Page 1

Manual 1:

SETUP MANUAL

Vision Sensor

F160

Cat. No. Z144-E1-03

Page 2

F160 Vision Sensor

Manual 1: Setup Manual

Revised January 2004

Page 3

APPLICATION CONSIDERATIONS

Precautions in using the Product

Read and Understand this Manual

Please read and understand this manual before using the products. Please consult your OMRON

representative if you have any questions or comments.

Warranty, Limitations of Liability

<WARRANTY>

OMRON’s exclusive warranty is that the products are free from defects in materials and

workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR

PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER

OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE

REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED.

<LIMITATIONS OF LIABILITY>

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE,

OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER

CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERL Y HANDLED, ST ORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR

REPAIR.

iv

Page 4

Application Considerations

<SUITABILITY FOR USE>

OMRON shall not be res po ns ibl e fo r c onformity with any standards, codes, or regulatio ns tha t ap pl y

to the combination of the products in the customer’s application or use of the product.

Take all necessary steps to determine the suitability of the product for the systems, machines, and

equipment with which it will be used.

Know and observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED

TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

<PROGRAMMABLE PRODUCTS>

OMRON shall not be responsi ble for the user ’s program ming of a programm able product , or any

consequence thereof.

Disclaimers

<PERFORMANCE DATA>

Performance data given in this manual is provided as a guide for the user in determining suitability

and does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the

users must correlate it to actual application requirements. Actual performance is subject to the

OMRON Warranty and Limitations of Liability.

<CHANGE IN SPECIFICATIONS>

Product specifications and accessories may be changed at any time based on improvements and

other reasons.

It is our practice to change model numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the product may

be changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON

representative at any time to confirm actual specifications of purchased products.

<DIMENSIONS AND WEIGHTS>

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even

when tolerances are shown.

<ERRORS AND OMISSIONS>

The information in this document has been carefully checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical, or proofreading errors, or

omissions.

v

Page 5

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always

heed the inf ormation pro vid ed with them . Failure to heed precautio ns can res ult in in jury to people

or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it

refers to an OMRON product, regardless of whether or not it appears in the proper name of the

product.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types

of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Precaution Indicates information required to take full advantage of the functions and per-

formance of the product. Incorrect application methods may result in the loss

of damage or damage to the product. Read and follow all precautionary information.

CHECK Indicates points that are important in using product functions or in application

procedures.

TwoCamera Indicates information required when using a 2-camera system.

SeeAlso Indicates where to find related information.

HELP Indicates information helpful in operation, such as the definition of terms.

OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retriev al system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information cont ained

in this manual is subject to change without notice. Every preca ution has been taken in the prepa ration

of this manual. Never theless, OMRON assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publication.

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 Special or Critical Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

3 Regulations and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Confirming Package Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Product Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 2

Installation and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-1 Basic System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Component Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-3 Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-4 Connecting Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-5 Overview of Available Cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-6 Power Supply and Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 3

Lenses, Lighting, and Memory Cards. . . . . . . . . . . . . . . . . . . . 21

3-1 CCTV Lenses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-3 Memory Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SECTION 4

Connecting External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-1 Connecting through the Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2 Connecting through the Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SECTION 5

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . . . 39

5-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-3 Regular Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5-4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5-5 F200/F300 Camera Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-6 Connecting a Strobe Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

vii

Page 7

Page 8

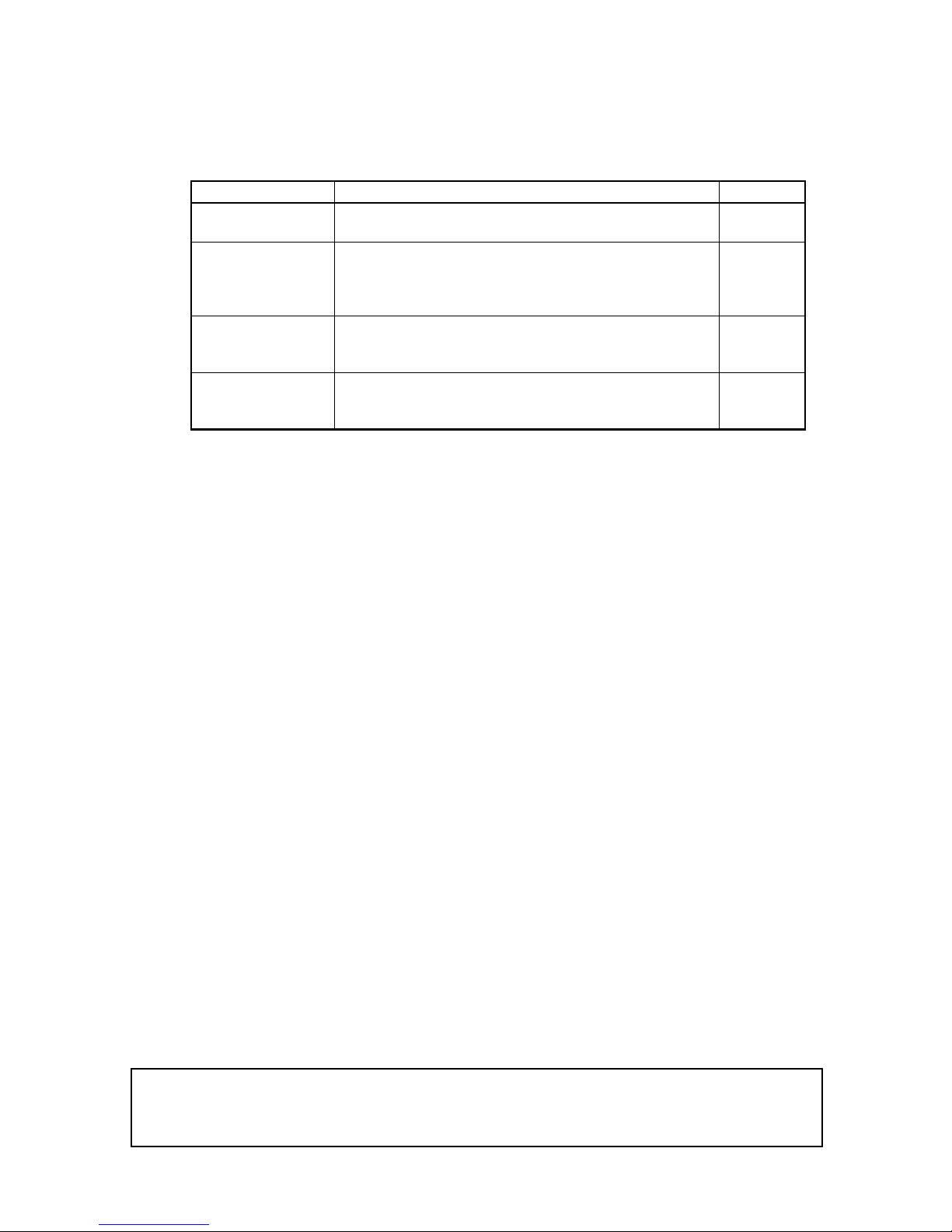

About this Manual:

This manual describes the hardware for the F160 Vision Sensor and how to install the components, and it includes the sections described below. This is one of four manuals used to

operate the F160. Refer to the following table for the contents of each manual.

Manual Contents Cat. No.

1:Setup Manual Provides information on system hardware and installation.

Be sure to read this manual first.

2:Conversational

Menu Operation

Manual

3: Expert Me nu

Operatio n Manual

4:Communications

Reference Manual

Please read the above manuals carefully and be sure you understand the information provided before attempting to install or operate the F160.

Section 1 Introduction describes the precautions that must be taken when installing and

operating the F160 Vision Sensor.

Section 2 Installation and Connections shows a basic F160 system configuration and

explains how to install the F160 and connect it to a power supply and peripheral devices.

Section 3 Lenses, Lighting, and Memory Cards describes how to select and use these

components most effectively.

Section 4 Connecting External Devices describes how to connect external devices

through a parallel interface (the I/O terminals or I/O connector) or serial interface (the RS232C/RS-422 connecto r).

Section 5 Troubleshooting and Maintenance provides tables to help identify and correct

hardware errors that may occur with the F160 as well as information on maintenance and

periodic inspections.

Describes operation of the F160 using the Conversational

Menus. The Conversational Menus enable the simplest operation based on registered images of acceptable and unacceptable products.

Describes operation of the F160 using the Expert Menus.

The Expert Menu enable application of all F160 capabilities,

including setting region images and criteria.

Describes the communications settings and communications

protocol used to transfer data through the parallel interf ace or

serial interface.

Z144

Z145

Z147

Z146

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section in

its entirety and be sure you understand the information provided in the section and related

sections before attempting any of the procedures or operations given.

ix

Page 9

Page 10

PRECAUTIONS

This section provides general precautions for using the F160 Vision Sensor.

The information contained in this section is important for the safe and reliable application of the F160

Vision Se nsor. Y ou must r ead thi s section and understa nd the inf o rmatio n containe d bef o r e attempting to

set up or operate an F160 Vision Sensor.

1 General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 Special or Critical Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

3 Regulations and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

xi

Page 11

General Safety Precautions 1

1 General Safety Precautions

Battery Precautions

!WARNING Do not disassemble the F160, apply pressure to the F160 that would deform

its shape, or incinerate the F160. A lithium battery is built into the F160 and it

may combust, explode, or burn if not treated properly.

!WARNING Do not short circuit, attemp t to ch arge , disa ssem b le, apply press ure that wo uld

deform, or incinerate the lithium battery. The lithium battery may start a fire,

explode, or burn if not treated properly.

Installation Environment Precautions

!Caution Do not use the F160 in environments with flammable or explosive gases.

!Caution Install the F160 away from high-voltage devices and moving machinery to

allow safe access during operation and maintenance.

!Caution Do not block the F160’s cooling vents.

Cooling vents

F

STEP

1

P

6

O

0

W

E

V

R

IS

IO

RESET

N

M

C

A

O

T

N

E

R

T

U

R

N

C

O

RUN

E

RROR

BUSY

GATE

OR

DO15

C

O

M

O

L

M

O

P

A

R

A

L

L

E

L

L

I

N

U

T

E

R

E

R

R

O

R

C

O

N

S

O

L

E

C

A

M

E

R

A

0

R

S

-2

3

2

C

/42

2

C

A

M

E

R

A

1

M

O

N

IT

O

R

+

24VDC

1.2A

-

Cooling vents

Before the F160 is shipped, a protective label is attached to the top of the

F160 to cover the cooling vents. This label prevents wire strands from falling

into the F160 during wiring, so it must not be removed until wiring is completed. The label must be removed after wiring to allow proper cooling during

operation.

!Caution Be sure to securely tighten the screws when mounting the F160.

Power Supply and Wiring Precautions

!Caution Use the F160 with the power supply voltages specified in this manual.

!Caution Use the wire and crimp term inals of the proper sizes as specified in this man-

ual. Do not connect the power supply wires by just twisting stranded wire and

connecting directly to the terminals.

!Caution Use a DC power supply with countermeasures against high-voltage spikes

(safe extra low-voltage circuits on the secondary side).

xii

Page 12

Special or Critical Applications 2

Note

1. Keep the power supply wires as short as possible.

2. Ground the F160’s ground terminal to less than 100 Ω.

3. Use a grounding point as close as possible to the F160 and keep the

ground line as short as possible.

4. Wire the F160 to the groun d with a se parate g round wire . To avoid gro unding problems, do not share the ground wiring with any other devices or

ground the F160 to the building’s steel framing/plumbing.

Other Precautions

!Caution Do not attempt to dismantle, repair, or modify the F160.

!Caution Do not touch fluorescent or halogen lights while the power is ON or immedi-

ately afte r the power is tur ned OFF. These l ights get ver y hot and c an cause

burns.

!Caution If you suspect an error or malfunction, stop using the F160 immediately, turn

OFF the power supply, and consult your OMRON representative.

Note Dispose of the F160 as industrial waste.

2 Special or Critical Applications

When the F160 will be used in one of the conditions or applications listed

below, allow extra safety marg ins in ratings and func tio ns, add extra s afety features such as fail-safe systems, and consult your OMRON representative.

• Operating conditions or environments which are not described in the

manual

• Nuclear power control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement equipment, or

safety equipment

• Other systems, machines, and equipment that may have a serious influence on lives and property and require extra safety features

xiii

Page 13

Regulations and Standards 3

3 Regulations and Standards

The F160 complies with the international regulations and standards below.

1. EU Regulations

EMC Directive: No. 89/336/EEC

2. EN Standards (European Standards)

EN 61000-6-2: 1999, EN 61326: 1993/Annex A+A1: 1998,

EN 50081-2: 1993/Class A

xiv

Page 14

SECTION 1

Introduction

This section describes the precautions that must be taken when installing and operating the F160 Vision Sensor.

1-1 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Component Installation and Handling. . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 Confirming Package Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Product Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1

Page 15

Installation Precautions Section 1-1

1-1 Installation Precautions

The F160 is highly reliable and resistant to most environmental factors. The

following guidelines, however, must be followed to ensure reliability and optimum use of the F160.

!Caution Read the Precautions section before proceeding with installation or operation.

1-1-1 Controller Installation

Installation Site

Do not install the F160 in locations subject to the following conditions:

1,2,3... 1. Ambient temperatures outside of the 0 to 50°C (32 to 122°F) range

2. Rapid temperature fluctuations (likely to cause c ondensation)

3. Relative humidities outside of the 35% to 85% range

4. Presence of corrosive or flammable gases

5. Presence of dust, salt, or iron particles

6. Direct vibration or shock

7. Direct sunlight

8. W a ter, oil, or chemical fumes or spr ay

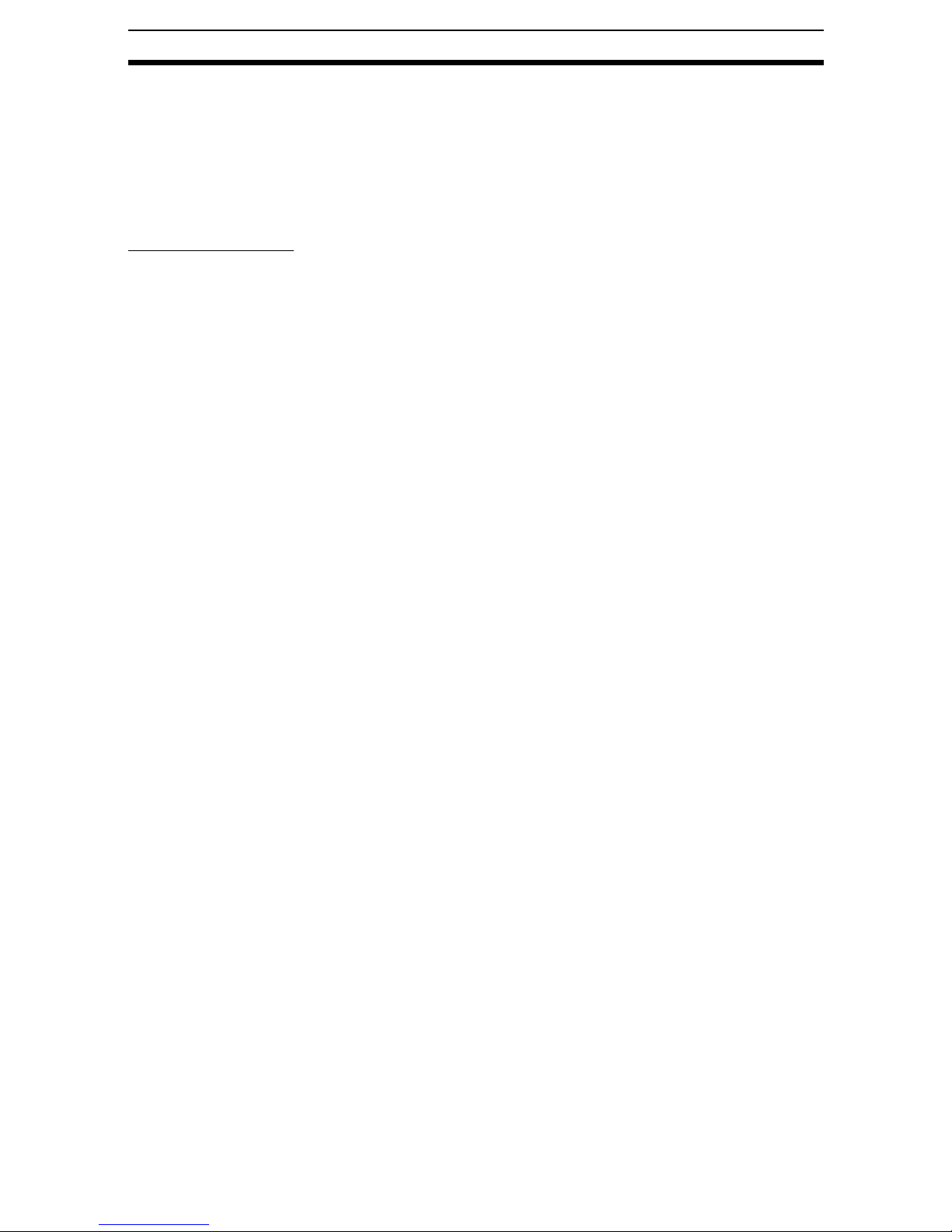

Orientation of Controller

To improve heat dissipation, install the Controller in the following orientation

only:

CORRECT

Do not install the Controller in the orientations shown in the following diagram.

INCORRECT

F160

S

T

E

P

P

O

W

E

V

R

IS

IO

R

E

N

S

M

E

T

C

A

O

T

N

E

R

T

U

R

N

O

C

L

O

L

M

E

I

N

R

R

E

U

N

R

R

O

R

E

R

R

O

R

B

U

S

Y

G

A

T

E

O

R

D

O

1

5

C

O

M

O

U

T

C

O

N

S

O

L

E

C

A

M

E

R

A

0

P

A

R

R

S

A

-2

3

2

C

L

/4

2

2

L

CAMERA 1

E

L

MONITOR

+

24V

D

C

1.2A

-

2

C/42

D

R

A

C

Y

R

O

M

E

-232

M

S

R

E

E

T

L

L

A

O

M

R

N

T

0

N

IO

6

O

IS

1

C

V

F

R

O

R

R

E

N

R

W

U

E

O

R

P

T

N

E

U

P

S

R

E

E

COMIN

T

R

S

R

0

A

R

E

E

L

M

O

A

S

C

N

O

C

P

T

U

O

5

M

1

O

E

O

R

C

Y

R

T

D

O

S

A

O

R

U

G

R

B

E

C

D

A

R

V

.2

O

4

1

2

IT

-

N

+

1

O

A

M

R

E

M

A

C

L

E

L

L

A

R

A

2

Page 16

Installation Precautions Section 1-1

Ambient Temperature

1,2,3... 1. Maintain a minim um clear a nce of 50 mm abo v e an d belo w the F16 0 to im -

prove air circulation.

2. Do not install the F160 immediately above significant heat sources, such

as heaters, transformers, or large-capacity resistors.

3. Do not let the ambient operating temperature exceed 50°C (122°F).

4. Provide a forced-air fan cooli ng or air con diti on ing if the am bie nt tem per a ture is near 50°C (122°F) so that the ambient temperature never exceeds

50°C (122°F).

Control panel

F160

Louver

Noise Resistance

Use the following measures to help increase noise resistance.

1,2,3... 1. Do not install the F160 in a cabinet containing high-voltage equipment.

2. Do not install the F160 within 200 mm of power cables.

Power cable

200 mm min.

200 mm min.

F160

1-1-2 Component Installation and Handling

OMRON Components

Use a Camera, Camera Cable, and Console designed specifically for the

F160.

Connecting Cables

Always turn OFF the F160’s power before connecting or disconnecting a camera or cable.

Handling the Camera

The Camera’s case is connected to th e 0 V li ne in th e i nternal circuits. Observe

the following precautions to prevent noise interference.

1,2,3... 1. Do not ground the Camera.

2. Do not remove the base attached to the Camera.

3. Do not remove the core attached to the F150-VS Camera Cable.

3

Page 17

Installation Precautions Section 1-1

Securing the Video Monitor (When Using the Recommended F150-M09)

Observe the following precautions to prevent noise interference, because the

video monitor case is connected to the 0V line in the internal circuits.

1,2,3... 1. Do not ground the video monitor.

2. Do not ground the metallic part of the connector.

3. Secure t he video monitor w ith plas tic scre ws if i t is bei ng moun ted to a metallic surf ac e .

Touching Signal Lines

To prevent damage from static electricity, use a wrist strap or another device

for preventing electrostatic discharges when touching terminals or signal lines

in connectors.

Removing the Memory Card

Before removing a Memory Card, stop the power supply to the Card or turn

OFF the F160. The Memory Card or the F160 itself may be damaged if a

Memory Card is removed while power is being supplied.

(Stop the power supply to the Memory Card from the menu.)

Turning OFF the Power

Do not turn OFF the power while a message is being displayed indicating that

processing is being performed. Data in memory will be corrupted, and the

F160 may not operate correctly the next time it is started.

0.Scn 0 MON

Saving data.

Using the RESET Signal

Do not use the RESET input immediately after power is turned ON. When

using the RESET input to synchronize startup timing, wait at least 1 second

after the F160’s power supply is turned ON before turning ON the RESET signal.

---- ---ms

4

Page 18

Confirming Package Contents Section 1-2

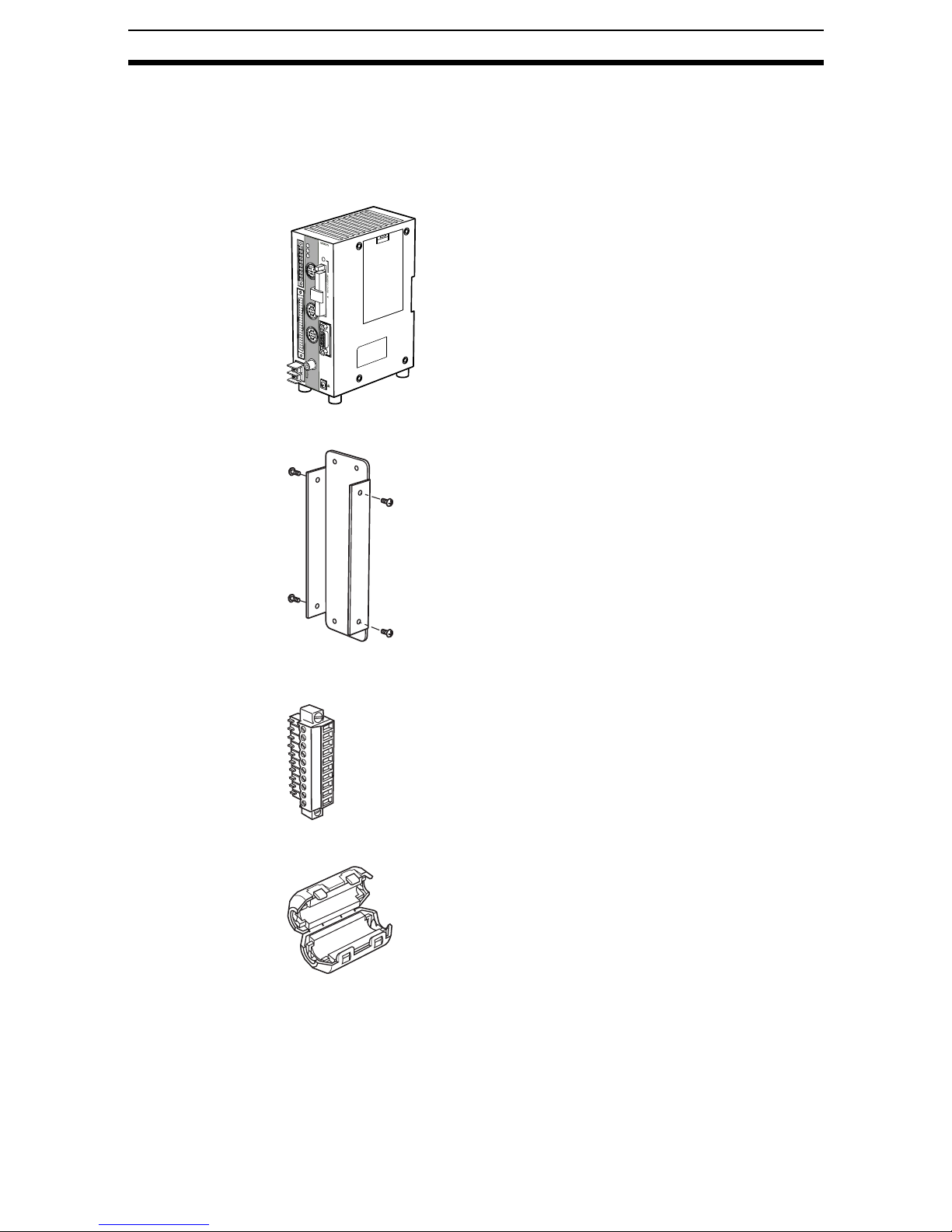

1-2 Confirming Package Contents

Check the contents of the package as soon as you receive the F160. It is

extremely rare for components to be missing, but contact the nearest OMRON

representative if any of the following items are missing.

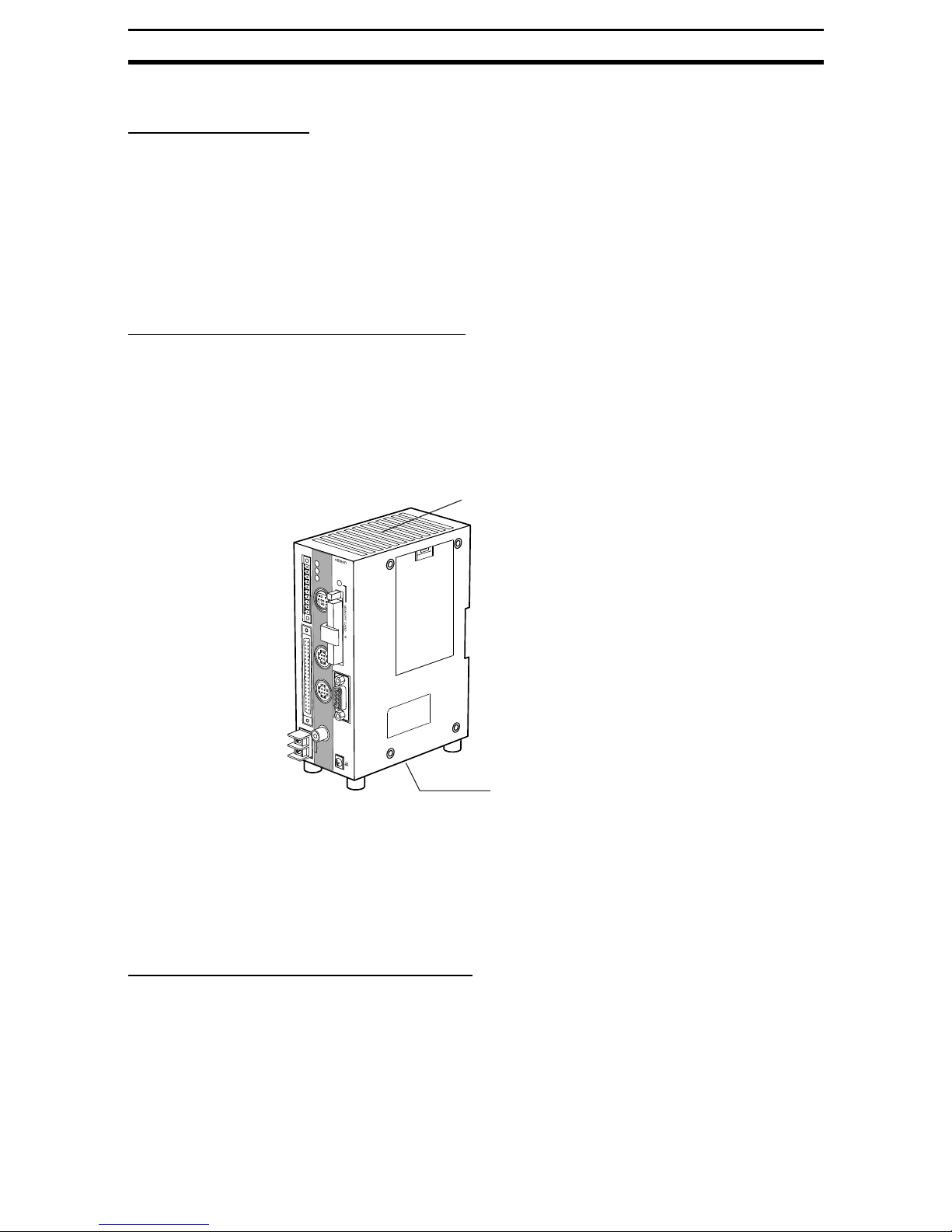

1,2,3... 1. F160 Vision Mate Controller Qty.: 1

F160

S

T

E

POWER

P

V

I

S

I

O

R

E

N

S

E

M

T

C

A

O

T

N

E

RUN

T

R

O

C

L

O

L

M

E

I

N

R

R

ERROR

U

N

E

R

R

O

R

B

U

S

Y

G

A

T

E

O

R

D

O

1

5

C

O

M

O

U

T

C

O

N

S

O

L

E

C

A

M

E

R

A

0

P

A

R

R

S

A

-

2

3

2

C

L

/

4

2

2

L

C

A

E

M

E

R

A

L

1

M

O

N

IT

O

R

+

2

4

V

D

C

1

-

.

2

A

2. Mounting B racket (for rear surface mounting)

Bracket: Qty: 1

Screws (M3 x 6): Qty: 4

3. Connector for I/O Terminals Qty.: 1

(Phoenix Contact model MC1.5/10-STF-3.5)

4. Ferrite Core for F150-VM Monitor Cable Qty.: 1

5. Setup Manual (this manual) Qty.: 1

6. Conversational Menu Operation Manual Qty.: 1

7. Expert Menu Operation Man ual Qty.: 1

8. Communications Reference Qty.: 1

5

Page 19

Product Availability Section 1-3

1-3 Product Availability

Some of the products listed may not be available in some countries. Please

contact your nearest OMRON sales office by referring to the addresses provided at the back of this manual.

6

Page 20

SECTION 2

Installation and Connections

This section shows a basic F160 system configuration and explains how to install and wire the F160.

2-1 Basic System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Component Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-3 Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3-1 DIN Track Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3-2 Rear Surface-mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-3-3 Side Surface-mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3-4 Bottom Surface-mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-4 Connecting Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-4-1 Connecting a Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-4-2 Connecting a Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-4-3 Connecting a Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-5 Overview of Available Cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-6 Power Supply and Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-6-1 Crimp Terminals and Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-6-2 Ground (Earth) Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-6-3 Wiring the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7

Page 21

Basic System Configuration Section 2-1

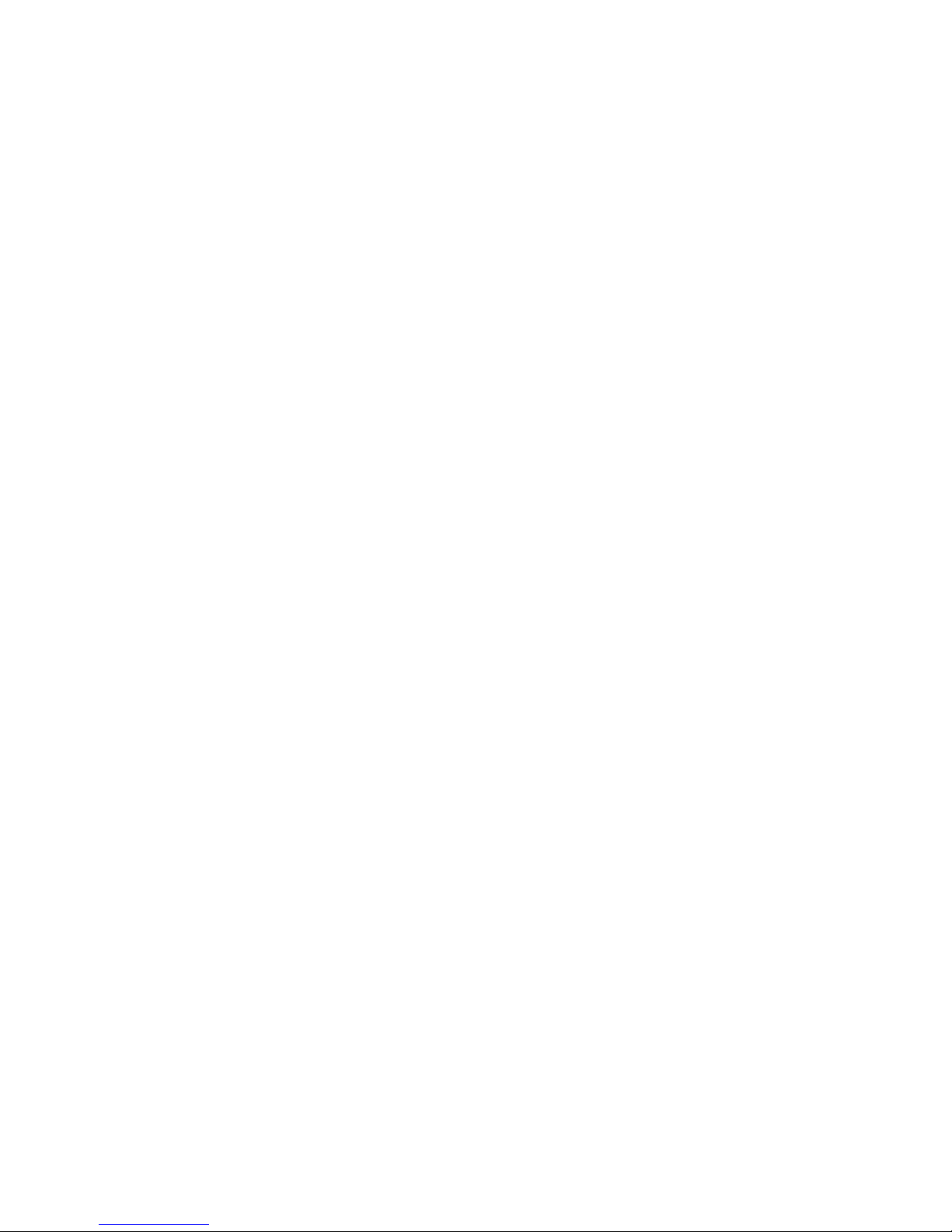

2-1 Basic System Configuration

Precaution The following diagram shows the basic F160 system configuration. Some of

the components shown in the configuration diagram are special OMRON

products that cannot be subst itu ted w ith co mp arable devices . These items are

indicated with an asterisk.

Console

Controller

The F160 performs the image

processing specified by the

user settings and outputs the

measurement results.

POWER

F160

STEP

RESET

COMIN

RUN

ERROR

OR

BUSY

GATE

DO15

COMOUT

RUN

ERROR

CONSOLE

VISION MATE

CONTROLLER

MEMORY CARD

F160-KP

(2-m cable)

F150-KP

(2-m cable)

Power Supply

page 18

Recommended model:

OMRON S82K-05024

Color LCD Monitor

(F150-M05L)

PARALLEL

CAMERA0

RS-232C/422

CAMERA1

MONITOR

+

24VDC

−

Monitor Cable

F150-VM (2 m)

BNC Jack

(Included with the F150-VM.)

Monitors

Monochrome CRT

Video Monitor(F150-M09)

*Camera Cable

F150-VS (3 m)

The Monitor is used to check the

image and display menus when

making settings.

POWER

SYNC

(RCA plug input)

8

(BNC input)

Page 22

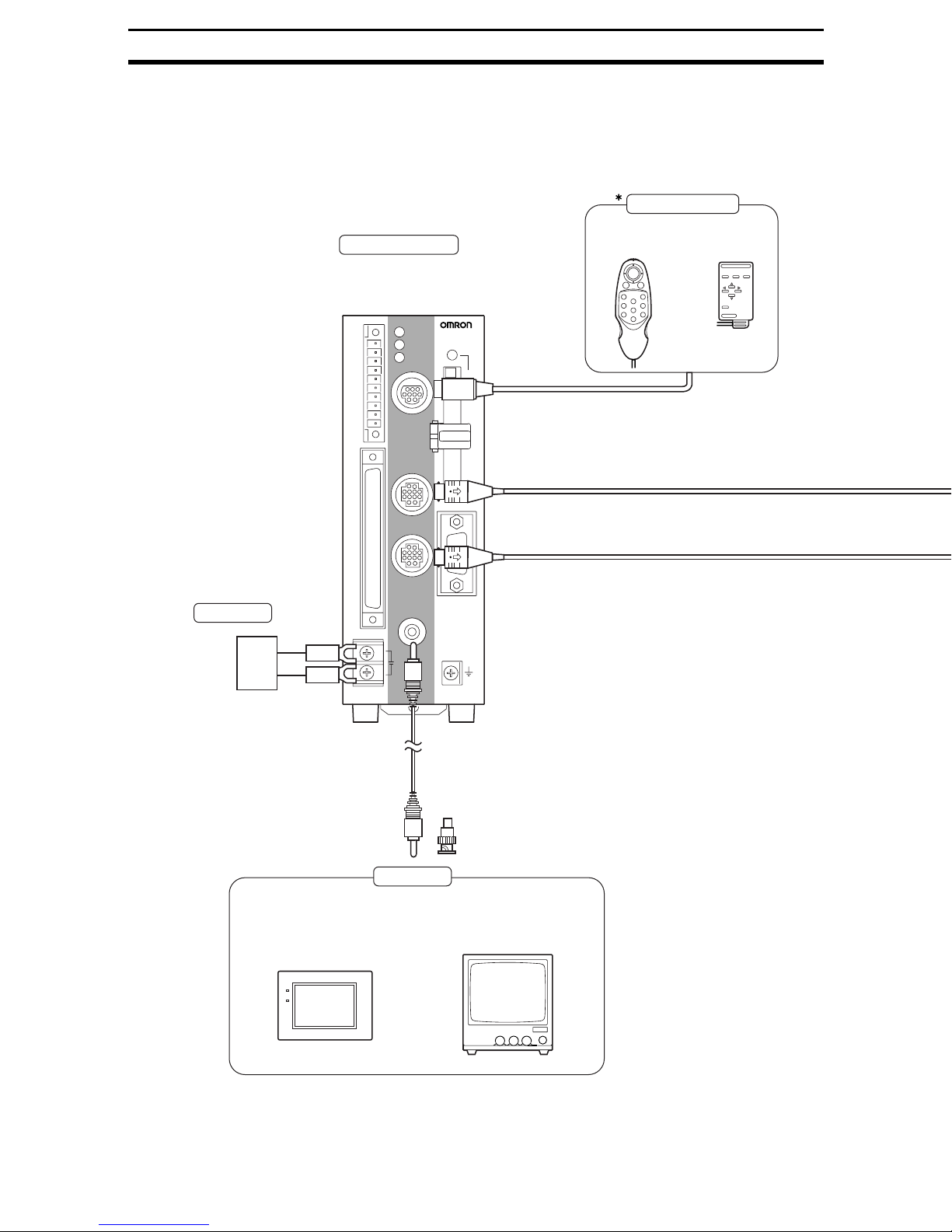

Basic System Configuration Section 2-1

Cameras

Images of measurement objects are obtained using Cameras. Up to 2

Cameras can be connected to an F160, but the 2 Cameras can be used

with the Expert Menu only. Just 1 Camera can be used with the

Conversational Menu.

Two different models of Camera can be connected as long as the Cameras

are of the same type. (The model number prefix (F150 or F160) indicates the

Camera's type, so two Cameras can be connected together if they have the

same prefix.)

Double-speed Cameras

Camera with Intelligent Lighting

F160-SLC20 (20-mm field of vision)

F160-SLC50 (50-mm field of vision)

Camera Only

Use the Camera by itself when the field of vision of

the Camera with Intelligent Light" does not match

the size of the measurement object. A standard

CCTV lens and light source will be needed.

F160-S1

CHECK

F150 Cameras

Camera with Intelligent Lighting

F150-SLC20 (20-mm field of vision)

F150-SLC50 (50-mm field of vision)

Camera with Light

F150-SL20A (20-mm field of vision)

F150-SL50A (50-mm field of vision)

Camera Only

Use the Camera by itself when the field of vision of

the Camera with Intelligent Light" does not match

the size of the measurement object. A standard

CCTV lens and light source will be needed.

F150-S1A

F200-series and F300-series Cameras can also be connected.

Camera type Camera Cable Max. number of Cameras

F200-S F160-VSR3 1 (Connect to camera connector 0.)

F300-S F160-VSR4 2

F300-S2R F160-VSR3

F300-S3DR

F300-S4R

(The 2 cameras must have the same model number.

Only one camera can be connected with the Conversational Menu.)

SeeAlso Refer to page 63 for details on parameter settings.

9

Page 23

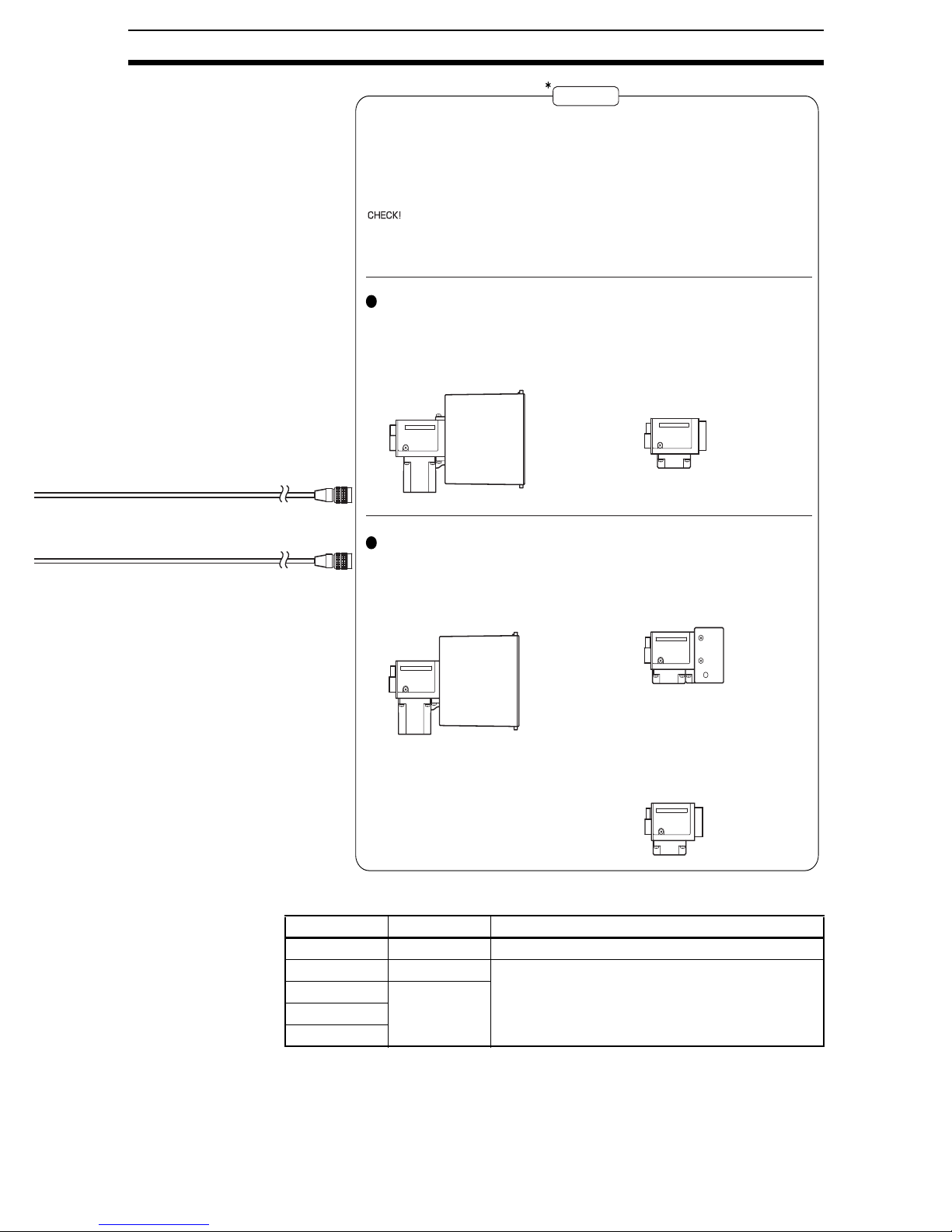

Component Names and Functions Section 2-2

2-2 Component Names and Functions

The following diagram shows the F160 Vision Mate Controller’s major external

components.

Console connector

Memory Card indicator

POWER indicator

RUN indicator

ERROR indicator

I/O terminals

(Control lines)

I/O connector

(Control and data lines)

Camera

connectors

Power supply

terminals

Monitor connector

P

O

W

E

R

U

N

E

R

R

O

C

O

N

S

O

LE

C

A

M

E

R

A

CAMERA 1

MONITOR

+

24V

D

C

-

F160

V

R

IS

IO

N

M

C

A

O

T

N

E

T

R

O

LL

E

R

R

Memory Card slot

Battery cover

0

R

S

-2

3

2

C

/4

2

2

Card lock

S

T

E

P

R

E

S

E

T

C

O

M

IN

R

U

N

E

R

R

O

R

O

R

B

U

S

Y

G

A

T

E

D

O

1

5

C

OM

OUT

PA

R

ALLE

L

RS-232C/RS-422 connector

Ground terminal

1. Lit while power is ON.

2. Lit while t he F160 is in R un Mode.

3. Lit when an error has occurred.

4. Connects the F160 to external devices such as a sync sensor or PLC.

5. Connects the F160 to external devices such as a sync sensor or PLC.

6. Connects to the Camera(s).

7. Connects to the power supply.

8. Connects to the monitor.

9. Connects to the ground wire.

10. Connects the F160 to an external device such as a personal computer or

PLC.

11. This lock se cures the M emory Card so that it does not disco nnect unin tentionally from vibration.

12. Covers the compartment that contains the F160’s battery.

13. This slot recei ves t he Memory Card.

10

Page 24

Mounting the Controller Section 2-3

14. Lit when powe r is being supplied to the Memory Card. (The Memo ry Card

must not be inserted or removed when this indicator is lit.)

15. Connects the F160 to a Console.

2-3 Mounting the Controller

There are four ways to mount the Vision Mate Controller: DIN Track mounting,

rear surface-mounting, side surface-mounting, or bottom surface-mounting.

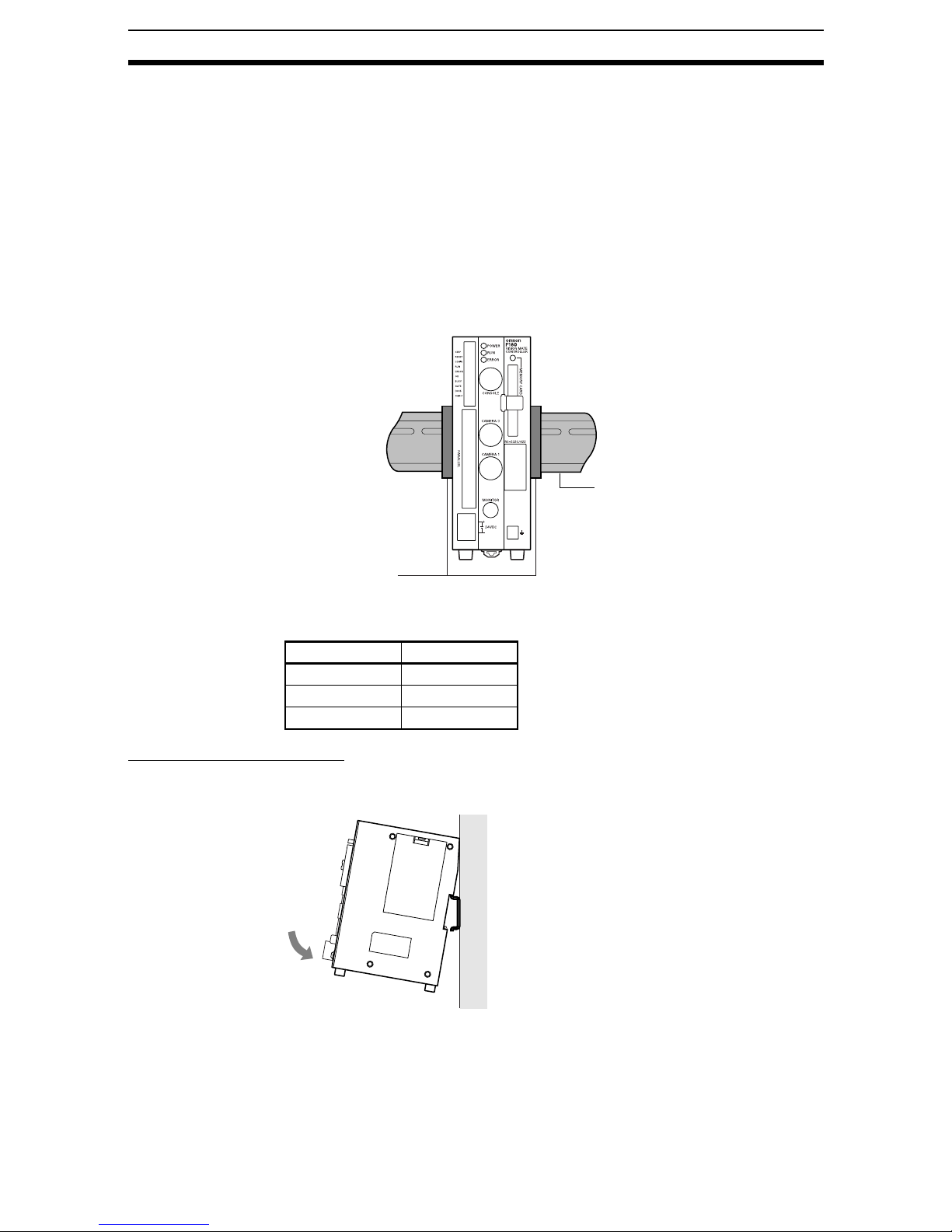

2-3-1 DIN Track Mounting

The Vision Mate Controller can be easily mounted to or removed from 35-mm

DIN Track.

DIN Track

PFP-M End Plate

(OMRON)

The following DIN Tracks are available from OMRON.

Model Length

PFP-100N 1 m

PFP-50N 50 cm

PFP-100N2 1 m

Mounting the Controller

Hook the Controller into the DIN Track as shown in the diagram and then

press in at the bottom until the Controller locks into place.

11

Page 25

Mounting the Controller Section 2-3

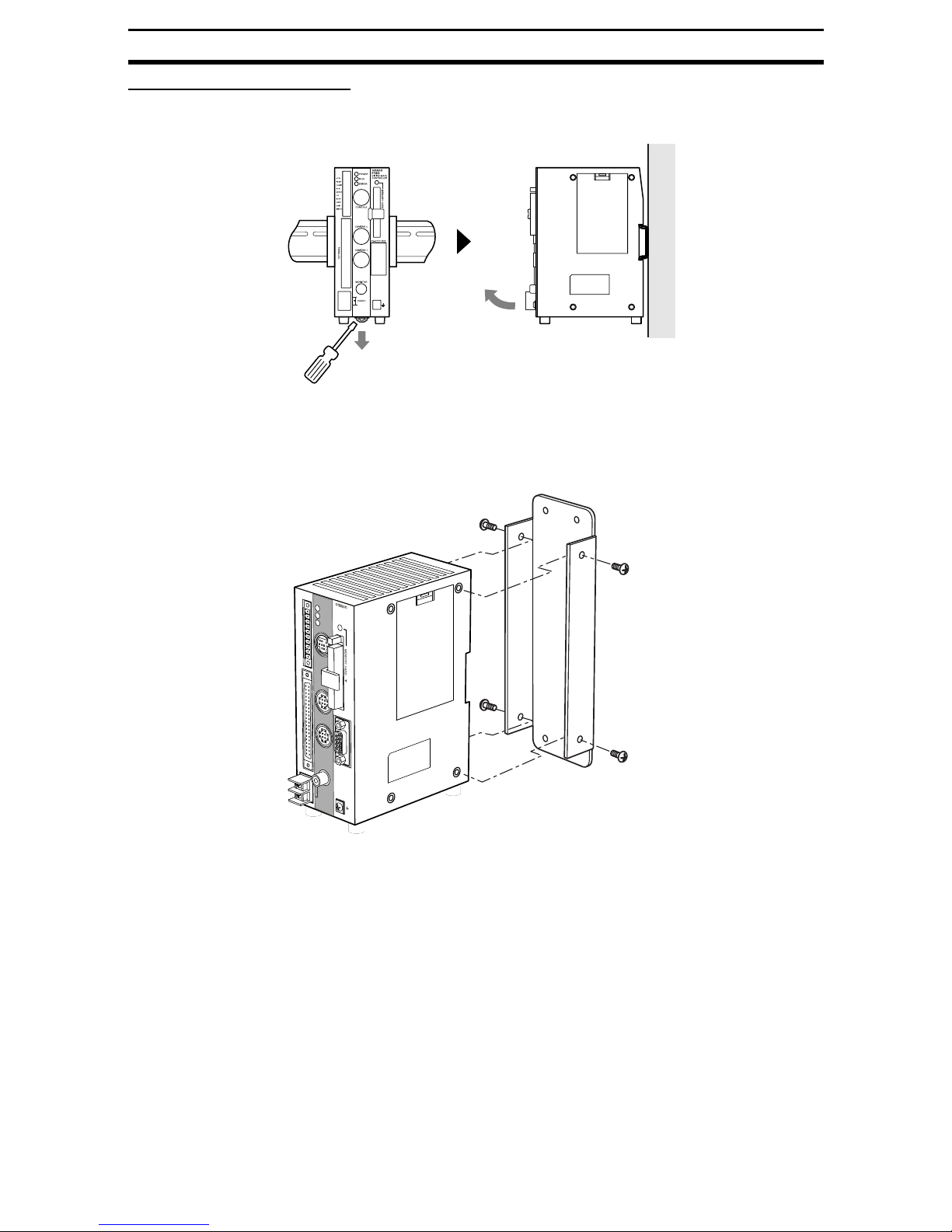

Removing the Controller

Use a screwdriver to pull the hook down and then pull out the Controller from

the bottom.

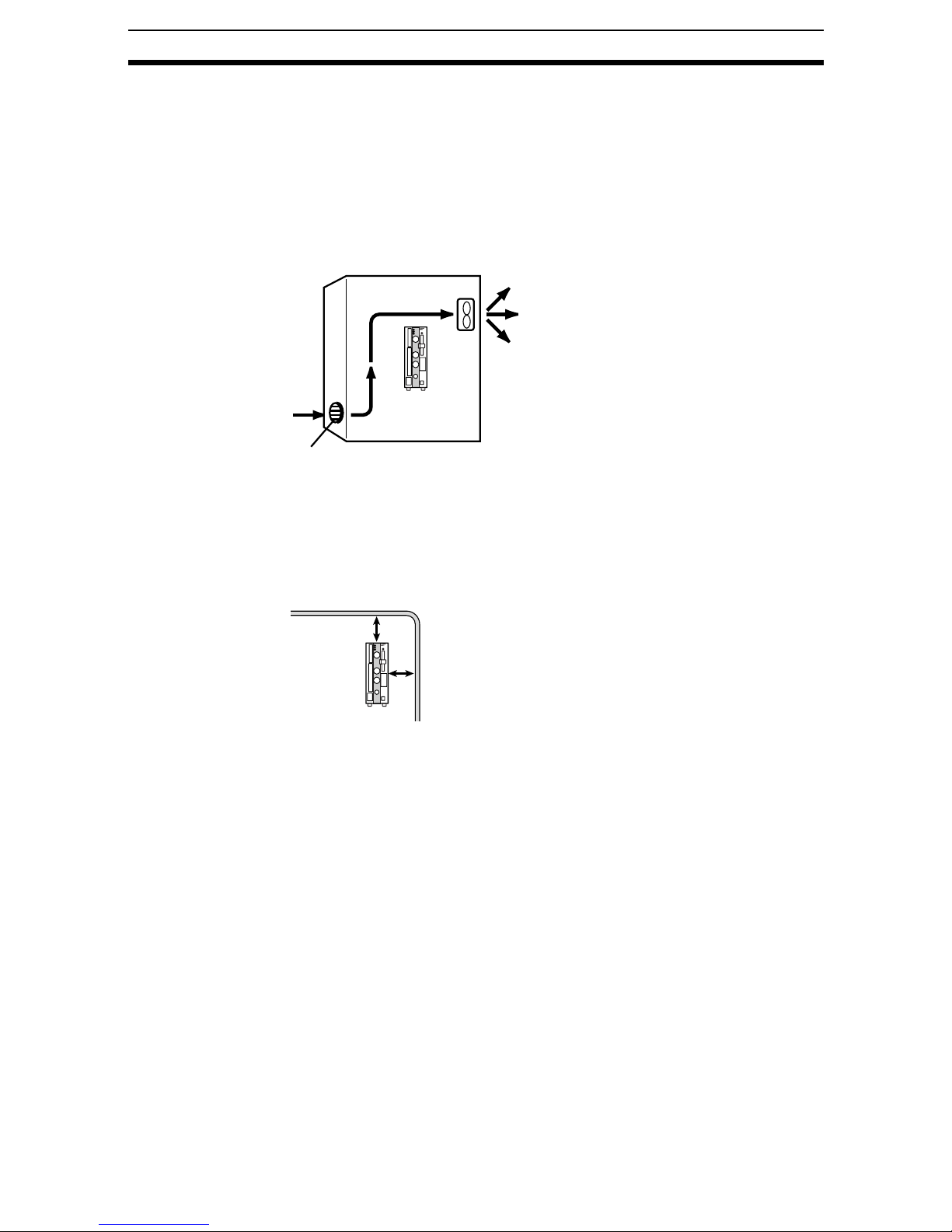

2-3-2 Rear Surface-mounting

1. Attach the mo unting br ac k et to the F16 0 Control ler usi ng the four machine

screws (M3 × 6) included with the bracket.

F

STEP

1

P

6

O

0

W

E

V

R

IS

IO

RESET

N

M

C

A

O

T

N

E

R

T

U

R

N

C

O

RUN

ERRO

BUSY

GATE

OR

DO15

C

O

O

L

M

I

N

R

M

O

U

T

P

A

R

A

L

L

E

L

L

E

R

E

R

R

O

R

C

O

N

S

O

L

E

C

A

M

E

R

A

0

R

S

-23

2C

/4

22

C

A

M

E

R

A

1

M

O

N

IT

O

R

+

24VDC

-

12

Page 26

Mounting the Controller Section 2-3

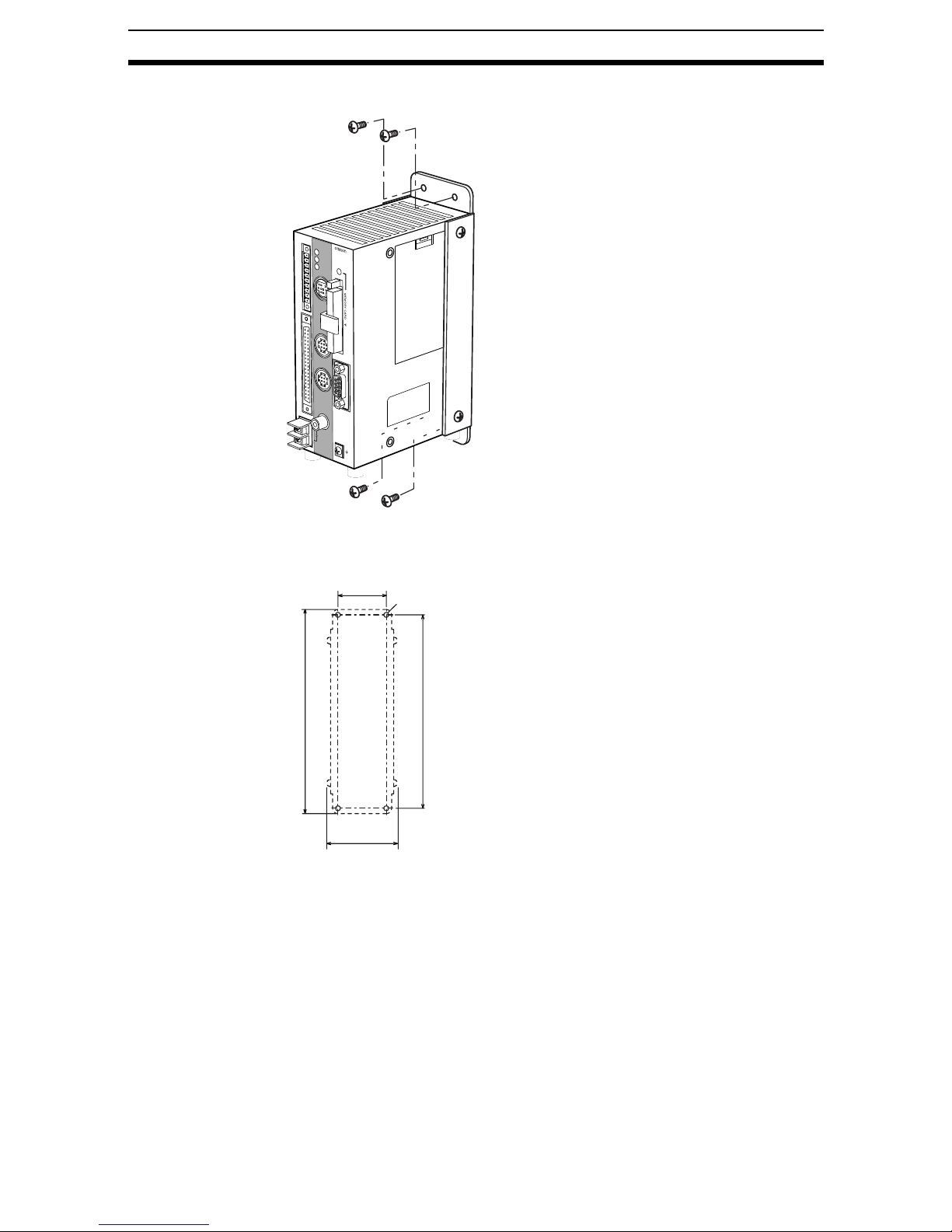

2. Fasten the F160 Controller and Mount ing Br a cket to the mounting surface

with four M4 screws.

F

STE

1

P

P

6

O

0

W

E

V

R

IS

IO

RE

N

SET

M

C

A

O

T

N

E

R

T

U

R

N

C

O

M

R

U

ERROR

BUSY

G

ATE

O

R

D

O15

C

O

M

O

L

L

I

N

N

O

U

T

P

A

R

A

L

L

E

L

E

R

E

R

R

O

R

C

O

N

S

O

L

E

C

A

M

E

R

A

0

R

S

-2

32

C

/422

C

A

M

E

R

A

1

M

O

N

IT

O

R

+

24VDC

-

Use the holes and dimensions shown in the following diagram.

Unit: mm

45±0.2

Four, M4

(190)

180±0.2

(62.2)

13

Page 27

Mounting the Controller Section 2-3

2-3-3 Side Surface-mounting

The F160 Controller can be side-mounted directly to a panel as shown in the

following diagram.

F

STEP

1

P

6

O

0

W

E

V

R

IS

IO

RESET

N

M

C

A

O

T

N

E

R

T

U

R

N

C

R

ER

BUSY

GATE

OR

D

C

O

O

M

UN

RO

O15

O

M

P

A

R

A

L

L

E

L

L

L

I

N

R

O

U

T

E

R

E

R

R

O

R

C

O

N

S

O

L

E

C

A

M

E

R

A

0

R

S-232C

/4

22

C

A

M

E

R

A

1

M

O

N

IT

O

R

+

24VDC

-

Use the holes and dimensions shown in the following diagram.

Unit: mm

(12)

60±0.46

Four, M3 (Screw depth: 4.8 mm max.)

(153)(7)

66.5±0.46 66.5±0.46

(110)

14

Page 28

Connecting Peripheral Devices Section 2-4

2-3-4 Bottom Surface-mounting

F

ST

1

EP

P

6

O

0

W

E

V

R

IS

I

O

RE

N

SET

M

C

A

O

T

N

E

R

T

U

R

N

C

O

R

U

ERR

BUSY

GA

OR

D

O

C

O

O

L

M

I

N

N

OR

TE

15

M

O

U

P

A

R

A

L

L

E

L

L

E

R

E

R

R

O

R

T

C

O

N

S

O

L

E

C

A

M

E

R

A

0

R

S

-23

2C

/4

22

C

A

M

E

R

A

1

M

O

N

IT

O

R

+

24VDC

-

Use the holes and dimensions shown in the following diagram.

Unit: mm

38±0.39

(9)

92±0.54

Four, M4 (Screw depth: 6 mm max.)

2-4 Connecting Peripheral Devices

This section shows how to connect peripheral devices to the F160.

Precaution Always turn OFF the power supply before connecting or disconnecting a

peripheral device’s cable. The peripheral device may be damaged if it is connected while the power is ON.

15

Page 29

Overview of Available Cameras Section 2-5

2-4-1 Connecting a Console

Connect the Console to the F160’s CONSOLE connector. An F160-KP or

F150-KP Console can be connected.

SHIFT

ENT

TRIGESC

CONSOLE

2-4-2 Connecting a Monitor

Connect the monitor cable to the F160’s MONITOR connector, and attach the

enclosed Ferrite Core to the monitor cable. The Ferrite Core should be

attached to the cable approximately 10 mm from the MONITOR connector.

MONITOR

Approx. 10 mm

2-4-3 Connecting a Camera

Connect the camera cable to the F160's CAMERA connector.

CAMERA

Note The connector is capped when the F160 is shipped. When not using the con-

nector, leave the cap in place to protect against dust, dirt, and static electricity.

Ferrite Core

Wrap the cable in one loop

in the Ferrite Core.

2-5 Overview of Available Cameras

The F160 Camera with Light is a special F160 Camera that has a special lens

and light source alread y attac hed. The li ght sourc e and len s are cont ained in a

single unit, so installation is very simple. Just mount the Camera at the proper

distance from the measurement object and it is ready to use.

16

Page 30

Overview of Available Cameras Section 2-5

Camera with Light

Item F150-SL20A F150-SL50A

Field of vision 20 mm

Mounting distance 61 to 71 mm 66 to 76 mm

Relationship

between Camera

and object

20 mm 50 mm 50 mm

Measurement

Mounting distance

object

Field of vision

Lighting precautions None in particular

Camera with Intelligent Lighting

Item F150-SLC20 or F160-SLC20 F150-SLC50 or F160-SLC50

Field of vision 20 mm

Mounting distance 15 to 25 mm 16.5 to 26.5 mm

Relationship

between Camera

and object

Measurement

object

Lighting precautions Use with DIP switch pins 1 and 2 both set

to OFF.

20 mm 50 mm 50 mm

Mounting distance

Field of vision

Use with DIP switch pins 1 and 2 both set

to OFF.

Camera Only

Item F150-S1A or F160-S1

Field of vision and

distance to object

Determine the required field of vision based on the size of the measurement object and

select an appropriate CCTV lens (C mount).

Lighting precautions Provide a light source appropriate for the measurement object.

CHECK Observe the following precautions when using a Camera with Light or Camera

with Intelligent Lighting.

12

O

1

F

F

2

17

Page 31

Power Supply and Ground Section 2-6

• The lens has a fixed focal point. The actual field of vision and focal point

vary from lens to lens, so adjust the distance to the measurement object

after replacing the lens or camera.

• The camera mounting distance listed in the following tables is an approximate value. Mount the Camera so that the distance to the measurement

object can be adjusted easily.

If the object size and field of vision are incompatible, use a standard CCTV

lens and light source.

SeeAlso page 22

2-6 Power Supply and Ground

Wire the power supply and the ground to their respective terminals. Tighten

the screws to a torque of between 0.49 N•m.

After wiring, confirm that the wiring is correct.

2-6-1 Crimp Terminals and Cables

The terminal block uses M3 terminal screws. Use appropriate crimp terminals

for M3 screws, as shown below.

Forked Round

6.2 mm max.

Applicable wire size: In su lated wire of 1.31 to 1.65 mm

2-6-2 Ground (Earth) Wiring

Always connect a ground wire to the F160's ground terminal. To avoid grounding problems, do not share the ground wire with any other devices or wire the

ground to th e building's steel framing.

Use a groundin g point t hat i s as clos e as po ssib le and k ee p the g rou nd wir e as

short as possible.

F160

6.2 mm max.

2

(AWG16 to AWG15)

18

Ground to 100 Ω or less.

Page 32

Power Supply and Ground Section 2-6

2-6-3 Wiring the Power Supply

Wire the Power Supply Unit independently of other devices. In particular, keep

the power supply wired separately from inductive loads. Also, keep the power

supply wiring as shor t as possible (less than 10 m).

Use a power supply that meets the following specifications. We recommend

using OMRON’s S82K-05024 Power Supply.

Item Specification

Output current 1.6 A min.

Power supply voltage

24 VDC

CHECK Use a DC power supply with countermeasures against high voltages (safe

extra low-voltage circuits on the secondary side). If the system must meet UL

standards, use a UL class II power supply.

F160

+10%

/

-15%

+

−

+

24VDC

−

24 VDC

!Caution After wiring, replace the protective cover on the power supply terminals.

19

Page 33

Page 34

SECTION 3

Lenses, Lighting, and Memory Cards

This section provides additional information on CCTV lenses, lighting, and Memory Cards.

3-1 CCTV Lenses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-1-1 Optical Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-1-2 Lenses and Lens Diameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-1-3 Extension Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-2 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-2-1 Lighting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-3 Memory Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-3-1 Installing a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-3-2 Removing the Memory Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-3-3 Using Memory Cards in a Personal Computer . . . . . . . . . . . . . . . . . 28

21

Page 35

CCTV Lenses Section 3-1

3-1 CCTV Lenses

When using a Camera without a light (F150-S1A or F160-S1), refer to the following graph to select the appropriate Lens and Extension Tube. The lens will

differ depending on the size of the measurement object and the distance from

the Camera.

3-1-1 Optical Chart

The values in the following chart are appro x im at ion s , and the Camera must be

adjusted after it is mounted.

Lens model: 3Z4S-LE

5,000

3,000

Camera distance A (mm)

2,000

1,000

500

300

200

100

50

4 5 10 20 30 50 100 200 300 500

Field of vision L (mm)

The X axis of the gra ph s ho ws fie ld o f vis io n L (mm), a nd th e Y axis shows the

camera distance A (mm). The curves on the graph show the relationship

between the field of vision and camera distance for each CCTV lens. The values are significantly different for each lens, so double-check the model of the

lens before using the graph. The “t” values indicate the lengths of the Extension Tubes. The value “t0” shows the case where an Extension Tube is not

needed and the value “t5.0” shows the case where a 5-mm Extension Tube is

used.

t: Extension Tube length

22

Page 36

CCTV Lenses Section 3-1

Example

When a 3Z4S-LE C1614A CCTV Lens is being used and a field of vision of

40 mm is needed at the measurement object, a camera distance of 200 mm

and 1-mm Ex tension Tube are required.

Camera

Extension Tube t@ (mm)

Lens

Camera distance A (mm)

Measurement object

Field of vision L (mm)

3-1-2 Lenses and Lens Diameters

Unit: mm

Max. outer dia.

Total length

Lens Focal length Bright-

ness

3Z4S-LE C418DX 4.8 mm F1.8 40.5 mm dia. 35.5 mm --3Z4S-LE B618CX-2 6.5 mm F1.8 48 mm dia. 42 mm

3Z4S-LE C815B 8.5 mm F1.5 42 mm dia. 40 mm M40.5

3Z4S-LE B1214D-2 12.5 mm F1.4 42 mm dia. 50 mm

3Z4S-LE C1614A 16.0 mm F1.4 30 mm dia. 33 mm M27

3Z4S-LE B2514D 25.0 mm F1.4 30 mm dia. 37.3 mm

3Z4S-LE B5014A 50.0 mm F1.4 48 mm dia. 48 mm M46

3Z4S-LE B7514C 75.0 mm F1.4 62 mm dia. 79 mm M58

1"-32UN

-2A

Maximum outer

diameter

30 dia.

Tota l le n gth Filter size

× P0.5

× P0.5

× P0.75

× P0.75

23

Page 37

Lighting Section 3-2

3-1-3 Extension Tubes

One or more Extension Tubes can be inserted between the lens and the Camera to focus the Camera image. Use a combination of one or more of the six

tubes to achieve the required length.

Extension Tube

Model M aximum outer

diameter

3Z4S-LE EX-C6 31 dia. Set of 6 tubes

0.5 mm, 1 mm, 5 mm, 10 mm, 20 mm, and

40 mm

Length: 40 mm 20 mm 10 mm 5 mm 1.0 mm 0.5 mm

Length

Precaution • Do not use the 0.5-mm and 1.0-mm Extension Tubes attached to each

other. Since these Extension Tubes are placed over the threaded section

of the Lens or other Extension Tube, the connection may loosen when

more than one 0.5-mm or 1.0-mm Extension Tube are used together.

• Reinforcement may be required for combinations of Extension Tubes

exceeding 30 mm if the Camera is subject to vibration.

3-2 Lighting

A stable image m us t be obtained to ensure accurate inspe cti on. Us e app ropriate lighting for the application and the measurement object if using a Camera

without a light (F150-S1A or F160-S1).

3-2-1 L ighting Methods

Back Lighti ng

A stable, high-contrast image can be obtained using back lighting.

24

Page 38

Lighting Section 3-2

Applications: Inspection of exterior shape or positioning inspection

Camera

Measurement object

Light source

Reflected Lighting

Ring Lights

Light is shone uniformly on the measurement object.

Applications: Surface inspections

Camera

Light source

Measurement object

Oblique Lighting

Detection can be made utilizing the difference in regular and diffuse reflected

light.

25

Page 39

Memory Card Section 3-3

Applications: Inspections for surface gloss

Camera

Light source

Measurement object

Coaxial Lighting

A stable image can be obtained with few shadows from uneven surfaces on

the measurement object.

Applications: Surface inspections, positioning, and hole inspections of comparatively small objects

Half mirror

3-3 Memory Card

Use a Memory Card to backup data such as settings and image data or

increase the number of scenes when you are using the Scene Group function.

Data from the F160 can be backed up in a personal computer just by inserting

the Memory Card into the computer and copying the desired data.

We recommend the OMRON F160-N64S(S) (64 MB) Memory Card.

CHECK A filler card with no memory is inserted into the F160’s Memory Card slot

before the F160 is shipped. Remove this filler card and install a Memory Card

to use this function.

If Memory Card is not being used, leave the filler card in place to prevent dust

or dirt from entering the Memory Card slot.

Camera

Light source

Measurement object

26

Page 40

Memory Card Section 3-3

MEMORY CARD

F

1

6

0

3-3-1 Installing a Memory Card

1. Open the Memory Card slot’s card lock.

F

1

6

0

MEMORY CARD

CHECK Do not force the lock open; lift the latch gently.

2. Insert the Memory Card.

F

1

6

0

MEMORY CARD

128MB

3. Close the card lock to secure the Memory Card.

3-3-2 Removing the Memory Card

1. Stop the power supply to the Memory Card or turn OFF the F160.

SeeAlso Refer to the Conversational Menu Operation Manual or th e Exper t Menu

Operation Man ual for details on turning OFF the power supply to the Mem-

ory Ca rd.

2. Verify that the Memory Card indicator is not lit.

F

1

6

0

Memory Card

MEMORY CARD

indicator

27

Page 41

Memory Card Section 3-3

MEMORY CARD

F

1

6

0

Precaution

Do not remov e the Me mory Card if the Mem ory Card indi ca tor i s lit. Do ing

so may damage the Memory Car d or the F160 itself.

3. Open the card lock.

Eject button

4. Press the eject button over the Memory Card slot.

5. Pull the Memory Card straight out from the slot.

3-3-3 Using Memory Cards in a Personal Computer

The F160’s Memory Cards can be used in a personal computer with a PC

Card drive (PCMCIA 2.0 or higher, type II compatible) or “Compact Flash”

drive.

The Memory Card must be inserted into a PC Card Adapter in order to be

used in a PC Card drive. We recommend the OMRON HMC-AP001 PC Card

Adapter.

PC Card

Adapter

28

Page 42

SECTION 4

Connecting External Devices

This section describes how to conne ct external devices through a parallel interface (the I/O terminals or I/O

connector) or serial interface (the RS-232C/RS-422 connector).

4-1 Connecting through the Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-1-1 I/O Terminal Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-1-2 I/O Connector Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-1-3 I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-2 Connecting through the Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-2-1 Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-2-2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2-4 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

29

Page 43

Connecting through the Parallel Interface Section 4-1

4-1 Connecting through the Parallel Interface

This section explains how to connect I/O to the F160 through its parallel interface to input signals such as measurement triggers or output signals such as

measurement results.

Either the I/O terminals or I/O connector can be used for the parallel interface.

The I/O terminals and I/O connector cannot be used simultaneously.

I/O Terminals

When the required control signals are being connected to the I/O terminals,

attach the control wires to the included connector (Phoenix MC1.5/10-STF-

3.5) and then inser t the connector into the F160.

I/O Connector

When you want to use the parallel interface to input commands and output

measurement results, prepare a parallel I/O cable and connect it to the I/O

connector . R ef er t o the Communications Reference Manual for details on communications settings and I/O formats.

4-1-1 I /O Terminal Connections

Wire the cable carrying the control signals to the connector that was included

with the F 160 and ins ert t he connect or into th e F160. The foll owing diagram

shows the I/O allocation of the F160’s I/O terminals. Just wire the terminals

that are needed.

CONSOLE

F160

ERROR

STEP

RESET

COMIN

RUN

ERROR

OR

BUSY

GATE

DO15

COMOUT

(Input: Measurement trigger signal)

(Input: Restarts the F160.)

(Common for input terminals)

(Output: ON for measurement mode)

(Output: ON when error occurred)

(Output: Combined judgement result)

(Output: ON while processing)

(Output: ON for set output time)

(Output: Measurement results)

(Common for output terminals)

STEP

RESET

COMIN

RUN

ERROR

OR

BUSY

GATE

DO15

COMOUT

(See note.)

Note 1. COMOUT is connected to COMOUT1 and COMOUT3 of the I/O connec-

tor.

2. Use wire of cross-sectional area 0.14 to 1.5 mm

2

(AWG 24 to AWG 16)

with a cable length not exceeding 30 m.

Precaution Do not input the RESET input immediately after turn ing ON the power. When

using RESET input to synchro nize startup timing, wait at least 1 s after turning

ON the F160’s power supply before turning ON the RESET signal.

CHECK Use a DC power supply with countermeasures against high voltages (safe

extra low-voltage circui ts on the s ec ond ary si de) for the COMIN terminal. If the

system must meet UL standards, use a UL class II power supply.

30

Page 44

Connecting through the Parallel Interface Section 4-1

Wiring the Connector

1. Use a flat-b lad e precisi on scre wd rive r to loosen the con necto r’ s set s crew.

Counter-clockwise

2. Insert the signal wire.

3. Tighten the set screw to secure the wire. Tighten to a torque of 0.22 to

0.25 N•m.

Clockwise

4. Insert the connector into the F160.

5. Tighten the connector’s mounting screws. Tighten to a torque of 0.22 to

0.25 N•m.

4-1-2 I/O Connector Connections

Use an F160-VP Parallel I/O Cable (sold separately) to connect to the F160’s

I/O connector. Align the connectors and insert the cable’s connector straight

31

Page 45

Connecting through the Parallel Interface Section 4-1

into the F160’s I/O connector. Tighten the connector’s mounting screws to

secure the connection.

F160

F160-VP Parallel I/O Cable (2 m)

A1

CAMERA1

A20

B1

RS-232C/422

B20

Wire color

FG terminals

Marking

(Ground to 100 Ω or less.)

Precaution • Turn OFF the power supply before connecting or disconnecting the Paral-

lel I/O Cable. Peripheral devices may be damaged if the cable is connected or disconnected with the power ON.

• A cover is screwed onto the connector when the F160 is shipped. When

not using the I/O connector, leave the cover in place to protect against

dust, dirt, and static electricity.

Pin Signal Wire color Marking Function

A1 RESET Light brown ■ (black) Restarts the F160.

A2 STEP Yellow ■ (black) Measurement trigger signal input

A3 DI0 Green ■ (black) Command input

A4 DI2 Gray ■ (black)

A5 DI4 White ■ (black)

A6 DI6 Light brown ■■ (black)

A7 DI8 Yellow ■■ (black)

A8 STGOUT0 Green ■■ (black) Strobe trigger 0 output

(See note 1.)

A9 RUN Gray ■■ (black) ON while in Run Mode

A10 BUS Y White ■■ (blac k ) ON during processing

A11 OR Light brown ■■■ (black) Combined judgement result

A12 DO0 Yellow ■■■ (black) Data output

A13 DO2 Green ■■■ (black)

A14 DO4 Gray ■■■ (black)

A15 DO6 White ■■■ (black)

A16 D O8 Light brown ■■■■ (black)

A17 DO9 Yellow ■■■■ (black )

A18 D O11 Green ■■■■ (black)

A19 DO13 Gray ■■■■ (black)

A20 DO15 White ■■■■ (black)

B1 COMIN Light brown ■ (red) Common for input signals

B2 DSA Yellow ■ (red) Data send request signal input

B3 DI1 Green ■ (red) Command input

B4 DI3 Gray ■ (red)

B5 DI5 White ■ (red)

B6 DI7 Light brown ■■ (red)

B7 DI9 Yellow ■■ (red)

32

Page 46

Connecting through the Parallel Interface Section 4-1

Pin Signal Wire color Marking Function

B8 STGOUT1 Green ■■ (red) Strobe trigger 1 output

(See note 1.)

B9 ERROR Gray ■■ (red) ON when an error occurred.

B10 GATE White ■■ (red) ON for the set output time.

B11 C OMO UT 1 Light brown ■■■ (red) Common for control signals

(See note 2.)

B12 DO1 Yellow ■■■ (red) Dat a output

B13 DO3 Green ■■■ (red)

B14 DO5 Gray ■■■ (red)

B15 DO7 White ■■■ (red)

B16 C OMO UT 2 Light brown ■■■■ (red) Common for DO0 to DO7

B17 DO10 Yellow ■■■■ (red) Data output

B18 D O12 Green ■■■■ (red)

B19 DO14 Gray ■■■■ (red)

B20 COMOUT3 White ■■■■ (red) Common for DO8 to DO15

Note

1. Use the STGO UT0 or STGOUT1 sig nal when you want to conn ect a strobe

device to the F160.

SeeAlso For details, refer to page 64.

2. Pins A8 to A11 and B9 to B10 are for control signals.

Precaution Do not input the RESET input immediately after turn ing ON the power. When

using RESET input to synchro nize startup timing, wait at least 1 s after turning

ON the F160’s power supply before turning ON the RESET signal.

CHECK Use a DC power supply with countermeasures against high voltages (safe

extra low-voltage circui ts on the s ec ond ary si de) for the COMIN terminal. If the

system must meet UL standards, use a UL class II power supply.

Making a Parallel I/O Cab le

A parallel I /O ca ble can be as sembled u sin g th e con necto r an d cover li sted i n

the following table or equivalent components. Keep the cable length less than

30 m.

Component Manufacturer Model number

Connector Fujitsu FCN-361J040-AU

Cover Fujitsu FCN-360C040-B

CHECK Double-check the connector wiring for mistakes before turning ON the power

supply for the first time.

4-1-3 I/O Specifications

Input Specifications

Item Specification

Model F160-C10E (NPN mode) F160-C15E (PNP mode)

Input voltage 12 to 24 VDC

ON current 5 to 15 mA

ON voltage 8.8 V max.

OFF current 0.1 mA max.

OFF voltage 4.5 V min.

ON delay RESET input: 10 ms max.

Other inputs: 0.5 ms max.

10%

33

Page 47

Connecting through the Serial Interface Section 4-2

Item Specification

OFF delay RESET input: 15 ms max.

Other inputs: 0.7 ms max.

Internal circuits

COM IN

+

Input

terminal

Input

terminal

COM IN

Output Specifications

Item Specification

Model F160-C10E (NPN mode) F160-C15E (PNP mode)

Output voltage 12 to 24 VDC

Load current 45 mA max.

ON residual voltage 2 V max.

OFF leakage current 0.1 mA max.

Internal circuits

10%

Output terminal

Load

COM OUT

+

CHECK The I/O contacts are shared by the I/O terminals and I/O connector. The fol-

lowing diagram shows the wiring diagram for the STEP signal as an example.

I/O terminals

COMIN

STEP

COM OUT

Load

Output terminal

I/O connector

4-2 Connecting through the Serial Interface

The F160’s serial interface (RS-232C/RS-422 connector) can be used to connect input signals such as measurement triggers or output signals such as

measurement results. Additionally, data that has been set in the F160 can be

backed up in a personal computer.

Refer to the Communications Reference Manual for details on communica-

tions settings and I/O formats.

34

COMIN

STEP

Page 48

Connecting through the Serial Interface Section 4-2

4-2-1 Connection Examples

1:1 Connection (No-protocol, Menu Operation)

RS-232C cable

F160

Multi-drop Connection (No-protocol)

Communications between one computer and several F160s is possible using

Link Adapters.

RS-422 cable

RS-422 cable

RS-422

cable

Link Adapter

OMRON

3G2A9-AL004-E

recommended

Link Adapter Link Adapter

RS-422 cable

Computer

31 Units max.

Computer

Link Adapter

OMRON

B500-AL001

recommended

F160

1:1 Connection (Host Link)

F160

F160

RS-232C cable

F160

PLC

35

Page 49

Connecting through the Serial Interface Section 4-2

4-2-2 Connector

The F160’s RS-232C/RS-422 Connector is a 9-pin D-SUB female connector.

The pin allocation is shown below.

9

8

7

6

Pin Signal Name

1 FG Protective frame ground

2 SD For RS-232C

3RD

4 NC Not connected

5 RDB(+) For RS-422

6 RDA(-)

7SDB(+)

8SDA(-)

9 GND Signal ground

5

4

3

2

1

The following plug and hood are recommended and are available from

OMRON.

Model Model No.

Plug XM2A-0901

Hood XM2S-0911

4-2-3 Wiring

RS-232C Wiring

The maximum cable length is 15 m for RS-232C or RS-422

Signal

SD

RD

GND

F160

Pin

2

3

9

Use only shielded cable.

External device

Pin

Signal

SD

RD

GND

RS/CS control

cannot be used.

36

Page 50

Connecting through the Serial Interface Section 4-2

RS-422 Wiring

F160

Signal

RDB

RDA

SDB

SDA

GND

Pin

5

6

7

8

9

Use only shielded cable.

Note Pin numbers on the external device will depend on the device being con-

nected. Refer to the manual for the personal computer or PLC being connected.

External device

Pin

Signal

RDB

RDA

SDB

SDA

GND

4-2-4 Connection

Align the connector with the socket and press the connector straight into

place. Tighten the two mounting screws to secure the connector.

F160

Precaution • Always turn OFF the power supply before connecting or disconnecting

cables. The peripheral device may be damaged if connected or disconnected with the pow er supply turned ON.

• The connector is capped when the F160 is shipped. When not using the

serial interface, leave the cap in place to protect against dust, dirt, and

static electricity.

37

Page 51

Page 52

SECTION 5

Troubleshooting and Maintenance

This section provide s tabl es to help identify and correc t hardware errors that may occur with the F160 as well as

information on maintenance and periodic inspections.

5-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-1-1 Connection Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-1-2 Menu Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-1-3 Parallel Interface Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-1-4 Serial Interface Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-1-5 Cabling Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-2-1 Replacing the Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5-2-2 Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5-3 Regular Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5-4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5-5 F200/F300 Camera Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-6 Connecting a Strobe Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

39

Page 53

Troubleshooting Section 5-1

5-1 Troubleshooting

5-1-1 Connection Errors

Problem Probable cause

The POWER indicator is not lit. The Power Supply is not connected properly.

The supply voltage is not 24 VDC

The Video Monitor is blank. The power to the Video Monitor is not ON.

The Monitor Cable is not connected properly.

The Video Monitor is malfunctioning.

When using an LCD Monitor, the power supply capacity is insufficient.

The Video Monitor image is not

clear.

Cannot make key inputs from the

Console.

Camera images do not appear on

the screen (for Cameras with Light

Source).

Camera images do not appear on

the screen (when a standard CCTV

lens and lighting are used).

The indicators do not turn ON (for

Cameras with Light Source).

There is electrical noise entering from the power supply or cables.

The Monitor Cable is not correctly connected.

The Console Cable is not correctly connected.

The Camera Cable is not correctly connected.

The lighting cable is not properly connected to the Camera.

The lens cap has not been removed.

The Camera Cable is not properly connected.

The lens iris is opened or closed too far.

The shutter speed is not suitable.

The lighting method is not suitable.

The lighting cable is not correctly connected to the Camera.

Power is not being supplied to the F160.

When using a Camera with Intelligent Lighting, the DIP switch pins are not

set to 0.

+10%

/

-15%

.

5-1-2 Menu Operation Errors

Problem Probable cause

The measurement results are not

displayed on the Video Monitor.

The F160 is not in Monitor or Run mode.

5-1-3 Parallel Interface Errors

Problem Probable cause

Trigger signals (input signals) are

not received.

Signals cannot be output externally. The trigger signal has not been input.

The cables are not correctly wired.

The signal line is disconnected.

The status of communications can be checked with the I/O monitor.

The F160 is not in Monitor or Run mode.

The cables are not correctly wired.

The signal line is disconnected.

The status of communications can be checked with the I/O monitor.

The F160 is not in Run mode.

40

Page 54

Maintenance Section 5-2

5-1-4 Serial Interface Errors

Problem Probable cause

No communications are possible. The cables are not correctly wired.

The F160’s communications specifications do not match those of the

external device.

The communications mode was not selected under System/Communica-

tions settings/Serial.

Select Normal, Host link, or Menu operations under RS-232C/Operat-

ing mode. (Normal is no-protocol.)

The status of communications can be checked with the I/O monitor.

The Unit operates well initially, but

after a while there is no response

from the F160.

Cannot perform menu operations

from the computer.

The reception buffer on the external device (e.g., computer) is full. Check

that settings allow the data to be properly received.

The communications mode was not set to Me nu operations in the Sys-

tem/Communications settings/Serial settings.

5-1-5 Cabling Errors

Problem Probable cause

A recommended OMRON RS-232C

cable is not being used.

One of the following OMRON cables can be used. Select a cable that

works with the device being connected.

Connecting to a PC/AT or compatible computer (9-pin connector)

• XW2Z-200S-V (2 m)

• XW2Z-500S-V (5 m)

Connecting to a SYSMAC device (9-pin connector)

• XW2Z-200T (2 m)

• XW2Z-500T (5 m)

5-2 Maintenance

5-2-1 Replacing the Light

• The Light will gradua lly lose brig htness over time (abou t 20% loss after

1,500 hours of use). Replace the Light after about 1,500 hours of use.

• Replace the Light if it is damaged or not fully functional.

41

Page 55

Maintenance Section 5-2

F150-SL20A/SL50A

Use the following procedure to replace a Light with the F150-LT10A Light.

(The F150-LT10A cannot be connected to the older F150-S1 Camera.)

Camera base

2

3

Hold this part when

removing the Cable.

1

4

Light

Lighting connector

1. Disconnec t the li ght cab le fro m the l ight co nnector o n the b ack of the Camera.

2. Remove the light cable from the slot in the camera base.

3. Remove the two screws securing the Light.

4. Remove the Light from the Camera.

5. Reverse steps 1 through 4 when installing the Lens and Light.

Camera cable

connector

Precaution Do not disassemble the Lens. Disassembly can damage the Lens.

F150-SLC20/SLC50 or F160-SLC20/SLC50

Use the following procedure to replace a Light with an F150-LTC20 (20-mm

field of vision) or F150-LTC50 (50-mm field of vision) Light.

5

3

Camera base

2

Light

4

1

Hold this part when

removing the Cable.

1. Disconnec t the li ght cab le fro m the l ight co nnector o n the b ack of the Camera.

2. Remove the light cable from the slot in the camera base.

3. Remove the two screws securing the Light at the top.

4. Remove the two screws securing the Light at the bottom.

42

Page 56

Maintenance Section 5-2

5. Remove the Light from the Camera.

6. Reverse steps 1 through 4 when installing the Lens and Light.

Precaution Do not disassemble the Lens. Disassembly can damage the Lens.

CHECK When you want to use the Camera alo ne witho ut c on nec tin g an Intelligent

Lighting, use M2 × 3 screws in the bottom of the Camera instead of the

long screws removed in step 4. The screws removed in step 3 are not

needed.

5-2-2 Replacing the Battery

The F160 contains a battery that backs up the time and date information.

When the battery is nearly discharged, the message “BATTERY LOW” will be

displayed at startup. Replace the battery with an OMRON 3Z49-BAT1 Battery.

Dispose of the spent battery properly.

CHECK • Always turn OFF the power supply before replacing the battery.

• The F 16 0' s cl ock wil l be r e se t i f t he new bat t ery is not c on n ec ted w it hi n 2

minutes of removing the spent battery.

If the clock is inadvertently reset, the time and date will have to be set

again.

SeeAlso Refer to the Conversational Menu Operation Manual or th e Exper t Menu

Operation Manual for details.

Replacement Procedure

1. Open the batte ry cover on the side of the F160. The cover can be opened

2. The battery is mounted to the inside of the battery cover. Hold the battery

with a small flat-blade screwdriver.

F160

S

T

E

P

P

O

W

E

V

R

IS

IO

R

E

N

S

M

E

T

C

A

O

T

N

E

R

T

U

R

N

O

C

L

O

L

M

E

I

N

R

R

E

U

N

R

R

O

R

E

R

R

O

R

O

R

B

U

S

Y

G

A

T

E

D

O

1

5

C

O

M

O

U

T

C

O

N

S

O

L

E

C

A

M

E

R

A

0

P

A

R

R

S

A

-2

3

2

C

L

/4

2

2

L

CAMERA 1

E

L