Omron G3ZA-4H203-FLK-UTU, G3ZA-4H403-FLK-UTU, G3ZA-8A203-FLK-UTU, G3ZA-8A403-FLK-UTU Brochure

Multi-channel power controller

A smart approach to fast, low-noise heater power regulation.

The G3ZA is a multi-channel power controller that provides clever

switching of up to eight solid state relays (SSRs). It is available

in four versions - either with 4 channels(with heater burnout

alarm) or 8 channels (without heater burnoutalarm), and for

high- or low-voltage power supplies.

This multi-channel power controller is designed to improve

performance of existing heater switching control components

while reducing complexity and costs. Installthe G3ZA beside

a bank of SSRs and reap the benefits of reduced wiring and

simplified programming control! The advantages of this

distributed control are immediately apparent. The small-sized

unit can control up to eight SSRs with only a single RS-485 2-wire

link to the PLC or PC. The manipulated variable control signal

(output %) from the PLC is automatically converted into a PWM

trigger signal within the G3ZA, so there is no need for an extra

conversion unit or digital output cards.

The G3ZA is designed according to Omron’sSmart Platform

concept for easy integration ofcomponents and systems.

PLC function blocks are available to significantly reduce ladder

programming time.

G3ZA

Actual

size

Advanced Industrial Automation

Product positioning

Phase angle

High speed

High resolution

Low speed

Coarse resolution

~0 0 1s 5s 10s +

G3ZA + SSRSCR SSR EM relay

Zero cross Standard SSR solutions

Features at a glance

•Compact size

•Capable of driving up to

eight SSRs

•Connects to RS-485 Compoway-F

network (ModBus in preparation)

•Better performance with

standard SSRs

•Lower noise than with Phase

Angle (SCR) control

•Lower peak current when using

offset control

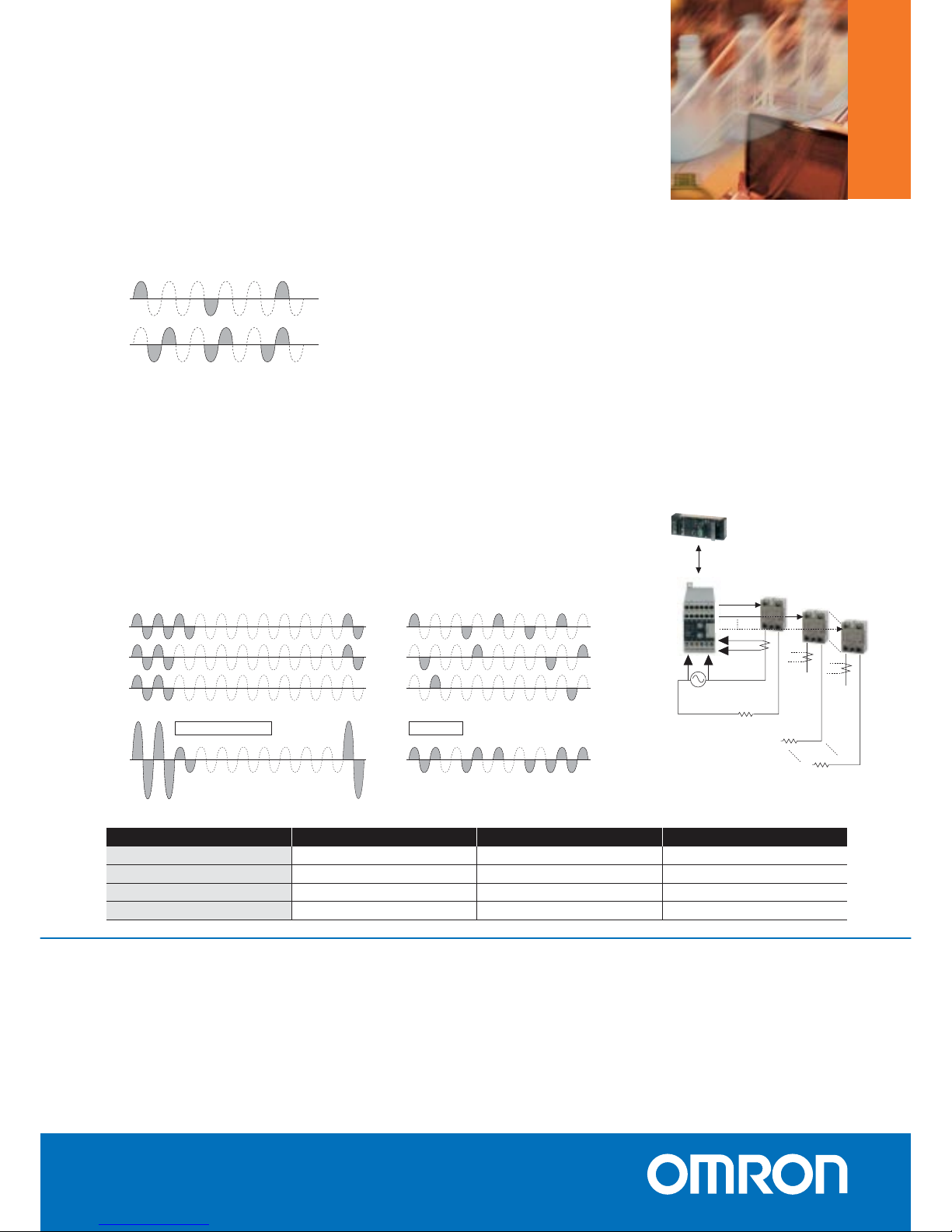

Optimum Cycle Control

The G3ZA uses Optimum Cycle Control to improve

overall performance and provide more accurate temperature control. When used together with any zeroswitching SSR (e.g. Omron’sG3NA) the G3ZA achieves

extremely low power noise levels that meet stringent

EMC standards. Power factor is significantly improved

and bulky filtering installations normally required for

phase control are not needed. In addition, the G3ZA

uses half-cycle switching and hasa resolution of 10ms,

making it ideal for applications where precise temperature control is crucial.

Offset control

By using an offset control algorithm for the various

channels, the G3ZA reduces peak switching currents

and enables the downsizing of ancillary units and

cabling. At lower powers in a full production cycle (for

example MV < 40%), the benefit becomes significant

because the total current is distributed more evenlyin

time. The more heaters you use the greater the benefit!

Monitoring and control

The G3ZA uses an RS-485 communications linkto

receive MV signals from a PLC or PC and to send back

status information (like heater burnout detection).

Because it only involves a two-wire link, the G3ZA can

be located inside the power cabinet, and the cabinet

can be placed close to the heater.

Typical applications for the

G3ZA include:

Multi-zone electrical ovens

In roller hearth continuousfurnaces, where temperatures reach 800°C, the G3ZA’s stable, distributed

switching is ideal during critical parts of the

heating process.

Thermo-moulding

The G3ZA is suitable for the PET bottle pre-forming

process where many heaters are needed along with

lots of power and precise heating control to get the

moulded product just right.

TV industry

The treatment and coating of glass windows, especially

in the flat-panel display manufacturing process,

requires fast, accurate heating and cooling. The G3ZA’s

ability to distribute power accurately and quickly

makesitsuitable for this application.

Available product types

Number of channels Heater burnout detection Load power supply

G3ZA-4H203-FLK-UTU

G3ZA-4H403-FLK-UTU

G3ZA-8A203-FLK-UTU

G3ZA-8A403-FLK-UTU

4

8

Yes

No

100 to 240 VAC

400 to 480 VAC

100 to 240 VAC

400 to 480 VAC

Host

(e.g. PLC or PC)

G3ZA

SSR

SSR

SSR

CT

Load

Load

Load

Load power

supply

20%

50%

ch1

ch2

ch3

ch1

ch2

ch3

Tot al

current

Traditional ON/OFF control

Offset control

Tot al

current

SF2P_G3ZA_EN_INT01_0305

Although we strive for perfection, Omron Europe BV

and/or its subsidiary and affiliated companies do not

warrant or make any representations regarding the

correctness or completeness of the information

described in this document. We reserve the right to

make any changes at any time without prior notice.

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD, Hoofddorp, The Netherlands. Tel: +31 (0) 23 568 13 00 Fax: +31 (0) 23 568 13 88 www.europe.omron.com

For the Middle East, Africa and other countries in Eastern Europe, Tel: +31 (0) 23 568 13 00 www.europe.omron.com

Austria

Tel: +43 (0) 1 80 19 00

www.omron.at

Belgium

Tel: +32 (0) 2 466 24 80

www.omron.be

Czech Republic

Tel: +420 234 602 602

www.omron.cz

Denmark

Tel: +45 43 44 00 11

www.omron.dk

Finland

Tel: +358 (0) 9 549 58 00

www.omron.fi

France

Tel: +33 (0) 1 56 63 70 00

www.omron.fr

Germany

Tel: +49 (0) 2173 680 00

www.omron.de

Hungary

Tel: +36 (0) 1 399 30 50

www.omron.hu

Italy

Tel: +39 02 32 681

www.omron.it

Netherlands

Tel: +31 (0) 23 568 11 00

www.omron.nl

Norway

Tel: +47 (0) 22 65 75 00

www.omron.no

Poland

Tel: +48 (0) 22 645 78 60

www.omron.com.pl

Portugal

Tel: +351 21 942 94 00

www.omron.pt

Russia

Tel: +7 095 745 26 64

www.omron.ru

Spain

Tel: +34 913 777 900

www.omron.es

Sweden

Tel: +46 (0) 8 632 35 00

www.omron.se

Switzerland

Tel: +41 (0) 41 748 13 13

www.omron.ch

Turkey

Tel: +90 (0) 216 474 00 40

www.omron.com.tr

United Kingdom

Tel: +44 (0) 870 752 08 61

www.omron.co.uk

Loading...

Loading...