Page 1

MicroHAWK F320-F / F330-F / F420-F / F430-F

Smart Camera

User Manual

Z433-E-01 (84-9000402-02)

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses base

on infringement by the Products or otherwise of any intellectual property right.

d

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Produ

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

cts

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

3

Page 4

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

4

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 5

Safety Precautions

CAUTION

Symbols and the meanings for safety precautions described in this manual.

In order for the product to be used safely, the following indications are used in this book to draw your

attention to the cautions. The cautions with the indications describe the important contents for

safety.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or moderate

WARNING

Meanings of Alert Symbols

injury, or may result in serious injury or death.

Additionally there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury or in property damage.

Safety Precautions

General Prohibition

Indicates general prohibitions, including warnings, for which there is no specific symbol.

General Caution

Indicates general cautions, including warnings, for which there is no specific symbol.

Electrical Hazard

Indicates the possible danger of electric shock under specific conditions.

High Temperature Caution

Indicates the possible danger of injury by high temperature under specific conditions.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

5

Page 6

Safety Precautions

Alert statements in this Manual

WARNING

This product must be used according to this manual or Instruction sheet.

Failure to observe this may result in impairment of functions and performance of the product.

This product is not designed or rated for ensuring safety of persons. Do not use it for such purposes.

Never connect the AC power supply with this product.

When the AC power supply is connected, it causes the electric shock and a fire.

When using equipment that is connected to an AC power source such as an AC adapter or PoE

injector, use it within the rated voltage range. Usage with a voltage higher than what it is rated for

may cause serious personal injury due to electric shock, or serious physical damage due to fire or

equipment failure. Do not touch any

OFF the power.

part of the device while in operation, or immediately after turning

Since camera that can be connected with this product emits a visible light that may have an adverse

effect on the eyes, do not stare directly into the light emitted from the LED. If a specular object is

used, take care not to allow reflected light enter your eyes.

Please take external safety measures so that the system as a whole should be on the safe side even

if a failure of a this product or an error due to an external factor occurred. An abnormal operation may

result in serious accident.

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal

conductor disconnection and/or momentary power interruption. An abnormal operation may result in

a serious accident.

CAUTION

Danger of burns. Do not touch the case while the reader is running or just after power is turned OFF,

since it remains extremely hot.

6

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 7

Precautions for Safe Use

Condition of the fitness of OMRON products

• Please do not use this product to directly or indirectly use to detect the human body for the purpose

of ensuring the safety. In the same application, please use the safety sensor that is published on our

sensor catalog.

• Omron products are designed and manufactured as general-purpose products for use in general

industrial applications. They are not intended to be used in the following critical applications. If you

are using Omron products in the following applications, Omron shall not provide any warranty for

such Omron products, unless otherwise specifically agreed or unless the specific applications are

intended by Omron.

(a) Applications with stringent safety requirements, including but not limited to nuclear power control

equipment, combustion equipment, aerospace equipment, railway equipment, elevator/lift

equipment, amusement park equipment, medical equipment, safety devices and other applications

that could cause danger/harm to people’s body and life

(b) Applications that require high reliability, including but not limited to supply systems for gas, water

and electricity, etc., 24 hour continuous operating systems, financial settlement systems and other

applications that handle rights and property

(c) Applications under severe condition or in severe environment, including but not limited to outdoor

equipment, equipment exposed to chemical contamination, equipment exposed to electromagnetic

interference and equipment exposed to vibration and shocks

(d) Applications under conditions and environment not described in specifications

*1. In addition to the applications listed from (a) to (d) above, Omron products (see definition) are not intended for

use in vehicles designed human transport (including two wheel vehicles). Please do NOT use Omron

products for vehicles designed human transport. Please contact the Omron sales staff for information on our

automotive line of products.

*2. The above is part of the Terms and Conditions Agreement. Please use carefully read the contents of the

guarantee and disclaimers described in our latest version of the catalog, data sheets and manuals.

Precautions for Safe Use

Installation Environment

• Do not use the product in areas where flammable or explosive gases are present.

• Be careful when unpacking this product, please. Injury may occur if the reader falls and strikes a

person.

• Do not install the product close to high-voltage devices and power devices in order to secure the

safety of operation and maintenance.

• Make sure to tighten all installation screws securely.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

7

Page 8

Precautions for Safe Use

Power Supply and Wiring

• Make sure to use the product with the power supply voltage specified by this manual.

• Do not connect AC power source to Sensor Controller. If connects AC power source, it might be a

cause of the failure.

• Use the wire of a suitable size (AWG 16 to 12)

• Use a DC power supply with safety measures against high-voltage spikes (safety extra low-voltage

circuits on the secondary side).

• Keep the power supply wires as short as possible.

• Do the following confirmations again before turning on the power supply.

• Is the voltage and polarity of the power supply correct?

• Is not the load of the output signal short-circuited?

• Is the load current of the output signal appropriate?

• Is not the mistake found in wiring?

according to the current consumption.

Ground

• Check wiring again before turning on the reader.

Other

• Use only the cables designed specifically for the reader. Use of other products may result in

malfunction or damage of the reader.

• Always turn OFF the power of the reader and peripheral devices before connecting or disconnecting

a cable. Connecting the cable with power supplied may result in damage of the reader or peripheral

devices.

• Do not apply torsion stress to the cable. It may damage the cable.

• Secure the minimum bending radius of the cable. Otherwise the cable may be damaged.

• Do not attempt to dismantle, repair, or modify the product.

• Should you notice any abnormalities, immediately stop use, turn OFF the power supply, and cont

your OMRON representative.

• While the power is ON or immediately after the power is turned OFF, the case are still hot. Do not

touch the case.

• The reader must be used with the special mounting bracket (-AM0 or -AM1: sold separately), or the

reader may generate heat.

• When disposing of the product, treat it as an industrial waste.

• Do not drop the product nor apply excessive vibration or shock to the product. Doing so may cause

malfunction or burning.

act

When controlling stages and robots using the read results (axis movement output based on calibration

and alignment measurement), always take fail-safe measures within the stage and robot systems, such

as checking whether the data obtained from the read results is within the range of movement of the

stages and robots.

8

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 9

Precautions for Correct Use

Installation and Storage Sites

Install and store the product in a location that meets the following conditions:

• Surrounding temperature of 0 to +40°C (-50 to +75°C in storage)

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 5 to 85%

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight

• Place where it will not come into contact with water, oils or chemicals

• Place not affected by strong electro-magnetic waves

• Place not near to high-voltage, or high-power equipment

Precautions for Correct Use

Ambient Temperature

• For good heat dissipation, keep the distance.

• Do not install the product immediately above significant heat sources, such as heaters, transformers,

or large-capacity resistors.

• Do not let the ambient temperature exceed an operating temperature range.

• Provide a forced-air fan cooling or air conditioning if the ambient temperature is near the upper range

of operating temperature range so that the ambient temperature never exceeds the upper range of

operating temperature range.

Noise Resistance

• Do not install the product in a cabinet containing high-voltage equipment.

• Do not install the reader within 200 mm of power cables.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

9

Page 10

Precautions for Correct Use

Component Installation and Handling

• Turning OFF the Power

When a message is displayed indicating that a task is in progress, do not turn OFF the power. Doing

so causes the data in the memory to be corrupted, resulting in the product not operating properly

upon the next start-up.

When turns OFF, conform the followings proceedings have completed. and then operate again.

• When saves using the reader:

Confirm the save processing is completed and next operation is possible.

• When saves using communication command:

Intended command is completed.

• Setting of Power Source

The power source need to be supplied from DC power source apparatus which is taken a save ultra-

low voltage circuit: to protect high voltage.

Maintenance

• Turn OFF the power and ensure the safety before maintenance.

• Clean the lens with a lens-cleaning cloth or air brush.

• Lightly wipe off dirt with a soft cloth.

• Do not use thinners or benzene.

• To ensure safe access for operation and maintenance, separate the reader as much as possible from

high-voltage equipment and power machinery.

Communication with High-order Device

• After confirming that this product is started up, communicate with the high-order device. Wh

product has started up, an indefinite signal may be output from the high-order interface. To avoid this

problem, clear the receiving buffer of your device at initial operations.

en this

Other

• For symbols with a highly gloss surface, reading errors may occur because of regular reflection of the

LED light. If this occurs, provide a skew angle of 15° against the symbol.

• Do not look into the light emitted from the LED directly. When this products has started up, the LED

flashes.

• Under an environment with high humidity and rapid changes in temperature, the inside of the front

plate might fog up. When the read rates lower due to the fog, leave the device with turned it on for 30

minutes to 2 hours. Use it again after checking there is no fog on the front plate.

11

LED Safety

• This product is classified into the IEC 62471-1:2006 Risk-Exempt Group. However, this product does

emit a strong visible light that may have an adverse effect on the eyes. Do not stare directly into the

lig

ht emitted from the LED. If a specular object is used, take care not to allow reflected light to enter

your eyes.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 11

Regulations and Standards

Using Product Outside Japan

This regulation applies to MicroHAWK readers and peripheral devices.

If you export (or provide a non-resident with) this product or a part of this product that falls under the

category of goods (or technologies) specified by the Foreign Exchange and Foreign Trade Control Law

as those which require permission or approval for export, you must obtain permission or approval or

service transaction permission) pursuant to the law.

Conformance to EC/EU Directives

This regulation applies to MicroHAWK readers and peripheral devices.

The reader is compliant with the standards below:

• EC Directive 2004/108/EC (Until April 19 2016) / EU Directive 2014/30/EU (After April 20 2016)

EN61326-1

Electromagnetic environment: Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices th

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions

of the equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall

machin

e conform to EMC standards.

Regulations and Standards

at

Conformance to UL Standards

This regulation applies to MicroHAWK readers and peripheral devices.

This product complies with UL Standards.

• UL60950-1 2

nd

-edition, 2014 (Class III)

Korean Radio Regulation (KC)

Guide for Users

This equipment has been evaluated for conformity in a commercial environment. When used in a residential

environment, it may cause radio interference.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

11

Page 12

Revision History

Revision History

The manual’s part number and revision letter appear on the first and last pages.

Z433-E-01

Revision Date Revised content

01

November 2019 First Publication.

Revision

12

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 13

Table of Contents

Terms and Conditions Agreement ..........................................................................3

Safety Precautions ...................................................................................................5

Precautions for Safe Use.........................................................................................7

Precautions for Correct Use....................................................................................9

Regulations and Standards...................................................................................11

Revision History .....................................................................................................12

Section 1 Introduction

CONTENTS

1-1 Product Summary.................................................................................................................... 1-2

1-2 Features and Benefits ............................................................................................................. 1-3

1-3 Applications ............................................................................................................................. 1-4

1-4 Package Contents ................................................................................................................... 1-5

1-5 MicroHAWK Smart Camera Models ....................................................................................... 1-6

Part Number Structure............................................................................................................. 1-8

1-6

Section 2 System Components

2-1 Label Information .................................................................................................................... 2-2

2-2 Camera Dimensions ................................................................................................................ 2-3

2-3 Accessories ........................................................................................................................... 2-10

2-4 Hardware Configurations......................................................................................................2-18

2-5

Mounting the Camera............................................................................................................. 2-22

I/O Wiring................................................................................................................................. 2-23

2-6

2-7

Grounding and Power ............................................................................................................ 2-31

2-8

I/O Filtering and Debounce....................................................................................................2-33

Camera Definition File Example............................................................................................ 2-34

2-9

10 Status Indicators .................................................................................................................... 2-35

2-

Section 3 Getting Started with AutoVISION

3-1 Setting Up a Job in AutoVISION............................................................................................. 3-2

Section 4 Optics and Lighting

4-1 Optics ....................................................................................................................................... 4-2

4-2 MicroHAWK Illumination......................................................................................................... 4-5

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

13

Page 14

CONTENTS

4-3 Machine Vision Lighting Principles ....................................................................................... 4-6

4-4 MicroHAWK F430-F External Illumination Control and Wiring............................................ 4-7

Appendices

A Connector Pinouts ..................................................................................................................A-1

B Cable Specifications ...............................................................................................................B-1

C General Specifications............................................................................................................C-1

D Serial Commands ....................................................................................................................D-1

E USB Power Management (MicroHAWK F420-F).................................................................... E-1

F TCP/UDP and General Port Usage ......................................................................................... F-1

14

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 15

Introduction

This section provides a product summary as well as an overview of features,

applications, package contents, smart camera models, part number structure, and

ordering inform

1-1 Product Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4 Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-5 MicroHAWK F320-F, F330-F, F420-F, and F430-F Smart Camera Models . 1-6

6 Part Number Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . .1-8

1-

1

ation.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-1

Page 16

1 Introduction

1-1 Product Summary

MicroHAWK F320-F, F330-F, F420-F and F430-F Smart Cameras are designed for reliable vision

performance in identification and inspection applications. As the world’s smallest fully-integrated vision

system, the compact size and wide variety of optics and illumination options of these cameras provide

the best performance available for virtually any machine vision application.

MicroHAWK F320-F, F330-F, F420-F and F430-F allow automation engineers to implement inspection,

color matching, symbol decoding, OCR, and more, in a single compact solution. The small form factor

of these cameras allows flexible positioning in tight spaces.

AutoVISION software, designed for use with the MicroHAWK F320-F, F330-F, F420-F and F430-F,

provides an intuitive interface, step-by-step configuration, and a library of presets that allow easy setup

and deployment. For more complex vision applications, the system can be upgraded from AutoVISION

to Visionscape.

1-2

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 17

1-2 Features and Benefits

• Simple Configuration of All Models with AutoVISION

• 5 Megapixel Color Sensor Available for All Models

• Smallest Camera in Class – All Models

• IP40 Enclosure (F320-F, F330-F)

• IP54 Enclosure (F420-F)

• IP65 / IP67 Enclosure (F430-F)

• Corner-Exit Cable (F420-F)

• Autofocus Available (F420-F, F430-F)

• Power over Ethernet (F330-F)

• RS-232 (MicroHAWK F320-F, F420-F, F430-F)

• USB 2.0 Full-Speed (F320-F)

• USB 2.0 High-Speed (F420-F)

• Ethernet over USB/HID (F320-F, F420-F)

• Ethernet TCP/IP (F330-F, F430-F)

• EtherNet/IP (F430-F)

• Single Locking RJ50 Connector and Cable (F320-F)

• Single Locking RJ45 Connector and Cable (F330-F)

• Ring Light Illumination Available (V430-F)

1 Introduction

1-2 Features and Benefits

1

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-3

Page 18

1 Introduction

1-3 Applications

• Inspection

• Guidance

• Gauging

• Part presence/absence

• Color detection and matching

• Medical device inspection

• Fiducial location

• Part location/orientation detection

• Packaging

• Robotics

• Auto ID (Data Matrix and other 2D symbologies, 1D, OCR)

• 1D and 2D Code Verification

• OCV (Optical Character Verification)

1-4

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 19

1-4 Package Contents

Before you install AutoVISION software and connect your MicroHAWK F320-F, F330-F, F420-F or

F430-F, please take a moment to confirm that the following items are available or accessible:

• A MicroHAWK F320-F, F330-F, F420-F or F430-F Smart Camera.

• An active internet connection to download the latest AutoVISION software installer from the

Download Center on your region’s Omron website.

• The cables or other accessories you have added to your order.

1 Introduction

1-4 Package Contents

1

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-5

Page 20

1 Introduction

1-5 MicroHAWK F320-F, F330-F, F420-F

and F430-F Smart Camera Models

MicroHAWK F320-F

Simple configuration with AutoVISION.

5 megapixel sensor available.

Smallest in class.

IP40 enclosure.

Single locking RJ50 connector and cable.

RS-232, Ethernet via USB.

MicroHAWK F330-F

Simple configuration with AutoVISION.

5 megapixel sensor available.

Smallest in class.

IP40 enclosure.

Single locking RJ45 connector and cable.

Ethernet TCP/IP.

Power over Ethernet.

MicroHAWK F420-F

Simple configuration with AutoVISION.

5 megapixel sensor available.

Autofocus available.

Smallest in class.

IP54 enclosure.

Corner-exit cable.

Serial RS-232, USB, or Ethernet over USB.

MicroHAWK F430-F

Simple configuration with AutoVISION.

5 megapixel sensor available.

Autofocus available.

Smallest in class.

IP65 / IP67 enclosure.

RS-232, Ethernet TCP/IP, EtherNet/IP.

Ring Light illumination available.

1-5-1 Software Options

1-6

AutoVISION Software provides a simple setup and runtime interface for solving basic to mid-range

vision and auto ID challenges. Scalable with Visionscape Software.

Visionscape Software provides a professional setup and runtime interface with access to Omron

Microscan’s full auto ID, verification, and machine vision tools.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 21

1 Introduction

1-5 MicroHAWK F320-F, F330-F,

F420-F and F430-F Smart

1-5-2 Feature Comparison

Features F320-F F330-F F420-F F430-F

Barcode Reading (1D/2D) • • • •

Complete Machine Vision Tool Set • • • •

Enclosure IP40 IP40 IP54 IP65 / 67

Ethernet TCP/IP ••

EtherNet/IP •

Ethernet over USB • •

Serial (RS-232) • • •

USB 2.0 High Speed / HID • •

Power over Ethernet (PoE) •

Outer Illumination ••

Liquid Lens Autofocus ••

Color Sensor ••••

AutoVISION Sensor (Vision Tools Only) • • • •

AutoVISION (Vision, Code Reading, and Verification) • • • •

Visionscape (Full Tool Set) • • • •

1

1-5-2 Feature Comparison

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-7

Page 22

1 Introduction

1-6 Part Number Structure

F320-F Part Number Structure

Use this legend when defining product part numbers. Please note that not all combinations of parameters are valid. For instance, fixed focus distance

of 50 mm is not available with Narrow Lens. When ordering, use valid part numbers from the tables in the Ordering Information section only.

F320-F[XXX][Y][ZZZ]-NN[P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

L Light Type N No Outer Light

C Light Color N No Outer Light

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

Example Part Number:

• F320-F050W50C-NNV: Fixed Focus at 50 mm, Wide Lens, 5 MP Color, No Light, Visionscape (Full AutoVISION and Visionscape Toolsets)

F320-F Valid Product Matrix

Model Category Focus Type Sensor Lens Focus Distance (mm) Light License

Monochrome Fixed Focus 03M, 12M W, M 50, 64, 81, 102, 133, 190, 300 None S, A, V

F320-F

Color Fixed Focus 50C W, M 50, 64, 81, 102, 133, 190, 300 None S, A, V

Monochrome Fixed Focus 03M, 12M N 64, 81, 102, 133, 190, 300 None S, A, V

Color Fixed Focus 50C N 64, 81, 102, 133, 190, 300 None S, A, V

1-8

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 23

1 Introduction

F320-F Ordering Information

Categories:

1. Fixed Focus Cameras

a) F320-F Monochrome and Color Fixed Focus Camera with Standard Lens

b) F320-F Monochrome and Color Fixed Focus Camera with Narrow Lens

1a) F320-F Mono and Color Camera with Standard Lens: Valid Combinations

F320-F[XXX][Y][ZZZ]-NN[P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1-6 Part Number Structure

1

1-5-2 Feature Comparison

1b) F320-F Mono and Color Camera with Narrow Lens: Valid Combinations

Note: 50 mm Fixed Focus option not available with Narrow Lens.

F320-F[XXX]N[ZZZ]-NN[P]

Key Classification Code Meaning

XXX Focus Distance (mm) 064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-9

Page 24

1 Introduction

F330-F Part Number Structure

Use this legend when defining product part numbers. Please note that not all combinations of parameters are valid. For instance, fixed focus distance

of 50 mm is not available with Narrow Lens. When ordering, use valid part numbers from the tables in the Ordering Information section only.

F330-F[XXX][Y][ZZZ]-NN[P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

L Light Type N No Outer Light

C Light Color N No Outer Light

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

Example Part Number:

• F330-F064W50C-NNV: Fixed Focus at 64 mm, Wide Lens, 5 MP Color – No Light, Visionscape (Full AutoVISION and Visionscape Toolsets)

F330-F Valid Product Matrix

Model Category Focus Type Sensor Lens Focus Distance (mm) Light License

Monochrome Fixed Focus 03M, 12M W, M 50, 64, 81, 102, 133, 190, 300 None S, A, V

F330-F

Color Fixed Focus 50C W, M 50, 64, 81, 102, 133, 190, 300 None S, A, V

Monochrome Fixed Focus 03M, 12M N 64, 81, 102, 133, 190, 300 None S, A, V

Color Fixed Focus 50C N 64, 81, 102, 133, 190, 300 None S, A, V

1-10

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 25

F330-F Ordering Information

Categories:

1. Fixed Focus Cameras

a) F330-F Monochrome and Color Fixed Focus Camera with Standard Lens

b) F330-F Monochrome and Color Fixed Focus Camera with Narrow Lens

1a) F330-F Mono and Color Camera with Standard Lens: Valid Combinations

F330-F[XXX][Y][ZZZ]-NN[P]

1 Introduction

1-6 Part Number Structure

1

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1b) F330-F Mono and Color Camera with Narrow Lens: Valid Combinations

Note: 50 mm Fixed Focus option not available with Narrow Lens.

F330-F[XXX]N[ZZZ]-NN[P]

Key Classification Code Meaning

XXX Focus Distance (mm) 064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1-5-2 Feature Comparison

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-11

Page 26

1 Introduction

F420-F Part Number Structure

Use this legend when defining product part numbers. Please note that not all combinations of parameters are valid. For instance, color cameras

are only available with white lighting, and 400 mm fixed focus is only available with UHD lenses. When ordering, use valid part numbers from

the tables in the Ordering Information section only

F420-F[XXX][Y][ZZZ]-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 000 Autofocus – Variable Distance

Y Lens W Wide Field of View – 5.2 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

L Light Type N No Outer Light

C Light Color N No Outer Light

P Software License S AutoVISION Sensor (Vision Toolset Only)

.

050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

400 Fixed Focus at 400 mm

M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

L Narrow 16 mm Lens – Autofocus to 1160 mm

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

S Standard Outer Light

RRed

WWhite

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

Example Part Numbers:

• F420-F081W03M-NNS: Fixed Focus at 81 mm, Wide Lens, 0.3 MP Monochrome Sensor, No Outer Light, AutoVISION Sensor

• F420-F000L50C-SWV: Autofocus, Long Range Lens, 5 MP Color, Standard Light, White, Visionscape (Full AutoVISION and Visionscape Toolsets)

F420-F Valid Product Matrix

Model Category Focus Type Sensor Lens Focus Distance (mm) Light License

F420-F

Monochrome

Color

Specialty

03M, 12M W, M

Fixed Focus

12M N 64, 400

03M W, M 50 <-> 300 Autofocus

Autofocus

12M W, M, N

Fixed Focus 50C W, M

Autofocus 50C W, M 50 <-> 300 Autofocus None, White S, A, V

Long Range

Autofocus

12M L 75 <->1160 Autofocus

50, 64, 81, 102, 133,

190, 300

50 <-> 300 (W, M)

40 <-> 150 (N)

Autofocus

50, 64, 81, 102, 133,

190, 300

None, Red,

White

None, Red,

White

None, Red,

White

None, Red,

White

None, White S, A, V

None, Red,

White

S, A, V

S, A, V

S, A, V

S, A, V

S, A, V

1-12

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 27

1 Introduction

F420-F Ordering Information

Categories:

1. Fixed Focus Camera

a.) F420-F Monochrome Fixed Focus Camera

b.) F420-F Color Fixed Focus Camera

c.) F420-F 1.2 MP Monochrome Fixed Focus Camera with Narrow Lens

2. Autofocus Camera

a.) F420-F 0.3 MP Monochrome Autofocus Camera (50 – 300 mm)

b.) F420-F 1.2 MP Monochrome Autofocus Camera (50 – 300 mm for Wide and Medium Lens, 40 – 150 mm

for Narrow Lens)

c.) F420-F Color Autofocus Camera (50 - 300 mm)

d.) F420-F 1.2 MP Monochrome Long Range Autofocus Camera (75 - 1160 mm)

1a) F420-F Monochrome Fixed Focus Camera: Valid Combinations

F420-F[XXX][Y][ZZZ]-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1-6 Part Number Structure

1

1-5-2 Feature Comparison

1b) F420-F 5.0 MP Color Fixed Focus Camera: Valid Combinations

Note: 5 MP Color cameras are available with No or White light options only.

F420-F[XXX][Y]50C-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-13

Page 28

1 Introduction

1c) F420-F 1.2 MP Monochrome Fixed Focus Camera with Narrow Lens: Valid Combinations

Note: Fixed Focus Narrow lens option available for 1.2 MP Mono camera only.

F420-F[XXX]N12M-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 064 Fixed Focus at 64 mm

400 Fixed Focus at 400 mm

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2a) F420-F 0.3 MP Monochrome Autofocus Cameras (50 – 300 mm): Valid Combinations

F420-F000[Y]03M-[L][C][P]

Key Classification Code Meaning

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2b) F420-F 1.2 MP Monochrome Autofocus Camera (50 – 300 mm for Wide and Medium, 40 – 150 mm

for Narrow): Valid Combinations

F420-F000[Y]12M-[L][C][P]

Key Classification Code Meaning

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1-14

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 29

1 Introduction

2c) F420-F 5.0 MP Color Autofocus Camera (50 - 300 mm): Valid Combinations

Note: Narrow Autofocus lens option not available for color camera.

F420-F000[Y]50C-[L][C][P]

Key Classification Code Meaning

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2d) F420-F 1.2 MP Monochrome Long Range Autofocus Camera (75 - 1160 mm): Valid Combinations

Note: Autofocus Long Range lens option available for 1.2 MP Monochrome camera only.

F420-F000L12M-[L][C][P]

1-6 Part Number Structure

1

1-5-2 Feature Comparison

Key Classification Code Meaning

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-15

Page 30

1 Introduction

F430-F Part Number Structure

Use this legend when defining product part numbers. Please note that not all combinations of parameters are valid. For instance, color cameras

are only available with white lighting, and 400 mm fixed focus is only available with UHD lenses. When ordering, use valid part numbers from

the tables in the Ordering Information section only.

F430-F[XXX][Y][ZZZ]-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 000 Autofocus – Variable Distance

050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

133 Fixed Focus at 133 mm

190 Fixed Focus at 190 mm

300 Fixed Focus at 300 mm

400 Fixed Focus at 400 mm

Y Lens W Wide Field of View – 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

L Narrow 16 mm Lens – Autofocus to 1160 mm

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

50C 2592 x 1944 (5 MP) Pixel, Color Sensor, Rolling Shutter

L Light Type N No Outer Light

S Standard Outer Light

R Ring Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

Example Part Numbers:

• F430-F081W03M-NNS: Fixed Focus at 81 mm, Wide Lens, 0.3 MP Monochrome Sensor, No Outer Light, AutoVISION Sensor

• F430-F000N12M-RRA: Autofocus, Narrow Lens, 1.2 MP Mono, Ring Light, Red, AutoVISION + Verification

• F430-F000L50C-SWV: Autofocus, Long Range Lens, 5 MP Color, Standard Light, White, AutoVISION + Verification + Visionscape

F430-F Valid Product Matrix

Model Category Focus Type Sensor Lens Focus Distance (mm) Light License

F430-F

Monochrome

Color

Specialty

03M, 12M W, M

Fixed Focus

12M N 64, 400

03M W, M 50 <-> 300 Autofocus

Autofocus

12M W, M, N

Fixed Focus 50C W, M

Autofocus 50C W, M 50 <-> 300 Autofocus None, White S, A, V

Ring Light

Autofocus

Long Range

Autofocus

12M M, N

12M L 75 <->1160 Autofocus

50, 64, 81, 102, 133,

190, 300

50 <-> 300 (W and M)

40 <-> 150 (N)

Autofocus

50, 64, 81, 102, 133,

190, 300

50 <-> 300 (M)

40 <-> 150 (N)

Autofocus

None, Red,

White

None, Red,

White

None, Red,

White

None, Red,

White

None, White S, A, V

Red, White

(Ring)

None, Red,

White

S, A, V

S, A, V

S, A, V

S, A, V

S, A, V

S, A, V

1-16

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 31

1 Introduction

F430-F Ordering Information

Categories:

1. Fixed Focus Camera

a.) F430-F Monochrome Fixed Focus Camera

b.) F430-F Color Fixed Focus Camera

c.) F430-F 1.2 MP Monochrome Fixed Focus Camera with Narrow Lens

2. Autofocus Camera

a.) F430-F 0.3 MP Monochrome Autofocus Camera (50 – 300 mm)

b.) F430-F 1.2 MP Monochrome Autofocus Camera (50 – 300 mm for Wide and Medium Lens, 40 – 150 mm

for Narrow Lens)

c.) F430-F Color Autofocus Camera (50 - 300 mm)

d.) F430-F 1.2 MP Monochrome Autofocus Camera with Ring Light (50 – 300 mm for Medium Lens, 40 – 150

mm for Narrow Lens)

e.) F430-F 1.2 MP Monochrome Long Range Autofocus Camera (75 - 1160 mm)

1a) F430-F Monochrome Fixed Focus Camera: Valid Combinations

F430-F[XXX][Y][ZZZ]-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1-6 Part Number Structure

1

1-5-2 Feature Comparison

1b) F430-F 5.0 MP Color Fixed Focus Camera: Valid Combinations

Note: 5 MP Color cameras are available with No or White light options only.

F430-F[XXX][Y]50C-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 050 Fixed Focus at 50 mm

064 Fixed Focus at 64 mm

081 Fixed Focus at 81 mm

102 Fixed Focus at 102 mm

300 Fixed Focus at 300 mm

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-17

Page 32

1 Introduction

1c) F430-F 1.2 MP Monochrome Fixed Focus Camera with Narrow Lens: Valid Combinations

Note: Fixed Focus Narrow lens option available for 1.2 MP Mono camera only.

F430-F[XXX]N12M-[L][C][P]

Key Classification Code Meaning

XXX Focus Distance (mm) 064 Fixed Focus at 64 mm

400 Fixed Focus at 400 mm

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2a) F430-F 0.3 MP Monochrome Autofocus Cameras (50 – 300 mm): Valid Combinations

F430-F000[Y]03M-[L][C][P]

Key Classification Code Meaning

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

ZZZ Sensor 03M 752 x 480 (0.3 MP) Pixel, Mono Sensor, Global Shutter

12M 1280 x 960 (1.2 MP) Pixel, Mono Sensor, Global Shutter

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2b) F430-F 1.2 MP Monochrome Autofocus Camera (50 – 300 mm for Wide and Medium, 40 – 150 mm

for Narrow): Valid Combinations

F430-F000[Y]12M-[L][C][P]

Key Classification Code Meaning

Y Lens W Wide Field of View – 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

1-18

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 33

1 Introduction

2c) F430-F 5.0 MP Color Autofocus Camera (50 - 300 mm): Valid Combinations

Note: Narrow Autofocus lens option not available for color camera.

F430-F000[Y]50C-[L][C][P]

Key Classification Code Meaning

Y Lens W Wide Field of View - 5.2 mm Focal Length Lens

M Medium Field of View – 7.7 mm Focal Length Lens

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2d) F430-F 1.2 MP Monochrome Autofocus Camera with Ring Light (50 – 300 mm for Medium, 40 –

150 mm for Narrow): Valid Combinations

Note: Ring Light version is available for Autofocus, Medium, and Narrow lens, 1.2 MP Monochrome camera only.

1-6 Part Number Structure

1

1-5-2 Feature Comparison

F430-F000[Y]12M-R[C][P]

Key Classification Code Meaning

Y Lens M Medium Field of View – 7.7 mm Focal Length Lens

N Narrow Field of View – 16 mm Focal Length Lens

C Light Color R Red

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

2e) F430-F 1.2 MP Monochrome Long Range Autofocus Camera (75 - 1160 mm): Valid Combinations

Note: Autofocus Long Range lens option available for 1.2 MP Monochrome camera only.

F430-F000L12M-[L][C][P]

Key Classification Code Meaning

L Light Type N No Outer Light

S Standard Outer Light

C Light Color N No Outer Light

RRed

WWhite

P Software License S AutoVISION Sensor (Vision Toolset Only)

A AutoVISION (Vision and Code Reading / Verification Toolsets)

V Visionscape (Full AutoVISION and Visionscape Toolsets)

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

1-19

Page 34

1 Introduction

1-20

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 35

System Components

2

This section contains camera dimensions, accessory dimensions, hardware configurations,

wiring diagrams, trigger debounce information, and an explanation of F420-F and

F430-F LED status indicators.

Note: There are no user-serviceable parts inside the camera.

2-1 Label Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Camera Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-4 Hardware Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2-5 Mounting the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2-6 I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2-7 Grounding and Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2-8 I/O Filtering and Debounce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2-9 Camera Definition File Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

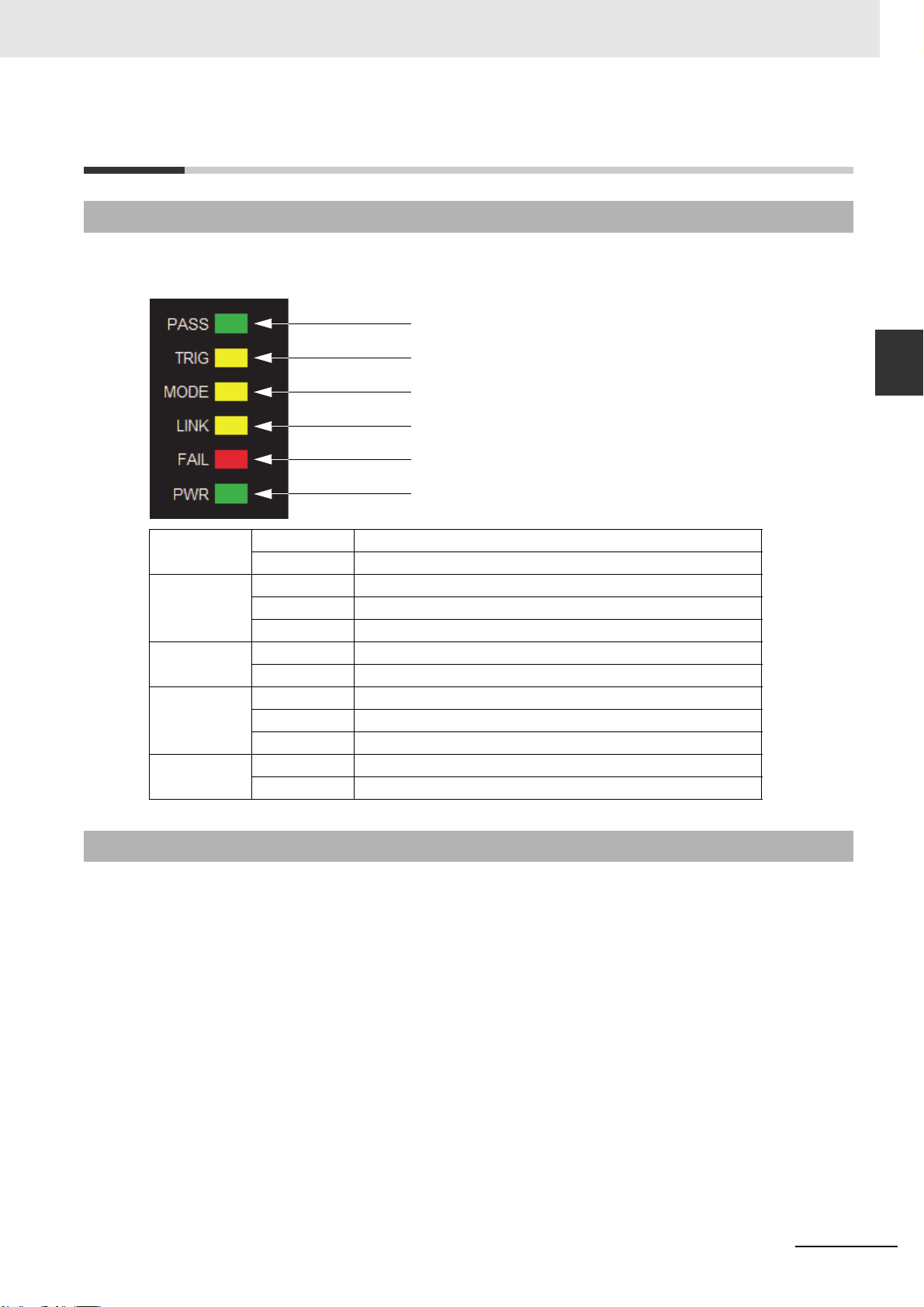

2-10 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-1

Page 36

2 System Components

2-1 Label Information

Each MicroHAWK F320-F, F330-F, F420-F, and F430-F Smart Camera has a label that contains important

information about that camera.

• Part Number – The Omron Microscan part number of your smart camera.

• Serial Number – The serial number of your smart camera.

• MAC Address – The MAC address of your smart camera.

2-2

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 37

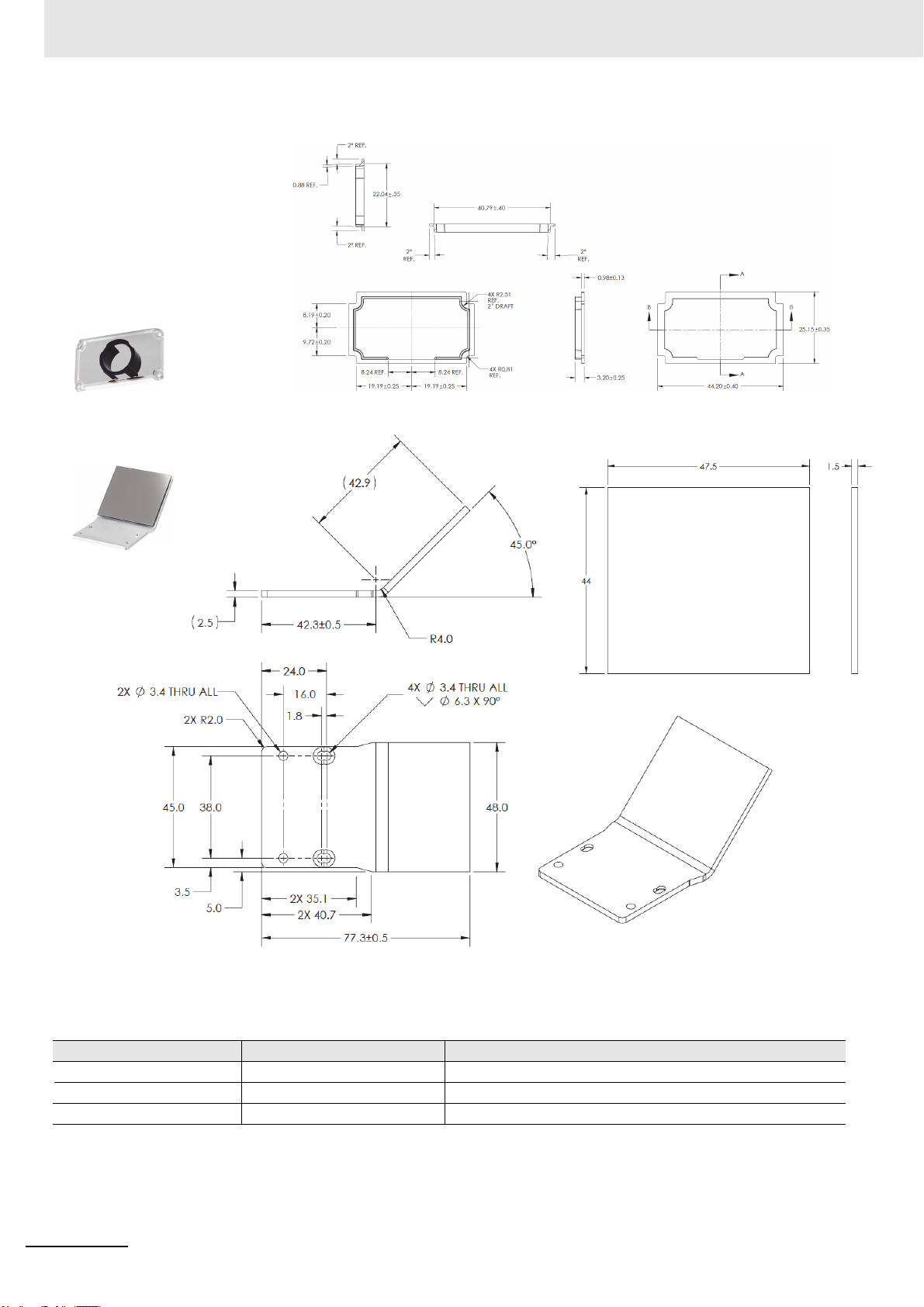

2-2 Camera Dimensions

2-2-1 MicroHAWK F320-F Front

2 System Components

2-2 Camera Dimensions

2

2-2-1 MicroHAWK F320-F Front

2-2-2 MicroHAWK F320-F Base

2-2-3 MicroHAWK F320-F Top

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-3

Page 38

2 System Components

2-2-4 MicroHAWK F330-F Front

2-2-5 MicroHAWK F330-F Base

2-4

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 39

2-2-6 MicroHAWK F330-F Top

2 System Components

2-2 Camera Dimensions

2

2-2-6 MicroHAWK F330-F Top

2-2-7 MicroHAWK F330-F Side

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-5

Page 40

2 System Components

2-2-8 MicroHAWK F420-F Front

2-2-9 MicroHAWK F420-F Base

2-6

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 41

2 System Components

2-2-10 MicroHAWK F420-F Top

2-2-11 MicroHAWK F420-F Side

2-2 Camera Dimensions

2

2-2-10 MicroHAWK F420-F Top

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-7

Page 42

2 System Components

2-2-12 MicroHAWK F430-F Front

2-2-13 MicroHAWK F430-F Base

2-8

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 43

2 System Components

2-2-14 MicroHAWK F430-F Top

2-2 Camera Dimensions

2

2-2-14 MicroHAWK F430-F Top

2-2-15 MicroHAWK F430-F Side

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-9

Page 44

2 System Components

Diffuser Kit – Peel and Stick Accessory. Exterior to unit.

V330-AF1

Polarizer Kit – Peel and Stick Accessory. Exterior to unit.

V330-AF2

2-3 Accessories

2-3-1 MicroHAWK F320-F and F330-F Accessories

Important: See Appendix B - Cable Specifications for cables, pin assignments, and wire colors.

2-10

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 45

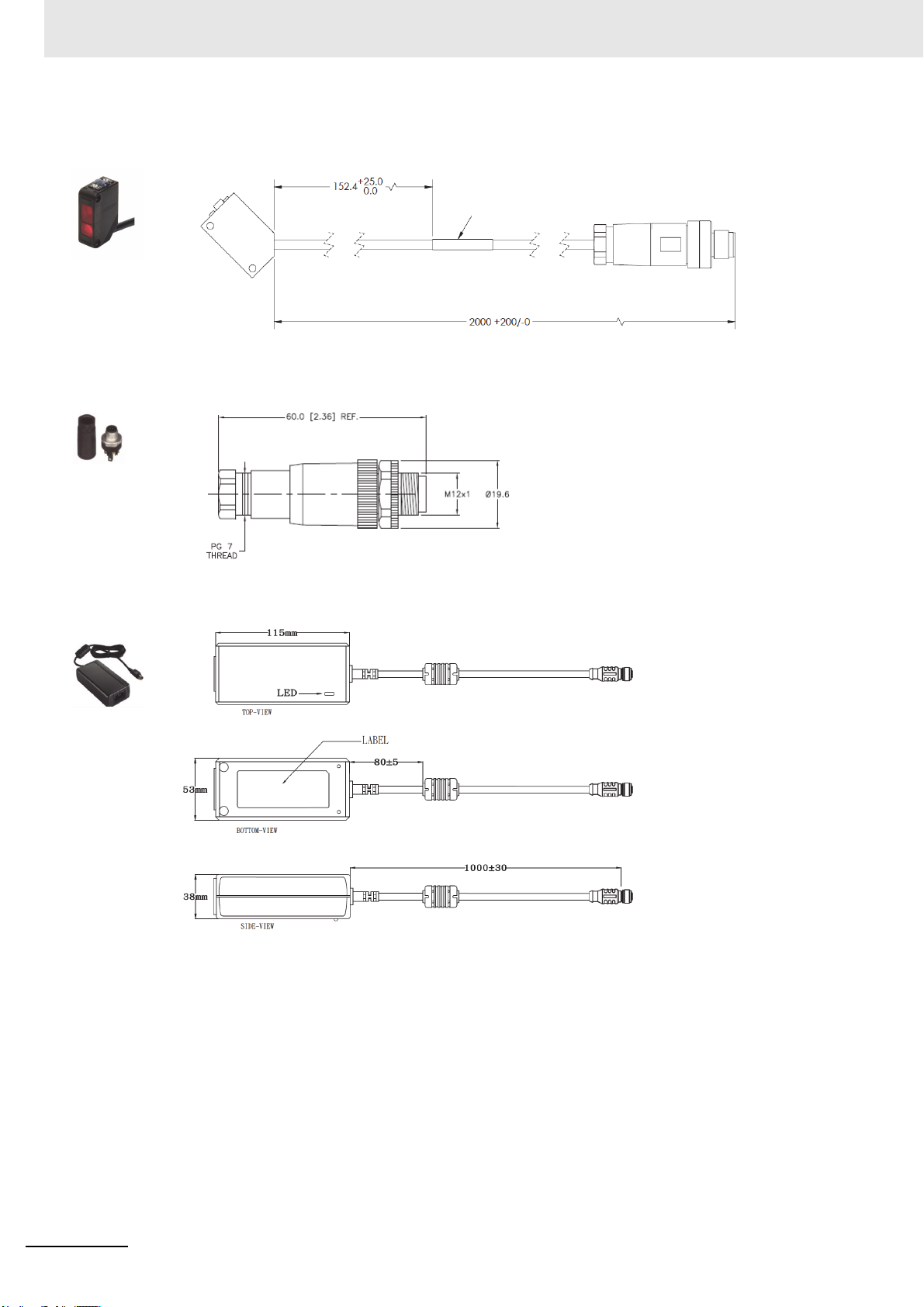

2-3-2 MicroHAWK F420-F and F430-F Accessories

L Bracket Adjustable Angle Mounting Kit

V430-AM0

¼-20 Camera Mounting Block Kit

V430-AM1

2 System Components

2-3 Accessories

2

2-3-2 MicroHAWK F420-F and F430-F Accessories

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-11

Page 46

2 System Components

4” (102 mm) Ram Mount Stand

V430-AM2

MS-4 / MINI to V/F4XX-F Adapter Plate

V430-AM5

2-12

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 47

2 System Components

Smart Ring Light to V/F4XX-F Mounting Bracket

V430-AM6

QX / Vision HAWK to V/F4XX-F Adapter Plate

V430-AM7

2-3 Accessories

2

2-3-2 MicroHAWK F420-F and F430-F Accessories

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-13

Page 48

2 System Components

Front Window Installation Kit

V430-AF10 *

Diffuser Installation Kit

V430-AF11 *

Polarizer Installation Kit

V430-AF12 *

YAG Filter Installation Kit

V430-AF4

ESD-Safe Window Installation Kit

V430-AF5

Right Angle Mirror Installation Kit

V430-AF3

* Note: The accessories V430-AF10, AF11, and AF12 are used for MicroHAWK F4X0-FXXXXXXX-XXX cameras in this manual. The prior

generation MicroHAWK F430-FXXXXXXX camera uses accessory part numbers V430-AF0, AF1, and AF2. Please select the correct

accessory from the table based on your camera part number format.

Accessory Prior F4X0-FXXXXXXX Camera

Front Window Installation Kit

Diffuser Installation Kit

Polarizer Installation Kit

V430-AF0

V430-AF1

V430-AF2

2-14

New F4X0-FXXXXXXX-XXX Camera

V430-AF10

V430-AF11

V430-AF12

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 49

2 System Components

Red Filter Installation Kit

V430-AF6

Blue Filter Installation Kit

V430-AF7

Red Light Installation Kit

V430-ALR

White Light Installation Kit

V430-ALW

Blue Light Installation Kit

V430-ALB

IR Light Installation Kit

V430-ALI

QX-1 Interconnect Module – Power, Trigger, Smart Light Control Breakout

98-000103-02

2-3 Accessories

2

2-3-2 MicroHAWK F420-F and F430-F Accessories

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-15

Page 50

2 System Components

QX-1 Photo Sensor, M12 4-Pin Plug, NPN – 2 Meters – Light ON / Dark ON

99-9000016-01

QX-1 Field-Wireable M12 4-Pin Plug for Any Trigger Source or Photo Sensor – Screw Terminals

98-9000239-01

Power Supply, 100-240VAC, +24VDC, M12 12-Pin Socket – 1 Meter – U.S. / Euro Plug

97-000012-01

2-16

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 51

2 System Components

Omron Microscan Smart Light Series – Integrated Power and Strobe Control Module

See Omron Microscan Smart Light Offering – Ring, DOAL, Large Area Lighting

2-3 Accessories

2

2-3-2 MicroHAWK F420-F and F430-F Accessories

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-17

Page 52

2 System Components

2-4 Hardware Configurations

Important: The following hardware configurations are examples only. Real-world application configurations may

vary considerably from those shown below.

2-4-1 Check Hardware and Connect the System

MicroHAWK F320-F

MicroHAWK F330-F

The F320-F supports Power over Ethernet (POE), allowing you to power and communicate with the device from

a single cable. The F320-F is considered a Class 0 PD (Powered Device) and will operate when connected to

appropriate PoE PSE (Power Sourcing Equipment). The PSE will either provide power on an unused data pair

(Alternative B) or on the data pair (Alternative A) which depends on the PSE. The F320-F supports both Mode A

and Mode B per the PoE standard, IEEE802.3af.

When the F320-F is connected to the Cat5E cable, it will automatically present a Powered Device (PD) signature

to the Power Sourcing Equipment (PSE), or PoE Mid-Span Equipment, when requested. The equipment will then

recognize that a powered device is connected to that line and will supply power.

Omron recommends that you contact your network or IT administrator for further configuration details. You can

connect to a non-PoE network using a PoE Injector, Omron part number V330-AP1.

2-18

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 53

2 System Components

F420-F with DB15 to BUS Power USB Type A

F420-F with DB15 to Ext. Power/USB Type A

Integrated

Corner-Exit

Cable

Accessory USB

Cable to Host

To H o s t

To H ost

Integrated

Corner-Exit

Cable

Accessory USB

Cable to Host

Power Supply

Note: BUS-powered cable delivers reduced illumination –

approximately 30% less brightness.

F420-F with DB15 to Ext. Power/RS-232

Power

Supply

To h ost

Integrated

Corner-Exit

Cable

F420-F with DB15 to Ext. Power/USB, I/O

To

Trigg er

Accessory

USB Cable

to Host

Integrated

Corner-Exit

Cable

To

Power

Supply

MicroHAWK F420-F

• Mount the camera securely in its stand (not supplied).

• Mount the camera as required by the application.

• Connect the integrated corner-exit cable to the MicroHAWK F420-F.

• Connect the accessory USB cable to the integrated corner-exit cable.

• Connect the USB Type A side of the USB cable to the host.

• Connect the power cable into the power source.

2-4 Hardware Configurations

2

2-4-1 Check Hardware and Connect the System

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-19

Page 54

2 System Components

F420-F with DB15 to USB/RS-232, Triggered

To H o s t

To Trigger

To Power Supply

To H o s t

(RS-232)

Integrated

Corner-Exit

Cable

Accessory

USB Cable

to Host

F420-F with IB-131 and IC-332

To

power

supply

IC-332

To external

trigger

To

Host

2-20

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 55

2 System Components

To P o w e r

Supply

(12-Pin Plug)

To H ost

(Ethernet

8-Pin Plug

to RJ45)

F430-F Simple Configuration

Common

(12-Pin Plug

to 12-Pin

Socket)

To H o s t

(Ethernet

8-Pin Plug

to RJ45)

To Trigger

To P ow er

Supply

F430-F with QX-1 Interface Device

F430-F M12 12-Pin Socket to 9-Pin Socket and M12 Plug

To Power Supply or: Flying Lead Cable

(61-000167-02); QX-1; MS-Connect 210.

To H ost

(RS-232)

To E t her n et

MicroHAWK F430-F

• Mount the camera securely in its stand (not supplied).

• Mount the camera as required by the application.

• Connect the power cable to the MicroHAWK F430-F.

• Connect the Ethernet cable to the MicroHAWK F430-F.

• Connect the Ethernet cable to the host.

• Connect the power cable into the power source.

2-4 Hardware Configurations

2

2-4-1 Check Hardware and Connect the System

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-21

Page 56

2 System Components

2-5 Mounting the Camera

2-5-1 Mount and Position the Camera

1

Position the camera at a focal distance of one inch or more from a test object.

2

Tip the camera relative to the object to avoid the glare of direct (specular) reflection. The case

parting line should be perpendicular to the plane of the symbol by either pitching the symbol or

the camera. Avoid excessive skew or pitch. Maximum skew is ±30°; maximum pitch is ±30°.

2-22

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 57

2-6 I/O Wiring

2 System Components

2-6-1 MicroHAWK F420-F

Direct Input / Output Diagrams

2-6 I/O Wiring

2

2-6-1 MicroHAWK F420-F

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-23

Page 58

2 System Components

Optoisolator Trigger Inputs for IC-332

2-24

New Master Pin

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 59

2-6-2 MicroHAWK F430-F

Optoisolated Outputs

2 System Components

The camera has optoisolated outputs that can transfer signals from the camera to

peripherals. Outputs can be configured as either NPN or PNP, but NPN and PNP cannot be mixed in a

system, because the output common is shared by all outputs.

NPN Output for Host Input

2-6 I/O Wiring

2

2-6-2 MicroHAWK F430-F

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-25

Page 60

2 System Components

NPN Output for External Load

2-26

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 61

PNP Output for Host Input

2 System Components

2-6 I/O Wiring

2

2-6-2 MicroHAWK F430-F

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-27

Page 62

2 System Components

PNP Output for Ecternal Load

2-28

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 63

2 System Components

Optoisolated Inputs

NPN Output for Host Input

All discrete inputs are optoisolated. Inputs can be configured as either NPN or PNP, but NPN and PNP

cannot be mixed in a system, because the input common is shared by all inputs.

NPN

2-6 I/O Wiring

2

2-6-2 MicroHAWK F430-F

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-29

Page 64

2 System Components

PNP

2-30

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 65

2-7 Grounding and Power

An earth ground is provided through the cable shields and chassis of the camera.

Smart

Camera

2-7-1 Ground and Shield Considerations

Proper grounding is necessary for operator safety, noise reduction, and the protection of equipment

from voltage transients. Buildings, including any steelwork, all circuits, and all junction boxes must be

grounded directly to an earth ground in compliance with local and national electrical codes.

2 System Components

2-7 Grounding and Power

2

2-7-1 Ground and Shield Considerations

Ground Loops

Ground loops (signal degradation due to different ground potentials in communicating devices) can be

eliminated or minimized by ensuring that both the host, imager, and their power supplies are connected

to a common earth ground.

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

2-31

Page 66

2 System Components

Expected Power and Ground Connections for Proper Operation

Grounding Notes

• Ensure that mounting bracket “Earth” is at the same potential as power source “Earth”.

• Supply “Return” and “Earth” ground must be stable, low-impedance reference points.

• “2-Terminal Power Supply” must still provide an “Earth” connection to the imager.

• “Signal Ground” can be used for communications and/or discrete signal ground reference. It must not

be used as Power Ground or Earth Ground.

Power Requirements

Refer to this table when determining the power requirements for your camera.

Power Supply Voltage Current Consumption

F320-F 5 VDC +/- 5% 450 mA at 5 VDC (max.)

F330-F Source: 44-57 VDC IEEE802.3af POE Max Current: 0.090 A

F420-F 5 VDC +/- 5% 650 mA at 5 VDC (max.)

F430-F 5 to 30.0 VDC, 200 mV p-p max ripple 0.18 A at 24 VDC (max.)

2-32

MicroHAWK F320-F / F330-F / F420-F / F430-F Smart Camera User Manual

Page 67

2 System Components

2-8 I/O Filtering and Debounce

Trigger Debounce is the ability of the system to accommodate switching noise on a trigger state

change – a common issue with relays that have some intermittent contact while engaging.

Trigger overruns (when the vision system is triggered faster than the device can process) can be