Page 1

New Product News

Power Relays

G7Z

High-capacity Power Relays Capable

of Carrying and Switching 40 A at 440 VAC

Compact

40%

smaller than

contactors (IEC-

AC1, 50-A

High

specifications)

High

Capacity

IEC-AC1 40-A rating

4-pole power fully applied:

160 A

Mirror Contacts

for

Safety Function

Insulation

Load switching for

400-VAC systems

Low

Noise

Approx. 70 dB

Low Power

Consumption

Less than 4 W DC

RoHS

Compliant

Simple

Mounting

Page 2

Current capacity

Conventional usage division

Contactor

current

range

G7Z

Expansion of relay range

G7Z

TH

SA

Downsizing of approximately 40% volume compared with contactors.*

Contributes to space savings in control panels.

* IEC-AC1 50-A specifications

The Relay can be easily mounted right on a DIN Track.

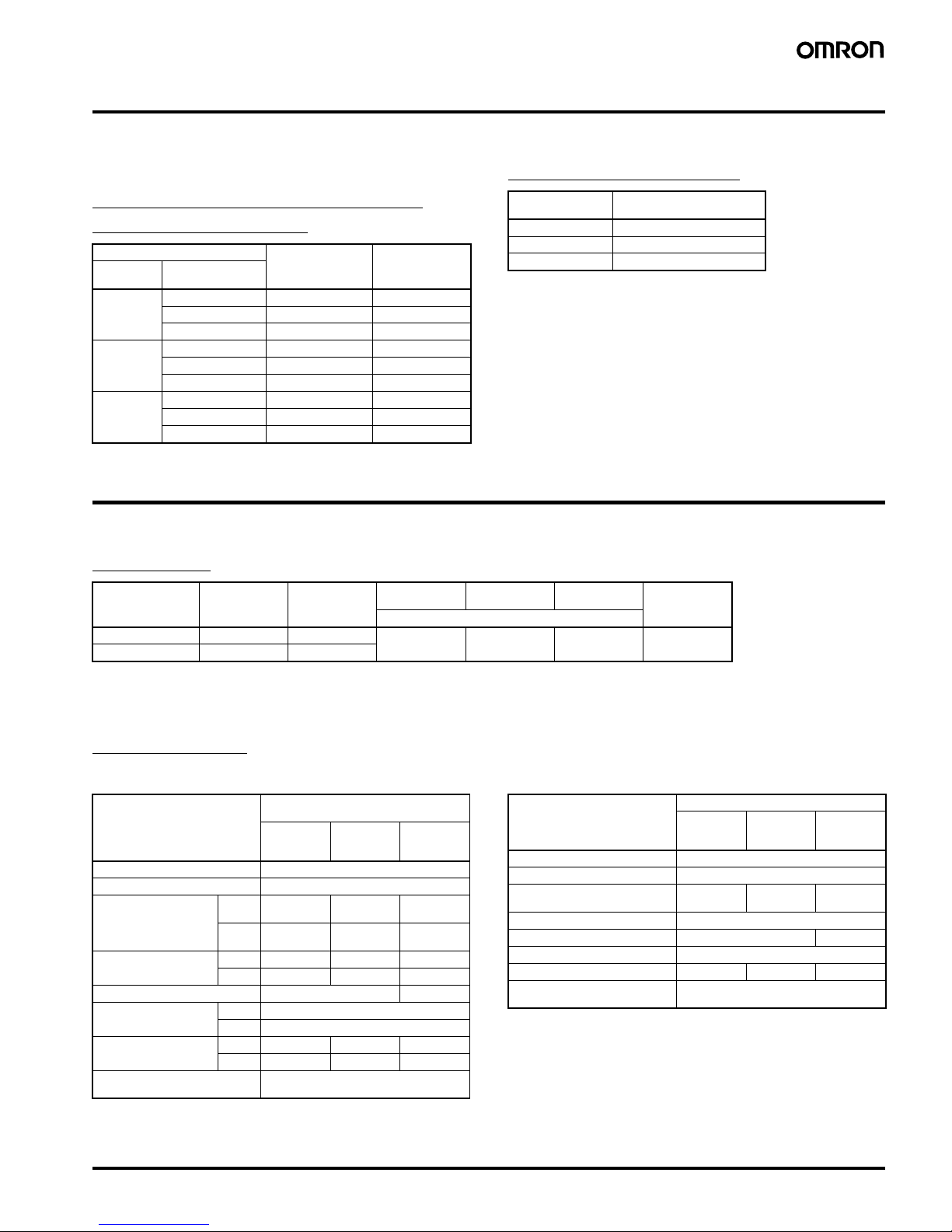

Application Example: General Safety Circuit

G9SA-301 (24-V AC/DC) (two limit switchinput channels with manual reset)

Compact Size

Safety Function with Mirror Contacts

Low Noise and

Low Power Consumption

DIN Track Mountable

Feedback circuit

Continuously apply 40 A at 440 VAC,

or apply up to a maximum of 160 A

by using 4-pole parallel connections

for full power application.*

The Relays are highly insulated to

support load switching

of 40 A at 440 VAC

EN 60947-4-1 certification for mirror contact mechanisms has been obtained by

using a combination of a relay and auxiliary contact blocks (5 VDC, 1 mA),

enabling application in feedback circuits of safety circuits.

* IEC-AC1 50-A specifications

Low noise of approx. 70 dB compared with the approx.

100 dB for contactors.* Low power consumption of less

than 4 W DC. Environmentally friendly specifications.

* Always consult with your OMRON representative

before using the maximum current of 160 A.

High Capacity and

High Insulation

84 mm

60 mm

62 mm

45 mm

Feedbackloop

Control

circuit

Open

Page 3

4 Power Relays G7Z

Power Relays

G7Z

Multi-pole Power Relay fo r Contactor Current

Range Capable of Carrying and Switching

40 A at 440 VAC

• One pole, 40 A can be carried and switched.

• The maximum loa d capacity of 160 A when using 4-pole par allel

connections.

• All materials used are compliant with the RoHS Directive

• EN 60947-4-1 certification for mirror contact mechanisms has

been obtained b y us ing a co mbin ation of t he rela y and auxi liary

contact blocks.

Note: Re fer to th e Pr ecaut ions for Correct Use on page 9.

Model Number Structure

■Model Numbe r Legend

Relay with Auxiliary Contact Block

1. Relay Contact Configuration

4A: 4PST-NO

3A1B: 3PST-NO/SPS T-NC

2A2B: DPST-NO/DPST-NC

2. Contact Configuration of Auxiliary Contacts

20: DPST-NO

11: SPST-NO/SPST-NC

02: DPST-NC

3. Contact Mechanism of Auxiliary Contacts

Z: Bifurcated crossbar contact

Auxiliary Contact Block

1. Contact Configuration of Auxiliary Contacts

20: DPST-NO

11: SPST-NO/SPST-NC

02: DPST-NC

2. Contact Mechanism of Auxiliary Contacts

Z: Bifurcated crossbar contact

■Configuration

Note: 1. Relay contact terminals are M5, and the coil terminals are M3.5.

2. Auxiliary contact block terminals are M3.5.

123

G7Z-@-@@

1 2

G73Z-@@

Structure Contact configuratio n Screw terminals

Classification Relay Auxiliary Contact

Block

Relay with Auxilia ry

Contact Block

4 poles +

2 poles

4PST-NO DPST-NO G7Z-4A-20Z

SPST-NO/SPST-NC G7Z-4A-11Z

DPST-NC G7Z-4A-02Z

3PST-NO/SPST-NC DPST-NO G7Z-3A1B-20Z

SPST-NO/SPST-NC G7Z-3A1B-11Z

DPST-NC G7Z-3A1B-02Z

DPST-NO/DPST-NC DPST-NO G7Z-2A2B-20Z

SPST-NO/SPST-NC G7Z-2A2B-11Z

DPST-NC G7Z-2A2B-02Z

Auxiliary Contact Block 2 poles --- DPST-NO G73Z-20Z

SPST-NO/SPST-NC G73Z-11Z

DPST-NC G73Z-02Z

Page 4

Power R elay s G7Z 5

Ordering Information

■Relay with Auxiliary Contact

Block

Relay with Auxiliary Contact Block

(for Screw Terminals)

■Accessories (Order Separately)

Auxiliary Contact Block

Specifications

■Ratings

Coil Ratings

Note: 1. Rated current and coil resistance were measured at a coil temperature of 23°C with coil resistance of ±15%.

2. Operating characteristics were measured at a co il temperature of 23

°C.

3. The maximum allowable voltage is the maximum value of the fluctuation range for the Relay coil operating power supply and was measured at an ambi ent

temperature of 23

°C.

There is, however, no continuous allowance.

Contact Ratings

Relay

Note: The ratings for the auxiliary contact block mounted on the G7Z are the

same as those for the G73Z auxiliary contact block.

Auxiliary Contact Block

Contact configuratio n Rated voltage Model

Relay Auxiliary contact

block

4PST-NO DPST-NO 12, 24 VDC G7Z-4A-20Z

SPST-NO/SPST-NC 12, 24 VDC G7Z-4A-11Z

DPST-NC 12, 24 VDC G7Z-4A-02Z

3PST-NO/

SPST-NC

DPST-NO 12, 24 VDC G7Z-3A1B-20Z

SPST-NO/SPST-NC 12, 24 VDC G7Z-3A1B-11Z

DPST-NC 12, 24 VDC G7Z-3 A1B-02Z

DPST-NO/

DPST-NC

DPST-NO 12, 24 VDC G7Z-2A2B-20Z

SPST-NO/SPST-NC 12, 24 VDC G7Z-2A2B-11Z

DPST-NC 12, 24 VDC G7Z-2 A2B-02Z

Contact

configuration

Model

DPST-NO G73Z-20Z

SPST-NO/SPST-NC G73Z-11Z

DPST-NC G73Z-02Z

Item Rated current Coil resistance Must operate

voltage

Must release

voltage

Maximum

voltage

Power

consumption

Rated voltage Percentage of rated voltage

12 VDC 333 mA 39

Ω 75% max. 10% min. 110% Approx. 3.7 W

24 VDC 154 mA 156

Ω

Model G7Z-4A-@Z, G7Z-3A1B-@Z,

G7Z-2A2B-@Z

Item Load Resistive

load

Inductive

load cos

φ =

0.3

Resistive

load L/R = 1

ms

Contact structure Double break

Contact materia l Ag alloy

Rated load NO 40 A at

440 VAC

22 A at

440 VAC

5 A at

110 VDC

NC 25 A at

440 VAC

10 A at

440 VAC

5 A at

110 VDC

Rated carry current NO 40 A 22 A 5 A

NC 25 A 10 A 5 A

Maximum contact voltage 480 VAC 125 VDC

Maximum contact

current

NO 40 A

NC 25 A

Maximum switching

capacity

NO 17,600 VA 9,680 VA 550 W

NC 1 1,00 0 VA 4,400 VA 550 W

Failure rate P value (reference

value)

2 A at 24 VDC

Model G73Z-20Z, G73Z-11Z, G73Z-02Z

Item Load Resistive

load

Inductive

load cos

φ =

0.3

Resistive

load L/R = 1

ms

Contact structure Double break

Contact material Au clad + Ag

Rated load 1 A at

440 VAC

0.5 A at

440 VAC

5 A at

110 VDC

Rated carry current 1 A

Maximum contact voltage 480 V AC 125 VDC

Maximum contact current 1 A

Maximum switching capacity 440 VA 220 VA 110 W

Failure rate P value (reference

value)

1 mA at 5 VDC

Page 5

6 Power Relays G7Z

■Characteristics

Note: 1. The above values are initial values.

2. The contact resistance for the Relay (G7Z) was measured with 1 A at 5 VDC using the voltage drop method.

The contact resistance for the auxiliary contact block (G73Z) was measured with 0.1 A at 5 VDC using the voltage drop method.

3. The operate time was measured with the rated voltage imposed with any contact bounce ignored at the ambient temperature of 23

°C.

4. The insulation resistance was measured with a 1,000-VDC megohmmeter applied to the same places as those used for checking the dielectric strength.

5. The electrical endurance was measured at an ambient temperature of 23

°C.

6. The specifications for the auxiliary contact block mounted on the G7Z are the same as those for the G73Z auxiliary contact block.

■Approved Standards

UL Standard: UL508, UL840 (File No.

E41643)

Note: Auxiliary contact ratings

CSA Standard: CSA Certification by

: CSA C22.2 No. 14

EN Standard/TÜV Certification: EN

60947-4-1 (Certification No. R50079155)

Note: Auxiliary contact ratings

Reference Information

UL 508: Industrial control devices

UL 840: Insulation coordination including clearance

and creepage distance for electrical devices

CSA C22.2 No. 14: Industrial control devices

EN 60947-4-1: Contactors

Classification Relay (See note 6.) Auxiliary contact block

Item Model G7Z-4A-@Z, G7Z-3A1B-@Z, G7Z-2A2B-@Z G73Z-20Z, G73Z-11Z, G73Z-02Z

Contact resistance (S ee note 2.) 100 mΩ max.

Operating time (See note 3.) 50 ms max.

Release time (See note 3.) 50 ms max.

Maximum operating

frequency

Mechanical 1,800 operations/h

Rated load 1,200 operations/h

Insulation resistance (See note 4.) 1,000 M

Ω min.

Dielectric strength Between coil and contacts 4,000 VAC, 50/60 Hz for 1 min ---

Between contacts of different polarity 4,000 VAC, 50/60 Hz for 1 min

Between contacts of the same polarity 2,000 VAC, 50/60 Hz for 1 min

Impulse withstand

voltage

Between coil and contacts 10 kV, 1.2

× 50 µs ---

Between contacts of different polarity 10 kV, 1.2

× 50 µs

Between contacts of the same polarity 4.5 kV, 1.2

× 50 µs

Vibration resistance Destruction 10 to 55 to 10 Hz, 0.5-mm single amplitude (1.0-mm double amplitude)

Malfunction NO: 10 to 55 to 10 Hz, 0.5-mm single amplitude (1.0-mm double amplitude)

NC: 10 to 32 to 10 Hz, 0.5-mm single amplitude (1.0-mm double amplitude)

Shock resistance Destruction

Screw mounting: 800 m/s

2

, DIN Track mountin g: 500 m/s2

Malfunction

NO: 100 m/s

2

NO: 25 m/s

2

Endurance Mechanical 1,000,000 operations min. (at 1,800 operations/h, contact no load)

Electrical (See note 5.) AC resistive load: 80,000 operations

AC indu ctive load: 80,000 operations

DC resistive load: 100,000 operations

(at 1,200 operations/h, rated load)

Failure rate P value (reference value) 2 A at 24 VDC 1 mA at 5 VDC

Ambient operating temperature

−25 to 60°C (with no icing or condensation)

Ambient operating humidity 5% to 85%

Weight Approx. 330 g

Model Coil

ratings

Contact ratings Numbe r of

test

operations

G7Z 12, 24 VDC NO

contact

40 A, 480 VAC, 60 Hz

(Resistive)

80,000

5 A, 120 VDC (Resistive) 100,000

22 A, 480 VAC, 60 Hz

(General Use)

100,000

D300* (1-A current applied) ---

NC

contact

25 A, 480 VAC, 60 Hz

(Resistive)

5 A, 120 VDC (Resistive)

10 A, 480 VAC, 60 Hz

(General Use)

100,000

D300* (1-A current applied) ---

Model Contact ratings

G73Z NO contact D300 (1-A current applied)

NC contact

Model Coil ratings Con tact ratings

G7Z 12, 24 VDC NO contact AC-1: 40 A, 440 V, 50/60 Hz

AC-3: 16 A, 440 V, 50/60 Hz

DC-1: 5 A, 110 V

*AC15: 0.5 A, 440 V, 50/60 Hz

*DC13: 0.5 A, 110 V

NC contact AC-1: 25 A, 440 V, 50/60 Hz

DC-1: 5 A, 110 V

*AC15: 0.5 A, 440 V, 50/60 Hz

*DC13: 0.5 A, 110 V

G73Z --- NO contact AC15: 0.5 A, 440 V , 50/60 Hz

DC13: 0.5 A, 110 V

NC contact

Page 6

Power R elay s G7Z 7

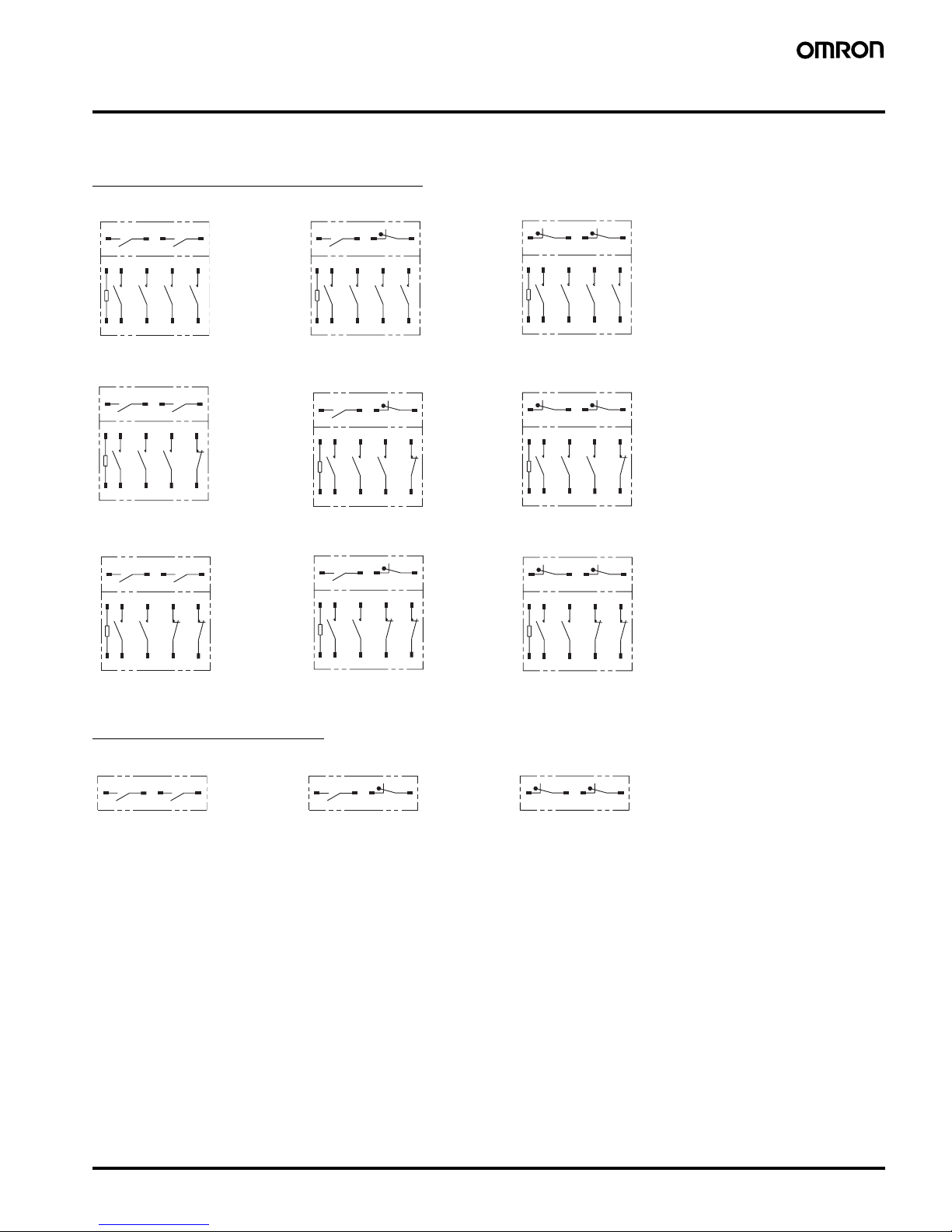

Connections

■Terminal Arrangement/Internal Connections

Relay with Auxiliary Contact Block

Auxiliary Contact Block

G7Z-4A-20Z G7Z-4A-11Z G7Z-4A-02Z

Note: The coil has no polarity. Note: The coil has no polarity. Note: The coil has no polarity.

G7Z-3A1B-20Z G7Z-3A1B-11Z G7Z-3A1B-02Z

Note: The coil has no polarity. Note: The coil has no polarity. Note: The coil has no polarity.

G7Z-2A2B-20Z G7Z-2A2B-11Z G7Z-2A2B-02Z

Note: The coil has no polarity. Note: The coil has no polarity. Note: The coil has no polarity.

53 54 63 64

7531A1

8642A2

53 54 61 62

7531A1

8642A2

51 52 61 62

7531A1

8642A2

53 54 63 64

21531A1

22642A2

21531A1

22642A2

53 54 61 62

21531A1

22642A2

51 52 61 62

53 54 63 64

211131A1

221242A2

211131A1

221242A2

53 54 61 62

211131A1

221242A2

51 52 61 62

G73Z-20Z G73Z-11Z G73Z-02Z

53 54 63 64

53 54 61 62

51 52 61 62

Page 7

8 Power Relays G7Z

Dimensions

Note: All units are in millimeters unless otherwise indicated.

Relay (12 VDC, 24 VDC) with Auxiliary Contact Block

Note: The dimensions are typical values.

Auxiliary Contact Block

Note: The dimensions are typical values.

DIN Track Mounting Height

(when using the PFP-100N or PFP-50N

mounting rail)

Note: The dimensions are typical values.

Application Examples

• Power supplies applied to Inverters and servo drivers for public and

industrial use

• Power supplies applied to uninterruptible power supplies plus

single- and three-phase power-supply switching for public and

industrial use

• Single- and three-phase power-supply switching of photovoltaic

power generation for public and industrial use

• Single- and three-phase power-supply switching of fuel cells for

public and industrial use

• Switching of heaters and motor for industrial use

75.5

60

51.5

62

45

47

Four, M3.5

Two, M3.5

84

92

70.7

15

Eight, M5

39±

0.2

Two, M4

4 Poles

Mounting Hole Dimensions

13

47

30

32.2

24.2

15

11

15.7

M3.5 × 4

88.3

96.3

15

75.0

64.3

Page 8

Power R elay s G7Z 9

Precautions

Be sure to read the common precautions provided in Best Control Devices Catalog Version 17 before using the Relay.

!WARNING

!CAUTION

■Precautions for Correct Use

Installation

• Mount the G7Z with the coil terminal at the top.

• Do not use the Relay with the terminal screw surfaces facing down.

• To mount the Relay, secure M4 screws in two locations.

Use a screw-tightening torque of 1.2 to 1.3 N·m.

• The Relay can be mounted directly on a mounting rail (PTP) or a

DIN Track (EN 50022-35

× 7.5, 15). The Relay cannot be mounted,

however, to some reinforced rails (e.g., those produced by Kameda

Denki or T oyogiken).

• Mount the Relay sideways when it is mounted on a rail.

• Use End Plates (PFP-M) on both sides of the Relay to make sure

that it is properly secured.

• Provide at least 5 mm of space between the sides and top of the

Relay and nearby grounded metal surfaces.

• Provide at least 30 mm of space between Relays when two or more

Relays are mounted in a row.

• The auxiliary contact block (G73Z) can be mounted on the Relay.

Mounting and Removal

Mounting

Insert the tab on the auxiliary contact

block into the groove on the Relay and

press down until the hook on the

auxiliary contact block catches in the

mounting hole on the Relay.

Removing

Slide the auxiliary contact block, remove

the auxiliary contact block tab from the

groove on the Relay, and remove the

auxiliary contact block hook from the

Relay.

Be careful not to apply excessive force

on the hook.

Take measures to prevent contact with charged parts

when using the Relay for high voltages.

Do not touch the terminal section (charged parts) when

power is being supplied.

Always use the Relay with terminal covers mounted.

Contact with charged parts may result in electric shock.

Do not touch the Relay when power is being su pplied or

right after the power has been turned OFF.

The hot surface may cause burn injury.

Up

Coil terminal

Terminal screw surface

Washer (external dia.: 7 max.)

39 mm

Up

DIN Track

(35 mm)

5 mm min

.

5 mm min.

5 mm min.

Grounded metal surface

30 mm min.

Tab

(1)

(2)

Hook

(2)

(1)

Tab

Hook

Page 9

10 Power Relays G7Z

Connecting

• Use round or open-end (Y-type) crimp terminals and connect the

terminals with the appropriate tightening torque. Refer to the

terminal section space in the following figure for the crimp terminal

dimensions.

Relay Contacts (Unit: mm)

Relay Coil

Auxiliary Contact Block

• One crimp terminal can be used for the Relay contact section (M5

screw). Two crimp terminals can be connected for the coil terminal

and auxiliary contact block.

Recommended Crimp Terminals and Wire

• Use the following tightening torque when tightening screws. Loose

screws may result in fire caused by abnormal heat generated when

the power is being supplied.

M5 screws: 2.0 to 2.2 N·m

M3.5 screws: 0.8 to 0.9 N·m

• Allow suitable slack on leads when wiring, and do not subject the

terminals to excessive force.

Microloads

The G7Z is used for switching power loads, such as current carry for

device power supplies and heater loads. Use an auxiliary contact

block (G73Z) if microloads are required for signal applicat ions and

operation status feedback.

Operating Coil

(Intern al Connectio ns of Coils)

DC Coil

• If a transistor drives the G7Z, check the leakage current and

connect a bleeder resistor if necessary.

• The must operate voltage is the minimum value for the Relay

armature to operate and the contacts to turn ON. Therefore,

fundamentally apply the rated voltage to the coils, taking into

consideration the increases in coil resistance caused by voltage

fluctuation and coil temperature rise.

Mirror Contact Mechanism

By combining a Relay with an auxiliary contact block, all NC contacts

of the auxiliary contact block will satisfy an impulse withstand voltage

of more than 2.5 kV or maintain a gap of more than 0.5 mm when the

coil is de-energized even if at least one NO contact (main contact) of

the Relay is welded (according to EN 60947-4-1).

Description of Mirror Contact Mechanism

Location Crimp

terminals

Appropriate wire size

Contact

section

5.5-5

2.63 to 6.64 mm

2

(AWG12, 10)

8-5

6.64 to 10.52 mm

2

(AWG8)

Coil

section

1.25-3.5

0.5 to 1.65 mm

2

(AWG20 to 16)

11

M5

14.5

12.5

6

6

6.8

4.3

M3.

5

9.5

6.8

5.5

5.5

M3.5

A2 A1

ab

Contact welding

NO NO NO

NCNC

NO

Auxiliary contact block

Relay

Impulse withstand voltage: 2.5 kV min. or

contact separation (a + b): 0.5 mm min.

Page 10

Power R elay s G7Z 11

Page 11

In the interest of product improvement, specifications are subject to change witho ut notic e.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. J160-E1-01

OMRON Corporation

Industrial Automation Company

Control Devices Division H.Q.

Industrial Components Department

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7119/Fax: (81)75-344-7149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg,

IL 60173 U.S.A.

Tel: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

239920 Singapore

Tel: (65)6835-3011/Fax: (65)6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Road (M),

Shanghai, 200120 China

Tel: (86)21-5037-2222/Fax: (86)21-5037-2200

0306

Warranty and Application Considerations

Read and Understand this Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any

questions or comme nt s.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other

period if specified) from dat e of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANT ABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES

THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS

OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS, OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY , REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS

UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTAL LED, AND

MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity wit h any standards, codes, or regulations that apply to the com b ination of products in

the customer's applicat i on or use of the products.

Take all necessary steps to determine the suitability of the product for the syste ms, machines, and equipment with which it will b e us ed .

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICA TION INV OL VING SERIOUS RISK TO LIFE OR PROPER TY WITHOUT ENSURING

THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Disclaimers

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty.

It may represent the result of OMRON's te st conditions, and the users must correlate it to a ct ual application requirements. Actual

performance is subject to th e O M RON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed a t any time based on improvements and other reasons. Consult with your

OMRON representative at any time to conf i rm actual specifications of pu rc hased product.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

Loading...

Loading...