Page 1

3G3RV-P10ST@-E

G7/F7/L7/E7 inverter PLC

The OMRON PLC technology embedded in

the OMRON Yaskawa inverter family

• OMRON PLC programmability in the

OMRON Yaskawa inverters.

• Flexibility and intelligence in the OMRON Yaskawa

inverter family.

• Wireless installation and seamless access to the

inverter parameters and analogue/digital inputs and

outputs.

• OMRON Compobus/S fieldbus inside. Thus, able to

control up to 256I/O's.

• Easy to integrate in the automation world:

DeviceNet type available.

• Standard OMRON tools can be used for programming and commissioning.

• Ideal for applications like:

• Pump sequencing, remote control, water

treatment,etc together with the HVAC inverter:

E7&E7 IP54.

• Lift as control sequence inside, using the lift

inverter: L7.

• Cranes, winding/rewinding, position control, oth-

ers combined with the powerful flux vector control

inverter: F7Z.

• General purpouse using the high technology of

G7 3-Level vector control.

System configuration

DeviceNet

RS-232C

RS-422

CX-One (CX-Drive)

(CX-Programmer)

HMI interface

Other serial devices

Varispeed + PLC

CompoBus/S communication path

Terminator

16 of 32 slaves max.

365G7/F7/L7/E7 inverter PLC

Page 2

Type designation

PLC inverter

3G3RV-P10ST8-DRT-E

Inverter series

Number of I/O's

Options

Output RTC RS422 Remarks

- NPN NO NO

1NPN NO YES

2 NPN YES NO

3 NPN YES YES

5 PNP NO NO

6 PNP NO YES

7PNP YES NO

8 PNP YES YES Standard

DeviceNet slave

-No

DRT Yes

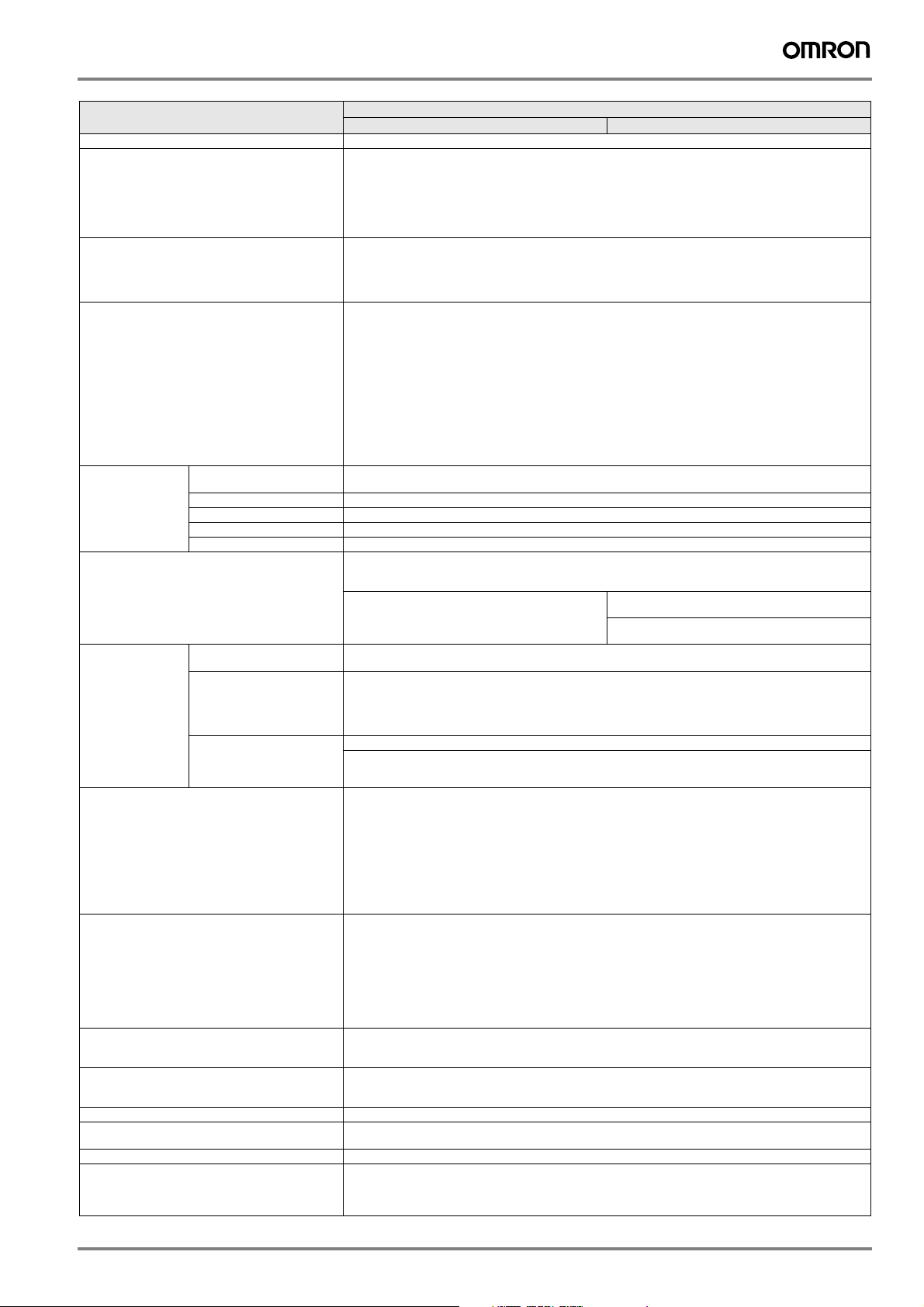

Specifications

Specifications by product

Item 3G3RV-P10ST8-E 3G3RV-P10ST8-DRT-E

PLC core CPM2C-S CPM2C-S

Inputs 6 24 VDC inputs 6 24 VDC inputs

Outputs 4 sourcing/PNP transistor outputs 4 sourcing/PNP transistor outputs

Peripheral port Yes Yes

RS-232C port Yes Yes

RS-422 port No Yes

Calendar/clock Yes Yes

Memory backup Flash memory and battery Flash memory and battery

Compobus/S master interface Yes Yes

Encoder interface Yes Yes

DeviceNet Slave interface No Yes

General specifications

Item Specifications

3G3RV-P10ST8-E 3G3RV-P10ST8-DRT-E

Rated power supply voltage 24 VDC

Communications power supply voltage --- 11 to 25 VDC (supplied by communications connector)

Power consumption

supply

Vibration resistance 10 to 20 Hz, 9.8 m/s2 max.

Ambient operating temperature -10 to 45 °C

Ambient operating relative humidity 10% to 90% (no condensation)

Ambient storage temperature -20 to 70 °C

Atmosphere Must be free from corrosive gas

Control method Store program method

I/O control method Cyclic scan method

Programming language Ladder chart method

Instruction length 1 step/1 instruction; 1 to 5 words/1 instruction

Instruction types Basic 14 types (same as for programmable slaves)

Processing speed Basic instructions 0.64 µs (LD)

Program capacity 4,096 words

Maximum number of I/O points 10

Input bits 00000 to 00015 (6 physical inputs)

Output bits 01000 to 01003 (4 physical outputs)

CompoBus/S input bits 128 bits: IR 02000 to IR 02715 (bits not used for CompoBus/S input bits can be used for work bits.)

CompoBus/S output bits 128 bits: IR 03000 to IR 03715 (bits not used for CompoBus/S output bits can be used for work bits.)

Inverter interface Direct interface with inverter through

Inverter interface bits 176 bits: IR 20000 to IR 21015

Encoder interface bits 48 bits: IR 02900 to IR 02915 and IR 04800 to IR 04915

Work bits 448 bits: IR 02800 to IR 02815, IR 03800 to IR 04715, and IR 21100 to IR 22715

Special bits (SR area) 448 bits: SR 22800 to SR 25507 (words SR 228 to SR 255)

Temporary bits (TR area) 8 bits (TR 0 to TR 7)

Holding bits (HR area) 320 bits: HR 0000 to HR 1915 (words HR 00 to 19)

Auxiliary bits (AR area) 384 bits: AR 0000 AR 2315 (words AR 00 to AR 23)

Internal power 2 W (supplied internally) (see note) 3 W (supplied internally) (see note)

Communications power supply --- 30 mA max.

Special 105 types, 185 instructions (same as for programmable slaves)

Special instructions 7.8 µs (MOV)

+10%

/

(external power supply for I/O)

-15%

20 to 50 Hz, 2 m/s2 max

• IR-memory

• DM-memory

• Transfer command

366 3G3RV-P10ST@-E

Page 3

Item Specifications

Link bits (LR area) 256 bits: LR 0000 to LR 1515 (words LR 00 to LR 15)

Timers/counters 256 timers/counters (TIM/CNT 000 to TIM/CNT)

CompoBus/S master functions Remote I/O devices can be allocated up to 256 I/O points (128 inputs and 128 outputs) in input area IR 020 to

DeviceNet slave functions Up to 64 words (32 input words and 32 output words) can be allocated to the DeviceNet master's I/O.

DM area Read/write 2,029 words (DM 0000 to DM 0999, DM 1019 to DM 2047)

Read only 456 words (DM6144 to 6599)

Inverter interface 19 words (DM 2022 to DM 2040)

Encoder interface 14 words (DM 1986 to DM 1999)

Interrupts Interrupt inputs

High-speed counters High-speed counter 1 input,

Encoder interface 3 input modes:

Pulse outputs • 2 outputs:

Synchronized pulse control 1 point, see notes 5 and 6

Pulse catch inputs 2 bits

Analog volume None

Input time constant

(ON response time = OFF response time)

Clock/Calendar function Shows the current year, month, day of the week, day of the month, hour, minute, and second.

Communication function Port 1 = Peripheral and RS-422:

PLC setup 56 words (DM 6599 to DM 6655)

see note 5

Differential phase mode (5 kHz)

Pulse plus direction input mode

(20 kHz)

Up/down input mode (20 kHz)

Increment mode (20 kHz)

Interrupt inputs (counter mode)

2 inputs

Incrementing counter (2 kHz)

Decrementing counter (2 kHz)

3G3RV-P10ST8-E 3G3RV-P10ST8-DRT-E

1-ms timers: TMHH(--)

10-ms timers: TIMH(15)

100-ms timers: TIM

1-s/10-s timers: TIML(--)

Decrementing counters: CNT

Reversible counters: CNTR(12)

IR 027 and output area IR 030 to IR 037.

• The node numbers can be set to 0 to 7 (128-point mode) or 0 to 15 (256-point mode).

• The communications mode can be set to high-speed mode (max. length 100 m) or long-distance mode

(max. length 500 m).

The master's I/O can be allocated to the following data areas:

• Explicit message communications are supported. Any 3G3RV-P10ST data area can be accessed from the

• The communications speed can be set to 500 kbps (total network length 100 m max.), 250 kbps (total network

DM 2000 to DM 2021: error log storage area

2 inputs

Response time: 50 µs

Interval timer interrupts

1 input

Set value: 0.5 to 319,968 ms

Precision: 0.1 ms

No interrupt

Count-check interrupt

(An interrupt can be generated when the count equals the set value or the count lies within a preset range.)

No interrupt

Count-up interrupt

Maximum input frequency 50 kHz

Maximum counter range 4,294,967,295 (232-1)

Two capture registers, 3 selectable registration inputs

One comparison value

Counter reset through software or Z-phase

Interrupt function

• 2 outputs:

• 1 output:

Minimum pulse input: 50 µs max.

Used in common by input interrupts and input interrupt counter mode.

Determines the input time constant for all inputs. (settings: 1, 2, 3, 5, 10, 20, 40, or 80 ms)

Port 2 = RS-232C port:

IR 000 to IR 049

IR 200 to IR 227

DM 0000 to DM 2047

LR 00 to LR 15

HR 00 to HR 19

AR 00 to AR 23 (3G3RV-P10ST ' master; read-only)

TC 000 to TC 255

DeviceNet master.

length 250 m max.), or 125 kbps (total network length 500 m max.).

Scheduled interrupts

One-shot interrupt

Differential-phase (up/down)

Pulse plus direction

Up/down pulse

Single-phase pulse output without acceleration/deceleration (see note 6.)

10 Hz to 10 kHz

Variable duty ratio pulse output (see note 6.)

0.1 to 999.9 Hz, duty ratio 0 to 100%

Pulse output with trapezoidal acceleration/deceleration (see note 6.)

Pulse plus direction output, up/down pulse output, 10 Hz to 10 kHz

Input frequency range: 10 to 500 Hz, 20 Hz to 1 kHz, or 300 Hz to 20 kHz

Output frequency range: 10 Hz to 10 kHz

Host link, peripheral bus, no-protocol, programming console

Host link, no-protocol, 1:1 PLC link, 1:1 NT link

G7/F7/L7/E7 inverter PLC 367

Page 4

Item Specifications

3G3RV-P10ST8-E 3G3RV-P10ST8-DRT-E

Power-interruption hold function Holds the contents of HR, AR, CNT, and DM areas.

Memory backup (see notes 1 and 2.) Flash memory: Program, read-only DM area, and PC setup

Memory backup: The read/write DM area, HR area, AR area, and counter values are backed up.

(The battery has a 5-year lifetime at 25 °C and it is replaceable.)

Self-diagnostic function CPU errors, memory errors, communications errors, setting errors, battery errors

Program check No END instruction, program errors (regularly checked during operation)

Connected tools CX-programmer After version 2.1

Programming console C200H-PRO27, CQM1-PRO01

SSS PC98 & PC/AT (SYSMAC support software, all versions)

CX-drive Version 1 or higher

Note: 1. The DM area, HR area, AR area, and counter values are

backed up. If the backup battery or capacitor is discharged,

the contents of these areas will be lost and the data values will

revert to the defaults.

2. The contents of the program area, read-only DM area

(DM6144 to DM6599), and PLC setup (DM 6600 to DM 6655)

are stored in flash memory. The contents of these areas will

be read from flash memory the next time the power is turned

ON, even if the backup battery or capacitor is discharged.

3. Changes made while in MONITOR mode using, for example,

online editing, are written to flash memory in real-time.

4. The above figure for power consumption includes the power

consumption of the programming console.

5. This input is shared by the high-speed counter and synchro-

nized pulse control functions.

6. This output is shared by the pulse output and synchronized

pulse control functions.

When data has been changed in any of these areas, write the

new values to flash memory by switching the 3G3RV-P10ST

to MONITOR or RUN mode, or by turning the power OFF and

then ON again.

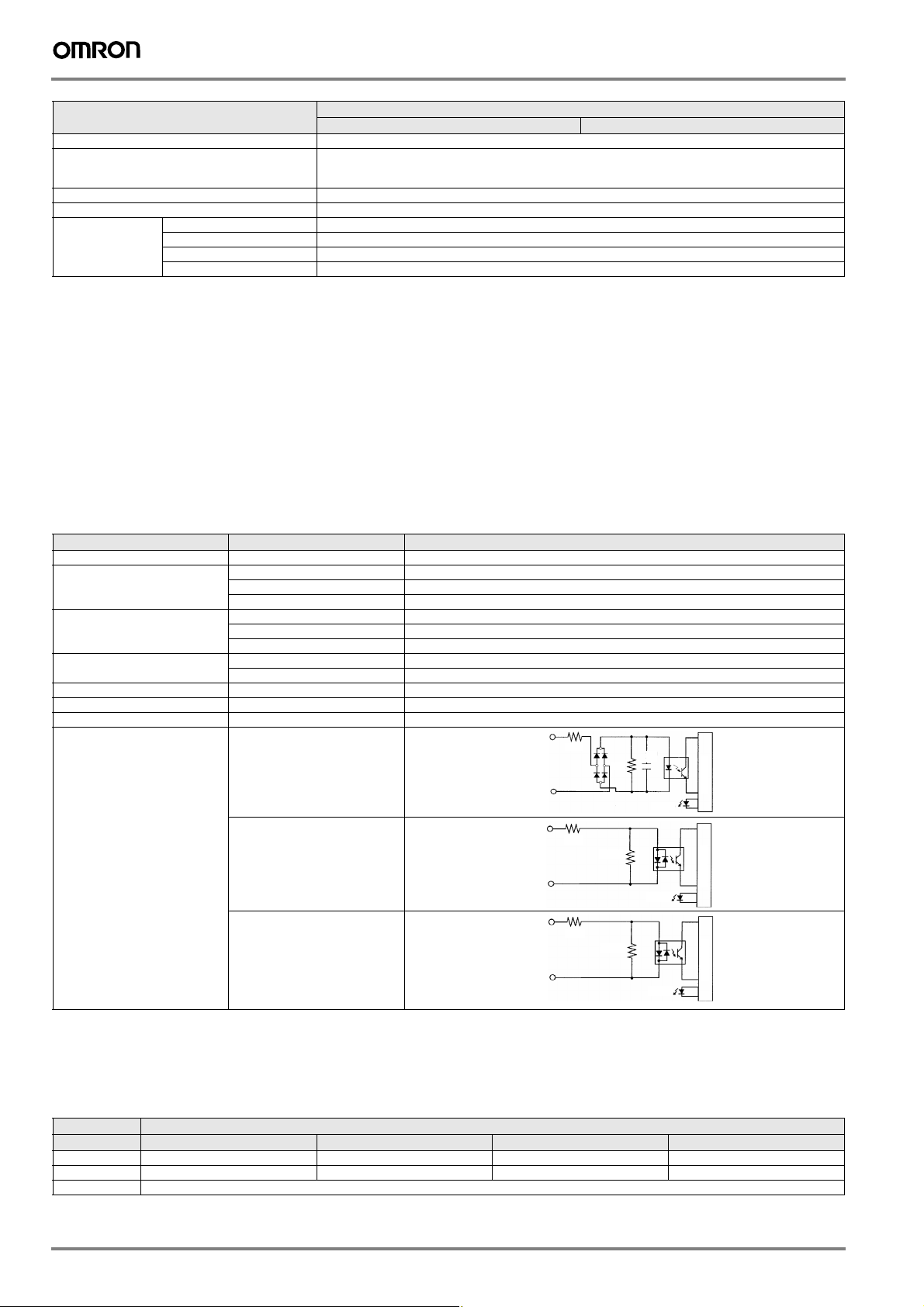

I/O specifications

Input specifications

Item Inputs Specification

Input voltage All 24 VDC

Input impedance IN 00000 to IN 00001 2.7 kΩ

IN 00002 to IN 00004 3.9 kΩ

IN 00005 4.7 kΩ

Input current IN 00000 to IN 00001 8 mA typical

IN 00002 to IN 00004 6 mA typical

IN 00005 5 mA typical

ON voltage/current IN 00000 to IN 00001 17 VDC min., 5 mA

IN 00002 to IN 00005 14.4 VDC min., 3.5 mA

OFF voltage/current All 5.0 VDC max., 1.1 mA

ON delay All 1 to 80 ms max. Default: 10 ms (see note.)

OFF delay All 1 to 80 ms max. Default: 10 ms (see note.)

Circuit configuration IN 00000 to IN 00001

IN 00002 to IN 00004

IN 00005

+10%

/

-15%

IN

2.7 kΩ

COM

COM

COM

IN

3.9 kΩ

IN

4.7 kΩ

820 Ω

750 Ω

0.01

µF

1kΩ

Input LED

Input LED

Input LED

Internal circuits

Internal circuits

Internal circuits

Note: The input time constant can be set to 1, 2, 3, 5, 10, 20, 40, or 80 ms in the PLC setup.

High-speed counter inputs

The following unit input bits can be used as high-speed counter inputs. The maximum count frequency is 5 kHz in differential phase mode and

20 kHz in the other modes.

Input Function

IN 00000 A-phase pulse input Pulse input Increment pulse input Increment pulse input

IN 00001 B-phase pulse input Direction input Decrement pulse input Normal input

IN 00002 Z-phase pulse input or hardware reset input (IN00002 can be used as a normal input when it is not used as a high-speed counter input.)

Differential phase mode Pulse plus direction input mode Up/down input mode Increment mode

368 3G3RV-P10ST@-E

Page 5

The minimum pulse widths for inputs IN00000 (A-phase input) and IN00001 (B-phase input) are as follows:

Pulse plus direction input mode,

Differential phase mode

up/down inputmode, Increment mode

100 µs min.

T

1T2T3T4

T

: 12.5 µs min.

1 T2 T3 T4

90%

50%

10%

90%

50%

10%

ON

OFF

50 µs min.

12.5 µs

min.

12.5 µs

min.

90%

50%

10%

Phase A

Phase B

ON

OFF

ON

OFF

The minimum pulse width for input IN00002 (Z-phase input) is as follows:

50 µs min.

Phase Z

ON

OFF

500 µs min.

90%

50%

10%

Interrupt inputs

3G3RV-P10ST is equipped with inputs that can be used as interrupt inputs (interrupt input mode or counter mode) and quick-response inputs.

The minimum pulse width for these inputs is 50 µs.

Inputs IN 00003 and IN 00004 can be used as interrupt inputs.

Output specifications

Transistor outputs (sourcing/PNP)

Item Specification

Maximum switching capacity 4.5 to 30 VDC, 0.2 A/output

Minimum switching capacity 0.5 mA

Maximum inrush current 0.9 A for 10 ms

Leakage current 0.1 mA

Residual voltage 1.5 V max.

ON response time 20 µs max.

OFF response time 40 µs max. for 4.5 to 26.4 VDC, 10 to 100 mA

Fuse One fuse per output (cannot be replaced by user)

Circuit configuration

0.1 ms max for 4.5 to 30 VDC, 10 to 200 mA

Internal

circuits

Output LED

COM (+)

OUT

24 VDC

Note: When using OUT 01000 or OUT 01001 as a pulse output, con-

nect a dummy resistor as required to bring the load current

between 0.01 and 0.1 A. If the load current is below 0.1 A, the

ON-to-OFF response time will be longer and high-speed pulses

(source-type transistor outputs) will not be output. If the load current is above 0.1 A, the transistor will generate more heat and

components may be damaged.

Encoder input specifications

Signal level All

Input impedance A- and B-phase

Z-phase

Response frequency A- and B-phase

Z-phase

Circuit configuration A- and B-phase

Z-phase

EIA RS-422-A standards

280 Ω

260 Ω

50 kHz max.

1 kHz max.

OUT

!Caution

Do not apply voltage in excess of the maximum switching capacity

to an output terminal. It may result in damage to the product or fire.

330 Ω

A

B

410 Ω

220 pF

/A

/B

/Z

330 Ω

180 Ω

Z

560 Ω

680 pF

180 Ω

Intrnal circuits

Intrnal circuits

G7/F7/L7/E7 inverter PLC 369

Page 6

Operation

CPU unit component descriptions

1. DI P switch

16. D eviceNet

node address

14. Battery15. Low battery detection switch

17. D eviceNet ind icators

18. CompoBus/S indicators

5. PLC status indicators

4. High-speed counter indicators

3. Output indicators

2. Input indicators

13. FE connection

10. Terminating resistance switch

7. Co mmunicatio ns switch

6. Communications port

9. RS-422/485 port

11. CompoBus/S port

1. DIP switch

RS-232C and peripheral port settings

•

Pin 1 Effective port settings

The ports operate according to the settings in the

OFF

(default)

PLC setup.

ON

1

3

4

2

RS-232C port settings: DM 6645 to DM 6649

Peripheral port settings: DM 6650 to DM 6654

ON The ports operate with the standard communications

settings.

• Operating mode at startup

Pin 2 determines the operating mode at startup only if there isn't a

programming device connected to the peripheral port.

Programming device

connected

None RUN mode PROGRAM mode

Programming console Operating mode set on the programming console's

Other device PROGRAM mode

Startup mode with

Pin 2 OFF (default)

mode switch

Startup mode with

Pin 2 ON

2. Input indicators (yellow)

IN0

IN1

IN2

IN3

IN4

IN5

OUT0

The input indicators are lit when the corresponding

OUT1

input terminal is ON. The status of an input indicator

OUT2

will reflect the status of the input even when that input

OUT3

is being used for a high-speed counter.

Note: 1. When interrupt inputs are used in interrupt input mode, the in-

dicator may not light even when the interrupt condition is met

if the input is not ON long enough.

2. Input indicators will reflect the status of the corresponding in-

puts even when the PLC is stopped, but the corresponding input bits will not be refreshed.

8. DeviceNet port

12. Digital I/O and

encoder interface

3. Output indicators (yellow)

The output indicators are lit when the corresponding output terminal is

ON. The indicators are lit during I/O refreshing. The status of an output

indicator will also reflect the status of the corresponding output when

the output is being used as a pulse output.

4. High-speed counter indicators (yellow)

A

B

Z

The indicators are lit when the corresponding input

terminal is ON.

5. PLC status indicators

The following indicators show the operating status of the PLC.

PWR

RUN

ERR/ALM

COMM1

COMM2

Indicator Status Meaning

PWR

(green)

RUN

(green)

ERR/ALM

(red)

ON Power is being supplied to the unit

OFF Power isn't being supplied to the unit

ON The PLC is operating in RUN or

MONITOR mode

OFF The PLC is in PROGRAM mode or

ON A fatal error has occurred.

a fatal error has occurred.

(PLC operation stops.)

Flashing A non-fatal error has occurred.

(PLC operation continues.)

OFF Indicates normal operation.

COMM1

(yellow)

COMM2

(yellow)

Flashing Data is being transferred via the

peripheral or RS-422/485 port.

OFF Data isn't being transferred via

Flashing Data is being transferred via the

communications port.

RS-232C port

OFF Data isn't being transferred via

communications port.

370 3G3RV-P10ST@-E

Page 7

6. Communications port

Connects the PLC to a programming device (including programming

consoles), host computer, or standard external device. Use a proper

connecting cable (CPM2C-CN111, CS1W-CN114, CS1W-CN118, or

CS1W-CN226).

Note: 1. A CQM1H-PRO01-E programming console can be connect-

ed directly to the PLC.

2. A C200H-PRO27-E programming console can be connected

directly to the PLC with a CS1W-CN224/CN624 connecting

cable.

3. Use a CPM2C-CN111 or CS1W-CN114 connecting cable to

connect to the communications port as a peripheral port. The

communications port can be used simultaneously as both a

peripheral port and RS-232C port by using the CPM2CCN111 connecting cable.

4. Use a CPM2C-CN111, CS1W-CN118 or CS1W-CN226 con-

necting cable to connect to the communications port as a RS232C port. The communications port can be used simultaneously as both a peripheral port and RS-232C port by using

the CPM2C-CN111 connecting cable

Note: The peripheral port and RS-422/485 port cannot be used simul-

taneously. When using the peripheral port disconnect any

devices connected to the RS-422/485 port.

7. Communications switch

Switch to select port 1 type of connected device

Position Communication port 1

OFF (up) (default) Programming console

ON (down) RS-422/485 communication

8. DeviceNet port (-DRT versions only)

Terminal arrangement

CAN-HCAN-L V+V- Shield

11. CompoBus/S port

Terminal arrangement

2

4BDH

3

BDL

1

Use special flat cable or VCTF cable for the transmission lines that connect the nodes in the CompoBus/S I/O Link. (Special flat cables and

VCTF cables cannot be combined in the same system.)

Name Model number Specifications

Flat cable XB1T-W10 4-core flat cable, 0.75 mm²

VCTF cable --- 2-core VCTF, 0.75 x 20

12. Digital inputs and outputs and encoder interface

Connects the CPU unit to external input and output devices.

Sourcing outputs

IN1(B)

IN3

COM

IN5

IN2(Z)

IN4OUT2

IN0(A)

Z- COM(+)

Z+B-B+

A-

A+

OUT0

OUT1

OUT3

13. Functional earth-wire

To be connected the earth connection inside the inverter.

14. Battery

15. Low battery detection switch

This switch enables or disables the detection of a low-battery error.

Position Low-battery detection

ON

OFF (right)

(default)

1

ON (left) Error detection disabled

Error detection enabled

9. RS-422/485 port

Used to connect to host computers, or standard external devices.

Terminal arrangement

Send

data

(output)

SDB+6

5

SDA-

Receive

data

(input)

RDB+

RDA-

Note: The maximum line length is 500 m.

The peripheral port and RS-422/485 port cannot be used simultaneously. When using the peripheral port disconnect any

devices connected to the RS-422/485 port.

When using RS-485 communication, connect RDA- to SDA- and

RDB+ to SDB+.

10. Terminating resistance switch

Position Termination

ON

OFF (right)

(default)

1

ON (left) Enabled

Disabled

Set this switch to ON only for double-ended connection to a host link

network.

16. DeviceNet node-number (-DRT versions only)

Please refer to the DeviceNet section

17. DeviceNet indicators (-DRT versions only)

Please refer to the DeviceNet section

18. CompoBus/S indicators

Indicator Status Meaning

SD

RD

ERC

SD

(yellow)

RD

(yellow)

ERC

(red)

Flashing Data is being transmitted via

OFF Data isn't being transmitted via

Flashing Data is being received via

OFF Data isn't being received via

Flashing A CompoBus/S communications

OFF A CompoBus/S communications

CompoBus/S

CompoBus/S

CompoBus/S

CompoBus/S

error occurred.

error hasn't occurred.

G7/F7/L7/E7 inverter PLC 371

Page 8

Dimensions

Application examples

G7 + PLC

Varispeed G7 is the OMRON Yaskawa solution using 3 level PWM control technology that provides lower surge voltage, low leakage current, low

bearing current, low acoustic noise and better EMC. By combining with PLC option board, it is the ideal solution for winding/unwiding applications,

handling / transfer / palletizer point-to-point positioning applications, press control applications, extruder control applications and pump

applications for examples ..

G7 + PLC in a water treatment application example

G7 + PLC

HMI interface

GSM modem

Compobus /S slav es

PH

sensor

Level

sensor

O2

sensor

Water

Note: For detailed information about the inverter, please see the Varispeed G7 series section.

372 3G3RV-P10ST@-E

Page 9

F7 + PLC

The F7 drive is a flux vector control inverter. It is intended to handle every conventional drive application found in a typical industrial manufacturing

plant from simple variable torque pumping to sophisticated networked material handling. By combining with PLC option board, is ideal solution

winding/unwiding applications, handling/ transfer/ palletizer point-to-point positioning applications, food processing, packaging, printing, and textile

machines for example .

F7 + PLC in a winding application example.

M

F7

M

F7

M

F7

Load cell

HMI interface

F7 + PLC

M

Encoder

PG

Note: For detailed information about the inverter, please see into the Varispeed F7 series section.

E7 + PLC

Varispeed E7 is the OMRON Yaskawa solution for energy saving applications The E7 is designed for variable torque applications such as fans

and centrifugal pumps. By combining with PLC option board, it is the ideal solution for water treatment, pump squencing, building automation and

fan applications for example...

E7 + PCL in HVAC application example

E7 + PLC

Scada

building controller

HMI interface

Analogue input s

Digital

outputs

Digital

inputs

Compobus/S

up to 16 / 32 slaves

Cooling tower

Water

Air

Air

Air

Air

Temperature

sensors

Note: For detailed information about the inverter, please see into the Varispeed E7 series section.

G7/F7/L7/E7 inverter PLC 373

Page 10

L7 + PLC

The L7 is the ultimate drive for lift applications up to 3m/s. High starting torque, silent operation, lift-specific operator interface and operation with

both AC and PM motors are standard features of the L7 inverter. By combining with PLC option board, it is the ideal solution for controlling

distributed I/O’s, lift cabin HMI, GSM modem to send alarms for example..

L7 + PLC in lift application example

L7 + PLC

Compobus /S

Brake

Contactor

GSM modem

Safety limits

HMI interface

Lift cabin

Note: For detailed information about the inverter, please see into the Varispeed L7 series section.

Up to 256 I/O’s

374 3G3RV-P10ST@-E

Page 11

Ordering information

3G3IV-PCN329-E

Inverter to PC cable

3G3IV-PCN126/326

Digital operator

extension cable

CX-One

C C C

Varispeed CompoBus/S

G7/F7/L7/E7

Inverter PLC

G7/F7/L7/E7 inverter PLC

Specifications Model

Inputs Ouptuts RTC Compobus/S master RS422 port DeviceNet slave

6 4 Yes Yes Yes No 3G3RV-P10ST8-E

6 4 Yes Yes NO Yes 3G3RV-P10ST8-DRT-E

A Varispeed

Specifications Model

The 3-Level control method inverter Varispeed G7

Flux vector control inverter Varispeed F7

The lift inverter Varispeed L7

The pumps and fans inverter Varispeed E7

slaves

B A

SRT2-ID

SRT2-OD

SRT2-ROC

SRT2-ROF

SRT2-ID_CL

SRT2-OD_CL

SRT2-AD

SRT2-DA

Note: For detailed information please refer to Varispeed G7/F7/L7/E7 series section.

B Cables

Specifications Model

Computer connecting cable CS1W-CN226

Programmable console cable CS1W-CN224

B Computer software

Specifications Model

PLC programming software: CX-programmer CX-One

Inverter configurator software: CX-drive

G7/F7/L7/E7 inverter PLC 375

Page 12

C Compobus/S slaves

Product Appearance Specifications Model

Digital I/O terminals 4 NPN inputs (+ common)

Relay output terminals 8 Relay outputs

4 PNP inputs (– common)

4 NPN outputs (– common)

4 PNP outputs (+ common)

8 NPN inputs (+ common)

8 PNP inputs (– common)

8 NPN outputs (– common)

8 PNP outputs (+ common)

16 NPN inputs (+ common)

16 PNP inputs (– common)

16 NPN outputs (– common)

16 PNP outputs (+ common)

8 Power MOS FET relay outputs

SRT2-ID04

SRT2-ID04-1

SRT2-OD04

SRT2-OD04-1

SRT2-ID08

SRT2-ID08-1

SRT2-OD08

SRT2-OD08-1

SRT2-ID16

SRT2-ID16-1

SRT2-OD16

SRT2-OD16-1

SRT2-ROC08

SRT2-ROF08

16 Relay outputs

16 Power MOS FET relay outputs

Waterproof terminals 4 NPN inputs (+ common)

Analog input terminal 1 to 4 inputs (set with DIP switch) SRT2-AD04

Analog output terminal 1 or 2 outputs (set with DIP switch) SRT2-DA02

4 PNP inputs (– common)

4 NPN outputs (– common)

4 PNP outputs (+ common)

8 NPN inputs (+ common)

8 PNP inputs (– common)

8 NPN outputs (– common)

8 PNP outputs (+ common)

SRT2-ROC16

SRT2-ROF16

SRT2-ID04CL

SRT2-ID04CL-1

SRT2-OD04CL

SRT2-OD04CL-1

SRT2-ID08CL

SRT2-ID08CL-1

SRT2-OD08CL

SRT2-OD08CL-1

Note: For detailed information about Compobus/S slaves, please refer to catalogue No. Y201-EN2-02 AS.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I25E-EN-02

In the interest of product improvement, specifications are subject to change without notice.

376 3G3RV-P10ST@-E

Loading...

Loading...