Vision Sensor

FQ

Short Manual

Cat. No. Z306-E1-01

Table of Contents

1. Introduction

1-1 FQ-series Vision Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 Measurement Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Startup Display and Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4 Basic Operational Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. Installation and Connections

2-1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-4 Setting Up Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Taking Images

3-1 Selecting a Sensor for Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-2 Adjusting Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-3 Adjusting the Object Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table of Contents

4. Setting Up Inspections

4-1 Inspection Item Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-2 Setup Procedure for Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-3 Inspecting with the Search Inspection Item . . . . . . . . . . . . . . . . . . . . . . . 36

4-4 Inspecting with the Edge Position Inspection Item . . . . . . . . . . . . . . . . . 38

4-5 Inspecting with the Edge Width Inspection Item . . . . . . . . . . . . . . . . . . . 40

4-6 Inspecting with the Area Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-7 Inspecting with Color Data Inspection Item . . . . . . . . . . . . . . . . . . . . . . . 44

5. Testing and Saving Settings

5-1 Performing Test Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5-2 Adjusting the Judgement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5-3 Checking a List of All Inspection Item Results . . . . . . . . . . . . . . . . . . . . 51

5-4 Saving Data to the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

FQ Short Manual

1

6. Operation

6-1 Starting Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6-2 Configuring the Run Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6-3 Adjusting Judgement Parameters during Operation. . . . . . . . . . . . . . . . 58

7. Communications with External Devices

7-1 Operation with Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7-2 Setting the Measurement Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7-3 Setting the Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7-4 Controlling the Sensor from an External Device . . . . . . . . . . . . . . . . . . . 68

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2

FQ Short Manual

Introduction

1-1 FQ-series Vision Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1-2 Measurement Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1-3 Startup Display and Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . .6

1-4 Basic Operational Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1

Introduction

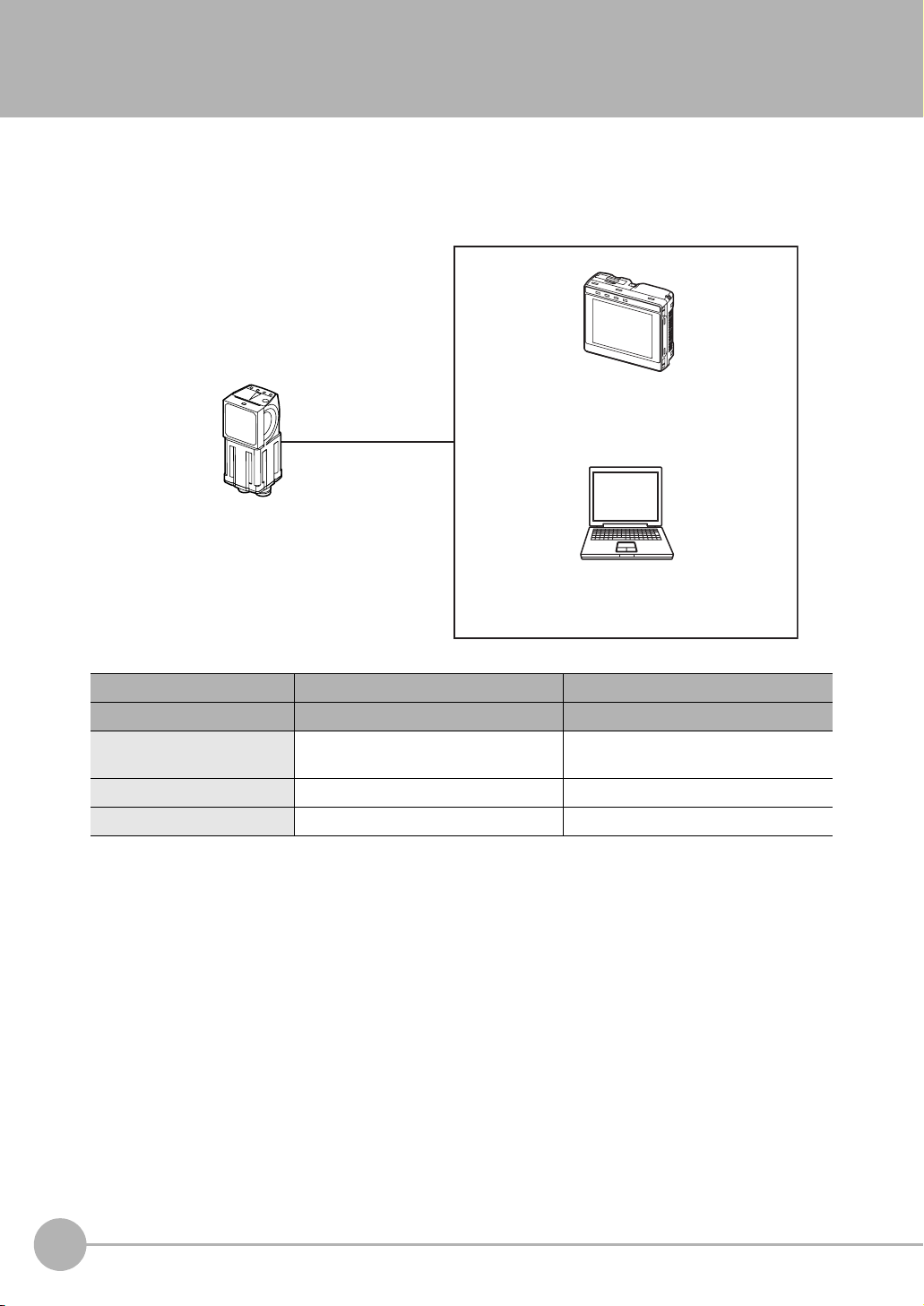

1-1 FQ-series Vision Sensors

FQ-series Vision Sensors are real-color Vision Sensors with integrated processing. Once configured, they are

used stand-alone for quality inspection of presence, position, and other product characteristics. To set up or

monitor the sensors, either the touch screen based console 'Touch Finder' or a 'PC Tool' can be used.

Setup, Image Confirmation, and Logging Tools

Touch Finder

FQ Vision Sensor

Used to check images and set the judgement

parameters. It can also be used to save

measurement results and check status during

operation.

PC Tool

Includes the camera, lighting, measurement

processor, and I/O functions.

After the Sensor has been set up, it can be

operated alone to perform measurements

without the Touch Finder or PC Tool.

The same functions as those that are provided

by the Touch Finder can be performed from a

computer. The PC Tool is available free of

charge.

FQ-series Vision Sensors are available in two different models. The differences are given in the following table.

Model Standard model Single-function model

Model number FQ-S2@@@@@ FQ-S1@@@@@

Number of simultaneous

measurements

Number of registered scenes 32 8

Position compensation Supported Not supported

32 1

4

FQ-series Vision Sensors

FQ Short Manual

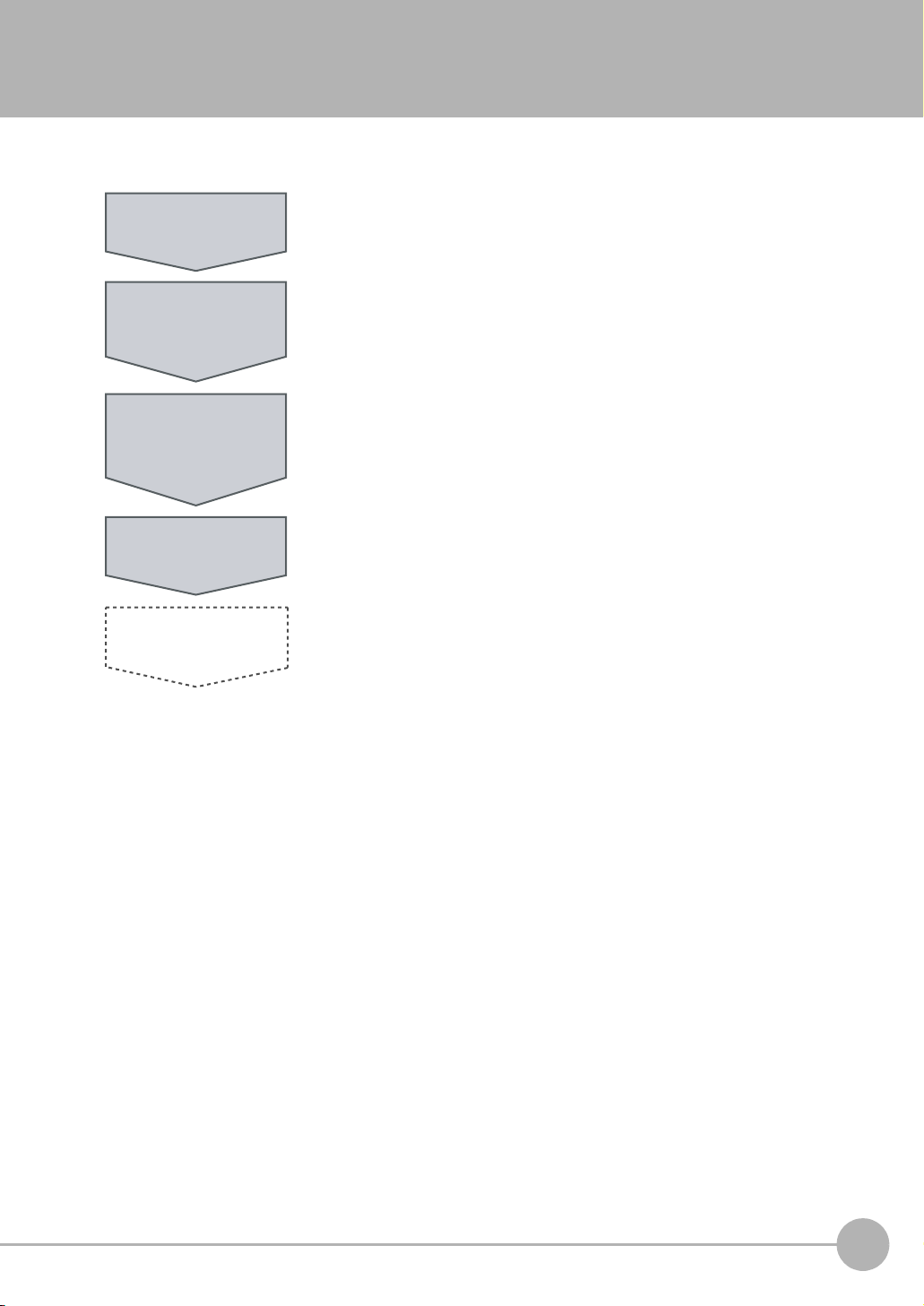

1-2 Measurement Process

This section describes the basic flow of the measurement process.

Trigger input

Take image

Measurement

Overall judgement

output

Logging

• The measurement is started by inputting a trigger signal from an external

device.

• Images are taken according to the trigger.

• The image is measured to see if it matches the configured settings.

• The overall judgement of all inspection items are output using OR logic.

• Measurement data and image data can be logged in memory in the Sensor or

in an SD card.

1

Introduction

FQ Short Manual

Measurement Process

5

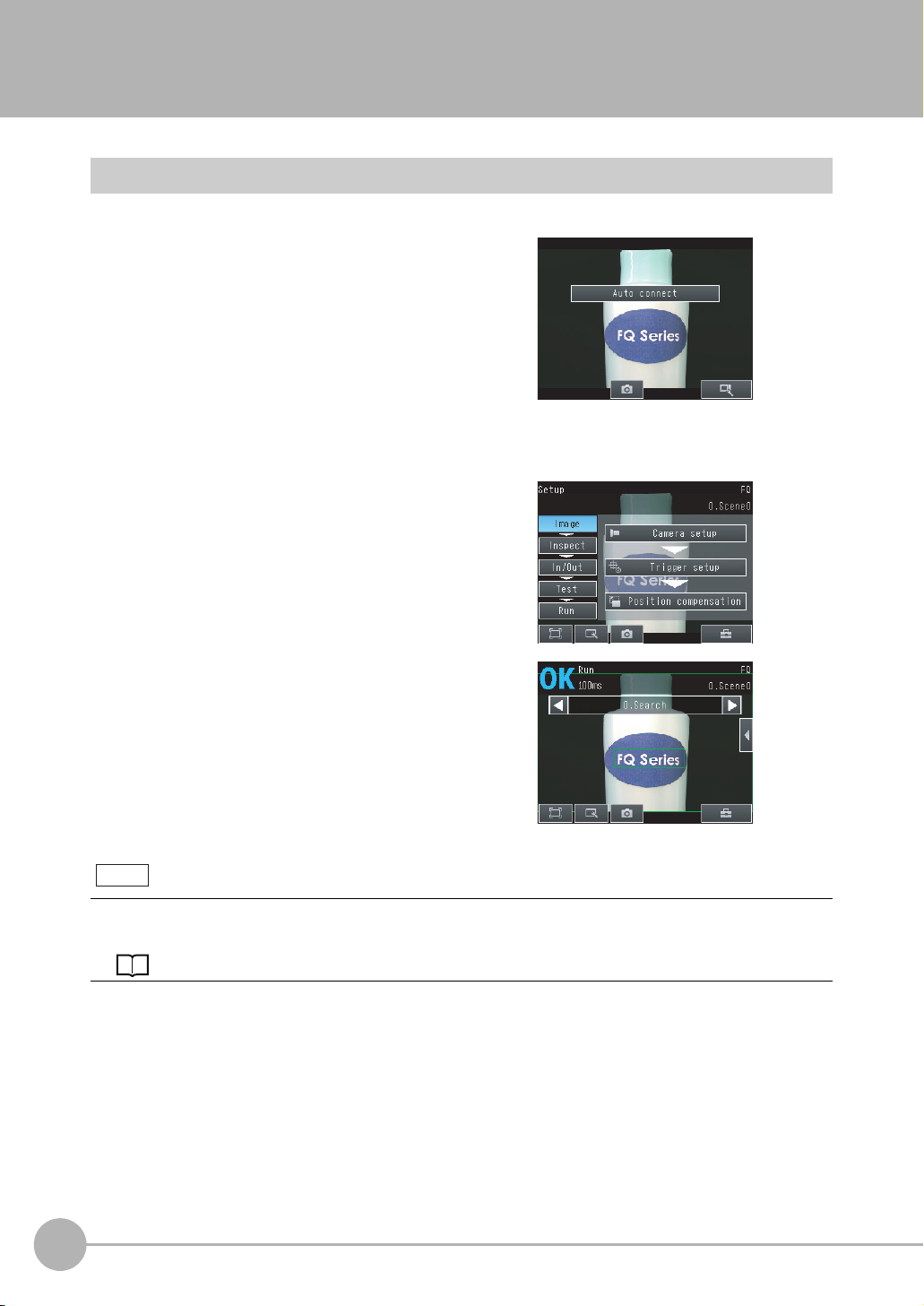

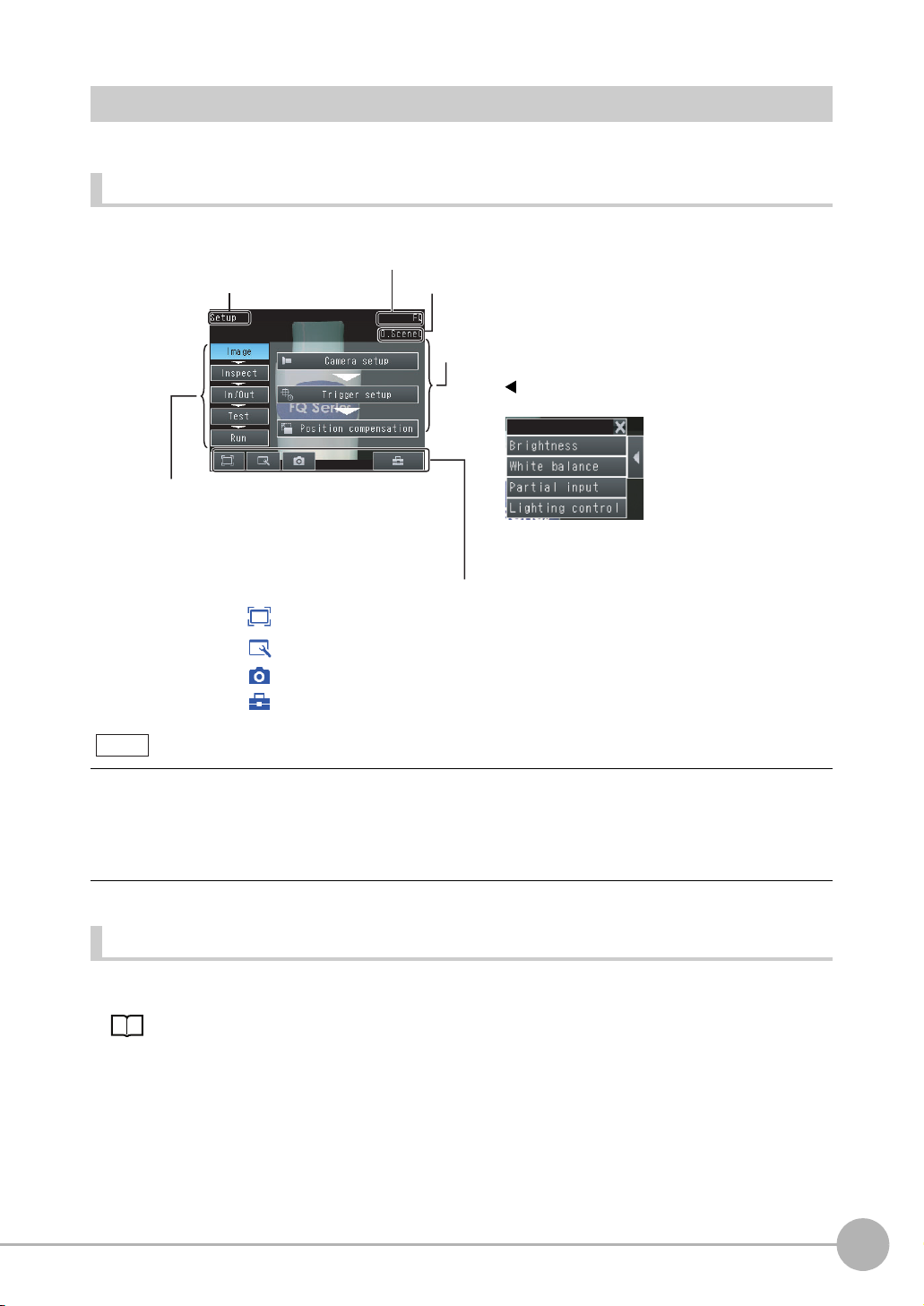

1-3 Startup Display and Display Elements

Startup Display

1 The Sensor is automatically detected by the Touch

Finder when power supply to the Sensor and Touch

Finder is turned ON.

The Auto Connect Display will appear if the Sensor cannot be detected. Check that cables are connected correctly to the Sensor and Touch Finder, and then press

[Auto connect].

2 When the Sensor is detected, the following display will appear.

• The Setup Mode will appear if a Sensor that has not been

set up is connected.

• The Run Mode will appear if a Sensor that has been set

up is connected.

Note

When the Touch Finder is started, IP addresses are automatically set for each Sensor.

To allocate specific IP addresses, set the IP address of each Sensor and the Touch Finder.

Setting Up Ethernet: p. 20

6

Startup Display and Display Elements

FQ Short Manual

Display Elements

This Sensor has a Setup Mode and a Run Mode.

Setup Mode

In Setup Mode, you can set the image conditions, judgement parameters, and I/O settings for the Sensor.

The name of the mode or the

menu hierarchy is displayed.

The setup flow is shown by these five tabs.

[Image]: Used to adjust the image.

[Inspect]: Used to set the inspection items.

[In/Out]: Used to set the I/O.

[Test]: Used to test and adjust the set measurements.

[Run]: Used to switch to Run Mode.

Only-image Button: Used to select either displaying the camera image and messages, or

Display Button: Used to select the source of the image or to zoom the image.

Capture Button: Used to capture the current screen to the SD card.

Tool Button: Used to call functions, such as saving data or select scenes.

The name of the Sensor being set up is displayed.

The selected scene number is displayed.

The menu changes according to the selected tab page.

• Buttons will appear on the right according to the mode.

• If the [ ] Button appears, pressing it will display the

sub-menu or commands.

This button menu is always displayed.

only the camera image.

1

Introduction

Note

The Display Button can be used to switch between the following images.

• Live: The live image is displayed.

• Freeze: The image that was taken last is displayed.

• Log: An image saved in internal memory is displayed.

• File: An image saved on an SD card is displayed.

Run Mode

In Run Mode, measurements are performed, and measurement results are output.

p. 53

FQ Short Manual

Startup Display and Display Elements

7

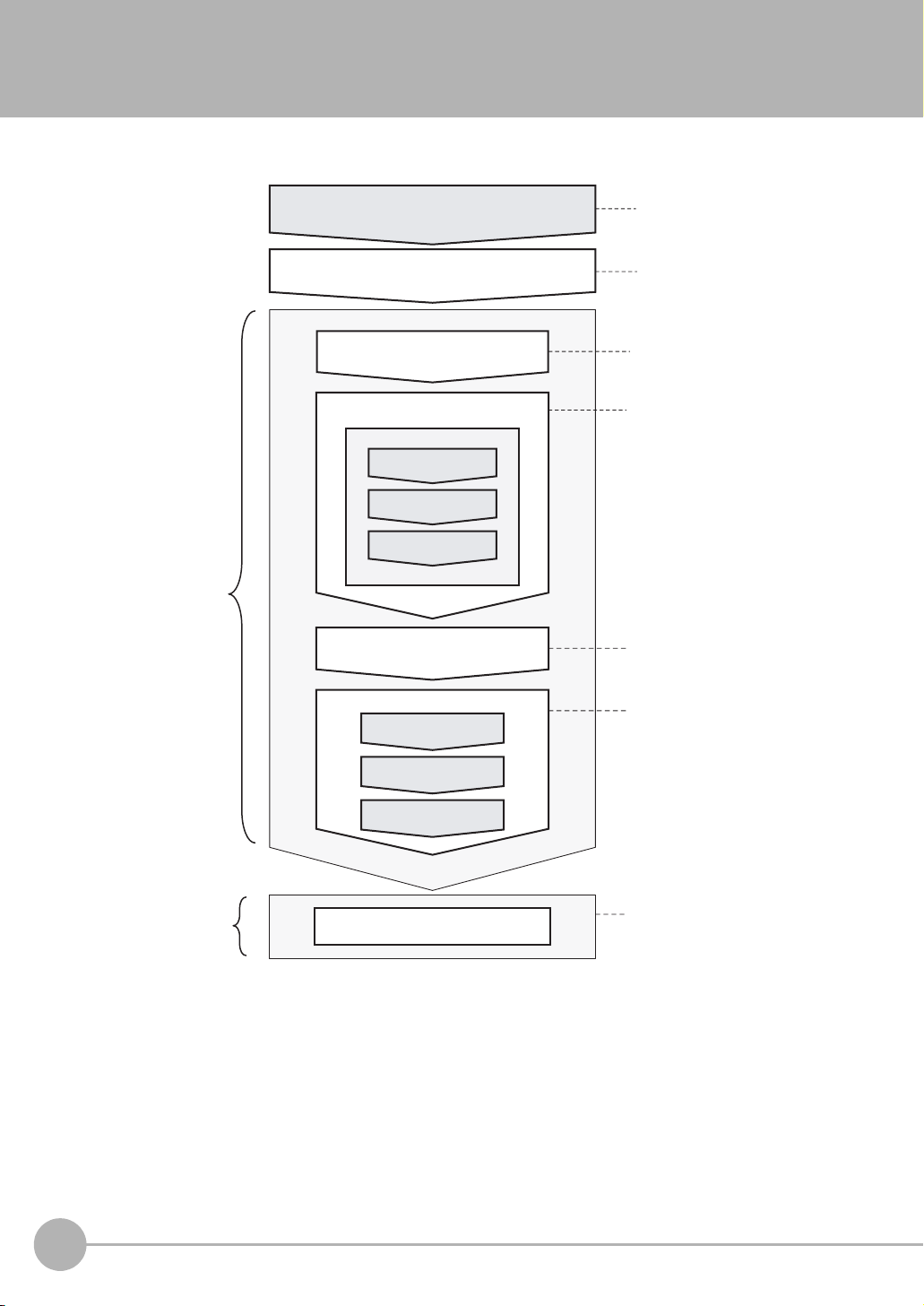

1-4 Basic Operational Flow

The following flow shows the basic operation of FQ-series Vision Sensors.

Setup Evaluation

Connections and Wiring

Starting the Sensor

Section 2 Installation

and Connections

Section 1

1-3 Startup Display

and Display Elements

Image Setup

([Image] Tab Page)

Inspection Setup

([Inspect] Tab Page)

Registering

Inspection Items

Teaching

Setting Judgement

Parameters

*1

Output Settings

([In/Out] Tab Page)

Section 3 Taking

Images

Section 4 Setting Up

Inspections

Section 7

Communications with

External Devices

Testing ([Test] Tab Page)

Test Measurement and

Results Verification

Adjusting Judgement

Parameters

Section 5 Testing and

Saving Settings

Saving the Settings

Operation

*2

Starting Operation (Run Mode)

Section 6 Operation

*1: In Setup Mode, the Sensor can be set up and adjusted, but it does not output signals on the I/O lines.

*2: In Run Mode, the Sensor performs measurements and outputs signals on the I/O lines.

8

Basic Operational Flow

FQ Short Manual

Installation and Connections

2-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2-4 Setting Up Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2

Installation and Connections

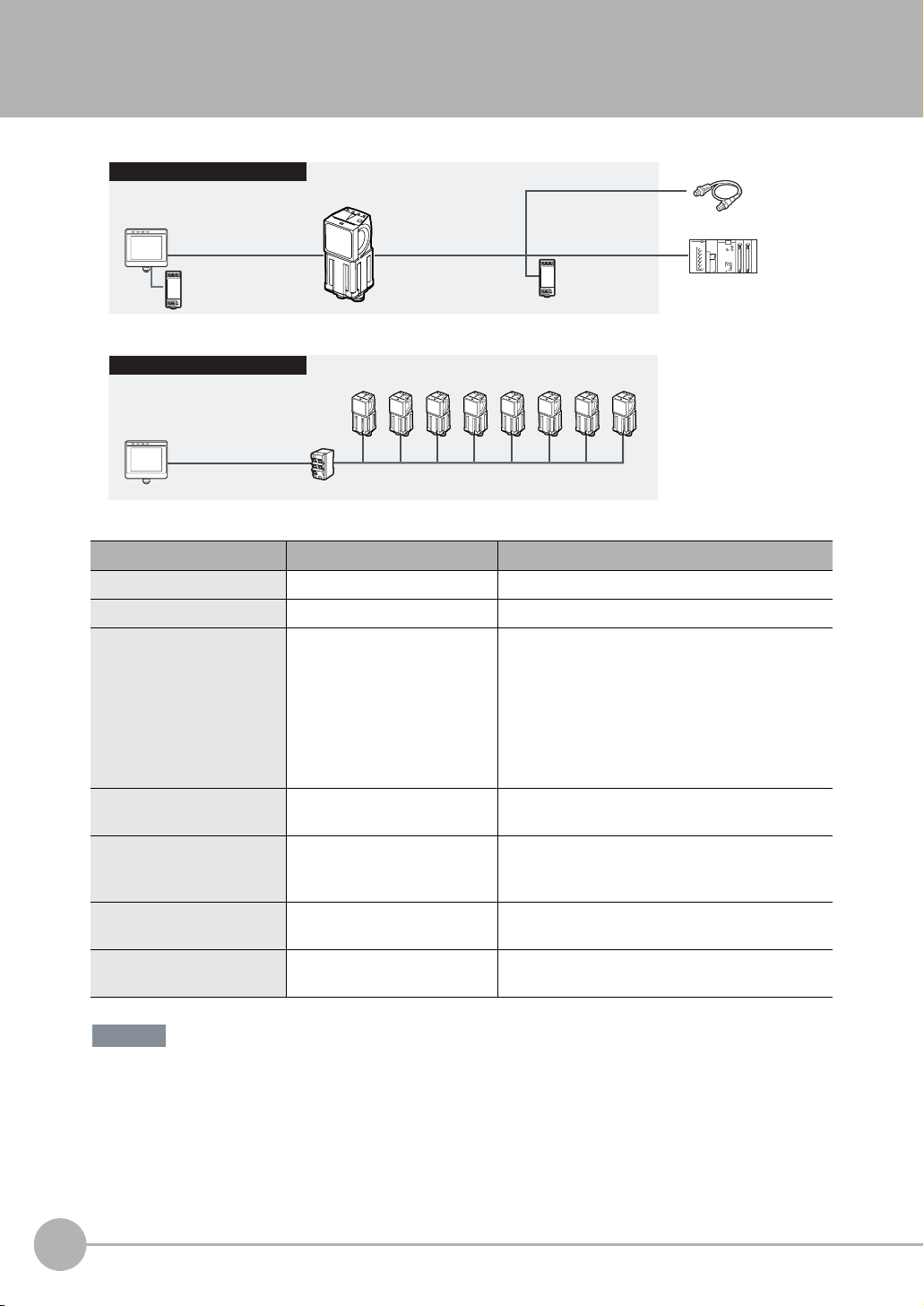

2-1 System Configuration

Standard Configuration

Setup Tool

Touch Finder or PC Tool

FQ Ethernet Cable I/O Cable

24-VDC power supply

Multiple Connection Sensors

Setup Tool

Touch Finder or PC Tool

Switching Hub

Standard RJ45 Ethernet

Cable

FQ Vision Sensor

FQ Vision Sensors

(8 max.)

FQ Ethernet Cable

24-VDC power

supply

Trigger Sensor

PLC

Connect the trigger

sensor, PLC, and

power supply to

each Sensor.

Product Model number Remarks

FQ Vision Sensor FQ-S@@@@@@ This is the Vision Sensor.

Touch Finder FQ-D@@ This is a setup console.

PC Tool --- The PC Tool can be used instead of the Touch

Finder. If you register as a member, you can download the free PC Tool as a special service to purchasers.

Refer to the Member Registration Sheet that is

enclosed with the Sensor for the member registration procedure and the download procedure for special member software.

FQ Ethernet Cable FQ-WN0@@ Connects the Sensor to the Touch Finder or com-

puter.

Standard RJ45 Ethernet

Cable

--- Connects the switching hub to the Touch Finder or

computer. (STP (shielded twisted-pair) cable, category 5e or 6, impedance: 100 Ω)

I/O Cable FQ-WD0@@ Connects the Sensor to the power supply and exter-

nal devices.

Switching Hub W4S1-0@@ Used to connect multiple Sensors to one Touch

Finder or PC Tool.

Important

Do not connect network devices other than PLCs on the same network as the Touch Finder or computer. If

another device is connected, the responsiveness of displays and settings of the Touch Finder or computer may

become slow.

10

System Configuration

FQ Short Manual

2-2 Installation

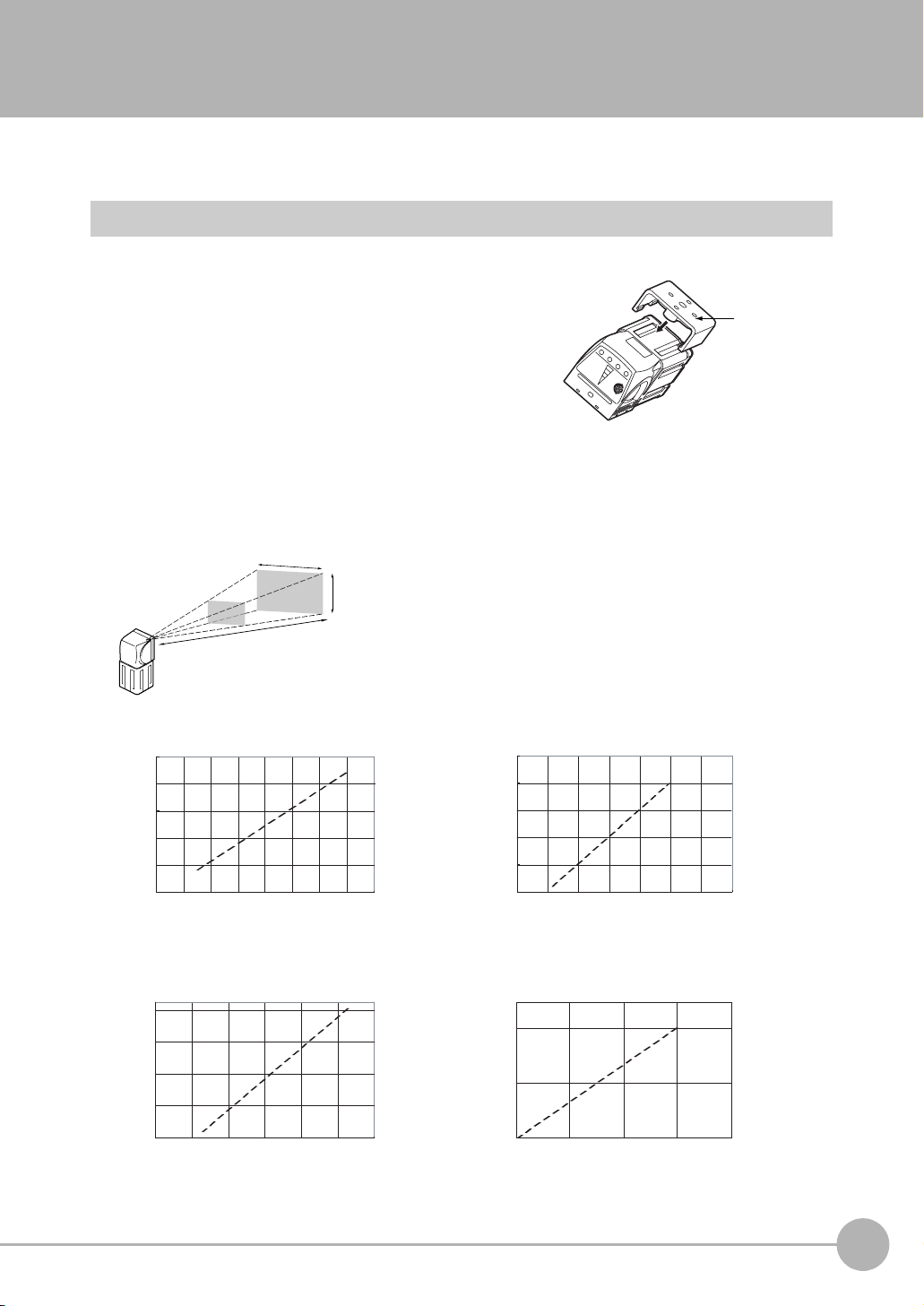

Installing the Sensor

Installation Procedure

1 Align the tabs on one side of the Mounting Bracket with

the slot on the Sensor.

The FQ-XL Mounting Bracket can be attached to the back,

side, or front of the Sensor.

2 Press the Mounting Bracket onto the Sensor until the oth-

er tabs click into place.

3 Use the following optical charts to check the field of view

and installation distance of the Sensor so that it is mounted at the correct position.

Tightening torque (M4): 1.2 N·m

Horizontal field of view

Vertical field

of view

Installation distance (L)

The optical chart indicates the horizontal

field of view. The vertical field of view will

be approximately 60% of the horizontal

field of view.

Note: The tolerance is ±10%.

Mounting

Bracket

2

Installation and Connections

FQ-S10010F, FQ-15010F,

FQ-S20010F, or FQ-25010F

Installation distance (L) (mm)

55

45

35

6

FQ-S10050F, FQ-S15050F,

FQ-S20050F, or FQ-S25050F

Installation distance (L) (mm)

210

130

50

0

8

Horizontal field of view (mm)

Horizontal field of view (mm)

10

20

40

12

14

60

FQ-S10100F, FQ-S15100F,

FQ-S20100F, or FQ-S25100F

Installation distance (L) (mm)

1,000

600

200

0100

Horizontal field of view (mm)

FQ-S10100N, FQ-S15100N,

FQ-S20100N, or FQ-S25100N

Installation distance (L) (mm)

400

0

0

200 400

Horizontal field of view (mm)

200

300

FQ Short Manual

Installation

11

Important

• There is a certain amount of deviation among Sensors in the center of the optical axis. For this reason, when install-

ing the Sensor, check the center of the image and the field of view on the LCD monitor of the Touch Finder and in

the PC Tool.

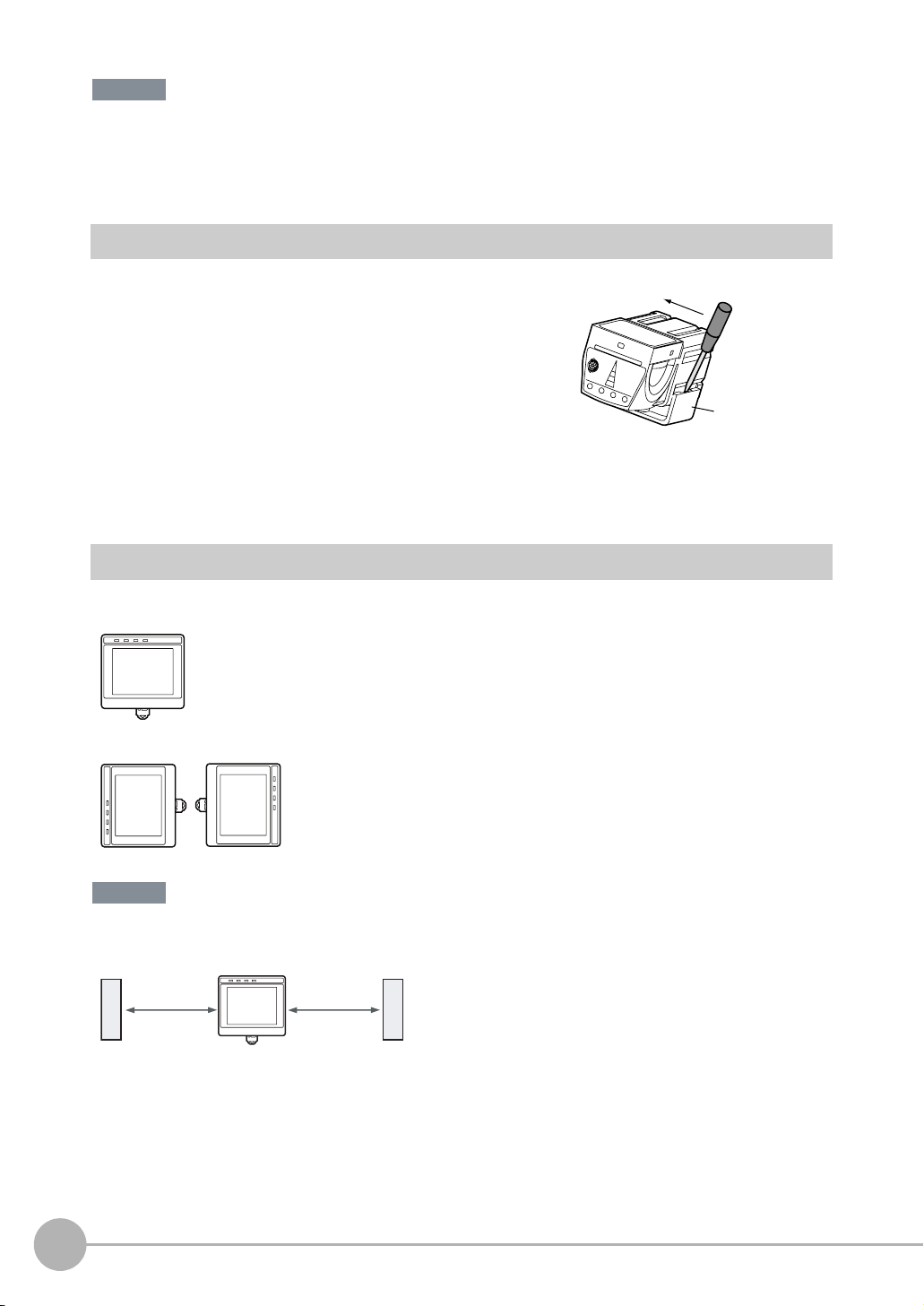

Removal Procedure

1 Insert a flat-blade screwdriver between the Mounting Brack-

et and the Sensor case on either side and remove the

Mounting Bracket.

Mounting

Bracket

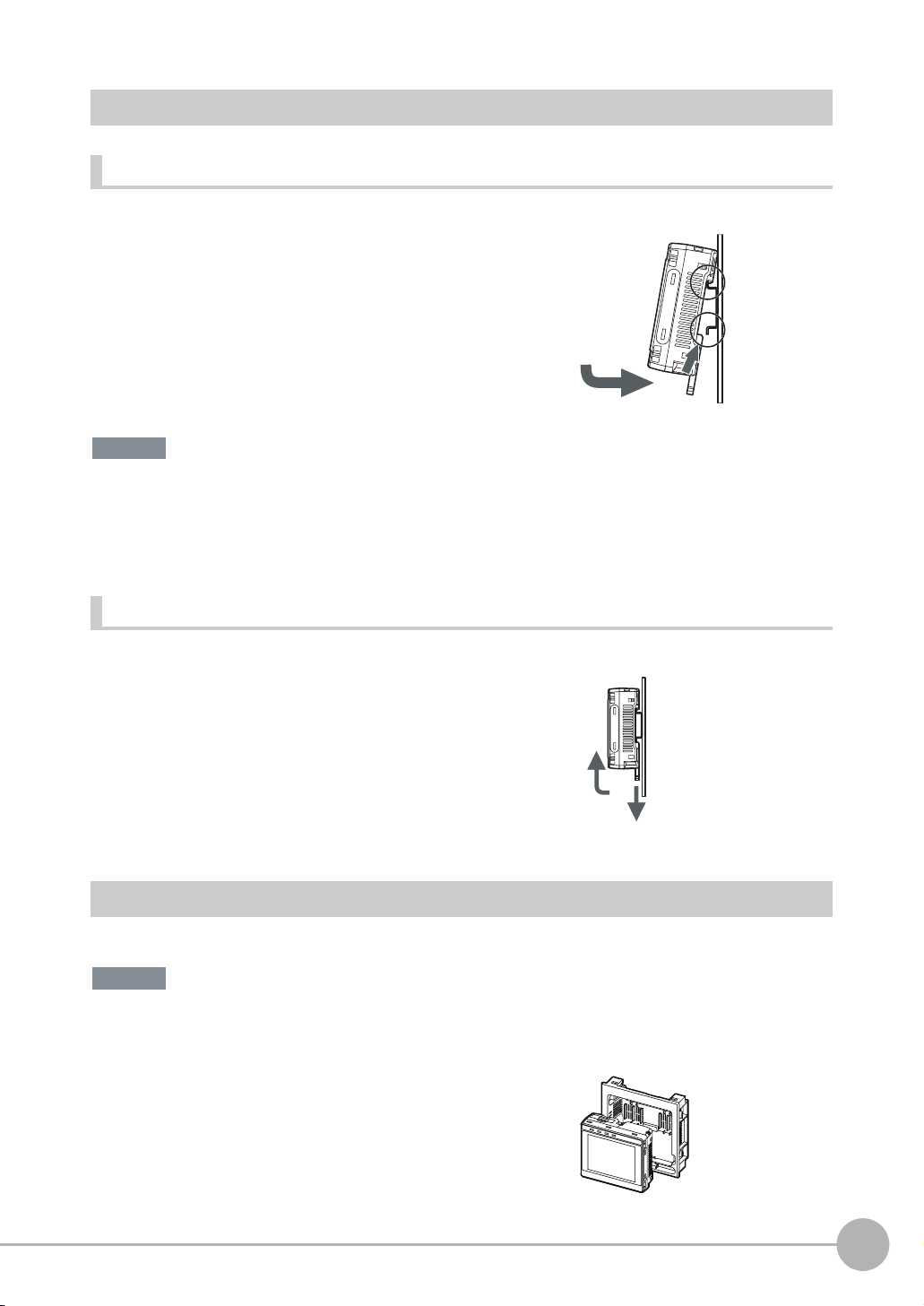

Installing the Touch Finder

Installation Precautions

Install the Touch Finder in the following orientation to allow sufficient heat dissipation.

Do not mount it in the following orientations.

Important

• To improve ventilation, leave space on both sides of the Touch Finder. The distance between the Touch Finder and

other devices should be at least that shown in the following diagram.

15 mm min.

• Make sure that the ambient temperature is 50°C or lower. If it exceeds 50°C, install an cooling fan or an air condi-

tioner and maintain the temperature at 50°C or lower.

• To prevent interference by noise, do not mount the Sensor on panels which contain high-voltage devices.

• To keep the level of noise from the surrounding environment to a minimum, install the Sensor and Touch Finder at

least 10 m away from power lines.

12

Installation

15 mm min.

FQ Short Manual

Mounting to DIN Track

Installation Procedure

1 Press the slider on the Touch Finder to the top.

2 Hook the clip at the top of the Touch Finder on to the DIN

Track.

3 Press the Touch Finder onto the DIN Track until the bottom

clip clicks into place.

3

Important

• Attach End Plates (sold separately) on the sides of the Touch Finder on the DIN Track.

• If other devices will be installed next to the Touch Finder on the same DIN Track, make sure that sufficient space is

kept between the devices as indicated on previous page.

• Always hook the clip at the top of the Touch Finder on the DIN Track first. If the lower clip is hooked on first, the

Touch Finder will not be mounted very securely.

Removal Procedure

2

3

1

1 Pull down on the slider on the Touch Finder.

2 Lift the Touch Finder at the bottom and remove it from the

DIN Track.

2

1

2

Installation and Connections

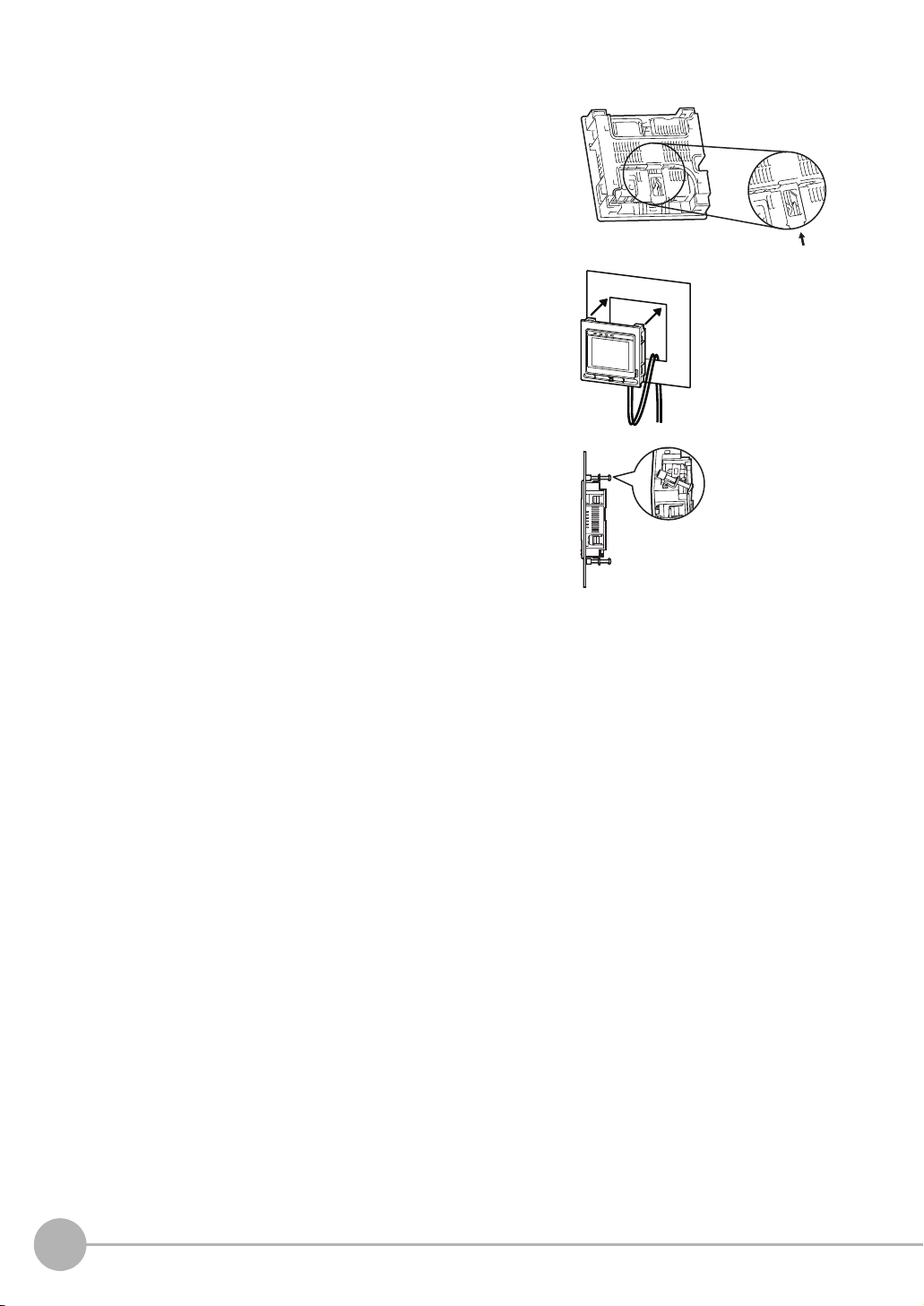

Mounting to a Control Panel

The Touch Finder can be mounted on a panel using the FQ-XPM Panel Mounting Adapter.

Important

• Always turn OFF the Touch Finder power before attaching or detaching the Panel Mount Adapter. Attaching or

detaching with the power turned ON may cause a failure.

1 Set the Touch Finder in the Panel Mount Adapter.

FQ Short Manual

Installation

13

2 Press the slider up on the Touch Finder.

3 Create holes in the panel for mounting.

4 Connect the cable to the Touch Finder.

5 Mount the Touch Finder with the Panel Mount Adapter from

the front of the panel.

6 Hook the hooks on the Mounting Bracket in the four holes

of the Panel Mount Adapter and secure them with screws.

(Tightening torque: 1.2 N·m)

7 Check that the Touch Finder is attached properly to the

Panel.

Mounting

Bracket

14

Installation

FQ Short Manual

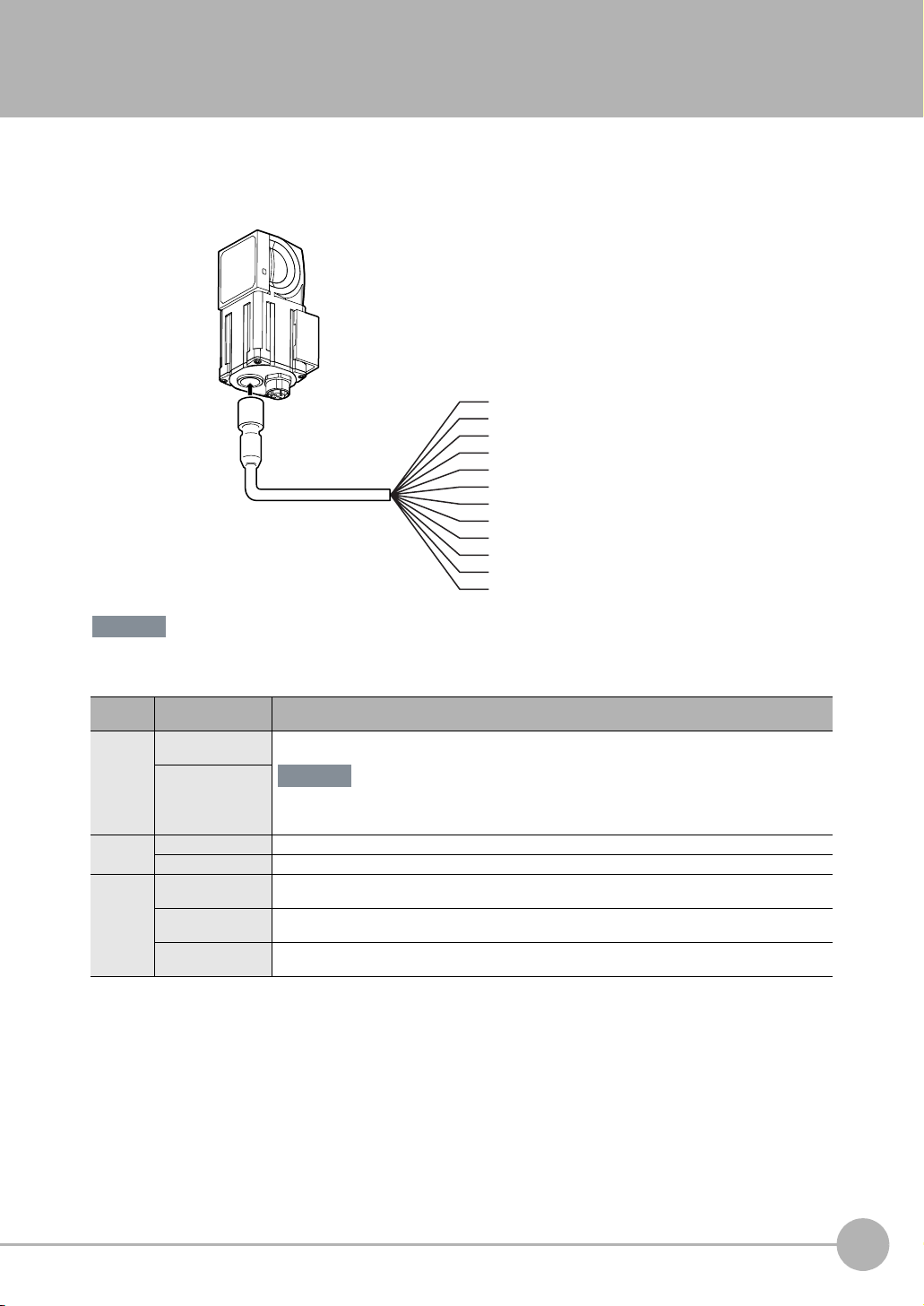

2-3 Wiring

Wiring the Sensor

Connect the I/O Cable to the I/O Cable connector located at the bottom of the Sensor.

2

Installation and Connections

Important

FQ-WD0@@

I/O Cable

Brown

Blue

Black

Orange

Light blue

Pink

Gray

Green

Red

White

Purple

Yellow

Power supply

GND

OUT0 (OR)

OUT1 (BUSY)

OUT2 (ERROR)

TRIG

IN0

IN1

IN2

IN3

IN4

IN5

Cut off lines that are not required so that they do not come into contact the other signal lines.

Classification

Powe r

supply

Inputs TRIG This terminal is the trigger signal input.

Outputs OUT0 (OR) By default, this is the OR output signal (overall judgement).

Signal Application

Power supply

(24 V)

GND

IN0 to IN5 These are the command input terminals.

OUT1 (BUSY) By default, this is the BUSY output signal.

OUT2 (ERROR) By default, this is the ERROR output signal.

These terminals are for the external power supply (24 V).

Important

Wire the power supply separately from other devices. If the wiring for other devices is placed

together or in the same duct as the wiring for the Vision Sensor, the influences of electromagnetic

induction may cause the Sensor to malfunction or may damage it.

The assignment can be changed to an individual judgement signal from OR0 to OR31.

The assignment can be changed to an individual judgement signal from OR0 to OR31.

The assignment can be changed to an individual judgement signal from OR0 to OR31.

FQ Short Manual

Wiring

15

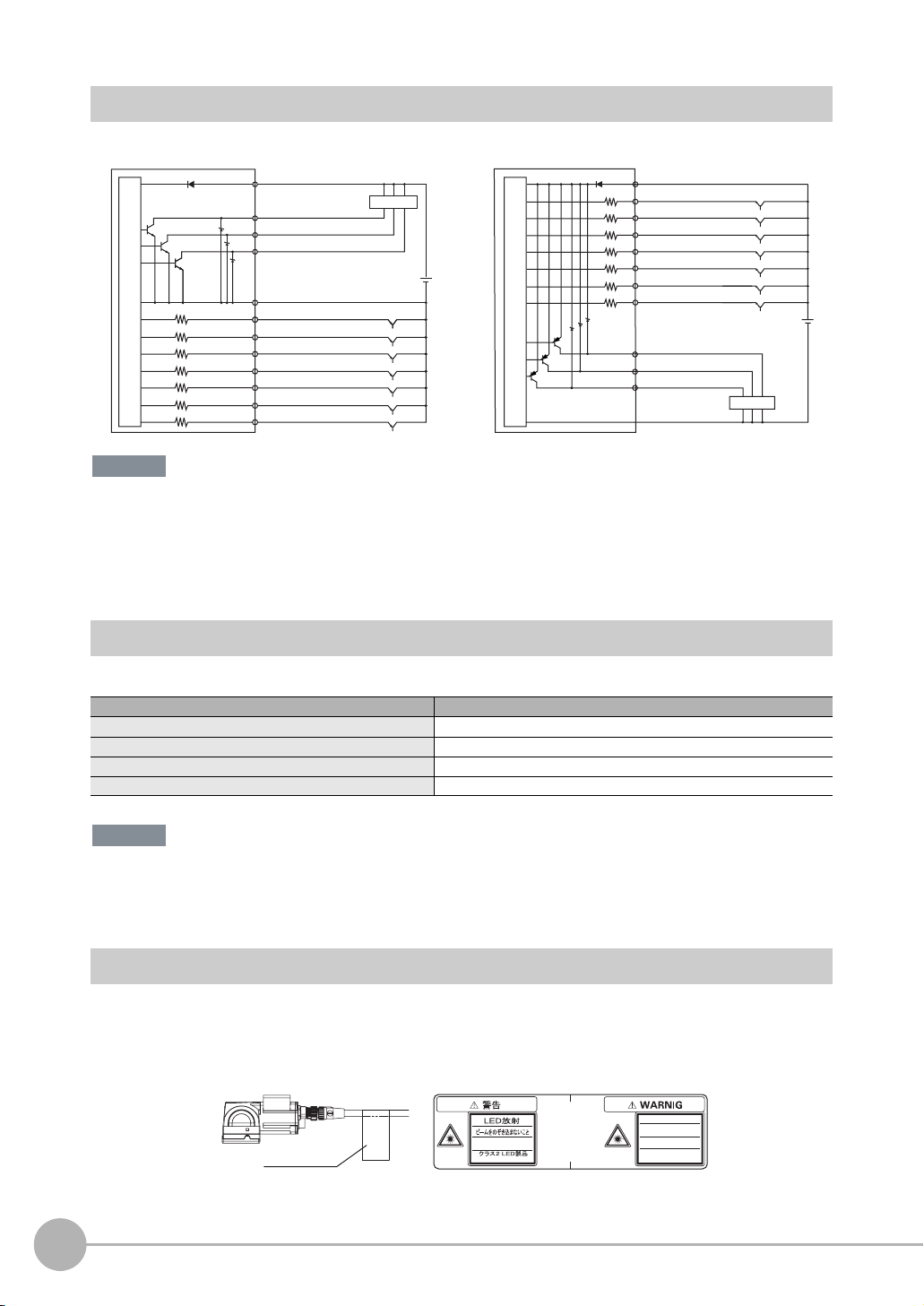

I/O Signal Circuit Diagrams

PNPNPN

Internal circuits

Power supply (24 VDC)

Brown

Black

OUT0 (OR)

OUT1 (BUSY)

Light blue

Blue

Pink

Gray

Green

Red

White

Purple

Yellow

OUT2 (ERROR)

GND (0V)

TRIG

IN0

IN1

IN2

IN3

IN4

IN5

Load

24 VDC

Internal circuits

Power supply (24 VDC)

Brown

Pink

TRIG

IN0

Gray

GreenOrange

IN1

Red

IN2

IN3

White

Purple

IN4

Yellow

IN5

Light blue

Orange

Black

Blue

OUT2 (ERROR)

OUT1 (BUSY)

OUT0 (OR)

GND (0V)

24 VDC

Load

Important

Preventing Chattering

• The Sensor is equipped with an anti-chattering function, but if the chattering is 100 µs or longer, a faulty input may

occur. (Input signals of 99 µs or shorter are ignored. Signals of 100 µs or longer are treated as input signals.)

• Use no-contact output devices (e.g., SSR or PLC transistor output) for the input signals. If contacts (e.g., relay) are

used, chattering may cause the trigger to be input again during execution of a measurement.

Power Supply Specifications When a Switching Regulator Is Connected

Use a power supply that meets the following specifications. (The power supply is sold separately.)

Item Description

Power supply voltage 24 VDC (21.6 to 26.4 V)

Output current 3.75 A min.

Recommended Power Supply S8VS-09024@ (24 VDC, 3.75 A)

External power supply terminal screws M4 (tightening torque: 1.2 N·m)

Important

Supply power from a DC power supply for which measures have been applied to prevent high voltages (e.g., a safety

extra low voltage circuit).

If UL certification is required for the overall system, use a UL Class II DC power supply.

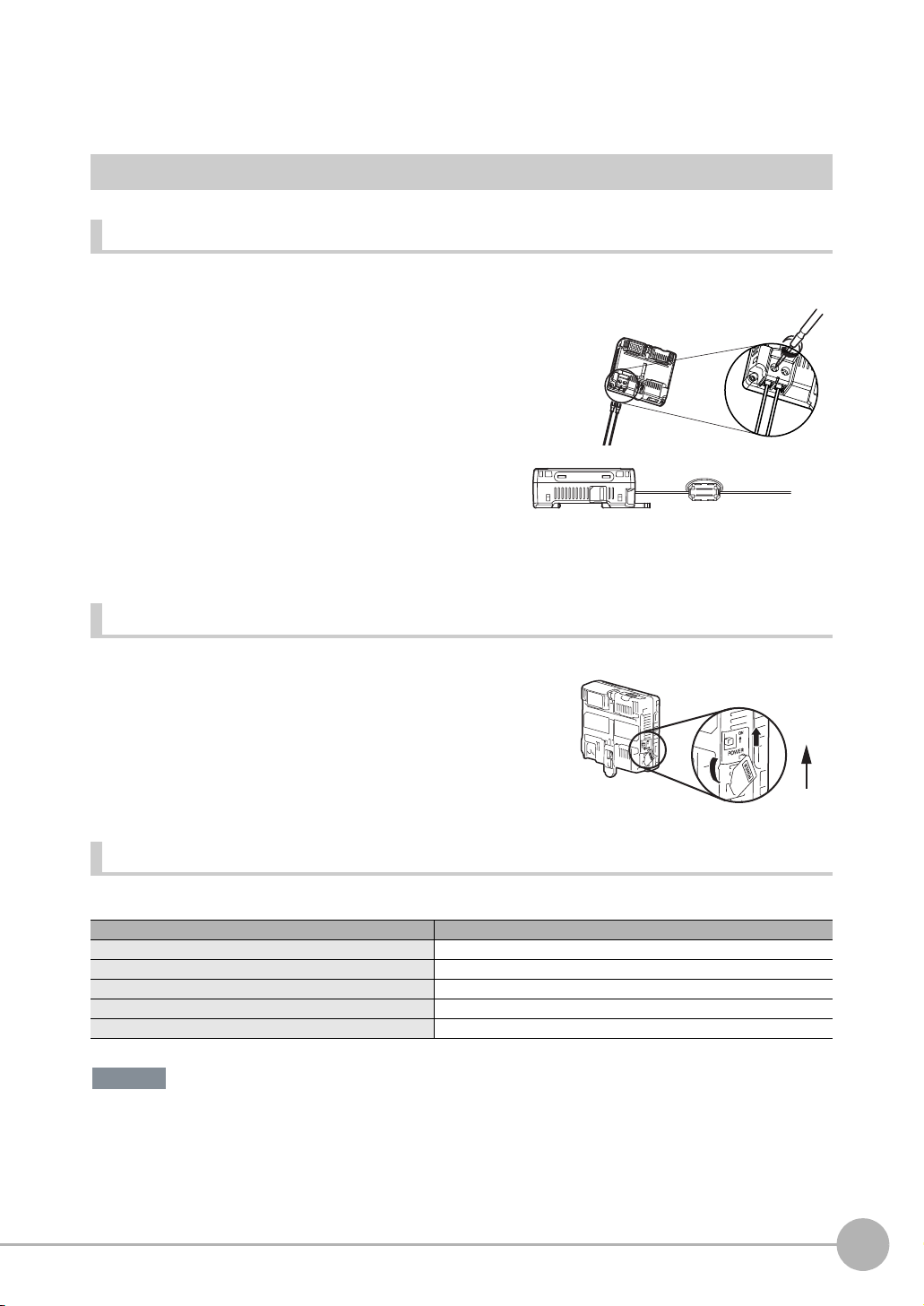

Attaching the LED Warning Label

Attach the enclosed LED warning label to the cable or other location. The LED warning label must be attached

to a location that is readily visible from the Sensor.

16

Attachment Example

Warning Label

Wiring

Warning Label

Max.60mW 400msec

400-700nm

JIS C 6802:2005

LED RADIATION

DO NOT STARE

INTO BEAM

Max.60mW 400msec

400-700nm

CLASS 2 LED PRODUCT

IEC 60825-1:1993 +A1:1997

+A2:2001

FQ Short Manual

Wiring the Touch Finder

Power Supply Wiring

Connecting the Power Supply

1 Loosen the two terminal screws using a Phillips

screwdriver.

2 Attach crimp terminals to the power lines.

Secure the positive and negative lines as indicated

using M3 screws.

Power supply tightening torque: 0.54 N⋅m

24 VDC

3 In environments where there is excessive noise, at-

tach a ferrite core (ZCAT1730-0730 from TDK or the

equivalent) to the power supply cable.

Turning ON the Touch Finder

1 Remove the cover from the power switch on the left side of

the Touch Finder.

2 Press the switch toward ON.

+

−

When you attach the ferrite core to

the power supply cable, wrap the

cable only one time.

2

1

2

Installation and Connections

ON

OFF

Power Supply Specifications

Use a power supply that meets the following specifications. (The power supply is sold separately.)

Item Description

Power supply voltage 24 VDC (21.6 to 26.4 V)

Output current 2.5 A min.

Recommended Power Supply S8VS-06024@ (24 VDC, 2.5 A)

External power supply terminal screws M4 (tightening torque: 1.2 N⋅m)

Recommended power line wire size AWG16 to AWG22 (length of 5 m max.)

Important

• Supply power from a DC power supply for which measures have been applied to prevent high voltages (e.g., a

safety extra low voltage circuit).

If UL certification is required for the overall system, use a UL Class II DC power supply.

• When using the FQ-D31, do not connect a switching regulator and AC Adapter (FQ-AC@) at the same time.

FQ Short Manual

Wiring

17

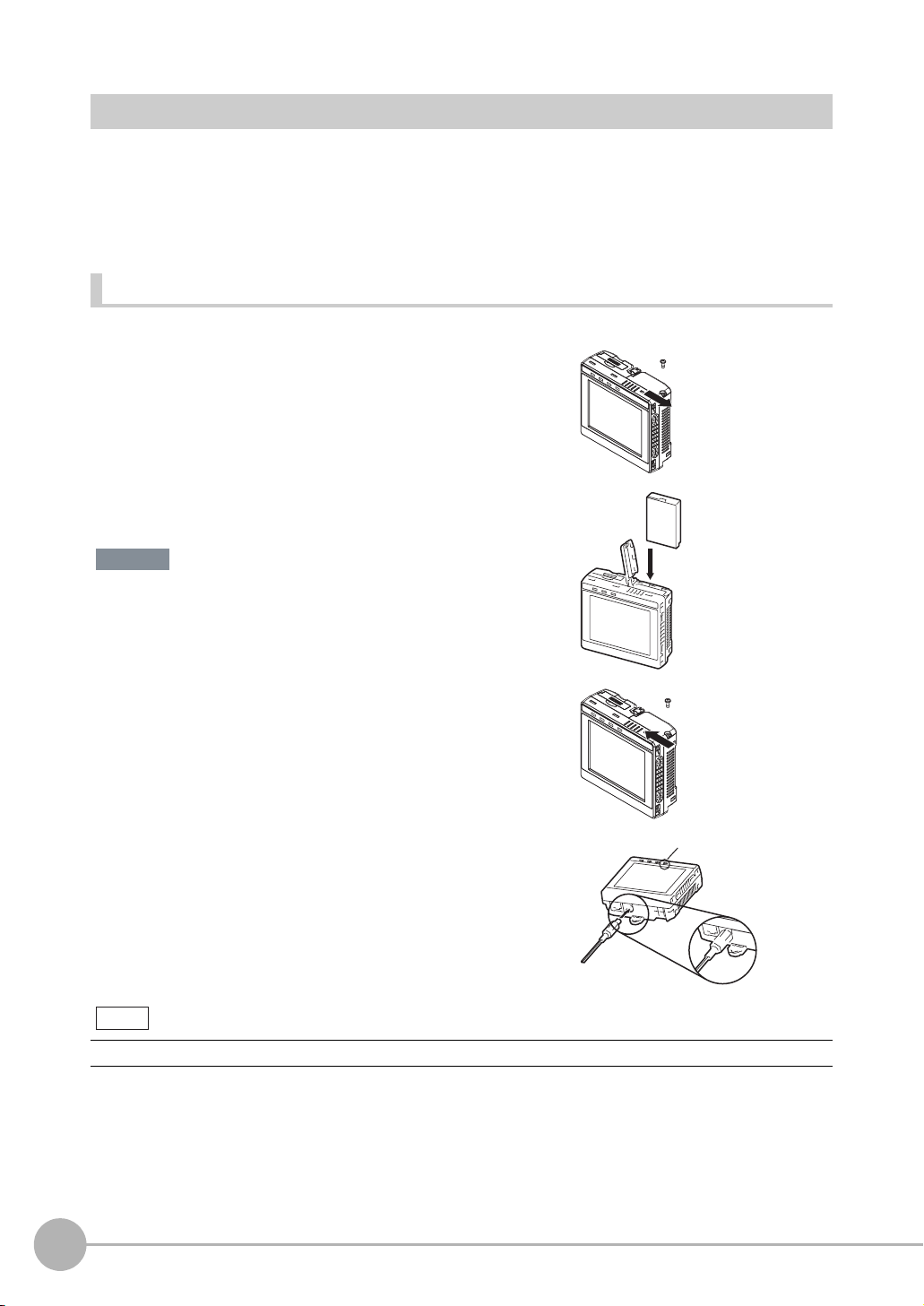

Charging the Battery

This section describes how to charge and install the FQ-D31 Battery and provides applicable precautions.

Charge the Battery while it is attached to the Touch Finder.

Use the AC adapter to charge the battery.

Mounting the Battery in the Touch Finder

1 Remove the screw from the battery cover on the top of the

Touch Finder, slide the cover in the direction of the arrow,

and open the battery cover.

2 Face the rounded side of the battery toward the back of the

Touch Finder and insert the battery.

Important

Do not insert the battery in the wrong orientation.

3 Close the battery cover, slide the battery cover in the direc-

tion of the arrow, and tighten the screw on the battery cover.

4 Attach the AC adapter to the Touch Finder to start changing

the battery.

The CHARGE indicator will be lit while the battery is being

charged. It will go out when charging the battery has been completed.

Note

The Touch Finder will operate even if the AC adapter is connected when no battery is mounted in the Touch Finder.

CHARGE indicator

18

Wiring

FQ Short Manual

Important

• If the Touch Finder (FQ-D31) will be installed permanently or semi-permanently, remove the Battery (FQ-BAT1). If

the rated temperature is exceeded with the Battery inserted, the protective circuit may activate and stop the Touch

Finder.

• The battery complies with the following recycling regulation.

Japan Taiwan

EU

Li-ion00

• California regulations concerning perchlorate:

This product is a lithium battery that contains perchlorate, which is regulated by the State of California. Please com-

ply with these regulations. For details see the following URL:

www.dtsc.ca.gov/hazardouswaste/perchlorate/

2

Installation and Connections

FQ Short Manual

Wiring

19

2-4 Setting Up Ethernet

Connecting to Sensors from the Touch Finder

When the Sensor is used with a Touch Finder, IP addresses are automatically assigned. No settings are

required to use Ethernet.

However, if a Sensor or Touch Finder is connected to a network where a PLC or computer is already

connected, the Ethernet must be set to be compatible with the existing network.

• Sensor

(Setup Mode) − [Sensor settings] − [Ethernet]

1 Set [Auto connection] to [OFF].

2 Set the IP address and subnet mask according to the network settings.

• Touch Finder

(Setup Mode) − [TF settings] − [Ethernet]

1 Set the IP address and subnet mask according to the network settings.

Connecting to Sensors from a Computer Using the PC Tool

When connecting the Sensor directly to a computer using an Ethernet Cable, set the network settings on the

computer as given below. Setting a fixed IP address is not required if there is a hub between the computer and

Sensor and a DHCP server is used.

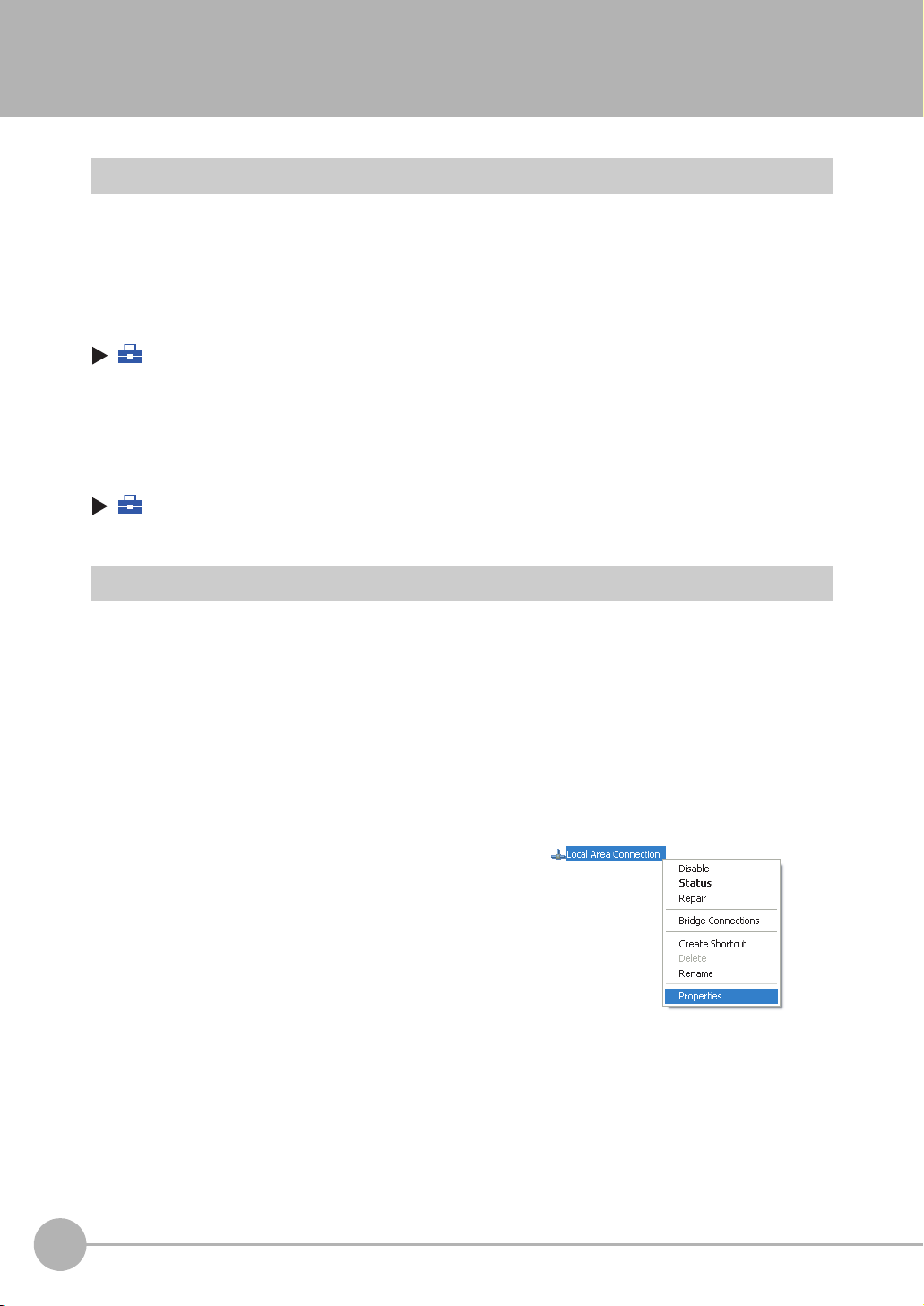

The following procedure is for Windows XP.

1 Select [Control Panel] from the Windows Start Menu.

2 Click [Network and Internet Connections] in the control

panel and then double-click [Network Connections].

3 Right-click the [Local Area Connection] Icon and select

[Properties].

20

Setting Up Ethernet

FQ Short Manual

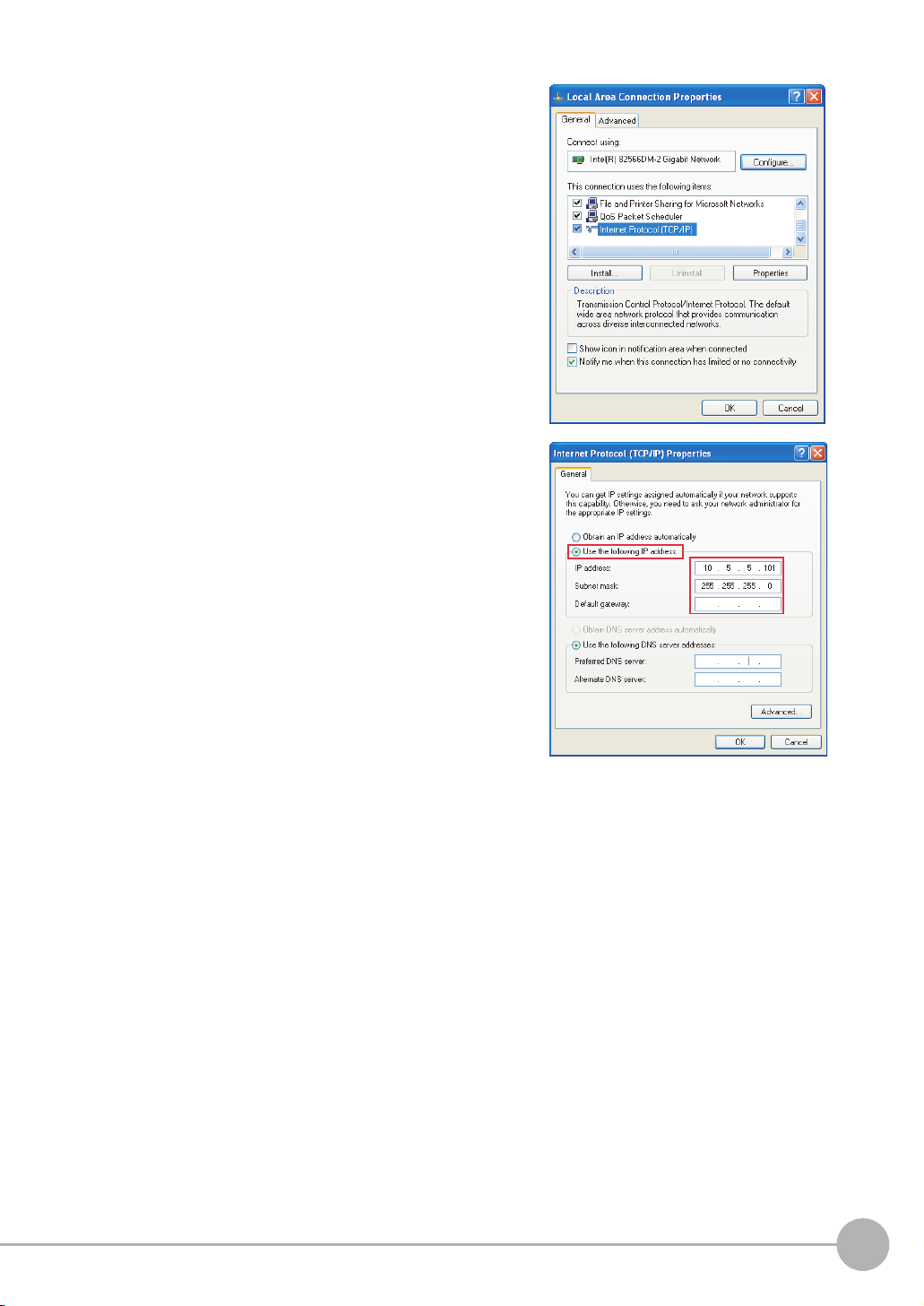

4 On the [General] Tab Page, double-click Internet Proto-

col (TCP/IC).

5 Select the Use the following IP address Option and en-

ter the following IP address and subnet mask.

• IP address: 10.5.5.101

• Subnet mask: 255.255.255.0

6 Click the [OK] Button. This completes the settings.

2

Installation and Connections

FQ Short Manual

Setting Up Ethernet

21

MEMO

22

Setting Up Ethernet

FQ Short Manual

Loading...

Loading...