Page 1

Ultra-flat multi-beam sensor for elevators

K

F3E

• Ultra-flat 9 mm shape for easy design-in in

elevator constructions

• Highest ambient light immunity

(200,000 lux) for installations with direct

sunlight exposition

• Triple crossing resolution maintained

close to zero distance

• Robust aluminum housing

• Ray failure toleration

• Test input

• Built-in amplifier

(operation with 10-30 VDC)

• Fulfills requirements of EN81-70

Designed & manufactured

by

STRAC

LIFT AUTOMATION

Ordering Information

Pitch Detection area channels

120 mm 1800 mm 16 46 5 m pre-wired potential-

40 mm 1800 mm 46 136 5 m pre-wired F3E-46-T1 5M

Number of

optical axis

Connection Output Model number

F3E-16-T1 5M

M8 Connector (4-pin) F3E-16-T6

M8 Connector (4-pin) F3E-46-T6

free output

Features

High reliability and flexibility:

Test input: Function of multi-beam sensor can be tested by transmitter cut off on test signal. A subsequent receiver cut off can be

monitored by control unit.

Ray failure toleration: As soon as one channel is not switching for more than 60 seconds, the F3E identifies a defect and deactivates this channel. The sensor then functions normally again showing the defect channel by a red error LED.

Easy parameterization: By test input of transmitter a parameterization of L-ON/D-ON operation and shading of LED areas is possible. No complicated programming or remote control needed

Potential free output: The F3E provides a wear-free electronic relay output for highest connection flexibility and life-time.

1F3E Multibeam sensor

Page 2

A/2

A/3 A/3

B

C

D

C

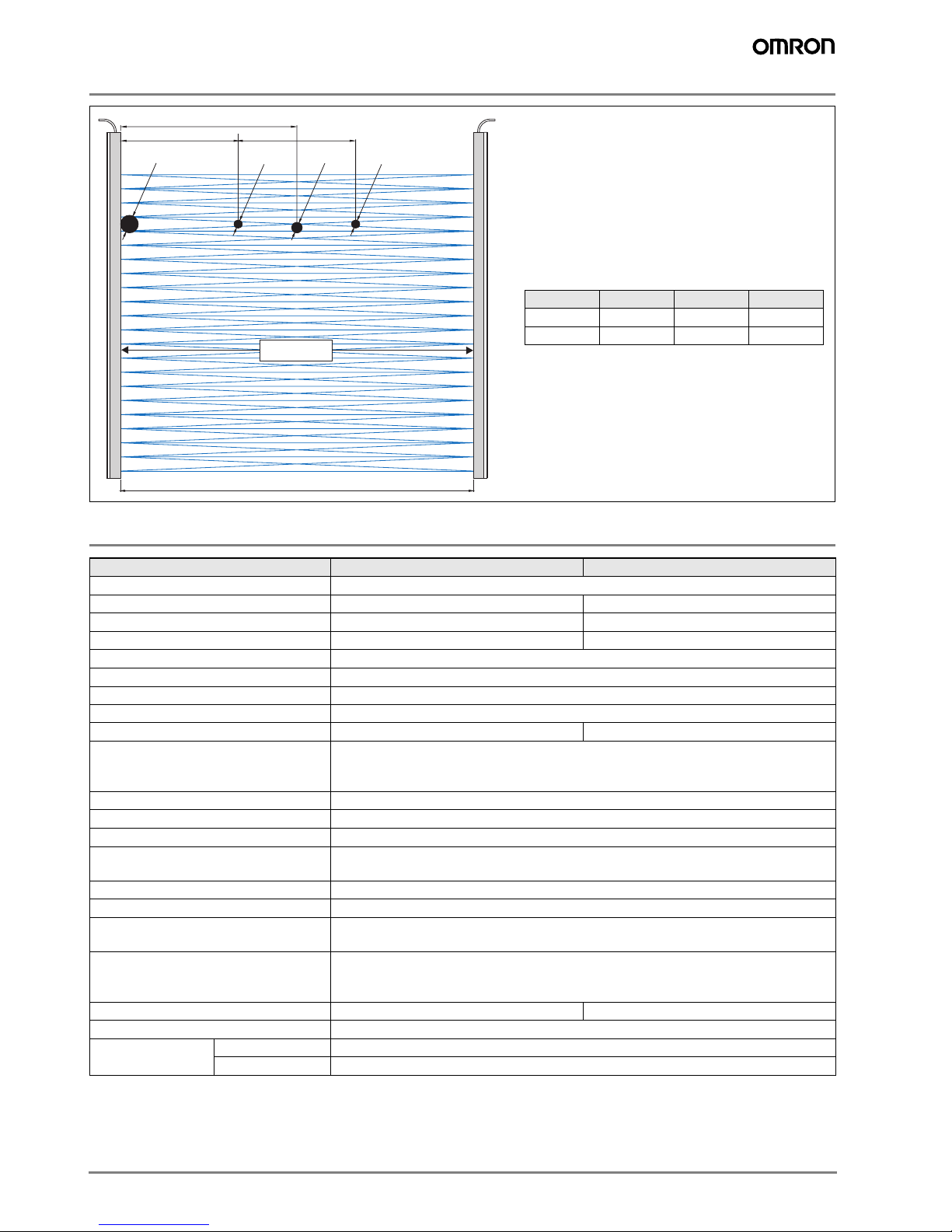

High resolution is realized by triple crossing of light

beams.

Automatic sensitivity control ensures steady and op-

timum light power. Even when sensors are operated

in dirty environment or at highest distances, no adjustment is necessary. Sensitivity control ensures

that the high resolution is maintained at small distances close to "zero".

Min. size of recognized objects:

Pitch B D C

120 mm 125 mm 65 mm 45 mm

40 mm 45 mm 35 mm 18 mm

protected area

A = current scanning radius

Rating/Specifications

ItemType F3E-16-T[..] F3E-46-T[..]

Rated sensing distance 0-5 m

Number LEDs 16 46

Number of optical axis 46 136

Resolution 120 mm 40 mm

Vertical detection area

Response time max. 110ms (signal interruption)

Light source (wave length) Infrared LED (880 nm)

Power supply voltage 10-30 VDC

Current consumption max. 120 mA / pair max. 240 mA / pair

Control output Wearless potential free output, 35 V AC/DC max., 150mA max. at 20°C, 100mA max.

Test input / light emission stop function 110 ms max. response time

Ambient light immunity

Ambient temperature -20…+60°C (operation)

EMC conformity/standards 73/23/EWG; 89/336/EWG; 95/16/EG; EN81-1; EN81-2; EN12015; EN12016;

Protective degree IP54

Connection methods Pre-wire type (5 m PVC cable), M8-4-PIN

Indicator LEDs Emitter: power indicator (yellow);

Error status indication Red LED blinking: unstable operation, contamination, max. exceeding sensing dis-

Dimension

1

Weight 880g (connector version), 1040g (cable version)

Material Case Aluminum

1

other sizes available on request

2

Measured at angle of 20°

3

No icing and condensation

1

20-1820 mm

at 60°C, D-ON (parameterization by emitter test input), max. leakage at open contact

0,001mA, contact resistance 4/12 Ohm

2

200.000 lux

EN61000-6-x

Receiver: output indicator (yellow), output indicator (red)

tance

Red LED ON + yellow LED ON: beam channel defect

2070x40,7x9 mm 2000x40,7x9 mm

Cable PVC

3

, -40…+70 (storage)

2 F3E Multibeam sensor

Page 3

Output circuits

Receiver

Status

(yellow)

(red)

Warning

Main

circuit

Connector PIN Arrangement

123

Dimensions

Mounting strap fixation

LED red

LED yellow

light rays

4

potential

free

9

8

I

brown

1

white

2

max. 250 mA /

35 V AC/DC

black

4

blue

3

Load

10 to 30 V DC

Load

alternatively

5

a

Dimension F3E-16… F3E-46…

Transmitter

Power indic

ator

(green)

Main

circuit

Connector PIN Arrangement

a5 25 mm 25 mm

4

123

brown

1

white

2

black (not used)

4

blue

3

test input and programming

10 to 30 V DC

alternatively

0 V

a4 690 mm 650 mm

a3 640 mm 650 mm

a2 690 mm 650 mm

4

a

a1 25 mm 25 mm

h 2070 mm 2000 mm

7

40.75

8

6

h

a3

9

1.5

5

4

3

2

a

2

ø 4.5

1

1

a

5.5

3F3E Multibeam sensor

Page 4

Accessories

Cable connectors

Type Size Cable Material Poles Length (m) LED Nut Order reference

slim line straight M8 PVC 4 5 no brass XS3F-M421-405-A

slim line angled M8 PVC 4 5 no brass XS3F-M422-405-A

robotic cable straight M8 PVC 4 5 no brass XS3F-M421-405-R

robotic cable angled M8 PVC 4 5 no brass XS3F-M422-405-R

Note: Complete portfolio of connector types see OMRON Accessory Datasheet

F3E-Accessories

Item Description Order reference

F3E-Installation Kit S Installation kit for stationary mounting on lift doors F3E-IK-S

F3E-Installation Kit M Installation kit for mounting to mobile doors panels F3E-IK-M

F3E-Power supply Power supply NTR 18/03 for operation with 240VAC/24DC,

buzzer function

F3E-PS1

4 F3E Multibeam sensor

Page 5

Installation Kit S

M5x16

Installation Kit M

The upper mounting angle is screwed

to the top of the door operator.

The lower mounting angle is screwed

to the underside of the door sill.

Then the vertical mounting angle

- with the sensor unit already screwed onto it is inserted with its conical end into the slot

in the lower mounting angle.

M4x10

sensor unit with

mounting strap

fixation

M4x12

M4x12

vertical

mounting angle

cone

upper

mounting

angle

vertical

mounting

angle

sensor unit with

mounting strap

fixation

lower

mounting

angle

M6x16

door panel

mounting clamps

sensor unit with

strap fixation

5F3E Multibeam sensor

Page 6

Precautions

@ WARNING

The F3E multi-beam photoelectric sensor is not a

safety component for ensuring the safety of people

which is defined in EC directive (2006/42/EC) or by

any other regulations or standards.

Power Supply Voltage and

Output Load Power Supply Voltage

Do not connect an AC power supply to the Sensor. If AC power (100 VAC or more) is supplied to the Sensor, it may explode or burn. Make sure that the power supply to the Sensor

is within the rated voltage range. If a voltage exceeding the

rated voltage range is supplied to the Sensor, it may explode

or burn.

Operating Environment

Do not use the Sensor in locations with explosive or flammable gas. Make sure that the product is operated in accordance

with IP54 standards.

Do not subject the multi-beam sensor to excessive shock

when mounting.

When you use the multi-beam sensor in the vicinity of an inverter motor, be sure to connect the protective earth ground

wire of the motor to earth. Failure to ground the motor may result in malfunction of the sensor.

Mounting the Sensor

Do not strike the Photoelectric Sensor with a hammer or any

other tool during the installation of the Sensor.

Cleaning

Never use paint thinners or other organic solvents to clean the

surface of the product

M8 Connector

Always turn OFF the power supply to the Sensor before connecting or disconnecting the metal connector. Hold the connector cover to connect or disconnect it.

Secure the connector cover by hand. Do not use pliers; otherwise the connector may be damaged.

If the connector is not connected securely, it may be disconnected by vibration or the proper degree of protection of the

Sensor may not be maintained.

In the interest of product improvement, specifications are subject to change without notice.Cat. No. E48E-EN-01A

OMRON EUROPE B.V.

Wegalaan 67-69,

NL-2132 JD, Hoofddorp,

The Netherlands

Phone: +31 23 568 13 00

Fax: +31 23 568 13 88

www.industrial.omron.eu

6 F3E Multibeam sensor

Loading...

Loading...