Page 1

Safety Light Curtain F3SG-□SR□ Series

User's Manual

Man. No. Z405I-E3-01

Page 2

Original instructions

Introduction

Thank you for purchasing the F3SG-SR Series Safety Light Curtain (hereafter called the "F3SG-SR", "F3SG-SRA",

"F3SG-SRB", or "sensor").

This is the instruction Manual describing the use of F3SG-SR.

Always heed the following points when using the F3SG-SR:

• Be sure to have F3SG-SR be handled by a "Responsible Person" who is well aware of and familiar with the machine to

be installed.

• The term "Responsible Person" used in this document means the person qualified, authorized and responsible to

secure"safety" in each process of the design, installation, operation, maintenance services and disposition of the machine.

• It is assumed that the F3SG-SR will be used properly according to the installation environment, performance and

function of the machine. Responsible Person should conduct risk assessment on the machine and determine the

suitability of this product before installation.

• Read this document thoroughly to understand and make good use of the descriptions before installing and operating

the product.

• Keep this document at the place where the operator can refer to whenever necessary.

Trademarks

• Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

• Windows, Windows 7, Windows 8, Windows 10, Microsoft .NET Framework, and Surface are either registered

trademarks or trademarks of Microsoft Corporation in the USA and other countries.

• Official name of Windows 7 is Microsoft Windows 7 Operating System.

• Official name of Windows 8 is Microsoft Windows 8 Operating System.

• Official name of Windows 10 is Microsoft Windows 10 Operating System.

• USB Type-C™ is a trademark of USB Implementers Forum.

• The Bluetooth

• Google and Android are trademarks of Google LLC.

• Xperia is either a registered trademark or a trademark of Sony Mobile Communications Inc.

• SHARP and AQUOS are registered trademarks of Sharp Corporation.

• ASUS is a trademark of ASUSTeK Computer Inc.

• GALAXY S is a registered trademark of Samsung Electronics Co., Ltd.

• HUAWEI is either a registered trademark or a trademark of HUAWEI TECHNOLOGIES Co., Ltd.

• Mi and XIAOMI are either registered trademarks or trademarks of BEIJING XIAOMI TECHNOLOGY CO., LTD.

• Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc.

Page 3

Legislation and Standards

1. The F3SG-SR does not receive type approval provided by Article 44-2 of the Industrial Safety and Health

Act of Japan. When using the F3SG-SR in Japan as a "safety system for pressing or shearing machines"

prescribed in Article 42 of that law, the machine control system must receive type approval.

2. The F3SG-SR is electro-sensitive protective equipment (ESPE) in accordance with European Union (EU)

Machinery Directive Index Annex V, Item 2.

3. EU Declaration of Conformity

OMRON declares that the F3SG-SR is in conformity with the requirements of the following EU Directives:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

4. Conforming Standards

(1)European standards

EN61496-1 (Type 4 and Type 2 ESPE), EN 61496-2 (Type 4 and Type 2 AOPD), EN61508-1 through -4

(SIL 3 for Type 4 and SIL 1 for Type 2),

EN ISO 13849-1:2015 (PL e, Category 4 for Type 4 and PL c, Category 2 for Type 2)

(2)International standards

IEC61496-1 (Type 4 and Type 2 ESPE), IEC61496-2 (Type 4 and Type 2 AOPD), IEC61508-1 through 4 (SIL 3 for Type 4 and SIL 1 for Type 2),

ISO 13849-1:2015 (PL e, Category 4 for Type 4 and PL c, Category 2 for Type 2)

(3)JIS standards

JIS B 9704-1 (Type 4 and Type 2 ESPE), JIS B 9704-2 (Type 4 and Type 2 AOPD)

(4)North American standards

UL61496-1 (Type 4 and Type 2 ESPE), UL61496-2 (Type 4 and Type 2 AOPD), UL508, UL1998,

CAN/CSA C22.2 No.14, CAN/CSA C22.2 No.0.8

(5)Chinese standards

GB/T 4584 (Specification of active opto-electronic protective devices for presses)

(Models: F3SG-4SR

The following configurations of the F3SG-SR are compliant with GB/T 4584.

Configurations using the F3SG-SR with detection capability of 14-mm or 25-mm dia. and 20 ms max. of

the ON to OFF response time

-14/-25 in the case of the ON to OFF response time not exceeding 20 ms max.)

Introduction

Detection capability Protective height

14-mm dia. 160 to 2000 mm - Single Optical Normal 18 ms max.

14-mm dia. 160 to 1400 mm - Single Wired Normal 17 ms max.

25-mm dia. 160 to 2480 mm - Single Optical/Wired Normal 17 ms max.

Combination of 14-mm and 25-mm

dia. in cascade connection

Combination of 14-mm and 25-mm

dia. in cascade connection

* Refer to 1-6-3. Calculation of Response Time of Cascaded Segments for more information on the response time for the F3SG-SR

in cascade connection.

The F3SG-SR's with detection capability of 45-mm and 85-mm dia. are not compliant with GB/T 4584.

Refer to 1-5. Ratings and Specifications for more information on the ratings and specifications by model.

- 255 max. Cascaded Optical Normal 18 ms max.*

- 140 max. Cascaded Wired Normal 15 ms max.*

Number

of beams

Configuration

Synchronization

method

Response Time

Adjustment

ON to OFF

response time

F3SG-SR

User’s Manual

E

i

Page 4

Introduction

5. Third-Party Certifications

6. Other Standards

(1)TÜV SÜD

• EC Type-Examination certificate:

EU Machinery Directive, Type 4 and Type 2 ESPE (EN61496-1), Type 4 and Type 2 AOPD (EN 61496-2)

• Certificate:

Type 4 and Type 2 ESPE (EN61496-1), Type 4 and Type 2 AOPD (EN61496-2), EN 61508-1 through 4 (SIL 3 for Type 4 and SIL 1 for Type 2), EN ISO 13849-1:2015 (PL e, Category 4 for Type 4, and PL c,

Category 2 for Type 2)

(2)UL

• UL Listing:

Type 4 and Type 2 ESPE (UL61496-1), Type 4 and Type 2 AOPD (UL61496-2), UL508, UL1998, CAN/

CSA C22.2 No.14, CAN/CSA C22.2 No.0.8

(3)China National Casting and Forging Machines Quality Supervision and Inspection Center

• Certificate:

GB/T 4584 (Specification of active opto-electronic protective devices for presses)

(Models: F3SG-4SR-14/-25 in the case of the ON to OFF response time not exceeding 20 ms

max.)

The F3SG-SR is designed according to the standards listed below. To make sure that the final system

complies with the following standards and regulations, you are asked to design and use it in accordance

with all other related standards, laws, and regulations. If you have any questions, consult with specialized

organizations such as the body responsible for prescribing and/or enforcing machinery safety regulations

in the location where the equipment is to be used.

• European Standards: EN415-4, EN691-1, EN692, EN693, IEC 62046

• U.S. Occupational Safety and Health Standards: OSHA 29 CFR 1910.212

• U.S. Occupational Safety and Health Standards: OSHA 29 CFR 1910.217

• American National Standards: ANSI B11.1 to B11.19

• American National Standards: ANSI/RIA R15.06

• Canadian Standards Association CSA Z142, Z432, Z434

• SEMI Standards SEMI S2

• Japan Ministry of Health, Labour and Welfare "Guidelines for Comprehensive Safety Standards of

Machinery", Standard Bureau's Notification No. 0731001 dated July 31, 2007.rms and Conditions

Agreement

• Chinese National Standards: GB17120, GB27607

7. Meaning of mark according to EU WEEE Directive

Dispose in accordance with applicable regulations.

8. Regions where F39-SGBT can be used

For the regions where the F39-SGBT can be used, refer to the following instruction manuals of the F39SGBT.

Document Title No.

F39-SGBT Instruction Sheet 4615743-0

F39-SGBT Regulations and Standards 4615744-8

F3SG-SR

ii

User’s Manual

Page 5

Terms and Conditions Agreement

Warranties.

(a) Exclusive Warranty. Omron's exclusive warranty is that the Products will be free from defects in materials

and workmanship for a period of twelve months from the date of sale by Omron (or such other period

expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

infringement by the Products or otherwise of any intellectual property right.

(c) Buyer Remedy. Omron's sole obligation hereunder shall be, at Omron's election, to (i) replace (in the form

originally shipped with Buyer responsible for labor charges for removal or replacement thereof) the noncomplying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to

the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for

warranty, repair, indemnity or any other claims or expenses regarding the Products unless Omron's

analysis confirms that the Products were properly handled, stored, installed and maintained and not

subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by Buyer

must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the

suitability or unsuitability or the results from the use of Products in combination with any electrical or

electronic components, circuits, system assemblies or any other materials or substances or environments.

Any advice, recommendations or information given orally or in writing, are not to be construed as an

amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Introduction

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which

liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which

apply to the combination of the Product in the Buyer's application or use of the Product. At Buyer's request,

Omron will provide applicable third party certification documents identifying ratings and limitations of use

which apply to the Product. This information by itself is not sufficient for a complete determination of the

suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to

Buyer's application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS

BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

F3SG-SR

User’s Manual

E

iii

Page 6

Introduction

Programmable Products.

Omron Companies shall not be responsible for the user's programming of a programmable Product, or any

consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user

in determining suitability and does not constitute a warranty. It may represent the result of Omron's test

conditions, and the user must correlate it to actual application requirements. Actual performance is subject to

the Omron's Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the Product may be changed

without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications

for your application. Please consult with your Omron's representative at any time to confirm actual

specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical or proofreading errors or omissions.

iv

F3SG-SR

User’s Manual

Page 7

Terms and Conditions Agreement (Software)

1.WARRANTY

(1) The warranty period for the Software is one year from the date of purchase, unless otherwise specifically

agreed.

(2) If the User discovers defect of the Software (substantial non-conformity with the manual), and return it to

OMRON within the above warranty period, OMRON will replace the Software without charge by offering

media or download from OMRON's website. And if the User discovers defect of media which is

attributable to OMRON and return it to OMRON within the above warranty period, OMRON will replace

defective media without charge. If OMRON is unable to replace defective media or correct the Software,

the liability of OMRON and the User's remedy shall be limited to the refund of the license fee paid to

OMRON for the Software.

2.LIMITATION OF LIABILITY

(1) THE ABOVE WARRANTY SHALL CONSTITUTE THE USER'S SOLE AND EXCLUSIVE REMEDIES

AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR

PARTICULAR PURPOSE. IN NO EVENT, OMRON WILL BE LIABLE FOR ANY LOST PROFITS OR

OTHER INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF USE

OF THE SOFTWARE.

(2) OMRON SHALL HAVE NO LIABILITY FOR DEFECT OF THE SOFTWARE BASED ON MODIFICATION

OR ALTERNATION TO THE SOFTWARE BY THE USER OR ANY THIRD PARTY. OMRON SHALL NOT

BE RESPONSIBLE AND/OR LIABLE FOR ANY LOSS, DAMAGE, OR EXPENSES DIRECTLY OR

INDIRECTLY RESULTING FROM THE INFECTION OF OMRON PRODUCTS, ANY SOFTWARE

INSTALLED THEREON OR ANY COMPUTER EQUIPMENT, COMPUTER PROGRAMS, NETWORKS,

DATABASES OR OTHER PROPRIETARY MATERIAL CONNECTED THERETO BY DISTRIBUTED

DENIAL OF SERVICE ATTACK, COMPUTER VIRUSES, OTHER TECHNOLOGICALLY HARMFUL

MATERIAL AND/OR UNAUTHORIZED ACCESS.

(3) OMRON SHALL HAVE NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY THIRD

PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

Introduction

3. APPLICABLE CONDITIONS

USER SHALL NOT USE THE SOFTWARE FOR THE PURPOSE THAT IS NOT PROVIDED IN THE

ATTACHED USER MANUAL.

4. CHANGE IN SPECIFICATION

The software specifications and accessories may be changed at any time based on improvements and other

reasons.

5. ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

F3SG-SR

User’s Manual

E

v

Page 8

Introduction

Indications and meanings for safe use

The precautions listed in this document indicated by alert symbols and statements must be followed for the

safe use of the F3SG-SR. Failure to follow all precautions and alerts may result in an unsafe use or operation.

The following word and symbols are used in this document.

<Meaning of signal words>

<Meaning of alert symbols>

Safety Precautions

Indicates an imminently hazardous situation which, if not avoided, is likely to result in

serious injury or may result in death. Additionally there may be severe property

damage.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally there may be

significant property damage.

Indicates prohibited actions.

Indicates mandatory actions.

Indicates the risk of electric shock.

Alert statements

Users

The F3SG-SR must be installed, configured, and incorporated into a machine control system by

a sufficiently trained and qualified person. An unqualified person may not be able to perform

these operations properly, which may cause a person to go undetected, resulting in serious

injury.

vi

F3SG-SR

User’s Manual

Page 9

Machines

Do not use this sensor for machines that cannot be stopped quickly by electrical control. For

example, do not use it for a pressing machine that uses full-rotation clutch. Otherwise, the

machine may not stop before a person reaches the hazardous part, resulting in serious injury.

To use the F3SG-SR in PSDI mode (initiation of cyclic operation by a presence sensing device),

you must configure an appropriate circuit between the F3SG-SR and the machine. For details

about PSDI, refer to OSHA 1910.217, IEC 61496-1, and other relevant standards and

regulations.

Installation

Make sure Responsible Person tests the operation of the F3SG-SR and F39-SGIT-IL3 after

installation to verify that the F3SG-SR and F39-SGIT-IL3 operate as intended. Make sure to stop

the machine until the test is complete. Unintended installation, wiring or function settings may

cause a person to go undetected, resulting in serious injury.

Make sure to install the F3SG-SR at the safety distance from the hazardous part of the machine.

Otherwise, the machine may not stop before a person reaches the hazardous part, resulting in

serious injury.

Introduction

Install a protective structure so that the hazardous part of a machine can only be reached by

passing through the sensor's detection zone. If access to the hazardous part by reaching over

the detection zone of a vertically mounted F3SG-SR cannot be excluded, the height of the

detection zone and the safety distance shall be determined in consideration of such a risk. Install

the sensors so that part of the person is always present in the detection zone when working in a

machine's hazardous zones. If a person is able to step into the hazardous zone of a machine

and remain behind the F3SG-SR's detection zone, configure the system with Restart Interlock

function. Failure to do so may result in serious injury due to unexpected startup.

Install the reset switch in a location that provides a clear view of the entire hazardous zone and

where it cannot be activated from within the hazardous zone.

Install the pre-reset switch always in the hazardous zone and where it cannot be activated from

outside the hazardous zone.

The F3SG-SR cannot protect a person from an object flying from the hazardous zone. Install

protective cover(s) or fence(s).

Install a protective structure to cover the whole blanked zone in order to prevent personnel

approach to hazardous part of the machine through the blanked zone.

Detection capability gets larger when Fixed Blanking, Floating Blanking or Reduced Resolution

function is used. When these functions are used, the safety distance calculation must be based

on the increased detection capability for these functions. Otherwise, the machine may not stop

before a person reaches to the hazardous part, resulting in serious injury.

F3SG-SR

User’s Manual

E

vii

Page 10

Introduction

If detection capability may get larger and a human body may pass a detection zone to reach a

hazardous source, additional safety protection equipment must be installed such as a safety

fence.

A warning zone must not be used for safety applications. Always install your system so that a

detection zone should be passed before reaching a hazardous part of the machine. If access to

the hazardous part by reaching over the detection zone of a vertically mounted F3SG-SR cannot

be excluded, the height of the detection zone and the safety distance shall be determined in

consideration of such a risk.

When a warning zone is configured, you must attach labels that indicate a border between

normal detection zone and warning zone. Otherwise, the machine may not stop before a person

reaches to the hazardous part, resulting in serious injury.

A warning zone must be configured based on a safety distance.

The Muting and Override functions disable the safety functions of the device. Especially setting

the Muting Time Limit parameter to infinite may cause the safety functions to be disabled for a

long time. Install the F3SG-SR, muting sensor and physical barrier and configure time settings

for Muting and Override so that an operator should not enter hazardous zone when the Muting

and Override are active.

Install muting sensors so that they can distinguish between the object that is being allowed to

pass through the detection zone and a person. If the Muting function is activated by the detection

of a person, the machine may not stop operating, resulting in serious injury.

Muting lamps that indicate the state of the Muting and Override functions must be installed where

they are clearly visible to workers from all the operating positions.

Use two independent input devices for muting inputs. Failure to do so may cause the MUTING

state due to a single muting sensor's failure.

Install the switch that activates the Override and that uses hold-to-run device, such as spring

return key switch, in a location that provides a clear view of the entire hazardous zone and where

it cannot be activated from within the hazardous zone. Make sure that nobody is in the

hazardous zone before activating the Override function.

Make sure to connect an override cancel switch to the RESET line when using the Override

function. Otherwise, the OVERRIDE state may not be released by the override cancel switch,

resulting in serious injury.

Install the F3SG-SR so that it is not affected by reflective surfaces. Failure to do so may hinder

detection, resulting in serious injury. For an installation distance from reflective surfaces, see 5-

1-3. Distance from Reflective Surfaces.

viii

When using more than one set of F3SG-SR's in adjacent areas, the emitter of one F3SG-SR

may interfere with the receiver of the other, causing the safety functions to stop working properly.

Install, configure and maintain them so that mutual interference does not occur.

To change the response time, calculate the safety distance based on the setting. Otherwise, the

machine may not stop before a person reaches the hazardous part, resulting in serious injury.

F3SG-SR

User’s Manual

Page 11

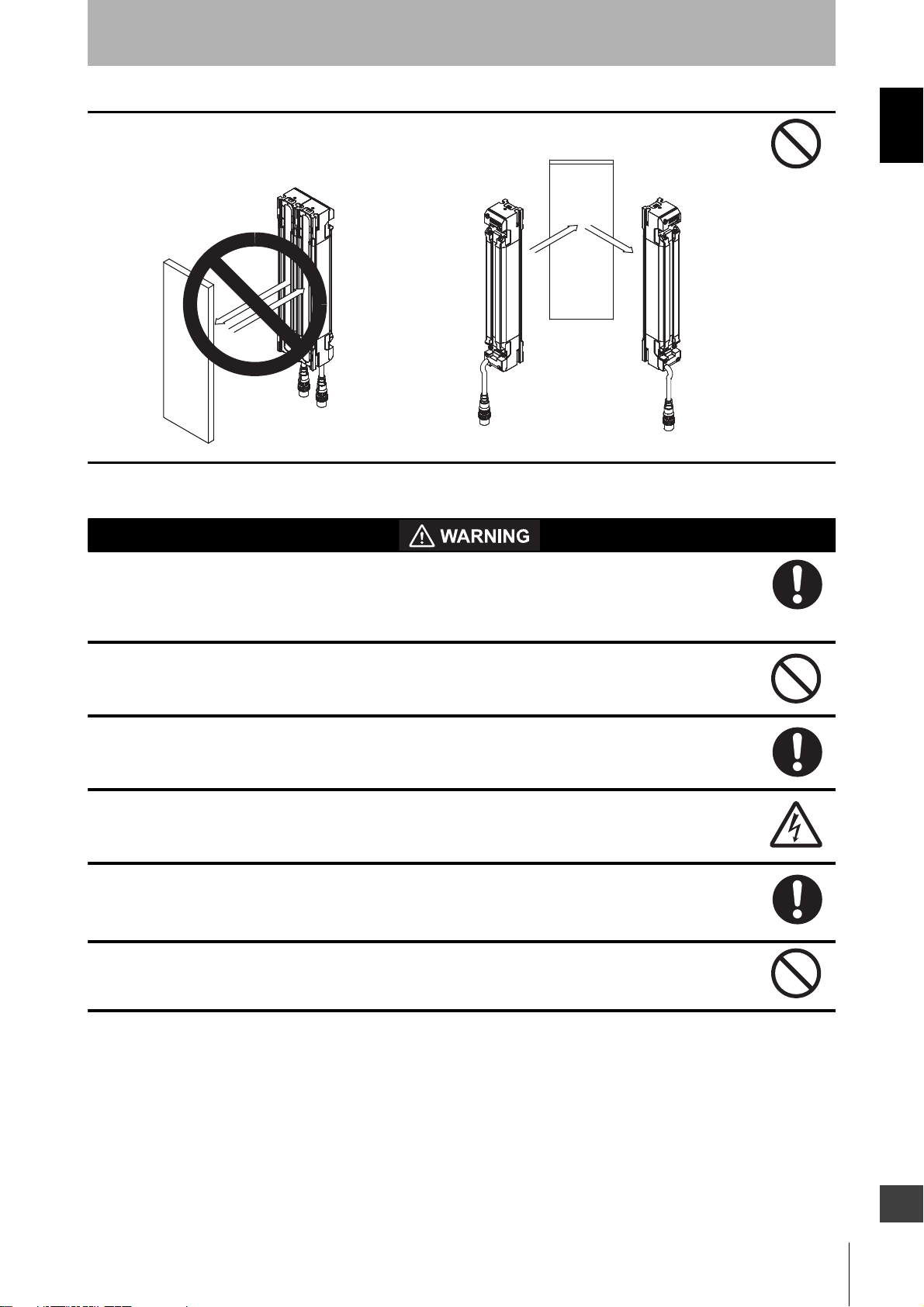

Do not use the F3SG-SR with mirrors in a retro-reflective configuration. Doing so may hinder

detection. It is possible to use mirrors to alter the detection zone to a 90-degree angle.

Mirror

Mirror

Introduction

Position with retro-reflection

Position with detection zone bent at 90°

Wiring

When using the PNP output, connect the load between the output and 0 V line. When using the

NPN output, connect the load between the output and +24 VDC line. Connecting the load

between the output and a different power supply line from the above line will result in a

dangerous condition because the operation mode of safety outputs are reversed to "Dark-ON".

When using the PNP output, do not ground +24 VDC line. When using the NPN output, do not

ground 0 V line. Otherwise, a ground fault may turn the safety outputs ON, resulting in a failure of

stopping the machine.

Configure the system by using the optimal number of safety outputs that satisfy the requirements

of the necessary safety category.

Do not connect each line of the F3SG-SR to a DC power supply of higher than 24 VDC+20%.

Also, do not connect it to an AC power supply. Failure to do so may result in electric shock.

Make sure to perform wiring while the power supply is OFF.

Do not use the output signal of the auxiliary output or IO-Link output for safety applications.

Failure to do so may result in serious injury when the F3SG-SR fails.

F3SG-SR

User’s Manual

E

ix

Page 12

Introduction

For the F3SG-SR to comply with IEC 61496-1 and UL 508, the DC power supply unit must

satisfy

all of the following conditions:

• The DC power supply operates within the rated power voltage (24 VDC ± 20%).

• The DC power supply has tolerance against the total rated current of devices if it is connected

to multiple devices.

• The DC power supply complies with EMC directives (industrial environment).

• Double or reinforced insulation is applied between the primary and secondary circuits.

• The DC power supply has an automatic recovery type of overcurrent protection characteristics.

• Output holding time is 20 ms or longer.

• The DC power supply satisfies output characteristic requirements for class 2 circuit or limited

voltage current circuit defined by UL 508. Refer to 5-4-2. Power Supply Unit.

• The DC power supply complies with laws and regulations, regarding EMC and electrical

equipment safety, of the country or region where the F3SG-SR is used. (For example, in EU,

the power supply must comply with the EMC Directive and the Low Voltage Directive.)

Double or reinforced insulation from hazardous voltage must be applied to all input and output

lines. Failure to do so may result in electric shock.

Extension of the cable must be within a specified length. If it isn't, safety functions may not work

properly, resulting in danger.

Settings

Make sure the Responsible Person tests the operation of the F3SG-SR after setting with the DIP

Switch on the F39-SGIT-IL3, Teach-in, SD Manager 3 or End Cap to verify that the F3SG-SR

operates as intended. Make sure to stop the machine until the test is complete. Unintended

settings may cause a person to go undetected, resulting in serious injury.

When performing the Backup, make sure to set the DIP Switch Position 1 at OFF (Unlock) before

turning on the power. If the DIP Switch Position 1 is at ON (Lock), the Restoration is performed,

which may case the settings of the F3SG-SR to be overwritten and a person to go undetected,

resulting in serious injury.

When performing the Restoration, make sure to set the DIP Switch Position 1 at ON (Lock)

before turning on the power. If the DIP Switch Position 1 at OFF (Unlock), the Backup is

performed, which may cause the settings of the Intelligent Tap to be overwritten and a person to

go undetected, resulting in serious injury.

When the Restoration is performed, if the DIP Switch Position 2 is at ON (DIP Switch Enabled)

and settings of the DIP Switch Positions 3 to 8 are different from the backup data in the F39SGIT-IL3, the settings in the DIP Switch takes priority and are saved in the F3SG-SR. To prevent

such an accident, it is recommended that you set the DIP Switch Position 2 at OFF before

performing the Restoration when you use the settings backed up from the F3SG-SR or make

settings with the SD Manager 3.

When pairing your device with the F39-SGBT Bluetooth® Communication Unit, make sure that

the model name and serial number of the sensor to be configured match the information on your

device.

F3SG-SR

x

User’s Manual

Page 13

Do not use the F39-SGBT Bluetooth® Communication Unit in close proximity to medical

equipment such as a pacemaker. Radio wave may affect the operation of such equipment.

Other

Perform daily and 6-month inspections for all F3SG-SR as described in Chapter 7 Checklists.

When using the F3SG-SR in cascade connection, perform inspections for every connected

F3SG-SR. Otherwise, the system may fail to work properly, resulting in serious injury.

Do not try to disassemble, repair, or modify the product. Doing so may cause the safety functions

to stop working properly.

Do not use the product in environments where flammable or explosive gases are present. Doing

so may result in explosion.

Do not use the F3SG-SR in environments where strong electromagnetic field may be produced.

Doing so may cause the safety functions to stop working properly.

Introduction

F3SG-SR

User’s Manual

E

xi

Page 14

Introduction

Make sure to observe the following precautions that are necessary for ensuring safe use of the product.

• Do not install, use, or store the product in the following types of environments:

• Do not drop the product.

• The rated life of the LEDs used for this product is 6 years.

• Loads must satisfy both of the following conditions:

• Make sure that the mounting brackets, fixing screws and connectors are properly secured with the torque

recommended in this document.

• Bending radii of cables must be equal to or higher than specified minimum values.

• When replacing the cables with those other than the dedicated cables, use cable connectors that provide a

protection grade of IP54 or higher, for the cables..

• To extend a cable length with a cable other than the dedicated cable, use a cable with the same or superior

specifications.

Precautions for Safe Use

- Areas exposed to intense interference light, such as direct sunlight

- Areas with high humidity where condensation is likely to occur

- Areas where corrosive gases are present

- Areas exposed to vibration or shock levels higher than in the specification provisions

- Areas where the pollution degree is harsher than 3, such as outdoor environment

- Areas where the product may get wet with liquid that can solve adhesive

- Not short-circuited

- Not used with a current that is higher than the rating

Refer to 5-4-3-10. Extending Cable Length with Commercially Available Cable

• Be sure to route the input/output lines for the F3SG-SR separate from high-potential power lines or through

an exclusive conduit.

• Make sure that foreign material such as water, oil, or dust does not enter the F3SG-SR, F39-SGIT-IL3 or the

connector while the end cap and root cables of the F3SG-SR or the cover of the DIP Switch on the F39SGIT-IL3 is removed.

• Make sure that foreign material such as water, oil, or dust does not enter the F39-SGBT or the connector

while the F39-SGBT is not connected to the F39-SGIT-IL3.

• The F39-SGIT-IL3 is dedicated to the F3SG-SR series. Do not use it for equipment other than F3SG-SR

series.

• In environments where foreign material such as spatter adheres to the F3SG-SR, attach a cover to protect

the F3SG-SR from the spatter.

• Some cutting oils may affect the product. Before using cutting oils, make sure that the oils should not cause

deterioration or degradation of the product.

• Do not use the product with degraded protective structure such as swelling and crack in housing and/or

sealing components. Otherwise cutting oil or other substance may enter the product, resulting in a risk of

corruption or burning.

• Use the F39-JGC- Root-Straight Cables, F39-JGR3K- Root-Plug Cables for Extended or F39-JGR3K- Conversion Cables and/or F39-JGR3W Cascading Cables for Extended or F39-JGR12L Side-byside Cascading Cables in environment where the product may be exposed to oil. Using the other cables in

such an environment may cause cutting oils or other substances to enter the cables, resulting in a risk of

damaging or burning the product.

• Do not connect the Conversion Cable for the following purposes. Failure to do so may result in failure.

1. Connecting with the F39-SGIT-IL3, F39-GCNY2 or F39-GCNY3

2. Connecting between the F3SG-SR's

• Dispose of the product in accordance with the relevant rules and regulations of the country or area where the

product is used.

xii

F3SG-SR

User’s Manual

Page 15

Precautions for Correct Use

Observe the precautions described below to prevent operation failure, malfunctions, or undesirable effects on

product performance.

Storage conditions and installation environment

• Do not install, use, or store the product in the following types of environments:

- Areas with a temperature or humidity out of the specified range

- Areas submerged in water or subject to rain water

• This is a class A product (for industrial environments). In residential areas it may cause radio

interference, in which case the Responsible Person may be required to take adequate measures to

reduce interference.

Wiring and installation

• Properly perform the wiring after confirming the signal names of all the terminals.

• Do not operate the control system until 3 s or more after turning ON the power of the F3SG-SR.

• When using a commercially available switching regulator power supply, make sure to ground the PE

terminal (protective earth terminal).

• Install the emitter and receiver to the same vertical direction.

• Use brackets of specified quantities and locations according to the dimensions. If the brackets

described above are not used, ratings and performance cannot be met.

• Do not install the F3SG-SR close to a device that generates high-frequency noise. Otherwise, take

sufficient blocking measures.

• Sharing the power supply with other devices may cause the F3SG-SR to be affected by noise or

voltage drop. It is recommended that the F3SG-SR use a power supply dedicated for safety

components, not shared with other devices.

• Do not change the scan code during normal operation. The F3SG-SR transitions to lockout.

• Do not apply load to the connectors.

• The operating range of the safety light curtain attached with the spatter protection cover is 10%

shorter than the rating. Install the product in consideration with the decrease of the operating range.

Cleaning

• Do not use thinner, benzene, or acetone for cleaning. They affect the product's resin parts and paint

on the housing.

• Use a soft cloth which is dry or wetted with clean water for cleaning. Do not use solvents.

Object detection

• The F3SG-SR cannot detect transparent and/or translucent objects.

Settings

• Do not operate the DIP Switch on the F39-SGIT-IL3 during normal operation of the F3SG-SR.

Otherwise, the F3SG-SR enters the LOCKOUT state.

• Do not operate the DIP Switch and Push Switch on the F39-SGIT-IL3 with tools that may damage the

product.

• Be sure that the F3SG-SR is in the SETTING state when making a change to the setting.

For more information on the SETTING state, refer to SETTING State under 2-2-1. Operating States of F3SG-SR and

Intelligent Tap.

Introduction

F3SG-SR

User’s Manual

E

xiii

Page 16

Introduction

Bluetooth® wireless technology

• The F39-SGBT Bluetooth® Communication Unit uses radio band of 2.4 GHz. The use of the product in

close proximity to the following examples of radio interference sources may cause radio interference

with the product, resulting in loss of or slow connection. Check the radio wave environment in your site

before installing the F39-SGBT.

Examples:

- Medical equipment such as a pacemaker

- RFID premises radio stations (license required) used in factory manufacturing lines

- Specified low power radio station

- Wireless LAN device

• When you use a PC, smartphone or tablet for Bluetooth® communication with the F39-SGBT, the

transmission distance may be shorter depending on structures of premises or obstructions. The

transmission may be interrupted especially by reinforced concrete.

- Use the product within the line of sight of 10 m.

- Use the product in conjunction with a Bluetooth device. It is not guaranteed that the product can

communicate with all Bluetooth devices.

xiv

F3SG-SR

User’s Manual

Page 17

Visual Aids

The following symbols appear in this document to help you locate different types of information.

Indicates important information or advice on a function or operation of the product.

Indicates page numbers or chapter title of related information.

Introduction

F3SG-SR

User’s Manual

E

xv

Page 18

Introduction

xvi

F3SG-SR

User’s Manual

Page 19

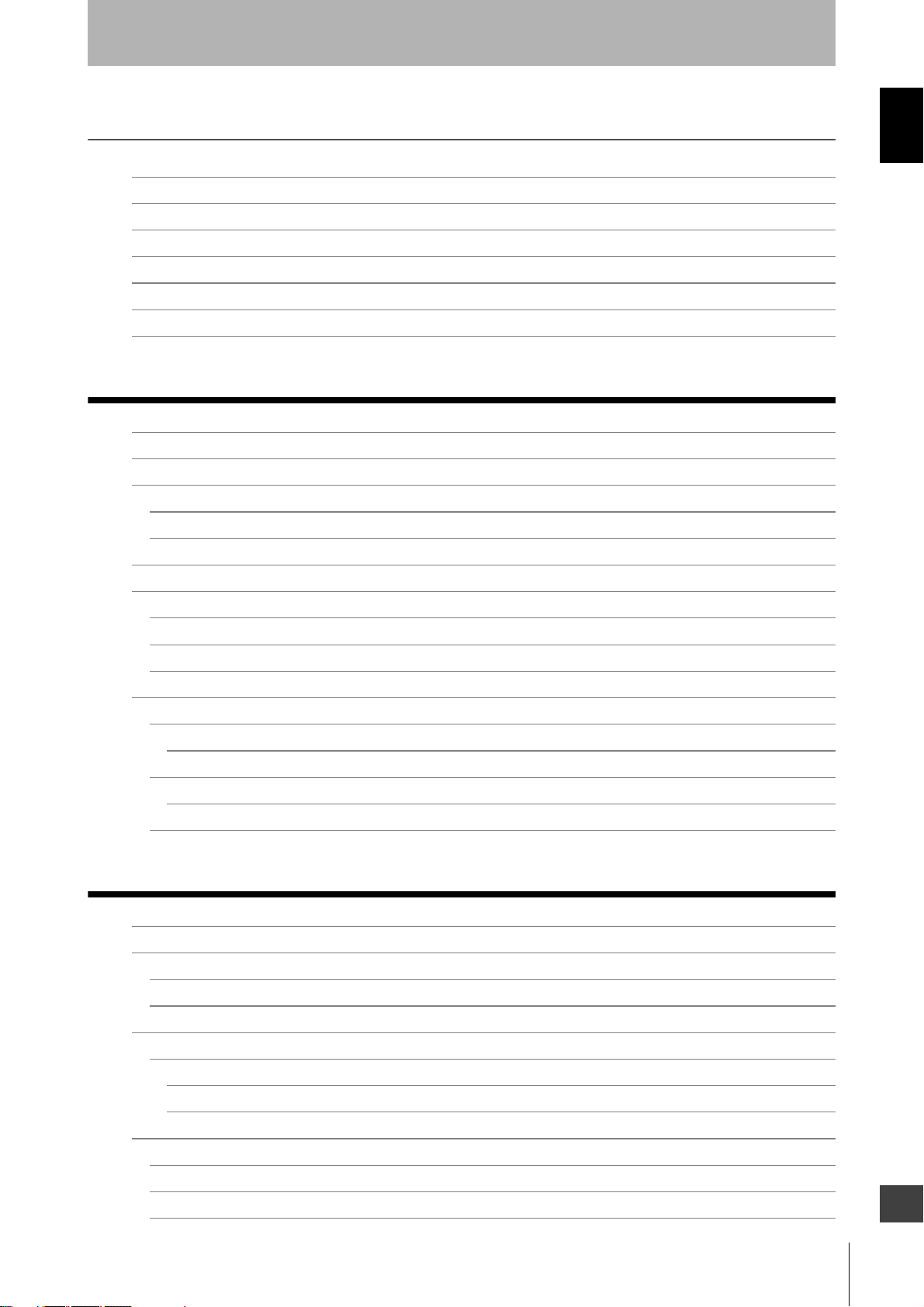

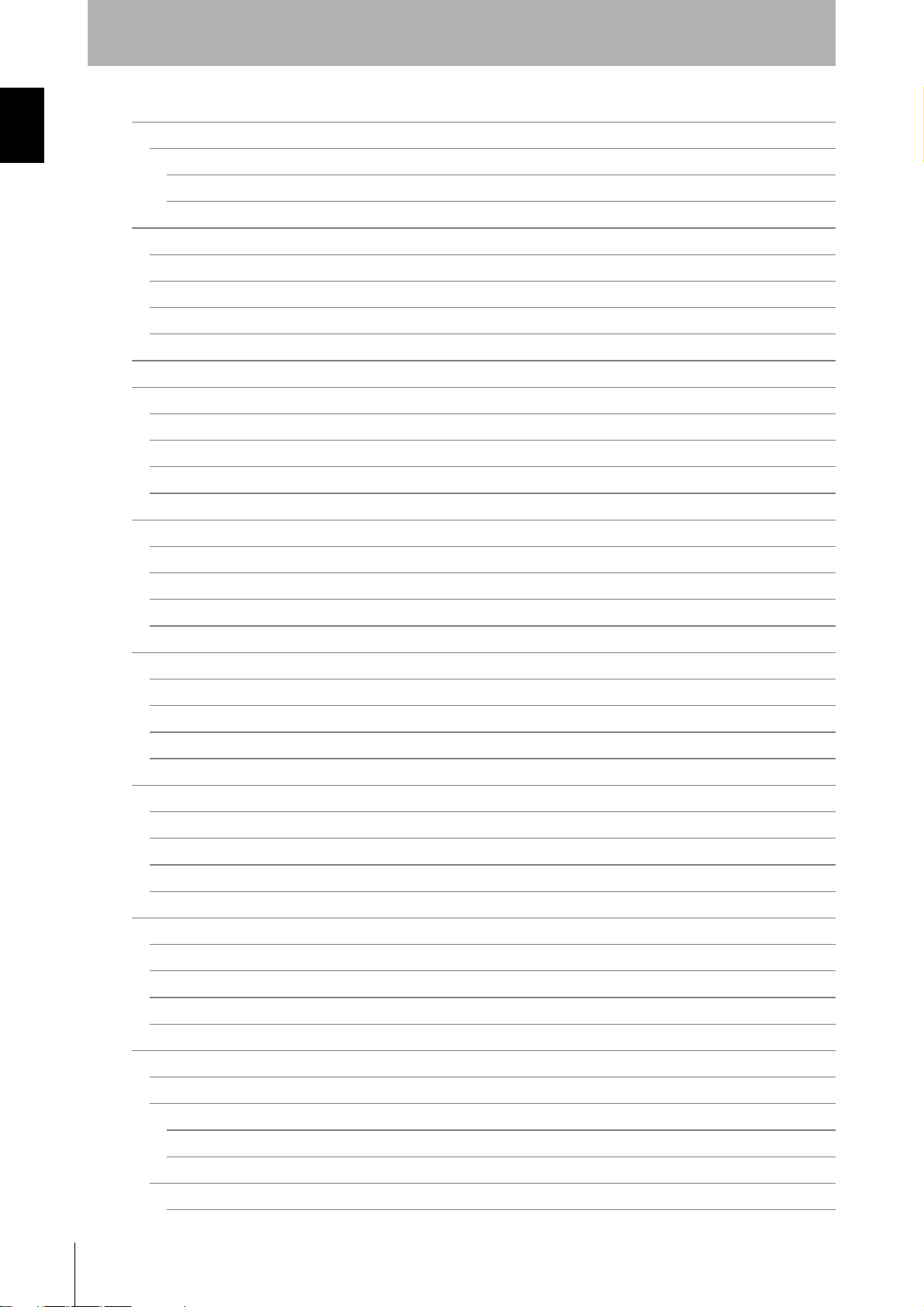

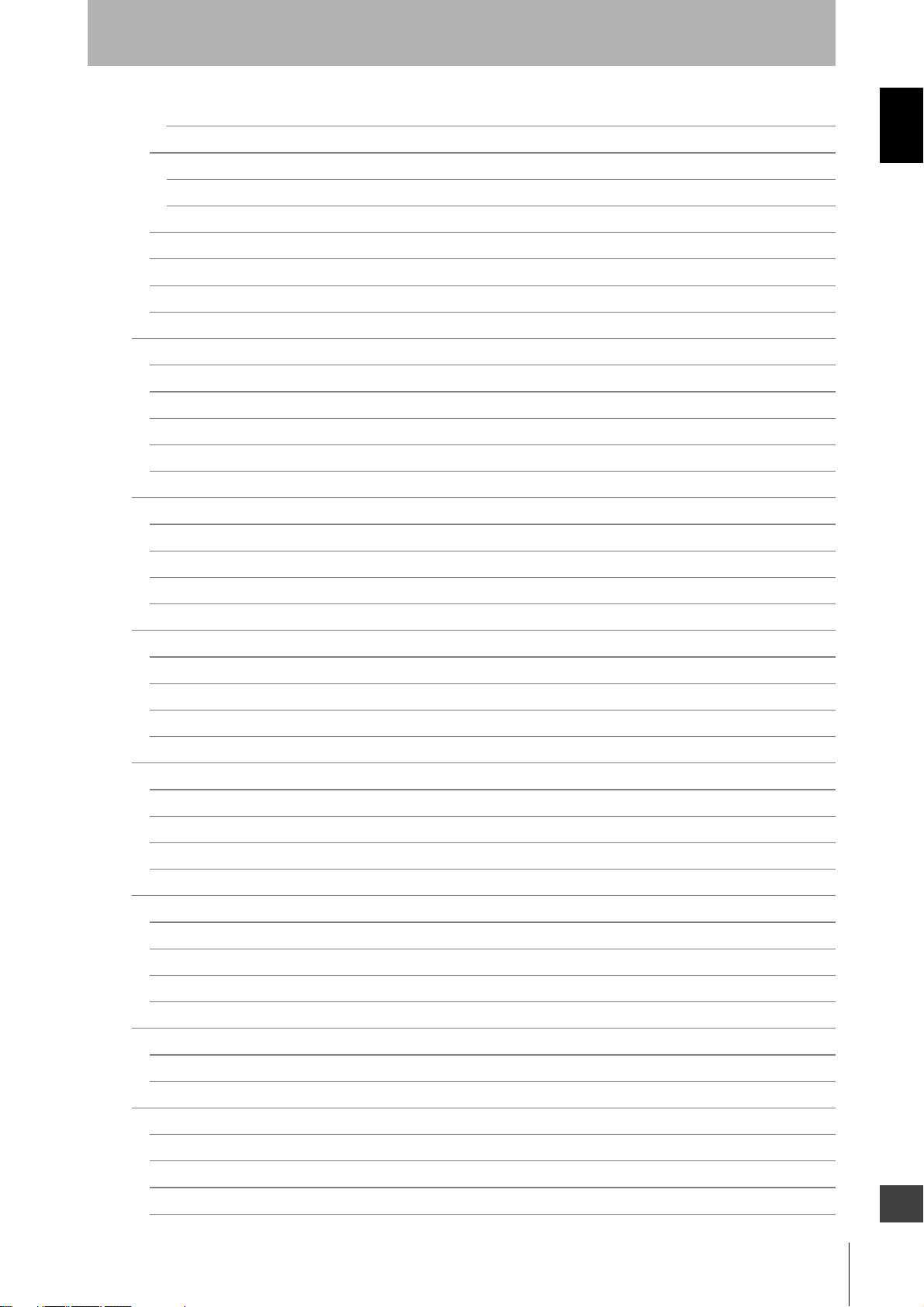

Table of Contents

Legislation and Standards i

Terms and Conditions Agreement iii

Terms and Conditions Agreement (Software) v

Safety Precautions vi

Precautions for Safe Use xii

Precautions for Correct Use xiii

Visual Aids xv

Chapter1 Overview and Specifications 1

1-1. What is Included 2

1-2. System Components 3

1-3. List of Key Features 5

1-3-1. Model Overview 5

1-3-2. List of Key Features 7

Introduction

1-4. LED Indicators on F3SG-SR 8

1-5. Ratings and Specifications 12

1-5-1. F3SG-SR Series 12

1-5-2. Intelligent Tap 19

1-5-3. Bluetooth® Communication Unit 20

1-6. List of Models 21

1-6-1. List of Models and Response Times 21

1-6-1-1. F3SG-SR 21

1-6-2. List of Models, Current Consumption and Weight 24

1-6-2-1. F3SG-SR 24

1-6-3. Calculation of Response Time of Cascaded Segments 28

Chapter2 System Operation and Functions 29

2-1. Combination of Functions 31

2-2. Operating States 33

2-2-1. Operating States of F3SG-SR and Intelligent Tap 33

2-2-2. Operating States of Intelligent Tap 34

2-3. Mutual Interference Prevention 35

2-3-1. Mutual Interference Prevention of F3SG-SR 35

2-3-1-1. Optical Synchronization 35

2-3-1-2. Wired Synchronization 38

2-4. PNP/NPN Selection 39

2-4-1. Overview 39

2-4-2. Setting with Intelligent Tap 39

2-4-3. Setting with SD Manager 3 39

F3SG-SR

User’s Manual

E

xvii

Page 20

Introduction

2-5. Self-Test 40

2-5-1. Overview 40

2-5-1-1. Self-Test details 40

2-5-1-2. Waveform of safety outputs 41

2-6. External Test 42

2-6-1. Overview 42

2-6-2. Factory Default Setting 43

2-6-3. Setting with Intelligent Tap 43

2-6-4. Setting with SD Manager 3 43

2-7. Lockout Reset 44

2-8. Interlock 45

2-8-1. Over view 45

2-8-2. Factory Default Setting 47

2-8-3. Setting with Intelligent Tap 47

2-8-4. Setting with SD Manager 3 47

2-9. Pre-Reset 48

2-9-1. Overview 48

2-9-2. Factory Default Setting 49

2-9-3. Setting with Intelligent Tap 50

2-9-4. Setting with SD Manager 3 50

2-10. PSDI 51

2-10-1.Overview 51

2-10-2.Factory Default Setting 53

2-10-3.Setting Change using Intelligent Tap 53

2-10-4.Setting Change using SD Manager 3 53

2-11. External Device Monitoring (EDM) 54

2-11-1.Overview 54

2-11-2.Factory Default Setting 55

2-11-3.Setting with Intelligent Tap 55

2-11-4.Setting with SD Manager 3 56

2-12. Auxiliary Output 57

2-12-1.Overview 57

2-12-2.Factory Default Setting 58

2-12-3.Setting with Intelligent Tap 58

xviii

2-12-4.Setting with SD Manager 3 59

2-13. Muting 61

2-13-1.Overview 61

2-13-2.Standard Muting Mode 63

2-13-2-1. Overview 63

2-13-2-2. Installation Example 1 of Standard Muting Mode (Using Two Muting Sensors) 66

2-13-3.Exit-Only Muting Mode 73

2-13-3-1. Overview 73

F3SG-SR

User’s Manual

Page 21

2-13-3-2. Installation Example of Exit-Only Muting Mode 75

2-13-4.Position Detection Muting Mode 78

2-13-4-1. Overview 78

2-13-4-2. Installation Example of Position Detection Muting Mode 80

2-13-5.Dynamic Muting 82

2-13-6.Factory Default Setting 83

2-13-7.Setting with Intelligent Tap 83

2-13-8.Setting with SD Manager 3 83

2-14. Override 85

2-14-1.Overview 85

2-14-2.Override at Normal Operation 86

2-14-3.Override upon Startup 88

2-14-4.Setting with Intelligent Tap 88

2-14-5.Setting with SD Manager 3 89

2-15. Fixed Blanking 90

2-15-1.Overview 90

Introduction

2-15-2.Factory Default Setting 94

2-15-3.Setting with Intelligent Tap 95

2-15-4.Setting with SD Manager 3 95

2-16. Floating Blanking 96

2-16-1.Overview 96

2-16-2.Factory Default Setting 100

2-16-3.Setting with Intelligent Tap 100

2-16-4.Setting with SD Manager 3 100

2-17. Reduced Resolution 101

2-17-1.Overview 101

2-17-2.Factory Default Setting 102

2-17-3.Setting with Intelligent Tap 102

2-17-4.Setting with SD Manager 3 103

2-18. Warning Zone 104

2-18-1.Overview 104

2-18-2.Factory Default Setting 107

2-18-3.Setting with Intelligent Tap 107

2-18-4.Setting with SD Manager 3 107

2-19. Setting Zone Adjacency Conditions 108

2-19-1.Zone Adjacency Condition 108

2-19-2.Zone Overlap Condition 108

2-20. Operating Range Selection 110

2-20-1.Overview 110

2-20-2.Factory Default Setting 111

2-20-3.Setting with Intelligent Tap 111

2-20-4.Setting with SD Manager 3 111

F3SG-SR

User’s Manual

E

xix

Page 22

Introduction

2-21. Response Time Adjustment 112

2-21-1.Overview 112

2-21-2.Factory Default Setting 112

2-21-3.Setting with Intelligent Tap 112

2-21-4.Setting with SD Manager 3 112

2-22. Area Beam Indicator (ABI) 113

2-22-1.Overview 113

2-22-2.Factory Default Setting 114

2-22-3.Setting Change using Intelligent Tap 114

2-22-4.Setting Change using SD Manager 3 114

2-23. Designated Beam Output 116

2-23-1.Overview 116

2-23-2.Factory Default Setting 116

2-23-3.Setting with Intelligent Tap 116

2-23-4.Setting with SD Manager 3 117

2-24. Stable Light Threshold Adjustment 118

2-24-1.Overview 118

2-24-2.Factory Default Setting 118

2-24-3.Setting Change using Intelligent Tap 118

2-24-4.Setting Change using SD Manager 3 118

2-25. Incident Light/Ambient Light 119

2-25-1.Incident Light Level Information 119

2-25-1-1. Overview 119

2-25-1-2. Setting with SD Manager 3 119

2-25-2.Ambient Light Level Information 119

2-25-2-1. Overview 119

2-25-2-2. Setting with SD Manager 3 119

2-26. Maintenance Information 120

2-26-1.Overview 120

2-26-2.Error Log 120

2-26-3.Warning Log 120

2-26-4.Power-ON Time 121

2-26-5.Load Switching Frequency 121

2-26-6.Muting Statistics Information 122

xx

2-26-7.Intelligent Tap Log 122

2-27. Operating Status Monitoring 123

2-27-1.Overview 123

2-27-2.Readout Information 123

2-28. Instantaneous Block Detection 124

2-28-1.Overview 124

2-28-2.Factory Default Setting 124

2-28-3.Setting Change using Intelligent Tap 124

F3SG-SR

User’s Manual

Page 23

2-28-4.Setting Change using SD Manager 3 124

2-29. Setting Recovery 125

2-30. Backup/Restoration 126

2-30-1.Overview 126

2-31. IO-Link 127

Chapter3 Setting with Intelligent Tap 129

3-1. List of Functions Configurable by Intelligent Tap and Initial Setup Method 130

3-1-1. Functions Configurable by Intelligent Tap 130

3-1-2. Initial Setup Method after Purchase 130

3-2. Connection 131

3-3. Wiring 132

3-4. LED Indicators on Intelligent Tap 133

3-5. DIP Switch on Intelligent Tap 134

3-6. Backup/Restoration 135

3-6-1. Description of Functions 135

Introduction

3-6-2. Performing Backup 136

3-6-3. Performing Restoration 138

3-6-4. Various Usage of Backup and Restoration 141

3-6-4-1. Plug and Work 141

3-6-4-2. Copy and Paste of Sensor Settings 141

3-6-4-3. Changing F3SG-SR Configuration to Connect to Intelligent Tap 141

3-6-4-4. Changing F3SG-SR's Settings with Intelligent Tap DIP Switch 141

3-7. Teach-in (Fix Blanking / Floating Blanking) 142

3-7-1. Setting Fixed Blanking by Teach-in 142

3-7-2. Setting Floating Blanking by Teach-in 146

3-8. Connection to SD Manager 3 150

3-9. IO-Link 151

3-9-1. Functional Description 151

3-9-2. Communication Specifications 151

3-9-3. Process Data 151

3-9-4. Service Data 153

Chapter4 Setting with SD Manager 3 157

4-1. Overview and Specifications 160

4-1-1. Overview of Configuration Tool 160

4-1-2. System Environment 161

4-1-2-1. PC Environment 161

4-1-2-2. Smartphone/Tablet Environment 161

4-1-3. Connection Method to Use Configuration Tools 162

F3SG-SR

User’s Manual

E

xxi

Page 24

Introduction

4-1-3-1. Connection Patterns of F3SG-SR, Intelligent Tap, and Each Device 162

4-1-3-2. Connection Procedure When Using USB Connector 164

4-1-3-3. Connection Procedure When Using Bluetooth® Communication Unit (F39-SGBT) 165

4-1-4. SETTING State of F3SG-SR with SD Manager 3 Connected 169

4-2. Basic Operation of SD Manager 3 170

4-2-1. How to Install/Uninstall SD Manager 3 170

4-2-1-1. Downloading SD Manager 3 170

4-2-1-2. Installing SD Manager 3 170

4-2-1-3. How to Uninstall SD Manager 3 172

4-2-1-4. Installing Driver of Intelligent Tap 173

4-2-2. How to Update SD Manager 3 173

4-2-3. Getting Started, Description on Top Page and Each Button, and Shutting Down 174

4-2-3-1. Getting Started 174

4-2-3-2. Description on Top Page and Each Button 175

4-2-3-3. Displaying/Hiding Docked Windows 177

4-2-3-4. Shutting Down 177

4-2-4. Starting SD Manager 3 Offline 178

4-2-4-1. Creating New Configuration File 178

4-2-4-2. Reading Configuration from PC 179

4-2-4-3. Saving New Configuration File to PC 179

4-2-4-4. Switching Offline to Online 179

4-2-5. Logging In/Logging Out 180

4-2-5-1. Logging In 180

4-2-5-2. Logging Out 182

4-2-6. Password Protection 183

4-2-6-1. Access Restriction 183

4-2-6-2. Changing Password 183

4-2-6-3. Forgot the Password? 183

4-2-6-4. Confirming Lot No. of Intelligent Tap 183

4-2-6-5. Resetting the Initial Password to “0000” 184

4-2-7. Reading/Saving/Writing Configuration of Intelligent Tap 185

4-2-7-1. Reading Configuration from Intelligent Tap 185

4-2-7-2. Saving Configuration of Intelligent Tap in PC 185

4-2-7-3. Writing Configuration into Intelligent Tap 186

xxii

4-2-8. Viewing Current Configuration 188

4-2-9. Safety Distance Calculation 189

4-3. Changing Settings with SD Manager 3 190

4-3-1. Preparing to Change Settings 190

4-3-2. I/O Settings 191

4-3-2-1. Interlock/External Device Monitoring (EDM)/PSDI 191

4-3-2-2. Reset Input Time 192

4-3-2-3. Teach-in Input 193

F3SG-SR

User’s Manual

Page 25

4-3-2-4. External Test Input 194

4-3-3. Auxiliary Output/Lamp Setting 195

4-3-3-1. Auxiliary Output 195

4-3-3-2. Designated Beam Output 197

4-3-3-3. Area Beam Indicator (ABI) 200

4-3-4. Safety Function Setting 202

4-3-4-1. Fixed Blanking 202

4-3-4-2. Floating Blanking 205

4-3-4-3. Muting/Override 207

4-3-4-4. Pre-Reset 212

4-3-4-5. Reduced Resolution 213

4-3-4-6. Warning Zone 214

4-3-4-7. PSDI 216

4-3-5. Operating State Setting 217

4-3-5-1. Response Time Change 217

4-3-5-2. Stable Light Threshold Adjustment 218

Introduction

4-3-5-3. Operating Range Selection 219

4-3-6. Setting Initialization 220

4-4. Monitoring with SD Manager 3 221

4-4-1. Monitoring 221

4-4-1-1. Incident Light/Ambient Light 221

4-4-1-2. Operating Status Monitoring 222

4-4-2. Muting Statistics Information 224

4-4-3. Maintenance Information 228

4-4-3-1. Error Log Information 228

4-4-3-2. Warning Log 230

4-4-3-3. Intelligent Tap Log 231

4-4-3-4. Power-On Time/Load Switching Frequency 232

4-4-3-5. Instantaneous Block Detection Information 234

4-5. Basic Operation of SD Manager 3 Mobile APP 235

4-5-1. How to Install/Uninstall SD Manager 3 Mobile APP 235

4-5-1-1. Installing SD Manager 3 Mobile APP 235

4-5-1-2. Uninstalling SD Manager 3 Mobile APP 235

4-5-2. How to Update SD Manager 3 Mobile APP 235

4-5-3. Pairing (Connection Verification) 235

4-5-4. Getting Started, Main Screen, Version Confirmation, and Shutting Down 237

4-5-4-1. Getting Started 237

4-5-4-2. Main Screen 239

4-5-4-3. Version Information 240

4-5-4-4. Shutting Down 241

4-5-5. Monitoring with SD Manager 3 242

4-5-5-1. Incident/Ambient Light Level Monitoring 242

F3SG-SR

User’s Manual

E

xxiii

Page 26

Introduction

4-5-5-2. Status Monitoring Information 243

4-5-5-3. Maintenance Information 245

Chapter5 Wiring and Installation 247

5-1. Installation Considerations 250

5-1-1. Detection Zone and Approach 250

5-1-2. Safety Distance 252

5-1-2-1. Safety Distance Formulas according to ISO 13855/EN ISO 13855 252

5-1-2-2. Safety Distance Formulas according to ANSI B11.19 256

5-1-3. Distance from Reflective Surfaces 257

5-1-3-1. F3SG-SR (Type 2 ESPE) 257

5-1-4. Mutual Interference Prevention 258

5-2. Dimensions 259

5-2-1. F3SG-SR Series 259

5-2-1-1. Mounted with Side-Mount Brackets (Intermediate Brackets) (F39-LSGF) 259

5-2-1-2. Mounted with Adjustable Side-Mount Brackets (Intermediate Brackets) (F39-LSGA) 261

5-2-1-3. Mounted with Adjustable Top/Bottom Brackets (F3SJ, F3SN Adapter) (F39-LSGTB-SJ)

and Side-Mount Brackets (Intermediate Brackets) (F39-LSGF) 263

5-2-1-4. Mounted with Adjustable Top/Bottom Brackets (F3SJ, F3SN Adapter) (F39-LSGTB-SJ)

and Adjustable Side-Mount Brackets (Intermediate Brackets) (F39-LSGA) 265

5-2-2. Bracket 267

5-2-2-1. Side-Mount Bracket (Intermediate Bracket) (F39-LSGF) 267

5-2-2-2. Adjustable Side-Mount Bracket (Intermediate Bracket) (F39-LSGA, sold separately)

267

5-2-2-3. Adjustable Top/Bottom Bracket (F3SJ, F3SN Adapter) (F39-LSGTB-SJ, sold separately)

267

5-2-2-4. Adjustable Top/Bottom Bracket (F3SG-RA/RE Adapter) (F39-LSGTB-RE, sold separate-

ly) 268

5-2-2-5. Adjustable Top/Bottom Bracket (MS4800, F3SR Adapter) (F39-LSGTB-MS, sold sepa-

rately) 268

5-2-3. Intelligent Tap 269

5-2-4. Intelligent Tap Bracket 269

5-2-5. Bluetooth® Communication Unit 271

5-2-6. Spatter Protection Cover 272

5-3. Mounting 273

xxiv

F3SG-SR

User’s Manual

5-3-1. Mounting Method 273

5-3-2. Number of Brackets Required 273

5-3-3. Proper Mounting 274

5-3-3-1. Proper Mounting Orientation 274

5-3-4. Mounting Procedure 276

5-3-4-1. Mounting with Side-Mount Brackets (Intermediate Brackets)

(F39-LSGF) 276

5-3-4-2. Mounting with Adjustable Side-Mount Brackets (Intermediate Brackets) (F39-LSGA) 277

Page 27

5-3-4-3. Mounting with Adjustable Top/Bottom Brackets (F3SJ, F3SN Adapter) (F39-LSGTB-SJ)

and Side-Mount Brackets (Intermediate Brackets) (F39-LSGF) 280

5-3-4-4. Mounting with Adjustable Top/Bottom Brackets (F3SJ, F3SN Adapter) (F39-LSGTB-SJ)

and Adjustable Side-Mount Brackets (Intermediate Brackets) (F39-LSGA) 284

5-3-5. Beam Alignment Procedure 289

5-4. Wiring 290

5-4-1. Wiring Precautions 290

5-4-2. Power Supply Unit 291

5-4-3. Cable Connections 292

5-4-3-1. Root-Straight Cable 292

5-4-3-2. Root-Plug Cable for Extended 293

5-4-3-3. Extended Socket-Straight Cable 294

5-4-3-4. Extended Plug-Socket Cable 295

5-4-3-5. Cascading Cable for Extended 297

5-4-3-6. Side-by-side Cascading Cable 298

5-4-3-7. F3SJ-B/A Conversion Cable 299

5-4-3-8. F3SG-RE Conversion Cable 301

Introduction

5-4-3-9. MS48 Conversion Cable 302

5-4-3-10. Extending Cable Length with Commercially Available Cable 303

5-4-3-11. Reduced Wiring Connector System with Y-Joint Plug/Socket Connector 304

5-4-3-12. Easy Wiring Connector System with Reset Switch Connector 305

5-4-4. Functional Earth Connection 307

5-5. Cascade Connection 308

5-5-1. Overview 308

5-5-2. Connection Procedure 310

Chapter6 Input/Output Circuit and Applications 313

6-1. Input/Output Circuit 314

6-1-1. Entire Circuit Diagram 314

6-1-2. Input Circuit Diagram by Function 315

6-2. Wiring Examples (for F3SG-SR) 316

6-2-1. Non-Muting System Wiring Examples 316

6-2-1-1. Auto Reset Mode with Optical Synchronization and EDM Unused 316

6-2-1-2. Auto Reset Mode with Wired Synchronization and EDM Unused 317

6-2-1-3. Auto Reset Mode with Optical Synchronization and EDM Used 318

6-2-1-4. Manual Reset Mode with EDM 319

6-2-1-5. Manual Reset Mode with EDM and Y-Joint Plug/Socket Connector 320

6-2-1-6. Manual Reset Mode with Intelligent Tap 321

6-2-1-7. Manual Reset Mode with Reset Switch Connector 322

6-2-1-8. Pre-Reset Mode with EDM Unused 323

6-2-1-9. Pre-Reset Mode with Reset Switch Connector 324

6-2-1-10. Single Break with EDM and Intelligent Tap 325

F3SG-SR

User’s Manual

E

xxv

Page 28

Introduction

Chapter7 Checklists 333

6-2-1-11. Double Break with EDM 326

6-2-2. Muting System Wiring Examples 327

6-2-2-1. Standard Muting Mode/Exit-Only Muting Mode 327

6-2-2-2. Standard Muting Mode/Exit-Only Muting Mode with Y-Joint Plug 328

6-2-2-3. Standard Muting Mode/Exit-Only Muting Mode with Intelligent Tap 329

6-2-2-4. Standard Muting Mode/Exit-Only Muting Mode with Reset Switch Connector 330

6-3. Connectable Safety Control Units 331

7-1. Pre-Operation Checklists 334

7-1-1. Checklists 334

7-1-1-1. Installation Condition Check 334

7-1-1-2. Wiring Check Before Power Is Turned ON 334

7-1-1-3. Operation Check While the Machine Is Stopped 335

7-1-1-4. Checking that Hazardous Parts Stop While the Machine Operates 336

7-2. Maintenance Checklists 337

7-2-1. Checklists 337

7-2-1-1. Inspection at Startup and When Changing Operators 337

7-2-1-2. Checking that Hazardous Parts Stop While the Machine Operates 338

7-2-1-3.

Items to Inspect Every 6 Months or When Machine Settings Are Changed 338

Chapter8 Appendix 341

8-1. Troubleshooting 342

8-1-1. LED Indicators (F3SG-SR) 342

8-1-2. LOCKOUT State 343

8-1-2-1. Description 343

8-1-2-2. Troubleshooting 344

8-1-3. Warning 349

8-1-3-1. Description 349

8-1-3-2. Troubleshooting 349

8-1-3-3. Muting Sequence Error Indication 350

8-1-3-4. Interlock Sequence Error Indication 351

8-1-3-5. PSDI Sequence Error Indication 352

xxvi

8-1-4. Troubleshooting for Intelligent Tap 353

8-1-5. Troubleshooting for Bluetooth® Communication Unit 356

8-2. Optional Accessories (Sold Separately) 357

8-3. Glossary 365

8-4. Revision History 369

F3SG-SR

User’s Manual

Page 29

Chapter 1 Overview and Specifications

1-1. What is Included 2

1-2. System Components 3

1-3. List of Key Features 5

1-3-1. Model Overview 5

1-3-2. List of Key Features 7

1-4. LED Indicators on F3SG-SR 8

1-5. Ratings and Specifications 12

1-5-1. F3SG-SR Series 12

1-5-2. Intelligent Tap 19

Chapter1 Overview and Specifications

1-5-3. Bluetooth® Communication Unit 20

1-6. List of Models 21

1-6-1. List of Models and Response Times 21

1-6-2. List of Models, Current Consumption and Weight 24

1-6-3. Calculation of Response Time of Cascaded Segments 28

F3SG-SR

User’s Manual

E

1

Page 30

Overview and Specifications

1-1. What is Included

Chapter1 What is Included

Before use, confirm that the items below are included with the product.

If you find that an item is missing, please contact your Omron representative.

F3SG-SR series

• Emitter 1

• Receiver 1

• Side-Mount Bracket (Intermediate Bracket) (F39-LSGF)*

• End Cap (for switching Scan Code Selection function) x 2 (End cap for Scan Code B is included.)

• Instruction Sheet x 7

• Quick Installation Manual x 1

• Troubleshooting Guide Sticker x 2

• Warning Zone Label x 1

* The quantity varies depending on the protective height.

Protective height of 0160 to 1440: 2 sets (total 4 pcs), 1520 to 2480: 3 sets (total 6 pcs)

F3SG-SR

2

User’s Manual

Page 31

1-2. System Components

-

5

4

-

Overview and Specifications

This section describes the system components and part names of the F3SG-SR system.

F3SG-SR series

Emitter

Beam

Indicator

Root cable

(Gray)

Extension cable

Beam center-line mark

Receiver

Root cable

(Black)

Marking on the side (Emitter)

-L

F3SG

“EMITTER” mark

Functional earth terminal on backside

· The marking "EMITTER" is on the side of emitter. And the marking

"RECEIVER" is on the side of receiver.

· The color of functional earth terminal screws is silver for the emitter and

black for the receiver.

Marking on the side (Receiver)

F3SG-

“RECEIVER” mark

Functional earth terminal

Chapter1 System Components

D

E

F3SG-SR

User’s Manual

3

Page 32

Overview and Specifications

F3SG-SR---

123 456

Appearance Model name Description

Chapter1 System Components

Emitter and receiver F3SG-4SR--- Select a model name based on the required protective height

and ESPE type.

The model name can be understood as follows:

1. ESPE type (4: Type 4 or 2: Type 2)*

2. Function (A: Advanced or B: Standard)

3. Protective height (mm)

4. Detection capability (14: 14 mm, 25: 25 mm, 45: 45 mm or 85:

85 mm)

5. L: emitter, D: receiver or blank: emitter and receiver

6. F: Flexible height model or blank

To distinguish between the emitter and receiver, find the word "EMITTER" or "Receiver" on the side of the F3SG-SR.

* Type 2 is not available in the Pan America’s.

F3SG-SR

4

User’s Manual

Page 33

1-3. List of Key Features

1-3-1. Model Overview

The F3SG-SR series is a safety light curtain intended to be used for humans protection.

F3SG-SR Series

The F3SG-SR series has two sub-series, F3SG-SRA and F3SG-SRB. Both are safety light curtains

comprising an emitter and a receiver.

The F3SG-SRA is a full-featured model having advanced functionality. The F3SG-SRB is a standard

model, yet it supports wide variety of functionality. The F3SG-SR series is suitable for finger, arm, leg

and body detection.

Intelligent Tap (F39-SGIT-IL3, sold separately)

The following setting functions are available by connecting the Intelligent Tap to the F3SG-SR.

(1) Setting with DIP Switch *1

(2) Setting with SD Manager 3 by connecting the Intelligent Tap to a PC *1

(3) Wireless communication with PC, smartphone or tablet by connecting the Intelligent Tap and

Bluetooth® Communication Unit (F39-SGBT, sold separately)

(4) IO-Link communication by connecting the Intelligent Tap and IO-Link Master

(5) Backup and Restoration of settings *2

Overview and Specifications

Chapter1 List of Key Features

*1. Refer to 1-3-2. List of Key Features for more information on configurable functions.

*2. Refer to Chapter 3 Setting with Intelligent Tap for more information on the Backup and Restoration.

(1)

Setting of F3SG-SR is possible with

DIP Switch on Intelligent Tap

DIP Switch

(3)

Bluetooth® communication

PC

BT

BT: Bluetooth

®

Communication Unit

(2)

USB

PC

Setting of F3SG-SR is possible

with SD Manager 3 via PC

(4)

Obtaining data is possible via IO-Link

communication by connecting IO-Link Master

IO-Link

Master

· PC: Setting is possible with SD Manager 3 via Bluetooth® communication

· Smartphone/Tablet: Monitoring is possible with SD Manager 3 Mobile APP

via Bluetooth

®

communication

F3SG-SR

User’s Manual

E

5

Page 34

Overview and Specifications

(5)

Chapter1 List of Key Features

<Backup>

F3SG-SR settings are backed up

to Intelligent Tap

<Restoration>

Settings saved in Intelligent Tap

are restored to F3SG-SR

<Plug and Work>

Settings backed up before F3SG-SR faults are

taken over to replaced F3SG-SR

<Copy and Paste>

Settings backed up in Intelligent Tap are

restored to multiple F3SG-SR's

NEW

F3SG-SR

6

User’s Manual

Page 35

Overview and Specifications

1-3-2. List of Key Features

The F3SG-SR has the following features. Some of the features are available or configurable by the

Intelligent Tap (F39-SGIT-IL3) or the SD Manager 3 (PC configuration tool). Sensor status monitoring

is available by the SD Manager 3 Mobile APP, which is the configuration tool for smartphones or

tablets.

Setting/Monitoring by

Availability

Feature

F3SG-

SRA

Mutual Interference

Prevention

PNP/NPN Selection X X X - - - - p.39

External Test X X X - - - - p.42

Interlock X X - - X X Auto Reset p.45

Pre-Reset X X - - X X Disabled p.48

PSDI X X - - - X Disabled p.51

External Device Monitoring

(EDM)

Auxiliary Output

Muting

Override X X - - - X Enabled p.85

Fixed Blanking X X - - X X Disabled p.90

Floating Blanking X X - - X X Disabled p.96

Reduced Resolution X X - - - X Disabled p.101

Warning Zone X X - - - X Disabled p.104

Operating Range Selection X X X - X X Long *5 p.110

Response Time Adjustment X X - - - X Normal p.112

Area Beam Indicator (ABI)

Designated Beam Output X X - - - X Disabled p.116

Stable Light Threshold

Adjustment

Light Level Monitoring X X - - - X - p.119

Maintenance Information X X - - - X - p.120

Operating Status Monitoring X X - - - X - p.123

Instantaneous Block

Detection Information

*1. DIP Switch is on the F39-SGIT-IL3 Intelligent Tap.

*2. The F39-SGIT-IL3 Intelligent Tap is necessary to use the SD Manager 3 or SD Manager 3 Mobile APP.

*3. Mutual interference can be prevented by Optical Synchronization or Wired Synchronization.

*4. Mutual interference can be prevented by Scan Code Selection.

*5. In the case of setting by DIP Switch or SD Manager 3. For the setting by wiring, it is selectable from the Long and Short modes.

F3SG-

SRB

XXX *3X *4- -

XX - - X X

XX - - - X

XX - - - X

X--- - X

XX - - - X

X--- - X

Sensor

Wiring

End

Cap

Intelligent

Tap

DIP

Switch

(*1)

PC /

Smartphone /

Tablet

SD Manager 3

SD Manager 3

Mobile APP (*2)

Factory default setting Page

Code A *4

Disabled

Safety output

information (Inverted

signal output: Enabled)

Enabled

(Standard Muting)

Block/Unblock

information

170%

Enabled

p.35

p.54

p.57

p.61

p.113

p.118

p.124

Chapter1 List of Key Features

F3SG-SR

User’s Manual

E

7

Page 36

Overview and Specifications

1-4. LED Indicators on F3SG-SR

Chapter1 LED Indicators on F3SG-SR

F3SG-SR Series

<Emitter>

F3SG-SR-14

F3SG-SR-25/-45/-85

7

15432

7

15432

6

6

<Receiver>

F3SG-SR-14

10

18432765

F3SG-SR-25/-45/-85

10

18432765

9

9

Shown below are indication statuses of the LED indicators on the F3SG-SR when you purchased.

F3SG-SR

8

User’s Manual

Page 37

Emitter (F3SG-SR)

Location Indicator Name Color Illuminated Blinking

Green Code A is selected

C

1 Scan code

2 Lockout Red

3

or

CODE

E

or

ERR

L

or

LONG

Operating

range

Orange Code B is selected

Automatic interference

prevention by wired

OFF

synchronization being

performed

LOCKOUT state. The

indicator is illuminated in

the emitter of another

sensor segment than that

having a lockout error

(when in cascade

connection or between the

emitter and receiver in the

Wired Synchronization)

Green

Long Mode is selected LOCKOUT state due to Operating

Short Mode is selected

OFF

LOCKOUT state. The indicator is

illuminated in the emitter of a sensor

segment having a lockout error

range selection setting error

Overview and Specifications

F3SG-

-XX

F3SG-

SRA

SRB

XX

XX

Chapter1 LED Indicators on F3SG-SR

T

4 Test Yellow -

5-

6 TOP

7 BTM

*1. The indicator of the emitter is illuminated only in the case the Wired Synchronization is enabled and is off in the case the

Optical Synchronization is enabled.

*2. Configurable by SD Manager 3.

*3. This is the case for the Standard Muting mode. For other muting modes, refer to "2-13. Muting".

*4. The Area Beam Indicator closer to the "TOP" mark on the F3SG-SR blinks.

*5. The Area Beam Indicator closer to the "BTM" mark on the F3SG-SR blinks.

*6. DIP switches is on the Intelligent Tap.

or

TEST

Area

Beam

Indicator

(ABI) (*1)

Top-beamstate (*1)

Bottombeamstate (*1)

Green

Orange

Red

OFF

Blue

Blue

The target beams of the

ABI are unblocked and

the safety outputs are

turned ON

Incident light level of

the target beams of the

ABI is 170% (factory

default setting (*2)) or

less of ON-threshold

(for 5 to 10 s)

The target beams of the

ABI are blocked

The target beams of the

ABI are unblocked (The

ABI then will be

illuminated in green

when the safety outputs

are turned ON.)

The top beam is

unblocked

The bottom beam is

unblocked

External Test is being performed

MUTING or OVERRIDE state. In the

MUTING state, only the ABI indicators

in the muting zone are blinking. Or the

target beams of the ABI are blocked

instantaneously

Incident light level of the target beams of

the ABI is 170% (factory default setting

(*2)) or less of ON threshold 5 to 10 s

after illuminated when incident light level

of the target beams of the ABI is 170%

(factory default setting (*2)) or less of ON

threshold. Or one muting input becomes

the ON state and the MUTING state has

not been started yet, or one muting input

becomes the OFF state and the other is

not in the OFF state yet. (*3)

LOCKOUT state due to Cap error or Other

sensor error (*4), or LOCKOUT state due

to DIP Switch setting error (*5 *6)

-

MUTING/OVERRIDE state, or

LOCKOUT state due to Cap error or

Other sensor error

MUTING/OVERRIDE, or LOCKOUT

state due to DIP Switch setting error (*6)

XX

X-

-X

-X

E

F3SG-SR

User’s Manual

9

Page 38

Overview and Specifications

Receiver (F3SG-SR)

Location Indicator Name Color Illuminated Blinking

Chapter1 LED Indicators on F3SG-SR

1 Scan code

CODE

2 Lockout Red

ERR

3 ON/OFF

OSSD

4

MAINT

5

PNP

C

or

E

or

O

or

M

or

P

or

Maintenance

PNP/NPN

mode

Green Code A is selected

Orange Code B is selected

Automatic interference

prevention by wired

OFF

synchronization being

performed

LOCKOUT state. The

indicator is illuminated in

the receiver of another

sensor segment than that

having a lockout error

(when in cascade

connection or between

the emitter and receiver

in the Wired

Synchronization)

Green

Orange

Green

Safety outputs are in ON

state

Safety outputs are in

Red

OFF state

LOCKOUT state due to a

recoverable error (When

in cascade connection,

Red

the indicator of only the

sensor segment having

the error is illuminated)

Safety outputs are

instantaneously turned

OFF due to ambient light,

vibration or noise.

Or sequence error in

Muting, Pre-Reset or

PSDI

PNP is configured Polarity of PNP is changed to NPN, or

NPN is configured

OFF

-XX

LOCKOUT state. The indicator is

illuminated in the receiver of a sensor

segment having a lockout error

-XX

LOCKOUT state due to Safety output

error, or error due to abnormal power

supply or noise

LOCKOUT state due to a

replacement-recommended error

(When in cascade connection, the

indicator of only the sensor segment

having the error blinks)

Intelligent Tap is in the LOCKOUT

state

vice versa, during operation, and

internal circuit is defective

F3SG-

F3SG-

SRA

SRB

XX

XX

XX

XX

XX

10

F3SG-SR

User’s Manual

F

6

7 Sequence Yellow

or

CFG

S

or

SEQ

Configuration

Green

Fixed or Floating

Blanking, Reduced

Resolution, Warning Zone

or Slow mode of

Response Time

Adjustment is enabled.

Or after the Muting zone

is determined by the

Dynamic Muting function.

INTERLOCK state Sequence or sequence error in

TEACH-IN mode, zone measurement

being performed by Dynamic Muting,

or LOCKOUT state due to Blanking

monitoring error, Configuration error

or Parameter error X X

Muting, Pre-Reset or PSDI (*1) or

Teach-in error

XX

Page 39

Overview and Specifications

Location Indicator Name Color Illuminated Blinking

The target beams of the

ABI are unblocked and

Green

Orange

Area

8-

9 TOP

10 BTM

*1. Refer to 8-1. Troubleshooting for more information on blinking patterns.

*2. Configurable by SD Manager 3.

*3. This is the case for the Standard Muting mode. For other muting modes, refer to 2-13. Muting.

*4. The Area Beam Indicator closer to the "TOP" mark on the F3SG-SR blinks.

*5. The Area Beam Indicator closer to the "BTM" mark on the F3SG-SR blinks.

*6. DIP switches is on the Intelligent Tap.

Beam

Indicator

(ABI)

Top-beamstate

Bottom-

beam-

state

the safety outputs are

turned ON

Incident light level of the

target beams of the ABI

is 170% (factory default

setting (*2)) or less of

ON-threshold (for 5 to 10

s)

The target beams of the

ABI are blocked

Red

The target beams of the

ABI are unblocked (The

ABI then will be

OFF

illuminated in green when

the safety outputs are

turned ON.)

The top beam is

Blue

unblocked

The bottom beam is

Blue

unblocked

MUTING or OVERRIDE state. In the

MUTING state, only the ABI

indicators in the muting zone are

blinking. Or the target beams of the

ABI are blocked instantaneously

Incident light level of the target

beams of the ABI is 170% (factory

default setting (*2)) or less of ON

threshold 5 to 10 s after illuminated

when incident light level of the target

beams of the ABI is 170% (factory

default setting (*2)) or less of ON

threshold. Or one muting input

becomes the ON state and the

MUTING state has not been started

yet, or one muting input becomes the

OFF state and the other is not in the

OFF state yet. (*3)

LOCKOUT state due to Cap error or

Other sensor error (*4), or LOCKOUT

state due to DIP Switch setting error

(*5 *6)

-

MUTING/OVERRIDE state, or

LOCKOUT state due to Cap error or

Other sensor error

MUTING/OVERRIDE state, or

LOCKOUT state due to DIP Switch

setting error (*6)

F3SG-

F3SG-

SRA

SRB

X-

-X

-X

Chapter1 LED Indicators on F3SG-SR

In the SETTING state to make settings with the SD Manager 3, the TEST, LONG and CODE indicators on the emitter

and the CFG, PNP and CODE indicators on the receiver blink.

(TEST: Yellow, LONG/CODE: Green, CFG/PNP/CODE: Green)

For more information on the statuses of the LED indicators in the SETTING state, refer to 4-1-4. SETTING State

of F3SG-SR with SD Manager 3 Connected.

F3SG-SR

User’s Manual

E

11

Page 40

Overview and Specifications

1-5. Ratings and Specifications

Chapter1 Ratings and Specifications

Extension of the cable must be within a specified length. If it isn't, safety functions may not work

properly, resulting in danger.

1-5-1. F3SG-SR Series

The in the model names indicate the protective heights in millimeters.

Model

Performance

Object resolution

(Detection capability)

Beam gap 10 mm 20 mm 40 mm 80 mm

Number of beams 15 to 199 8 to 124 6 to 38 4 to 12

Lens size

Protective height 160 to 2,000 mm 160 to 2,480 mm 240 to 1,520 mm 280 to 920 mm

Operating

range

Response time

F3SG-SRA-14

F3SG-SRB-14

Opaque objects

14-mm dia. 25-mm dia. 45-mm dia. 85-mm dia.

4.4 3.4 mm (W H) 6.7 4.5 mm (W H)

Long 0.3 to 10.0 m * 0.3 to 20.0 m

Short 0.3 to 3.0 m * 0.3 to 7.0 m

* When operating at an ambient temperature of -10 to -30°C, use the F3SG-SR with the operating range

of 0.3 to 5.0 m in Long Mode and 0.3 to 1.5 m in Short Mode.

*1Normal

mode

×2 Slow

mode *2

×4 Slow

mode *2

ON to

OFF

OFF

to ON

ON to

OFF

OFF

to ON

ON to

OFF

OFF

to ON

Optical

synchronization:

8 to 18 ms

Wired

synchronization:

10 to 21 ms

Optical

synchronization:

40 to 90 ms

Wired

synchronization:

50 to 105 ms

Optical

synchronization:

16 to 36 ms

Wired

synchronization:

20 to 42 ms

Optical

synchronization:

80 to 180 ms

Wired

synchronization:

100 to 210 ms

Optical

synchronization:

32 to 72 ms

Wired

synchronization:

40 to 84 ms

Optical

synchronization:

160 to 360 ms

Wired

synchronization:

200 to 420 ms

F3SG-SRA-25

F3SG-SRB-25

Optical

synchronization:

8 to 13 ms

Wired

synchronization:

10 to 17 ms

Optical

synchronization:

40 to 65 ms

Wired

synchronization:

50 to 85 ms

Optical

synchronization:

16 to 26 ms

Wired

synchronization:

20 to 34 ms

Optical

synchronization:

80 to 130 ms

Wired

synchronization:

100 to 170 ms

Optical

synchronization:

32 to 52 ms

Wired

synchronization:

40 to 68 ms

Optical

synchronization: