Page 1

F3G-C1R70

Safety Laser Scanner

Instruction Manual

April, 2003

© OMRON Corporation 2003 All Right Reserved.

Note: Specifications subject to change without notice.

Page 2

Instruction Manual

F3G-C1R70

List of contents

List of contents

1 About this document .......................................................................................................................... 3

1.1 The function of this document..................................................................................3

1.2 The target group of this document ........................................................................... 3

1.3 Depth of information of this document.................................................................... 3

1.4 Abbreviations and terms...........................................................................................3

1.4.1 Abbreviations.................................................................................................3

1.4.2 Important terms ............................................................................................3

1.5 Symbols used.............................................................................................................4

2 On safety ................................................................................................................................................. 5

2.1 Use of the device....................................................................................................... 6

2.2 Correct use of the device ..........................................................................................7

2.3 General safety information and protective measures.............................................7

2.3.1 Stationary application ................................................................................... 8

2.3.2 Application on automated guided vehicles (AGVs)....................................11

2.4 Protection of the environment................................................................................14

3 Product description...........................................................................................................................15

3.1 Construction of the device ......................................................................................15

3.2 Operating principles of the device..........................................................................18

4 Installation and mounting ...............................................................................................................20

4.1 Operating conditions ...............................................................................................20

4.2 Mounting the device................................................................................................20

4.3 Minimum distance from objects.............................................................................22

5 Electrical installation........................................................................................................................23

5.1 Integrating the safety laser scanner F3G-C1R70’s outputs into the

machine control system..........................................................................................23

5.2 Connecting the power supply and signal cables....................................................25

5.3 Connecting the data cables ....................................................................................27

6 Configuration.......................................................................................................................................28

6.1 Delivery status .........................................................................................................28

6.2 Preparing the configuration ....................................................................................28

7 Commissioning ...................................................................................................................................29

7.1 Access authorization ...............................................................................................29

7.2 Testing the Monitor functions.................................................................................29

7.3 Regular examinations..............................................................................................30

8 Transport and storage ......................................................................................................................31

8.1 Transporting the safety laser scanner F3G-C1R70 ...............................................31

8.2 Storage.....................................................................................................................32

Page 3

Instruction Manual

F3G-C1R70

List of contents

9 Maintenance and care .....................................................................................................................33

10 Troubleshooting .......................................................................................................................34

10.1 Correcting faults...................................................................................................... 34

10.2 System error indications......................................................................................... 34

11 Technical data ..........................................................................................................................35

11.1 Data sheet............................................................................................................... 35

11.2 Device accuracy and safety supplements .............................................................37

12 Order data...................................................................................................................................38

12.1 Delivery.................................................................................................................... 38

12.2 Optional accessories...............................................................................................38

13 Appendix.....................................................................................................................................39

13.1 Dimensional drawings, safety laser scanner F3G-C1R70 .................................... 39

13.2 Standards and directives........................................................................................ 40

13.3 Checklist for the manufacturer ..............................................................................41

13.4 List of tables............................................................................................................ 42

13.5 List of illustrations...................................................................................................42

2

Page 4

Instruction Manual Chapter 1

F3G-C1R70

About this document

1 About this document

Please read this chapter carefully before working with this documentation and the safety

laser scanner F3G-C1R70.

1.1 The function of this document

This document provides information on the technical properties of the Safety Laser

Scanner F3G-C1R70 (Rotating Laser Scanner). You will find information on:

• Safety

• Structure and operation

• Planning

• Maintenance and care

1.2 The target group of this document

This document is intended for those persons who constructively integrate the safety laser

scanner F3G-C1R70, and commission and operate it as a protective device.

ESPE

CSL

OSSD

Machine

Scanning range

1.3 Depth of information of this document

This document contains all the information necessary for planning, acquisition and

maintenance of the safety laser scanner F3G-C1R70. Information is provided on its

operating principle, possible uses and mounting.

More information is available from OMRON directly.

1.4 Abbreviations and terms

1.4.1 Abbreviations

Electro-sensitive protective equipment (e.g. safety laser scanner F3G-C1R70)

Configuration Software for Laserscanner. With a PC and the CSL, as a user, you can define

the monitored areas, and define or check the correct configuration of the safety laser

scanner F3G-C1R70.

The safety laser scanner F3G-C1R70 uses a reference target fixed to the F3G-C1R70 for

self-checking. Any change to this target is interpreted as a system error.

Output signal switching device

1.4.2 Important terms

Please distinguish between the following terms:

In this instruction manual,

dangerous state or a dangerous movement that rules out the presence of persons or

objects in the protective field is involved in the operation of the machine.

The maximum scanning range describes an arc of 300° around the sensor with a radius

of max. 7.5 m.

machine is used as a term for the system to be monitored. A

3

Page 5

Chapter 1 Instruction Manual

F3G-C1R70

About this document

Protective field

Protective field size

Monitored areas

Warning field

Response time

Reactivation time

The safety area that, when infringed, results in the immediate shut down of the dangerous

movement is termed the protective field. If a person or object enters the protective field,

the safety laser scanner F3G-C1R70 provides a stop signal to the machine via the OSSD

switching outputs.

The maximum protective field size is defined by the distance of the safety laser scanner

scanning head to the most distant point of the protective field including the safety

supplement.

Monitored areas are a general term used for protective fields (up to 6 m) and/or warning

fields (up to 7.5 m). Monitored areas can have irregular shapes or shapes adapted to the

surroundings. The safety laser scanner F3G-C1R70 monitors them continuously by means

of individual radial laser beams.

The warning field is described as that safety area whose infringement causes an optical or

acoustic warning signal. If a person or object enters the warning field, the safety laser

scanner F3G-C1R70 provides a signal to the monitored machine via the warning output.

The response time is maximum time between intrusion of objects in monitored areas and

making OSSDs into OFF-state (Open).

The reactivation time is time between removal of objects from monitored areas and

making OSSDs into ON-state (Close).

1.5 Symbols used

Recommendation

Note

, Red, + Yellow,

- Green

Action

%

WARNING

!

Particular emphasis is given to some information in this document to make it easier to find

quickly.

Recommendations are designed to give you assistance in your decision-making process

with respect to a function or a technical measure.

Such notes provide information on special device features.

LED symbols describe the state of a diagnostics LED. Examples:

, Red The red LED is illuminated constantly.

+ Yellow The yellow LED is flashing.

- Green The green LED is off.

An arrow indicates that some action is required. Carefully read and follow the instructions

for the action to be taken.

Warning!

A warning indicates an actual or potential risk or health hazard. They are designed to

prevent accidents.

Always read warnings attentively and follow instructions carefully!

Software notes show the location in the CSL (Configuration Software for Laserscanner)

where you can make the appropriate settings and adjustments.

The term “dangerous state”

The dangerous state (standard term)

diagrams of this document as a movement of a machine part. In practical operation, there

may be a number of different dangerous states:

• Machine movements

• Electrical conductors

• Visible or invisible radiation

• A combination of several hazards

of the machine is always shown in the drawings and

4

Page 6

Instruction Manual Chapter 2

F3G-C1R70

On safety

2 On safety

This chapter deals with your safety and the safety of the equipment operators.

Safety notes

%

WARNING

Please observe the following items in order to ensure the correct and safe use of the

safety laser scanner F3G-C1R70.

Prior to commissioning the safety laser scanner F3G-C1R70 for the first time, please read

this instruction manual and the users manual for the CSL (Configuration Software for

Laserscanner) carefully. Get to know the system and the CSL. Please contact your nearest

OMRON representative if you have any questions. We will be pleased to provide assistance.

All appropriate legal regulations, the requirements of the trade associations and the

instructions of the manufacturer of the machine to be monitored must be observed

without fail.

The protective function of the safety laser scanner F3G-C1R70 depends on the correct

definition and programming of the warning field and protective field.

Installation of the safety laser scanner F3G-C1R70, definition and programming of the

areas to be monitored and integration in the machine control system, must be carried out

only by authorised personnel who are appropriately trained.

After completing the programming, the arrangement of the protective and warning fields

are to be tested on the machine while it is switched on, but not running. On this topic see

Section 7.2 "Testing the Monitor functions" on page 29.

5

Page 7

Chapter 2 Instruction Manual

F3G-C1R70

On safety

2.1 Use of the device

The safety laser scanner F3G-C1R70 has been developed and approved as a Type 3

electro-sensitive protective equipment according to the IEC/EN 61)496-1 standard.

Fig. 1: Schematic diagram of

the monitored areas

Measuring range

Warning field (example)

Maximum protective field

Protective field (example)

6 m

7.5 m

60°

Test range

(reference target)

The safety laser scanner F3G-C1R70 has been designed for industrial use. Its task is to

detect access of persons to hazardous areas and stop the dangerous movement of a

machine in this area. A signal is triggered as soon as a person or object enters the

monitored area:

• If a person or object is present within the warning field, the safety laser scanner F3G-

C1R70 switches a relay contact at the corresponding signal output. This signal can be

used for acoustic and optical warnings. Warning is to indicate that the hazardous area is

to be left before the protective field is activated and the safety laser scanner F3GC1R70’s OSSDs issue a stop signal that triggers a machine stop.

• If a person or object is present within the protective field, the safety laser scanner F3G-

C1R70 switches two independent relay contacts, OSSDs. These signals must lead to an

immediate switching off of the dangerous machine movement.

The CSL (Configuration Software for Laserscanner) is included with the safety laser

scanner F3G-C1R70 for the definition and testing of the protective field and warning field.

6

Page 8

Instruction Manual Chapter 2

F3G-C1R70

On safety

2.2 Correct use of the device

The safety laser scanner F3G-C1R70 can only be used as protective equipment for

detecting persons or objects (horizontal protective field). Operation of the device is only

permissible according to the technical specifications. All warranty claims against OMRON

are forfeited in the case of any other use, or if alterations are made to devices, even as

part of their mounting or installation.

2.3 General safety information and protective measures

The safety laser scanner F3G-C1R70 must only be employed for monitoring tasks

%

WARNING

fulfilling all the following conditions:

• The safety laser scanner F3G-C1R70 must be able to terminate the dangerous state

within a defined time period by triggering the stop signal.

• The safety distance monitored by the safety laser scanner F3G-C1R70 must be smaller

than the maximum protective field.

• The maximum value of the machine’s stopping time plus the safety laser scanner F3GC1R70’s response time must be calculated so that nobody can gain access to the

hazardous point before the dangerous movement has come to a complete stop.

The safety laser scanner F3G-C1R70 is of laser safety class 1.

Additional measures for screening the laser radiation are not

necessary (eye safe).

LASER CLASS 1

7

Page 9

Chapter 2 Instruction Manual

F3G-C1R70

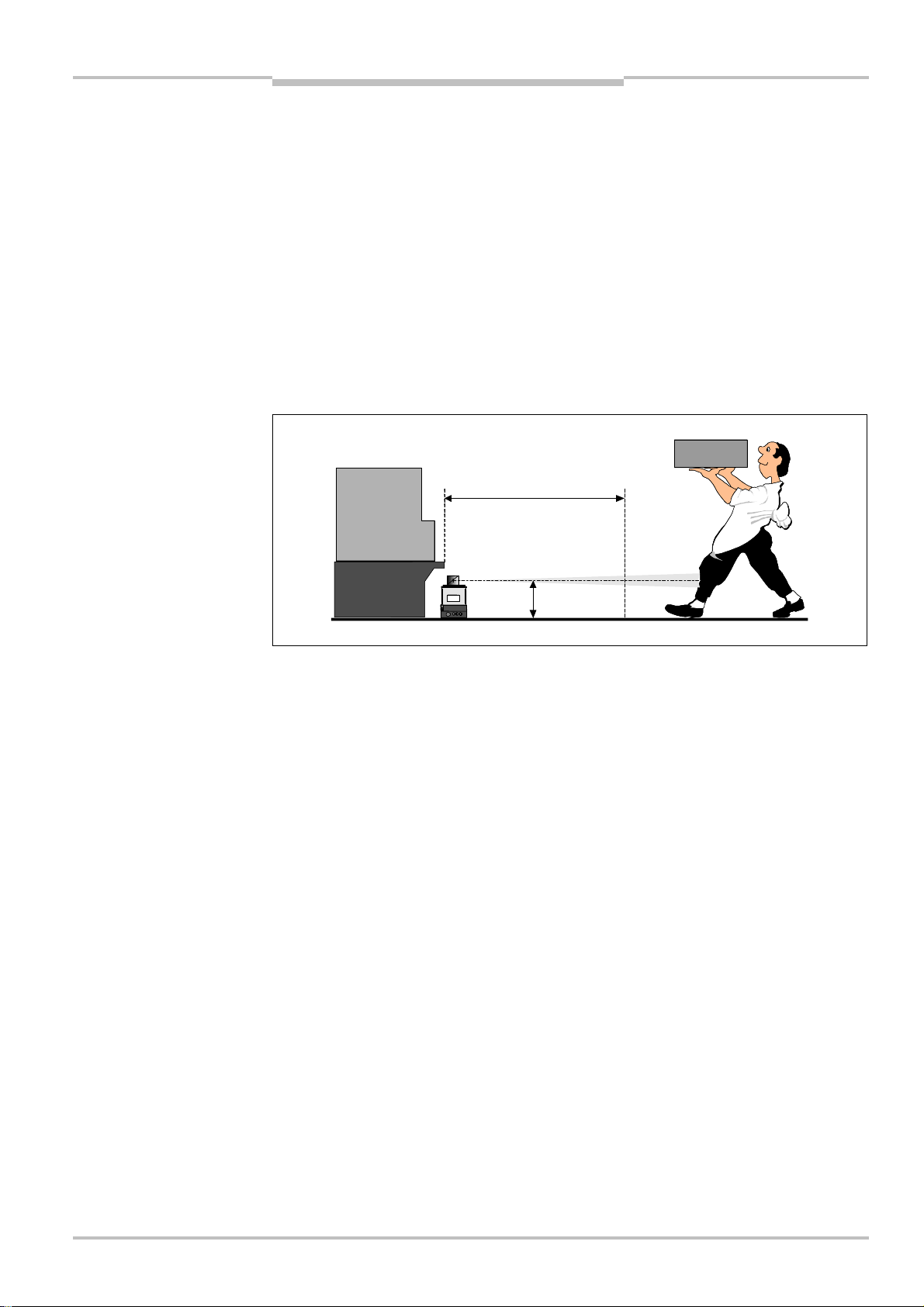

Fig. 2: Calculation of the

safety distance for a

stationary application

On safety

2.3.1 Stationary application

According to Chapter 6.2 of the EN 999 standard, the safety distance between the limit of

the protective field and the hazardous area of a stationary machine is calculated as

follows:

S

h

S = 1.6 × (t1 + t2) + (1200 – 0.4 h) + ZM

Please note: 1200 – 0.4 h ≥ 850

Here…

S = The safety distance (in mm)

= The response time of the F3G-C1R70 (in ms) (see Chapter 11 “Technical data” on

t

1

page 35)

= The machine stopping/run-down time (in ms)

t

2

h = Height of protective field above the floor (in mm) 300 ≤ h ≤ 1000

1.6 = The assumed approach speed (in m/s)

ZM = Maximum measuring error of the F3G-C1R70 (see Chapter 11 “Technical data” on

page 35)

%

WARNING

%

WARNING

Ensure that the correct mounting height is used!

When selecting the mounting height ensure that it is not possible to enter the hazardous

area from below the protective field.

The safety laser scanner F3G-C1R70 must be supplemented by further safety devices if

one of the following situations applies:

• A hazardous point can be reached without passing through the monitored areas.

• The area monitored by the safety laser scanner F3G-C1R70 can be reached from above,

below or from the side.

• According to EN 999, possible access by crawling below the protective field must be

taken into account above the regulation minimum protective field height of 300 mm.

8

Page 10

Instruction Manual Chapter 2

F3G-C1R70

On safety

Example for a stationary application

Machine width M = 2.2 m = 2200 mm

Response time of the F3G-C1R70 = 280 ms

The machine stopping/run-down time = 300 ms

Height of protective field above the floor = 0.5 m = 500 mm

Maximum measuring error of the F3G-C1R70 = 350 mm

Protective field width = M + safety supplement left and right

S = 1.6 m/s × (280 ms + 300 ms) + (1200 mm – 0.4 × 500 mm) + 350 mm = 2278 mm

Protective field width = 2200 mm + 350 mm + 350 mm = 2900 mm

Maximum protective field size = (S

2

+ ½ protective field width2)½ = 2700 mm

Please note: The example only applies if no access from the side is possible. Access from

the side must be prevented either by a wider protective field and/or other measures.

Fig. 3: Example: minimum

distance for stationary

application

S = 2278 mm

500 mm

9

Page 11

Chapter 2 Instruction Manual

t

F3G-C1R70

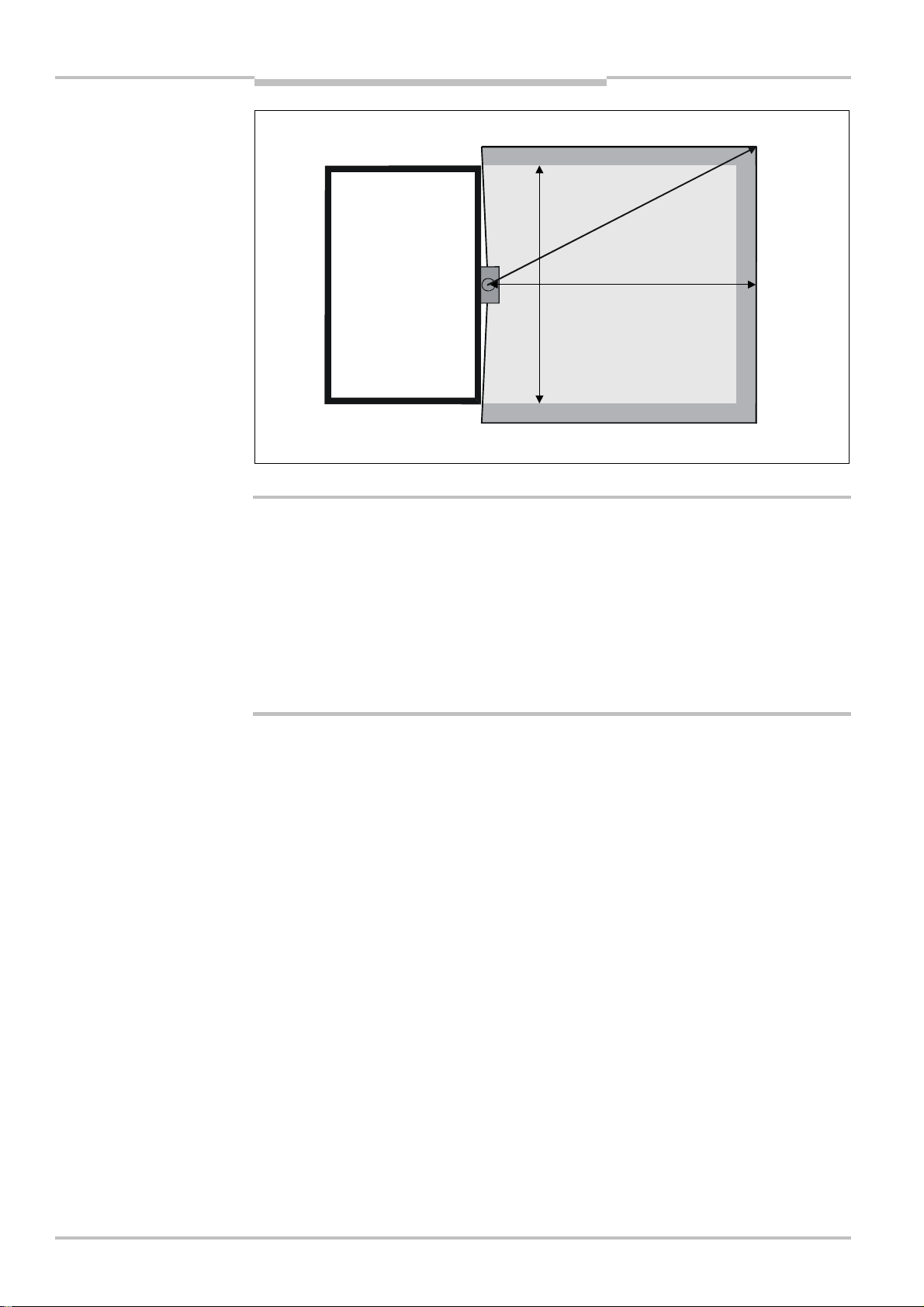

Fig. 4: Example: maximum

protective field size and

safety supplements for

stationary applications

On safety

Machine to be

safeguarded

Safety supplement left

Maximum protective

field size

S

%

WARNING

Protective field

Safety supplement right

Safety supplements are to be determined for maximum protective field sizes.

The following applies if the access of persons from behind cannot be hindered by

appropriate sizing of the protective field:

• A manual restart interlock must be present in the machine control system (generally

necessary). The switch to reset the interlock condition must be installed so that the

entire hazardous area is visible and free of personnel, also the switch must not be able

to be operated from within the hazardous area.

• The width of the accessible, unmonitored area directly in front of the machine must be

smaller than 35 mm for a maximum protective field size of up to 3 m. For larger

maximum protective field sizes, the distance must be reduced to zero.

Safety supplement fron

10

Page 12

Instruction Manual Chapter 2

F3G-C1R70

Fig. 5: Calculating the

minimum distance for

automated guided vehicles

On safety

2.3.2 Application on automated guided vehicles (AGVs)

Taking the regulations for automated guided vehicles (e.g. EN 1525: Safety of industrial

trucks - Driverless trucks and their systems) into account, the minimum distance between

the edge of the protective field and the hazardous area of the AGV is calculated as follows:

S

200 mm > h > 100 mm

%

WARNING

S = 1.1 × ((V

Here…

S = Minimum distance (in mm) = max. stopping distance of the AGV

= Response time of the F3G-C1R70 (in ms) (see Chapter 11 “Technical data”

t

1

t

= AGV control system reaction time (in ms)

2

= Maximum speed of the AGV (m/s)

V

max

B = Maximum braking path for the AGV (in mm)

ZM = Maximum measuring error of the F3G-C1R70 (see Chapter 11 “Technical

F = Foot clearance: 150 mm (for the AGV with a floor clearance of less than

h = Height of protective field above the floor (in mm)

1.1 = Safety supplement for possible brake wear

The safety laser scanner F3G-C1R70 must be supplemented by further safety devices if

one of the following situations applies:

• A hazardous point can be reached without passing through the monitored areas.

• The area monitored by the safety laser scanner F3G-C1R70 can be reached from above,

below or from the side.

× (t1 + t2)) + B) + ZM + F1)

max.

on page 35)

data” on page 35)

120mm)

%

WARNING

Define protective field cover correctly!

The protective field must cover the entire width of the AGV. The protective field must be

increased at the sides by the safety supplements (see Chapter 11 “Technical data” on

page 35).

1)

F only applies when there is no foot clearance according to EN 1493.

11

Page 13

Chapter 2 Instruction Manual

F3G-C1R70

%

WARNING

%

WARNING

Fig. 6: Prevent undercutting

of the AGV protective field

On safety

Define the protective field correctly where routes bisect each other!

At “crossroads” where there are “blind spots”, the protective field must have the same

configuration as in the direction of motion.

Avoid undercutting of the protective field!

The protective field must be configured in such a way that stepping between the protective

field and the AGV from behind in the direction of motion (undercutting) is not possible. The

safety laser scanner F3G-C1R70 has a maximum scanning angle of 300°.

The protective field is to be selected so that it is not possible for a person to pass

unnoticed between the protective field and vehicle.

%

WARNING

%

WARNING

AGV

The following must be considered!

• In cases where it is not possible to prevent undetected personnel from standing in front

of the AGV by appropriate sizing of the protective field, then a manual restart interlock

must be included in the AGV. The switch to reset the interlock condition must be

installed so that the entire hazardous area is visible and free of personnel, also the

switch must not be able to be operated from within the hazardous area.

• The width of the accessible area that is not monitored directly in front of the AGV must

be less than 35 mm for a maximum protective field size of up to 3 m. For larger

maximum protective field sizes, the distance must be reduced to zero.

Program reactivation delay!

In case of AGV applications, you must program a reactivation delay for the safety laser

scanner F3G-C1R70. The reactivation delay defines the length of time [ms] before the

relay is reactivated after the monitored field is clear (automatic restart after time).

With automatic restart, the restart period must be set to a minimum of 2000 ms.

12

!

You can stipulate the reactivation delay independently for the warning field and the

protective field (Right-click on the device symbol in the navigation area > Configuration

draft > Edit parameters). The values permitted are between 200 and 5000 ms.

Page 14

Instruction Manual Chapter 2

t

d

F3G-C1R70

Fig. 7: Example: minimum

distance for automated

guided vehicles

On safety

Example for application on AGVs

AGV

Response time of the F3G-C1R70 = 280 ms

AGV control system reaction time = 300 ms

Maximum speed of the AGV = 1 m/s

Maximum braking distance for the AGV = 0.3 m = 300 mm

Maximum measuring error of the F3G-C1R70 = 250 mm

F unnecessary: the AGV has foot clearance

Safety supplement for possible brake wear = 1.1

Protective field width = AGV

S = 1.1 × ((1 m/s × (280 ms + 300 ms)) + 300 mm) + 250 mm = 1218 mm

Protective field width = 1600 mm + 250 mm + 250 mm = 2100 mm

Maximum protective field size = (S

= 1.6 m = 1600 mm

width

+ safety supplement left and right

width

2

+ ½ protective field width2)½ = 1608 mm

Fig. 8: Example: maximum

protective field size and

safety supplements for AGVs

S = 1218 mm

200 mm

Safety supplement left

Maximum protective

field size

S

AGV

Protective fiel

Safety supplement right

Safety supplement fron

13

Page 15

Chapter 2 Instruction Manual

F3G-C1R70

On safety

2.4 Protection of the environment

The safety laser scanner F3G-C1R70 is constructed in such a way that it adversely affects

the environment as little as possible. It emits and contains no environmentally damaging

substances and requires only a minimum of energy and resources.

At work, always act in an environmentally responsible manner. For this reason, please note

the following information on disposal.

Disposal

Note

Always dispose of unusable or irreparable devices according to the particular waste

disposal regulations applicable in the country of use.

14

Page 16

Instruction Manual Chapter 3

l

F3G-C1R70

Product description

3 Product description

3.1 Construction of the device

The sensor of the safety laser scanner F3G-C1R70 is housed in a sturdy aluminum housing.

The housing is protected against water spray according to IP 65 (only applicable if the

connection sockets are equipped with plugs or covers).

Do not damage seals!

%

WARNING

Fig. 9: Construction of the

safety laser scanner F3GC1R70

The housing screws are sealed. Any damage to seals leads to forfeiture of the

manufacturer’s warranty.

The mirror and laser optics are located on the top of the housing in a rotating housing

component. The laser transmitter and receiver use the same lens. This complex co-axial

construction prevents angular error resulting from separate transmitter and receiver optics.

Rotating scanning

head

Optical surface

%

WARNING

Indicators

The invisible laser beams emitted conform to laser safety class 1. The measurement area

begins immediately in front of the optical surface.

Do not mount the device at eye level!

Fix the safety laser scanner F3G-C1R70 so that the measuring beam is not at eye level

during use.

Electrica

connections

15

Page 17

Chapter 3 Instruction Manual

F3G-C1R70

Product description

There are four indicators on the side of the housing showing the state of the system.

Fig. 10: LEDs on the safety

laser scanner F3G-C1R70

Reference target

Rotating scanning head

Tab. 1: Status of the LEDs for

the safety laser scanner F3GC1R70

Green ON-state indictor

Red OFF-state indicator

Yellow Warning indicator

Yellow Diagnostic indicator

:Outputs for protective field (OSSDs) in ON state

:Outputs for protective field (OSSDs) in OFF state

:Outputs for warning field in OFF state

:System state

Indicator Status

ON OFF Warning Diag.

Green Red Yellow Yellow

Meaning

- - - - Device switched off

, , , , Test LEDs for 1 sec. after Power On2)

The system is ready for operation, the outputs for

, - - -

protective field (OSSDs) and for warning field are in

an ON state

- , - Outputs for protective field (OSSDs) are in OFF-state.

, - Output for warning field is in OFF-state.

- , , +)3)System error

2)

The diagnostic indicator lights up during the start-up test after Power On. During the last 5 seconds before

operational readiness is achieved and the release of the release of outputs for protective field (OSSDs), this

indicator blinks at 2 Hz.

3)

For more on this topic see Section 10.2 “System error indications” on page 34.

16

Page 18

Instruction Manual Chapter 3

t

A

s

r

g

F3G-C1R70

Product description

There are two connection sockets on the opposite side of the housing, indicated as

Interface and 24 V DC/signal.

Fig. 11: Housing

connection side

Rotating scanning head

Power supply connector

(24V DC/signal)

Interface connector

(Interface)

Reference targe

Fuse 3.15

low blow under cove

medium

with sealing rin

Protective cap

for interface

Earth terminal

• Interface connector

This connector is used for communication with the computer. At this connection, an

RS 232 interface is available.

• Power supply connector

This connector is used for connecting the power supply, the two outputs for protective

field, OSSD1 and OSSD2, and the output for warning field.

17

Page 19

Chapter 3 Instruction Manual

r

s

r

r

A

r

s

s

s

D =

2

Product description

F3G-C1R70

3.2 Operating principles of the device

Measurement principle

The safety laser scanner F3G-C1R70 emits pulsed laser beams throughout a complete

360° with the help of a rotating mirror. The light pulses are reflected diffusely from objects

in the vicinity and received by a photodiode in the sensor. The safety laser scanner F3GC1R70 determines the distance to the object from the propagation time that the light

requires from emission to reception of the reflection at the sensor.

Fig. 12: Schematic diagram

of operating principle

Stopwatch

Sampling

∆ T × V

stop

start

Light

Rotating mirro

Laser optic

Laser receive

Laser sende

trigger

ngular encode

Motor

Laser reflection

Laser beam

The direction of each individual measurement beam is determined with the help of an

angular encoder.

The measurement data for distance and direction can be called up by a computer via the

interface.

18

Page 20

Instruction Manual Chapter 3

F3G-C1R70

Product description

Monitoring of protective field and warning field

Two distance limit values, representing the warning field and protective field, can be

defined for each measurement beam with the help of the CSL. While monitoring, the safety

laser scanner F3G-C1R70 compares the measured object distance with defined limit

values.

Fig. 13: Configuration of

monitored areas

Warning field

Protective field

F3G

°

60

F3G

Warning field

Protective

field

Possible configuration Impossible configuration

The tables of distance limit values are determined with a computer and laid down in the

safety laser scanner F3G-C1R70. The warning and protective field limits can be of any

shape and ideally adapted to the surroundings. The safety laser scanner F3G-C1R70 must

therefore be within the limits of both the warning field and the protective field.

Self-testing

Comprehensive internal tests run continuously within the safety laser scanner F3G-C1R70.

This ensures the system’s high level of operational reliability. All basic components are

either present in duplicate, or are monitored by testing logics that operate independently.

The so-called reference or test target is an important constituent of the self-testing

systems. This involves a stationary target firmly mounted on the safety laser scanner F3GC1R70, detected on each rotation. Any alteration in the measurement value indicates a

system error and leads to an error state.

During monitoring the safety laser scanner F3G-C1R70 checks that it is functioning

correctly.

The system sensitivity of the device is monitored through the measurement of the light

reflected from the reference target. Contamination of the optical surface or the reference

target can thus lead to the system error: Device insensitive/reference target error (LED

indicators). If this happens, clean the optical surface as well as the reference target as per

the instructions given in Section 9 “Maintenance and care” on page 33.

19

Page 21

Chapter 4 Instruction Manual

F3G-C1R70

Installation and mounting

4 Installation and mounting

4.1 Operating conditions

Please note the following points before using the device:

• The device is only for use in predominantly enclosed areas.

• The safety laser scanner F3G-C1R70 is protected against water spray according to IP 65

and operates within a temperature range of 0 to 50 °C. Protect the system from

moisture and temperatures that are outside the temperature range.

• Protect the safety laser scanner F3G-C1R70 from continuous direct sunlight.

• To prevent condensation, do not expose the safety laser scanner F3G-C1R70 to rapidly

changing temperatures.

• Do not expose the safety laser scanner F3G-C1R70 to aggressive chemicals (detergents).

• Glass panes or reflective surfaces are not reliably detected by the safety laser scanner

F3G-C1R70 as objects.

• The safety laser scanner F3G-C1R70 only detects objects that are visible from its

location and not covered up.

• Rain, snow, dust and smoke are detected as “objects” and may trigger warning field or

protective field states.

%

WARNING

4.2 Mounting the device

Observe the machine manufacturer’s safety regulations!

It is essential that the safety instructions for working on the machine, defined by the

machine manufacturer, are observed when mounting the safety laser scanner F3G-C1R70.

Mounting of the safety laser scanner F3G-C1R70 may only be carried out by qualified

personnel.

The safety laser scanner F3G-C1R70 can be mounted in any orientation (standing, hanging,

lying).

20

Page 22

Instruction Manual Chapter 4

F3G-C1R70

%

WARNING

Fig. 14: Minimum distance to

the floor

Installation and mounting

The emitted laser beam has a divergence of ≤ 1°.

It is essential that during mounting a minimum distance of 100 mm to the floor must be

maintained.

Measuring range

Minimum distance to the floor

%

WARNING

Fig. 15: Mounting several

safety laser scanners

When installing several safety laser scanners, mounting must be carried out in a way

that does not allow any mutual interference.

h

Invalid configuration

min. 500 mm

Possible configuration

Possible configuration

Possible configuration

Screening

21

Page 23

Chapter 4 Instruction Manual

F3G-C1R70

Installation and mounting

The followings are required for mounting the device:

• 4 M4 bolts

• 4 washers and locking washers

• If necessary, a spirit level for ensuring level mounting

Fit safety laser scanner F3G-C1R70 to machine:

1. Turn off the machine and check that you are not taking any risks!

2. Turn the mounting screws (with the washers and locking washers in place) and tighten

them finger tight.

3. When attaching to non-mobile machines, it is recommended that the spirit level is

used in two axes to ensure level mounting.

4. Tighten the screws.

– Tightening torque: 2.6 N·m

– Minimum meshing length: 8mm

4.3 Minimum distance from objects

Fig. 16: Minimum distance of

the area monitored by the

safety laser scanner F3GC1R70 from surrounding

objects

When mounting in front of a wall, for reasons of availability, the programmed monitored

areas may not be closer than 25 cm to the wall.

Wall

Minimum distance

Monitored areas

F3G

Machine to be

safeguarded

22

Page 24

Instruction Manual Chapter 5

F3G-C1R70

Electrical installation

5 Electrical installation

5.1 Integrating the safety laser scanner F3G-C1R70’s

outputs into the machine control system

Connection only by qualified personnel!

%

WARNING

Fig. 17: Example of

integration of the

warning field signal

Connection of the safety laser scanner F3G-C1R70 to the machine may only be carried out

by appropriately qualified personnel.

These persons must have all the information provided by the suppliers of the machine.

30 V max. L

Warning field1.1

Warning field1.2

0 V N

Three potential-free switching outputs are available for connection to the machine for

warning field and protective field states. The outputs are designed as N.)O. contacts.

Switching output for warning field (Non-safety output)

The switching output for warning field can be used for the output of a warning signal. The

switching output for warning field is opened when the warning field is activated, or when

there is a safety laser scanner F3G-C1R70 fault.

If an object is again removed from the warning field, its switching output closes after an

adjustable time between 200 and 5000 ms (reactivation delay).

The switching output for warning field can be switched with a maximum of 30 Volts and is

internally fuse-protected with 2 Amps.

23

Page 25

Chapter 5 Instruction Manual

-

F3G-C1R70

Fig. 18: Example of

integration of OSSDs. The

wiring is to be laid down in

such a way that it is

protected against mechanical

effects.

* = Screen to rule out crosscircuits

Electrical installation

24 V

OSSD2.1

OSSD2.2

Monitoring of K1

and K2

K1

K2

!

OSSD1.1

OSSD1.2

Suppression diode Suppression diode

*

K1 K2

0 V

*

Relay with positively

K1

K2

driven contacts

Safe controller as a

minimum category3

in accordance with

the EN 954-1

OSSD switching outputs (Safety outputs)

The OSSD switching outputs can be used as emergency stop trips in the system controller.

The OSSD switching outputs are open if

• the protective field has been activated

or

• the safety laser scanner F3G-C1R70 has a fault.

The switching output closes after a programmable time of between 200 and 5000 ms

(reactivation delay), assuming that there is no system fault.

You can stipulate the reactivation delay independently for the warning field and the

protective field (Right-click on the device symbol in the navigation area > Configuration

draft > Edit parameters).

The OSSD1 and OSSD2 outputs can be wired with a maximum of 30 Volts and are

internally fuse-protected with 2 Amps.

24

Page 26

Instruction Manual Chapter 5

F3G-C1R70

Electrical installation

5.2 Connecting the power supply and signal cables

Electrical work is to be carried out only by appropriately trained electrical specialists!

%

WARNING

Fig. 19: Plug allocation for

connection of the power

supply and the signal cables

Electrical connection of the power supply and connection of the signal cables for the

warning field, OSSD1 and OSSD2 take place together via the middle socket on the right-

hand side of the housing. The power supply cable F39-JG5A (optional) is available for those

electrical connections.

2

4

1

5

8

3

Tab. 2: Plug allocation for

connection of the power

supply and the signal cables

Fig. 20: Dimension of the

power supply cable

6

Pin Signal Explanation Colour Marking

1 +24 V DC 24 V DC supply Brown +

2 0 V Ground Blue –

3 OSSD2.1 White S2

4 OSSD2.2

5 OSSD1.1 Black S1

6 OSSD1.2

7 Warning output1.1 Red A

8 Warning output1.2

FE Functional earth (shield) Black FE

Relay contact of the OSSD 2

Relay contact of the OSSD 1

Relay contact of the warning

output

7

Grey S2

Green S1

Pink A

18

±10

150

±100

5000

55

Unit: mm

25

Page 27

Chapter 5 Instruction Manual

F3G-C1R70

Electrical installation

Connecting the power supply to the safety laser scanner F3G-C1R70:

1. Wiring is to be protected.

2. Turn off the machine and make sure that you are not exposed to any danger.

3. Avoid short-circuits.

4. Earth the safety laser scanner F3G-C1R70 from the earth terminal

– cross-section for functional earth/ground 1 … 2 mm

2

5. Prepare the power supply:

– operating voltage for the safety laser scanner F3G-C1R70: 24 V DC ± 25)%

– power consumption in operation: typically 750 mA at 24 V DC (switch on current:

2 A for 100 ms)

6. Connect the plug of the power supply cable to the power supply connector of the

safety laser scanner F3G-C1R70 and tighten the screw.

7. Connect safety laser scanner F3G-C1R70 and computer.

8. Switch on safety laser scanner F3G-C1R70.

9. The rotating scanning head starts to rotate. After a few seconds the diagnostic

indicator goes out and the safety laser scanner F3G-C1R70 is ready for configuration

of the areas to be monitored.

Notes

• On connecting the safety laser scanner F3G-C1R70, it is imperative to ensure that the

earth is connected correctly. The safety laser scanner F3G-C1R70 must be provided with

a safety insulating transformer according to IEC 742 or equivalent means of isolation.

This also applies for the charging devices for vehicle batteries, if charging is to take

place on the vehicle.

• For stationary applications, the safety laser scanner F3G-C1R70 must be earthed (for

more on earth connection, see Section 3.1 “Construction of the device” on page 15).

• The functional earth is to be connected with ground potential for installation on

transport vehicles. For applications with battery-powered vehicles, a DC voltage

transformer must be connected in series before the safety laser scanner F3G-C1R70. On

request, please consider a relevant protection against “low dump” (voltage drop).

Fig. 21: Example of the power

supply and grounding of

stationary applications

Fig. 22: Example of the power

supply and grounding on a

transport vehicle

26

24 V DC

0 V

FE

24 V DC

On-board voltage

0V

Page 28

Instruction Manual Chapter 5

F3G-C1R70

Electrical installation

5.3 Connecting the data cables

The interface cable F39-JG5R (optional) is available to connect the safety laser scanner

F3G-C1R70 to the PC.

Fig. 23: Pin allocation of the

interface cable

Tab. 3: Pin allocation of the

interface cable

Fig. 24: Dimension of the

interface cable

J

Pin Signal Explanation Direction Level

A GND Ground, RS 232 --- --C RTS RS 232: Ready to send Output 24 V

E CTS RS 232: Clear to send Input 24 V

G TxD RS 232: Transmit data Output 24 V

J RxD RS 232: Receive data Input 24 V

L --- Do not connect! --- --M RES Reset (active LOW) Input 24 V

N --- Do not connect! --- --O --- Do not connect! --- ---

P --- Do not connect! --- ---

R --- Do not connect! --- ---

S --- Do not connect! --- ---

T --- Do not connect! --- ---

U --- Do not connect! --- ---

E

G

P

R

S

T

I

O

C

N

MU

A

55

±100

5000

Unit: mm

Connecting the interface cable between the PC and the safety laser scanner F3GC1R70:

1. Prevent short-circuits and switch off the safety laser scanner F3G-C1R70 and the PC.

2. Connect the interface cable to the interface connector of the safety laser scanner F3GC1R70 and the serial interface port of the PC.

3. Make sure to screw connectors tight.

The device only conforms to enclosure rating IP65 if the interface connector is

connected with the interface cable, or covered with a cap.

27

18

Page 29

Chapter 6 Instruction Manual

F3G-C1R70

Configuration

6 Configuration

6.1 Delivery status

Protective field and warning field are set for maximum size in the safety laser scanner F3GC1R70 as a default when supplied. The relay reactivation delay is set to the standard

value of 200 ms. Prior to commissioning, the safety laser scanner F3G-C1R70 must be

configured for the planned application with the aid of the CSL (Configuration Software for

Laserscanner) supplied.

6.2 Preparing the configuration

How to prepare the configuration:

Make sure that the safety laser scanner F3G-C1R70 has been properly mounted, and

that the electrical connections are correct and in place.

Plan all necessary settings (warning field, protective field, reactivation delay, etc.).

To configure the safety laser scanner F3G-C1R70, you need:

– CSL (Configuration Software for Laserscanner) on CD-ROM

– Users manual for CSL on CD-ROM

– PC/Notebook with Windows 9x/NT 4/2000 Professional/XP with a serial interface (RS

232) (PC/Notebook is not included.)

– Interface cable F39-JG5R for communication between PC and safety laser scanner

F3G-C1R70 (Interface cable is not included.)

To configure the device, please read the users manual for the CSL (Configuration

Software for Laserscanner) and use the online help in the program.

28

Page 30

Instruction Manual Chapter 7

F3G-C1R70

Commissioning

7 Commissioning

7.1 Access authorization

Access to the safety laser scanner F3G-C1R70 is password protected.

• The password is F3GC on delivery.

• The user (Safety Officer) must ensure that the password is known only by authorized

persons.

Recommendation

!

It is recommended that the F3GC password is replaced by a new password that you

select.

Right-click on the device symbol in the navigation area > Access rights > Change

password

• Without a password, it is possible to select the Monitor function on the PC and edit

protective fields, but it is not possible to change the protective field or parameters.

• Using a password, it is possible to change the protective field and parameters.

7.2 Testing the Monitor functions

After you have defined the monitored areas with the CSL, you must check and accept the

installation. For this purpose, proceed in two steps:

• First, check the definition of the protective field with a computer connected, and

document the test.

• Then, connect to the machine and repeat the test.

Check definition of the protective field and document:

Insert a dark test object with a diameter of about 70 mm from all sides into the

protective field. Check every section of the protective field limit.

The ON-state indicator (green LED) must go out, and the OFF-state indicator (red LED) on

the front of the safety laser scanner F3G-C1R70 must light up.

Add test-results to your documentation.

Check installation of the safety system to the machine:

When you are sure that the definition of the protective field is correct, connect the safety

laser scanner F3G-C1R70 signal cables to the machine control system. Repeat the test

with the machine switched on, but not running. Check as far as possible the behaviour

of the protective device.

Also, check the behavior when the safety laser scanner F3G-C1R70 is switched off.

Switch on the machine. Carefully insert an object, e.g. a box, into the monitored areas.

Observe the machine’s reaction.

Prepare a report.

29

Page 31

Chapter 7 Instruction Manual

F3G-C1R70

Commissioning

Before accepting the system, consider the following points:

Test to ensure that no dangerous state can be set in motion as long as an object is

present in the hazardous area.

Ensure that the dangerous state or the dangerous movement comes to a stop before

any part of a person’s body can reach the hazardous point. When defining the protective

field, take the machine stopping/run-down time and the safety laser scanner F3GC1R70’s response time into account.

Ensure that the safety laser scanner F3G-C1R70 and other protective devices monitor all

access points to the hazardous areas.

Check that the safety laser scanner F3G-C1R70 is firmly mounted. Check that the

system doesn’t move under normal operating conditions and that its position cannot be

changed.

Train the machine operating personnel to operate the safety laser scanner F3G-C1R70.

Explain its design and how to use the system (Indicators, faults).

7.3 Regular examinations

%

WARNING

Carry out regular tests!

Daily tests can be carried out by the machine’s operating personnel.

The six-monthly maintenance (see below) and testing of the monitored areas must only be

carried out by authorised Safety Officers.)

Daily tests

Check the state and installation of the safety laser scanner F3G-C1R70 for any changes.

If in doubt, switch off the safety laser scanner F3G-C1R70 and immediately inform the

Safety Officer.

Keep the optics clean. Only use a soft brush or optical cloth for cleaning the optics.

Check the surroundings for changes (e.g. structural alterations) that may have taken

place since configuration.

Six-monthly tests

Check the definition of the protective field at least every six months.

Follow the regulation procedure described in Section 7.2 "Testing the Monitor functions"

on page 29.

30

Page 32

Instruction Manual Chapter 8

F3G-C1R70

Transport and storage

8 Transport and storage

8.1 Transporting the safety laser scanner F3G-C1R70

Adhere to the following instructions when transporting the safety laser scanner F3GC1R70:

Notes

Fig. 25: Place F3G-C1R70 on

its side in the original

packaging

1. Remove all plugs to prevent buckling of the cable.

2. Fix rotating parts with adhesive tape to prevent scratching of the optics.

3. Do not allow any mechanical loads to affect the rotating parts.

4. Use the original packaging.

This is how you pack the safety laser scanner in its original packaging:

1. Place the lower membrane cushion upright in the box and lay the safety laser scanner

F3G-C1R70 on it on its side.

Fig. 26: Place the upper

membrane cushion on top of

the F3G-C1R70

2. Place the upper membrane cushion on top of the safety laser scanner F3G-C1R70.

31

Page 33

Chapter 8 Instruction Manual

F3G-C1R70

Fig. 27: Put the accessories

in the original packaging

Transport and storage

3. Finally, place the accessories in the box.

4. Before sending the package label it clearly: “Sensitive measurement device – fragile!”

8.2 Storage

Adhere to the following instructions when storing the safety laser scanner F3G-C1R70:

Notes

Carefully dry the system before storage. Condensation can damage optical parts.

Do not store the system in closed airtight containers, so that any remaining dampness

can evaporate. If possible, use the original packaging.

Store with an air humidity of 5 to 95)%RH (without condensation)

Storage temperature –20 to +70 °C

32

Page 34

Instruction Manual Chapter 9

F3G-C1R70

Maintenance and care

9 Maintenance and care

The safety laser scanner F3G-C1R70 requires no maintenance apart from the regular

examinations already mentioned. No adjustments or calibration is necessary.

Please observe the following general instructions for handling the safety laser scanner

F3G-C1R70:

Notes

To ensure the error-free operation of the sensor, clean the optical surface of the

scanning head as soon as there is evidence of visible contamination. Do not touch the

optical surface directly when cleaning. Use a plastic cleaner with a soft optical cloth to

clean the optical surface. Never use rough cloths or aggressive detergents such as

acetone.

Clean the safety laser scanner F3G-C1R70’s housing with a soft, damp cloth. Do not use

aggressive detergents.

Protect the safety laser scanner F3G-C1R70 from continuous direct sunlight.

Do not expose the safety laser scanner F3G-C1R70 to rapid temperature changes to

prevent the formation of condensation.

Never open the safety laser scanner F3G-C1R70! The system does not contain any

components that can be repaired or maintained by the operator.

If errors occur or you have difficulty using the safety laser scanner F3G-C1R70, contact

your nearest OMRON representative.

%

WARNING

Never open the safety laser scanner F3G-C1R70. The system does not contain any

components that can be repaired or maintained by the operator.

33

Page 35

Chapter 10 Instruction Manual

t

F3G-C1R70

Troubleshooting

10 Troubleshooting

10.1 Correcting faults

All the indicators are off and the rotating scanning head is not rotating:

• Power supply 18 … 30 V (24 V ± 25)%) present?

• Fuse intact?

• Plug correctly mounted on the safety laser scanner F3G-C1R70 and tightly connected?

• Connect the power supply with correct polarity?

The ON-state indicator (green LED) does not light up, Output contacts are open:

• Clean the optical surface (see Section 7.3 “Regular examinations” on page 30).

• Check power supply for high current.

• Connect the computer and display the CSL diagnosis.

Right-click on the device symbol in the navigation area > Diagnosis > Show.

!

• If you cannot solve the problem, please contact to your nearest OMRON representative.

Fig. 28: System error

indications

!

Objects within the monitored areas are not detected:

• Is the diagnostic indicator (yellow LED) lit or blinking?

– Yes: the safety laser scanner F3G-C1R70 has found an error: Check the optical surface

and the reference target.

– No: With the aid of the computer and the CSL, check the definitions for the protective

and warning field.

Right-click on the device symbol in the navigation area > Configuration draft > Edit field

setting…

Objects are reported within the monitored areas without actually existing:

• Check the surroundings for changes (e.g. structural alterations) that may have taken

place since configuration.

• Rain, snow, smoke and dust could be the cause of the spurious object detection!

10.2 System error indications

Diagnostic indicator (Yellow LED) Meaning

No error

Error at reference target

Rotational frequency error

Comparison error

Relay error

0.5 s 0.5 s

ON OFF

Error, self-

No configured fields

Repetition 8 sRepetition 8 s

est

34

Page 36

Instruction Manual Chapter 11

F3G-C1R70

Technical data

11 Technical data

11.1 Data sheet

Tab. 4: Technical data for

the safety laser scanner

F3G-C1R70

Safety classes

Safety category Type 3 ESPE acc. to EN/IEC 61)496-1

error-proof acc. to EN/IEC 61)496-1

Laser protection class Laser Class 1 acc. to EN60825-1, IEC825-1,

Laser Class I of FDA (21 CFR1040.10)

Characteristic data for the safety laser scanner F3G-C1R70

Measurement and tolerance

range

Range for a safe detection of

the “nominal leg”4)

Detection capability Non-transparent:

Response time 280 ms

Reactivation time 200 to 5000 ms (adjustable)

Maximum scanning angle 300°

Laser and angular measurement

Laser diode Infrared laser diode (Avalanche Photo Diode)

Wavelength 905 nm

Pulse frequency 5.76 KHz + 5)%

0 to 7.5 m

0 to 6 m (incl. safety supplement)

70 mm min. in diameter (with 1.8% min. reflectivity)

Scanning frequency 8 Hz + 5)%

Scanning angle 300°

Angle encoder resolution 360)×)4 increments

Point resolution 0.5°

Optics (co-axial transmitter and receiver optics)

Laser beam divergence 15 mrad

Focal length 30 mm

Optical surface diameter 30 mm

Power supply

Supply voltage 24 V DC ± 25)% (ripple 5Vp-p max.) without voltage

drop due to cable, (via a safety insulating transformer

acc. to IEC 742, see section 5.2 “Connecting the

power supply and signal cable” on page 25).

Current uptake Approx. 1 A at 24 V DC

Switch on current 2 A for 100 ms

Power consumption 24 W total

Circuit protection Fuse 3.15 A medium slow blow

4)

Definition of the “nominal leg”: black cylinder with 70 mm diameter and 1.8)% reflectivity. This corresponds

approximately to a leg in child’s clothing made of black corduroy.

35

Page 37

Chapter 11 Instruction Manual

F3G-C1R70

Technical data

Tab. 4: Technical data for the

safety laser scanner F3GC1R70 (continued)

Housing and environmental resistance

Material Housing: Aluminum

Optical surface, Indicator: Glass

Degree of protection IP 65 (IEC 60529)

Length 168 mm

Width 108 mm

Height 176 mm

Weight 3.5 kg

Ambient temperature During operation: 0 to 50 °C

During storage: -20 to 70 °C

Ambient humidity During operation: 5 to 95 %RH (without condensation)

During storage: 5 to 95 %RH (without condensation)

Vibration resistance Normal operation: 10 to 55 Hz,

double amplitude 0.7 mm,

X, Y and Z directions 20 sweeps

Shock resistance Normal operation: 100 m/s2,

X,Y and Z directions 1000 times

Interfaces

Data interfaces to computer RS 232: 9600 baud, 8 data bits, 1 stop bit, no parity

Signal outputs for warning field,

OSSD1, OSSD2

Cable Connection

Interface connection 14-pin circular connector (Binder: Series 423)

24 V DC/signal connection 8-pin circular connector (Binder: Series 423)

Cable

(optional)

Accessories

Accessories Instruction manual, CSL on CD-ROM, Mounting screws

for power supply

and output

for PC interface 5 m max., allowable bending radius: 112 mm

Potential-free relay outputs, max. 2 A, max. 30 V,

purely Ohmic load, number of operations 2 million,

Self-resetting fuse (2 A)

0.5 mm2 x 8 cores, with braided wire shield,

20 m max., allowable bending radius: 90 mm

36

Page 38

Instruction Manual Chapter 11

F3G-C1R70

Technical data

11.2 Device accuracy and safety supplements

The accuracy of the device depends on distance. Accuracy is as follows:

Tab. 5: Accuracy of the

F3G-C1R70 in relation to

distance

Distance up to Safety supplement

2 metres5) 25 cm

3 metres5) 35 cm

4 metres5) 45 cm

5 metres5) 55 cm

6 metres5) 70 cm

All possible influences, and particularly the reflective properties of the materials that could

come into question and all background effects, have been taken into consideration in

these tolerances.

Please note that when programming the device the safety supplement must be calculated

in.

5)

All distance figures include safety supplement.

37

Page 39

Chapter 12 Instruction Manual

F3G-C1R70

Order data

12 Order data

12.1 Delivery

The following components are included in the safety laser scanner F3G-C1R70 package:

• Safety laser scanner F3G-C1R70 qty. 1

• Instruction manual (this manual) qty. 1

• Notes to user qty. 1

• CD-ROM including CSL (Configuration Software for Laserscanner) and the users manual

for the CSL qty. 1

• Mounting screw set

– 4 bolts (M)4)×)10)

– 4 washers

– 4 locking washers

12.2 Optional accessories

• Power supply cable F39-JG5A (5m)

• Interface cable F39-JG5R (5m)

38

Page 40

Instruction Manual Chapter 13

Appendix

F3G-C1R70

13 Appendix

13.1 Dimensional drawings, safety laser scanner F3G-C1R70

Approx. 60

Interface cable

Bending radius 90 mm min.

Bending radius 112 mm min.

Power cable

Min. 175 distance

56.5

115

±1

137.5

Diagnostic indicator

Warning indicator

OFF-state indicator

ON-state indicator

176

11

Mounting area

Interface protective cap

176

Interface connector

±1

±1

178

158

10

Power supply connector

Fuse 3.15 A

Earth terminal

15.5

19

15

Holes diagram, four-point fastening

+0.2

4 × 4.5

Fig. 29: Dimensional

drawings, safety laser

scanner F3G-C1R70

mm

115

144

±0.2

Fastening thread M 4 × 10 deep

±0.2

86

Mounting area

Unit: mm

39

Page 41

Chapter 13 Instruction Manual

F3G-C1R70

Appendix

13.2 Standards and directives

The most important standards and directives, valid for the use of opto-electronic protective

devices in Europe, are listed below. Further regulations may be of importance to you,

depending on the type of use. Further information on device-specific standards can be

obtained from the authorities responsible, or from your trade association.

If the machine or vehicle is to be operated in a country that does not belong to the

European Union, we recommend that you contact the plant operator or local authorities.

On the application and installation of protective equipment

• The Machinery Directive 98/37/EC

• Safety of machinery – Basic concepts, general principles for design (EN 292-1, -2)

• The safety of integrated production systems (DIN EN 1921)

• Safety of machinery – Electrical machine equipment – Part 1: General requirements

(EN 60)204)

• Safety of machinery – Safety distances to prevent danger zones being reached by the

upper limbs (EN 294)

• Safety requirements for robots (EN 775)

• Safety rules for electro-sensitive protective equipment on power-driven equipment

(ZH 1/597)

• Safety of machinery – The positioning of protective equipment in respect of approach

speeds of parts of the human body (EN 999)

• Safety of machinery – Principles for risk assessment (EN 1050)

On the construction and equipping of protective equipment

• Safety of machinery – Electro-sensitive protective equipment – Part 1: General

requirements (IEC/EN 61)496-1 as well as based on IEC/EN 61)496-3)

• Basic safety considerations for MCR safety systems (DIN V 19)250)

• Safety of machinery – Electrical equipment of machines – Part 1: General requirements

(EN 60)204)

• Safety of machinery – Safety-related parts of control systems – General principles for

design (EN 954)

40

Page 42

Instruction Manual Chapter 13

F3G-C1R70

Appendix

13.3 Checklist for the manufacturer

PNSPO!

Check list for the manufacturer/OEM for the installation of

electro-sensitive protective equipment (ESPE).

The details on the items listed below must be available at the latest when the system is commissioned for the first

time, depending, however, on the various applications the requirements of which must be reviewed by the

manufacturer/OEM.

This checklist should be retained and kept with the machine documentation to serve as reference during recurring

tests.

1. Have the safety rules and regulations been observed in compliance with the

directives/standards applicable to the machine?

2. Are the applied directives and standards listed in the declaration of conformity? Yes No

3. Does the protective device comply with the required safety category? Yes No

4. Is the access to the hazardous area/ hazardous point only possible through the protective field

of the ESPE?

5. Have appropriate measures been taken to prevent (mechanical point-of-operation guarding) or

monitor unprotected presence in the hazardous area when protecting a hazardous

area/hazardous point and have these been secured against removal?

6. Are additional mechanical protective measures fitted and secured against manipulation, which

prevent reaching below, above or around the ESPE?

7. Has the maximum shutdown and/or stopping/run-down time of the machine been measured,

specified and documented (at the machine and/or in the machine documentation)?

8. Has the ESPE been mounted such that the required safety distance from the nearest hazardous

point has been achieved?

9. Are the ESPE devices properly mounted and secured against manipulation after adjustment? Yes No

10. Are the required protective measures against electric shock in effect (protection class)? Yes No

11. Is the command unit for resetting the protective equipment (ESPE) or restarting the machine

present and correctly installed?

12. Are the outputs of the ESPE (OSSDs) integrated in compliance with the required safety category

and does the integration comply with the circuit diagrams?

13. Has the protective function been checked in compliance with the test notes of this

documentation?

14. Are the given protective functions effective at every setting of the operating mode selector

switch?

15. Are the switching elements activated by the ESPE, e.g. contactors, valves, monitored? Yes No

16. Is the ESPE effective over the entire period of the dangerous state? Yes No

17. Once initiated, will a dangerous state be stopped when switching the ESPE on or off and when

changing the operating mode, or when switching to another protective device?

This checklist does not replace the initial commissioning, or the regular inspection by specialist personnel.

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

41

Page 43

Chapter 13 Instruction Manual

F3G-C1R70

Appendix

13.4 List of tables

Tab. 1: Status of the LEDs for the safety laser scanner F3G-C1R70 ...............................16

Tab. 2: Plug allocation for connection of the power supply and the signal cables.......... 25

Tab. 3: Pin allocation of the interface cable ......................................................................27

Tab. 4: Technical data for the safety laser scanner F3G-C1R70...................................... 35

Tab. 5: Accuracy of the F3G-C1R70 in relation to distance.............................................. 37

13.5 List of illustrations

Fig. 1: Schematic diagram of the monitored areas............................................................ 6

Fig. 2: Calculation of the safety distance for a stationary application.............................. 8

Fig. 3: Example: minimum distance for stationary application.......................................... 9

Fig. 4: Example: maximum protective field size and safety supplements for

stationary applications............................................................................................10

Fig. 5: Calculating the minimum distance for automated guided vehicles..................... 11

Fig. 6: Prevent undercutting of the AGV protective field.................................................. 12

Fig. 7: Example: minimum distance for automated guided vehicles ..............................13

Fig. 8: Example: maximum protective field size and safety supplements for AGVs....... 13

Fig. 9: Construction of the safety laser scanner F3G-C1R70 .......................................... 15

Fig. 10: LEDs on the safety laser scanner F3G-C1R70 ...................................................... 16

Fig. 11: Housing connection side ....................................................................................... 17

Fig. 12: Schematic diagram of operating principle.............................................................18

Fig. 13: Configuration of monitored areas .......................................................................... 19

Fig. 14: Minimum distance to the floor............................................................................... 21

Fig. 15: Mounting several safety laser scanners................................................................ 21

Fig. 16: Minimum distance of the area monitored by the safety laser scanner F3G-

C1R70 from surrounding objects........................................................................... 22

Fig. 17: Example of integration of the warning field signal............................................... 23

Fig. 18: Example of integration of OSSDs. The wiring is to be laid down in such a

way that it is protected against mechanical effects. ............................................ 24

Fig. 19: Plug allocation for connection of the power supply and the signal cables..........25

Fig. 20: Dimension of the power supply cable.................................................................... 25

Fig. 21: Example of the power supply and grounding of stationary applications ............. 26

Fig. 22: Example of the power supply and grounding on a transport vehicle ...................26

Fig. 23: Pin allocation of the interface cable ......................................................................27

Fig. 24: Dimension of the interface cable...........................................................................27

Fig. 25: Place F3G-C1R70 on its side in the original packaging........................................ 31

Fig. 26: Place the upper membrane cushion on top of the F3G-C1R70........................... 31

Fig. 27: Put the accessories in the original packaging....................................................... 32

Fig. 28: System error indications......................................................................................... 34

Fig. 29: Dimensional drawings, safety laser scanner F3G-C1R70 .................................... 39

42

Loading...

Loading...