O

N

P

O

W

E

R

P

W

P

M

5

0

0

O

U

T

T

M

R

/

P

M

O

D

h

E

m

P

O

A

U

T

O

F

/ W

N

O

F

1

D

C

L

R

S

E

L

E

C

T

d

S

E

T

+

1

h

H

O

L

ID

A

Y

T

E

S

T

1

0

0

to

2

4

0

V

A

C

5

0

/6

0

H

z

1

5

A

2

2

.4

5

0

V

V

A

A

m

C

a

x

2

.

1

0

A

2

4

V

D

C

3

R

E

S

.

4

50

92

Y92A-48 Hard Cover (sold separately)

48

6

50.6

50

Y92A-48E

Hard Cover

(sold separately)

49

42.1

63.7

84.8

88.7

14

Terminal cover (provided)

44.8

37.7

Note: The Time Switch

uses M3.5

terminals.

Mounting Dimensions

(50)

(92)

Panel Cutout Dimensions

(according to DIN43700)

+0.5

45

+0.5

45

Note: Recommended panel thickness: 1 to 5 mm.

8

76

1.5

H5F-KB

(Surface/Track Mounting)

H5F

TIME SWITCH

S

U

M

O

T

U

W

E

T

H

F

R

S

A

PM

3

O

U

T

00

O

N

P

O

W

E

R

P

W

P

M

5

00

O

U

T

T

M

R

/

P

M

O

D

h

E

m

P

/

O

N

A

U

T

O

O

F

F

W

D

C

L

R

S

E

L

E

C

T

d

S

E

T

+

1

h

H

O

L

ID

A

Y

T

E

S

T

1

2

.4

V

A

m

a

x

2

.

3

R

E

S

.

4

101.2

Terminal cover

(provided)

Wiring cutout sections:

Cut out as required for wiring.

50

Y92A-48E

Hard Cover

(provided)

68

50.5

Terminal cover (provided)

31

Note: The Time Switch

uses M3.5

terminals.

M4 tapping screws provided.

Approximate pilot hole dimensions:

Panel thickness of 0.8 to 1.2 mm: 3.6 mm dia.

Panel thickness of 1.6 to 4.0 mm: 3.7 mm dia.

Mounting Hole Cutout Dimensions

73

42

50

35.3

90

43.1

60

25

(101.2)

117.4

104 to 106

(50.5)

M4 tapping screws provided.

Approximate pilot hole dimensions:

Panel thickness of 0.8 to 1.2 mm: 3.6 mm dia.

Panel thickness of 1.6 to 4.0 mm: 3.7 mm dia.

6 Digital Daily Time Switch H5F

Page 7

■Accessories (Order Separately)

Note: Depending on the operating environment, resin products may deteriorate, contract, or harden. They must be replaced on a regular basis .

Soft Cover

Y92A-48F1

Settings can be changed by pressing on the front of the Cover. The

settings are harder to change, however, with the Cover mounted.

Confirm that this does not hamper operation. Although the Soft

Cover provides protection equivalent to IP54F, do not use the Time

Switch in locations where it may be directly subject to splashes of oil.

Flush Mounting Adapter

(provided with H5F-B)

Y92F-30

The Flush Mounting Adapter can be purchased individually if it is lost

or damaged.

Hard Cover

(provided with H5F-KB)

Y92F-48 (for H5F-B)

Y92A-48E (for H5F-FB/-KB)

Mounting T rack

PFP-100N, PFP-50N

4.5

15 25 25

10

1,000 (500)

(see note)

25

10

Note: The values shown in parentheses are for the PFP-50N.

7.3±0.15

35±0.3

25

*

27±0.15

1

End Plate

PFP-M

10

6.2

1.8

1

1.3

4.8

1.8

35.5 35.3

50

11.5

10

M4 x 8

pan head

screw

PFP-100N2

4.5

15 25 25

Spacer

PFP-S

10 10

25 25

1,000

16

1

34.8

29.2

1.5

24

27

35±0.3

15

5

16

12

44.3

16.5

Digital Daily Time Switch H5F 7

Page 8

Precautions

!Caution

Do not touch any of the terminals while power is being supplied.

Doing so may result in electric shock. Be sure to mount the terminal cover after wiring.

Do not use the Time Switch in locations s ubject to flammable or

explosive gases. Doing so may result in explosion.

Do not disassemble, repair, or modify the Time Switch. Doing so

may result in electric shock, fire, or malfunction.

Before changing times or other settings while power is being s upplied, either turn OFF the power on the load side or set the output

ON/OFF switch to OFF and confirm the safety of the system.

The life expectancy of the output relays depends on the switching

capacity and switching conditions. Consider the actual application

conditions and use the Time Switch within the rated load and electrical service life. If using the Time Switch beyond its ratings is

unavoidable, use it together with an electromagnetic switch or contactor as shown in the following diagram.

Electromagnetic

contactor or

electromagnetic

switch

Crossover

Power supply

Load

Power supply

Circuit

H5F

Using the Time Switch beyond its life expectancy may result in contact deposition or burning.

Do not disassemble the Time Switch, deform the Time Switch by

applying pressure, heat the Time Switch to temperatures above

100

°C, or incinerate the Time Switch. Doing any of these may

cause the built-in lithium battery to ignite or rupture.

■Wiring

• Be sure to wire the terminals correctly.

• Do not connect more than two crimp terminals to each Time Switch

terminal. Faulty contact may result in burn injury or fire.

• Perform wiring using appropriate wires of the type specified in this

document. Using a different type of wire may result in burn injury or

fire due to abnormal heat generation.

■Power Supplies

• Make sure that the fluctuation of the supply voltage is within the

permissible range.

• Make sure that the voltage applied is within the specified range,

otherwise the internal elements of the Time Switch may be damaged.

• Apply the power supply voltage through a breaker, relay or switch in

such a way that the voltage reaches a fixed value immediately, otherwise they may not be reset or a Time Switch error may result.

• When the power is turned ON, an inrush current will flow for a short

time (approx. 2 A for 0.3 ms at 264 VAC). Depending on the power

supply capacity, operation may not start. Be sure to use a power

supply with a sufficient capacity and a breaker.

■Operat ing Environment

• Do not use t he Time Switch in locations where condens ation may

occur due to high humidity or where temperature changes are

severe.

• Do not leave the Time Switch for long periods (i.e., one month or

longer) at a high temperature with output current in the ON state.

Doing so may result in the premature deterioration of internal components (e.g., electrolytic capacitors).

• Separate the Time Switch from any potential sources of noise, such

as high-voltage lines. When using inductive loads (e.g., electromagnetic relays), connect noise-absorbing elements (resistor and

capacitor) to both ends of the coil.

• Separate the Time Switch from t he sour ce of st atic electr icity when

using the Time Switch in an environment where a large amount of

static electricity is produced (e.g., forming compounds, powders, or

fluid materials being transported by pipe).

• Use the Time Switch within the ratings specified for temperature

and humidity.

• Do not use t he Time Switch in environments subject to shocks or

vibration beyond the ranges specified in this document.

• Do not us e the Time Switch in locations subject to dust, corrosive

gases, or direct sunlight.

• Store at the specified temperature. If the H5F has been stored at a

temperature of less than

-10°C, allow the H5F to stand at room

temperature for at least 3 hours before use.

• This Time Switch is not waterproof or oil-proof. Do not use it in

locations where water or oil may enter the Time Switch interior.

• Organic solvents (such as paint thinner), as well as very acidic or

basic solutions might damage the outer casing of the H5F.

■Installation

• Mounting the Time Switches side-by-side may reduce the life

expectancies of internal components.

• When using heat ers, be sure to use a therm al switch for the load

circuit.

• When driving an inductive load (e.g., coil), a surge voltage is generated when the contacts (i.e., Time Switch output) are switched, and

in some cases this may damage other devices connected to the

Time Switch or the same line. Absorb the surge with a capacitor

and resistor as shown in the following diagram.

Time Switch output

C

Power supply

As a rough guide, the capacitor (C) and resistor (R) should have the

following specifications:

C: 0.5 to 1

R: 0.5 to 1

mF for a switching current of 1 A

W for a switching voltage of 1 V

Use a capacitor with a dielectric strength appropriate for the power

supply voltage. Use an AC-type capacitor with AC circuits. There

may be cases where, due to inconsistencies in the nature and characteristics of the load, delays in restoring the load may cause problems. Be sure to confirm that correct operation is possible under the

actual operating conditions.

Inductive

load

R

8 Digital Daily Time Switch H5F

Page 9

■Precautions for EN6101 0- 1

Conformance

The H5F Time Switch conforms to EN61010-1 provided that the following conditions are satisfied:

Basic insulation is provided between the power supply and output

terminals of the H5F.

• Output terminals are connected to devices without exposed

charged parts.

• Output terminals are connected to devices with basic insulation that

is suitable for the maximum operating voltage.

■Others

None of the Time Switch components are user-replaceable, including

the battery.

Digital Daily Time Switch H5F 9

Page 10

Operating Method

■Operating Method

Selecting the Mode

All of the modes can be selected using , , and

Keys.

• The days and times

when output will

actually turn

ON/OFF are

displayed

chronologically.

Program check

function

test

TEST

(See note 1.)

TEST

(2 s min.)

• Set a special day

when the Time

Switch will not

operate temporarily

HOLIDAY HOLIDAY

Run Mode

(See note 2.)

MODE

Time Adjustment Mode

MODE

Operation Time Setting Mode

MODE

Operation Date Setting Mode

MODE

Note: 1. After the last item is displayed, the mode automatically re-

turns to ru n m o de.

2. At the time of delivery, the mode is the run mode.

MODE HOLIDAY

Holiday Setting Mode

hday

• Control output operates according

to the settings.

(1 s min.)

• Set the present day

and time.

• Set, confirm, change,

P

or clear the operation

time setting. Also, set

the pulse width for

pulse-output

operation.

• Set, confirm, change,

P

or clear the operation

day and specified day

settings.

(2 s min.)

Setting the Time

Example: Changing the current time setting from

Wednesday 10:30 am to Monday 4:00 am.

1. Press the Key for 1 s min. to

enter time adjustment mode. The

2. Move the symbol to Monday

using the Key. Change the

time to 4:00 am using the

and Keys.

MODE

symbol flashes.

d

P

m/ WD

h

The color indicates flashing

SU MO TU WE TH FR SA

AM

10 30

ON

PW

SU MO TU WE TH FR SA

AM

4 00

ON

PW

TEST

3. Press the Key. The colon

will flash and the clock will start

(from 0 s).

WRITE

SU MO TU WE TH FR SA

AM

4 00

PW

4. Press the Key 3 times to

return to the run mode.

MODE

SU MO TU WE TH FR SA

AM

4 00

PW

AM

8 30

Factory Setting

At the time of delivery, the mode is run

mode and there is no current time setting. Before making any other settings,

press the Key for 1 s min. to

enter time adjustment mode and set

the current time using the above procedure.

Note: 1. The set time is enabled when the Key is pressed.

MODE

2. The time can be displayed in either 12-hour (am/pm) or 24hour display. (Refer to page 14.)

Display of factory setting

SU MO TU WE TH FR SA

-- --

-- --

WRITE

Setting Timer Operation

Example: Setting the Time Switch to operate from

Monday to Friday between 8:30 am and 5:15 pm

Non-operation Operation

Sunday

1. Enter operation time setting mode

Monday

8:30 am 5:15 pm

using the Key. The symbol flashes.

Operation Operation Operation Operation Non-operation

Friday Saturday

The color indicates flashing

SU MO TU WE TH FR SA

MODE

Tuesday

Wednesday

P

Thursday

-- --

2. Set the ON time to 8:30 am using

P

WRITE

m/ WD

P

m/ WD

h

the and Keys.

3. Press the Key.

(If only the hour or the minute (but

not both) is set, the operation setting time display will flash to indicate an error.)

4. Set the OFF time to 5:15 pm using

h

the and Keys.

PW

SU MO TU WE TH FR SA

AM

PW

SU MO TU WE TH FR SA

PW

SU MO TU WE TH FR SA

PM

PW

1

8 30

1

-- --

1

5 15

1

P

P

P

P

10 Digital Daily Time Switch H5F

Page 11

5. Press the Key.

(Repeat steps 2 to 5 to make other

WRITE

SU MO TU WE TH FR SA

settings if necessary.)

-- --

P

P

P

Saturday

6. Press the Key to enter oper-

MODE

ation date setting mode.

7. Move the symbol to Saturday (or

Sunday) using the Key.

d

PW

SU MO TU WE TH FR SA

PW

SU MO TU WE TH FR SA

2

Clear the operation day indicator

( ) by pressing the Key.

WRITE

8. Press the Key.

MODE

WRITE

Lit (operation day)

Not lit (non-operation day)

PW

WRITE

SU MO TU WE TH FR SA

The Time Switch will enter run

mode and operation based on the

settings will start.

AM

10 30

ON

PW

PM

5 15

Note: 1. Up to 12 sets of ON-OFF settings are possible.

2. Be sure to set both ON and OFF times. If only the ON time

is set, the setting will be invalid.

3. At the time of delivery, all days are set as operation days.

4. Multiple-day operation is possible.

5. Continuous operation for more than 24 hours is possible b y

combining 2 or more sets of settings. (Refer to page16.)

6. Both the timer operation and the pulse-output operation

cannot be programmed together.

Setting Pulse-output Operation

Using pulse-output operation, the Time Switch can be set to operate

at the same time every day for a fixed period.

Example: Setting the Time Switch to turn ON for 30 s from

8:25 am, Monday to Friday

Non-operation Operation Operation Operation Operation Operation Non-operation

Sunday

Monday

8:25 am

30 s

Tuesday

Wednesday

1. Enter operation time setting mode

using the Key. The sym-

MODE

P

bol flashes.

Thursday

Friday

The color indicates flashing

SU MO TU WE TH FR SA

-- --

P

P

P

2. Press the Key to set the

TMR/

Time Switch for pulse-output operation. The symbol flashes. (The

P

Time Switch is set for timer operation at the time of delivery.)

PW

SU MO TU WE TH FR SA

PW

1

--

P

3. Set the pulse width to 30 s using

P

m/ WD

the Key. (The pulse width

SU MO TU WE TH FR SA

can be set in the range 1 to 59 s or

1 to 60 min.)

4. Press the Key.

WRITE

5. Set the ON time (the time when

pulse-output operation starts) to

8:25 am using the and

P

m/ WD

Keys.

6. Press the Key.

WRITE

h

30

P

PW

SU MO TU WE TH FR SA

-- --

P

PW

The color indicates flashing

SU MO TU WE TH FR SA

AM

8 25

P

PW

SU MO TU WE TH FR SA

(Repeat steps 5 and 6 to make

other settings if necessary.)

-- --

P

PW

7. Press the Key to enter the

operation date setting mode.

8. Move the symbol to Saturday (or

Sunday) using the Key.

MODE

SU MO TU WE TH FR SA

P

PW

d

SU MO TU WE TH FR SA

Clear the operation day indicator

( ) by pressing the Key.

WRITE

9. Press the Key. The Time

MODE

WRITE

Lit (operation day)

Not lit (non-operation day)

P

PW

WRITE

SU MO TU WE TH FR SA

Switch will enter run mode and

operation based on the settings will

start.

AM

7 30

P

PW

Note: 1. U p to 24 sets of settings are possible.

2. Switching between timer operation and pulse-output oper-

ation will clear the operation start time, operation day, and

pulse width settings.

3. Both the timer operation and pulse-output operation cannot be programmed together.

1

1

2

AM

8 25

s

P

P

P

P

P

P

Digital Daily Time Switch H5F 11

Page 12

Setting Partial Operation on Specified

Day

The Time Switch can be set to operate according to only some of the

settings on a user-specified day.

Example:

Monday to Friday: ON at 8:30 am; OFF at 0:30 pm

ON at 1:15 pm; OFF at 5:15 pm

Saturday: ON at 8:30 am; OFF at 0:30 pm

Non-operation Operation

Sunday

Monday

Operation Operation Operation Operation Specified day

Friday

Tuesday

Wednesday

Thursday

Saturday

8. Move the symbol to Saturday

using the Key. Make the

d

operation day indicator flash by

pressing the Key. Move the

WRITE

present day indicator to Sunday

using the Key. Clear the

d

operation day indicator by pressing

WRITE

the Key.

WRITE

WRITE

Lit: Operation day

Not lit: Non-operation day

Flashing: Specified operation day

SU MO TU WE TH FR SA

PW

WRITE

P

8:30 am to 0:30 pm (Specified Day Operation)

1:15 pm to 5:15 pm

1. Enter operation time setting mode

using the Key .

2. Press the Key. The

MODE

SELECT

symbol will be displayed. Set the

ON time for the specified day to

8:30 am using the and

P

m/ WD

Keys.

3. Press the Key.

WRITE

h

4. Set the OFF time for the specified

day to 0:30 pm using the

P

m/ WD

and Keys.

5. Press the Key.

WRITE

h

Set the time to 1:15 pm using the

P

h

6. Press the Key.

m/ WD

and Keys.

WRITE

Set the time to 5:15 pm using the

P

h

7. Press the Key.

Press the Key to enter oper-

m/ WD

and Keys.

WRITE

MODE

ation date setting mode.

9. Press the Key.

The Time Switch will enter run

MODE

SU MO TU WE TH FR SA

mode and operation based on the

AM

10 30

ON

PW

PM

0 30

The color indicates flashing

SU MO TU WE TH FR SA

settings will start. The operation

day indicator ( ) of the specified

day will flash.

Note: 1. Partial operation on specified day can be set for two or

-- --

PW

S

SU MO TU WE TH FR SA

AM

PW

SU MO TU WE TH FR SA

1

8 30

1

P

S

P

Changing Timer Operation Settings

Example: Changing the ON time for p rogr am 1 from 8 :30

1. Enter operation time setting mode

S

-- --

PW

SU MO TU WE TH FR SA

PM

PW

SU MO TU WE TH FR SA

PM

1 15

PW

SU MO TU WE TH FR SA

PM

5 15

PW

SU MO TU WE TH FR SA

PW

1

0 30

1

The color indicates flashing

2

2

P

2. Change the ON time to 7:45 am

S

P

P

P

3. Press the Key. The OFF

4. Press the Key to enter oper-

5. Press the Key.

P

Note: Operation based on the changed settings will start as soon as

more programs. For each program, however, the must

be displayed by pressing the Key.

SELECT

2. Two or more days can be specified as specified days.

3. Partial operation on specified day can also be set for pulse-

output operation.

am to 7:45 am

using the Key. The ON time

for program 1 will be displayed.

using the and Keys.

time for program 1 will be display ed.

MODE

h

WRITE

P

m/ WD

The color indicates flashing

SU MO TU WE TH FR SA

AM

8 30

ON

PW

SU MO TU WE TH FR SA

AM

ON

PW

SU MO TU WE TH FR SA

1

7 45

1

(Make changes, if necessary, using

the same procedure as for ON

time.)

MODE

ation date setting mode. The opera-

PM

6 30

ON

PW

SU MO TU WE TH FR SA

1

tion dates will be displayed. (Make

changes, if necessary, using the

d

WRITE

and Keys.)

MODE

ON

PW

SU MO TU WE TH FR SA

The Time Switch will enter run

mode and operation will start.

AM

10 30

ON

PW

PM

6 30

S

P

P

P

P

the Time Switch returns to run mode.

12 Digital Daily Time Switch H5F

Page 13

Changing Pulse-output Operation

Settings

Clearing the ON/OFF Settings for

Individual Programs

Example: Changing the pulse width from 30 s to 20 s

1. Enter operation time setting mode

MODE

using Key. The pulse width

is displayed.

2. Change the pulse width to 20 s

P

m/ WD

using Key.

3. Press the Key. The ON time

for program 1 will be displayed.

(Make changes, if necessary, using

the , and

Key.)

4. Press the Key to enter oper-

ation date setting mode. The operation dates will be displayed. (Make

changes, if necessary, using the

WRITE

m/ WD

h

MODE

d

WRITE

and Keys.)

P

WRITE

The color indicates flashing

SU MO TU WE TH FR SA

30

P

PW

SU MO TU WE TH FR SA

20

P

PW

SU MO TU WE TH FR SA

AM

7 40

P

PW

SU MO TU WE TH FR SA

PW

1

P

Example: Clearing the settings for program 2

1. Enter operation time setting mode

MODE

using Key. The ON time for

program 1 will be displayed.

s

P

2. Press the Key twice. The

ON time for program 2 will be displayed.

s

P

3. Press the Key. (Both the ON

and OFF settings are cleared with

just one operation. If this operation

is performed while output is ON,

P

P

output stays ON until the Time

Switch returns to run mode.)

4. Press the Key twice. The

Time Switch will enter run mode

and operation based on the new

settings (i.e. without the cleared

programs) will start.

WRITE

CLR

MODE

The color indicates flashing

SU MO TU WE TH FR SA

AM

8 30

ON

PW

SU MO TU WE TH FR SA

PM

ON

PW

SU MO TU WE TH FR SA

ON

PW

SU MO TU WE TH FR SA

AM

ON

PW

1

1 15

2

-- --

2

10 30

PM

0 30

S

P

P

P

5. Press the Key. The Time

Switch will enter run mode and

operation will start.

Note: Operation based on the changed settings will start as soon as

the Time Switch returns to run mode.

MODE

SU MO TU WE TH FR SA

AM

7 30

P

PW

AM

7 40

Note: Sett ings for pulse-output operation can be cleared for individ-

ual programs in the same way.

Clearing all Settings

1. Enter operation time setting mode

or operation date setting mode

using the Key.

2. Press the Key for 3 s min.

The clearing process will be completed 3 s has elapsed. Output will

turn OFF immediately.

3. When all the settings have been

cleared, the operation time, operation day, pulse width, holiday , partial

operation on specified day, and

override and automatic return operation settings will be returned to

their factory settings.

Note: The c lear ing pro cess will be canceled if the Key is re-

MODE

CLR

leased while clr is still flashing and only the settings for the

display program will be cleared.

The color indicates flashing

SU MO TU WE TH FR SA

AM

8 30

ON

PW

SU MO TU WE TH FR SA

c lr

ON

PW

SU MO TU WE TH FR SA

1

-- --

PW

1

CLR

S

P

P

Digital Daily Time Switch H5F 13

Page 14

Holiday Setting Function

The following example shows how to stop operation for a certain day

in the present week and restore normal operation from the following

week using the holiday setting function.

Example: Stopping operation for Friday and Saturday in

the current week and resuming normal

operation from the following week

1. Press the Key for 2 s min.

HOLIDAY

in run mode to enter holiday setting

mode. hday will flash and the operation day indicator ( ) will light

under the days set for operation

day.

2. Move the symbol to Friday using

d

Key. Clear the operation day

indicator ( ) by pressing the

WRITE

Key. Repeat the procedure

for Saturday. (P ress the Key

WRITE

again to clear the holiday setting.)

3. Press the Key. The T ime

HOLIDAY

Switch will enter run mode and the

operation day indicator under the

days set as holidays will turn OFF.

(When a day set as a holiday has

passed, the ( ) indicator under

that day will automatically turn ON

again.)

The color indicates flashing

SU MO TU WE TH FR SA

ON

PW

SU MO TU WE TH FR SA

ON

PW

SU MO TU WE TH FR SA

AM

ON

PW

hd ay

hd ay

10 30

PM

5 15

Switching between 12-hour (am/pm)

and 24-hour Display

PM

5 15

h

24-hour Display12-hour (am/pm) Display

The color indicates flashing

SU MO TU WE TH FR SA

h

(2 s min.)

15 30

ON

PW

17 15

Each time the Key is pressed for 2 s min. in run mode, the

time display switches between 12-hour (am/pm) and 24-hour display.

SU MO TU WE TH FR SA

PM

3 30

ON

PW

Note: 1. Switching is possible only in run mode.

2. The factory setting is 12-hour (am/pm) display.

Override and Automatic Return

Operation

Override and automatic return operation can be used to handle sudden schedule changes without making changes to the program. The

output status can be set to ON or OFF directly using the output ON/

OFF switch. This output status is then held until the next ON/OFF

operation time.

Example 1: Starting operation earlier than the sche duled

time on the present day only

Regular setting: ON at 8:30 am; OFF at 5:15 pm

Note: 1. Any day in the 7-day period starting from the present day

can be set as a holiday.

2. Operation based on the new settings (i.e., including the

holiday setting) will start as soon as the Time Switch returns to run mode.

3. Holiday setting mode can be entered from run mode only.

4. If the present day setting in time adjustment mode is

changed, all holiday settings will be cleared.

5. If a day set as a holiday is changed in operation date setting mode, the holiday setting for that day will be cleared.

Summer Time (DST) Function

The summer time function allows the Time Switch to be used in

regions that observe daylight saving time during the summer.

Each time the Key is pressed in run mode, the present time

will switch between the (standard) present time and the present time

+ 1 hour (summer time).

SU MO TU WE TH FR SA

PM

3 30

ON

PW

Note: 1. The summer time indicator ( ) is displayed while

2. The contents of the programs are not changed.

3. The summer time setting can only be set or cleared in run

+1h

PM

5 15

summer time is set.

mode.

+1h

The color indicates flashing

SU MO TU WE TH FR SA

PM

4 30

ON

PW

+1h

PM

5 15

+1h

Use the following proc edure to sta rt operatio n at 7:00 a m

for the present day only.

Present day Next day

Regular

program

Override and

automatic return

operation ON

Output

7:00 am

8:30 am 5:15 pm 8:30 am 5:15 pm

7:00 am

5:15 pm

8:30 am

5:15 pm

From the next day, output

operates according to the

regular program.

1. Change the setting of the output ON/OFF switch from AUTO to

ON.

2. Return the setting of the output ON/O FF switch from

ON to AUTO while holding down the Key.

WRITE

The ON state will be held from the point at which this

operation is performed (indicated by the arrow) until

the next (regular) OFF time.

Switch

ON

AUTO

OFF

Example 2: Stopping operation earlier than the

scheduled time on the present day only

Regular setting: ON at 8:30 am; OFF at 5:15 pm

Use the following proc edure to stop operatio n at 3: 00 pm

for the present day only.

Next day

8:30 am 5:15 pm

From the next day, output

operates according to the

regular program.

Regular

program

Override and

automatic return

operation ON

Output

Present day

3:00 pm

8:30 am

8:30 am

3:00 pm

5:15 pm 8:30 am 5:15 pm

14 Digital Daily Time Switch H5F

Page 15

1. Change the setting of the output ON/OFF switch from AUTO to

OFF.

2. Return the setting of the output ON/OFF switch from

OFF to AUTO while holding down the Key.

The OFF state will be held from the point at which this

operation is performed (indicated by the arrow) until

the next (regular) ON time.

Note: 1. This operation is possible in run mode only.

2. Override and automatic return operation can be cleared by

setting the output ON/OFF switch to the opposite of the

present status. For example, if the output is ON, override

and automatic return operation can be cleared by setting

the output ON/OFF switch to OFF.

3. Override and automatic return operation cannot be set or

cleared if power is not being supplied to the Time Switch.

4. Override and automatic return operation is cleared if any of

the settings are changed.

WRITE

Switch

ON

AUTO

OFF

Using Override and Automatic Return Operation for

Pulse-output Operation

Override and automatic return operation proc eeds in the following

way when used for pulse-output operation.

• If override and automatic return operation star ts with a forced ON,

output is turned ON for the time corresponding to the set pulse

width.

• If override and automatic return operation starts from a forced OFF,

output remains OFF until the pulse output ends.

The operation method is the same as for timer operation.

Example 1: Override and automatic return operation

starting with a forced ON while output is ON

(pulse width: 30 min)

Regular

program

Output

Point at which the Output ON/OFF Key changes from

AUTO to ON.

Point at which the Output ON/OFF Key changes from

ON to AUTO with the Key held down.

30 min

From the next

time onwards,

output operates

according to the

regular program.

WRITE

Example 2: Override and automatic return operation

starting with a forced ON while output is OFF

(pulse width: 30 min)

Regular

program

Output

Point at which the Output ON/OFF Key changes from

AUTO to ON.

Point at which the Output ON/OFF Key changes from

ON to AUTO with the Key held down.

30 min

From the next time

onwards, output

operates

according to the

regular program.

WRITE

Example 3: Override and automatic return operation

starting from a forced OFF while output is ON

(pulse width: 30 min)

Regular

program

Output

Point at which the Output ON/OFF Key changes from

AUTO to OFF.

Point at which the Output ON/OFF Key changes from

OFF to AUTO with the Key held down.

WRITE

From the next

time onwards,

output operates

according to the

regular program.

Program Check Function

The days and times at which output turns ON or OFF over the course

of one week can be displayed continuously in the actual order in

which they will occur.

1. Press the Key for 2 s min. in

run mode to start the program

check.

The display will flash test and the

day and time of the next change in

output status will be displayed.

2. Press the Key.

The display will change to the day

and time of the next change in output status. (Continue pressing the

WRITE

times for one week.)

3. If the Key is pressed with

the last setting for the week displayed, end is displayed for 2 s and

then the Time Switch automatically

returns to run mode.

Note: 1. The program check can be started from run mode only.

TEST

WRITE

Key to display the days and

WRITE

The color indicates flashing items.

SU MO TU WE TH FR SA

PM

1 15

PW

In the above example, output will

turn ON at 1:15 pm on Monday.

SU MO TU WE TH FR SA

PM

5 30

PW

In the above example, output will

turn OFF at 5:30 pm on Monday.

SU MO TU WE TH FR SA

te st

te st

e nd

PW

2. Press the Key again to return to run mode before

reaching the end of the program check function display sequence.

3. The ON and OFF symbols ( / ) displayed during

program check have no effect on the present operation.

4. Only ON times are displayed for pulse-output operation.

TEST

Digital Daily Time Switch H5F 15

Page 16

■Setting Examples

As shown in the following examples, continuous operation for more

than 24 hours is possible by combining two or more settings. Refer to

Setting Precautions for more details.

Example 1: Use the settings given below to turn ON

output from 8:30 am on Monday right

through to 0:30 pm on Saturday.

SU MO TU

1:00 pm

8:30 am

0:30 pm

2:00 pm

Operation time settings:

1:00 pm to 0:30 pm

8:30 am to 2:00 pm

WE TH

FR

SA

0:30 pm

Example 3: Use the settings given below to turn ON

output from 8:00 pm to 7:00 am from Monday

to Thursday and from 8:00 pm on Frid ay right

through to 7:00 am on Monday.

SU MO TU

6:00 am

9:00 am

8:00 pm 8:00 pm7:00 am7:00 am

Operation time settings:

8:00 pm to 7:00 am (specified day operation)

6:00 am to 9:00 pm

Operation day settings:

Specified day ( ): Monday, Tuesday, Wednesday, Thursday,

Operation day ( ): Saturday, Sunday

Friday

WE TH

FR

SA

Operation day settings:

Operation day ( ): Monday, Tuesday, Wednesday, Thursday,

Friday

Example 2: Use the settings given below to turn ON

output from 1:00 pm on Monday right

through to 8:00 am on Saturday.

SU MO TU

7:00 am

1:00 pm 8:00 am 8:00 am

Operation time settings:

1:00 pm to 8:00 am (specified day operation)

7:00 am to 2:00 pm

Operation day settings:

Specified day ( ): Monday

Operation day ( ): Tuesday, Wednesday, Thursday, Friday

2:00 pm

WE TH

FR

SA

■Setting Precautions

1. If settings overlap, the earliest ON time and the latest OFF time

will be used.

Program 1

+

Program 2

Output

• Output will stay ON continuously without interruption.

• If an ON and OF F setting are made for the same time, the out-

put status will not change at that time.

2. If there is a switch between timer operation and pulse-output

operation, the operation time, operation day, and pulse width settings will all be cleared.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. L015-E1-04

In the interest of product im provement, specifications are subje ct to c ha nge without notice.

OMRON Corporation

Industrial Automation Company

Industrial Control Components Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7119/Fax: (81)75-344-7149

16

Printed in Japan

1202-1M (0696) (A)

Loading...

Loading...