Page 1

Safety Light Curtain

F3S-B

Suitable for

Detecting Human

Bodies in a

Dangerous Area

Safety Design for Category 2.

Features

• The F3S-B is a type 2 Safety Light curtain intended to be

used as or with the safety related parts of the control system

of a machine to category 2, 1 or B as defined in the European standard EN954-1.

• Compliance with IEC 61496-2, EN 61496-1 standards and

machine and EMC directive.

• Received certificates from Notified Bodies as Type 2 ESPE

(Electro-Sensitive-Protective-Equipment).

• UL/CSA approved.

• Pursuing safety with high level of safety design and FMEA.

• Series configuration of two units is possible.

• Units available with an axis pitch of 25 mm (hand protection), 50 mm (arm protection) or 75 mm (body protection) in

protective height ranging from 300 mm to 1650 mm.

• Human body detection system without a dedicated control

box.

• M12 Connector

F3S-B

G-31F3S-B

Page 2

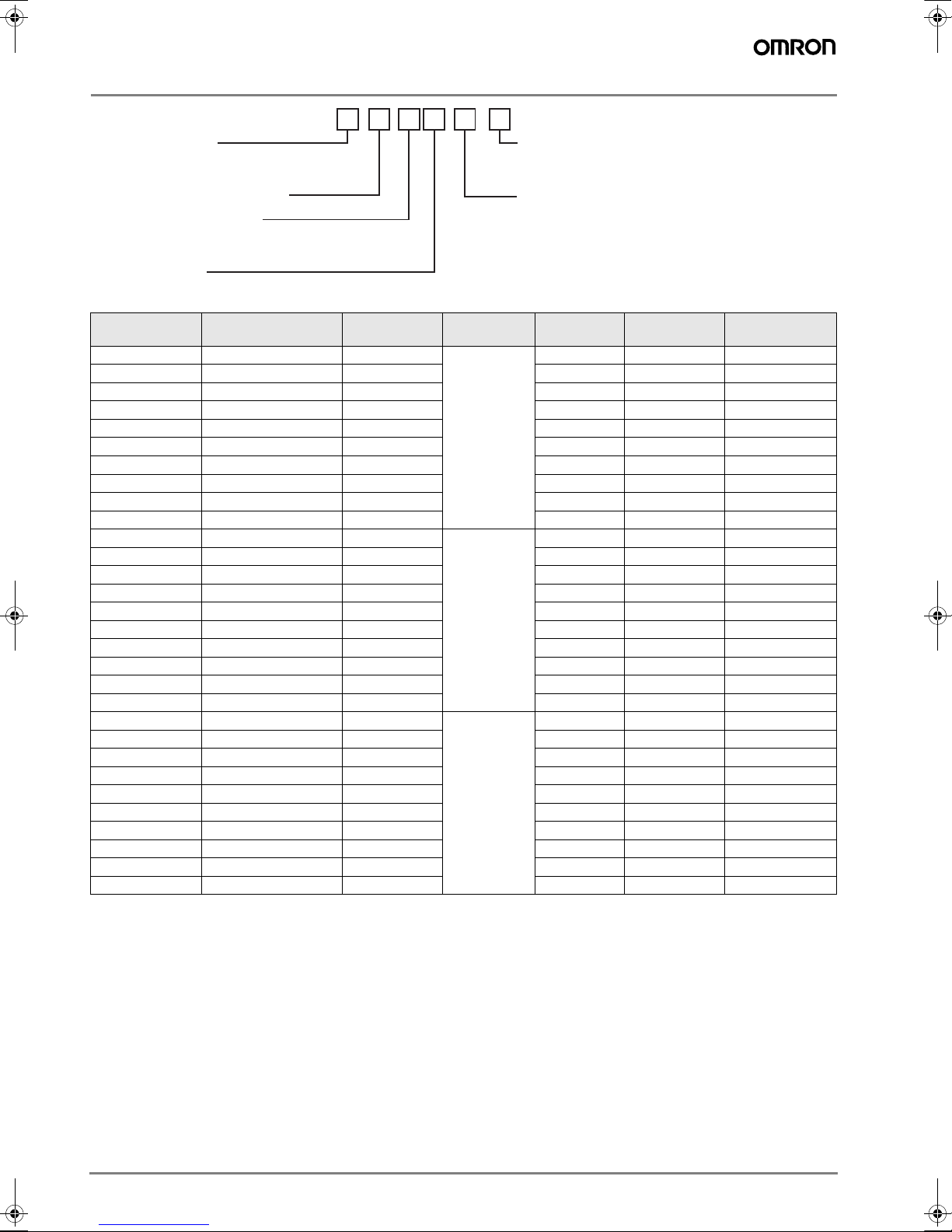

Ordering Information

F3S-B M 36 2 P 12 - L

blank Stand-alone

M Master unit for series connection

S Slave unit for series connection

36 No. of optical axis (4-66)

2 25 mm optical pitch

5 50 mm optical pitch

7 75 mm optical pitch

blank Slave unit

P PNP outputs

blank Complete set of emitter and receiver

L Emitter unit only

D Receiver unit only

blank Stand-alone or slave unit

12 No. of optical axis of the connected slave unit

for 25 mm optical pitch type: 12, 18, 24, or 30

for 50 mm optical pitch type: 06, 09, 12, or 15

for 75 mm optical pitch type: 04, 06, 08, or 10

Stand-alone Master unit Slave unit Optical

F3S-B122P F3S-BM122P

F3S-B182P F3S-BM182P

F3S-B242P F3S-BM242P

F3S-B302P F3S-BM302P

F3S-B362P F3S-BM362P

F3S-B422P F3S-BM422P

F3S-B482P F3S-BM482P

F3S-B542P F3S-BM542P

F3S-B602P F3S-BM602P

F3S-B662P F3S-BM662P

F3S-B065P F3S-BM065P

F3S-B095P F3S-BM095P

F3S-B125P F3S-BM125P

F3S-B155P F3S-BM155P

F3S-B185P F3S-BM185P

F3S-B215P F3S-BM215P

F3S-B245P F3S-BM245P

F3S-B275P F3S-BM275P

F3S-B305P F3S-BM305P

F3S-B335P F3S-BM335P

F3S-B047P F3S-BM047P

F3S-B067P F3S-BM067P

F3S-B087P F3S-BM087P

F3S-B107P F3S-BM107P

F3S-B127P F3S-BM127P

F3S-B147P F3S-BM147P

F3S-B167P F3S-BM167P

F3S-B187P F3S-BM187P

F3S-B207P F3S-BM207P

F3S-B227P F3S-BM227P

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

##

F3S-BS122 30 mm 12 300 mm 0.9 kg

F3S-BS182 18 450 mm 1.2 kg

F3S-BS242 24 600 mm 1.5 kg

F3S-BS302 30 750 mm 1.8 kg

- 36 900 mm 2.1 kg

- 42 1,050 mm 2.5 kg

- 48 1,200 mm 2.8 kg

- 54 1,350 mm 3.1 kg

- 60 1,500 mm 3.4 kg

- 66 1,650 mm 3.7 kg

F3S-BS065 55 mm 6 300 mm 0.9 kg

F3S-BS095 9 450 mm 1.2 kg

F3S-BS125 12 600 mm 1.5 kg

F3S-BS155 15 750 mm 1.8 kg

- 18 900 mm 2.1 kg

- 21 1,050 mm 2.5 kg

- 24 1,200 mm 2.8 kg

- 27 1,350 mm 3.1 kg

- 30 1,500 mm 3.4 kg

- 33 1,650 mm 3.7 kg

F3S-BS047 80 mm 4 300 mm 0.9 kg

F3S-BS067 6 450 mm 1.2 kg

F3S-BS087 8 600 mm 1.5 kg

F3S-BS107 10 750 mm 1.8 kg

- 12 900 mm 2.1 kg

- 14 1,050 mm 2.5 kg

- 16 1,200 mm 2.8 kg

- 18 1,350 mm 3.1 kg

- 20 1,500 mm 3.4 kg

- 22 1,650 mm 3.7 kg

resolution

No. of

optical axes

Protective height Weight (without

accessories)

G-32 Safety Sensors / Components

Page 3

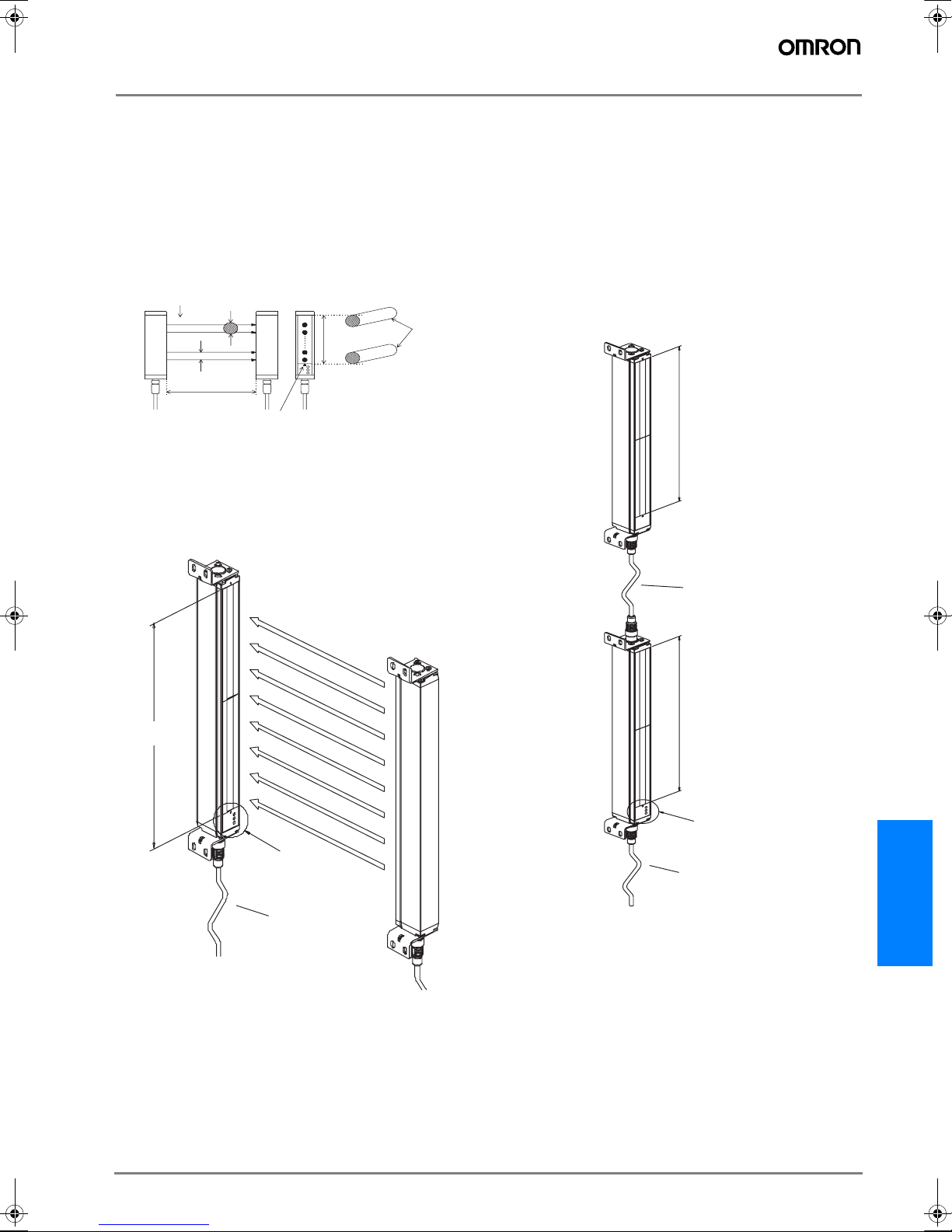

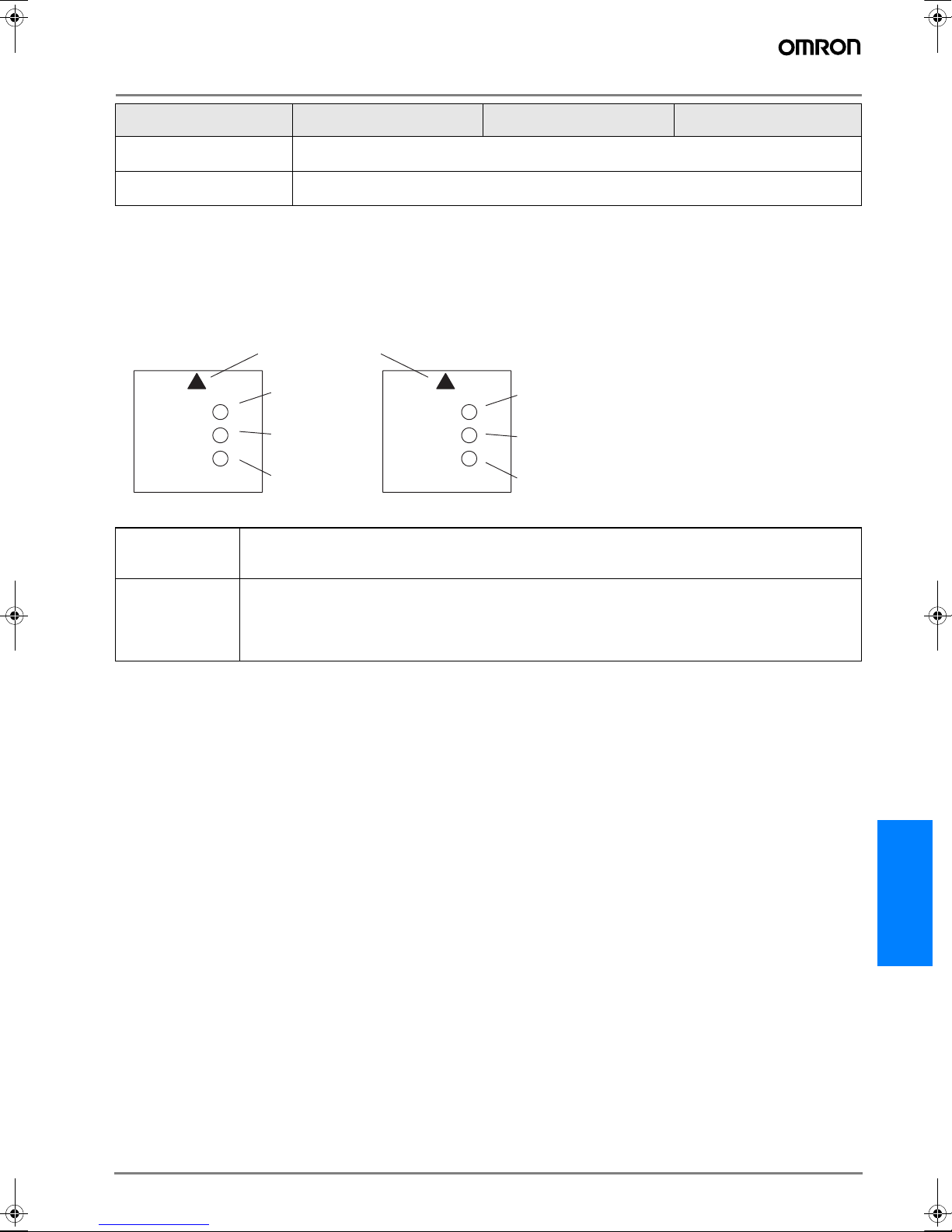

Nomenclature

Protective height

The F3S-B can detect in the area indicated by ”Protective

height” in the figure below. The protective height is from ”the

Optical-axis line mark above the indicator area” to ”the end of

the yellow metal case”.

Optical-axis line mark

The center line for optical axes is indicated by the triangle

mark. This position is a reference line for measuring safety

distance.

No.ofopticalaxes

n-1

Emitter

Detection distance

n

2

1

Optical resolution

Optical- axis

pitch

Receiver

Optical- axis

line mark

Protective

height

Limit position

for detection

Stand-alone type

This is the most common configuration, and it is used to protect a hazardous part of a machine when approached from

one direction only.

Receiver

Series connection types

When your application requires an additional protective zone,

for example, to prevent someone from staying behind a primary detection zone, the F3S-B may be connected in series.

The system consists of a master unit, a slave unit, and a series connection cable, type F39-JB1B.

The series connection allows up to 96 axes and 2.4 m of protective height in total.

Series connection types have the same characteristics as a

stand-alone types. When the detection zone of the master

unit or that of the slave unit is interrupted, the outputs of the

master unit go to the OFF-state.

Protective

Slave unit

height

Protective

height

Indicator area

Extension cable

Emitter

Series connection cable

Protective

Master unit

height

Indicator area

Extension cable

Note: Slave unit does not have indicators.

Master unit and slave unit need to be ordered separately.

F3S-B

G-33F3S-B

Page 4

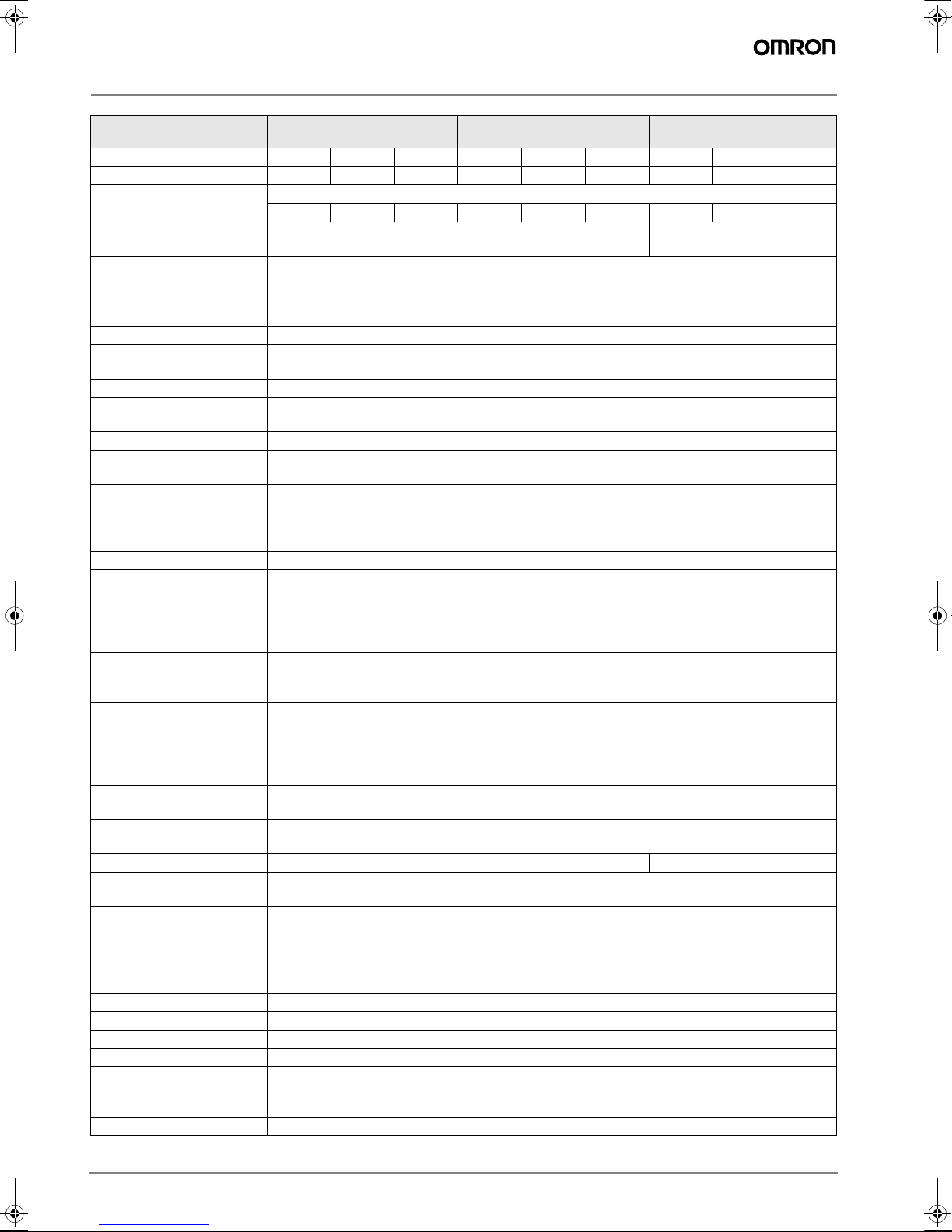

Rating and Performance

Type

F3S-B

###

Stand-alone

*1

P

F3S-BM

###P##

Master unit for series connection

*1

F3S-BS

Slave unit for series connection

###

*1

No. of optical axes 12 to 66 6 to 33 4 to 22 12 to 66 6 to 33 4 to 22 12 to 30 6 to 15 4 to10

Optical-axis pitch 25 mm 50 mm 75 mm 25 mm 50 mm 75 mm 25 mm 50 mm 75 mm

Optical resolution

(Detection capability)

Protective height 300 / 450 / 600 / 750 / 900 / 1,050 / 1,200 / 1,350 / 1,500 /

Non-transparent: in diameter

30 mm 55 mm 80 mm 30 mm 55 mm 80 mm 30 mm 55 mm 80 mm

300 / 450 / 600 / 750 mm

1,650 mm

Detection distance 0.3 to 5.0 m, up to 8 m on request

Response time ON to OFF: See table “Response Time”

OFF to ON*2: Default 100 ms (selectable with F39-U1E, 80 to 400 ms)

Startup waiting time 2 s max.

Supply voltage: Vs 24 VDC ± 20% (including 5 Vp-p ripple)

Current

400 mA max. (under no-load conditions)

consumption

Light source Infrared LED (880 nm wavelength). Lifetime: 50,000 hrs. at 25 °C.

Effective aperture angle Within ± 5° for the emitter and receiver at a detection distance of at least 3 m according to IEC

61496-2

Operating mode Light ON

Control output Two PNP transistor outputs, load current 200 mA max., residual voltage 2 V max. (except for volt-

age drop due to cable extension)

Instability output PNP transistor output (not safety-related control output),

activated during an insufficient light detection, failure detection and connection with F39-E1,

load current 100 mA max., residual voltage 2 V max. (except for voltage drop due to cable exten-

sion)

Protection circuit Output short-circuit protection, power supply reverse connection protection

Start/restart

interlock function

Mode selection before power ON by connecting ”Interlock selection input” line to:

Active: No connection or 0 to 2.5 VDC, 3 mA max.

Inactive: Instability output line

Reset of start/restart interlock by connecting ”Interlock selection input” line to:

Interlock reset: 17 VDC to Vs, 20 mA max. Duration time 15 to 2,500 ms

External test function Mode selection by connecting ”External test input” line to:

Active: 17 VDC to Vs, 10 mA max. Duration time at least 15 ms

Inactive: No connection or 0 to 2.5 VDC, 2 mA max.

Relay monitoring

function (optional)

Default inactive, selectable with F39-U1E

Relay monitoring input line with NC contact connected,

Available level: 17 VDC to Vs, 10 mA max.

Allowed relay delay time

*3

: Selectable between 20 and 300 ms

Termination when not selected: No connection or 0 to 2.5 VDC, 2 mA max.

Start interlock function

Default inactive, selectable with F39-U1E

(optional)

Blanking function

Default inactive, selectable with F39-U1E

(optional)

Indicator See ”Indicators” No indicators

Connection method For Extension cable: 8 pins, M12 connector

For Series connection cable: 6 pins, M12 connector

Ambient temperature During operation: –10 to 55 °C (with no freezing)

During storage: –25 to 70 °C

Ambient humidity During operation: 35 to 85 %RH (with no condensation)

During storage: 35 to 95 %RH

Insulation resistance 20 MΩ min. (at 500 VDC)

Dielectric strength voltage 1,000 VAC 50/60 Hz for 1 min

Degree of protection IEC60529 IP65

Vibration resistance Normal operation: 10 to 55 Hz, double-amplitude: 0.7mm, X, Y and Z directions 20 sweeps

2

Shock resistance Normal operation: 100 m/s

[10 G], X, Y and Z directions: 1000 times

Materials Case: Aluminum

Front cover: PMMA (acrylic resin)

End caps: PA6

Size (cross section) 30 x 40 mm

G-34 Safety Sensors / Components

Page 5

Type

F3S-B

Stand-alone

Accessories Test rod*3, mounting brackets (top and bottom), mounting brackets (intermediate)*4, mounting

plates

*1

###

P

*5

, Instruction manual

F3S-BM

###P##

Master unit for series connection

*5

*1

F3S-BS

###

*1

Slave unit for series connection

Applicable standard IEC(EN)61496-1 TYPE 2 ESPE (Electro-Sensitive Protective Equipment)

IEC 61496-2 TYPE 2 AOPD (Active Opto-electronic Protective Devices)

Note: 1 . For detailed type names and optical specifications, see „Type Naming Rule“

2 .Nominal value (set time). The accuracy is -0 ... +70% of the ON to OFF response time.

3 .Only with F3S-B

4 .For the 1,050 mm protective height and longer types.

5 .Only with F3S-B

###

2P and BM

###P#

###2P##

and BM##2P##.

.

Indicators

<Emitter Indicators>

POWER

INTER-

LOCK

EXT.TEST

BLANKING

Optical- axis

line mark

IR-power indicator

(Orange)

Interlock indicator

(Yellow)

External test /

blanking indicator

(Green)

<Receiver Indicators>

ON

OFF

UNSTAB

ON-state indicator

(Green)

OFF-state indicator

(Red)

Instability indicator

(Orange)

Emitter IR-power indicator: Lit when emitting.

Interlock indicator: Lit during start/restart interlock or start interlock.

External test/ blanking indicator: Lit during external test. / Flashing when using blanking function.

Receiver ON-state indicator: Lit when receiving light.

OFF-state indicator: Lit with interrupted light.

Flashing during connection with F39-E1 or with failure.

Instability indicator: Lit with an insufficient light reception or failure.

Flashing during connection with F39-E1.

F3S-B

G-35F3S-B

Page 6

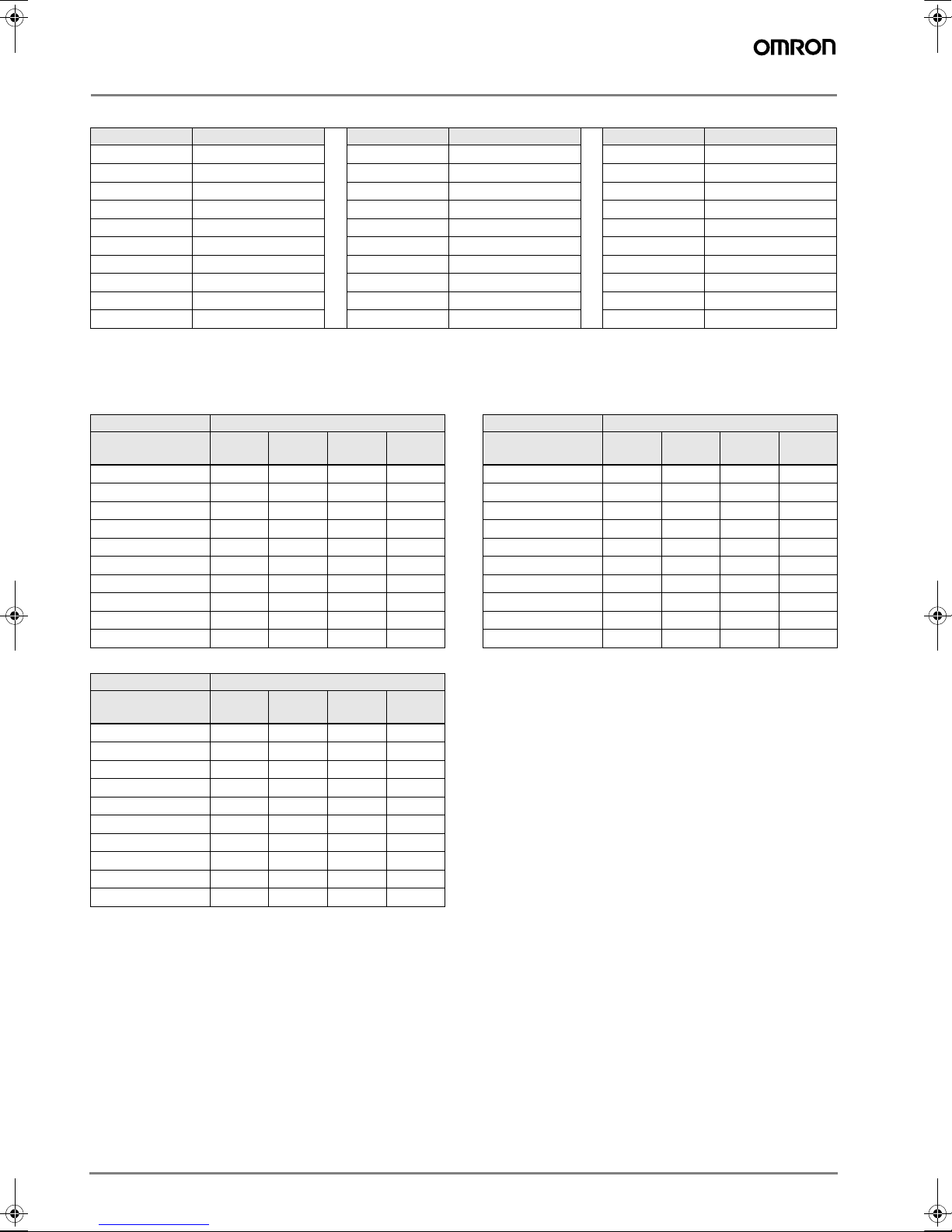

Table of Response Time

Stand-alone type

Response time [ms ] Response time [ms ] Response time [ms ]

F3S-B122P 20 F3S-B065P 20 F3S-B047P 20

F3S-B182P 20 F3S-B095P 20 F3S-B067P 20

F3S-B242P 20 F3S-B125P 20 F3S-B087P 20

F3S-B302P 23 F3S-B155P 20 F3S-B107P 20

F3S-B362P 27 F3S-B185P 20 F3S-B127P 20

F3S-B422P 30 F3S-B215P 21 F3S-B147P 20

F3S-B482P 34 F3S-B245P 22 F3S-B167P 20

F3S-B542P 37 F3S-B275P 24 F3S-B187P 20

F3S-B602P 41 F3S-B305P 26 F3S-B207P 20

F3S-B662P 45 F3S-B335P 28 F3S-B227P 21

Series connection types

The following chart shows the response time of combinations of a master unit and a slave unit connected in series. For example,

the response time of the combination of F3S-BM122P30 and F3S-BS302 is 30 ms.

Slave unit F3S-

Master unit

F3S-BM122P

F3S-BM182P

F3S-BM242P

F3S-BM302P

F3S-BM362P

F3S-BM422P

F3S-BM482P

F3S-BM542P

F3S-BM602P

F3S-BM662P

Slave unit F3S-

Master unit

F3S-BM065P

F3S-BM095P

F3S-BM125P

F3S-BM155P

F3S-BM185P

F3S-BM215P

F3S-BM245P

F3S-BM275P

F3S-BM305P

F3S-BM335P

Response time [ms]

BS122 BS182 BS242 BS302

##

20 23 27 30

##

23 27 30 34

##

27 30 34 37

##

30 34 37 41

##

34 37 41 45

##

37 41 45 49

##

41 45 49 54

##

45 49 54 57

##

49 54 57 61

##

54 57 61 65

Response time [ms]

BS065 BS095 BS125 BS155

##

20 20 20 21

##

20 20 21 22

##

20 21 22 24

##

21 22 24 26

##

22 24 26 28

##

24 26 28 30

##

26 28 30 32

##

28 30 32 34

##

30 32 34 35

##

32 34 35 37

Slave unit F3S-

Master unit

F3S-BM047P

F3S-BM067P

F3S-BM087P

F3S-BM107P

F3S-BM127P

F3S-BM147P

F3S-BM167P

F3S-BM187P

F3S-BM207P

F3S-BM227P

Response time [ms]

BS047 BS067 BS087 BS107

##

20 20 20 20

##

20 20 20 20

##

20 20 20 20

##

20 20 20 20

##

20 20 20 21

##

20 20 21 23

##

20 21 23 24

##

21 23 24 25

##

23 24 25 26

##

24 25 26 27

G-36 Safety Sensors / Components

Page 7

Characteristic data

Operating Range

F3S-B122P

Parapendicular to Center Line of Lenses Parallel to Center Line of Lenses

300

300

200

100

0

-100

Distance Y (mm)

-200

-300

0 2 4 6 8

Distance X (m)

Y

X

200

100

0

-100

Distance Y (mm)

-200

-300

0 2 4 6 8

Distance X (m)

F3S-B662P

Parapendicular to Center Line of Lenses Parallel to Center Line of Lenses

300

200

100

0

-100

Distance Y (mm)

-200

-300

0 2 4 6 8

Distance X (m)

Y

X

300

200

100

0

-100

Distance Y (mm)

-200

-300

0 2 4 6 8

Distance X (m)

Y

X

Y

X

F3S-B

G-37F3S-B

Page 8

I/O Circuit Diagram

IR-light

indicator

Grey

5

Pink

6

ON-state

RS-485(A)

RS-485(B)

indicator

Interlock

indicator

Main emitter

circuit

OFF-state

indicator

Ext. test/blanking

indicator

Instability

indicator

Brown

2

Green

3

External test

input

White

1

Relay monitoring

input

Yellow

4

Blue

7

Brown

2

Interlock selection

input

+24 V

0 V

Pink

Grey

Green

6

Main receiver

5

circuit

3

Control output 1

White

1

Control output 2

Yellow

4

Instability

output

Blue

7

Load

Load

Load

G-38 Safety Sensors / Components

Page 9

Dimensions

Safety Light Curtain

F3S-B

M12 connector

Master unit

9.5

3

B

3

M12 connector

A (Protective height)

34

10.5

40.3

Type A

Protective

height

F3S-B122, -B065, -B047 300 343

F3S-B182, -B095, -B067 450 493

F3S-B242, -B125, -B087 600 643

F3S-B302, -B155, -B107 750 793

F3S-B362, -B185, -B127 900 943

F3S-B422, -B215, -B147 1050 1093

F3S-B482, -B245, -B167 1200 1243

F3S-B542, -B275, -B187 1350 1393

F3S-B602, -B305, -B207 1500 1543

F3S-B662, -B335, -B227 1650 1693

Note:All units are in Millimeters unless otherwise indicated.

B

Full length

30

Accessoires

Mounting Bracket (Top and Bottom) Mounting Plate

Only supplied with types which have a protective height of 1050 mm or longer (Including inter-

5.5

12

16

22

20

20˚

35˚

46

30

2

R1.75

36

R2.75

Ø 25.5

3.5

mediate brackets). Only needed for rear mounting

R4.5

6.25

42.74

36.5

20

3

4

5.5

22.5

R2.75

7

5

F3S-B

28.74

12

G-39F3S-B

Page 10

Intermediate Mounting Bracket

Only needed for types which have a protective height of 1050 mm or longer

Mounting screw for sensor (M6x8)

Flat intermediate bracket

Options (Order Separately)

Extension Cable

(Set of 2: Emitter > gray, Receiver > black)

F39-JB1A (L = 3 m)

F39-JB2A (L = 7 m)

F39-JB3A (L = 10 m)

M12

Series Connection Cable

(Set of 2: Emitter > gray, Receiver > black)

F39-JB1B

Ø 15

Rubber

L-shaped intermediate bracket

42 L

48.5

U-shaped intermediate bracket

Fixing screw for bracket (M4x10)

Round vinyl-insulated cord

5.7 mm dia. (32/0.1 mm dia.) 8 cores

Unit:mm

300

Ø 15

M12

Optional Function Kit

F39-EU1E

This set includes the following items:

· F39-U1E OptionalFunction Software

· F39-E1 Interface Unit

· F39-JB1C Interface Cable

The F39-U1E Optional Function Software is the WINDOWS®

-based software for use with the F39-E1 Interface Unit to program the F3S-B Safety Light Curtain, and provided with one

3.5 inch floppy disk. This software has the following features:

· Set the following functions to the F3S-B

- Start interlock function

- Relay monitoring function

- Blanking function

Display each axis and each input line condition of the F3S-B

·

· Change the ON delay time

Unit: mm

Note: The F3S-B is not in normal operation during connection with the F39-E1.

The control outputs are held in their OFF-state. For detailed information

please refer to “Details of F39-EU1E” in this data sheet.

!WARNING

After setting the blanking function, check that the F3S-B detects a test

rod at any position in the F3S-B detection zone through which a person reaches the hazardous part of the machine. If any positions are

found by check above, install protective structures to there to prevent

intrusion which F3S-B can not detect. Failure to do so may result in

serious injury.

Perform the installation check and the periodical inspection described

in the F3S-B manual.

Disconnect the outputs of the F3S-B from the load when programming it using the F39-U1E software and with F39-E1 interface unit.

Failure to do so may result in serious injury.

Do not connect the F39-E1 to a power supply with a voltage higher than

24 VDC +20 %. Do not connect the F39-E1 to an AC power supply.

G-40 Safety Sensors / Components

Page 11

Installation

Wiring

Disconnect all sources of power before wiring the F3S-B to a

machine.

· Connect the emitter extension cable (F39-JBxA-L optional,

gray color outer jacket) to the emitter. (The emitter uses

gray color plastic caps.)

· Connect the receiver extension cable (F39-JBxA-D optional, black color outer jacket) to the receiver. (The receiver

unit uses black color plastic caps.)

· Connect the 0 V line of the power supply directly to protective earth (PE).

Note: Note:Be sure to wire correctly. Failure to do so may damage the F3S-B.

Front View Pin No.

1 Control output 2 Relay monitoring input White

2 24 VDC 24 VDC Brown

7

1

865

2

4

3

3 Control output 1 External test input Green

4 Instability output Interlock selection input Yellow

5 RS-485 (A) RS-485 (A) Grey

6 RS-485 (B) RS-485 (B) Pink

70 V0 VBlue

8 N.C. / reserved*1 N.C. / reserved Red

*1. N.C. / reserved: do not connect

Emitter

Signal Name

Receiver Emitter

Receiver

RS-485(A) (Grey 5)

RS-485(B) (Pink 6)

Wire Color

of Extension Cable

E1: 24 VDC Power supply

S1: External test switch

K1, K2: Relay

K3: Relay to indicate unstable condition

Relay monitoring (White 1)

Ext. test (Green 3)

S1

0 V (Blue 7)

24 VDC (Brown 2)

E1

Interlock selection (Yellow 4)

Output 2 (White 1)

Output 1 (Green 3)

0 V (Blue 7)

24 VDC (Brown 2)

Instability (Yellow 4)

K1

K2

K3

F3S-B

G-41F3S-B

Page 12

When using START/RESTART FUNCTION When using optional RELAY MONITORING FUNCTION

Emitter

24 VDC (Brown 2)

S2

0 V (Blue 7)

RS-485(A) (Grey 5)

RS-485(B) (Pink 6)

Interlock selection (Yellow 4)

Receiver

Instability (Yellow 4)

24 VDC (Brown 2)

0 V (Blue 7)

k1

k2

Relay monitoring (White 1)

Emitter

Ext. test (Green 3)

24 VDC (Brown 2)

S1

0 V (Blue 7)

E1

S2: Restart interlock reset switch

K3

Details of F39-EU1E Optional Function Kit

1. Installation

1.1 Preparation

!WARNING

Perform the installation check and the periodical inspection

described in the F3S-B manual.

Do not disassemble, repair or modify the F39-E1.

Do not use the F39-E1 in flammable or explosive environments.

To use the F39-U1E software, the following items are necessary.

· Personal Computer (not included)

- Windows® 95, Windows® 98, or Windows NT®

- 133MHz Pentium® processor or better

- 32MB RAM or higher for Windows® 95 and Windows® 98

- 64MB RAM or higher for Windows NT®

- A 115kBd RS-232 serial interface port or better

· F39-E1 Interface Unit

E1

k1, k2: Auxiliary contact to moni

tor the condition of the final relay

· F39-JB1C Interface cable 5 m cable length, M8 connector

(4 pins)

30.5

Ø 15

5000

Round vinyl-insulated cord

5 mm dia. (32/0.1 mm dia.) 4 cores

Unit : mm

· RS-232C cable (not included)

1.2 Component Names and Functions of the F39-E1 Interface Unit

SEND to RS-485 indicator (Red)

SEND to RS-232C indicator (Yellow)

M8 Connector (RS-485)

9pin D-Sub Connector

(RS-232C)

35

60

8

G-42 Safety Sensors / Components

114

Unit : mm

Communication indicator (Green)

SEND to RS-485 Indicator (Red)

Lit when the F39-E1 sends data to the F3S-B via RS-485.

SEND to RS-232C Indicator (Yellow)

Lit when the F39-E1 sends data to the PC via RS-232C.

COMMUNICATION Indicator (Green)

Flashing during communication between the F3S-B and the

F39-E1.

Page 13

1.3 Hardware Connection

!WARNING

Disconnect the outputs of the F3S-B from the load when programming it using the F39-U1E software and with F39-E1 interface unit.

Failure to do so may result in serious injury.

Do not connect the F39-E1 to a power supply with a voltage higher than

24 VDC +20 %.

Do not connect the F39-E1 to an AC power supply.

1.3.1 Wiring Diagram

F39-U1 E

PC

RS-232C

Note 1

Emitter

F3S- B

No. 1 axi s

RS-485(A) (Grey 5)

RS-485(B) (Pi nk 6)

Rece iver

Note 1

Start/Restart interlock is a function which is selected by wiring.

Refer to the instruction manual of the F3S-B for more detailed

information.

2.2 Relay Monitoring

MPCEs (Machine Primary Control Elements) are usually relays or contactors used to control hazardous movement directly. The state of the MPCEs can be checked with the Relay

monitoring function.

A voltage of 17 VDC to Vs (Supplied voltage to F3S-B) has to

be applied to the Relay monitoring input through the NC contacts of the MPCEs when the F3S-B control outputs are in the

OFF-state (see the F3S-B manual for wiring information). To

ensure this logic relation, the MPCEs must be safety approved types, with forcibly guided contacts.

Allowed Relay Delay Time

The allowed relay delay time can be set between 20 and 300

ms. This delay time has to be set at least 20 milliseconds

shorter than the Outputs ON delay time.

F39-E1

0V (Bluie 7)

F39- JB1 C

0V (Bluie 7)

24 VDC (Braun 2)

+24 V (B rown 1)

0V(Blue3)

RS- 485(A) (Black4)

RS- 485(B) (White 2)

Note 1: See thei nstruction manual of F3S-B for wiring

24 VDC (Braun 2)

Open Output 1 (Green 3)

1.3.2 Wiring Procedure

1. Connect the F3S-B (see the instruction manual of the F3SB for wiring.)

2. Connect the Interface cable (F39-JB1C) to the Interface

unit (F39-E1).

3. Connect the 4 wires of the Interface cable to each appropriate line of the F3S-B.

4. Connect an RS-232C cable to the PC and the Interface

unit.

1.4 Software-Installation

Copy the file „F39-U1E_ver#.#.exe“ and F39-U1E_ver#.#dat

from the enclosed 3.5-inch floppy disk onto the hard disk of

the PC.

2. Function Description

2.1 Start Interlock

When the Start interlock function is used, the F3S-B does not

go to the ON-state automatically after power ON. Interrupting

one or more axes resets the start interlock condition of the

F3S-B then starts normal operation. The duration of the interruption must be equal or shorter as defined in the „Max. interruption time (sec)“.

Max. Interruption Time

The max interruption time can be set between 0.3 and 2 s.

Note: In the case both the Start interlock and the Start/restart interlock are se-

lected, only the Start/restart interlock will be activate.

2.3 Outputs ON Delay

You can set the ON delay time of control outputs between 80

and 400 ms. This corresponds to the time which the control

Open Output 2 (White 1)

outputs go to ON-state after the detection zone is not interrupted.

Note: 1 .When the Relay monitoring function is also used, the ON delay time

2.4 Blanking

With the Blanking function, one or more axes can be disabled.

This function is useful in an application where a part of the

F3S-B detection zone is always interrupted. The Manual-setting and the Teaching-setting are available to select the

blanked axes.

Note: 1 . In the case the blanked zone is not filled with structure completely and

must meet the formula below.

2 . ON delay time Allowed relay delay time + 20 ms After the Relay mon-

itoring function is set, if the ON delay time does not meet the above

formula, the ON delay time will be changed automatically into ”Allowed

relay delay time” + 20 ms.

remains some opening, the opening must be filled with the protective

structure.

2 .All axes can not be disabled. At least one axis needs to be active.

F3S-B

G-43F3S-B

Page 14

3. Ratings and Performance

Type F39-E1 Interface unit

Supply voltage 24 VDC ± 20% (including 5 Vp-p ripple)

Current Consumption 120 mA max.

Interface RS-232C interface, RS-485 interface

Indicator See 1-2

Connection method RS-485: 4pins, M 8 connector

RS-232C: D-SUB connector, 9 pins

Protection circuit RS 485 protection against wrong wiring

Ambient Temperature During operation: –10 to 55° C (with no freezing)

During storage: –25 to 70° C

Ambient Humidity During operation : 35 to 85% RH (with no condensation)

Ambient Humidity During storage: 35 to 95% RH

Insulation Resistance 20 MΩ min. (at 500 VDC)

Dielectric strength voltage 500 VAC 50/60 Hz for 1 min.

Degree of Protection IEC60529 IP20

2

Shock resistance Normal operation: 150 m/s

[15 G], ±X, ±Y and ±Z directions: 3 times

Vibration resistance Normal operation: 10 to 55 Hz, double-amplitude: 0.3mm, X, Y and Z directions: 10 sweeps

2

Cable length RS-485 cable: 5 m (4 pin 0.25 mm

)

RS-232C cable: Standard

Materials Case: Aluminum

Size 122 x 60 x 35 mm

Conformity EMC Directive

G-44 Safety Sensors / Components

Page 15

Precautions

!WARNING

1. Do not use the F3S-B on machines that can not be stopped by electrical control in case of an emergency.

2. Do not use the F3S-B in flammable or explosive environments

3. Always maintain the safety distance between F3S-B and a hazardous part of the machine. Serious injury may result if the machine does not stop before someone reaches the hazardous part.

4. Install protective structures around a machine so that you must pass through the detection zone to reach a hazardous part of

the machine.

5. Install F3S-B so that some parts of the operator’s body remain in the detection zone at all times when the operator works in the

hazardous area.

6. Failure to do so may result in serious injury.

Correct installation Incorrect installation

A hazardous part of a machine can be

reached only by passing through the sensor detection zone.

A hazardous part of the machine can be

reached without passing through the sensor detected zone.

Some part of the operator’s body remains

in the detection zone while they are work-

A worker is between the sensor detection

zone and a hazardous part of a machine.

ing.

!WARNING

1. Be sure to install the F3S-B to minimize the effects of reflections from reflective surfaces. Failures to do so will create an inability

to detect and may result in serious injury

2. Install the F3S-B with a minimum distance D as shown below form the reflective surface (highly reflective surfaces) like metal

walls, floors, ceilings, and work pieces.

<Side View>

Reflecting ceiling

Emitter Receiver

D

Detection zone

L

D

Reflecting floor

Emitter Receiver

<Top View>

Reflecting surface

D

5˚

5˚

L

F3S-B

Distance between emitter and receiver (detection distance L) Minimum installation distance D

0.3 to 3 m 0.26 m

3 to 5 m L x tan 5° = L x 0.088 (m)

G-45F3S-B

Page 16

!WARNING

When using multiple sets of the F3S-B, install them so that mutual interference is not incurred.

(Incorrect) (Incorrect)

Emitter 1

Receiver 1

RS-485

Emitter 2

RS-485

(Incorrect)

Emitter 1

Emitter 2

Receiver 1

Receiver 2

Alternate emitters and receivers

Correct installations are shown below to prevent mutual interference.

(Correct)

Receiver 1

Emitter 1

Emitter 2

Receiver 2

Receiver 2

Emitter 1

Emitter 2

Emitter 1

Receiver 1

Receiver 2

RS-485

(Correct)

Receiver 1

RS-485 RS-485

Receiver 1

Emitter 2

Emitter 1

RS-485 RS-485

G-46 Safety Sensors / Components

(Correct)

(Correct)

Receiver 1

Emitter 2

Emitter 1

Receiver 2

Receiver 2

Receiver 2

RS-485

Emitter 2

RS-485

Page 17

!WARNING

1. The F3S-B is a TYPE 2 Electro-sensitive protective equipment, intended to be used as or with the safety related part

of control system to category 2, 1 or B as defined in the European standard EN954-1.

Do not use the F3S-B in category 3 or 4 systems.

2. A qualified person, as determind by local regulations, must

confirm that installation, inspection and maintenance are

implemented correctly.

3. Do not short the output lines to the +24 V line. Doing so will

cause the output to be always ON, creating a hazardous situation.

4. Do not connect the F3S-B to a power supply with voltage

higher than 24 VDC + 20%. Do not connect the F3S-B to an

AC power supply.

5. Be sure to conduct inspections regularly.

6. The F3S-B cannot be used in applications where hazardous projectiles may exit the protected zone.

7. Do not disassemble, repair or modify the F3S-B.

8. DC power supply units must satisfy all of the conditions below so that the F3S-B can comply with the applicable standards IEC 61496-1 and UL 508.

(1.) The power supply voltage must be within rating

(24 VDC ± 20%).

(2.) The power supply is connected only to the F3S-B and

to the electro-sensitive protective function of the F3SB, such as a safety controller and muting sensors, and

it has enough rated current for all the devices.

(3.) The power supply uses double or reinforced insulation

between the primary and secondary circuits.

(4.) The power supply automatically resets overcurrent

protection characteristics (voltage drop).

(5.) The power supply maintains an output holding time of

at least 20 ms.

(6.) FG (frame ground terminal) must be connected to PE

(protective earth) when using a commercially available

switching regulator.

(7.) The power supply must have output characterisitics re-

quired for the power source for Class 2 Circuit or Limited Voltage / Current Circuit as defined in UL508.

(8.) The power supply must conform to regulatory require-

ments and standards, regarding EMC and electrical

equipment safety, of the country where the F3S-B is installed and where machinery will be operated, for example: The EMC Directive (industrial environment)

and the Low Voltage Directive in EU.

9. Do not use the F3S-B in a direct retroreflective configuration. Otherwise detection may fail.

F3S-B

G-47F3S-B

Page 18

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E503-E2-01-X

In the interest of product improvement, specifications are subject to change without notice.

G-48 Safety Sensors / Components

Loading...

Loading...