Page 1

PNSPO!

Model F39-MC11(ver. 3)

Setting Console

INSTRUCTION MANUAL

Thank you for selecting OMRON product. This manual primarily

describes precautions required in installing and operating the product.

Before operating the product, read this manual thoroughly to acquire

sufficient knowledge of the product. For your convenience, always keep

this manual at hand.

©OMRON Corporation 2001-2003 All Rights Reserved.

i

Read and Understand this Instruction Manual

Please read and understand this instruction manual before storing,

installing, programming, operating, maintaining, or disposing of the

products. Please consult your OMRON representative if you have any

questions or comments.

Warranty, Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from

defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION,

EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE

OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES

THAT THE BUYER OR USER ALONE HAS DETERMINED THAT

THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF

THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the

individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR

WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED,

AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION,

ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR

REPAIR.

Page 2

- ii -

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards,

codes, or regulations that apply to the combination of the products in

the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party

certification documents identifying ratings and limitations of use that

apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in

combination with the end product, machine, system, or other

application or use.

The following are some examples of applications for which particular

attention must be given. This is not intended to be an exhaustive list

of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or

electrical interference, or conditions or uses not described in this

instruction manual.

• Nuclear energy control systems, combustion systems, railroad

systems, aviation systems, medical equipment, amusement

machines, vehicles, and installations subject to separate

industry or government regulations.

Systems, machines, and equipment that could present a risk to

life or property.

Please know and observe all prohibitions of use applicable to the

products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING

THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a

programmable product, or any consequence thereof.

- iii -

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time

based on improvements and other reasons.

It is our practice to change model numbers when published ratings or

features are changed, or when significant construction changes are

made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers

may be assigned to fix or establish key specifications for your

application on your request. Please consult with your OMRON

representative at any time to confirm actual specifications of

purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for

manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this instruction manual has been carefully checked

and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical, or proofreading errors, or omissions.

Meanings of Signal Words

The following signal words are used in this instruction manual.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, will result in minor or moderate

injury, or may result in serious injury or death.

Additionally there may be significant property

damage.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury or in property damage.

Page 3

- iv -

Meanings of Alert Symbols

The following alert symbols are used in this instruction manual.

Indicates the possibility of explosion under specific

conditions.

Alert statements in this Instruction Manual

The following alert statements apply to the products in this instruction

manual. Each alert statement also appears at the locations needed in

the manual to attract your attention.

WARNIG

F39-MC must be managed and used only by qualified persons.

Operation by un-qualified persons could create a hazardous condition

which may lead to a loss of safety function.

After the changing the setting of the sensor, a start-up check must

be conducted. Normal operation can only be allowed after safety

is confirmed.

In order prevent access to a dangerous area, fixed barrier guards must

be placed in fixed blanked areas.

Failure to do so may result in serious injury.

Use of floating blanking function involves a change of the safety distance.

Always recalculate and re-measure the safety distance to confirm that it

meets the applicable standards, after the change.

Failure to do so may cause the machine to fail to stop before an operator

reaches a dangerous area, and may result in serious injury.

A change of the setting can only be done under observance of laws/

standards which are related to safe operation of the product.

CAUTION

Do not connect the F39-MC to any equipment other than for

what it intended to be used with.

- v -

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

• Do not connect to voltage exceeding the stated values. Doing so

may cause damage to the product.

• Do not expose the F39-MC to water on the product. Doing so

may cause damage to the product.

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate,

malfunctions, or undesirable effects on product performance.

• Always power OFF the sensor when connecting or

disconnecting the F39-MC11.

• When F39-MC is not in use, disconnect it from the sensor.

Page 4

- vi -

Table of Contents

1 DESCRIPTION .............................................................................. 1

1.1 Outline of operation procedure .................................................2

1.2 Available function and Sensor serial number ...........................3

2 RATING ......................................................................................... 4

3 NOMENCLATURE......................................................................... 5

4 WIRING/CONNECTION ................................................................ 7

4.1 Mounting branching connector .................................................7

4.2 Diagram for Wiring of Branching Connector.............................8

4.3 Connecting F39-MC .................................................................9

5 POWER ON................................................................................. 10

6 FUNCTION SELECTION..............................................................11

7 CHANNEL SELECTION .............................................................. 12

8 MONITOR/SET............................................................................ 14

8.1 Fixed blanking ........................................................................16

8.2 Floating blanking ....................................................................21

8.3 Auxiliary output .......................................................................24

8.4 Output2 ...................................................................................24

8.5 External indicator output .........................................................27

8.6 External device monitoring .....................................................30

8.7 Start interlock.......................................................................... 31

8.8 Restart interlock...................................................................... 32

8.9 Threshold adjustment ............................................................. 33

8.10 Setting initialization.................................................................34

8.11 ID setting ................................................................................ 35

8.12 Threshold teach......................................................................36

8.13 Error log view..........................................................................40

9 COPY .......................................................................................... 41

9.1 Upload (Copy Sensor data to F39-MC) .................................. 42

9.2 Download (Copy F39-MC data to Sensor) ............................. 43

9.3 Bank Lock (Prohibit overwriting to bank data) ........................44

10 PROTECT ............................................................................. 45

10.1 Setting lock............................................................................. 46

10.2 Change password...................................................................47

10.3 Setting limitation.....................................................................48

11 DISCONNECT F39-MC......................................................... 50

12 MC11 ERROR CODES ......................................................... 51

13 TROUBLESHOOTING .......................................................... 52

ANNEX1 INDEX .................................................................................. 53

ANNEX2 FUNCTION LIST (according to sensor type) ....................... 56

ANNEX3 ERROR CODE LIST ............................................................ 60

ANNEX4 FUNCTION SETTING CARD ............................................... 61

0

Page 5

- 1 -

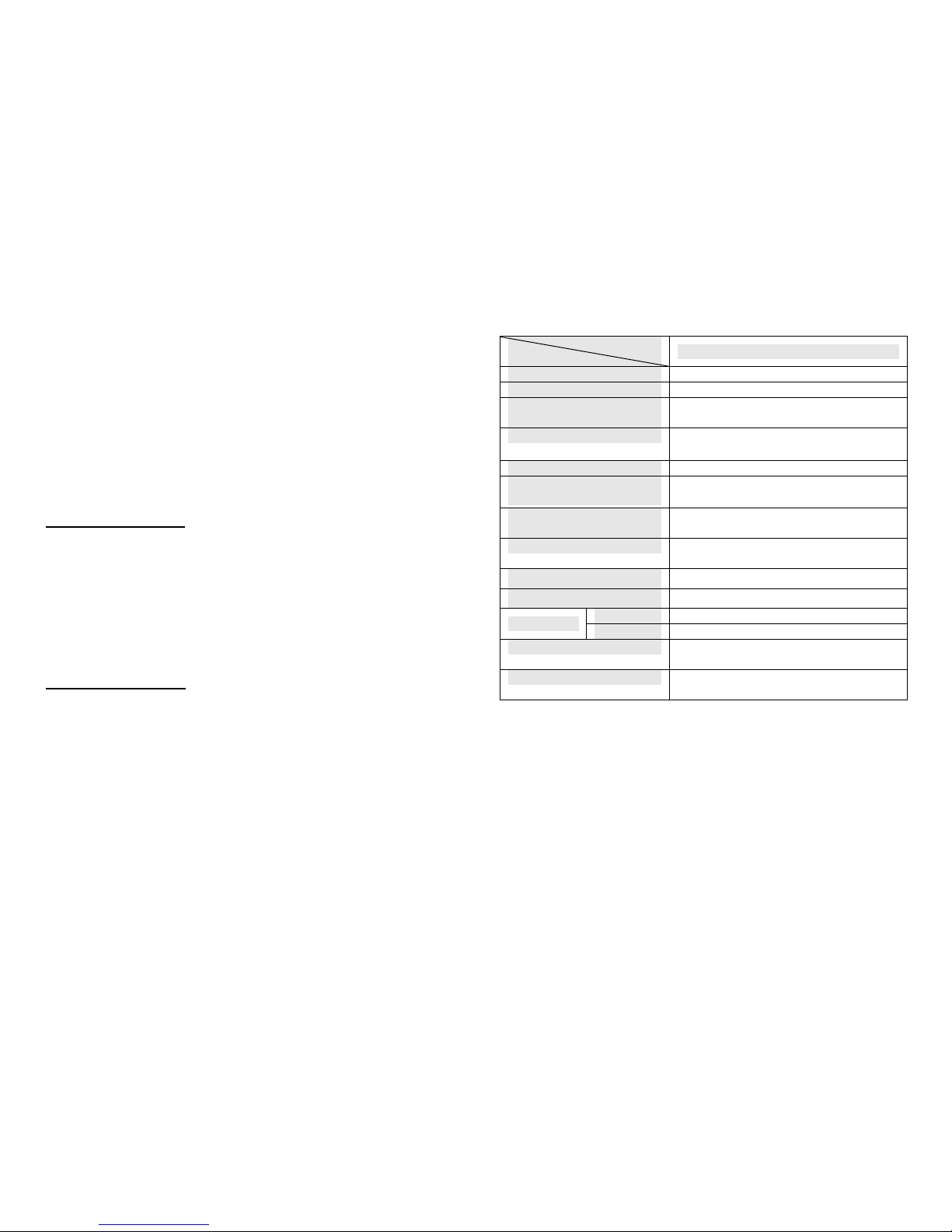

1 DESCRIPTION

The Setting consol Model F39-MC11 (hereafter referred to as F39-MC)

can be connected to Safety Light Curtain Series—Model F3SN,

Multi-beam Safety Sensor series—Model F3SH, and Area Scanner

series—Model F3ZN. The F39-MC allows you to change or monitor the

setting of these sensors.

Available setting functions are as follows;

Function Setting F3SN F3SH F3ZN

Fixed blanking

Floating blanking

Auxiliary output

Output2

External indicator output

External device monitoring

Start interlock

Restart interlock

Threshold adjustment

Setting initialization

ID setting

Threshold teach *

Monitor/

Set

Error log view

Copy Upload

Download

Bank lock

Protect Setting lock

Change password

Setting limitation

: Accessible

* For the sensor having the specific serial number, this function is

unavailable.

Refer to “ 1.2 Available function and Sensor serial number ”.

- 2 -

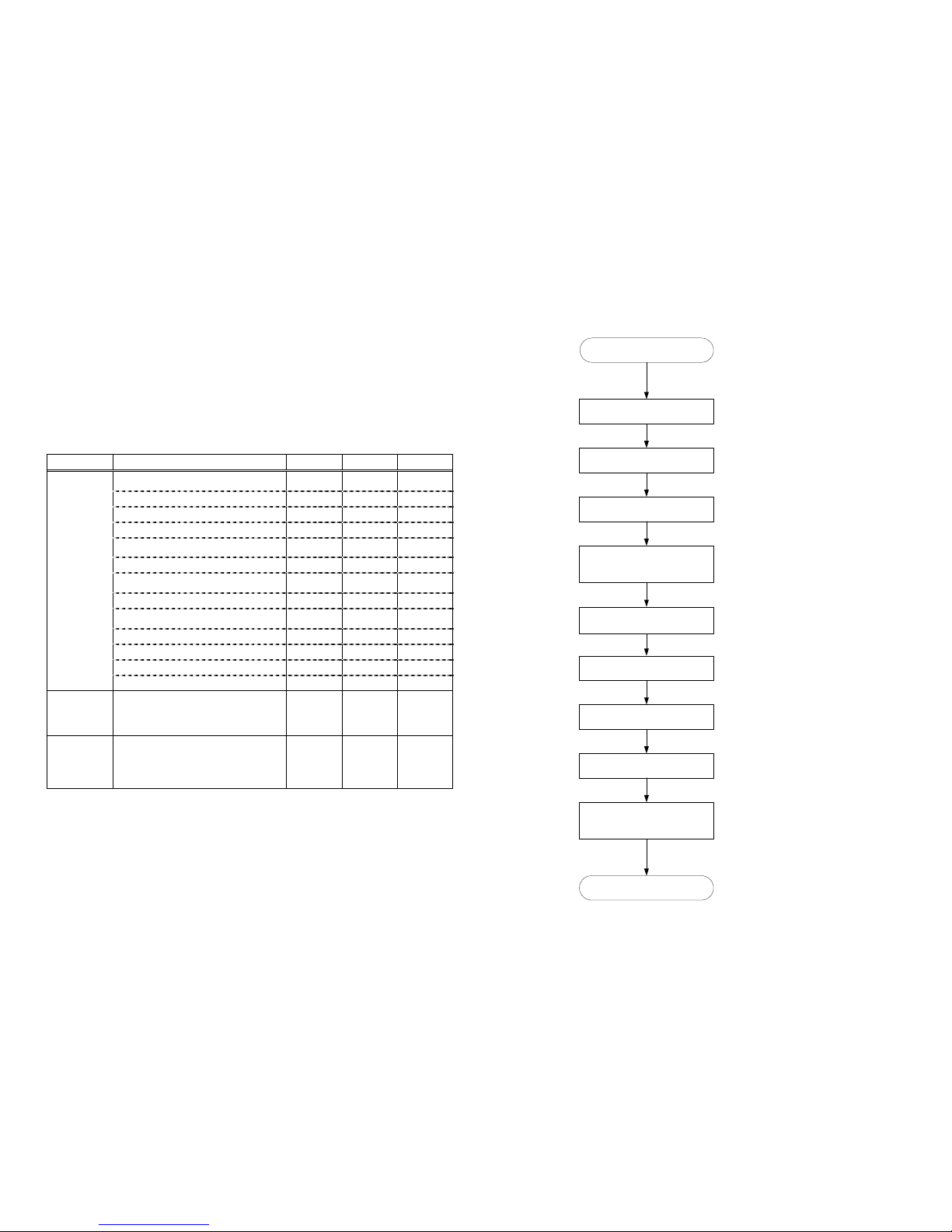

1.1 Outline of operation procedure

Shown in the following flow chart.

⑨Power on sensor(s) and

confirm correct function

by the test.

Outline of operation

procedure

Setting completed.

(Able to normal use)

See section 6

See section 7

See section 4.1

See section 4.3

See section 5

①Mount branching connector

②Connect cable and F39-MC

③Power on both sensor(s)

and F39-MC

④Select function

(MONITOR/SET, COPY,

PROTECT)

⑤Select channel of sensor

to be set

⑥Select sensor function to

be set, and change value

⑦Send changed setting to

sensor(s)

⑧Power OFF, and detach

F39-MC and cable

See section 8 to 10

See section 11

See section 8 to 10

Page 6

- 3 -

1.2 Available function and Sensor serial number

For the sensor having the specific serial number, there are some

unavailable functions in the functions of the F39-MC11.

Check the serial number on the type label of the sensor for both emitter

and receiver to make sure available functions for the sensor.

New functions are divided into two function groups, the functional group

A and the functional group B, by the serial number of the sensor.

Refer to “ANNEX2 FUNCTION LIST (according to sensor type)”(Page

56) about functions corresponding to each group.

The method to distinguish between the functional group A and the

functional group B is as follows.

The functional group A

The following serial numbers correspond to the functional group A.

Serial number:

aaaa402, aaaa502, aaaa602, aaaa702, aaaa802, aaaa902,

aaaaX02, aaaaY02, aaaaZ02, or aaaabcc

'aaaa' can be any numeric characters.

'b' can be any alphanumeric characters.

'cc' is greater than '03'

The functional group B

The following serial numbers correspond to the functional group B.

Serial number:

0001803~, aaaa903, aaaaX03, aaaaY03, aaaaX03, or aaaabcc

'aaaa' can be any numeric characters.

'b' can be any alphanumeric characters.

'cc' is greater than '04'.

- 4 -

2 RATING

Models

Items

F39-MC11

Applicable sensor F3SN, F3SH, F3ZN Series

Communication method Specified method

Communication

connecting method

RS-485

Power supply

24VDC±10%

(share sensor’s power supply)

Current consumption 55mA maximum

Ambient temperature

(during operation)

-10℃ to 55℃

(with no freezing)

Ambient temperature

(during storage)

-25℃ to 65℃

Ambient humidity 25 to 85%RH

(with no condensation)

Insulation resistance

20MΩ min.(at 500VDC)

Dielectric strength voltage 1,000VAC at 50/60Hz for 1min.

Case ABS

Material

Window Polycarbonate

Weight Approx. 87g (without accessories)

Approx. 360g (when packed)

Accessories Branching connector, Cable(2m),

Connector cap, Instruction manual

Page 7

- 5 -

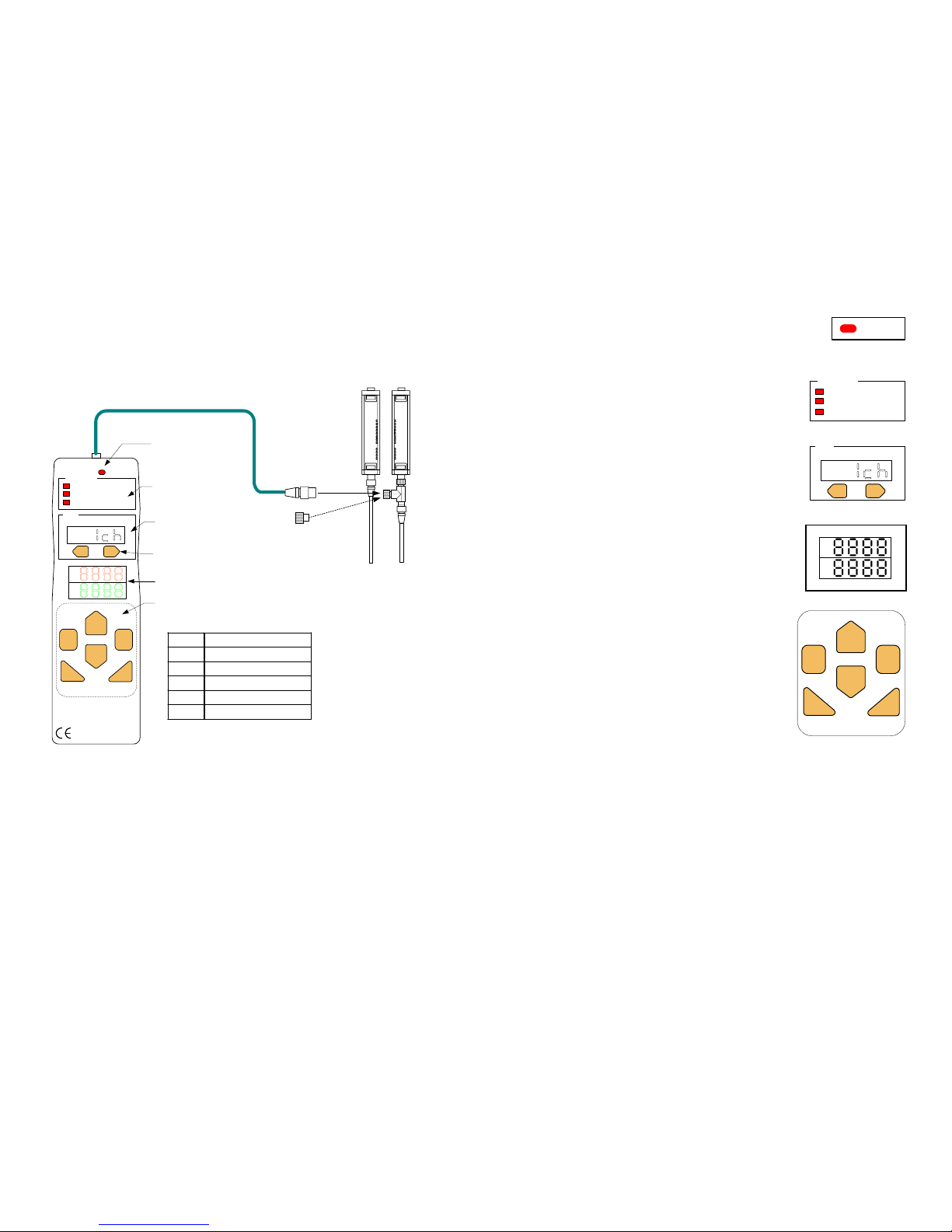

3 NOMENCLATURE

Cable (Length: 2m)

+

|

CONNECT

PNSPO

+

-

MONITOR / SET

COPY

PROTECT

MENU

Setting Console

F39-MC11

CANCEL ENTER

Communication

connection indicator

(CONNECT)

DOWN

UP

RL

Function indicators

(FUNCTION)

Channel display

(CH)

Channel keys(CH)

Mode display

Operation keys

UP Change mode, increase value

DOWN Change mode, decrease value

RIGHT digit position down

LEFT digit position up

CANCEL To cancel

ENTER To se t

Branching

Connector

Sensor

(F3SN, F3SH, or

F3ZN series)

MADE IN JAPAN

FUNCTION

CH

Connector Cap

Please set this to branching

connector when F39-MC is

not in use.

Brief description of Operation keys

- 6 -

+

-

CANCEL ENTER

DOWN

RL

UP

MONITOR / SET

COPY

PROTECT

FUNCTION

3.1 Communication connection indicator (CONNECT)

This indicator will light up when F39-MC is

connected to the sensor.

F39-MC cannot be used when this indicator is not lit.

3.2 Function indicators (FUNCTION)

The indicator of the function being set is lit.

3.3 Channel display(CH) and channel keys

Using +/- keys, select sensor to be set by

F39-MC.

Number of selected channel appears on

display.

3.4 Mode display

Displays function and value when making a

setting.

Basically the top row indicates Setting

function and the bottom row Setting value.

3.5 Operation keys

Used for mode change, setting and

canceling.

+

|

CH

CONNECT

Page 8

- 7 -

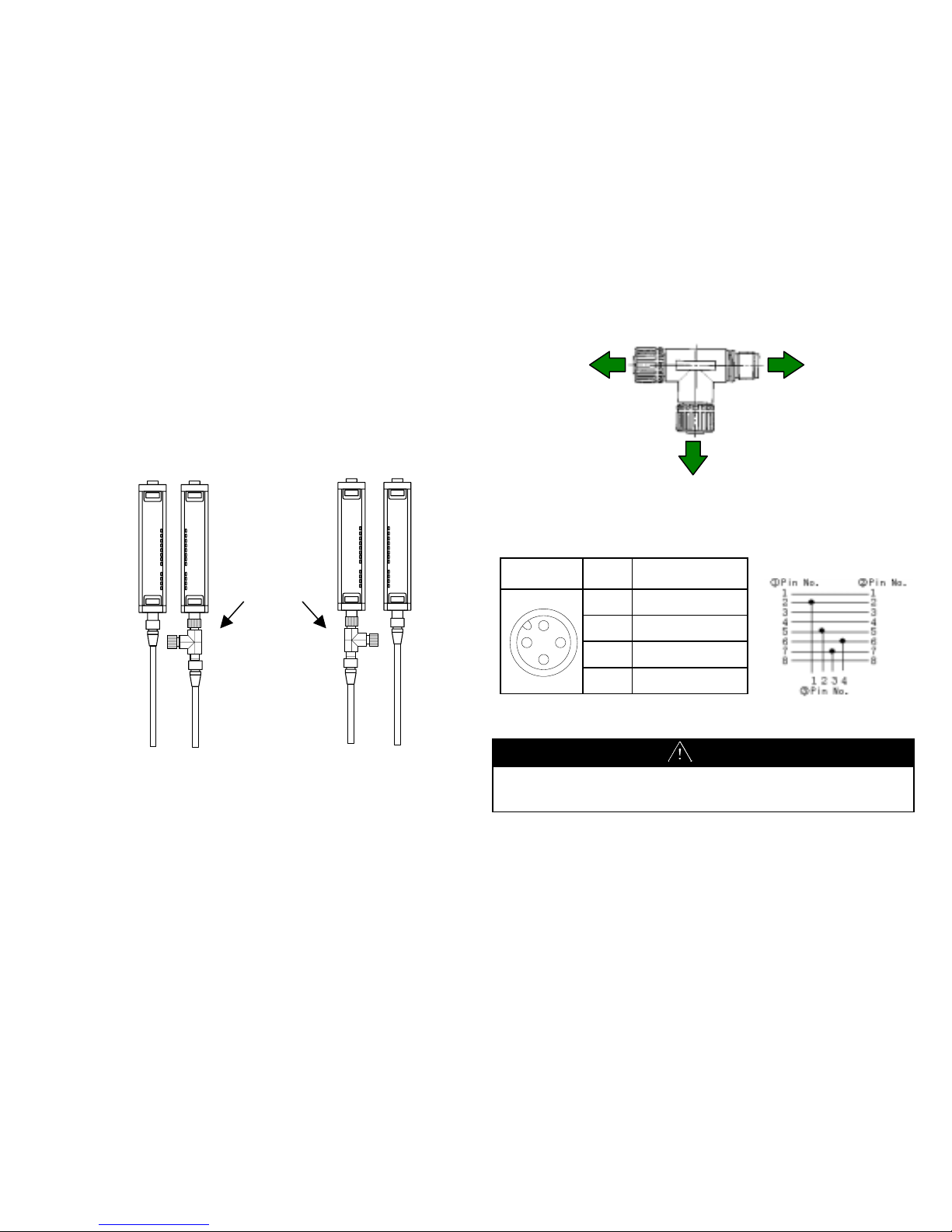

4 WIRING/CONNECTION

4.1 Mounting branching connector

Mount a branching connector to sensor. The connector can be

mounted either on emitter or receiver.

When mounted on receiver When mounted on emitter

Branching

connector

Emitter Receiver

Emitter Receiver

- 8 -

4.2 Diagram for Wiring of Branching Connector

Front View

Pin

No.

Signal

1

+24 V(24VDC)

2 RS-485(A)

3 0V

4 RS-485(B)

CAUTION

The F39-MC receives its power from the sensor. Select a power supply

with sufficient current to allow for the additional consumption of the

F39-MC (55mA maximum).

①8Pin female

To sensor

②8Pin male

To po w er

supply circuit

③4Pin female

To F3 9 -MC

2

4

31

Page 9

- 9 -

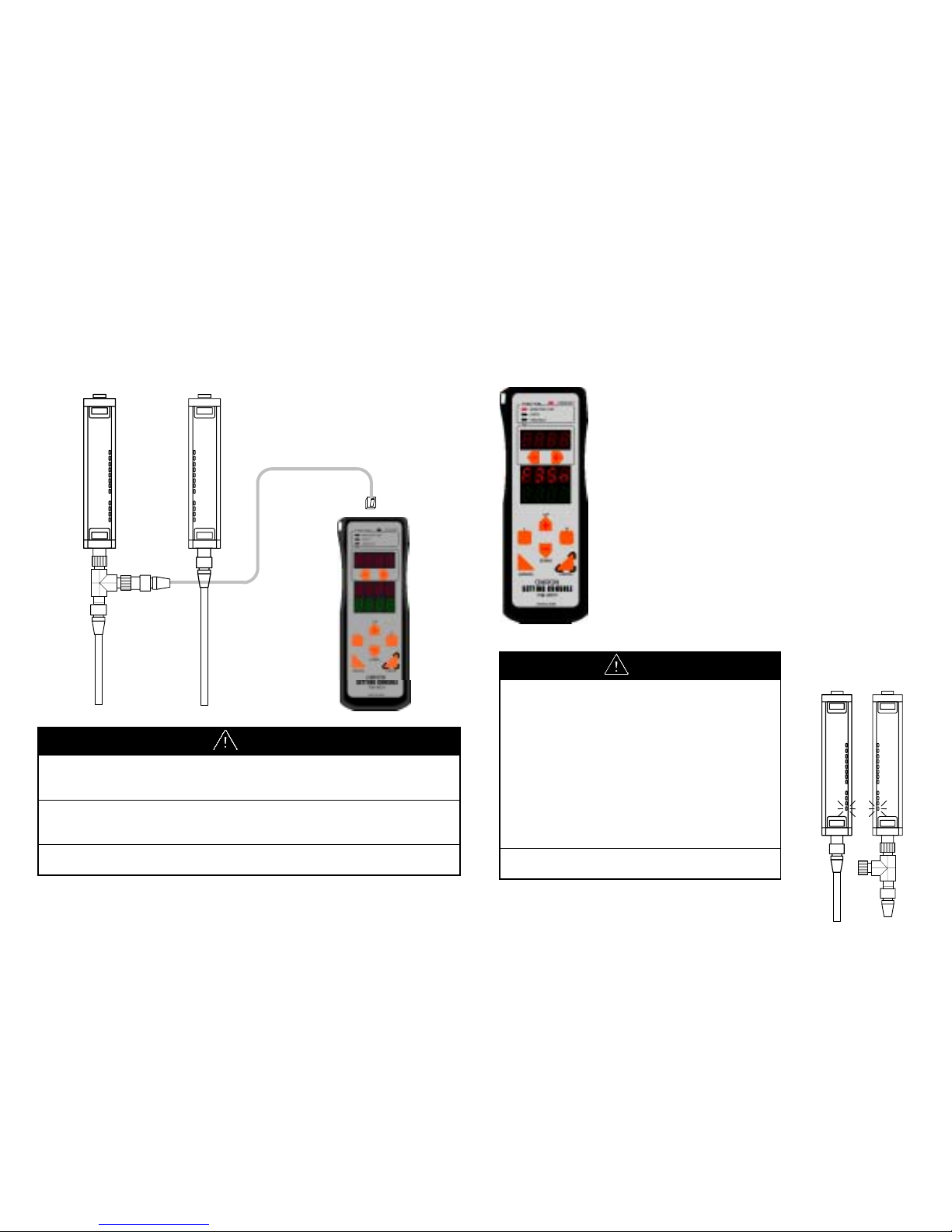

4.3 Connecting F39-MC

Insert M12 connector of the cable into Branching connector and the

other end into the F39-MC11.

CAUTION

Do not connect 2 or more F39-MC to one pair of sensor. Normal

operation cannot be achieved. Also, combined use of F39-MC and

F3ZP, area scanner controller, is not allowed.

When F39-MC is not in use, the cable and F39-MC must be removed

and Branching connector must be covered with connector cap (Model

XS2Z-12).

When connecting or disconnecting the F39-MC, be sure that the power

is OFF.

- 10 -

5 POWER ON

Power supply of F39-MC is shared with that of the sensor.

The F39-MC turns ON with the power supply of the sensor.

When the F39-MC power is ON, it confirms its

connection to sensor. When connection is succeeded,

it displays as follows;

・Communication connecting indicator is lit.

・Displays F39-MC’s model and version in mode

display (for 1 second)

・Displays connected sensor model in mode display,

(for 1 second)

(Figure shown left represents when connected to

Model F3SN-A.)

CAUTION

When F39-MC power is ON, the state of sensor

becomes as follows.

• The safety output of F3SN and F3SH is OFF.

Also, indicators located at bottom (see fig. on

right) are flashing.

• The output of F3ZN is OFF only during

sending data to F3ZN. During non-access

time, normal operation can be conducted

except that the response time increases by

1ms.

Do not disconnect the F39-MC during power

ON-state. Malfunction may result.

Page 10

- 11 -

6 FUNCTION SELECTION

1. Using [UP][DOWN] keys, select the function. Display of selected

function flashes.

2. Function selecting method is shown below.

3. By pressing [ENTER] when the selected function is displayed,

editing of selected function becomes possible. The indicator of the

function selected will light.

4. For editing method of each function, please refer to the item of

respective function.

・ Monitor/Set Section8 page14

・ Copy Section9 page41

・ Protect Section10 page45

-

DOWN

+

UP

MONITOR / SET

COPY

PROTECT

FUNCTION

MONITOR / SET

COPY

PROTECT

FUNCTION

MONITOR / SET

COPY

PROTECT

FUNCTION

-

DOWN

+

UP

- 12 -

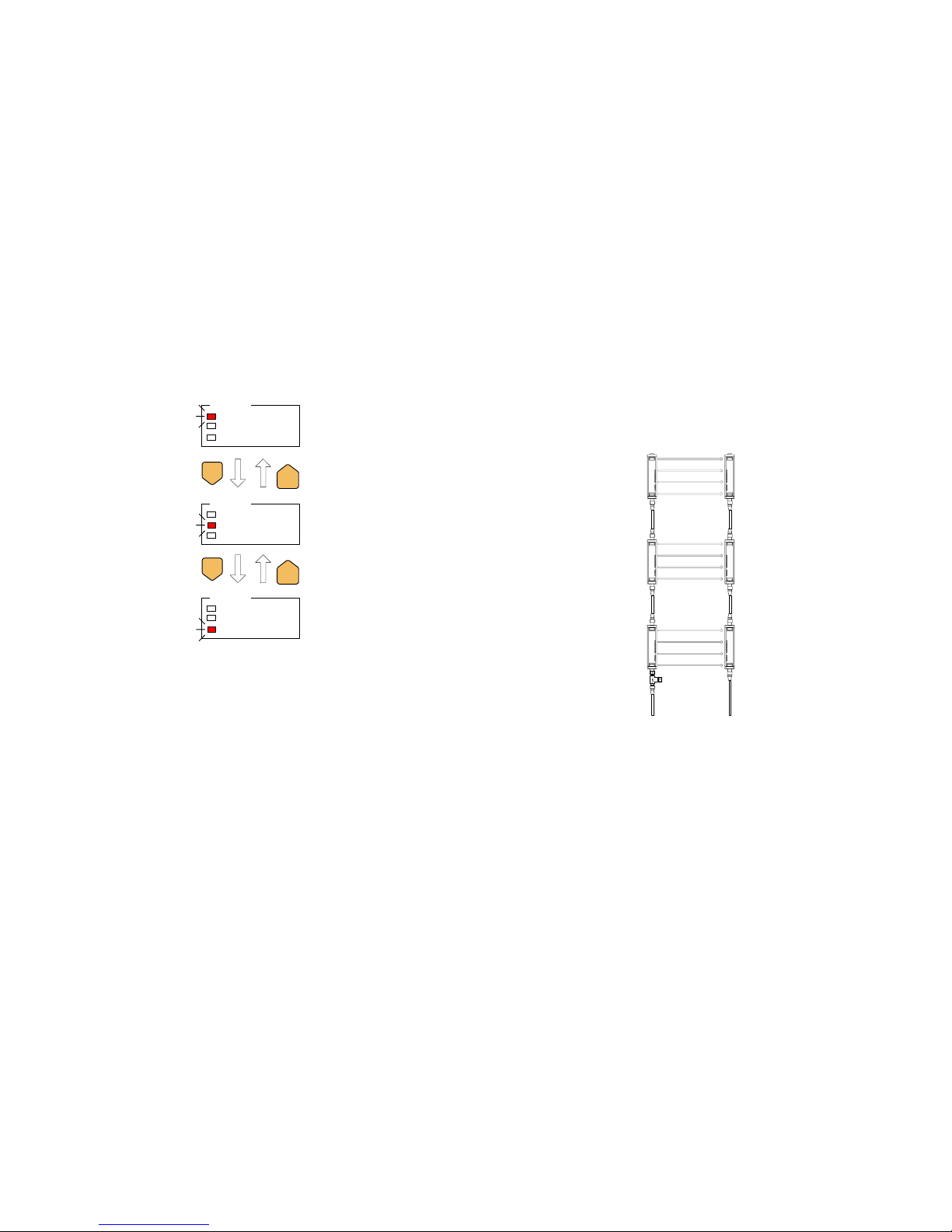

7 CHANNEL SELECTION

When changing the setting of the sensor with the F39-MC, select the

channel in order to determine which sensor is to be set.

Selecting channel (CH) method is as follows;

When series connected, the closest sensor to the extension cable

becomes 1CH and the second closest becomes 2CH.

Channel Numbers in Series Connection

3CH

2CH

1CH

Page 11

- 13 -

Changing selected channel

when connected to three sensors

+

|

CH(+)CH(-)

+

|

CH(+)CH(-)

+

|

CH(+)CH(-)

1ch is selected

(After power on)

2ch is selected

3ch is selected

1ch is selected

The indicator will be displayed as illustrated below, depending on which

function is to be set. This indicates that a setting item is to be

proceeded to all the sensors.

CAUTION

If the channel is changed while making a setting, content of the setting

will be cancelled.

- 14 -

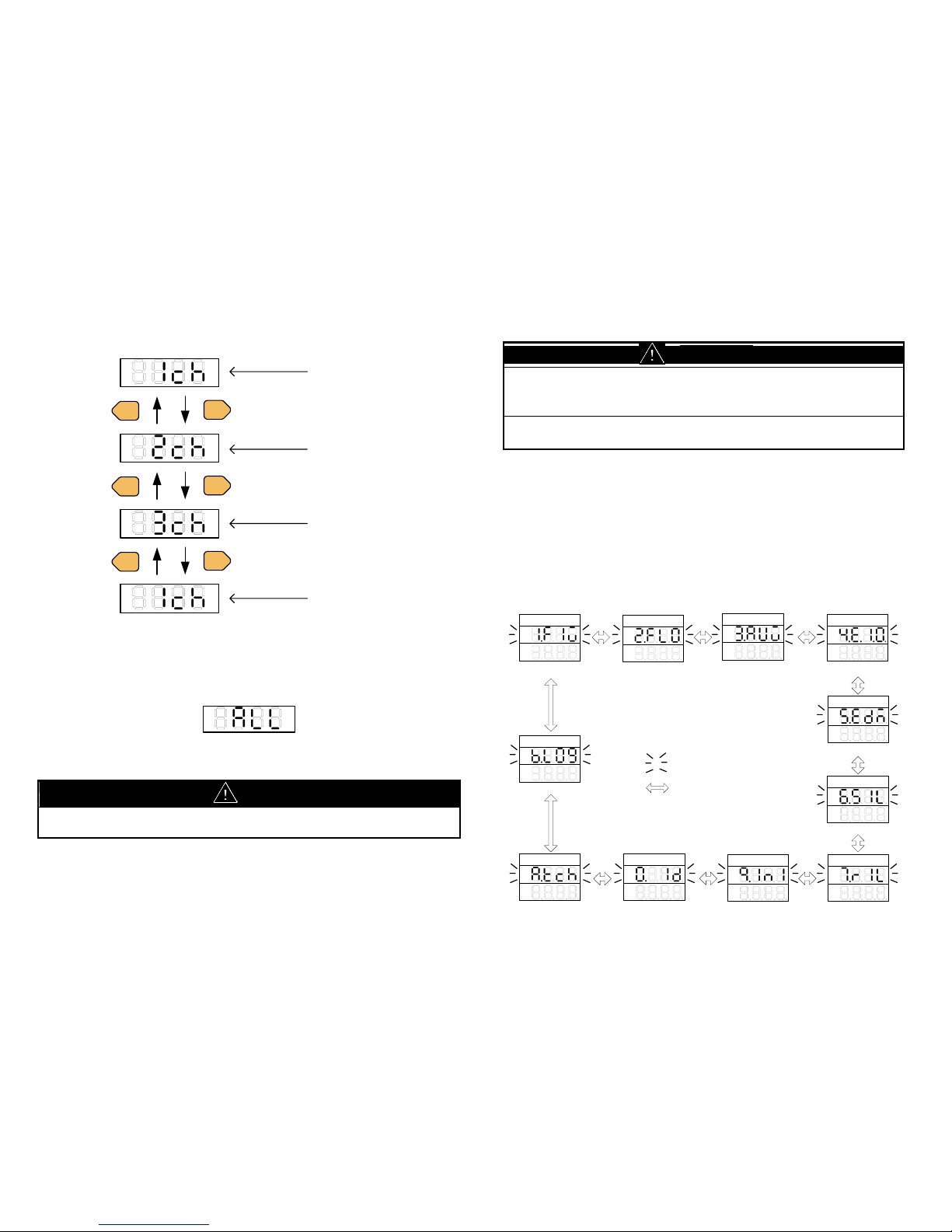

8 MONITOR/SET

CAUTION

After the changing the setting of the sensor, a start-up check must

be conducted. Normal operation can only be allowed after safety is

confirmed.

A change of the setting can only be done under observance of laws/

standards which are related to safe operation of the product.

This function enables the monitoring of current set values and functions

of the sensor. When a set value is changed, content of the change is

reflected on sensor. The value which is indicated first in each category

is the current set value.

The method of change into each mode is as illustrated below.

By pressing [ENTER] key when the selected function is displayed,

editing of selected function becomes possible.

(i)F3SN

1.Fixed blanking

2.Floating blanking

4.Ext. indicator output

3.Auxiliary output

5.Ext. device monitor

9.initialize

0.ID

7.Restart in terlock

6.Start interlock

1.FIX

2.FLO

3.AUX 4.E.I.O.

5.EDM

6.SIL

7.RIL9.INI0.ID

[UP][DOWN]Key

Blinking

A.Threshold teach

A.TCH

B.Error log view

B.LOG

Page 12

- 15 -

(ii)F3SH

3.Auxiliary output

9.Initialize

0.ID

7.Restart interlo ck

6.Start interlock

3.AUX

4.E.I.O.

4.Ext. indicator output

5.Ext. device monitor

5.EDM

6.SIL

7.RIL

9.INI0.ID

A.Threshold teach

A.TCH

B.Error log view

B.LOG

(iii)F3ZN

1.Fixed blanking 3.Output #2

8.Threshold

2.Floating blanking

4.Ext. indicator output

9.Initialized

0.ID

9.INI0.ID

1.FIX 2.FLO

3.OU2

4.E.I.O.

8.TH

B.Error log view

0.LOG

<Common Note for MONITOR/SET function>

1. Edited value will not become active if NOT “SEND” to sensor, nor

“Function Valid (1.Fun-on)” is not selected.

2. “Loc” may display if “Setting lock” or “Setting limitation” has been

set. See clause10.1 and 10.3.

3. Please do not drop a power supply on the "Send" display after

pushing the [ENTER] key before being displayed as "Good." When

a power supply should be dropped, a sensor may not carry out

normal operation.

- 16 -

8.1 Fixed blanking

<F3SN, F3ZN>

CAUTION

In order prevent access to a dangerous area, fixed barrier guards

must be placed in fixed blanked areas.

Failure to do so may result in serious injury.

When Floating blanking function is enabled simultaneously, the

beam more than a plan may become invalid.

Please perform sufficient verification, when you confirm both

functions simultaneously.

Failure to do so may result in serious injury.

Fixed blanking function partly voids detection zone of sensor. Entrance

of object into invalid detection zone does not change output status.

There are two ways to choose which zone is to be blanked.

1. Teaching: Blocked beams are set as beams for blanking. Error will

be displayed if there are no blocked beams.

2. Manual: Select beam number first, and then choose

blanked/not blanked for each selected beam. Beams are

numbered as below figure.

7

6

5

4

3

2

1

Page 13

- 17 -

<Surveillance mode>

F3SN can set up the following operation in consideration of safety.

1. Setting release at the light receiving condition

In case a blanked beam becomes clear, F3SN will automatically

invalids fixed blanking function. In other words, no blanked beam

will exist. Reset of power makes previous fixed blanking setting

active.

2. Lockout mode at the light receiving condition

In case a blanked beam becomes clear, F3SN will become lockout

condition. Reset of power, or Reset input makes previous fixed

blanking setting active.

Make sure to make blanked areas so that no one can reach to the

dangerous part from blanked areas. All blanked beams need to be

blocked by object.

The above functions are only implemented on F3SN, where safety is

necessary. For F3ZN, fixed blanking function continues even if blanked

beam becomes clear.

<Note>

Models produced before April 2002 can not use setting of "Surveillance

mode". Sensors which has specific serial number also can not use the

setting. (If the surveillance mode is set to above model, "setting release

at the light receiving" is always set.) Please confirm at the time of a

setup.

- 18 -

<F3SN>

Go to ②-2

001:Select beam num.

①

z

②-1 ②-2 ②-3

②-4

Go to ①

after 1 sec.

Go to ②-4

after 1 sec

Fixed blanking

Error

Function Valid

Beam select (manual)

Beam select (manual)

Beam select (manual)

Setting completed

Function Valid

Beam select (Teach)

Beam select (Teach)

Send to sensor

ON:Valid

OFF:Invalid

ON:Beam selected

OFF:Beam un-selected

ENT:Beam(s) selected

Go to ②-3

after 1 sec

CLR:Clear selected

beam(s)

When "teached", blocked

beams are selected.

Note: When "Enter" key

pressed with no blocked

beams, "Err" is displayed.

OR

OR

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

1.FIX

②-1-1

1.FUN 2.TCH

②-2-1

3.MAN

②-3-1 ②-4-1

SEND

②-2-2

GOOD

ERR

②-3-2

GOOD

ERR

②-3-3

GOOD

ERR

②-5

Surveillance mode

Go to ②-5

Surveillance mode

Lockout mode at the

light receiving condition

Setting release at the

light receiving condition

3.MON

Page 14

- 19 -

<F3SN, F3ZN>

About F3SN, it becomes the following displays by the serial number.

Go to ②-2

001:Select beam num.

①

z

②-1 ②-2 ②-3 ②-4

Go to ①

after 1 sec.

Go to ②-4

after 1 sec

Fixed blanking

Error

Function Valid

Beam select (manual)

Beam select (manual)

Beam select (manual)

Setting completed

Function Valid

Beam select (Teach)

Beam select (Teach)

Send to sensor

ON:Valid

OFF:Invalid

ON:Beam selected

OFF:Beam un-selected

ENT:Beam(s) selected

Go to ②-3

after 1 sec

CLR:Clear selected

beam(s)

When "teached", block ed

beams are selected.

Note: When "Enter" key

pressed with no blocke d

beams, "Err" is dis played.

OR

OR

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

1.FIX

②-1-1

1.FUN 2.TCH

②-2-1

3.MAN

②-3-1 ②-4-1

SEND

②-2-2

GOOD

ERR

②-3-2

GOOD

ERR

②-3-3

GOOD

ERR

- 20 -

Example of how to set fixed blanking.

Example1:Set Fixed Blanking using "teaching"

②-1-1:Select "1.Fun-on"(Function valid)

Place an object where you want to be "blanked"

②-2-1:Select "2.tch-Ent"(Beams select)

②-4:Send setting to sensor

Setting completed

[good] displayed

ONE POINT:

After setting has complete d, you can confirm the

blanked beam numbers by using ②-3:Manual Beam

select menu.

[good] displayed

[Err] displayed・・・Object is not mounted properly.

Replace it and try ②-2 again.

[Err] displayed・・・Couldn't send setting to sensor.

Check wiring, etc. and try a gain from the beginning

Example2:Set Fixed Blanking using "manual"

②-1-1:Select "1.Fun-on"(Function valid)

②-3:Select "3.man"(manual beam select)

②-3-1:Input beam number to be "blanked"

②-3-2:Select "on"(beam selected)

②-4:Send setting to sensor

Setting completed

[good] displayed

[good] displayed

In order to "blank" more than one beam, repeat

Select beam number -> select "on" -> [CANCEL] Key

command, and push [ENTER] key at the end.

[Err] displayed・・・Couldn't send setting to sensor.

Check wiring, etc. and try again from the beginning

[Err] displayed・・・Wrong beam number was inputted.

Input correct number and try again .

Page 15

- 21 -

8.2 Floating blanking

<F3SN, F3ZN>

CAUTION

Use of floating blanking function involves a change of the safety

distance. Always recalculate and re-measure the safety distance to

confirm that it meets the applicable standards, after the change.

Failure to do so may cause the machine to fail to stop before an operator

reaches a dangerous area, and may result in serious injury.

When Fixed blanking function is enabled simultaneously with floating

blanking function, more beams than your plan may become invalid.

Perform sufficient verification, when you use both functions

simultaneously.

Failure to do so may result in serious injury.

Floating blanking function allows the output to remain ON when beams

of the sensor are interrupted anywhere in the field. In contrast with fixed

blanking function, which invalids fixed detection area, floating blanking

function ignores object smaller than specified radius.

Floating can be set for 1 to 3 floating beams.

(When 1 floating beam is set, sensor will turn OFF when 2 or more

beams are blocked).

- 22 -

CAUTION

Use of floating blanking function involves a change of the safety

distance. Always recalculate and re-measure the safety distance to

confirm that it meets the applicable standards, after the change.

Failure to do so may cause the machine to fail to stop before an operator

reaches a dangerous area, and may result in serious injury.

Resolution

(mm)

Undetectable

dia.(mm)

Floating beam

Beam gap(mm)

0 1 2 3 1 2 3

9 14 23 32 41 4 13 22

15 25 40 55 70 5 20 35

30 40 70 100 130 20 50 80

60 70 130 190 250 50 110 170

The following modes can be set in floating blanking function;

1. Sequential beam mode

- ON: Output becomes OFF when consecutive blocked beams

exceeds floating beams. Output will not becomes OFF

when plural objects smaller than undetectable diameter

exist.

- OFF: Output becomes OFF when sum of blocked beams exceeds

floating beams. Output may becomes OFF when plural

objects smaller than undetectable diameter exist.

2. Outermost beam invalid mode

Outermost beam invalid mode excludes outermost beams from

floating blanking.

When this mode is valid, the output will turn OFF if one of the

outermost beams is blocked, even if floating blanking is active.

Page 16

- 23 -

①

②-1 ②-2 ②-3 ②-4 ②-5

Go to ②-3

Go to ②-4

Go to ②-5

Floating blanking

Sequential modeFunction Valid Floating beam no.

Outermost beam invalid

Function valid Floating beam no. Sequential mode

Outermost beam invalid

Send to sensor

Setting completed

Error

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

1:1 floating beam

Go to ①

after 1 sec.

2:2 floating beams

3:3 floating beams

CLR: floating beams

clear

2.FLO

1.FUN

②-1-1

2. NO. 3.SEQ 4.O.B.I. SEND

②-2-1 ②-3-1 ②-4-1 ②-5-1

Go to ②-2

ON:Valid

OFF:Invalid

ON:Valid

OFF:Invalid

ON:Valid

OFF:Invalid

GOOD

ERR

- 24 -

8.3 Auxiliary output

<F3SN, F3SH>

This is a non-safety related output used to display a status.

This output cannot be used for the purpose of safety.

This can be selected to the following output;

1. Dark ON

2. Light ON

3. Light diagnosis

4. Lockout

5. Outermost beam monitoring

6. Blanking monitoring

7. Specified beam

For detail of each output, please refer to ANNEX1 INDEX.

<Note>

Because F3SH does not have fixed blanking function, “6. Blanking

monitoring” is not selectable.

8.4 Output2

<F3ZN>

This is a output of F3ZN used to display a status.

Available signals are the same as 8.3 Auxiliary output.

Page 17

- 25 -

③-2

①

Auxiliary output

Setting completed

Error

Send to sensor

②-7

Specified beam

②-6

Blanking monitor

②-5

Outermost beam monitor

②-4

Lockout

②-3

Light diagnosis

②-2

Light ON

②-1

Dark ON

Beam select (Teach)

③-1(from ②-7)

OR

ENT:Beam(s) selected

CLR:Clear selected

beam(s)

Go to ③-2

after 1 sec.

(Only when ②-7 is

selected, go to ③-1)

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

When "teached", blocked

beams are selected.

Note: When "Enter" key

pressed with no blocked

beams, "Err" is displayed.

3.AUX

1.D.ON 2.L.ON 3.L.DG 4.L.OU

5.O.B.M.6.BLN7.SPC

③-1-1

GOOD

ERR

SEND

③-2-1

GOOD

ERR

- 26 -

③-2

①

Setting completed

Error

Send to sensor

②-7

Specified beam

②-6

Blanking monitor

②-5

Outermost beam m onitor

②-4

Lockout

②-3

Light diagnosis

②-2

Light ON

②-1

Dark ON

Beam select (Teach)

③-1(from ②-7)

OR

ENT:Beam(s) selected

CLR:Clear selected

beam(s)

Go to ③-2

after 1 sec.

(Only when ②-7 is

selected, go to ③-1)

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

When "teached", blocked

beams are selected.

Note: When "Enter " key

pressed with no blocked

beams, "Err" is displayed.

1.D.ON 2.L.ON 3.L.DG 4.L.OU

5.O.B.M.6.BLN7.SPC

③-1-1

GOOD

ERR

SEND

③-2-1

GOOD

ERR

Output #2

3.OU2

Page 18

- 27 -

8.5 External indicator output

<F3SN, F3SH F3ZN>

This is a non-safety related output which can be connected to an

optional indicator, such as F39-A01P-.

Applicable only to the models which can be connected in series.

This can be selected to the following output;

1. Dark ON

2. Light ON

3. Light diagnosis

4. Lockout

5. Test input-ON

6. Test input-OFF

7. Blanking setting

For detail of each output, please refer to ANNEX1 INDEX.

<Lighting pattern setup>

Display Lighting pattern setup

LIHt Light

bln.1 It blinks in a cycle of 0.5 seconds.

bln.2 It blinks in a cycle of 1 seconds.

bln.3 It blinks in a cycle of 2 seconds.

<Note>

1. F3ZN can set up only 1-4.

2. There are some which cannot set up above 5-7 by the serial

number about F3SN and F3SH.

3. There are some which cannot set up a blink pattern by the serial

number. (Light only)

4. Because F3SH does not have fixed blanking function, “7.

Blanking setting” is not selectable.

- 28 -

<F3SN, F3SH>

⑤-1

①

Setting completed

Error

Send to sensor

②-4

Lockout

②-3

Light diagnosis

②-2

Light ON

②-1

Dark ON

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

1.D.ON 2.L.ON 3.L.DG 4.L.OU

SEND

⑤-2

GOOD

ERR

Ext. indicator output

4.E.I.O.

②-6 ②-5

Test input-ON

Test input-OFF

7.b.L.S

6.t.OF

5.t.on

④-1

Lighting pattern setup

LIHt

bLn.1

bLn.2

bLn.3

②-7

Blanking setting

③

Lighting pattern setup

FLSH

Page 19

- 29 -

<F3SN, F3SH, F3ZN>

About F3SN and F3SH, it becomes the following displays by the serial

number.

③-1

①

Setting completed

Error

Send to sensor

②-4

Lockout

②-3

Light diagnosis

②-2

Light ON

②-1

Dark ON

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

1.D.ON 2.L.ON 3.L.DG 4.L.OU

SEND

③-2

GOOD

ERR

Ext. indicator output

4.E.I.O.

- 30 -

8.6 External device monitoring

<F3SN, F3SH>

This function can detect malfunction of external device which controls

hazardous area of machine. (e.g. contact welding)

The determination time can be set in respect to the response time of

relay being used. The setting time must be between 100ms to 600ms

and can be set in 5ms increments.

①

②-1

Go to ②-2

Change delay time

using [UP][DOWN]

[L][R]keys.

(100 to 600 ms;

every 5ms)

②-2

Go to ②-3

②-3

Ext. device monitor

Function valid

Acceptable delay time

Send to senso r

Function valid

Error

Setting completedSelect time (ms)

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

5.EDM

②-1-1 ②-2-1

②-3-1

1.FUN 2.TIM SEND

ON:Valid

OFF:Invalid

300

GOOD

ERR

Page 20

- 31 -

8.7 Start interlock

<F3SN, F3SH>

When this function is ON, the outputs remain in the OFF-state (i.e.

interlock state) after power ON. Interlock state can be released by a

manual reset when there are no obstructions in the detection zone.

CAUTION

This function is valid only when using manual reset mode. When in

auto reset mode, the start interlock function is automatically

disabled.

②-1

②-2

Start interlock

Setting completed

Error

Function Valid

Function Valid Send to sensor

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

①

6.SIL

1.FUN SEND

②-1-1

②-2-1

GOOD

ERR

Go to ②-2

ON:Valid

OFF:Invalid

- 32 -

8.8 Restart interlock

<F3SN, F3SH>

When this function is ON, the outputs remain in their OFF-state (i.e.

interlock state) when sensor is interrupted. Interlock state can be

released by a manual reset when there are no obstructions in the

detection zone.

CAUTION

This function is valid only when using manual reset mode. When in

auto reset mode, the start interlock function is automatically

disabled.

②-1

②-2

Setting completed

Error

Function Valid

Function Valid Send to sensor

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

①

1.FUN SEND

②-1-1

②-2-1

GOOD

ERR

Go to ②-2

ON:Valid

OFF:Invalid

Restart interlock

7.RIL

Page 21

- 33 -

8.9 Threshold adjustment

<F3ZN>

This function enables to adjust threshold value of F3ZN.

Upper row displays current minimum light level (minimum value

throughout all beams in the sensor), and lower row displays current

threshold value.

Threshold value of the sensor can be adjusted between 18 (the default

value at shipment from factory) and 100.

Current minimum light level

Threshold value.

Change this valud using

[UP][DOWN] [L][R] keys.

(18 to 100)

Threshold adjustment

Threshold adjustment

Setting completed Error

Send to sensor

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

8. TH

①

②

③

18

SEND GOOD ERR

- 34 -

8.10 Setting initialization

<F3SN, F3SH, F3ZN>

This function returns the sensor setting to their default value.

Default value of each function

Function F3SN F3SH F3ZN

Fixed blanking Invalid – Invalid

Floating blanking Invalid – Invalid

Auxiliary output / Output2 Dark ON

External indicator output Light ON

External device monitoring Valid –

Start interlock Valid –

Restart interlock Valid –

Threshold value – – 18

<Note>

ID setting will not be changed by Initialization Setting.

Initialization

Initialization Send to sensor

Setting completed Error

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Go to ①

after 1 sec.

CANC:Cancel SEND

Go to ①

①

9.INI

②-1 ②-2

②-3

GOOD ERR

Page 22

- 35 -

8.11 ID setting

<F3SN, F3SH, F3ZN>

ID number can be set specific to each sensor.

The possible setting number range is between 0000 and 9999.

(Default will be 0000)

ID Setting

ID Setting Send to sensor

Setting completed Error

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

Change ID valud using

[UP][DOWN] [L][R] keys.

(0000 to 9999)

Go to ①

after 1 sec.

①

②

0. ID

0000 SEND

GOOD ERR

- 36 -

8.12 Threshold teach

<F3SN, F3SH>

This function can be used to display receiving light level of sensor or

adjust ON-threshold level to most suitable value. So, it makes possible

to shorten the detection distance depending on the installation condition.

This function is effective in preventing mutual interference and external

light interference.

Threshold teach function consists of three steps of following.

1. Display for receiving light level value.

2. Calculate the optimal value of ON threshold level and adjust

manually.

3. Write ON-threshold level into sensor.

CAUTION

Perform this function at the condition that all the beams of a sensor are

incident state. The sensor cannot be set correctly when any beams are

blocked.

1. Display for receiving light level value

This function displays receiving light level value of sensor.

It has three kinds of display modes of receiving light level as follows.

Min-Max light level display mode

Maximum value and minimum value in receiving light levels of all

beams are displayed. The maximum value is displayed on the top

row in the display. The minimum value is displayed with the

approximate beam position having the minimum value on the

bottom row in the display.

Individual light level display mode

The receiving light level of the selected beam is displayed.

The beam number is displayed on the top row. The receiving light

level corresponding to the beam number is displayed on the

bottom row.

Page 23

- 37 -

Individual max light level display mode

The maximum receiving light level of the selected beam is

displayed.

The beam number is displayed on the top row. The maximum

receiving light level corresponding to the beam number is

displayed on the bottom row.

Threshold teach

TCH

(1)

(2)-1

P.123

Max-Min Level

Go to

2. threshold

calculate.

(2)-2

Individual Level

U/D

Individual Level

A.123

A.122

L/R

Individual Max. Level

L/R

(2)-3

L.123

Individual Max. Level

U/D

L.122

L/R

U/D

ENTER Key

CANCEL Key

[L]/[R] Key

[UP]/[DOWN] Key

Beam number is

changed

Beam number is

changed

Go to (1)

Go to

2. threshold calculate.

Go to (1)

Go to

2. threshold calculate.

The fourth figure of the bottom row indicator of “(2)-1” indicates that

the approximate beam position having the minimum light level.

The beam positions of the sensor are divided in to three groups, top,

middle, and bottom, and displayed as show in the figure below. (The

bottom position means the side with power supply lines.)

Max-Min Level

Lower position:

Top

Lower position:

Middle

Lower position:

Bottom

- 38 -

2. Calculate the optimal value of ON threshold level and adjust

manually.

The sensor automatically calculates the optimal value of

ON-threshold on the basis of the minimum light level. After automatic

calculation is completed, “Good” is displayed on top row and the

calculated ON-threshold is displayed on bottom row.

Additionally, the displayed ON-threshold value can be adjusted

manually. ON-threshold can adjust in the range of 18 to 100.

NOW CALC

ON-threshold calculate

(1)

Good 20

(2)

Adjustment of ON-threshold

Calculate

complete

U/D

Good 19

(2)-1

Adjustment of ON-threshold

Manual adjustment of

ON-threshold

Go to 1. Display for receiving

light level value No.(2)-1

Go to 3. ON-threshold

write in to sensor

ENTER

CANCEL

One-point advice:

A

djust beams of the sensor with this function so that the

minimum receiving light level becomes higher. By doing this, the

sensor detects stably.

Page 24

- 39 -

3. Writing ON-threshold level into sensor.

ON threshold level obtained by calculation is written in a sensor.

When the writing is failed, check connecting condition between the

sensor and the F39-MC11 and start from the first.

A.TCH SEND

Threshold write

(1)

Go to 1. display for receiving

light level value No. (2)-1.

ENTER

A.TCH Good

Threshold write

A.TCH ERR

Threshold write

Write-in success Write-in failure

After 1

second.

Go to 1. display

for receiving light

level value No.

(1).

- 40 -

8.13 Error log view

<F3SN, F3SH, F3ZN>

The error log recorded in sensor is displayed.

The error log is written with error codes. See the contents of error code

at “ANNEX3 ERROR CODE LIST” (Page 60 ) for detailed information.

The error code having smaller error number is newer error.

d1.35

Error Log View

Error Log View

b.Log

(1)

CH

U/D

Error Log View

d2.21

L/R

Change emitter / receiver

Change sensor channel

(2) (3)

(5)(4)

Error Log View

Error Log View

L1.61

d1.21

Change Error number

L/R

U/D

ENTER Key

CANCEL Key

[L]/[R] Key

[UP]/[DOWN] Key

CH

CH Key

Error Code

Error Number

L :Emitter

D :Receiver

Page 25

- 41 -

9 COPY

This function allows you to copy settings of one sensor and transfer

them to another sensor. The settings which can be changed in

Monitor/Set mode, will be copied. (Including ID)

Inside the F39-MC are banks of the memory to store the date of sensor.

The data will not be deleted in case of power OFF since the data in the

bank is stored in EEPROM.

Bank lock setting protects data from being deleted by mistake.

The numbers of banks are listed below. Each bank can store setting

data of one sensor.

F3SN : 1

F3SH : 1

F3ZN : 9

<Note>

1. Banks will be allocated independently to sensor models (F3SN/F3SH

/F3ZN). Copying to a sensor with different model is not possible. For

example, copying from F3SN to F3ZN is not possible.

2. Copying to sensor with different detection capability (or beam gap) is

not possible.

Switch modes are illustrated below;

Section9.1(42page) Section9.2(43page) Section9.3(44page)

1.Upload

2.Download

3.Bank Lock

1.U.LD 2.D.LD 3.B.LC

[UP][DOWN]KeyBlinking

- 42 -

9.1 Upload (Copy Sensor data to F39-MC)

Copy the setting data of one sensor to the bank of F39-MC.

Select <1.U.Ld> and press [ENTER] key. Bank from 1 to 9 can be

changed with using [UP][DOWN] keys (F3ZN only).

The illustration below shows that setting data from the sensor is stored

into bank 1 of F39-MC.

Select bank number using

[UP][DOWN] keys.

Note: F3SN/F3SH has only

Bank1

Upload

Upload Setting completed Error

Blinking

[Cancel] Key

[Enter] Key

1.U.LD

①

②

BK 1:Bank #1 GOOD ERR

Go to ①

after 1 sec.

③

<Note>

Bank 1 for F3SN, F3SH and F3ZN are stored in different memories.

Page 26

- 43 -

9.2 Download (Copy F39-MC data to Sensor)

WARNING

After the changing the setting of the sensor, a start-up check must

be conducted. Normal operation can only be allowed after safety is

confirmed.

A change of the setting can only be done under observance of laws/

standards which are related to safe operation of the product.

Copy the setting data of one sensor stored in the bank of F39-MC to

another sensor.

<Note>

1. Banks will be allocated independently to sensor models

(F3SN/F3SH/F3ZN). Copying to sensor with different model is not

possible. For example, copying from F3SN to F3ZN is not possible.

2. Copying to sensor with different detection capability (or beam gap) is

not possible.

3. Please do not drop a power supply on the "bk 1" display after

pushing the [ENTER] key before being displayed as "Good." When a

power supply should be dropped, a sensor may not carry out normal

operation.

Download

Download Setting completed Error

Select bank number using

[UP][DOWN] keys.

Note: F3SN/F3SH has only

Bank1

Blinking

[Cancel] Key

[Enter] Key

①

②

2.D.LD

BK 1:Bank #1 GOOD ERR

Go to ①

after 1 sec.

③

- 44 -

9.3 Bank Lock (Prohibit overwriting to bank data)

To prohibit overwriting to a bank that has been stored with the setting

data of the sensor, select this function by following means;

Select <3.b.Lc>, then press [ENTER] key to enter Bank lock mode.

Select the bank with [UP][DOWN] keys and set to either prohibit writing

<Loc> or permit writing <FrEE> with [ENTER] key.

Bank lock

Bank lock

Bank lock

Bank lock

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

LOC:Overwrite

disabled

FREE:Overwrite

enabled

3.B.LC

①

②-1

BK 1:Bank #1 BK 2:Bank #2

②-2

Selectable from BK2 to BK9

(Only F3ZN)

④-1

Setting completed

GOOD

Go to ②

after 1 sec

③-1

<Note>

The Locked bank cannot be selected when uploading the setting data.

(The bank is not displayed.)

Page 27

- 45 -

10 PROTECT

WARNING

F39-MC must be managed and used only by qualified persons.

Operation by un-qualified persons could create a hazardous

condition which may lead to a loss of safety function.

This mode enables the lock function which disallows setting changes

without a password, setting limitations can also be set to restrict the

changes that can be made.

<Note>

This function resides with the F39-MC and not the sensor. If the

F39-MC is not protected, it could enable un-authorized persons to

change the setting of the sensors.

We strongly recommend, to set “Protect” to all purchased F39-MCs.

Switching modes is illustrated below;

Section10.1(46page) Section10.2(47page) Section10.3(48page)

[UP][DOWN]KeyBlinking

1.Setting lock

3.Setting limitation

2.Change password

1.S.LC 2.PAS 3.LMT

- 46 -

10.1 Setting lock

Prohibit setting change. Select from [Lock all sensors], [Lock only

F3SN+F3SH], [Lock only F3ZN] or [Unlock all sensors].

A password (4 digit number) is required to change locked status.

When locked, the following is prohibited;

-Sending to sensor in Set/Monitor function

-Download to sensor in Copy function

Enter password except current

setting is "Unlock".

Setting lock

Setting lock

Enter password

Setting completed

RST:Unlock all

sensors

ALL:Lock all

sensors

SN.SH:Lock F3SN &

F3SH

ZN:Lock only

F3ZN

Enter 4 digit number (0000 to 9999)

ERR:Password

unmatched

OR

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

①

1.S.LC

②

③

④

0000

GOOD

Go to ①

after 1 sec

Page 28

- 47 -

10.2 Change password

Change password (4 digit number) to release setting lock.

The default value is “0000”.

Change password

Enter old password

Password change

Enter new password

Blinking

[Cancel] Key

[Enter] Key

Enter 4 digit number (0000 to 9999)

"ERR" is displayed if password unmatched

Enter 4 digit number (0000 to 9999)

①

2.PAS

②

OLD

③

NEW

④

GOOD

Go to ①

after 1 sec

<Usage>

We strongly recommend to use with password other than “0000”, and

with Setting lock function. This will prevent unauthorized setting

change by un-qualified person.

<Note >

Please remember changed password.

If you forget, please contact OMRON.

- 48 -

10.3 Setting limitation

Limit the re-settable functions in order to prevent hazardous setting by

mistake.

The following can be set;

・Maximum fixed blanking zones (0 to 3 zones)

・Maximum fixed blanking beams (1 to 9 beams)

・Maximum floating blanking beams (0 to 3 beams)

The value which exceeds above set value, cannot be set to the sensor.

<How to use>

Set limitation beforehand.

This prevents hazardous settings caused by mistake.

<Description>

“Fixed blanking zone” means is number of set of beam(s) that can be

blanked.

<Note >

This function does not protect against “COPY” function. (Only

protected against MONITOR/SET function).

Page 29

- 49 -

①

②-1 ②-2 ②-3

Setting limitation

No.of fixed zones No.of fixed beams No.of floating beams

No.of fixed zones No.of fixed beams

No.of floating be ams

2: 2 zones

3: 3 zones

1: 1 zone

0: 0 zone (disabled)

1: 1 beam

2: 2 beams

9: 9 beams

0: 0 beam (disabled)

Setting completed

Setting completed Setting completed

③-1 ③-2 ③-3

Go to ②-1

after 1 sec

・ ・ ・

3.LMT

1.X.FD 2.X.NO. 3.L.NO.

④-1 ④-2 ④-3

RST: Reset limitation

1: 1 beam

2: 2 beams

3: 3 beams

GOOD GOOD G OOD

Go to ②-2

after 1 sec

Go to ②-3

after 1 sec

RST: Reset limitationRST: Reset limitation

Blinking

[Cancel] Key

[Enter] Key

[Up][Down] Key

- 50 -

11 DISCONNECT F39-MC

After the setting has completed, be sure to disconnect cable and

F39-MC before normal use.

Operation procedure;

1. Disconnect F39-MC and cable from branching connector.

2. Attach connector cap to branching connector.

(Without the connector cap, water resistance cannot be maintained.)

CAUTION

Be sure that the machine power is OFF when disconnecting.

Disconnecting with the power ON may cause the F39-MC to

malfunction.

Connector Cap

Please set this to branching

connector when F39-MC is

not in use.

①

②

Page 30

- 51 -

12 MC11 ERROR CODES

“Err” may appear on the display indicating an error.

Please refer to the table below for detail of the

error codes.

Code Description of error Remedy

C001 Sensor Model error

Sensors with different model are

series connected.

Match all the sensor

models to be connected

in series.

C002 Sensor connection error

Communication error occurred

during connecting to sensor.

Confirm correct wiring.

C003 Communication error during

connection

Confirm that there are

no unloosen connector,

terminals or excessive

noise does not exists.

C004 EEPROM error

EEPROM data has been

corrupted.

Contact OMRON.

C005

and

others

F39-MC destructed Contact OMRON.

Error code

- 52 -

13 TROUBLESHOOTING

1. F39-MC is not powered ON.

Cause: 1.Cable or branching connector is not correctly mounted.

2. Capacity of power supply is not enough.

Remedy: 1.Mount correctly (see section 4)

2. Use power supply with enough capacity.

2. Communication connection indicator of F39-MC will not lit, or “not

conn” is displayed.

Cause: 1. F39-MC has powered on after sensor has powered on.

2. Plural F39-MC is connected, or F3ZP is connected.

Remedy: 1. Power on both F39-MC and sensor at same time.

2. Connect only one F39-MC to the sensor.

3. Test indicator and/or blanking indicator of sensor flashed or lit.

Cause: Normal condition. When communicating with F39-MC,

sensor becomes above condition.

Remedy: After setting completed, disconnect F39-MC and then

power on sensor.

4. “none” is displayed for bank number, when uploading.

Cause: Bank lock function is set for all banks.

Remedy: Unlock the bank. (see clause 9.3)

5. Unable to send to sensor; “Loc” is displayed

Cause: 1. Setting lock or 2. Setting limitation has been set.

Remedy: Unlock above function before sending. (See clause 10.1 or

10.3)

6. “Err” is displayed when teaching

Cause: Teaching is not completed with a blocked beam.

Remedy: Teach with one or more beams blocked.

Page 31

- 53 -

ANNEX1 INDEX

Terms Explanation

Auto reset mode

[F3SN, F3SH]

Interlock function is invalid in this mode. This mode can be

selected with wiring interlock selection input and reset input.

This mode voids all, despite the setting value of start/restart

interlock function.

A

Auxiliary output

[F3SN, F3SH]

Non-safety related output used to display a status.

This output cannot be used for the purpose of safety.

Blanking monitoring

output

(Auxiliary output, output2)

Output ON when the blanked beam becomes light

reception-state, when the fixed blanking function is valid.

B

Blanking setting

(Ext. indicator)

Output ON when fixed blanking function or floating blanking

function is effective.

D Dark ON

(Auxiliary output, output2,

Ext. indicator)

Output ON when sensor detects objects. In case series

connected, output ON when one or more sensors detects

objects.

External indicator output Non-safety related output which can be connected to an

optional indicator.

Applicable only to the models which can be connected in series.

E

External device

monitoring

[F3SN, F3SH]

This function can detect malfunction of external device which

controls hazardous area of machine. (e.g. contact welding)

Fixed blanking function [F3SN, F3ZN]

Partly voids detection zone of sensor. Entrance of object into

blanked detection zone does not change output condition.

F3SN: 1. Fixed blanking function becomes invalid when blanked

zone becomes clear, or lockout condition. Fixed

blanking function becomes valid again, after power has

reset.

2. It becomes lockout condition when blanked zone

becomes clear. Fixed blanking function becomes valid

again, after power has reset, or reset input.

F3ZN: Fixed blanking function is valid even after blanked zone

becomes light reception-state.

F

Floating blanking function [F3SN, F3ZN]

This function allows the output to remain ON when beams of

the sensor are interrupted anywhere in the field.

Floating can be set for 1 to 3 beams.

I ID Indicates numbers 0000 to 9999 which can be set specific to

each sensor.

L Light diagnosis

(Auxiliary output, output2,

Ext. indicator)

Output ON when unstable condition lasts for 3 seconds or

more.

Can detect deterioration of optical performance caused by dirty

optical surface, displacement of beams or deterioration of LED.

“Unstable condition” indicates that the light level remains within

+/-20% of threshold value.

- 54 -

Terms Explanation

Light ON

(Auxiliary output, output2,

Ext. indicator)

Output ON when detection area is clear. In case series

connected, output ON when all sensors’ detection area is clear.

Lockout output

(Auxiliary output, output2,

Ext. indicator)

Output ON when the sensor is in lockout condition (i.e. mode

which detects abnormality and stop the sensing function).

Lighting pattern setup The lighting pattern of external indicator is set up. A default is

"lighting." The blink cycle can set up 0.5 seconds, 1 second,

and 2 seconds.

Manual reset mode

[F3SN, F3SH]

Interlock function is valid in this mode.

This mode can be selected by wiring interlock selection input

and reset input.

Max. number of fixed

beams

(Protect)

Maximum number of beams which can be blanked by fixed

blanking function. Beams exceeding this number cannot be set

blanked.

Max. number of fixed

zones

(Protect)

Maximum number of set of beam(s) which can be blanked by

fixed blanking function.

One zone is defined as blanked beam(s) which is surrounded

by not-blanked beams.

M

Max. number of floating

beams

(Protect)

Maximum number of beams which can be set by floating

blanking function. Floating beams exceeding this number

cannot be set.

Outermost beam invalid

(Floating blanking)

This mode excludes outermost beams from floating blanking.

When this mode is valid, the output will turn OFF if one of the

outermost beams is blocked, even if floating blanking is active.

Outermost beam

monitoring output

(Auxiliary output, output2)

Output ON when only outermost beam(s) is/are interrupted.

O

Output2 [F3ZN]

Output of F3ZN used to display a status.

R Restart interlock function [F3SN, F3SH]

Outputs remain in the OFF-state (i.e. interlock state) when

sensor is interrupted. Interlock state can be released by a

manual reset when there are no obstructions in the detection

zone.

This function is valid only when using manual reset mode.

Sequential beam mode

(Floating blanking)

If this mode is valid, output becomes OFF when consecutive

blocked beams exceeds floating beams.

If this mode is invalid, output becomes OFF when sum of

blocked beams exceeds floating beams.

S

Specified Beam

(Auxiliary output, output2)

Output ON when any of specified beams are blocked.

When this signal is selected, it is necessary to specify beam.

Page 32

- 55 -

Terms Explanation

Start interlock function [F3SN, F3SH]

Outputs remain in the OFF-state (i.e. Interlock state) after power

ON. Interlock state can be released by a manual reset when

there are no obstructions in the detection zone.

This function is valid only when using manual reset mode.

Surveillance mode

(Fixed blanking)

It is the function which supervises whether a blanked beam

becomes clear. “setting release at the light receiving condition”

or “lockout mode at the light receiving condition” can be chosen.

Threshold teach It is the function which unites ON-threshold of a sensor with the

receiving light level value of a sensor, and is changed into the

optimal value.

Test input-ON

(Ext. indicator)

When a test input is ON, external indicator lights up. If a test

input turns ON, a sensor will operate an external diagnostic

function.

T

Test input-OFF

(Ext. indicator)

When a test input is OFF, external indicator lights up. If a test

input turns on, a sensor will operate an external diagnostic

function.

- 56 -

ANNEX2 FUNCTION LIST (according to sensor type)

F3SN

Function

Sensor

CH

Mode display

(Top row)

Mode display

(Bottom row)

ALL Function Valid / Invalid

Teach Teaching / Clear

Manual

Valid / Invalid (Set each beam)

1 to 3

Surveillance mode

(Note1)

Lockout mode at the light

receiving condition / Setting

release at the light receiving

condition

ALL

Fixed blanking

- Send to sensor

ALL Function Valid / Invalid

Floating Beam 1 / 2 / 3 / Clear

Sequential beam Valid / Invalid

1 to 3

Outermost beam invalid

Valid / Invalid

ALL

Floating blanking

- Send to sensor

Setting value L-on / D-on / Light diagnosis /

Lockout / Outermost beam /

Specified beam / Blanking

Auxiliary output

- Send to sensor

Setting value L-on / D-on / Light diagnosis /

Lockout / Test input-ON

(Note1) / Test input-OFF

(Note1) / Blanking setting

(Note1)

Lighting pattern setup

(Note1)

Light / Blink in a cycle of 0.5

seconds / Blink in a cycle of

1 seconds / Blink in a cycle

of 2 seconds

External indicator

output

- Send to sensor

Function Valid / Invalid

Setting time 100 to 600ms; every 5ms

External device

monitoring

- Send to sensor

Function Valid/Invalid Start interlock

- Send to sensor

Function Valid / Invalid Restart interlock

- Send to sensor

Initialization Cancel / Send to sensor

Setting value 0000 to 9999

ALL

ID setting

- Send to sensor

Receiving light level

value view

Receiving light level value

Adjusting threshold ON-threshold

1 to 3 Threshold teach

(Note 2)

- Send to sensor

SET/

MONITOR

1 to 3 Error log view Error log view Error code

1 to 3

Upload Bank number

1 to 3

Download Bank number

COPY

– Bank lock Bank number LOCK / FREE

Page 33

- 57 -

Lock object All / Only F3SN+F3SH / Only

F3ZN / Clear

– Setting lock

Input password Input 4 digit number

Old password Input 4 digit number – Change password

New password Input 4 digit number

No. of fixed

zones

Clear, 0 to 3

Max. no. of Fixed

beams

Clear, 1 to 9

PROTEC

T

– Setting limitation

Max. no. of

floating beams

Clear, 0 to 3

Note1: There are some which cannot be set up by the serial number.

See Group A of “1.2 Available function and Sensor serial number” (Page 3 )

Note2: There are some which cannot be set up by the serial number.

See Group B of “1.2 Available function and Sensor serial number” (Page 3 )

- 58 -

F3SH

Function

Sensor

CH

Mode display

(Top row)

Mode display

(Bottom row)

Setting value

L-on / D-on / Light diagnosis

/

Lockout / Outermost beam /

Specified beam

Auxiliary output

- Send to sensor

Setting value

L-on / D-on / Light diagnosis /

Lockout / Test input-ON /

Test input-OFF / Blanking

setting

Lighting pattern setup

(Note1)

Light / Blink in a cycle of 0.5

seconds / Blink in a cycle of

1 seconds / Blink in a cycle

of 2 seconds

External indicator

output

- Send to sensor

Function Valid / Invalid

Setting time 100 to 600ms; every 5ms

External device

monitoring

- Send to sensor

Function Valid / Invalid Start interlock

- Send to sensor

Function Valid / Invalid Restart interlock

- Send to sensor

Initialization Cancel / Send to sensor

Setting value 0000 to 9999

ALL

ID setting

- Send to sensor

Receiving light level

value view

Receiving light level value

Adjusting threshold ON-threshold

1 to 3 Threshold teach

(Note 2)

- Send to sensor

SET /

MONITOR

1 to 3 Error log view Error log view Error code

1 to 3

Upload Bank number

1 to 3

Download Bank number

COPY

– Bank lock Bank number LOCK / FREE

Lock object All / Only F3SN+F3SH /

Only F3ZN / Clear

– Setting lock

Input password Input 4 digit number

Old password Input 4 digit number – Change password

New password Input 4 digit number

No. of fixed zones Clear, 0 to 3

Max. no. of Fixed

beams

Clear, 1 to 9

PROTECT

– Setting limitation

Max. no. of floating

beams

Clear, 0 to 3

Note1: There are some which cannot be set up by the serial number.

See Group A of “1.2 Available function and Sensor serial number” (Page 3 )

Note2: There are some which cannot be set up by the serial number.

See Group B of “1.2 Available function and Sensor serial number” (Page 3 )

Page 34

- 59 -

F3ZN

Function

Sensor

CH

Mode display

(Top row)

Mode display

(Bottom row)

ALL Function Valid / Invalid

Teach Teaching / Clear 1 to 3

Manual

Valid / Invalid (Set each beam)

ALL

Fixed blanking

- Send to sensor

ALL Function Valid / Invalid

Floating Beam 1 / 2 / 3 / Clear

Sequential beam Valid / Invalid

1 to 3

Outermost beam invalid

Valid / Invalid

ALL

Floating blanking

- Send to sensor

Setting value L-on / D-on / Light diagnosis

/ Lockout / Outermost beam /

Specified beam / Blanking

Output2

- Send to sensor

Setting value L-on / D-on / Light diagnosis

/ Lockout

External indicator

output

- Send to sensor

Min. light level Threshold value

Threshold adjustment

- Send to sensor

Initialization Cancel / Send to sensor

Setting value 0000 to 9999

ALL

ID setting

- Send to sensor

SET/

MONITOR

1 to 3 Error log view Error log view Error code

1 to 3 Upload Bank number

1 to 3 Download Bank number

COPY

– Bank lock Bank number LOCK / FREE

Lock object All / Only F3SN+F3SH / Only

F3ZN / Clear

– Setting lock

Input password Input 4 digit number

Old password Input 4 digit number – Change password

New password Input 4 digit number

No. of fixed zones Clear, 0 to 3

Max. no. of Fixed

beams

Clear, 1 to 9

PROTECT

– Setting limitation

Max. no. of floating

beams

Clear, 0 to 3

- 60 -

ANNEX3 ERROR CODE LIST

Error code Contents and remedy

A8, AA Wiring error

Wiring is not performed correctly.

Please confirm a sensor instruction manual and check wiring.

A3 Error of the EDM function

Feed back signal is not returned to EDM line or a relay may be

welding.

Please improve wring or change a relay so that feed back signal is

returned correctly.

A7, 32 Communication error

The communication error has occurred by the wiring error, or a noise.

Please improve installation environment and wiring environment.

When you cannot solve, please contact our sales office.

35 to 38, 27 OSSD error

OSSD outputs are shorted together or OSSD output is shorted to

+24V line, 0V line, or the other I/O line or failure of OSSD output

circuit.

Please improve wiring. When you cannot solve, please contact our

sales office.

A2 Error by interference light

The sensor receives interference light from another sensor. Please

adjust an optical-axis including that of surrounding sensors. In

addition, please do interference light countermeasure as described in

sensor instruction manual.

A0, A1, A4, A5 Incorrect configuration on sensor connection

The model of emitter and receiver differs. When sensor is connected

in series, sensor connection is incorrect. Please check the sensor

model and connection status.

Other codes Internal error

Irreparable Error has occurred inside the sensor. Please contact our

sales office.

Page 35

- 61 -

ANNEX4 FUNCTION SETTING CARD

F3SN

FUNCTION SETTING VALUE

Function Valid/Invalid Fixed blanking

Blanked beam ________________ (List selected beams)

Function Valid/Invalid

Floating Beam 1/2/3/Clear

Sequential beam Valid/Invalid

Floating blanking

Outermost beam invalid Valid/Invalid

Auxiliary output Setting value L-on/D-on/Light diagnosis/ Lockout/

Outermost beam/ Specified beam/Blanking

Ext. indicator output Setting value L-on/D-on/Light diagnosis/ Lockout

Function Valid/Invalid External device

monitoring

Acceptable delay time ___________ms (100 to 600ms)

Start interlock Function Valid/Invalid

Restart interlock Function Valid/Invalid

ID setting Setting value ___________ (0000 to 9999)

F3SH

FUNCTION SETTING VALUE

Auxiliary output Setting value L-on/D-on/Light diagnosis/ Lockout/

Outermost beam/ Specified beam

Ext. indicator output Setting value L-on/D-on/Light diagnosis/ Lockout

Function Valid/Invalid External device

monitoring

Acceptable delay time ___________ms (100 to 600ms)

Start interlock Function Valid/Invalid

Restart interlock Function Valid/Invalid

ID setting Setting value ___________ (0000 to 9999)

F3ZN

FUNCTION SETTING VALUE

Function Valid/Invalid Fixed blanking

Blanked beam ________________ (List selected beams)

Function Valid/Invalid

Floating Beam 1/2/3/Clear

Sequential beam Valid/Invalid

Floating blanking

Outermost beam invalid Valid/Invalid

Output2

Setting value L-on/D-on/Light diagnosis/ Lockout/

Outermost beam/ Specified beam/Blanking

Ext. indicator output Setting value L-on/D-on/Light diagnosis/ Lockout

Threshold Adj. Setting value ___________ (18 to 100)

ID setting Setting value ___________ (0000 to 9999)

OMRON CORPORATION

Industrial Automa tion Company

Industrial Sensors Division

Sensing Devices and Components Division H.Q.