Page 1

Measuring lightcurtain in robust aluminium housing

F3EM

Measuring lightcurtain

in robust aluminium

housing

The F3EM provides easy to install and set

up height and profile measurement. The

analog output provides a simple overall

height detection and the serial output models provide single beam evaluation for profile measurements.

• Robust aluminium housing

• Analog output for simple height detections

• Serial output with single beam evaluation

for profile measurement

Ordering Information

Sensor

type

Throughbeam

(measuring)

1

Models with 7.5 mm pitch are available. Contact your OMRON representative.

2

Models with RS485 serial output are available. Contact your OMRON representative.

Measurement

range (MaxM)

150 5 mm 3 m 30 – 5 pin – – F3EM-005-150-AV F3EM-005-150-D2

300 5 mm 3 m 60 – – – F3EM-005-300-AV F3EM-005-300-D2

600 5 mm 3 m 120 – – – F3EM-005-600-AV F3EM-005-600-D2

900 5 mm 3 m 180 – – – F3EM-005-900-AV F3EM-005-900-D2

2000 5 mm 3 m 400 – – – – F3EM-005-2000-D2

2100 18 mm 15 m 112 – – – F3EM-018-2100-AV F3EM-018-2100-D2

Pitch

18 mm 15 m 8 – – – F3EM-018-150-AV F3EM-018-150-D2

18 mm 15 m 16 – – – F3EM-018-300-AV F3EM-018-300-D2

18 mm 15 m 32 – – – F3EM-018-600-AV F3EM-018-600-D2

18 mm 15 m 48 – – – F3EM-018-900-AV F3EM-018-900-D2

distance

Sensing

1

Channels

Lightcurtain accessories

Shape Type Comment Order Code

Laser alignment kit snap-on Laser beam generator and level F39-TGR-LLK2-SB

Connection method Order code

Analog output RS232 output

2

Protective tube for F3ET-_ -150 F3ET-IP150

for F3ET-_ -300 F3ET-IP300

for F3ET-_ -600 F3ET-IP600

for F3ET-_ -900 F3ET-IP900

1F3EM Measuring lightcurtain in robust aluminium housing

Page 2

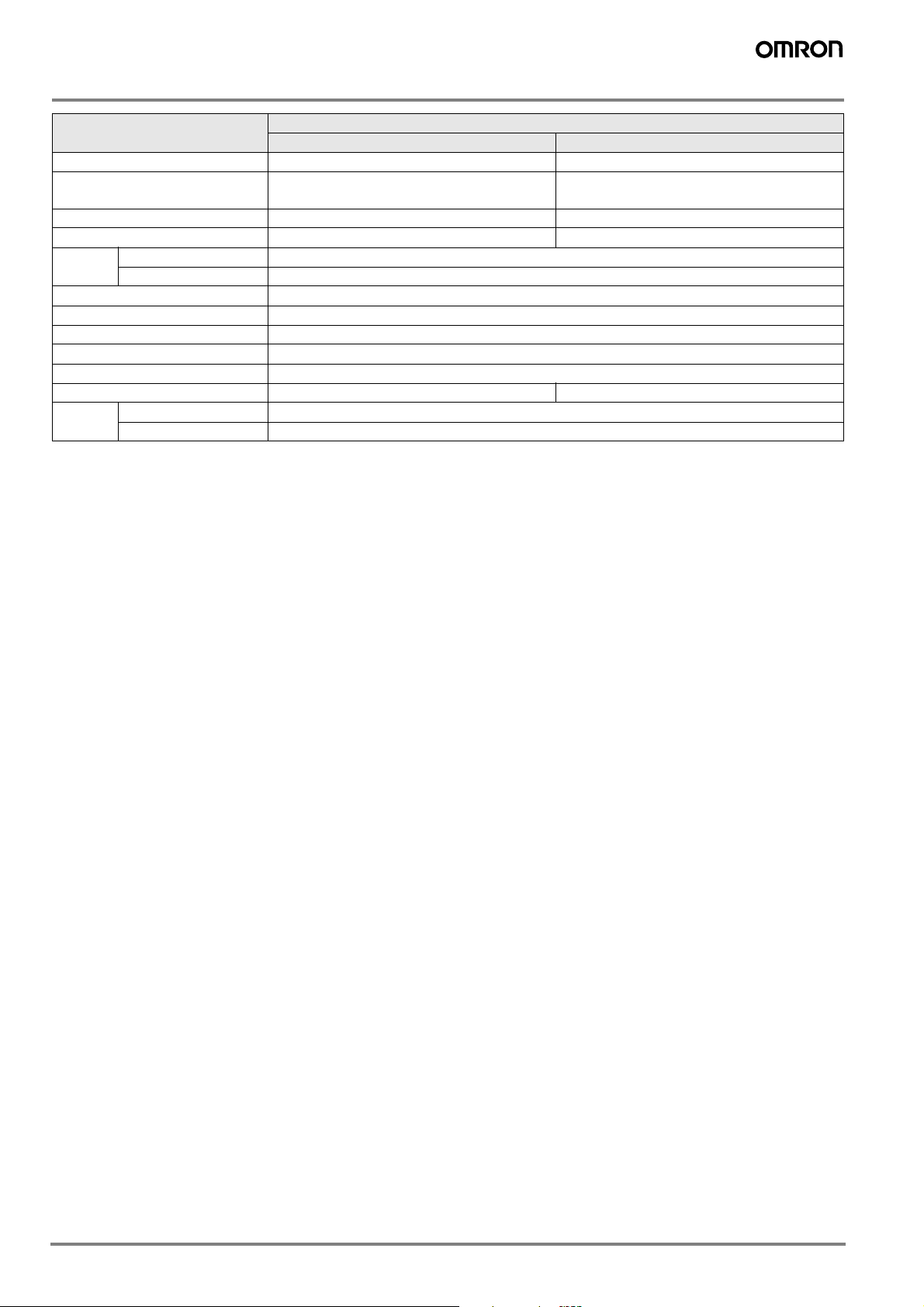

Rating/Specifications

Item

Through-beam

F3EM-005_ F3EM-018_

Sensing distance 0 to 3 m 0 to 15 m

Vertical measurement range 0 to MaxM mm; MaxM: 150, 300, 600, 900,

2000

1

0 to MaxM mm; MaxM: 150, 300, 600, 900,

2

2100

Minimum detectable object size 10 mm 30 mm

Pitch 5 mm 18 mm

Control

output

Analog models 0-10 VDC, max. load current 30 mA

Serial models RS 232

Response time Analog output: 5 ms + 0,18 x channels; Serial output: 4.5 ms + 0.38 x channels at 4800 bps

Light source (wave length) Infrared LED (950 nm)

Power supply voltage 24 VDC ±10%

Ambient temperature 0 to 50°C

Degree of protection IEC 60529 IP65

Dimensions (see also page 4) 35 x 45 x (55 + 1.06 x Max

) mm 35 x 45 x (55 + 0.98 x MaxM) mm

M

Material Case Aluminium

Cover Polycarbonate

1

Models with different measurement ranges between 150 mm and 2000 mm are available in 50 mm intervals. Please note that measurement

ranges between 1000 mm and 2000 mm are only available for serial output models.

2

Models with different measurement ranges between 150 mm and 2100 mm are available in 150 mm intervals.

2 F3EM Measuring lightcurtain in robust aluminium housing

Page 3

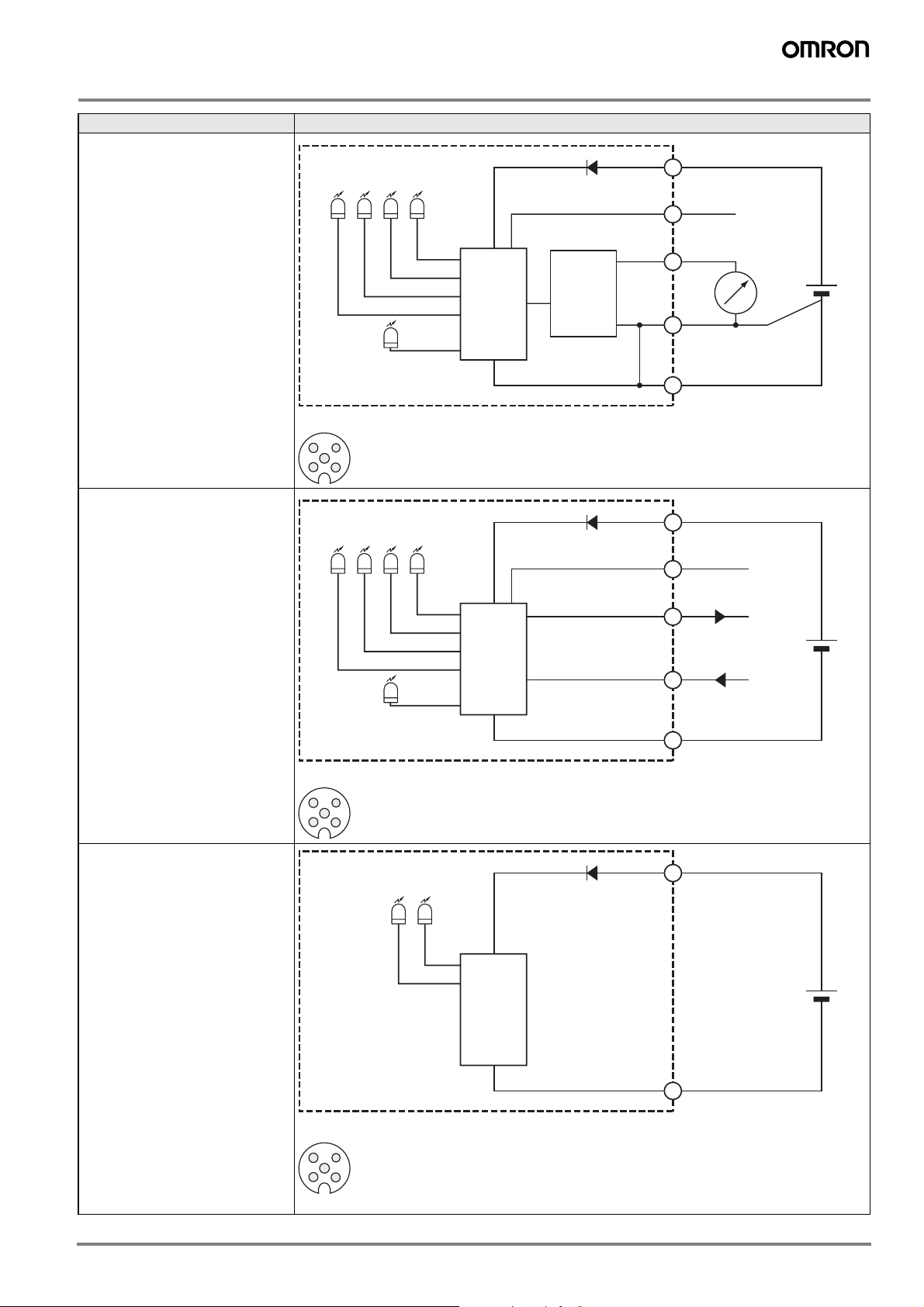

Output circuits

Type Output circuit

Receiver analog output

Out OFF

Out ON

(red)

(green)

Near/Far

(yellow)

Run OK

(yellow)

Power

(green)

Main

circuit

D/A

Converter

1

5

2

4

Brown

Grey

White

Black

24 VDC

+

0-10 V

-

Receiver serial output

Connector pin arrangement

3 4

5

2

1

Out OFF

Out ON

(green)

Near/Far

(yellow)

Run OK

(yellow)

Power

(green)

(red)

Connector pin arrangement

3 4

5

2

1

Main

circuit

3

Blue

Brown

1

5

Grey (Strobe Input)

White TxD

2

Black RxD

4

3

Blue

0 V

24 VDC

0 V

Emitter

Status OK

(yellow)

Power

(green)

Connector pin arrangement

3 4

5

2

1

Note: Terminal 2, 4 and 5 are not used

Main

circuit

1

3

Brown

Blue

24 VDC

0 V

3F3EM Measuring lightcurtain in robust aluminium housing

Page 4

Dimensions

35 mm

Operation

45 mm

Item number

Sensing area

S (mm)

Total length

L (mm)

F3EM-005-150-_ 159 225

F3EM-018-150-_ 147 213

F3EM-005-300-_ 318 384

F3EM-018-300-_ 294 360

F3EM-005-600-_ 636 702

F3EM-018-600-_ 588 654

F3EM-005-900-_ 954 1020

F3EM-018-900-_ 882 948

F3EM-005-2000-D2 2120 2186

F3EM-018-2100-_ 2058 2124

10

S

L

43

12

The F3EM measuring lightcurtain features optical synchronization. This function is provided by the upper beam located on the

opposite side of the connector (see illustration below). During operation this beam must always be kept free. Otherwise it will result

a loss of synchronism between the transmitter and receiver.

For applications where all beams are interrupted there are special

models with synchronization by wire. Please contact your

OMRON representative.

Indicator LEDs

For functions of indicator LEDs please refer to the tables below:

Name of indicator Colour

Power Green

Run ok Yellow

Out on Green

Out off Red

Near/Far Yellow

Name of indicator Colour

Power Green

Status ok Yellow

SYNCHRONISM

S

D

S: Sensing area

D: Pitch

Selector switches (dip switches)

Operation mode, distance setting (analog models) and transmission speed (serial models) can be changed by selector

switches. To access selector switches unscrew the end cap

of the receiver unit:

M12

Note: Selector setting must only be carried out when the receiver is not con-

nected to the power supply.

4 F3EM Measuring lightcurtain in robust aluminium housing

Page 5

Analog Output Models (F3EM-_-AV)

DIP Switch Settings

If F3EM is operated in a distance < 1m, the sensitivity can be

set to NEAR operation. This could be necessary, if multiple

light curtains are installed close to each other, or if the light

curtain detects semi-transparent objects.

The analog output can operate either in STANDARD mode or

INVERTED mode:

• STANDARD mode: 0 V (if no beams is interrupted) to 10 V

(if all beams are interrupted)

• INVERTED mode: 10 V (if no beams is interrupted) to 0 V

(if all beams are interrupted)

Please find the DIP switch setting below:

Switch

1 2 3 4

Distance setting (NEAR

position recommended if

distance is <1 m

ON NEAR ON DECREASING

not used

not used

OFF FAR (default) OFF INCREASING

Operation mode

(default)

Communication protocol

The communication of serial interface provides two possible

operation modes:

• Command-response

• Triggered by external input

A) In command-response mode the command is 1 byte:

Command (hexadecimal) = 'BF'

The light curtain responds with a fixed number of bytes depending on the number of light beams.

E.g. the response of a light curtain with 20 beams is 3 bytes:

1st

87654321

byte

nd

2

16 15 14 13 12 11 10 9

byte

rd

3

0 0 0 0 20191817

byte

The response bytes are composed by each bit representing

the status of each beam in the order as in the example above.

Remaining unused bits in the last byte are set to zero.

Each bit signals:

Analog output value

The output value is related linear to the number of beams interrupted by the object to be measured. For STANDARD

mode:

Output voltage = (10/ n° of optical units) * n° of interrupted

beams [VDC]

If multiple objects are inside the sensing area, the system will

read the total number of beams interrupted accordingly. Referring to the illustration below, the F3EM provides an output

signal in proportion with the sum of A+B:

A

B

Serial Output Models - RS232 (F3EM-_-D2)

The RS232 serial interface of F3EM is specified as follows:

• Full duplex operation

• Data format: 8-N-1 (bit start - 8-bit data - 1-bit stop - no

parity)

Transmission speed setting (Baud Rate)

The baud rate can be set by DIP switch 1 and 2.

@

The baud rate must be set both on the receiver bar

dip-switches as well as the transmitter bar dip-switches to align the timing synchronism of the two bars.

0 = BEAM NOT INTERUPTED

1 = BEAM INTERRUPTED

This drawing shows how the beams

are numbered on the light curtain

As a result each response byte contains 8 beams. The following formula applies for the calculation if the number of response bytes:

number of bytes = INT (number of optical units + 7) / 8)

The maximum number of optical beams that can be managed

is 400.

B) Trigger by external input

Alternatively the response can be forced by signal on the

STROBE input (PNP logic); the light curtain responds on the

serial line with the same protocol explained above.

Measurement method

In order to avoid missing information the light curtain stores interruption of beam signals until the status is sent in the next

protocol response. After the response is sent the interruption

status is reset (all bits to zero).

The beams are scanned sequentially. Therefore it can occur

that a command or trigger arrives before the scan is completed. In this case the scan is interrupted and the status of the

scan before is transferred in the response protocol.

DIP Switch 1 DIP Switch 2 Baud Rate (bps)

OFF OFF 4800

OFF (default) ON (default) 9600 (default)

ON OFF 19200

ON ON 38400

5F3EM Measuring lightcurtain in robust aluminium housing

Page 6

Mounting

Mechanical attachment and alignment

Standard Mounting Bracket (provided with the sensor)

When the mounting bracket is attached to the surface, the mounting

screws can be inserted into the mounting rail of the light curtain. This

allows a vertical position adjustment.

Adjustable Mounting Bracket

Order separately under: F39-TGR-ST-ADJ

For adjustment of the optical axis angle, the adjustable mounting

bracket allows a turning of the light curtain.

Laser Alignment

Order separately under: F39-TGR-LLK2-SB

The laser alignment kit can be snapped onto the light curtain and

emits a high visibility laser beam for ensuring the optimal optical axis

angle adjustment.

Cable connectors

For pin arrangement and connecting the wires refer to Output Circuits.

Material Order code

Size Shape Type Features

M12 General purpose

(screw)

5 wire Brass (CuZn) PVC 2M XS2F-M12PVC5S2M XS2F-M12PVC5A2M

Nut Cable

PUR 2M XS2F-M12PUR5S2M XS2F-M12PUR5A2M

6 F3EM Measuring lightcurtain in robust aluminium housing

Page 7

Precautions

@ WARNING

The F3EM multi-beam photoelectric sensor with beam

evaluation function is not a safety component for ensuring the safety of people which is defined in EC directive (2006/42/EC) or by any other regulations or

standards.

Power Supply Voltage and

Output Load Power Supply Voltage

Do not connect an AC power supply to the Sensor. If AC power (100 VAC or more) is supplied to the Sensor, it may explode or burn. Make sure that the power supply to the Sensor

is within the rated voltage range. If a voltage exceeding the

rated voltage range is supplied to the Sensor, it may explode

or burn.

Operating Environment

Do not use the sensor in locations with explosive or flammable gas. Make sure that the product is operated in accordance

with IP65 standards.

Do not subject the sensor to excessive shock when mounting.

When you use the sensor in the vicinity of an inverter motor,

be sure to connect the protective earth ground wire of the motor to earth. Failure to ground the motor may result in malfunction of the sensor.

Mounting the Sensor

Do not strike the sensor with a hammer or any other tool during the installation of the Sensor.

Cleaning

Never use paint thinners or other organic solvents to clean the

surface of the product

M12 Connector

Always turn OFF the power supply to the sensor before connecting or disconnecting the metal connector. Hold the connector cover to connect or disconnect it.

Secure the connector cover by hand. Do not use pliers; otherwise the connector may be damaged.

If the connector is not connected securely, it may be disconnected by vibration or the proper degree of protection of the

sensor may not be maintained.

7F3EM Measuring lightcurtain in robust aluminium housing

Page 8

In the interest of product improvement, specifications are subject to change without notice.Cat. No. E62E-EN-01A

OMRON EUROPE B.V.

Wegalaan 67-69,

NL-2132 JD, Hoofddorp,

The Netherlands

Phone: +31 23 568 13 00

Fax: +31 23 568 13 88

www.industrial.omron.eu

8 F3EM Measuring lightcurtain in robust aluminium housing

Loading...

Loading...