Omron F3S-TGR-NLPC-20-M1J8, F3S-TGR-NLPC-20-02, F3S-TGR-NLPC-20-05, F3S-TGR-NLPC-20-10, F3S-TGR-NLPC-21-02 Datasheet

...Page 1

Compact Magnetic Non-contact Safety Switches

F3S-TGR-N@C

Magnetic Coded Non-contact

switches are designed to interlock hinge, sliding or removal

guard doors. All coded Non-contact switches have a LED for

easy diagnosis.

• Coded actuator for applications requiring

anti tamper switches

• Non-contact = no abrasion =

no particles

• Excellent coverage of mechanical

tolerances

• Can operate behind stainless steel fittings

• Screw-hole covers support hygienic

design (NMPC)

• Conforms to safety categories up to

4 acc. EN 954-1 and PDF-M acc.

EN60947-5-3.

Model Number Structure

F3S-TGR-N@@C-@@-@@

1. Type

L: Elongated Sensor

S: Small Sensor for NLPC and NSMC

M: Miniature Sensor

2. Housing Material

P: Plastic Housing

M: Stainless Steel Housing

3: Contact configuration

20: 2 Normally Closed Contacts (NC)

21: 2 Normally Closed Contacts (NC) +

4: Cable Length/connection

02: 2m Cable

05: 5m Cable

10: 10m Cable

M1J8: M12 male connector, 8pin

4: Cable Length/connection for NMPC

02: 2m Cable, cable exit to the left

05: 5m Cable, cable exit to the left

10: 10m Cable, cable exit to the left

M1J8: M12 male connector, 8-pin, cable exit to the left

12 3 4

1 Normally Open Contact (NO)

1F3S-TGR-N@C

Page 2

Ordering Information

Elongated Sensors Type Cable Connection Contact Configuration

F3S-TGR-NLPC-20-02 2 m pre-wired 2NC

F3S-TGR-NLPC-20-05 *

F3S-TGR-NLPC-20-10 10 pre-wired 2NC

F3S-TGR-NLPC-20-M1J8 M12, 8-pin 2NC

F3S-TGR-NLPC-21-02 2 m pre-wired 2NC/1NO

F3S-TGR-NLPC-21-05 * 5 m pre-wired 2NC/1NO

F3S-TGR-NLPC-21-10 10 pre-wired 2NC/1NO

F3S-TGR-NLPC-21-M1J8 M12, 8-pin 2NC/1NO

*. Preferred stock items.

Small Sensor Type Cable Connection Contact Configuration

F3S-TGR-NSMC-20-02 2 m pre-wired 2NC

F3S-TGR-NSMC-20-05 *

F3S-TGR-NSMC-20-10 10 pre-wired 2NC

F3S-TGR-NSMC-20-M1J8 M12, 8-pin 2NC

F3S-TGR-NSMC-21-02 2 m pre-wired 2NC/1NO

F3S-TGR-NSMC-21-05 * 5 m pre-wired 2NC/1NO

F3S-TGR-NSMC-21-10 10 pre-wired 2NC/1NO

F3S-TGR-NSMC-21-M1J8 M12, 8-pin 2NC/1NO

*. Preferred stock items.

5 m pre-wired 2NC

5 m pre-wired 2NC

Miniature Sensor Type Cable Connection Contact Configuration

F3S-TGR-NMPC-20-02 2m pre-wired 2NC

F3S-TGR-NMPC-20-05 *

F3S-TGR-NMPC-20-10 10m pre-wired 2NC

F3S-TGR-NMPC-20-M1J8 M12, 8pin 2NC

F3S-TGR-NMPC-21-02 2m pre-wired 2NC/1NO

F3S-TGR-NMPC-21-05 * 5m pre-wired 2NC/1NO

F3S-TGR-NMPC-21-10 10m pre-wired 2NC/1NO

F3S-TGR-NMPC-21-M1J8 M12, 8pin 2NC/1NO

*. Optional cable exit to the right is available for F3S-TGR-NMPC - types. Please contact your Omron distributor

5m pre-wired 2NC

2 Safety Sensors / Components

Page 3

Accessories

Safety relay units

G9SA G9SA-301

G9SA-501

G9SA-321-T075

G9SA-321-T15

G9SA-321-T30

G9SB G9SB-2002-C

G9SB-2002-A

G9SB-200-B

G9SB-200-D

G9SB-3012-A

G9SB-301-B

G9SB-3012-C

G9SB-301-D

G9SX G9SX-BC202-R_

G9SX-AD322-T15-R_

G9SX-AD322-T150-R_

G9SX-ADA222-T15-R_

G9SX-ADA222-T150-R_

Programmable

Controllers

Cables 8-pin

T-Connector

Connection cable

Standalone controller 16 inputs NE1A-SCPU01L

Standalone controller 40 inputs NE1A-SCPU02L

Safety Network controller 16 inputs NE1A-SCPU01-V1

Safety Network controller 40 inputs NE1A-SCPU02

Safety input terminal DST1-ID12SL-1

Safety mixed terminal DST1-MD16SL-1

Safety mixed terminal (relay out) DST1-MRD08SL-1

2 m F39-TGR-CVL-B-2-R

5 m F39-TGR-CVL-B-5-R

10 m F39-TGR-CVL-B-10-R

for M12 connector - types F39-TGR-NT

2m M12-8pin, 2m F39-TGR-CVL-N-2

5m M12-8pin, 5m F39-TGR-CVL-N-5

10m M12-8pin, 10m F39-TGR-CVL-N-10

3F3S-TGR-N@C

Page 4

Specifications

Mechanical Data

Elongated Sensor Small Sensor Miniature Sensor

Operating distance

Actuator approach

speed

Switching frequency 1Hz

Operating temperature -25°C…+80°C -25°C…+105°C -25°C…+80°C

Enclosure protection

Material Black Polycarbonate Stainless Steel 316 Black Polyester

Mounting bolts 2 x M4 recommended

Tightening torque 1Nm 0,8Nm

Mounting position any

Mechanical life

expectancy

Electrical life

expectancy

Cable diameter

and material

OFF Î ON (Sao) 12mm Close 8mm Close

ON Î OFF (Sar) 17mm Open 12mm Open

Min. 4mm/s

Max. 1000mm/s

Flying lead

M12 connector

De-rating Safety

factor 2

IP67

10.000.000 cycles

1.000.000 cycles

2.000.000 cycles @ 24VDC/100mA

6mm PVC

Electrical Data

Elongated Sensor Small sensor Miniature Sensor

Power supply 24VDC ±15%

Power consumption Max. 50mA

Switching current Min. 10mA @ 10VDC

Rated loads

Insulation resistance 100MΩ

Rated insulation

voltage

Output type electronic output (potential-free optocoupler output)

NC contacts

NO contacts

100mA @ 24VDC

100mA @ 24VDC

250VAC

Approved Standards

• EN standards certified by TÜV Rheinland

• EN 954-1

• EN 60204-1

• EN/IEC 60947-5-3

• UL 508, CSA C22.2

• BS 5304

• EN 1088-1 conformance

4 Safety Sensors / Components

Page 5

Connection diagram

Cable version

Pin No. Signal name

red

blue

black

white

yellow

green

brown

orange

+24 VDC

GND

NC Channel 1, +

NC Channel 1, NC Channel 2, +

NC Channel 2, NO Channel +

NO Channel, -

M12-Connector version

Pin No. Signal name Wire color (F39-TGR-SB4-CVLB)

+24 VDC

2

GND

3

5

6

4

3

7

8

2

1

7

1

4

6

5

8

NC Channel 1, +

NC Channel 1, NC Channel 2, +

NC Channel 2, NO Channel +

NO Channel, -

Brown

Green

Blue

White

Yellow

Pink

Grey

Red

Operating characteristics

-5 -4 -3L-2 -1 0 1 2 3 4 5

5 mm misalignment tolerance after setting

5F3S-TGR-N@C

Page 6

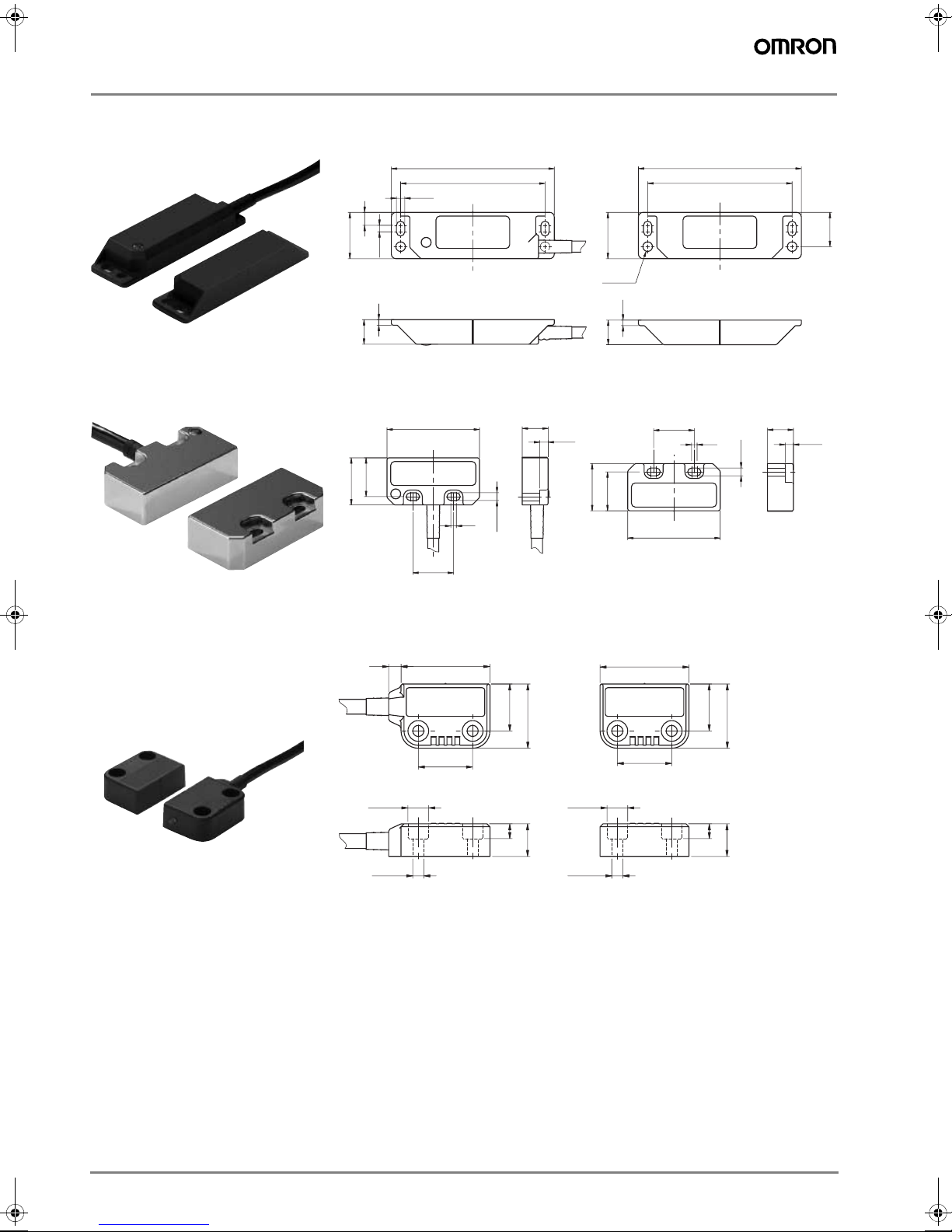

Dimensions

Elongated Sensor (Sensor/Actuator)

F3S-TGR-NLPC

88

4.50

7

25

3.50

78

25

Ø5.20

88

78

18.50

Small Sensor (Sensor/Actuator)

F3S-TGR-NSMC

Miniature Sensor (Sensor/Actuator)

F3S-TGR-NMPC

25.50

25.50

3

13

22

3

21

50

36

19

26

13

4.50

4.20

3

13

4.20

13

4.50

19

26

50

21

3

22

5

36

6 Safety Sensors / Components

Ø 8.40

Ø4.50

22

Ø 8.40

6

13

Ø 4.50

22

6

13

Page 7

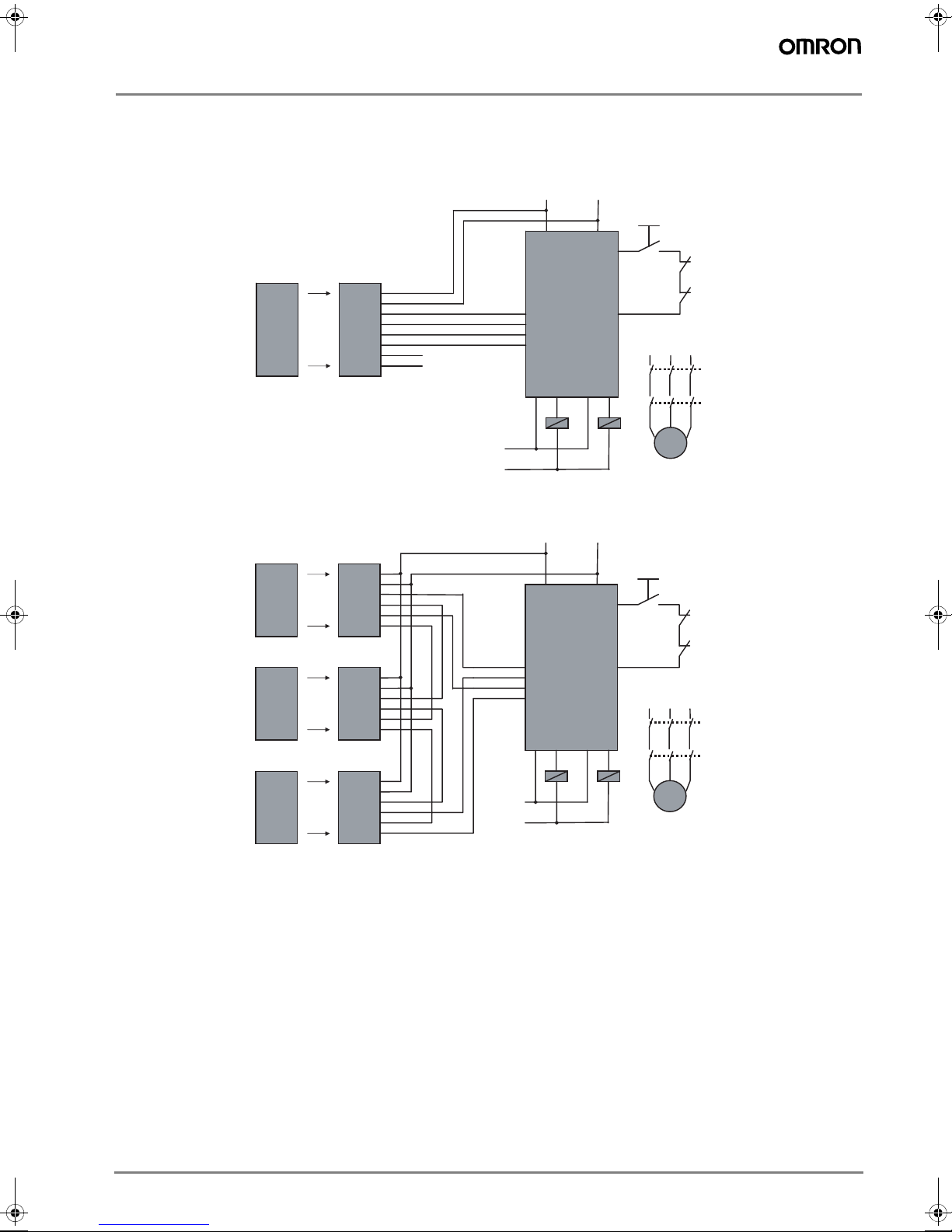

Wiring examples (Single head connection up to category 4 acc. EN954-1)

G9SA

Single Sensor Application with G9SA-301

(up to Safety Category 4 acc. EN954-1)

+24V GND

Start

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

brown

orange

NO

contact

+Us

GND

Series connection Application, up to 6 Sensors with G9SA-301

(up to Safety Category 3 acc. EN954-1)

Magnetic

Actuator

Magnetic

Actuator

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

+Us

GND

A1 A2

G9SA-301

T11

T12

T22

T21

14

13

33 34

KM1

+24V GND

A1 A2

T31

G9SA-301

T11

T12

T22

T21

13

14

T32

33 34

KM1

T31

T32

KM2

KM2

Start

Feed-

back-

loop

M

Feedback-

loop

M

KM1

KM2

KM1

KM2

KM1

KM2

KM1

KM2

7F3S-TGR-N@C

Page 8

G9SB

Single Sensor Application with G9SB-2002-C

(up to Safety Category 4 acc. EN954-1)

+24V GND

Start

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

brown

orange

NO

contact

+Us

GND

Series connection Application, up to 6 Sensors with G9SB-2002-C

(up to safety Category 3 acc. EN954-1)

Magnetic

Actuator

Magnetic

Actuator

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

+Us

GND

A1 A2

T31

G9SB-2002-C

T11

T12

T22

T21

13

14

T32

23 24

KM1

+24V GND

A1 A2

T31

G9SB-2002-C

T11

T12

T22

T21

13

14

T32

23 24

KM1

KM2

KM2

Start

Feed-

back-

loop

M

Feed-

back-

loop

M

KM1

KM2

KM1

KM2

KM1

KM2

KM1

KM2

8 Safety Sensors / Components

Page 9

G9SX

Single Sensor Application with G9SX-AD322-T15

(up to Safety Category 4 acc. EN954-1)

+24V GND

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

brown

orange

NO

contact

G9SX-AD322

T11

T12

T21

T22

GND

Series connection Application, up to 6 Sensors with G9SX-AD322-T15

(up to Safety Category 3 acc. EN954-1)

GND

+24V GND

G9SX-AD322

T11

T12

T21

T22

Magnetic

Actuator

Magnetic

Actuator

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

T33

A1

S14 S24

KM1 KM2

T33

S14 S24

KM1 KM2

Start

A2

T31

T32

Feedback-

loop

KM1

KM2

KM1

KM2

M

Start

A2A1

T31

T32

Feedback-

loop

KM1

KM2

KM1

KM2

M

9F3S-TGR-N@C

Page 10

DeviceNet Safety NE1A and DST1-I/O-Terminals

Single Sensor Application with NE1A and DST1-Safety-IO

(up to safety Category 4 acc. EN954-1)

+24V GND

V0 G0

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

brown

orange

NO

contact

Test 0

In 0

Test 1

In 1

Series connection Application, up to 6 Sensors with NE1A or DST1-Safety-IO

(up to Safety Category 3 acc. EN954-1)

Magnetic

Actuator

Magnetic

Actuator

Magnetic

Actuator

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

F3S-TGR-NxxC

Sensor

red

blue

black

white

yellow

green

+24V GND

V0 G0

Test 0

In 0

Test 1

In 1

NE1A-…

DST1-ID

DST1-MD

DST1-MRD

NE1A-…

DST1-ID

DST1-MD

DST1-MRD

Application with multiple Sensors with NE1A or DST1-Safety-IO

(up to Safety Category 4 acc. EN954-1)

Magnetic

Actuator

Magnetic

Actuator

Magnetic

Actuator

F3S-TGR-NxxC

F3S-TGR-NxxC

F3S-TGR-NxxC

10 Safety Sensors / Components

Sensor

red

blue

black

white

yellow

green

Sensor

red

blue

black

white

yellow

green

Sensor

red

blue

black

white

yellow

green

+24V

V0 G0

Test 0

Test 1

Test 2

In 0

In 1

In 2

In 3

NE1A-…

DST1-ID

DST1-MD

In 4

In 5

GND

Switch 1:

Test 0 In 0

Test 1 In 1

Switch 2:

Test 0 In 2

Test 2 In 3

Switch 3:

Test 1 In 4

Test 2 In 5

Page 11

Safety Precautions

!WARNING

Be sure to turn OFF the power before performing wiring.

Do not touch charge parts (e.g., terminals) while power is

ON. Doing so may result in electric shock.

Do not allow the actuator to come close to the switch with

the door open. Doing so may cause machinery to start

operating and may result in injury.

Keep actuators (magnets) away from magnetically

sensitive equipment like PC harddisks, floppy disks etc.

The magnetic field of the magnet will damage existing

data.

Mutual Interference

If the switch and actuator are mounted in parallel, be sure to

separate them by at least 25 mm, as shown below.

25 mm min.

Switch Switch

Actuator

Actuator

Guard door

Using for Hinged Doors

On hinged doors, install the Sensor at an opening edge as shown

below.

!CAUTION

Use guard stops in the way shown below to ensure that

the switch and actuator do not make contact when the

guard door is closed.

Guard door

Switch

Guard Stops

Actuator

min. 2 mm

max. 5 mm

(Standard Sensor)

max. 4 mm (Elongated Sensor)

Application Precautions

• Do not use the product in locations subject to explosive or

flammable gases.

• Do not use load currents exceeding the rated value.

• Be sure to wire each conductor correctly.

• Be sure to confirm correct operation after completing mounting and

adjustment.

• Do not drop or attempt to disassemble the product.

• Be sure to use the correct combination of switch and actuator.

• Use a power supply of the specified voltage. Do not use power

supplies with large ripples or power supplies that intermittently

generate incorrect voltages.

• Capacitors are consumable and require regular maintenance and

inspection.

Precautions for Safe Use

Mounting Direction of Switch and Actuator

The Sensor will not operate properly if the switch and actuator come

towards each other diagonally. The Sensor will, however, operate

properly if the switch and actuator come towards each other headon, horizontally or vertically (as long as the faces have the same

orientation).

CORRECT

2 mm

INCORRECT

Solvents

Ensure that solvents, such as alcohol, thinner, trichloroethane, or

gasoline do not adhere to the product. Solvents may cause markings

to fade and components to deteriorate.

Installation Location

Do not install the product in the following locations. Doing so may

result in product failure or malfunction.

• Locations subject to direct sunlight

• Locations subject to humidity levels outside the range 35% to 85%

or subject to condensation due to extreme temperature changes

• Locations subject to corrosive or flammable gases

• Locations subject to shocks or vibration in excess of the product

ratings

• Locations subject to dust (including iron dust) or salts

Take appropiate and sufficient countermeasures when using the

product in the following locations.

• Locations subject to static electricity or other forms of noise

• Locations subject to possible exposure to radioactivity

• Locations subject to power supply lines

• It is advisable to mount the switches on non ferrous materials.

The presence of ferrous material can effect switching sensitivity.

Wiring

Perform wiring using wire with the following dimensions.

Stranded wire: 2.5 mm

Solid wire: 4.0 mm

Tighten the terminal screws with the specified torque. Not doing so

may result in malfunction or abnormal heat generation.

Terminal screw tightening torque: 1 Nm for NLPC and NSMC

2

2

0,8 Nm for NMPC

CORRECT INCORRECTCORRECT CORRECT

11F3S-TGR-N@C

Page 12

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E14E-EN-02

In the interest of product improvement, specifications are subject to change without notice.

12 Safety Sensors / Components

Loading...

Loading...