Page 1

Distance setting laser photoelectric sensor

F3C-AL

• 700 mm max setting distance

• small visible Laser light spot for simple

adjustment

F3C-AL

Features

Clear red spot ensures easy setting.

With its wide setting range 170 to 700 mm, F3C-AL is compatible with standard conveyors. In the setting distance of 700

mm, the distance can be set easily with a 1.5x4 mm red spot.

700mm

Secure detection of shiny surface

Ensures stable detection of a 45-degree shiny surface. Detection of pouches, laminated packages or like minimizes setup

change time.

170mm

Unaffected by a shiny background.

Insensitive to shiny objects in the background, the Sensor can

be installed in any place.

Small Black/White error:

2% (Setting distance 300 mm),

8% max. (Setting distance 500 mm)

A little black/white error saves adjustment time during setup

change.

Full hysteresis detection range 0.5% max.

(for white paper)

6-turn adjuster ensures ease of adjustment.

A-177F3C-AL

Page 2

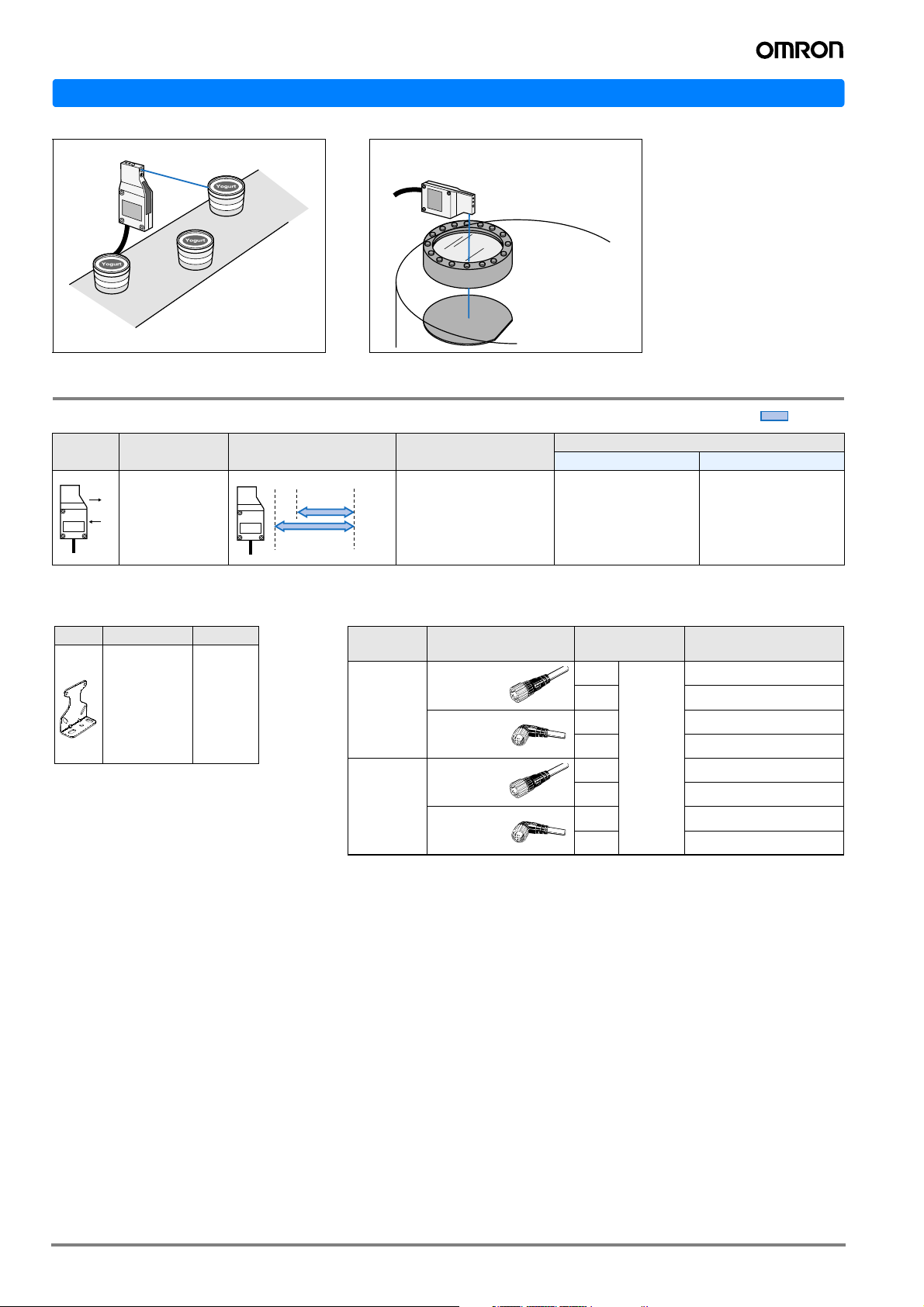

Application

yp

Detection of food being transferred

Detection of wafers through view port

(Reflective model)

F3C

The cup of yogurt

Detection of the object

between 150 to 700 mm max.

on the conveyor.

F3C

Since it is a reflection

type, a viewport is

OK with one place!

Wafer

Ordering Information

Sensors

Shape

Connection

method

Sensing/Setting range Operating mode

Pre-wired with

M12-connector

Accessories (Order Separately)

Mounting Brackets

Shape Model Quantity

E39-L40 1

120 170

Setting range

Sensing distance

120 to 700 mm

700 mm

Light-ON/Dark-ON cable

connection selectable

Sensor I/O Connectors

Cable spec-

ifications

Straight

e

Standard

t

cable

L type

Robot cable

(for vibra-

Straight

type

tion resis-

tance)

L type

Shape

NPN output PNP output

F3C-AL14-M1J

Cable type

2 m

5 m

2 m

5 m

2 m

4 con-

ductors

5 m

2 m

5 m

Model

F3C-AL44-M1J

XS2F-D421-D80-A

XS2F-D421-G80-A

XS2F-D422-D80-A

XS2F-D422-G80-A

XS2F-D421-D80-R

XS2F-D421-G80-R

XS2F-D422-D80-R

XS2F-D422-G80-R

Red light

Model

A-178 Standard Photoelectric Sensors

Page 3

Rating/Performance

Item Model F3C-AL14-M1J F3C-AL44-M1J

Sensing 120 to 700 mm (White paper 100 x 100 mm) (Setting distance 700 mm)

Setting distance range

Black-/white-error 20% max. (of setting distance, 90%/6% remission)

Spot Diameter 1.5 x 4 mm (Setting distance 700 mm)

Light source

Power supply voltage 10 to 30 VDC [ripple (p-p) 10% included]

Current consumption 30 mA max.

Control output

Protective circuits Reverse polarity protection, output short-circuit protection, mutual interference prevention

Response time Operation and reset: 10 ms max.

Sensitivity adjustment 6-turn adjuster

Ambient illuminance Incandescent lamp/Sunlight: 5,000 lux max.

Ambient temperature Operating: 0°C to 50°C, Storage: -25°C to 60°C (with no icing or condensation)

Ambient humidity Operating/Storage: 35% to 85%RH (with no condensation)

Insulation resistance 20 M min. at 500 VDC

Vibration resistance 10 to 55 Hz double amplitude 1.5 mm or 300 m/s2 for 2 h in each of X, Y, Z directions

Shock resistance Destruction: 500 m/s2 for 3 times each in X, Y, and Z directions

Protective structure IEC Standard IP40

Connection method M12 connector joint type (standard cable length 200 mm) / 4 x 0.34 mm² (PVC)

Weight (packed state) Approx. 80 g

Material

Accessories Adjusting screwdriver, Laser warning label, instruction manual

Case

Lens Acrylics (PMMA)

170 to 700 mm (White paper, 90% remission, 100 x 100 mm)

170 to 560 mm (White paper, 6% remission, 100 x 100 mm)

Pulsed red light semiconductor laser

Class II: < 1mWeff. / 670 nm / 5% duty cycle

(Impulse time 60 µs, Period time: 1.2 ms)

Load supply voltage 30 VDC max., load

current 150 mA max. (residual voltage: 2 V max.)

NPN open collector output type, Light-ON/Dark-ON

cable connection selectable

ABS

Load supply voltage 30 VDC max., load

current 150 mA max. (residual voltage: 2 V max.)

PNP open collector output type, Light-ON/Dark-ON

cable connection selectable

F3C-AL

A-179F3C-AL

Page 4

Characteristic data (typical)

a

Parallel operating range Black/White error Short distance characteristic chart

4

3

2

Distance Y (mm)

1

0

100

-1

-2

-3

-4

Hysteresis

3.0

Sensing object

White paper: reflectivity 90 %

Black paper: reflectivity 5 %

Hysteresis (%)

2.0

150mm

400mm

200

300

400

700mm

500 600 700

Distance X (mm)

20

Sensing object

White paper: reflectivity 90 %

Black paper: reflectivity 5 %

15

10

Black and white error (%)

5

0

150 200 300 400 500 600 700

Setting distance (mm)

800

700

600

Distance (mm)

500

400

300

200

100

0

90

mm

50mm

Setting distance 700mm

170mm

185mm

70mm

White paper Black paper

Materi

1.0

0 100 200 300 400 500 600 700

Black paper

White paper

Setting distance (mm)

A-180 Standard Photoelectric Sensors

Page 5

Output Circuit Diagram

NPN output

Model

F3C-AL14-M1J

Operating status of

output transistor

Light ON

Dark ON

Interrupted

Light

indicator

(red)

Output

transistor

Load

(Relay)

Interrupted

Light

indicator

(red)

Output

transistor

Load

(Relay)

Timing chart

Incident

ON

OFF

ON

OFF

Operate

Reset

(Between 1 and 4)

Incident

ON

OFF

ON

OFF

Operate

Reset

(Between 1 and 4)

Mode

selection

Connect B

to

A

or dis-

connect

B

Connect B

to

C

.

Output circuit

Light

indicator

(red)

Stability

indicator

(green)

Main

circuit

.

1

4

Z

D

3

2

10 to 30 VDC

Load

(Relay)

150 mA

max.

0V

Operation selectable

F3C-AL

Connector Pin Arrangement

1

2

4

3

10 to 30 VDC

Load

(Relay)

150 mA

max.

0V

Operation selectable

10 to 30 VDC

Light

indicator

(red)

Stability

indicator

(green)

Main

circuit

Connector Pin Arrangement

1

2

4

3

1

4

Z

D

3

2

PNP output

Model

F3C-AL44-M1J

Operating status of

output transistor

Light ON

Dark ON

Interrupted

Light

indicator

(red)

Output

transistor

Load

(Relay)

Interrupted

Light

indicator

(red)

Output

transistor

Load

(Relay)

Timing chart

Incident

ON

OFF

ON

OFF

Operate

Reset

(Between 3 and 4)

Incident

ON

OFF

ON

OFF

Operate

Reset

(Between 3 and 4)

Mode

selection

Connect B

to

A

or dis-

connect

B

Connect B

to

C

.

Output circuit

Light

indicator

(red)

Stability

indicator

(green)

Main

circuit

.

1

Z

D

4

3

2

10 to 30 VDC

150 mA

max.

Operation selectable

Load

(Relay)

0V

Connector Pin Arrangement

1

2

4

3

10 to 30 VDC

150 mA

Load

max.

(Relay)

0V

Operation selectable

Light

indicator

(red)

Stability

indicator

(green)

Main

circuit

1

D

Z

4

3

2

Connector Pin Arrangement

1

2

4

3

Connectors (Sensor I/O connectors)

Terminal No. Cable core

2

13

4

1

2

3

4

XS2F-D42

#

-D80-#

#

-D80-#

XS2F-D42

wire jacket color

Brown

White

Blue

Black

Wire, outer Connector

Class

Brown A Power supply (+V)

For

DC

White B Operation switching

Blue C Power supply (0 V)

Black D Output

Application

A-181F3C-AL

Page 6

Sensitivity Adjustment

Item Position A Position B and C Setting

Adjustment

procedure

Detecting

condition

Place the detected object at the desired location and turn the LIGHT indicator (red) lights. This is position A

Photoelectric

sensor

Detected object

A

Background object

Remove the detected object and turn

the adjustment knob clockwise until the

LIGHT indicator(red) lights. This is the

position B.

Then turn the adjustment knob counterclockwise until the LIGHT indicator

(red) goes out. This is position C.

No Background object

The maximum adjustment setting is

used as position C.

Photoelectric

sensor

Detected object

Background

B

C

Set the adjustment to halfway between

A and C. Confirm that the STAB indicator (green) remains lit both with the detected object present and not present.

If the STAB indicator does not remain

lit, review the detection method to enable stable operation.

object

Status of distance

A

setting

knob

Indicators

OFF ON

STABILITY

(green)

LIGHT

(red)

OFF OFF

Special hints

Recommended adjustment

To assure stable working conditions the green stability LED should

be always turned on.

The green LED displays two stability conditions:

1. Output stable ON (red LED on)

2. Output stable OFF (red LED off)

Best performance can be achieved if the sensing object is located

closer than -10 % of the setting distance or the shiny background is

fixed +10 % behind the switching position.

STABILITY

(green)

A

C

B

ON OFF

LIGHT

(red)

STABILITY

(green)

C

LIGHT

(red)

A-182 Standard Photoelectric Sensors

Page 7

Precautions

Safety Precaution

Laser beam!

Laser protection class 2

Do not look into the laser beam.

Pay attention to the accident prevention regulations and the

laser protection class.

Visible laser emission!

Avoid any indirect or direct radiation of

reflected or emitted laser light!

Laser safety

The laser safeguards have been stipulated for laser equipment in and outside Japan. The following gives brief description for use in Japan.

The JIS C6802 Standard stipulates safety preventives that

must be taken by the user according to the laser product

class. (The outline is given in the following table.)

User's Requirements

Class

Item 3B*

Using remote

interlock

Key control Not required

Beam breaker

or attenuator

Warning sign Not required

Beam path

Mirror

reflection

Eye protect Not required

Protection

clothes

Training Not required

* 5 mW or less in the visible range

Class 1 Class 2

The laser beam must be terminated and, as a rule,

Not re-

must be enclosed. If the laser beam is exposed,

quired

the vertical height of the beam must not be the

same as that of the eyes.

Not required

Not required

Class

3A

Not required

Not required

Wear protection clothes if exposure of

the skin to the laser beam may exceed

the MPE of the skin.

The laser system must be operated by

only properly trained people.

Classification of F3C

Class 2

Handle laser equipment in accordance with the following pre-

cautions.

• Do not look into the beam.

• Do not disassemble the product. Doing so will release the

laser beam to wander around.

Please obtain or prepare the "Laser product safety standards"

on your own responsibility.

Class 3B

Connect the remote interlock of

the laser beam to

the emergency

main interlock, the

interlock of the

room, or the interlock of the door.

Do not keep the

key in the lock

when the laser

beam is not used.

Used to protect

people from accidental radiation by

the laser beam.

Post a proper warning sign on

the door to the room where

laser beam equipment is installed.

Appropriate optical elements

must be securely attached

and you must be able to control the optical elements during laser radiation.

Use eye protectors

except in special,

specified locations.

3B

Class 4

Labels related to laser

The following warning label is applied to the side face of the

photoelectric sensor.

DO NOT LOOK DIRECTLY INTO THE BEAM!

LASER LIGHT

NOT EVEN THROUGH OPTICAL

INSTRUMENTS.

LASER PROTECTION CLASS 2

Pout < 1mW 670nm

For use in Japan, change the above label for the one that

meets the JIS Standards.

Handling Instructions

F3C radiates a visible-light laser. Do not look into it directly.

Use F3C so that the light path of the laser beam is terminated.

If there is a mirror-smooth reflector in the light path, confine

the beam away from the reflected light path. If F3C must be

used with the light path open, avoid placing the light path on

the eye level.

Correct Use

Design

Power Reset Time

The Photoelectric Sensor is ready to sense an object in 300

ms after power-on. Therefore, use it 300 ms after power-on. If

the load and Sensor are connected to different power supplies, always switch on power for the Sensor first.

Wiring Considerations

Load short-circuit protection

• The F3C-AL has load short-circuit protection. If a load shortcircuit or like has occurred, the output turns OFF. Therefore,

recheck the wiring and switch power on again. This resets

the short-circuit protection circuit. Load short-circuit protection is activated when a current of 1.8 times or more of the

rated load current flows. When using an L load, use the one

the inrush current of which is less than 1.8 times of the rated

load current.

• Do not use the input power exceeding the rated voltage.

Doing so can cause damage.

• Do not shorten the load with the open collector output. Otherwise, damage might be caused.

• Run the wiring of F3C separately from the high voltage and

power cables.

F3C-AL

A-183F3C-AL

Page 8

• Avoid wiring them together or running them within the same

duct. Doing so may get them induced, causing a malfunction or damage.

2

• For extension of the cable, use a 0.3-mm

or more cable

and run it within 50 m.

Mounting

• Install the photoelectric sensor so that the sun, fluorescent

lamp, incandescent lamp or any other strong light will not

enter the directional angle range of the sensor.

• If Sensors are installed face-to-face, ensure that no optical

axes cross each other. Otherwise, mutual interference may

result.

• Use M4 screws to mount the unit.

• When mounting the case tighten it to the torque of 1.2 Nm

max.

• Depending on their material and/or shape, some objects

may not be detected or may be detected with low accuracy.

(Mirror-smooth material, transparent material, material of

extremely low reflectivity, object smaller than spot diameter)

Correct operation

The moving direction of the sensor or object should be prefer-

ably along the optical axis of the light beam. Lateral approach

is also possible. Movement from the top to the bottom or opposite can cause malfunction and should be avoided.

Green LED (stability)

Red LED (light received)

Movement of object

Light beam

Miscellaneous

Operating Environment

• Avoid using the Sensor in a strong disturbance light (e.g. laser beam or arc welding beam) or strong electromagnetic

field.

Dimensions (Unit: mm)

Sensors

F3C-AL14-M1J

F3C-AL44-M1J

Emitter

8

4.7

(55)

90

Receiver

Stability indicator (green)

Light indicator (red)

Distance adjuster

32

Three,

42

4.2 dia.

4

4

18

37

45

Sensing distance

adjustor

Termi-

nal No.

1+V

Terminal No.

2

1+V

2

30V

30V

4 Output

4 Output

Note: Connection 1 to 2 is L-ON

Note. L-ON when 1-2 are connected

inyl-insulated round cable of 4 dia.

4 cores conductorStandard length:

200 mm

Specifications

Specifications

L-ON/D-ON

selection

L-ON/D-ON selectable

Connection 2 to 3 is D-ON

D-ON when 2-3 are connected

M12 x 1

4

1

3

2

Accessories (Order Separately)

Mounting Brackets

H-5

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E510-E2-01-X

In the interest of product improvement, specifications are subject to change without notice.

A-184 Standard Photoelectric Sensors

Loading...

Loading...