Page 1

PC Vision System 形FJシリーズ

形FJ-300□/形FJ-305□/形FJ-H300□/形FJ-H305□

形FJ-300□-10/形FJ-305□-10/形FJ-H300□-10/形FJ-H305□-10

取扱説明書(セットアップ)

このたびは、形FJシリーズをお買い上げいただきましてありがとうございます。

本書は、形FJ-300□/形FJ-305□/形FJ-H300□/形FJ-H305□/

形FJ-300□-10/形FJ-305□-10/形FJ-H300□-10/形FJ-H305□-10の取扱説明書です。

ご使用に際して、下記のことを守ってください。

・ 電気の知識を有する専門家が扱ってください。

・ 本書をよくお読みになり、十分にご理解のうえ、正しくご使用ください。

・ 本書はいつでも参照できるよう大切に保管してください。

※形式の□の意味は下記のとおりです。

0:NPN入出力タイプ 5:PNP入出力タイプ

OMRON Corporation2011AllRightsReserved.

©

Page 2

オムロン商品ご購入のお客さまへ

ご注文 ・ ご使用に際してのご承諾事項

当社制御機器商品をご注文いただく際、見積書、契約書、仕様書などに特記事項のない場合には、次の保証内容、責任の制限、適合用

途の条件などを適用いたします。

下記内容をご確認いただき、ご承諾のうえご注文およびご使用ください。

1.保証内容

①保証期間

本製品の保証期間は、ご購入後またはご指定の場所に納入後1年といたします。

②保証範囲

上記保証期間中に当社側の責により本製品に故障を生じた場合は、代替品の提供または故障品の修理対応を、

製品の購入場所において無償で実施いたします。

ただし、故障の原因が次に該当する場合は、この保証の対象範囲から除外いたします。

a)カタログまたは取扱説明書などに記載されている以外の条件・環境・取扱いならびにご使用による場合

b)本製品以外の原因の場合

c)当社以外による改造または修理による場合

d)本製品本来の使い方以外の使用による場合

e)当社出荷当時の科学・技術の水準では予見できなかった場合

f)その他、天災、災害など当社側の責ではない原因による場合

なお、ここでの保証は、本製品単体の保証を意味するもので、本製品の故障により誘発される損害は保証の対象

から除かれるものとします。

2.責任の制限

①本製品に起因して生じた特別損害、間接損害、または消極損害に関しては、当社はいかなる場合も責任を負いません。

②プログラミング可能な本製品については当社以外の者が行ったプログラム、またはそれにより生じた結果について当社は責任を負

いません。

3.適合用途の条件

①安全を確保する目的で直接的または間接的に人体を検出する用途に、本製品を使用しないでください。 同用途には、当社センサカ

タログに掲載している安全センサをご使用ください。

②本製品を他の商品と組み合わせて使用される場合、お客様が適合すべき規格 ・ 法規または規制をご確認ください。 また、お客様が

使用されるシステム、機械、装置への本製品の適合性は、お客様自身でご確認ください。 これらを実施されない場合は、当社は本製

品の適合性について責任を負いません。

③下記用途に使用される場合、当社営業担当者までご相談のうえ仕様書などによりご確認いただくとともに、定格 ・ 性能に対し余裕を

持った使い方や、万一故障があっても危険を最小にする安全回路などの安全対策を講じてください。

a)屋外の用途、潜在的な化学的汚染あるいは電気的妨害を被る用途またはカタログ ・ 取扱説明書などに記載のない条件や環境で

の使用

b)原子力制御設備、焼却設備、鉄道 ・ 航空 ・ 車両設備、医用機械、娯楽機械、安全装置、および行政機関や個別業界の規制に従う

設備

c)人命や財産に危険が及びうるシステム ・ 機械 ・ 装置

d)ガス、水道、電気の供給システムや24時間連続運転システムなど高い信頼性が必要な設備

e)その他、上記a) ~d)に準ずる、高度な安全性が必要とされる用途

④お客様が本製品を人命や財産に重大な危険を及ぼすような用途に使用される場合には、システム全体として危険を知らせたり、冗

長設計により必要な安全性を確保できるよう設計されていること、および本製品が全体の中で意図した用途に対して適切に配電 ・

設置されていることを必ず事前に確認してください。

⑤カタログなどに記載されているアプリケーション事例は参考用ですので、ご採用に際しては機器 ・ 装置の機能や安全性をご確認のう

え、ご使用ください。

⑥本製品が正しく使用されずお客様または第三者に不測の損害が生じることがないよう使用上の禁止事項および注意事項をすべて

ご理解のうえ守ってください。

4.仕様の変更

カタログ ・ 取扱説明書などに記載の商品の仕様および付属品は改善またはその他の事由により、必要に応じて、

変更する場合があります。 当社営業担当者までご相談のうえ本製品の実際の仕様をご確認ください。

5.適用範囲

以上の内容は、日本国内での取引および使用を前提としております。

日本国外での取引および使用に関しては、当社営業担当者までご相談ください。

1

Page 3

安全上のご注意

●安全に使用していただくための表示と意味について

この取扱説明書では、形FJシリーズコントローラ(以下コントローラと呼びます)を安全にご使用いただくために、注意事項を次のような表示と記

号で示しています。ここで示した注意事項は安全に関する重大な内容を記載しています。必ず守ってください。表示と記号は次のとおりです。

警告

注意

●図記号の意味

禁止

一般的な禁止を示します。

破裂注意

特定の条件において、破裂する可能性を示します。

高温注意

特定の条件において、高温による傷害が起こる可能性を示します。

●警告表示

正しい取扱いをしなければ、この危険のために、軽傷 ・ 中程度の傷害を負ったり、万一の場合には重症や死亡

にいたる恐れがあります。 また、同様に重大な物的損害を受ける恐れがあります。

正しい取扱いをしなければ、この危険のために、時に軽傷 ・ 中程度の傷害を負ったり、あるいは物的損害を受

ける恐れがあります。

感電注意

特定の条件において、感電する可能性を示します。

レーザ光線

レーザ光線による危害が生じる可能性を示します。

警告

本製品は必ず取扱説明書に従った方法でご使用ください。 指定された方法でご使用されない場合は、本製品の機能 ・ 性

能が損なわれる可能性があります。

安全を確保する目的で直接的または間接的に人体を検出する用途に本製品は使用できません。

人体保護用の検出装置として本製品を使用しないでください。

高電圧のため感電の恐れがあります。 ケースを開けないでください。

リチウムバッテリを内蔵しており、発火、破裂、燃焼により重度の傷害がまれに起こるおそれがあります。 廃棄時は産業廃

棄物として処理し、本体の分解、加圧変形、 100℃以上の加熱、焼却などは絶対にしないでください。

本製品は可視光を放射しており、まれに目に悪影響を及ぼす恐れがあります。 LEDの照射光を直視しないでください。

被写体が鏡面反射体の場合は、反射光が目に入らないようにしてください。

注意

万一の場合、軽い火傷の恐れがあります。

LEDが点灯中や電源を切った直後は、ケースが大変熱くなっており、ケースに触れないでください。

安全上の要点

●設置環境について

・ 引火性、爆発性ガスの環境では使用しないでください。

・ 通風口をふさがないように本体を設置してください。

・ 操作、保守の安全性を確保するため、高圧機器や動力機器から離して設置してください。

・ 取付けにおいて、ねじの締め付けは確実に行ってください。

●電源、配線について

・ 本書で指定した電源電圧で使用してください。

・ ケーブル、圧着端子は、指定サイズのものを使用してください。 撚り合わせただけの電線を直接端子台に接続しないでください。

-推奨電線サイズ:1.31 ~ 2.63mm

-端子ねじ : M4

・ 電源線の長さができるだけ短くなるように(最大10mまで)配線してください。

・ 電源は、高電圧が発生しないように対策(安全超低電圧回路)されている直流電源装置から供給してください。

・ D種接地 (接地抵抗100Ω以下) をしてください。

・ 接地点はできるだけ近くし、接地線の長さをできるだけ短くしてください。

・ 接地線はコントローラ単独で配線してください。 他の機器と共用したり、建物の梁に接続すると、悪影響を受けることがあります。

・ 電源投入前に再度配線を確認してください。

●その他

・ 専用のカメラ、ケーブル以外を使用しないでください。 誤動作、破損の恐れがあります。

・ カメラやケーブル類を着脱するときは、必ずコントローラの電源を切ってください。

・ この製品を分解したり、修理、改造しないでください。

・ 万一、異常を感じたときには、すぐに使用を中止し、電源を切った上で当社支店 ・ 営業所までご相談ください。

・ 通電中や電源を切った直後は、蛍光灯、ハロゲンランプに触らないでください。

・ 廃棄するときは、産業廃棄物として処理してください。

●法規と規格

本コントローラは、以下の規格に準拠しています。

EN規格(ヨーロッパ規格) EN61326-1

Electromagneticenvironment:Industrialelectromagneticenvironment

(EN/IEC61326-1Table2)

また本製品は、イミュニティ試験において、以下の条件を適用しています。

: モニタ表示において、文字が判読可能な映像の乱れは合格とする。

2

-圧着端子

8.5mm以下

8.5mm以下

2

Page 4

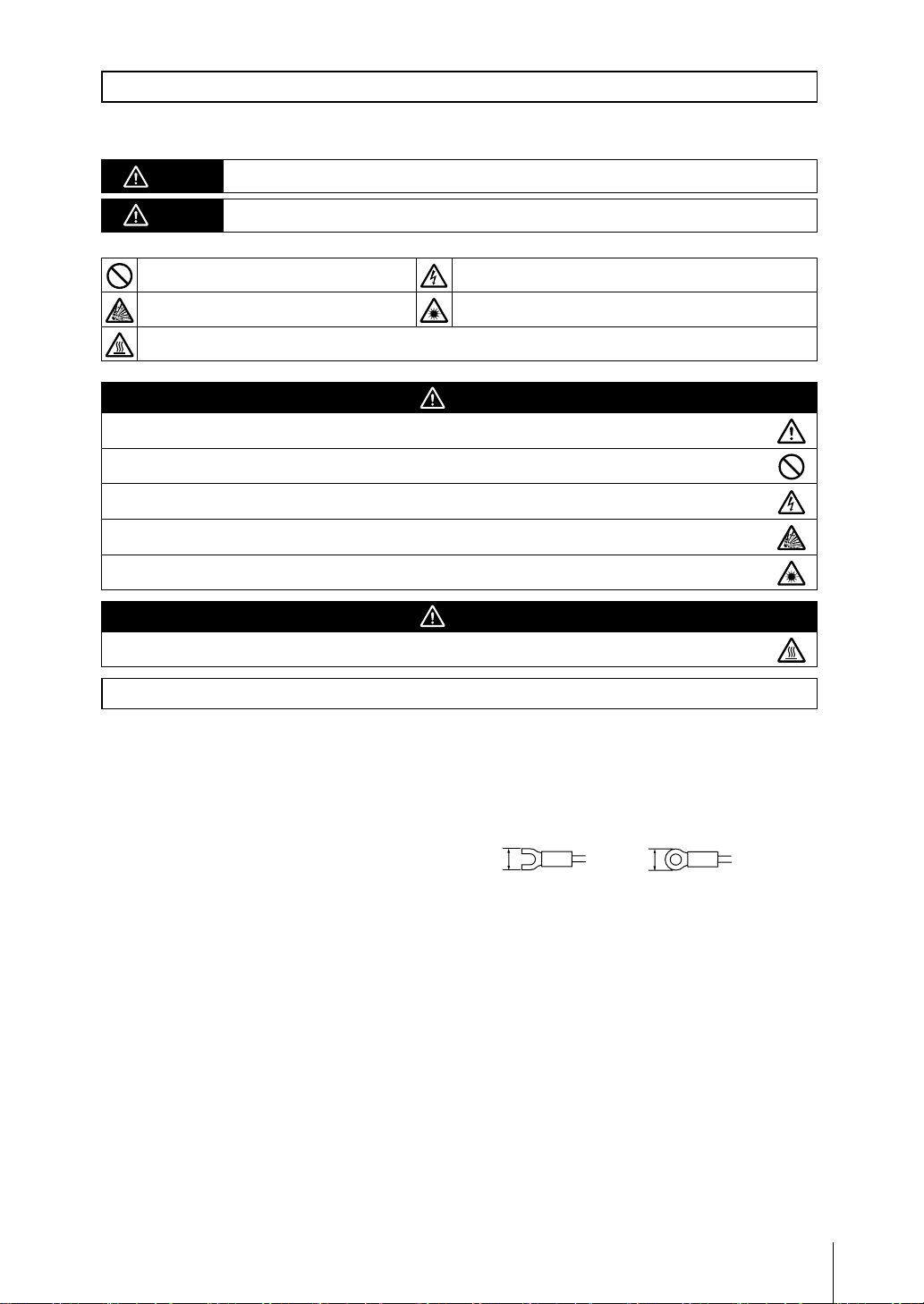

●接地について

・コントローラの電源回路は内部回路と絶縁されていません。

・24VDC電源のプラス(+)端子を接地する場合は、コントローラのFG端子、 PLCのFG端子を接地しないでください。 【①、②】

パソコンの外郭とSG(0V)がパソコン内部で接続されていますので、下図のような経路で電流が流れ焼損の原因になります。

・パソコンのようなSG(0V)とFGが短絡する経路が無い場合には、コントローラのFG端子を接地しても問題ありません。 PLCについては、ご

使用のPLCの仕様をご確認の上、配線してください。

・コントローラに接続するカメラは、必ず台座を使用して取り付けてください。 【③】

カメラ本体の外郭はSG(0V)ですので、台座が無い場合には、 SG(0V)とFGが短絡する恐れがあります。

・プラス(+)端子を接地する場合は、 SG(0V)(例 : カメラ本体、電源端子)を指等で触れないでください。 感電の恐れがあります。

・BOXタイプのコントローラ(形FJ-305□/形FJ-305□-10/形FJ-H305□/形FJ-H305□-10)を底面で取り付ける場合、底面がSG(0V)に接

続されていますので、お客様装置のFGと短絡します。 絶縁スペーサを用意しておりますので、弊社営業担当にお問い合わせください。

カメラケーブル

SG(0V)

SG SG

SG

SG

RS-232C

FG FG

RS-232C

電源

コントローラ

24V

0V

SG

FG

1

電源回路

FG

SG: Signal Ground

FG: Frame Ground

SG(0V)

パラレルI/O

コネクタ外郭

RS-232C

コネクタ外郭

使用上の注意

●設置場所、保管場所について

次のような場所に設置、保管してください。

・ 周囲温度が0~+50℃(保管時-20~+65℃)の場所 ・ 塵埃、塩分、鉄粉のない場所

・ 温度が急激に変化しない場所 (結露しない場所) ・ 振動や衝撃のない場所

・ 相対湿度が35~85%RHの場所 ・ 直射日光があたらない場所

・ 腐食性ガス、可燃性ガスのない場所 ・ 水 ・ 油 ・ 化学薬品の飛沫がない場所

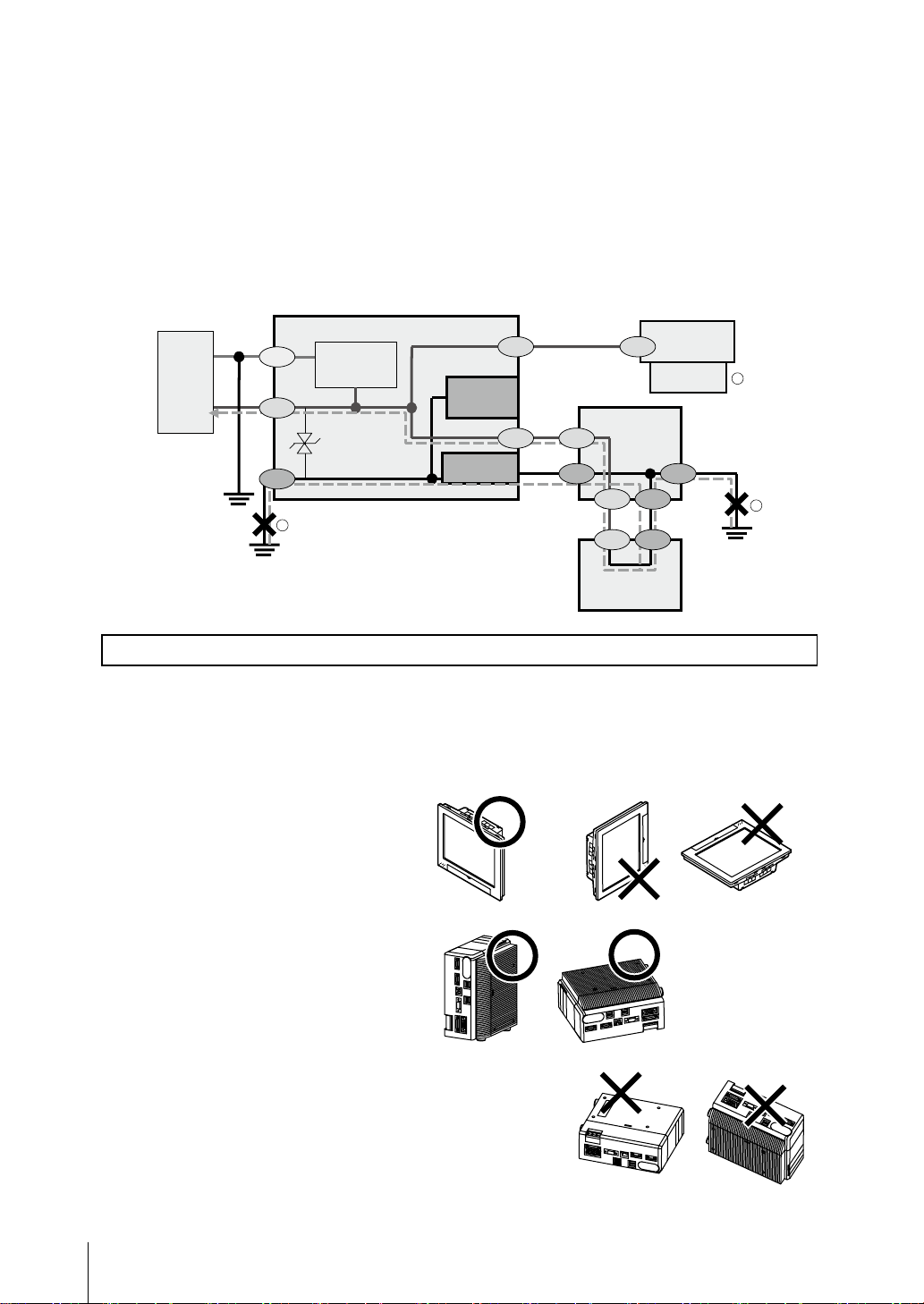

●設置方向

放熱を良くするため、

右記の方向のみで設置してください。

●周囲温度

・通風を良くするため、コントローラの上下は

他の機器と50mm以上の間隔をあけてください。

左右は、他の機器またはコントローラと10mm以上

隙間をあけて設置してください。 ただし、上下左右に

隣接するものが発熱体でない場合、上部は同じく

50mm以上、下部および左右は取付け方法に従って

設置してください。

・ヒータ、トランスや大容量の抵抗など、発熱量の

高い機器の真上には取付けないでください。

・使用周囲温度は50℃以下にしてください。

・使用周囲温度が50℃に近い場合は、強制ファン

やクーラーを設置して、常時50℃を超えないようにして

ください。

●液晶一体タイプ

●BOXタイプ

カメラ

取付台座

(絶縁)

3

PLC

SG

FG

SG FG

外郭

パソコン

このような方向で設置しないでください

通風経路を確保するため、

側面(下になる面)に

脚を取付けてください。

このような方向で設置しないでください

2

3

Page 5

●耐ノイズ性

・高圧機器の設置されている盤内には取付けないでください。

・動力線からは、 200mm以上離してください。

●構成品の設置や取扱いについて

・信号線に触れる

端子部分やコネクタ内部の信号線に触れる場合は、静電気による破損を防ぐため、リストストラップなどを使用して帯電防止措置を行って

ください。

・USBメモリの取扱い

USBメモリを取外す場合は、データの読み/書き中でないことを確認して取外してください。 データの読み/書き中はUSBメモリ本体のLED

が点滅しますので、点灯状態になったことを確認して取外してください。

・電源を切る

処理を実行中であることを示すメッセージが画面に表示されているときは、電源をOFFしないでください。 メモリ上のデータが破損し、次に

起動したとき正常に動作しません。

・RESET信号について

電源ON直後にRESET入力をしないでください。 起動タイミングを同期させるためなどにRESET入力を使用する場合は、コントローラの電

源をONした後、 15秒以上おいてからRESET信号をONしてください。

・液晶一体タイプ (形FJ-300□/形FJ-300□-10/形FJ-H300□/形FJ-H300□-10)に使用している液晶ディスプレイは精密な技術で作ら

れておりますが、ごくわずかに画素欠陥がある場合があります。 これは液晶パネルの構造によるもので故障ではありません。

●メンテナンスについて

・お手入れをするときは、電源を切って、安全を確認してから行ってください。

・レンズの汚れは、レンズ専用の布、またはエアブラシを使用して取除いてください。

・装置の汚れは柔らかい布で軽く拭き取ってください。

・CCDの汚れは、エアブラシを使用して取除いてください。

・シンナー、ベンジンは使用しないてください。

●上位機器との通信について

本製品の起動を確認後、上位機器との通信を行ってください。

また、本製品の起動時は上位インターフェースから不定な信号が出る可能性がありますので、初期動作時はご使用機器の受信バッファを

クリアするなどの処置を実施してください。

■パッケージ内容の確認

・コントローラ......................................................1台

・取扱説明書(本書).......................................1冊

・SYSMAC会員 登録のご案内.................1枚

・取付金具(パネルマウント用)..................6個 ※液晶一体タイプのみ付属しています。

・タッチペン.........................................................1本 ※液晶一体タイプのみ、コントローラ内部に収納されています。

■米国カリフォルニア州過塩素酸塩規制について

この製品はカリフォルニア州法で規制されている過塩素酸塩を含むリチウムバッテリーを内蔵しておりますので、この州法への対応をして

ください。

詳しくは、下記URLをご覧ください。

www.dtsc.ca.gov/hazardouswaste/perchlorate

4

Page 6

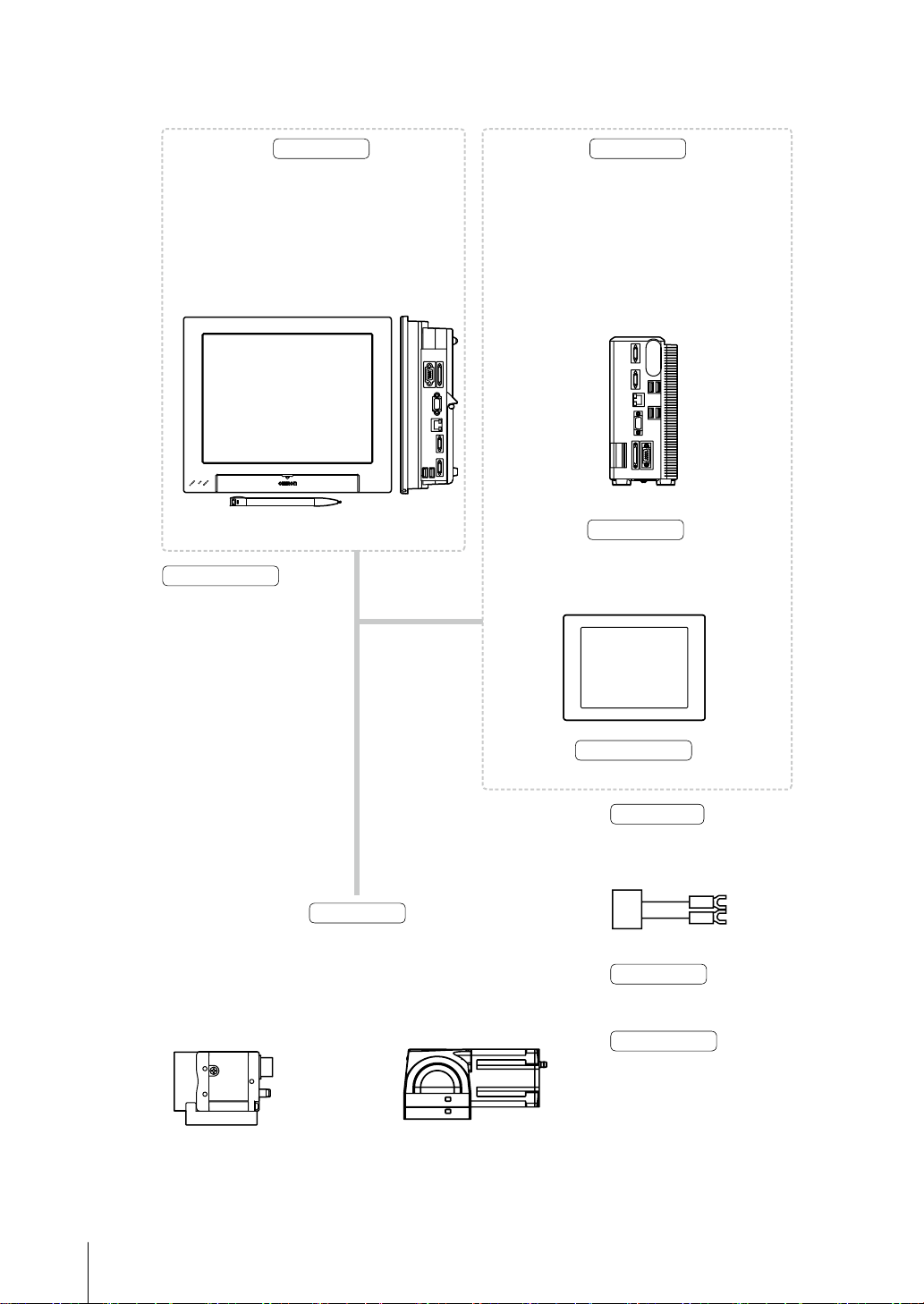

■基本構成 カメラ2chタイプ

*印は専用品です。 これら以外は使用できません。

*

コントローラ

画像の確認や条件設定用メニューを表示するために使用

します。 また、設定条件に従った画像処理を行い、計測結

果を出力する部分です。

液晶一体タイプ

形FJ-3000/形FJ-3005

形FJ-H3000/形FJ-H3005

正面 右側面

*

コントローラ

設定条件に従った画像処理を行い、

計測結果を出力する部分です。

BOXタイプ

形FJ-3050/形FJ-3055

形FJ-H3050/形FJ-H3055

タッチペン(付属品)

*

カメラケーブル

カメラケーブル

カメラケーブル

形FZ-VS(2m、5m、10m)

形FZ-VS3(2m、3m、5m、10m)

耐屈曲カメラケーブル

耐屈曲カメラケーブル

形FZ-VSB(2m、5m、10m)

形FZ-VSB3(2m、3m、5m、10m)

ライトアングルカメラケーブル

ライトアングルカメラケーブル

形FZ-VSL(2m、5m、10m)

形FZ-VSL3(2m、3m、5m、10m)

長距離カメラケーブル

耐屈曲ライトアングルカメラケーブル

形FZ-VS2(15m)

形FZ-VSLB3(2m、3m、5m、10m)

長距離ライトアングルカメラケーブル

形FZ-VSL2(15m)

長距離カメラケーブル

形FZ-VS4(15m)

長距離ライトアングルカメラケーブル

形FZ-VSL4(15m)

インテリジェントカメラ

形FZ-SLC15/形FZ-SLC100

*

計測物を画像として取込む部分です。

単体カメラ

形FZ-SC/形FZ-S/形FZ-SC2M

形FZ-S2M

形FZ-SC5M2/形FZ-S5M2

形FZ-SFC/形FZ-SF/形FZ-SPC

形FZ-SP/形FZ-SHC/形FZ-SH

カメラ

画像の確認や条件設定用メニュー

を表示するために使用します。

*

オートフォーカスカメラ

形FZ-SZC15/形FZ-SZC100

インテリジェントコンパクトカメラ

形FZ-SQ010F/形FZ-SQ050F

形FZ-SQ100F/形FZ-SQ100N

*

液晶モニタ

形FZ-M08(8.4インチ)

モニタケーブル

形FZ-VM(2m、5m)

電源装置

推奨品

オムロン(株)製

形S8VS-12024

周辺機器

*USBメモリ

形FZ-MEM2G/FZ-MEM8G

入力デバイス

マウス、トラックボール

(USBインタフェースの市販品)

5

Page 7

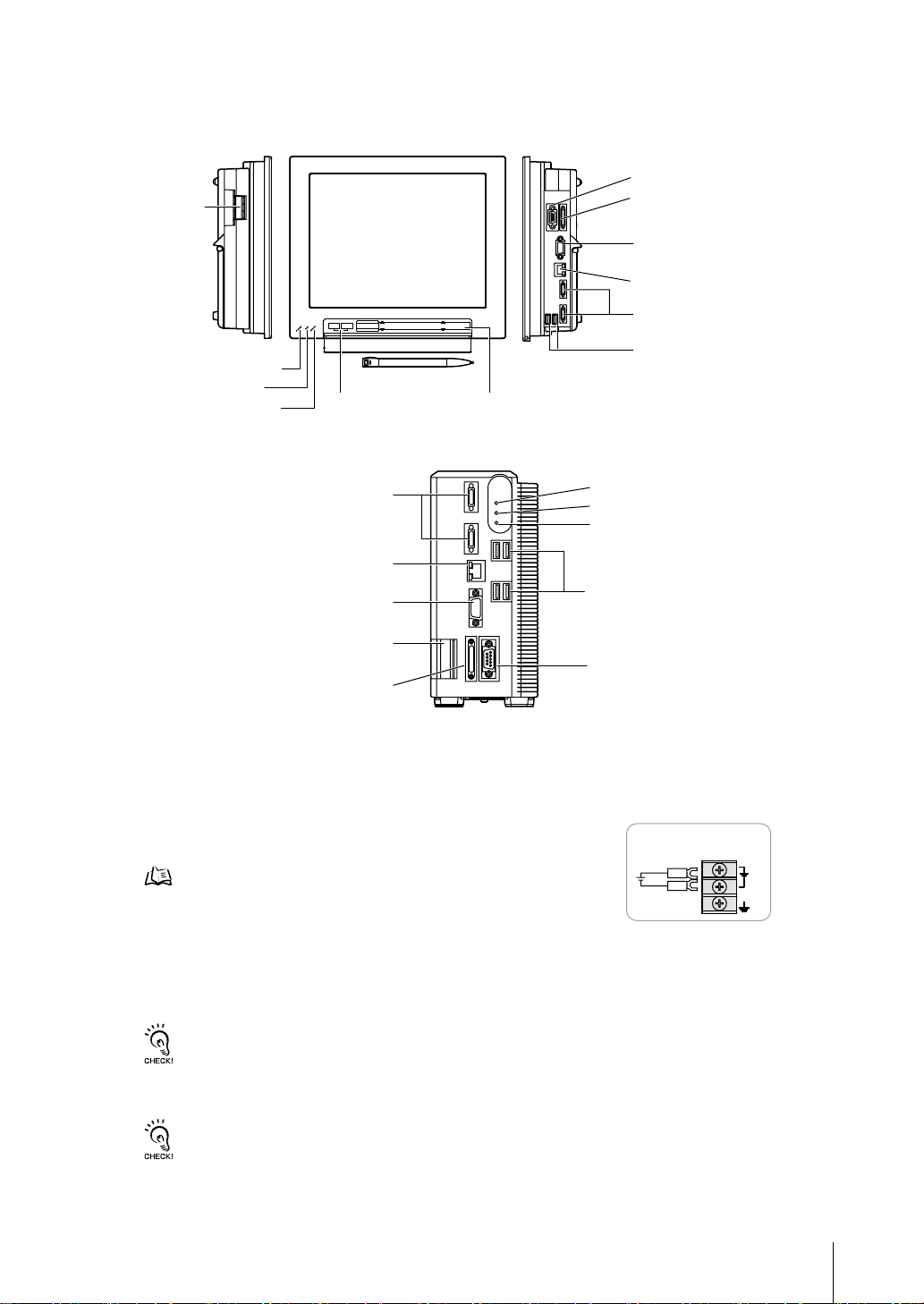

■各部の名称とはたらき

●液晶一体タイプ 形FJ-3000/形FJ-3005/形FJ-H3000/形FJ-H3005

左側面 正面 右側面

⑥⑦

電源・

接地端子

①

POWER LED

②

RUN LED

③

ERROR LED

●BOXタイプ 形FJ-3050/形FJ-3055/形FJ-H3050/形FJ-H3055

⑪

イーサネット接続コネクタ

⑧

モニタ接続コネクタ(アナログRGB)

⑩

⑤

カメラコネクタ

USBコネクタ

⑫

タッチペン (収納)

⑨

RS-232C/422接続コネクタ

④

入出力コネクタ

⑧

モニタ接続コネクタ

⑪

イーサネット接続コネクタ

⑤

カメラコネクタ

⑩

USBコネクタ

①

POWER LED

②

RUN LED

③

ERROR LED

⑩

USBコネクタ

(制御線、データ線)

(アナログRGB)

⑥⑦

電源・接地端子

⑨

④

入出力コネクタ(制御線、データ線)

①

通電中、点灯します。

②

表示中のレイアウトにしたがって点灯/消灯します。

③

異常が発生したときに点灯します。

④

同期センサ、プログラマブルコントローラなどの外部装置と接続します。

⑤

カメラを接続します。

⑥

DC電源を接続します。他の機器とは独立して配線してください。配線後は、

端子カバー(透明)を元の場所に取付けてください。

電源、配線についてp.2

⑦

接地線を配線します。 必ずコントローラ単独で配線してください。

⑧

モニタを接続します。

⑨

パソコン、プログラマブルコントローラなどの外部装置と接続します。

⑩

トラックボール、マウス、 USBメモリと接続します。 計4ポートありますが、どのポートを使用しても問題ありません。

RS-232C/422接続コネクタ

電源の配線

㪉㪋㪭㪛㪚

㪂

㪄

ただし、 USBメモリは隣り合ったポートに接続しないでください。 USBメモリ同士が接触し誤動作や破損の恐れが

あります。

・ USBコネクタの接続対象は右記のとおりです。 ・ 市販のトラックボール、マウス ・ USBメモリ

・ 計測稼動中にUSB機器を抜き差ししないでください。 計測時間に影響が出る可能性があります。

⑪

パソコンと接続します。

⑫

操作用のタッチペンが収納されています。(液晶一体タイプのみ)

・ タッチペンは必ずコントローラに向かってペン先が右向きなるよう収納してください。

・取出す時はペンの左側 (持ち手) を奥へ押してください。 ペンの右側 (ペン先) が前に飛出しますので、摘んで取出してください。

6

Page 8

■基本構成 カメラ4chタイプ

*印は専用品です。 これら以外は使用できません。

*

コントローラ

画像の確認や条件設定用メニューを表示するために使用します。 また、

設定条件に従った画像処理を行い、計測結果を出力する部分です。

液晶一体タイプ

形FJ-3000-10/形FJ-3005-10

形FJ-H3000-10/形FJ-H3005-10

正面 右側面

タッチペン(付属品)

*

カメラケーブル

カメラケーブル

カメラケーブル

形FZ-VS3(2m、3m、5m、10m)

形FZ-VS(2m、5m、10m)

耐屈曲カメラケーブル

耐屈曲カメラケーブル

形FZ-VSB3(2m、3m、5m、10m)

形FZ-VSB(2m、5m、10m)

ライトアングルカメラケーブル

ライトアングルカメラケーブル

形FZ-VSL(2m、5m、10m)

形FZ-VSL3(2m、3m、5m、10m)

長距離カメラケーブル

耐屈曲ライトアングルカメラケーブル

形FZ-VS2(15m)

形FZ-VSLB3(2m、3m、5m、10m)

長距離ライトアングルカメラケーブル

長距離カメラケーブル

形FZ-VSL2(15m)

形FZ-VS4(15m)

長距離ライトアングルカメラケーブル

形FZ-VSL4(15m)

インテリジェントカメラ

形FZ-SLC15/形FZ-SLC100

*

計測物を画像として取込む部分です。

カメラ

オートフォーカスカメラ

形FZ-SZC15/形FZ-SZC100

*

コントローラ

設定条件に従った画像処理を行い、計測

結果を出力する部分です。

BOXタイプ

形FJ-3050-10/形FJ-3055-10

形FJ-H3050-10/形FJ-H3055-10

*

液晶モニタ

画像の確認や条件設定用メニュー

を表示するために使用します。

形FZ-M08(8.4インチ)

*

モニタケーブル

形FZ-VM(2m、5m)

電源装置

推奨品

オムロン(株)製

S8VS-18024

単体カメラ

形FZ-SC/形FZ-S/形FZ-SC2M

形FZ-S2M

形FZ-SC5M2/形FZ-S5M2/形FZ-SFC

形FZ-SF/形FZ-SPC/形FZ-SP

形FZ-SHC/形FZ-SH

インテリジェントコンパクトカメラ

形FZ-SQ010F/形FZ-SQ050F

形FZ-SQ100F/形FZ-SQ100N

周辺機器

*USBメモリ

形FZ-MEM2G/FZ-MEM8G

入力デバイス

マウス、トラックボール

(USBインタフェースの市販品)

7

Page 9

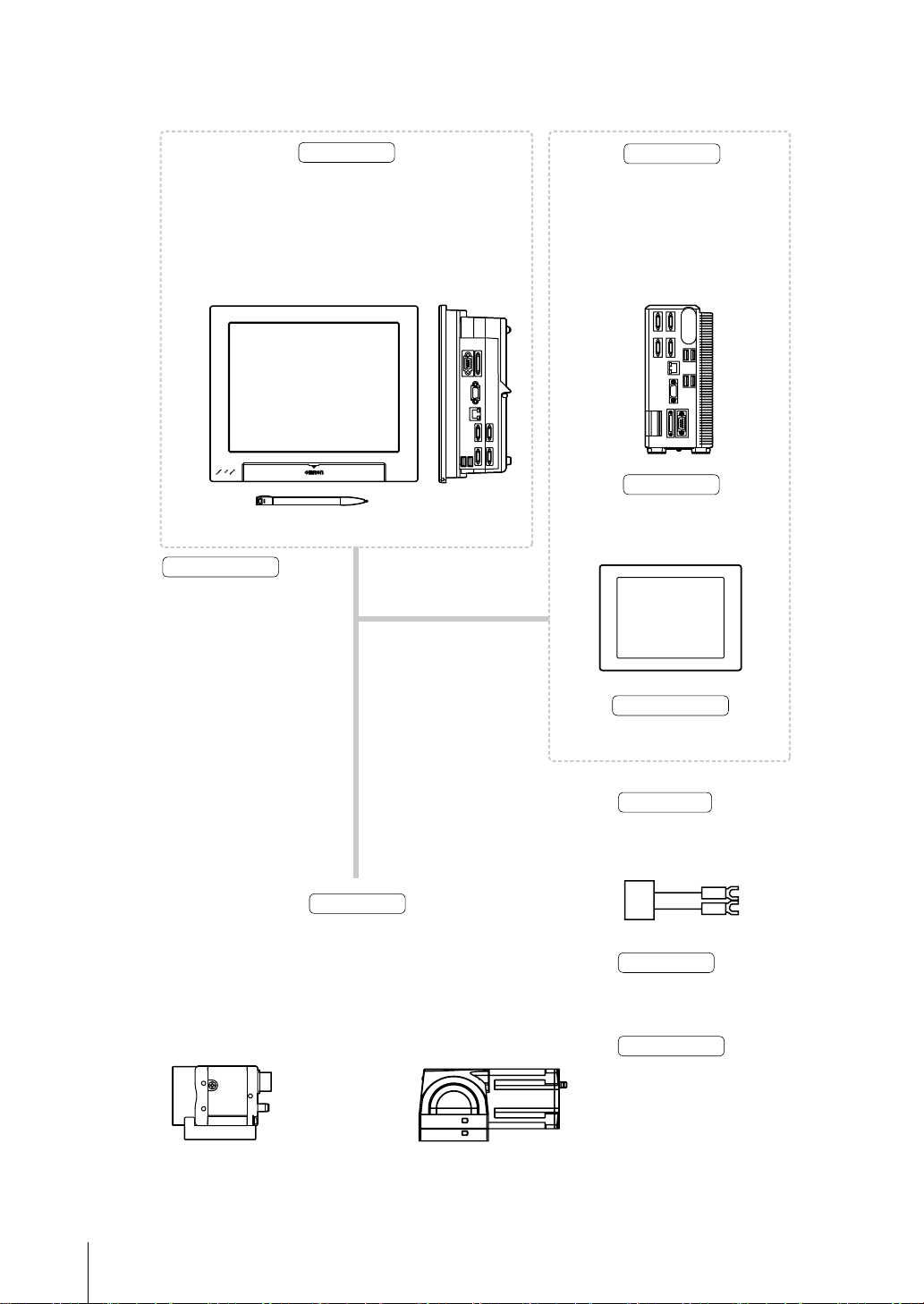

■各部の名称とはたらき

●液晶一体タイプ 形FJ-3000-10/形FJ-3005-10/形FJ-H3000-10/形FJ-H3005-10

左側面 正面 右側面

⑥⑦

電源・

接地端子

①

POWER LED

②

RUN LED

③

ERROR LED

●BOXタイプ 形FJ-3050-10/形FJ-3055-10/形FJ-H3050-10/形FJ-H3055-10

⑪

イーサネット接続コネクタ

⑧

モニタ接続コネクタ(アナログRGB)

⑩

USBコネクタ

⑤

カメラコネクタ

⑫

タッチペン (収納)

①

②

③

⑩

USBコネクタ

⑨

RS-232C/422接続コネクタ

④

入出力コネクタ

(制御線、データ線)

⑧

モニタ接続コネクタ

(アナログRGB)

⑪

イーサネット接続コネクタ

⑤

カメラコネクタ

⑩

USBコネクタ

POWER LED

RUN LED

ERROR LED

⑥⑦

電源・接地端子

⑨

④

入出力コネクタ(制御線、データ線)

①

通電中、点灯します。

②

表示中のレイアウトにしたがって点灯/消灯します。

③

異常が発生したときに点灯します。

④

同期センサ、プログラマブルコントローラなどの外部装置と接続します。

⑤

カメラを接続します。

⑥

DC電源を接続します。他の機器とは独立して配線してください。配線後は、

端子カバー(透明)を元の場所に取付けてください。

電源、配線についてp.2

⑦

接地線を配線します。 必ずコントローラ単独で配線してください。

⑧

モニタを接続します。

⑨

パソコン、プログラマブルコントローラなどの外部装置と接続します。

⑩

トラックボール、マウス、 USBメモリと接続します。 計4ポートありますが、どのポートを使用しても問題ありません。

RS-232C/422接続コネクタ

電源の配線

㪉㪋㪭㪛㪚

㪂

㪄

ただし、 USBメモリは隣り合ったポートに接続しないでください。 USBメモリ同士が接触し誤動作や破損の恐れが

あります。

・ USBコネクタの接続対象は右記のとおりです。 ・ 市販のトラックボール、マウス ・ USBメモリ

・ 計測稼動中にUSB機器を抜き差ししないでください。 計測時間に影響が出る可能性があります。

⑪

パソコンと接続します。

⑫

操作用のタッチペンが収納されています。(液晶一体タイプのみ)

・ タッチペンは必ずコントローラに向かってペン先が右向きなるよう収納してください。

・取出す時はペンの左側 (持ち手) を奥へ押してください。 ペンの右側 (ペン先) が前に飛出しますので、摘んで取出してください。

8

Page 10

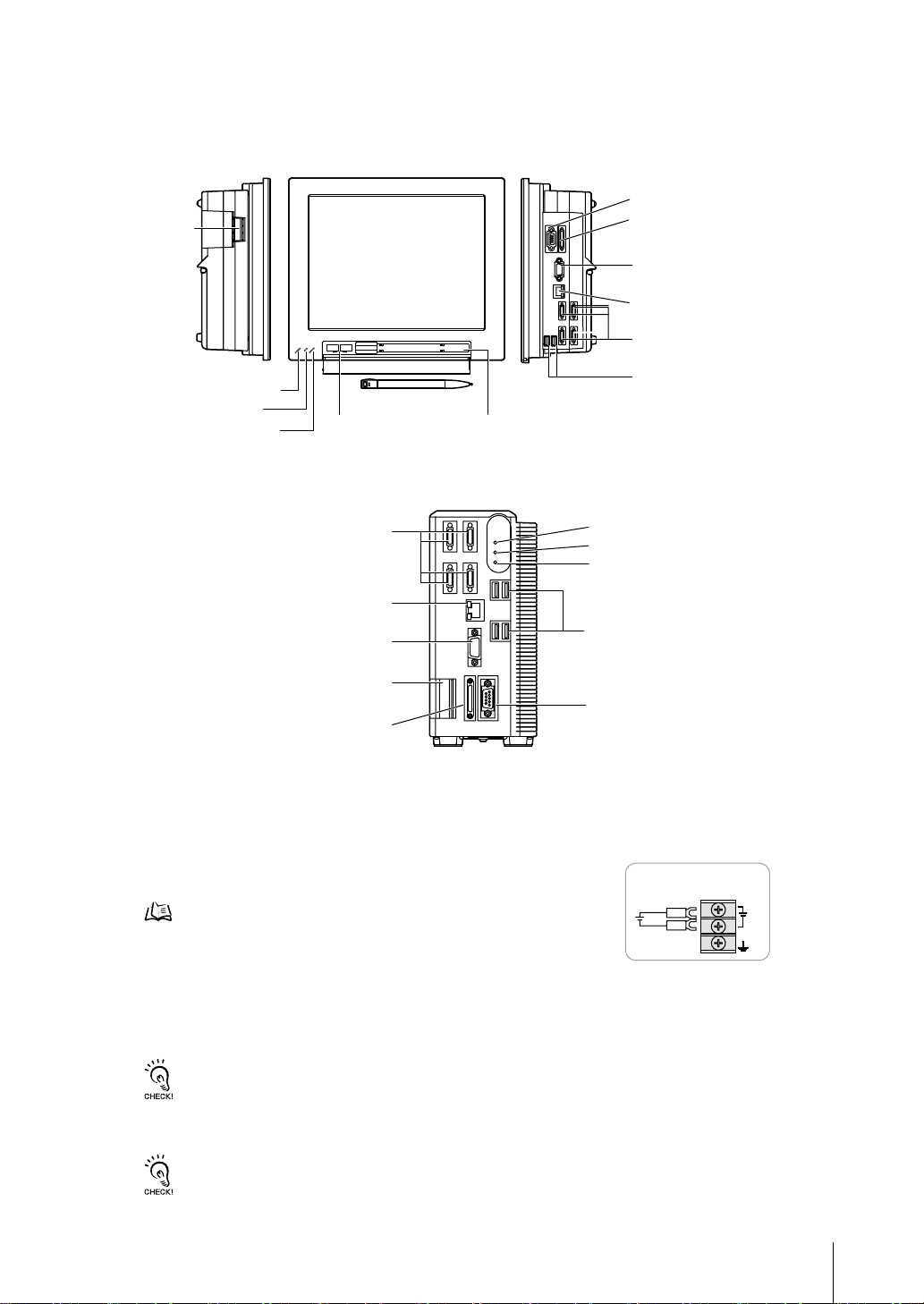

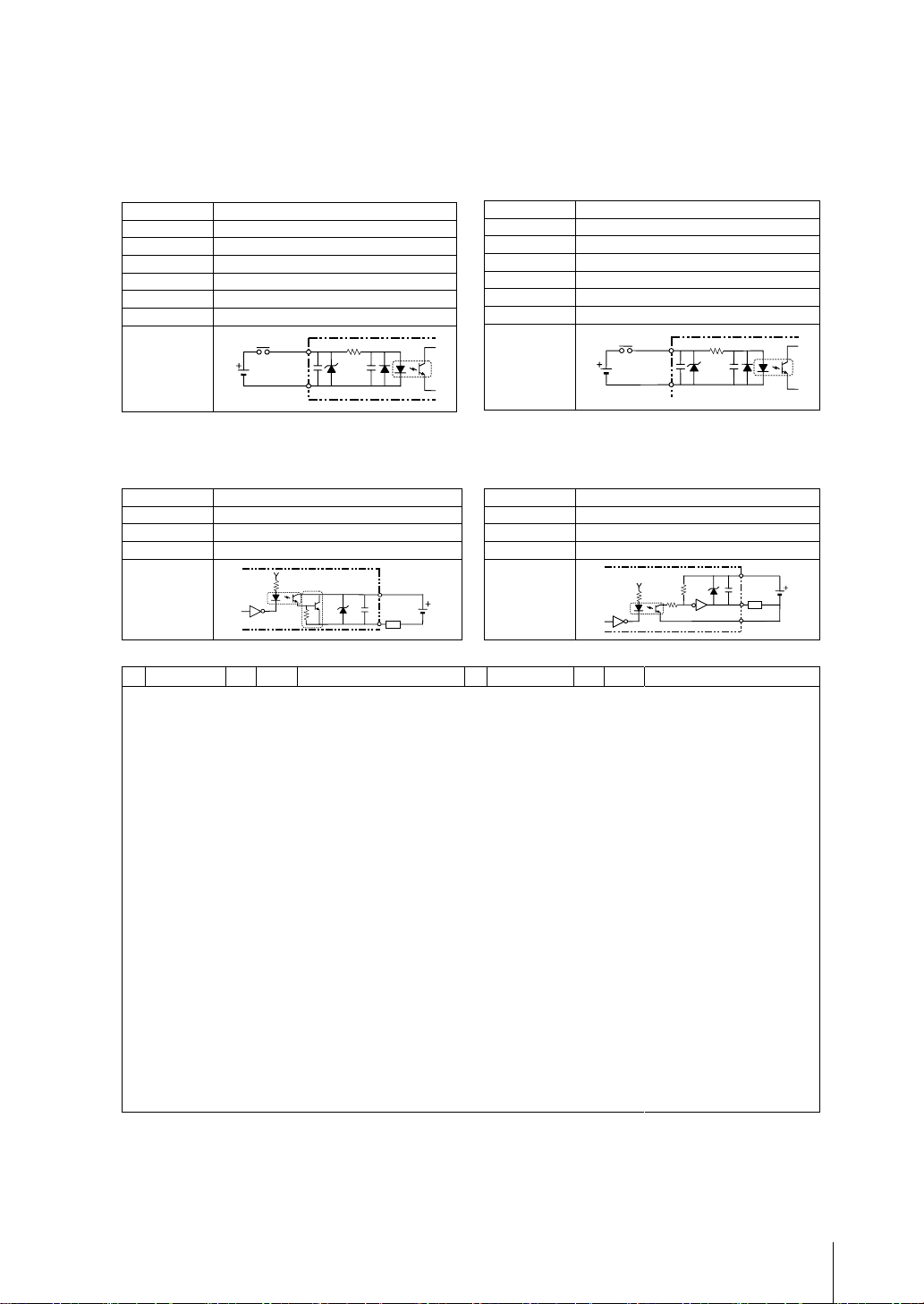

■パラレルインタフェース

COM OUT

NPN入出力タイプ形FJ-3000/形FJ-3050/形FJ-H3000/形FJ-H3050

形FJ-3000-10/形FJ-3050-10/形FJ-H3000-10/形FJ-H3050-10

●内部仕様

【入力】対象信号/ RESET、 DI0~DI7、 DSA0、 DSA1

入力電圧

ON電流 ※1

ON電圧 ※1

OFF電流※2

OFF電圧※2

ONディレー 5ms以下

OFFディレー 0.7ms以下

内部回路図

※1ON電流/ON電圧 OFF→ON状態にさせる電流値または電圧値のことです。 ON電圧の値は、 COMINと各入力端子間の電位差となります。

※2OFF電流/OFF電圧 ON→OFF状態にさせる電流値または電圧値のことです。 OFF電圧の値は、 COMINと各入力端子間の電位差となります。

【出力】対象信号/

出力電圧

負荷電流

ON残留電圧 2V以下

OFF漏れ電流 0.2mA以下

内部回路図

DC12~24V ±10%

最小5mA

最小8.8V

最大0.5mA

最大1.1V

COM IN

BUSY0、 RUN/BUSY1、 OR0~1、 GATE0~1、

ERROR、 DO0~15、 READY0~1

DC12~24V ±10%

45mA以下

各出力端子

負荷

COM OUT

【入力】対象信号/

入力電圧

ON電流 ※1

ON電圧 ※1

OFF電流※2

OFF電圧※2

ONディレー 0.1ms以下

OFFディレー 0.1ms以下

内部回路図

【出力】対象信号/

STGOUT0~3使用時はCOM IN端子を接続してください。

出力電圧

負荷電流

ON残留電圧 2V以下

OFF漏れ電流 0.2mA以下

内部回路図

STEP0/ENCTRIG_Z0、 STEP1/ENCTRIG_Z1、

ENCTRIG_A0~1、 ENCTRIG_B0~1

DC12~24V ±10%

最小5mA

最小8.8V

最大0.5mA

最大0.8V

COM IN

各入力端子各入力端子

STGOUT0~3

DC12~24V ±10%

45mA以下

COM IN

負荷

各出力端子

●入出力コネクタ

No.

信号名

A1

COMIN 橙 入力信号用コモン

A2

ENCTRIG_A1(※2)

A3

ENCTRIG_B1(※2)

A4

STEP1(※2)/

ENCTRIG_Z1(※2)

A5

DSA1(※2) 桃 データ送信要求信号

A6

DI1 橙 コマンド入力

A7

DI3 灰

A8

DI5 白

A9

DI7 黄

A10

STGOUT1 桃 ストロボトリガ出力(※1)

A11

STGOUT3 橙 ストロボトリガ出力(※1)

A12

ERROR 灰 エラー発生時にON

A13

COMOUT1 白 制御信号用コモン

A14

GATE1(※2) 黄 設定した出力時間中ON

A15

OR1(※2) 桃 総合判定結果

A16

READY1(※2) 橙 画像入力が許可されるときON

A17

COMOUT2 灰 出力信号用コモン

A18

DO1 白 データ出力

A19

DO3 黄

A20

DO5 桃

A21

DO7 橙

A22

DO9 灰

A23

DO11 白

A24

DO13 黄

A25

COMOUT3 桃 出力信号用コモン

・ 出力用コモン端子の対応

COMOUT1 : STGOUT0~3、 RUN/BUSY1、 ERROR、 BUSY0、 OR0~1、 GATE0~1 COMOUT2 : READY0~1、 DO0~7 COMOUT3 : DO8~15

※1コントローラにストロボ装置を接続したい場合に使用する信号です。 カメラ2chタイプでは、 STGOUT0、 STGOUT1のみ使用できます。

※22ラインランダムトリガモード時のみ使用できます。

線色

マーク(赤)

灰 エンコーダトリガ入力(A相)

白 エンコーダトリガ入力(B相)

黄 計測トリガ入力/

エンコーダトリガ入力(Z相)

役割

No.

信号名

B1

RESET 橙 コントローラ再起動

B2

ENCTRIG_A0 灰 エンコーダトリガ入力 (A相)

B3

ENCTRIG_B0 白

B4

STEP0/

ENCTRIG_Z0

B5

DSA0 桃 データ送信要求信号

B6

DI0 橙 コマンド入力

B7

DI2 灰

B8

DI4 白

B9

DI6 黄

B10

STGOUT0 桃 ストロボトリガ出力(※1)

B11

STGOUT2 橙 ストロボトリガ出力(※1)

B12

RUN/BUSY1(※2)

B13

BUSY0 白 処理実行中にON

B14

GATE0 黄 設定した出力時間中ON

B15

OR0 桃 総合判定結果

B16

READY0 橙 画像入力が許可されるときON

B17

DO0 灰 データ出力

B18

DO2 白

B19

DO4 黄

B20

DO6 桃

B21

DO8 橙

B22

DO10 灰

B23

DO12 白

B24

DO14 黄

B25

DO15 桃

線色

マーク(黒)

黄 計測トリガ入力/

灰

エンコーダトリガ入力 (B相)

エンコーダトリガ入力 (Z相)

レイアウト設定によりON/処理実行中にON

役割

9

Page 11

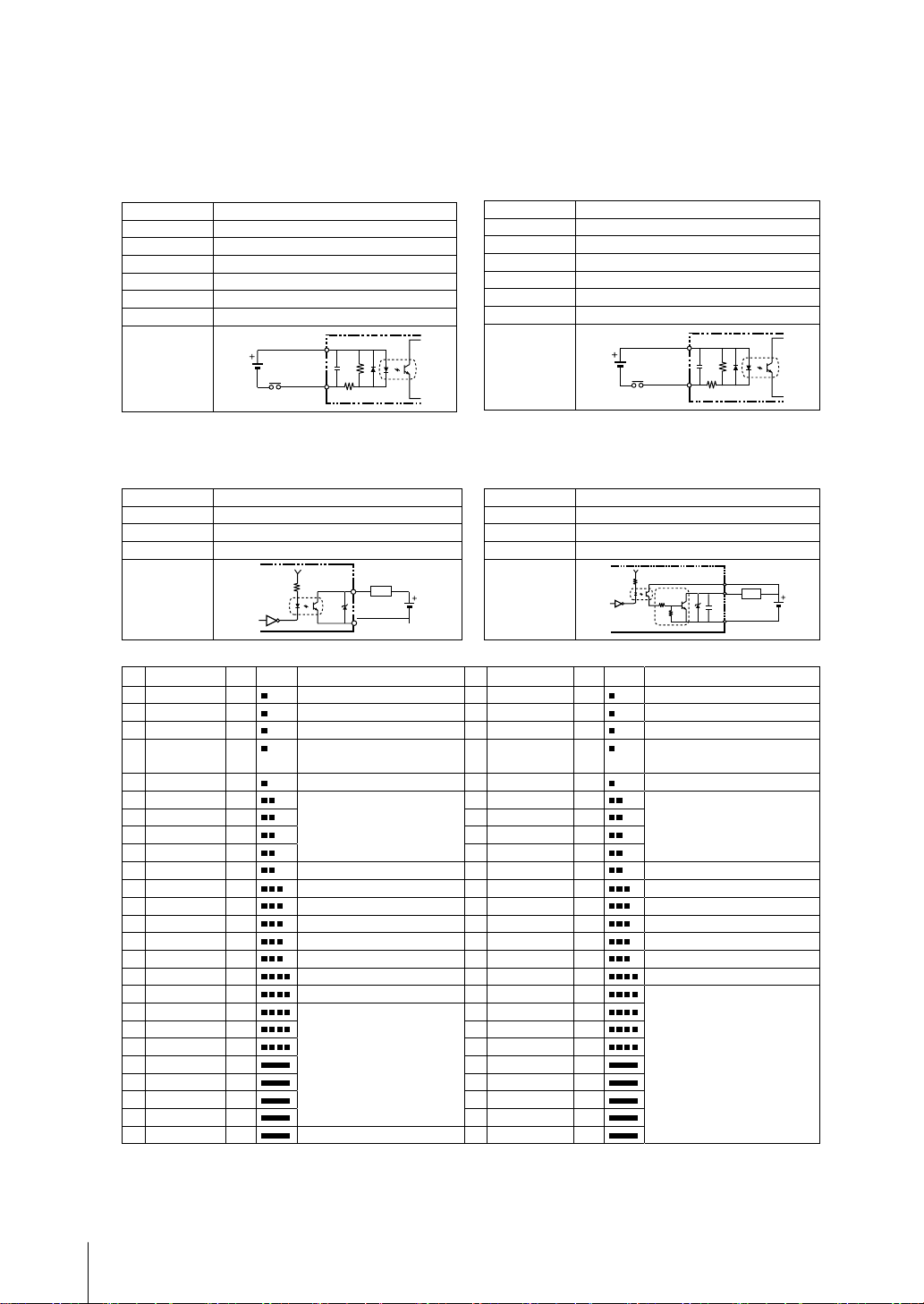

COM OUT

COM IN

■パラレルインタフェース

PNP入出力タイプ形FJ-3005/形FJ-3055/形FJ-H3005/形FJ-H3055

形FJ-3005-10/形FJ-3055-10/形FJ-H3005-10/形FJ-H3055-10

●内部仕様

【入力】対象信号/ RESET、 DI0~DI7、 DSA0、 DSA1

入力電圧

ON電流 ※1

ON電圧 ※1

OFF電流※2

OFF電圧※2

ONディレー 5ms以下

OFFディレー 0.7ms以下

内部回路図

※1ON電流/ON電圧 OFF→ON状態にさせる電流値または電圧値のことです。 ON電圧の値は、 COMINと各入力端子間の電位差となります。

※2OFF電流/OFF電圧 ON→OFF状態にさせる電流値または電圧値のことです。 OFF電圧の値は、 COMINと各入力端子間の電位差となります。

【出力】対象信号/

出力電圧

負荷電流

ON残留電圧 2V以下

OFF漏れ電流 0.2mA以下

内部回路図

DC12~24V ±10%

最小5mA

最小8.8V

最大0.5mA

最大1.1V

COM IN

BUSY0、 RUN/BUSY1、 OR0~1、 GATE0~1、

ERROR、 DO0~15、 READY0~1

DC12~24V ±10%

45mA以下

COM OUT

負荷

各入力端子

【入力】対象信号/

入力電圧

ON電流 ※1

ON電圧 ※1

OFF電流※2

OFF電圧※2

ONディレー 0.1ms以下

OFFディレー 0.1ms以下

内部回路図

【出力】対象信号/

STGOUT0~3使用時はCOM IN端子を接続してください。

出力電圧

負荷電流

ON残留電圧 2V以下

OFF漏れ電流 0.2mA以下

内部回路図

STEP0/ENCTRIG_Z0、 STEP1/ENCTRIG_Z1、

ENCTRIG_A0~1、 ENCTRIG_B0~1

DC12~24V ±10%

最小5mA

最小8.8V

最大0.5mA

最大0.8V

各入力端子各入力端子

STGOUT0~3

DC12~24V ±10%

45mA以下

各入力端子

負荷

COM IN

㩷

●入出力コネクタ

No.

信号名

線色

マーク(赤)

役割

No.

信号名

線色

マーク(黒)

役割

入出力コネクタの配線はNPNタイプと同じです。

10

Page 12

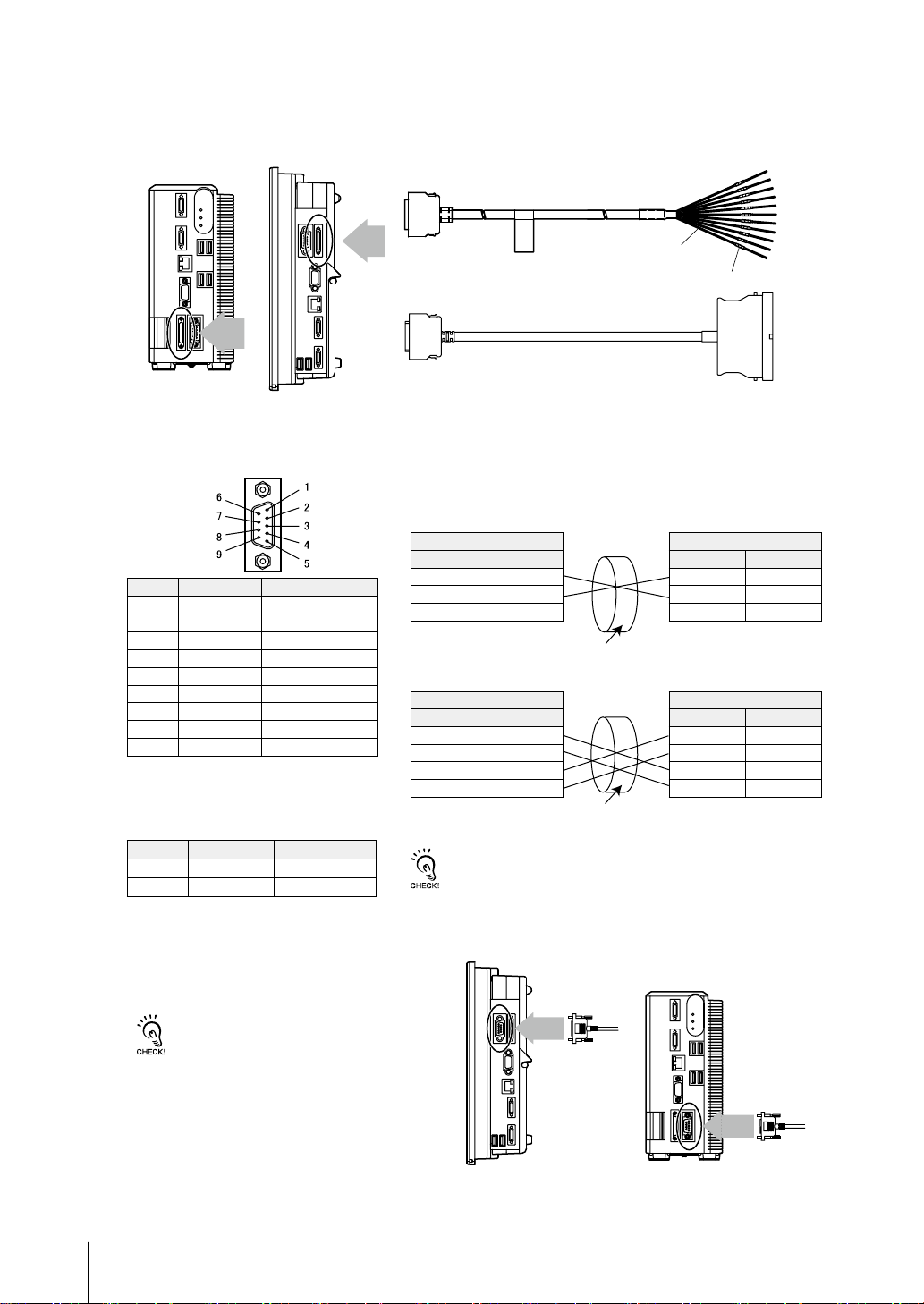

●コネクタ

パラレルI/Oケーブル形FZ-VP、 FZ-VPX(別売)を接続します。

BOXタイプ

液晶一体タイプ

■シリアルインタフェース

●コネクタ

ピンNo. 信号名 役割

1 RDB(+) RS-422用

2 RD/RDA(-)

3 SD/SDA(-)

4 SDB(+)

5 GND

6 NC

7 NC

8 NC

9 NC

適合するコネクタをご用意ください。

・ 推奨品

メーカー 形式

ソケット

フード

オムロン (株)

オムロン (株)

RS-232C用/RS-422用

RS-232C用/RS-422用

RS-422用

信号用接地

無接続

無接続

無接続

無接続

形XM3D-0921

形XM2S-0913

形FZ-VP(2m、5m)

線色

No.

マーク

形FZ-VPX(2m、5m)

●配線

ケーブル長は、 15m以下にしてください。

・ RS-232C

コントローラ 接続する外部装置

信号名 ピンNo. ピンNo. 信号名

RD 2

SD 3

GND 5

シールドされたケーブルを使用してください。

・ RS-422

コントローラ 接続する外部装置

信号名 ピンNo. ピンNo. 信号名

RDB(+) 1

RDA(-) 2

SDA(-) 3

SDB(+) 4

シールドされたケーブルを使用してください。

ピン番号は、接続する外部装置の種類や機種によって異なります。 お手持ち

のプログラマブルコントローラやパソコンの取扱説明書を確認してください。

*

*

*

RS/CS制御はできません。

*

*

*

*

RD

SD

GND

RDA(-)

RDB(+)

SDB(+)

SDA(-)

11

●接続方法

コネクタの向きを合わせ、 まっすぐに差込み、

コネクタの両端のねじで固定してください。

電源を切った状態でケーブルを着脱してください。

周辺機器の破損の原因になります。

液晶一体タイプ

BOXタイプ

Page 13

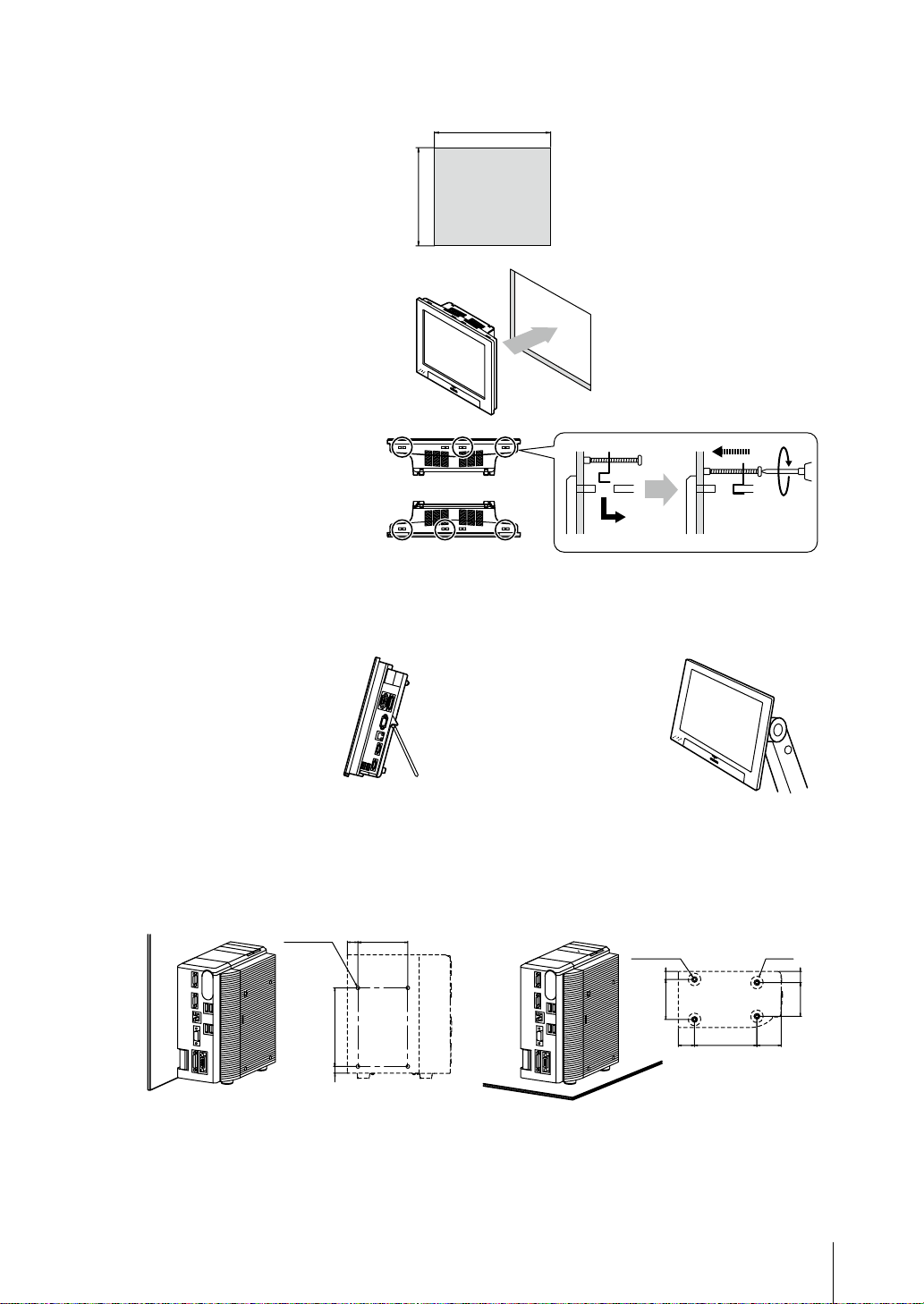

■取付け

●液晶一体タイプ

・ パネル取付け

①

パネルに取付け用の穴をあけます。

パネルの板厚範囲 : 1.6 ~ 4.8mm

パネルの材質 : 金属製 (鉄、アルミ、

またはステンレス)

②

液晶一体タイプコントローラを

パネル前面から挿入します。

③

付属の取付金具で、液晶一体タイプ

コントローラとパネルを固定します。

締付トルク : 0.5 ~ 0.6Nm

上面

下面

1

0

247

297

1

0

(単位:mm)

※バリなきこと

・ 卓上コントローラスタンド(別売)取付け

別売りの卓上コントローラスタ

ンド形FZ-DSを背面に装着す

ることにより、 卓上に据え置き

することができます。

※詳しくは卓上コントローラスタンドの

取扱説明書をご参照ください。

・ VESAアタッチメント(別売)取付け

別売りのVESAアタッチメント

形FZ-VESAを背面に装着す

ることによりVESA規格のマ

ウントができます。

※詳しくはVESAアタッチメントの取

扱説明書をご参照ください。

● BOX タイプ

・ 側面取付け ・ 底面取付け

(17)

4-M4 深さ6

80r0.25

126r0.25

(11)

※底面で固定する場合は通風経路を確保するため、

脚を外さず共締めしてください。

4-M4 深さ6

(13)

64r0.25

(26)

100r0.25

4-㱢 20

()

39

(18)

54r0.25

12

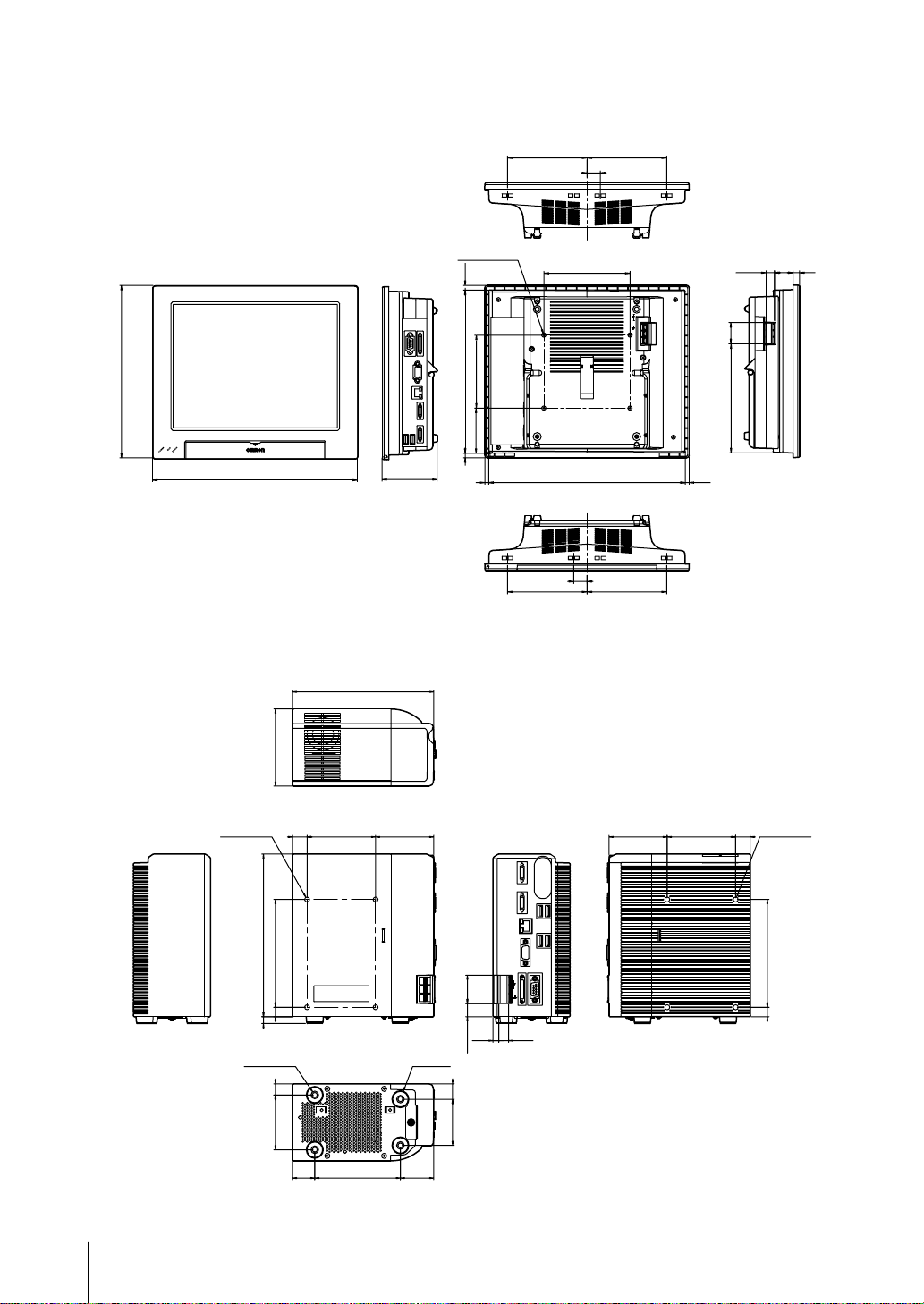

Page 14

()

■コントローラ外形寸法

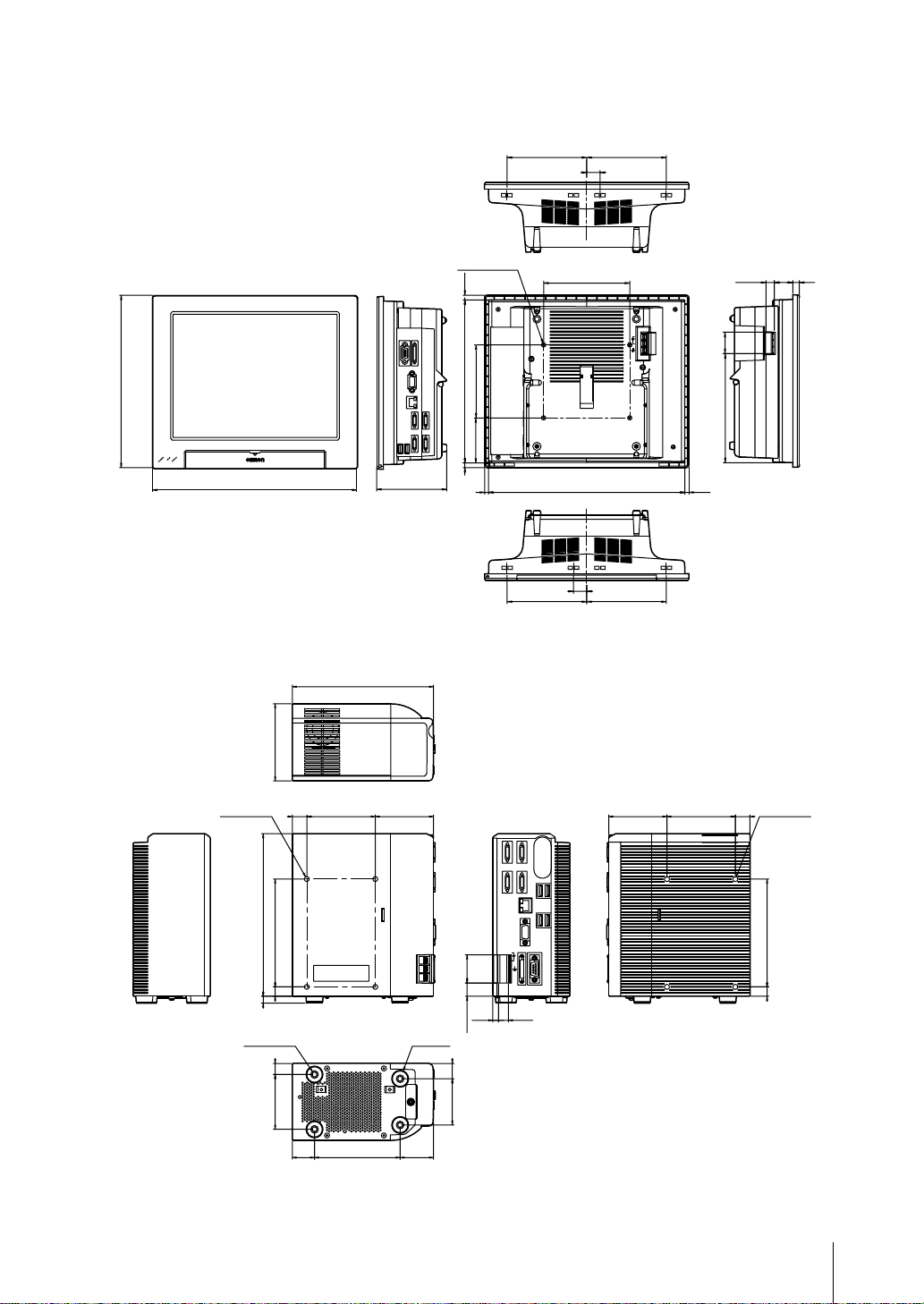

●液晶一体タイプ 形FJ-3000/形FJ-3005/形FJ-H3000/形FJ-H3005

4-M 3

7

()

260

308

83

246

7

110

68

6

●BOXタイプ 形FJ-3050/形FJ-3055/形FJ-H3050/形FJ-H3055

深さ6

120 120

20

130

296

20

120 120

㪂

㪄

()

6

(単位mm)

28.412.8 10

33

163.5

()

4-M4

深さ6

4-M4

190

8

90

11 126

深さ6

13

64

17 80

26

100

165

()

68

()

39

4-㱢20

33

()

6.8

15.45

()

1854

11.5

(単位mm)

()

68

㪂

㪄

80 17

4-M4

126

11

深さ6

13

Page 15

100

26

260

()

120 120

■コントローラ外形寸法

●液晶一体タイプ 形FJ-3000-10/形FJ-3005-10/形FJ-H3000-10/形FJ-H3005-10

20

4-M 3

308

7

()

246

104

7

深さ6

110

68

6

130

296

20

120 120

●BOXタイプ 形FJ-3050-10/形FJ-3055-10/形FJ-H3050-10/形FJ-H3055-10

㪂

㪄

33

163.5

()

()

6

(単位mm)

28.412.8 10

4-M4

深さ6

4-M4

190

8

90

11 126

深さ6

13

64

17 80

165

()

68

()

39

4-㱢20

33

()

6.8

15.45

()

1854

11.5

(単位mm)

()

68

㪂

㪄

80 17

4-M4

126

11

深さ6

14

Page 16

■コントローラの仕様

操作 液晶一体タイプ :タッチペン、マウスなどによる操作

BOXタイプ :マウスなどによる操作

シリアル通信 RS-232C/422:1CH

ネットワーク通信 Ethernet100BASE-TX/10BASE-T

EtherNet/IP通信 Ethernetポート使用

伝送速度 : 100Mbps(100BASE-TX)

パラレル入出力

モニタI/F 液晶一体タイプ :コントローラと一体型12.1インチTFTカラー液晶 (解像度XGA1024×768)

USBI/F 4CH (USB1.1/2.0準拠)

電源電圧 DC24V(DC20.4 ~ 26.4V)

消費電流

(DC24.0V使用時)

絶縁抵抗

耐電圧 DC外部端子一括とアース端子間 :AC1000V 50/60Hz

漏れ電流 10mA以下

耐ノイズ性 1kV、パルス立上がり :5ns パルス幅 :50ns

耐振動 10 ~ 150Hz 片振幅0.1mm(加速度最大15m/s

耐衝撃 150m/s

周囲温度範囲 動作時 : 0 ~+50℃

周囲湿度範囲 動作時 ・ 保存時:各35 ~ 85% RH(ただし結露しないこと)

周囲雰囲気 腐食性ガスのないこと

接 地 D種接地 (接地抵抗100Ω以下)*従来の第三種接地

保護構造 IEC60529規格IP20

ケースの材質 ABS

質 量 液晶一体タイプ : 約3.4kg BOXタイプ : 約1.9kg

入力17点 (RESET、STEP0/ENCTRIG_Z0、STEP1/ENCTRIG_Z1、DSA0~1、ENCTRIG_A0~1、ENCTRIG_B0~1、DI0~7)

出力29点 (RUN/BUSY1、 BUSY0、 GATE0~1、 OR0~1、 READY0~1、 ERROR、 STGOUT0~3、 DO0~15)

※STGOUT2、 3はカメラ4chタイプのみ

BOXタイプ :アナログRGBビデオ出力1ch (解像度XGA1024×768)

接続カメラの種類により消費電流が異なります。

形FZ-S□/形FZ-S□2M/形FZ-S□5M2/形FZ-SF□/形FZ-SP□/形FZ-SH□ 接続時 :

カメラ2chタイプ : 約3.7A以下 カメラ4chタイプ : 約4.9A以下

DC外部端子一括とアース端子間:20MΩ以上(DC100Vメガにて ただし、内蔵サージアブソーバを外した場合)

バースト継続時間 :15ms 周期 :300ms

2

6方向各3回

周囲温度を設定可能、設定に応じて冷却ファンの回転速度を切替

0 ~+45℃ : 低速回転 0 ~+50℃ : 高速回転

保存時 : -20 ~+65℃(ただし氷結 ・ 結露しないこと)

2

)3方向各8分10回

055‑

977‑6389

Page 17

PC Vision System

FJ-300_/FJ-305_/FJ-H300_/FJ-H305_

FJ-300_-10/FJ-305_-10/FJ-H300_-10/FJ-H305_-10

FJ Series

INSTRUCTION MANUAL

Thank you for selecting the FJ Series PC Vision System.

This manual explains how to use the FJ Series PC Vision System.

When using the FJ Series PC Vision System, make sure to observe the following:

The FJ Series PC Vision System must be operated by personnel knowledgeable

•

in electrical engineering.

To ensure correct use, please read this manual thoroughly to deepen your

•

understanding of the product.

Please keep this manual in a safe place so that it can be referred to whenever necessary.

•

The meaning of “_” in model is described below.

*

0:NPN I/O type 5:PNP I/O type

TRACEABILITY INFORMATION:

Importer in EU:

Omron Europe B.V.

Wegalaan 67-69 2132 JD Hoofddorp,The Netherlands

Manufacturer:

Omron Corporation,

Shiokoji Horikawa,Shimogyo-ku, Kyoto 600-8530 JAPAN

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio interference,

in which case the user may be required to take adequate measures to reduce

interference.

© OMRON Corporation 2011 All Rights Reserved.

(SETUP)

Page 18

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship

for a period of one year (or other period if specied) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer

to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certication documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufcient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products. NEVER USE THE

PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED

USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

1

Page 19

Meanings of Signal Words

The following signal words are used in this manual.

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not avoided, will result in minor or moderate injury, or

may result in serious injury or death. Additionally there may be signicant property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury or

in property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Indicates general prohibitions for which there is no

specic symbol.

Indicates the possibility of explosion under specic

conditions.

Indicates the possibility of injury by high temperature under specic conditions.

Indicates the possibility of electric shock under specic

conditions.

Indicates the possibility of laser radiation.

Alert statements in this Manual

The following alert statements apply to the products in this manual. Each alert statement also appears at the locations needed in this

manual to attract your attention.

WARNING

This product must be used according to the instruction manual. Failure to observe this may result in impairment of functions

and performance of the product.

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

Do not open the cover. Doing so may result in electric shock from internally used high voltages.

A lithium battery is built into the Controller and may occasionally combust, explode, or burn if not treated properly. Dispose of the Controller

as industrial waste, and never disassemble, apply pressure that would deform, heat to 100°C or higher, or incinerate the Controller.

Since this product emits a visible light that may have an adverse affect on the eyes, do not stare directly into the light emitted

from the LED. If a specular object is used, take care not to allow reected light enter your eyes.

CAUTION

Danger of burns

Do not touch the case while the LED is ON or just after power is turned OFF, since it remains extremely hot.

Precautions for Safe Use

Installation Environment

●

Do not use the product in areas where ammable or explosive gases are present.

•

Install the product so that air can ow freely through its cooling vents.

•

Do not install the product close to high-voltage devices and power devices in order to secure the safety of operation and maintenance.

•

Make sure to tighten all installation screws securely.

•

Power Supply and Wiring

●

Make sure to use the product with the power supply voltage specied by this manual.

•

Use a power supply cable and crimp terminals of the specied size. Do not simply connect the twisted ends of the wires directly to

•

the terminal block.

- Applicable wire size: 1.31 to 2.63 mm

- Terminal screw: M4

Keep the power supply wires as short as possible (Max. 10 m).

•

Use a DC power supply with safety measures against high-voltage spikes (safety extra low-voltage circuits on the secondary side).

•

Ground the product’s ground terminal to less than 100 Ω .

•

Use a grounding point that is as close as possible and keep the ground wire as short as possible.

•

Wire the Controller to the ground with a separate ground wire. To avoid grounding problems, do not share the ground wire with any

•

other devices or wire the ground to the building’s steel framing.

Before turning on the power supply, conrm that the wiring is correct again.

•

Other

●

Use only the camera and cables designed specically for the product. Failure to observe this may result in malfunction or damage of the product.

•

Always turn OFF the Controller’s power before connecting or disconnecting a camera or cable.

•

Do not attempt to dismantle, repair, or modify the product.

•

Should you notice any abnormalities, immediately stop use, turn OFF the power supply, and contact your OMRON representative.

•

Do not touch uorescent or halogen lights while the power is ON or immediately after the power is turned OFF.

•

Dispose of this product as industrial waste.

•

Regulations and Standards

●

The Controller complies with the following standards.

EN Standards(European Standards), EN61326-1 (Electromagnetic environment : Industrial electromagnetic environment

(EN/IEC 61326-1 Table 2)

Also, the following condition is applied to the immunity test of this product.

: If the level of disturbance of the video is that with characters on the monitor are readable, the test is pass.

2

- Crimp terminals 8.5 mm max. 8.5 mm max.

2

Page 20

Regulation of KC marking

●

A급 기기(업무용 방송통신기자재)

이 기기는 업무용 ( A급 ) 전자파적합기기로서 판매자

또는 사용자는 이 점을 주의하시기 바라며 , 가정외의

지역에서 사용하는 것을 목적으로 합니다 .

Ground

●

The controller power circuit is not insulated from its internal circuit.

•

When grounding the positive terminal of the 24 V DC power supply, do not ground the controller’s FG terminal or the PLC’s FG

•

terminal.

Since the PC’s shell and the SG (0V) are connected inside the PC, current would run through the route shown in the gure below

and cause burnout.

As in the case with a PC, you can safely ground the controller’s FG terminal without a problem when there is no possibility that the

•

SG (0V) and the FG will short-circuit. For information about the PLC wiring, check the specications of your PLC before wiring.

Be sure to use a spacer when connecting a camera to the controller. ③

•

As the shell of the camera is the SG (0V), it can cause short-circuiting between the SG (0V) and the FG if a spacer is not used.

To avoid receiving an electric shock when grounding a positive terminal, do not touch the SG (0V) (camera, power supply terminal).

•

When mounting a box-shaped controller (FJ-305_/FJ-H305_/FJ-305_-10/FJ-H305_-10) at its base, it will short-circuit to the FG

•

of your device since the bottom surface is connected to the SG (0V). In order to avoid this, we provide insulating spacers. Please

consult your OMRON representative for information.

① , ②

Power

supply

Controller

24V

0V

SG

FG

1

Power supply

circuit

FG

SG: Signal ground

FG: Frame ground

SG(0V)

Parallel I/O

connector’s

shell

RS-232C

connector’s shell

Camera cable

SG(0V)

SG SG

SG

SG

RS-232C

PLC

FG FG

SG

RS-232C

SG FG

Camera

Mounting spacer

(insulator)

FG

Shell

3

2

Precautions for Correct Use

Installation and Storage Sites

●

Install and store the product in a location that meets the following conditions:

Surrounding temperature of 0 to +50 °C (-20 to + 65 °C in storage)

•

No rapid changes in temperature (place where dew does not form)

•

Relative humidity of between 35 to 85 %

•

No presence of corrosive or ammable gases

•

Place free of dust, salts and iron particles

•

Place free of vibration and shock

•

Place out of direct sunlight

•

Place where it will not come into contact with water, oils or

•

chemicals

Orientation of Product

●

To improve heat dissipation, install the product in the following

orientation only.

Ambient Temperature

●

Maintain a minimum clearance of 50 mm above and below

•

the controller to improve air circulation. A minimum clearance

of 10 mm between other devices must also be maintained on

the right and left sides of the product. However, if the adjacent

devices do not generate heat, provide at least 50 mm of

clearance from the top of the Controller. For the clearance at

the bottom and sides, follow the mounting method.

Do not install the product immediately above signicant heat

•

sources, such as heaters, transformers, or large-capacity

resistors.

Do not let the ambient temperature exceed 50 °C (122 °F).

•

Provide a forced-air fan cooling or air conditioning if the

•

ambient temperature is near 50 °C (122 °F) so that the

ambient temperature never exceeds 50 °C (122 °F).

LCD integrated type Do not install in this orientation.

●

Box type

●

PC

To reserve ventilation path,

the feet must be mounted

to the side panel that is

positioned at the base.

Do not install in this orientation.

3

Page 21

Noise Resistance

●

Do not install the product in a cabinet containing

•

high-voltage equipment.

Do not install the product within 200 mm of power cables.

•

Component Installation and Handling

●

Touching Signal Lines

•

To prevent damage from static electricity, use a wrist strap or another device for preventing electrostatic discharges when touching

terminals or signal lines in connectors.

Handling a USB Memory

•

To remove a USB memory, make sure that data is not being read or written to it.

The LED on the USB memory ashes while data is being read or written, so make sure that it is lit steadily before removing the

memory.

Turning OFF the Power

•

Do not turn OFF the power while a message is being displayed indicating that processing is being performed. Data in memory will

be corrupted, and the product may not operate correctly the next time it is started.

Using the RESET Signal

•

Do not use the RESET input immediately after power is turned ON. When using the RESET input to synchronize startup timing, wait

at least 15 second after the Controller’s power supply is turned ON before turning ON the RESET signal.

The LCD panel used for the LCD-integrated type (FJ-300_/FJ-300_-10/FJ-H300_/FJ-H300_-10) has been made using precision

•

technology, and sometimes a few pixcels are missing in the panel. This is due to the structure of the LCD panel, and is not a

malfunction.

Maintenance

●

Turn OFF the power and take safety precautions before conducting inspections. Electrical shock can result from attempting safety

inspections with the power turned ON.

Clean the lens with a lens-cleaning cloth or air brush.

•

Lightly wipe off dirt with a soft cloth.

•

Dirt on the CCD must be removed using an air brush.

•

Do not use thinners or benzene.

•

Communication with High-order Device

●

After conrming that this product is started up, communicate with the high-order device.

When this product has started up, an indenite signal may be output from the high-order interface.

To avoid this problem, clear the receiving buffer of your device at initial operations.

Conrming Package Contents

Controller ............................................................ Qty:1

•

Instruction Manual (this manual) ........................ Qty:1

•

Member Registration Sheet ................................ Qty:1

•

Mounting bracket (for panel) ............................... Qty:6 * Supplied with the LCD integrated type only.

•

Touch pen ........................................................... Qty:1 * Supplied with the LCD integrated type only.

•

(Provided inside the controller)

U.S. California Notice:

This product contains a lithium battery for which the following notice applies :Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

4

Page 22

Basic Conguration Camera 2ch type

* Items indicated with an asterisk are dedicated items, and cannot be substituted.

*

Use the monitor to check images and display the

condition-setting menus. The Controller performs

the image processing specied by the user settings

and outputs the measurement results.

Controller

LCD integrated type

FJ-3000/FJ-3005

FJ-H3000/FJ-H3005

Front view Right-side view

The Controller performs the image

processing specied by the user settings

and outputs the measurement results.

Box type

FJ-3050/FJ-3055

FJ-H3050/FJ-H3055

*

Controller

Touch pen (standard accessory)

*

Camera cable

Camera cable

Camera cable

FZ-VS (2 m, 5 m, 10 m)

FZ-VS3 (2 m, 3m, 5 m, 10 m)

Bend resistant camera cable

Bend resistant camera cable

FZ-VSB (2 m, 5 m, 10 m)

FZ-VSB3 (2 m, 3m, 5 m, 10 m)

Right-angle camera cable

Right-angle camera cable

FZ-VSL (2 m, 5 m, 10 m)

FZ-VSL3 (2 m, 3m, 5 m, 10 m)

Long-distance camera cable

Bend resistant

FZ-VS2 (15m)

Right-angle camera cable

FZ-VSLB3 (2 m, 3m, 5 m, 10 m)

Long-distance Right-angle

camera cable

Long-distance camera cable

FZ-VSL2 (15m)

FZ-VS4 (15m)

Long-distance Right-angle

camera cable

Intelligent camera

FZ-VSL4 (15m)

FZ-SLC15/FZ-SLC100

*

Camera

Detects workpieces as images.

Standalone camera

FZ-SC/FZ-S/FZ-SC2M

FZ-S2M

FZ-SC5M2/FZ-S5M2/FZ-SFC

FZ-SF/FZ-SPC/FZ-SP

FZ-SHC/FZ-SH

Use the monitor to check images

and display the condition-setting

menus.

Automatic focus camera

FZ-SZC15/FZ-SZC100

Intelligent compact camera

FZ-SQ010F/FZ-SQ050F

FZ-SQ100F/FZ-SQ100N

*

LCD monitor

FZ-M08 (8.4-inch)

*

Monitor cable

FZ-VM (2 m, 5 m)

Power Supply

Recommended Model

By OMRON Corporation

S8VS-12024

Peripheral Device

USB memory

FZ-MEM2G/FZ-MEM8G

Input Device

Mouse, track ball

(Commercially available

USB devices)

5

Page 23

Component Names and Functions

LCD integrated type FJ-3000/FJ-3005/FJ-H3000/FJ-H3005

●

Left-side view Front view Right-side view

⑥⑦

Power/

ground terminal

① POWER LED

② RUN LED

③ ERROR LED

Box type FJ-3050/FJ-3055/FJ-H3050/FJ-H3055

●

⑤ Camera connector

⑪

Ethernet connector

⑧ Monitor connector (analog RGB)

⑥⑦

Power/ground terminal

④ I/O connector (control lines, data lines)

⑩ USB connector

⑨ RS-232C/RS-422

connector

④ I/O connector

(control lines, data lines)

⑧ Monitor connector

(analog RGB)

⑪ Ethernet connector

⑤ Camera connector

⑩ USB connector

⑫ Touch pen (holder)

① POWER LED

② RUN LED

③ ERROR LED

⑩ USB connector

⑨ RS-232C/RS-422 connector

① Lit while power is ON.

② Lit or turned off according to the layout under the display.

③ Lit when an error has occurred.

④ Connect the controller to external devices such as a sync sensor and PLC.

⑤ Connect cameras.

⑥ Connect a DC power supply. Wire the power supply unit independently of

other devices. After wiring, replace the terminal cover.

Power Supply and Wiring p.3

⑦ Connect the ground wire. Make sure that the controller is grounded with a

separate ground wire.

⑧ Connect a monitor.

⑨ Connect an external device such as a personal computer or PLC.

⑩ Connect a track ball, mouse and USB memory. A total of four USB ports are provided and any of them can be

used. However, when connecting two or more USB memories, do not connect them to adjacent ports. Doing so

may cause the USB memories to come into contact, resulting in malfunction or damage.

• The following items can be connected to USB ports. • Commercially available track ball and mouse • USB memory

• Never insert/remove USB devices during measurement. Doing so may affect measurement time.

⑪ Connect the controller to a personal computer.

⑫ A touch pen is stored. (Provided with the LCD integrated type only)

• The touch pen must be stored so that the pen tip faces to the right when viewed toward the controller.

• To remove the touch pen, push the left side (handle) of the pen to the rear. The pen’s right side (pen tip) will pop out, so hold

and remove the pen.

Power Supply Wiring

24VDC

+

–

6

Page 24

Basic Conguration Camera 4ch type

* Items indicated with an asterisk are dedicated items, and cannot be substituted.

*

Controller

Use the monitor to check images and display the condition-setting

menus. The Controller performs the image processing specied by

the user settings and outputs the measurement results.

LCD integrated type

FJ-3000-10/FJ-3005-10

FJ-H3000-10/FJ-H3005-10

Front view Right-side view

Touch pen (standard accessory)

*

Camera cable

Camera cable

Camera cable

FZ-VS (2 m, 5 m, 10 m)

FZ-VS3 (2 m, 3m, 5 m, 10 m)

Bend resistant camera cable

Bend resistant camera cable

FZ-VSB (2 m, 5 m, 10 m)

FZ-VSB3 (2 m, 3m, 5 m, 10 m)

Right-angle camera cable

Right-angle camera cable

FZ-VSL (2 m, 5 m, 10 m)

FZ-VSL3 (2 m, 3m, 5 m, 10 m)

Long-distance camera cable

Bend resistant

FZ-VS2 (15m)

Right-angle camera cable

Long-distance Right-angle

FZ-VSLB3 (2 m, 3m, 5 m, 10 m)

camera cable

FZ-VSL2 (15m)

Long-distance camera cable

FZ-VS4 (15m)

Long-distance Right-angle

camera cable

Intelligent camera

FZ-VSL4 (15m)

FZ-SLC15/FZ-SLC100

Automatic focus camera

FZ-SZC15/FZ-SZC100

The Controller performs the image

processing specified by the user settings

and outputs the measurement results.

Box type

*

*

Use the monitor to check images

and display the condition-setting

menus.

FZ-M08 (8.4-inch)

*

FZ-VM (2 m, 5 m)

Power Supply

Recommended Model

By OMRON Corporation

S8VS-18024

Controller

FJ-3050-10/FJ-3055-10

FJ-H3050-10/FJ-H3055-10

LCD monitor

Monitor cable

*

Camera

Detects workpieces as images.

Standalone camera

FZ-SC/FZ-S/FZ-SC2M

FZ-S2M

FZ-SC5M2/FZ-S5M2/FZ-SFC

Intelligent compact camera

FZ-SQ010F/FZ-SQ050F

FZ-SQ100F/FZ-SQ100N

Peripheral Device

* USB memory

FZ-MEM2G/FZ-MEM8G

FZ-SF/FZ-SPC/FZ-SP

FZ-SHC/FZ-SH

Input Device

Mouse, track ball

(Commercially available USB devices)

7

Page 25

Component Names and Functions

LCD integrated type FJ-3000-10/FJ-3005-10/FJ-H3000-10/FJ-H3005-10

●

Left-side view Front view Right-side view

⑥⑦

Power/

ground

terminal

① POWER LED

② RUN LED

③ ERROR LED

Box type FJ-3050-10/FJ-3055-10/FJ-H3050-10/FJ-H3055-10

●

⑤

Camera connector

⑪ Ethernet connector

⑧ Monitor connector (analog RGB)

⑥⑦

Power/ground terminal

④ I/O connector (control lines, data lines)

⑩ USB connector

⑫ Touch pen (holder)

① POWER LED

② RUN LED

③ ERROR LED

⑩ USB connector

⑨ RS-232C/RS-422 connector

⑨ RS-232C/RS-422

connector

④ I/O connector

(control lines, data lines)

⑧ Monitor connector

(analog RGB)

⑪ Ethernet connector

⑤

Camera connector

⑩ USB connector

① Lit while power is ON.

② Lit or turned off according to the layout under the display.

③ Lit when an error has occurred.

④ Connect the controller to external devices such as a sync sensor and PLC.

⑤

Connect cameras.

⑥

Connect a DC power supply. Wire the power supply unit independently of

other devices. After wiring, replace the terminal cover.

Power Supply and Wiring p.3

⑦

Connect the ground wire. Make sure that the controller is grounded with a

separate ground wire.

⑧ Connect a monitor.

⑨ Connect an external device such as a personal computer or PLC.

⑩ Connect a track ball, mouse and USB memory. A total of four USB ports are provided and any of them can be

used. However, when connecting two or more USB memories, do not connect them to adjacent ports. Doing so

may cause the USB memories to come into contact, resulting in malfunction or damage.

• The following items can be connected to USB ports. • Commercially available track ball and mouse • USB memory

• Never insert/remove USB devices during measurement. Doing so may affect measurement time.

⑪ Connect the controller to a personal computer.

⑫ A touch pen is stored. (Provided with the LCD integrated type only)

• The touch pen must be stored so that the pen tip faces to the right when viewed toward the controller.

• To remove the touch pen, push the left side (handle) of the pen to the rear. The pen’s right side (pen tip) will pop out, so

hold and remove the pen.

Power Supply Wiring

24VDC

+

–

8

Page 26

Parallel Interface

COM OUT

NPN I/O type FJ-3000/FJ-3050/FJ-H3000/FJ-H3050

FJ-3000-10/FJ-3050-10/FJ-H3000-10/FJ-H3050-10

Internal Specications

[Input] signals: RESET, DI0 to DI7, DSA0, DSA1

Input voltage 12 to 24 V DC ±10 %

ON current *1 5 mA min.

ON voltage *1 8.8 V min.

OFF current *2 0.5 mA max.

OFF voltage *2 1.1V max.

ON delay 5 ms max.

OFF delay 0.7 ms max.

Internal circuit

*1 ON current/ON voltage

This refers to the current or voltage values needed to shift from the OFF → ON state. The ON voltage value is the potential difference

between each of the input terminals and COM IN.

*2 OFF current/OFF voltage

This refers to the current or voltage values needed to shift from the ON → OFF state. The OFF voltage value is the potential difference

between each of the input terminals and COM IN.

COM IN

[Output] signals: BUSY0, RUN/BUSY1, OR0 to 1, GATE0 to 1,

ERROR, DO0 to 15, READY0 to 1

Output voltage 12 to 24 V DC ±10 %

Load current 45 mA max.

ON residual voltage 2 V max.

OFF leakage current 0.2 mA max.

Internal circuit

Output terminal

Load

COM OUT

I/O Connector

No.

Signal name

A1

COMIN Orange Common for input signals

A2

ENCTRIG_A1 (*2)

A3

ENCTRIG_B1 (*2)

A4

STEP1 (*2)/

ENCTRIG_Z1 (*2)

A5

DSA1 (*2) Pink Data send request signal

A6

DI1 Orange Command inputs

A7

DI3 Gray

A8

DI5 White

A9

DI7 Yellow

A10

STGOUT1 Pink Strobe trigger output (*1)

A11

STGOUT3 Orange Strobe trigger output (*1)

A12

ERROR Gray ON when there is an error.

A13

COMOUT1 White Common for control signals

A14

GATE1 (*2) Yellow ON for the set output time

A15

OR1 (*2) Pink Overall judgment result

A16

READY1 (*2) Orange

A17

COMOUT2 Gray Common for output signals

A18

DO1 White Data output

A19

DO3 Yellow

A20

DO5 Pink

A21

DO7 Orange

A22

DO9 Gray

A23

DO11 White

A24

DO13 Yellow

A25

COMOUT3 Pink Common for output signals

•Handling the output common terminals

COMOUT1: STGOUT0 to 3, RUN/BUSY1, ERROR, BUSY0, OR0 to 1, GATE0 to 1 COMOUT2: READY0 to 1, DO0 to 7 COMOUT3: DO8 to 15

*1

This is a signal that is used when the strobe device is connected to the Controller. In camera 2ch type, only STGOUT0 and STGOUT1 can be used.

*2 This signal is only available in the Random trigger mode.

Wire color

Mark (red)

Gray

White

Yellow Measurement trigger input/

Function

Encoder trigger input (Phase A)B2ENCTRIG_A0

Encoder trigger input (Phase B)B3ENCTRIG_B0

Encoder trigger input (Phase Z)

ON when image input is allowed

[Input] signals: STEP0/ENCTRIG_Z0, STEP1/ENCTRIG_Z1,

ENCTRIG_A0 to 1, ENCTRIG_B0 to 1

Input voltage 12 to 24 V DC ±10 %

ON current *1 5 mA min.

ON voltage *1 8.8 V min.

OFF current *2 0.5 mA max.

OFF voltage *2 0.8 V max.

ON delay 0.1 ms max.

OFF delay 0.1 ms max.

Internal circuit

[Output] signals: When STGOUT0 to 3 are used,

COM IN

Input terminalInput terminal

connect the COMIN terminal.

Output voltage 12 to 24 V DC ±10 %

Load current 45 mA max.

ON residual voltage 2 V max.

OFF leakage current 0.2 mA max.

Internal circuit

No.

Signal name

B1

RESET Orange Controller restart

B4

STEP0/

ENCTRIG_Z0

B5

DSA0 Pink Data send request signal

B6

DI0 Orange Command inputs

B7

DI2 Gray

B8

DI4 White

B9

DI6 Yellow

B10

STGOUT0 Pink Strobe trigger output (*1)

B11

STGOUT3 Orange Strobe trigger output (*1)

B12

RUN/BUSY1 (*2)

B13

BUSY0 White ON during processing

B14

GATE0 Yellow ON for the set output time

B15

OR0 Pink Overall judgment result

B16

READY0 Orange

B17

DO0 Gray Data output

B18

DO2 White

B19

DO4 Yellow

B20

DO6 Pink

B21

DO8 Orange

B22

DO10 Gray

B23

DO12 White

B24

DO14 Yellow

B25

DO15 Pink

Wire color

Gray

White

Yellow

Gray

Mark (blk)

Encoder trigger input(Phase A)

Encoder trigger input(Phase B)

Measurement trigger input/

Encoder trigger input(Phase Z)

ON by layout setting/ON during processing

ON when image input is allowed

COM IN

Load

Output terminal

Function

9

Page 27

Parallel Interface

COM IN

COM OUT

PNP I/O type FJ-3005/FJ-3055/FJ-H3005/FJ-H3055

FJ-3005-10/FJ-3055-10/FJ-H3005-10/FJ-H3055-10

Internal Specications

[Input] signals: RESET, DI0 to DI7, DSA0, DSA1

Input voltage 12 to 24 V DC ±10 %

ON current *1 5 mA min.

ON voltage *1 8.8 V min.

OFF current *2 0.5 mA max.

OFF voltage *2 1.1V max.

ON delay 5 ms max.

OFF delay 0.7 ms max.

Internal circuit

*1 ON current/ON voltage

This refers to the current or voltage values needed to shift from the OFF → ON state. The ON voltage value is the potential difference

between each of the input terminals and COM IN.

*2 OFF current/OFF voltage

This refers to the current or voltage values needed to shift from the ON → OFF state. The OFF voltage value is the potential difference

between each of the input terminals and COM IN.

[Output] signals: BUSY0, RUN/BUSY1, OR0 to 1, GATE0 to 1,

ERROR, DO0 to 15, READY0 to 1

Output voltage 12 to 24 V DC ±10 %

Load current 45 mA max.

ON residual voltage 2 V max.

OFF leakage current 0.2 mA max.

Internal circuit

COM OUT

Load

Output terminal

I/O Connector

No.

Signal name

Wire color

Mark (red)

Function

[Input] signals: STEP0/ENCTRIG_Z0, STEP1/ENCTRIG_Z1,

ENCTRIG_A0 to 1, ENCTRIG_B0 to 1

Input voltage 12 to 24 V DC ±10 %

ON current *1 5 mA min.

ON voltage *1 8.8 V min.

OFF current *2 0.5 mA max.

OFF voltage *2 0.8 V max.

ON delay 0.1 ms max.

OFF delay 0.1 ms max.

Internal circuit

[Output] signals: When STGOUT0 to 3 are used,

Input terminalInput terminal

COM IN

connect the COMIN terminal.

Output voltage 12 to 24 V DC ±10 %

Load current 45 mA max.

ON residual voltage 2 V max.

OFF leakage current 0.2 mA max.

Internal circuit

Output terminal

COM IN

No.

Signal name

Wire color

Mark (blk)

Function

㩷

Load

I/O Connector wiring is the same as NPN I/O type.

10

Page 28

Connector

Connect the optional parallel I/O cable (FZ-VP or FZ-VPX).

Box type

LCD integrated type

Serial Interface

Connector

Pin No. Signal name Function

1 RDB(+) For RS-422

2 RD/RDA(-)

3 SD/SDA(-)

4 SDB(+) For RS-422

5 GND Signal ground

6 NC Not connected

7 NC Not connected

8 NC Not connected

9 NC Not connected

Use a compatible connector.

• Recommended items

Socket

Hood

Manufacturer Model

OMRON Corporation

OMRON Corporation

For RS-232C/RS-422

For RS-232C/RS-422

XM3D-0921

XM2S-0913

FZ-VP (2 m, 5 m)

Wire Color

No. mark

FZ-VPX (2 m, 5 m)

Wiring

The maximum cable length is 15 m.

• RS-232C

Controller

Signal name Pin No. Pin No. Signal name

RD 2 * RD

SD 3 * SD

GND 5 * GND

Use a shielded cable.

• RS-422

Controller

Signal name Pin No. Pin No. Signal name

RDB(+) 1 * RDA(-)

RDA(-) 2 * RDB(+)

SDA(-) 3 * SDB(+)

SDB(+) 4 * SDA(-)

Use a shielded cable.

Pin numbers will depend on the external device being connected. Refer

to the manual for the personal computer or PLC being connected.

External device to be connected

RS/CS control cannot be used.

External device to be connected

11

Connection Method

Align the connector with the socket and

press it straight into place, then x it with

the screws on both sides of the connector.

Turn OFF the power supply before connecting

or disconnecting a Cable. Peripheral devices

may be damaged if the cable is connected or

disconnected with the power ON.

LCD integrated type

Box type

Page 29

Mounting

LCD integrated type

• Panel mounting

297

1

+

0

(Unit: mm)

① Make a mount hole on the panel.

Panel thickness range: 1.6 to 4.8 mm

Panel material: Metal (iron, aluminum

or stainless)

② Insert the LCD integrated controller

into the hole, from the front panel.

③ Use the bracket (supplied with the

product) to secure the controller

and the panel.

Tightening torque: 0.5 to 0.6 Nm

Mounting the controller to the optional

•

desktop stand.

The controller can be placed on

a desk by attaching the optional

desktop stand (FZ-DS) to the

rear of the controller.

For details, refer to the instruction

*

manual of the desktop stand.

0

1

+

247

Top face

Bottom face

* No burr allowed

Mounting the controller to the optional

•

VESA attachment unit.

VESA-compatible mounting

of the controller is possible by

attaching the optional VESA

attachment unit (FZ-VESA) to

the rear of the controller.

For details, refer to the instruction

*

manual of the VESA attachment

unit.

Box type

• Side mounting • Bottom mounting

(17)

126 ± 0.25

(11)

80 ± 0.25

When mounting the controller on its bottom, it must be xed

*

without removing the feet to reserve ventilation path.

4-M4 Depth 6

4-M4 Depth 6

(13)

0.25

±

64

(26)

100 ± 0.25

4-

()

39

20

(18)

0.25

±

54

12

Page 30

Controller External Dimensions

LCD integrated type FJ-3000/FJ-3005/FJ-H3000/FJ-H3005

260

308

83

Box type FJ-3050/FJ-3055/FJ-H3050/FJ-H3055

4-M3

7

()

246

7

110

68

6

Depth 6

120 120

20

130

296

20

120 120

(Unit: mm)

()28.412.8 10

+

–

33

163.5

()

()

6

4-M4

Depth 6

4-M4

90

190

11 126

8

Depth 6

13

64

17 80

26

100

165

()

68

()

(Unit: mm)

()

68

+

–

33

()

6.8

11.5

15.45

()

20

4-

1854

39

80 17

4-M4

126

11

Depth 6

13

Page 31

Controller External Dimensions

LCD integrated type FJ-3000-10/FJ-3005-10/FJ-H3000-10/FJ-H3005-10

4-M3

Depth 6

7

()

260

308

104

246

7

110

68

6

Box type FJ-3050-10/FJ-3055-10/FJ-H3050-10/FJ-H3055-10

120 120

20

130

296

20

120 120

(Unit: mm)

()28.412.8 10

+

-

()

6

33

(163.5)

4-M4

Depth 6

4-M4

165

90

()

()

100

68

()

+

–

33

()

6.811.5

15.45

()

20

4-

1854

39

17 80 80 17

190

11 126

8

Depth 6

13

64

26

68

(Unit: mm)

4-M4

126

11

Depth 6

14

Page 32

Controller Specications

Operation LCD integrated type: Touch pen, mouse etc.

BOX type: Mouse or similar device

Serial communications RS-232C/422: 1 channel

Network communications Ethernet 100BASE-TX/10BASE-T

EtherNet/IP communication

Parallel I/O 17 inputs (RESET, STEP0/ENCTRIG_Z0, STEP1/ENCTRIG_Z1, DSA0 to 1,

Monitor interface LCD integrated type: Integrated Controller and 12.1 inch TFT color LCD

USB interface 4 channels (supports USB1.1 and 2.0)

Power supply voltage 24 V DC (20.4 to 26.4 V DC)

Current consumption

(At Power supply voltage

24 V DC)

Insulation resistance Between the group of external DC terminals and the ground terminal: 20M Ω min.

Dielectric strength Between the group of external DC terminals and the ground terminal: 1,000 VAC,

Leakage current 10 mA max.

Noise resistance 1 kV, pulse rise: 5 ns Pulse width: 50 ns

Vibration resistance 10 to 150 Hz, one-side amplitude 0.1 mm (Max. acceleration 15m/s

Shock resistance 150 m/s

Ambient temperature

range

Ambient humidity range Operating and storage: 35 % to 85 % (no condensation)

Ambient environment No corrosive gases

Ground D-type ground (ground resistance 100 Ω or less) * conventional class 3 ground

Degree of protection IEC60529 IP20

Environmental conditions

(according to

IEC61010-1)

Case materials ABS

Weight LCD integrated type: Approx. 3.4 kg Box type: Approx. 1.9 kg

Use Ethernet port.

Transmission speed: 100Mbps (100BASE-TX)

ENCTRIG_A0 to 1, ENCTRIG_B0 to 1, DI0 to 7)

29 outputs (RUN/BUSY1, BUSY0, GATE0 to 1, OR0 to 1, READY0 to 1, ERROR,

STGOUT0 to 3, DO0 to 15)

- Only camera 4ch type : STGOUT2 and 3.

(Resolusion: XGA 1024×768)

BOX type: Analog RGB video output 1 channel (Resolusion: XGA 1024×768)

Consumption of current varies depending on the type of camera connected.

When FZ-S_/FZ-S_2M/FZ-S_5M_/FZ-SP_/FZ-SF_/FZ-SH_ is connected:

Camera 2ch type : Approx. 3.7A max / Camera 4ch type : Approx. 4.9A

When FZ-SQ____ is connected :

Camera 2ch type : Approx. 5.0A / Camera 4ch type : Approx.7.5A

(DC100V megger, with internal surge absober removed)

50/60 Hz

Burst continuing time: 15 ms Cycle: 300 ms

2

)

10 times for 8 minutes for each three direction

2

; 3 times each in 6 directions

Operating: 0 to +50 °C (with no icing or condensation)

Ambient temperature speciable. The cooling fan speed can be

switched according to the setting.

0 to +45 °C: Low speed, 0 to +50 °C: High speed

Storage: –20 to +65 °C (with no icing or condensation)

Indoor use

Maximum altitude of 2,000 m

Supply voltage uctuations of +10 %, –15 % of the rated voltage

Installation category I

Pollution degree 2

Page 33

PC Vision System

FJ-300_/FJ-305_/FJ-H300_/FJ-H305_

FJ-300_-10/FJ-305_-10/FJ-H300_-10/FJ-H305_-10

FJ 系列

说明书 (安装)

感谢您选择 FJ 系列 PC 视觉系统。

本说明书介绍如何使用 FJ 系列 PC 视觉系统。

使用 FJ 系列 PC 视觉系统时, 请务必查看以下内容 :

•

FJ 系列 PC 视觉系统必须由精通电子工程的人员操作。

•

为了确保正确使用, 请通读本说明书, 加深对产品的了解。

•

请妥善保管说明书, 以便随时参阅。

模型中 “_” 的含义如下所述。

*

0:NPN 输入 / 输出类型 5:PNP 输入 / 输出类型

以下公告只适用于带 CE 标志的产品 :

公告 :

此为 A 级产品。 在居民区可能会干扰收音机, 如出现这种情况, 用户可能需要采

取适当措施降低干扰。

© OMRON Corporation 2011 保留所有权利。

Page 34

阅读理解本文件

使用产品前请阅读理解本文件, 有任何问题或建议请咨询 OMRON 代表处。

保修期

OMRON 保证产品材料无瑕疵或做工缺陷, 保修期为自 OMRON 售出产品之日起一年 (或其它指定时

期)。

OMRON 对该产品关于无损害、 适销性或特定目的恰当性不作担保或声明、 表明或暗示。 任何卖家或

用户已被告知其自身单独确定该产品是否适合应用。 OMRON 拒绝承认其它保修、 表明或暗示。

责任限制

对与该产品相关的特殊、 间接或继发损害、 任何形式的利润或商业损失, 不论此类声明是否基于合同、

保修、 疏忽或严格责任, OMRON 对此不承担责任。

对于超出担责产品单价的任何事件, OMRON 不承担责任。

任何情况下,OMRON 均不承担保修、修理或其它关于产品的声明,OMRON 分析确认产品搬运、处理、

安装以及维护均适当, 产品无污染、 滥用、 误用或不当修改或修理的情况除外。

适用性

本文件所述产品未经过安全等级认定。 设计或等级不针对保障人身安全, 不得作为安全组件或类似目的

的防护装置。 请参见 OMRON 安全等级评定产品的单独目录。

OMRON 不担保产品符合对客户应用的产品组合适用的标准、 法典或规定。

客户提出请求情况下, OMRON 将提供第三方认证文件, 确认产品的等级及限制条件。 本信息本身不

足以确定产品是否适合结合终端产品、 机器、 系统或其它应用或用途。

下面给出了必须特别注意的应用的几个示例。 这并不是该产品用途的详单, 也并非暗示所列用途适合该

产品。

• 户外使用、 包括潜在化学品污染或电子干扰、 或本文件未描述的条件或用途。

• 核能控制系统、 燃烧系统、 铁路系统、 航空系统、 医疗设备、 娱乐机器、 车辆、 安全设备以及

符合单独行业或政府规定的安装。

• 系统、 机器以及可能危害生命财产的设备。

请了解并查看有关产品的所有用途禁令。 未确定系统整体的设计可承担相应风险前, 以及未对 OMRON

产品适当定级或妥善安装进整体设备或系统前, 禁止将该产品用于对生命或财产有严重风险的用途。

1

Page 35

本说明书采用以下信号语。

警告

信号语含义

表示潜在危险状态, 如不加以避免, 则会导致轻度或中等伤害或 可能导致严重伤害或死亡。 另外, 还可

能有严重财产损失。

注意

表示潜在危险状态, 如不加以避免, 则可能导致轻度或中等伤害或 财产损失。

警示标志含义

本说明书采用以下警示标志。

表示无特定标志时的通用禁止。 表示特定条件下发生触电的可能性。

表示特定条件下发生爆炸的可能性。 表示激光辐射的可能性。

表示特定条件下高温损伤的可能性。

本说明书内的警示语句

以下警示语句适用于本说明书内产品。 说明书内相关位置也采用警示语句, 以引起您的注意。

警告

使用产品时必须遵照说明书。 否则可能导致产品功能或性能故障。

该产品设计或定级未考虑保障人身安全。

不要将产品用于此类目的。

不要打开箱盖。 否则内部高压可能导致触电。

控制器内部装有一块锂电池, 如处理不当, 有时可能烧毁、 爆炸或燃烧。 将控制器做工业废物处理, 不得拆卸、 施加可

导致变形的压力、 加热至 100 °C 或更高温度或焚烧控制器。

由于该产品发射的可见光可能危害眼睛, 因此不要直视 LED 发出的光。 如果使用了可反射的物体, 注意不要让反射光线进

入眼睛。

注意

烧伤危险

LED 开启时或刚刚关闭后, 箱盖还非常热, 不要立即触摸。

安全使用预防措施

安装环境

●

不要在含易燃易爆气体的区域使用该产品。

•

安装产品时, 使冷却通风口气流通畅。

•

不要安装在在高压装置和电源装置附近, 确保操作和维修安全。

•

确保拧紧全部安装螺丝。

•

电源和接线

●

确保使用该产品时采用本说明书指定的电源电压。

•

采用指定规格的电源电缆和压接端子。 不要将绞线端简单地直接连到接线板上。

•

- 适用的线规格 : 1.31 到 2.63 mm

- 端接螺钉 : M4

电源线越短越好 (最大值 10 m)。

•

采用直流电源, 并采取安全措施防止高压峰值 (二级边有安全超低压电路)。

•

将产品接地至小于 100 Ω。

•

选用尽可能近的接地点, 接地线越短越好。

•

用单独的接地线将控制器接地。 为了避免接地问题, 不要与其它装置共用接地线, 也不要将接地线连至建筑物的钢筋框架。

•

接通电源前, 再次确定接线正确。

•

其它事项

●

仅采用专为该产品设计的摄像机和电缆。 否则可能导致产品功能故障或损坏产品。

•

连接或断开摄像机或电缆前, 给控制器断电。

•

不要尝试拆卸、 修理或修改该产品。

•

发现反常情况时, 立即停止使用, 关闭电源, 联系 OMRON 代表处。

•

通电时或刚关闭电源后, 不要触摸荧光灯或卤素灯。

•

按工业废物处理该产品。

•

规定及标准

●

该控制器符合以下标准 :

EN standard EN61326-1

Electromagnetic environment :

Industrial electromagnetic environment

(EN/IEC 61326-1 Table 2)

于本产品的 imyuniti 考试, 以下的条件被适用。

于显示器表示, 文字的辨认可能的

映像的混乱作为合格。

2

- 接线端子 最大值 8.5 mm 最大值 8.5 mm

2

Page 36

接地

●

控制器电源电路未与内部电路绝缘。

•

将 24 V 直流电源正极端接地时, 不要将控制器的 FG 端或 (PLC)的FG 端接地。 ① , ②

•

由于 PC 壳体和 SG (0V)在PC 内部相连接, 电流将沿下图所示路径运行, 并导致烧毁。

如果没有类似 PC 的 SG (0V)与FG 短路的路径, 则可以将控制器 FG 端安全接地。 有关 PLC 的接线信息, 接线前请查看您

•

的 PLC 规格。

将摄像机连至控制器时, 一定要采用垫片。 ③

•

由于摄像机壳体为 SG (0V), 如果不采用垫片, 可导致 SG (0V)和FG 间短路。

将正极端接地时, 为避免触电, 不要触摸 SG (0V) (摄像机本体、 电源端)。

•

在底部安装箱型控制器(FJ-305_/FJ-H305_/FJ-305_-10/FJ-H305_-10)时,由于底部表面与SG(0V)相连,将与设备的FG 短路。

•

为避免这种情况, 我们提供绝缘垫片。 请咨询 OMRON 代表处, 了解相关信息。

控制器

24V

电源

电源电路

0V

SG

FG

1

FG

SG : 信号接地

FG : 框架接地

正确使用预防措施

安装及储存场所

●

在满足以下条件的场所安装储存该产品 :

周围温度 0 到 +50 °C (-20 到 + 65 °C 储存)

•

无剧烈温度变化 (安置在无露珠形成的地方)

•

相对湿度在 35 % 到 85 % 之间。

•

无腐蚀性或易燃性气体

•

产品安装朝向

●

为了改善散热, 仅按右述朝向安装该产品。

周围温度

●

控制器上下各保留 50 mm 的间隙, 以改善空气循环。 该产

•

品左侧和右侧与其它装置间必须至少留出 10 mm 的空隙。

但是, 如果临近装置不产生热量, 在控制器上方至少留出

50 mm 的空隙。 底部和边的空隙, 遵照安装方法。

不要将产品安装到重要热源上方, 如加热器、 变压器或大容

•

量电阻。

不要让周围温度超过 50 °C (122 °F)。

•

如果周围温度接近 50 °C (122 °F), 配备强制风扇冷却或

•

空调, 确保环境温度不超过 50 °C (122 °F)。

SG(0V)

连接器壳体

RS-232C

连接器壳体

并联 I/O

摄像机电缆

SG SG

SG

SG(0V)

SG

RS-232C

FG FG

SG

RS-232C

SG FG

安置场所无灰尘、 盐和铁粒子

•

无震动或撞击的场所

•

无阳光直射的场所

•

不会接触水、 油或化学品的场所

•

LCD 组合型 不要以此朝向安装。

●

箱型

●

PC

PLC

FG

摄像机

安装垫片

(绝缘体)

3

外壳

为保留通风路径, 必须将

支脚安装在位于底部的侧

板上。

2

不要以此朝向安装。

3

Page 37

抗干扰性

●

请勿安装在设置有高压机器的柜内。

•

请勿安装在距离动力线 200 mm 范围内。

•

组件安装及使用

●

触摸信号线

•

为防止静电危害, 触摸端子部分及连接器的内部信号线时, 请采用防静电手环或其它装置。

USB 存储器的使用

•

拆除 USB 存储器时, 确保没有正在读取或写入数据。

执行读取或写入操作时, USB 存储器上的 LED 闪烁, 请确认 LED 熄灭后再取下装置。

关闭电源

•

如果有消息显示程序正在执行, 请不要关闭电源。 否则将毁坏存储的数据, 下次启动时产品可能无法正确运行。

使用 RESET 信号

•

开启电源后不要立即使用 RESET 输入。 使用 RESET 输入同步化启动时间时, 开启控制器电源后, 至少等待 15 秒再开启 RESET

信号。

LCD- 组合型 (FJ-300_/FJ-300_-10/FJ-H300_/FJ-H300_-10)的LCD 面板采用精密技术制作, 有时一些像素缺失。 这是 LCD

•

面板的结构决定的, 并非故障。

维修

●

关闭电源, 检查前采取安全预防措施。 未切断电源尝试安全检查可导致触电。

用擦镜布或气刷清洁镜头。

•

用软布轻轻擦去污垢。

•

CCD 上的污垢必须用气刷清除。

•

不要用稀释剂或挥发油。

•

与上位装置通信

●

确认该产品启动后, 与上位装置通信。

启动该产品后, 上位接口可能输出一个模糊信号。

为避免这一问题, 初始操作时清理接收缓冲器。

确认包装内容

控制器 ................................................................. 数量 : 1

•

说明书 (本手册) ............................................. 数量 : 1

•

会员注册表 ..........................................................数量 : 1

•

安装支架 (面板用) ......................................... 数量 : 6 * 仅 LCD 组合型配备。

•

手写笔 ................................................................. 数量 : 1 * 仅 LCD 组合型配备。

•

(收纳于控制器内部)

美国加利福尼亚通告 :

该产品包含一块锂电池, 所含有的高氯酸盐材料受到加利福尼亚州法的限制, 出口时请做好对此州法的对应。

参见 www.dtsc.ca.gov/hazardouswaste/perchlorate

4

Page 38

基本配置 2ch 型摄像机

* 标注星号的物品为专用物品, 除这些以外无法使用。

*

控制器

利用显示器查看图像、 显示条件设置菜单。 控制器

根据设定条件进行图像处理并输出测量结果。

LCD 组合型

FJ-3000/FJ-3005

FJ-H3000/FJ-H3005

正视图 右侧视图

手写笔 (标准附件)

*

摄像机电缆

摄像机电缆

摄像机电缆

FZ-VS (2 m, 5 m, 10 m)

FZ-VS3 (2 m, 3m, 5 m, 10 m)

抗弯摄像机电缆

抗弯摄像机电缆

FZ-VSB (2 m, 5 m, 10 m)

FZ-VSB3 (2 m, 3m, 5 m, 10 m)

直角摄像机电缆

直角摄像机电缆

FZ-VSL (2 m, 5 m, 10 m)

FZ-VSL3 (2 m, 3m, 5 m, 10 m)

远距离摄像机电缆

抗弯直角摄像机电缆

FZ-VS2 (15 m)

FZ-VSLB3 (2 m, 3m, 5 m, 10 m)

远距离直角

远距离摄像机电缆

摄像机电缆

FZ-VS4 (15m)

FZ-VSL2 (15 m)

远距离直角摄像机电缆

FZ-VSL4 (15m)

智能摄像机

FZ-SLC15/FZ-SLC100

控制器根据设定条件进行图像处理并输出测

量结果。

箱型

FJ-3050/FJ-3055

FJ-H3050/FJ-H3055

自动调焦摄像机

FZ-SZC15/FZ-SZC100

*

控制器

*

LCD 显示器

利用显示器查看图像、 显示条件设

置菜单。

FZ-M08 (8.4-inch)

*

显示器电缆

FZ-VM (2 m, 5 m)

电源

推荐型号

OMRON 公司推荐

S8VS-12024

*

摄像机

将检测工件拍摄成图像。

单机式摄像机

FZ-SC/FZ-S/FZ-SC2M

FZ-S2M

FZ-SC5M2/FZ-S5M2/FZ-SFC

FZ-SF/FZ-SPC/FZ-SP

FZ-SHC/FZ-SH

智能袖珍摄像机

FZ-SQ010F/FZ-SQ050F

FZ-SQ100F/FZ-SQ100N

外围装置

USB 存储器

Z-MEM2G/FZ-MEM8G

输入装置

鼠标、 跟踪球

(市售 USB 接口的装置)

5

Page 39

组件名称及功能

Ẕᶹ

Ẕᶹ

●

LCD 组合型 FJ-3000/FJ-3005/FJ-H3000/FJ-H3005

左侧视图

⑥⑦ 电源 /

接地端子

① 电源 LED 指示灯

② 运行 LED 指示灯

③ 错误 LED 指示灯

●

箱型 FJ-3050/FJ-3055/FJ-H3050/FJ-H3055

⑧ 显示器连接器 (模拟量 RGB)

⑥⑦ 电源 / 接地端子

④ 输入 / 输出连接器 (控制线、 数据线)

⑩ USB 连接器

⑤ 摄像机连接器

⑪以太网连接器

正视图 右侧视图

⑨ RS-232C/RS-422

连接器

④ 输入 / 输出连接器

(控制线、 数据线)

⑧ 显示器连接器

(模拟量 RGB)

⑪ 以太网连接器

⑤ 摄像机连接器

⑩ USB 连接器

⑫ 手写笔 (收纳在内)

① 电源 LED 指示灯

② 运行 LED 指示灯

③ 错误 LED 指示灯

⑩ USB 连接器

⑨ RS-232C/RS-422 连接器

① 通电时变亮。

② 根据显示中的布局变亮或不亮。

③ 发生错误时变亮。

④ 将控制器连接到同步传感器和 PLC 等外部设备。

⑤ 连接摄像机。

⑥连接直流电源。 将电源单独与其它装置连线。 连接后,请将端子盖(透明)

安装回原来的地方。

电源和接线 p.3

⑦连接接地线。 确保控制器以单独的接地线接地。

⑧ 连接显示器

⑨ 连接外部装置, 例如个人电脑或 PLC。

⑩连接跟踪球、 鼠标和 USB 存储器。 共计四个 USB 端口, 每个都可以使用。 但是, 连接两个或多个 USB 记

忆装置时, 不要连到相邻端口。 否则 USB 记忆装载可能接触, 导致误动作或损坏。

• 以下装置可连接 USB 端口。 • 市售跟踪球和鼠标 • USB 存储器

• 测量时不要插入 / 取下 USB 装置。 否则可能影响测量时间。

⑪ 将控制器连接到个人电脑。

⑫ 存放有手写笔。 (仅 LCD 组合型配备)

• 存放手写笔时, 请务必面向控制器, 笔尖朝右进行收纳。

• 取出时将手写笔左侧 (柄) 推到尾部, 取下手写笔。 因笔右侧 (笔尖) 会向前突出, 请拿住笔将其取下。

电源接线

24VDC

+

–

6

Page 40

基本配置 4ch 型摄像机

* 标注星号的物品为专用物品, 除这些以外无法使用。

*

控制器

利用显示器查看图像、 显示条件设置菜单。 控制器根据设定条件

进行图像处理并输出测量结果。

LCD 组合型

FJ-3000-10/FJ-3005-10

FJ-H3000-10/FJ-H3005-10

正视图 右侧视图

手写笔 (标准附件)

*

控制器

控制器根据设定条件进行图像处理并输出

测量结果。

箱型

FJ-3050-10/FJ-3055-10

FJ-H3050-10/FJ-H3055-10

*

LCD 显示器

利用显示器查看图像、 显示条件

设置菜单。

*

摄像机电缆

摄像机电缆

摄像机电缆

FZ-VS (2 m, 5 m, 10 m)

FZ-VS3 (2 m, 3m, 5 m, 10 m)

抗弯摄像机电缆

抗弯摄像机电缆

FZ-VSB (2 m, 5 m, 10 m)

FZ-VSB3 (2 m, 3m, 5 m, 10 m)

直角摄像机电缆

直角摄像机电缆

FZ-VSL (2 m, 5 m, 10 m)

FZ-VSL3 (2 m, 3m, 5 m, 10 m)

远距离摄像机电缆

抗弯直角摄像机电缆

FZ-VS2 (15 m)

FZ-VSLB3 (2 m, 3m, 5 m, 10 m)

远距离直角

摄像机电缆

远距离摄像机电缆

FZ-VSL2 (15 m)

FZ-VS4 (15m)

远距离直角摄像机电缆

FZ-VSL4 (15m)

智能摄像机

FZ-SLC15/FZ-SLC100

*

摄像机

将检测工件拍摄成图像。

单机式摄像机

FZ-SC/FZ-S/FZ-SC2M

FZ-S2M

FZ-SC5M2/FZ-S5M2/FZ-SFC

FZ-SF/FZ-SPC/FZ-SP

FZ-SHC/FZ-SH

自动调焦摄像机

FZ-SZC15/FZ-SZC100

智能袖珍摄像机

FZ-SQ010F/FZ-SQ050F

FZ-SQ100F/FZ-SQ100N

FZ-M08 (8.4-inch)

*

显示器电缆

FZ-VM (2 m, 5 m)

电源

推荐型号

OMRON 公司推荐

S8VS-18024