Page 1

Cat. No. E77E-EN-01

ZX-T Series

F3EM2

Measuring Light Curtain

OPERATION MANUAL

Page 2

Manufacturer: OMRON Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp, THE NETHERLANDS

WWW www.industrial.omron.eu

User‘s Manual: Version 0.2 dated 18-10-2011

Page 3

Precautions

WARNING

The F3EM2 multi-beam photoelectric sensor with beam evaluation function is not a safety

component for ensuring the safety of people which is defined in EC directive (2006/42/EC) or

by any other regulations or standards.

GENERAL INFORMATION

The instructions in this manual must be followed in order to safeguard correct installation. The

barrier does not contain any parts that are subject to maintenance; do not remove any

electronic parts from the housing for any reason. In case of malfunction, please contact your

sales representative with a description of the failure found and its period of operation. Do not

touch the front protective cover with your hands as dust and/or grease may decrease

performance.

Precautions

OPERATING ENVIRONMENT

Do not use the light curtain in locations with explosive or flammable gas. Make sure that the

product is operated in accordance with IP65 standards. Do not subject the light curtain to

excessive shock when mounting. When using the light curtain in the vicinity of an inverter

motor, be sure to connect the protective earth ground wire of the motor to earth. Failure to

ground the motor may result in malfunction of the light curtain. Further it is recommended to

use shielded cables and to connect the shield to the ground in such cases.

CLEANING

When cleaning the front covers please do not use woollen cloths or organic solvents. The

interval between cleaning depends on conditions in the environment (dust, fog).

POWER SUPPLY VOLTAGE AND OUTPUT LOAD

Do not connect an AC power supply to the Sensor. If AC power (100 VAC or more) is supplied

to the Sensor, it may explode or burn. Make sure that the power supply to the Sensor is within

the rated voltage range. If a voltage exceeding the rated voltage range is supplied to the

Sensor, it may explode or burn.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

1

Page 4

Page 5

Table Of Contents

Precautions ........................................................................................... 1

Chapter 1 Overview

1-1 Applications ............................................................................................1-2

1-2 Model line up ..........................................................................................1-3

Chapter 2 Installation

2-1 General...................................................................................................2-2

2-2 Mechanical installation ...........................................................................2-3

2-3 Operating environment ...........................................................................2-4

2-4 Operating distances................................................................................2-4

2-5 Wiring & output circuit.............................................................................2-5

2-6 Setting the internal selector-switches .....................................................2-7

Chapter 3 Operation - General aspects and definitions

3-1 Beam order.............................................................................................3-2

3-2 Output modes .........................................................................................3-3

Chapter 4 Operation - Analog models

4-1 DIP switch setting ...................................................................................4-2

4-2 Analog output value................................................................................4-3

Chapter 5 Operating serial output models (RS-232C)

5-1 DIP switch setting - Overview.................................................................5-2

5-2 Transmission speed (baud rate).............................................................5-4

5-3 Beam aquisition and data aquisition.......................................................5-4

5-4 Communication protocol for serial output ...............................................5-5

Chapter 6 Order codes

Chapter 7 Technical specifications

7-1 Ratings ...................................................................................................7-2

Chapter 8 LED indicators and error indication

8-1 LED indication on receiver unit...............................................................8-2

8-2 LED indication on emitter unit.................................................................8-3

8-3 Troubleshooting for error indication........................................................8-4

Chapter 9 Dimensions

Chapter 10 Accessories

10-1 Mounting bracket ..................................................................................10-2

10-2 Cables ..................................................................................................10-2

Manual Revision History .............................................................................. 1

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

3

Page 6

4

Page 7

Overview

1-1 Applications ..................................................................1-2

1-2 Model line up.................................................................1-3

1

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 8

1-1 Applications

1-1 Applications

F3EM2 is a multi-beam measuring light curtain designed for easy height and profile

measurement for various applications. Programming via dip switches makes it easy to set up

F3EM2 everywhere without external controller or Remote PC. Due to its robust housing

F3EM2 is also suitable for hash environments in industry.

Overview

Volume measurement Position control

Profile

scan Hole detection

1-2

Wood industry

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 9

1-2 Model line up

F3EM2 is provided with 3 output versions:

Analogue 0-10 V

RS-232C + analogue 0-10 V

RS485 + analogue 0-10 V (on request)

1-2 Model line up

F3EM2 is available in two resolutions:

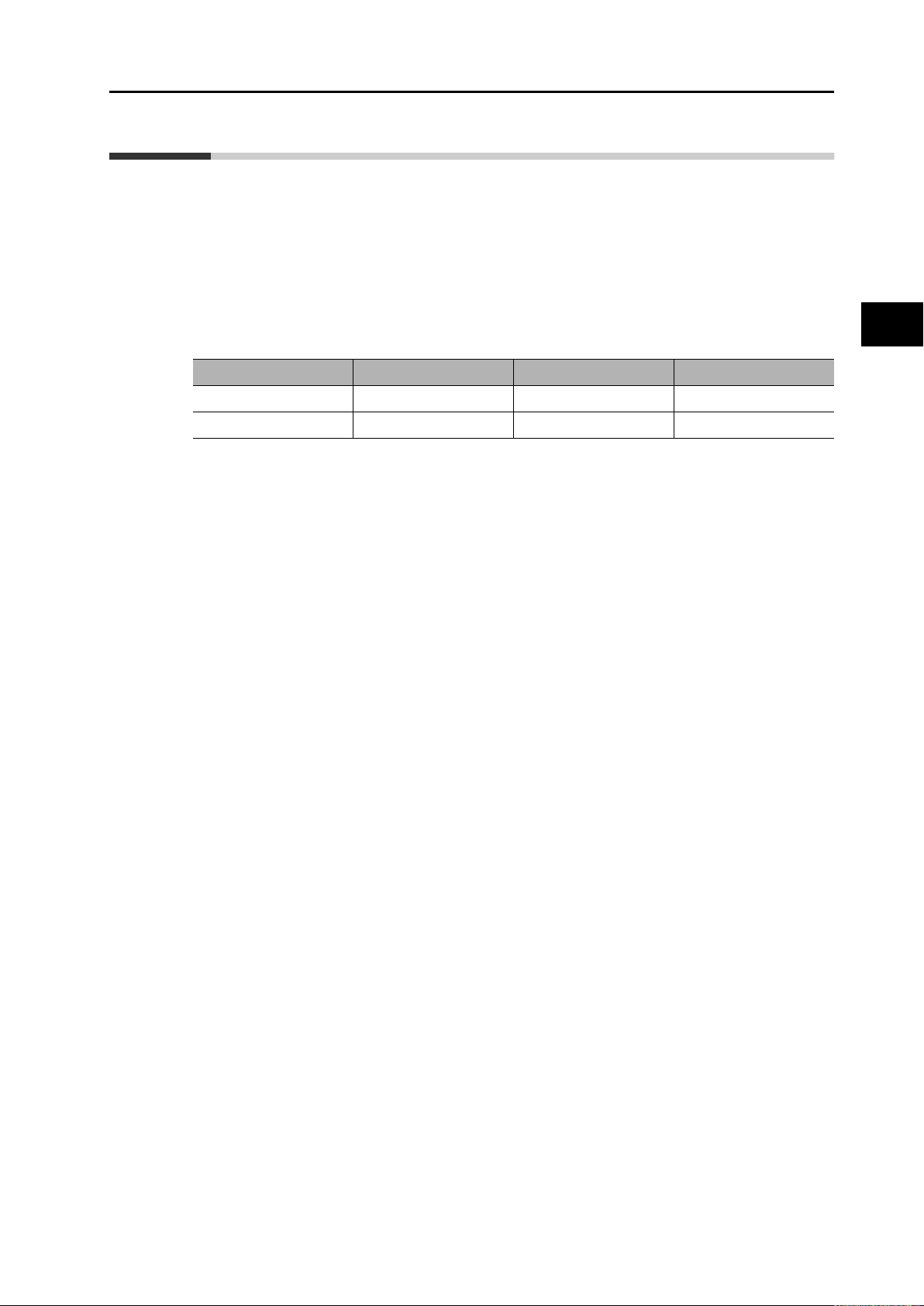

Model Sensing distance Pitch resolution Min. detectable object

F3EM2-005-[…] 0 to 3 m 5 mm 10 mm

F3EM2-018-[…] 0 to 15 m 18 mm 30 mm

Models with 7.5mm resolution are available upon request.

Due to its modular design F3EM2 can be provided in various sizes. For standard sizes please

refer to model list in chapter 6.

1

Overview

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

1-3

Page 10

Page 11

Installation

2-1 General ..........................................................................2-2

2-2 Mechanical installation ................................................2-3

Mounting accessories ..................................................................... 2-3

Additional mounting rigidity ............................................................. 2-3

Mechanical Mounting ...................................................................... 2-4

2-3 Operating environment ................................................2-4

2-4 Operating distances .....................................................2-4

Analogue models ............................................................................ 2-5

Models with serial & analogue output ............................................. 2-6

2-5 Wiring & output circuit .................................................2-5

2-6 Setting the internal selector-switches........................2-7

2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 12

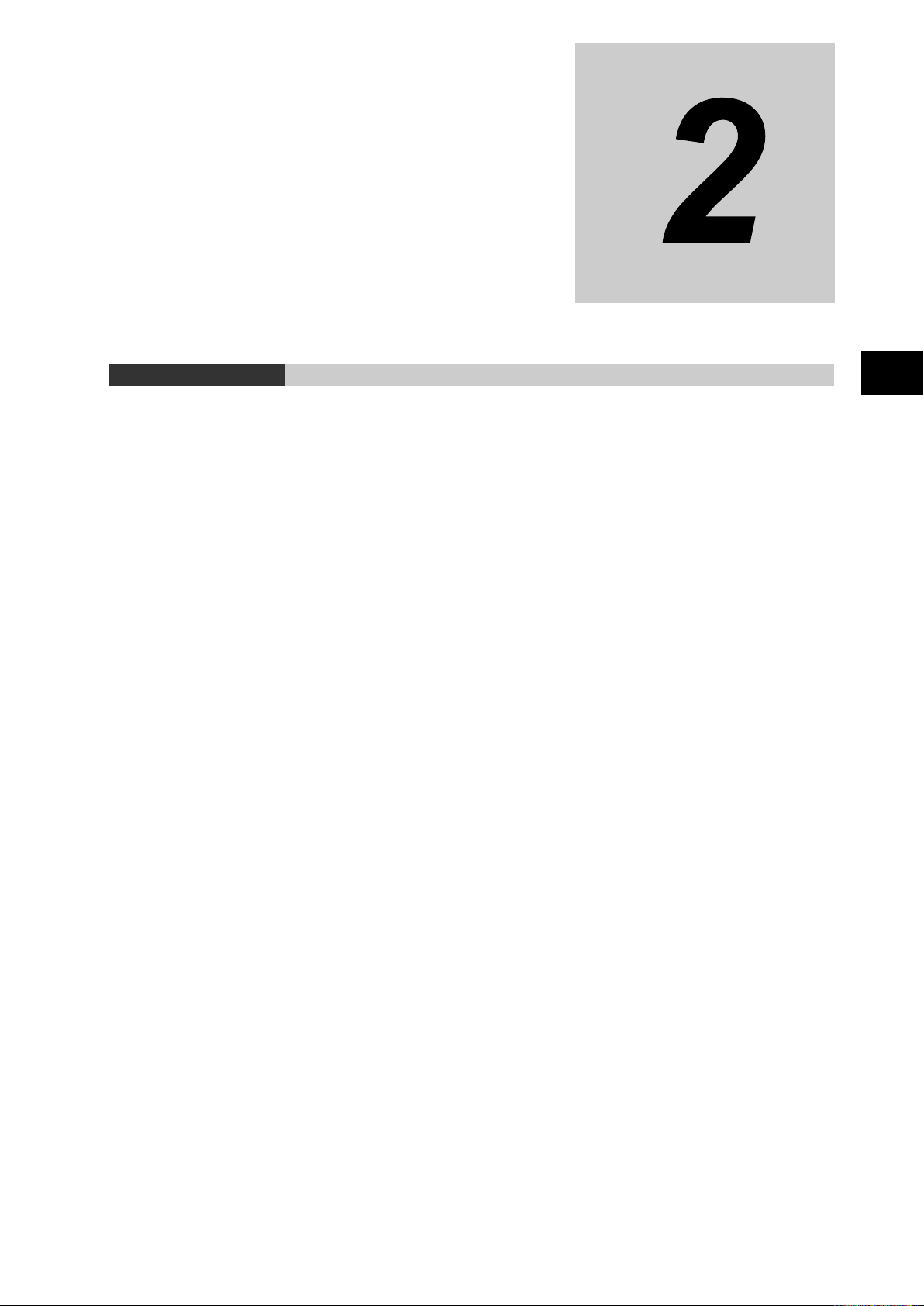

2-1 General

X: measuring direction

L: Maximum measurement area

D: System resolution

2-1 General

The light curtain consists of one bar with light emitting optical elements and of one with

receiving optical elements. The photosensitive elements are scanned in sequence, thus

broken rays are detected.

F3EM2 features optical synchronisation and does not require synchronization wire between

transmitter and receiver. The sync-function is provided by the upper beam located on the

opposite side of the connector (see illustration below). During operation this beam must always

be kept free. Otherwise it will result a loss of synchronism between the transmitter and

receiver.

Installation

1st BEAM

D

x

X: measuring direction

L

L: Maximum measurement area

D: System resolution

For applications where also the upper beam is needed for measurement synchronization by

wire can be activated (see ’4-1 DIP switch setting’ on page 4-2). In this case transmitter and

receiver must be connected by a sync-wire (see ’2-5 Wiring & output circuit’ on page 2-5).

x

D

L

2-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 13

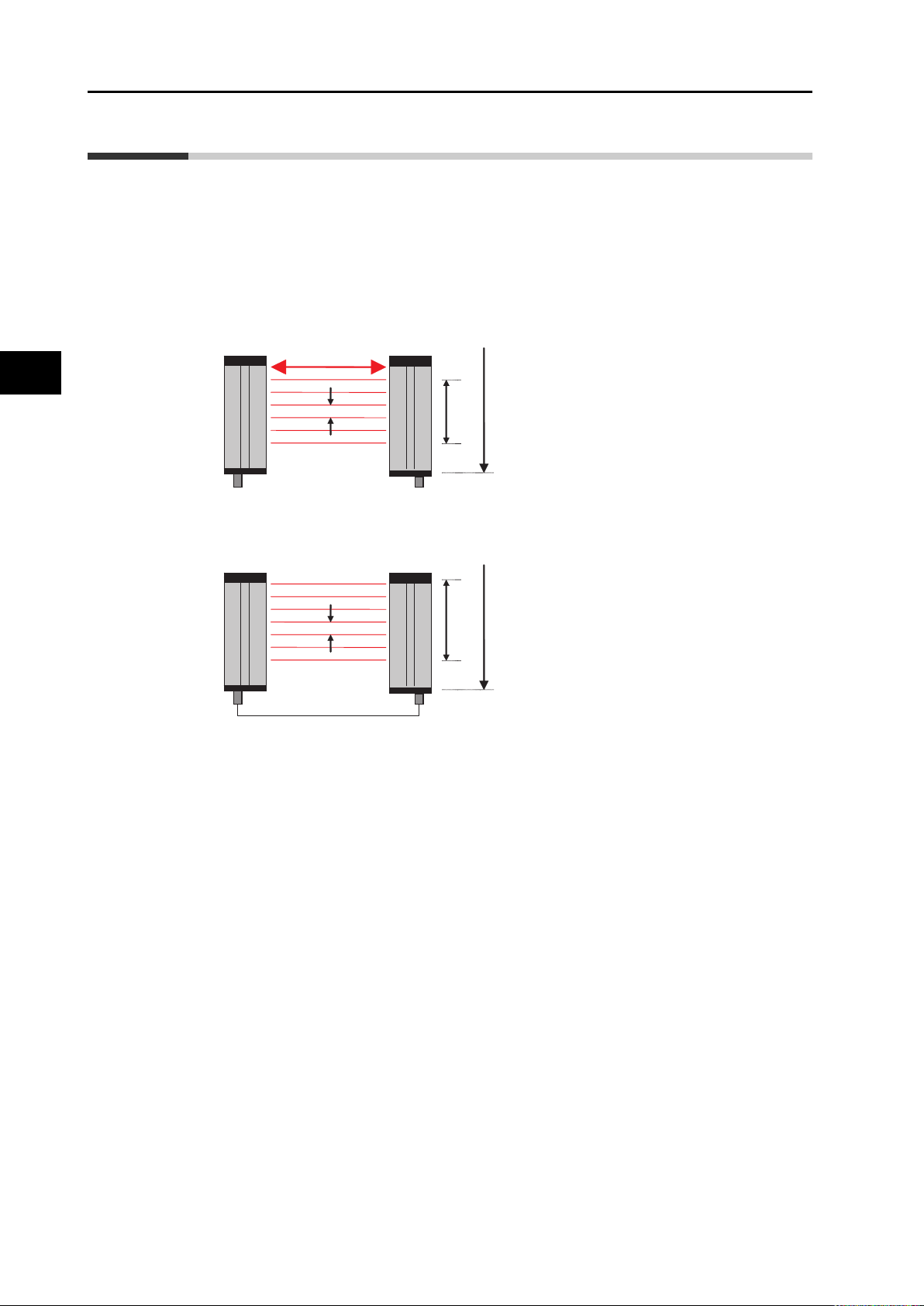

2-2 Mechanical installation

ID Description

1 movable M6 bolt

2 fixing braket

3 M6 washer

4 M6 Grower

5M6 nut

Mounting accessories

The F3EM2 system is mechanically installed by using the T-slots on the two sides or the backside of the housing.

Use the movable bolts, washers, growers and nuts to fix the mounting brackets as shown in

the picture

2-2 Mechanical installation

2

Note: Shipment contains different quantity of brackets, depending on the length of the SLC. Longer SLC

contains a higher number of brackets, following the rule of every 400 mm one bracket.

Additional mounting rigidity

It is recommended that the distance between the mounting brackets is 400 mm or less for

optimum performance of the F3EM2 system.

Installation

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

2-3

Page 14

2-3 Operating environment

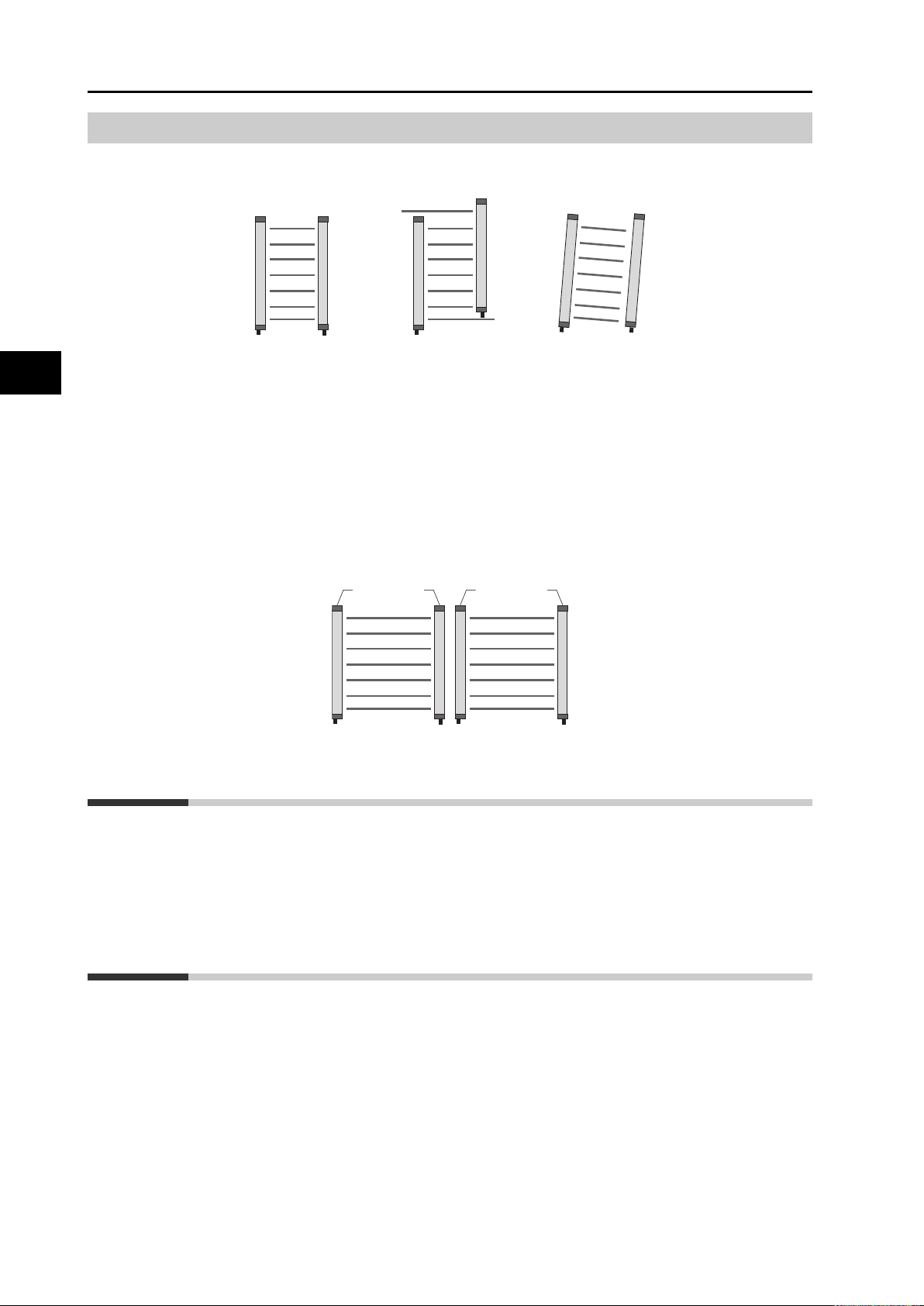

OK NG NG

Mechanical Mounting

Please mount the light curtains in proper alignment as shown in the pictures below by using

the brackets provided with the light curtains.

For serial output models the STROBE input can be used for easier alignment. Please follow

this procedure:

• Turn on the light curtain with the STROBE input connected to +24 VDC

• Move the light curtain to reach the alignment using the led indication on receiver (see led

table 5-1)

• Turn off the light curtain and remove the +24 VDC strobe input connection

Installation

2-3 Operating environment

2-4 Operating distances

If F3EM2 is installed at long distances the laser alignment aid F39-TGR-LLK2-CL provides a

visible laser spot for simplified installation.

If several light curtains are installed close to each other, interference of the light curtains must

be avoided. In this case the assembly should be carried out as follows:

TX TXRXRX

The area for the installation of the light curtain must be suitable according to the technical

specifications. The temperature of the environment, interference caused by electromagnetic

disturbance and ambient light must be considered. Please contact the manufacturer for any

information not contained in this manual.

The operating distances, which are given in the technical specifications, are guaranteed values

for reliable operation. Operating F3EM above the specified sensing distance may cause

greater sensitivity to vibration and possible electro magnetic disturbances.

If the F3EM2 is operated in a distance <1m, the sensitivity can be set to NEAR operation by

dip-switch setting at transmitter (see ’4-1 DIP switch setting’ on page 4-2).

This should be considered for following application conditions:

a) Multiple light curtains are installed close to each other (avoiding mutual interference)

b) Detection of small or semi-transparent objects

If none of above mentioned cases applies, FAR setting should be kept in order to provide

maximum detection reliability.

2-4

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 15

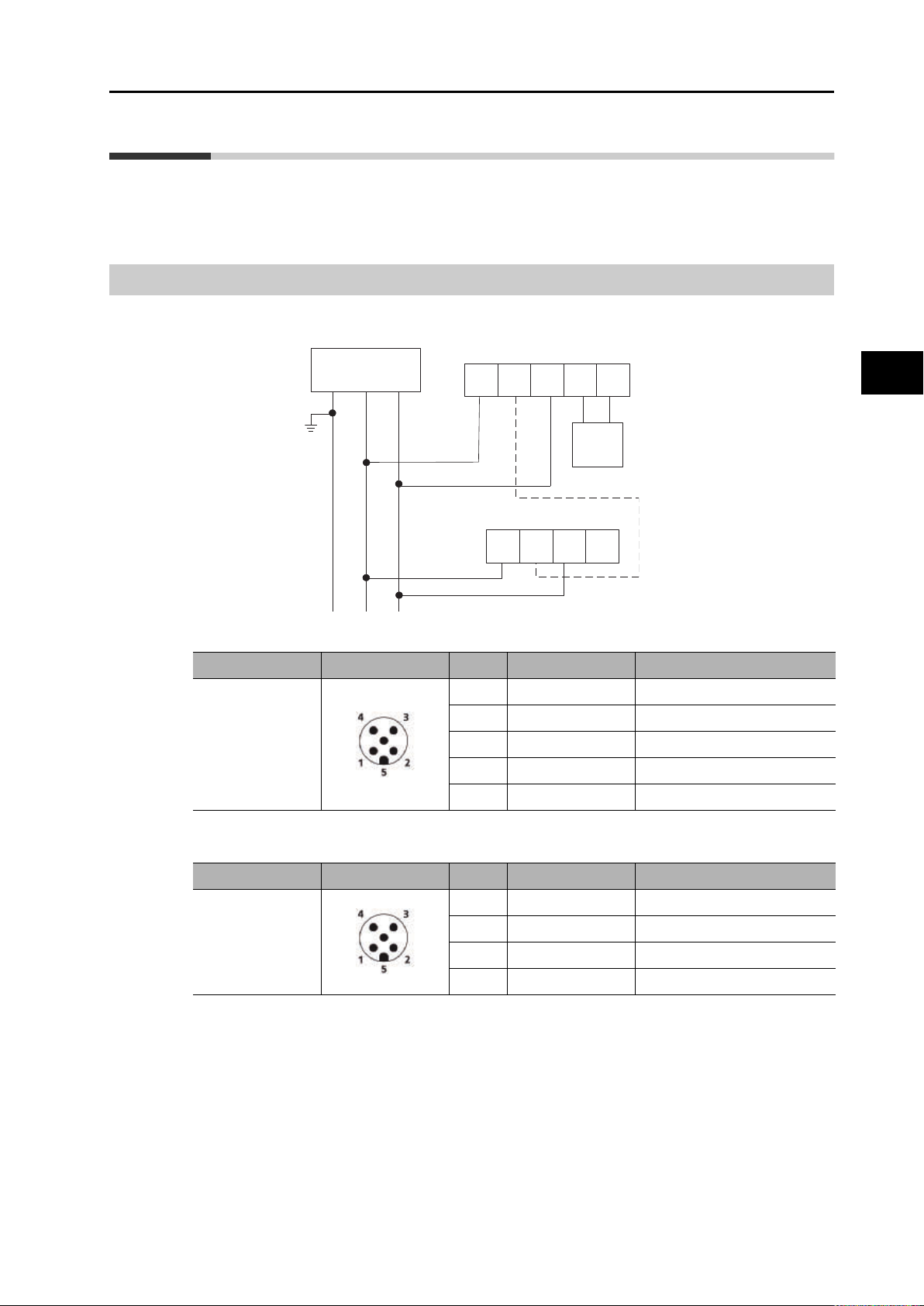

2-5 Wiring & output circuit

The F3EM2 can be operated with analogue output or serial output. Please connect the light

curtain as described below:

Analogue models

2-5 Wiring & output circuit

Connector PIN assignment - Receiver

Type Internal wiring Pin Colour Signal name

M12 n5 pole

Variable

Power Supply

Earth

Ground +24 VDC 0 VDC

RECEIVER F3EM2

analogue out only

Br Wh Bl Bk

EMITTER F3EM2

Br Wh Bl Bk

1Brown +Vs

2 White Wire sync

3Blue 0V

4 Black Analogue +

Gr

Analogue

2

Installation

5 Gray Analogue reference

Connector PIN assignment - Transmitter

Type Internal wiring Pin Colour Signal name

1Brown+Vs

2 White Wire sync

M12 n4 pole

3Blue 0V

4 Black Not used

For synchronization by wire please connect white wires of transmitter and receiver.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

2-5

Page 16

2-5 Wiring & output circuit

Safety Points

Models with serial & analogue output

Variable

Power Supply

Earth

Ground +24 VDC 0 VDC

Wh Br Gn Ye Gr Pk Bl Rd

RECEIVER F3EM2

Connector PIN assignment - receiver

Installation

RS out

S

1

EMITTER F3EM2

Br Wh Bl Bk

Analogue

SYNC.

Type Internal wiring Pin Colour Signal name

1

White Strobe input/alignment

(normally open)

2Brown +Vs

3 Green RS+ or RS TX

M12 n8 pole

4 Yellow RS- or RS RX

5 Gray Analogue +

6 Pink Analogue reference

7Blue 0V

8 Red Wire synch

Connector PIN assignment - transmitter

Type Internal wiring Pin Colour Signal name

M12 n4 pole

For synchronization by wire please connect the red wire of receiver with white wire of

transmitter.

We recommend protecting the control unit with an external fuse, whose rated breaking current

must be 1A, even if the appliance is provided with its own internal, self-resetting fuse.

2-6

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

1Brown +Vs

2 White Wire sync

3Blue 0V

4 Black Not used

Page 17

2-6 Setting the internal selector-switches

Precautions for Correct Use

1 2 3 4 5 6 7 8

OFF

ON

1 2 3 4 5 6 7 8

OFF

ON

2-6 Setting the internal selector-

switches

All the operations listed below must only be carried out when the receiver is disconnected to

the power supply.

Settings like operation mode, baud rate and distance can be changed by selector switches.

To access the selector switches unscrew the end cap of the receiver and transmitter unit:

2

There are two lines of dip switches in each transmitter and receiver. The settings must

be done for both lines. Change the setting of the dip-switch and close the cap again. The light

curtain can now be reconnected to the power supply.

The functions of dip-switches are explained in chapter 4-1 ’DIP switch setting’ on page 4-2.

Installation

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

2-7

Page 18

Page 19

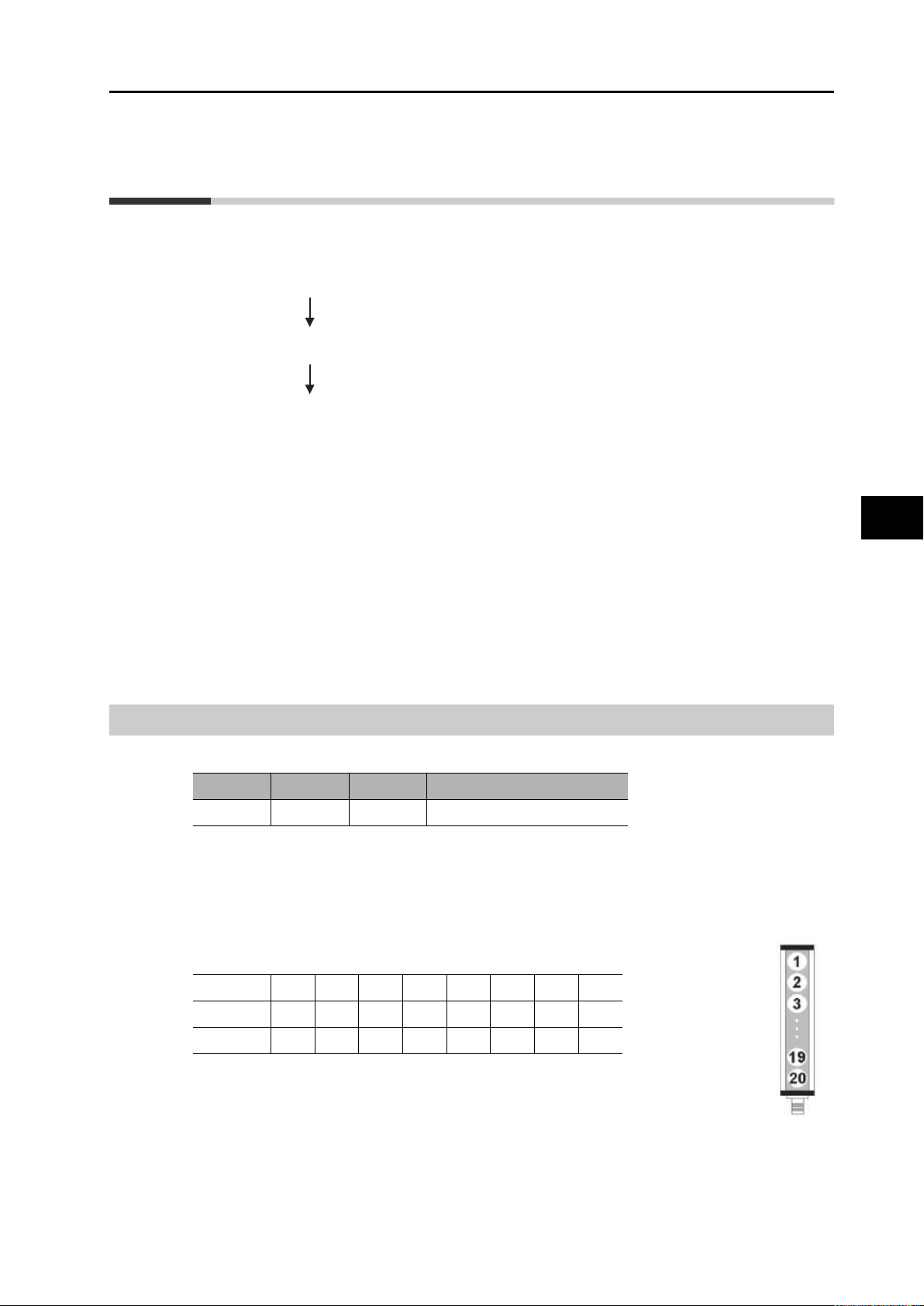

Operation - General aspects and definitions

F3EM2 is not a safety device. The usage of F3EM2 as Safety protection

equipment is dangerous and prohibited and expose personnel to serious injury.

3-1 Beam order....................................................................3-2

3-2 Output modes ...............................................................3-3

3

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 20

3-1 Beam order

Safety Points

F3EM2 is not a safety device. The usage of F3EM2 as Safety protection equipment is

dangerous and prohibited and expose personnel to serious injury.

The light curtain consists of an array of beams that can be obscured by an object between

transmitter and receiver. The status of each beam (open or blocked) is controlled every scan

cycle and the output reflects the current status accordingly. Thus size and position of objects

can be detected.

Different output modes are available to adapt F3EM2 operation to the given application and to

simplify installation into the machine.

3-1 Beam order

Beams are numbered in the way as shown in the picture; starting from beam 1

opposite to connector to the last beam at the connector side of the light curtain.

Operation - General aspects and

Beam status in the protocol is defined as follows:

Beam open = 0

Beam blocked = 1

3-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 21

3-2 Output modes

The F3EM2 light curtain can provide various output modes and combination of these to

describe the position and the size of an object:

FBB (First Beam Blocked) First beam in chain obscured by object

FBM (First Beam Made) First beam in chain that is open

NBB (Number of Beams Blocked) Total number of blocked beams - no holes included

NAB (Number of Area Blocked) Number of beams from 1st blocked to last blocked beam

(including holes)

LBB (Last Beam Blocked) Last blocked beam in the chain

LBM (Last Beam Made) Last open beam in the chain

Bitmap The status of each beam (serial models)

Example:

FBM

FBB

1

3-2 Output modes

3

Operation - General aspects and defi-

LBB

LBM

9

In serial operation F3EM2 can transmit status of each single beam or a combination of two

output values. See 3 examples how this is reflected for each function:

Examples:

1

9

Case A Case B Case C

Case A Case B Case C

Function Output values Output values Output values

Bitmap

FBB + NBB 4 and 4 7 and 3 2 and 3

FBM + NAB 1 and 4 1 and 3 1 and 7

F3EM2 provides the status of

each single beam

1

9

F3EM2 provides the status of

each single beam

1

9

F3EM2 provides the status of

each single beam

LBB + NBB 7 and 4 9 and 3 8 and 3

LBM + NAB 9 and 4 6 and 3 9 and 7

Specification and settings of each function and the serial protocol configuration are described

in chapter 5 ’Operating serial output models (RS-232C)’ on page 5-1.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

3-3

Page 22

Page 23

Operation - Analog models

4-1 DIP switch setting.........................................................4-2

4-2 Analog output value .....................................................4-3

4

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 24

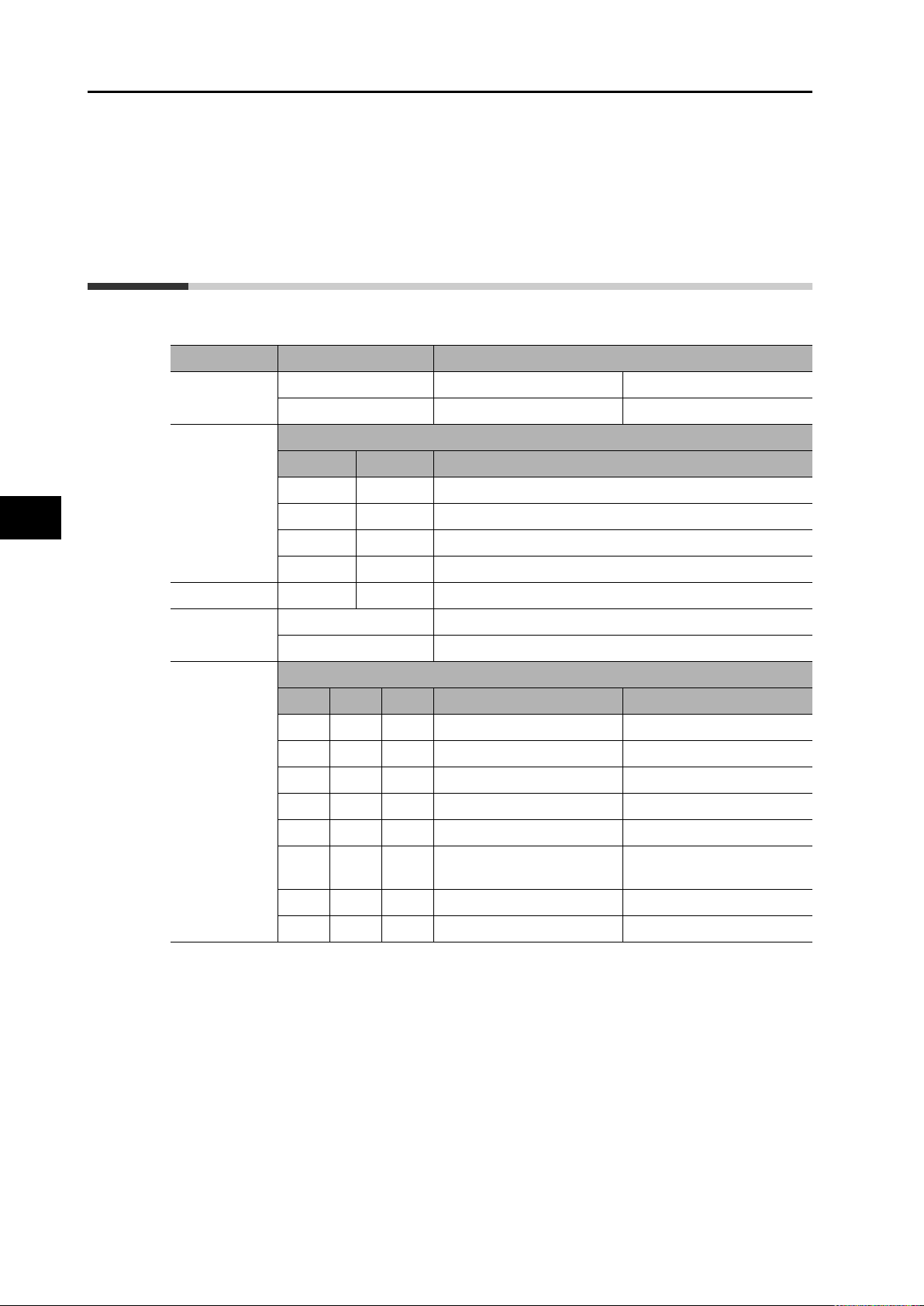

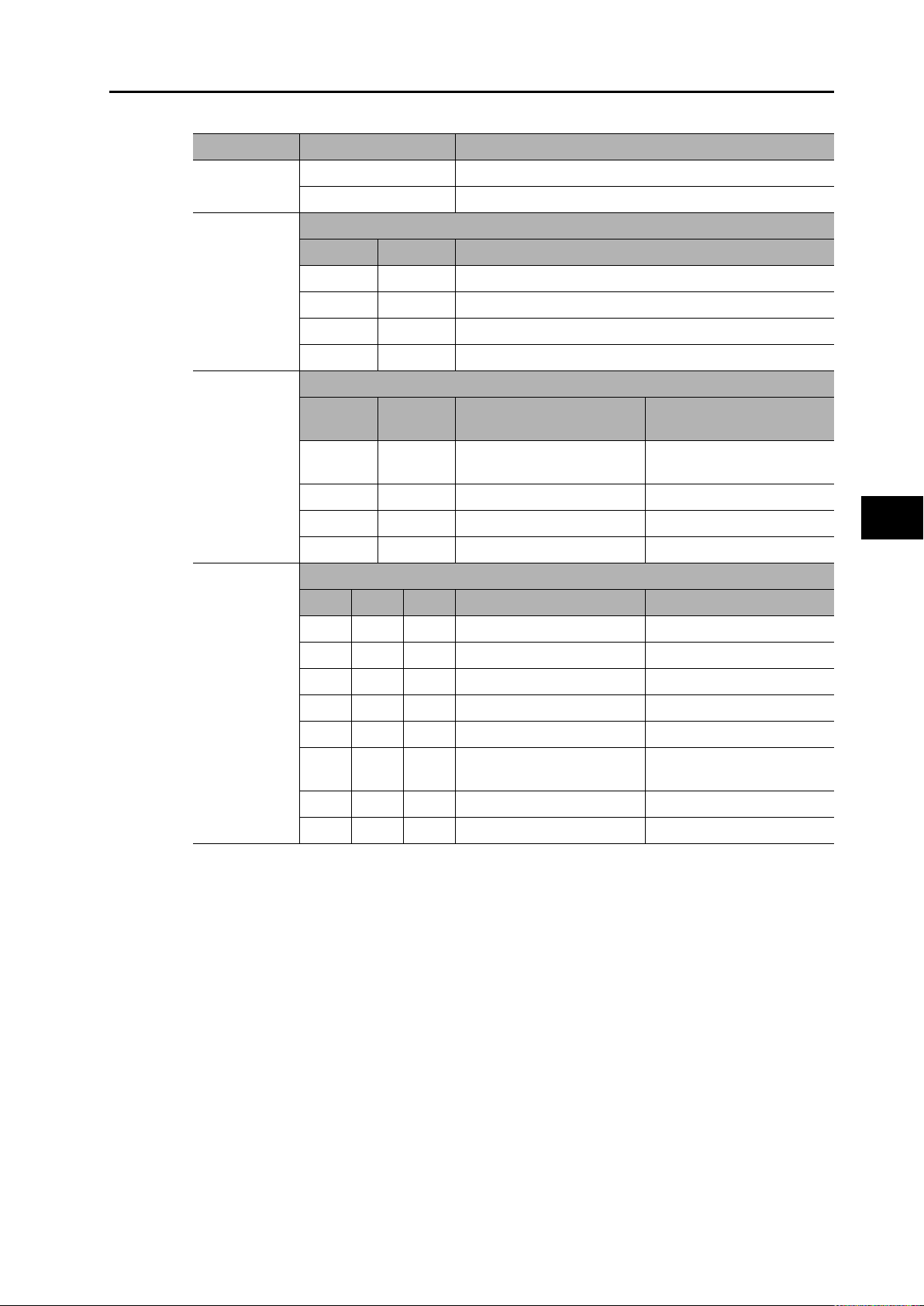

4-1 DIP switch setting

4-1 DIP switch setting

Transmitter:

Dip-SW Status Function

Receiver:

1

2 Not used

OFF OFF NAB (default)

3 + 4

5

6 Not used

7 Not used

8 Not used

Dip-SW Status Function

1

2

OFF ON LBB

ON OFF NBB

ON ON FBB

OFF OFF NAB (default)

OFF Optical Sync (default)

ON Wire sync

3 4 Output signal

OFF FAR (default)

ON NEAR

OFF Optical Synch (default)

ON Wire synch

OFF 0 to 10V (default)

ON 10 to 0V

3 4 Output signal

Operation - Analog models

3 + 4

5 Not USED

6 Not USED

7 Not USED

8 Not USED

There are two lines of dip switches in each transmitter and receiver. The settings must

be done for both lines.

4-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

OFF ON LBB

ON OFF NBB

ON ON FBB

Page 25

4-2 Analog output value

Output voltage

(total No° of beams blocked) 10

Total numbers of beams

---------------------------------------------------------------------------------------- V D C=

Output voltage

(index No° of first beam blocked) 10

Total numbers of beams

----------------------------------------------------------------------------------------------------VDC=

The output value has linear relationship to the number of interrupted beams (NBB or NBM

setting) or to the position index of beam (FBB or LBB).

Example for NAB setting:

Example for FBB setting:

The analogue output is refreshed every scanning cycle.

4-2 Analog output value

4

Operation - Analog models

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

4-3

Page 26

Page 27

Operating serial output models (RS-232C)

5-1 DIP switch setting - Overview......................................5-2

5-2 Transmission speed (baud rate) .................................5-4

5-3 Beam aquisition and data aquisition ..........................5-4

5-4 Communication protocol for serial output.................5-5

Bitmap of optics .............................................................................. 5-5

FBB + NBB ..................................................................................... 5-6

FBM + NAB..................................................................................... 5-6

LBB + NBB...................................................................................... 5-7

LBM + NBM .................................................................................... 5-7

Continues bitmap transmission ....................................................... 5-7

Bitmap + Analogue out (FBB) ......................................................... 5-8

Holes detection function.................................................................. 5-8

5

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 28

5-1 DIP switch setting - Overview

The RS-232C serial interface of F3EM is specified as follows:

• Full duplex operation

• Data format: 8-N-1 (bit start - 8-bit data - 1-bit stop - no parity)

• The signal on analogue output is calculated as shown in chapter 4-2 ’Analog output value’

on page 4-3

5-1 DIP switch setting - Overview

Dip switch setting transmitter:

Dip-SW Status Function

Operating serial output models

1

2+3

4 Not used

5

OFF OFF OFF Bitmap of optics (default) NAB (default)

OFF OFF ON FBB + NBB (4 byte total) NAB

OFF ON OFF FBM + NAB (4 byte total) LBB

6+7+8

OFF ON ON LBB + NBB (4 byte total) NBB

ON OFF OFF LBM + NAB (4 byte total) FBB

ON OFF ON

ON ON OFF FBB + LBB (4 byte total) NBB

ON ON ON Holes detection disabled

OFF Optical Synch (default)

ON Wire synch

RS baud rate

2 3 Speed

OFF OFF 9600bps (default)

OFF ON 19200bps

ON OFF 38400bps

ON ON 76800bps

OFF FAR (default)

ON NEAR

Output function

6 7 8 Serial output Analogue output

Continuous bitmap

transmission

disabled

5-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 29

5-1 DIP switch setting - Overview

Dip-switch setting receiver:

Dip-SW Status Function

1

OFF Optical Synch (default)

ON Wire synch

RS baud rate for serial operation

2 3 Speed

2+3

4+5

6+7+8

OFF OFF 9600bps (default)

OFF ON 19200bps

ON OFF 38400bps

ON ON 76800bps

Interrogation byte for serial operation

4 5

OFF OFF

OFF ON FBh / 11111011 0-10V

ON OFF FCh / 11111100 10-0V

ON ON FDh /11111101 10-0V

6 7 8 Serial output Analogue output

OFF OFF OFF Bitmap of optics (default) NAB (default)

OFF OFF ON FBB + NBB (4 byte total) NAB

OFF ON OFF FBM + NAB (4 byte total) LBB

OFF ON ON LBB + NBB (4 byte total) NBB

Hexadecimal code /

binary code

FAh

11111010 (default)

Output function

Analogue output

0-10V (default)

5

Operating serial output models (RS-

ON OFF OFF LBM + NAB (4 byte total) FBB

ON OFF ON

ON ON OFF FBB + LBB (4 byte total) NBB

ON ON ON Holes detection disabled

Continuous bitmap

transmission

disabled

There are two lines of dip switches in each transmitter and receiver. The settings must

be done for both lines.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

5-3

Page 30

5-2 Transmission speed (baud rate)

Precautions for Correct Use

5-2 Transmission speed (baud rate)

The baud rate can be set by DIP switch 2 and 3.

RS baud rate

2 3 Speed

OFF OFF 9600bps (default)

OFF ON 19200bps

ON OFF 38400bps

ON ON 76800bps

The baud rate must be set both on the receiver bar dip-switches as well as the transmitter bar

dip-switches to align the timing synchronism of the two bars.

5-3 Beam aquisition and data aquisition

In order to understand the functions of F3EM2 and to choose the right operation mode it is

important to differentiate:

Beam acquisition = Conditions of beams checked at one scanning cycle of the light curtain.

Data acquisition = Sum of beam acquisitions gathered in the time frame between 2 external

interrogations.

The light curtain saves the beam acquisition made at each scanning cycle and executes a

logical "OR" between the status of new acquired beams and the previous one.

See an example of a data acquisition resulting from two beam acquisitions:

Operating serial output models

Triggered by an interrogation code the light curtain sends the acquired data and cleans the

beam status memory again.

1 0 0 0 0 1

1 0 0 1 0 0 1 0 1

1 0 0 1 0 1 1 0 1

1 0 0

Previous beam acq.

Last beam acq.

Data ready to be sent

In practice this process enables for example the measuring of the maximum height of an

irregular shaped object that is moving through the light curtain. Thus only the relevant

information is transmitted.

Because the beams are scanned sequentially it can occur that a command or trigger arrives

before the scan is completed. In this case the scan is interrupted and the status of the scan

before is transferred in the response protocol.

Note:F3EM2 also provides continuous bitmap transmission. In this mode the light curtain continuously

sends each beam acquisition to the host / PLC. In this case however the host has to process a much

higher amount of data.

5-4

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 31

5-4 Communication protocol for serial output

Number of bytes INT number of optical units 7+8=

5-4 Communication protocol for serial

output

The communication of the serial interface provides various possible operation modes

depending the dip-switch setting. All of them respect the following timeline:

Host sends interrogation code

F3EM2 reply with acquired data & cleans the data memory.

F3EM2 starts again with data acquisition & waits for next interrogation code

The interrogation codes can be set by dip switches 4+5 (see chapter 5-1 on page 5-2).

Note:After power-on F3EM2 starts automatically with data acquisition (without interrogation code).

The communication can also be forced by signal on the STROBE input (PNP logic); the light

curtain responds on the serial line with the desired data.

Note: This STROBE line can be used also as a check for the correctness of the serial wiring and/or

communication protocol.

The different operation modes are described below.

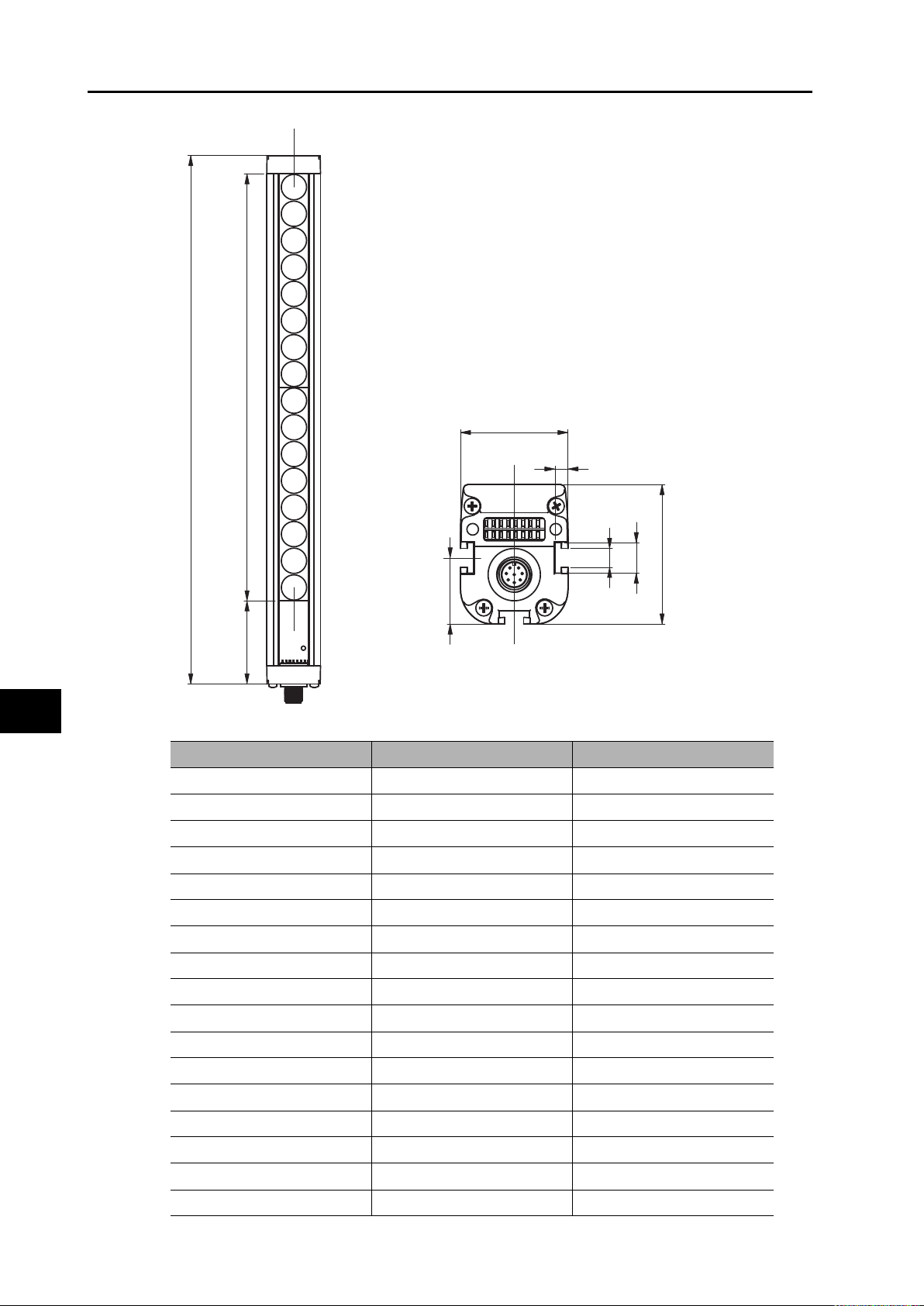

Bitmap of optics

Dip switch setting:

6 7 8 Type of function

OFF OFF OFF Bitmap of optics (default)

The light curtain responds with a serial of bytes. The quantity of bytes depends on the total

number of beams.

Each beam status is reflected by one bit. The beam index numbers are addressed to bits as

shown in the example below. Remaining unused bits in the last byte are set to zero.

E.g. the response of a light curtain with 20 beams is 3 bytes.

The numbers in the table reflect the beam index No:

st

byte12345678

1

nd

byte 9 10111213141516

2

rd

byte 17 18 19 20 0 0 0 0

3

5

Operating serial output models (RS-

The beam with index 1 starts opposite from the connector.

As a result each response byte contains 8 beams. The following formula applies

for the calculation if the number of response bytes:

The maximum number of optical beams that can be managed by serial interface is 400.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

5-5

Page 32

5-4 Communication protocol for serial output

Bit signal vs. beam status is:

0 = BEAM NOT INTERUPTED

1 = BEAM INTERRUPTED

FBB + NBB

Dip switch setting:

6 7 8 Type of function

OFF OFF ON FBB + NBB

The reply received from the light curtain is composed of 4 bytes.

The first two bytes are related to FBB data

The second two bytes are related to NBB.

FBB data is the binary conversion of the FBB id number.

NBB data is the binary conversion of the NBB number.

Example of the response protocol of a light curtain with 9 beams and FBB + NBB settings:

FBB

NBB

Operating serial output models

FBM + NAB

Dip switch setting:

1

9

st

1

byte H

FBB

nd

2

FBB

rd

byte H

3

NBB

th

byte L

4

NBB

byte L

00000000

00000100

00000000

00000100

H = high order byte

L = low order byte

6 7 8 Type of function

OFF ON OFF FBM + NAB

FBB = 4, NBB = 4 (HEX FORMAT)

5-6

The reply received from the light curtain is composed of 4 bytes.

The first two bytes are related to FBM data

The second two bytes are related to NAB.

FBM data is the binary conversion of the FBM id number.

NAB data is the binary conversion of the NAB number.

The order of bytes in the protocol is same as example described for FBB + NBB setting.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 33

LBB + NBB

Dip switch setting:

OFF ON ON LBB + NBB

The reply received from the light curtain is composed of 4 bytes.

The first two bytes are related to LBB data

The second two bytes are related to NBB.

LBB data is the binary conversion of the LBB id number.

NBB data is the binary conversion of the NBB number.

The order of bytes in the protocol is same as example described for FBB + NBB setting.

LBM + NBM

5-4 Communication protocol for serial output

6 7 8 Type of function

Dip switch setting:

6 7 8 Type of function

ON OFF OFF LBM + NAB

The reply received from the light curtain is composed of 4 bytes.

The first two bytes are related to LBM data

The second two bytes are related to NAB.

LBM data is the binary conversion of the LBM id number.

NAB data is the binary conversion of the NAB number.

The order of bytes in the protocol is same as example described for FBB + NBB setting.

Continues bitmap transmission

Dip switch setting:

6 7 8 Type of function

ON ON OFF Bitmap + Analogue out (FBB)

This setting allows the light curtain to transmit the bitmap of optics every cycle time.

5

Operating serial output models (RS-

The interrogation code is used as a start and stop trigger.

After power-on the LC waits for the interrogation code to start transmitting.

When interrogation code was received the LC continuously sends out the updated bitmap of

optics every cycle time. When the light curtain receives a further interrogation code it stops

transmitting and waits for the next interrogation code to start again the transmission.

The order of bitmaps is described in ’Bitmap of optics’ on page 5-5.

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

5-7

Page 34

5-4 Communication protocol for serial output

Bitmap + Analogue out (FBB)

Dip switch setting:

6 7 8 Type of function

ON OFF ON

In this set-up the light curtain drives together the Serial and the analogue output.

Note:The analogue output reflects the status of the FBB and is constantly updated. The serial output, on

the contrary, transmit its data only after interrogation code receipt.

The order of bitmaps is described in ’Bitmap of optics’ on page 5-5.

Holes detection function

Dip switch setting:

6 7 8 Type of function

ON ON ON Holes detection

This function transmits the bitmap of beams with inverted bit signals.

The default setting

"0 = beam free and 1 = beam broken"

is converted into

"0 = beam occupied and 1= beam free".

Continuous bitmap

transmission

Thus without object the bitmap of all optics will show "1", if the light curtain is aligned correctly.

Acquired data reflects the sum of beam acquisitions and is sent on interrogation code as

described in 5-3 ’Beam aquisition and data aquisition’ on page 5-4.

The order of bitmaps is described in ’Bitmap of optics’ on page 5-5.

Operating serial output models

5-8

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 35

Order codes

6

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 36

Order code

RS232C Serial/

analogue output

models

F3EM2-005-150 F3EM2-005-150-AV

F3EM2-018-150 F3EM2-018-150-AV 18 mm 15 m 8

F3EM2-005-300 F3EM2-005-300-AV

F3EM2-018-300 F3EM2-018-300-AV 18 mm 15 m 16

*2

Analogue models

Measurement

range

150

300

Pitch

5mm 3 m 30

5mm 3 m 60

*1

Sensing

distance

Channels

F3EM2-005-450 F3EM2-005-450-AV

450

F3EM2-018-450 F3EM2-018-450-AV 18 mm 15 m 24

F3EM2-005-600 F3EM2-005-600-AV

600

F3EM2-018-600 F3EM2-018-600-AV 18 mm 15 m 32

F3EM2-005-900 F3EM2-005-900-AV

900

F3EM2-018-900 F3EM2-018-900-AV 18 mm 15 m 48

F3EM2-005-1200 F3EM2-005-1200-AV

1200

F3EM2-018-1200 F3EM2-018-1200-AV 18 mm 15 m 64

F3EM2-005-1500 F3EM2-005-1500-AV

1500

F3EM2-018-1500 F3EM2-018-1500-AV 18 mm 15 m 80

F3EM2-005-1800 F3EM2-005-1800-AV

1800

F3EM2-018-1800 F3EM2-018-1800-AV 18 mm 15 m 96

F3EM2-018-2100 F3EM2-018-2100-AV 2100 18 mm 15 m 112

*1. Models with 7.5 mm pitch are available. Contact your OMRON representative.

*2. Models with RS485 serial output are available. Contact your OMRON representative.

5mm 3 m 90

5mm 3 m 120

5mm 3 m 180

5mm 3 m 240

5mm 3 m 300

5mm 3 m 360

Order codes

6-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 37

Technical specifications

7-1 Ratings...........................................................................7-2

7

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 38

7-1 Ratings

7-1 Ratings

Models F3EM2-005-… F3EM2-018-…

Operating distance 3 m 15 m

Light source (wave length) Infrared (880 nm)

Pitch 5.3 mm 18.3 mm

Max. number of beams 400 max on serial output

Operation temperature –10° to +55°C

Storage temperature –10° to +75°C

Degree of protection IP65 (IEC 60529)

Operating voltage 24 VDC ±20%

Current consumption 150 mA max (excluded load on digital)

Power-on delay <1 s

Response time 4 ms + 80 µs x number of beams (+ transmitting time for serial

operation*1)

Outputs RS-232C / RS485 / Analogue 0-10 V (12 bits)

External input Strobe input

Protective circuits Reverse polarity protection, output short-circuit protection

Max. load on analog output 15 mA

Insulation resistance >20 M

Dielectric voltage strength 350 VAC (1 min)

Configuration By dip-switches

Operating modes Analogue output 0-10 V or 10-0 V

Housing material Aluminum

Front Window Material Acrylic Lexan

End Cap and Connector ABS

Sealing Gasket Material EPDM

*1) Serial transmission time = 1/bps x 10 x number of transmitted byte

Technical specifications

Serial output: RS-232C (RS485 on request)

7-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 39

LED indicators and error indication

8-1 LED indication on receiver unit...................................8-2

8-2 LED indication on emitter unit.....................................8-3

8-3 Troubleshooting for error indication ..........................8-4

8

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 40

8-1 LED indication on receiver unit

POWER

RUN

FREE

BREAK

STATUS

RX

Meaning of symbols

SYMBOL MEANING

Diagnosis LED off

Diagnosis LED on

Diagnosis LED blinking

8-1 LED indication on receiver unit

Status of Receiver is displayed by 5 LEDs:

Disposition of indicator Name of indicator Colour

POWER Green

RUN Yellow

FREE Green

BREAK Red

STATUS Yellow

Normal operation indication on receiver:

LED signal pattern Description

No object in field. Running ok

Object in field. Running ok

Correct alignment reached

LED error indication on receiver:

ID LED signal pattern Description

1

2

3

4

LED indicators and error indication

Low supply voltage

Error on microcontroller

Error on optical system

Wrong dip switch configuration

8-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 41

8-2 LED indication on emitter unit

POWER

STATUS 1

RANGE

STATUS 2

TX

8-2 LED indication on emitter unit

Status of Emitter is displayed by 4 LEDs:

Disposition of indicator Name of indicator Colour

POWER Green

STATUS 1 Yellow

RANGE Green

Not used Red

STATUS 2 Yellow

Normal operation indication on emitter:

LED signal pattern Description

Emitter working, short range selected.

Emitter working, long range selected.

LED error indication on emitter:

ID LED signal pattern Description

1

2

3

4

Low supply voltage

Error on microcontroller

Error on optical system

Wrong dip switch configuration

8

LED indicators and error indication

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

8-3

Page 42

8-3 Troubleshooting for error indication

ID Actions

1 Check if power supply is within specification of 24Vdc ± 20%

2 Turn the unit ON and OFF again. If the error persist, please contact manufacturer

3 Turn the unit ON and OFF again. If the error persist, please contact manufacturer

4 Check the setting of switches

Page 43

Dimensions

9

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 44

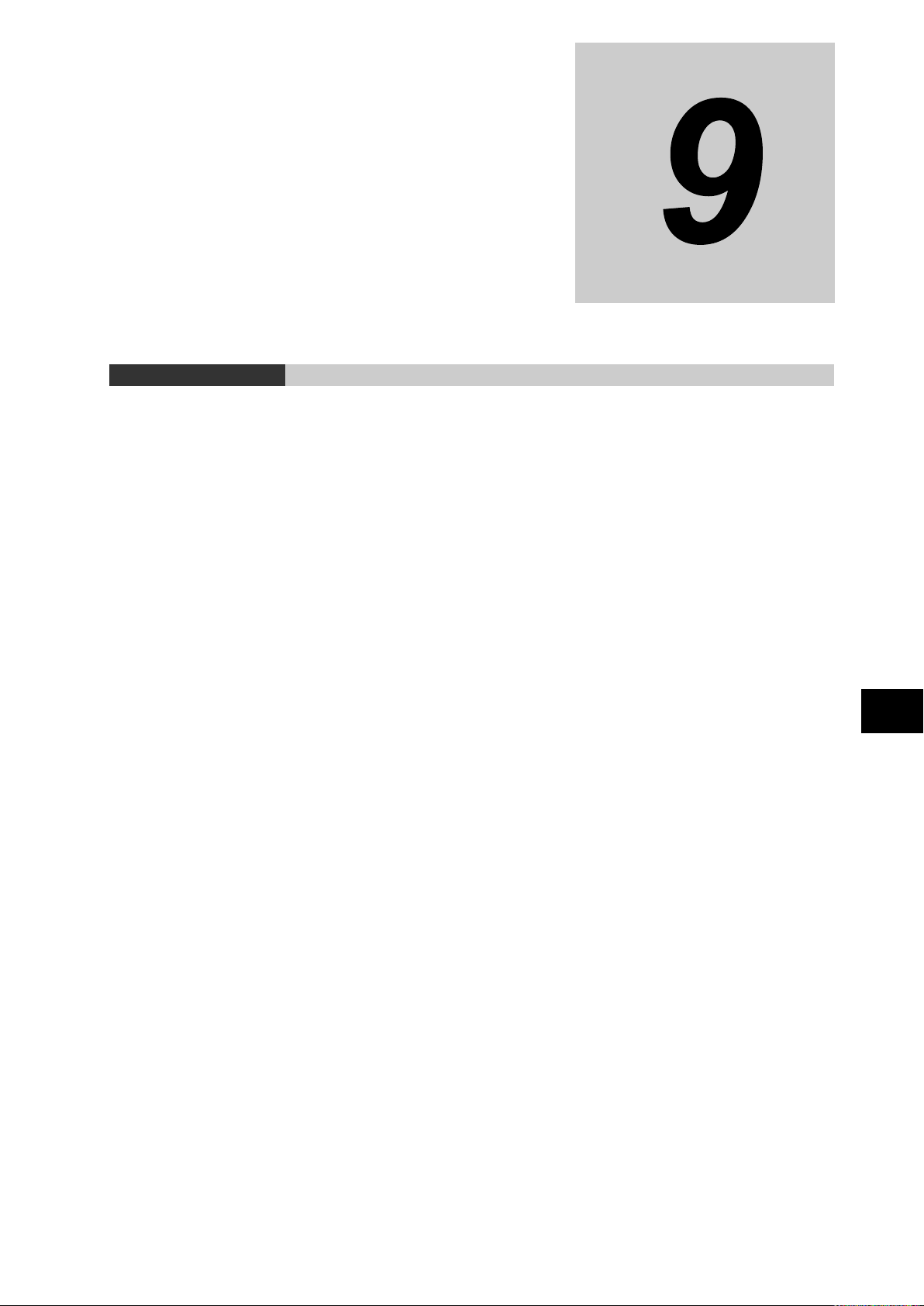

L: Total length

E: Detection zone

A: Dead zone without detection capability

E

Dimensions

L

22.75

A

37

4.5

6.5

All dimensions shown are in mm

Item number Detection Zone E (mm) Total length L (mm)

F3EM2-005-150(-AV) 159 218

F3EM2-018-150(-AV) 147 217

F3EM2-005-300(-AV) 318 277

F3EM2-018-300(-AV) 294 364

F3EM2-005-450(-AV) 477 536

F3EM2-018-450(-AV) 441 511

F3EM2-005-600(-AV) 636 695

F3EM2-018-600(-AV) 588 658

10.5

48

9-2

F3EM2-005-900(-AV) 954 1013

F3EM2-018-900(-AV) 882 952

F3EM2-005-1200(-AV) 1272 1331

F3EM2-018-1200(-AV) 1176 1246

F3EM2-005-1500(-AV) 1590 1649

F3EM2-018-1500(-AV) 1470 1540

F3EM2-005-1800(-AV) 1908 1967

F3EM2-018-1800(-AV) 1764 1834

F3EM2-018-2100(-AV) 2058 2128

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 45

Accessories

10-1 Mounting bracket........................................................10-2

10-2 Cables..........................................................................10-2

10

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 46

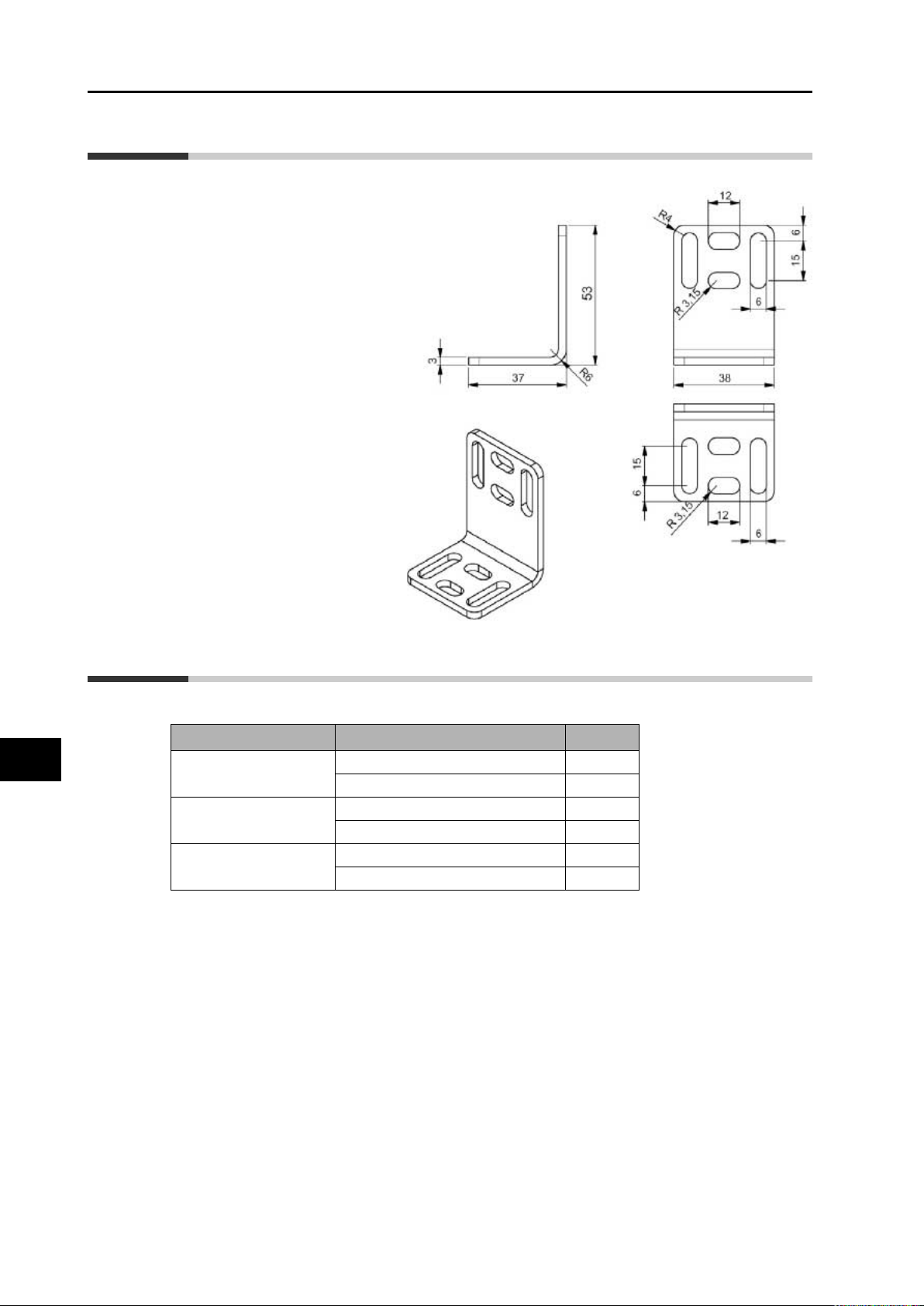

10-1 Mounting bracket

10-1 Mounting bracket

(provided with the product)

10-2 Cables

Accessories

Order Code Length

M12-8pin

(straight, shielded)

M12-5pin

(straight)

M12-5pin

(angled)

For other accessories like alignment kit, special brackets or connector cables please contact

your sales representative.

Y92E-M12PURSH8S2M-L 2 m

Y92E-M12PURSH8S5M-L 5 m

XS2F-M12PVC5S2M 2 m

XS2F-M12PVC5S5M 5 m

XS2F-M12PVC5A2M 2 m

XS2F-M12PVC5A5M 5 m

10-2

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

Page 47

Manual Revision History

The manual revision symbol is an alphabet appended at the end of the manual number found

in the bottom left-hand corner of the front or back cover.

Example

E77E-EN-01

Revision symbol

Revision

symbol

01 January 2012 First Print.

Revision date Description of revision and revised page

F3EM2 MEASURING LIGHT CURTAINS OPERATION MANUAL

1

Loading...

Loading...