Page 1

High-performance Vision Sensor

F250

Advanced algorithm enables ultra high

speed and maximum flexibility

F250

Features

Inspection and positioning that was difficult with previous vision sensors is now surprisingly easy!

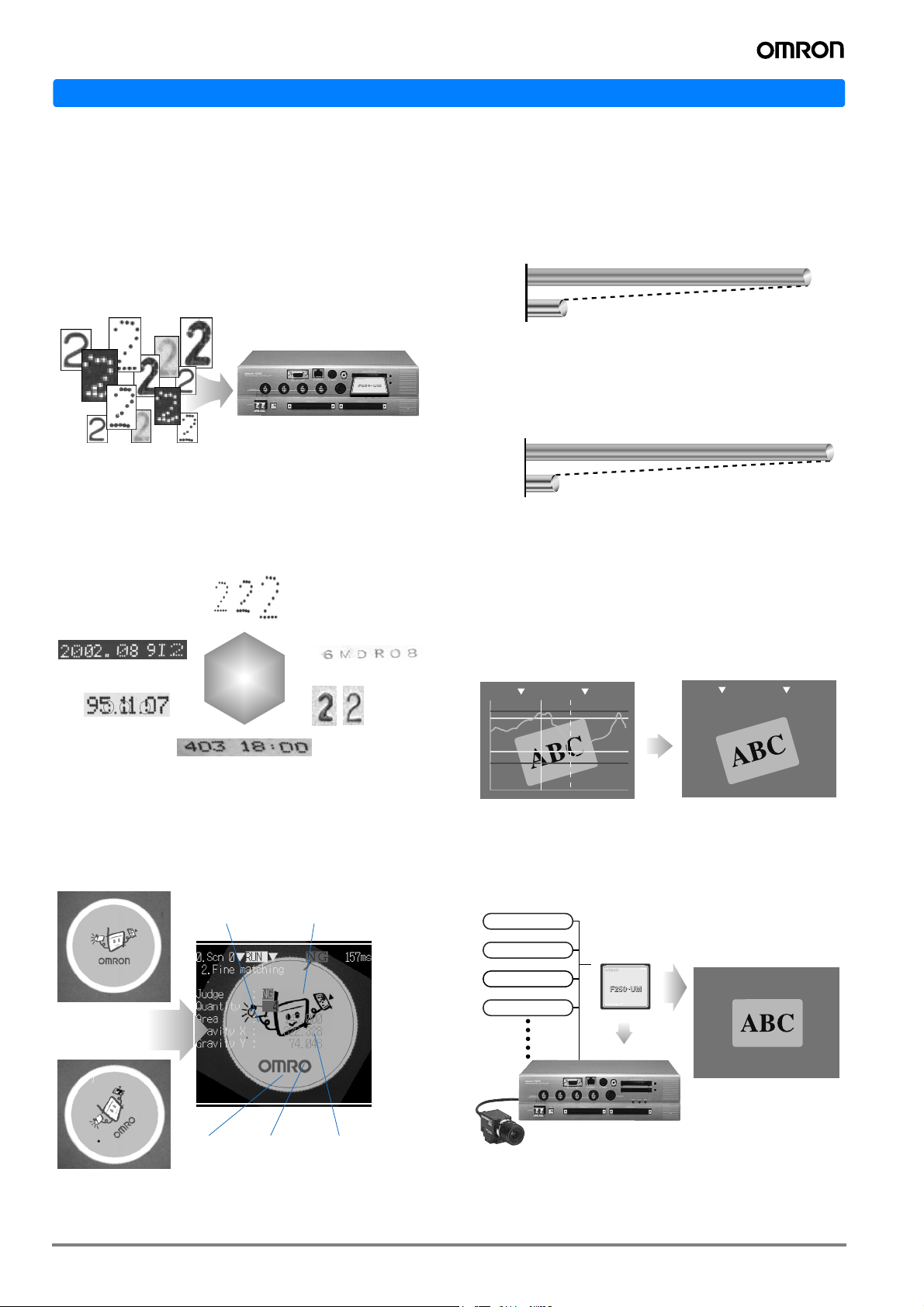

ED defect inspection

High-precision detection of

minute defects that could not

be detected previously .

High-precision position measurement even if the inside of

the work changes or the view changes.

● Positioning of PWB fiducial marks

Certain detection of rubber

packing deformities.

Low contrast Revolution Internal dirt

EC positioning

Detection of low-contrast

defects on metal surfaces

C-45F250

Page 2

Features

2

s

QUEST character checking

Even if the shape or size of a character varies, "QUEST Logic" finds printed characters with certainty. The built-in dictionary makes "simple settings" possible.

● No need to store a character dictionary

Various character fonts for factory automation have been prestored. This eliminates the need to store a dictionary or model

names, and allows a dramatic reduction in man-hours for initial setup.

● The "six character variations" can also be recognized with

certitude.

Checks characters printed on the production line such as

"Best before" dates and lot numbers. Even if there are deviations in shape, size, or line width, the characters are accurately checked.

For fast increasing line speeds and ever

stricter quality demands.

● Real time Revolution Search is amazing

Executes a real time search of 72 models. Even with works

that rotate 360°, positioning corrections are completed at the

same time as image read-in.

Our company

conventional model

F250

8.3ms

360-degree rotation correction speed

(field mode)

12x speed

● Fast image processing

Inspection functions following camera image read-in are also

up to 10 times faster thanks to a newly developed parallel processing technology.

Our company

conventional model

F250

2 to 10 times

● Fast image read-in

The F160-S1 double-speed camera achieves a maximum image read-in speed of 8.3 ms.

100m

Size

2

2

Fade

2

Width

2

Break

Fine matching

Detects differences from the stored "good" image quickly and

with high accuracy. Dramatic improvement in ability to inspect

characters and patterns with minute border defects.

● Example of application to soft drink cap inspection

Registration image

An inspection result is displayed

and outputted.

Fine

Fine

Matching

Matching

Inspection image

2

Tilt

2

Line

width

Lack of edge

"Non-stop" adjustment without stopping the line

All settings can be adjusted and reset while inspection

continues. There is no need to stop the line for adjustments,

subsequently, no capacity drops.

Scene 0 Measurement NG

7. Trend Monitor

0. Label Position X

It adjusts checking an inspection history

by the trend monitor.

● Easy and flexible settings by means of software application

1. Functions needed for inspection are selected and installed

from the software application.

EC position compensation

QUEST Optical Character Recognition

Fine matching

Expression

F250-UM E

application

software

Scene 0 Measurement NG

0. Position Measurement of Label

Position X: 286.344

Position Y: 207.457

Test measurement is performed as compared

with previous NG picture.

Scene 0= setting =

Camera setting

0. Camera Picture Input

1. EC Position compensation

2.2 value defective inspection

3. QUEST Optical Character Recognition

4. DO Judging Output

5. Trend Monitor

ENT: Set SFT+ESC: Edit

2. Combine required inspection functions from

Dirt in a figureLack of a charactorMinute dirt

the menu.

C-46 Vision Systems

Page 3

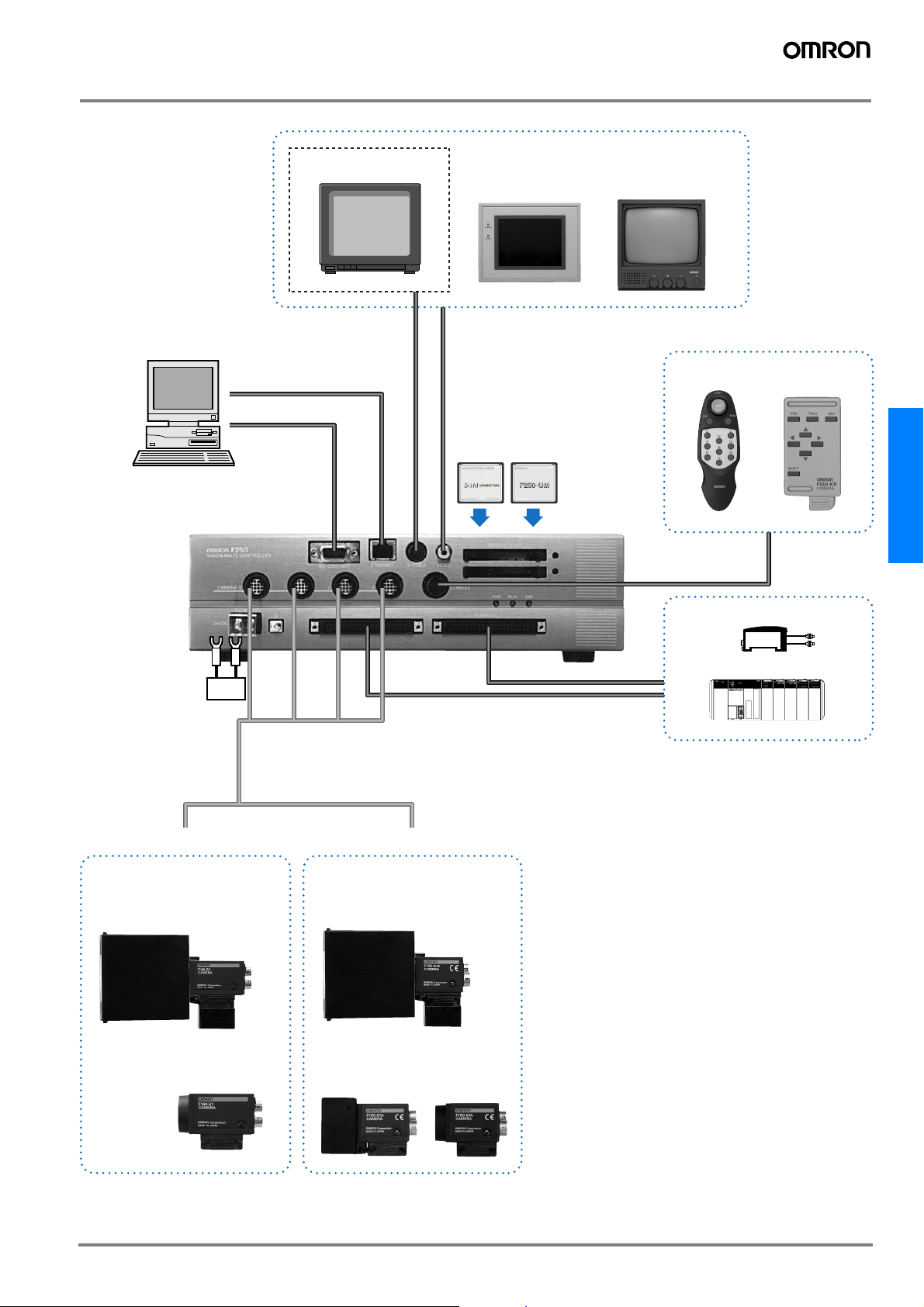

System configuration

Monitor

Personal

computer

Controller

F250-C50/C55

Monitor with S-video terminal

Ethernet (Cross cable)

RS-232C/422

Color LCD

Monitor

F150-M05L

Monitor cable

F150-VM

Memory card

F160-N64S (64MB)

Application software

F250-UM3@E

Monochrome CRT

Video Monitor

F150-M09

Console

F150-KPF160-KP

F250

Power

supply

Camera cable

F150-VS

Camera with Intelligent Lighting

F160-SLC20

F160-SLC50

Camera

F160-S1

F160-S2

Compatible F150 CamerasDouble-speed Camera

Camera with Intelligent Lighting

F150-SLC20

F150-SLC50

Camera with Light

F150-SL20A

F150-SL50A

Camera

F150-S1A

Synchronous sensor

Programmable controller

Parallel cable

F160-VP

C-47F250

Page 4

Ordering Information

Name Model Remarks

Controller

Camera with intelligent

Double-speed

camera

F150

Compatible cameras

Console

LCD monitor F150-M05L

Video monitor F150-M09

Memory card F160-N64S(S) Memory capacity 64 MB

Application software

Camera cable F150-VS

Monitor cable F150-VM Cable length: 2 m

Parallel cable F160-VP

lighting

Camera only

Camera with intelligent

lighting

Camera with lighting

Camera only F150-S1A

F250-C50 NPN Input/Output

F250-C55 PNP Input/Output

F160-SLC20

F160-SLC50

F160-S1

F160-S2 Includes Partial Scan functionality

F150-SLC20

F150-SLC50

F150-SL20A

F150-SL50A

F160-KP

F150-KP

F250-UM3ME with Macro function

F250-UM3FE without Macro function

Length of cable for double-speed camera

and F150 common camera: 3 m

Length of pigtail cable for parallel

input/output connector: 2 m

C-48 Vision Systems

Page 5

Rating/Performance

Controller: F250-C50/C55

Connected camera F150-S1A/SL20A/SL50A/SLC20/SLC50, F160-S1/S2/SLC20/SLC50

Number of connectable cameras 4

Processing resolution 512(H) x 484(V)

Number of scenes 32 scenes (expansion possible using memory card)

Image storage function Maximum 35 images

Image pre-processing

Operation and Settings

Menu language Japanese/English (changeable)

Operation customization function

Screen customization

function

Non-stop adjustment function Yes

Trend monitor function Yes

Memory card slot 2 slots

Monitor Composite video output: 1 CH, S-video output: 1 CH

Ethernet 10Base-T 1CH

Serial communication RS-232C/422A 1CH

Parallel input/output Inputs: 21 points, outputs: 46 points

Strobe 4 CH (included in parallel outputs)

Power supply voltage 20.4 to 26.4 VDC

Current consumption Approximately 3.7 A (when four F160-SLC50 units are connected)

Ambient temperature Operating: 0 to +50°C, storage: -25 to +65°C (no ice formation or condensation)

Ambient humidity Operating/storage: 35 to 85% RH (with no condensation)

Dimensions 270(W) x 81(H) x 197(D)

Weight Approximately 3.1kg (unit only)

Double-speed camera: F160-S1/S2

Picture element 1/3“ Interline CCD

Effective pixels 659 x 44 (H x V)

Scanning method 1/60-s non-interlace (frame) mode, 1/120-s 2:1 interlace (field) mode

Shutter Electronic shutter; select from 8 shutter-speed settings (1/120 to 1/20,000 s) using menu

Camera with Intelligent Light-

ing

Ambient temperature

Ambient humidity Operating and Storage: 35 to 85% RH (with no condensation)

External Dimensions 31 x 40 x 54.5 (W x H x D) mm (not including connectors and other protruding parts)

Weight Approx. 85 g (Camera only)

Monitor

Model number

Item

Size 5.5 inches 9 inches

Type Liquid crystal color TFT CRT monochrome

Resolution 320 x 240 dots 800TV or min. (at center)

Input signal NTSC composite video (1.0 V / 75 )

Power supply voltage 20.4 to 26.4 VDC 100 to 240 VAC (-15%, +10%)

Current consumption Approx. 700 mA Approx. 400 mA

Ambient temperature

Ambient humidity

Weight (Monitor only) Approx. 610 g Approx. 4.5 kg

Accessories Instruction manual and 4 mounting brackets Instruction manual

Name

Smoothing (strong/weak), edge enhancement, edge extraction (horizontal, vertical, both),

erosion, dilation, median, background deletion

Install measurement routines from a software application, combine and establish settings for

measurement routines from menus.

Password function, short-cut key function

Display items: Character strings (measured values, decisions, time, any character string,

measurement area names), graphics (straight lines, rectangles, circles, cross-hair cursors)

Parameters specified: display color, postion, size

F160-SLC20 (field of vision: 20 mm), F160-SLC50 (field of vision: 50 mm)

Operating: 0 to +50°C

Storage: -25 to +60°C

(with no icing or condensation)

F150-M05L

Color LCD monitor

Operating: 0 to +50°C

Storage: -25 to +65°C

(with no icing or condensation)

Operating or storage: 35% to 85%

(with no condensation)

Monochrome CRT Video Monitor

Operating: -10 to +50°C

Storage: -20 to +65°C

(with no icing or condensation)

Operating or Storage: 10% to 90%

(with no condensation)

F150-M09

F250

C-49F250

Page 6

Name and function of each part

Controller: F250-C50/C55

L

E N CBADI

KJM H

G

F

A

POWER LED (green)

Illuminates while the power is on.

B

RUN LED (orange)

Illuminates while the system is in measurement mode.

C

ERROR LED (red)

Illuminates when a problem occurs.

D

Input connectors 0, 1

Connects to a synchronous sensor or programmable controller.

E

Power terminal

Connects to a DC power supply.

F

Console connector

Connects to the console.

G

Memory card LEDs 0, 1

Illuminates while power is supplied to the memory card.

H

Memory card slots 0, 1

A memory card or software application is inserted here.

I

CAMERA 0 - 3 connectors

Connects to a camera.

J

Monitor connector (S-Video output)

Connects to a monitor with an S-Video input

K

Ethernet connector

Connects to a computer.

L

RS-232C/422 connector

Connects to a computer or programmable controller.

M

Monitor connector (composite video output)

Connects to a monitor.

N

Ground terminal

Connect the ground wire to this terminal.

C-50 Vision Systems

Page 7

Function menu

Processing routine list

The F250-UME application software contains approximately 50 processing routines.

Image input related

Camera image input

Camera switch

Pre-processing change

Repeat preprocessing

Measurement supplement

related

Computing

Acquire processing unit data

Set processing unit data

Wait

Elapsed time

Trend monitor

Position compensation

related

Binary position correction

Model position correction

Circular work position correction

Edge position correction

EC position correction

Scroll return

Scroll

Branch control related

Condition branch

DI branch

End

General measurement

related

QUEST character

checking

Binary defect

inspection

Density defect

inspection

Fine matching

Pattern inspection

Sorting

EC defect inspection

EC circular piece

count inspection

Rotation

positioning

Result output related

Memory card data output

DO data output

Significant link data output

Non-protocol data output

DO decision output

Dark-light edge

position

ECM search

EC positioning

Lot number

checking 1

Dark-light edge

number

Density average/

deviation

Labeling

Label data

F250

Result display related

Any character display

Measured value display

Decision character display

Processing task name display

Measurement time display

Fixed graphic display

Straight line result display

Rectangle result display

Circle result display

Cross-hair cursor result display

C-51F250

Page 8

Dimensions (Unit: mm)

Controller

F250-C50/C55

115 min.

73

8

Four M4 mounting holes *

* Screw length: L (10+T<L<13+T)

136±0.5

(14)

(25)

(40)

270

220±0.6

190±0.6

Double-speed camera

F160-S1/S2

(15.5)

(14.5)

1"-32UN-2A

(C mount)

54.5

8 (46.5)

30.5

31.25±2

21.25±2

20±0.1

(23.25)

(6)

(6.2)

2911

(21.7)

8

Two, M4 depth: 8

1/4-20UNC depth: 8

(13.25)

(6.2)

Light connector

(8.8 dia.)

(30.7)

Camera cable connector

31

(11.8 dia.)

F160-SLC20 (with F150-LTC20 intelligent lighting)

70

2.52.5 70

12

12

12 12

31

40

42.5

(96.25)

(86.25)

46.573

30.5 8

(23.25)

20±0.3

(85)

(10) 25

4 dia.

1/4-20UNC depth: 10

Two, M4 depth: 10

(13.25)

F160-SLC50 (with F150-LTC50 intelligent lighting)

90

16

90

16 16

16

31

60

2.5

2.5

80 46.5 (85)

52.5

(103.25)

(10) 25

4 dia.

830.5

(23.25)

1/4-20UNC depth: 10

Console

F160-KP

(29.7)

48

135.5

200040

SHIFT

ENT

ESC

F1

F2

F4F5F6

F7F8F9

TRIG

F3

197

10 to 13

Thickness: T

12 dia.

20

F150-KP

131.5

87

12.5

12 dia.

50

ESC TRIG

ENT

SHIFT

CONSOLE

232000 5 10

LCD monitor

F150-M05L

POWER

SYNC

(100)

Panel cut figure

185

174

Attachable thickness: 1.6 to 4.8

(46 max.)

Mounting bracket

(155)

143

(5.5)

42.2

175.5

(145)

132

Monitor cable (F150-VM)

Tolerance:±1 mm

( ) dimensions are reference value

133.5

+0.5mm

0

50min

+0.5mm

0

Video monitor

F150-M09

222

2335

143

250

(93.25)

20±0.3

Two, M4 depth: 10

(13.25)

190

50

160

22

C-52 Vision Systems

Page 9

F250

C-53F250

Page 10

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. Q11E-EN-01

In the interest of product improvement, specifications are subject to change without notice.

C-54 Vision Systems

Loading...

Loading...