Page 1

&DW1R=(

)80(

$SSOLFDWLRQ6RIWZDUH

23(5$7,210$18$/

Front Matter

Contents

About this Manual

Basic Operating Procedures

Processing Items Setting Procedures

Monitor Mode and Run Mode

Other Functions

System Settings

Communicating with External Devices

Appendices

Revision History

Page 2

)80($SSOLFDWLRQ6RIWZDUH

2SHUDWLRQ0DQXDO

5HYLVHG'HFHPEHU

Page 3

iii

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always

heed the information prov ided w ith them . Failure to heed precau tions c an resul t in injury to people

or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it

refers to an OMRON product, regardless of whether or not it appears in the proper name of the

product.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types

of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... ,QGLFDWHVOLVWVRIRQHVRUWRUDQRWKHUVXFKDVSURFHGXUHVFKHFNOLVWVHWF

Precaution Indicates information required to take full advantage of the functions and per-

formance of the product. Incorrect application methods may result in the loss

of damage or damage to the product. Read and follow all precautionary information.

CHECK Indicates points that are important in using product functions or in application

procedures.

SeeAlso Indicates where to find related information.

HELP Indicates information helpful in operation, such as the definition of terms.

¸ OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information contained

in this manual is subject to change without notice. Every preca ution has been taken in the prepa ration

of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publication.

iv

Page 5

TABLE OF CONTENTS

SECTION 1

Basic Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . 1-(1)

1-1 Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(2)

1-2 Operational Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(3)

1-3 Installing the Application Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(4)

1-4 Displaying Images and Focussing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(10)

1-5 Menu Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(12)

1-6 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(28)

1-7 Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(62)

1-8 Saving Settings and Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(64)

SECTION 2

Processing Items Setting Procedures . . . . . . . . . . . . . . . . . . 2-(1)

2-1 Inputting Camera Images. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1-(1)

2-2 Switching Cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2-(1)

2-3 Changing Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3-(1)

2-4 Filtering Again. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4-(1)

2-5 Binary Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5-(1)

2-6 EC Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6-(1)

2-7 Edge Position Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7-(1)

2-8 Model Position Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8-(1)

2-9 Circle Position Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9-(1)

2-10 Reset Scroll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10-(1)

2-11 Scroll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11-(1)

2-12 Detecting Binary Defects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12-(1)

2-13 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13-(1)

2-14 Density Defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14-(1)

2-15 EC Defect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15-(1)

2-16 EC Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16-(1)

2-17 Edge Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17-(1)

2-18 Fine Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18-(1)

2-19 EC Circle Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19-(1)

2-20 Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20-(1)

2-21 QUEST Character Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21-(1)

2-22 Rotation Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22-(1)

2-23 ECM Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23-(1)

2-24 Lot Number OCV 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24-(1)

2-25 Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25-(1)

2-26 Label Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26-(1)

v

Page 6

TABLE OF CONTENTS

2-27 Edge Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27-(1)

2-28 Density Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28-(1)

2-29 Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29-(1)

2-30 Elapsed Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30-(1)

2-31 Get Unit Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31-(1)

2-32 Wait . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32-(1)

2-33 Set Unit Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33-(1)

2-34 Trend Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34-(1)

2-35 Conditional Branching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35-(1)

2-36 DI Branch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36-(1)

2-37 End. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -37-(1)

2-38 Memory Card Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38-(1)

2-39 DO Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39-(1)

2-40 DO Judgement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -40-(1)

2-41 Host Link Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41-(1)

2-42 Normal Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42-(1)

2-43 Display String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43-(1)

2-44 Display Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44-(1)

2-45 Display Judgement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45-(1)

2-46 Display Item. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46-(1)

2-47 Display Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47-(1)

2-48 Display Figure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48-(1)

2-49 Display Line, Dis play Box, Display Circle, and Display Cursor . . . . . . .2-49-(1)

SECTION 3

Monitor Mode and Run Mode. . . . . . . . . . . . . . . . . . . . . . . . 3-(1)

3-1 Testing Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-(2)

3-2 Starting Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-(5)

SECTION 4

Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-(1)

4-1 Changing Scenes and Scene Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-(2)

4-2 Backing Up Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-(9)

4-3 Clearing Measurement Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-(24)

4-4 Checking Image Density Distribution: Line Brightness . . . . . . . . . . . . . . . 4-(25)

4-5 Checking I/O Status with External Devices . . . . . . . . . . . . . . . . . . . . . . . . 4-(28)

4-6 Memory Card Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-(33)

vi

Page 7

TABLE OF CONTENTS

SECTION 5

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(1)

5-1 Entering System Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(2)

5-2 Camera Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(3)

5-3 Screen Display and Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(5)

5-4 Customizing Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(17)

5-5 Setting Conditions for Saving Measurement Images . . . . . . . . . . . . . . . . . 5-(27)

5-6 Using BUSY Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(31)

5-7 Setting Startup Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(33)

5-8 Setting the Calendar Date and Time (Date/Time). . . . . . . . . . . . . . . . . . . . 5-(34)

5-9 Checking System Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-(35)

SECTION 6

Communicating with External Devices. . . . . . . . . . . . . . . . . 6-(1)

6-1 Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1-(1)

6-2 Normal Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2-(1)

6-3 Host Link Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3-(1)

6-4 Serial Interface Menu Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4-(1)

SECTION 7

Appendices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(1)

7-1 Set Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(2)

7-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(4)

7-3 FAQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(9)

7-4 Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(12)

7-5 Character Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(15)

7-6 Menu Hierarchy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-(16)

Revision History

vii

Page 8

$ERXWWKLV0DQXDO

This manual describes the operation of the F250-UME Application Software and it includes

the sections described below.

This is one of a pai r of manuals. R efer to the fo ll o w in g ta ble for the co nte nts of eac h m an u al .

Manual Contents Cat. No.

1:Setup Manual Provides information on system hardware and installa-

tion. Be sure to read this manual first.

This manual is provided with the Controller.

2:Operation Manual Describes the operation of the F250-UME Application

Software, including installation of the Application Software, basic operating methods, setting methods for processing items, communications methods for external

devices, and other operating procedures.

This manual is provided on CD-ROM.

Please read the above manuals carefully and be sure you understand the information provided before attempting to install or operate the Application Software.

Section 1 Basic Operating Procedures describes the basic operating procedures for the

Application Software.

Section 2 Processing Item Setting Procedures explains in more detail the basic setting

operations for the processing items that control Application Software operation.

Section 3 Testing and Starting Measurements describes the procedures used to test

operation and then actually take measurements.

Section 4 Other Functions describes additional functions, such as changing the measurement setup or backing up data.

Section 5 System Settings describes how to set conditions related to the system environ-

ment.

Section 6 Communicating with External Devices describes the methods used to connec t

to and communicate with external devices.

Section 7 Ap p e nd ic es provides information on terminology, character codes, troubleshoot-

ing, and answers to FAQs.

SCHB-736

Z153-E1-02

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section in

its entirety and be sure you understand the information provided in the section and related

sections before attempting any of the procedures or operations given.

viii

Page 9

SECTION 1

Basic Operating Procedures

This section describes the basic operating procedures for the Application Software.

1-1 Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(2)

1-2 Operational Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(3)

1-3 Installing the Application Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(4)

1-3-1 Starting the Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(4)

1-3-2 Selecting Installation Processing Items. . . . . . . . . . . . . . . . . . . . . . . 1-(6)

1-3-3 Executing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(7)

1-4 Displaying Images and Focussing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(10)

1-5 Menu Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(12)

1-5-1 Input Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(12)

1-5-2 Screen Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(13)

1-5-3 Creating Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(14)

1-5-4 Drawing a Region . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(24)

1-5-5 Inputting Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(26)

1-5-6 Inputting Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(27)

1-6 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(28)

1-6-1 STEP 1: Settings for Image Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(29)

1-6-2 STEP 2: Settings for Position Displacement Compensation. . . . . . . 1-(38)

1-6-3 STEP 3: Setting Measurement Methods . . . . . . . . . . . . . . . . . . . . . . 1-(40)

1-6-4 STEP 4: Setting Results Output Methods. . . . . . . . . . . . . . . . . . . . . 1-(58)

1-6-5 STEP 5: Start Test or Measurement . . . . . . . . . . . . . . . . . . . . . . . . . 1-(59)

1-7 Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(62)

1-7-1 Entering Run Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(62)

1-7-2 Performing Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(63)

1-8 Saving Settings and Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-(64)

1-(1)

Page 10

Using this Manual Section 1-1

1-1 Using this Manual

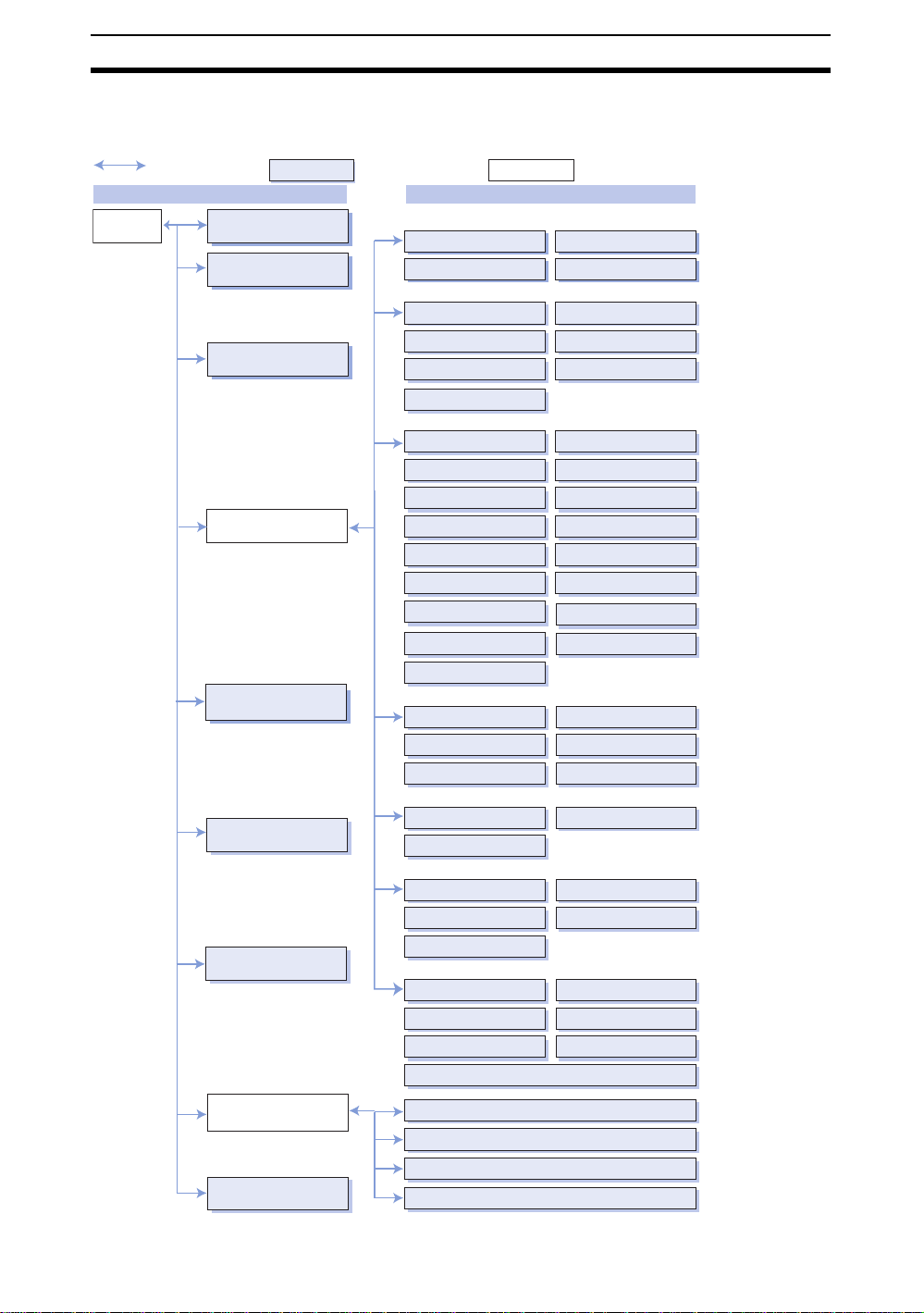

The structure of the PDF files in this manual is shown below. Bookmarks are

provided to link the initial file to sections and sections to detailed information.

Linked files

Initial File a nd Section File s

Initial file

Front Matter

About this Manual

SECTION 1

Basic Operating Procedures

SECTION 2

Detailed Setting Operations

SECTION 3

Executing Tests and

Measurements

SECTION 4

Other Functions

SECTION 5

System Settings

SECTION 6

Communicating with External

Devices

SECTION 7

Appendices

Individual files

Processing Item Files

Inputtin g I m ages

Camera image

Change filtering

Position Compensation

Binary pos. comp

Edge pos. comp

Circle pos. comp

Scroll

General Measurements

Binary defect Classification

Density defect

EC position Edge position

Fine matching

Pattern

Rotate position

Lot No. OCV1

Label data

Density data

Measurement Support

Calculation Elapsed time

Get unit data

Set unit data

Branch Control

Branch

End

Results Output

Memory card data

DO judge

Normal data

Results Display

Display string Display measure

Display judge

Display time Display figure

Display line/box/circle/cursor

Parallel Interface

Serial Interface: Normal

Serial Interface: Host Link

Serial Interface: Menu Operations

Files containing only links

Switch camera

Filtering again

EC pos. comp

Model pos. comp

Reset scroll

EC defect

EC circle count

QUEST OCV

ECM search

Labeling

Edge pitch

Wait

Trend monitor

DI branch

DO data

Host link data

Display item

This manual can

be printed out by

opening the file

and following the

instructions in the

Acrobat printing

dialog box.

1-(2)

Page 11

Operational Flow Section 1-2

1-2 Operational Flow

Preparations

Install the Application Software in the Controller. Refer to 1-3 Installing the

Application Software.

SeeAlso Refer to 1-6 Basic Operations to learn about the basic operational flow from

setting detection conditions to executing measurements.

Setting Detection Conditions

STEP 1: Make the settings required to input images. Refer to1-6-1 STEP 1:

Settings for Image Input.

STEP 2: Make settings to correct positioning. Refer to 1-6-2 STEP 2: Settings

for Position Displacement Compensation.

STEP 3: Set the actual measu remen t method s. Ref er to 1-6-3 STEP 3: Setting

Measurement Methods.

STEP 4: Make settings to output the results. Refer to 1-6-4 STEP 4: Setting

Results Output Methods.

Confirming Settings and Executing

STEP 5: Perform test measurements and start executing measurements.

Refer to 1-6-5 STEP 5: Start Test or Measurement and to SECTION 3 Monitor

Mode and Run Mode.

Selecting Processing Items that Suit the Application

Refer to SECTION 2 Processing Items Setting Procedures.

Changing and Deleting Settings

Copy, clear, and change un its and uni t names by refer to &KDQJLQJ WR2WKHU

3URFHVVLQJ,WHPVRQSDJH .

Saving Settings

1. Save detection conditions. Refer to 1-8 Saving Settings and Shutting

Down.

2. Back up imag e, s ystem, and scene data. Refer to 4-2 Backing Up Data for

information on how to back up settings.

Application Setting Operations

1. Set conditions by product type. Refer to 4-1 Changing Scenes and Scene

Groups for information on scene and scene-group functions.

2. Set system environmen t conditions . Ref er to SECTION 5 System Settings.

3. Initialize the measurem ent co nditio ns that ha v e bee se t. Ref er to 4-1-3 Ini-

tializing Measu rement Conditi ons: Clearing S cenes and 7-1 Set Up Menu.

4. Set commu nications s pecifications and I/O format f or comm unication s with

external device s. Refer to SECTION 6 Communicating with External De-

vices.

Additional Functions

1. Use Memor y Cards if required. Refer to 4-6 Memory Card Operations.

2. Check communications status with external devices if required. Refer to 4-

5 Checking I/O Status with External Devices.

Troubleshooting

HELP When an error message is displayed on the screen, refer to 7-4 Terminology.

HELP If you have a question, refer to 7-3 FAQ.

HELP If you don’t understand a term, refer to 7-4 Terminology.

1-(3)

Page 12

Installing the Application Softwar e Section 1-3

1-3 Installing the Application Software

This section describes how to install the processing items in the F250-UME

Applicati on Software to the Contr oller. The Setup Menus are used to install

these processing items.

1-3-1 Starting the Setup M enu

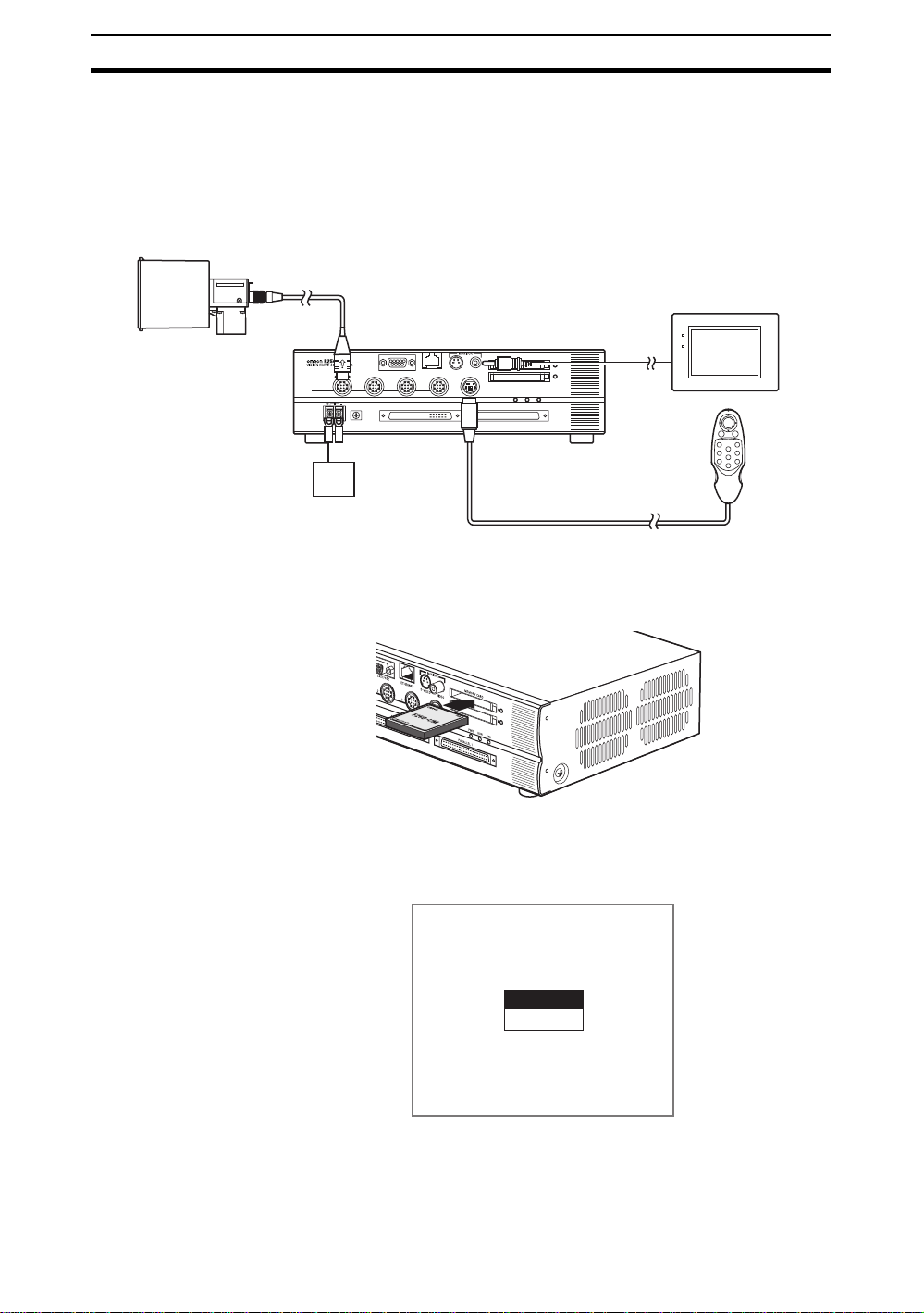

1. Check that the basic components are connected.

Camera

Monitor

Power supply

Console

POWER

SYNC

CHECK Always refer to the Setup Manual when connecting components or wiring the

power supply or ground wires.

2. Mount the F250-UME Application Software Card to Memory Card slot 0.

3. Turn ON the power supply switch to the Monitor.

4. Turn ON the Controller power supply.

The Language Selection Screen for the Setup Menus will be displayed.

1-(4)

Language

Japanese

English

CHECK The language selected here applies only to the Setup Menus.

Page 13

Installing the Application Softwar e Section 1-3

5. Select a language.

Use the Up or Down Key on the Console to move the cursor.

Japanese: Messages will be displayed in Japanese.

English: Messages will be displayed in English.

This manual shows screens displayed with English messages.

6. Press the ENT Key on the Console to confirm the language selection.

After a short time, the Basic Screen for the Setup Menus will be displayed.

Set up

Select items

Install

Backup data load

Clear memory

Precaution About the F250-UME Application Software

If the F250-UME Application Software Card is mounted to a personal computer or other device and the data changed, the Setup Menus will no longer

start properly. Never perform any of the following operations.

• Do not change file names.

• Do not move or delete files.

• Do not write data to the F250-UME Application Software Card.

• Do not format the F250-UME Application Software Card.

1-(5)

Page 14

Installing the Application Softwar e Section 1-3

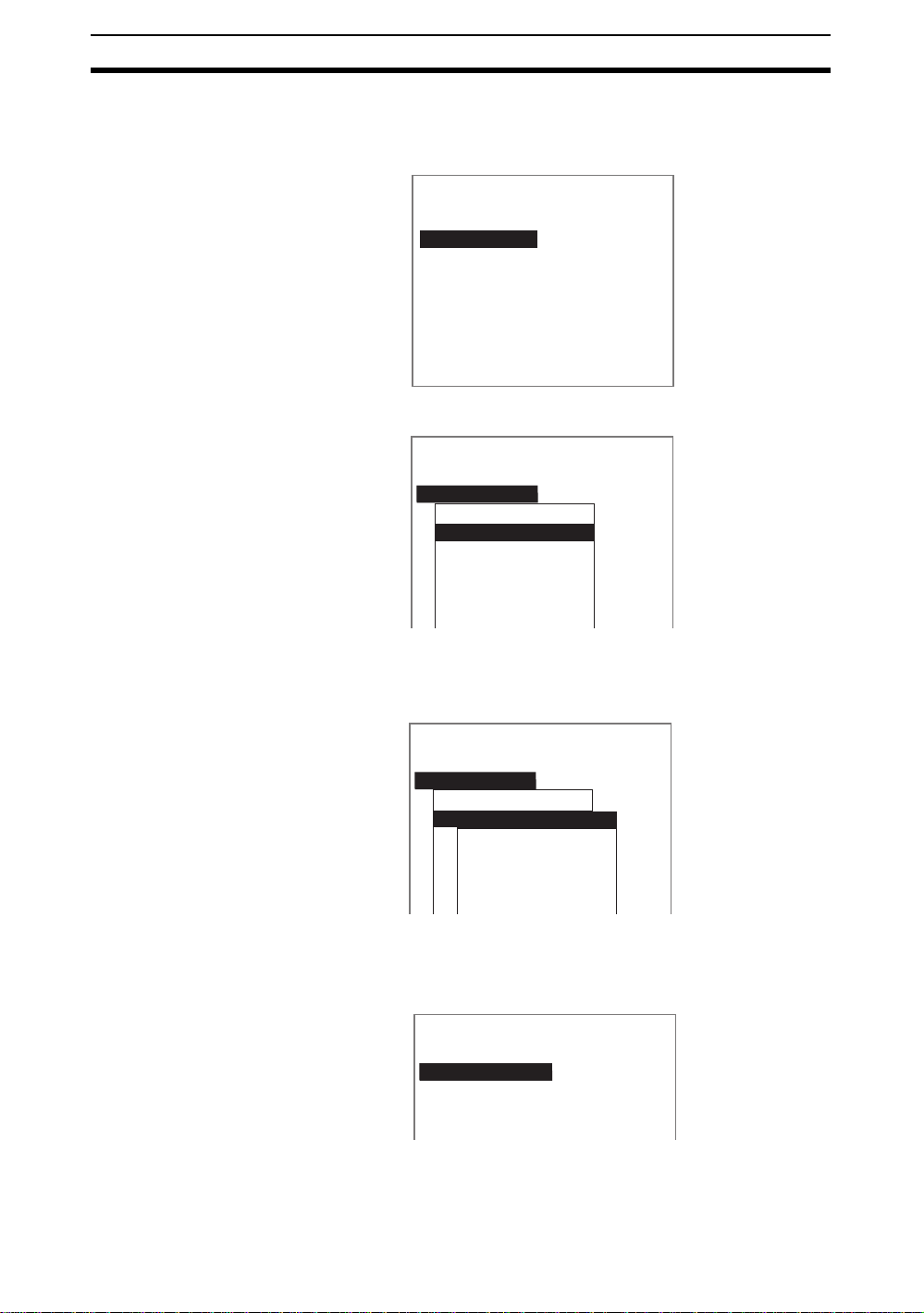

1-3-2 Selecting Installation Processing Items

The F250-UME has many processing items. Select the processing items

required for the application. Refer to SECTION 2 Processing Items Setting

Procedures for an outline of each processing item.

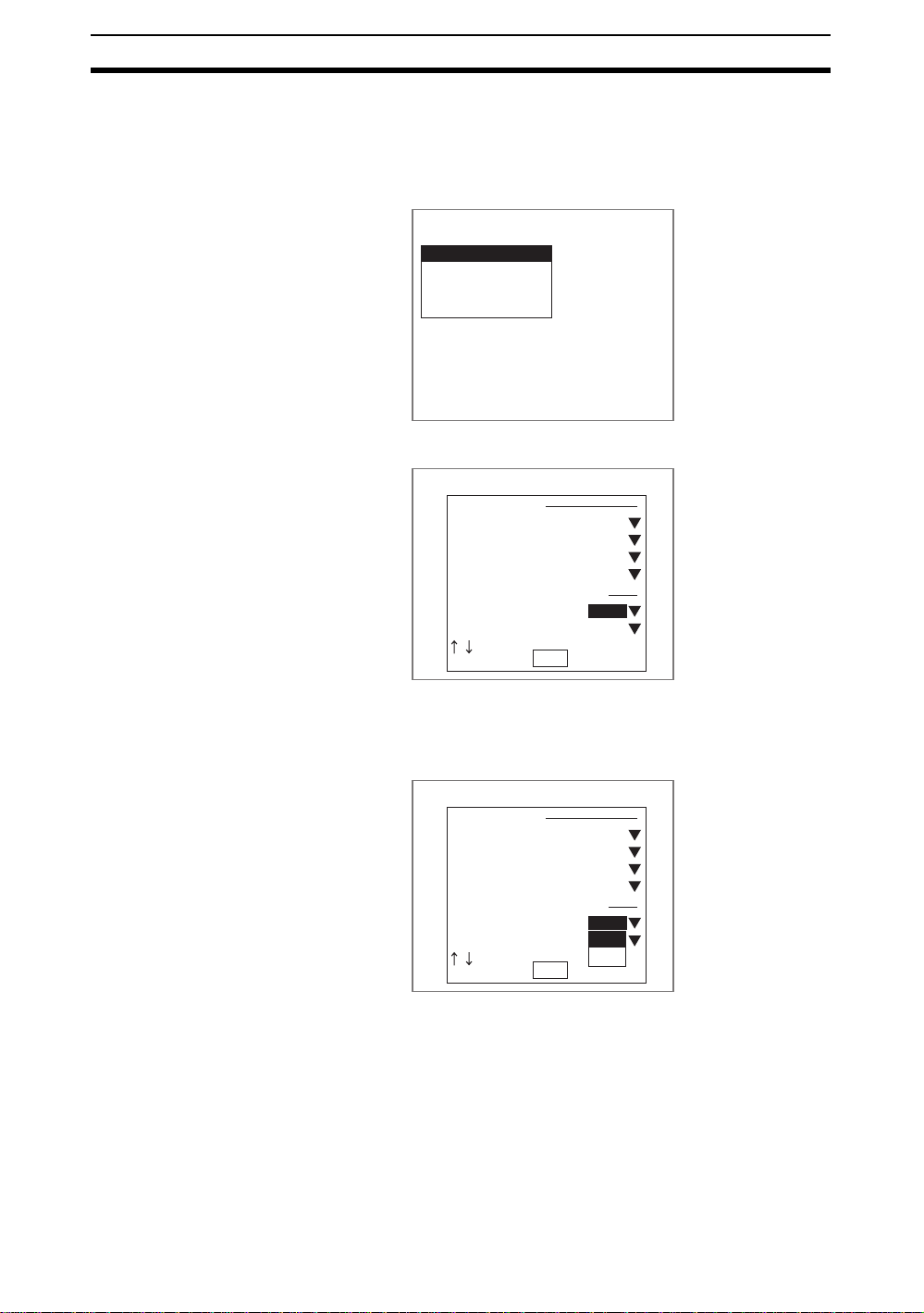

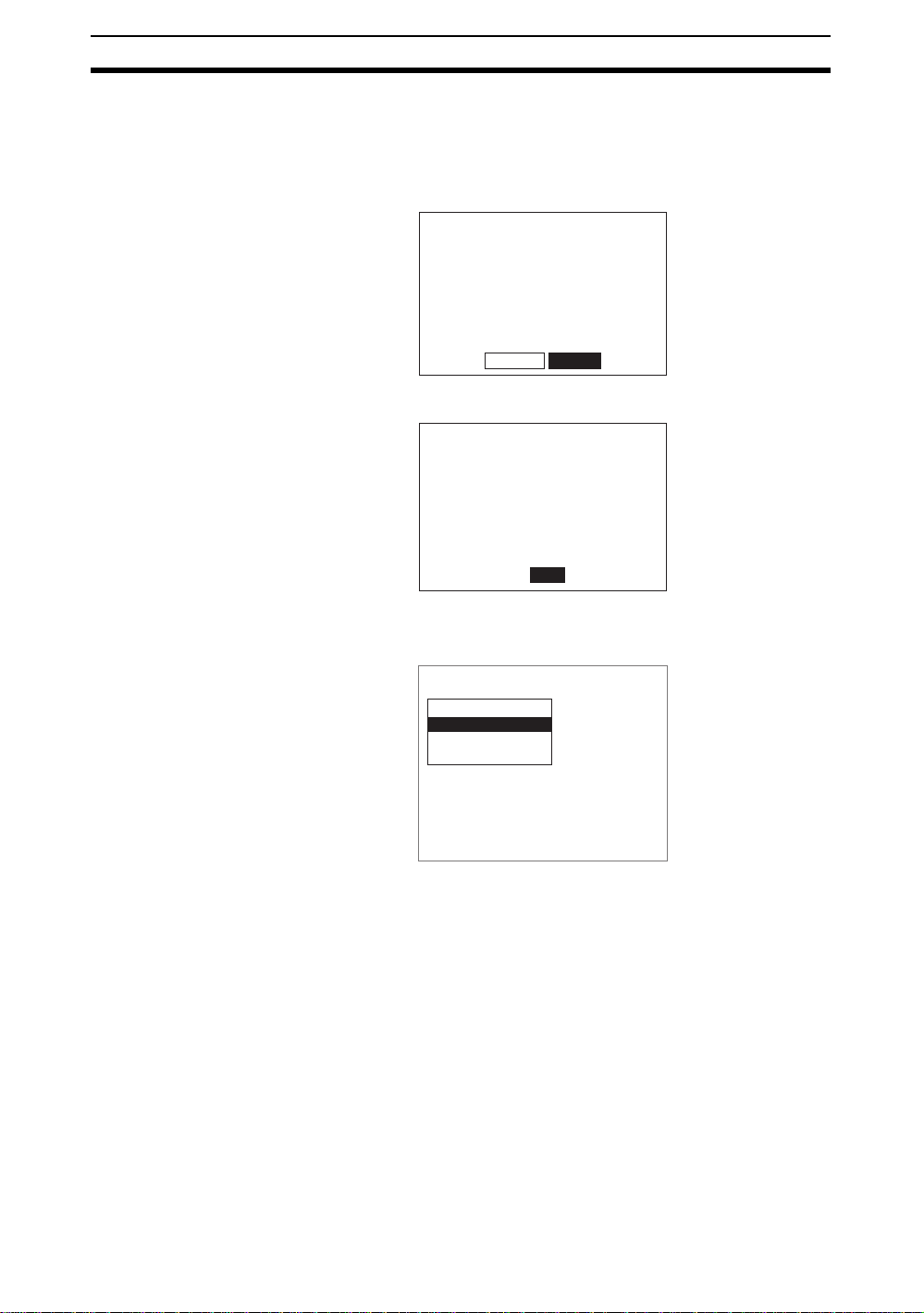

1. Select Select items.

Set up

Select items

Install

Backup data load

Clear memory

A list of processing items will be displayed.

Select items

Input Image

Camera image

Switch camera

Change Filtering

Filtering again

Position Compensation

Binary pos. comp

Model pos. comp

End

ON

ON

ON

ON

OFF

OFF

2. Move the cursor to the item to be installed.

3. If that item is “OFF,” press the ENT Key.

The selections (ON/OFF) will be displayed.

Select Items

Input Image

Camera image

Switch camera

Change Filtering

Filtering again

Position Compensation

Binary pos. comp

Model pos. comp

End

ON

ON

ON

ON

OFF

ON

OFF

OFF

4. Select ON.

5. Repeat this process to set to ON the processing items to be installed and

set to OFF the items that are not to be installed.

6. Select END.

The settings will be registered and the screen in (1.) will return.

1-(6)

Page 15

Installing the Application Softwar e Section 1-3

1-3-3 Executing Installation

This section describes how to install the selected processing items to the Controller.

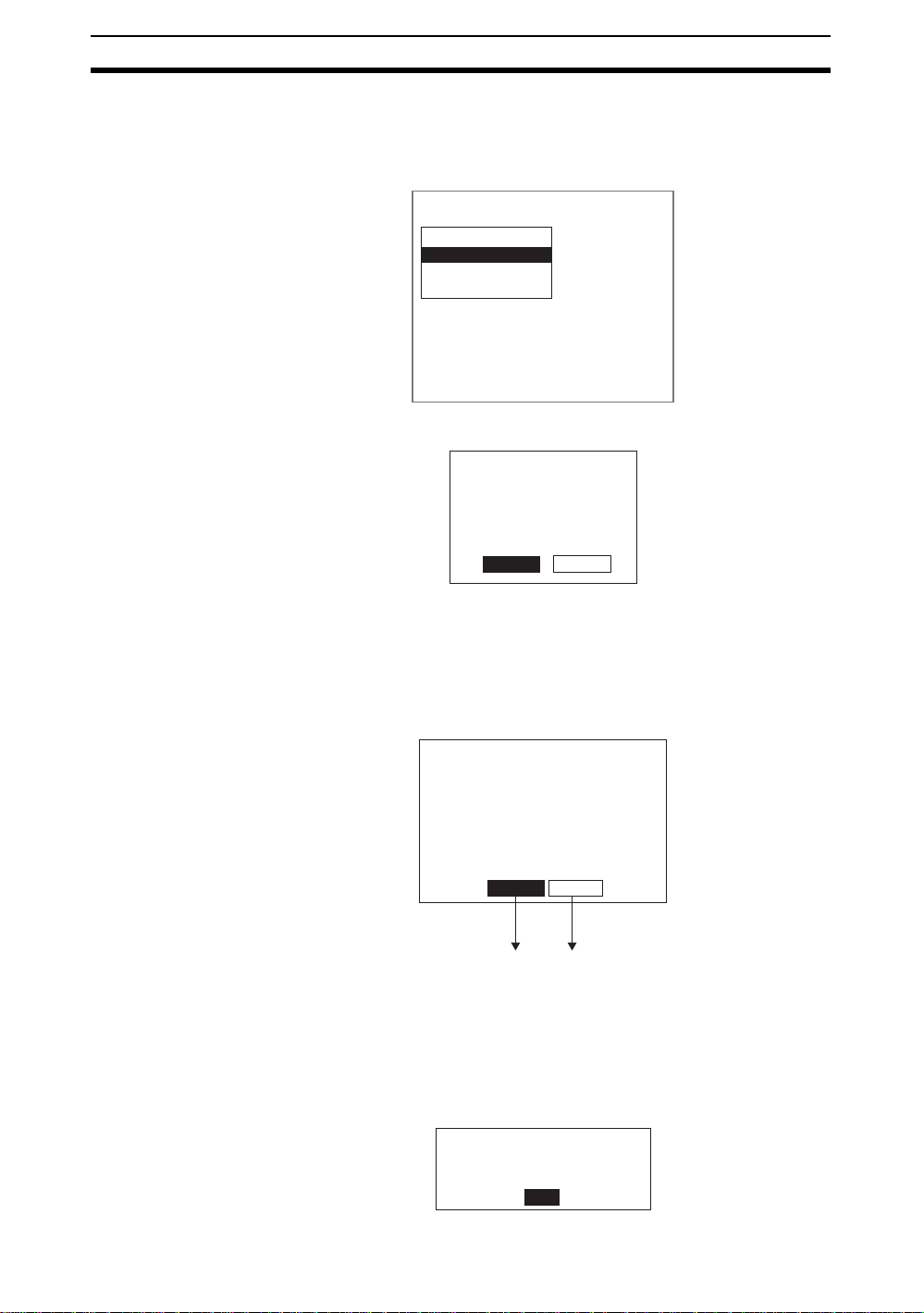

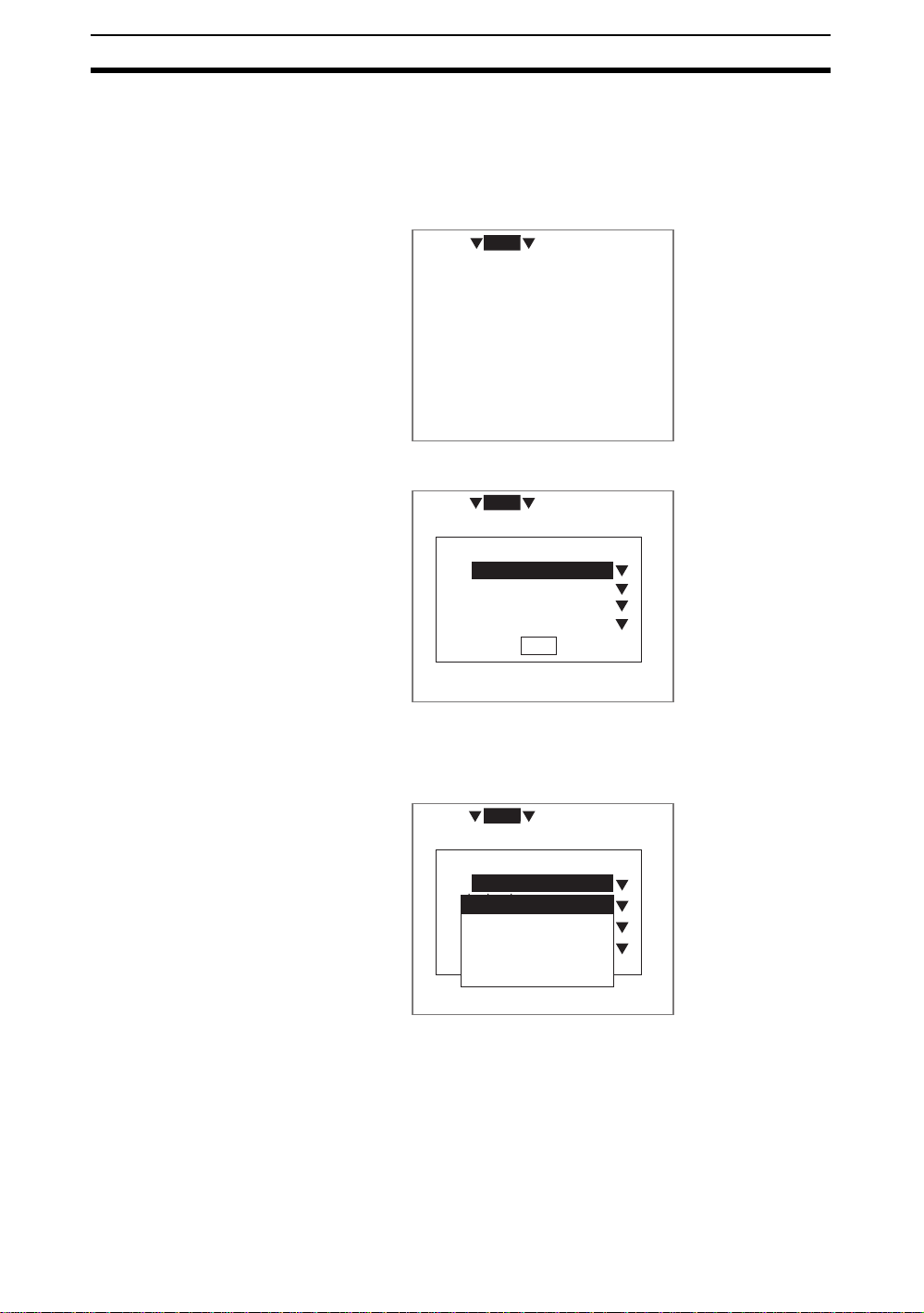

1. Select Install.

Set up

Select items

Install

Backup data load

Clear memory

A confirmation message will be displayed.

Selected Programs

will be installed.

The programs and data

stored at present

are cleared.

Execute Cancel

2. Select Execute.

The size of the p roces sing items will be calcul ated t o d etermine if the y c an

be installed.

If the total size of the se lected proc essing it ems is too larg e to be install ed,

a confirmation message will be displayed to ask if the files are to be compressed.

Total size of selected items

is too large to install.

Compressing programs make

the installation possible,

but startup time will

be longer.

Compress programs?

Execute Cancel

To STEP 3 Refer to page 1-(9).

Precaution Do not input the RESET signal or turn OFF the power supply while the pro-

cessing message is being displayed. If the RESET signal is input or the power

is turned OFF, data may be lost and the Controller may not start correctly the

next time.

A confirmation message will be displayed once the installation has been

completed.

Installation finished.

Put off the memory card

and restart.

OK

1-(7)

Page 16

Installing the Application Softwar e Section 1-3

3. Press the ENT Key.

The Main Screen for the Setup Menu will return.

Set up

Select items

Install

Backup data load

Clear memory

4. Turn OFF the power supply to the Controller.

5. Remove the F250-UME from Memory Card slot 0.

6. Turn ON the Controller power supply.

CHECK If the power is turned ON while the F250-UME is still mounted, the Setup

Menus will open. Always remove the F250-UME before turning ON the power

supply.

After a while the Camera Settings Screen will be displayed.

Camera settings

Camera :F160-S1

Intelligent Lighting 0:

Out of use

Intelligent Lighting 1:

Out of use

Intelligent Lighting 2:

Out of use

Intelligent Lighting 3:

Out of use

End

SeeAlso Refer to page SECTION 5 System Settings.

7. Select the camera to be connected.

8. If using Intelligent Lighting, select the model.

9. Select END.

The Basic Screen will be displayed.

0.Scn 0 MON

---- ---ms

1-(8)

Image 0 freeze

Page 17

Installing the Application Softwar e Section 1-3

Installation

without

Compressing

Files

If the total program size of the selected items is greater than the file size that

can be installed, a confirmation message will be displayed asking if the files

are to be compressed. If the files are compressed, the Controller startup time

will be longer. Use the following procedure to change the selected processing

items without compressing the files.

1. Select Cancel from the confirmation message.

Total size of selected items

is too large to install.

Compressing programs make

the installation possible,

but startup time will

be longer.

Compress programs?

Execute

Cancel

The program size and capacity will be displayed.

If you don't want to

compress programs,

please select items again

and make the total size

smaller than the capacity

Program size:5120KB

Capacity :3840KB

OK

2. Select OK.

The Main Screen for the Setup Menu will return.

3. Select Select items and reselect the items so that the memory capacity is

not exceeded.

SeeAlso Refer to page 1-(6).

Set up

Select items

Install

Backup data load

Clear memory

1-(9)

Page 18

Displaying Images and Focussing Section 1-4

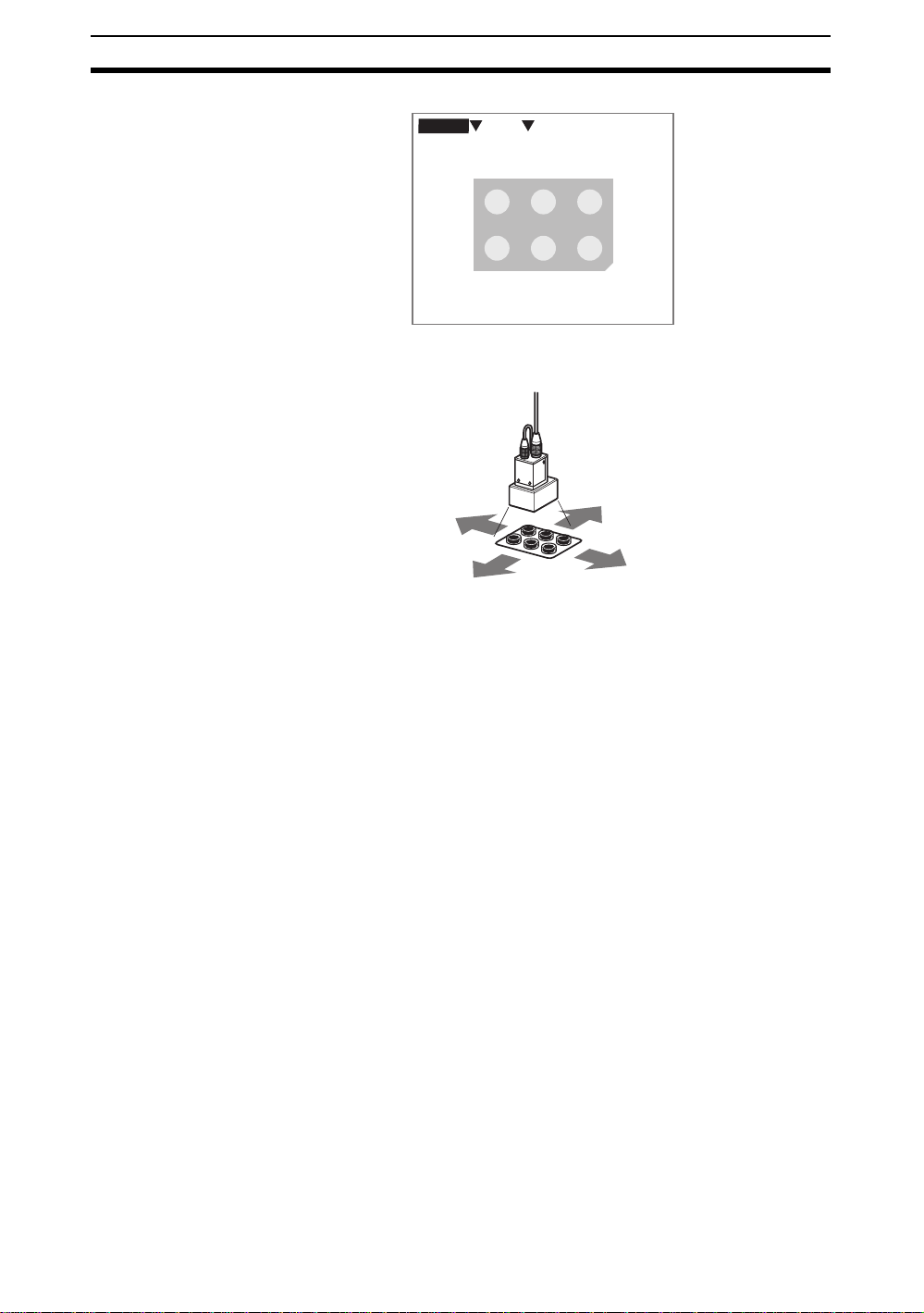

1-4 Displaying Images and Focussing

This section explains how to check what kind of image is being displayed by

changing the display image to through display and how to adjust the position

of the measurement object and focus the camera.

1. Change the display image to through display to check what kind of image

is being displayed by pressing the SHIFT + ESC Keys.

0.Scn 0 MON

---- ---ms

Image 0 freeze

The screen for changing the display image will be displayed.

0.Scn 0

MON

Image status

Freeze(Before scroll)

Display image

Image size

Display results

End

---- ---ms

:

:Image0

: All

: None

Image 0 freeze

2. Move the cursor to Freeze (Before Scroll).

3. Press the ENT Key .

A list of options will be displayed.

1-(10)

4. Select Through.

5. Select End.

0.Scn 0

MON

Image status

Freeze(Before scroll)

Display image

Image size

Freeze (Before scroll)

Display results

Freeze(After scroll)

Last NG(Before scroll)

Last NG (After scroll)

:

:Image0

Through

: All

: Details

End

Image 0 freeze

---- ---ms

Page 19

Displaying Images and Focussing Section 1-4

The Through Display Screen will be displayed.

0.Scn 0 MON

---- ---ms

Image 0 through

6. Adjust the position of the measurement object so that it appears at the center of the monitor screen.

Adjusting the position of

the measurement object.

7. Focus the Camera.

• Cameras with a light (including Intelligent Lighting) have lenses with a

fixed focal point. Adjust the Camera position based on the positioning distances in the Setup Manual to focus the Camera.

CHECK The light level for Intelligent Lighting can be adjusted from the Controller.

Refer to page1-(31).

• When using a Camera Unit that does not have a light, turn the focus ring

to focus the Camera.

1-(11)

Page 20

Menu Operations Section 1-5

1-5 Menu Operations

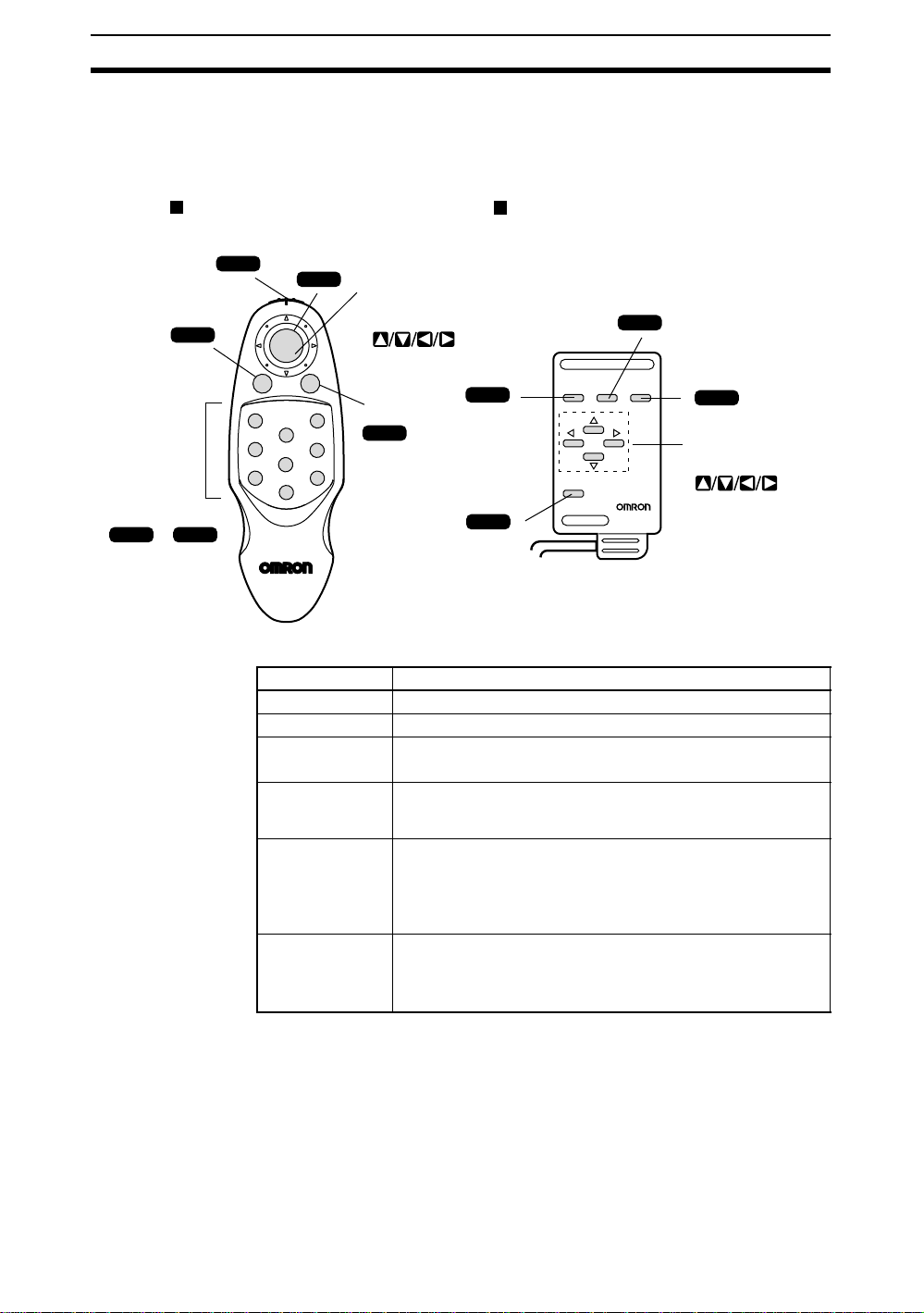

1-5-1 Input Devices

Menu operation s are performed from either the Conso le or th e se rial inte rface.

F160-KP Console

ESC (escape) Key

Function Keys

F1

to

SHIFT Key

ESC

F9

F150-KP Console

SHIFT

ENT (enter) Key

ENT

SHIFT

ENT

F1

F2

F4

F5

F7

F8

Up, Down, Left, and

Right Keys (Press left,

right, up, or down.)

TRIGESC

F3

TRIG (trigger) Key

TRIG

F6

F9

ESC (escape) Key

ESC

SHIFT Key

SHIFT

TRIG (trigger) Key

TRIG

ESC TRIG

SHIFT

F150-KP

CONSOLE

ENT (enter) Key

ENT

Up, Down, Left, and

Right Keys

ENT

Key Function

ESC: Escape Key Returns the user to the previous menu display or operation.

TRIG: Trigger Key Starts object measurement.

ENT: Enter Key Execute s a fu nction or sets a value.

Note: On the F160-KP, also functions as a Cursor Key.

SHIFT Key Must be pressed in combination with another key to have any

effect. Specific functions are assigned to combinations of the

SHIFT Key and other keys for specific screens.

Up, Down, Left,

and Right Keys

The Up and Down Keys are used to move the cursor up and down

and also to set values. The Up Key will increase a value by 1 and

the Down Key will decrease a value by 1. Hold down the Up or

Down Key to quickly increase or decrease a value.

The Left and Right Keys are used to move the cursor left or right.

Function Keys Functions can be assigned to function keys F1 to F8. Refer to 5-

4-1 Changing Console Key Allocations.

The display can be captured using F9. Refer to 5-4-2 Capturing

and Saving Images.

1-(12)

CHECK Menu operations can be performed from a personal computer via a serial

interface. Refer to 6-4 Serial Interface Menu Operations.

Page 21

Menu Operations Section 1-5

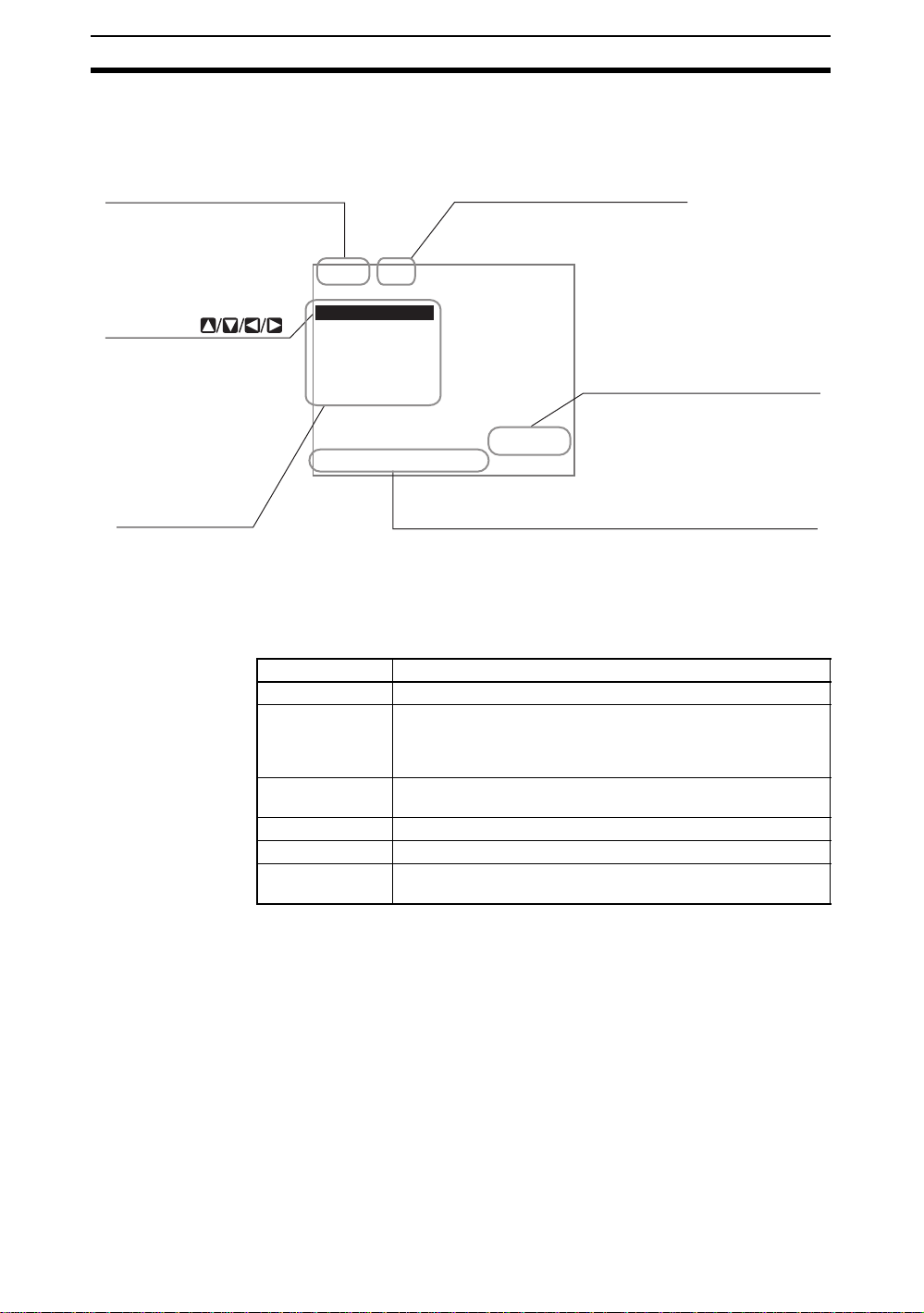

1-5-2 Screen Displays

The Application Software is operated by selecting functions from menus displayed on the screen. Familiarize yourself with each function before operating

the Controller.

Scene Number

There are 32 screens. Setting

different measurement

conditions for each one allows

easy switching between

different setups.

0.Scn 0=SET=

Mode

The current operating mode is

displayed.

Cursor Keys

The cursor is moved to the

desired function by pressing

the Cursor Keys.

Units

A processing item is set for each

unit.

When a measurement command is

input, units are processed in order

from unit 0.

Mode

SET Used to set the inspection conditions.

MON (Monitor) Used to check whether inspections are being performed correctly

RUN Performs inspection. The measurement results are output to an

SYS (System) Used to set system conditions.

TOOL Used to save settings and images to a computer as backup.

SAVE Used to saves data to flash memory in the Controller. If new set-

0.Camera image

1.

ENT:Set SFT+ESC:Edit

Key Operations

Displays special key combinations at the bottom of the screen

when available.

“SFT” refers to the SHIFT Key. “SFT+ESC” indicates that the

ESC Key should be pressed while the SHIFT Key is pressed.

Sometimes the SFT Key display is abbreviated to just “S”.

Display Meaning

under the set inspection conditions. The measurement results are

displayed on the monitor only. The results cannot be output to

external devices.

external device via the parallel interface or serial interface.

tings have been made, be sure to save the data before quitting.

The type of image shown on the

screen is displayed in Monitor and

Run Modes.

Refer to 5-5-1 Displaying

Stored Images.

1-(13)

Page 22

Menu Operations Section 1-5

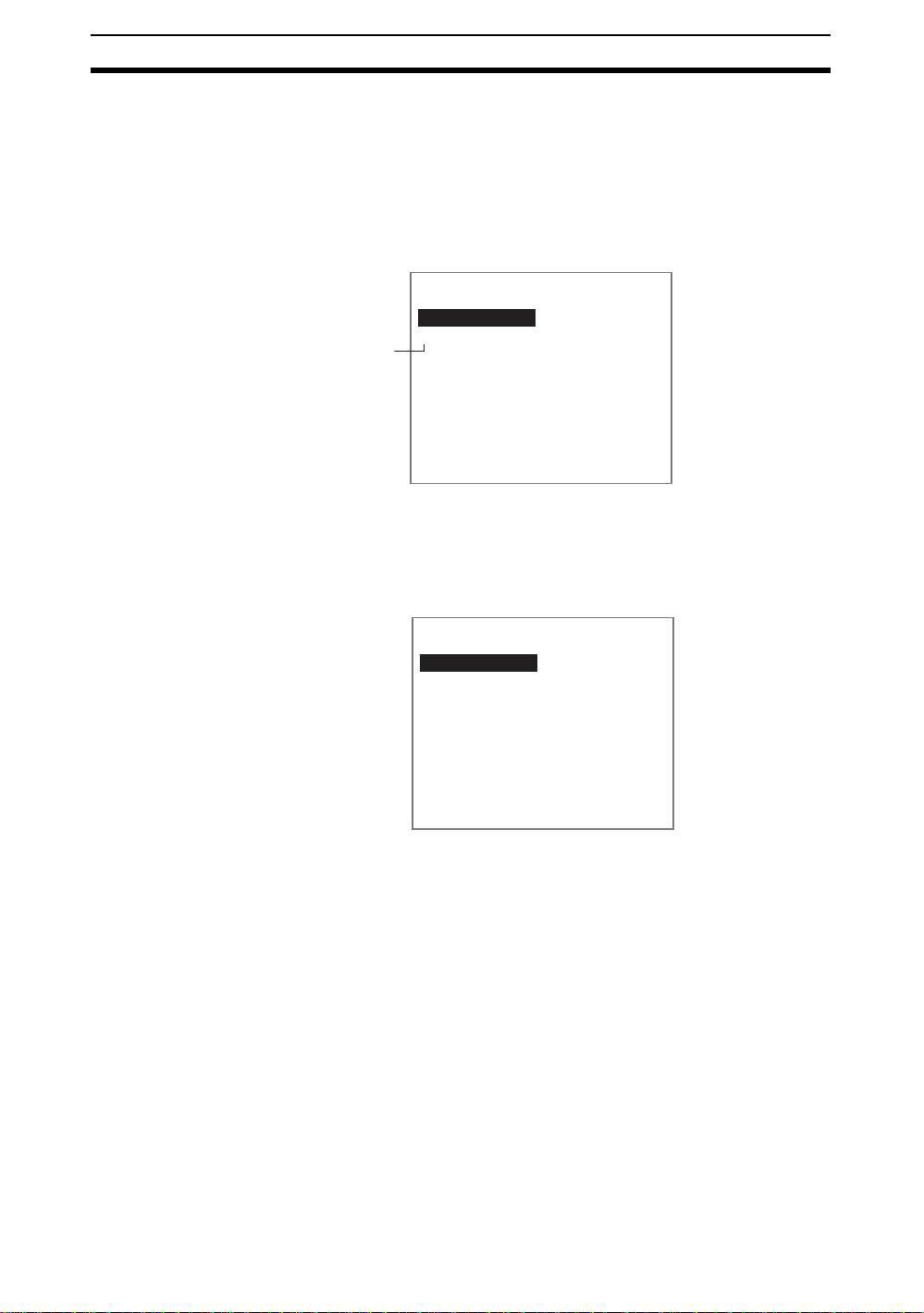

1-5-3 Creating Flowcharts

In the Application Software, measurement processing is broken up into different processing items to facilitate a variety of applications.

Flowchar ts are c reated usi ng a comb ination o f proces sing item s to suit e ach

application.

When Set Mode is entered, the number 1 will be displayed below 0.Camera

image. This number is calle d th e u ni t n um be r. Processing items set for t he u ni t

numbers.

0.Scn 0=SET=

0.Camera image

Unit number

CHECK “Camera image” is set for unit 0 as the default processing item.

The processing items are set in order from unit 0.

Once a processing item is set for unit 1, unit 2 will automatically be displayed.

1.

ENT:Set SFT+ESC:Edit

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.

ENT:Set SFT+ESC:Edit

CHECK There is no limit to the number of units. Any number of units can be set pro-

vided the Controller has enough free memory.

SeeAlso Refer to SECTION 5 System Settings for information on how to check the

remaining free work memory (main memory) space.

1-(14)

Page 23

Menu Operations Section 1-5

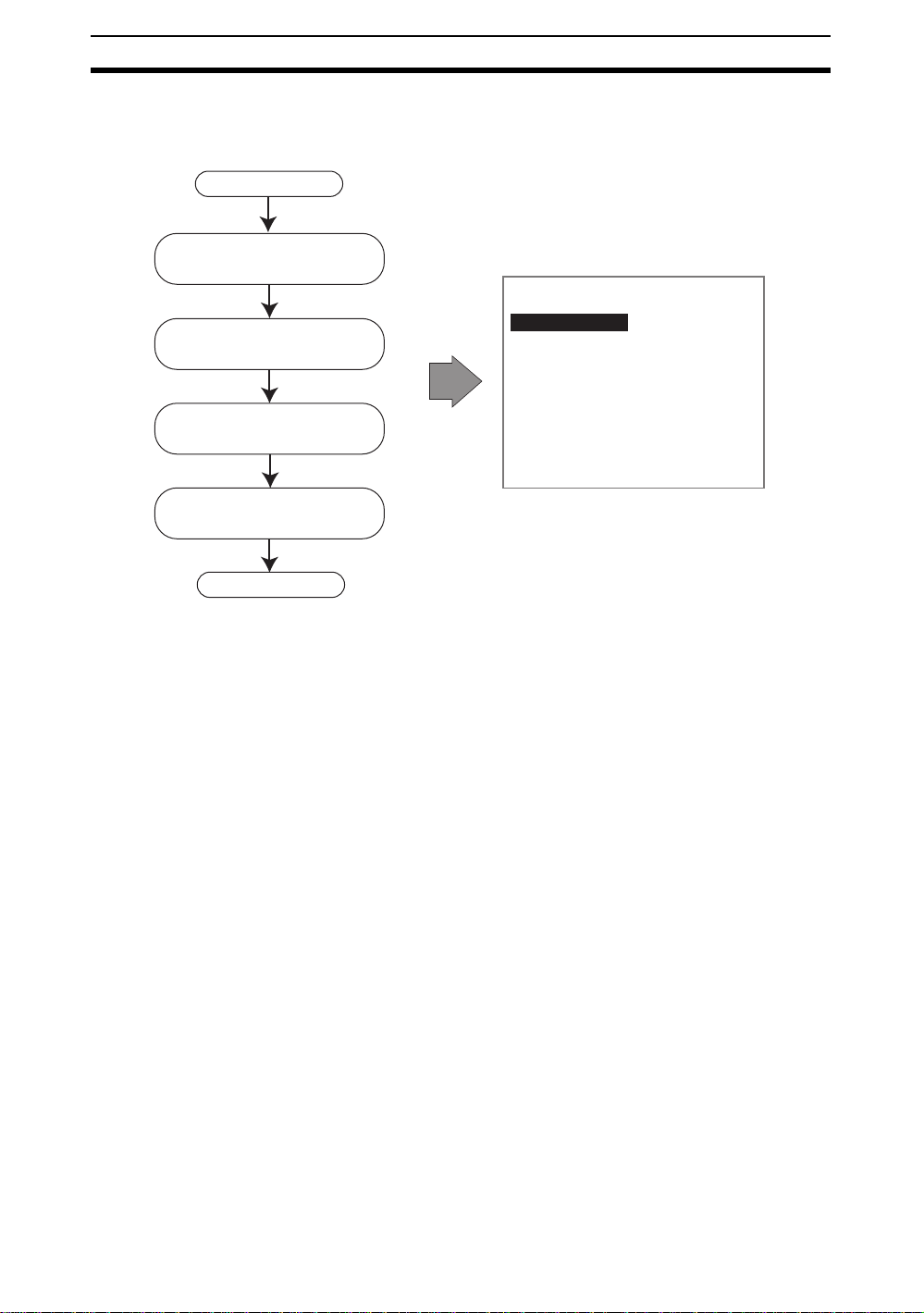

When a measurement command is input, the processing will be executed in

order from the item set to unit 0. Register processing items for each unit, just

like creating a flowchart.

Flowchart Image

Start

0.

Read image from Camera.

1.

Perform position

displacement compensation.

2.

Inspect for defects.

3.

Output measurement result

to external device.

End

Screen Image

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.DO judge

4.

ENT:Set SFT+ESC:Edit

1-(15)

Page 24

Menu Operations Section 1-5

The following type of processing is also possible by adjusting the registered

order.

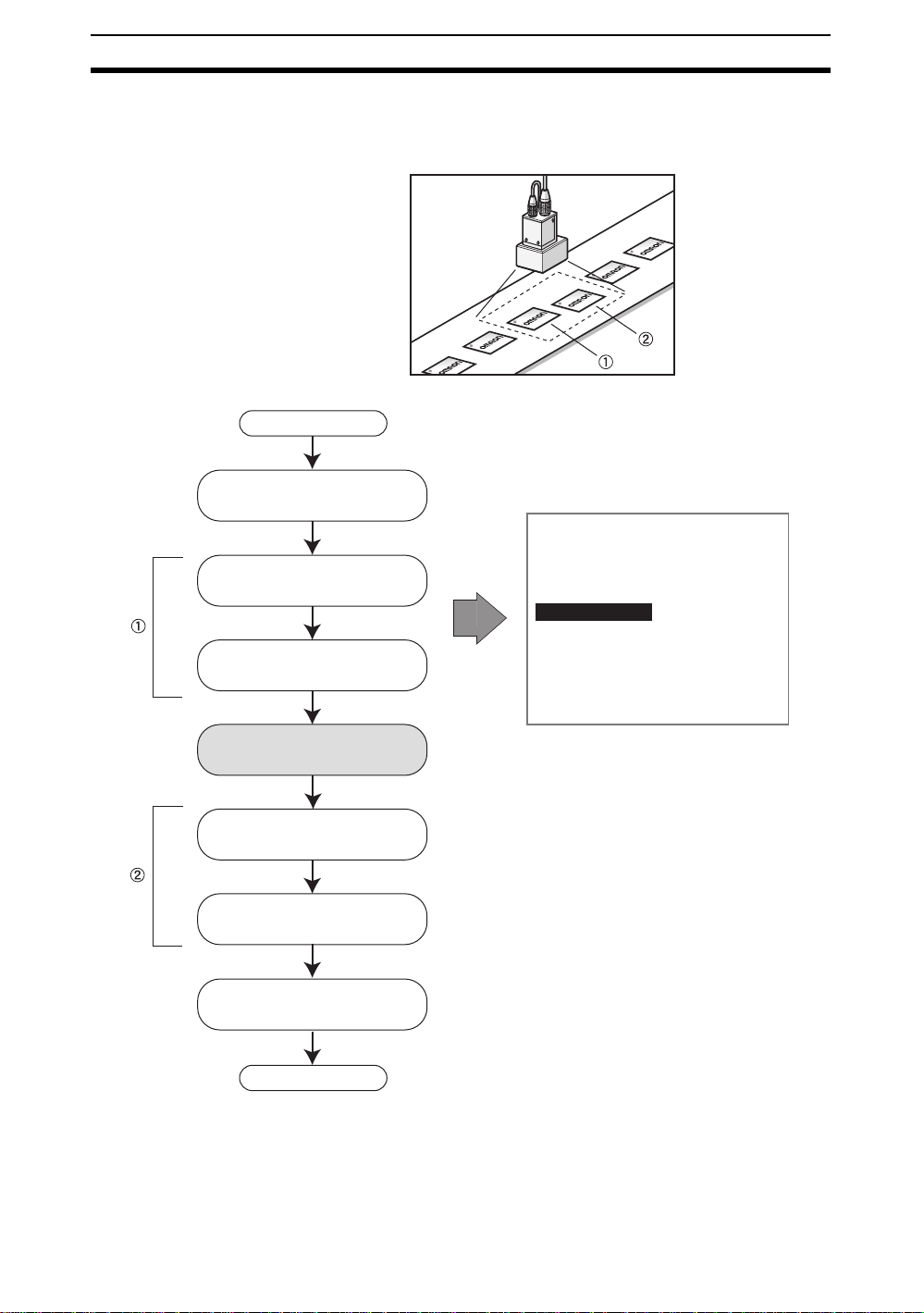

Example: Performing Position Displacement Compensation for Two Measurement Objects in the Same Field of Vision

Flowchart Image

Start

0.

Read image from Camera.

1.

Perform position displacement

compensation for

measurement object 1.

2.

Inspect for defects on

measurement object 1.

3.

Return the image to its original

position if it has been scrolled after

position displacement compe nsat i on.

Screen Image

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.Reset scroll

4.EC pos. comp

5.Fine matching

6.DO judge

7.

ENT:Set SFT+ESC:Edit

1-(16)

4.

Perform position displacement

compensation for measurement

object 2.

5.

Inspect for defects on

measurement object 2.

6.

Output measurement result

to external device.

End

Page 25

Menu Operations Section 1-5

The Application Software also has branch control processing items.

Example: Changing Inspection Conditions Based on the Upcoming Product

Product 2

Product 1

Flowchart Image

Start

0.

Read image from Camera.

1.

Recognize model.

2.

Change measurement

conditions based on product

type.

3.

Inspect product 1 for

defects.

4. 6.

End End

5.

Screen Image

0.Scn 0 =SET=

0.Camera image

1.Classification

2.Branch

3.Fine matching

4.End

5.Fine matching

6.End

7.

ENT:Set SFT+ESC:Edit

Inspect product2 for

defects.

1-(17)

Page 26

Menu Operations Section 1-5

play

play

eset scro

Registering

Processing

Items to Units

The registration procedure will be explained using the example of registering

binary position compensation, one of the position compensation processing

items. Change the procedure as required to register other processing items.

1. Move the cursor to a free unit number and press the ENT Key.

0.Scn 0=SET=

0.Camera image

1.

ENT:Set SFT+ESC:Edit

The processing item groups will be displayed.

0.Scn 0=SET=

0.Camera image

1.

Input Image

Position Compensation

Measurement

Measurement Support

Branch Control

Results Output

Results Dis

2. Select Position Compensation.

A list of the installed position compensation processing items will be dis-

played.

0.Scn 0=SET=

0.Camera image

1.

Input Image

Position Compensation

Binary pos. comp

Measurement

EC pos. comp

Measurement Support

Edge pos. comp

Branch Control

Model pos. comp

Results Output

Circle pos. comp

Results Dis

R

ll

3. Select Binary pos. comp.

Binary position compensation w ill be set for un it 1 and the next un it number

(unit 2 in this case) will be displayed.

0.Scn 0=SET=

0.Camera image

1.Binary pos. comp

2.

1-(18)

Page 27

Menu Operations Section 1-5

Changing to

Other

Processing

Items

1. Move the cursor to the unit number of the processing item to be changed.

Press the SHIFT+ESC Keys.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

ENT:Set SFT+ESC:Edit

A list of options will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

Change

2.Fine matching

Insert

3.

Copy

Delete

Comment

2. Select Change.

A list of processing items will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.

Input Image

3.

Position Compensation

Measurement

Measurement Support

Branch Control

Results Output

Results Display

3. Use the same procedure as for registering new processing items to register a different item.

1-(19)

Page 28

Menu Operations Section 1-5

Inserting Units

CHECK When a unit is inserted, the subsequent unit numbers will be increased. The

unit numbers set in other units for outputting results and branching will also be

increased automatically.

1. Move the cursor to the unit number where a new unit is to be inserted.

Press the SHIFT+ESC Keys.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

ENT:Set SFT+ESC:Edit

A list of options will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

Change

3.

Insert

Copy

Delete

Comment

ENT:Set SFT+ESC:Edit

2. Select Insert.

A list of processing items will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

Input Image

3.

Position Compensetion

Measurement

Measurement Support

Branch Control

Results Output

Results Display

ENT:Set SFT+ESC:Edit

3. Use the same procedure as for registering new processing items to register items for the inserted unit.

The selected processing ite m will be ins erted.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.EC defect

3.Fine matching

4.

1-(20)

Page 29

Menu Operations Section 1-5

Copying from

Other Units

Settings data can be copied, which is convenient for reusing data when only a

part of the settings need to be changed.

1. Move the cursor to the unit where the data to be copied is located.

Press the SHIFT+ESC Keys.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

ENT:Set SFT+ESC:Edit

A list of options will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

Change

Insert

Copy

Delete

Comment

ENT:Set SFT+ESC:Edit

2. Select Copy.

A screen for selecting the source unit for the data to be copied will be dis-

played.

Original unit : Unit 0

Execute

Unit 0

Unit 1

Unit 2

3. Select the appropriate unit number.

4. Select Execute.

The data will be copied.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.Fine matching

4.

1-(21)

Page 30

Menu Operations Section 1-5

Deleting Units

CHECK When units are deleted, the subsequent unit numbers will be decreased. The

unit numbers set in other units for outputting results and branching will also be

reduced automatically.

1. Move the cursor to the unit to be deleted.

Press the SHIFT+ESC Keys.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

ENT:Set SFT+ESC:Edit

A list of options will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

Change

2.Fine matching

Insert

3.

Copy

Delete

Comment

ENT:Set SFT+ESC:Edit

2. Select Delete.

The selected unit will be deleted and the subsequent unit numbers will be

moved up one.

0.Scn 0=SET=

0.Camera image

1.Fine matching

2.

ENT:Set SFT+ESC:Edit

1-(22)

Page 31

Menu Operations Section 1-5

Changing

Processing Item

Names

The names of pro ce ssing items set to units ca n be changed to any name up to

16 characters long. This is a useful function for easy understanding of the settings and when setting the same processing item to many units.

1. Mov e the cu rsor to the unit f or w hich the na me of the process ing item is to

be changed. Press the SHIFT+ESC Keys.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

A list of options will be displayed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Fine matching

3.

Change

Insert

Copy

Delete

Comment

ENT:Set SFT+ESC:Edit

2. Select Comment.

A software keyboard will be displayed.

Input comment

[LABEL

ABCDEFGHI J K MN

OPQRST UVWXYZ

abcdefgh i jk lmn

opqrs tuvwxyz

0123456789. #$

SPC INS END

ENT:Select

()^

%

DEL BS

]

L

!

`

-

Ins.

SeeAlso Refer to page 1-(27) for information on inputting characters.

3. Set an item name of up to 16 characters long.

4. Move the cursor to END and press the ENT Key.

The item name will be changed.

0.Scn 0=SET=

0.Camera image

1.EC pos. comp

2.Label

3.

1-(23)

Page 32

Menu Operations Section 1-5

1-5-4 Drawing a Region

Use the following method to draw model regions and measurement regions.

The region figures that can be drawn depend on the processing item. Refer to

the explanation for each processing item for information on what figures can

be drawn.

Move the cursor with the Up, Down, Left, and Right Keys. Use these keys

together with the SHIFT Key to move the cursor quickly. Press the ENT Key at

the desired positions and press the ESC Key to undo the setting.

Measurement

region selection

Box

Ellipse

The whole

region moves.

The whole

region moves.

The lower right

coordinates move.

ENT

ESC

The lower right

coordinates move.

ENT

ESC

Drawing method

ENT

The figure is set.

ENT

The figure is set.

Circle

Circumference

Polygon

The whole

region moves.

The whole

region moves.

Specify the

first point.

ENT

ESC

The circumference

changes.

ENT

ESC

Specify the

second point.

ENT

ESC

The diameter

changes.

ENT

ESC

ENT

The figure is set.

The width changes.

ENT

ESC

Specify the third

and other points.

(Up to 10 points

can be specified.)

ENT

The figure is set.

ENT

Press the ENT

Key twice.

The figure is set.

1-(24)

Page 33

Menu Operations Section 1-5

Measurement

Drawing method

region selection

Line

The whole

region moves.

ENT

The length

changes.

The width changes.

ENT

ENT

The figure is set.

Arc

The whole

region moves.

ENT

ESC

ESC

ESC

The end

point moves.

The mid-point

moves.

ENT

ESC

ESC

ENT

ESC

The width

changes.

ENT

The

figure

is set.

Drawing Mode For many processing items, up to 3 figures can be combined to draw a mea-

surement region. Select either the OR or NOT drawing mode.

Drawing

mode

OR Us e this mode to draw a shape as a model or measurement region.

All of the shapes that are drawn are registered as one region.

NOT Use to delete part of a region.

Function

In this example, the gray area will be the measurement region.

Regions with complicated shapes can be drawn and areas can be omitted

from the measurement region b y co mbi ni ng figu res.

Figure 1 (drawn using OR)

Figure 2 (drawn using NOT)

Figure 3 (drawn using OR)

1-(25)

Page 34

Menu Operations Section 1-5

y

1-5-5 Inputting Values

This section explains how to input values when setting measurement conditions or communications specifications.

1. Move the cursor to the item for which a value is to be changed.

Judgement conditions

Area : 2035.000

[ 2000.000 : 247808.000]

Gravity X : 180.000

[ 0.000 : 511.000]

Gravity Y : 250.000

[ 0.000 : 483.000]

End

2. Press the ENT Key.

The cursor will change to a cursor the size of a single digit.

Judgement conditions

Area : 2035.000

[ 2000.000 : 0247808.000]

Gravity X : 180.000

[ 0.000 : 511.000]

Gravity Y : 250.000

[ 0.000 : 483.000]

End

3. Move the cursor to the digit to be changed.

Use the Left and Right Keys to move the cursor.

4. Change the val ue.

Use the Up Key to increase the value.

Use the Down Key to decrease the value.

Judgement conditions

Area : 2035.000

[ 2000.000 : 0047808.000]

Gravity X : 180.000

[ 0.000 : 511.000]

Gravit

Y : 250.000

0

5. Repeat these steps to change other values.

6. Press the ENT Key .

The values will be set.

Judgement conditions

Area : 2035.000

[ 2000.000 : 25000.000]

Gravity X : 180.000

[ 0.000 : 511.000]

Gravity Y : 250.000

[ 0.000 : 483.000]

End

1-(26)

Page 35

Menu Operations Section 1-5

1-5-6 Inputting Characters

This section explains how to input characters. The software keyboard shown

below is displayed on the screen where characters are input.

ABCDEFGHI J K MN

OPQRSTUVWXYZ

abcdefgh i jk lmn

opqrs tuvwxyz

0123456789. #$

SPC

%

DEL

()^

BSBSINS

`

L

!

-

END

1. Move the cursor to the character to be input.

cursor Cursor

[

ABCDEFGHI J K MN

OPQRSTUVWXYZ

abcdefgh i jk lmn

opqrs tuvwxyz

0123456789. %

#$

SPC DEL BS INS

2. Press the ENT Key.

The character is set and the I cursor moves one space to the right.

These characters can be input.

Inserts a space.

SPC

Deletes 1character to the right of the I cursor.

DEL

Deletes 1character to the left of the I cursor.

Switches between insert (default)/overwrite.

INS

Moves the I cursor to the left.

Moves the I cursor to the right.

Ends character input.

END

]

L

()^

`

←→

!

END

3. Repeat these steps to in put more characters.

4. Once all required characters have been input, move the cursor to END.

()^

%

DEL BS

]

L

!

`

←→

-

END

Ins.

[LABEL

ABCDEFGHI J K MN

OPQRSTUVWXYZ

abcdefgh i jk lmn

opqrs tuvwxyz

0123456789. #$

SPC INS

ENT:Select

5. Press the ENT Key .

The characters will be set.

CHECK Characters can be input from a personal computer via a serial interface. Refer

to 6.4 Serial Interface (Menu Ope r atio ns ).

1-(27)

Page 36

Basic Operations Section 1-6

1-6 Basic Operations

This section describes the basic flow of operations up to the setting of measurement conditions and executing measurements. The explanation is based

on the use of the Fine Matching proc essi ng item f o r the meas uremen t method .

Detecting Label Defects

0.Scn0 RUN

Minor defect

step

1

step

2

step

3

step

4

NG

Pattern defects

Edge defect

Settings for image input

Settings for position

displacement compensation

of measurement object

Setting measurement method

Settings for measurement

result output method

Printing defect

1-(28)

step

5

Start test or measurement.

Page 37

Basic Operations Section 1-6

1-6-1 STEP 1: Settings for Image Input

To set the inspection conditions, change first to Set Mode.

When Set Mode is entered, th e de fault processing ite m for unit 0 will be “Cam-

era image.” The conditions for inputting images are set under this processing

item.

1. Display the Bas ic Screen and m ov e th e curs or to MON and press the ENT

Key.

0.Scn 0 MON

SET

MON

RUN

SYS

TOOL

SAVE

---- ---ms

Image 0 freeze

2. Select SET.

The initial screen for Set Mode will be displayed.

Camera Image is the default processing item for unit 0.

0.Scn 0=SET=

0.Camera image

1.

ENT:Set SFT+ESC:Edit

3. Select 0. Camera image.

The initial screen for Camera Image will be displayed.

0.Camera image

Camera settings

Select camera

Filtering order(Image0)

Filtering(Image0)

BGS levels(Image0)

Filtering order(Image1)

Filtering(Image1)

BGS levels(Image1)

Frame/Field

1-(29)

Page 38

Basic Operations Section 1-6

The items that can be set under Camera Image can be broadly classified into

three groups:

• The shutter speed and other conditions relating to when t he i ma ge i s c ap tured (camera settings).

• Selection of which camera image will be measured (camera s election).

• Settings to make the image easier to measure (filtering).

Camera Image

Camera

settings

Camera

0

Camera

1

Camera

2

Camera

3

Image buffer

(for Camera 0)

Image buffer

(for Camera 1)

Image buffer

(for Camera 2)

Image buffer

(for Camera 3)

Camera

selection

* Only one camera can be selected.

Filtering

0

Filtering

1

Image 0

Image 1

The Controller has two image memories. Two images, Image 0 and Image 1,

are stored for the camera image selected under Select Camera. Both images

are for the same Camera but different filtering can be applied to each of the

images.

Some processing items require selection of either Image 0 or Image 1 for

object measurement and other processing items me asure only Image 0. Refe r

to the explanations for each item for details.

In this section wh ere the e xam ple o f Fine M atchi ng is used, meas uremen ts w ill

be performed on Image 0.

1-6-1-1 Camera Settings

Shutter Speed Change the shutter speed when the object is moving quickly, causing the

For F150-S1A Cameras

Object movement

Slow

Fast

image to be blurred.

The shutter speed can be changed from the menu for F150-S1A and F160-S1

Cameras only.

For F160-S1 Cameras

Shutter speed

1/100 s

1/500 s

1/2000 s

1/10000 s

(Default setting: 1/2000 s)

Object movement

Slow

Fast

Shutter speed

1/120 s

1/200 s

1/500 s

1/1000 s

1/2000 s

1/4000 s

1/8000 s

1/20000 s

(Default setting: 1/2000 s)

1-(30)

Page 39

Basic Operations Section 1-6

0s

00s

500s

000s

000s

000s

8000s

0000s

1. Select Camera settings.

0.Camera image

Camera settings

Select camera

Filtering order(Image0)

Filtering(Image0)

BGS levels(Image0)

Filtering order(Image1)

Filtering(Image1)

BGS levels(Image1)

Frame/Field

The initial Camera Settings Screen will be displayed.

Camera settings

Shutter speed(Cam0)

Light control(Cam0)

Calibration(Cam0)

Shutter speed(Cam1)

Light control(Cam1)

Calibration(Cam1)

Shutter speed(Cam2)

Light control(Cam2)

2. Select Shutter speed for the Camera to be used.

The shutter speed selections will be displayed.

Shutter speed(Camera0)

1/ 12

1/ 2

1/

1/ 1

1/ 2

1/ 4

1/

1/2

3. Select the shutter speed while monitoring the image.

4. Press the ENT Key .

The setting will be registered and the screen in (1.) will return.

Light Control When using Cameras with Intelligent Lighting, the light level can be adjusted

from the Co ntroller. Before using Inte lligent Lighting , be sure to change the

settings in SYS/Camera settings.

SeeAlso Refer to 5-2 Camera Settings.

CHECK When the shutter speed is faster than 1/2000 s, the brightness of the lighting

may not change even if the light level is changed.

Intelligent lighting uses pulse lighting synchronized with the shutter speed and

the light level can be adjusted by changing the pulse width. If the light level is

at the maximum setting of 7, the pulse width is approximately 450 ms and the

time the shutter is open is about the same as when the shutter speed is set to

1/2000 s. This means that settings will become invalid (the brightness will not

1-(31)

Page 40

Basic Operations Section 1-6

change) if the shutter speed is f aster tha n 1/20 00 s and the light le vel setting is

high.

Example: When Shutter Speed is 1/4000 s, Light Level Adjusted to 4

Light level: 7 (Approx. 450ms max.)

Light level: 4

(Approx. 260 ms max.)

Flash

Shutter

■ Lighting Control Screen

Light level adjustment:

Enabled

Light level adjustment:

Disabled

B. Light level

Light control(Camera 0)

Lighting pattern 1 50000

A. Segment displays

C. Sample lighting pattern number

A. Segment Display

As viewed from

this perspective

F150-LTC20

F160-LTC20

B

A

E

C

D

Lighting can be adjusted

for 5 areas.

F150-LTC50

F160-LTC50

E

A

DH

BF

C

G

Lighting can be adjusted

for 8 areas.

CHECK The lit segments are di spl ayed wit h thi ck lines. The b right ne ss dep end s o n the

set light level. Refer to page 1-(33).

Segment A level

Segment B level

1-(32)

B. Light Levels

The light level for each segment is displayed in a 5- or 8-digit value, with each

digit representing the light level of one of the segments. The light levels are

displayed from 0 to 7 , wi th 0 indicating that the light is OFF. The hi ghe r th e setting, the higher the light level.

F150-LTC20

F160-LTC20

3 3 3 3 3

Segment C level

Segment E level

Segment D level

Segment A level

Segment B level

Segment C level

Segment D level

F150-LTC50

F160-LTC50

3 3 3 3 3 3 3 3

Segment H level

Segment G level

Segment F level

Segment E level

C. Number of Sample Lighting Patterns

There are 15 sample lighting patterns registered in advance.

Page 41

Basic Operations Section 1-6

00004444

00007777

70707070

■ Adjustment Method 1: Sample Lighting Patterns

There are 15 lighting patterns registered in advance. The lighting can be set

simply by going through the different patterns in order and selecting the one

that gives the clearest image. Use the SHIFT+Left and Right Keys to switch

between sample patterns.

F150-LTC20, F160-LTC20

■ Not lit

@ Lit (maximum light level)

Pattern

LIght level Pattern

No.

1 4 7 10 13

50000

Light level Pattern

No.

07070 22727 00070 52222

Light level Pattern

No.

Light level Pattern

No.

Light level

No.

2 5 8 11 14

3 6 9 12 15

03333 27272 07000 00007 17777

07777 00707 00700 51111 27777

F150-LTC50, F160-LTC50

Pattern

Light level Pattern

No.

1471013

77777777

2581114

44440000

3691215

77770000

Light level Pattern

No.

Light level Pattern

No.

07070707

70000000

07000000

Light level Pattern

No.

00700000

00070000

00007000

Light level

No.

00000700

00000070

00000007

1-(33)

Page 42

Basic Operations Section 1-6

■ Adjustment Method 2: Adjusting Light Levels by Segment

The light level for each segment can be set separately to a value between 0

and 7. The setting “0” represents the unlit state, and the higher the setting

value the higher the light level. Light levels can also be set by adjusting the

light levels for the segments separately after selecting a sample lighting pattern.

Use the Left and RightKeys to select the segment to be adjusted and use the

Up and Down Keys to adjust the light level.

F150-LTC20, F160-LTC20

F150-LTC50, F160-LTC50

1. Select Camera settings.

0.Camera image

Camera settings

Select camera

Filtering order(Image0)

Filtering(Image0)

BGS levels(Image0)

Filtering order(Image1)

Filtering(Image1)

BGS levels(Image1)

Frame/Field

1-(34)

The initial Camera Settings Screen will be displayed.

Camera settings

Shutter speed(Cam0)

Light control(Cam0)

Calibration(Cam0)

Shutter speed(Cam1)

Light control(Cam1)

Calibration(Cam1)

Shutter speed(Cam2)

Light control(Cam2)

2. Select Light control for the Camera number being used.

Page 43

Basic Operations Section 1-6

The Light Control Settings Screen will be displayed.

Light control(Camera0)

Lighting pattern5:27272

SFT+ :Sample

:Segment :Light volume

Graphic showing light level

3. Switch the s ampl e patt ern light ing l e v el using the SHIFT+Left/Right Keys.

CHECK For fine adjustment of light levels, move to the desired segment using the

Right and Left Keys and adjust the light level using the Up and Down Keys.

4. Press the ENT Key.

The setting will be registered and the screen in (1.) will return.

CHECK If all light adjustments are set to 5 or higher, there may be insufficient light

emitted if the distance between measurements is approximately 15 ms or less.

If this happens, set the light level to 4 or less.

Calibration Calibration can be set to output the measurement results in physical units.

Set the relationship between the physical coordinates and the camera coordinates to convert the measurement results from pixels to physical units, such

as mm, mm, or cm.

This section gives an outline only. Refer to 2-1 Inputting Camera Images for

details on calibration.

CHECK To output measurem ent res ults in physical units, set Coordinate mode/Calibra-

tion to ON for each processing item.

If Calibration remains set to OFF, the default settings will remain, and mea-

surements using the Camera coordinates will be output.

1-6-1-2 Selecting the Camera

Up to 4 Cameras can be connected. The Select Camera setting is used to

select the Camera image that will be used for measurement.

CHECK The Camera image selected here will be used for all subsequent unit mea-

surements. To switch to a different Camera part way through processing, use

the Switch Camera processing item. Other Camera images stored in the

image buffers can be imported to Image 0 and Image 1.

0.Scn 0=SET=

0.Camera image

1.Density defect

2.Binary defect

3.Fine matching

4.Switch camera

5.Density defect

6Binary defect

The Camera image selected at

0. Camera image will be used

for measurement.

The Camera image selected

using 4. Switch camerawill be

used for measurement.

1-(35)

Page 44

Basic Operations Section 1-6

Note Switch camera only switches between the images saved to Image 0 and

Image 1 from the image b uff e rs . Ne w imag es can not be se nt to the i mage b uff ers using th is processing item.

1. Select Select camera.

0.Camera image

Camera settings

Select camera

Filtering order(Image0)

Filtering(Image0)

BGS levels(Image0)

Filtering order(Image1)

Filtering(Image1)

BGS levels(Image1)

Frame/Field

A list of Camera numbers will be displayed.

Select camera

Camera 0

Camera 1

Camera 2

Camera 3

2. Select the number of the Camera to be used.

3. Press the ENT Key.

The setting will be registered and the screen in (1.) will return.

1-6-1-3 Filtering

The image read by the Camera can be manipulated to create an image that is

easier to measure. Image filtering is set by using 3 functions: Filtering Order,

Filteri ng, and BGS Levels.

0.Camera image

Camera settings

Select camera

Filtering order(Image0)

Filtering(Image0)

BGS levels(Image0)

Filtering order(Image1)

Filtering(Image1)

BGS levels(Image1)

Frame/Field

The Controller has tw o i ma ge memories, and Filte ring, BG S L evels, and Filtering Order can be set for each.

This section gives an outline only. Refer to 2-1 Inputting Camera Images for

details on filtering.

1-(36)

Page 45

Basic Operations Section 1-6

1-6-1-4 Frame/Field

The Frame/Field function is used to select the unit for one image. Normally, it

is sufficient to use the default setting of Frame.

If the unit is changed to Field, the resolution in the vertical direction is halved

but the image input time is reduced, allowing faster processing.

Field images

Even Odd

Images showing alternate fields

Resolution: 512 × 242 (H × V) Resolution: 512 × 242 (H × V)

One frame image is created when

two field images are combined.

Frame image

Resolution: 512 × 484 (H × V)

This section gives an outline only. Refer to 2-1 Inputting Camera Images for

details on Frame/Field.

1-(37)

Page 46

Basic Operations Section 1-6

1-6-2 STEP 2: Settings for Posi tion Di splacement Compensation

The position displacement compensation processing items are used when the

position and orientation of measurement objects are not consistent. By using

this function, the displacement between a reference position and the current

position is obtained, and this displacement is compensated for in measurements.

Select the position compensation processing items suitable for the measurement object.

Reference Position

The reference po s it ion i s us ed so tha t t h e me a su r em en t r e gi on an d me a su rement object are in the correct positions.

Measurement region

Measurement object

1-(38)

Page 47

Basic Operations Section 1-6

Measurement Object Displ ace d

Without compensation, measurement is

performed with part of the measurement

object outside the measurement region.

By making position displacement compensation settings...

Measurement is performed after the

image is returned to the reference

position.

In either case, measurement is performed with

the whole measurement object in the

measurement region.

Measurement is performed after the

measurement region is moved to

compensate for the displacement.

1-(39)

Page 48

Basic Operations Section 1-6

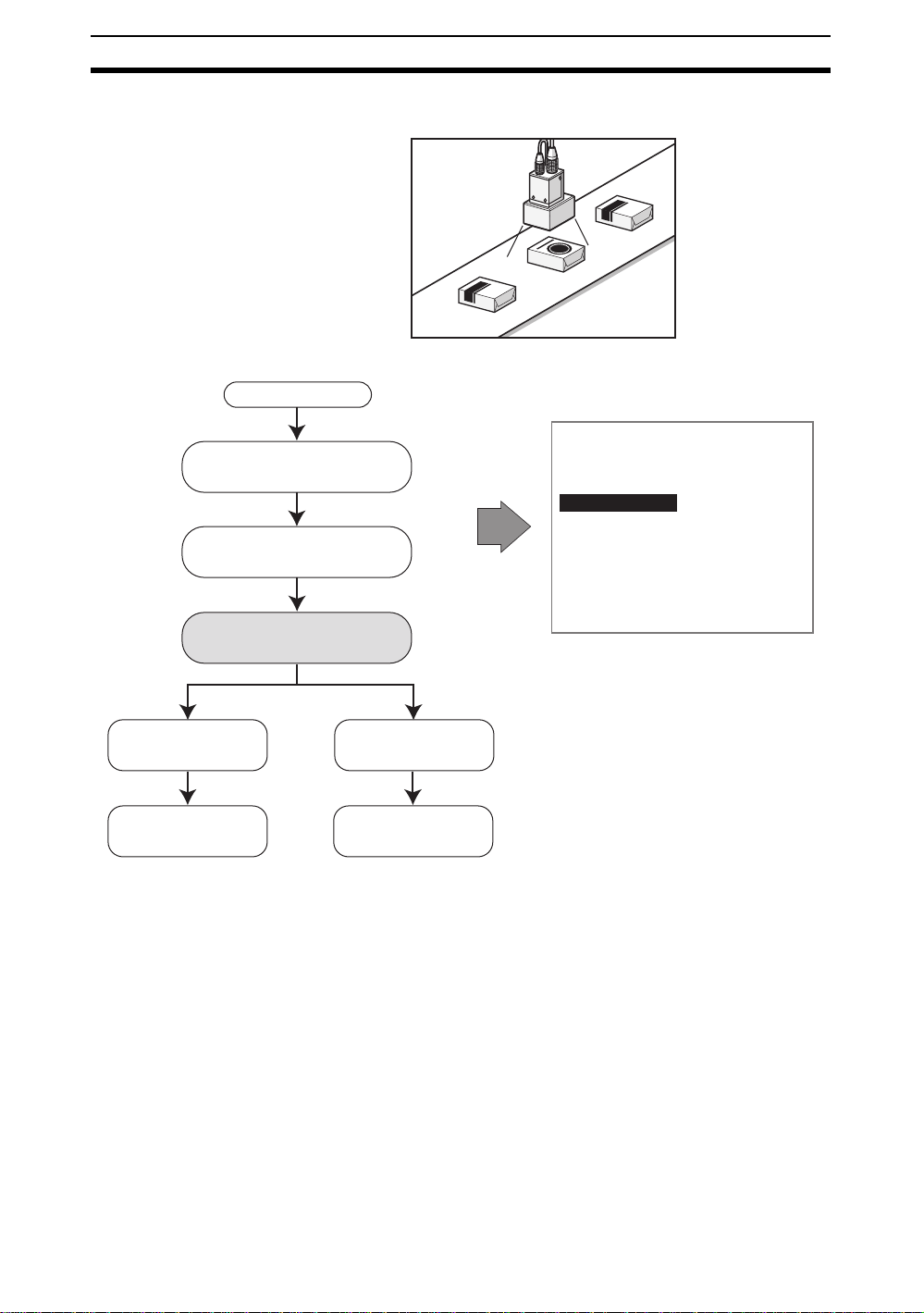

1-6-3 STEP 3: Setting Measurement Methods

This section describes how to inspect for defects using the F ine Matching processing item.

The registered image for an acceptable product and the input image are overlaid (matched) and the differences are detected. This enables small defects in

the pattern and wr iti ng on t he me asu rem ent obj ect t o b e de tect ed w ith a hi gh

level of accuracy.

OK Image

(registered)

Images overlaid

Defects are displayed using the NG

color. Defects are judged b y the area of

difference from the OK image.

0.Scn 0 MON

Image to be

inspected

NG

Pattern defect

Minute defect

Edge defect

Printing error

Use the following procedure to set Fine Matching for unit 1.

1. Move the cursor to unit 1 and press the ENT Key.

0.Scn 0=SET=

0.Camera image

1.

ENT:Set SFT+ESC:Edit

1-(40)

Page 49

Basic Operations Section 1-6

The processing item groups will be displayed.

0.Scn 0=SET=

0.Camera image

1.

Input Image

Position Compensation

Measurement

Measurement Support

Branch Control

Results Output

Results Display

ENT:Set SFT+ESC:Edit

2. Select Measurement.

A list of processing items will be displayed.

0.Scn 0=SET=

0.Camera image

1.

Input Image

Position Compensation

Measurement

Measurement Support

Branch Control

Results Output

Results Display

ENT:Set SFT+ESC:Edit

3. Select Fine matching.

Fine Matching will be set for unit 1.

CHECK If processing items are set for units after the unit to which Fine Matching has

been set, care must be taken when manipulating images. Refer to page 1(57).

Operational Flow

(As required) (As required) (As required) (As required)

1 3 4 6 7 85

Select the

method for

matching with

the model.

2

Change the

labeling

conditions.

Register the

model.

Set the

judgement

conditions.

Binary defect

Classification

Density defect

EC defect

ECM search

EC position

Edge position

Fine matching

Change the

differential

judgement

value.

Change the

detailed

conditions.

Set the

coordinate

mode.

Reference

the model.

1-(41)

Page 50

Basic Operations Section 1-6

1-6-3-1 Selecting the Method for Matching with Model

This section describes how to select a matching method suitable for the measurement object.

Measurement conditions

Boundary inspection:

Defect inspection :

Target :

End

Use the following as a guide for selection:

To detect patter n

defects

To detect minute

defects

ON

Labeling

Both

(Choose the most stable method.)

For the fastest

inspections

When there are

defects near the edge

of the measurement

object

Color for defects (Both*, white, black)

Processing time is reduced if either white or black

is selected when the defect color is consistent.

The asterisk (*) indicates the default setting.

Boundary inspection: ON

Defect inspection: Labeling

Boundary inspection: ON

Defect inspection: Binary

Boundary inspection: OFF

Defect inspection: Labeling

Boundary inspection: ON

Defect inspection: Labeling

1-(42)

HELP Refer to page 1-(43) for inf o rmation on bou ndary inspec tion an d defect inspec-

tion methods.

1. Select Fine matching.

0.Scn 0=SET=

0.Camera image

1.Fine matching

2.

ENT:Set SFT+ESC:Edit

Page 51

Basic Operations Section 1-6

The initia l screen for fine matching will be displayed.

Measurement conditions

Labeling

Model registration

Judgement conditions

Differencial image

Detailed conditions

Coordinate mode

Model reference

2. Select Measurement conditions.

The Measurement Conditions Settings Screen will be displayed.

Measurement conditions

3. Make the settings for each item.

4. Select End.

The setting will be registered and the screen in (1.) will return.

HELP Boundary Inspections

Boundary inspections match the boundary areas (areas where the density

changes).

•OFF

This method masks the boundary, excluding it from inspection. This

means that any defects near the boundary will not be detected. The

boundary level sets the number of pixels near the boundary that will be

excluded from the inspection.

SeeAlso See page 1-(53).

Boundary inspection:

Defect inspection :

Target :

Model Inspection image

1 square = 1 pixel

Labeling

End

ON

Both

If the measurement object is

displaced slightly higher, the

boundary will be detected as

differing from the registered

model.

When Boundary inspection is

OFF: The range of pixels set

for the boundary level are

excluded from the

measurement on both sides of

the boundary.

•ON*

The whole area is inspected and defects near the boundary will be

detected. The processing time, however, will be longer because eroded

and dilated mode ls are match ed t o pre vent inspection m ista k es ca used by

measurement object displacement. Only defects detected for both models

will be judged as d ef e cts . The s iz e of di lation and ero sion c an be set us ing

the boundary level.

The asterisk (*) indicates the default setting.

1-(43)

Page 52

Basic Operations Section 1-6

SeeAlso

See page 1-(53).

Dilated Model

Example: Dilation by 3

pixels when the boundary

level is set to 3.

HELP Defect Inspection Methods

An image showing the difference between the model image and inspection

image will be converted internally to a binary image. The method for inspecting defects from those binary images is selected here.

• Labeling*

One group of white pixels is detected as one label and one label that

matches th e set co nditions will b e evaluated to d eter mine if it is a defect

or not.

The asterisk (*) indicates the default setting.

• Binary

The total area of the white pixels is evaluated to determine if there are

defects or not.

Eroded Model

Example: Erosion by 3

pixels when the boundary

level is set to 3.