Page 1

24-hour/Weekly Time Switch

H2F

Up to 96 ON/OFF Cycles from DIN-sized

(72 x 72 mm) Timer

• Easy setting with color-coded programming tabs.

• Choose from 24-hour or 1-week models wi th either SPST-NO or

SPDT control outputs.

• Minute dial assures accur ate settings.

• Models with memory protection available.

• Control outputs can be manual ly turned ON/OFF.

• Designed for surface, flush, or trac k mounting.

Model Number Structure

■Model Number Legend

H2F-@@@@

1 2 34

1. Operation cycle

D: 24-hour

W: 1-week

2. Motor type

None:Synchronous motor

M: Quartz motor

3. Mounting method

None:Flush mounting

F: Surface mounting, DIN track mounting

4. Output type

None:SPST-NO

C: SPDT

24-hour/Weekly Time Switch H2F 1

Page 2

Ordering Information

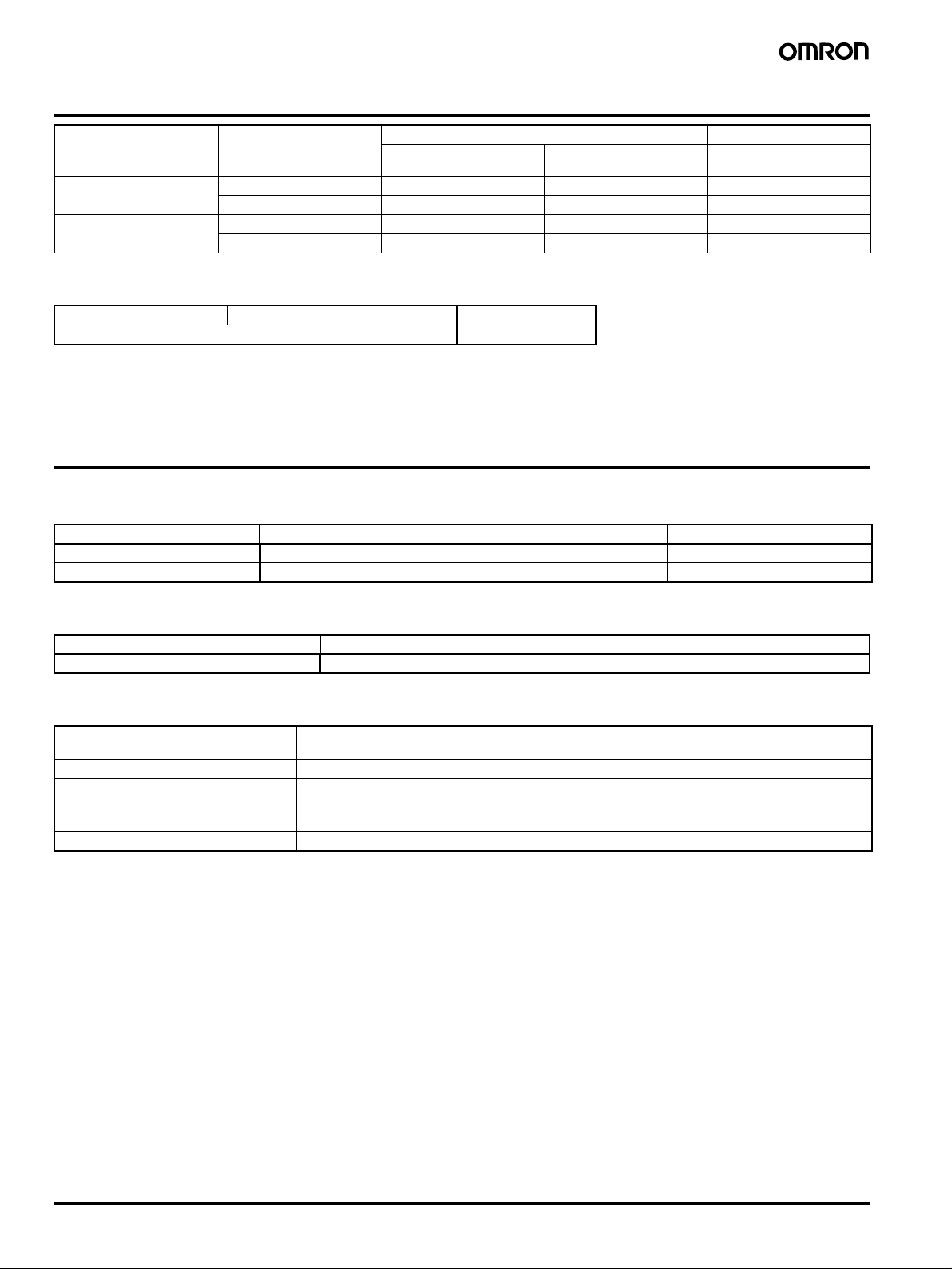

Mounting method Control output 24-hour operation 1-week operation

Synchron ous motor Quartz motor (with

memory protection)

Flush SPST-NO H2F-D H2F-DM H2F-WM

SPDT H2F-DC H2F-DMC H2F-WMC

Surface/track SPST-NO H2F-DF H2F-DMF H2F-WMF

SPDT H2F-DFC H2F-DM F C H2F-WMFC

Quartz motor (with

memory protection)

■Accessories (Order Separately)

Extra Programmi ng Tabs 1 pair for each ON/OFF (See note 1.) Y92S-21

Rechargeable Battery (See note 2.) Y92S-42

Note: 1. The 24-hour models are supplied with three pairs of programming tabs.

The 1-week models are supplied with seven pairs of programming tabs.

2. A Rechargeable Battery is provided in the H2F. When the life of the Battery has expired, order a replacement using this model number.

Specifications

■Time Ranges

Operation period Minimum division Minimum set time Maximum set time

24-hour 15 min 15 min 23 h 45 min

1-week 1 h 2 h 166 h

■ON/OFF Cycle

Operation period 24-hour 1-week

Maximum cycles 96 84

■Ratings

Rated supply voltage Synchronous motor: 100/110/120 VAC, 200/220/240 VAC (50/60 Hz) (See note.)

Operating voltage range 85% to 110% of rated supply voltage

Power consumption Synchronous motor: 3 VA max.

Control outputs 15 A at 250 VAC, resistive load, SPST-NO, SPDT

Terminal screw tightening t orque 0.98 N·m max.

Note: Select the appropriate frequency using the frequency selector switch provided on the upper part of the rear panel.

Quartz motor: 100 to 240 VA C (50/60 Hz)

Quartz motor: 1 VA max. at 100 to 120 VAC, 4 VA max. at 200 to 240 VAC

2 24-hour/Weekly Time Switch H2F

Page 3

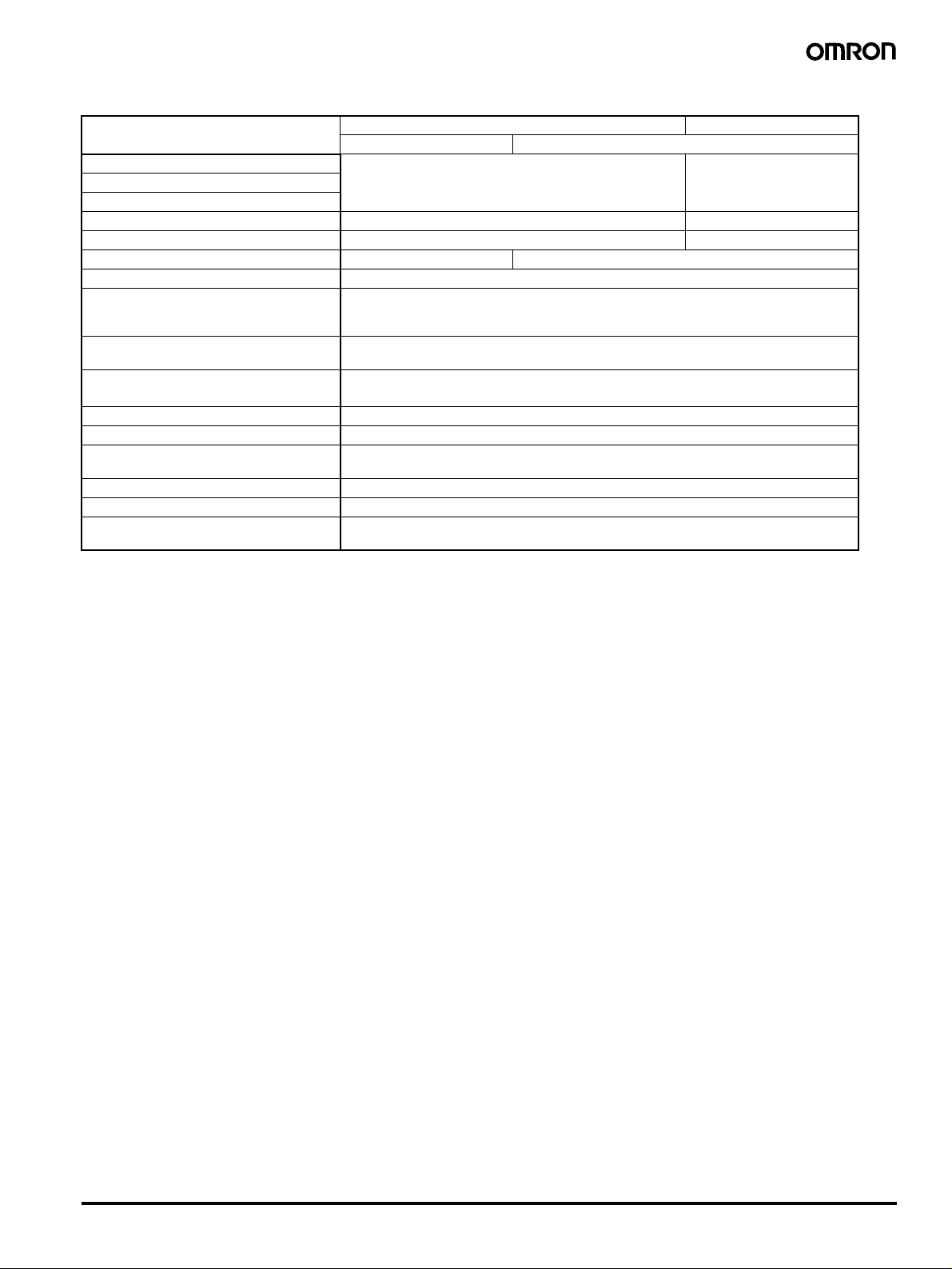

■Characteristics

Item 24-hour operation 1-week operation

Synchronous motor Quartz motor

Accuracy of operating time (See note 1.)

Influence of voltage

Influence of temperature

Setting error (See note 2.)

Cyclic error

Memory protection a gainst power failure --- 180 h min. (See note 3.)

Insulation resistance 100 M

Dielectric strength 2,000 VA C, 50/60 Hz for 1 min (between current-carrying terminals and non-current-carrying

Vibration resistance Destruction: 16.7 Hz, 2-mm single amplitude

Shock resistance

Ambient temperature Operating: –10°C to 55°C

Ambient humidity Operating: 35% to 85%

Life expectancy Contacts: 10,000 operations min.

Approved standards UL917, CSA C22.2 No. 14

Case color Light gray (Munsell 5Y7/1)

Weight Flush mounting: approx. 150 g

Note: 1. Accuracy of operating time of when the H2F is ON or when the H2F is OFF.

2. Difference between the set and actual operation time with the pointer set to the present time.

3. When the H2F is used for the first time after energization for 72 h.

±3 min max. ±30 min max.

±3 min max. ±30 min max.

±3 min max. ±30 min max.

Ω min. (at 500 VDC)

metal parts)

1,000 VAC, 50/60 Hz for 1 min (between non-continuous contacts)

Malfunction: 10 to 55 Hz, 0.25-mm single amplitude

Destruction: 1,000 m/s

Malfunction: 200 m/s

Motor: 20,000 hours

Surface mounting:approx. 200 g

2

2

24-hour/Weekly Time Switch H2F 3

Page 4

Connections

Synchronous Motor Model

(SPST-NO Output)

H2F-D

(SPDT Output)

H2F-DCH2F-DF H2F-DFC

Quartz Motor Model

(SPST-NO Output)

H2F-DM/H2F-WM

Note 1: Connect an independent power source to the load.

2: Do not exceed the following torque when tightening the screws.

Specified torque: 0.8 N·m

Maximum torque: 0.98 N·m

3: When connecting leads to the terminal block, use the same wire size for all leads. If different wire sizes are used,

the thinner leads may come off during operation.

4: Recommended lead wires: AWG18 to AWG24 (cross-section: 0.205 to 0.823 mm

5: When using crimp terminals, connect a maximum of two crimp terminals to any one terminal.

(SPDT Output)

H2F-DMC/WMCH2F-DMF/H2F-WMF H2F-DMFC/WMFC

2

2

), solid or twisted wire

4 24-hour/Weekly Time Switch H2F

Page 5

Dimensions

Note: All units are in millimeters unless otherwise indicated.

Mounting Dimensions

Surface Mounting: H2F-DF/-DMF/-WMF

Track Mounting: H2F-DFC/-DMFC/-WMFC

M3.5

6

29

Mounting Holes

Two, M3 holes

Flush Mounting: H2F-D/-DM/-WM/-DC/-DMC/-WMC

Screw size

M3 x 45

(included)

65.5

Panel Cutout

Recommended panel thickness: 1 to 3.2 mm

Note: The mounting adapter and

screws are included.

24-hour/Weekly Time Switch H2F 5

Page 6

Precautions

Flush Mounting

1. To mount the adapter to the panel cutout, first deform the adapter

by pushing it on the two opposing corners (as indicated by arrows

A. Then push part B into t he cutout (i.e., toward the back of the

panel).

Panel

Adapter

B

A

2. After the adapter is mounted, inser t the H2F as shown in the figure below. Secure the H2F b y tightening the two mounting screws

(M3 x 16) included as accessories.

3. If the lead wires have been connected to the H2F from the front of

the panel before the H2F is mounted in the panel, engage the

H2F to part A of the adapter and push it in the direction of B. Then

tighten the two screws as described in 2.

Panel

B

H2F Time Switch

Lead wire

A

Time Setting

To set the time, turn the center knob clockwise to the correct time.

Turning it counterclockwise or turning it with your fingers hooked on

the setting bracket may cause a malfunction.

With 24-hour models, set the hour to the arrow on the upper left corner of the front panel and the minute to the arrow on the center knob.

With 1-week models, set the day of the week to the arrow on the

upper left corner of the front panel and the hour to the arrow on the

center knob.

6 24-hour/Weekly Time Switch H2F

Use the gold setting tabs to set the ON time and the silver ones to set

the OFF time. Position the thick leg of the tab toward the outside of

the dial and insert the tab securely into the groove on the dial.

Three pairs of setting tabs are attached.

Store the spare tabs in the compartment at the lower right corner of

the front panel.

Page 7

Manual Switch

H2F-@M Series (Quartz Motor Models)

SPST-NO Output

A 3-position selector switch, located at the lower left corner of the

front panel, determines output operation. In the OFF position, the

control output is forcibly turned OFF regardless of the setting of the

programming tabs. Set to the A UTO position, the output is turned ON

and OFF according to the settings of the programing tabs. In the ON

position, the output is forcibly turned ON regardless of the setting of

the programming tabs.

SPDT Output

When the manual switch at the lower left corner of the front is set to

the OFF position, both load 1 (connected across terminals 4 and 5)

and load 2 (across 5 and 6) are turned OFF.

When it is set to the AUTO position, the output is turned ON and OFF

according to the setting of the programming tabs.

When the manual switch is set to the ON position, load 1 (connected

across terminals 4 and 5) is turned ON and load 2 (across 5 and 6) is

turned OFF.

Output Indicator

The output indicator at the upper left corner of the front panel shows

the status of the output when the manual switch is set to the AUTO

position.

In addition, the output can be manually turned ON or OFF by rotating

the knob clockwise (in the arrow direction). The knob will not tur n

counterclockwise.

Precaution for the H2F-D, -DF Serie s (Synchronous Motor

Models)

Before using the H2F, select the appropriate frequency of your area

by the frequency selector switch provided on the upper part of the

rear panel.

Battery

Remove the battery cover on the rear panel of the H2F, load the provided Battery into the battery box, then turn ON the H2F. Be sure to

load the Battery before using the H2F. If the Battery is not loaded, the

H2F will not work properly.

Press down.

Battery cover

Slide out

Be sure to load the Battery with the correct polar ity. The polarity is

indicated in the battery box. After loading the Battery, be sure to

place the cover on the battery box.

Battery

The Battery is fully charged before shipment. The Battery may lose

its charge while the Battery is stored. Therefore, there is a backup

function that is guaranteed for 180 hours on condition that the Battery is loaded into the H2F and charged continuously for 72 hours. If

the Battery has no charge, the H2F may not operate immediately

after it is turned ON. In that case, continue providing power to the

H2F for three or more minutes before setting the time.

If the H2F is turned ON and OFF frequently, the Battery life will be

greatly reduced. Use the H2F with a continuous supply of power.

The Battery has a life of approximately three years at room temperature. If three years have passed since the Battery was loaded,

replace the Battery as soon as possible with a AAAA-size NiCd

rechargeable battery.

If the H2F is idle over a long time, unload the Battery from the H2F

and store the Battery separately in order to prevent the Battery from

being overly discharged.

Always turn OFF the power supply before replacing the Battery.

Use only the specified Replacement Batter y (Y92S-42). Using any

other battery may result in leakage of battery fluid or battery r upture,

possibly causing equipment damage or injury.

Upper part of rear panel

(cycles per second)

Other Precautions

When connecting to a heater, alwa ys use a thermal switch in the load

circuit.

Do not exceed the specified ranges for vibration and shock.

The H2F is neither waterproof nor oil-proof. Do not use the H2F

where it would be subjected to water or oil.

24-hour/Weekly Time Switch H2F 7

Page 8

!WARNING

Do not short the terminals of, disassemble, deform under

pressure, or incinerate the Battery. Doing so may result in

minor injury due to bursting, ignition, or leakage of fluid.

!CAUTION

Do not touch any of the terminals or the back panel while

power is being supplied. Doing so may result in electric

shock. Be sure to mount the terminal cover after wiring.

Before changing times or other settings while power is

being supplied, either turn OFF the power on the load

side or set the output ON/OFF switch to OFF and confirm

the safety of the system. Unexpected operation may

occasionally result.

Tighten the terminal screws to the specified torque.

Loose screws may occasionally result in fire or

malfunction.

Do not allow metal fragments or lead wire scraps to fall

inside the Product. This may occasionally cause electric

shock, fire, or malfunction.

Never disassemble, repair, or modify the Product. This

may occasionally cause electric shock, fire, or

malfunction.

Do not use the Product where flammable or explosive gas

is present. There may occasionally be a risk of explosion

resulting in minor injury.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. L013-E1-05

In the interest of product im provement, specificatio ns are subje ct to cha nge wi thout n otice.

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Analog Controller Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7080/Fax: (81)75-344-7189

Printed in Japan

0506-0.3C (0696) (M)

Loading...

Loading...