Cat. No. E502-E2-01

F3S-B Series

Safety Light Curtain

Instruction Manual

F3S-B

Introduction

Thank you for purchasing the F3S-B series Safety Light Curtain.

Always heed the following points when using the F3S-B:

• Make sure that personnel operating the F3S-B are knowledgeable about the machine on which it is

installed

• Read this manual completely and be sure you understand the information provided before attempting

to operate the F3S-B

• Keep the manual in a secure and convenient location and refer to it as necessary.

Regulations and Standards

(1) The F3S-B has not received the type approval provided by Article 44-2 of the Industrial Safety and

Health Law of Japan. Therefore, it cannot be used in Japan as a safety device for pressing or shearing

machines provided by article 42 of that law.

(2) The F3S-B is electro-sensitive protective equipment (ESPE) in accordance with European Union (EU)

Machinery Directive Annex IV, B. Safety Components, Item 1.

The F3S-B complies with the following regulations and standards.

• EU regulations and technical standards:

– Machinery Directive: No. 98/37/EC

– EMC Directive: No. 89/336/EEC

– EN 61496-1 (06/98) (Type 2 ESPE), IEC 61496-2 (1997) (Type 2 AOPD)

• IEC standards

– IEC 61496-1 (1997) (Type 2 ESPE), IEC 61496-2 (1997) (Type 2 AOPD)

(3) The F3S-B received the following approvals from the EU accredited bodies.

- Certificate of a Notified Body for EC Type-Examination referred to in the EU Machinery Directive

Annex IV, from TÜV Hannover/Sachsen-Anhalt e.V.

- Certificate of a Competent Body referred to in the EU EMC Directive, from Technischer Überwachungs-Verein Nord

(4) The F3S–B received the following approvals from the third–party testing laboratory UL.

– UL Listed (UL508, IEC61496-1 and –2)

– UL Listed to Canadian safety standards (CSA C22.2 No. 14 and No.0.8, IEC61496-1 and –2)

– Programmable system certificate (UL1998, IEC61496–1)

(5) The following standards are referenced when designing the F3S–B. To comply with these standards,

be sure to design and use in accordance with all regulations and standards related to them.

Contact an expert agency such as TÜV and UL if any of the above points are unclear.

– EN415–4

– OSHA 29 CFR 1910. 212

– ANSI/RIA 15.06 (Risk reduction category : R2B)

Precaution on Safety

! General conventions for safe use

The following conventions are used for precautionary items in this manual in order to ensure safe and

proper use of the F3S-B. Items listed here are critical for safety and must be heeded at all times.

WARNING

!

!

!!

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates prohibited actions.

3

F3S-B

WARNING

The F3S-B is a TYPE 2 Electro-sensitive protective equipment, intended to be used as or with the safety

related part of control system to category 2,1, or B as defined in the European standard EN954-1.

Do not use the F3S-B in category 3 or 4 systems.

Do not use the F3S-B on machines that cannot be stopped by electrical control in case of an emergency.

Install protective structures around the machine so that you must pass through the detection zone to

reach a hazardous part of the machine (see “2-1 Installation Conditions”).

Install the F3S-B so that some part of the operator’s body remains in the detection zone at all times

when the operator works in a hazardous area (see “2-1 Installation Conditions”).

Failure to do so may result in serious injury.

A qualified person, as determined by local regulations, must confirm that installation, inspection and

maintenance are implemented correctly.

Always maintain the safety distance between the F3S-B and a hazardous part of a machines (see “2-1

Installation Conditions”).

Do not install the F3S-B in a location affected by wall reflections (see “2-1 Installation Conditions”).

Do not short the output lines to the +24 V line. Doing so will cause the output to be always ON, creating

a hazardous situation.

Do not connect the F3S-B to a power supply with voltage higher than 24 VDC + 20 %.

Do not connect the F3S-B to an AC power supply.

Be sure to conduct inspections regularly (see “6 Maintenance”).

The F3S-B cannot be used in applications where hazardous projectiles may exit the protected zone.

Do not disassemble, repair or modify the F3S-B.

Do not use the F3S-B in flammable or explosive environments.

DC power supply units must satisfy all of the conditions below so that the F3S-B can comply with the

applicable standards IEC 61496-1 and UL 508.

• The power supply voltage must be within rating (24 VDC ± 20 %).

• The power supply is connected only to the F3S-B and to the devices related to the electro-sensitive

protective function of the F3S-B, such as a safety controller and muting sensors, and it has enough

rated current for all the devices. The power supply is not connected to other devices or machines.

• The power supply uses double or reinforced insulation between the primary and secondary circuits

• The power supply has automatic reset characteristics (voltage drop) to protect overcurrent.

• The power supply maintains an output holding time of at least 20 ms.

• FG (frame ground terminal) must be connected to PE (protective earth) when using a commercially

available switching regulator.

• The power supply must have output characteristics required for the power source for Class 2 Circuit

or Limited Voltage/Current Circuit as defined in UL508 (see “2-3-1 Remark”).

• The power supply must conform to regulatory requirements and standards, regarding EMC and elec-

trical equipment safety, of the country where the F3S-B is installed and where machinery will be operated, for example: The EMC Directive (industrial environment) and the Low Voltage Directive in

EU.

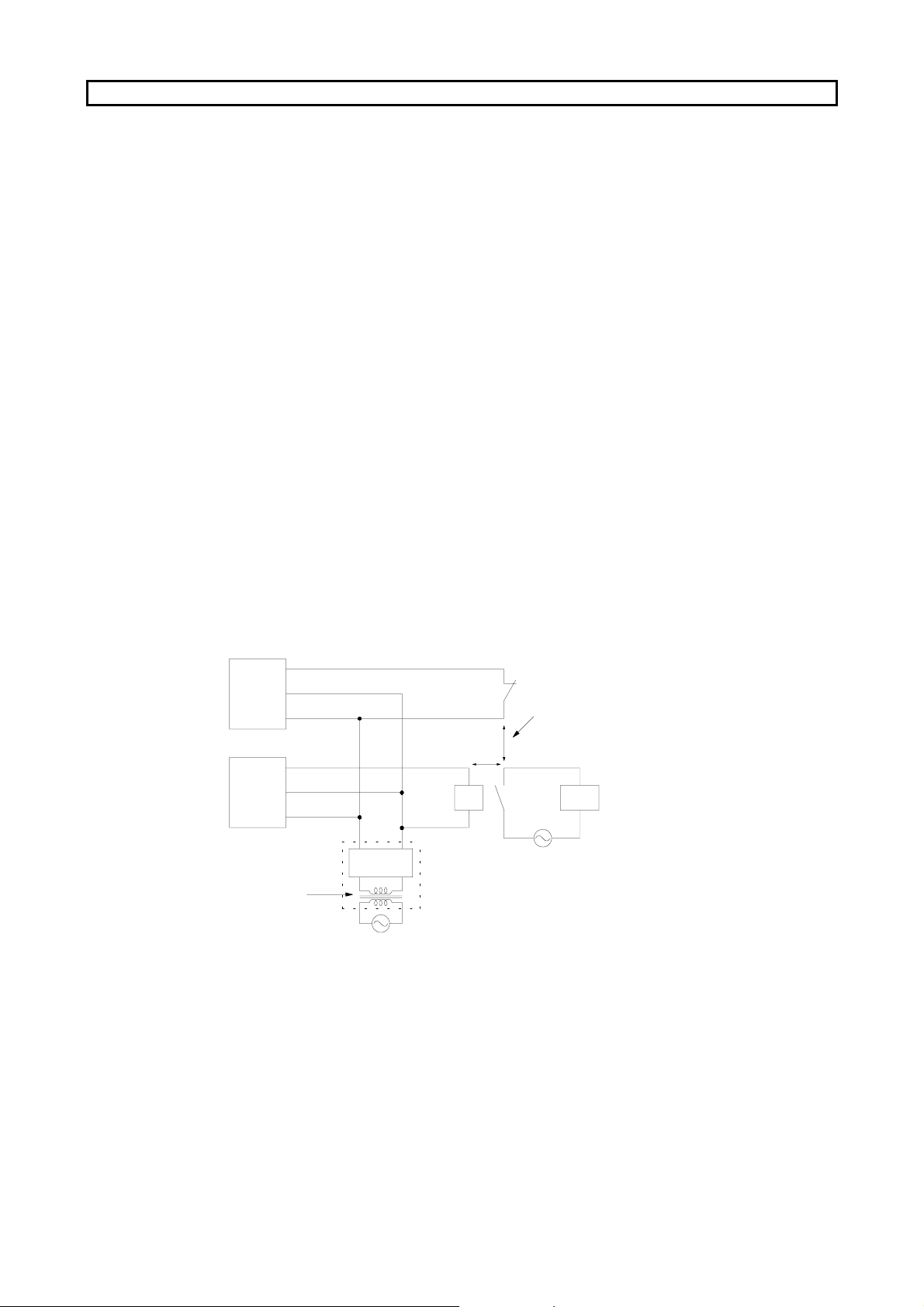

Do not use the F3S-B in a retroreflective configuration. Otherwise detection may fail.

4

F3S-B

Notice

For your safety, always pay attention to the following:

# Installation Environment

• Do not install the F3S-B in the following environments:

− Areas exposed to intense interference light such as direct sunlight.

− Areas with high-humidity where condensation is likely to occur.

− Areas exposed to corrosive gases.

− Areas exposed to vibration or shock levels higher than specification provisions.

− Areas where the light curtain may come in direct contact with water.

• Do not use radio equipment, such as cellular phones, walkie-talkies, or transceivers with high power,

near the F3S-B.

# Wiring and Mounting

• Be sure to route the F3S-B cable separate from high-potential power lines or through an exclusive

conduit.

• Be sure to turn OFF the power prior to wiring. Otherwise, the diagnostic function may prevent the

sensor from operating.

• When using cables with a connector other than the F39-JB series cable, make sure the connector is

rated IP54 or higher.

• The F3S-B will start operating in two seconds after the power is turned ON. Make sure that no op-

eration faults will occur in the control system during this time.

• The emitter and receiver are to be mounted in parallel and facing one another.

# Loads must satisfy all the conditions below.

• Is not short-circuited.

• Is not used with current higher than the rating.

• Is reinforced insulated or double insulated as shown in the following figure to prevent the output

from being subjected to a hazardous voltage when the load is a relay. The insulation shown in the

figure below should insulate against hazardous voltage levels (230 VAC, etc.), not simply against 24

VDC.

Relay monitoring input

Emitter

Receiver

Reinforced

insulation or

double

insulation

0 V

+24 V

Output

0 V

+24 V

Power

supply unit

k1

K1

Hazardous

voltage level

Reinforced insulation or double

insulation between the coil and

contacts, between contacts

k1

Hazardous

voltage level

Motor, etc.

# Two control outputs must be used.

# The procedures of installation and inspection in this manual should be read carefully.

# Do not use any solvents such as paint thinners, benzene or acetone to clean the F3S-B because they

will dissolve resin and paint.

# Do not use screw-locking adhesives (screw lock) to secure the cap unit or connector cap screws be-

cause the adhesive may cause the resin to deteriorate and crack.

# The F3S-B can not detect transparent or semi-transparent materials.

# After unpacking the emitter and receiver, install them facing each other.

# Be sure to dispose of the F3S-B as industrial waste.

5

F3S-B

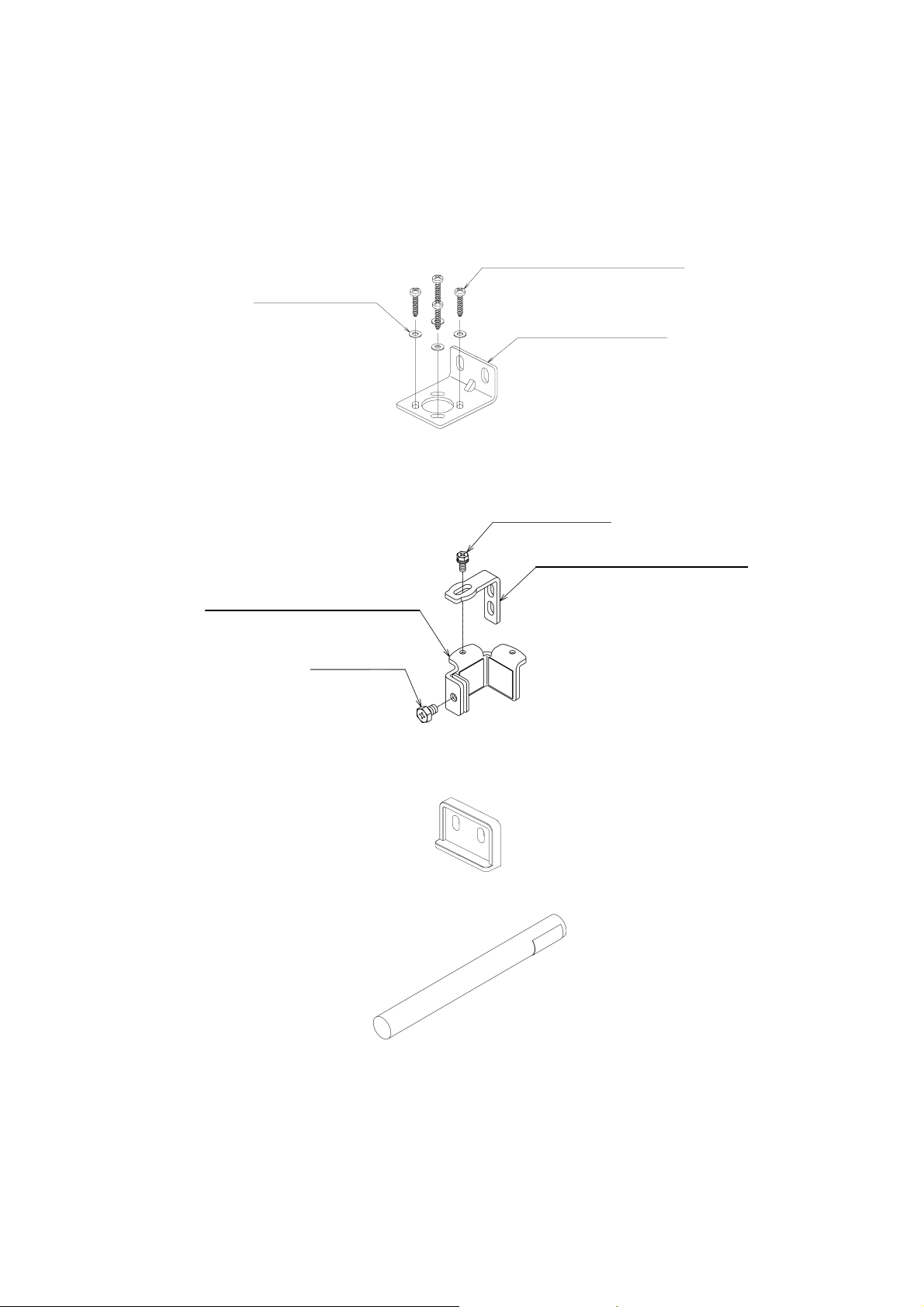

PRIOR TO USE

Make sure the following items were supplied with each F3S-B, contact your nearest OMRON

representative or distributor if any item is missing.

• F3S-B unit (emitter qty. 1, receiver qty. 1)

• Mounting brackets (top and bottom) qty. 4

Sixteen M3 x 10 tapping screws

Sixteen M3 washers

Four L-shaped brackets

• Mounting brackets (intermediate) qty. 2

(Supplied with types which have a protective height of 1050 mm or longer)

Two M4×10 screws

Two L-shaped intermediate brackets

Two U-shaped intermediate brackets

Two M6×8 screws

• Mounting plates qty. 4

(Supplied with types which have a protective height of 1050 mm or longer)

• Test Rod Ø 30 mm qty. 1

(Supplied with F3S-B2P and BM2P)

• Instruction manual (this manual) qty. 1

(Supplied with F3S-BP and BMP)

6

F3S-B

TABLE OF CONTENTS

DESCRIPTION ................................................................................................................Section 1 ............................ 8

1-1 Basics .................................................................................................................................................. 8

1-2 Features............................................................................................................................................... 8

1-3 Standard Functions.............................................................................................................................. 8

1-3-1 Start/restart interlock................................................................................................................ 8

1-3-2 Testing ..................................................................................................................................... 8

1-3-3 Instability Output ...................................................................................................................... 9

1-4 Optional Functions ............................................................................................................................... 9

1-4-1 Start Interlock........................................................................................................................... 9

1-4-2 Relay Monitoring ...................................................................................................................... 9

1-4-3 Blanking ................................................................................................................................... 9

1-5 Detection zone ................................................................................................................................... 10

1-6 Configuration variation ....................................................................................................................... 10

1-6-1 Stand-alone type.................................................................................................................... 10

1-6-2 Series connection types......................................................................................................... 11

1-7 Ratings and Performance .................................................................................................................. 12

1-8 Indicators ........................................................................................................................................... 13

1-9 Table of Types ................................................................................................................................... 14

1-10 Table of Response Time.................................................................................................................. 15

1-10-1 Stand-alone type................................................................................................................... 15

1-10-2 Series connection types........................................................................................................ 15

WIRING and MOUNTING ............................................................................................Section 2.......................... 16

2-1 Installation Conditions........................................................................................................................ 16

2-1-1 Detection Zone and Intrusion Path ........................................................................................ 16

2-1-2 Safety Distance...................................................................................................................... 16

2-1-3 Distance from Reflective Surfaces......................................................................................... 19

2-1-4 How to Prevent Mutual Interference ...................................................................................... 19

2-2 Dimensional Drawings ....................................................................................................................... 21

2-2-1 F3S-B..................................................................................................................................... 21

2-2-2 Mounting Bracket (Top and Bottom)...................................................................................... 25

2-2-3 Mounting Plate ....................................................................................................................... 25

2-2-4 Mounting Bracket (Intermediate) ........................................................................................... 26

2-3 Wiring................................................................................................................................................. 27

2-3-1 Power Supply Units and Loads.............................................................................................. 27

2-3-2 Wiring Diagram ...................................................................................................................... 28

2-3-3 Wiring Procedure ................................................................................................................... 29

ADJUSTMENT ................................................................................................................Section 3..........................30

3-1 Adjustment Procedure ....................................................................................................................... 30

3-2 Check List .......................................................................................................................................... 30

I/O CIRCUIT....................................................................................................................Section 4 .......................... 32

APPLICATIONS.............................................................................................................. Section 5.......................... 33

5-1 Application (1) .................................................................................................................................... 33

5-2 Application (2) .................................................................................................................................... 33

MAINTENANCE .............................................................................................................Section 6 .......................... 34

6-1 Daily Inspections................................................................................................................................ 34

6-2 Inspection Every Six Month ............................................................................................................... 34

6-3 Cleaning............................................................................................................................................. 34

ACCESSORIES (OPTIONAL) ....................................................................................... Section 7 ..........................35

TROUBLESHOOTING................................................................................................... Section 8 .......................... 36

7

F3S-B

DESCRIPTION Section 1

1-1 Basics

WARNING

Use the F3S-B only in category 2, 1, or B applications as defined in pr EN 1050 or EN 954-1.

Do not use the F3S-B in category 3 or 4 systems.

The F3S-B Safety Light Curtain is a multi-axis

transmissive-type light array which uses

microprocessor technology.

It is used to stop a machine before the hazard is

reached when any part of the detection zone is

interrupted.

It consists of an IR (infrared) Emitter and a Receiver. Optional devices are available for the system with further safety requirements.

1-2 Features

• Self-test

• Optical resolution of 30, 55 or 80 mm in diame-

ter

• Detection distance from 0.3 to 5.0 m

• Max. protective height of 1,650 mm

• TÜV approvals and CE marking

• UL listed to U.S. and Canadian safety standard

• IP 65 enclosure rating

• Start/restart interlock function selectable

• Blanking, Start Interlock, Relay monitoring func-

tions optionally available

• Series connection types available

1-3 Standard Functions

1-3-1 Start/restart interlock

This function keeps the F3S-B in the OFF-state after power ON and every interruption of the detection

zone. To reset this condition, 17 VDC to Vs (nominal 24 VDC) must be applied to the Interlock selection

input of the emitter for 15 to 2500 ms. Otherwise the OFF-state continues even if nothing interrupts the

detection zone.

This function can be selected/deselected as follows;

Active mode: By not connecting the Interlock selection input line or by connecting it to 0V line before

turning the power ON.

Inactive mode (Automatic start): By connecting the Interlock selection input line to the Instability output

line before turning the power ON (see “2-3-2 Wiring diagram”).

Note: The switch to reset the start/restart interlock condition has to be installed out of the hazardous area.

When the start/restart interlock is reset, the hazardous area must be visibly free.

1-3-2 Testing

Self-test after Power-ON

After the power is turned ON, the F3S-B performs a complete self-test within 2 seconds. If no failure is

found, the F3S-B goes into normal operation.

Self-test during Normal Operation

The F3S-B periodically checks all safety related functions at least every 2 seconds. All components and

memories are tested in this periodic check.

8

F3S-B

p

p

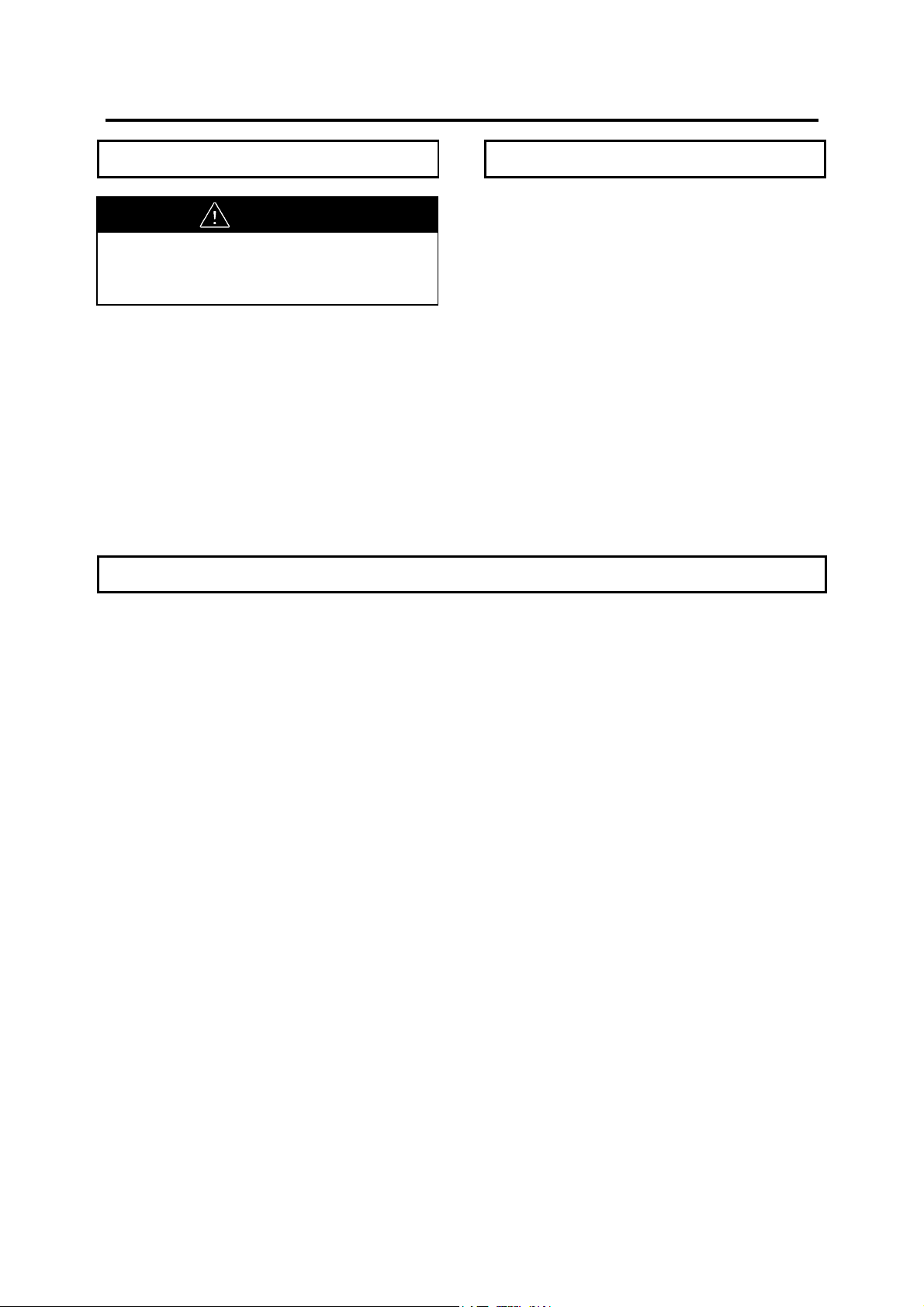

External Test

If your application requires periodic testing more

often than every 2 seconds an external control

system is able to initiate an external test with the

External test function. If a signal of 17 VDC to Vs

is applied to the External test input at least 15 ms,

a self-test starts and the outputs turn to the OFFstate in 15 ms. If no failure is detected, the outputs

return to the ON-state after a maximum of 150 ms.

External test

in

ut

Control

uts

out

H

L

(open)

Approx. 15 ms

H

(open)

L

Failure detection and restoration

When a failure is detected through the tests above, the F3S-B keeps the outputs in the OFF-state and the

indicators show the type of failure, refer to section “8 Troubleshooting”. After the failure is eliminated, in

most cases the F3S-B operation will be restored automatically.

1-3-3 Instability Output

When the received light is insufficient, the instability output and the instability indicator turn ON. In normal

operation, both are OFF. See also “1-8 Indicators”.

This output makes it possible for customers to monitor deterioration of optical performance due to aging or

other factor, such as reduction of LED power, misalignment between the emitter and receiver, or dust on

the lens.

Also, when a failure is detected, or the F3S-B is

connected with the F39-E1 interface unit, the

instability output turns ON as well.

Note: After the power is turned ON, the instability

output goes to the ON-state for approximately 150 ms as shown in the timing chart

for Interlock mode selection.

Power

supply

Instability

output

H

L

Approx.

30 ms

H

L

2 s max.

(Startup waiting time)

Approx.

150 ms

> 15 ms

150 ms max.

F3S-B available

1-4 Optional Functions

These functions can be activated by the optional function software, F39-U1E (see the F39-U1E manual for

detailed information).

Note: The F39-U1E Optional Function Software is used with the F39-E1 Interface Unit, a PC (running

Microsoft

Windows

95, Windows98 or Windows NT

), the F39-JB1C Interface Cable, and a RS-

232C cable.

1-4-1 Start Interlock

When the Start interlock function is used, the F3S-B does not go to the ON-state automatically after power

ON. Interrupting one or more axes resets the start interlock condition, so the F3S-B can start normal operation.

1-4-2 Relay Monitoring

MPCEs (Machine Primary Control Elements) are usually relays or contactors used to control hazardous

movement directly. The state of the MPCEs can be checked with the Relay monitoring function.

A voltage of 17 VDC to Vs has to be applied to the Relay monitoring input through the NC contacts of the

MPCEs when the F3S-B control outputs are in the OFF-state (see “2-3-2 Wiring diagram”). To ensure this

logic relation, the MPCEs must be safety approved types, with forcibly guided contacts.

1-4-3 Blanking

With this function, one or more axes can be disabled. To select the blanking axes, a manual setting function or teaching function is available. This function is useful when part of the F3S-B detection zone is interrupted.

9

F3S-B

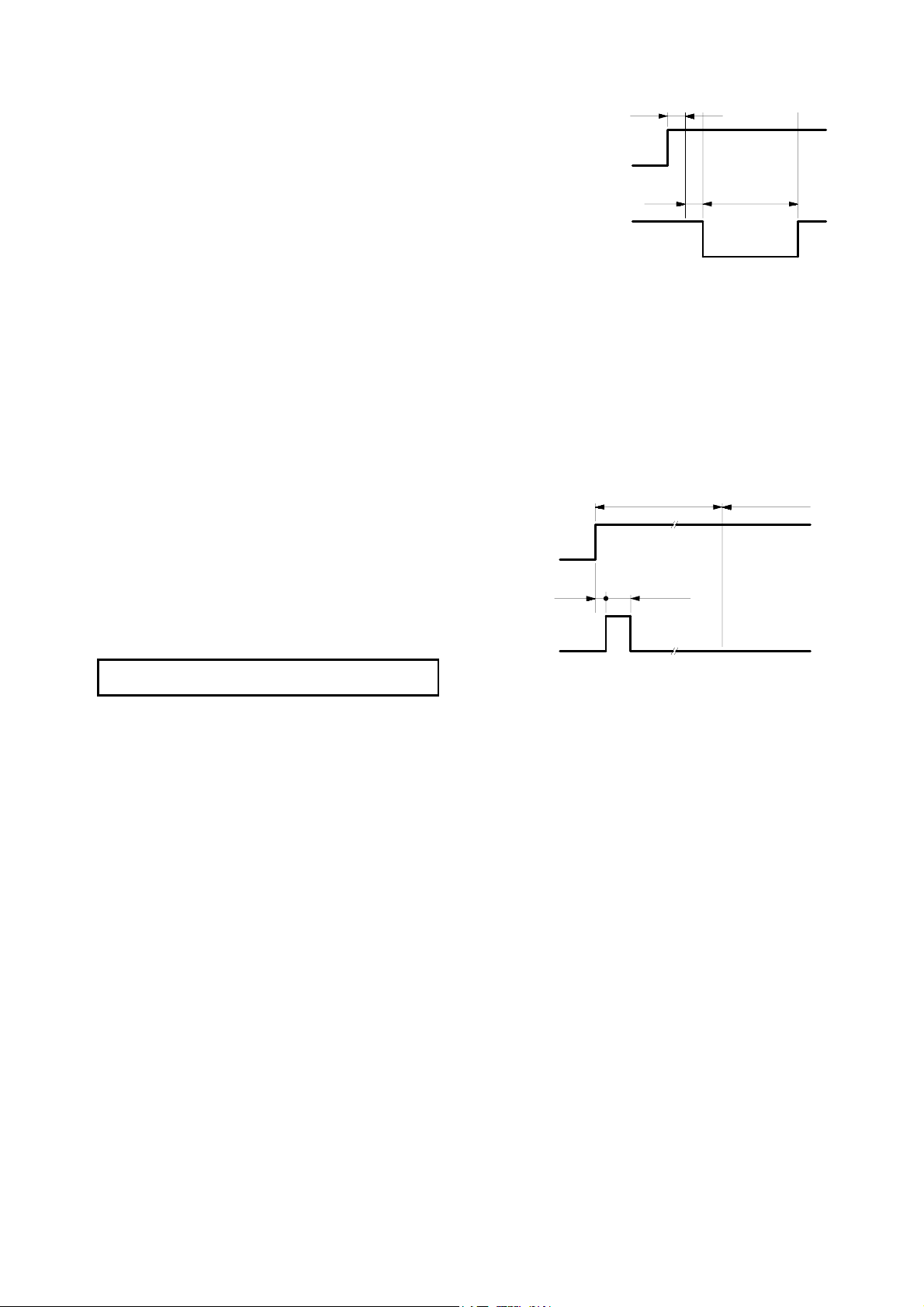

1-5 Detection zone

Protective height

The F3S-B can detect in the area indicated by “Protective height” in the figure below. The protective height

is from “the Optical-axis line mark above the indicator area” to “the end of the yellow metal case”.

Optical-axis line mark

The center line for optical axes is indicated by the triangle mark. This position is a reference line for measuring safety distance.

No. of optical axes

n

n-1

2

Emitter

1

Detection distance

Optical resolution

Optical-axis

pitch

Receiver

Protective

height

Limit position

for detection

Optical-axis

line mark

1-6 Configuration variation

1-6-1 Stand-alone type

This is the most common configuration, and it is used to protect a hazardous part of a machine when approached from one direction only.

Receiver

Emitter

Protective height

10

Indicator area

Extension cable

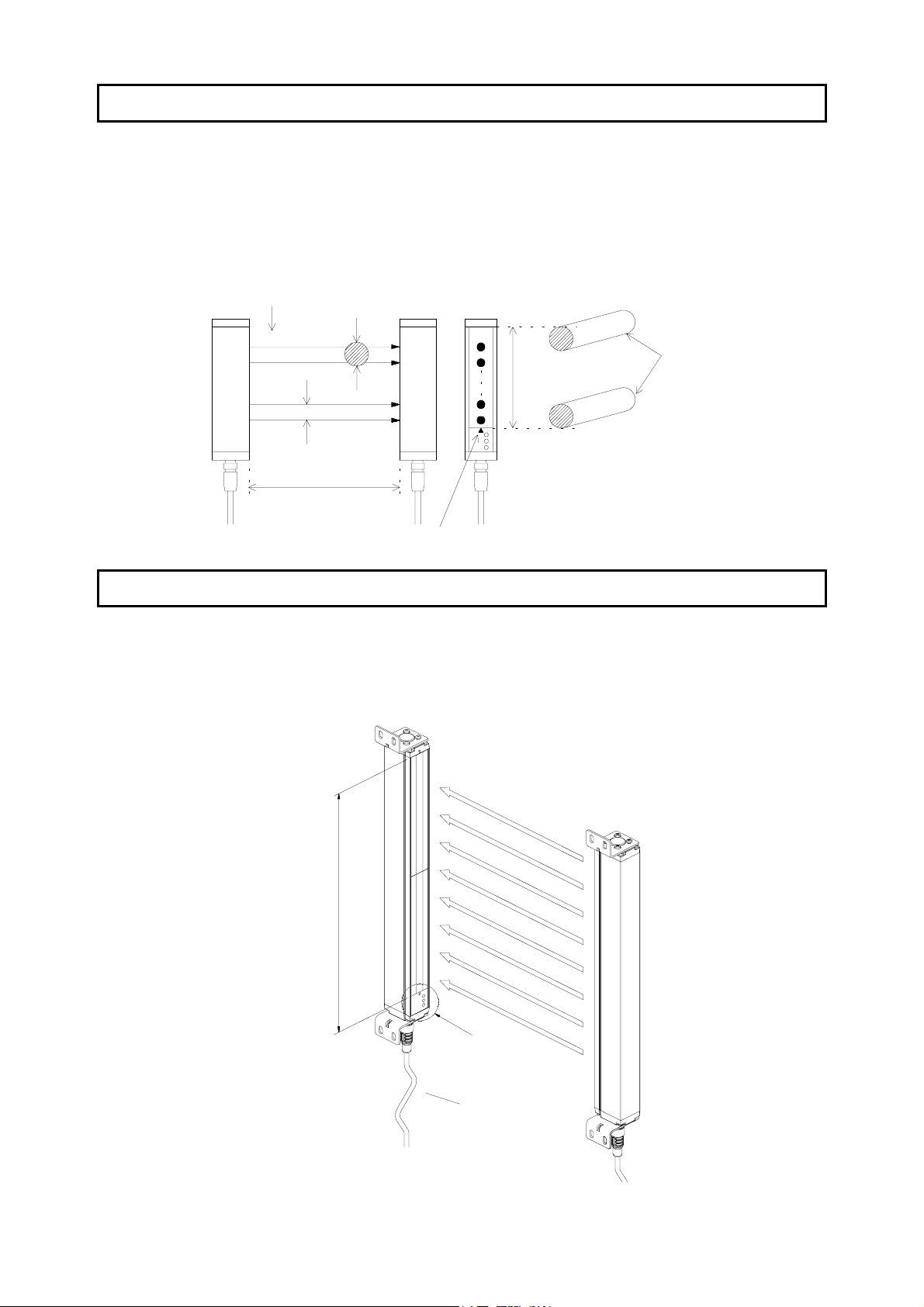

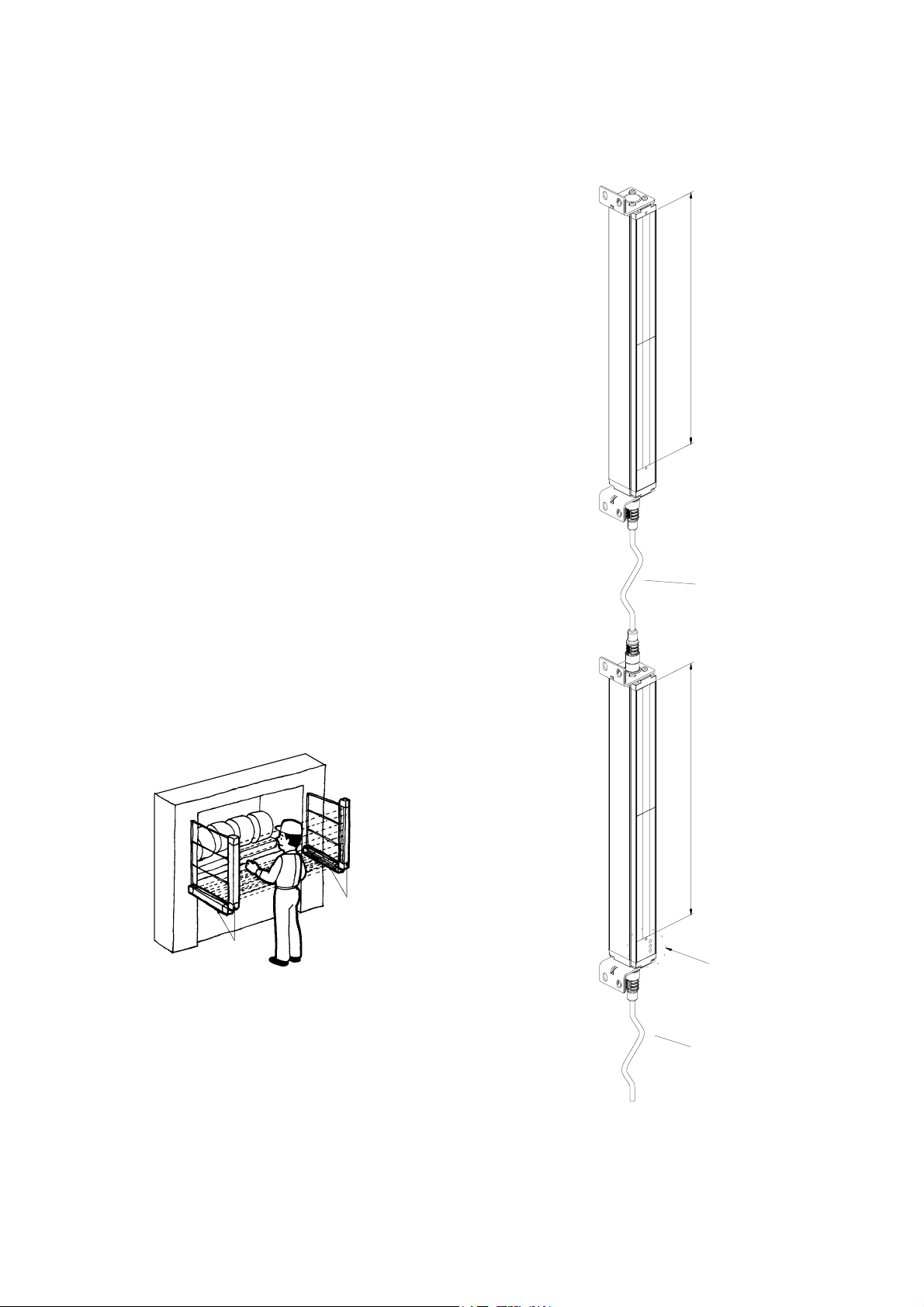

1-6-2 Series connection types

When your application requires an additional protective zone, for example, to prevent someone

from staying behind a primary detection zone, the

F3S-B may be connected in series. The system

consists of a master unit, a slave unit, and a series

connection cable, type F39-JB1B (refer to “2-3-2

Wiring diagram” and “7 Accessories (Optional)”).

The series connection allows up to 96 axes and

2.4 m of protective height in total.

Series connection types have the same characteristics as a stand-alone types. When the detection

zone of the master unit or that of the slave unit is

interrupted, the outputs of the master unit go to the

OFF-state.

However, please note that a slave unit does not

have indicators.

Note: Both the master unit and the slave unit need

to be ordered separately.

F3S-B

Slave unit

Protective height

Emitters

Series connection cable

Master unit

Protective height

Receivers

Indicator area

Extension cable

11

F3S-B

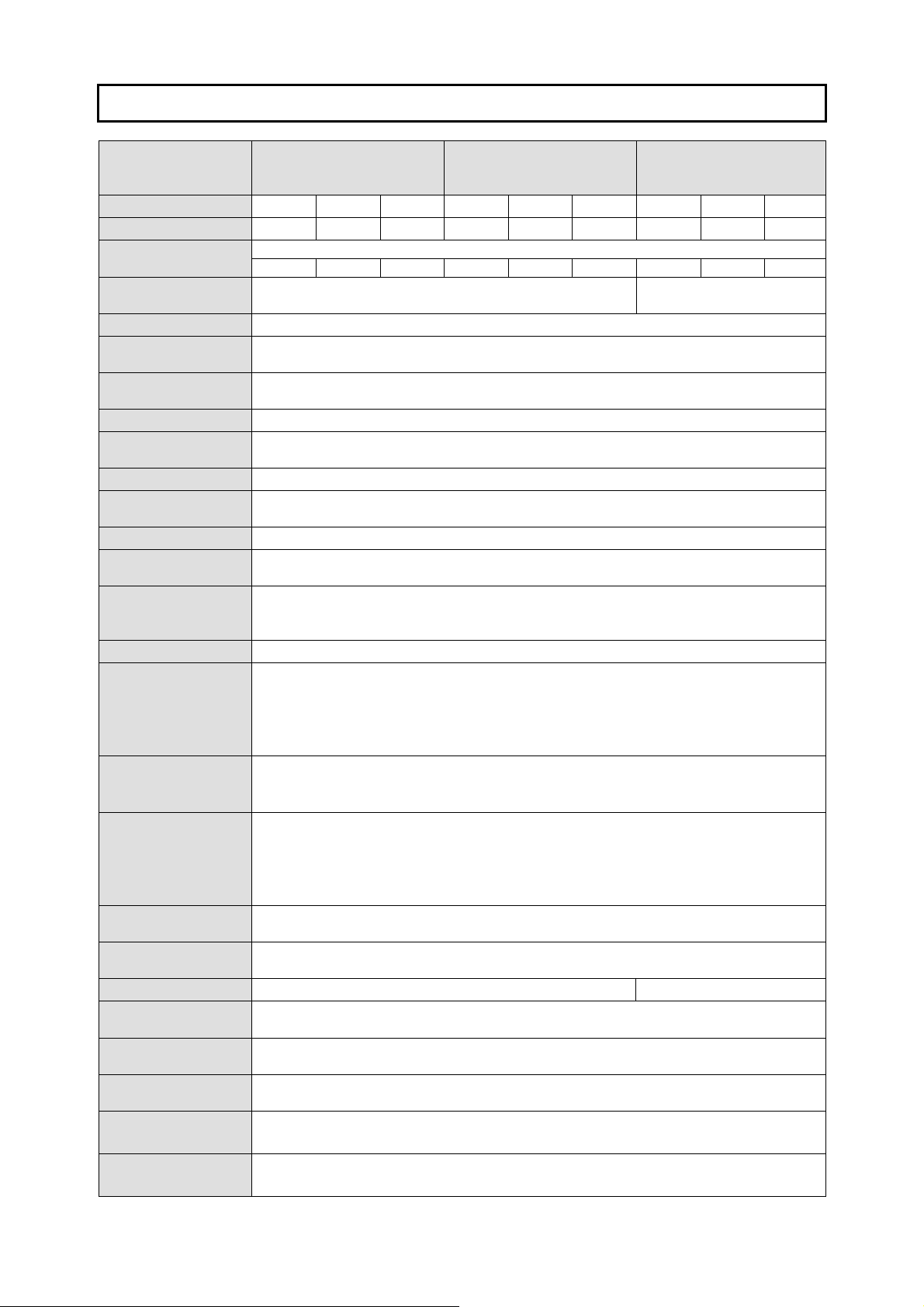

1-7 Ratings and Performance

Type

Item

No. of optical axes

Optical-axis pitch

Optical resolution

(Detection capability)

Protective height

Detection distance

Response time

Startup waiting

time

Supply voltage: Vs

Current

consumption

Light source

Effective

aperture angle

Operating mode

Control output

Instability output

Protection circuit

Start/restart

interlock function

External

test function

Relay monitoring

function (Optional)

Start interlock

function (Optional)

Blanking function

(Optional)

Indicators

Connection

method

Ambient

temperature

Ambient humidity

Insulation

resistance

Dielectric strength

voltage

F3S-BP (*1)

Stand-alone

12 to 66 6 to 33 4 to 22 12 to 66 6 to 33 4 to 22 12 to 30 6 to 15 4 to10

25 mm 50 mm 75 mm 25 mm 50 mm 75 mm 25 mm 50 mm 75 mm

Non-transparent: in diameter

30 mm 55 mm 80 mm 30 mm 55 mm 80 mm 30 mm 55 mm 80 mm

300 / 450 / 600 / 750 / 900 / 1,050 / 1,200 / 1,350

/ 1,500 / 1,650 mm

0.3 to 5.0 m

ON to OFF : See “1-10 Table of Response Time”

OFF to ON (*2): Default 100 ms (selectable with F39-U1E, 80 to 400 ms)

2 s max.

24 VDC ± 20% (including 5 Vp-p ripple)

400 mA max. (under no-load conditions)

Infrared LED (880 nm wavelength). Lifetime: 50,000 hrs. at 25 °C.

Within ± 5° for the emitter and receiver at a detection distance of at least 3 m

according to IEC 61496-2

Light ON

Two PNP transistor outputs, operational current (load current) 200 mA max., re-

sidual voltage 2 V max. (except for voltage drop due to cable extension)

PNP transistor output (not safety-related control output),

load current 100 mA max., residual voltage 2 V max. (except for voltage drop due

to cable extension)

Output short-circuit protection, power supply reverse connection protection

Mode selection before power ON by connecting “Interlock selection input” line to:

Active : No connection or 0 to 2.5 VDC, 3 mA max.

Inactive : Instability output line

Reset of start/restart interlock by connecting “Interlock selection input” line to:

Interlock reset : 17 VDC to Vs, 20 mA max. Duration time 15 to 2,500 ms

Mode selection by connecting “External test input” line to:

Active : 17 VDC to Vs, 10 mA max. Duration time at least 15 ms

Inactive : No connection or 0 to 2.5 VDC, 2 mA max.

Default inactive, selectable with F39-U1E

Relay monitoring input line with NC contact connected,

Available level : 17 VDC to Vs, 10 mA max.

Allowed relay delay time (*2) : Selectable between 20 and 300 ms

Termination when not selected : No connection or 0 to 2.5 VDC, 2 mA max.

Default inactive, selectable with F39-U1E

Default inactive, selectable with F39-U1E

See “1-8 Indicators” No indicators

For Extension cable : 8 pins, M12 connector

For Series connection cable : 6 pins, M12 connector

During operation : –10 to 55 °C (with no freezing)

During storage : –25 to 70 °C

During operation : 35 to 85 %RH (with no condensation)

During storage : 35 to 95 %RH

20 MΩ min. (at 500 VDC)

1,000 VAC 50/60 Hz for 1 min

F3S-BMP (*1)

Master unit for series

connection

F3S-BS (*1)

Slave unit for series

connection

300 / 450 / 600 / 750 mm

12

F3S-B

Type

Item

Degree of

protection

Vibration

resistance

Shock resistance

F3S-BP (*1)

Stand-alone

F3S-BMP (*1)

Master unit for series

connection

F3S-BS (*1)

Slave unit for series

connection

IEC60529 IP65

Normal operation : 10 to 55 Hz, double-amplitude: 0.7mm, X, Y and Z directions

20 sweeps

Normal operation : 100 m/s2 [10 G], X, Y and Z directions: 1000 times

Case: Aluminum

Materials

Front cover: PMMA (acrylic resin)

End caps: PA6

Size

(cross section)

Accessories

Applicable

standard

30 x 40 mm

Test rod (*3), mounting brackets (top and bottom), mounting brackets (intermediate) (*4), mounting plates (*4), Instruction manual(*5)

IEC(EN)61496-1 TYPE 2 ESPE (Electro-Sensitive Protective Equipment)

IEC 61496-2 TYPE 2 AOPD (Active Opto-electronic Protective Devices)

*1 For detailed type names and optical specifications, see “1-9 Table of Types”.

*2 Nominal value (Set time). The accuracy is – 0 / + 70% of ON to OFF response time.

*3 Only with F3S-B2P and BM2P.

*4 For the 1,050 mm protective height and longer types.

*5 Only with F3S-BP and BMP.

1-8 Indicators

Emitter

Receiver

IR-power indicator

Interlock indicator

External test/ blanking indicator

ON-state indicator

OFF-state indicator

Instability indicator

<Emitter Indicators>

POWER

INTER-

LOCK

EXT.TEST/

BLANKING

Optical-axis line mark

IR-power indicator

(Orange)

Interlock indicator

(Yellow)

External test /

blanking indicator

: Lit when emitting.

: Lit during start/restart interlock and start interlock.

: Lit during external test. / Flashing when using blanking

function.

: Lit when receiving light.

: Lit with interrupted light.

Flashing during connection with F39-E1 or with failure.

: Lit with an insufficient light reception or failure.

Flashing during connection with F39-E1.

<Receiver Indicators>

ON

OFF

UNSTAB

ON-state indicator

(Green)

OFF-state indicator

(Red)

Instability indicator

(Orange)

13

F3S-B

1-9 Table of Types

Type Naming Rule

F3S - B M 36 2 P 12 - L

blank

M

S

36

2

5

7

blank

P

blank

12

blank

L

D

Stand-alone Master unit Slave unit Optical

F3S-B122P F3S-BM122P F3S-BS122 30 mm 12 300 mm 0.9 kg

F3S-B182P F3S-BM182P F3S-BS182 18 450 mm 1.2 kg

F3S-B242P F3S-BM242P F3S-BS242 24 600 mm 1.5 kg

F3S-B302P F3S-BM302P F3S-BS302 30 750 mm 1.8 kg

F3S-B362P F3S-BM362P 36 900 mm 2.1 kg

F3S-B422P F3S-BM422P 42 1,050 mm 2.5 kg

F3S-B482P F3S-BM482P 48 1,200 mm 2.8 kg

F3S-B542P F3S-BM542P 54 1,350 mm 3.1 kg

F3S-B602P F3S-BM602P 60 1,500 mm 3.4 kg

F3S-B662P F3S-BM662P 66 1,650 mm 3.7 kg

F3S-B065P

F3S-B095P F3S-BM095P F3S-BS095 9 450 mm 1.2 kg

F3S-B125P F3S-BM125P F3S-BS125 12 600 mm 1.5 kg

F3S-B155P F3S-BM155P F3S-BS155 15 750 mm 1.8 kg

F3S-B185P F3S-BM185P 18 900 mm 2.1 kg

F3S-B215P F3S-BM215P 21 1,050 mm 2.5 kg

F3S-B245P F3S-BM245P 24 1,200 mm 2.8 kg

F3S-B275P F3S-BM275P 27 1,350 mm 3.1 kg

F3S-B305P F3S-BM305P 30 1,500 mm 3.4 kg

F3S-B335P

F3S-B047P F3S-BM047P F3S-BS047 80 mm 4 300 mm

F3S-B067P F3S-BM067P F3S-BS067 6 450 mm 1.2 kg

F3S-B087P F3S-BM087P F3S-BS087 8 600 mm 1.5 kg

F3S-B107P F3S-BM107P F3S-BS107 10 750 mm 1.8 kg

F3S-B127P F3S-BM127P 12 900 mm 2.1 kg

F3S-B147P F3S-BM147P 14 1,050 mm 2.5 kg

F3S-B167P F3S-BM167P 16 1,200 mm 2.8 kg

F3S-B187P F3S-BM187P 18 1,350 mm 3.1 kg

F3S-B207P F3S-BM207P 20 1,500 mm 3.4 kg

F3S-B227P F3S-BM227P 22 1,650 mm

$ Stand-alone

$ Master unit for series connection

$ Slave unit for series connection

$ No. of optical axis (4-66)

$ 25mm optical pitch

$ 50mm optical pitch

$ 75mm optical pitch

$ Slave unit

$ PNP outputs

$ Stand-alone or slave unit

$ No. of optical axis of the connected slave unit

for 25mm optical pitch type : 12, 18, 24, or 30

for 50mm optical pitch type : 06, 09, 12, or 15

for 75mm optical pitch type : 04, 06, 08, or 10

$ Complete set of emitter and receiver

$ Emitter unit only

$ Receiver unit only

resolution

No. of

optical

axes

Protective

height

Weight

(without

accessories)

F3S-BM065P F3S-BS065 55 mm 6 300 mm 0.9 kg

F3S-BM335P 33 1,650 mm 3.7 kg

0.9 kg

3.7 kg

14

F3S-B

1-10 Table of Response Time

1-10-1 Stand-alone type

F3S-B122P

Response

time [ms ]

20

F3S-B065P

F3S-B182P 20 F3S-B095P 20 F3S-B067P 20

F3S-B242P 20 F3S-B125P 20 F3S-B087P 20

F3S-B302P 23 F3S-B155P 20 F3S-B107P 20

F3S-B362P 27 F3S-B185P 20 F3S-B127P 20

F3S-B422P 30 F3S-B215P 21 F3S-B147P 20

F3S-B482P 34 F3S-B245P 22 F3S-B167P 20

F3S-B542P 37 F3S-B275P 24 F3S-B187P 20

F3S-B602P 41 F3S-B305P 26 F3S-B207P 20

F3S-B662P

45

F3S-B335P

1-10-2 Series connection types

The following chart shows the response time of combinations of a master unit and a slave unit connected

in series. For example, the response time of the combination of F3S-BM122P30 and F3S-BS302 is 30 ms.

Slave unit

Master unit

F3S-BM122P

F3S-BS122 F3S-BS182

20 23 27 30

F3S-BM182P 23 27 30 34

F3S-BM242P 27 30 34 37

F3S-BM302P 30 34 37 41

F3S-BM362P 34 37 41 45

F3S-BM422P 37 41 45 49

F3S-BM482P 41 45 49 54

F3S-BM542P 45 49 54 57

F3S-BM602P 49 54 57 61

F3S-BM662P

Slave unit

Master unit

54 57 61 65

F3S-BS065 F3S-BS095 F3S-BS125 F3S-BS155

F3S-BM065P 20 20 20 21

F3S-BM095P 20 20 21 22

F3S-BM125P 20 21 22 24

F3S-BM155P 21 22 24 26

F3S-BM185P 22 24 26 28

F3S-BM215P 24 26 28 30

F3S-BM245P 26 28 30 32

F3S-BM275P 28 30 32 34

F3S-BM305P 30 32 34 35

F3S-BM335P 32 34 35 37

Slave unit

Master unit

F3S-BM047P

F3S-BS047

20 20 20 20

F3S-BM067P 20 20 20 20

F3S-BM087P 20 20 20 20

F3S-BM107P 20 20 20 20

F3S-BM127P 20 20 20 21

F3S-BM147P 20 20 21 23

F3S-BM167P 20 21 23 24

F3S-BM187P 21 23 24 25

F3S-BM207P 23 24 25 26

F3S-BM227P

24 25 26 27

Response time [ms]

F3S-BS067 F3S-BS087 F3S-BS107

Response

time [ms ]

20

F3S-B047P

28

F3S-B227P

F3S-BS242 F3S-BS302

Response

time [ms ]

20

21

15

F3S-B

WIRING and MOUNTING Section 2

2-1 Installation Conditions

WARNING

Do not use the F3S-B on machines that can not be stopped by electrical control in case of an emergency.

Do not use the F3S-B in flammable or explosive environments.

2-1-1 Detection Zone and Intrusion Path

WARNING

Install protective structures around a machine so that you must pass through the detection zone to reach

a hazardous part of the machine.

Install the F3S-B so that some part of the operator’s body remains in the detection zone at all times

when the operator works in a hazardous area.

Failure to do so may result in serious injury.

Correct installation

A hazardous part of a

machine can be reached only

by passing through the

sensor detection zone.

Incorrect installation

A hazardous part of a

machine can be reached

without passing through the

sensor detection zone.

!

!

!!

2-1-2 Safety Distance

Some part of the operator’s

body remains in the detection

zone while they are working.

A worker is between the

sensor detection zone and a

hazardous part of a machine.

!

!

!!

WARNING

Always maintain the safety distance between the F3S-B and a hazardous part of a machine. Serious

injury may result if the machine does not stop before someone reaches the hazardous part.

The “Safety distance” is the minimum distance that must be maintained between the F3S-B and a hazardous part of a machine in order to stop the machine before someone or something reaches it.

The calculation of safety distance varies according to with national standards and individual machine

standards. It also depends on the direction of intrusion to the detection zone of the light curtain, perpendicular, parallel, or angled approach, and depends on the application, e.g. non-industrial applications

where children are present.

See related standards for more details.

16

F3S-B

Using EN 999 Formula

#

Safety distance is calculated based on the following equation.

S = K x T + C (1)

S : Safety distance

K : Intrusion speed into the detection zone

T : Total response time for the machine and light curtain

C : Additional distance calculated or defined based on the optical resolution of the light curtain

When safety distance is not provided by European standards for individual machine, the distance can be

calculated using EN 999.

Calculation for intrusion perpendicular to the detection zone

1) 30 mm optical resolution type

Substitute K = 2,000 mm/s and C = 8 (d-14 mm) in equation (1) and calculate as shown below.

where:

S = safety distance (mm)

Tm = machine response time (s) (see Note 2)

Ts = light curtain response time (s) (see Note 3)

d = optical resolution of light curtain (mm)

e.g.:

Use S = 100 mm if the result of equation (2)

Recalculate using the following equation with K = 1,600 mm/s if the result is over 500 mm.

Use S = 500 mm if the result from equation (3) is 500 mm or less.

2) 55 mm and 80 mm optical resolution type

Substitute K =1,600 mm/s and C = 850 mm in equation (1) and calculate as shown below:

Note:

1. EN 999 : European Standard. Safety of machinery – The positioning of protective equipment in

2. The machine response time (Tm) refers to the maximum time from the moment the machine receives

3. The light curtain response time (Ts) refers to the time required for output changing from ON to OFF.

S = 2,000 mm/s x ( Tm + Ts ) + 8 ( d - 14 mm ) (2)

Tm = 0.05 s, F3S-B122P (Ts = 0.02 s, d = 30 mm)

S = 2,000 mm/s x ( 0.05 s + 0.02 s) + 8 (30 mm-14 mm)

= 268 mm

S = 1,600 mm/s x ( Tm + Ts ) + 8 ( d – 14 ) mm (3)

S =1,600 mm/s x ( Tm + Ts ) + 850 mm

respect of approach speeds of parts of the human body

a stop signal to the moment a hazardous part of the machine stops. The machine response time

should be measured and confirmed periodically.

(See Note 1)

is 100 mm or less.

Hazardous

part

Safety distance

Detection

zone

Optical-axis line

Intrusion

direction

17

F3S-B

4.

Using ANSI/RIA R15.06 Formula

#

Safety distance is calculated based on the following equation when a person moves perpendicular to the

detection zone of a light curtain.

S = K x ( Ts + Tc + Tr ) + Dpf (4)

S : Safety Distance (mm)

K : Speed constant of 1,600 mm/s (63 inches/s) minimum based on the movement being the

hand/arm only and the body being stationary.

A greater value may be required in specific applications and when body motion must also be

considered.

Ts : Worst stopping time of machine/equipment

Tc : Worst stopping time of the control system.

Tr : Maximum response time of the light curtain (see Note 5)

Dpf : Depth penetration factor.

Additional distance calculated or defined based on the optical resolution of the light curtain

Calculation for intrusion perpendicular to the detection zone

1) 30 mm and 55 mm optical resolution type

Substitute K = 1,600 mm/s and Dpf = 3.4 x ( Os – 6.875 mm ) in equation (4) and calculate as shown below.

S = 1,600 mm/s x ( Ts + Tc + Tr ) + 3.4 x ( Os – 6.875 mm ) (5)

where:

S = safety distance (mm)

Os = object sensitivity ( =optical resolution) of light curtain (mm) (see Note 6)

e.g.:

Ts + Tc = 0.06 s, F3S-B542P (Tr = 0.037 s, Os = 30 mm )

S = 1,600 mm/s x ( 0.06 s + 0.037 s ) + 3.4 x ( 30 mm – 6.875 mm )

= 234 mm

2) Flashing when receiving light in start/restart interlock.80 mm optical resolution type

Substitute K =1,600 mm/s and Dpf = 900 mm in equation (4) and calculate as shown below:

S =1,600 mm/s x ( Ts + Tc + Tr ) + 900 mm (6)

Note:

4. ANSI/RIA R15.06 1999 : American National Standard for Industrial Robots and Robot Systems Safety

Requirements

5. The light curtain response time (Tr) refers to the time required for output changing from ON to OFF.

6. When the optional blanking function is used, the entire (from emitter to receiver) blanked area should be

physically filled. Otherwise, d must be calculated as follows:

Os = (Size of the largest blanked area ) + (Original optical resolution)

(See Note 4)

18

F3S-B

2-1-3 Distance from Reflective Surfaces

WARNING

Be sure to install the F3S-B to minimize the effects of reflection from reflective surfaces.

Failure to do so will cause detection to fail and may result in serious injury.

Install the F3S-B with minimum Distance D shown below from reflective surfaces (highly reflective surfaces) like metal walls, floors, ceilings, and work pieces.

<Side View>

Reflecting ceiling

Reflecting surface

<Top View>

Emitter Receiver

Detection zone

D

L

D

Reflecting floor

D

5°

Emitter Receiver

5°

L

Distance between emitter and

receiver (detection distance L)

Minimum installation

distance D

0.3 to 3 m 0.27 m

3 to 5 m L x tan 5° = L x 0.087 (m)

2-1-4 How to Prevent Mutual Interference

Take action to prevent mutual interference when two or more sensors are installed. The following figures

show configurations in which mutual interference may occur.

(Incorrect) (Incorrect)

Emitter 1

RS-485

Emitter 1

Emitter 2

Receiver 1

(Incorrect)

Emitter 2

Receiver 2

RS-485

Receiver 1

Receiver 2

Emitter 1Emitter 2

Receiver 1

Receiver 2

RS-485

19

F3S-B

Correct installations are shown below to prevent mutual interference.

• Alternate emitters and receivers

(Correct)

(Correct)

Receiver 1

Receiver 1

Emitter 2

RS-485

Emitter 1

(Correct)

Emitter 2

Receiver 2

RS-485

Emitter 1

Receiver 2

Emitter 1

Receiver 2

Receiver 1

RS-485

Emitter 2

RS-485

• Install barriers

(Correct)

Emitter 1

RS-485 RS-485

Receiver 1

Emitter 2

Receiver 2

• Keep enough distance between each set of sensors

Arrange the sets so that distance between their protective height marks is greater than “D” in the following

table.

(Correct)

L

Emitter 1

D

Emitter 2

RS-485

Receiver 1

Receiver 2

Distance between emitter and receiver

(detection distance L)

0.3 to 3 m 0.54 m

3 to 5 m L x tan 10° = L x 0.18 (m)

20

Emitter 1

Emitter 2

(Correct)

10°

D

10°

L

Minimum installation

distance D

Receiver 1

Receiver 2

2-2 Dimensional Drawings

2-2-1 F3S-B

• Side Mounting

4-MOUNTING HOLES

MOUNTING BRACKET

(TOP AND BOTTOM)

MOUNTING BRACKET

(INTERMEDIATE)

(note 4)

2-MOUNTING HOLES

F3S-B

D

C

B

A (PROTECTIVE HEIGHT)48

54.25 25

M12 CONNECTOR

(note 2, 3)

2-M5 (note 1)

4-M5

20

15 (note 1)

E (note 1)

28 (note 1)

MOUNTING SCREW HOLES

28

OPTICAL AXIS

E (note 1)

D

40.3

8

20.336

15

30

(59.6)

Type A

Protective

height

F3S-B122, B065, B047 300 343 387 371 ----F3S-B182, B095, B067 450 493 537 521 ----F3S-B242, B125, B087 600 643 687 671 ----F3S-B302, B155, B107 750 793 837 821 ----F3S-B362, B185, B127 900 943 987 971 ----F3S-B422, B215, B147 1050 1093 1137 1121 560.5

F3S-B482, B245, B167 1200 1243 1287 1271 635.5

F3S-B542, B275, B187 1350 1393 1437 1421 710.5

F3S-B602, B305, B207 1500 1543 1587 1571 785.5

F3S-B662, B335, B227 1650 1693 1737 1721 860.5

B

Full length of

the sensor

C

Full length

with brackets

D

Mounting hole

center width

Intermediate

mounting

bracket

position

Unit: mm

E

21

F3S-B

• Rear Mounting (with Intermediate Mounting Bracket)

55.3

MOUNTING BRACKET

(INTERMEDIATE)

(note 4)

C

40.3

15

2-M5 (note 1)

15 (note 1)

D

E (note 1)

4-M5

B

M12 CONNECTOR

(note 2, 3)

MOUNTING BRACKET

(TOP AND BOTTOM)

4-MOUNTING HOLES

2-MOUNTING HOLES

OPTICAL AXIS

MOUNTING PLATE

(SEE "2-2-3 Mounting plate")

24

E (note 1)

42.74

30

A (PROTECTIVE HEIGHT)

2554.25

48

11.25 D

20

24 (note 1)

MOUNTING SCREW HOLES

32 (29.7)

Type A

Protective

height

F3S-B422, B215, B147 1050 1093 1143.5 1121 560.5

F3S-B482, B245, B167 1200 1243 1293.5 1271 635.5

F3S-B542, B275, B187 1350 1393 1443.5 1421 710.5

F3S-B602, B305, B207 1500 1543 1593.5 1571 785.5

F3S-B662, B335, B227 1650 1693 1743.5 1721 860.5

B

Full length of

the sensor

C

Full length

with brackets

D

Mounting hole

center width

Intermediate

mounting

bracket

position

22

Unit: mm

E

• Rear Mounting (without Intermediate Mounting Bracket)

F3S-B

50.3

C

40.3

10

MOUNTING BRACKET

(TOP AND BOTTOM)

4-MOUNTING HOLES

D

OPTICAL AXIS

B

A (PROTECTIVE HEIGHT)

2554.25

48

D

4-M5

20

MOUNTING SCREW HOLES

M12 CONNECTOR

(note 2, 3)

Unit: mm

Type A

Protective

height

B

Full length of

the sensor

C

Full length

with brackets

Mounting hole

center width

F3S-B122, B065, B047 300 343 387 371

F3S-B182, B095, B067 450 493 537 521

F3S-B242, B125, B087 600 643 687 671

F3S-B302, B155, B107 750 793 837 821

F3S-B362, B185, B127 900 943 987 971

D

36

30

8

23

F3S-B

Note:

1. The intermediate bracket and mounting screw holes are only applied to types which have a protective

height of 1050 mm or longer.

2. The master unit has an M12 connector on both ends of the sensor (for the extension cable and the series connection cable).

3. Keep the following distance for the extension cable and the series connection cable when the cable is

bent.

Series connection cord

of the Master unit side

and Slave unit side

81 min.

Extension cord

73 min.

4. The figures on the previous pages show the L-shaped intermediate bracket (see 2-2-4) on the left side

of the F3S-B. In case the L-shaped intermediate bracket needs to be on the right side of the sensor, the

intermediate mounting bracket needs to be oriented upside down as shown the figure below. The position of the mounting screw holes for the L-shaped intermediate bracket changes from left side to right

side. This also applies in the case of side mounting, the figures below show the rear mounting style only.

2-M5

D

15

2-M5

15

D

E

MOUNTING SCREW HOLES MOUNTING SCREW HOLES

24

4-M5

20

4-M5

20

24

24

E

2-2-2 Mounting Bracket (Top and Bottom)

12

16

22

F3S-B

5.5

R2.75

20

20°

°

5

3

46

30

2

R1.75

36

5

.

5

2

ø

5

3.

R4.5

Unit: mm

2-2-3 Mounting Plate

Only supplied with types which have a protective height of 1050 mm or longer.

The mounting plates are only required when the F3S-B is mounted in the rear mounting configuration with

the intermediate brackets.

42.74

36.5

20

6.254

22.5 3

7

5

28.74

5.5

How to use

1. Combine the mounting bracket (top and bottom)

with the mounting plate.

2. Then affix the assembled bracket with M5 screws.

R2.75

Mounting bracket

(top and bottom)

M5 screw

12

Unit: mm

Mounting plate

Sensor

25

F3S-B

2-2-4 Mounting Bracket (Intermediate)

Only supplied with types which have a protective height of 1050 mm or longer.

MOUNTING SCREW FOR SENSOR (M6x8)

FLAT INTERMEDIATE BRACKET

RUBBER

U-SHAPED INTERMEDIATE BRACKET

FIXING SCREW FOR BRACKET (M4x10)

L-SHAPED INTERMEDIATE BRACKET

Configuration of U-shaped Intermediate Bracket Mounted at 90 Degree Angle

How to use

1. Assembly

Choose the mounting direction for the L- and Ushaped intermediate bracket combination based on

the mounting direction (side or rear) and temporarily

secure the brackets with the M4 x 10 screw.

2. Installation

Clasp the center of the case with the U-shaped

bracket and temporarily secure the bracket to the

F3S-B with the M6 x 8 screw. The mounting bracket

(intermediate) for the emitter is oriented upside down

when compared to the bracket of the receiver.

L-shaped intermediate bracket

U-shaped intermediate bracket

Side mounting

U-shaped intermediate bracket

Unit: mm

Rear mounting

Case

26

F3S-B

2-3 Wiring

WARNING

Do not connect the F3S-B to a power supply with a voltage higher than 24 VDC + 20%.

Do not connect the F3S-B to an AC power source.

2-3-1 Power Supply Units and Loads

WARNING

DC power supply units must satisfy all of the conditions below so that the F3S-B can comply with the

applicable standards IEC 61496-1, and UL 508.

• The power supply voltage should be within rating (24 VDC ± 20 %).

• The power supply is connected only to the F3S-B and to the devices related to the electro-sensitive

protective function of the F3S-B, such as a safety controller and muting sensors, and it has enough

rated current for all the devices. The power supply is not connected to other devices or machines.

• The power supply uses double or reinforced insulation between the primary and secondary circuits

• The power supply has automatic reset characteristics (voltage drop) to protect overcurrent.

• The power supply maintains an output holding time of at least 20 ms.

• FG (frame ground terminal) must be connected to PE (protective earth) when using a commercially

available switching regulator.

• The power supply must have output characteristics required for the power source for Class 2 Circuit

or Limited Voltage/Current Circuit as defined in UL508 (see “Remark”).

• The power supply must conform to regulatory requirements and standards, regarding EMC and elec-

trical equipment safety, of the country where the F3S-B is installed and where machinery will be operated, for example: The EMC Directive (industrial environment) and the Low Voltage Directive in

EU.

[Remark] The power supply must conform to the following requirements (1) or (2) regarding a secondary

circuit, in accordance with UL 508, to avoid a fire.

(1) The power supply includes a limited voltage/current circuit supplied by an isolating source like

the secondary winding of an isolating type transformer. In the limited voltage/current circuit,

- the current available is limited to a value not exceeding 8 A (including the case of

short-circuit), or

- a secondary fuse or other such secondary circuit protective device used to limit the

available current shall be rated at not more than a value 4.2 amperes (for the power

supply voltage of 24 VDC).

(2) The power supply includes a Class 2 circuit supplied by an isolating source that complies

with the requirement in the Standard for Class 2 Power Units, UL 1310, or the requirements

in the Standard for Class 2 and Class 3 Transformers, UL 1585.

Recommended power supply: S82K (15 W, 30 W, 50 W, 90 W type) made by OMRON, UL Listed (UL508,

Power supply and loads must be reinforced insulated or double insulated as shown in the following figure

to protect against electrical shock. The insulation shown in the figure should insulate against hazardous

voltage levels (230 VAC, etc.), not simply against 24 VDC.

Class2 Output) and CE Marked (EMC and Low Voltage Directives)

Relay monitoring input

Emitter

0 V

+24 V

k1

Reinforced insulation or double

insulation between the coil and

contacts, between contacts

Receiver

Power

supply unit

Reinforced

insulation or

double

insulation

Output

0 V

+24 V

k1

K1

Hazardous

voltage level

Hazardous voltage level

Motor, etc.

27

F3S-B

2-3-2 Wiring Diagram

Disconnect all sources of power before wiring the F3S-B to a machine.

Emitter

RS-485(A) (Grey 5)

RS-485(B) (Pink 6)

Receiver

0 V (Blue 7)

Ext. test (Green 3)

Relay monitoring (White 1)

24 VDC (Brown 2)

S1

E1

E1: 24 VDC Power supply

S1: External test switch

K1, K2: Relay or PLC input to control the dangerous movement of a machine

Load: Inductive load with surge suppressor (Note) or resistive load to indicate unstable condition

Interlock selection (yellow 4)

Instability (yellow 4)

Load

0 V (Blue 7)

Output2 (White 1)

24 VDC (Brown 2)

Output1 (Green 3)

K2

K1

When using Start/restart interlock Function When using optional Relay Monitoring Function

Emitter

24 VDC (Brown 2)

Interlock selection

S2

0 V (Blue 7)

(yellow 4)

RS-485(A) (Grey 5)

RS-485(B) (Pink 6)

S3

Receiver

Instability (yellow 4)

(White 1)

Relay monitoring

k1

0 V (Blue 7)

24 VDC (Brown 2)

k2

Emitter

0 V (Blue 7)

Ext. test (Green 3)

24 VDC (Brown 2)

S1

E1

S2: Restart interlock reset switch

S3: Mode change switch for inspection

28

Load

E1

k1, k2: Auxiliary contact to monitor the

condition of the final relay

F3S-B

2-3-3 Wiring Procedure

1. Connect the emitter extension cable (F39-JBA-L optional, gray color outer jacket) to the emitter.

(The emitter uses gray color plastic caps.)

2. Connect the receiver extension cable (F39-JBA-D optional, black color outer jacket) to the receiver.

(The receiver unit uses black color plastic caps.)

3. Connect the 0 V line of the power supply directly to protective earth (PE).

Note: Be sure to wire correctly. Failure to do so may damage the F3S-B.

• Connector (Main Unit End)

Wire Color

of Extension

Cable

Front View Pin No.

Receiver Emitter

1 Control output 2 Relay monitoring input White

7

1

865

2

4

3

2 24 VDC 24 VDC Brown

3 Control output 1 External test input Green

4 Instability output Interlock selection input Yellow

5 RS-485 (A) RS-485 (A) Grey

6 RS-485 (B) RS-485 (B) Pink

7 0 V 0 V Blue

8 N.C. / reserved N.C. / reserved Red

N.C. / reserved: do not connect

• Extension Cable (F39-JBA Optional)

Signal Name

42 L

ø15

M12

Round vinyl-insulated cord

5.7 mm dia. (32/0.1 mm dia.) 8 cores

Type (Set name) for Emitter for Receiver L

F39-JB1A F39-JB1A-L F39-JB1A-D 3000

F39-JB2A F39-JB2A-L F39-JB2A-D 7000

Gray outer

jacket color

F39-JB3A F39-JB3A-L

• Series Connection Cable (F39-JB1B Optional)

48.5

Ø15

M12

Type (Set name) for Emitter for Receiver

F39-JB1B F39-JB1B-L Gray outer

jacket color

Unit: mm

Black outer

jacket color

F39-JB3A-D

300

Unit: mm

10000

F39-JB1B-D Black outer

jacket color

29

F3S-B

ADJUSTMENT Section 3

3-1 Adjustment Procedure

1. Ensure the following points.

• A hazardous part of a machine cannot move during the adjustment.

• The optical surfaces of the emitter and receiver are clean.

• There should be no light-interrupting objects in the F3S-B detection zone.

2. Adjust the torsion angle of the emitter while monitoring the indicator on the receiver and locate the point

where the ON-state indicator (lit: green) is lit and the Instability indicator (UNSTAB: orange) goes OFF.

3. Adjust the torsion angle so that the light-receiving condition becomes as stable as possible. When the

above adjustments have been completed, tighten all brackets and mounting screws while being careful

not to change the optical axis adjustment for the F3S-B. The tightening torque for these screws is shown

in the following table.

Mounting bracket types Screw designation and length (mm) Tightening torque

Mounting brackets

(top and bottom)

(intermediate)

4. If a stable light receiving condition is not obtained through the angle adjustment of the emitter, perform the

following adjustments.

If the Instability indicator does not go OFF, temporarily fix the emitter at the most stable state and

conduct angle adjustment for the receiver according to the procedure described in the above step 2.

5. If a stable light receiving condition is not obtained through the above angle adjustment of the receiver,

check for parallelism between the emitter mounting surface and the receiver mounting surface and also

check if the emitter and receiver are mounted to the same height.

M3 x 10

(tapping screw)

M4 x 10 1.2 N·m (12.2 kg·cm) Mounting brackets

M6 x 8 4.3 N·m (43.9 kg·cm)

0.54 N·m (5.5 kg·cm)

3-2 Check List

Check the following items to make sure the installation is correct

1. % Machine structure does not hinder stop and other safety functions.

2. % Intrusion into a hazardous part of the machine is not possible without passing through the F3S-B detection zone.

3. % Protective structure that allows the F3S-B to detect an operator when he/she works in the hazardous

area.

4. % The actual safety distance is greater than the calculated distance.

5. % Reflective surfaces are not installed in prohibited areas.

Check the following items to make sure wiring is correct before turning ON power.

1. % The power supply is connected only to the F3S-B and to the devices related to the electro-sensitive

protective function of the F3S-B, such as a safety controller and muting sensors, and it has enough

rated current for all the devices.

2. % The power supply unit is a 24-VDC unit that conforms to the EMC Directive, Low-voltage Directive

and output holding specifications.

3. % The polarity of the power supply connection is not reversed.

4. % The emitter extension cable is properly connected to the emitter and the receiver extension cable is

properly connected to the receiver.

5. % Double insulation or reinforced insulation is used between the output and the hazard potential

(commercial power supplies, etc.), and between the Relay monitoring input and the hazard potential.

6. % Outputs are not shorted to the +24V line.

7. % Loads are not connected to the +24V line.

8. % No lines are connected to a commercial power supply.

30

F3S-B

9. % When two or more units are used in close proximity, they are mounted properly to prevent mutual

interference.

Turn ON power to the F3S-B and make sure the F3S-B is operating properly as described below with

the machine stopped.

10. % The F3S-B will begin operating normally within 2 seconds after power is turned ON. When the protective field is free of obstructions, IR-Power indicator (orange) of the emitter and the ON-state indicator (green) of the receiver will light.

11. % A test rod can be detected at any position in the detection zone. In other words, the OFF-state indicator (red) will remain lit and the ON-state indicator (green) will be never lit as long as the test rod is

present in the detection zone.

Detection checkpoints are:

(A) Protective height directly in front of the emitter.

(B) Protective height directly in front of the receiver.

(C) Protective height midway between the emitter and receiver.

* Be sure to use the correct test rod which has the same diameter as the optical resolution of the

F3S-B to be tested.

* Make the start/restart interlock function inactive to carry out this check.

(A)

(C)

(B)

Emitter

Test rod

Receiver

12. % The external test function can be activated and outputs are momentarily turned OFF if the external

test input terminal is connected to a voltage of 17 VDC to Vs.

Operate the machine and check to see if a hazardous part stops under the conditions below.

13. % The hazardous part stops within the calculated time when a test rod is inserted into the detection

zone directly in front of the emitter, directly in front of the receiver and midway between the emitter

and receiver.

14. % The hazardous part remains stopped as long as the test rod is present in the detection zone.

15. % The hazardous part stops when the F3S-B power supply is turned OFF.

16. % The overall measured machine response time is less than the calculated response time.

31

F3S-B

I/O CIRCUIT Section 4

IR-light

indicator

Grey

5

Pink

6

Interlock

indicator

Main emitter

circuit

Ext. test/

blanking

indicator

Brown

2

Green

3

External test

input

White

1

Relay monitoring

input

Yellow

4

Blue

7

Interlock selection

input (*1)

+24 V

0 V

Instability

OFF-state

Pink

Grey

6

5

ON-state

indicator

indicator

Main receiver

circuit

indicator

Brown

2

Green

3

Control output 1

White

1

Control output 2

Yellow

4

Instability

output

Blue

7

Load

Load

Load

RS-485(B)

RS-485(A)

*1 See “2-3 Wiring” for wiring information

32

F3S-B

APPLICATIONS Section 5

5-1 Application (1)

- without Start/restart interlock function

- without Relay monitoring function

R

KM1

KM2

M

M: 3-phase motor

E1: 24 VDC Power supply

S1: External te st switch

KM1, KM2: Electromagnet contactor (with Reinforced insulation)

Note: KM1 and KM2 must have reinforced insula-

tion between the coil and contacts.

Emitter

g

n

i

r

o

t

i

n

o

m

y

a

l

e

Ext. test

Vcc

S1

E1

RS-485(A)

RS-485(B)

Gnd

Interlock selection

Receive r

Instability

Output1

Gnd

Vcc

KM1

Output2

KM2

5-2 Application (2)

- with Start/restart interlock function

- with Relay monitoring function

R

KM1

KM2

M

M: 3-phase motor

E1: 24 VDC P ower supply

S1: External te st switch

S2: Restart interlock reset switch

KM1, KM2: Electromagnet contactor (with Reinforced insulation)

Note: KM1 and KM2 must have reinforced insula-

tion between the coil and contacts as well as

between contacts.

Emitter

g

n

i

r

o

t

i

n

o

m

y

a

l

e

Ext. test

Vcc

S1

E1

RS-485(A)

RS-485(B)

Gnd

Interlock selection

S2

Receiver

Instability

Output1

Output2

Gnd

Vcc

KM1

KM2

33

F3S-B

MAINTENANCE Section 6

WARNING

Do not use the F3S-B until the following inspections are completed.

Failure to do so may result in loss of life or serious injury.

Do not disassemble, repair or modify the F3S-B.

Note:

1. For Safety, be sure to record and store inspection results.

2. Make sure you are thoroughly familiar with the F3S-B and the machine prior to conducting an inspection.

3. Make sure all personnel have adequate guidelines for performing maintenance and inspections.

4. Check all items in “3-2 Check List” again if the protective structures preventing access to the hazard

are changed.

6-1 Daily Inspections

Be sure to inspect the following items at the start of work or after a shift change.

1. % No intrusion paths into a hazardous part of a machine except through the F3S-B detection zone.

2. % Some part of the operator’s body remains in the F3S-B detection zone at all times while the operator

works in the hazardous area.

3. % The actual safety distance is greater than the calculated distance.

4. % No dirt or scratches on the optical surface.

Operate the machine and check to see if the hazardous part stops under the conditions below.

5. % The hazardous part moves when there is nothing in the detection zone (normal operation).

6. % The hazardous part stops within the calculated time when the test rod is inserted into the detection

zone directly in front of the emitter, directly in front of the receiver and midway between the emitter

and receiver.

7. % The hazardous part remains stopped as long as the test rod is present in the detection zone.

8. % The hazardous part stops when the F3S-B power supply is turned OFF.

6-2 Inspection Every Six Month

Inspect the following items every six months or when a machine setting is changed.

1. % Machine structure does not hinder stop and safety functions.

2. % There is no machine modification or connection change that will adversely affect the control system.

3. % The F3S-B outputs are correctly wired to the machine.

4. % The actual overall response time of the machine is less than the calculated response time.

5. % The control relay and connector are in good condition.

6. % The brackets are securely tightened.

6-3 Cleaning

If the surface of the F3S-B is extremely dirty, F3S-B will stop activating outputs. In this case, use a clean soft

cloth and clean the surface without pressure. Do not use any solvents such as paint thinners, benzene or

acetone to clean the F3S-B because they will damage the translucent surface.

34

ACCESSORIES (OPTIONAL) Section 7

• F39-JBA Extension Cable : 2 pcs./set

Type Length Specification

F39-JB1A

F39-JB2A

F39-JB3A

• F39-JB1B Series Connection Cable : 2 pcs./set

Type Length Specification

F39-JB1B 300 mm M12 connector (6 pins)

• F39-EU1E Optional Function Kit

The following three accessories, the F39-E1 Interface Unit, the F39-U1E Optional Function Software,

and the F39-JB1C Interface Cable are packed in one package.

• F39-E1 Interface Unit

3 m

7 m

10 m

M 12 connector (8 pins)

F3S-B

• F39-U1E Optional Function Software

Contained on one 3.5 Inch floppy disk and runs with Windows

Hardware requirements: PC/Laptop Pentium

133 (32 MB for Windows

• F39-JB1C Interface Cable

5 m cable length, M8 connector (4 pins)

95, Windows

98 or Windows NT

95, 64 MB for Windows NT

)

35

F3S-B

TROUBLESHOOTING Section 8

The F3S-B runs internal self-tests after the power is turned ON and while the F3S-B is in normal operation. The external test is also available. If a failure is detected, a corresponding flicker pattern is indicated

by the red LED (OFF-state indicator) of the receiver. Each failure indication sequence, other than continuous flashing, will repeat after a two-second interval. This repetition will continue until a remedy is effected.

Indication Cause Remedy

Flashing

continuously

Flashing

once

Flashing

twice

Flashing

three times

Flashing

four times

Flashing

five times

Flashing

six times

Flashing

seven times

Relay monitoring failure during

ON-state

(In the case that the Relay monitoring function is activated, the

wrong status of the relay NC contact is detected when the control

outputs are in the ON-state.)

Internal parameter failure of a

receiver

Communication failure between

an emitter and receiver,

or internal failure of an emitter

Internal memory failure of a

receiver

Relay monitoring failure during

OFF-state

(In case that Relay monitoring

function is activated, wrong status

of the relay NC contact is detected

when the control outputs are OFFstate.)

Control output failure

(High level voltage is detected

although a control output is in

OFF-state.)

Internal hardware failure of a

receiver

Series connection system failure of receivers

0.5 sec 0.5 sec

N times flashing

2 sec

− Check connection of the relay monitoring input.

− Check the voltage of the relay monitoring input.

(When control outputs are ON-state, the relay monitoring input must show 0 V )

* Regarding only this failure, the interruption and

restoration of power is necessary to restore F3S-B.

− Change the setting parameters by the optional soft-

ware F39-U1E, or reset the setting parameters to

factory setting status also by F39-U1E.

− Replace the receiver.

− Check connection of the emitter and the receiver.

− Check series connection of the emitters.

− Check if the emitter and the receiver have the same

type name.

− Check if the type name of the slave unit emitter is

same as the indicated one on the label of the master unit emitter

− Replace the emitter.

− Replace the receiver.

− Check connection of relay monitoring input.

− Check the voltage of the relay monitoring input.

(When control outputs are OFF, the relay monitoring

input must be at a level of 17 VDC to Vs.)

− Check connection of control outputs for a short cir-

cuit with Vs (cables, connected devices)

− Replace the receiver.

− Replace the receiver.

− Check series connection between the receivers.

− Check if the type name of the slave unit receiver is

same as the indicated one on the label of the master unit receiver

− Replace the master unit receiver and /or the slave

unit receiver.

36

Fig. Timing Chart for flashing pattern of red LED (OFF-state indicator)

OMRON Corporation

Industrial Automation Company

Industrial Sensors Division

Sensing Devices and Components Div. H.Q.

Shiokoji horikawa

Shimogyo-ku, Kyoto 600-8530

JAPAN

Tel: +81-75-344-7068 / Fax: +81-75-344-7107

OMRON EUROPE SENSOR BU

Carl-Benz-Str.4

71154 Nufringen

GERMANY

Tel: +49-7032-811-0 / Fax: +49-7032-811-199

OMRON ELECTRONICS, INC.

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel: +1-847-843-7900 / Fax: +1-847-843-7787

OMRON ASIAPACIFIC PTE. LTD.

83 Clemenceau Avenue, #11-01, UE Square,

Singapore 239920

SINGAPORE

Tel: +65-835-3011 / Fax: +65-835-2711

Authorised Distributor:

Cat. No. E502-E2-01 Note: Specifications subject to change without notice ©OMRON Corporation 2001 All Rights Reserved.

Part No. 7490-00098 Rev. A2 Printed in Germany

Loading...

Loading...