Page 1

Fleet Operations Workspace Core

User’s Manual

I635-E-04

Page 2

Copyright Notice

The information contained herein is the property of OMRON, and shall not be reproduced in whole or in

part without prior written approval of OMRON The information herein is subject to change without

notice and should not be construed as a commitment by OMRON The documentation is periodically

reviewed and revised.

OMRON, assumes no responsibility for any errors or omissions in the documentation.

Copyright 2020 by OMRON Corporation. All rights reserved.

Any trademarks from other companies used in this publication

are the property of those respective companies.

This manual was originally written in English. Created in the United States of America

Page 3

Table Of Contents

Chapter 1: Introduction

1.1 Fleet Operations Workspace Core Overview

1.2 How the Fleet Operations Workspace Components Work Together

EM2100

MobilePlanner

SetNetGo

ARAMCentral

ARAM

MARC/Polo

1.3 Fleet Operations Workspace Licensing

1.4 How Can I Get Help?

Related Manuals

Chapter 2: Safety and Regulatory Information

2.1 Safety and Regulatory

2.2 Warnings, Cautions, and Notes

2.3 General Safety Precautions

2.4 Safety Commissioning

2.5 What to Do in an Emergency

2.6 Additional Safety Information

Mobile Robot LD Safety Guide (Cat. No. I616) and Mobile Robot HDSafety Guide (Cat. No. I647)

Chapter 3: Fleet Manager Configuration and Operation

3.1 EM2100 Configuration Overview

Configuration Tasks Overview

3.2 Power Interruptions

Power Interruptions on a Standalone EM2100

Power Interruptions on an Autosync Appliance

3.3 Set the IP Address on a Client PC's Network Adapter

3.4 Connect Your PC to SetNetGo on the EM2100

Configure Access and Security

3.5 Configure Management Interface Network Settings

3.6 Configure the Operating Mode

3.7 Configure the Fleet Interface Network Settings

3.8 Configure Paired Appliances

EM2100 Autosync — Ethernet Cabling

Tasks in Autosync Setup

Configure the Primary Appliance

Configure the Secondary Appliance

3.9 Configure Each AMR to Connect to the Fleet Manager

AMR Configuration Settings

Fleet-Level Settings

3.10 What to do if a Primary Fleet Manager Fails

3.11 Remove and Replace EM2100 Appliances from Autosync

10

10

11

12

12

13

14

14

14

14

15

16

18

18

18

19

19

19

19

19

22

22

22

23

23

23

24

24

25

25

26

26

28

28

28

29

30

31

31

32

33

33

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 3

Page 4

Table of Contents

Remove a Primary Fleet Manager Appliance from Autosync

Remove a Secondary Fleet Manager from Autosync

Chapter 4: Fleet Operations Workspace Core Software

4.1 How Do I Begin?

4.2 End-User License Agreement (EULA)

Definitions

The Click-to-Accept (CTA) EULA will pop up:

Once the CTA EULA Prompt is Triggered

Capturing CTA Interactions

4.3 Install the MobilePlanner Software

System Requirements

Installing MobilePlanner

4.4 Configure the AMR’s Wireless Communications

Step 1: Connect Your PCto the AMR via Ethernet

Step 2: Set the IPAddress on Your PC

Step 3: Access SetNetGo Software

Step 4: Configure Your AMR's Network and Security Settings

Step 5: Connect to the AMR Wirelessly

Chapter 5: Using MobilePlanner Software

5.1 Overview of MobilePlanner

5.2 MobilePlanner Interface

Configuration (Config) Tab

SetNetGo Tab

5.3 MobilePlanner Operator Account Overview

MobilePlanner Operator Account Interface

MobilePlanner Operator Mode Jobs Tab

Statistics Tab

5.4 The MobilePlanner Menu

5.5 The MobilePlanner Toolbars

Main Toolbar

Robot and Map Toolbars

5.6 Using Monitor

To Access Monitor

Adjusting Audio Levels

5.7 The MobilePlanner Map Window

Map Zoom

Map Controls

Map Features

Map Modes

Map Legend

5.8 MobilePlanner Status and Tray Displays

Status Information

Tray Information

33

34

36

37

37

37

38

38

39

39

39

39

41

41

43

45

47

48

50

50

51

52

53

54

54

54

55

55

63

63

65

68

68

70

70

71

72

72

73

75

75

75

78

Chapter 6: AMR Driving Overview

6.1 Before Driving the AMR

6.2 Manual Override

To drive with Autonomous Drive mode OFF:

4 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

80

80

80

81

Page 5

Table of Contents

6.3 Driving Using the Pendant

Preparation

6.4 Driving Using the Software Interface (Drive Pad or keyboard)

To drive the AMR using the software:

Chapter 7: Scans and Maps

7.1 Map Overview

7.2 Scan Overview

7.3 Scanning Overview

What Gets Scanned?

Scanning Tips

Scanning the Operating Area

Convert the Scan into a Map

7.4 Working with Map Files

Making a Map

Loading an Existing Map File

Editing a Map File

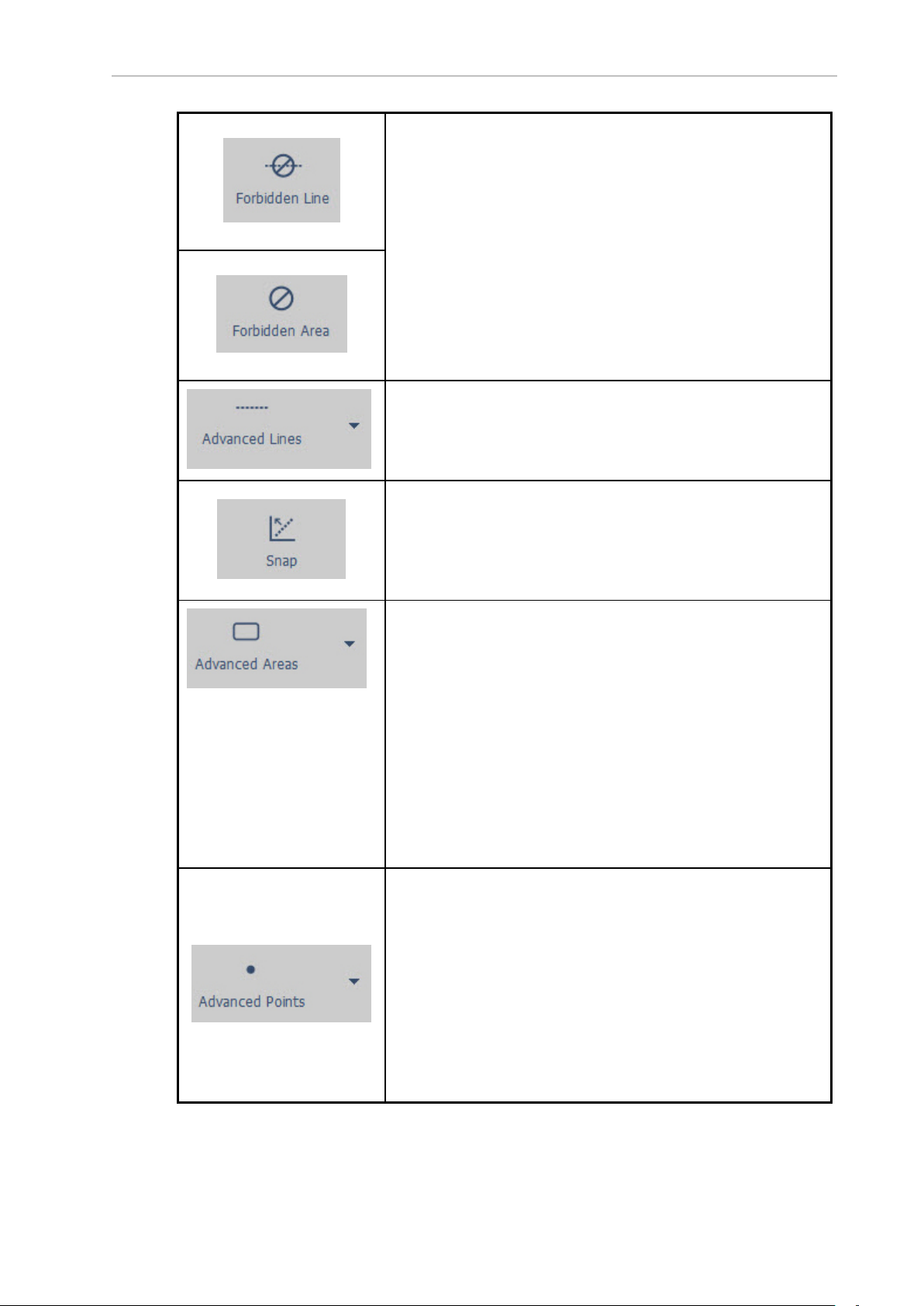

Draw Tab

Adding Forbidden Lines and Areas

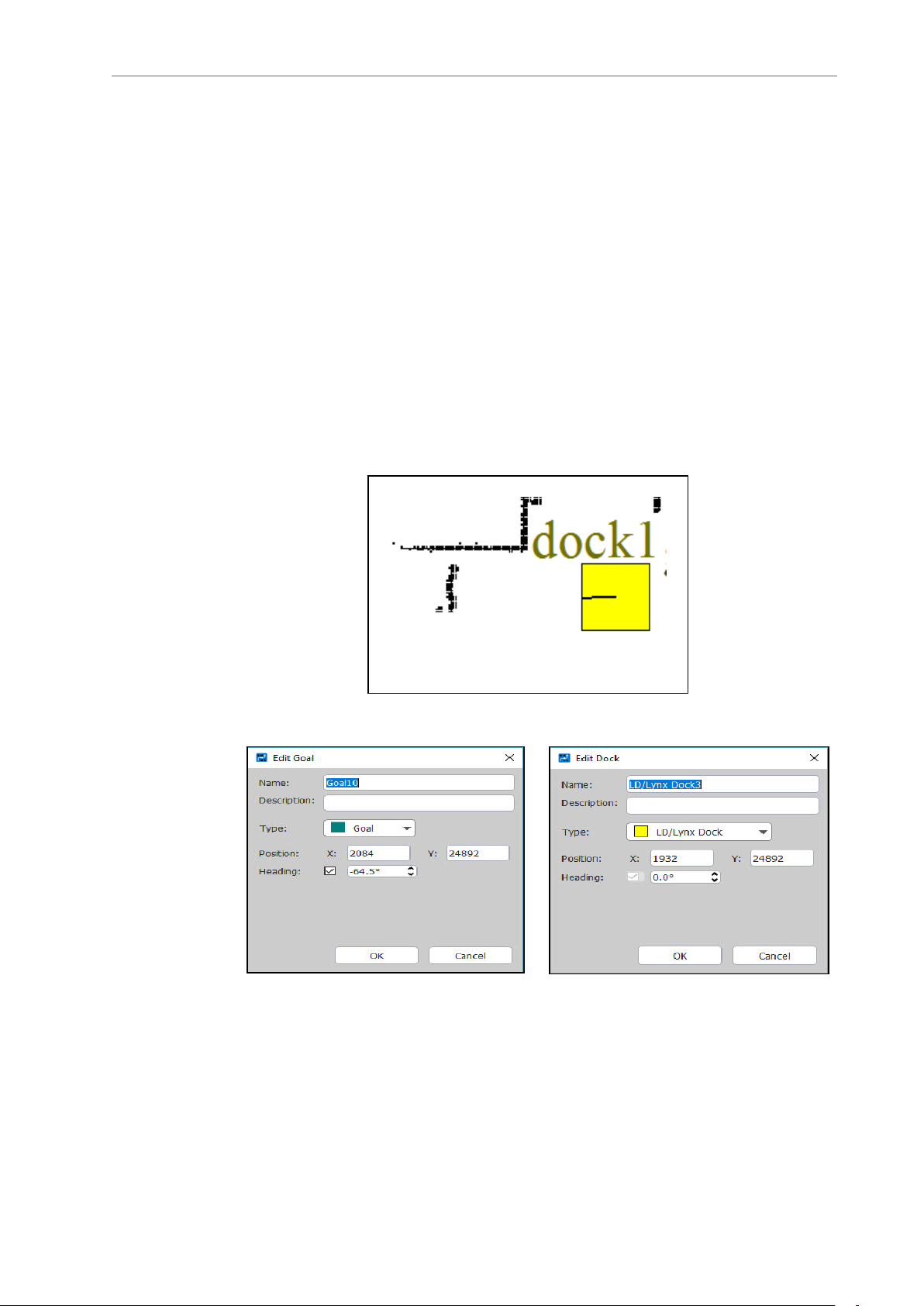

Creating and Adding Goals and Docks

Advanced Lines and Areas

Inserting a Map File into an Existing Map File

Saving the Map on the AMR

7.5 After the Map

Changing the Scan Settings

Set the AMR's Initial Location

After Driving the AMR

81

81

83

83

86

86

86

86

86

87

88

89

90

91

91

93

94

99

99

103

104

108

108

109

111

113

Chapter 8: Using the SetNetGo Software

8.1 Overview of the SetNetGo OS

Connecting to SetNetGo

8.2 Using the SetNetGo Interface

8.3 Viewing the Status Logs

8.4 Network Tab

8.5 Software Tab

ARAMCentral/ARAM

Manage Installed Software

8.6 Licensing Tab

8.7 Uploading, Backing up, and Restoring SetNetGo

8.8 Uploading a New SetNetGo OS

8.9 Backing Up and Restoring SetNetGo

8.10 SetNetGo Recovery Mode

8.11 Configuring ARAM

Setting Up User Accounts

Updating Fleet Operations Workspace Core

Chapter 9: Configuring the AMR

9.1 AMR WiFi Capabilities

9.2 Available Options and Peripherals

9.3 Types of Configurations

114

114

114

116

121

121

125

125

126

126

128

129

130

132

132

132

136

140

140

141

141

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 5

Page 6

Table of Contents

General Configurations

Model and Calibration Configurations

9.4 Setting the Configuration Parameters

9.5 Saving and Importing the Configuration Parameters

Importing

9.6 Managing Files

Downloading, Uploading, and Saving Files

9.7 Setting Up Data Logging

Chapter 10: Working with Macros, Tasks, and the

Route Builder

10.1 AMR Tasks

Assigning Tasks

Using Instant and Non-Instant Tasks

Using a Wait Task

Using Driving Tasks

Cell Alignment Positioning System (CAPS)

Using Speech and Sound Tasks

Adjusting the Audio

I/O Tasks - LD-series AMRs

I/O Tasks - HD-1500 AMRs

Setting Up Special Tasks

Editing a Task

10.2 AMR Jobs Overview

10.3 Using the Route Builder

The Route Builder Interface

Macros

The Build Tab

Creating Macros

Macro Templates

Custom Groups

Adding New Goals to the AMR’s Current Location

Creating Routes

10.4 Managing Queuing

Queuing and Job Definitions

Queuing Examples

Queuing Parameters

Manually Clearing (Flushing) the Entire Queue

142

142

142

145

146

147

147

147

150

150

150

152

155

156

158

169

170

172

174

174

178

178

180

180

183

184

185

188

190

192

193

195

195

197

198

200

Chapter 11: Traffic Management

202

11.1 Understanding Traffic Control

11.2 Traffic Control Concepts

Taxi Line (Multi-Robot Standby Goal)

Managed Motion Sectors

Standby Buffering

Preferred Lines and Directions

Resisted Areas and Lines

Forbidden Areas and Lines

DistanceUncrossable and DistanceAdjustment Lines

6 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

202

202

202

204

204

205

205

205

205

Page 7

Table of Contents

11.3 Path Planning and Collision Avoidance

Cost-Based Path Planning

Path Planning Parameters

Dealingwith Difficult Spaces

Virtual Doors

11.4 Directing Traffic

Using Preferred Lines

Using Preferred Directions

11.5 Controlling AMR Speed

Adding Movement Parameter Areas to theMap

Editing Movement Parameter Areas

11.6 Restricting Traffic

Using Forbidden Lines and Areas

Using Resisted Lines and Sectors

Using Need-to-Enter Sectors

Using Single AMR Sectors

Chapter 12: AMR Localization

12.1 What is Localization?

Overview of Localization Process

12.2 Comparing Laser and Light Localization

12.3 What Causes the AMR to be Lost?

Adjusting the Confidence Threshold

12.4 Optimizing Localization

Before Changing Parameter Values

12.5 Using Laser Localization

Overview of Laser Localization

Limitations of Laser Localization

Localization Parameters

12.6 Using Acuity For Light Localization

Overview of Light Localization

Creating the Light Map

Limitations of Light Localization

Light Localization Parameters

205

205

206

207

208

209

209

211

214

214

214

215

216

220

223

225

228

228

228

228

229

230

230

230

231

231

232

232

235

235

235

237

238

Chapter 13: Glossary and Definitions

240

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 7

Page 8

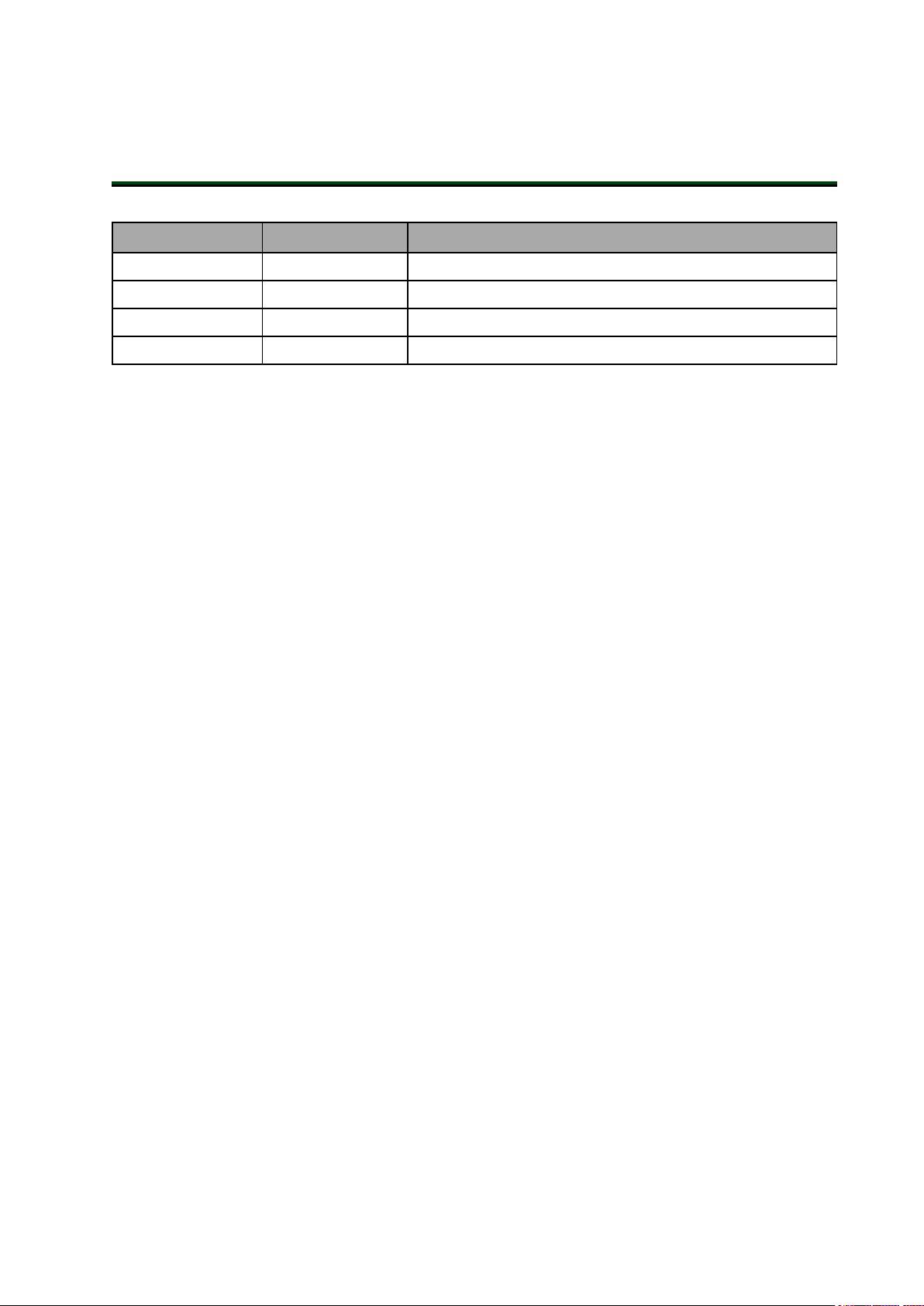

Revision code Date Revised Content

01 June, 2019 Original release

02 October, 2019 Corrected errors

03 March, 2020 Added information for Fleet Simulator.

04 June, 2020 Added HD-1500, EULA, and PrecisionDrive support.

Revision History

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 8

Page 9

Page 10

Chapter 1: Introduction

The Fleet Operations Workspace Core (FLOW Core) is OMRON's solution for setting up, integrating and managing an autonomous mobile robot (AMR) fleet within a factory environment.

FLOW Core provides the software tools to connect the autonomous mobile robot (AMR) fleet,

the factory's manufacturing control solution, establish maps, define operational rules, and

ensure safe, consistent operation on the factory floor.

This user's guide covers the basic procedures for installing and using the FLOWCore software

to set up and manage your AMR fleet. Some advanced operating procedures are discussed in

later chapters of the guide.

The following topics provide an introduction to the Fleet Operations Workspace Core.

1.1 Fleet Operations Workspace Core Overview

The Fleet Operations Workspace (FLOW) Core is a suite of mobile-robotics software applications for programming and operating a fleet of AMRs within a factory environment.

The FLOW Core software fully integrates OMRON’s autonomous AMRs and fleet management

appliances (EM2100) to provide complete AMR fleet solutions. It incorporates specific tools to

simplify integration with factory equipment and material-movement solutions (MES and ERP

Solutions - refer to Related Manuals on page 16).

NOTE: While this manual focuses primarily on fleet applications, the tools, capabilities, and techniques explained here can be used by customers deploying

single AMRs as well.

FLOW Core software releases are coordinated to update both the AMR platforms and the fleet

management systems for optimal performance with every new release.

FLOW Core software is installed at the OMRON factory on every AMR that OMRON produces. These AMRs can operate on their own, but are most effectively used in fleets. To support fleet operations, an additional Fleet Manager appliance is necessary.

OMRON provides two Fleet Manager configurations based on its standard EM2100 appliance,

providing customers the option to purchase a Secondary unit as a backup, if desired. See Configure Paired Appliances on page 28 for setting up pairedFleet Managers.

NOTE: The EM2100 is also the platform on which the Fleet Simulator runs.

Refer to the Fleet Simulator User's Manual for information on the Fleet Simulator.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 10

Page 11

Chapter 1: Introduction

ARAMCentral

SetNetGo OS

SetNetGo OS

ARAM

MARC

MobilePlanner

EM2100

Core

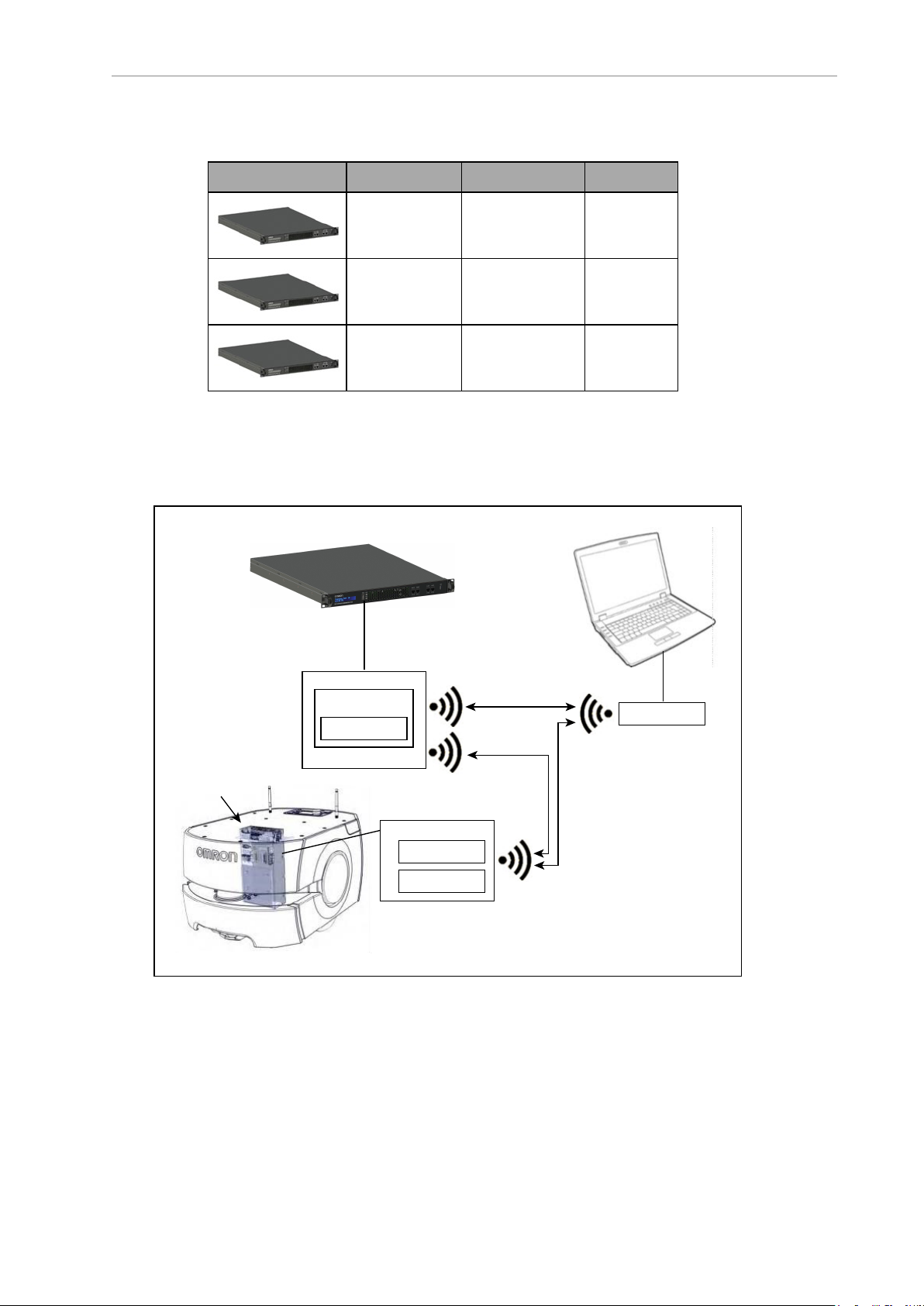

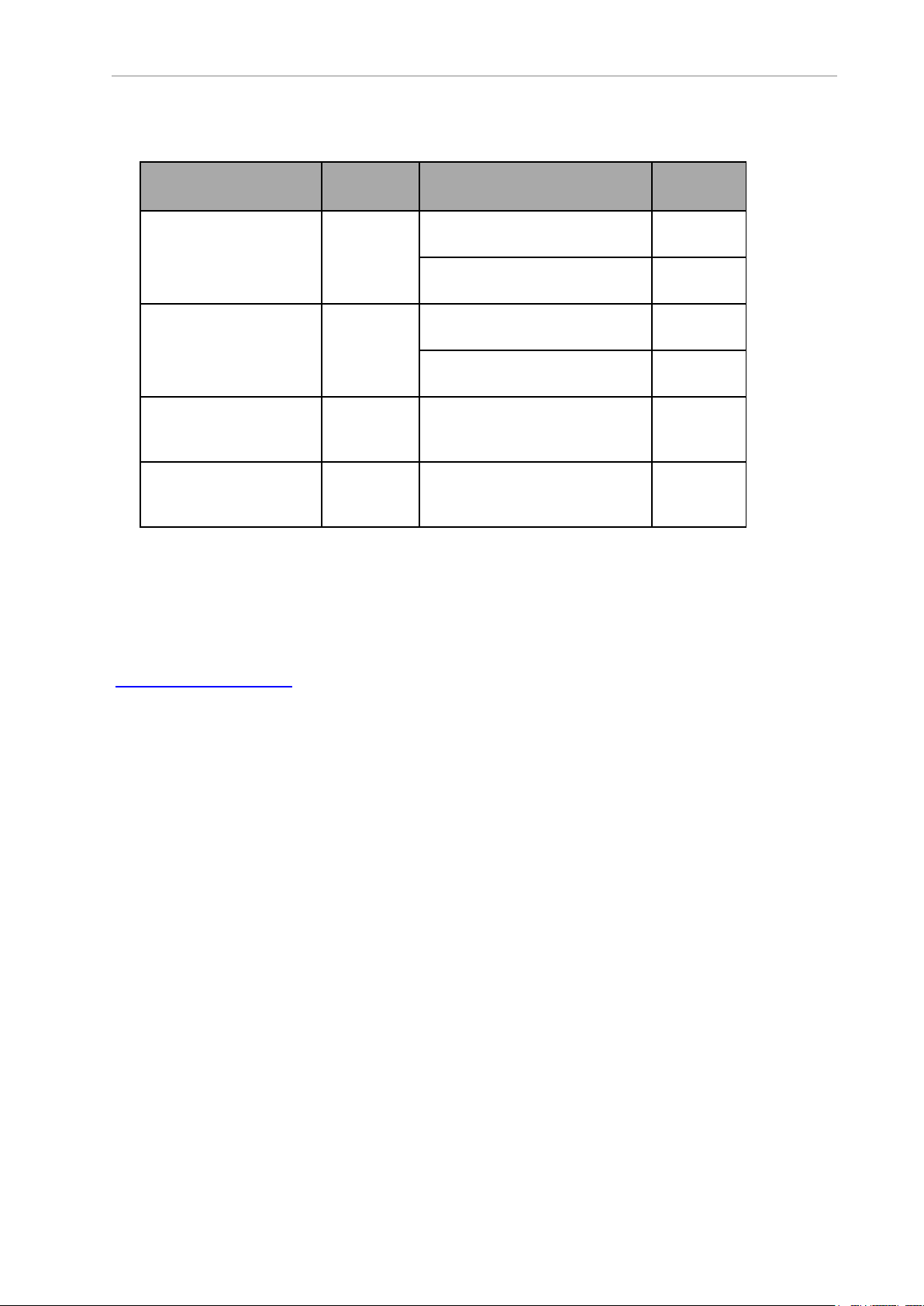

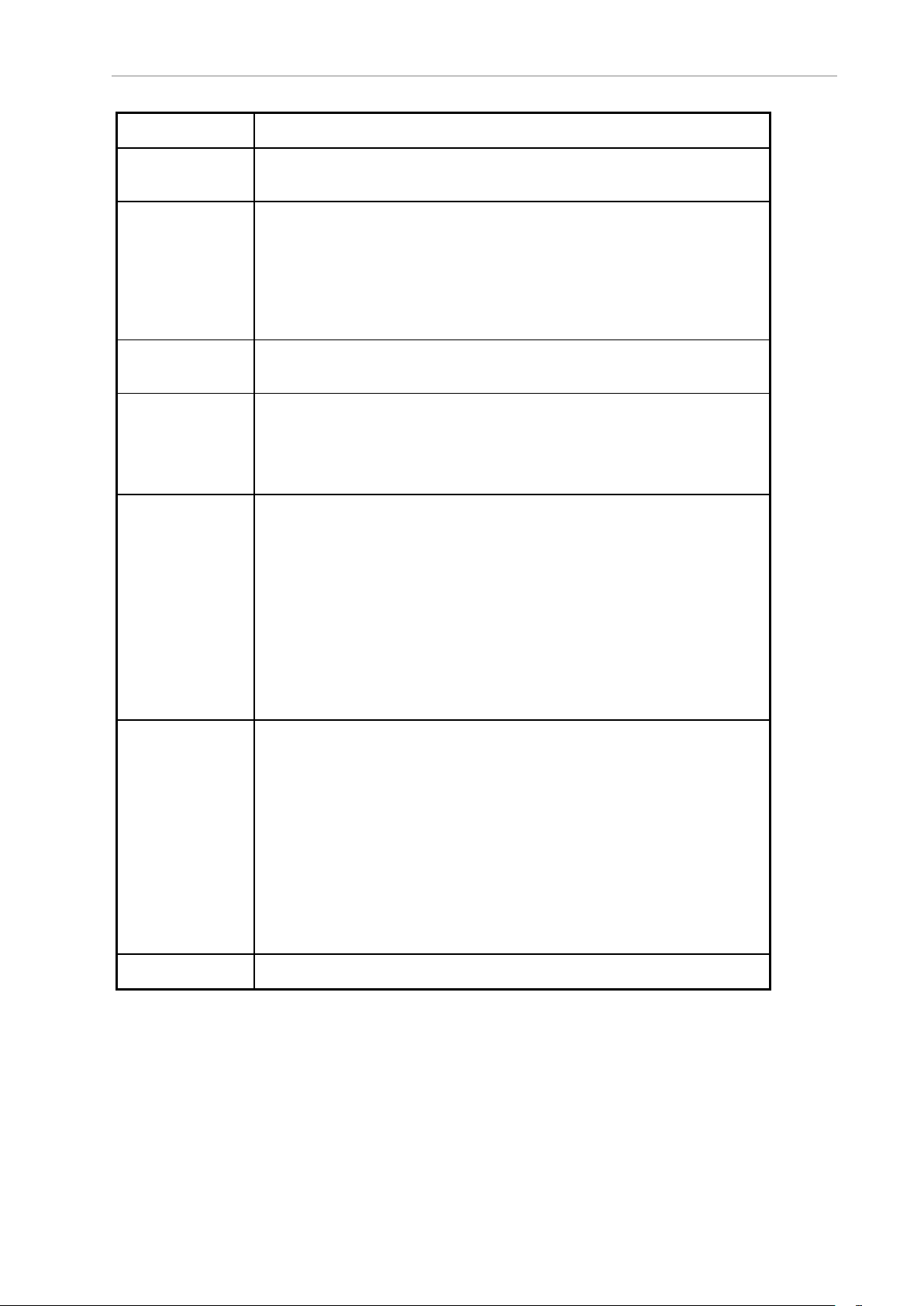

Appearance Product Type Product Name Model

Table 1-1. OMRON Fleet Managers

EM2100

Platform

EM2100

Platform

EM2100

Platform

Primary

Fleet Manager

Secondary

Fleet Manager

Fleet Simulator 20271-903

20271-900

20271-901

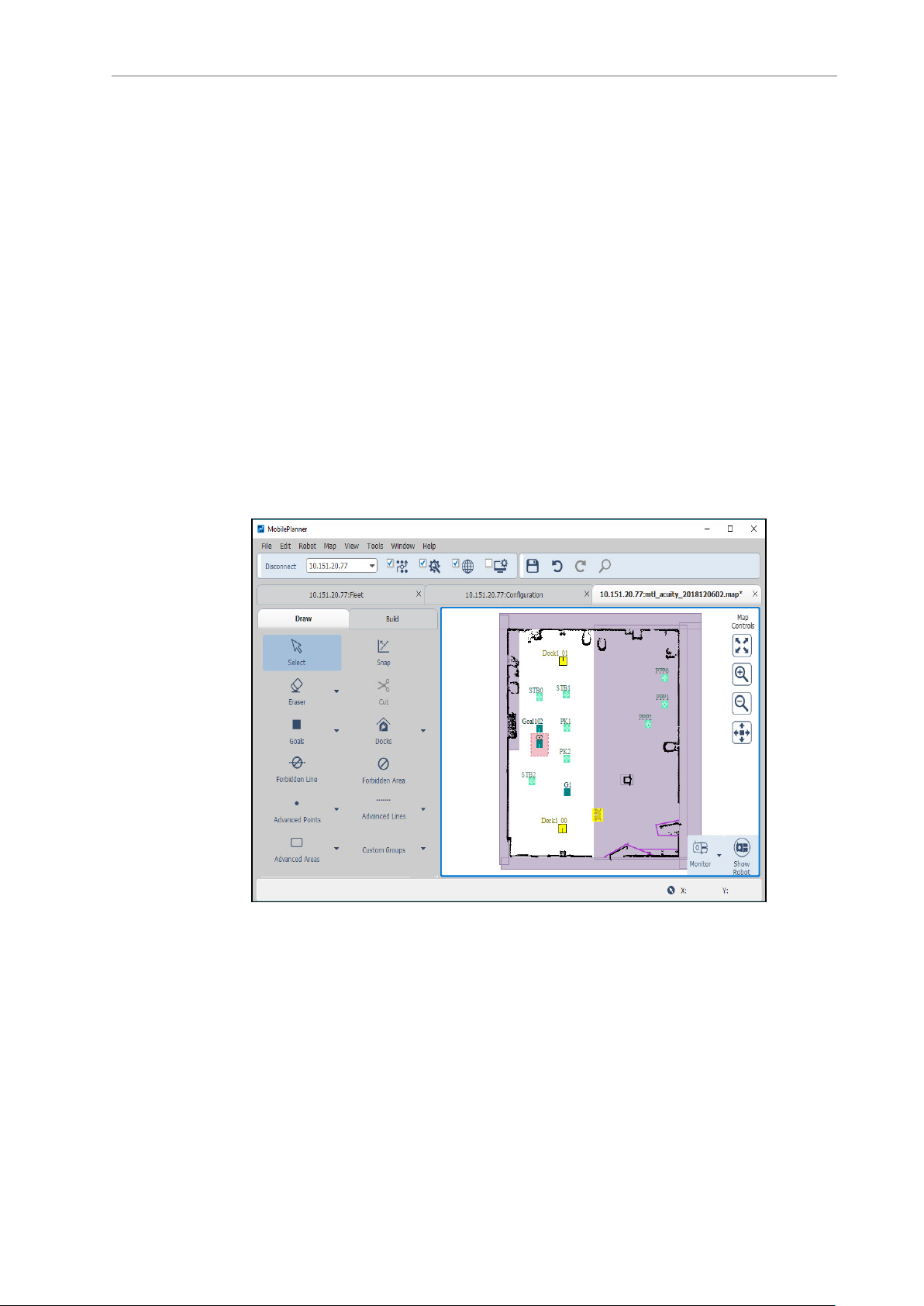

1.2 How the Fleet Operations Workspace Components Work Together

The figure below is a basic system architecture (for a fleet of AMRs) and illustrates the interrelationship between Fleet Operations Workspace Core’s various applications.

11 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Figure 1-1. Components Working Together (LD-60 AMRShown)

Page 12

EM2100

The EM2100 is a network appliance, with built-in processor. It can be used to run the

FLOWCore fleet management software or the Fleet Simulator software. As a Fleet Manager, the

EM2100 coordinates the movement of up to 100 AMRs. It manages maps, AMR configurations, traffic control, and job queuing. FLOW Core licenses are activated on the Fleet Manager.

Version Information: Fleet Simulator support was added in FLOWCore version

1.1.

MobilePlanner

MobilePlanner is the graphical user interface (GUI) for communicating with and configuring

the AMR, and displaying and editing AMR map files. It is the "control center" of the Fleet Operations Workspace Core. Its user interface has the tools for all major AMR activities, such as

observing a fleet of AMRs, commanding individual AMRs to drive, creating and editing map

files, goals, and tasks, modifying AMR configurations, and more.

The AMRs use map files to determine where they are, plan navigable paths to goals, execute

tasks at programmed goals, and to control other AMR tasks.

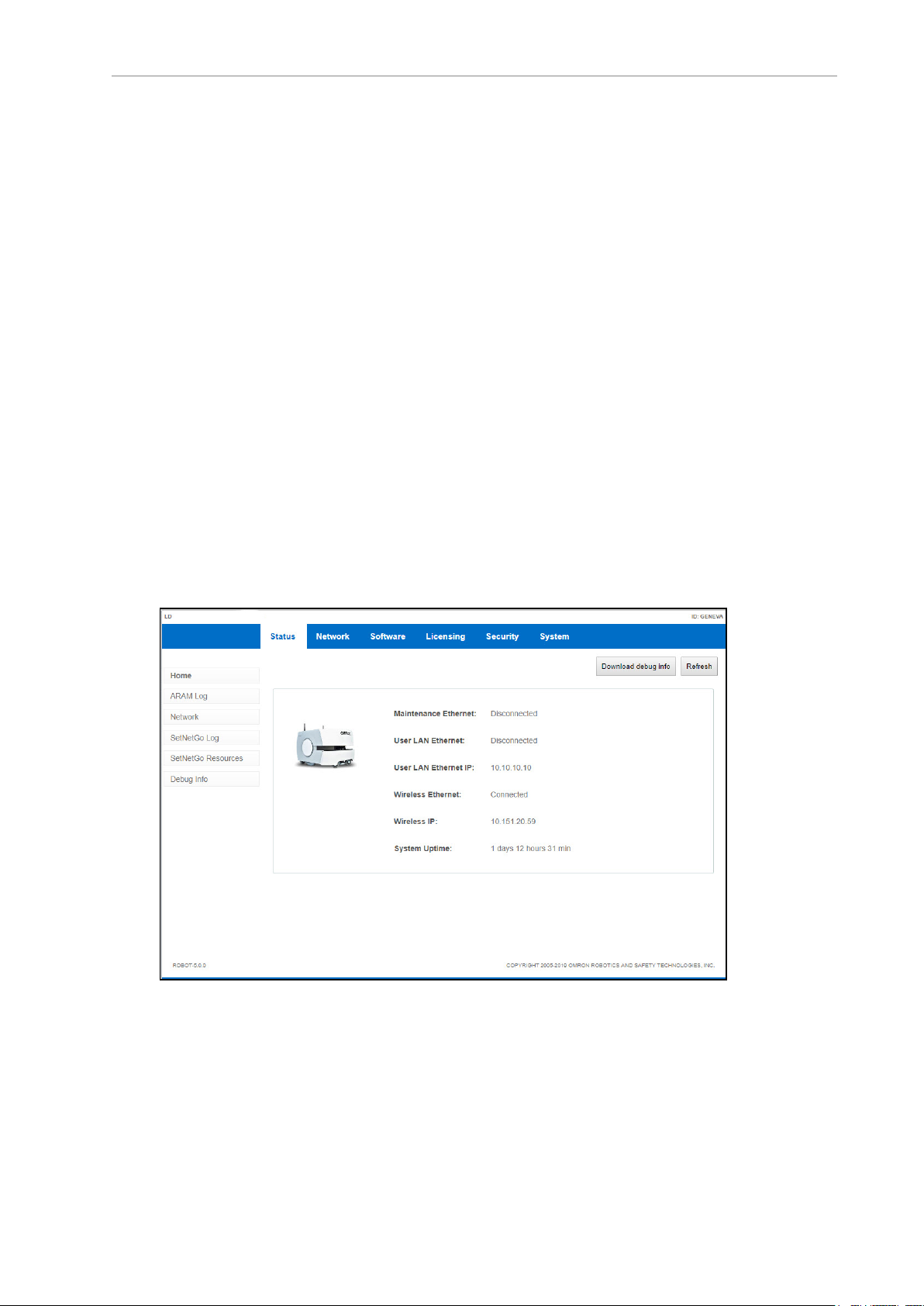

Figure 1-2. MobilePlanner Interface

From the MobilePlanner interface, you can:

l

Connect to and drive the AMR.

l

Create maps of the environment by importing and analyzing an AMR’s scan data.

l

Edit maps by adding goals (and adding tasks to those goals), docks, forbidden areas,

and more. You can also erase stray or unwanted artifacts, combine pieces of maps, and

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 12

Page 13

Chapter 1: Introduction

make other changes.

l

Download and upload files, including maps and scan data, to and from an AMR.

l

Set the system configuration parameters for the fleet.

l

With the Fleet Manager, monitor the location and status of all AMRs in a fleet.

l

View and interact with the job queuing manager.

For details, see MobilePlanner Interface on page 51.

MobilePlanner Accounts

User accounts with limited privileges provide the user with access to a limited set of tools for

monitoring AMR and AMR job status, and allow for simple interventions in job execution

sequences. For more information, see MobilePlanner Operator Account Overview on page 54.

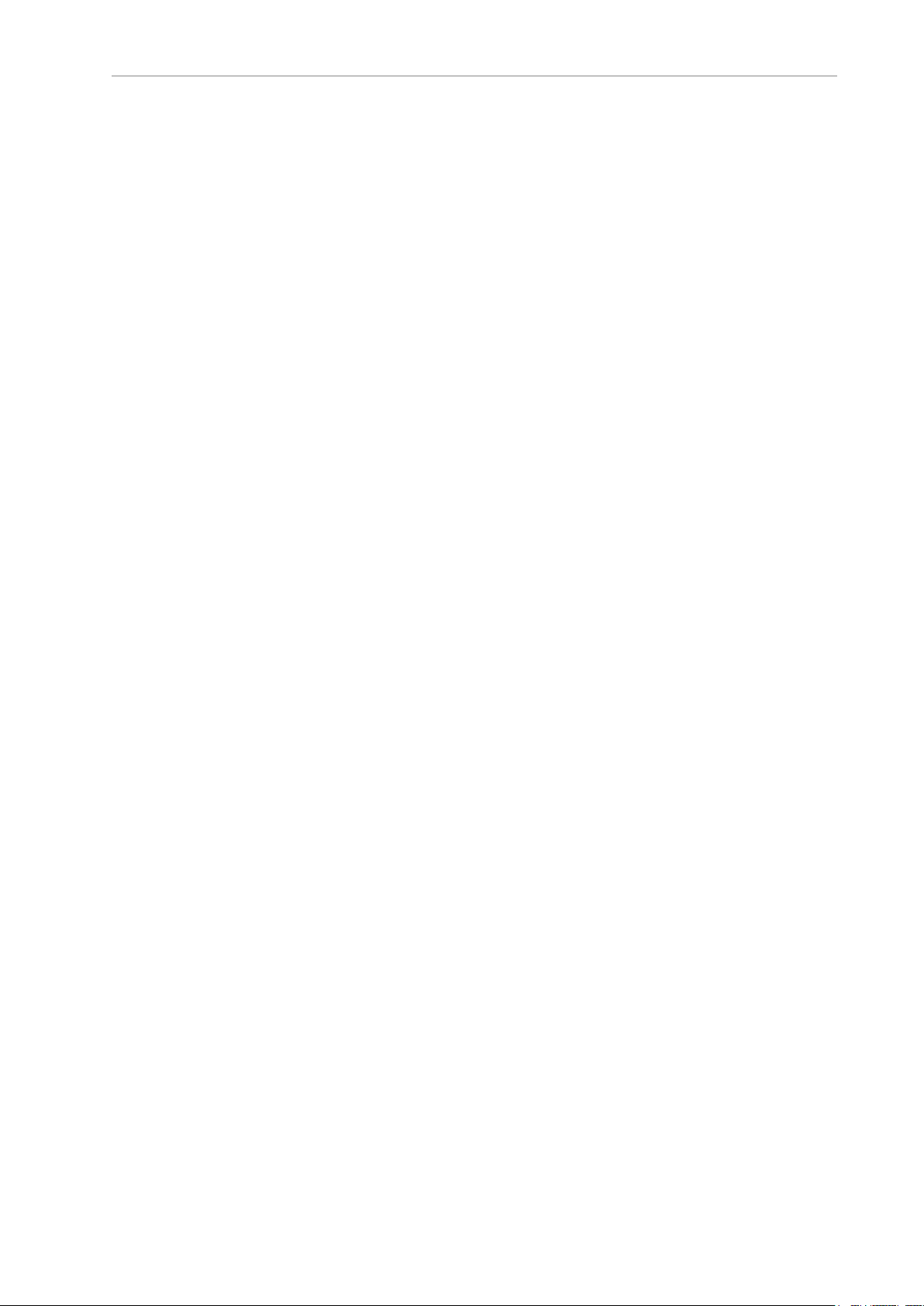

SetNetGo

SetNetGo is the operating system that resides on AMRs and the EM2100 appliance. You can

use the SetNetGo software to establish and configure your AMR's communication parameters,

access diagnostic information (for example, download debug info file for service provider use,

manage restore points, etc.), and perform software maintenance (upgrades). You most commonly access the SetNetGo interface through a tab in the MobilePlanner software, and then

use that interface to enable the parameters needed.

Figure 1-3. SetNetGo Interface

For details, see Overview of the SetNetGo OS on page 114.

NOTE: Optionally, you can connect to SetNetGo through a web browser. Refer

to Connecting to SetNetGo via web browser on page 115.

13 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 14

ARAMCentral

As the fleet management software running on the EM2100 appliance, Advanced Robotics Automation Management (ARAMCentral) provides:

l

Centralized configuration and map management.

l

Job queuing and dispatch.

l

Traffic management.

l

Single-point of integration and communication for software clients and other automation equipment.

ARAM

The Advanced Robotics Automation Management (ARAM) software runs on the AMR's core,

and does the following:

l

Performs all the high-level, autonomous robotics functions, including obstacle avoidance, path planning, localization, and navigation, culminating in the AMR’s motion.

l

Manages wired and wireless Ethernet communications with off-board software, for

external monitoring, development, and systems coordination, including coordination of

a fleet of AMRs through the Fleet Manager.

l

Enables external monitoring and control with the MobilePlanner application.

MARC/Polo

Mobile Autonomous Robot Controller (MARC), which resides on the LD-series AMR core, manages the AMR’s speed and heading, sensor readings, emergency stop systems, bumpers, and

pendant. It also computes and reports the AMR’s odometry readings (X, Y, and heading) and

other low-level operations which it reports to ARAM.

Polo performs the same functions for the HD-1500 AMRs.

1.3 Fleet Operations Workspace Licensing

There are licensing options for both FLOW Core and advanced features. These licenses help

customers manage the costs of their AMR fleets through lower, annual subscription payments

for FLOW Core and activation of advanced features only if they provide benefits to your specific applications. The licenses currently available are listed in the following table. Contact

your OMRONrepresentative or Sales Office for pricing.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 14

Page 15

Chapter 1: Introduction

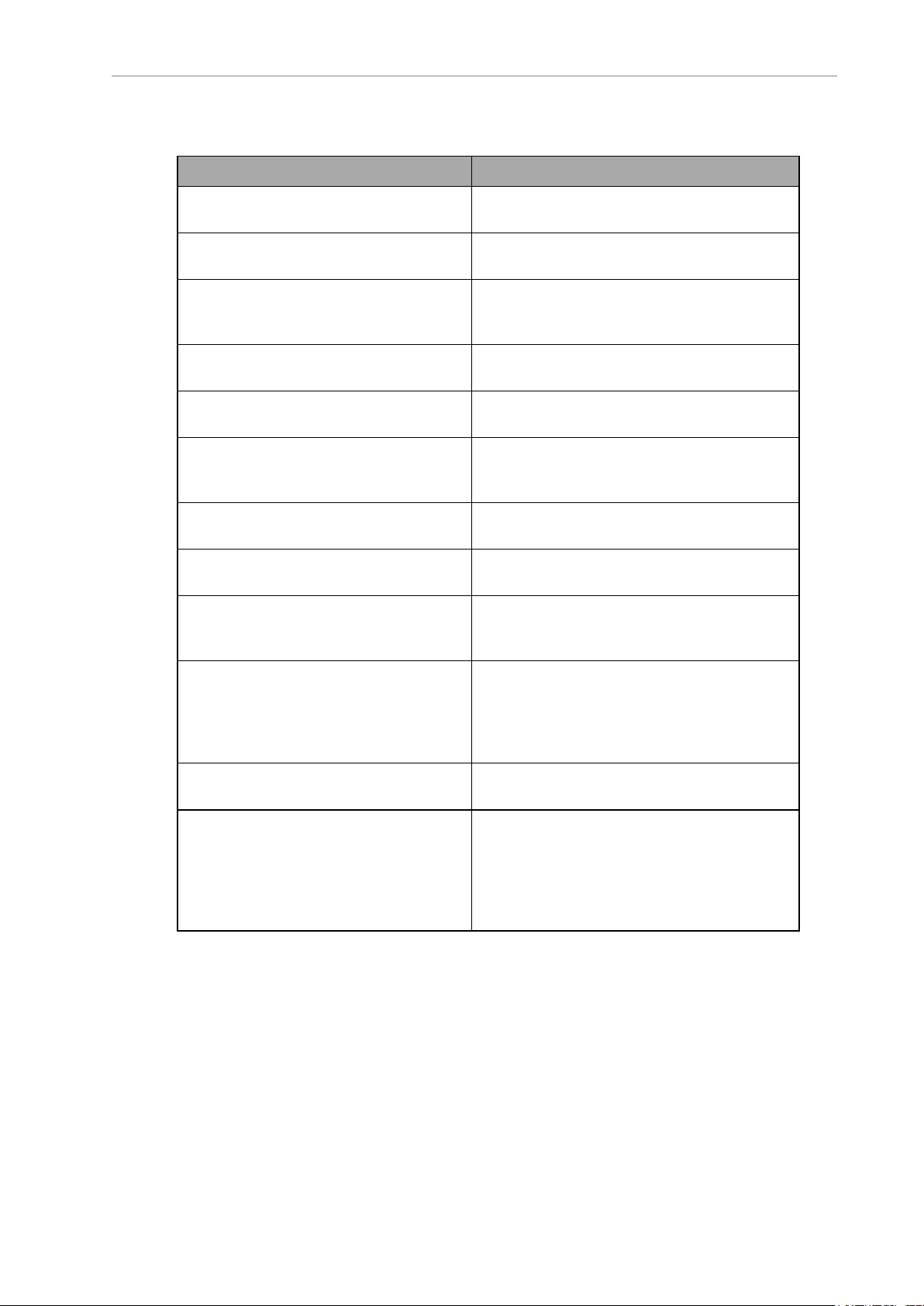

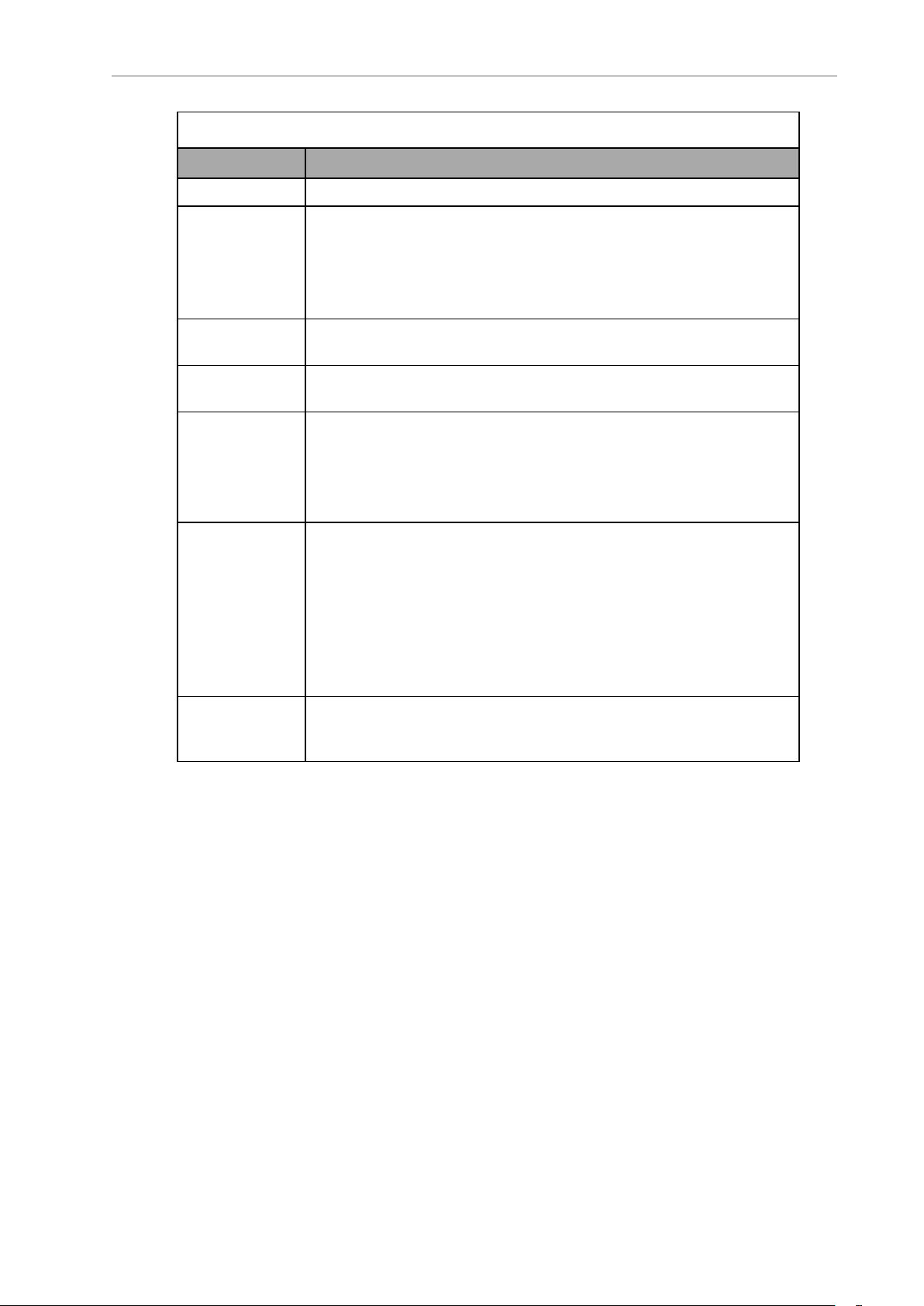

Table 1-2. Available Fleet Operations Workspace Licenses

Product License

Type

Primary Fleet

Management

Secondary Fleet

Management

Cell Alignment

Positioning System

(CAPS)

Fleet Simulator Perpetual

Subscription

Operating

License

Subscription

Operating

License

Perpetual

Feature

License

Feature

License

Product Description

License, 1 Yr Fleet Operations

Workspace Core, Primary

License, 5 Yr Fleet Operations

Workspace Core, Primary

License, 1 Yr Fleet Operations

Workspace Core, Secondary

License, 5 Yr Fleet Operations

Workspace Core, Secondary

License, High Accuracy cell alignment feature for OMRON AMRs

License, Fleet Simulator 20271-804

Model

20271-800

20271-806

20271-802

20271-807

20271-805

All of these licenses are field-upgradable. Section 7.6 shows the steps required to acquire or

update FLOW Core subscription, and Fleet Simulator and CAPS perpetual licenses.

1.4 How Can I Get Help?

For details on getting assistance with your OMRON software or hardware, you can access the

corporate website:

http://www.ia.omron.com.

If you need help beyond what is covered in the manual, contact your OMRONrepresentative.

15 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 16

Related Manuals

Manual Description

Mobile Robot LD Safety Guide (Cat. No.

I616)

Mobile Robot HDSafety Guide (Cat. No.

I647)

LDPlatform OEMUser's Guide (Cat. No.

I611)

LD-250 Platform User's Guide (Cat. No.

I642)

HD-1500 Platform User's Manual (Cat.

No. I645)

LD Platform Peripherals Guide (Cat. No.

I613)

Mobile Robots - HD Platform Peripherals

Manual (Cat. No. I646)

EM2100 Installation Guide (Cat. No.

I634)

Fleet Operations Workspace Migration

Guide (Cat. No. I636)

Describes safety information for OMRON LDseries AMRs.

Describes safety information for OMRON HD1500AMRs.

Describes the installation, start-up, operation,

and maintenance of the LD-60 and LD-90

AMRs.

Describes the installation, start-up, operation,

and maintenance of the LD-250 AMR.

Describes the installation, start-up, operation,

and maintenance of the HD-1500 AMR

Covers peripherals for LD AMRs, such as the

Touchscreen, Call/Door box, and Acuity Localization options.

Covers peripherals for HDAMRs, such as

HAPS.

Describes the installation and initial configuration of an EM2100 appliance.

Describes the procedures for migrating your

AMR from legacy to FLOW Core software, and

from an EM1100 to an EM2100.

Fleet Operations Workspace Core Integration Toolkit User's Guide (Cat. No.

I637)

Fleet Simulator User's Manual (Cat. No.

I641)

Advanced Robotics Command Language

Enterprise Manager Integration Guide

(Cat. No. I618)

Describes specific tools to simplify integration

with factory equipment and material-movement solutions such as manufacturing execution systems (MES)and equipment

resource planning (ERP) solutions.

Describes the operation of the Fleet Simulator.

Describes the Advanced Robotics Command

Language (ARCL) version for use with the

EM2100 software. ARCL is a simple text-based

command and response server used for integrating the Fleet Operations Workspace Core

platform with an external automation system.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 16

Page 17

Page 18

Chapter 2: Safety and Regulatory Information

!

!

2.1 Safety and Regulatory

OMRON LD AMRs adhere to the following domestic and international safety regulations:

l

EN 1525 “Safety of Industrial Trucks. Driverless Trucks and their Systems”

l

ANSI 56.5:2012 “Safety Standard for Driverless, Automatic Guided Industrial Vehicles

and Automated Functions of Manned Industrial Vehicles”

l

JISD 6802:1997 “Automated Guided Vehicle Systems - General Rules on the Safety”

OMRON's HD-1500 AMRs are evaluated to the following standards:

l

EN ISO 10218-1

l

UL 1740

l

EN 60204-1

l

EN ISO 13849-1

2.2 Warnings, Cautions, and Notes

Where needed, this user guide calls out critical, important, or emphasized text via special alert

notifications. Below are explanations of the special alert notifications used in this manual:

WARNING: This indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or serious injury or death.

Additionally, there may be significant property damage.

CAUTION: This indicates a situation which, if not avoided, could result in

minor or moderate injury or in property damage.

IMPORTANT: Important indicates information that the user needs to know to

use the system correctly.

NOTE: Notes provide supplementary information, emphasize a point or procedure, or give a tip for easier operation.

Version Information: This indicates information that only applies to certain versions of software or hardware.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 18

Page 19

Chapter 2: Safety and Regulatory Information

2.3 General Safety Precautions

Read the installation and operation instructions, as well as the appropriate robot user's guide

and robot safety guide before using the equipment.

l

Do not ride on the AMR.

l

Do not exceed the AMR’s maximum weight limit.

l

Limit operation to areas with no slope.

l

Do not drop the AMR, run it off a ledge, or otherwise operate it in an irresponsible manner.

l

Do not get the AMR wet, or expose the AMR to rain or moisture. The AMR has an IP

rating of IP20.

l

Do not use power extension cords with the docking station unless properly rated.

l

Do not run the AMR if hair, yarn, string, or any other items are wound around the

AMR’s axles or wheels.

l

Never access the AMR’s interior with the charger attached. Immediately disconnect the

battery after opening the battery compartment door.

l

Never short the battery’s terminals together.

l

Do not use parts (including charging docks, etc.) not authorized by OMRON

2.4 Safety Commissioning

Safety standards require testing of the AMR's safety systems by a trained and qualified person,

both before leaving the factory and again at the customer's site.

Safety commissioning is executed from the MobilePlanner main menu. Access and execute the

safety commissioning procedure from MobilePlanner by selecting Robot > Safety Commissioning.

The safety commissioning procedure is guided by on-screen prompts. The instructions that

you see will be based on the type of robot that you have connected. The procedures will test

each E-Stop and Safety Laser on the AMR, as well as the E-Stop on the pendant. Details for

running these procedures are given in each AMR user guide.

2.5 What to Do in an Emergency

Press the E-Stop button (a red push-button on a yellow background/field) and then follow the

internal procedures of your company or organization for an emergency situation. If a fire

occurs, use a type D extinguisher: foam, dry chemical, or CO2.

2.6 Additional Safety Information

We provide more safety information in the following manual:

Mobile Robot LD Safety Guide (Cat. No. I616) and Mobile Robot

HDSafety Guide (Cat. No. I647)

The Mobile Robot LD Safety Guide (Cat. No. I616) and Mobile Robot HDSafety Guide (Cat. No.

I647) provide detailed information on safety for our AMRs. They also give resources for more

19 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 20

information on relevant standards. A safety guide ships with each AMR.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 20

Page 21

Page 22

Chapter 3: Fleet Manager Configuration and

Operation

The Fleet Manager capabilitieswithin FLOWCore provide tools for programming and configuring individual AMRs and fleets, and for centralized job dispatch and real-time AMR monitoring within your facility.

3.1 EM2100 Configuration Overview

This section provides instructions for setting up and connecting the AMRs and Fleet Manager

to a network.

OMRON's EM2100 appliance provides the operating environment for the FLOW Core software. It will be the primary interface device to the network and any PC(s) running MobilePlanner. The EM2100 appliance comes pre-loaded with a temporary, 120 day, FLOW Core license,

which allows initial set-up, testing, and validation to begin immediately, without a full subscription license. A FLOW Core license must be purchased after the 120 day set-up period.

NOTE: The EM2100 can also run in the Fleet Simulator operating mode, with a

Fleet Simulator license. Refer to the Fleet Simulator User's Guide.

Configuration Tasks Overview

NOTE: This section assumes that you have read and followed the instructions

in the EM2100 Installation Guide (Cat. No. I634).

To configure the EM2100 appliance as a Fleet Manager, you must do the following tasks,

which are described in detail later in this guide:

l

Configure the network settings for the appliance Management Ethernet port.

l

Configure the network settings for the FLEET ETH2 Ethernet port.

l

Connect the Management and Fleet ports to the LAN.

l

Define the login information.

l

Configure each AMR to connect to the EM2100.

l

Customize each AMR, if desired.

If you install a Secondary EM2100 appliance and configure Autosync, you must also:

l

Install the same FLOWCore software version on the Secondary as is on the Primary

appliance.

l

Configure a unique IP address for the Management port.

l

Connect the Management port to the LAN.

l

Connect the FLEET ETH2 port to the LAN.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 22

Page 23

Chapter 3: Fleet Manager Configuration and Operation

l

Enter the Secondary Management IP address on the Primary appliance.

l

Generate and download a key from the Primary appliance.

l

Set the Secondary appliance Autosync role to Secondary.

l

Upload the key to the Secondary appliance.

l

Verify that the status of both appliances is active.

l

Create a direct network connection between the Primary and Secondary appliances.

3.2 Power Interruptions

Use the front momentary power switch to turn the EM2100 on and off. The rear power switch

should remain on unless you are uninstalling the appliance.

Power Interruptions on a Standalone EM2100

If there is an interruption to the power supply for any reason or duration, a standalone

EM2100 automatically returns to its previous power state.

l

A standalone appliance that was shut down and powered off when the interruption

occurred remains shut down after you restore power.

l

A standalone appliance that was powered on when the interruption occurred restarts

automatically after you restore power.

After recovery from a power interruption, the EM2100 saves its job queue status and recovers

the queue automatically after it restarts following a power failure. This does not apply to an

operator-initiated emergency power off. Refer to: Power Interruptions on page 23.

Power Interruptions on an Autosync Appliance

This section assumes that you configured Autosync on two EM2100 appliances and connected

each appliance to separate power circuits for redundancy. Providing that only one circuit was

affected, one appliance should remain operating normally during the power interruption. The

sequence of events and method of recovery depends on which appliance is affected:

A power interruption on the Primary appliance results in a loss of connectivity with

AMRs and MobilePlanner. You should:

l

Determine whether the problem is a power outage or a loss of network connectivity.

l

Manually reconfigure the Secondary appliance to become the Primary Appliance. Fleet

Management functions are restored but Autosync status is now disabled.

Autosync will need to be re-configured once the power issue with the original EM2100

appliance is resolved.

l

Verify that MobilePlanner and AMRs reconnect to the Fleet IP address.

l

Review the job queue status in MobilePlanner and verify the status of AMRs to make

sure that no jobs are incomplete.

l

Restore power to the former Primary appliance.

l

Change the former Primary appliance to a role of Secondary appliance.

23 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 24

A power interruption on the Secondary appliance results in no loss of connectivity

with AMRs and MobilePlanner. You should:

l

Verify that MobilePlanner and AMRs are connected to the Fleet IP address.

l

Review the job queue status in MobilePlanner and verify the status of AMRs to make

sure that no jobs are incomplete.

l Restore power to the Secondary appliance. Autosync will be restarted if it was running

when the power was interrupted. Fleet operations should be unaffected.

If both Autosync appliances are affected by a power interruption, they both behave

as described in: Power Interruptions on a Standalone EM2100 on page 23:

l

All fleet operations are terminated during the power interruption.

l

Normal Active Autosync operation resumes automatically after you restore power to

both appliances.

l

The Primary EM2100 saves its job queue status and recovers the queue automatically

after it restarts. Autosync will reconnect automatically when power is restored.

3.3 Set the IP Address on a Client PC's Network Adapter

Use the Maintenance Ethernet port to connect a client PC to the SetNetGo operating system.

IMPORTANT: You must assign a static IP address. Do not use a DHCP server.

Configure the network adapter IPv4 address on the Client PC as follows:

1.

Connect an Ethernet cable from the client PC’s Ethernet port to the Maintenance Ethernet port on the EM2100 appliance.

2.

In the command field on the Windows taskbar, enter the following command to open

the Network Connections dialog: ncpa.cpl

3.

Open the network properties of the PC ethernet network adapter used to connect to the

Maintenance Ethernet port on the EM2100 appliance.

4. Double-click TCP/IPv4 to open the Internet Protocol properties dialog.

5.

Enter as the IP address: 1. 2. 3. 5, or any IP address in the range 1. 2. 3. 0 to 1. 2. 3. 255,

excluding 1. 2. 3. 4. (this is reserved for the Maintenance port).

6.

Enter as the subnet mask: 255. 255. 255. 0.

7.

Click OK to close the Internet Protocol dialog, and then click OK to close the Ethernet

Adapter dialog.

In future, you can use the Maintenance Ethernet port for emergency access to the Appliance at

IP address 1.2.3.4. (For example, if you lose the password or if there is a network IP address

conflict.)

3.4 Connect Your PC to SetNetGo on the EM2100

SetNetGo enables you to configure and manage EM2100 and AMRsettings. This section

describes how to access SetNetGo through the Maintenance port to perform initial configuration.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 24

Page 25

Chapter 3: Fleet Manager Configuration and Operation

The user interface for SetNetGo on an EM2100 provides a different set of parameters and

options compared to SetNetGo on an AMR. The upper left of the screen shows EM2100, LD,

LD-250, or HD depending on your SetNetGo context (the device on which it runs, such as the

OMRON LD-series AMRs).

Configure Access and Security

After you connect to the Maintenance Port as described in: Set the IP Address on a Client PC's

Network Adapter on page 24 you can open the SetNetGo web interface.

Connect your browser to SetNetGo and configure SetNetGo access as follows:

1.

In the SetNetGo web interface, click the Security Tab and then click SetNetGo Access

and check Enabled next to the following:

Maintenance Interface is automatically enabled.

l

Wireless Ethernet/User LANEthernet

l

(Optional) Remote Reboot.

2.

Change the account password (default is no password) as required and click Apply.

NOTE: Passwords are limited to a maximum of 20 alphanumeric characters.

For increased security, specify a long (10+ characters) password string with both

uppercase and lowercase letters. Include several digits.

3.5 Configure Management Interface Network Settings

To configure the Management Network, you require:

l A dedicated static IP address. (Do not use 1.2.3.4. That address is permanently assigned

to the Maintenance Ethernet port.)

l The subnet mask for the Management network.

l The IP address of the network Gateway.

l The IP address of a Domain Name Server (DNS) (this is only required if any hostnames

will be used in the Fleet Manager configuration), so that the Fleet Manager can resolve

all IP addresses.

Configure the Management Interface network connections as follows:

1.

In the SetNetGo web interface, click the Network tab.

2.

Click Management Interface and enter the:

a.

IP address.

b.

Subnet mask.

c.

Network Gateway IP address (typically a router).

3.

Enter the IP address of your Domain Name Server (DNS), if required for devices other

than the appliance and the fleet. Otherwise, leave it as 0.0.0.0.

4.

Click Apply.

25 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 26

A message dialog informs you of the status of the change, and whether there is any affect on

operations such as a restart or a time delay before the change takes effect.

3.6 Configure the Operating Mode

Configure the Operating Mode as follows:

1.

In the SetNetGo web interface, click the System tab.

2.

Click Mode.

3.

Select the operating mode in which you will be using this EM2100.

The choices will be:

l

Unconfigured (this is how the EM2100 ships)

l

Standalone Fleet Manager

l

Paired Fleet Manager

l

Fleet Simulator

If a mode is greyed out, it means that you don't have the license to support that operating mode. Refer to Licensing Tab on page 126.

4.

Click Apply.

You will be shown several warning pop-ups. Respond OK to all.

The EM2100 will reboot.

At this time, Status > Home > Mode of Operation should show the operating mode

that you selected.

A message dialog informs you of the status of the change, and whether there is any effect on

operations such as a restart or a time delay before the change takes effect.

3.7 Configure the Fleet Interface Network Settings

To configure the Fleet Interface, you require:

l A dedicated static IP address to assign to the Fleet Interface port. This IP is allowed, but

not required, to be on the same subnet as the Management IP. Do not use 1.2.3.4,

because that address is permanently assigned to the Maintenance Ethernet port.

l The subnet mask for the network that your Fleet will use.

l The IP address of the network Gateway.

Configure the Fleet Interface network connections as follows:

1.

In the SetNetGo web interface, click the Network tab.

2.

Click Fleet Interface and enter the:

a.

IP address.

b.

Subnet mask.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 26

Page 27

Chapter 3: Fleet Manager Configuration and Operation

c.

Network Gateway IP address (typically a router).

3.

Click Apply.

A message dialog informs you of the status of the change, and whether there is any affect on

operations such as a restart or a time delay before the change takes effect.

27 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 28

3.8 Configure Paired Appliances

The default (shipped) configuration for an EM2100 is Unconfigured. The user will need to configure it as either Standalone or Paired Fleet Manager.

To create an Autosync pair, refer to Configure the Primary Appliance on page 29 and Configure the Secondary Appliance on page 30. The paired appliances then function as follows:

l

The Primary unit is a fully-functional EM2100, running the Fleet Operations Workspace

Core and actively controlling the fleet.

l

The Secondary unit is powered on, with its web interface accessible to the Primary unit.

However, the fleet management functions are inactive on the Secondary unit, and it is

inaccessible from MobilePlanner or AMRs.

The Primary Fleet Manager has two active IP addresses, while the Secondary has only one active IP address.

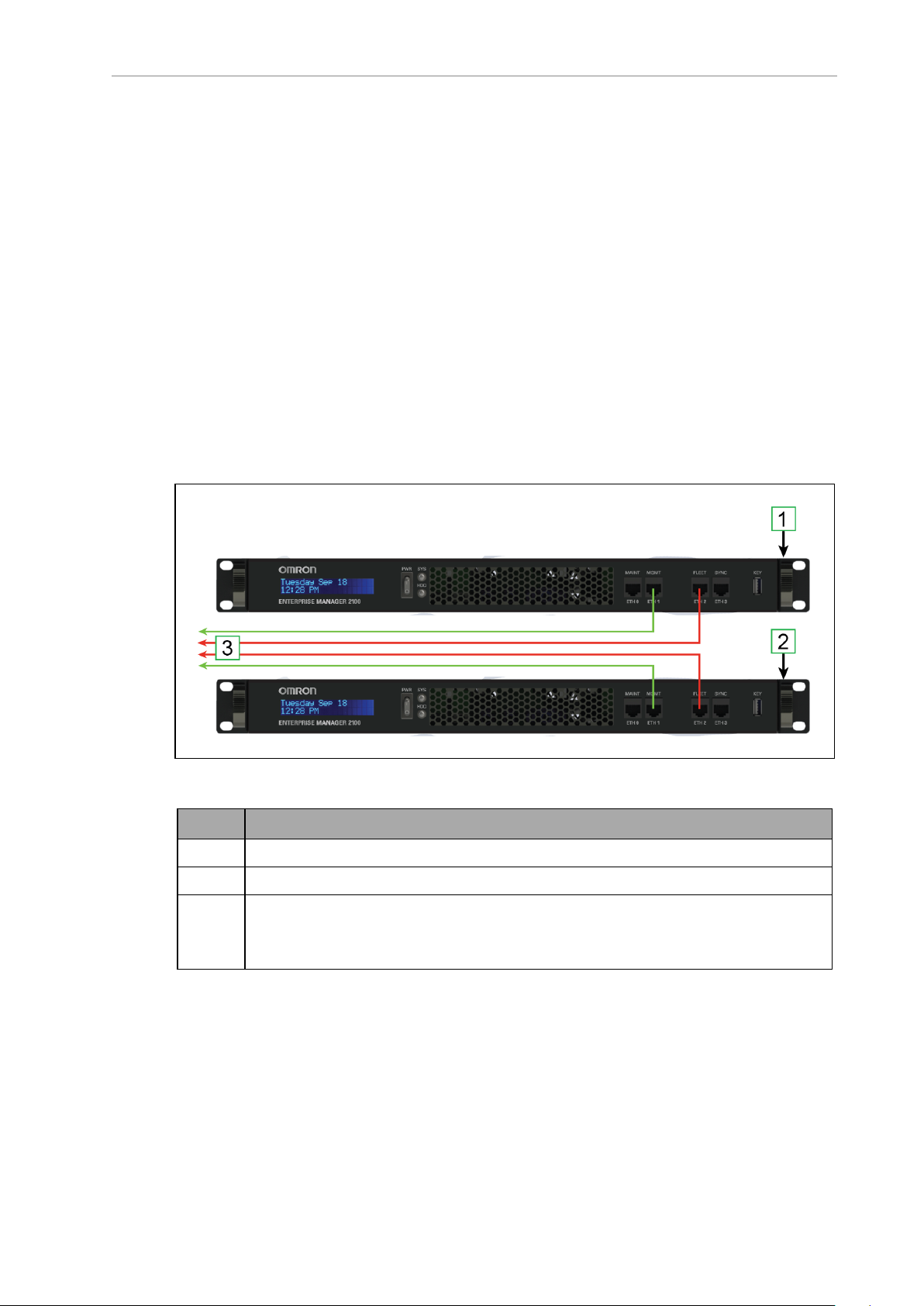

EM2100 Autosync — Ethernet Cabling

The following figure shows the physical connection of Ethernet cables to the appliances.

Figure 3-1. Cabling for an EM2100 Fleet Manager Pair

Callout Description

1 EM2100 configured as a Primary appliance.

2 EM2100 configured as a Secondary appliance.

3 Ethernet cables to the LAN switch:

l Primary and Secondary MGMT ETH1

l Primary and Secondary FLEET ETH2

Tasks in Autosync Setup

Before you set up Autosync, make sure that you have:

l

Installed the Primary appliance and connected it to the network.

l

Configured the Maintenance Ethernet interface on the Primary appliance.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 28

Page 29

Chapter 3: Fleet Manager Configuration and Operation

l

Physically installed the Secondary appliance hardware, as described in the EM2100

Installation Guide.

The tasks required to set up autosync between a Primary and Secondary appliance are:

l

Configure the Primary appliance with a Fleet IP Address.

l

Enter the Secondary appliance IP Address in the Primary appliance.

l

Generate and Download the Primary key (to your PC).

l

Set the Secondary appliance Autosync role to Secondary.

l

Upload the Primary key to the Secondary appliance.

Configure the Primary Appliance

Do this only if you have two Fleet Manager appliances, and you want to configure one as a

Primary Fleet Manager. You must first configure the Management and Fleet networks and

cable the appliances.

1.

In the SetNetGo web interface, click the System tab, then Mode.

2.

Select Paired Fleet Manager from the drop-down menu. Click Apply.

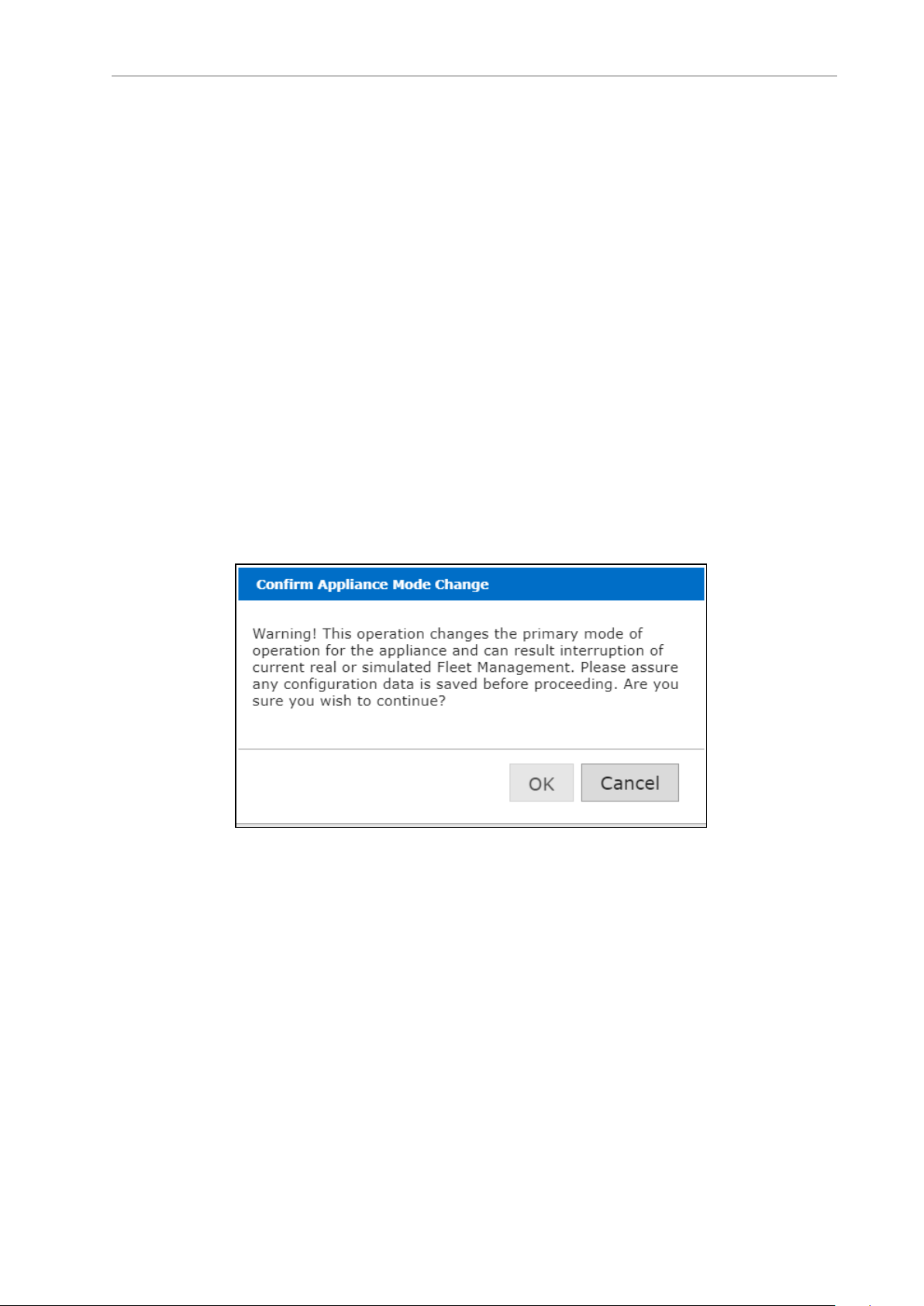

You will get a "Confirm Appliance Mode Change" pop-up message.

Figure 3-2. Confirm Appliance Mode Change Window

3.

Click OK.

You will get a second pop-up with a warning that this operation will interrupt the

fleet management.

4. Click OK.

5.

Click the Pairing button that appears in the left margin of the screen.

6.

From the drop-down menu next to the Pairing Role, select Primary, and click Apply.

7.

Enter the IP Address of the Secondary appliance. Click Apply.

29 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 30

8.

You will get a message to confirm changes, saying that ARAMCentral will restart, disconnecting AMRs and clients. Click OK.

9.

You will get a confirmation message that the changes were successfully applied. Click

OK.

10.

Click Generate New Key to create an SSL key, or Download Existing Key, if you pre-

viously created an SSL key.

Uploading the SSLkey to the Secondary appliance grants permission for the Primary

to perform RPC calls required for synchronization.

11.

You are prompted for a location to save the key file. Enter a location (path) where you

want to save the file on your PC, so you can later upload it to the Secondary appliance.

12.

A warning message indicates the pending disconnection of AMRs and clients. Click

OK.

Your Primary Fleet Manager is now configured to run as part of a pair.

Configure the Secondary Appliance

Do this only if you have two Fleet Manager appliances, and you want to configure one as a

Secondary Autosync appliance. You must first:

1.

In the SetNetGo web interface, click System tab, then Mode.

2.

From the drop-down menu choose Paired Fleet Manager and click Apply.

3.

You will get a "Confirm Appliance Mode Change" pop-up message. Click OK.

4.

You will get a second pop-up with a warning message that this operation will interrupt

the fleet management. Click OK.

5.

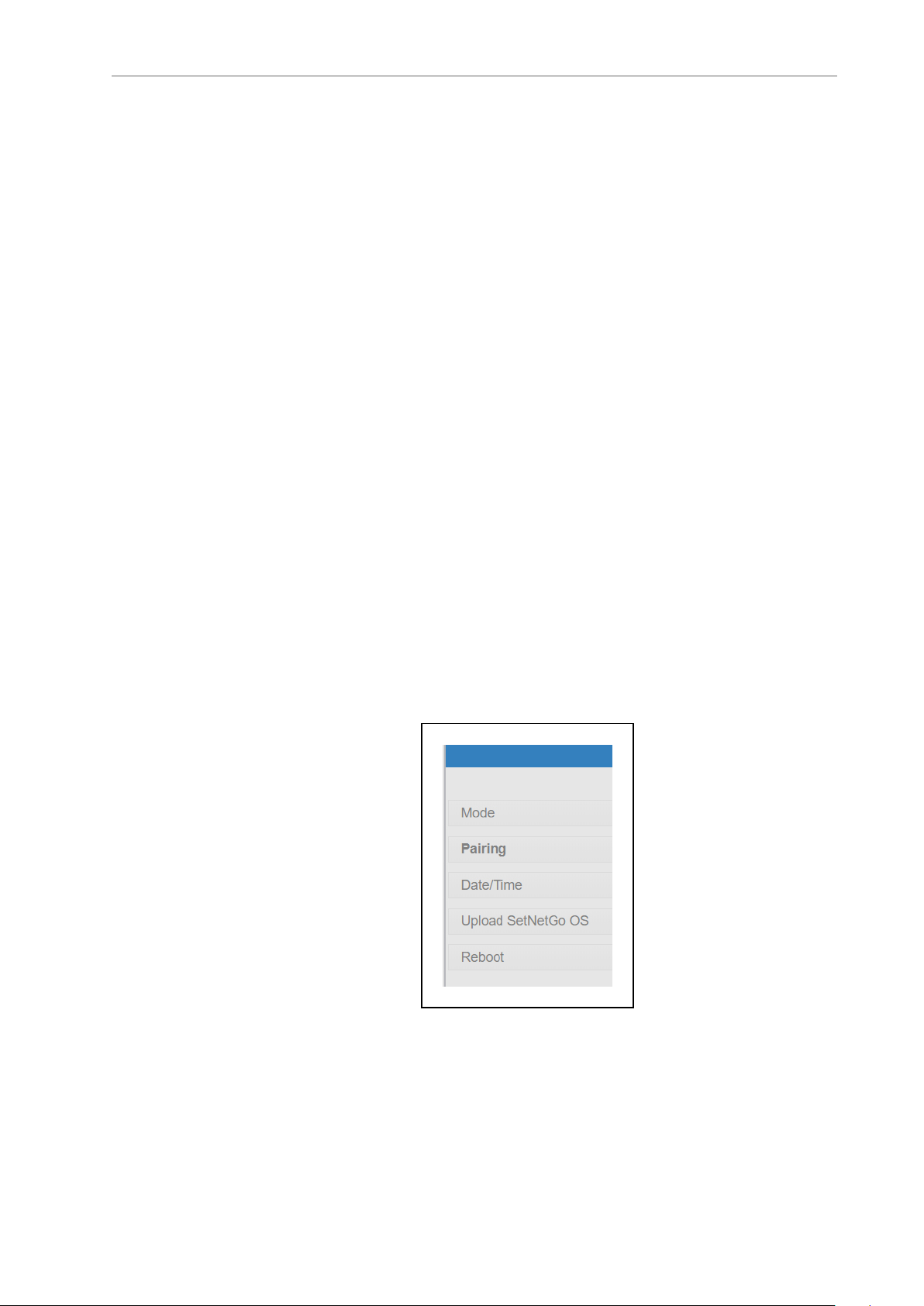

A Pairing selection will appear in the left margin of the screen. Click on Pairing.

Figure 3-3. Pairing Selection, Left Bar

6.

From the drop-down menu, next to the Pairing role, choose Secondary. Click Apply.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 30

Page 31

Chapter 3: Fleet Manager Configuration and Operation

You will get a Confirm changes message that ARAMCentral will halt, disconnecting

AMRs and clients. Click OK.

7.

You will get a confirmation message that the changes successfully applied. Click OK.

Figure 3-4. Changes Successfully Applied Window

8.

Click Choose File to select the Primary SSLkey from your PC to chose the proper file.

Enter the name and path of the file to upload the key from the PC.

9.

Click Upload.

Your appliance is now configured as a Secondary appliance.

NOTE: Although the Fleet Interface settings are saved for the Secondary appliance, the interface is inaccessible.

When the connection is complete, the Primary and Secondary appliances show a Current

Status of active.

3.9 Configure Each AMR to Connect to the Fleet Manager

Before you can use the Fleet Manager appliance to manage AMRs, you must configure each

AMR to connect to the appliance. To do so, you must connect to each AMR.

When an AMR connects to the appliance, the Fleet Operations Workspace Core overwrites the

AMR's configuration parameters with Fleet parameters.

AMR Configuration Settings

To connect an AMR to the EM2100 appliance:

1.

Launch MobilePlanner on your client PC and connect to the AMR's IP address.

If this is a new AMR, its IP address will be the factory setting of 1.2.3.4 for LD-series

AMRs, and 169.254.10.15 for the HD-1500 AMR. The connection must be hard-wired,

because the AMR's wireless won't be configured yet.

2.

Open the Config tab.

31 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 32

3. Check Show Expert Parameters to show the advanced configuration parameters.

4.

From MobilePlanner, Config select Fleet and then Fleet Manager Connection.

Figure 3-5. Fleet Manager Connection Screen

5.

Check the ConnectToFleetManager checkbox.

6.

Enter the IP address of the EM2100 appliance in the

FleetManagerAddress field.

NOTE: This is the Fleet IPaddress, not the Management IP address of the

EM2100.

7.

Enter an identifier in the Identifier field. You must use unique identifiers for each AMR.

Do not change this identifier after initial setup.

Repeat these steps for each AMR that you want to add to the fleet controlled by this EM2100

Fleet Manager.

Fleet-Level Settings

From MobilePlanner, Config, on the Fleet Manager:

1.

Select Fleet and then Fleet Features.

2.

Check the FleetManagerGatherScans box.

This enables Fleet Operations Workspace Core to gather any scan files created by the

AMRs.

3.

Back up (copy) any required maps to a storage location.

4.

[OPTIONAL] Check DeleteUnusedMaps to permanently delete unnecessary map files

from each AMR.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 32

Page 33

Chapter 3: Fleet Manager Configuration and Operation

3.10 What to do if a Primary Fleet Manager Fails

This section applies only if you installed a second EM2100, autosynchronized with the

Primary Fleet Manager.

In event of failure:

1.

Using the SetNetGo interface, connect to the Management IP address for the Secondary

Fleet Manager EM2100 appliance.

2.

Click Apply (or click Reset to retain the previous values without your changes).

The AMRs automatically reconnect to the new Primary appliance.

The queue, configuration, and map data on the new Primary is identical to that of the old

Primary, prior to failure. Depending on exact network configuration, it takes between 1-3

minutes for AMRs to reconnect and resume operation.

The original (failed) Primary appliance can now be safely removed from the rack without causing disruption to the fleet. The following considerations apply:

l

The new Primary operates on the same Fleet IP as the old Primary appliance. Do not

reconnect the old Primary to the network without first reconfiguring it. Doing so might

cause a network IP conflict.

l

The failed Primary has the queue file, which is no longer current. Before putting the

failed Primary back into service, you should manually clear the queue. See Manually

Clearing (Flushing) the Entire Queue on page 200.

3.11 Remove and Replace EM2100 Appliances from Autosync

This section describes how to remove an appliance from an Autosync configuration.

Remove a Primary Fleet Manager Appliance from Autosync

You might need to remove a Primary Fleet Manager appliance from an Autosync configuration while maintaining fleet operations. For example, if the Primary appliance is generating errors that indicate a potential failure or degraded performance. This procedure

assumes that you do not make any changes to the software and data stored on the removed

appliance.

To safely remove an EM2100 Primary Fleet Manager appliance from an Autosync configuration, you must promote the Secondary appliance to the Primary role as covered in the

previous section. You can then safely remove the Primary as follows:

1.

Verify that fleet operations are normal and job processing is on schedule.

2.

Reconfigure the Primary appliance as a Secondary appliance. See: Configure the Secondary Appliance on page 30.

MobilePlanner and fleet AMRs might lose their network connection to the appliance.

3.

Reconfigure the Secondary appliance as the Primary appliance. See: EM2100 Configuration Overview on page 22.

4.

Power off the Secondary appliance.

5.

The Status tab in SetNetGo will now show that Autosync for the new Primary appliance

33 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 34

is disabled (it is now a standalone appliance).

6.

Verify that MobilePlanner can connect to the Fleet IP, that fleet AMR operations resume,

and jobs are processed as scheduled.

To restore a removed EM2100 appliance or to replace it with a new appliance, it should be put

into the role of Secondary Fleet Manager, not Master. This will cause less disruption to the

fleet.

Remove a Secondary Fleet Manager from Autosync

You might need to remove a Secondary Fleet Manager appliance from an Autosync configuration while maintaining fleet operations. For example, if the Secondary Fleet Manager

appliance is generating errors that indicate a potential failure or degraded performance. This

operation is less disruptive than removing a Primary Fleet Manager.

IMPORTANT: This procedure assumes that you do not make any changes to

the Fleet Manager configuration or to the software and data stored on the appliance.

To remove a Secondary Fleet Manager appliance from an Autosync configuration:

1.

Verify that fleet operations are normal and job processing is on schedule.

2.

Power off the Secondary Fleet Manager appliance.

If a soft shutdown doesn't work, use a hard shutdown. Refer to the EM2100 Installation

Guide for details on hard- vs. soft-shutdowns.

3.

Verify that MobilePlanner can connect to the Fleet IP, that fleet AMR operations continue, and that jobs are processed as scheduled.

To restore a removed Secondary Fleet Manager appliance:

1.

Verify that fleet operations are normal and job processing is on schedule.

2.

If you have removed any network cables, reinstall them. Configure Paired Appliances

3.

Power on the Secondary Fleet Manager appliance. (This should not affect fleet operations or Ethernet connections to MobilePlanner and AMRs.)

Both appliances now indicate that Autosync is Active.

If no changes have been made to the configuration, the Secondary appliance will come

back up as a Secondary, but the Primary will be running as a Standalone.

4. Reconfigure the Primary appliance to be paired with the Secondary. See Configure the

Primary Appliance on page 29.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 34

Page 35

Page 36

Chapter 4: Fleet Operations Workspace Core

Software

The Fleet Operations Workspace Core (FLOWCore)software has the tools and features to help

you get your AMR up and running quickly. This chapter covers the initial steps needed to

access your AMR with the PCand to begin using the Fleet Operations Workspace Core software.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 36

Page 37

Chapter 4: Fleet Operations Workspace Core Software

4.1 How Do I Begin?

Before you can start using your AMR, there are a number of initial set-up and configuration

steps you need to complete.

NOTE: It is assumed that, prior to beginning fleet programming with FLOW

Core, all AMRs and EM2100 appliances being used in the fleet have been

unpacked, installed and set-up according to their respective user guides.

Procedure Reference

Install the MobilePlanner software on your PC. Install the MobilePlanner Software on page

39

Connect your PC to the AMR via Ethernet cable. Step 1: Connect Your PCto the AMR via Eth-

ernet on page 41

Configure the AMR for wireless communication. Step 4: Configure Your AMR's Network and

Security Settings on page 47

Establish a wireless connection to the AMR. Step 5: Connect to the AMR Wirelessly on

page 48

Scan the AMR's environment. Scanning the Operating Area on page 88

Convert the scan to a map. Convert the Scan into a Map on page 89

Use MobilePlanner software to edit (erase stray

and other dynamic features from) the map.

Add docks, forbidden zones, goals, and route(s)

between goals, etc. to the map.

Save the edited map on the AMR. Saving the Map on the AMR on page 108

Localize the AMR. Set the AMR's Initial Location on page 111

Create some tasks, and have the AMR

begin performing them.

Editing a Map File on page 93

Working with Map Files on page 90

AMR Tasks on page 150

4.2 End-User License Agreement (EULA)

Users will be presented with and must agree to the End User License Agreement (EULA) in

order to access and use any of the FLOW Core software content and functionality.

Definitions

l

An End User is the person, company, or organization that actually uses the software

and OMRON Mobile Robotics equipment.

l

System Integrators are not End Users when they are installing OMRON Mobile Robotics solutions for another business.

l

System Integrators are End Users when they own and install OMRON Mobile Robotics

solutions for their own use (e.g. for test or demonstration fleets).

37 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 38

The Click-to-Accept (CTA) EULA will pop up:

l

When the FLOW Core software is installed.

l

Whenever the FLOW Core software is updated.

l

Upon first launching SetNetGo software (Out Of the Box).

l Whenever the SetNetGo software is updated.

l

Whenever a V2C (license) file is uploaded (first time, updates, and renewals).

New entitlements are not required when existing dongles are transferred from a failed

EM2100 or AMR to new EM2100 or AMR hardware. Therefore, no EULA is required in

these cases.

l

Whenever a new user-facing language is selected (in order to ensure delivery of the CTA

EULA in the appropriate language).

Once the CTA EULA Prompt is Triggered

1.

The CTA EULA pop-up will display in the language that matches the software

installed.

2.

The User must scroll through the entire End User License Agreement before the Accept

button is enabled (this button is greyed-out until then).

3.

The User must check either "End User" or "Manufacturer or System Integrator" before

the Accept button is enabled.

Accepting as "End User" will stop the CTA from re-triggering upon launching the software. All other triggers will still prompt user with the CTA pop-up.

Accepting as "Manufacturer or System Integrator" will not stop the CTA from re-triggering upon launching the software. This is to ensure that the End User gets prompted

when first launching the software "out of the box".

4.

The User can either click Accept, or abort the process.

Aborting the CTA EULA process will cancel and close out of the process that triggered

the CTA EULA pop-up (V2C Upload, Language Change, Software Update, Software

Install, First-Time/Out Of the Box Software Start Up).

In this case, the User can re-trigger the CTA EULA prompt by initiating one of the trigger processess listed above.

5.

If the software license is activated at the factory, in the Fleet Simulator bundle for

example, the CTA EULA pop-up will be displayed and a selection must be made prior

to the Simulator performing its intended functions.

The intent here is that the Fleet Simulator should be able to connect to SetNetGo and

MobilePlanner but no configuration or simulations can be run until the user clicks the

Accept button.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 38

Page 39

Chapter 4: Fleet Operations Workspace Core Software

Capturing CTA Interactions

1.

Every time the CTA EULA process is initiated and completed, the following data shall

be captured and logged:

l

What triggered the CTA EULA prompt (e.g "Software Update", "V2C Upload",

etc.)

l

Date/Time CTA EULA process was triggered

l

Date/Time CTA EULA process was completed

l

Whether CTA EULA was Accepted, or the process was aborted (either of these

will be considered as completed.

2.

Users can access a reference log file, but will not have access to or the ability to make

changes to the source data populating these logs.

NOTE: The Click-to-Accept EULA functions only apply to the FLOW Core software. There is no impact on the Legacy MSS 4.X software.

4.3 Install the MobilePlanner Software

Before setting up a wireless connection to your AMR, you will need to install MobilePlanner

on your PC. This software is the primary interface to the Fleet Manager and AMRs, and allows

programming of the AMR fleet.

System Requirements

Verify that your PC meets the following requirements before installing MobilePlanner:

l OS: Windows 7 (32-bit/64-bit), Windows 8 (32-bit/64-bit),or Windows 10 (32-bit/64-bit).

l CPU: 1.5 GHz Dual-core (min).

l RAM: 1.5 GB (min) 4 GB RAM recommended).

l GPU: 256 MB (min).

l HDD/SSD: At least 250 MB available space.

l Monitor: XGA 1024 x 768.

Installing MobilePlanner

Ensure that your PC meets the system requirements, then install (or download and install)

MobilePlanner.

NOTE: The MobilePlanner software installs into a MobilePlanner5 directory.

This different install directory allows you to use the relevant MobilePlanner version with your fleet.

Version Information: Only MobilePlanner software version 5 or higher is compatible with FLOW Core. It is not compatible with OMRON fleets running on

Mobile Software Suite version 4.X or earlier. Refer to https://automation.omron.com for release notes or contact your OMRONrepresentative for

more information.

39 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 40

1. Use one of the following methods to locate and/or install the MobilePlanner software:

a.

By USB drive: insert the software media(USB drive included with your AMR’s

documentation) into your PC, and browse to the USBdrive to locate and install

the software.

From your EM2100: Open SetNetGo > Software >Manage Installed Software

>MobilePlanner > It can be downloaded here. (Click on the "here" link in the

EM2100 user interface, shown near the bottom of the following figure.)

Figure 4-1. Manage Software Download

b.

c.

By download: Contact your OMRONrepresentative for assistance with down-

loading MobilePlanner software.

To download MobilePlanner from the internet, access www.robotics.omron.com

or contact your OMRONrepresentative.

2.

Launch the installer and, when the welcome screen appears, follow the prompts in each

installation wizard window to complete the installation.

If you used SetNetGo or downloaded the software, this will usually be in your Downloads folder. The actual location is determined by the settings in the browser that you

use.

3.

Click Finish when done.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 40

Page 41

Chapter 4: Fleet Operations Workspace Core Software

4.4 Configure the AMR’s Wireless Communications

Before you can start working with your AMR, you have to configure it for wireless communication (via WiFi) using your PC. To do this, you will first have to connect your PC to the

AMR via Ethernet cable to gain access to the AMR's wireless settings. In general, the set-up

process is as follows:

l Connect your PC to the AMR via Ethernet

l Set your PC’s IP address

l Connect to SetNetGo

l Configure the AMR’s network settings

l Establish a wireless connection to the AMR

NOTE: The setup steps above assume that the AMR is fully-charged, powered

up, and ready. If this is not the case, please refer to your AMR’s user guide for

complete setup instructions.

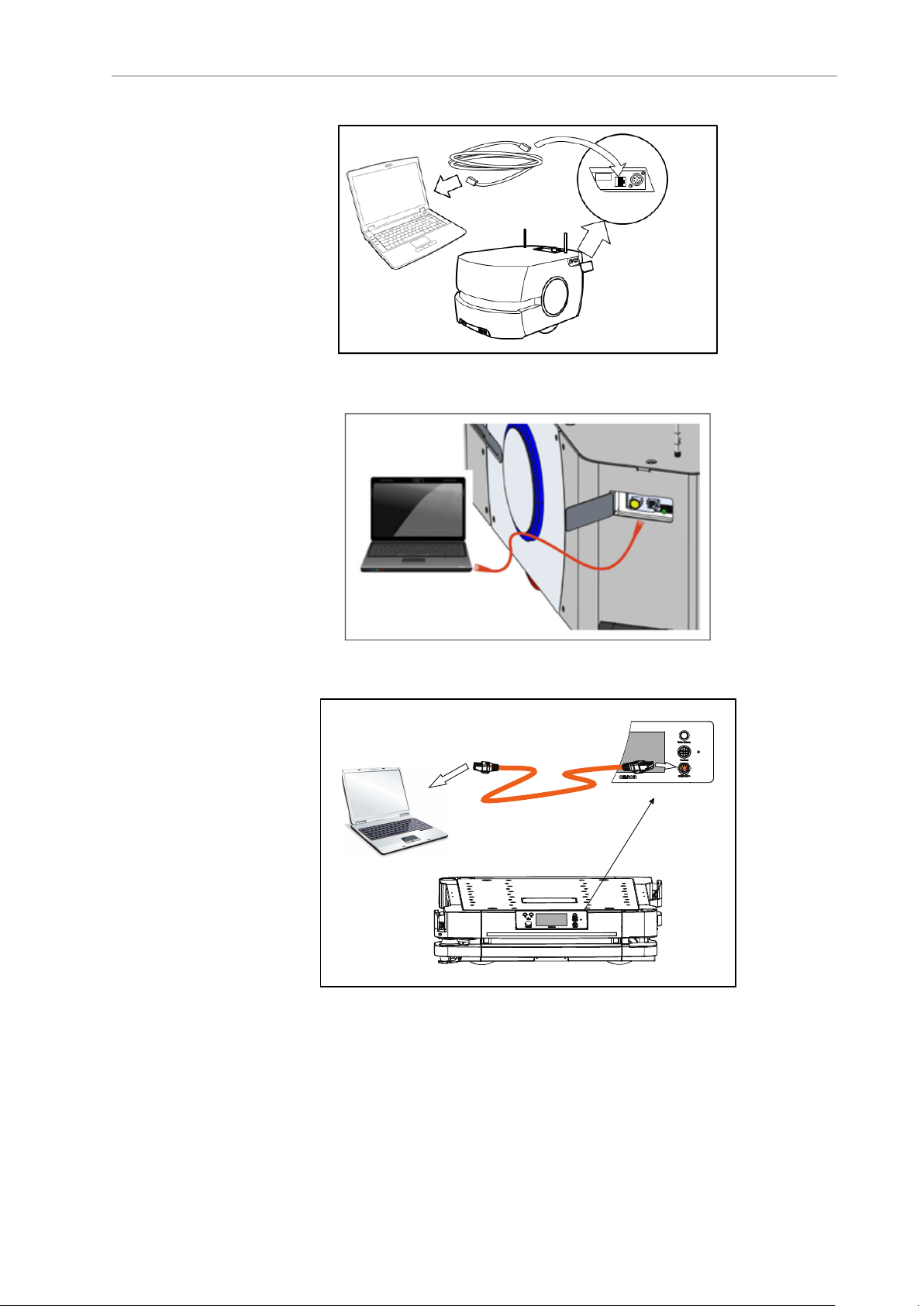

Step 1: Connect Your PCto the AMR via Ethernet

To connect your PC to the AMR:

1.

Open the AMR's maintenance access panel (left side, upper right corner), by pressing

the access panel’s upper left corner (see image below) into the side of the AMR.

Figure 4-2. Maintenance Door Location

2.

Using a standard (pass-through) or cross-over Ethernet cable, connect your PCdirectly

to the AMR's maintenance Ethernet port. Refer to the following three figures. The AMR

will auto-detect the cable type.

41 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 42

Figure 4-3. Maintenance Port Connection, LD-60 and LD-90

Pendant

Figure 4-4. Maintenance Port Connection, LD-250

Figure 4-5. Maintenance Port Connection, HD-1500

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 42

Page 43

Chapter 4: Fleet Operations Workspace Core Software

Step 2: Set the IPAddress on Your PC

In order to configure WiFi on your AMRs, the LD-series AMRs and the HD-1500 AMRs are

accessed differently. If you have a combination of the two, we suggest that you set up all of the

LD-series AMRs and all of the HD-1500 AMRs as two separate procedures.

LD-Series AMR IPAddress Setup

Manually set your PC’s Ethernet port IP address to 1.2.3.x, where x is any number 1 - 254,

except 4 (which the AMR uses), and a Subnet mask of 255.255.255.0. No special DNS or gateway settings are needed.

NOTE: The LD-series AMR's maintenance Ethernet port is always enabled and

permanently set to IP address 1.2.3.4, with a Subnet mask of 255.255.255.0, for

direct, wired access to the on-board systems.

1. Open your PC's Network Connections window.

2.

Right-click on your PC’s Local Area Connection Ethernet connection, and select Prop-

erties.

Figure 4-6. Windows Local Area Connection Properties Dialog

3.

In the Local Area Connection Properties dialog box, click on the TCP/IP protocol your

network uses (for example, Internet Protocol Version 4 (TCP/IPv4)), then click Prop-

erties.

43 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 44

Figure 4-7. Windows Internet Protocol Properties Dialog

4. In the TCP/IP properties dialog box, click the Use the following IPaddress: radio button

and enter an appropriate IPaddress (for example, 1.2.3.5) and Subnet mask

255.255.255.0.

5. Click OK.

6. Close the Network Connections window.

HD-1500 AMR IPAddress Setup

To enable DHCP or change other TCP/IP settings (Windows 10)

1.

Select Start, then select Settings > Network & Internet.

2.

Do one of the following:

l

For a Wi-Fi network, select Wi-Fi > Manage known networks. Choose the net-

work you want to change the settings for, then select Properties.

l

For an Ethernet network, select Ethernet, then select the Ethernet network you’re

connected to.

3.

Under IP assignment, select Edit.

4.

Under Edit IP settings, select Automatic (DHCP) or Manual.

To specify IPv4 settings manually (IPv6 is not supported)

a.

Under Edit IP settings, choose Manual, then turn on either IPv4.

b.

To specify an IP address, in the IP address, Subnet prefix length, and Gateway

boxes, type the IP address settings.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 44

Page 45

Chapter 4: Fleet Operations Workspace Core Software

c.

To specify a DNS server address, in the Preferred DNS and Alternate DNS

boxes, type the addresses of the primary and secondary DNS servers.

l

When you select Automatic (DHCP), the IP address settings and DNS server

address setting are set automatically by your router or other access point (recommended).

l

When you select Manual, you can manually set your IP address settings and

DNS server address.

5.

When you’re done, select Save.

Step 3: Access SetNetGo Software

The SetNetGo software lets you manage a variety of settings related to the AMR's connectivity.

You can access SetNetGo from MobilePlanner (most common), or a secure web browser (for

example, Chrome, Firefox, or Internet Explorer).

To Access SetNetGo from MobilePlanner

NOTE: Only start the following procedures if your computer is connected to the

AMR via Ethernet cable.

1.

Open the MobilePlanner software.

2.

For an LD-series AMR, enter 1.2.3.4 into the AMR address field, then click Connect.

For an HD-1500 AMR, enter 169.254.10.15 into the AMR address field, then click Con-

nect.

3.

Click the SetNetGo button (the large part of that icon, not the checkbox).

4.

Click the SetNetGo tab.

To Access SetNetGo via Web Browser

1. Start a web browser on your computer.

2.

Enter the URL https://1.2.3.4 in the address bar of the web browser.

This is the AMR’s maintenance Ethernet address. When accessing the software from a

wired maintenance Ethernet port, you do not need a username or password.

Figure 4-8. Browser Address Field

NOTE: You can ignore the certificate error that appears on the SetNetGo webpage; the error appears because the hardware is not attached to the Internet.

45 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 46

The SetNetGo startup screen is shown the following figure.

Figure 4-9. SetNetGo Interface

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 46

Page 47

Chapter 4: Fleet Operations Workspace Core Software

Step 4: Configure Your AMR's Network and Security Settings

To access your AMR remotely, you should set up a static IP address for each AMR. The

SetNetGo interface allows you to configure your hardware’s Ethernet settings, configure serial

and TCP forwarding, and upgrade the on-board software. If you are not familiar with setting

up a network or do not have an assigned IPaddress for the AMR, please see your system

administrator.

IMPORTANT: If you change any values in a SetNetGo screen, you must click

Apply before switching to another sub-screen, or those values will not be saved.

For example, when changing wireless Ethernet settings, be sure to click Apply

before navigating back to the dashboard.

To configure network settings, click the Network tab at the top of the SetNetGo screen.

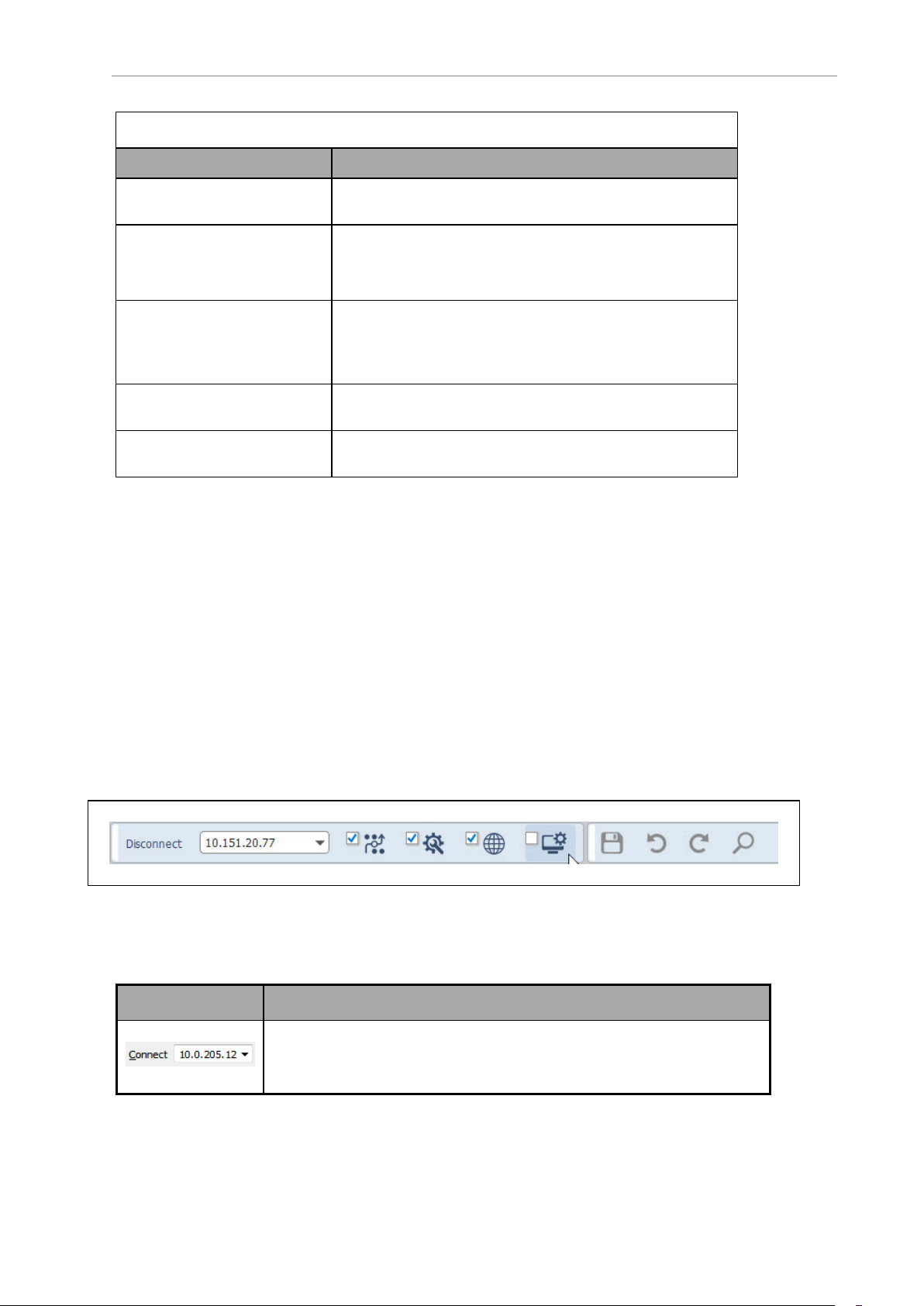

Figure 4-10. SetNetGo Interface

Network

Menu

Wireless

Ethernet

User LAN

Ethernet

RS-232 Port

Forwarding

Sets up your wireless Ethernet connection to your AMR, including

IPsettings, WiFi network settings, security settings, and radio settings.

This screen has user-configurable settings for interface mode, IP

address, netmask, DHCP server for accessories, and DHCP IP range.

Controls forwarding of serial data to a TCP port on the wireless and

internal wired Ethernet networks, where the data is re-directed to a

TCP port on an IP address accessible via the Wired Ethernet interface

(which must be set to accessory mode). There is also port-forwarding

for the two extra on-board serial ports to a TCP port on the wireless Ethernet interface.

Description

47 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 48

Network

Menu

Description

Ethernet

Forwarding

Utilities

Set the Username and Password to secure access to the AMR

Use the settings on this screen to control TCP port forwarding from

your User LAN Ethernet interface to the wireless Ethernet interface.

Use this screen to ping an IP address for testing and diagnostic purposes.

You must add one or more users, and assign usernames and passwords. Click the Security

tab, then click the Enabled radio button and populate the username/password fields (see Setting Up User Accounts on page 132).

Step 5: Connect to the AMR Wirelessly

Now that you have installed the Fleet Operations Workspace Core and configured the AMR for

wireless communications, connect to your AMR.

1.

(If not already running) double-click the MobilePlanner icon on your PCdesktop.

Figure 4-11. MobilePlanner Desktop Icon

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 48

Page 49

Chapter 4: Fleet Operations Workspace Core Software

Figure 4-12. MobilePlanner Interface

NOTE: If running MobilePlanner from an Operator account, the interface

will look slightly different than above.

By default, the Fleet, Config, and Map buttons have checkmarks indicating those features will automatically load when you connect to the AMR.

2.

In the Connect field, enter the IPaddress of the AMR, then click Connect.

3.

Enter User Name and Password in the User Name and Password dialog box, then click

OK.

NOTE: If the SetNetGo button is checked, this User Name and Password

dialog appears.

A login dialog appears in which you must enter a user name, password, and AMR

server IPaddress.

NOTE: After connecting to the AMR the first time, MobilePlanner remembers your user name. When connecting to the AMR again, you can select

your user name from a combo box instead of having to re-enter, but you

must still enter your password.

MobilePlanner completes its connection to the AMR. At this point, there is no map to load, so

MobilePlanner opens with a blank map window.

49 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 50

Chapter 5: Using MobilePlanner Software

The MobilePlanner software is the "control center" of the Fleet Operations Workspace Core. Its

user interface has the tools for all major AMR activities, such as observing a fleet of AMRs,

commanding individual AMRs to drive, creating and editing map files, goals, and tasks, modifying AMR configurations, and more.

The following topics provide details on understanding and using the MobilePlanner features.

5.1 Overview of MobilePlanner

MobilePlanner has features you can use to scan the AMR environment, configure the AMR,

create and edit maps, and more. The interface is designed to be user-friendly and efficient,

which reduces the learning curve and the time needed for deployment.

The MobilePlanner interface supports the following languages:

l English l Italian

l French l Korean

l German l Simplified Chinese

l Japanese l Traditional Chinese

l Spanish

Table 5-1. MobilePlanner User Interface (with Map)

NOTE: While MobilePlanner is not necessary for each AMR, you must have at

least one copy of MobilePlanner to create a map.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 50

Page 51

Chapter 5: Using MobilePlanner Software

From the MobilePlanner interface, you can:

l

Connect to and drive the AMR.

l

Create maps of the environment by importing and analyzing an AMR’s scan data.

l

Edit maps by adding goals (and adding tasks to those goals), docks, forbidden areas,

and more. You can also erase stray or unwanted artifacts, combine pieces of maps, and

make other changes.

l

Download and upload files, including maps and scan data, to and from an AMR.

l

Set the system configuration parameters for the fleet.

l

With the Fleet Manager, monitor the location and status of all AMRs in a fleet.

l

View and interact with the job queuing manager.

These features allow you to create a map with goals, docks, and advanced lines and areas,

and to start the AMR working in its environment.

5.2 MobilePlanner Interface

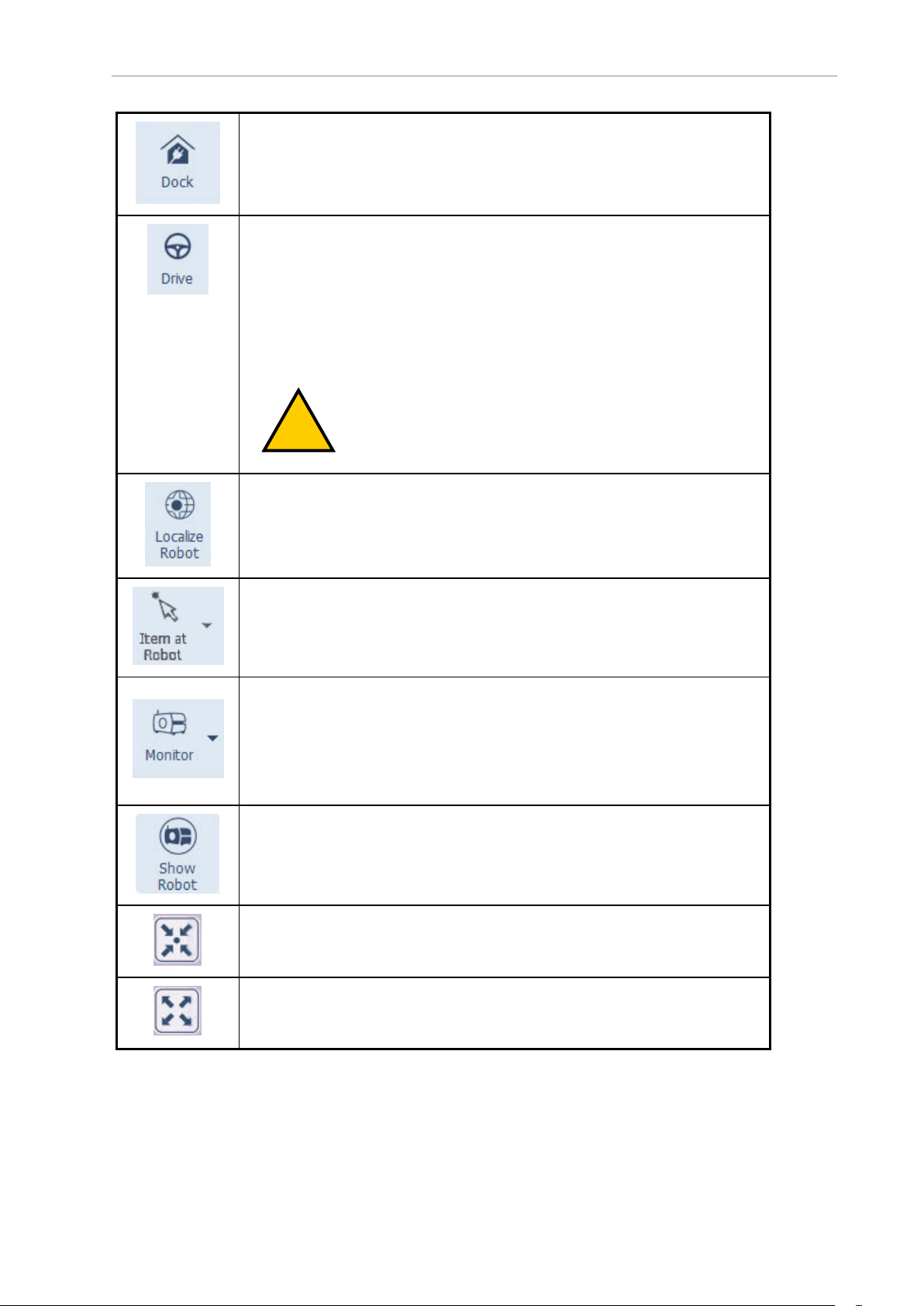

The MobilePlanner interface consists of the following main sections:

l Toolbar: Provides quick access to connection, mode buttons (Fleet, Config, Map,

SetNetGo), file save, and undo/redo functions. Some of these items are also available

from the File and Edit menus.

l Fleet button

l Config button

l Map button

l SetNetGo button

NOTE: By default, the Fleet, Config, and Map buttons are checked, and

will open each when you launch MobilePlanner and connect to an AMR.

The following figure is an example of the MobilePlanner interface showing a map of a single

AMR, containing routes and goals. Show Robot is on, in the figure.

51 Fleet Operations Workspace Core User's Manual 20569-020 Rev. D

Page 52

1

2

6

5

4

3

Figure 5-1. Sample MobilePlanner Interface

Table 5-2. MobilePlanner Interface Description

Item Description

1 Main Menu

2 Toolbars

3 Mode Tabs

4 Function Tabs

5 Map Window

6 Tray

Configuration (Config) Tab

There are five tabs under the Config tab: Robot Interface, Robot Operation, Robot Physical,

Fleet, and Debug. The many configuration parameters are covered in Configuring the AMR on

page 140.

Map Tab

l

When the map tab is selected, the main window displays a map of the AMR's operating space. The map consists of points and lines representing the walls, doors and

other stationary features within the environment. For more details, see The MobilePlanner Map Window on page 70.

20569-020 Rev. D Fleet Operations Workspace Core User's Manual 52

Page 53

Chapter 5: Using MobilePlanner Software

l

The Draw and Build Tabs, to the left of the map, provide map editing tools, and tools

for setting the AMR up to do tasks at goals (route building).

l

Robot tools are visible below the map when Show Robot is toggled on. You can use

these tools to drive, dock, adjust speed, etc. These items are also available from the

Robot menu.

l

To the right of the Robot tools is the Monitor icon. For details, see Using Monitor on

page 68.

l

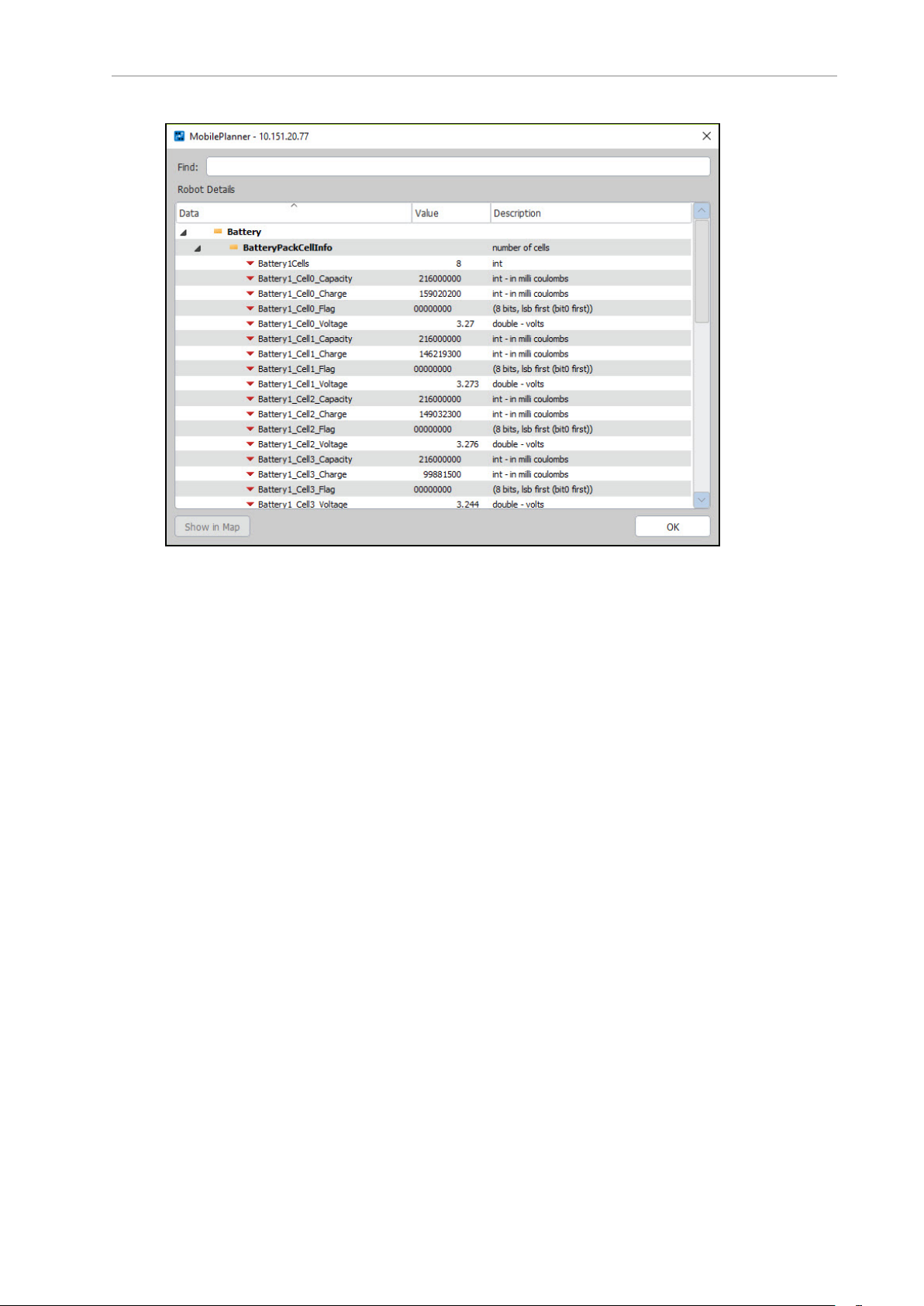

The Status area, located below the map, (shown with Show Robot button toggled on)

provides information on the AMR position, temperature, odometer, and battery charge.