Page 1

Power Relay G7L

A High-capacity,

High-dielectric-strength Relay

Compatible with Momentary Voltage

Drops

No contact chattering for momentary voltagedrops

up to 50% of rated voltage.

Wide-range AC-activated coil that handles 100 to

120 or 200 to 240 VAC at either 50 or 60 Hz.

Miniature hinge for maximum switching power,

particularly for inductive loads.

Flame-resistance materials (UL94V-0-qualifying)

used for all insulation material.

Quick-connect, screw,andPCBterminals,andDIN

track mounting available.

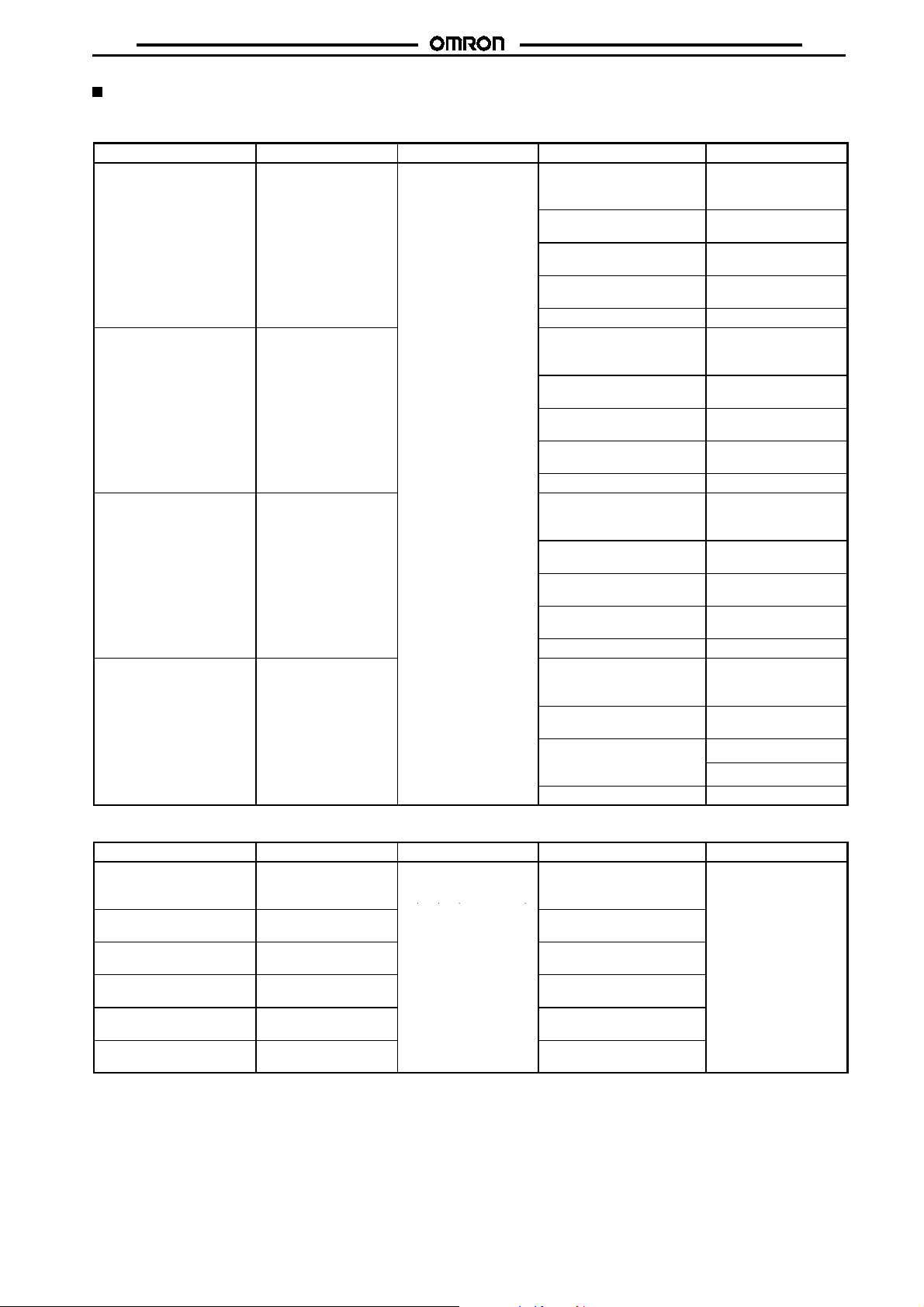

Ordering Information

R

CE

Mounting type Contact form

E-bracket

E-bracket (with test button)

Upper bracket

Upper bracket

(with test button)

PCB mounting

1. When ordering, add the rated coil voltage to the model number.

Note:

Example: G7L-1A-T 12 VAC (~)

SPST-NO G7L-1A-T G7L-1A-B --DPST-NO G7L-2A-T G7L-2A-B --SPST-NO G7L-1A-TJ G7L-1A-BJ --DPST-NO G7L-2A-TJ G7L-2A-BJ --SPST-NO G7L-1A-TUB G7L-1A-BUB --DPST-NO G7L-2A-TUB G7L-2A-BUB --SPST-NO G7L-1A-TUBJ G7L-1A-BUBJ --DPST-NO G7L-2A-TUBJ G7L-2A-BUBJ --SPST-NO --- --- G7L-1A-P

DPST-NO --- --- G7L-2A-P

Rated coil voltage

Quick-connect

terminals

Screw terminals

PCB

terminals

1

Page 2

G7L

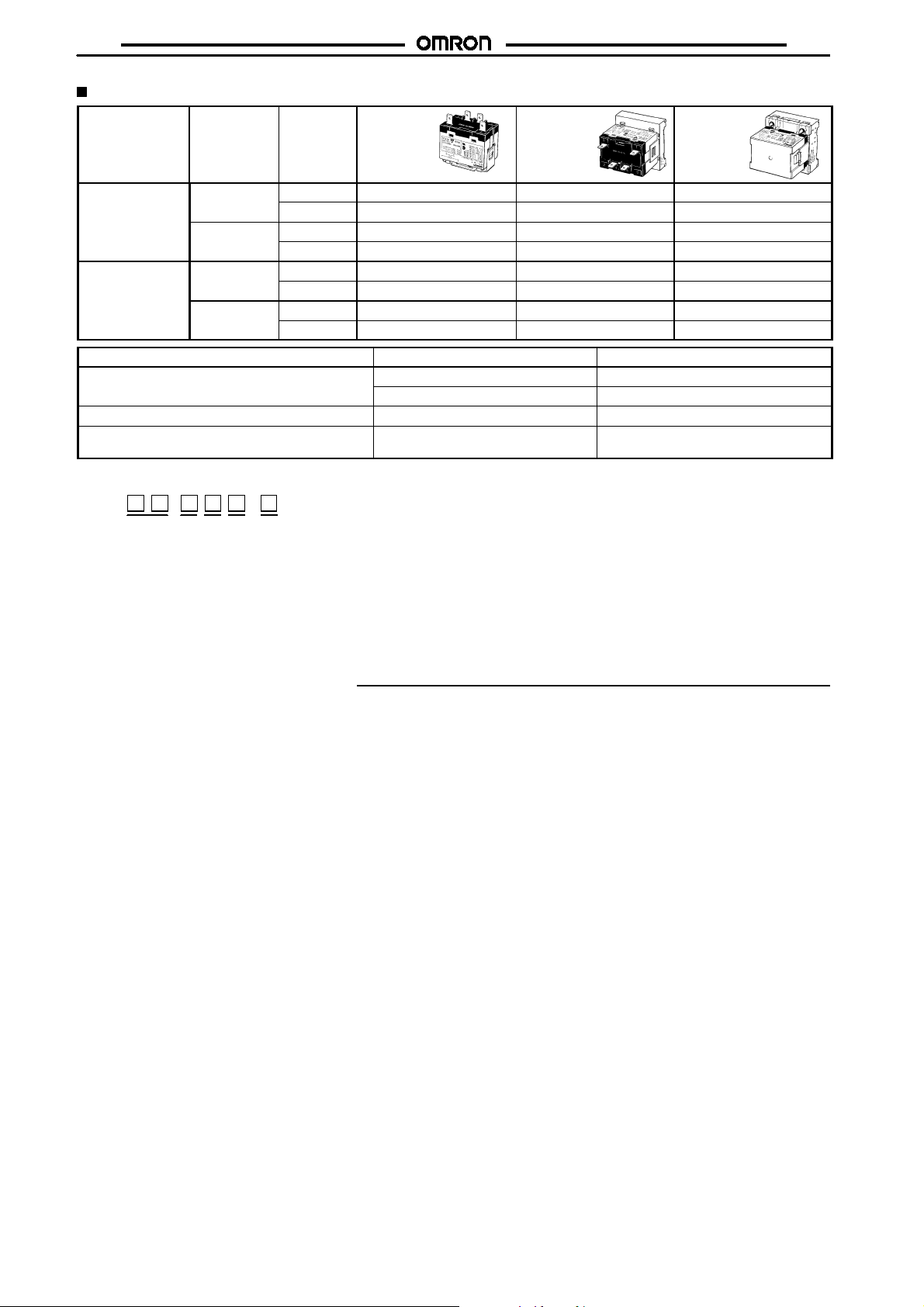

Accessories (Order Separately)

Terminals Contact form Model R99-07

E-brackets

P7LF-D DIN

Track

Mounting

Adapter

G7L

P7LF-06

Front-con

necting

Socket

Quick-connect

terminals

Screw terminals

G7L-1A-T/G7L-1A-TJ/G7L-1A-B/G7L-1A-BJ E-bracket R99-07

G7L-2A-T/G7L-2A-TJ/G7L-2A-B/G7L-2A-BJ Adapter P7LF-D

G7L-1A-T/G7L-1A-TJ/G7L-2A-T/G7L-2A-TJ Front-connecting Socket P7LF-06

G7L-1A-B/G7L-1A-BJ/G7L-1A-BUB/G7L-1A-BUBJ

G7L-2A-B/G7L-2A-BJ/G7L-2A-BUB/G7L-2A-BUBJ

SPST-NO G7L-1A-T Yes Yes Yes

G7L-1A-TJ Yes Yes Yes

DPST-NO G7L-2A-T Yes Yes Yes

G7L-2A-TJ Yes Yes Yes

SPST-NO G7L-1A-B Yes Yes No

G7L-1A-BJ Yes Yes No

DPST-NO G7L-2A-B Yes Yes No

G7L-2A-BJ Yes Yes No

Applicable Relay Name Model

Cover P7LF-C

Model Number Legend

G7L - -

1234,5

1. Contact Form

1A: SPST-NO

2A: DPST-NO

2. Terminal Shape

T: Quick-connect terminals

P: PCB terminals

B: Screw terminals

3. Mounting Construction

Blank: E-bracket

UB: Upper bracket

4. Special Functions

Blank: Standard mode

J: With test button

5. Rated Coil Voltage

AC: 12, 24, 50, 100 to 120, 200 to 240

DC: 6, 12, 24, 48, 100

Application Examples

Compressors for air conditioners and heater switching

!

controllers.

Switching controllers for power tools or motors.

!

Power controllers for water heaters.

!

Power controllers for dryers.

!

Lamp controls, motor drivers, and power supply switching in

!

copymachines,facsimilemachines,andother officeequipment.

Lighting controllers.

!

Power controllers for packers or food processing equipment.

!

Magnetron control in microwaves.

!

2

Page 3

G7L

(

)

(

)

Specifications

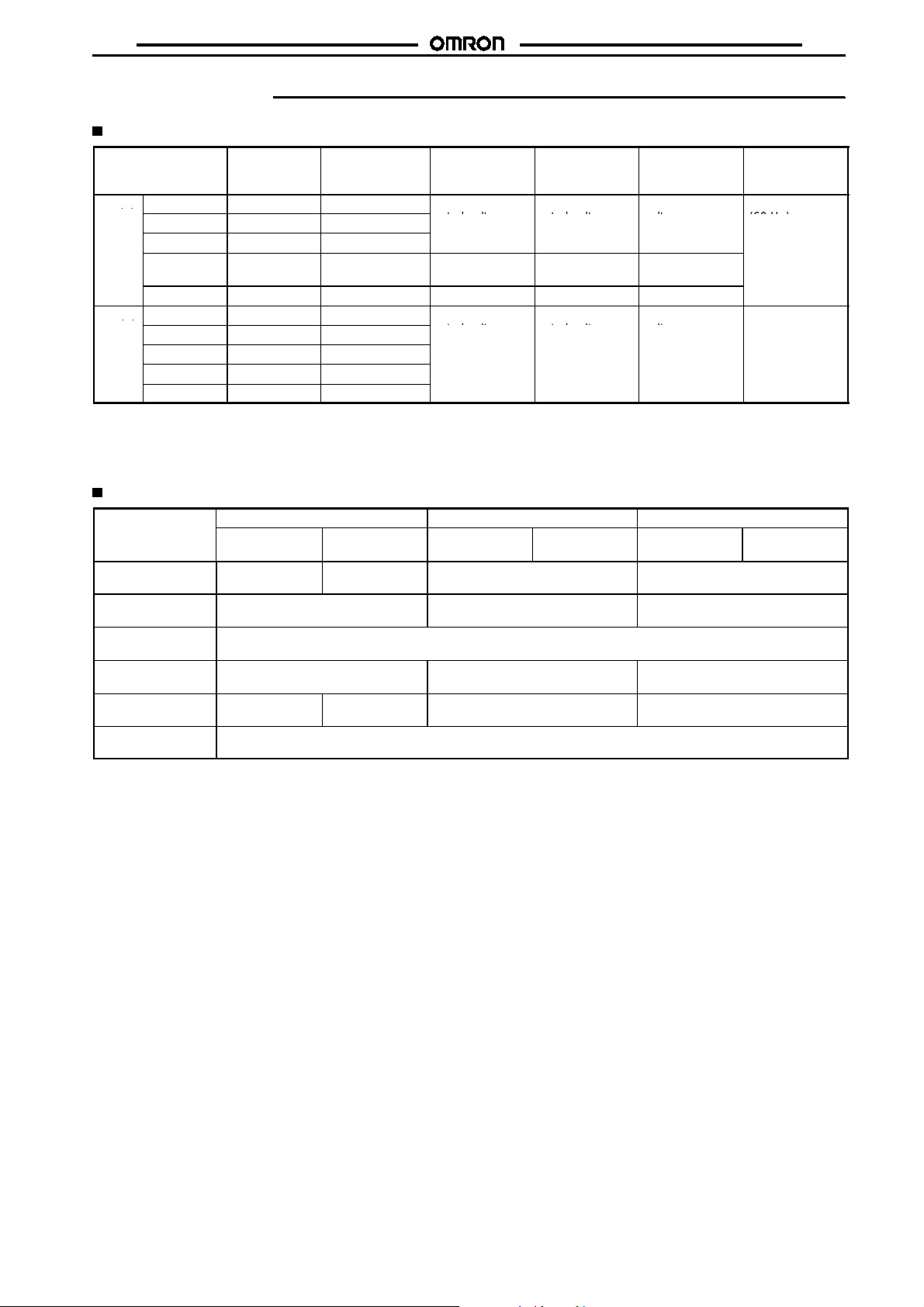

Coil Ratings

Rated voltage Rated

AC (~)

DC (=)

Note:

12 V 142 mA --24 V 71 mA --50 V 34 mA --100 to 120 V 17.0 to

200 to 240 V 8.5 to 10.2 mA --- 150 V 36 V 264 v

6V 317 mA 18.9

12 V 158 mA 75

24 V 79 mA 303

48 V 40 mA 1220

100 V 19 mA 5260

1. Theratedcurrentandcoilresistancearemeasuredatacoiltemperatureof 23#Cwithtolerances of+15%/--20%forAC ratedcurrent

and$15% for DC coil resistance.

2. Performance characteristic data are measured at a coil temperature of 23#C.

3.~indicates AC and=indicates DC (IEC417 publications).

current

20.4 mA

Contact Ratings

Model

Rated load

Rated carry

current

Max. switching

voltage

Max. switching

current

Max. switching

power

Min. permissible

load*

P level:

*Note:

&

60

G7L-1A-Tj/G7L-1A-B

Resistive load

(cos%=1)

30 A, 220 VAC

)

(

~

30 A 25 A 20 A

250 VAC

30 A 25 A 20 A

6,600 VAC

100 mA, 5 VDC

=0.1x10-6/operation

(

~

Coil resistance Must operate

--- 75 V 18 V 132 V

"

"

"

"

"

j

Inductive load

(cos%=0.4)

25 A, 220 VAC

)

(

~

)

) 5,500 VAC

(

~

)

(

=

) 5,500 VAC

(

~

voltage

75% max. of

rated voltage rated voltage voltage (60 Hz)

75% max. of

rated voltage rated voltage voltage

G7L-2A-Tj/G7L-2A-B

Resistive load

(cos%=1)

25 A, 220 VAC

(

Must release

voltage

15% min. of

15% min. of

Inductive load

(cos%=0.4)

) 20 A, 220 VAC

(

~

) 4,400 VAC

~

Max. voltage Power

110% of rated

110% of rated

j

G7L-1A-P/G7L-2A-P

Resistive load

(cos%=1)

(

~

)

(

~

)

G7L

consumption

(approx.)

1.7to2.5VA

1.9 W

Inductive load

(cos%=0.4)

3

Page 4

G7L

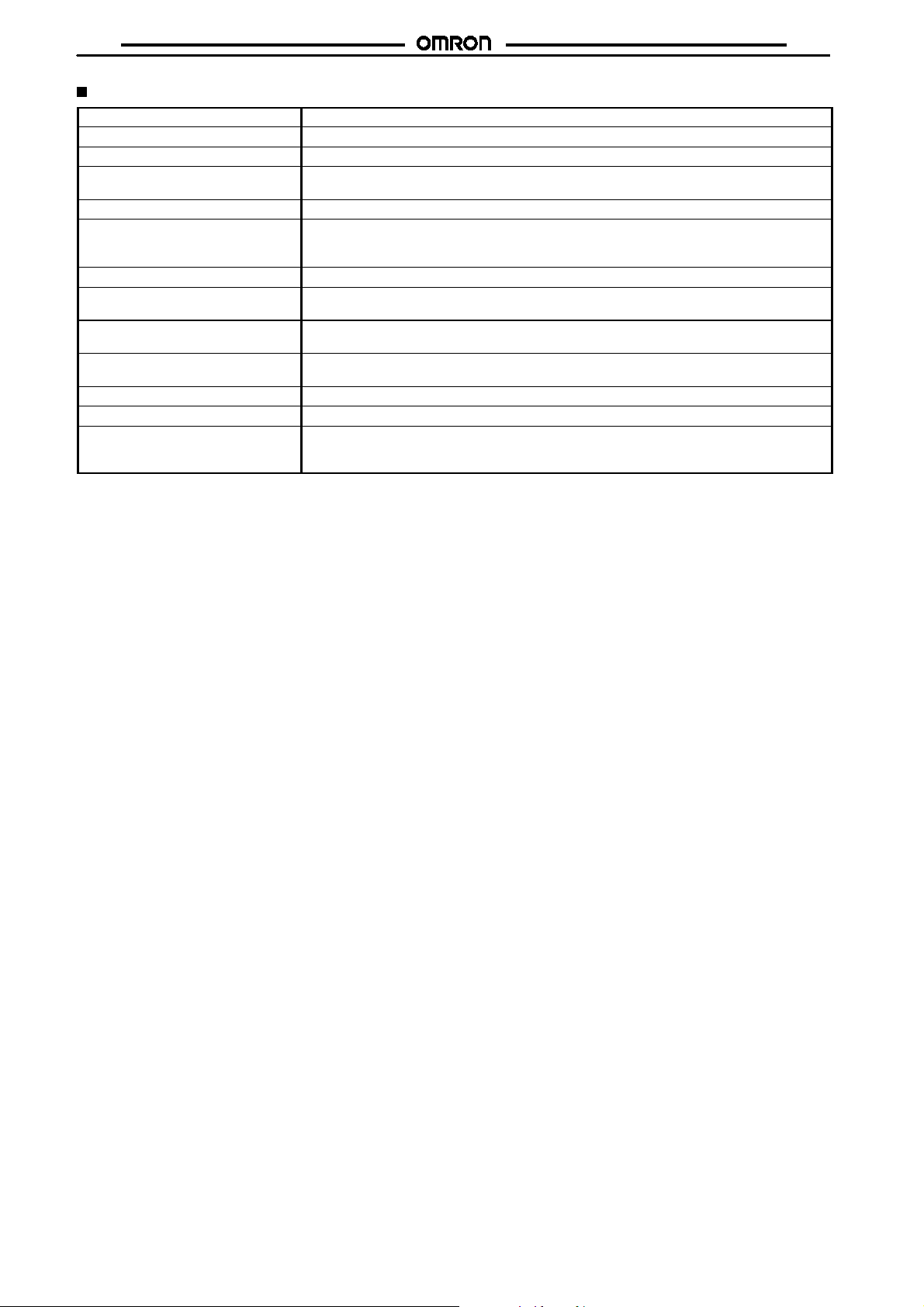

Characteristics

Contact resistance

Operate time

Release time

Max. operating frequency

Insulation resistance

Dielectric strength

Impulse withstand voltage

Vibration resistance

Shock resistance

Life expectancy

Ambient temperature

Ambient humidity

Weight

The values given above are initial values.

Note:

50 m"max.

30 ms max.

30 ms max.

Mechanical: 1,800 operations/hr

Electrical: 1,800 operations/hr (under rated load)

1,000 M"min. (at 500 VDC)

4,000 VAC min., 50/60 Hz for 1 min between coil and contacts

2,000 VAC, 50/60 Hz for 1 min between contacts of same polarity

2,000 VAC, 50/60 Hz for 1 min between contacts of different polarity (DPST-NO model)

10,000 V between coil and contact (with 1.2 x 50's impulse wave)

Destruction: 10 to 55 Hz, 1.5-mm double amplitude

Malfunction: 10 to 55 Hz, 1.5-mm double amplitude

Destruction: 1,000 m/s

Malfunction: 100 m/s

Mechanical:1,000,000 operations min. (at 1,800 operations/hr)

Electrical: 100,000 operations min. (at 1,800 operations/hr under rated load)

Operating: --25#Cto60#C (with no icing)

Operating: 35% to 85%

Quick-connect terminal models: approx. 90 g

PCB terminal models: approx. 100 g

Screw terminal models: approx. 120 g

2

2

G7L

4

Page 5

G7L

FLA

/

LRA

VAC

,,,

,

Approved by Standards

UL 508, 1950 Recognitions (File No. E41643)

CSA 22.2 No.14 Listings (File No.LR35535)

Model Contact Form Coil ratings Contact ratings Operations

G7L-1A-T

G7L-1A-B

G7L-2A-T

G7L-2A-B

j

j

j

j

G7L-1A-P SPST-NO

G7L-2A-P DPST-NO

SPST-NO 12 to 240 VAC

5to220VDC

DPST-NO

30 A, 277 VAC (RES)

100 x 10

25 A, 277 VAC (GEN)

30 A, 120 VAC (GEN)

1.5 kW, 120 VAC (T)

6x10

3

1.5 HP, 120 VAC

3 HP, 277 VAC 100 x 10

(CSA; 6 x 103)

20 FLA/120 LRA, 120 VAC

30 x 10

17 FLA/102 LRA, 265 VAC

TV-10, 120 VAC 25 x 10

25 A, 277 VAC (RES)

100 x 10

25 A, 277 VAC (GEN)

25 A, 120 VAC (GEN)

1.3 kW, 120 VAC (T)

6x10

3

1 HP, 120 VAC

2 HP, 277 VAC 100 x 10

(CSA; 6 x 103)

20 FLA/120 LRA, 120 VAC

30 x 10

17 FLA/102 LRA, 265 VAC

TV-8, 120 VAC 25 x 10

20 A, 277 VAC (RES)

100 x 10

20 A, 277 VAC (GEN)

20 A, 120 VAC (GEN)

1.5 kW, 120 VAC (T)

6x10

3

1.5 HP, 120 VAC

3 HP, 277 VAC 100 x 10

(CSA; 6 x 103)

20 FLA/120 LRA, 120 VAC

30 x 10

17 FLA/102 LRA, 265 VAC

TV-10, 120 VAC 25 x 10

20 A, 277 VAC (RES)

100 x 10

20 A, 277 VAC (GEN)

20 A, 120 VAC (GEN)

1.3 kW, 120 VAC (T)

6x10

3

1 HP, 120 VAC

2 HP, 277 VAC

20

120

, 120

17 FLA/102 LRA, 265 VAC

100 x 10

30 x 10

TV-8, 120 VAC 25 x 10

G7L

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

TÜV: File No. R9051158 (VDE 0435, IEC 255, IEC 950, EN60950)

Model Contact Form Coil ratings Contact ratings Operations

G7L-1A-B

G7L-2A-B

G7L-1A-T

G7L-2A-T

j

j

j

j

SPST-NO

DPST-NO

SPST-NO 25 A, 240 VAC (cos%=1.0)

DPST-NO 25 A, 240 VAC (cos%=1.0)

G7L-1A-P SPST-NO 20 A, 240 VAC (cos%=1.0)

G7L-2A-P DPST-NO 20 A, 240 VAC (cos%=1.0)

6, 12, 24, 48, 100, 110,

200, 220 VDC

12, 24, 50, 100 to 120,

200 to 240 VAC

30 A, 240 VAC (cos%=1.0)

25 A, 240 VAC (cos%=0.4)

30 A, 120 VAC (cos%=0.4)

25 A, 240 VAC (cos%=1.0)

25 A, 240 VAC (cos%=0.4)

25 A, 240 VAC (cos%=0.4)

25 A, 240 VAC (cos%=0.4)

20 A, 240 VAC (cos%=0.4)

20 A, 240 VAC (cos%=0.4)

100 x 10

3

5

Page 6

G7L

Engineering Data

G7L-1A-T/G7L-1A-B

Maximum Switching Power

AC inductive load

(cos%=0.4)

G7L

Life Expectancy

AC resistive load

3

220 VAC resistive load

Switching current (A)

Switching voltage (V)

G7L-2A-T/G7L-2A-B

Maximum Switching Power

AC resistive load

AC inductive load

(cos%=0.4)

Switching current (A)Switching current (A)

Switching voltage (V)

G7L-1A-P/G7L-2A-P

Maximum Switching Power

220 VAC

inductive load

Life expectancy (x10 operations)

(cos%=0.4)

Switching current (A)

Life Expectancy

3

Life expectancy (x10 operations)

220 VAC resistive load

220 VAC

inductive load

(cos%=0.4)

Switching current (A)

Life Expectancy

AC resistive load

AC inductive load

(cos%=0.4)

3

220 VAC resistive load

220 VAC

inductive load

(cos%=0.4)

Life expectancy (x10 operations)

Switching voltage (V)

Switching current (A)

6

Page 7

G7L

Dimensions

1. All units are in millimeters unless otherwise indicated.

Note:

2. E-brackets are sold separately.

Quick-connect Terminals with E-bracket

G7L-1A-T

G7L-2A-T

Terminal Arrangement/

Internal Connections

(Top View)

Mounting Holes

Two, 4.5-dia. hole or

M4 tapped holes

G7L

G7L-1A-TJ

with Test Button

G7L-2A-TJ

with Test Button

Quick-connect Terminals with DIN Track Mounting Adapter

1. The DIN Track Mounting Adapter and DIN tracks are sold separately.

Note:

2. The DIN Track Mounting Adapter can be track-mounted or screw-mounted.

G7L-1A-T

PFP-jN

G7L

P7LF-D

Terminal Arrangement/

Internal Connections

(Top View)

51.5 max.

01

Mounting Holes

Two, M4 or

4.5-dia. holes

55.5 max. 63 max.

66.5 max.

46

5

40$0.1

7

Page 8

G7L

G7L

G7L-2A-T

G7L-1A-TJ

with Test Button

G7L-2A-TJ

with Test Button

PFP-jN

PFP-jN

PFP-jN

55.5 max.

55.5 max.

G7L

63 max.

66.5 max.

G7L

2

63 max.

66.5 max.

G7L

P7LF-D

51.5 max.

P7LF-D

51.5 max.

P7LF-D

Terminal Arrangement/

Internal Connections

(Top View)

01

24 68

5

01

46

5

01

51.5 max.

Mounting Holes

Two, M4 or

4.5-dia. holes

40$0.1

2

55.5 max.

63 max.

66.5 max.

Quick-connect Terminals with Front-connecting Socket

1. The Front-connecting Socket and DIN tracks are sold separately.

Note:

2. The Front-connecting Socket can be track-mounted or screw-mounted.

G7L-1A-T

G7L-2A-T

PFP-jN

PFP-jN

Two, M3.5 screws

for coil

55.5 max.

Four, M4 screws

for contact

Two, M3.5 screws

for coil

G7L

G7L

61.5 max.

65 max.

P7LF-06

51.5 max.

5

P7LF-06

51.5 max.

24 68

5

Terminal Arrangement/

Internal Connections

(Top View)

01

46

01

Mounting Holes

Two, M4 or

4.5-dia. holes

40$0.1

24 68

55.5 max.

Four, M4 screws

for contact

61.5 max.

65 max.

5

8

Page 9

G7L

G7L

G7L-1A-TJ

with Test Button

G7L-2A-TJ

with Test Button

PFP-jN

PFP-jN

Two, M3.5 screws

for coil

55.5 max.

Two, M4 screws

for contact

55.5 max.

Two, M3.5 screws

for coil

Four, M4 screws

for contact

G7L

2

61.5 max.

65 max.

G7L

2

61.5 max.

65 max.

Quick-connect Terminals with Upper Bracket

G7L-1A-TUB

P7LF-06

P7LF-06

Terminal Arrangement/

Internal Connections

(Top View)

51.5 max.

5

51.5 max.

5

01

46

01

24 68

Terminal Arrangement/

Internal Connections

(Top View)

Mounting Holes

Two, M4 or

4.5-dia. holes

40$0.1

Mounting Holes

Two, 4.5-dia. hole or

M4 tapped holes

G7L-2A-TUB

G7L-1A-TUBJ

with Test Button

Terminal Arrangement/

Internal Connections

(Top View)

Terminal Arrangement/

Internal Connections

(Top View)

9

Page 10

G7L

G7L

G7L-2A-TUBJ

with Test Button

Screw Terminals with E-bracket

E-brackets are sold separately.

Note:

G7L-1A-B

Two, M3.5 screws

for coil

G7L-2A-B

Two, M3.5 screws

for coil

Internal Connections

(Top View)

Two, M4 screws

for contact

Terminal Arrangement/

Internal Connections

(Top View)

Four, M4 screws

for contact

Mounting HolesTerminal Arrangement/

Two, 4.5-dia. hole or

M4 tapped holes

Mounting Holes

Two, 4.5-dia. hole

or M4 tapped holes

G7L-1A-BJ

with Test Button

G7L-2A-BJ

with Test Button

Two, M3.5 screws

for coil

Two, M3.5 screws

for coil

Two, M4 screws

for contact

Four, M4 screws

for contact

10

Page 11

G7L

Screw Terminals with DIN Track Mounting Adapter

1. The DIN Track Mounting Adapter and DIN tracks are sold separately.

Note:

2. The DIN Track Mounting Adapter can be track-mounted or screw-mounted.

G7L

G7L-1A-B

G7L-2A-B

G7L-1A-BJ

with Test Button

PFP-jN

PFP-jN

PFP-jN

55.5 max.

55.5 max.

G7L

65.5 max.

69 max.

G7L

65.5 max.

69 max.

G7L

P7LF-D

P7LF-D

P7LF-D

51.5 max.

5

51.5 max.

5

Terminal Arrangement/

Internal Connections

(Top View)

01

46

01

24 68

Mounting Holes

Two, M4 or

4.5-dia. holes

40$0.1

2

55.5 max.

G7L-2A-BJ

with Test Button

PFP-jN

2

55.5 max.

Screw Terminals with Upper Bracket

G7L-1A-BUB

Two, M3.5 screws

for coil

65.5 max.

69 max.

G7L

65.5 max.

69 max.

51.5 max.

5

P7LF-D

51.5 max.

5

Two, M4 screws

for contact

01

46

01

24 68

Terminal Arrangement/

Internal Connections

(Top View)

Mounting Holes

Two, 4.5-dia. hole

or M4 tapped holes

11

Page 12

G7L

G7L-2A-BUB

G7L

G7L-1A-BUBJ

with Test Button

G7L-2A-BUBJ

with Test Button

Two, M3.5 screws

for coil

Two, M3.5 screws

for coil

Two, M3.5 screws

for coil

Four, M4 screws

for contact

Terminal Arrangement/

Internal Connections

(Top View)

Two, M4 screws

for contact

Terminal Arrangement/

Internal Connections

(Top View)

Four, M4 screws

for contact

Terminal Arrangement/

Internal Connections

(Top View)

Mounting Holes

Two, 4.5-dia. hole

or M4 tapped holes

PCB Terminals with PCB Mounting

G7L-1A-P

G7L-2A-P

Mounting Holes

(Bottom View)

Terminal Arrangement/

Internal Connections

(Top View)

Mounting Holes

(Bottom View)

Terminal Arrangement/

Internal Connections

(Top View)

12

Page 13

G7L

G7L

R99-07G5D

E-bracket

P7LF-D Adapter

P7LF-06

Front-connecting

Socket

26 24 17.8

24

Two, M3.5 screws

for coil

40

46

7

30

55

50

40$0.1

55.5 max.

Two, 4.5-dia.

holes

8

Mounting Holes

(Bottom View)

Two, M4 or

10

3

19.7

4.4

4.5-dia. holes

40$0.1

Mounting Holes

(Bottom View)

Two, M4 or

4.5-dia. holes

40$0.1

35.2 max.

14.5

51.5 max.

5

Mounting Holes

(Bottom View)

Four, M4 screws

for contact

P7LF-C Cover

Internal Coil Circuit

DC Operating Coil AC Operating Coil

34.5 max.

40$0.1

55.5 max.

50.5 max.

9.2

6max.

51.5 max.

25

46 max.

1

Put the P7LF-C cover onto the terminals in order

to protect the user from electric shock.

5

Two, M4 or

4.5-dia. holes

40$0.1

13

Page 14

G7L

Precautions

Refer to page NO TAG for general precautions.

Handling

To preserve performance, do not drop or otherwise subject the

!

Power Relay to shock.

Thecase is notdesigned to be removed during normal handling

!

and operation. Doing so may affect performance.

Use the Power Relay in a dry environment free from excessive

!

dust, SO

Do not allow a voltage greater than the maximum allowable coil

!

voltage to be applied continuously.

Do not use the Power Relay outside of specified voltages and

!

currents.

Do not allow the ambient operating temperature to exceed the

!

specified limit.

Installation

Although there are not specific limits on the installation site, it

!

should be as dry and dust-free as possible.

PCB Terminal-equippedRelays weigh approximately 100 g. Be

!

sure that the PCB is strong enough to support them. We

recommend dual-side through-hole PCBs to reduce solder

cracking from heat stress.

Quick-connectterminals canbeconnectedtoFastonreceptacle

!

#250 and positive-lock connectors.

Allowsuitableslack onleadswhenwiring,anddonot subjectthe

!

terminals to excessive force.

Cleaning PCB Terminals

PCB terminals have flux-tight construction which prevents flux

!

from penetrating into the Relay base housing, e.g., due to

capillaryactionuptheterminals whenRelayis solderedontothe

PCB. This type of Relay cannot be immersed for cleaning.

Connecting

Refer to the following table when connecting a wire with a

!

crimp-style terminal to the G7L.

Terminals

Coil

Contact

Rated Current Flow

When using B-series (screw) products, the rated current from the

screw terminals (M4) should be 20 A or less according to jet standard (electrical appliance and material control law of Japan).

S, or organic gas.

2,H2

Screw terminals Front-connecting

8

5.8

5

M3.5

M4

5.5

6.5

9.2

Socket

8

6.5

5.3

M3.5

M4

5.5

7

9.2

Operating Coil

As a rule, either a DC battery or a DC power supply with a

!

maximumof5%ripplemustbeusedfortheoperatingvoltagefor

DC Relays. Before using a rectified AC supply,confirm that the

rippleisnot greater than 5%. Ripplegreaterthan this can leadto

variations in the operating and reset voltages.

As excessive ripple can generate pulses, the insertion of a

smoothing capacitor is recommended as shown below.

Smoothing

capacitor

Emin.Emax. Emean

% of ripple = x 100

Emax

Emin.

E mean

When driving a transistor, check the leakage current and

!

connect a bleeder resistor if necessary.

Emax.--E

E mean

.: Max. ripple

: Min. ripple

: Mean DC value

Relay

Ripple

DC fraction

min.

DIN Track Mounting Adapter and

Front-connecting Socket

DIN Track Mounting

Use a DIN-conforming 50-cm track or 1-m track (both are sold

!

separately) for mounting a number of G7L Relays.

Cut and shorten the track to an appropriate length it if the

required track length is less than 50 cm.

The DIN Track Mounting Adapter and Front-connecting Socket

!

can be mounted on the G7L with just one hand and dismounted

with ease by using a screwdriver.

To support the G7L mounted on a DIN Track Mounting Adapter

!

or Front-connecting Socket, use the PFP-M End Plate. Put the

End Plate onto the DIN Track Mounting Adapter or

Front-connecting Socket so that the surface mark of the End

Plate faces upwards. Then tighten the screw of the End Plate

securely with a screwdriver.

Screw Mounting

Screw-mounttheDINTrackMountingAdapterorFront-connect-

!

ing Socket securely after opening screw mounting holes on

them.

When cutting or opening holes on the panel after the

!

Front-connecting Socket is mounted, take proper measures so

that the cuttingchips will notfall onto theRelay terminals. When

cutting or opening holes on the upper part of the panel, maskthe

Front-connecting Socket properly with a cover.

G7L

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. J055-E1-3A

14

Loading...

Loading...